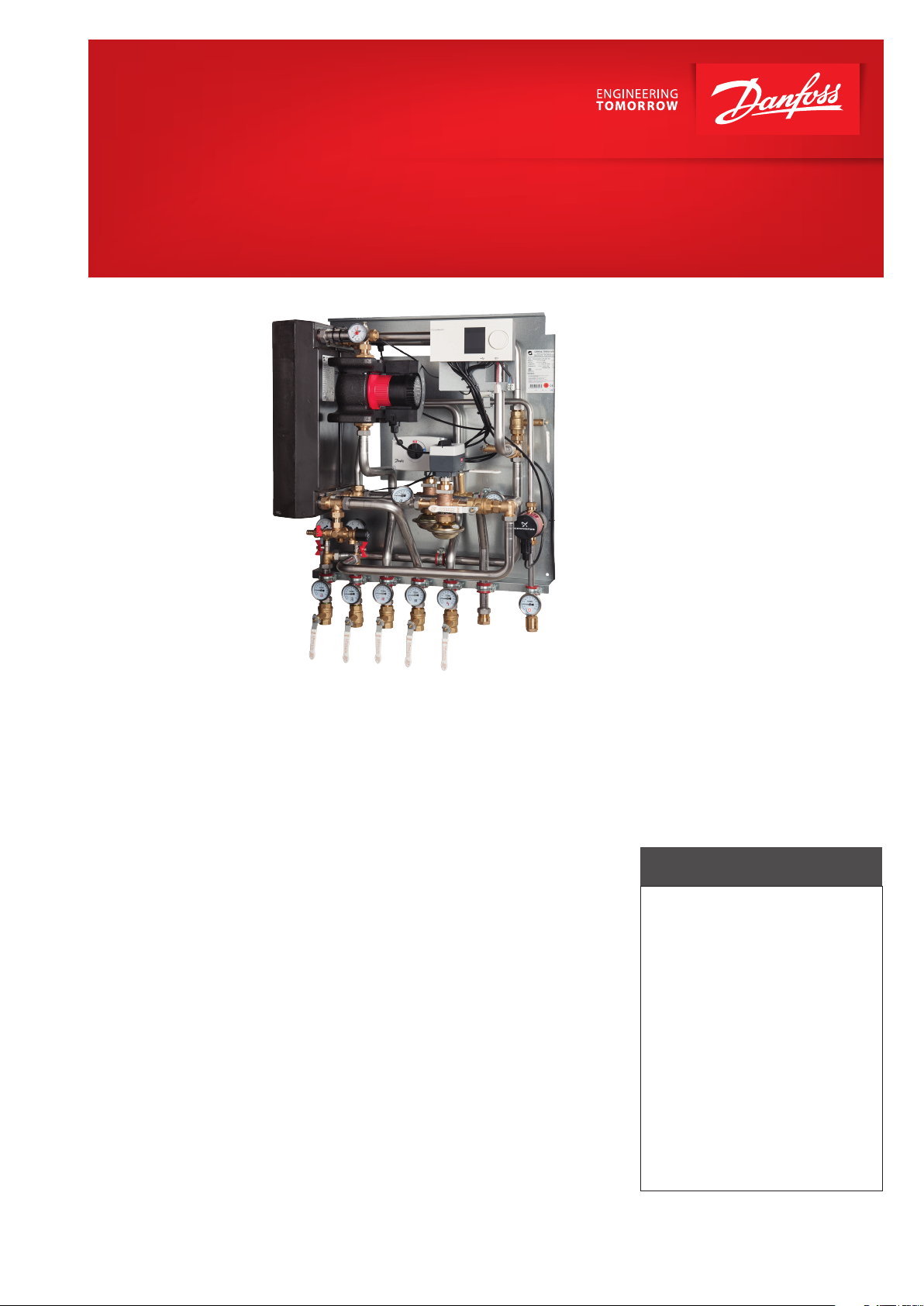

Danfoss VVX Compact 28 Fact sheet

Fact sheet

Termix VVX Compact 28

Indirect substation for buildings with up to 25 apartments

Application

The Termix VVX Compact 28 is acomplete solution for hot water and space

heating with optimal safety, ecient

energy transfer, service-friendly construction and a compact design. The

substation is applicable, if a heat exchanger is required or on a conversion to district heating, where the

existing equipment is unsuitable for

direct connection.

District heating (DH)

The district heating circuit is prefabricated with a ow controller with integrated control valve as well as thermometers and ball valves.

Heating (HE)

The heating circuit consists of a plate

heat exchanger, safety valve, manometer, thermometers, ball valves,

drain valve, air valve and circulation

pump. The heating circuit is controlled with an electronic controller

with an outdoor temperature sensor.

Domestic hot water (DHW)

The domestic hot water is prepared

in the plate heat exchanger and the

temperature is regulated with an

electronic controller. The efficient

heat exchanger offers exceptionally good heat extraction with high

output. No readjustment of the

DHW temperature is required after

installation and initial setting of the

controls. The electronic control automatically retains the comfort temperature of the hot water, even when

the heating system is in reduced

operation during summer or if the

district heating plant changes operating parameters between summer

and winter. An integrated circulation

pump for DHW is installed.

Options

Termix VVX Compact 28 can be delivered with white-lacquered steel

cover and lling line between primary

and secondary side.

Construction

All pipes are made of stainless steel.

The connections are made by nuts

and gaskets.

FEATURES AND BENEFITS

• Substation for apartment buildings

• Thermostatic or electronic control

of heating and DHW temperature

• Capacity: 150 kW heating, 150 kW DHW

• DHW in sufficient quantity

• Operates independent of differential

pressure and flow temperature

• Minimum space required

for installation

• Pipes and plate heat exchanger

made of stainless steel

• Minimized risk of lime scale

and bacteria formation

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

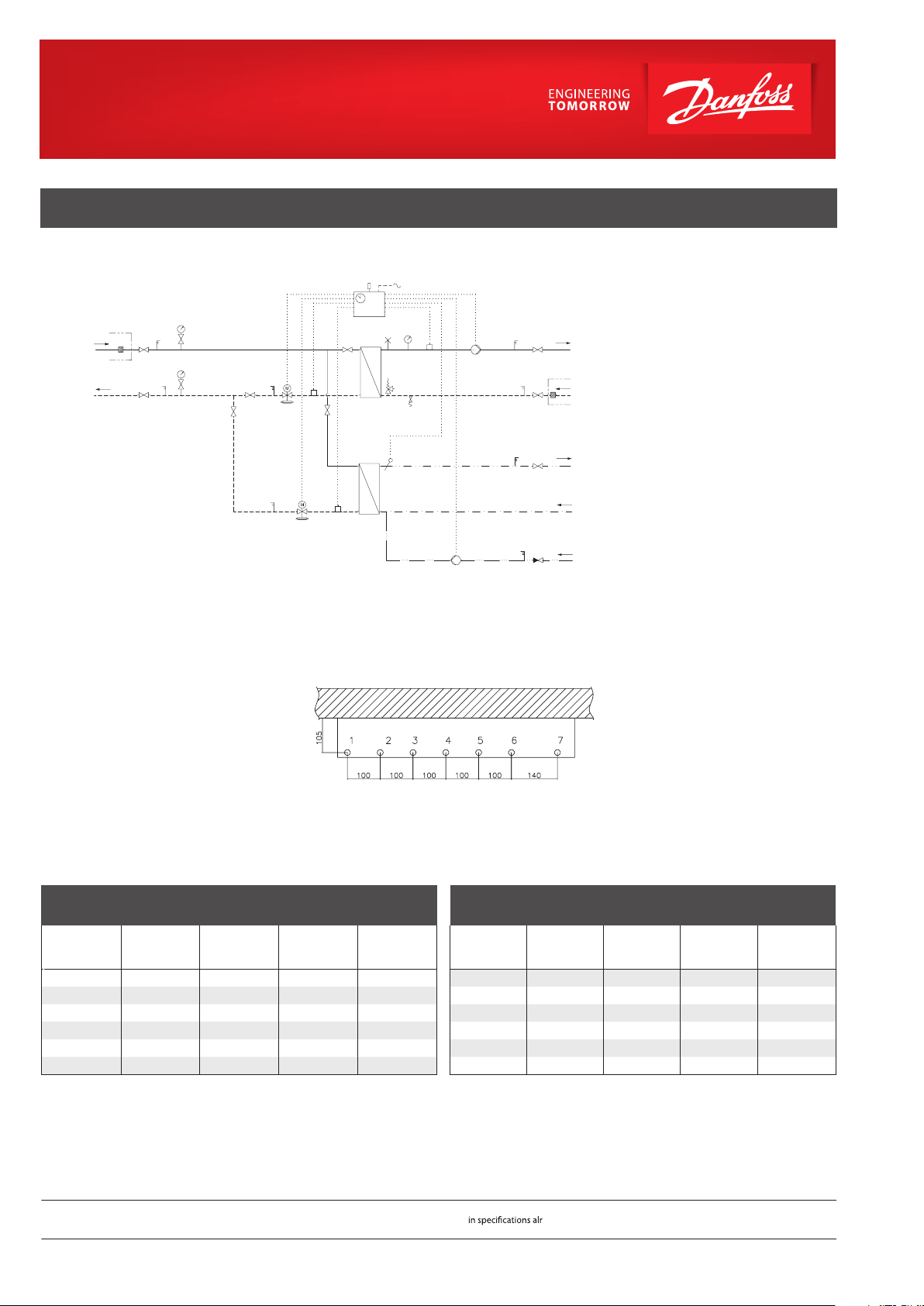

CIRCUIT DIAGRAM - EXAMPLE

1 18

25 bar

25

25 bar

25

1

DH

supply

DH

return

24

9 1 18

A Heat exchanger HE

16

230 V

B Heat exchanger DHW

F Electronic controller

1 Ball valve

F

4 bar

48

1 1

27

1

19

30

1

26

4

20

A

10 18

19

18

HE

supply

24

9

1

HE

return

2 Non-return valve

4 Safety valve

9 Strainer

10 Circulation pump

11 DHW pump

16 Outdoor sensor

18 Thermometer

19 Surface sensor

20 Filling/drain valve

40

18

27

19

30

B

1

18

DHW

DCW

24 Delivered loose with unit

25 Manometer with ball valve

26 Manometer

27 Actuator

30 Flow control w. control valve

48 Air escape, manual

Technical parameters:

Nominal pressure: PN 16

DH supply temperature: T

DCW static pressure: P

Brazing material (HEX): Copper

= 120 °C

max

= 0,5 bar

min

Weight: approx. 75 kg

Dimensions (mm)

Without cover: H 970 × W 750 × D 440

With cover: H 970 × W 800 × D 522

Electrical supply: 230 V AC

DHW: CAPACIT Y EXAM PLES, 10 °C / 50 °C

DHW

capacity

[kW]

100 70 22 50 2150

110 70 22 50 2365

120 70 22 50 2580

130 70 22 50 2795

140 70 22 50 3010

150 70 22 50 3225

Supply flow

primary

[°C]

Return flow

primary

[°C]

Pressure loss

primary

[kpa]

Flow rate

secondary

[l/h]

18 211

Circ.

Connections:

1. District heating (DH) supply

wall

2. District heating (DH) return

3. Heating (HE) supply

4. Heating (HE) return

5. Domestic hot water (DHW)

6. Domestic cold water (DCW)

7. DHW circulation (Circ.)

Connections sizes:

DH + HE + DCW + DHW: G 1” (int. thread)

Circulation: G 3/4” (int. thread)

Options:

• Cover

• Filling line

HEATING: CAPACITY EXAMPLES

Heating

capacity

[kW]

110 90 / 45 40 / 70 50 3153

120 90 / 45 40 / 70 50 3440

140 90 / 45 40 / 70 50 4013

150 90 / 45 40 / 70 50 4300

Heating circuit

primary

[°C]

Heating circuit

secondary

[°C]

Pressure loss

primary

[kpa]

secondary

70 90 / 45 40 / 70 50 2007

90 90 / 45 40 / 70 50 2580

Flow rate

[l/h]

Danfoss Randall Ltd . • Unit A4, Centre Point Business Park, Oak Road • Dublin 12 • Ireland

Tel.: +353 1800 930 243 • Fax: +353 1800 556 691 • districtheating@danfoss.com • www.dh.danfoss.com

© Danfoss | DHS-SRMT/ PL | 2016. 02

VL.EH.K3.02

Loading...

Loading...