Fact sheet

Termix VVX-B

District heating substation for indirect heating and instantaneous domestic hot water with thermostatic control.

Application

The Termix VVX-B is a complete solution

for hot water and space heating with optimal safety, ecient energy transfer, service-friendly construction and a compact

design. The substation is used if a heat exchanger is required or on a conversion to

district heating where the existing equipment is unsuitable for direct connection.

District heating (DH)

The substation is prefabricated with adifferential pressure controller, tting piece

and sensor pockets for insertion of a heat

meter as well as strainers and ball valves.

Heating (HE)

The heating side consists of a plate heat

exchanger, safety valve, manometer,

thermometers, ball valves, drain valve, air

valve, expansion vessel and circulation

pump. The temperature of the heating

can be controlled thermostatically or by an

electronic controller with an outdoor temperature sensor. Depending on the application, dierent heat exchangers

dimensioned for central or underoor

heating can be used.

Domestic hot water (DHW)

The domestic hot water is prepared in

the heat exchanger and the temperature

is regulated with a thermostatic control

valve. The patented sensor accelerator accelerates the closing of the Danfoss AVTB

valve and protects the heat exchanger

against overheating and lime scale formation. The sensor accelerator helps to

ensure a stable hot water temperature

by varying loads, ow temperatures and

dierential pressure without the need for

readjusting the valve. The heat exchanger

cools the DH water very eciently, thereby creating a very good operating economy. The sensor accelerator and AVTB

valve also works as a bypass keeping the

house supply line warm. This shortens the

waiting periods during summer when the

heating system is in reduced operation

Options

The water heater can be supplied with

built in nonreturn valve and safety valve

mounted in the cold water supply. The

water heater can also be supplied with a

thermostatic circulation valve.

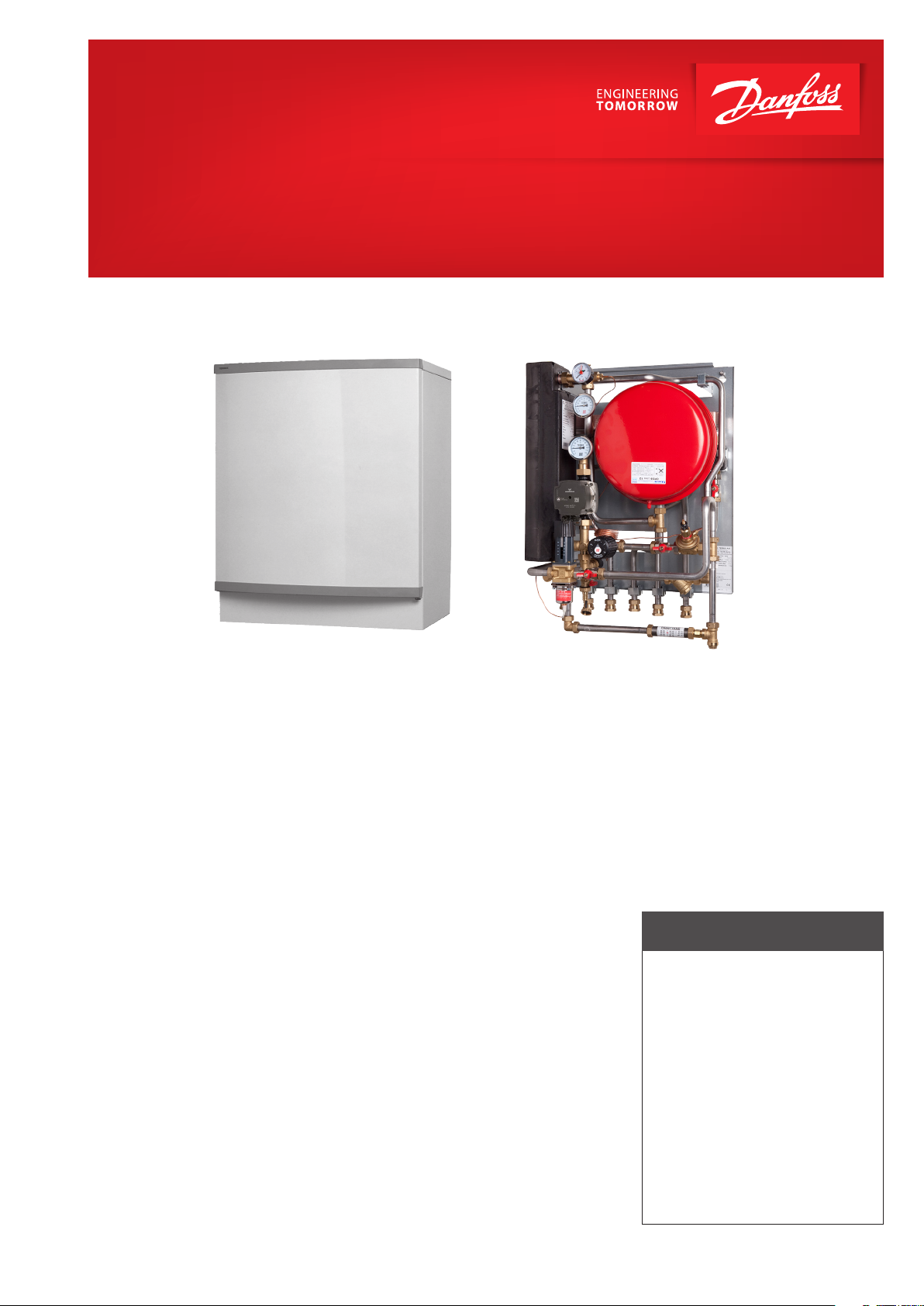

Construction

All pipes are made of stainless steel.

The connections are made by nuts

and gaskets. The Termix VVX-B is

completed by a white steel cover in

modern and attractive design.

FEATURES AND BENEFITS

• Substation with high eciency brazed

plate heat exchangers for properties

of between 1 to 30 apartments, made

from acid-proof stainless steel

• Wall-mounted construction

• Suitable for new buildings as

well as renovation projects

• Small, lightweight, compact construction

• Electronic controllers for heating

and domestic hot water systems

• Advanced gasket system - primary side

• Fast and reliable delivery

• Danfoss substations and heat exchangers

are manufactured according to European

Pressure Directive PED 9979797/23/WE

www.heating.danfoss.com

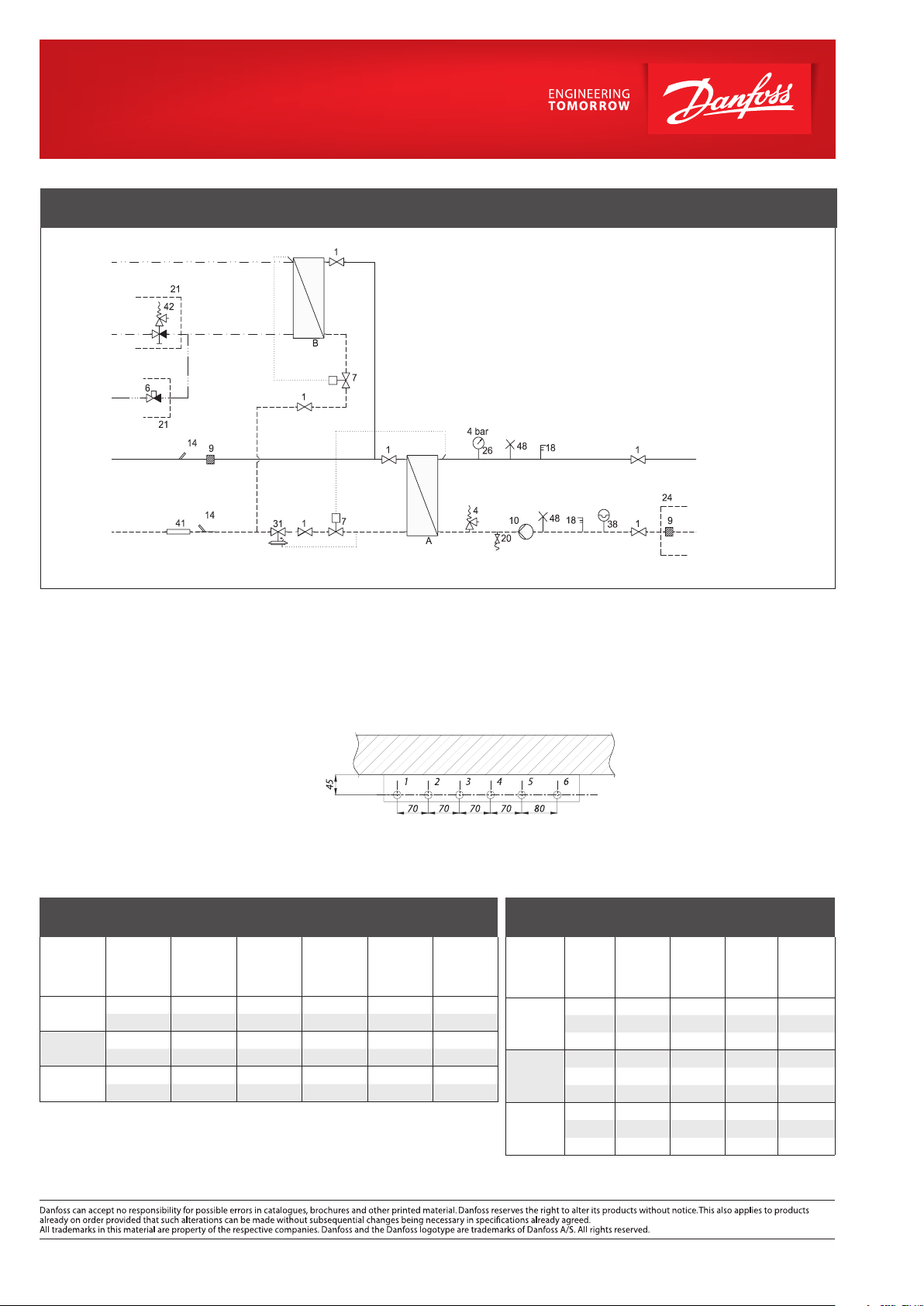

CIRCUIT DIAGRAM - EXAMPLE

DHW

DCW

Circ.

DH

Supply

DH

Return

Technical parameters:

Nominal pressure: PN 10*

DH supply temperature: Tmax = 120 °C

DCW static pressure: Pmin = 0.5 bar

Brazing material (HEX): Copper

*PN 16 versions are available on enquiry

Weight incl. cover: 35 kg

(incl. packing)

Cover: White-lacquered steel

Dimensions (mm):

Without cover: H 810 × W 525 × D 360

With cover: H 810 × W 540 × D 430

A Plate heat exchanger HE

B Plate heat exchanger DHW

1 Ball valve

4 Safety valve

7 Thermostatic valve

9 Strainer

10 Circulation pump

14 Sensor pocket, heat meter

Connections:

1. District heating (DH) supply

2. District heating (DH) return

3. Heating (HE) supply

4. Heating (HE) return

5. Domestic hot water (DHW)

6. Domestic cold water (DCW)

wall

seen from above

Connections sizes:

DH + HE: G ¾“ (int. thread)

DCW + DHW: G ¾“ (int. thread)

18 Thermometer

20 Fitting-drain valve

26 Manometer

31 Dierential pressure controller

38 Expansion vessel

41 Fitting piece, heat meter

48 Air escape, manual

HE

Supply

HE

Return

Options:

• Cover, white-lacquered steel

(Design Jacob Jensen)

• Safety valve

• GTU Pressure equalizer

• Circulation set, Danfoss MTCV

and check valve

• Booster pump (increases DH ow)

• Pipe insulation

• Mixing circuits for under oor heating

• Underoor heating manifold system

• Safety thermostat surface type

• Weather compensation,

electronic controls

• Filling line, rell from DH

for heating circuit

• Room thermostat

• Zone valve with actuator

• Air screw (DH supply)

DHW: CAPACITY EXAMPLES, 10°C / 50°C

Substation

type

VVX 1-x

VVX 2-x

VVX 3-x

DHW

capacity

Supply flow

primary

[°C]

33 60 20 10/45 25 810

40 70 20 10/45 40 1228

50 60 20 10/45 40 1228

58 70 20 10/45 40 1247

65 60 20 10/45 40 1597

75 70 20 10/45 40 1612

[°C]

Return flow

primary

[°C]

DCW/DHW

[°C]

Pressure

loss primary

[kPa]

Flow rate

secondary

[l/h]

HEATING: CAPACITY EXAMPLES

Substation

type

VVX x-1

VVX x-2

VVX x-3

Heating

capacity

Heating

circuit

primary

[ kW]

18 70/40 35/60 25 650

20 80/45 40/70 25 603

24 90/45 40/70 25 724

30 70/40 35/60 35 1084

34 80/45 40/70 35 1025

40 90/45 40/70 35 1206

45 70/40 35/60 45 1629

50 80/45 40/70 45 1509

54 90/45 40/70 45 1629

[°C]

Gemina Termix A/S · Member of the Danfoss Group · Navervej 15-17 · DK-7451 Sunds · Denmark

Tel.: +45 9714 1444 · Fax: +45 9714 1159 · mail@termix.dk · www.heating.danfoss.com

© Danfoss | DHS-SRMT/ PL | 2016.02

Heating

circuit

secondary

[°C]

Pressure

loss

primary

[ kPa]

Flow rate

secondary

[l/h]

VC.LB.B4.02

Loading...

Loading...