Page 1

Technical Information

Steering

VSPP Steering Unit

www.danfoss.com

Page 2

Technical Information

VSPP Steering Unit

Revision history Table of revisions

Date Changed Rev

July 2021 Minor corrections to MMC section 0102

October 2020 First edition 0101

2 | © Danfoss | July 2021 BC358854914884en-000102

Page 3

Technical Information

VSPP Steering Unit

Contents

Overview

A wide range of steering components..................................................................................................................................... 4

Conversion factors........................................................................................................................................................................... 5

Survey of literature with technical data on Danfoss steering components................................................................5

Steering unit type VSPP

General.................................................................................................................................................................................................6

VSPP.......................................................................................................................................................................................................6

Load Sensing dynamic steering unit with built in priority valve, VSPP LS............................................................. 6

Non-reaction.................................................................................................................................................................................6

Gear set...........................................................................................................................................................................................7

VSPP versions, overview.................................................................................................................................................................7

VSPP circuits....................................................................................................................................................................................... 8

Technical data, VSPP LS

Displacement, flow and pressure............................................................................................................................................... 9

Valve functions................................................................................................................................................................................10

Pilot pressure relief valve; (P-T, Qp) characteristic............................................................................................................. 11

Check valve function in LS..........................................................................................................................................................11

Pressure drop, P-EF........................................................................................................................................................................12

Shock valves.....................................................................................................................................................................................12

Suction valves..................................................................................................................................................................................13

Check valve in P..............................................................................................................................................................................13

Weights..............................................................................................................................................................................................14

Port thread versions

Dimensions

VSPP....................................................................................................................................................................................................16

VSPP dimensions details..............................................................................................................................................................17

VSPP: Variants and ordering specifications

VSPP MMC.........................................................................................................................................................................................18

Variants codes for VSPP MMC....................................................................................................................................................19

©

Danfoss | July 2021 BC358854914884en-000102 | 3

Page 4

Technical Information

VSPP Steering Unit

Overview

A wide range of steering components

Danfoss is one of the largest producers in the world of steering components for hydrostatic steering

systems on off-road vehicles. Danfoss offers steering solutions both at component and system levels. Our

product range makes it possible to cover applications of all types, ranging from ordinary 2 wheel steering

(also known as Ackermann steering) to articulated steering, automatic steering (for example, by sensor)

and remote controlled steering via satellite. We can offer more than 1,800 different steering units and 250

different priority valves categorized in types, variants and sizes.

Danfoss offers:

For hydrostatic steering systems:

Product type Displacement Rated Flow Steering Pressure

Mini steering units

Steering units

Priority valves

Pilot operated flowamplifiers (factors: 4, 5, 8,

or 10)

Pilot operated steering

valves

32 – 100 cm3/rev

[1.95 – 6.10 in3/rev]

40 – 1200 cm3/rev

[2.44 to 73.2 in3/rev]

–

– 240 and 400 l/min [63.4 and

–

max. 20 l/min

[5.28 US gal/min]

max. 100 l/min

[26.4 US gal/min]

40, 80, 120, 160, 320 l/min

[10.6, 21.1, 31.7, 42.3, 84.5

US gal/min]

105.7 US gal/min]

max. 100 l/min

[26.4 US gal/min]

max. 150 bar

[2180 psi]

max. 240 bar

[3481 psi]

max. 350 bar

[5076 psi]

max. 240 bar

[3480 psi]

max. 250 bar

[3625 psi]

For electrohydraulic steering systems

Product type Displacement Rated flow Steering pressure

Pilot operated steering

valves

Integrated electrical

operated steering valve

Electrical operated

steering valve

- 100 l/min [26.4 US gal/min] 250 bar [3625 psi]

100 - 500 cm3/rev

[6.10 - 30.51 in3]

- 70 l/min [18.5 US gal/min] 210 bar [3045 psi]

50 l/min [13.2 US gal/min] 210 bar [3045 psi]

4 | © Danfoss | July 2021 BC358854914884en-000102

Page 5

Technical Information

VSPP Steering Unit

Overview

Characteristic features for steering units:

•

Low steering torque: from 0.5 to 3 N•m in normal steering situations

•

Low noise level

•

Low pressure drop

•

Many types available: Open center Non-reaction, Open center Reaction, Power Beyond, Closed center

Non-reaction, Load Sensing, Load Sensing Reaction

•

One or more built-in valve functions: relief valve, shock valves, suction valves, non-return valve in Pline and LS-line

•

Optional port connections according to ISO, SAE or DIN standards

Characteristics for EH steering systems with OSPE, EHPS, and EHi:

•

Possibility of GPS, row sensor, variable steering ratio and joystick steering

•

Possibility of manual steering even on very heavy vehicles

•

EHPS:

High steering pressure requiring smaller cylinders and flow

‒

Low pilot pressure and flow giving extremely low noise in the cabin

‒

Combined with Danfoss PVG 32 proportional valve

‒

Conversion factors

1 N•m = [8.851 lbf•in] 1 l = [0.264 US gal]

1 N = [0.2248 lbf] 1 bar = [14.5 psi]

1 mm = [0.0394 in] °F = [1.8°C + 32]

1 cm3 = [0.061 in3]

Survey of literature with technical data on Danfoss steering components

Detailed data on all Danfoss steering components and accessories can be found in our steering

component catalogues, which is divided into the following individual sub-catalogues:

General information Steering components

Technical data on mini steering units OSPM

Technical data on open center and closed center steering

units

Technical data on load sensing steering units, priority

valves and flow amplifiers

Technical data on load sensing steering unit with

amplification

Technical data on steering units VSP

Technical data on steering units VSPP

Technical data on hydraulic and electrohydraulic pilot

operated steering valves, electrical actuation modules

and appropriate steering units

Technical data on combined sterering unit/

electrohydraulic steering valves

Technical data on electrohydraulic steering valves EHi

Technical data on steering wheel sensors SASA

OSPB, OSPC, and OSPD

OSPB, OSPC, OSPF, OSPD, OSPL, OSPBX, OSPLX, OVPL,

OLS, and OSQ

OSPU

EHPS, EHPS w. OLS 320, PVE for EHPS and OSPCX

OSPE

For technical information on individual variants, please contact the Danfoss Sales Organization.

©

Danfoss | July 2021 BC358854914884en-000102 | 5

Page 6

Technical Information

VSPP Steering Unit

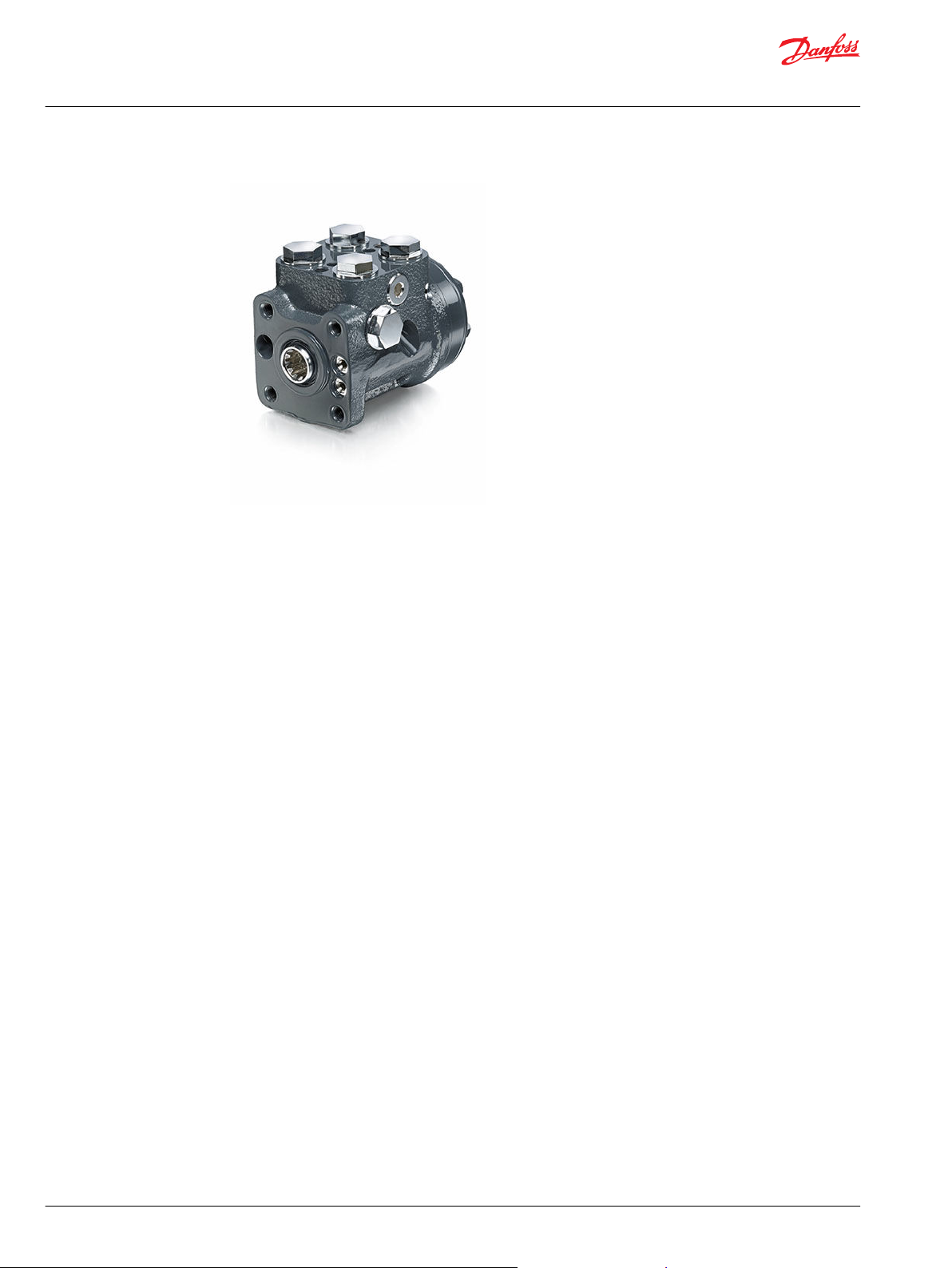

Steering unit type VSPP

General

VSPP

The VSPP is a steering unit with integrated priority valve inside the envelope of a standard steering unit

housing.

This brings about a very compact solution minimizing installation space, cost and time.

VSPP is the perfect solution for smaller vehicles like e.g. low horse power tractors, mini wheel loaders and

light fork lift trucks, where one gear pump is in use for steering and working hydraulic.

All VSPP products are black painted as standard.

All VSPP's are High Spec. for maximum steering pressure 190 bar [2755 psi].

Load Sensing dynamic steering unit with built in priority valve, VSPP LS

The VSPP is a steering unit with integrated priority valve inside the envelope of the standard VSP

housing. VSPP LS are all of load sensing dynamictype and so the integrated priority valve is dynamic type.

Spool/sleeve sets for 2 levels of LS dynamic flow are available:

•

Standard LS spool/sleeve set: 0.6 - 0.9 l/min [0.16 - 0.24 US gal/min]

•

High dynamic LS spool/sleeve set: 1.0 - 1.3 l/min [0.26 - 0.34 US gal/min]

High dynamic is recommended, when extreme fast response is requested, e.g. when unloading working

hydraulic load (EF) very rapidly during steering. Trade off with high dynamic is slightly higher energy

consumption.

Non-reaction

VSPP’s are non-reaction steering units, where there is no movement of the steering wheel, when the

driver is not steering the vehicle. The vehicle keeps the steering direction independent of forces on the

steering cylinder.

6 | © Danfoss | July 2021 BC358854914884en-000102

Page 7

Technical Information

VSPP Steering Unit

Steering unit type VSPP

VSPP versions, overview

Gear set

The gear set meters the volume of oil/revolution on the steering wheel, cm3/rev. 2 versions of gear set are

available for VSPP:

•

Low Noise is default for VSPP up to and including 250 cm3/rev. VSPP 315 and VSPP 400 will have gear

set with standard profile

•

Seal star: reduces slippage, when steering cylinder is at end stroke. Seal star gear sets are available in

50, 70, 80, 100 and 125 cm3/rev.

All seal star gear sets have standard profile.

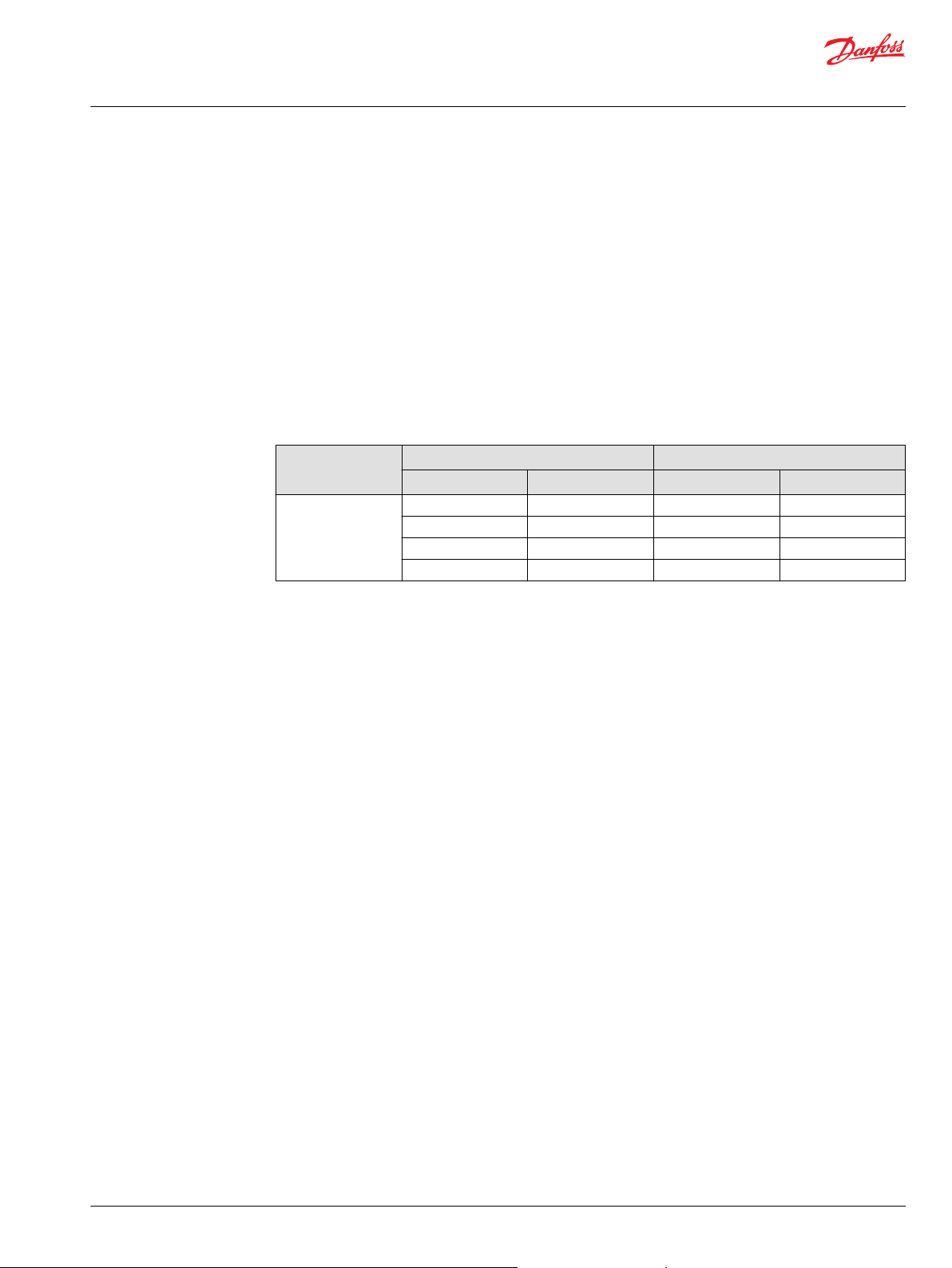

The VSP's are available in the x-marked combinations:

Type Spool/sleeve set Gear set

Standard LS: High dynamic Low Noise Seal star

VSPP LS: Load

Sensing non reaction

w. int. Priority valve

X X

X X

X X

X X

©

Danfoss | July 2021 BC358854914884en-000102 | 7

Page 8

Technical Information

VSPP Steering Unit

Steering unit type VSPP

VSPP circuits

VSPP Load Sensing dynamic, steering unit with integrated valve functions

VSPP LS Load Sensing Non-reaction

8 | © Danfoss | July 2021 BC358854914884en-000102

Page 9

Technical Information

VSPP Steering Unit

Technical data, VSPP LS

Displacement, flow and pressure

For common data: Look in sub catalog: "General Steering Components"

Rated oil flow

Displacement

Steering unit

VSPP 50 LSH 50 [3.05] 5 [1.32]

VSPP 70 LSH 70 [4.27] 7 [1.85]

VSPP 100 LSH 100 [6.10] 10 [2.64]

VSPP 125 LSH 125 [7.63] 13 [3.43]

VSPP 160 LSH 160 [9.76] 16 [4.23]

VSPP 200 LSH 200 [12.20] 20 [4.23]

VSPP 250 LSH 250 [15.26] 25 [6.60]

VSPP 315 LSH 315 [19.22] 32 [8.45]

VSPP 400 LSH 400 [24.41] 40 [10.57]

1

Any VSPP LSH can withstand 190 bar [2755 psi] in max steering system pressure. However, VSPP w small gear set and high pressure will have

relatively high slippage values.

cm3 /rev [in3/

rev]

for steering @

100 rpm

l/min [US gal/

min]

Max. oil flow

from pump

l/min [US gal/

min]

80[21.1]

Max. pressure, bar [psi]

System

pressure1/

P-T

portpressure

140 [2030]

170 [2465]VSPP 80 LSH 80 [4.88] 8 [2.11]

190 [2755]

T, absolute

port pressure

30 [435] 250 [3625] 230[3335]

L-T/R-T port

pressure

P and EF,

absolute

port pressure

©

Danfoss | July 2021 BC358854914884en-000102 | 9

Page 10

Technical Information

VSPP Steering Unit

Technical data, VSPP LS

Valve functions

All VSPP LS have the following valves built in:

•

Priority valve (7)

•

P-Check valve in CF line (5)

•

Pilot relief valve (4)

•

Check valve in LS (6)

•

Emergency steering check valve (3)

All VSPP LS with UNF and Metric ports also have the following valves built in:

•

Shock valves (1)

•

Suction valves (2)

VSPP LS with G-thread ports can be specified with or without shock and suction valves

Shock and suction are always combined

10 | © Danfoss | July 2021 BC358854914884en-000102

Page 11

P-T

l/min

A

B

60

80

100

120

140

160

180

200

900

1150

1400

1650

1900

2150

2400

2650

2900

psi

bar

0

10

20

30

40

50

60

70

80

2

4

6

8

10

12

14

16

18

20

US gal/min

Technical Information

VSPP Steering Unit

Technical data, VSPP LS

Pilot pressure relief valve; (P-T, Qp) characteristic

The pilot pressure relief valve protects the steering unit against excessive pressure. The pilot pressure

relief valve in the VSPP LS steering unit together with the integrated priority valve spool, limits the

maximum steering pressure P-T. The pilot pressure relief valve is set at an oil flow to the P-port of the

VSPP valve of 25 l/min [6.60 US gal/min].

For VSPP load sensing dynamic steering units with standard LS spool/sleeve set, the setting values are

valid at a dynamic flow of 0.6 l/min [0.16 US gal/min].

For VSPP load sensing high dynamic steering units with low noise/high dynamic spool/sleeve set, the

setting values are valid at a dynamic flow of 1.1 l/min [0.29 US gal/min].

Setting tolerance:

</= 170 bar [2465 psi]: rated value +5 bar [72.5 psi].

> 170 bar [2465 psi]: rated value +10 bar [145 psi].

Check valve function in LS

A 170 + 5/-0 bar [2465+ 73/-0 psi]

B 140 + 5/-0 bar [2030 + 73/-0 psi]

The check valve in the LS line of VSPP LS dynamic steering units protects the driver against steering

wheel jerks. The check valve prevents oil from flowing backwards into the LS line to the priority valve,

©

Danfoss | July 2021 BC358854914884en-000102 | 11

when steering against a high pressure on the cylinder side. The need for the LS check valve is very system

dependent. It is recommended to be included in VSPP LS up to and including 200 cm3/rev sizes.

Page 12

0

10

20

30

40

50

60

70

80

7 bar

4 bar

min.

0

2

4

6

8

10

12

14

16

18

bar

P-EF, VSPP

Qp

l/min

US gal/min

psi

30

60

90

120

150

180

210

240

0

3

6

9

12

15

18

21

0

Technical Information

VSPP Steering Unit

Technical data, VSPP LS

Pressure drop, P-EF

This data comes from measurements on a representative sample of VSPP LS w. standard spool/sleeve set.

Oil with viscosity of 21 mm²/s at 50 °C [102 SUS at 122 °F] was used during measuring. Measurement

made when pressure on the LS connection is zero (steering unit in neutral position). The minimum curves

apply when the pressure on the EF connection is higher than the actual control spring pressure. The

curves for control spring pressure of 4 or 7 bar [58 or 101 psi] apply when pressure on the EF connection

is zero.

Pressure drop, P-EF, for VSPP LS w. standard dynamic LS spool/sleeve set

Shock valves

The shock valves protect the steering unit and reduce external forces on the steering cylinder by limiting

the pressure difference from L to T and from R to T.

The shock valves are set at 3 l/min [0.792 US gal/min]

At higher flow, pressure peaks may occur.

The shock valves are of the direct acting type, so they react very quickly.

12 | © Danfoss | July 2021 BC358854914884en-000102

Setting tolerance: rated value +20 bar [290 psi].

Page 13

100

80

60

40

20

0

7

6

5

4

3

2

1

0

psi bar

150-374.10

0 1 2 3 4 5 6 7 8 9 10 11 l/min

T-R

T-L

T-R

T-L

Q

p

Q

p

0 0.25 0.50 0.75 1 1.25 1.50 1.75 2 2.25 2.50 2.75 US gal/min

∆

∆

psi

bar

p

p

90

75

60

45

30

15

6

5

4

3

2

1

0

0

0

10

20

30

40

50

l/min

Qp

Qp

0

3

6

9

12

USgal/min

Technical Information

VSPP Steering Unit

Technical data, VSPP LS

Suction valves

The suction valves allow oil suction to avoid cavitation in the steering cylinder. To provide correct

suction, a back pressure valve must be fitted in the tank line from the steering unit.

Generally Danfoss recommend a back pressure of 2 bar [29 psi], but on vehicles with strong selfstraightening tendencies and on articulated steered vehicles, we recommend 5-10 bar [72.5 - 145 psi]. For

further advice, please contact the Danfoss Sales Organisation.

A connection which incorporates a check valve must be established to allow oil flow to by-pass the back

pressure valve (and filter) from the tank to steering unit. See diagram examples in sub catalogue “General

Steering Components” page 37 - 39.

Check valve in P

The check valve in the P connection of the steering unit protects the driver against steering wheel jerks.

The check valve prevents oil from flowing backwards into the pump line when steering against a high

pressure on the cylinder side. The pressure drop across the check valve is indicated on the following

graph, which assumes the use of port adaptors with 11 mm [0.43 in] minimum bore.

©

Danfoss | July 2021 BC358854914884en-000102 | 13

Page 14

Technical Information

VSPP Steering Unit

Technical data, VSPP LS

Weights

Type Weight, kg [lb]

VSPP 50 LS 5.2 [11.46]

VSPP 70 LS 5.3 [11.68]

VSPP 80 LS 5.3 [11.68]

VSPP 100 LS 5.4 [11.90]

VSPP 125 LS 5.5 [12.13]

VSPP 160 LS 5.6 [12.35]

VSPP 200 LS 5.8 [12.79]

VSPP 250 LS 6.0 [13.23]

VSPP 315 LS 6.2 [13.67]

VSPP 400 LS 7.0 [15.43]

14 | © Danfoss | July 2021 BC358854914884en-000102

Page 15

P, T, L, R: max 0.6[0.024]

Ø28.3[1.114]

Ø28.6[1.126]

N

min.15[0.59]

D

P, T, L, R: max 0.6[0.024]

Ø28.6[1.126]

Ø28.3[1.114]

P

min.15[0.59]

F

S

Ø20.8 [0.819]

Ø20.6 [0.812]

Ø28.6 [1.126]

Ø28.3 [1.114]

P, T, L, R: max 0.6 [0.024]

min 15 [0.59]

I

Technical Information

VSPP Steering Unit

Port thread versions

D G port w. spot face (P, T, L, R, EF)

N DIN 3852-2 – G1/2

F Metric ports w. spot face and O-ring chamfer (P, T, L, R, EF)

P ISO 6149-1 - M18 x 1.5

I UNF ports w. spot face and O-ring chamfer (P, T, L, R, EF)

S ISO 11926-1 ¾-16UNF O-ring boss port

©

Danfoss | July 2021 BC358854914884en-000102 | 15

Page 16

33.5

30.2

EF

ø44.4±0.05

ø25.4

L1

min. 7.1

44

A

L2

44

L

R

T

P

45.5

29

7

2.8

ø82±0.3

B

79

ø91

EF

min. ø28.6

102

45°

max. 87

max. 5.3

38

57

Technical Information

VSPP Steering Unit

Dimensions

VSPP

VSPP LS

G ½ w. spot face (G, DIN 3852-2) 15 mm [0.59 in] deep

Or: M18 x 1.5 ISO 6149-1, 15 mm [0.59 in] deep

A (P, T, L, R, and EF)

Or: 3/4 - 16 UNF O-ring boss ISO 11926-1 15 mm [0.59 in] deep

B M10 x 1.5, 16 mm [0.63 in] deep

16 | © Danfoss | July 2021 BC358854914884en-000102

Page 17

Technical Information

VSPP Steering Unit

Dimensions

VSPP dimensions details

VSPP dimensions

Type

VSPP 50 125 [4.92] 6.5 [0.26]

VSPP 70 127 [4.99] 9.1 [0.36]

VSPP 80 128 [5.04] 10.4 [0.41]

VSPP 100 131 [5.16] 13.0 [0.51]

VSPP 125 134 [5.28] 16.2 [0.64]

VSPP 160 139 [5.47] 20.8 [0.82]

VSPP 200 144 [5.67] 26.0 [1.02]

VSPP 250 150 [5.91] 32.5 [1.28]

VSPP 315 159 [6.26] 40.9 [1.61]

VSPP 400 170 [6.69] 52.0 [2.05]

L1

mm [in]

L2

mm [in]

©

Danfoss | July 2021 BC358854914884en-000102 | 17

Page 18

Technical Information

VSPP Steering Unit

VSPP: Variants and ordering specifications

VSPP MMC

Determine Master Model Code (MMC). Fill in with codes from Variants codes for VSPP MMC on page 19,

to specify VSPP steering unit.

MMC-pos. 1 2 3 4 5 6 7

Type Displ. Circuit type PTL&R size

Your VSPP

Example* VSPP## 0100 LSH# UUUU C M H

MMC-pos. 8 9 10 11 12 13 14

EF interface

Your VSPP

Example* C 9 180 240 1 4 N03

MMC-pos. 15 16 17 18 19

Your VSPP

*

Example

*

Example is a valid for Catalog code of VSPP 100 LSH: 11189283

PTL&R

interface

EF location

Spool/sleeve set Gear set Special Label Paint

SV5 G01 NN DNFS PB

Relief valve Shock valves

Suction

valves

Column

thread

Check valves

EF size

Neutral

springs

18 | © Danfoss | July 2021 BC358854914884en-000102

Page 19

Technical Information

VSPP Steering Unit

VSPP: Variants and ordering specifications

Variants codes for VSPP MMC

MMC pos. 1 Main steering product Type1

VSPP## VSPP Steering units w. integrated priority valve

MMC pos. 2 Displacement, cm3/rev

0050 50

0070 70

0080 80

0100 100

0125 125

0160 160

0200 200

0250 250

0315 315

0400 400

MMC pos. 3 Circuit type

LSH# Load Sensing non reaction, High spec.

MMC pos. 4 P, T, L & T Port Size

MMMM M18x1.5 (ISO 6149-1)

UUUU 3/4"-16 UNF (ISO 11926-1)

GGGG G1/2" (DIN 3852-2)

MMC pos. 5 P, T, L & T Port Interface

A O-ring boss + Spot-face (ISO 6149-1)

C O-ring boss + Spot-face (ISO 11926-1)

E Spot-face (for G-thread, DIN 3852-2)

MMC pos. 6 Column Thread

M M10x1,5

MMC pos. 7 EF Port Size

M M18x1.5 (ISO 6149-1)

H 3/4"-16 UNF (ISO 11926-1)

G G1/2" (DIN 3852-2)

MMC pos. 8 EF Port Interface

A O-ring boss + Spot-face (ISO 6149-1)

C O-ring boss + Spot-face (ISO 11926-1)

E Spot-face (for G-thread, DIN 3852-2)

MMC pos. 9 EF Port Location

9 On Side

©

Danfoss | July 2021 BC358854914884en-000102 | 19

Page 20

Technical Information

VSPP Steering Unit

VSPP: Variants and ordering specifications

MMC pos.10Relief valve setting

140

MMC pos.11Shock valves

NNN No shock valves (only possible for VSPP with G-thread, DIN 3852-2)

200

MMC pos.12Suction valves

N No suction valves (only possible for VSPP with G-thread, DIN 3852-2)

1 Shock and suction valves are belonging

MMC pos.13Check valves

1 Check valve in P (standard)

4 Check valve in P and in LS (standard in LS up to and included 200 ccm/rev)

MMC pos.14Neutral Springs

Value for setting (140 bar), P-T.

All VSPP's have relief valve.

Range VSPP: 50 - 190 bar

Value for setting (200 bar), R-T/L-T.

Shock and suction valves are belonging

Range: 110 - 250 bar, last digit: 0 or 5

N01 11124634, torque 0.7-1.7 Nm in normal steering situations. Soft

N03 150N4019, torque 0.6-2.5 Nm in normal steering situations. Medium

N05 150-4209, torque 0.8-4 Nm in normal steering situations. Standard

MMC pos.15Spool/ Sleeve Set

SV5 LSH: Dynamic flow recommended 0.6-0.9 l/min. Constant pressure. High Spec.

SV6

MMC pos.16Gear set

G03 Gear set, Standard cross grinded

G01 Gear set, Low Noise/profile grinded, available up to and including 250 ccm/rev

G04

MMC pos.17Special

NN Not Applicable

XX Special feature

LSH High dynamic: Dynamic flow recommended 1.0-1.3 l/min. Constant pressure.

High Spec.

Gear set, Standard cross grinded, with Seal Star (for low slippage)

Available in 50, 70, 80, 100 and 125 ccm/rev

20 | © Danfoss | July 2021 BC358854914884en-000102

Page 21

Technical Information

VSPP Steering Unit

VSPP: Variants and ordering specifications

MMC pos.18Label

DNFS Danfoss name tag

XXXX Special Label

MMC pos.19Paint

PB Black, Powder, RAL 9005, Corrosion class C3. Standard covering

©

Danfoss | July 2021 BC358854914884en-000102 | 21

Page 22

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | July 2021 BC358854914884en-000102

Loading...

Loading...