MAKING MODERN LIVING POSSIBLE

VSH系列变速涡旋压缩机

用于商用空调系统

50 - 60 Hz - R410A

选型和应用指南

www.danfoss.com.cn

Performer VSD

Variable speed A/C compres sors

™

应用指南

目录

VSH 涡旋压缩机规格 ........................................................................................................................... 3

变速压缩机 .......................................................................................................................................... 4

压缩机选型 ........................................................................................................................................................................4

变频器选型 ........................................................................................................................................................................4

压缩机和变频器组合 .....................................................................................................................................................4

命名和规格 .......................................................................................................................................... 5

压缩机命名 ........................................................................................................................................................................5

变频器命名 ........................................................................................................................................................................5

技术规格 .............................................................................................................................................. 6

压缩机规格 ........................................................................................................................................................................6

变频器规格 ........................................................................................................................................................................6

喷油控制 .............................................................................................................................................................................6

轴承润滑 .............................................................................................................................................................................6

EN12900 标准能力 ..........................................................................................................................................................7

ARI 标准能力 .....................................................................................................................................................................8

尺寸 ...................................................................................................................................................... 9

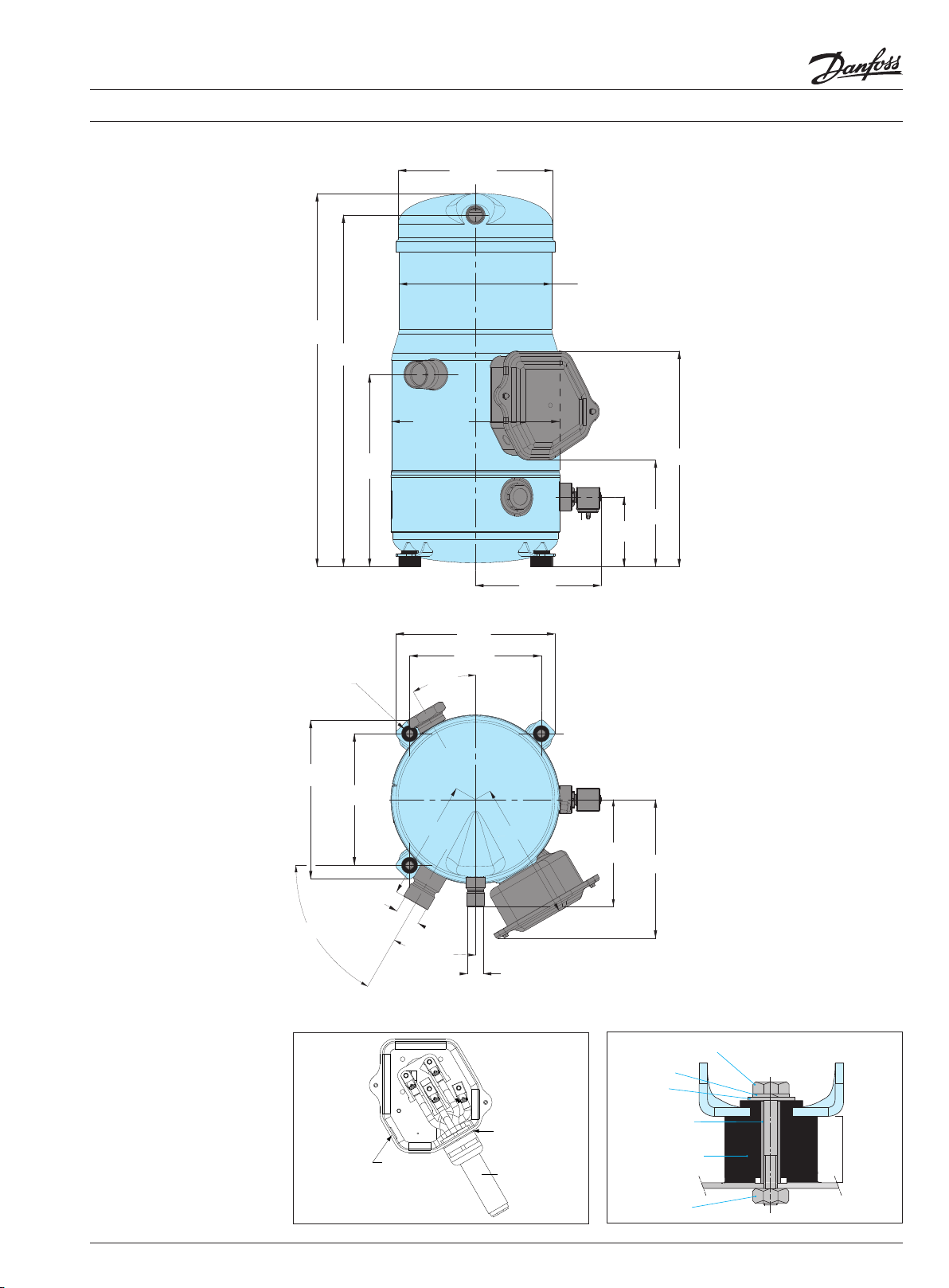

VSH088-G & H .................................................................................................................................................................... 9

VSH088-J ........................................................................................................................................................................... 10

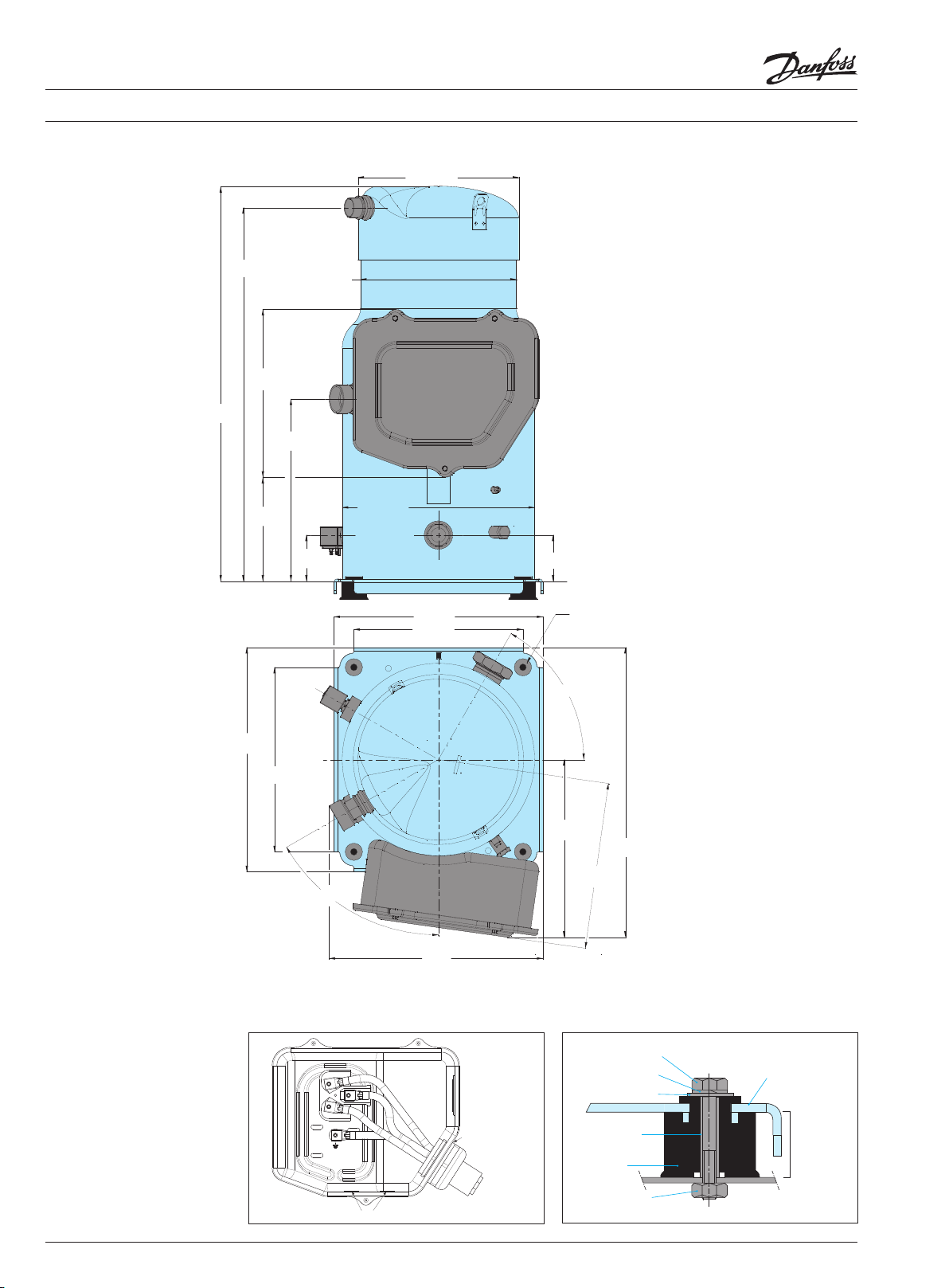

VSH117-G & H ................................................................................................................................................................. 11

VSH117-J ........................................................................................................................................................................... 12

VSH170- G - H & J ........................................................................................................................................................... 13

视液镜 ............................................................................................................................................................................... 14

快速接头 .......................................................................................................................................................................... 14

油平衡链连接 ................................................................................................................................................................ 14

排油部件 .......................................................................................................................................................................... 14

吸排气连接 .....................................................................................................................................................................14

变频器尺寸 .....................................................................................................................................................................14

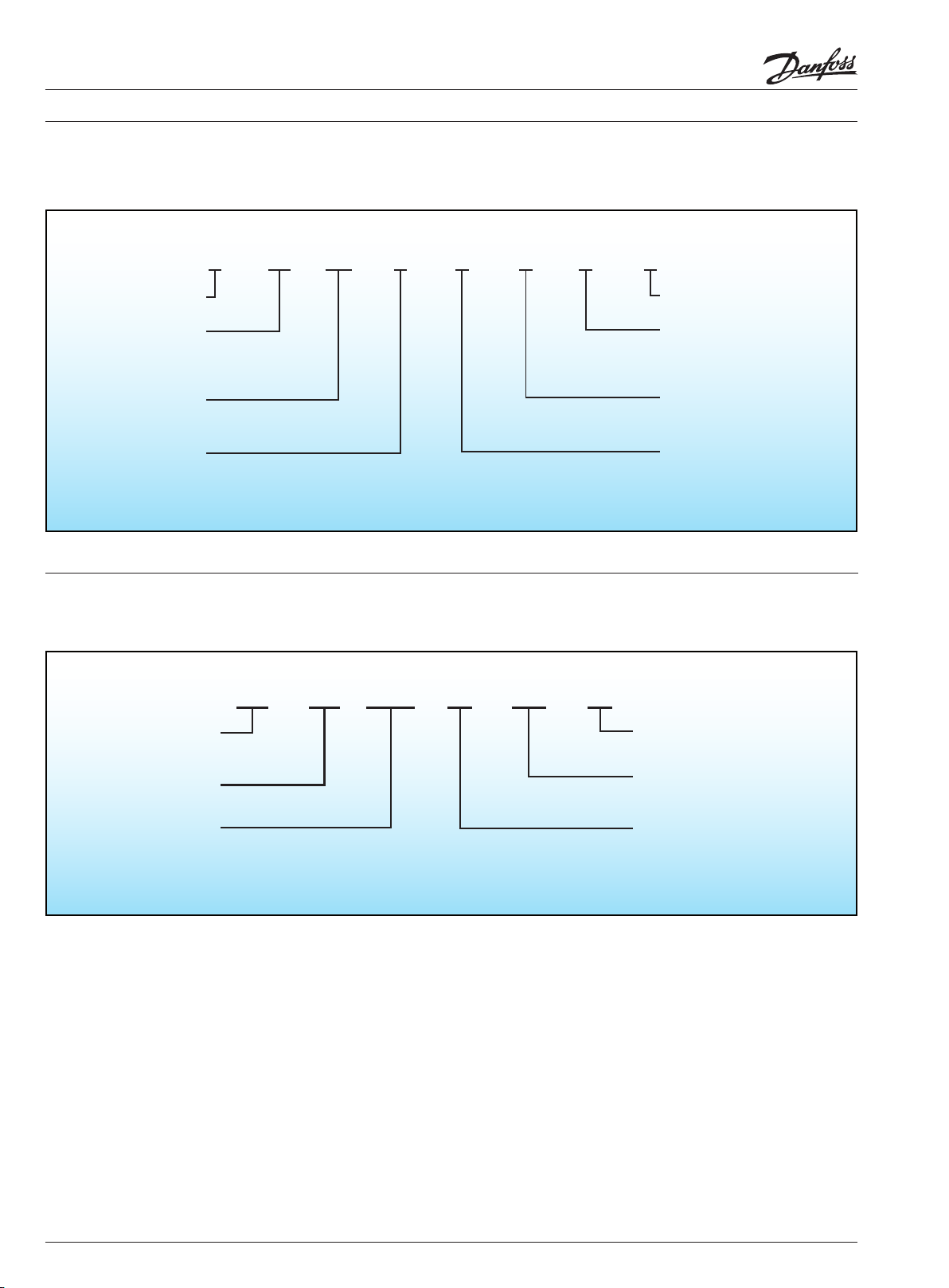

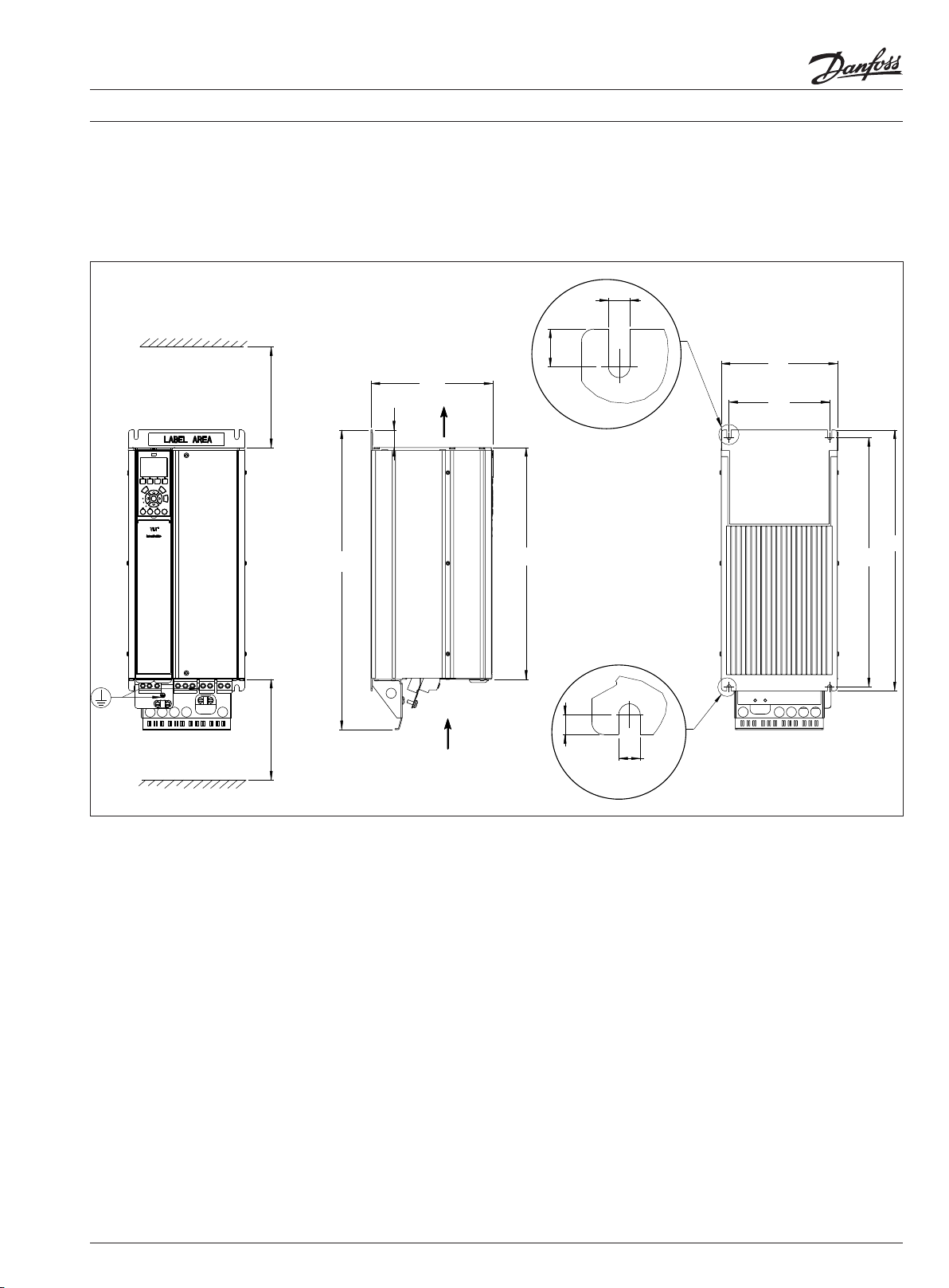

CDS302 变频器外壳 B1 ..............................................................................................................................................15

CDS302 变频器外壳 B2 ..............................................................................................................................................16

CDS302 变频器外壳 B3 ..............................................................................................................................................17

CDS302 变频器外壳 B4 ..............................................................................................................................................18

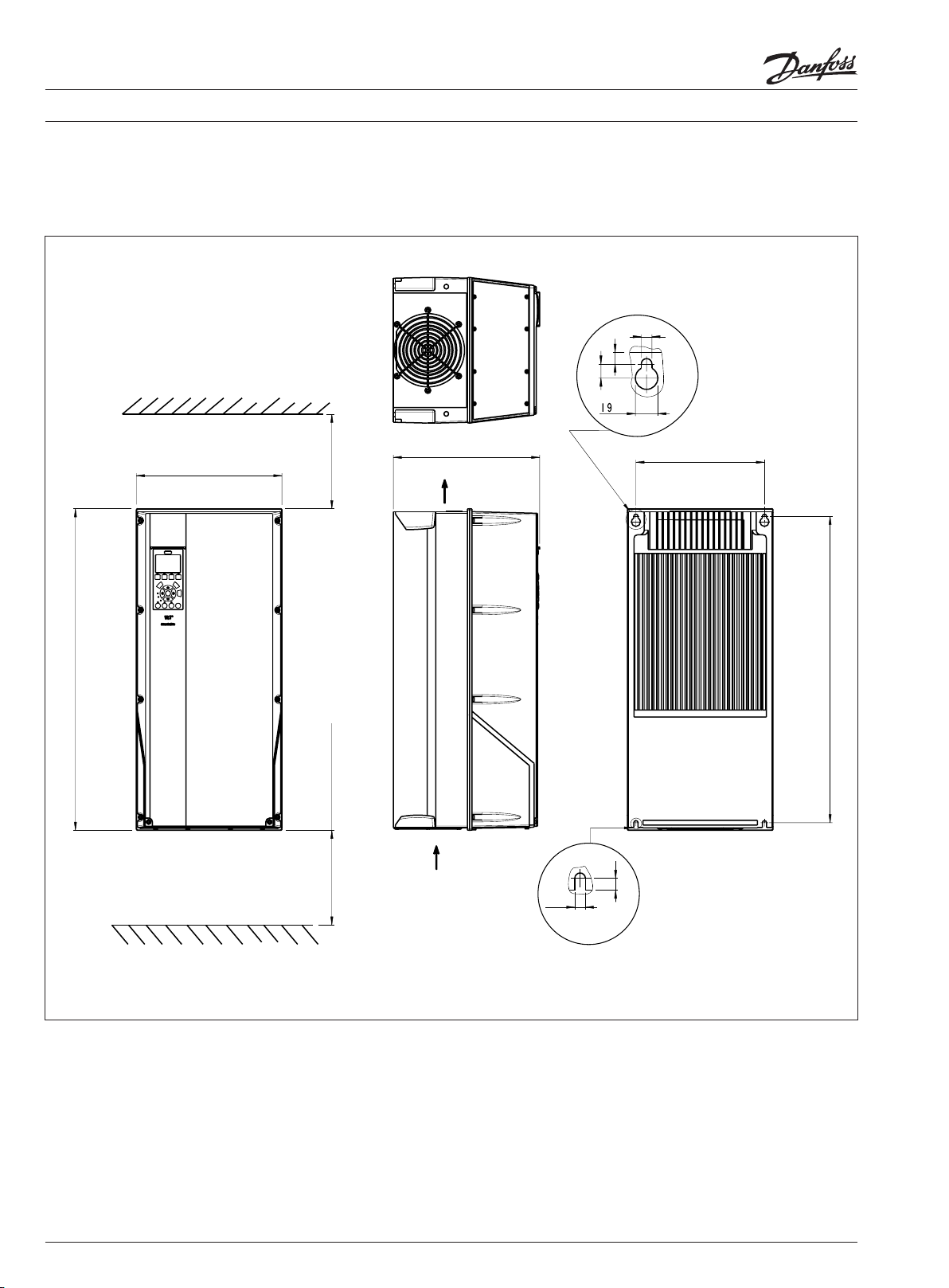

CDS302 变频器外壳 C1 .............................................................................................................................................. 19

CDS302 变频器外壳 C3 .............................................................................................................................................. 20

电气数据, 接线 ................................................................................................................................... 21

供电电源 .......................................................................................................................................................................... 21

压缩机电气规格 ............................................................................................................................................................ 21

保险 .................................................................................................................................................................................... 21

电线规格 .......................................................................................................................................................................... 22

接线和EMC 保护 ........................................................................................................................................................... 22

IP20变频驱动CDS302的EMC正确安装 ................................................................................................................ 23

接线图 ............................................................................................................................................................................... 24

接线 .................................................................................................................................................................................... 25

电气连接 .......................................................................................................................................................................... 26

软启动控制 .....................................................................................................................................................................26

相序和反转保护 ............................................................................................................................................................ 26

IP等级 ................................................................................................................................................................................ 26

电机保护 .......................................................................................................................................................................... 26

电压不平衡 .....................................................................................................................................................................26

认证和标准 ........................................................................................................................................ 27

认证和证书 .....................................................................................................................................................................27

压力设备规定97 / 23 / EC .......................................................................................................................................... 27

内部自由容积 ................................................................................................................................................................ 27

1

应用指南

目录

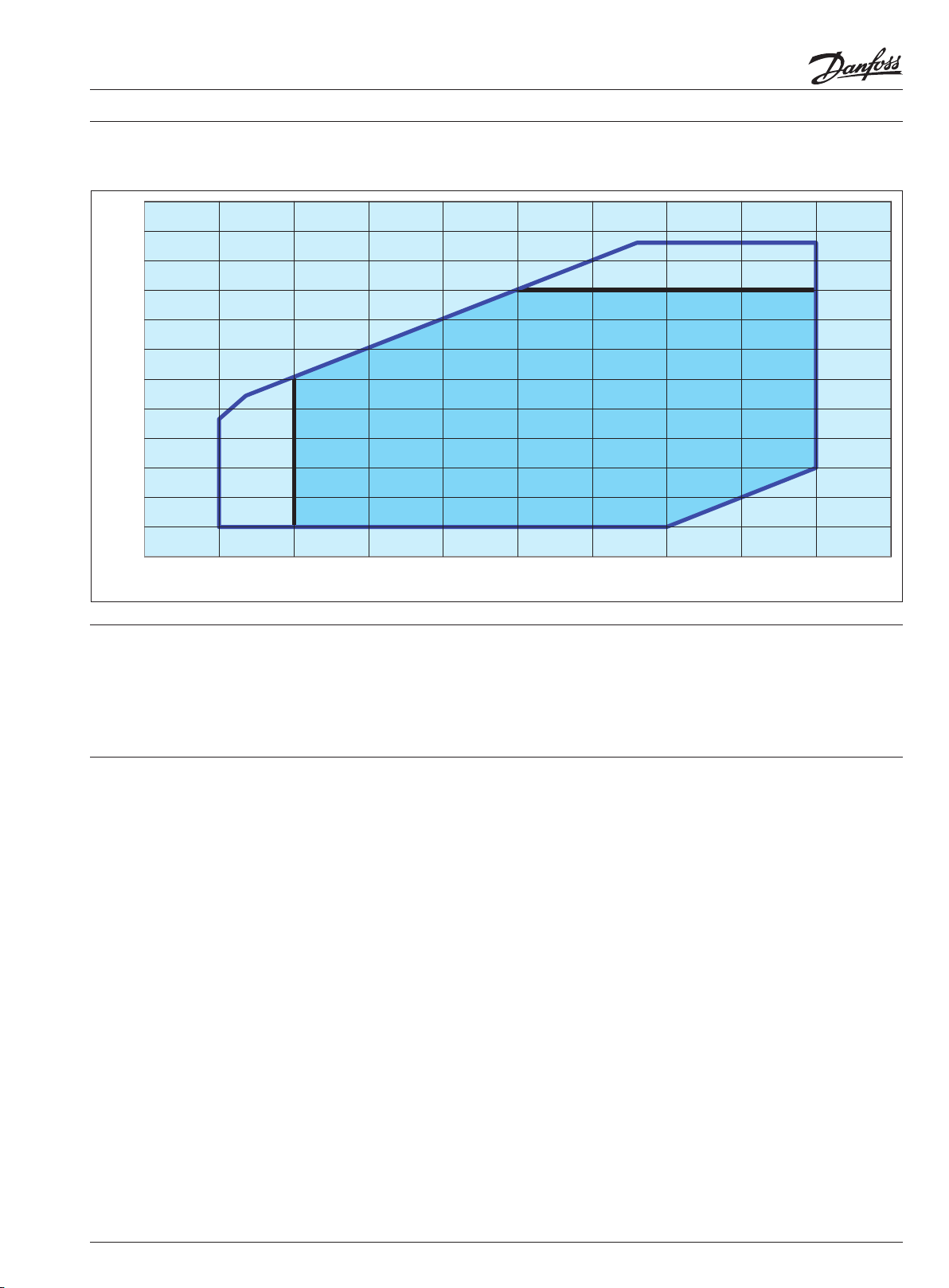

运行工况 ............................................................................................................................................28

应用范围 .......................................................................................................................................................................... 28

短循环计时器功能 ....................................................................................................................................................... 28

排气温度保护 ................................................................................................................................................................ 28

排气温控器 .....................................................................................................................................................................29

回油管理 .......................................................................................................................................................................... 29

高低压保护 .....................................................................................................................................................................30

系统设计推荐 .................................................................................................................................... 31

基本的管路设计 ............................................................................................................................................................ 31

热交换器 .......................................................................................................................................................................... 32

冷媒充注限制 ................................................................................................................................................................ 32

停机冷媒迁移 ................................................................................................................................................................ 32

运行时回液 .....................................................................................................................................................................33

特殊应用推荐 .................................................................................................................................... 34

低环境温度压缩机运行 ............................................................................................................................................. 34

板式热交换器 ................................................................................................................................................................ 35

可逆热泵系统 ................................................................................................................................................................ 35

排气管和换向阀 ............................................................................................................................................................ 36

声音和振动控制 ................................................................................................................................. 37

运行噪音水平 ................................................................................................................................................................ 37

制冷或空调系统里产生的噪音 ............................................................................................................................... 37

压缩机噪音辐射 ............................................................................................................................................................ 37

机械震动 .......................................................................................................................................................................... 37

速度跳过 .......................................................................................................................................................................... 37

气流脉动 .......................................................................................................................................................................... 37

安装 .................................................................................................................................................... 38

压缩机搬运 .....................................................................................................................................................................38

安装 .................................................................................................................................................................................... 38

移除连接搬运挂钩 ....................................................................................................................................................... 38

系统清洁 .......................................................................................................................................................................... 39

连管 .................................................................................................................................................................................... 39

干燥过滤 .......................................................................................................................................................................... 39

焊接 .................................................................................................................................................................................... 39

压缩机连接 .....................................................................................................................................................................39

系统压力测试 ................................................................................................................................................................ 40

验漏 .................................................................................................................................................................................... 40

抽真空和驱除湿气 ....................................................................................................................................................... 41

充注冷媒 .......................................................................................................................................................................... 41

调试 .................................................................................................................................................................................... 41

油位检查 .......................................................................................................................................................................... 41

附件 .................................................................................................................................................... 42

压缩机 ............................................................................................................................................................................... 42

变频器附件 .....................................................................................................................................................................42

订单信息和包装 ................................................................................................................................. 43

附件订单和运输 ............................................................................................................................................................ 43

包装 .................................................................................................................................................................................... 43

订单信息和包装 ................................................................................................................................. 44

VSH电压类型 J – 200-240伏 ..................................................................................................................................... 44

VSH电压类型 G – 380-480伏 ................................................................................................................................... 45

VSH电压类型 H – 525-600伏 ................................................................................................................................... 46

2

应用指南

VSH涡旋压缩机tv规格

强化的球墨铸铁涡旋盘

将油和制冷剂分离开,减小压缩机

高速运行时的带油率

喷油由变频器控制, 避免了压缩机

高速运行时带油率的增加

专利喷油系统确保压缩机在

所有运行速度下都能得到最

佳的润滑

新开发的内齿轮油泵确保低

速时候轴承的有效润滑

油过滤器防止喷油管路杂

质的影响

3

应用指南

变速压缩机

压缩机选型

变频器参数

压缩机和变频器组合

在压缩机选型方面,变速压缩机比定速压缩机从

技术上提供了更多的可能性,选择正确的变速压

缩机可以通过以下几种不同的方法:

1. 最大制冷量: 所选压缩机在最高转速时的制冷

量应能满足系统的高峰负荷。

2. 名义制冷量: 所选压缩机在转速3600–4500

rpm (60-75Hz)时制冷量应能满足系统的名义制

冷量。

3. 最佳季节能效比: 所选压缩机在最低转速时的

按照如下所示有不同的变频器可供选择:

1. 主电源电压

2. IP等级(CD302驱动器可有IP20和IP55两种等级

外壳)

3. RFI等级(无线电频率干扰) H2或者H3

当 根 据 上 述 选 型 标 准 确 定 压 缩 机 和 主 电 源

后,“订购信息和包装”部分的订货代码表给

制冷量应能满足系统的最小负荷需求,并能够满

足系统的高峰负荷需求。这样所选的压缩机能够

在部分负荷最长时间运行,效率最高。

下一页可以参考性能表格3,详细的性能数据请参

见数据表和选型软件。

4. 是否存在本地控制板天线电频率冲突

5. 印刷电路板是否涂漆

出了合适的变频器大小,以及16个其所对应的

压缩机型

号订货代码。

4

应用指南

压缩机命名

压缩机型号说明

ANAGA117SHV

系列, 冷媒

单位: cm³/rev(毫升每转)

变频器命名

VSH涡旋压缩机

专用变频器

变速

VSH涡旋,

POE, R410A

排气量

标准认证

索引

UL

302系列

改型代码

电机保护

没有内置电机保护

N:

(变频器保护)

机器版本

焊接连接方式

A:

电机电源代码

J: 200-240V / 3 相 / 50 & 60 Hz

G: 380-480V / 3 相 / 50 & 60 Hz

H: 525-600V / 3 相 / 50 & 60 Hz

H2E20T4P15K302CDS

RFI等级

防护等级

IP 等级

输出功率, kW

主电源

T2: 200-240V/3 ph / 50 - 60 Hz

T4: 380-480V/3 ph/50-60 Hz

T6: 525-600V/3 ph/50-60 Hz

5

应用指南

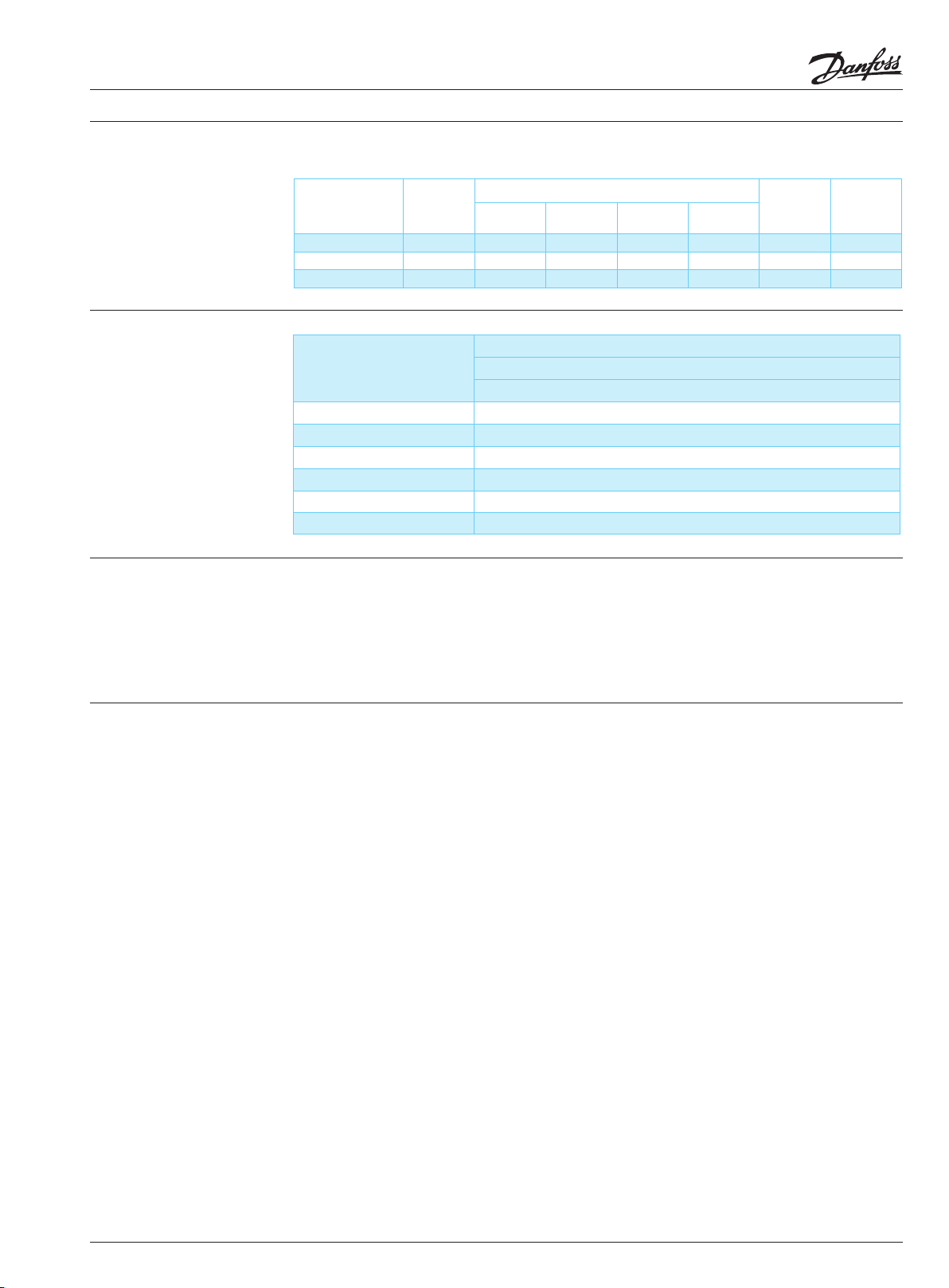

技术参数

压缩机规格

变频器规格

喷油控制

压缩机型号

VSH088 88.4 9.3 15.4 18.6 27.8 3 59

VSH117 116.9 12.3 20.3 24.6 36.6 3.3 65

VSH170 170.2 17.8 29.6 35.7 53.3 6.7 107

主电源

供电频率

输出电压

输入

可编程输出

保护功能 过电流保护, 过调节控制, 高/低电流控制

压缩机功能 排气温度保护, 压力/温度继电器, 短循环保护, 回油控制

排气量(cm³/

rev)

最小转速

(m³/h)

T2: 200 - 240 V +/-10% (3-phase)

T4: 380 - 480 V +/-10% (3-phase)

T6: 525 - 600 V +/-10% (3-phase)

50 / 60 Hz

供电电压的 0 - 100 %

6个数字量(0-24V), 2个模拟量(-10/+10v或者0/4-20mA)

2个数字量(0-24V), 2个模拟量(0-24v), 2个继电器

VSH压缩机设计有一个喷油系统,能够在各种运行

工况下确保涡旋盘的润滑并控制带油率,变频器通

过喷油阀来控制这个系统。该阀是一个常闭阀门,

低转速时阀关闭,油被喷射到动涡旋盘的下面。

排气

50 Hz

(m³/h)

60 Hz

(m³/h)

最大转速

(m³/h)

油量(dm³) 净重(kg)

件(请参考附件页)。

控制参数是出厂前预设好的,该只读值可参见参

数列表。

轴承润滑

压缩机附带230V的电磁阀线圈,24V线圈为可选配

内齿轮油泵确保压缩机各种转 速下轴承的最佳

润滑。

6

应用指南

技术参数

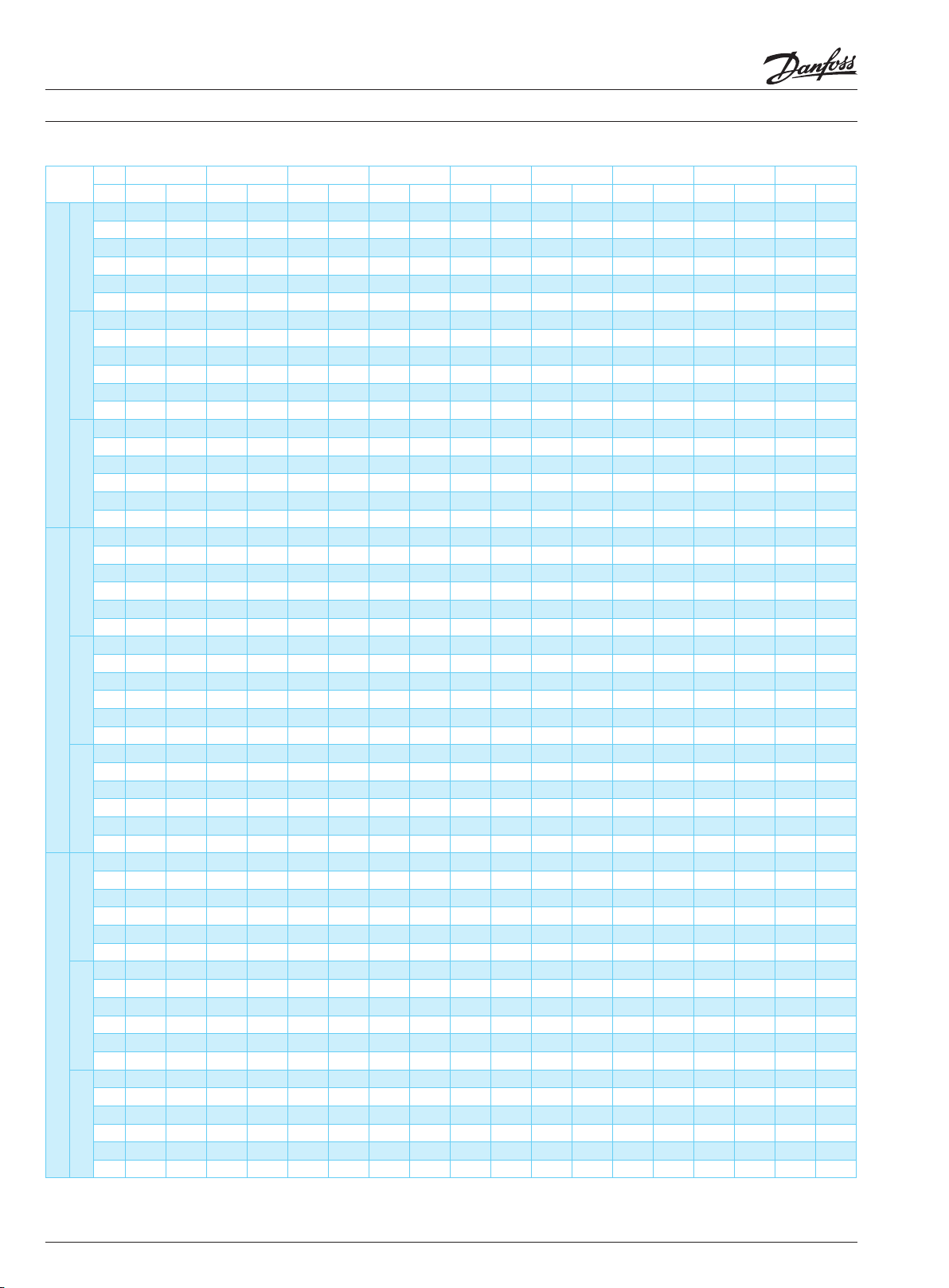

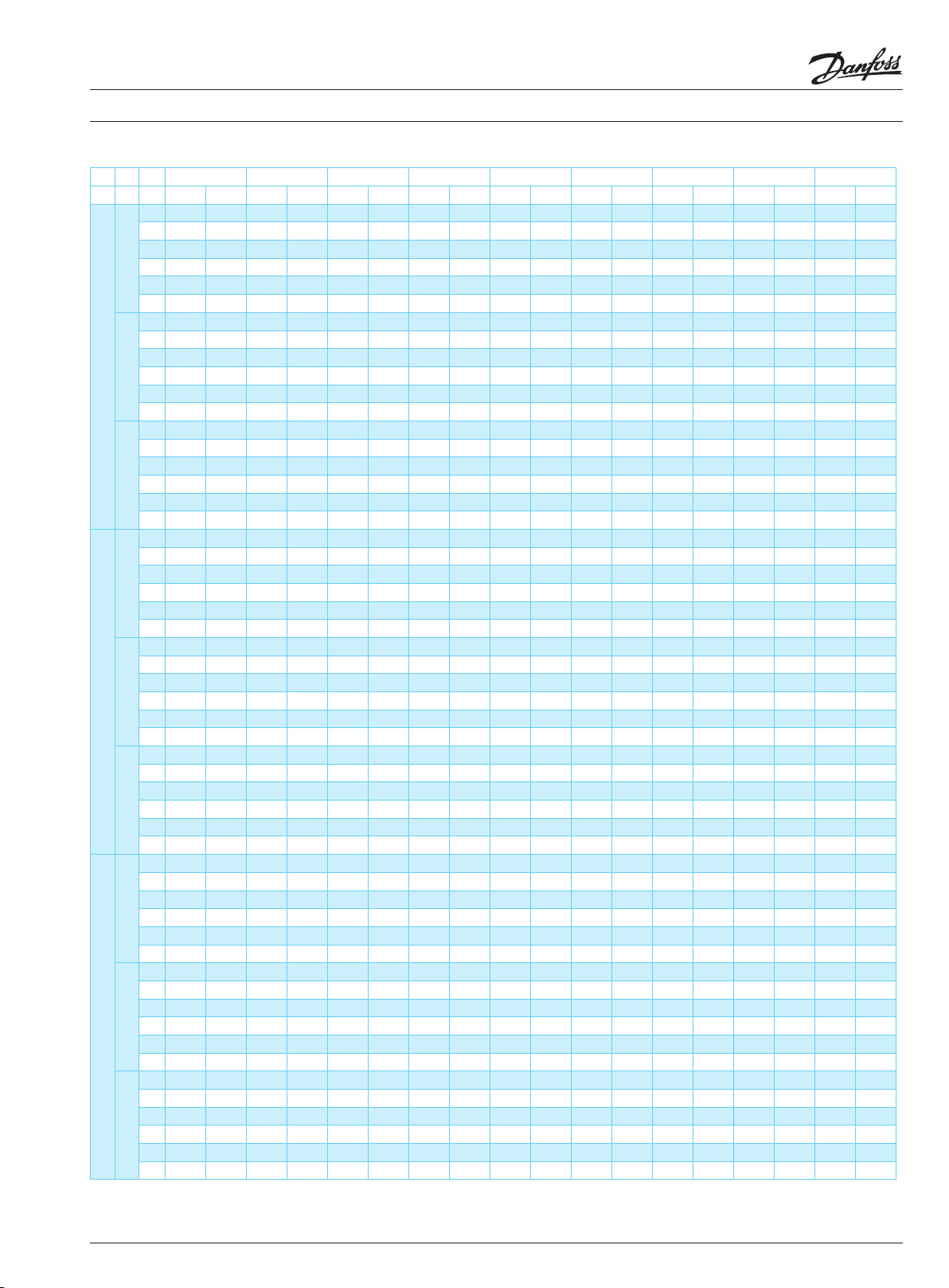

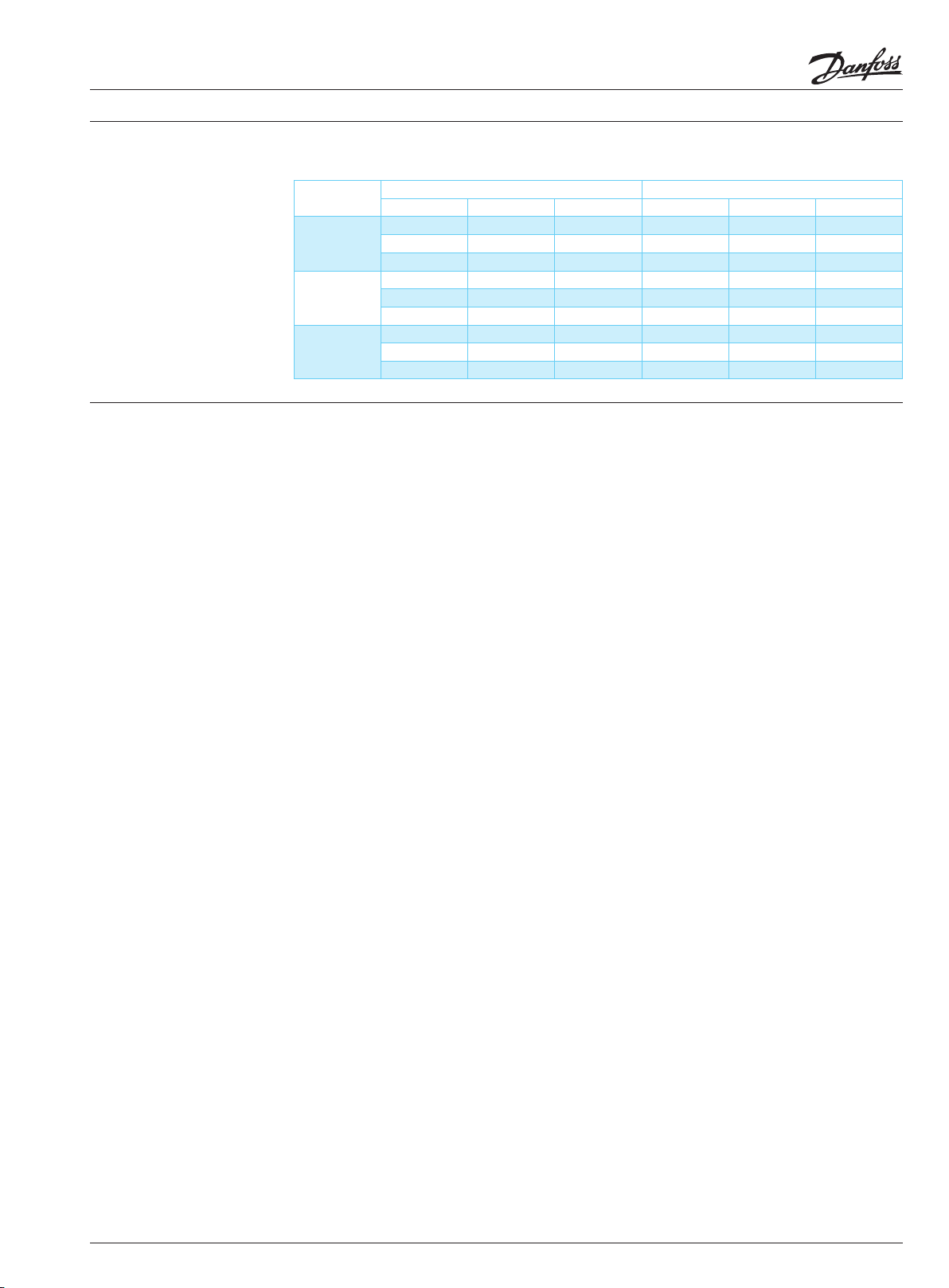

EN12900标准工况制冷量

To -25 -20 -15 -10 -5 0 5 10 15

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

20 - - 6 200 2.25 7 600 2.25 9 300 2.24 11 300 2.20 13 500 2.14 16 200 2.06 - - - -

30 - - 5 500 2.81 6 900 2.82 8 500 2.83 10 400 2.82 12 500 2.80 15 000 2.75 17 800 2.68 21 000 2.58

40 - - 4 700 3.51 6 000 3.52 7 400 3.52 9 100 3.52 11 100 3.51 13 300 3.49 15 900 3.45 18 800 3.39

50 - - - - - - 6 100 4.47 7 600 4.46 9 300 4.45 11 300 4.43 13 500 4.41 16 100 4.37

1800 rpm

60 - - - - - - - - - - 7 200 5.75 8 800 5.73 10 700 5.70 12 900 5.66

68 - - - - - - - - - - - - - - - - - -

20 10 800 4.31 13 300 4.38 16 300 4.44 19 800 4.50 23 800 4.53 28 600 4.54 34 000 4.51 - - - -

30 9 400 5.34 11 800 5.39 14 600 5.45 17 900 5.52 21 700 5.59 26 000 5.65 31 000 5.68 36 700 5.68 43 100 5.65

40 - - 10 300 6.58 12 900 6.63 15 900 6.70 19 400 6.78 23 300 6.86 27 800 6.94 33 000 7.00 38 800 7.04

50 - - - - - - 13 700 8.18 16 700 8.26 20 200 8.35 24 200 8.45 28 700 8.55 33 900 8.65

VSH088

3600 rpm

60 - - - - - - - - - - 16 600 10.27 20 000 10.37 23 900 10.50 28 300 10.63

68 - - - - - - - - - - - - 16 100 12.32 19 400 12.45 23 200 12.60

20 16 300 5.76 19 900 5.95 24 300 6.10 29 400 6.21 35 500 6.29 42 500 6.34 50 500 6.37 - - - -

30 14 300 8.00 17 800 8.23 22 000 8.42 26 800 8.58 32 500 8.71 39 100 8.82 46 600 8.91 55 200 8.98 64 900 9.05

40 - - 15 700 10.00 19 500 10.24 24 000 10.45 29 100 10.63 35 100 10.80 42 000 10.95 49 800 11.09 58 700 11.22

50 - - - - - - 20 700 12.36 25 300 12.60 30 500 12.82 36 600 13.04 43 600 13.25 51 500 13.45

5400 rpm

60 - - - - - - - - - - 25 100 15.45 30 300 15.73 36 200 16.01 43 100 16.28

68 - - - - - - - - - - - - 24 400 18.69 29 500 19.02 35 400 19.36

20 - - 7 000 2.82 8 900 2.86 11 200 2.86 13 900 2.86 17 100 2.85 20 700 2.85 - - - -

30 - - 6 500

40 - - 5 800 4.56 7 500 4.59 9 600 4.61 11 900 4.61 14 600 4.61 17 600 4.62 21 000 4.65 24 900 4.71

50 - - - - - - 8 100 5.80 10 100 5.80 12 400 5.79 15 000 5.79 18 000 5.82 21 300 5.87

1800 rpm

60 - - - - - - - - - - 9 800 7.36 11 900 7.35 14 300 7.36 17 100 7.40

68 - - - - - - - - - - - - - - - - - -

20 15 100 5.81 18 600 5.92 22 700 6.04 27 500 6.17 33 200 6.31 39 700 6.44 47 100 6.58 - - - -

30 12 700 7.05 15 900 7.13 19 700 7.24 24 100 7.39 29 300 7.55 35 200 7.73 42 000 7.93 49 800 8.12 58 500 8.32

40 - - 13 600 8.65 17 100 8.72 21 100 8.84 25 700 8.99 31 000 9.18 37 100 9.39 44 000 9.62 51 900 9.87

50 - - - - - - 18 000 10.75 22 100 10.85 26 700 11.00 32 100 11.19 38 200 11.42 45 200 11.68

VSH117

3600 rpm

60 - - - - - - - - - - 22 100 13.43 26 700 13.55 31 900 13.74 38 000 13.97

68 - - - - - - - - - - - - 21 900 16.01 26 400 16.12 31 600 16.30

20 21 700 8.51 26 600 8.84 32 500 9.23 39 500 9.64 47 700 10.05 57 200 10.42 68 100 10.71 - - - -

30 18 700 10.49 23 500 10.73 29 100 11.07 35 700 11.49 43 300 11.94 52 200 12.40 62 300 12.83 73 800 13.19 86 900 13.46

40 - - 20 600 12.90 25 700 13.12 31 700 13.46 38 700 13.89 46 700 14.36 55 900 14.86 66 400 15.33 78 300 15.75

50 - - - - - - 27 400 15.93 33 500 16.26 40 600 16.68 48 700 17.16 58 000 17.67 68 600 18.17

5400 rpm

60 - - - - - - - - - - 33 600 19.71 40 500 20.11 48 400 20.58 57 600 21.09

68 - - - - - - - - - - - - 32 900 23.18 39 700 23.57 47 500 24.03

20 - - 9 700 4.08 13 300 4.10 17 400 4.11 22 100 4.07 27 500 3.96 33 600 3.74 - - - -

30 - - 7 900 5.30 11 100 5.31 14 800 5.34 19 100 5.37 23 800 5.36 29 100 5.29 34 900 5.12 41 300 4.84

40 - - 6 200 6.84 9 200 6.77 12 600 6.77 16 400 6.80 20 600 6.83 25 200 6.84 30 200 6.80 35 700 6.68

50 - - - - - - 10 100 8.70 13 500 8.67 17 300 8.68 21 300 8.71 25 700 8.73 30 400 8.71

1800 rpm

VSH170

3600 rpm

5400 rpm

To: 蒸发温度, °C 过热度 = 10 K 电机电源电压为G: 380-480V/3ph/50-60Hz

Tc: 冷凝温度, °C 过冷度 = 0 K

Qo: 制冷量, W Pe: 输入功率, kW

- - - - - - - - - - 13 500 11.22 17 100 11.21 20 900 11.22 24 900 11.24

60

68 - - - - - - - - - - - - - - - - - -

20 20 600 8.23 25 500 8.35 31 300 8.47 38 100 8.56 46 100 8.60 55 500 8.58 66 200 8.46 - - - -

30 17 700 10.66 22 300 10.71 27 700 10.80 34 100 10.90 41 600 10.98 50 200 11.04 60 000 11.04 71 300 10.97 84 000 10.81

40 - - 19 300 13.26 24 300 13.27 30 100 13.32 36 800 13.39 44 600 13.48 53 500 13.54 63 700 13.57 75 200 13.55

50 - - - - - - 25 700 16.30 31 600 16.31 38 500 16.36 46 300 16.44 55 300 16.52 65 500 16.58

60 - - - - - - - - - - 31 500 20.17 38 200 20.21 45 800 20.28 54 600 20.37

68 - - - - - - - - - - - - 30 800 24.16 37 300 24.19 44 800 24.26

20 31 800 12.66 39 100 12.95 47 800 13.26 58 000 13.59 70 000 13.89 83 800 14.15 99 600 14.35 - - - -

30 27 500 16.01 34 500 16.21 42 700 16.48 52 300 16.79 63 400 17.11 76 100 17.43 90 700 17.72 107 200 17.96 125 800 18.12

40 - - 30 200 19.70 37 800 19.87 46 600 20.11 56 600 20.41 68 200 20.73 81 300 21.06 96 300 21.37 113 100 21.64

50 - - - - - - 40 300 24.13 49 300 24.34 59 500 24.61 71 100 24.93 84 300 25.26 99 200 25.60

60 - - - - - - - - - - 49 300 29.65 59 300 29.90 70 700 30.21 83 500 30.54

68 - - - - - - - - - - - - 48 400 35.05 58 100 35.30 69 300 35.60

7

3.62 8 400 3.66 10 600 3.67 13 200 3.68 16 100 3.68 19 500 3.69 23 300 3.71 27 700 3.77

应用指南

技术参数

ARI标准工况制冷量

To -25 -20 -15 -10 -5 0 5 10 15

Tc Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe Qo Pe

20 - - 6 600 2.25 8 100 2.25 9 900 2.24 12 000 2.20 14 400 2.14 17 200 2.06 - - - -

30 - - 6 000 2.81 7 400 2.82 9 100 2.83 11 100 2.82 13 500 2.80 16 100 2.75 19 100 2.68 22 500 2.58

40 - - 5 100 3.51 6 500 3.52 8 100 3.52 9 900 3.52 12 100 3.51 14 500 3.49 17 300 3.45 20 400 3.39

50 - - - - - - 6 800 4.47 8 400 4.46 10 300 4.45 12 500 4.43 15 000 4.41 17 800 4.37

1800 rpm

60 - - - - - - - - - - 8 300 5.75 10 100 5.73 12 300 5.70 14 700 5.66

68 - - - - - - - - - - - - - - - - - -

20 11 600 4.31 14 200 4.38 17 400 4.44 21 100 4.50 25 400 4.53 30 400 4.54 36 100 4.51 - - - -

30 10 200 5.34 12 700 5.39 15 700 5.45 19 200 5.52 23 300 5.59 28 000 5.65 33 300 5.68 39 400 5.68 46 200 5.65

40 - - 11 300 6.58 14 100 6.63 17 400 6.70 21 100 6.78 25 400 6.86 30 300 6.94 35 800 7.00 42 100 7.04

50 - - - - - - 15 200 8.18 18 600 8.26 22 500 8.35 26 800 8.45 31 800 8.55 37 500 8.65

VSH088

3600 rpm

60 - - - - - - - - - - 19 100 10.27 23 000 10.37 27 400 10.50 32 400 10.63

68 - - - - - - - - - - - - - - 23 700 12.45 28 300 12.60

20 17 500 5.76 21 300 5.95 25 900 6.10 31 400 6.21 37 800 6.29 45 200 6.34 53 800 6.37 - - - -

30 15 400 8.00 19 200 8.23 23 700 8.42 28 900 8.58 35 000 8.71 42 000 8.82 50 000 8.91 59 200 8.98 69 600 9.05

40 - - 17 100 10.00 21 300 10.24 26 100 10.45 31 800 10.63 38 300 10.80 45 700 10.95 54 200 11.09 63 800 11.22

50 - - - - - - 23 000 12.36 28 100 12.60 33 900 12.82 40 600 13.04 48 300 13.25 57 000 13.45

5400 rpm

60 - - - - - - - - - - 28 900 15.45 34 800 15.73 41 600 16.01 49 400 16.28

68 - - - - - - - - - - - - - - 36 100 19.02 43 200 19.36

20 - - 7 500 2.82 9 500 2.86 12 000 2.86 14 900 2.86 18 200 2.85 22 100 2.85 - - - -

30 - - 7 100

40 - - 6 300 4.56 8 200 4.59 10 400 4.61 13 000 4.61 15 800 4.61 19 100 4.62 22 800 4.65 27 000 4.71

50 - - - - - - 9 000 5.80 11 300 5.80 13 800 5.79 16 700 5.79 19 900 5.82 23 600 5.87

1800 rpm

60 - - - - - - - - - - 11 300 7.36 13 700 7.35 16 400 7.36 19 500 7.40

68 - - - - - - - - - - - - - - - - - -

20 16 200 5.81 19 900 5.92 24 200 6.04 29 400 6.17 35 300 6.31 42 200 6.44 50 100 6.58 - - - -

30 13 700 7.05 17 200 7.13 21 200 7.24 26 000 7.39 31 500 7.55 37 800 7.73 45 100 7.93 53 400 8.12 62 700 8.32

40 - - 14 900 8.65 18 600 8.72 23 000 8.84 28 000 8.99 33 700 9.18 40 300 9.39 47 900 9.62 56 400 9.87

50 - - - - - - 20 100 10.75 24 500 10.85 29 700 11.00 35 600 11.19 42 300 11.42 50 000 11.68

VSH117

3600 rpm

60 - - - - - - - - - - 25 500 13.43 30 700 13.55 36 700 13.74 43 500 13.97

68 - - - - - - - - - - - - - - 32 300 16.12 38 600 16.30

20 23 100 8.51 28 400 8.84 34 700 9.23 42 200 9.64 50 900 10.05 60 900 10.42 72 500 10.71 - - - -

30 20 200 10.49 25 300 10.73 31 400 11.07 38 400 11.49 46 600 11.94 56 100 12.40 66 900 12.83 79 200 13.19 93 200 13.46

40 - - 22 500 12.90 28 100 13.12 34 600 13.46 42 200 13.89 50 900 14.36 60 800 14.86 72 200 15.33 85 000 15.75

50 - - - - - - 30 500 15.93 37 300 16.26 45 100 16.68 54 100 17.16 64 300 17.67 75 900 18.17

5400 rpm

60 - - - - - - - - - - 38 600 19.71 46 500 20.11 55 600 20.58 65 900 21.09

68 - - - - - - - - - - - - - - 48 600 23.57 58 000 24.03

20 - - 10 400 4.08 14 100 4.10 18 500 4.11 23 600 4.07 29 300 3.96 35 700 3.74 - - - -

30 - - 8 600 5.30 12 000 5.31 16 000 5.34 20 500 5.37 25 600 5.36 31 200 5.29 37 500 5.12 44 300 4.84

40 - - 6 800 6.84 10 100 6.77 13 700 6.77 17 800 6.80 22 400 6.83 27 400 6.84 32 900 6.80 38 800 6.68

50 - - - - - - 11 300 8.70 15 100 8.67 19 200 8.68 23 700 8.71 28 500 8.73 33 700 8.71

1800 rpm

VSH170

3600 rpm

5400 rpm

To: 蒸发温度, °C 过热度 = 10 K 电机电源电压为G: 380-480V/3ph/50-60Hz

Tc: 冷凝温度, °C 过冷度 = 0 K

Qo: 制冷量, W Pe: 输入功率, kW

- - - - - - - - - - 15 600 11.22 19 600 11.21 24 000 11.22 28 600 11.24

60

68 - - - - - - - - - - - - - - - - - -

20 22 000 8.23 27 200 8.35 33 400 8.47 40 600 8.56 49 200 8.60 59 000 8.58 70 400 8.46 - - - -

30 19 100 10.66 24 000 10.71 29 900 10.80 36 700 10.90 44 700 10.98 53 900 11.04 64 500 11.04 76 500 10.97 90 100 10.81

40 - - 21 100 13.26 26 500 13.27 32 800 13.32 40 100 13.39 48 500 13.48 58 200 13.54 69 200 13.57 81 600 13.55

50 - - - - - - 28 700 16.30 35 200 16.31 42 700 16.36 51 300 16.44 61 200 16.52 72 400 16.58

60 - - - - - - - - - - 36 300 20.17 43 900 20.21 52 600 20.28 62 500 20.37

68 - - - - - - - - - - - - - - 45 700 24.19 54 700 24.26

20 34 000 12.66 41 700 12.95 51 000 13.26 61 900 13.59 74 600 13.89 89 200 14.15 106 000 14.35 - - - -

30 29 700 16.01 37 200 16.21 46 000 16.48 56 300 16.79 68 100 17.11 81 800 17.43 97 400 17.72 115 000 17.96 134 900 18.12

40 - - 33 100 19.70 41 300 19.87 50 800 20.11 61 700 20.41 74 200 20.73 88 500 21.06 104 600 21.37 122 800 21.64

50 - - - - - - 44 900 24.13 54 800 24.34 66 000 24.61 78 800 24.93 93 400 25.26 109 800 25.60

60 - - - - - - - - - - 56 800 29.65 68 200 29.90 81 100 30.21 95 700 30.54

68 - - - - - - - - - - - - - - 71 100 35.30 84 500 35.60

3.62 9 100 3.66 11 400 3.67 14 200 3.68 17 300 3.68 21 000 3.69 25 000 3.71 29 700 3.77

8

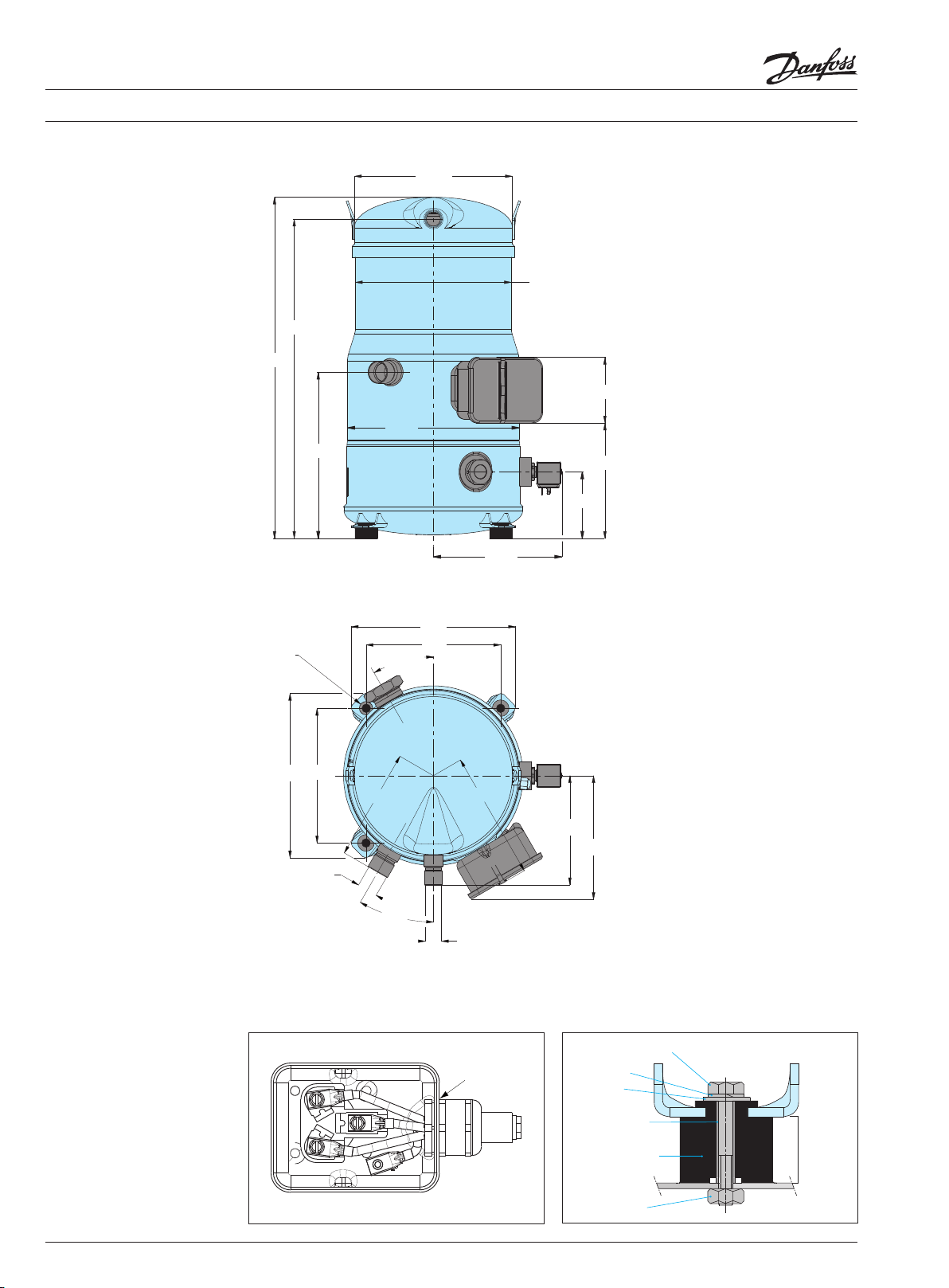

应用指南

外形尺寸

VSH088-G & H

483

4XØ19.05

4 x hole

孔

Ø 19.05

452

235

Ø 224

Ø 220.8

93

Ø 243

163

94.4

181.9

232

191

30°

电器盒

232

191

Ø 29

158

30°

180.7

Ø 22

Ø 33 mm 孔

154

175

软脚垫

弹簧垫圈

平垫圈

HM 8 螺栓

钢护套

橡胶垫

螺母

所有尺寸单位mm

15 mm

9

应用指南

外形尺寸

VSH088-J

483

4 x holes

4XØ19.05

Ø 19.05

孔

452

235

Ø 243

30°

Ø 224

230

190.5

181.9

Ø 220.8

94.4

264

107

230

190.5

60°±1°

Ø29

Ø 16.5 mm

敲落孔

158

30°±1.5°

200.4

Ø22

Ø 40.5 mm 孔

电源线

154

201

软脚垫电器盒

弹簧垫圈

平垫圈

钢护套

HM 8 螺栓

橡胶垫

所有尺寸单位mm

15 mm

螺母

10

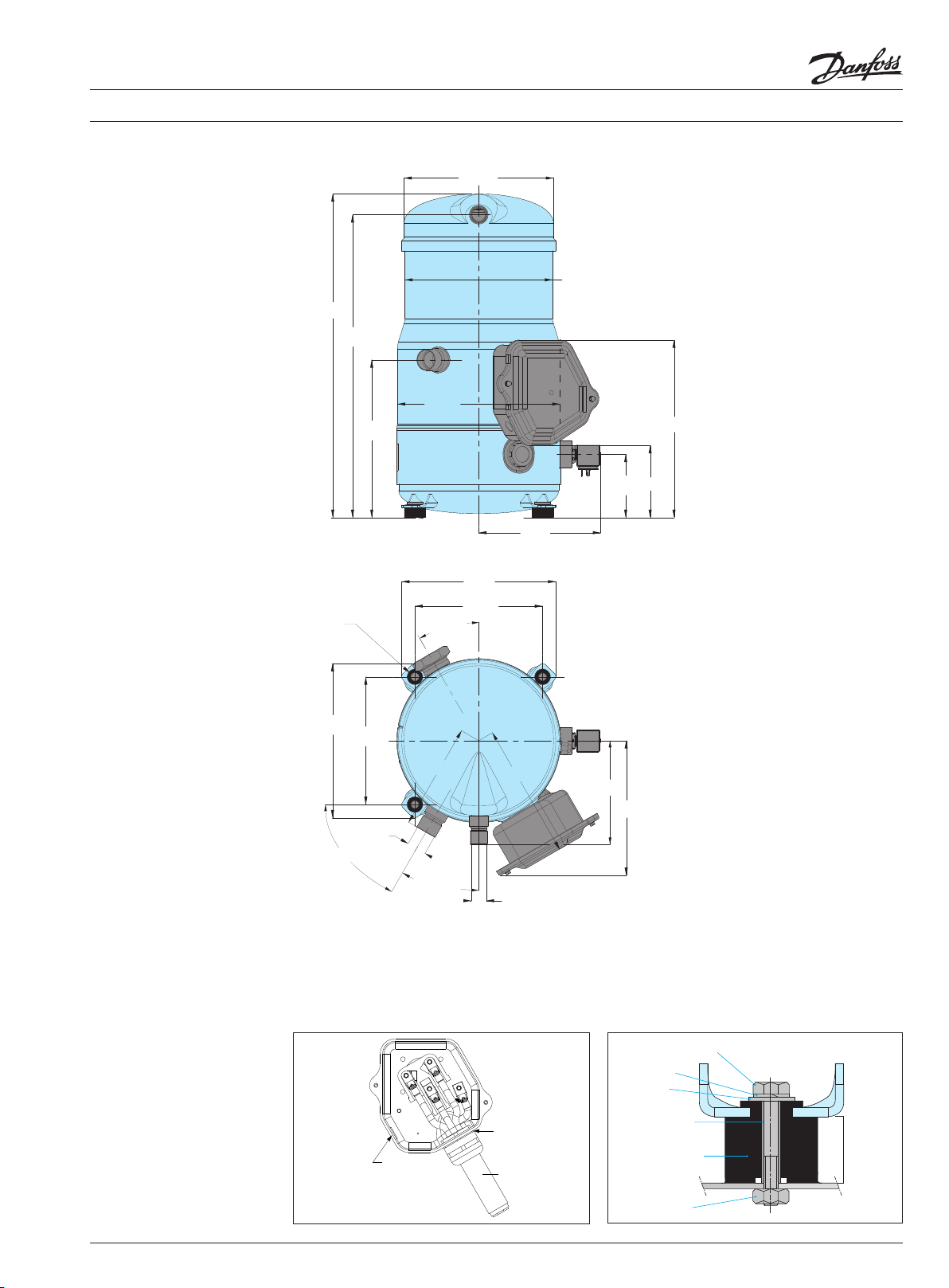

应用指南

螺栓

外形尺寸

VSH117-G & H

540

509

278

Ø224

Ø220.8

93

Ø243

210

101.3

181.9

4XØ19.05

4 x hole

孔

Ø19.05

232

电器盒

191

Ø35

173

30°

30°

232

191

180.7

Ø 22

Ø 33 mm 孔

154

175

所有尺寸单位mm

软脚垫

HM 8

弹簧垫圈

平垫圈

11

钢护套

橡胶垫

螺母

15 mm

应用指南

外形尺寸

VSH117-J

540

509

278

Ø 224

Ø 220.8

Ø 243

311

154

101.3

181.9

4 x hole

4XØ19.05

Ø 19.05

孔

230

60° ±1°

电器盒

190.5

Ø 35

30°

173

30° ±1.5°

230

190.5

200.4

Ø 22

154

软脚垫

201

所有尺寸单位mm

HM 8 螺栓

弹簧垫圈

平垫圈

Ø 16.5 mm

敲落孔

Ø 40.5 mm 孔

电源线

钢护套

橡胶垫

螺母

15 mm

12

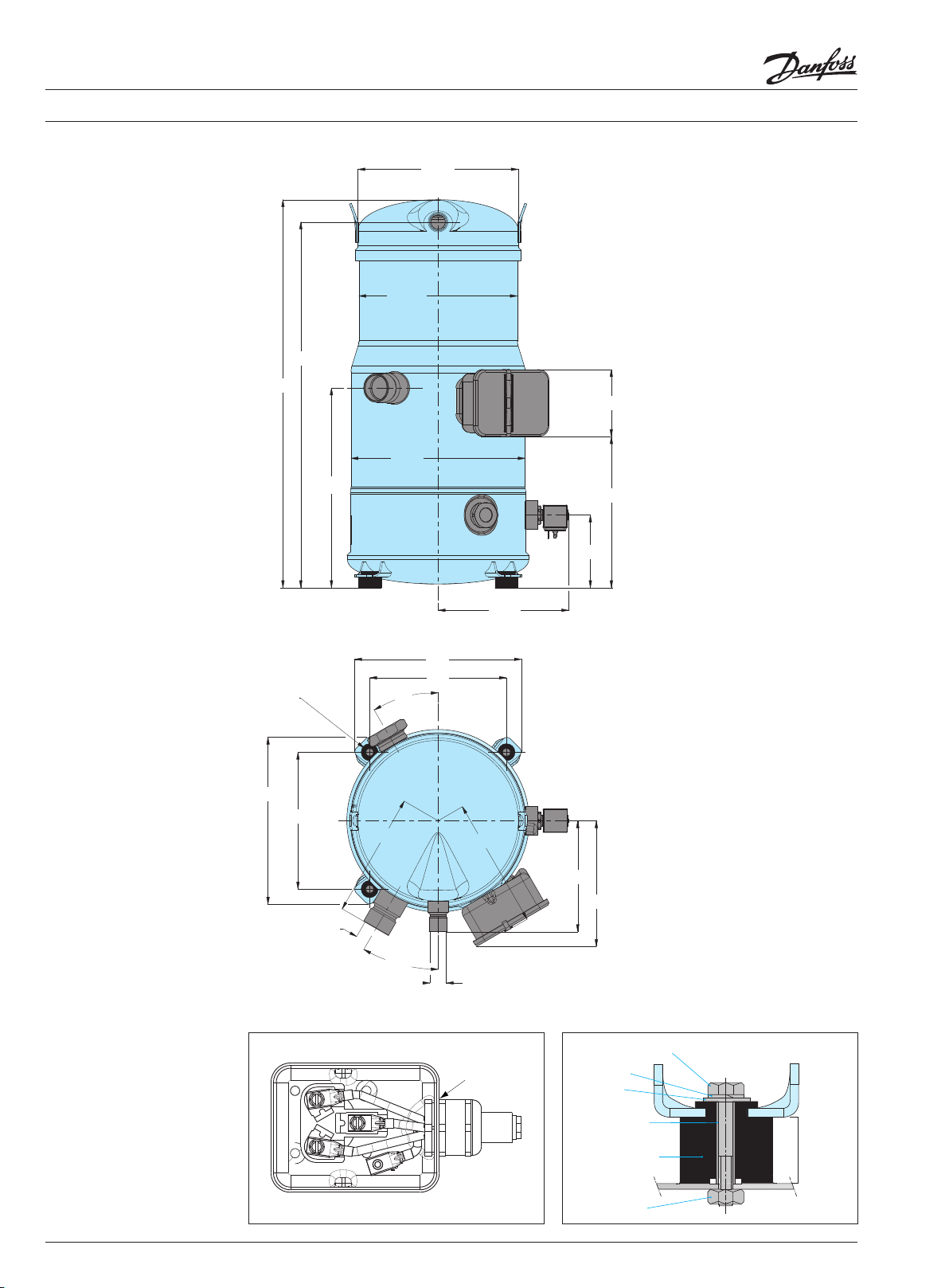

应用指南

外形尺寸

VSH170- G - H & J

652

617

277.4

171.6

301

Ø 257.5

76.1

Ø 317.8

Ø 265.9

345.4

279.4

76.1

4XØ19孔

4 x holes

Ø 19

370.8

304.8

60°

353

Ø 50.5 mm

Ø 63.5 mm 敲落孔

294

60°

软脚垫电器盒

275

HM8螺栓

锁紧垫片

钢衬套

橡胶垫

479

所有尺寸单位mm

压缩机底板

平垫片

28 mm

13

Ø 22.5 mm 敲落孔

螺母

应用指南

尺寸

油视境

针阀接口

油平衡接口

排油口

吸排气接管

所有VSH压缩机都有油视镜(1”1/8 – 18 UNEF),可用

于判断油池中油量和状况。也可用油控制设备来

代替油视镜。

用于加油和压力表接口,1/4”外螺纹喇叭口,带

针阀。

所有VSH压缩机都配有螺纹接口的油平衡接口,

并联压缩机的油平衡管只能连接到油平衡口上。

更多信息请咨询丹佛斯。

VSH170配有排油口,可将油池的油排出,以便换油

或检测。接口带有伸入油池的管子,可更有效地排

油。接口为内螺纹1/4”NPT,

VSH088和VSH117没有排油孔。

所有VSH压缩机在发货时带有吸气管和排气管,

采用黄铜和钢管焊接的方式连接。

也可以采用螺纹连接,请参考附件。

VSH088 螺纹接口1" 3/4

VSH117 螺纹接口1" 3/4

VSH170 螺纹接口2" 1/4

VSH088 1" 1/8 7/8"

VSH117 1" 3/8 7/8"

VSH170 1" 5/8 1" 1/8

油平衡

吸气 排气

变频器尺寸

驱动器电压

T2: 200-240/3/50-60

T4: 380-480/3/50-60

T6: 525-600/3/50-60

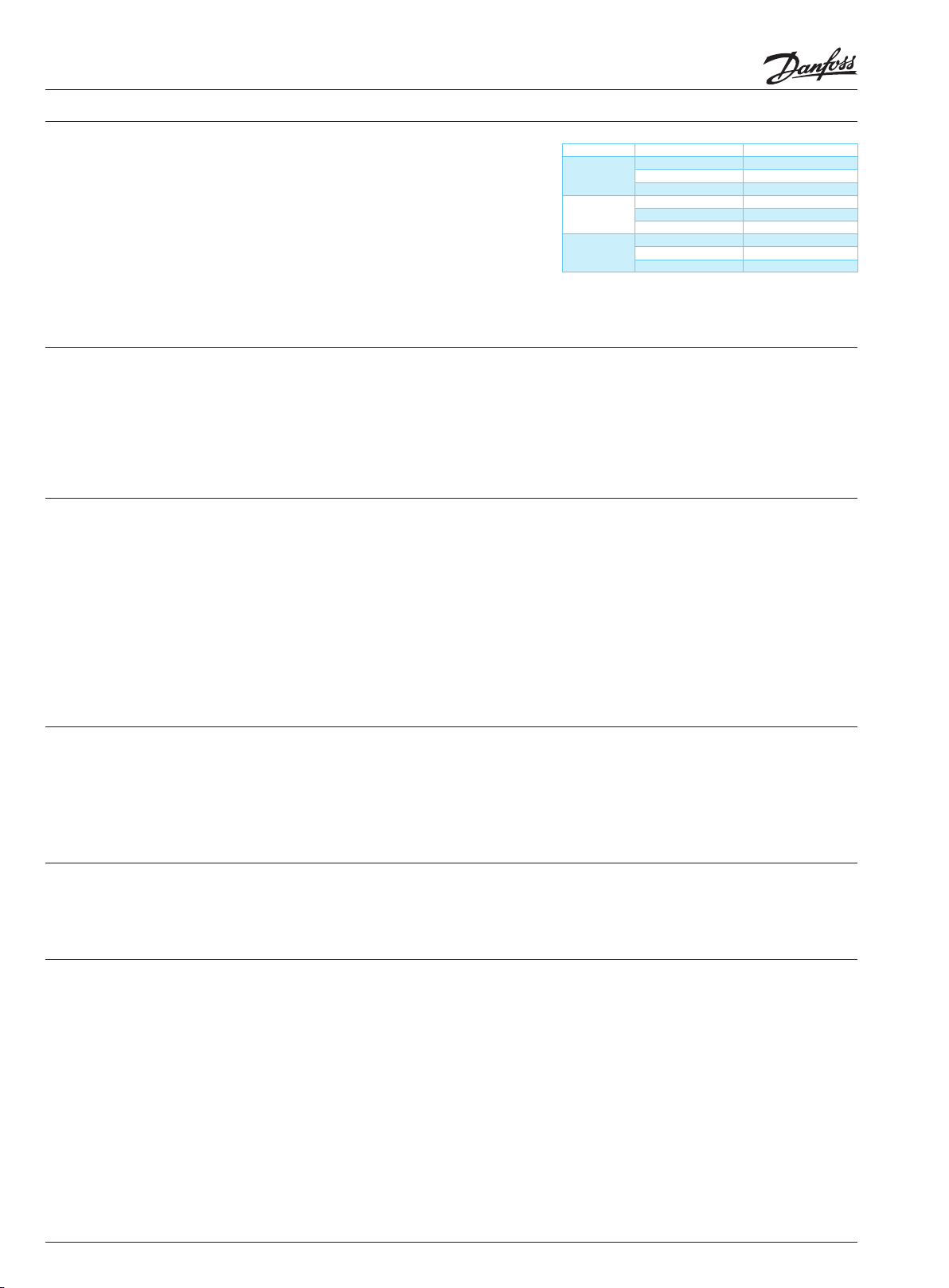

变频器尺寸由供电电压、IP等级和功率决定。下表

汇总了全部尺寸和驱动器壳体(B1-C3)。在后面的

章节中有各个驱动器壳体的详细介绍。

驱动功率

kW

15

18.5 VSH117 C3 630x308x334 C1 680x308x310

22 VSH170 C3 630x308x334 C1 680x308x310

15

18.5 VSH117 B4 595x231x242 B2 650x242x260

22 VSH170 B4 595x231x242 B2 650x242x260

15

18.5 VSH117 B4 595x231x242 B2 650x242x260

22 VSH170 B4 595x231x242 B2 650x242x260

电机电源

J

G

H

压缩机型号

VSH088 B4 595x231x242 C1 680x308x310

VSH088 B3 419x165x248 B1 480x240x260

VSH088 B3 419x165x248 B1 480x240x260

驱动器

外壳

IP20 IP55

整体驱动器尺寸

(h x w x L) mm

驱动器

外壳

整体驱动器尺寸

(h x w x L) mm

14

应用指南

CDS302驱动器-外壳 B1

380-480 V - 15 kW - IP55 外壳

525-600 V - 15 kW - IP55 外壳

尺寸

242

最小进风空间

100

180

进风

260

40

34

11

12

37

43

41

84

9

9

19

比例 1:2

480

最小进风空间

100

出风

454

210

9

安装部位

9

比例 1:2

15

应用指南

34

尺寸

CDS302 驱动器-外壳 B2

380-480 V – 18-22 kW - IP55 外壳

525-600 V – 18-22 kW - IP55 外壳

180

37

43

30

11

84

9

9

650

242

最小进风空间

200

40

260

进风

12

Ø19

比例 1:2

624

最小出风空间

200

出风

210

9

9

比例 1:2

安装部位

16

应用指南

CDS302驱动器-外壳B3

380-480 V - 15 kW - IP20 外壳

525-600 V - 15 kW - IP20 外壳

尺寸

8

8

Ø12

比例 1:2

6.8

最小进风空间200

最小出风空间200

419

248

165

140

进风

399

380

出风

17

安装部位

6.8

比例 1:2

应用指南

尺寸

CDS302驱动器-外壳B4

380-480 V – 18-22 kW - IP20 外壳

525-600 V – 18-22 kW - IP20 外壳

200-240 V – 15 kW - IP20 外壳

8.5

最小进风空间200

最小出风空间200

595

15

242

35

进风

460

出风

比例 1:1

8

8.5

比例 1:1

231

200

518

495

安装部位

18

应用指南

尺寸

CDS302驱动器-外壳C1

200-240 V – 15-18-22 kW - IP55 外壳

680

308

最小进风空间200

310

进风

9.8

12

比例 1:2

9

272

648

19

最小进风空间200

出风

9

比例 1:2

10

安装部位

应用指南

CDS302驱动器-外壳C3

200-240 V – 18-22 kW - IP20外壳

最小进风空间200

尺寸

进风

最小出风空间200

出风

安装部位

20

应用指南

电器参数,连接和配线

供电电压

压缩机电气规格

因为VSH压缩机是由变频器驱动,所以主频率,50

或60Hz,已不是问题。只需要考虑主电源。3种电

机的电压代码,已包含了常用的电压和频率。绝不

允许直接把VSH压缩机直接连接到主电源。

压缩机

VSH088-J 0.0191 61.5 76.9 346

200 - 240 Volt

380 - 480 Volt

525 - 600 Volt

RW: 每个绕组的阻值

RLA: 额定负载电流

MMT: 最大保护电流

LRA: 堵转电流

注意变频器参数1-30的设定反映的是每个绕组的阻值。这个和电机两接线端的测量值是不同的。

VSH117-J 0.0138 80 100 471

VSH170-J 0.0280 120 150 699

VSH088-G 0.26 29.9 37.4 159

VSH117-G 0.185 37.7 47.1 225

VSH170-G 0.127 57.3 71.6 346

VSH088-H 0.518 21 26.3 115

VSH117-H 0.366 30.8 38.5 157

VSH170-H 0.238 44 55.0 246

RW RLA MMT LRA

(Ohm) (A) (A) (A)

电压代码

J

G

H

200-240 V / 3 ph / 50 Hz &

200-240 V / 3 ph / 60 Hz (±10%)

380-480 V / 3 ph / 50 Hz &

380 - 480 V / 3 ph / 60 Hz (±10%)

525-600 V / 3 ph / 50 Hz &

525-600 V / 3 ph / 60 Hz (±10%)

电压驱动范围

堵转电流

额定负载电流

最大保护电流

保险丝

变频器

CDS-15kW 125 A gG KTN-R125 JKS-150 JJN-125 2028220-125 KLN-R125 A2K-125R

CDS-18.5 kW 125 A gG KTN-R125 JKS-150 JJN-125 2028220-125 KLN-R125 A2K-125R

200-240 V

CDS-22 kW 160 A gG FWX-150 - - 2028220-150 L25S-150 A25X-150

CDS-15 kW 63 A gG KTS-R50 JKS-50 JJS-50 5014006-050 KLS-R50 A6K-50R

CDS-18.5 Kw 63 A gG KTS-R60 JKS-60 JJS-60 5014006 -063 KLS-R60 A6K-60R

380-480 V

CDS-22 kW 80 A gG KTS-R80 JKS-80 JJS-80 2028220-100 KLS-R80 A6K-80R

CDS-15 kW - - KTS-R50 JKS-50 JJS-50 5014006-050 KLS-R50 A6K-50R

CDS-18.5 kW - - KTS-R60 JKS-60 JJS-60 5014006-063 KLS-R60 A6K-60R

525-600 V

CDS-22 kW - - KTS-R80 JKS-80 JJS-80 2028220-100 KLS-R80 A6K-80R

堵转电流是在额定电压下,将转子锁定后测得的

电流。根据UL的规则,这个值打印在铭牌上。此值

额定负载电流是在允许运行范围内最大负载和最

大运行速度下的电流值。

最大保护电流是为没有内置电机保护的压缩机定

义的。这个MMT值是在超出压缩机运行范围外能

短暂运行的最大电流值。外部电流保护的设置电

流不能超过MMT值。

EN50178

标准保险丝

规格 类型

类型 RK1 类型 J 类型 T 类型 RK1 类型 RK1 类型 RK1

Bussmann SIBA Little fuse

在VSH压缩机上不能达到,因为变频器将会根据

MMT值切断主电源。

对于VSH压缩机,根据UL规则要求,MMT值是RLA

值的125%,并打印在压缩机铭牌上。

UL标准保险丝

21

应用指南

电器参数,连接和配线

电线规格

连线与EMC保护

下表给出了压缩机电机电源线的推荐规格。线长20m以下下表的推荐规格都有效。.

从电网到变频器 从变频器到压缩机

变频器型号 截面积mm² 线规格AWG 变频器型号 截面积mm² 线规格AWG

CDS-15kW 25 4 VSH088-J 25 4

200 - 240 V

380 - 400 V

525 - 600 V

从变频器到压缩机的电源连线必须是麻花型的屏

蔽线。这些屏蔽线的两头均需接地。需防止线的

末端相互绞在一起,因为这可能导致天线效应从

而降低线的效率。

CDS302变频器的控制信号线必须遵从与电源线

相同的安装原则。

CDS-18.5 kW 35 2 VSH117-J 35 2

CDS-22 kW 50 1 VSH170-J 50 1

CDS-15 kW 6 10 VSH088-G 6 10

CDS-18.5 Kw 10 8 VSH117-G 10 8

CDS-22 kW 16 6 VSH170-G 16 6

CDS-15 kW 4 12 VSH088-H 4 12

CDS-18.5 kW 6 10 VSH117-H 6 10

CDS-22 kW 10 8 VSH170-H 10 8

在安装板上安装变频器必须保证安装板与变频器

金属基座之间有良好的电气接触。使用星型垫片

和导电良好的安装片以确保良好的电气连接。关

于紧固力矩和螺栓尺寸,参考指引MG.34.M1.02。

注意:CDS302必须安装在平板上并确保散热器通

风良好。

压缩机电机线必须装在一个独立的线槽内并与控

制线和主电源线隔开。

22

应用指南

电器参数,连接和配线

IP20变频器CDS302符合EMC的正确安装方法

基于丹佛斯技术支持要求的安装,EMC验证报告才有效。

PLC等 安装面板

PLC

接地槽

主电源

L1

L2

L3

PE

加强型保护地线

最小0.025 in ²

(16 mm²)

的地平衡线

控制线

控制线、电机

线和主电源线之

间保持最小7.9in

(200mm)的距离

绝缘条

所有线从面板的一侧进入

电机线

电机线:3相及保护地线

23

应用指南

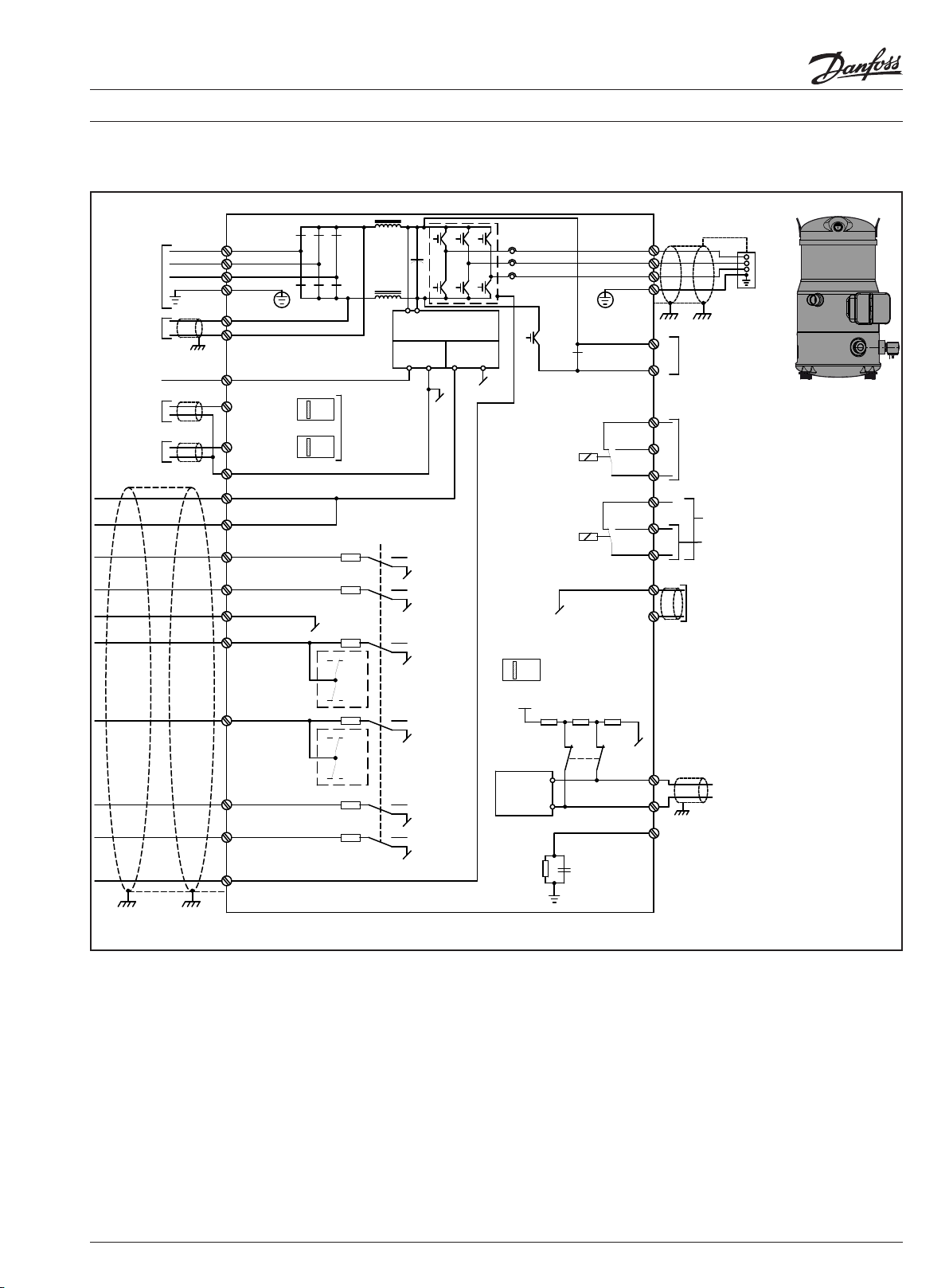

接线图

电器参数,连接和配线

3相输入

电源

DC bus

+10Vdc

-10Vdc +10Vdc

0/4-20 mA

-10Vdc +10Vdc

0/4-20 mA

91 (L1)

92 (L2)

93 (L3)

95

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

12 (+24V OUT)

13 (+24V OUT)

18 (D IN)

19 (D IN)

20

(COM D IN)

27

(D IN/OUT)

*

29

(D IN/OUT)

32 (D IN)

33 (D IN)

*

37 (D IN)

S201

1 2

S202

21

ON

ON/I=0-20mA

OFF/U=0-10V

ON

24V

0V

24V

0V

直流母线

10Vdc

15mA 130/200mA

+ - + -

P 5-00

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24V (NPN)

0V (PNP)

24Vdc

S801

21

RS-485

界面

5V

ON

ON开/电流

OFF关/电压

S801

relay1

relay2

*

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

(U) 96

(V) 97

(W) 98

(PE) 99

(R+) 82

(R-) 81

03

02

01

06

05

04

0V

制动电阻

240Vac, 2A

240Vac, 2A

400Vac, 2A

模拟信号输出

0/4-20 mA

RS-485

(PNP) = 信号源

(NPN) = 接收器

130BA025.17

24

应用指南

RELAY

2

CDS302

电器参数,连接和配线

连线

L1 91 L1 U 96 T1/U

L2 92 L2 V 97 T2/V

L3 93 L3 W 98 T3/W

95 PE PE 99

39 模拟输出COM端

42 模拟输出+

50 模拟输入 +10v NC

53 模拟输入0±10v NO 02

54 模拟输入0±10v COM 01

55 模拟输入COM端

12 +24V COM 04

13 +24V

18 数字输入

19 数字输入

27 数字输入/输出

29 数字输入/输出

32 数字输入 N- RS485 69

33 数字输入 P+ RS485 68

20 数字输入COM端 COM RS485 61

37 数字输入

1

RELAY

NC 06

NO 05

230 V

~

2 A max

说明:

Ana: 模拟

Dig:数字

in:输入

out: 输出

COM:公共端

NC:常闭

NO:常开

开环控制 过程控制

91, 92, 93 3相主输入 X X

95

39, 42

50

接地

模拟输出

模拟输入

X X

- -

- 53 PLC+(0到10v) X -

54 传感器- - X

55 PLC- X 12

12

高压/低压 开关

外部开关

X X

X X

13 出厂连接至37 X X

13 传感器+ - X

18 外部开关(NO) X X

19

数字输入

- 27 高压/低压 开关/安全装置(NC) X X

29

32, 33

20

数字输入/输出

数字输入

数字输入公共端

- -

- -

- 37 出厂连接至13 X X

98 到压缩机端子T3 X X

97 到压缩机端子T2 X X

96 到压缩机端子T1 X X

99

到压缩机地线

X X

02, 01 回油电磁阀继电器1 X X

06, 05, 04 继电器2 - -

69, 68 RS485通讯端子 - -

61 RS485通讯端子公共端 - -

- : 可选连接

X : 必选连接

CDS302变 频器的出厂设 置 参 数 默 认为开 环 控

制。

通过修改Quick Menu菜单中的参数,可选择过程

控制。

开环控制:在输入53上预设

过程控制:在输入54上预设

0-10v控制方式

4-20mA控制

开环控制:变频器为被动控制方式

过程控制:变频器自己的PID控制

25

应用指南

电器参数,连接和配线

电器连接

软启动控制

相序和反转保护

IP等级

连接压缩机电源需使用直径4.8mm(3/16’’)的螺

栓。最大紧固力矩为3Nm。在电源线上使用1/4’’的

环形端子。

CDS302变频器通过设计产生一个初始0.9秒的压

缩机斜坡软启动。

电流峰值是变频器的最大电流值。

基本上从主电源看到的电流峰值仅比额定电流值

CDS302变频器对于VSH压缩机预设的是顺时针旋

转,因此只需将变频器的输出与压缩机端子连好

就行:

• CDS302端子U(96)连至VSH的端子T1/U ;

• CDS302端子V(97)连至VSH的端子T2/V;

• CDS302端子W(98)连至VSH的端子T3/W;

CDS302变频器主电源的顺序对相序输出没有影响

根据CEI529,如果使用大小合适的IP54 等级的护线套,压缩机端子盒的IP等级也可达到IP54等级。

为保证麻花线能接地良好,过线管必须符合EMC

设计。

电控盒上的未喷涂区允许正确的连续接地。

高很少的百分比。

因为变频器能自行管理电源相序。

电机保护

电压不平衡保护

电机保护由变频器提供。所有出厂预设的参数都

是为了保护电机不致于堵转或过流。如果当前运

行达到报警状态,CDS变频器会自动降低压缩机

每相之间允许的最大电 压偏差为3%。相与相之

间的电压不平衡会导致某一相或几相的电流值过

高,从而可能导致驱动过热甚至损坏。CDS302变

的频率以保证压缩机电机的电流在允许的最大电

流值之下。

频器关于主电源相序不平衡的保护功能可通过参

数14.12设为[0]停机或[1]报警。出厂的默认设置值

为[1]报警。

26

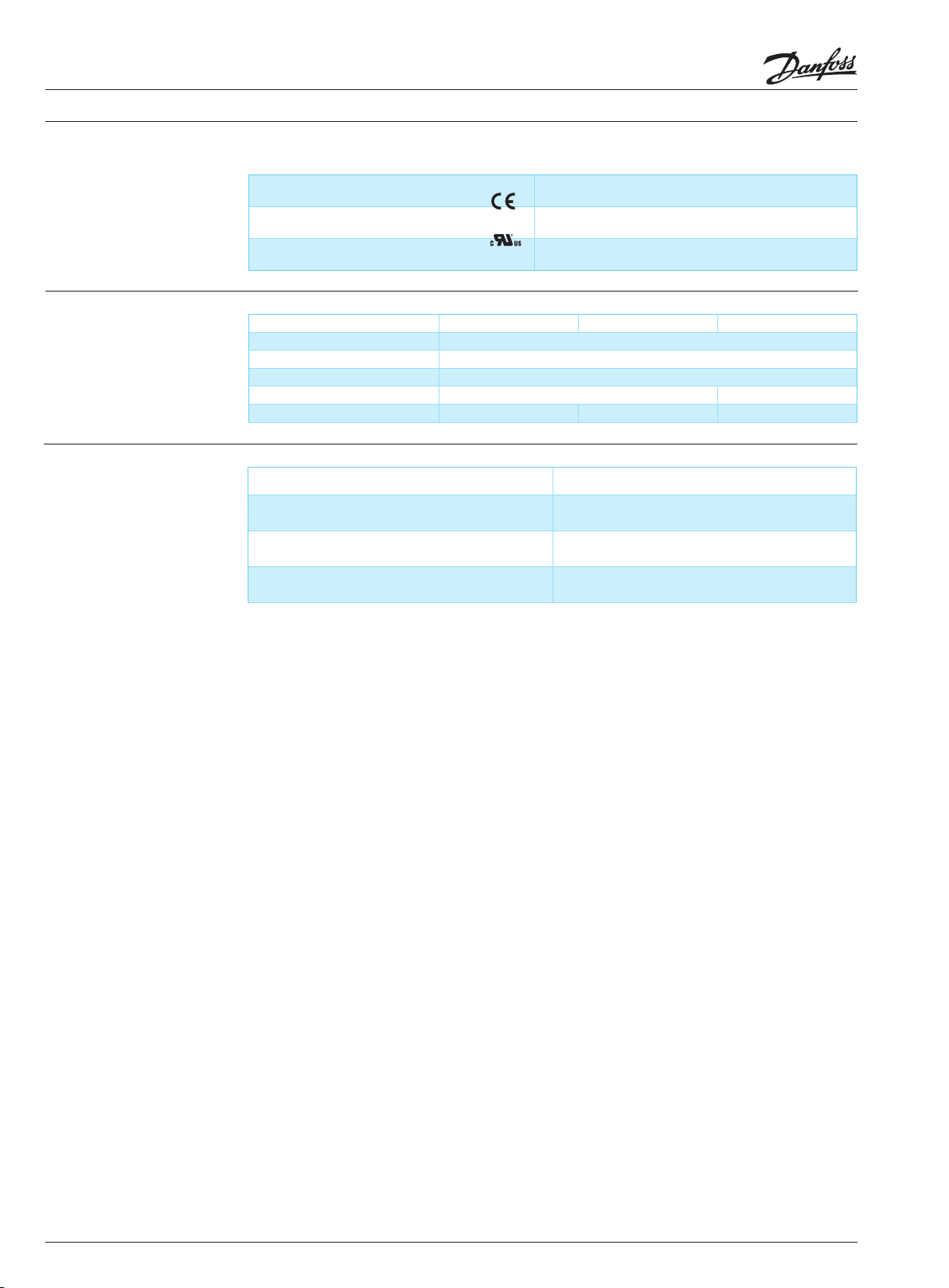

应用指南

认证

认证

压力设备法规97/23/EC

内部自由容积

压缩机符合以下认证要求,并获得相关证书

CE 0062 or CE 0038

(欧洲法规)

UL

(保险商实验室)

EMC

2004 / 108 / EC

产品

流体

PED分类 II

模块评级

TS – 维修保养温度 低压侧 -35°C < TS < +55°C -35°C < TS < +51°C

PS – 维修保养压力 低压侧 33.3 bar(g) 33.3 bar(g) 30.2 bar(g)

产品

VSH088 11

VSH117 12.8

VSH170 28.7

VSH088 VSH117 VSH170

除H系列外的所有VSH型号

所有VSH型号

所有VSH型号

2级

D1

低压侧不含油时内部自由容积

27

应用指南

75

°C

应用范围

70

运行工况

65

60

50 - 90 Hz

过热度: 6 K

55

50

45

40

35

冷凝温度

30

25

20

15

-30 -25 -20 -15 -10 -5 0 5 10 15 20

短循环计时器功能

50 - 90 Hz

蒸发温度 °C

当参数28.0*被激活时,CDS302变频器将直接提

供短循环控制。

30 - 90 Hz

在压缩机功能菜单内,在参数表28.0*中,可设定

该时间周期。

出厂设置该功能是被激活的,最小运行时间为12

秒,启动之间的时间间隔为300秒

排气温度保护功能

可通过变频器激活排气温度监控功能。所有设定

均可通过参数表28.7*来修改,出厂的默认设置如

下:

• 28.20: [0] 无 – 温度来源(传感器输入)

• 28.21: [60] °C – 温度单位

• 28.24: 130 – 报警点

• 28.25: [1] 降低制冷 能力– 报警动作

• 28.26: 145 – 紧急停机点

• 28.27: 由传感器测到的实际排气温度值

按出厂设置,要激活排气温度监控功能,唯一要

做的是将传感器连至端子13和54之间的模拟输入

54(4.20mA)上并将参数28.20设成“[2]模拟输入

54”。当排气温度达到报警点时,通过每3分钟降

低10赫兹压缩机速度,“降低制冷能力”的保护

开始动作,直到排气温度低于在28.24参数上设定

的报警点值或者超出28.26参数上设定的紧急停机

值。当排气温度达到紧急停机值,压缩机将会停

止运行,变频器同时报出相应故障。

28

应用指南 运行工况

排气温控器

如果压缩机超出规定的应用范围而高低压开关的

设定又起不到相应的保护压缩机的作用,这时就

要求进行排气温度保护。

请参考以下示例,在示例1中,表明需要进行排气

70

65

60

55

50

45

40

35

冷凝温度 (°C)

30

25

20

15

10

-30 -25 -20 -15

例 1

DGT - 范围

LP1

LP2

-10

例 2

R410A

-5 0 5 10 15 20

蒸发温度 (°C)

HP1

HP2

排气温度不得超过135°C。

排气温 度保护装置必须安装在所有热泵型机器

上。在冷热型风风和风水热泵空调上,厂家必须

在研发测试阶段监控排气温度值。

当排气温 度超标时,不允许循环运行压缩机。连

续超出压缩机运行范围的运行将严重损坏压缩

机。

丹佛斯可提供一个排气温度控制器组件:参考本

手册后面的附页。

温度保护而在示例2中,则不需要。

示例1 R410A, 过热度11k

低压开关设定

LP1=3.3bar(-15.5

°C)

高压开关设定

HP1=38bar(62

°C)

超出压缩机应用范围的运

行风险

需要排气温度保护

示例2 R410A, 过热度11k

低压开关设定

LP2=4.6 bar(-10.5

°C)

高压开关设定

HP2=31bar(52

°C)

没有超出压缩机应用范围运

行的风险

不需要排气温度保护

排气温度控制组件(代码7750009)包含了安装需要

的所有元器件,如下所示。温控器必须安装在从

压缩机排气口出来后150mm内的排气管上,

进行

保温和紧固处理。

温控器

排气管

保温材料

线夹

回油管理功能

油在管 道内和散热 器内的沉积均可能导致压缩

机油不足。在定期的时间间隔或当压缩机运行

速度太低而 不能保证 合 适的回油时,通过短时

间内提高压缩机的运行速度,能将沉积的油带

回曲轴箱。

通过回油管理,这两个回油机制可被写入CDS302

的程序中。

当激活CDS302的回油管理功能后,变频器通过提

高压缩机转速到4200rpm(70赫兹)并运行一段时

间来保证回油。该时间可通过参数28.13来选择。

在定期的时间间隔内(该间隔可通过参数28.12设

置)或当压缩机转速长时间( 该时间可通过参数

28.11设置)低于3000rpm(50赫兹)时,不论哪一个

v条件先达到,变频器都会进行回油运行。两次连

续回油运行之间的最大时间可通过参数28.12进行

设置。

29

应用指南

高低压压力保护

运行工况

高压

低压

压力设定

根据EN378-2,要求安装一个高压压力安全开关以

停止压缩机。高压压力开关的设定值根据应用和

环境条件的不同可以设成较低值。高压开关必须

接入停止压缩机运行的锁止电路中或由手动复位

要求必须使用低压压力安全开关。对于涡旋压缩

机而言,严重的抽真空运行能导致内部电路产生

电弧和涡盘的不稳定。VSH压缩机有很高的容积

效率,能导致很低的真空度,从而引发这类问题。

最小的低压安全开关设定值请参照下表。对于没

装置组成以防止压缩机在高压极限值附近循环起

停。如果用了排气阀,那么高压开关必须连到维修

阀的测量口,不得隔离。锁止电路或高压开关必

须连到CDS302的27号输入端口。

行的锁止电路中或由手动复位。低压开关的精度

必须能保证压缩机不进行抽真空运行。对带有自

动复位的抽空循环,低压开关的设定值也列在下

表中。锁止电路或低压开关或其它安全开关(高压

等)必须串连到CDS302的27号输入端口。

有抽空的系统,低压开关必须接入停止压缩机运

压力设定 R410A

高压侧工作压力范围 bar (g) 13.5 - 44.5

低压侧工作压力范围 bar (g) 2.3 - 11.6

最大高压开关设定值 bar (g) 45

最小低压开关设定值 * bar (g) 1.5

抽空时最小低压开关设定值 ** bar (g) 2.3

* 低压安全开关不得短接

** 推荐抽空开关设定值:低于名义蒸发温度压力值1.5bar,最低2.3bar

电子膨胀阀

曲轴箱加热功能

对于变能力系统,电子膨胀阀是处理变制冷剂流

量的最好解决方案。必须很好地处理压缩机转速

升降和电子膨胀阀开关的关系。EXV打开的时间

必须短于压缩机转速上升的时间以避免压缩机吸

气侧的低压运行。在压缩机启动之前,EXV也可直

接开至某一固定开度。EXV关闭的时间必须长于压

如果不用外部曲轴箱加热带,当压缩机停止时也可

以用通过电机绕组的直流电流来加热压缩机。

对于VSH088和VSH117,该功能的出厂默认设置值

是“激活”。在变频器的参数表28.3*中可进行相

关参数设定(出厂时已有预设值)。

缩机转速下降的时间,也是为了避免低压运行(抽

真空除外)。

EXV在压缩机停止时必须关闭并保持关闭状态以

防止液态制冷剂进入压缩机。

对于VSH170,该功能不可用,出厂设置值为“无

效”。必须使用外部曲轴箱加热带,推荐使用底部

加热带。相关工厂代码参考附近清单。

30

应用指南

系统设计推荐

基本的管路设计

吸气管

R410A系统的工作压力比R22或R407C系统高60%

左右。因此,所有系统元器件和管路必须按能耐

受高压进行设计。

正确的管路应保证,即使在最小负荷工况下,通

过对从蒸发器过来的铜管尺寸和倾斜度的特殊考

虑,也能满足系统的回油需要。从蒸发器过来的铜

管应避免存油设计并在压缩机停止时能防止油和

管路设计应该具有合适的3D灵活性。它不应与周

边的结构相接触,除非装了合适的防碰管夹。为避

免过大的振动,这种保护是必要的。振

动引起的

磨损和疲劳最终会导致焊接裂开、铜管破裂。除

了能引起铜管破裂和焊接裂开,过大的振动可能

会传递到周边的结构件从而引起令人无法接受的

如果蒸发器在压缩机之上,这种情况在分体式机

器或远程室外机系统中经常会碰到,强烈推荐增

加一个额外的抽空循环。如果没有抽空循环,在蒸

发器出口的吸气侧必须增加一个弯以防止制冷剂

在压缩机停机时进入压缩机。

制冷剂向压缩机迁移。在R410A系统中,制冷剂的

流量会小于R22/R407C系统。为保持可接受的压

降和最小气体流速,制冷剂管路的尺寸应比R22/

R4 07C系统小。也要注意不要使压降过大,因为

R410A系统中大的压降对系统效率的负面影响比

R22/R407C系统要大。

噪音。有关振动和噪音的更多信息,参考“振动和

噪音管理”一节。

CDS302变频器在压缩机功能中整合了一个特殊的

控制以提高并确保系统回油安全,参考“回油管

理”一节。

去冷凝器

HP

U型弯

0.5%的斜度

最高4m

4m/s或更大

LP

排气管

当冷凝器安装在比压缩机高的位置时,应在靠近

压缩机排气口处增加一个大小合适的U型弯,这

样可以防止离开压缩机的油在停机后回流到压

缩机排气侧。上面的倒U型弯排气管往上弯一圈

也有助于避免在压缩机停止时液态制冷剂倒回

流到压缩机。

最高4m

U型弯

U型弯,尽可能短

8 to 12 m/s

蒸发器

0.5%的斜度

4m/s或更大

U型弯,尽可能短

向上弯

高压

冷凝器

低压

3D灵活性

31

应用指南

系统设计推荐

换热器

制冷剂最大充注量

为了获得制冷系统优化的效率,必 须使 用优化的

R410A换热器。R410A制冷剂传热性能好: 值得为

其特别设计换热器以改善尺寸和效率。

带有为R410A优化的分配器和回路的蒸发器,在出

口可获得合适的过热度并优化利用换热面积。这

对于板式换热器来说更加重要,因为跟壳管式换

热器和风冷盘管相比,它的回路更短容积更小。

对所有蒸发器类型,都要特别留意蒸发器出口的

过热度控制和回

冷凝器的过冷管路提供的过冷度可提高系统效

率。

VSH压缩机在一定范围内容许液态制冷剂,而不

发生大问题。然而在压缩机中存有过多的液态制

冷剂会对使用寿命不利。此外,制冷剂过多还会

使蒸发过程在压缩机中发生,或蒸发过程在吸气

管中发生,而非在蒸发器中。这将导致系统制冷

量变小系统设计时必须考虑到制冷剂流 量是有

限制的。因此,在这方面,请先参考“基本管路设

计建议”。

如果制冷剂充注量超过下表中的值,强烈推荐使用

吸气侧气液分离器。

油。

R410A系统过冷度对系统效率带来的好处比R22/

R407C系统要大很多

因此,为了膨胀阀正常工作和蒸发器高效换热,获

得高的液体过冷度是很重要的。没有足够的液体

过冷度,在节流装置处会有过多的闪发气体增加

蒸发器进口气体比例,使得换热效率降低。.

Model Refrigerant charge limit (kg)

VSH088 5.9

VSH117 7.9

VSH170 13.5

更多的信息请见随后的章节,如果与本文的内容

有不相符的地方请联系丹佛斯技术支持。

停机迁移

液态制冷剂可通过停机迁移或运行回液进入压缩机。

当压缩机安装位置的温度是最低的时候,当系统

使用带泄流功能的膨胀装置,液体可在重力的左右

下从蒸发器迁移到压缩机曲轴箱,容易发生制冷

剂迁移。如果过多的液态制冷剂聚集在油池会稀

释润滑油,导致带液启动:当压缩机启动时, 曲轴箱

压力突然降低,制冷剂剧烈蒸发,在油里产生大量

泡沫.在极端情况下,这可能导致液击(液体进入涡

旋盘),必须避免发生这种情况,因为可能会对压缩

机造成不可修复的损害。

曲轴箱里液态制冷剂的存在可以通过油视镜观察

油位来检查,油箱里有泡沫说明是带液启动。

在系统充注量不超过压缩机允许最大值时,VSH

压缩机能承受偶尔的带液启动。

停机迁移可通过增加曲轴箱加热带,液管电磁阀

或抽空循环来避免。

32

应用指南

系统设计推荐

曲轴箱加热器: 当压缩机停机时,油箱的温度必

须在低压侧制冷剂饱和温度的10K以上。此要求

使得液体制冷剂不能汇集到油箱里。

只有能维持这样的温差,曲轴箱加热器才是有

效的。必须有测试保证在所有环境状况下(温度

和通风),油温都能维持在合适的温度。当压缩

液管电磁阀(LLSV):液管电磁阀LLSV可以隔断

冷凝器侧的加液,防止充注时制冷剂进入或停

机时制冷剂迁移进入压缩机 。

抽空循环: 抽空循环是防止制冷剂迁移的最有效

方法。停机后,液管电磁阀可以隔断冷凝器侧

的液体。蒸发器侧的剩余制冷剂可以借助抽空

循环转移到冷凝器和储液罐,抽空循环时压缩

机靠抽空低压开关

压侧的制冷剂量,防止停机时的迁移。

储液罐:制 冷 剂 最 优 充注量 随 压 缩 机 转速变

化。为 了 避 免 低速时的闪发气体 , 需要使用 储

液罐。

控制停机。此过程减少了低

机停机时必须保持通电。给加热器提供独立的

电源,使得在机组不使用的时候加热器也保持通

电(如季节性停机)

VSH内置 的曲轴箱加热功能详细内容 参考章节

“曲轴箱加热功能”

如果安装电子膨胀阀 EXV也有这个功能。

系统低压侧的制冷剂量可以通过利用液管电磁

阀的抽空循环来减少。

抽空低压开关设定值建议为低于名义蒸发压力

1. 5 bar,且不低于2.3 bar 。

储液罐尺寸要特别注意。储液罐要足够大以能

容纳部分充注量,但不能太大,以防维修时制冷剂

充注过量。

运行时回液

当压缩机运行时液态制冷剂进入压缩机就是回

液。通常情况下,制冷剂以过热气体的形式进

入压缩机。回气可能仍然带有液态制冷剂,例

如膨胀阀选型错误,设置错误,出现故障,或

者蒸发器风扇故障,空气过滤器堵塞。持续的

回液会稀释润滑油, 在极端情况下会造成液击

当压缩机运行时液态制冷剂进入压缩机就是回

液。通常情况下,制冷剂以过热气体的形式进

入压缩机。回气可能仍然带有液态制冷剂,例

如膨胀阀选型错误,设置错误,出现故障,或

者蒸发器风扇故障,空气过滤器堵塞。持续的

回液会稀释润滑油,在极端情况下会造成液击。

可以靠测量油池温度和排气温度来检测回液。

在运行的任何时候,如果油池温度不超过饱和吸

气温度10K以上,或者排气温度不超过饱和排气

温度35K以上,就说明有回液。

必须在膨胀阀极限工作状态:高压比和最小的

蒸发器负载情况下进行反复的回液测试,测量

吸气过热度,油池温度和排气温度。

33

应用指南

低环境温度压缩机运行

特定运用推荐

低环境温度运行和在稳定

运行工况下的最小压差

低环境温度启动

低环境温度下排气

压力控制

VSH系列涡旋压缩机必须要有最小6至7Bar的吸、

排气压差,以确保动涡旋盘水平坐落于止推轴承

面上的油膜之上。小于这个压差,动涡旋盘会抬

起,导致金属与金属接触。所以要保持足够的排

当环境温度较低时,冷凝器温度很低,压缩机启

动后无法建立合适的冷凝压力,膨胀阀两侧没有

足够的压差推动液体进入蒸发器。结果压缩机很

快进入抽真空状态。真空状态会引起内部电弧和

涡盘不稳定。任何情况下都不允许压缩机在真空

环境下运行。为了避免发生这种情况,低压控制

低环境温度下的冷凝压力控制: 防止压缩机真空

运行和低吸排气压差,通常有好几种方法。

对风冷机组,用冷凝压力控制器控制风扇启停,可

以保证在冷凝压力达到正常之前,风扇一直处于

停转状态。也可用变速风扇控制冷凝压力。对于

水冷机组,同样可以用冷凝压力控制的水流量调

节阀,从而保证冷凝压力达到正常值之前,

直关闭。

最小冷凝压力必须依据运行区间里的最小饱和冷

凝温度来设置。

水阀一

气压力以获得足够的压差。低环境温度下运行需

要小心,风冷冷凝器换热量达到最大,有必要使

用排气压力控制器。低压差运行可以通过压缩机

噪音会显著增加来判定。

必须依据“低压开关”一节的规定来设置。提早

给蒸发器供液,控制排气压力能有助于削弱这种

影响。

过小的压差也会引起膨胀阀波动,从而引起蒸发

温度不稳和压缩机回液。低环境温度引起的低负

载常常引发这种现象。

使用储液罐、冷凝压力调节阀和储液罐压力调节

阀。

强烈建议使用冷凝压力控制阀以提高系统效率。

对于风冷冷凝器最好将冷凝温度控制在比环境温

度高12K。

如需更多的信息,请联系丹佛斯。

曲轴箱加热器

低负荷运行

在非常低的环境温度下,如果测试显示以上的方

法可能都不能获得满意的冷凝和吸气压力,建议

曲轴箱加热器会减少由于压缩机和系统其他部件

之间的大温差引起的制冷剂迁移。

建议机组进行最小负载和低温环境下的运行测

试。为保证 系统正常运行,应该考虑以下几个方

面。

膨胀阀的过热度设置要能确保低负载时有合适的

过热度。通常需要最少5-6K的稳定过热度。

此外,制冷剂的充注量应确保其在冷凝器有足够

详细请参考“附件”。

的过冷,从而避免在膨胀阀前液管里出现闪发。膨

胀阀的大小要合适,以正确控制进入蒸发器的制

冷剂流量。

34

应用指南

特定运用推荐

板式换热器

可逆热泵系统

过大的阀会造成控制不稳定,这一点对于并联机

组特别重要。在变负荷下,如果膨胀阀不能稳定控

制制冷剂过热度,就会导致液体进入压缩机。

冷凝器风扇循环运行以保证吸气和排气压力之

间维持最小压差。也可用变速风速来控制冷凝

器带走的热量。

板式换热器只需要很小的内部容积就可以满足

换热的需要,所以板式换热器留给压缩机吸气

侧抽气的 空 间 很 小 , 压缩机 能 很 快 进 入抽真

空。因此,膨胀阀的大小选择,以及膨胀阀两

侧足够的压差非常重要,以保证有足够的制冷

剂能进入蒸发器。在低温环境和低负荷工况下

运行的系统,这一点特别重要。更多的信息请

参考前面的章节。

可逆热泵系统常出现瞬态工况,例如从制冷到

制热的转换、除霜和低负荷时的短循环。这些

非稳态运行有可能引起回液,以及过热度很小

的湿蒸汽返回压缩机的情况。正因为如此,可

逆循环的应用需要特别的预防措施,以保证压

缩机长期可靠运行,并满足运行条件。为了确

认是否有必要加装气液分离器,不管制冷剂加

注多少,对反复回液都要进行专门测试。

压缩机运转要有一

有足够的时间让油回到压缩机,并且电机能够

在流量较低时有足够的冷却。

参考章节“回油控制功能”。

因为板换的容积很小,所以通常不需要抽空循

环。从板 换到压 缩机的管路必须要 有U型弯以

防止制冷剂迁移到压缩机。

当板换被用作冷凝器时,内容积小,很容易出

现开机时压力过高的现象。因此

于1米,以 补充板换 的容积。此外, 开机前冷

却水要先循环起来,以预冷板换,增大冷凝能

力,缓解开机时的瞬时高压问题。

下面几点涵盖了压缩机正常应用时的最重要的

问题。每个应用都应该有彻底的测试,来保证

运行特性可以接受。

个最小的运行时间,以保证

排气管不能少

排气温度控制

热泵通常利用高冷凝温度,以便被加热介质获

得足够的温升。同时,热泵需要低蒸发压力,

以保证蒸发器与环境之间足够的温差。这种情

况就会导致高排气温度,所以必须在排气管上

安装排气温度保护器,防止压缩机过热。

排气温度过高会造成压缩机的机械损伤,降低

润滑油的性能,并导致润滑不良。

变频器设 置 及 配 件 请 参见“ 排 气 温 度 保护”

部分。

35

应用指南

特定运用推荐

排气管路和换向阀

除霜和逆循环

回气管路气液分离器

VSH系列压缩机的容 积效率很高,如果气体在

排气管里有 短暂的 堵塞(如热泵机组换向阀切

换太慢) ,都会 建立起 很高的压力。排气压力

过高会造成轴承和电机过载,并引起高压开关

误动作。

为了避免这种情况的发生,建议压缩机排气口

与换向阀(或其他障碍)之间的管路长度不小于1

米,这一点很重要。

这就为排气提供了足够的自由空间,缓解了换

向阀在切换期间造成的压力暴增。同时,必须

当四通换 向 阀 被 移 到 化霜位 置 , 为 了 减少化

霜时间, 在 化 霜 周 期 压缩机 应 该 保 持 运行在

70HZ。当压缩机化霜后应该在30HZ运行10秒,

对于可

逆向运行的应用,强烈建议使用回气管

路气液分离器。因 为在蒸 发器( 制热时的冷凝

器)可能有大量的液态制冷剂滞留,这些液体制

冷剂会进入压缩机,稀释润滑油,并在开机运

行时引起液击。

选择大小 合 适 的 四 通 换向阀 , 以 保 证 切换迅

速,防止产生过高的压力和高压开关误动作。

请咨询换向阀供应商,寻求选型和安装位置的

建议。

建议在移动四通换向阀之前将压缩机运行频率

降低到30HZ。

请同时参考高低压保护部分相关信息。

之后在50HZ运行10-15秒,以防止多余制冷剂流

回压缩机曲轴箱。

持续和反复的回液,会严重降低润滑油对压缩

机轴承的润滑能力。这种现象在潮湿的天气里

可以看到 , 因 为 风 冷 热泵的 外 机 需 要 频繁除

霜。在这种情况下必须使用气液分离器。太太

系统中的水

除了安装调试时系统中残余的水分,水也会在

运行时进入到制冷循环。系统中要避免水分的

存在,不仅因为水分会引起电气短路失效,则

留在油池,引起生锈和腐蚀,而且还会导致严

重的安全问题。

通常情况下,腐蚀和结冰会导致系统泄漏。

腐蚀:系统材料必须与水兼容,并且可以防锈。

结冰: 当水结成 冰 时 , 体 积会增大,这会破 坏

换热器管壁,引起泄漏。在停机时,当环境温

度小 于0℃时, 换热器 内的水容 易结冰。在运

行时,当负荷长时间很低时,换热器有结冰可

能。可以通过压力和温度开关来避免上述情况

发生。

36

应用指南

噪音和振动控制

启动噪音

制冷系统中的噪音

压缩机噪音辐射

对于VSH170压缩机,SSH曲轴箱加热器附带的

底罩被用 来 提 高 加 热 效率。 在 下 表 格 所示的

VSH170噪音值包括了底部的噪音衰减。

对于VSH088和VSH117压缩机没有此底罩。

设计和服务工程师遇到的空调和制冷噪声可以

分为下列三大类:

噪声辐射:这种噪声是通过空气传播的。

机械振动:这种振动通常是通过系统部件和结构

来传播的。

压缩机的噪声辐射是靠空气传播的。噪声波从

压缩机向各个方向传播出去。

VSH涡旋压缩机采用静音设计,压缩机发出的

音频向高频延伸。这样不仅便于降噪,同时也

没有产生低频噪声的穿透力。

在机组板 壁 内 采 用 隔 音材料 是 将 噪 声 与外部

隔绝的有 效 方 法 。 确 保所有 能 够 传 递 噪声和

振动的部 件 都 跟 机 组 板壁上 无 降 噪 保 护的部

件分离开。

机型

VSH088

VSH117

VSH170

该噪音值在ARI A/C标准工况下的自由空间测得。

(*)噪音测量时在压缩机底部安装了曲轴箱加热器及底罩

频率 (Hz) 噪音等级 (dBA)

30 67

60 74

90 84

30 68

60 77

90 85

30 68 (*)

60 79 (*)

90 88 (*)

气流脉动:这种噪声是在冷媒中传播的,如制冷

剂。

下列章节将关注上述噪声源的产生原因和传播

方式。

VSH压缩机采用了完全吸气冷却电机这种独特

的设计,因此很容易实现对压缩机体的隔音。

隔音罩可以作为压缩机附件从丹佛斯购买,以

满足低噪音的需求。隔音罩的隔音材料可以提

供有效的高低频传换。

隔音罩安装方便,对压缩机外形尺寸影响不大。

机械振动噪音

跳频

气流脉动

振 动 隔 离 主 要 是 采 用 控 制 结 构 振 动 的 方

法。VS H涡 旋压缩机在设计上力图使得运行时

产生的振动最小。压缩机地脚的橡胶垫或并联

机架上的橡胶垫都可有效地减少压缩机振动向

机组的传播。合适地安装橡胶垫后,经由压缩

如果 振 动 发生 在 VS H压缩 机 系 统的 一 些频 率

上,应检查支架、管道及管路用软垫夹。如果

有些振动仍然过大,可调节变频器来跳频。

实验证明,VSH涡旋压缩机在设计上能确保常

用空调压 比 下 , 压 缩 机的气 流 脉 动 最 小。其

它一些像热泵机组这种对压比有特殊要求的机

组,必须通过测试,以确保压缩机在所有可能

出现的运行工况和运行点气流脉动最小。

机传递到 机 组 上 的 振 动将被 控 制 在 最 小值。

此外,支

撑压缩机的机架应有足够的刚度和重

量,以缓解传到机架上的振动。如需了解更多

关于安装要求的信息,请参看“安装”。

四个跳频范围可参考参数4.6*。

如果产生的气流脉动无法接受,则需要安装一

个容积和质量合适的排气消声器。该信息可以

从部件制造商处获得。

37

应用指南

螺栓

安装

搬运与储藏

压缩机安装

每个VSH压缩机都配有安装指南。安装指南也可

以通过丹佛斯网站下载: www.danfoss.com

每一台VSH涡旋压缩机的顶盖上都有两个吊环。

搬运压缩机时一定要使用这两个吊环。应选择大

小合适的起重设备,起吊时建议使用延伸臂以均

匀分配重量。此外,吊钩要带锁扣,吊钩的大小要

能承受压缩机重量。起吊压缩机时,一定要注意有

关机种和重量的起吊规定。压缩机搬 运时,请保

持垂直。

一旦压缩机安装好以后,切勿使用吊环来起吊整

个机组。这样可能造成吊环从压缩机脱落,或者

压缩机从机组脱落,

造成设备损坏或人身伤害。

VSH压缩机附带有4个橡胶垫和钢衬套,以便压缩

机与机组底盘隔离。橡胶垫只用于压缩机单台应

用。请用力拧紧地脚螺栓,直到平垫圈碰到钢衬

或:http://instructions.cc.danfoss.com

切勿只用一个吊环来搬运压缩机。压缩机很重,

只用一个吊环的话,吊环可能会脱落,造成压缩机

损坏或人身伤害。

切勿推动接线盒来移动压缩机,那样很可能会损

坏接线盒及其内部的零件。

重物

HEAVY

do not lift

不要人工搬运

manually

套。地脚垫能够在一定程度上减小压缩机振动向

机组底盘的传播。

氮气充注

VSH088以及VSH117压缩机使用HM8-40螺栓,紧

固力矩为15Nm

HM 8

弹簧垫圈

平垫圈

钢护套

橡胶垫

螺母

15 mm

在拿掉吸排气管橡胶塞之前,必须先通过针阀释

放保压氮气,以避免压缩机喷出油雾。请先拿掉吸

气端密封塞,然后再拿掉排气端密封塞。密封塞

VSH170压缩机使 用HM 8- 55螺栓,紧固力矩为

21Nm

HM8螺栓

锁紧垫片

平垫片

钢衬套

橡胶垫

螺母

压缩机底板

28 mm

只有在将压缩机连接到系统时才能拿掉,以避免

水汽进入压缩机。密封塞拿掉后,应保持压缩机

直立,以免油流出。

38

应用指南

B

C

A

隔热板

安装

系统清洁

管路

一个制冷系统,如果系统中仅含有其设计规定的

制冷 剂和油,那么不管 它采用何 种形式的压缩

机,整个系统的效率、可靠性和寿命均会得到可

靠的保障。然而系统中的异物不但不会提高系统

的性能,在通常情况下,还会对系统运行造成严

重损害。

R410A压缩机使用的POE润滑油,具有较高的吸湿

性,应尽可能不暴露在空气中。

系统杂质是影响设备可靠性和压缩机寿命的一个

主要因素。因此,装配制冷系统时,保证系统清洁

是十分重要的。

只能使用干净干燥的制冷用铜管。铜管切割时应

注意不要破坏铜管的圆度,并确保没有任何残屑

留在铜管里。只能选用制冷专用配管,这些配管设

计和选管应确保整个系统的压降最小。管路焊接

不凝性气体以及诸如金属屑、焊料和焊剂这样的

系统杂质在系统中出现,会影响压缩机的使用寿

命。很多杂质都非常小,足以穿过滤网而进入压缩

机,对压缩机轴承造成伤害。

在生产过程中带来的系统杂质可能会是:

•钎焊或焊接氧化物

•管路削边打磨过程中产生的毛刺、碎屑

•钎焊剂

•水分和空气

因此,在安装设备和系统时,必须采用以下防护

措施。

请参照下面的焊接说明。应注意:完成管路连接

后绝不可在管路上再钻孔,这样产生的碎屑无法

清除。

干燥过滤器

焊接

铜管和铜管的连接

不同金属连接

压缩机连接

VSH压缩机使用POE润滑油,因此 对于一个使用

VSH压缩机的新系统,使用DML型(100%分子筛)

固体滤芯干燥过滤器,而不要使用其它那些滤芯

松散的分子筛干燥过滤器。而对一个已经产生酸

性物质的系统进行维修时,推荐使用DCL型(固体

滤芯)含活性铝的干燥过滤器。

在进行铜-铜接口焊接时,建议使用含银5%以上的

铜磷钎焊条作为焊料。焊接温度低于 800°C. 不需

要助焊剂。

不同金属间焊接时,例如铜与黄铜或钢,需要使用

银焊料和抗氧化助焊剂。

进行压缩机管路焊接时,注意不要过分加热压缩

机壳体,以免严重损坏压缩机内部的零件。因此,

强烈建议使用隔热罩或吸热混合物。由于VSH压

缩机的管路和接头直径相对较大,建议使用双嘴

乙炔焊枪进行管路焊接。

干燥过滤器的选择,宁可选大一号,也别选小了。

选型时,要考虑干 燥过滤器的吸水能力,系统制

冷量和系统制冷剂充注量。

39

应用指南

安装

系统压力测试

焊接吸、排气口时,建议遵循以下步骤:

• 确保没有任何电气接线与压缩机相连。

• 保护接线盒和压缩机喷涂表面不受火焰损伤。

(如图所示)。

• 在螺纹接口上焊接焊口接头时,请先拿掉聚四

氟乙烯垫片。

• 只使用制冷专用铜管,并且把接口处弄干净。

• 所使用焊料的含银量不得低于5%。

• 向压缩机内吹入氮气或CO2,以防止压缩机内部

• 的氧化或燃烧。压缩机在空气中不要暴露太长

时间。

• 建议采用双嘴焊枪。

• 在A处均匀加热,直到达到焊接温度。然后将焊

枪移至B处,均匀加热,直至达到焊接温度,然

后开始使用焊料。将焊枪在连接处均匀移动,

焊料无需施加太多,均匀覆盖整个接口处圆周

即可。

• 将焊枪移至C处,不要停留太长时间以免将焊料

带入压缩机。

• 接口焊好后, 用钢丝刷或者湿抹布清除所有的

残余助焊剂,以免残余助焊剂腐蚀管路。

使用惰性气体如氮气来进行压力测试 ,且勿用氧

气、空气或乙炔,因为这样会形成可燃混合物。

应确保没有任何助焊剂进入管路或者压缩机。助

焊剂是酸性的,会对系统或压缩机内部造成相当

大的损害。

VSH压缩机使用的POE润滑油,具有较高的吸湿

性,会迅速吸收空气中的水分。因此压缩机不能长

时间暴露在空气中。压缩机接口的橡胶塞只有在

焊接前才能拿掉。压缩机永远是最后一个焊接进

系统的部件。

在焊拆压缩机或任何系统部件时,必须先将系

统中的制冷剂从高、低压端同时放掉。否则可能会

导致严重的人身伤害。必须使用压力表进行检查,

以确保系统各处压力均在大气压水平。

关于焊接所需材料的更多详细信息,请咨询产品

制造商或零售商。此处未涉及到的某些应用事项,

请联系丹佛斯。

系统检漏

压缩机最大测试压力(低压侧)

压缩机最大测试压力(高压侧)

压缩机高低压侧最大压差

VSH088, VSH117: 33.3 bar(g)

VSH170: 30.2 bar(g)

44.5 bar (g)

37 bar

高压侧先加压,低压侧后加压,以防止涡旋盘转动,切勿让低压侧的压力高于高压侧的压力5bar以上。

系统检漏应使用下表所示的氮气与制冷剂或氮气

与氦气的混和气来进行(有些国家禁止用制冷剂

制冷剂检漏

氮气和R410A

检漏),且勿使用氧气、干空气或乙炔这种可能会

形成可燃混合物的气体。

惰性气体检漏 氮气和氦气

40

应用指南

安装

系统抽真空和除湿

制冷剂充注

调试

水分会影响压缩机和系统的正常运行。空气和水

汽会缩短压缩机的使用寿命。系统中的空气和水

汽会增大冷凝压力并造成排气温度过高,从而降

低润滑油的润滑性能。由于水汽和空气的存在,

系统中形成酸 的几率 增大,这也会导致镀铜 现

初次充注制冷剂时,不要开启压缩机,也不要打开

检修阀。在开启压缩机之前,制冷剂的充注量应

尽可能接近设计量。初次充注的制冷剂必须为液

体。而充注的最佳位置为冷凝器出口与干燥过滤

器之间的液管。

开机调试期间,如果需要的话,可从低压侧的节流

阀前充注液态制冷剂。充注位置离压缩机吸气口

越远越好。制冷剂的充注量必须能同时符合夏季

和冬季运行的要求。

系统初次启动后必须监测至少60分钟,以保证下

面的运行参数正常:

• 测量装置工作正常,过热度可接受。

• 吸气和排气压力在可接受额范围内。

• 压缩机油位正常,回油正常。

• 油视镜内泡沫少,曲轴箱温度在饱和温度10K以

上,说明没有制冷剂迁移。

• 可接受的压缩机启停频率,压缩机最短运行时

间。

象。所有这些,都会引起压缩机的机械或电气故

障。因此,当系统 组装完成后,有必要对系统进

行真空除湿。系统抽真空应抽至绝对压力500微

米汞柱(0.67mbar)以下。更对详细信息,请参见公

告“抽真空与干燥过程”。

更多详细信息,请参见公告“制冷系统充注操作

指

南”。

CDS302变频器带有短循环保护并在出厂前预设了

以下参数:

28.01 两次启动间隔时间:300s

28.02 最短运行时间:12s

• 设置最小运行时间是要保证有足够的时间,增

加制冷剂流速以将油带回油池。压缩机实际电

流在可接受范围内(额定电流RLA)

• 没有异常的噪音和振动

油位与润滑油补充

系统管路回油良好,总长度不超过20m,一般不需

要补充油。当系统管路超过20米时,可能需要补充

润滑油。润滑油的补充大约为系统充注制冷剂总

重量的1-2%。但必须根据压缩机油视镜里的油位

来调整补充量。

压缩 机 稳定运转时,油视镜内必须能观测到油

位。

油视镜里有大量泡沫说明油里有大量的制冷剂或

压缩机回液。

压缩机油位

在油视镜的1/4和3/4之间。

当压缩机停机后,油视镜内油位可能会受油中制冷

剂的影响。

请使用丹佛斯原装的160SZ系列POE罐装油。

压缩机停机的时候再补充润滑油。用针阀连接头

或其它类似的连接头将压缩机的吸气管和泵连接

起来。请参考 «丹佛斯商用压缩机润滑油补充指

南»。

也可在停机几分钟后检查,油位必须

41

应用指南

压缩机

压缩机

订货代码 描述 包装 包装数量

120G0001 V5H088AGANA压缩机

120G0002 V5H117AGANA压缩机

120G0003 V5H170AGANA压缩机

120G0004 V5H088AJANA压缩机

120G0005 V5H117AJANA压缩机

120G0006 V5H170AJANA压缩机

120G0007 V5H088AHANA压缩机

120G0008 V5H117AHANA压缩机

120G0009 V5H170AHANA压缩机

120Z0143 线圈 / 230V

120Z014 4 线圈 / 24V

120Z0145

8173230 T型连接器 V5H088-117 G/H

8173021 T型连接器 V5H088-117 J & V5H170 G/H

8173331 T型连接器 V5H170 J

120Z0146 接线盒 (V5H088 -117G/H)

120Z0147 接线盒 (V5H170G/H/J)

120Z0148 接线盒 (V5H088 -117J)

120Z0149 接线盒 (V5H088-117G/H)

120Z0150 接线盒 (V5H170G/H/J)

120Z0151 接线盒 (V5H088-117J)

120Z0152 隔音罩 V5H088-G/H

120Z0153 隔音罩 V5H117-G/H

120Z0154 隔音罩 V5H170-G/H/J

120Z0155 隔音罩 V5H088-J

120Z0156 隔音罩 V5H117-J

120Z0157 排气温度传感器/转换器

120Z0158

120Z0159

7750009

120Z0066 安装附件: 胶垫 + 衬套 + 螺栓 + 垫片 V5H088-117

8156138 安装附件: 胶垫 + 衬套 + 螺栓 + 垫片 V5H170

7754023 润滑油 1升 160SZ, POE

7754024 润滑油 2升 160SZ, POE

7773110 曲轴箱加热带 V5H170 (75W, 110V, UL, CE)

7773108 曲轴箱加热带 V5H170 (75W, 230V, UL, CE)

7773118 曲轴

120Z0125 螺纹口适配套件 V5H088-117

7765028 螺纹口适配套件V5H170

120Z0388 80W 24V 表面式曲轴箱加热器 CE & UL - V5H088-117

120Z0389 80W 230V表面式曲轴箱加热器 CE & UL - V5H088-117

120Z0390 80W 400V表面式曲轴箱加热器 CE & UL - V5H088-117

120Z0391 80W 460V表面式曲轴箱加热器 CE * - V5H088-117

120Z0402 80W 575V表面式曲轴箱加热器 CE * - V5H088-117

120Z0360 56W 24V表面式曲轴箱加热器 + 底罩 CE & UL - V5H170

120Z0376 56W 230V 表面式曲轴箱加热器 + 底罩, CE & UL - V5H170

120Z0377 56W 40 0V 表面式曲轴箱加热器 + 底罩, CE & UL - V5H170

120Z0378 56W 460V 表面式曲轴箱加热器 + 底罩, CE * - V5H170

120Z0379 56W 575V 表面式曲轴箱加热器 + 底罩, CE * - V5H170

* UL认证申请中

电磁阀 单包装

排气温度传感器 单包装

排气温度转换器 单包装

排气温度保护包 单包装

箱加热带 V5H170 (75W, 400V, UL, CE)

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

工业包装

1

1

1

1

1

1

1

1

1

1

1

1

10

10

10

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

12

8

6

6

6

6

6

8

8

8

8

8

6

6

6

6

6

变频器附件

订货代码 描述 包装 包装数量

120Z0326 LCP液晶控制板

120Z0327 R5-LCP液晶控制板接线

120Z0328 风扇 1 (主) - 15kW IP20

120Z0329 风扇1 (主) - 18.5kW IP20

120Z0330 风扇1 (主) - 22kW IP20

120Z0331 风扇1 (主) - 15kW IP55

120Z0332 风扇1 (主) - 18.5kW IP55

120Z0333 风扇1 (主) - 22kW IP55

120Z0334 风扇2 (内部) - 15kW IP55

120Z0335 风扇2 (内部) - 18.5kW IP55

120Z0336 风扇2 (内部) - 22kW IP55

120Z0337

120Z0338 动力板 - 15kW IP20

120Z0339 动力板- 18,5kW IP20

120Z0340 动力板- 22kW IP20

120Z0341 动力板- 15kW IP55

120Z0342 动力板- 18,5kW IP55

120Z0343 动力板- 22kW IP55

120Z0344 附件包 15kW IP20

120Z0345 附件包18.5kW IP20

120Z0346 附件包22kW IP20

120Z0347 附件包15kW IP55

120Z0348 附件包18.5kW IP55

120Z0349 附件包22kW IP55

120Z0350

120Z0351 R5232/R5485 转换器

120Z0352 U5B/R5485 转换器

120Z0418 动力开关 - 18,5kW IP55

120Z0419 动力开关 - 22kW IP55

控制板 单包装

继电器板 单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

单包装

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

42

应用指南

订货信息和包装

订货和运输

包装

压缩机 单台包装

变频器 单台包装

变频器

电源

T2

T4

T6

变频器

功率(kW)

18 - 22 437 805 405 36 437 805 405 46

18 - 22 346 810 320 24 346 810 320 28

18 – 22 346 810 320 24 346 810 320 28

以上表格列出了VSH压缩机和CDS302变频器附

件的订货代码

重量

(kg)

重量

(kg)

高

(mm)

宽

(mm)

重量

(kg)

压缩机型号

VSH088 578 455 355 59

VSH117 578 455 355 65

VSH170 765 515 450 106

IP20 IP55

宽

(mm)

15 346 810 320 24 430 805 405 46

15 349 500 330 13 346 810 320 24

15 349 500 330 13 346 810 320 24

长

(mm)

长

(mm)

宽

(mm)

长

(mm)

高

(mm)

高

(mm)

43

应用指南

VSH 电源代码 J - 200-240

订货信息和包装

压缩机 变频器

型号 订货代码 型号及功率

LCP液

晶控 制板IP 等级 RFI 等级

涂漆 订货代码

VSH088-J 120G0004

VSH117-J 120G0005

VSH170-J 120G0006

CDS302

15.0kW

CDS302

18.5kW

CDS302 22.0

kW

No

Yes

No

Yes

No

Yes

IP20

IP55

IP20

IP55

IP20

IP55

IP20

IP55

IP20

IP55

IP20

IP55

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

131H9122

131H9123

131H9124

131H9125

131H9127

131H9128

131H9129

131H9130

131F5246

131H9131

131H9132

131H9133

131H9134

131H9135

131H9136

131H9137

131H9138

131H9139

131H9140

131H9141

131H9142

131H9143

131H9144

131H9145

131F0395

131H9146

131H9147

131H9148

131H9149

131H9150

131H9151

131H9152

131H9153

131H9154

131H9155

131H9156

131H9157

131H9158

131H9159

131H9160

131F0394

131H9161

131H9162

131H9163

131H9164

131H9165

131H9166

131H9167

44

应用指南

VSH 电源代码 G - 380-480

订货信息和包装

压缩机 变频器

型号 订货代码 型号及功率

LCP液

晶控 制板IP 等级 RFI 等级

涂漆 订货代码

VSH088-G 120G0001

VSH117-G 120G0002

VSH170-G 120G0003

CDS302

15.0kW

CDS302

18.5kW

CDS302 22.0

kW

No

Yes

No

Yes

No

Yes

IP20

IP55

IP20

IP55

IP20

IP55

IP20

IP55

IP20

IP55

IP20

IP55

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

H3

H2

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

131H4380

131H9079

131H9078

131H9080

131H9081

131H9082

131H9083

131H9084

131B8789

131H9085

131H9086

131H9087

131H9088

131H9089

131H9090

131H9091

131H4381

131H9092

131H9093

131H9094

131H9098

131H9095

131H9096

131H9097

131F5247

131H9099

131H9100

131H9102

131H9103

131H9104

131H9105

131H9106

131H4382

131H9107

131H9108

131H9109

131H9110

131H9111

131H9112

131H9113

131F5248

131H9114

131H9116

131H9117

131H9118

131H9119

131H9120

131H9121

45

应用指南

VSH 电源代码 H - 525-600

订货信息和包装

压缩机 变频器

型号 订货代码 型号及功率

LCP液

晶控 制板IP 等级 RFI 等级

涂漆 订货代码

VSH088-H 120G0007

VSH117-H 120G0008

VSH170-H 120G0009

CDS302

15.0kW

CDS302

18.5kW

CDS302 22.0

kW

No

Yes

No

Yes

No

Yes

IP20 HX

IP55 HX

IP20 HX

IP55 HX

IP20 HX

IP55 HX

IP20 HX

IP55 HX

IP20 HX

IP55 HX

IP20 HX

IP55 HX

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

否

是

131N3583

131N6978

131N6979

131N6980

131N6981

131N6982

131N6983

131N6984

131N6985

131N6986

131N6987

131N6988

131N6989

131N6990

131N6991

131N6992

131N6993

131N6994

131N6996

131N6997

131N6998

131N6999

131N7000

131N7001

46

丹佛斯制冷与空调

丹佛斯在空调、制冷、食品冷链以及工业冷冻方面位居世界领先地位。

丹佛斯致力于其核心业务领域,坚持开发和生产高品质的空调与制冷产品、元件和系

统。

商用制冷控制元件 工业制冷控制元件

工业自控元件

冷凝机组

家用压缩机

温控器

电子控制器和传感器

商用压缩机

板式换热器

member of:

www.asercom.org

丹佛斯(上海)自动控制有限公司

上海市宜山路900号

科技大楼C楼20层

邮编:200233

电话:(021)61513000

传真:(021)61513100

Danfoss对于其目录,手册以及其他印刷材料中可能存在的差错概不负任何责任。Danfoss公司保留不预先通知便可自行改变其产品的权利。倘若这种改变对于已定产品

的基本性能规格没有发生变化,则这种权利也适用于已经定购的产品。本资料里各商标的所有权属于相关各公司。Danfoss以及Danfoss徽标字形是Danfoss A/S的商业标

志

。版权所有。

FRCC.014.A2.41 2012

丹佛斯(上海)自动控制有限公司北京办事处

北京市朝阳区工体北路甲2号

盈科中心A座20层

邮编:100027

电话:(010)85352588

传真:(010)85352599

丹佛斯(上海)自动控制有限公司广州办事处

广州市珠江新城花城大道87号

7楼04单元

邮编:510623

电话:(020)28348000

传真:(020)28348001

Loading...

Loading...