Page 1

Data sheet

Seated valves (PN 16)

VRG 2 – 2-way valve, external thread

VRG 3 – 3-way valve, external thread

Description

VRG 3VRG 2

VRG valves provide a quality, cost effective

solution for most water and chilled applications.

The valves are designed to be combined with

following actuators:

• With AMV(E) 335, AMV(E) 435 or AMV(E) 438

SU actuators.

• With AMV(E) 25, 25 SU/SD, 35 actuators (with

adapter 065Z0311).

Combinations of actuators is evident under

section “Dimension”.

Features:

• Bubble tight design

• Snap mechanical connection together with

AMV(E) 335, AMV(E) 435

• Dedicated 2-port valve

• Suitable for diverting applications (3-port)

Main data:

• DN 15-50

• kVS 0.63 -40 m3/h

• PN 16

• Temperature:

- Circulation water / glycolic water up to 50 %:

2 (–10*) … 130 °C

* At temperatures from 10 °C up to +2 °C use stem heater

• Connections:

- External thread

Ordering

Example:

3-way valve; DN 15; kVS 1.6 ; PN 16;

T

130 °C; ext. thread

max

- 1× VRG 3 DN 15 valve

Code No.: 0 65 Z011 3

Option:

- 3× Tailpieces

Code No.: 06 5Z0291

2 & 3-way valves VRG (external thread)

Picture DN

15

20 6.3 065Z0136 06 5Z0116

25 10 065 Z0137 06 5Z0 117

32 16 06 5Z0138 0 65Z 0118

40 25 06 5Z0139 065Z0119

50 40 06 5Z0140 0 65Z0 120

kVS

(m3/h)

0.63 06 5Z0131 06 5Z0111

1.0 06 5Z0132 06 5Z0112

1.6 06 5Z0133 06 5Z0113

2.5 065Z 0134 065Z 0114

4.0 065Z 0135 065 Z011 5

VRG 2 VRG 3

Code No.

© Danfoss | 2021.06 AI157486475069en-010503 | 1

Page 2

Data sheet Seated valves VRG 2, VRG 3

Ordering (continued)

Technical data

Accessories - Tailpieces

Typ e DN Code No.

Rp ½ 15 065Z0291

Rp ¾ 20 065Z0292

Rp 1 25 065Z0293

1)

Tailpiece

1)

1 tailpiece inter nal thread for VRG ext . thread (Ms - CuZn39Pb3)

Nominal diameter DN 15 20 25 32 40 50

kVS value m3/h 0.63 1.0 1.6 2.5 4.0 6.3 10 16 25 40

Stroke mm 10 15

Control range 30:1 50:1 100 :1

Control characteristic LOG: port A-AB; LIN: por t B-AB

Cavitation factor z ≥ 0.4

Leakage

Nominal pressure PN 16

Max. closing pressure bar

Medium Circulation water / glycolic water up to 50 %

Medium pH Min. 7, Max. 10

Medium temperature °C 2 (–10 1) ) … 130

Connections ext. thread

Materials

Valve body Grey cast iron EN-GJL-250 (GG-25)

Valve stem Stainless steel

Valve cone Brass

Stuffing box sealing EPDM

1)

At temperature s from -10 up to +2 °C use stem heate r

Rp 1¼ 32 065Z0294

Rp 1½ 40 065Z0295

Rp 2 50 065Z0296

Accessories - Adapter & stem heater

Typ e for actuators Code No.

Adapter AMV(E) 25/35 065 Z0311

Stem heater AMV(E) 335/435 0 65Z0315

Service kits

Typ e DN Code No.

15 0 65Z0321

20 065Z0322

Stuffing box

A - AB bubble tight design

B - AB ≤ 1.0 % of kVS

Mixing: 4

Diverting: 1

25 065Z0323

32 065Z0324

40/50 065Z0325

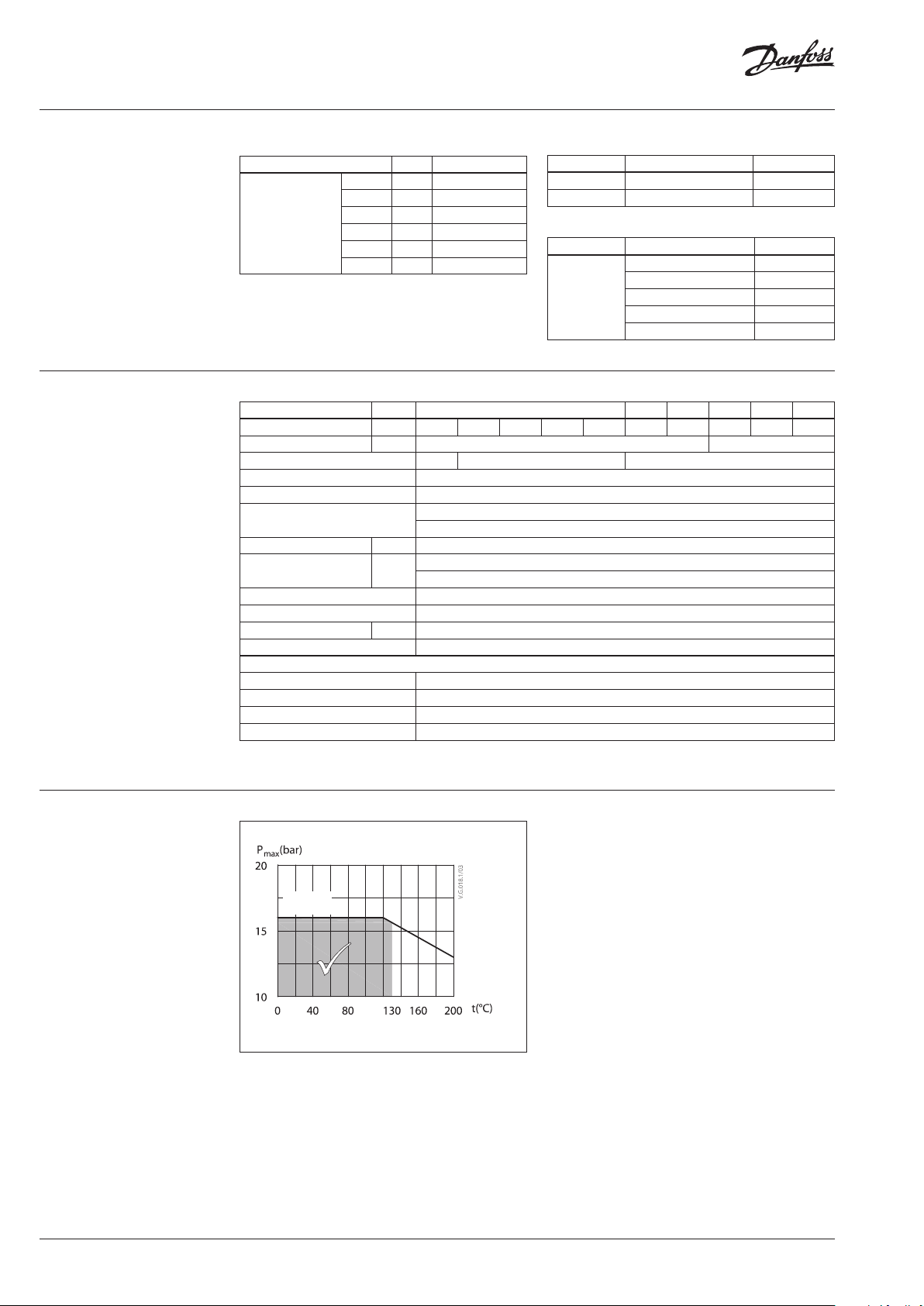

Pressure temperature

diagram

PN 16

EN -GJ L-25 0

(GG -25)

Maximum allowed operating pressure as a function of

medium temperature.

2 | AI157486475069en-010503 © Danfoss | 2021.06

Page 3

Data sheet Seated valves VRG 2, VRG 3

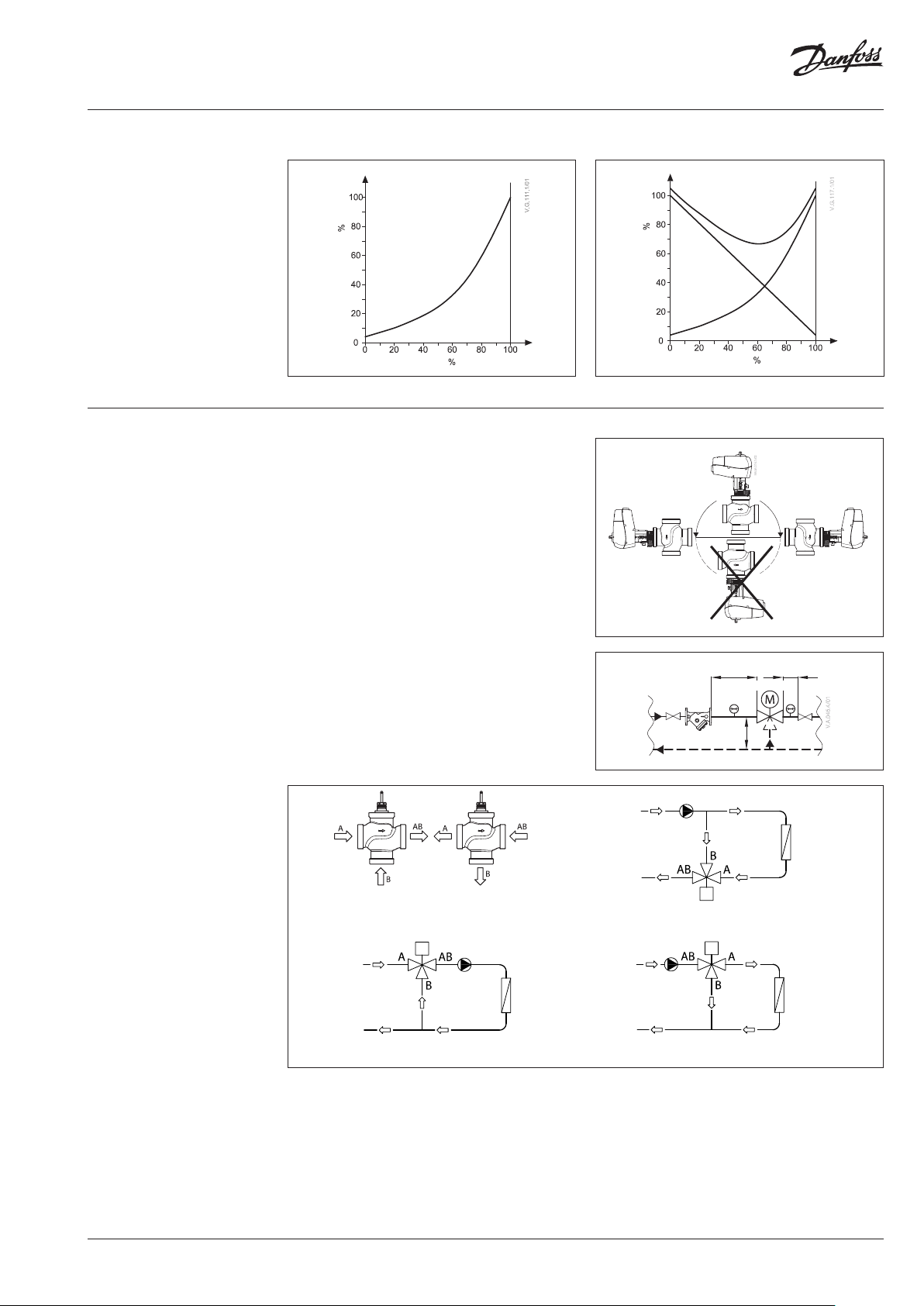

Valve characteristics

Valve characteristics log (2-way) Valve characteristics log/lin (3-way)

Capacity

Installation Valve mounting

Before valve mounting the pipes have to be

cleaned and free from abrasion. Valve must

be mounted according to flow direction as

indicated on valve body except by diverting,

where valve can be mounted oposite to the

flow direction (flow oposite to indication on

the valve body). Mechanical loads of the valve

body caused by the pipes are not allowed. Valve

should be free of vibrations as well.

Stroke

A+BAB

B

A

Stroke

AB

B

A

Capacity

B

A

A

Note:

Install a strainer upstream of the

valve (e.g. D anfoss FVR/ FVF)

Installation of the valve with the actuator is

allowed in horizontal position or upwards.

Installation downwards is not allowed.

Always install the valve with the arrow on

the body in the same direction as the flow. In

order to avoid turbulence, which will affect the

measuring accuracy, it is recommended to have a

straight length of pipe up and down stream from

the valve as shown (D - diameter of pipe).

Mixing Diverting

Fig. 1: Mixing or diverting connection

Fig. 2: Mixing valve used in mixing application

5D

FVR/FVF

2D

AMV(E)

5D

Fig. 3: Mixing valve used in diver ting application

Fig. 4: Diverting valve used in diverting application

Mixing or diverting connection

3-way valve can be used either as mixing or

diverting valve (fig.1).

If 3-way valve is installed as mixing valve

meaning that A and B ports are inlet ports, and

AB port is outlet port it can be installed in mixing

(fig.2) or diverting application (fig.3).

3-way valve can be also installed as diverting

valve in diverting application (fig.4) meaning that

AB port is inlet and A and B ports are outlets.

Note:

Maximal closing pressure for mixing and diverting

insta llation are no t the same. Plea se refer to value s stated

in Technical data section.

AI157486475069en-010503 | 3© Danfoss | 2021.06

Page 4

Data sheet Seated valves VRG 2, VRG 3

21

1

pp

p

a authority, Valve

∆+∆

∆

=

5.0

pp

p

a

21

1

=

∆−∆

∆

=

62.0

557.90

7.90

autority valve hance =

+

=

395.0

5536

36

autority value hence =

+

=

Sizing

Flow Rate

(liquid with specific a gravity of 1)

l/sec m3/h

max

p

FLOW Pressure drop kPa (100 kPa = 1bar = ~ 10 m H2O)

Example

Design data:

Flow rate: 6 m3/h

System pressure drop: 55 kPa

Locate the horizontal line representing a flow

rate of 6 m3/h (line A-A). The valve authority is

given by the equation:

Where:

p1 = pressure drop across the fully open

valve

p2 = pressure drop across the rest of the

circuit with a full open valve

The ideal valve would give a pressure drop equal

to the system pressure drop (i.e. an authority of

0.5 ):

if: p1 = p

2

In this example an authority of 0.5 would be

given by a valve having a pressure drop of

55 kPa at that flow rate (point B). The intersection

of line A–A with a vertical line drawn from B lies

between two diagonal lines; this means that no

ideally-sized valve is available.

The intersection of line A–A with the diagonal

lines gives the pressure drops stated by real,

rather than ideal, valves. In this case, a valve with

kVS 6.3 would give a pressure drop of 90.7 kPa

(point C):

The second largest valve, with kVS 10, would give

a pressure drop of 36 kPa (point D):

Generally, for a 3 port application, the smaller

valve would be selected (resulting in a valve

authority higher than 0.5 and therefore

improved control). However, this will increase

the total pressure and should be checked by the

system designer for compatibility with available

pump heads, etc. The ideal authority is 0.5 with a

preferred range of between 0.4 and 0.7 .

4 | AI157486475069en-010503 © Danfoss | 2021.06

Page 5

Data sheet Seated valves VRG 2, VRG 3

6

7

Design

(Design variati ons are possible)

VRG 2

1. Valve body

2. Valve insert

3. Valve cone

4. Valve stem

5. Moving valve seat

(pressure relieved)

6. Stuffing box

VRG 3

1. Valve body

2. Valve insert

3. Valve cone

4. Valve stem

5. Valve seat

6. Pressure relieve chamber

7. Stuffing box

AI157486475069en-010503 | 5© Danfoss | 2021.06

Page 6

Data sheet Seated valves VRG 2, VRG 3

Dimensions

Rp

(see ordering

part acc essories,

page 2)

Rp

(see ordering

part acc essories,

page 2)

Min 20.5

L

1

1

H

A

H

L

AMV(E) 335, 435 + VRG 2

Min 20.5

2

H

L

1

A

1

H

A

2)

G

Typ e DN

VRG 2

VRG 3

1)

G … extern al thread DIN ISO 228/01

If stem heater is use d dimension H1 is increased for 31 mm.

Connection L H H

1)

G

15 1 80 29 191 128

20 1⁄ 80 31 193 128 0.78

25 1⁄ 95 32 197 151 1. 07

32 2 112 35 201 178 1.48

40 2⁄ 132 45 213 201 2.60

50 2 ¾ 160 48 217 234 3.64

15 1 80 40 191 128 64 0.71

20 1⁄ 80 45 193 12 8 69 0.90

25 1⁄ 95 50 196 151 78 1.22

32 2 112 58 201 178 91 1.82

40 2⁄ 132 75 230 201 110 3.17

50 2 ¾ 160 83 243 234 120 5.01

mm

AMV(E) 335, 435 + VRG 3

L

1

H

1

H

L

Weight

2

(kg)

0.66

-

6 | AI157486475069en-010503 © Danfoss | 2021.06

Page 7

Data sheet Seated valves VRG 2, VRG 3

Dimensions (continued)

Min 100

Min 100

A

L

AMV(E) 438 SU + VRG 2

AMV(E) 25/35 + VRG 2 +

adapter 065Z0311

Typ e DN

VRG 2

VRG 3

1)

G … extern al thread DIN ISO 228/01

If stem heater is use d dimension H1 is increased for 5 m m.

A

1

H

2)

G

H

Connection

1)

G

15 1 80 29 216

20 1⁄ 80 31 218

25 1⁄ 95 32 222

32 2 112 35 226

40 2⁄ 132 45 237

50 2 ¾ 160 48 242

15 1 80 40 216

20 1⁄ 80 45 218

25 1⁄ 95 50 222

32 2 112 58 226

40 2⁄ 132 75 255

50 2 ¾ 160 83 268

L H H

mm

A

L

AMV(E) 438 SU + VRG 3

AMV(E) 25/35 + VRG 3 +

adapter 065Z0311

1

1

H

H

AI157486475069en-010503 | 7© Danfoss | 2021.06

Page 8

Data sheet Seated valves VRG 2, VRG 3

© Danfoss | DCS-S/SI | 2021.068 | AI157486475069en-010503

Loading...

Loading...