Page 1

Data Sheet

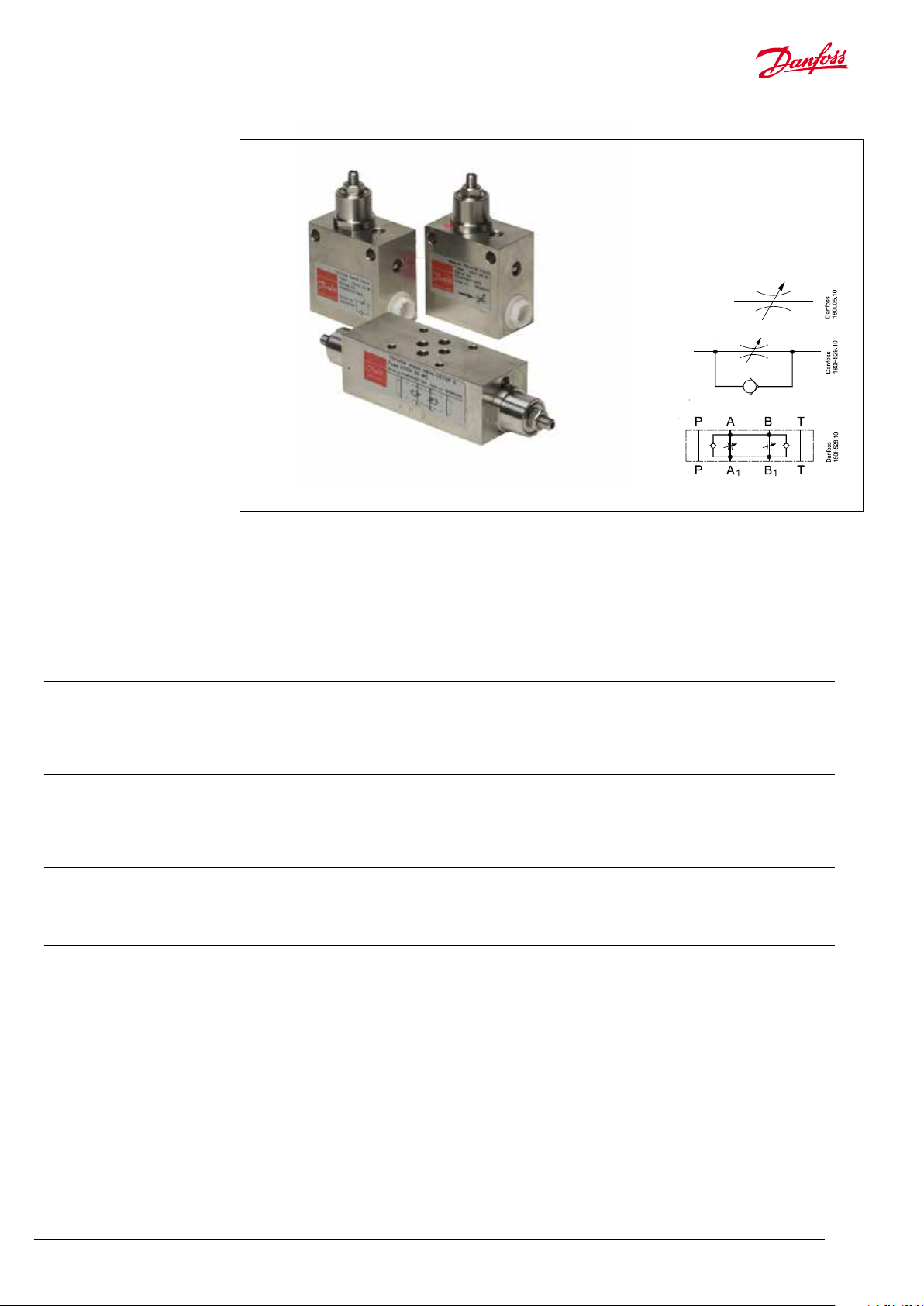

Throttle valves

VOH 30 M, VOCH 30 M and VOCH 30 MC

hpp.danfoss.com

Page 2

Data Sheet | Throttle valves VOH 30 M, VOCH 30 M and VOCH 30 MC

Application

Function

Advantages

Variants

Manually Variable Throttle Valve

Manually Variable Throttle Check

Valve

• VOH 30 M (inline mounted)

VOH 30 M regulates the ow in both directions.

The valves regulate ow and thus e.g. the speed

of an actuator (motor or cylinder).

The valves are designed for ordinary tap water

without additives of any kind, but are also suit-

The valves are designed to operate according to

the needle controlled valve principle.

• Accurate ow regulation

• Flow rates easy to set

The valve housing comes as standard in stainless

steel AISI 304 (W.nr. 1.4301). On request the valve

housing for VOCH 30 MC is available in stainless

• VOCH 30 M (inline mounted)

• VOCH 30 MC (cetop 3 block mounted)

VOCH 30 M and VOCH 30 MC regulate the ow

in one direction and allow for free passage in the

opposite direction via an integrated check valve.

able for applications operating on air, neutral

gases and oil compatible with the NBR O-ring

material used.

VOCH 30 MC is a double throttle check valve

working as an intermediate block to a cetop 3

standard, consisting of a block, VOCH 30 MC and

directional valve, type VDH 30EC4/3.

• Corrosion resistant surfaces,

mainly stainless steel

• Adjustment position secured with lock nut

steal AISI 316L (W.nr. 1.4401).

Please contact your Danfoss sales organization.

2 | © Danfoss | DCS (im) | 2020.02 AI318130630645en-001001 | 521B0802

Page 3

Data Sheet | Throttle valves VOH 30 M, VOCH 30 M and VOCH 30 MC

Filtration

Temperature

Antifreeze Protection

Technical Data and

Code numbers

The water supplied to the valve must be ltered:

50 μm absolute lter is recommended.

Storage temperature:

• -40°C to +70°C – provided that the valve is

drained of uid and stored “plugged”

Operation on (clean) water:

• Fluid temperature and ambient temperature:

+2°C to +80°C

If a system requires antifreeze protection, Danfoss

recommends Dowcall N or Chillsafe mono propylene glycol from the Dow Chemical Company

and Arco Chemical Company, respectively. Both

antifreezes are biologically degradable and must

be used together with demineralized water.

Mixing ratio must be:

VOH 30 M VOCH 30 M VOCH 30 MC

For further information on lters, please contact

your Danfoss sales organization.

Operation on water containing antifreeze:

• Fluid temperature and ambient temperature:

-30°C 1) to +50°C

1) please see paragraph on antifreeze protection

• min. 30% antifreeze and 70% demineralized

water providing frost protection to –13°C.

• max. 50% antifreeze and 50% demineralized

water due to increased viscosity, providing frost

protection to –30°C.

Function symbol

Code number 180H0141 180H0140 180H0143

Max pressure cont. 140 bar 140 bar 140 bar

Max pressure drop across the valve 140 bar 140 bar 140 bar

Max. ow 30 l/min 30 l/min 30 l/min

Pressure loss at 30 l/min 15 bar 15 bar 23 bar

Pressure loss at 15 l/min 4 bar 4 bar 8 bar

Min. adjustable ow at 140 bar 3 l/min 3 l/min 3 l/min.

Max. leakage for closed valve at 140 bar 50 ml/min. 50 ml/min. 50 ml/min.

Pressure loss across check valve at 30 l/min – 4.5 bar 5 bar

Adjustment screw (from min. to max. ow) 7 ½ turn 7 ½ turn. 7 ½ turn

Port connection G ³⁄₈” G ³⁄₈” Cetop 3

Steel type AISI 304 AISI 304 AISI 304

O-ring material NBR NBR NBR

Weight 1,30 kg 1,30 kg 1,90 kg

© Danfoss | DCS (im) | 2020.02

AI318130630645en-001001 | 521B0802 | 3

Page 4

Data Sheet | Throttle valves VOH 30 M, VOCH 30 M and VOCH 30 MC

Flowrate curves

(for water)

VOH 30 M

Pressure losses at varaious opening degrees

Primary ow direction Secundary ow direction

VOCH 30 M

Pressure losses at various opening degrees

VOCH 30 MC

Pressure losses at various opening degrees

N is the number of rotations of the adjusting screw.

At N = 0 the valve is fully closed (lower position).

VOCH 30 M and VOCH 30 MC

Pressures drop across the check valve as a function of the ow

4 | © Danfoss | DCS (im) | 2020.02 AI318130630645en-001001 | 521B0802

Page 5

Data Sheet | Throttle valves VOH 30 M, VOCH 30 M and VOCH 30 MC

Mounting of inline valves

Mounting of valve on Cetop

block

Inline valves

Dimensions (mm)

VOH 30 M and VOCH 30 M

Inline valves are mounted in line in ow direction

(follow the arrow on the valve) and xed either

The valve is designed to be mounted on a block

with cetop 3-port connection. Four stainless steel

screws and four O-rings are supplied with the

valve for mounting. Remember to smear/spray

directly in the pipe connections or with bolts in

the xation holes on the valve.

the threads on the screws with Molykote® D pasta

from Dow Corning, or Klüber UH1 84-201 from

Klüber lubrication, before mounting the valve.

CETOP valves

Dimensions (mm)

VOCH 30 MC

Double throttle check valve

© Danfoss | DCS (im) | 2020.02

AI318130630645en-001001 | 521B0802 | 5

Page 6

Danfoss A/S

High Pressure Pump

Nordborgvej 81

DK-6430 Nordobrg

Denmark

© Danfoss | DCS (im) | 2020.02

AI318130630645en-001001 | 521B0802 | 6

Loading...

Loading...