Page 1

VLT® HVAC Drive Design Guide Contents

Contents

1. How to Read this Design Guide

Copyright, Limitation of Liability and Revision Rights 3

Approvals 4

Symbols 4

Abbreviations 5

Definitions 5

2. Introduction to VLT HVAC Drive

Safety 11

CE labelling 12

Air humidity 13

Aggressive Environments 14

Vibration and shock 14

VLT HVAC Drive Controls 28

PID 30

General aspects of EMC 39

Galvanic isolation (PELV) 41

PELV - Protective Extra Low Voltage 41

3

11

Control with brake function 42

Extreme running conditions 45

Safe Stop 48

3. VLT HVAC Drive Selection

Options and Accessories 51

4. How to Order

Ordering Numbers 63

5. How to Install

Mechanical Dimensions 72

Electrical Installation 79

Final Set-Up and Test 104

Additional Connections 106

DC bus connection 106

Brake Connection Option 106

Relay Connection 107

Installation of misc. connections 111

51

61

71

Safety 113

EMC-correct Installation 114

Mains supply interference/Harmonics 118

Residual Current Device

MG.11.B7.02 - VLT® is a registered Danfoss trademark

118

1

Page 2

Contents VLT® HVAC Drive Design Guide

6. Application Examples

Start/Stop 119

Pulse Start/Stop 119

Potentiometer Reference 120

Automatic Motor Adaptation (AMA) 120

Smart Logic Control Programming 120

SLC Application Example 121

BASIC Cascade Controller 122

Pump Staging with Lead Pump Alternation 123

System Status and Operation 123

Fixed Variable Speed Pump Wiring Diagram 124

Lead Pump Alternation Wiring Diagram 124

Cascade Controller Wiring Diagram 124

Start/Stop conditions 125

7. RS-485 Installation and Set-up

RS-485 Installation and Set-up 127

FC Protocol Overview 129

119

127

Network Configuration 130

FC Protocol Message Framing Structure 130

Examples

Modbus RTU Overview 135

Modbus RTU Message Framing Structure 137

How to Access Parameters 140

Examples 142

Danfoss FC Control Profile 148

8. General Specifications and Troubleshooting

General Specifications 153

Efficiency 164

Acoustic noise 165

Peak voltage on motor 165

Special Conditions 166

Alarms and warnings 167

Alarm words 171

Warning words 172

134

153

Extended status words 173

Fault messages 174

Index

2

MG.11.B7.02 - VLT® is a registered Danfoss trademark

177

Page 3

VLT® HVAC Drive Design Guide 1. How to Read this Design Guide

1. How to Read this Design Guide

1

VLT HVAC Drive

FC 100 Series

Software version: 2.8.x

This guide can be used with all VLT HVAC Drive frequency converters

with software version 2.8.x.

The actual software version number can be read from

par. 15-43 Software

1.1.1. Copyright, Limitation of Liability and Revision Rights

This publication contains information proprietary to Danfoss. By accepting and using this manual the user agrees that the information contained herein

will be used solely for operating equipment from Danfoss or equipment from other vendors provided that such equipment is intended for communication

with Danfoss equipment over a serial communication link. This publication is protected under the Copyright laws of Denmark and most other countries.

Danfoss does not warrant that a software program produced according to the guidelines provided in this manual will function properly in every physical,

hardware or software environment.

Although Danfoss has tested and reviewed the documentation within this manual, Danfoss makes no warranty or representation, neither expressed nor

implied, with respect to this documentation, including its quality, performance, or fitness for a particular purpose.

In no event shall Danfoss be liable for direct, indirect, special, incidental, or consequential damages arising out of the use, or the inability to use information

contained in this manual, even if advised of the possibility of such damages. In particular, Danfoss is not responsible for any costs, including but not

limited to those incurred as a result of lost profits or revenue, loss or damage of equipment, loss of computer programs, loss of data, the costs to substitute

these, or any claims by third parties.

Version

.

Danfoss reserves the right to revise this publication at any time and to make changes to its contents without prior notice or any obligation to notify former

or present users of such revisions or changes.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

3

Page 4

1. How to Read this Design Guide VLT® HVAC Drive Design Guide

1.1.2. Available Literature

1

- Operating Instructions MG.11.Ax.yy provide the neccessary information for getting the frequency converter up and running.

- Design Guide MG.11.Bx.yy entails all technical information about the frequency converter and customer design and applications.

- Programming Guide MG.11.Cx.yy provides information on how to programme and includes complete parameter descriptions.

- Mounting Instruction, Analog I/O Option MCB109, MI.38.Bx.yy

-

PC-based Configuration Tool MCT 10, MG.10.Ax.yy enables the user to configure the frequency converter from a Windows

ment.

- Danfoss VLT Energy Box software at

- VLT 6000 HVAC Application Booklet, MN.60.Ix.yy

- Operating Instructions VLT HVAC Drive BACnet, MG.11.Dx.yy

- Operating Instructions VLT HVAC Drive Profibus, MG.33.Cx.yy.

- Operating Instructions VLT HVAC Drive Device Net, MG.33.Dx.yy

- Operating Instructions VLT HVAC Drive LonWorks, MG.11.Ex.yy

- Operating Instructions VLT HVAC Drive High Power, MG.11.Fx.yy

- Operating Instructions VLT HVAC Drive Metasys, MG.11.Gx.yy

x = Revision number

yy = Language code

Danfoss technical literature is also available online at

www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations/Technical+Documentation.htm

www.danfoss.com/BusinessAreas/DrivesSolutions

then choose PC Software Download

.

™

based PC environ-

1.1.3. Approvals

1.1.4. Symbols

Symbols used in this guide.

NB!

Indicates something to be noted by the reader.

Indicates a general warning.

Indicates a high-voltage warning.

* Indicates default setting

4

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 5

VLT® HVAC Drive Design Guide 1. How to Read this Design Guide

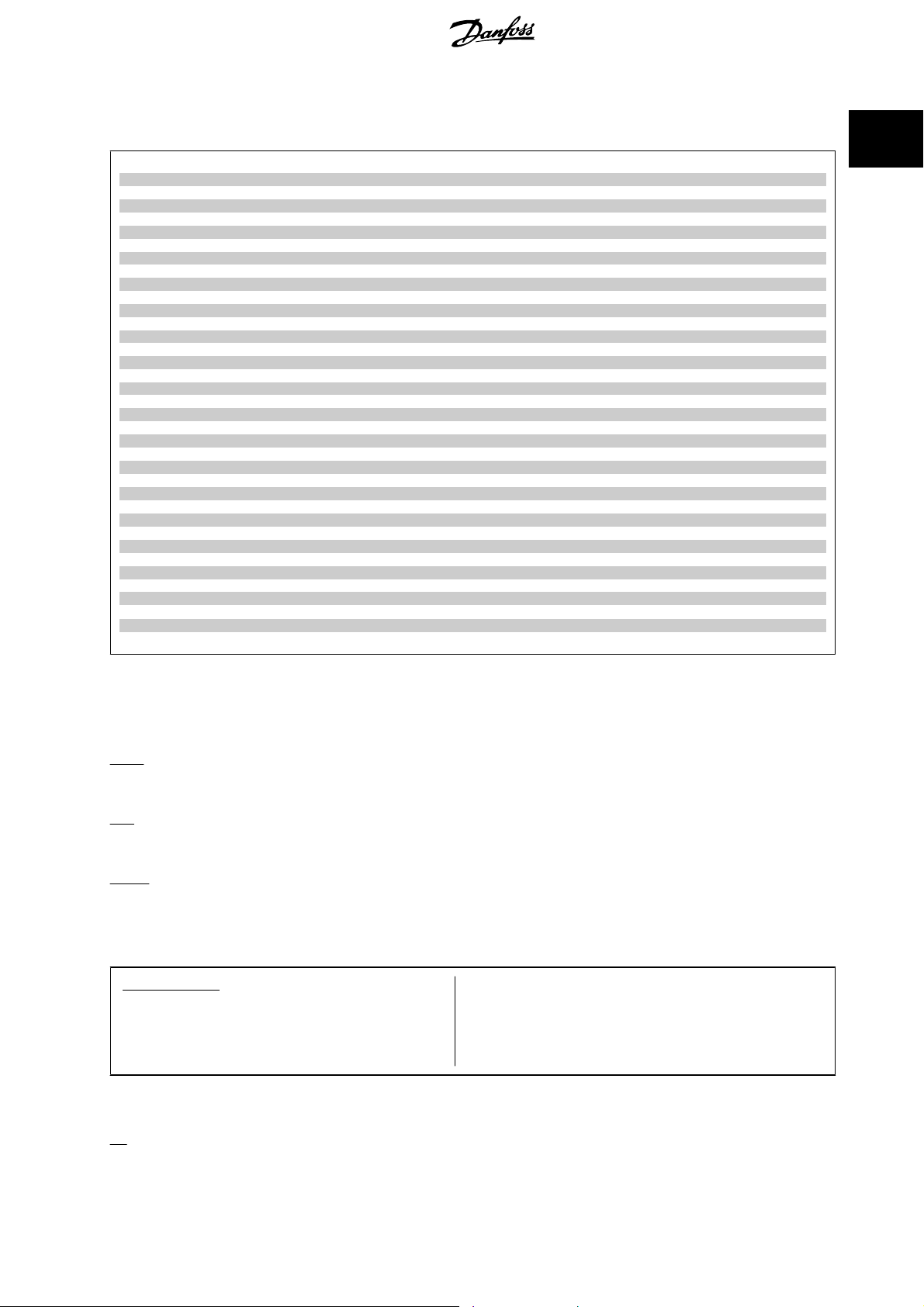

1.1.5. Abbreviations

1

Alternating current AC

American wire gauge AWG

Ampere/AMP A

Automatic Motor Adaptation AMA

Current limit I

Degrees Celsius °C

Direct current DC

Drive Dependent D-TYPE

Electro Magnetic Compatibility EMC

Electronic Thermal Relay ETR

drive FC

Gram g

Hertz Hz

Kilohertz kHz

Local Control Panel

Meter m

Millihenry Inductance mH

Milliampere mA

Millisecond ms

Minute min

Motion Control Tool MCT

Nanofarad nF

Newton Meters Nm

Nominal motor current I

Nominal motor frequency f

Nominal motor power P

Nominal motor voltage U

Parameter par.

Protective Extra Low Voltage PELV

Printed Circuit Board PCB

Rated Inverter Output Current I

Revolutions Per Minute RPM

Regenerative terminals Regen

Second s

Synchronous Motor Speed n

Torque limit T

Volts V

LIM

M,N

M,N

M,N

M,N

INV

s

LIM

1.1.6. Definitions

Drive:

I

VLT,MAX

The maximum output current.

I

VLT,N

The rated output current supplied by the frequency converter.

U

VLT, MAX

The maximum output voltage.

Input:

Control command

You can start and stop the connected motor by means of

LCP and the digital inputs.

Functions are divided into two groups.

Functions in group 1 have higher priority than functions in

group 2.

Motor:

Group 1

Group 2

Reset, Coasting stop, Reset and Coasting stop, Quickstop, DC braking, Stop and the "Off" key.

Start, Pulse start, Reversing, Start reversing, Jog and

Freeze output

f

JOG

The motor frequency when the jog function is activated (via digital terminals).

MG.11.B7.02 - VLT® is a registered Danfoss trademark

5

Page 6

1. How to Read this Design Guide VLT® HVAC Drive Design Guide

f

M

The motor frequency.

1

f

MAX

The maximum motor frequency.

f

MIN

The minimum motor frequency.

f

M,N

The rated motor frequency (nameplate data).

I

M

The motor current.

I

M,N

The rated motor current (nameplate data).

n

M,N

The rated motor speed (nameplate data).

P

M,N

The rated motor power (nameplate data).

T

M,N

The rated torque (motor).

U

M

The instantaneous motor voltage.

U

M,N

The rated motor voltage (nameplate data).

Break-away torque

η

VLT

The efficiency of the frequency converter is defined as the ratio between the power output and the power input.

Start-disable command

A stop command belonging to the group 1 control commands - see this group.

Stop command

See Control commands.

6

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 7

VLT® HVAC Drive Design Guide 1. How to Read this Design Guide

References:

Analog Reference

A signal transmitted to the analog inputs 53 or 54, can be voltage or current.

Bus Reference

A signal transmitted to the serial communication port (FC port).

Preset Reference

A defined preset reference to be set from -100% to +100% of the reference range. Selection of eight preset references via the digital terminals.

Pulse Reference

A pulse frequency signal transmitted to the digital inputs (terminal 29 or 33).

Ref

MAX

Determines the relationship between the reference input at 100% full scale value (typically 10 V, 20mA) and the resulting reference. The maximum

reference value set in par. 3-03.

Ref

MIN

Determines the relationship between the reference input at 0% value (typically 0V, 0mA, 4mA) and the resulting reference. The minimum reference value

set in par. 3-02.

Miscellaneous:

Analog Inputs

The analog inputs are used for controlling various functions of the frequency converter.

There are two types of analog inputs:

Current input, 0-20 mA and 4-20 mA

Voltage input, 0-10 V DC.

1

Analog Outputs

The analog outputs can supply a signal of 0-20 mA, 4-20 mA, or a digital signal.

Automatic Motor Adaptation, AMA

AMA algorithm determines the electrical parameters for the connected motor at standstill.

Brake Resistor

The brake resistor is a module capable of absorbing the brake power generated in regenerative braking. This regenerative braking power increases the

intermediate circuit voltage and a brake chopper ensures that the power is transmitted to the brake resistor.

CT Characteristics

Constant torque characteristics used for screw and scroll refrigeration compressors.

Digital Inputs

The digital inputs can be used for controlling various functions of the frequency converter.

Digital Outputs

The frequency converter features two Solid State outputs that can supply a 24 V DC (max. 40 mA) signal.

DSP

Digital Signal Processor.

Relay Outputs:

The frequency converter features two programmable Relay Outputs.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

7

Page 8

1. How to Read this Design Guide VLT® HVAC Drive Design Guide

ETR

Electronic Thermal Relay is a thermal load calculation based on present load and time. Its purpose is to estimate the motor temperature.

1

GLCP:

Graphical Local Control Panel (LCP102)

Initialising

If initialising is carried out (par. 14-22), the programmable parameters of the frequency converter return to their default settings.

Intermittent Duty Cycle

An intermittent duty rating refers to a sequence of duty cycles. Each cycle consists of an on-load and an off-load period. The operation can be either

periodic duty or none-periodic duty.

LCP

The Local Control Panel (LCP) makes up a complete interface for control and programming of the frequency converter. The control panel is detachable

and can be installed up to 3 metres from the frequency converter, i.e. in a front panel by means of the installation kit option.

The Local Control Panel is available in two versions:

- Numerical LCP101 (NLCP)

- Graphical LCP102 (GLCP)

lsb

Least significant bit.

MCM

Short for Mille Circular Mil, an American measuring unit for cable cross-section. 1 MCM 0.5067 mm

2

.

msb

Most significant bit.

NLCP

Numerical Local Control Panel LCP101

On-line/Off-line Parameters

Changes to on-line parameters are activated immediately after the data value is changed. Changes to off-line parameters are not activated until you enter

[OK] on the LCP.

PID Controller

The PID controller maintains the desired speed, pressure, temperature, etc. by adjusting the output frequency to match the varying load.

RCD

Residual Current Device.

Set-up

You can save parameter settings in four Set-ups. Change between the four parameter Set-ups and edit one Set-up, while another Set-up is active.

SFAVM

Switching pattern called

Slip Compensation

The frequency converter compensates for the motor slip by giving the frequency a supplement that follows the measured motor load keeping the motor

speed almost constant..

Stator Flux oriented Asynchronous V ector M odulation (par. 14-00).

Smart Logic Control (SLC)

The SLC is a sequence of user defined actions executed when the associated user defined events are evaluated as true by the SLC.

8

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 9

VLT® HVAC Drive Design Guide 1. How to Read this Design Guide

Thermistor:

A temperature-dependent resistor placed where the temperature is to be monitored (frequency converter or motor).

Trip

A state entered in fault situations, e.g. if the frequency converter is subject to an over-temperature or when the frequency converter is protecting the

motor, process or mechanism. Restart is prevented until the cause of the fault has disappeared and the trip state is cancelled by activating reset or, in

some cases, by being programmed to reset automatically. Trip may not be used for personal safety.

Trip Locked

A state entered in fault situations when the frequency converter is protecting itself and requiring physical intervention, e.g. if the frequency converter is

subject to a short circuit on the output. A locked trip can only be cancelled by cutting off mains, removing the cause of the fault, and reconnecting the

frequency converter. Restart is prevented until the trip state is cancelled by activating reset or, in some cases, by being programmed to reset automatically.

Trip locked may not be used for personal safety.

VT Characteristics

Variable torque characteristics used for pumps and fans.

plus

VVC

If compared with standard voltage/frequency ratio control, Voltage Vector Control (VVC

reference is changed and in relation to the load torque.

60° AVM

Switching pattern called 60°

Asynchronous Vector Modulation (See par. 14-00).

plus

) improves the dynamics and the stability, both when the speed

1.1.7. Power Factor

1

The power factor is the relation between I1 and I

The power factor for 3-phase control:

The power factor indicates to which extent the frequency converter im-

poses a load on the mains supply.

The lower the power factor, the higher the I

formance.

In addition, a high power factor indicates that the different harmonic currents are low.

The frequency converters' built-in DC coils produce a high power factor, which minimises the imposed load on the mains supply.

.

RMS

for the same kW per-

RMS

Power factor

I

cos

×

1

=

I

RMS

I

RMS

2

=

I

1

=

ϕ1

+

=

I

3×U×

3×U×

I

1

I

RMS

2

2

I

+

5

7

I

1×

since cos

+..+

COS

I

RMS

ϕ1=1

ϕ

2

I

n

MG.11.B7.02 - VLT® is a registered Danfoss trademark

9

Page 10

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

10

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 11

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2. Introduction to VLT HVAC Drive

2.1. Safety

2.1.1. Safety note

The voltage of the frequency converter is dangerous whenever connected to mains. Incorrect installation of the motor, frequency

converter or fieldbus may cause damage to the equipment, serious personal injury or death. Consequently, the instructions in this

manual, as well as national and local rules and safety regulations, must be complied with.

Safety Regulations

1. The frequency converter must be disconnected from mains if repair work is to be carried out. Check that the mains supply has been disconnected

and that the necessary time has passed before removing motor and mains plugs.

2. The [STOP/RESET] key on the control panel of the frequency converter does not disconnect the equipment from mains and is thus not to be

used as a safety switch.

3. Correct protective earthing of the equipment must be established, the user must be protected against supply voltage, and the motor must be

protected against overload in accordance with applicable national and local regulations.

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is set by par. 1-90

(default value) or data value [ETR warning]. Note: The function is initialised at 1.16 x rated motor current and rated motor frequency. For the

North American market: The ETR functions provide class 20 motor overload protection in accordance with NEC.

6. Do not remove the plugs for the motor and mains supply while the frequency converter is connected to mains. Check that the mains supply has

been disconnected and that the necessary time has passed before removing motor and mains plugs.

7. Please note that the frequency converter has more voltage inputs than L1, L2 and L3, when load sharing (linking of DC intermediate circuit) and

external 24 V DC have been installed. Check that all voltage inputs have been disconnected and that the necessary time has passed before

commencing repair work.

Installation at High Altitudes

Motor Thermal Protection

. If this function is desired, set par. 1-90 to data value [ETR trip]

2

By altitudes above 2 km, please contact Danfoss regarding PELV.

Warning against Unintended Start

1. The motor can be brought to a stop by means of digital commands, bus commands, references or a local stop, while the frequency converter

is connected to mains. If personal safety considerations make it necessary to ensure that no unintended start occurs, these stop functions are

not sufficient.

2. While parameters are being changed, the motor may start. Consequently, the stop key [STOP/RESET] must always be activated; following which

data can be modified.

3. A motor that has been stopped may start if faults occur in the electronics of the frequency converter, or if a temporary overload or a fault in

the supply mains or the motor connection ceases.

Warning:

Touching the electrical parts may be fatal - even after the equipment has been disconnected from mains.

Also make sure that other voltage inputs have been disconnected, such as external 24 V DC, load sharing (linkage of DC intermediate circuit), as well as

the motor connection for kinetic back up. Refer to

VLT® HVAC Drive Operating Instructions MG.11.Ax.yy

for further safety guidelines.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

11

Page 12

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

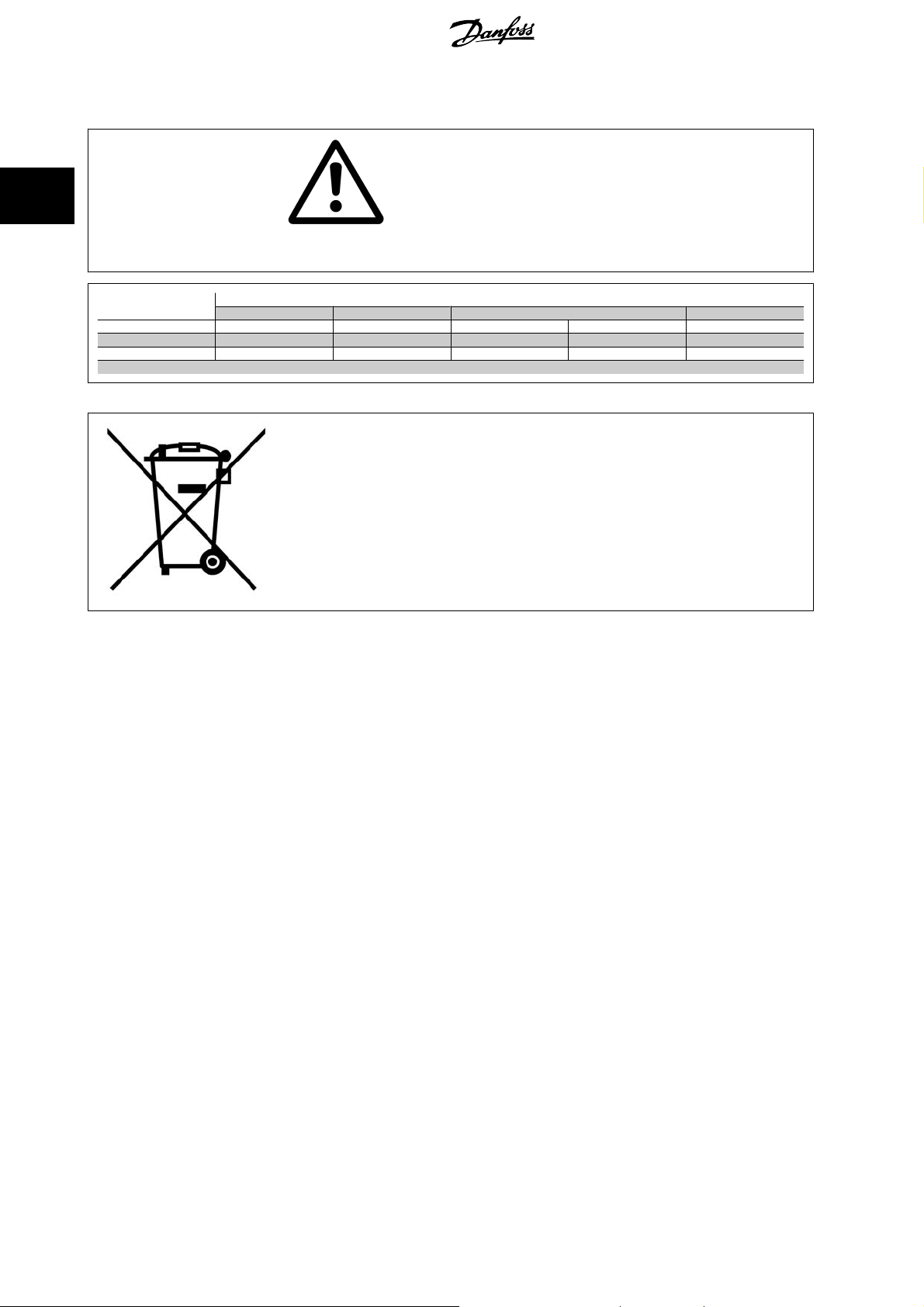

2.1.2. Caution

Caution

The frequency converter DC link capacitors remain charged after power has been disconnected. To avoid an electrical shock hazard, disconnect the

frequency converter from the mains before carrying out maintenance. Wait at least as follows before doing service on the frequency converter:

Voltage

200 - 240 V 1.1 - 3.7 kW 5.5 - 45 kW

380 - 480 V 1.1 - 7.5 kW 11 - 90 kW 110 -200 kW 250 - 450 kW

525 - 600 V 1.1 - 7.5 kW 110 - 250 kW 315 - 560 kW

4 min. 15 min. 20 min. 30 min. 40 min.

Be aware that there may be high voltage on the DC link even when the LEDs are turned off.

Minimum Waiting Time

Equipment containing electrical components may not be disposed of together with domestic

waste.

It must be separately collected with electrical and electronic waste according to local and currently

valid legislation.

2.2. CE labelling

2.2.1. CE Conformity and Labelling

What is CE Conformity and Labelling?

The purpose of CE labelling is to avoid technical trade obstacles within EFTA and the EU. The EU has introduced the CE label as a simple way of showing

whether a product complies with the relevant EU directives. The CE label says nothing about the specifications or quality of the product. Frequency

converters are regulated by three EU directives:

The machinery directive (98/37/EEC)

All machines with critical moving parts are covered by the machinery directive of January 1, 1995. Since a frequency converter is largely electrical, it does

not fall under the machinery directive. However, if a frequency converter is supplied for use in a machine, we provide information on safety aspects

relating to the frequency converter. We do this by means of a manufacturer's declaration.

The low-voltage directive (73/23/EEC)

Frequency converters must be CE labelled in accordance with the low-voltage directive of January 1, 1997. The directive applies to all electrical equipment

and appliances used in the 50 - 1000 V AC and the 75 - 1500 V DC voltage ranges. Danfoss CE-labels in accordance with the directive and issues a

declaration of conformity upon request.

The EMC directive (89/336/EEC)

EMC is short for electromagnetic compatibility. The presence of electromagnetic compatibility means that the mutual interference between different

components/appliances does not affect the way the appliances work.

The EMC directive came into effect January 1, 1996. Danfoss CE-labels in accordance with the directive and issues a declaration of conformity upon

request. To carry out EMC-correct installation, see the instructions in this Design Guide. In addition, we specify which standards our products comply

with. We offer the filters presented in the specifications and provide other types of assistance to ensure the optimum EMC result.

The frequency converter is most often used by professionals of the trade as a complex component forming part of a larger appliance, system or installation.

It must be noted that the responsibility for the final EMC properties of the appliance, system or installation rests with the installer.

12

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 13

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2.2.2. What Is Covered

The EU "

Guidelines on the Application of Council Directive 89/336/EEC

coverage and CE labelling.

" outline three typical situations of using a frequency converter. See below for EMC

1. The frequency converter is sold directly to the end-consumer. The frequency converter is for example sold to a DIY market. The end-consumer

is a layman. He installs the frequency converter himself for use with a hobby machine, a kitchen appliance, etc. For such applications, the

frequency converter must be CE labelled in accordance with the EMC directive.

2. The frequency converter is sold for installation in a plant. The plant is built up by professionals of the trade. It could be a production plant or a

heating/ventilation plant designed and installed by professionals of the trade. Neither the frequency converter nor the finished plant has to be

CE labelled under the EMC directive. However, the unit must comply with the basic EMC requirements of the directive. This is ensured by using

components, appliances, and systems that are CE labelled under the EMC directive.

3. The frequency converter is sold as part of a complete system. The system is being marketed as complete and could e.g. be an air-conditioning

system. The complete system must be CE labelled in accordance with the EMC directive. The manufacturer can ensure CE labelling under the

EMC directive either by using CE labelled components or by testing the EMC of the system. If he chooses to use only CE labelled components,

he does not have to test the entire system.

2.2.3. Danfoss Frequency Converter and CE Labelling

CE labelling is a positive feature when used for its original purpose, i.e. to facilitate trade within the EU and EFTA.

However, CE labelling may cover many different specifications. Thus, you have to check what a given CE label specifically covers.

The covered specifications can be very different and a CE label may therefore give the installer a false feeling of security when using a frequency converter

as a component in a system or an appliance.

Danfoss CE labels the frequency converters in accordance with the low-voltage directive. This means that if the frequency converter is installed correctly,

we guarantee compliance with the low-voltage directive. Danfoss issues a declaration of conformity that confirms our CE labelling in accordance with the

low-voltage directive.

2

The CE label also applies to the EMC directive provided that the instructions for EMC-correct installation and filtering are followed. On this basis, a

declaration of conformity in accordance with the EMC directive is issued.

The Design Guide offers detailed instructions for installation to ensure EMC-correct installation. Furthermore, Danfoss specifies which our different prod-

ucts comply with.

Danfoss gladly provides other types of assistance that can help you obtain the best EMC result.

2.2.4. Compliance with EMC Directive 89/336/EEC

As mentioned, the frequency converter is mostly used by professionals of the trade as a complex component forming part of a larger appliance, system,

or installation. It must be noted that the responsibility for the final EMC properties of the appliance, system or installation rests with the installer. As an

aid to the installer, Danfoss has prepared EMC installation guidelines for the Power Drive system. The standards and test levels stated for Power Drive

systems are complied with, provided that the EMC-correct instructions for installation are followed, see the section

EMC Immunity

.

2.3. Air humidity

2.3.1. Air Humidity

The frequency converter has been designed to meet the IEC/EN 60068-2-3 standard, EN 50178 pkt. 9.4.2.2 at 50°C.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

13

Page 14

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

2.4. Aggressive Environments

A frequency converter contains a large number of mechanical and electronic components. All are to some extent vulnerable to environmental effects.

2

The frequency converter should not be installed in environments with airborne liquids, particles, or gases capable of affecting and

damaging the electronic components. Failure to take the necessary protective measures increases the risk of stoppages, thus reducing

the life of the frequency converter.

Liquids can be carried through the air and condense in the frequency converter and may cause corrosion of components and metal parts. Steam, oil, and

salt water may cause corrosion of components and metal parts. In such environments, use equipment with enclosure rating IP 54/55. As an extra

protection, coated printet circuit boards can be orded as an option.

Particles such as dust may cause mechanical, electrical, or thermal failure in the frequency converter. A typical indicator of excessive levels of

Airborne

airborne particles is dust particles around the frequency converter fan. In very dusty environments, use equipment with enclosure rating IP 54/55 or a

cabinet for IP 00/IP 20/TYPE 1 equipment.

In environments with high temperatures and humidity,

on the frequency converter components.

Such chemical reactions will rapidly affect and damage the electronic components. In such environments, mount the equipment in a cabinet with fresh

air ventilation, keeping aggressive gases away from the frequency converter.

An extra protection in such areas is a coating of the printed circuit boards, which can be ordered as an option.

NB!

Mounting frequency converters in aggressive environments increases the risk of stoppages and considerably reduces the life of the

converter.

corrosive gases such as sulphur, nitrogen, and chlorine compounds will cause chemical processes

Before installing the frequency converter, check the ambient air for liquids, particles, and gases. This is done by observing existing installations in this

environment. Typical indicators of harmful airborne liquids are water or oil on metal parts, or corrosion of metal parts.

Excessive dust particle levels are often found on installation cabinets and existing electrical installations. One indicator of aggressive airborne gases is

blackening of copper rails and cable ends on existing installations.

2.5. Vibration and shock

The frequency converter has been tested according to the procedure based on the shown standards:

The frequency converter complies with requirements that exist for units mounted on the walls and floors of production premises, as well as in panels

bolted to walls or floors.

IEC/EN 60068-2-6: Vibration (sinusoidal) - 1970

IEC/EN 60068-2-64: Vibration, broad-band random

14

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 15

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2.6. Advantages

2.6.1. Why use a frequency converter for controlling fans and pumps?

A frequency converter takes advantage of the fact that centrifugal fans and pumps follow the laws of proportionality for such fans and pumps. For further

information see the text

The Laws of Proportionality

.

2.6.2. The clear advantage - energy savings

The very clear advantage of using a frequency converter for controlling the speed of fans or pumps lies in the electricity savings.

When comparing with alternative control systems and technologies, a frequency converter is the optimum energy control system for controlling fan and

pump systems.

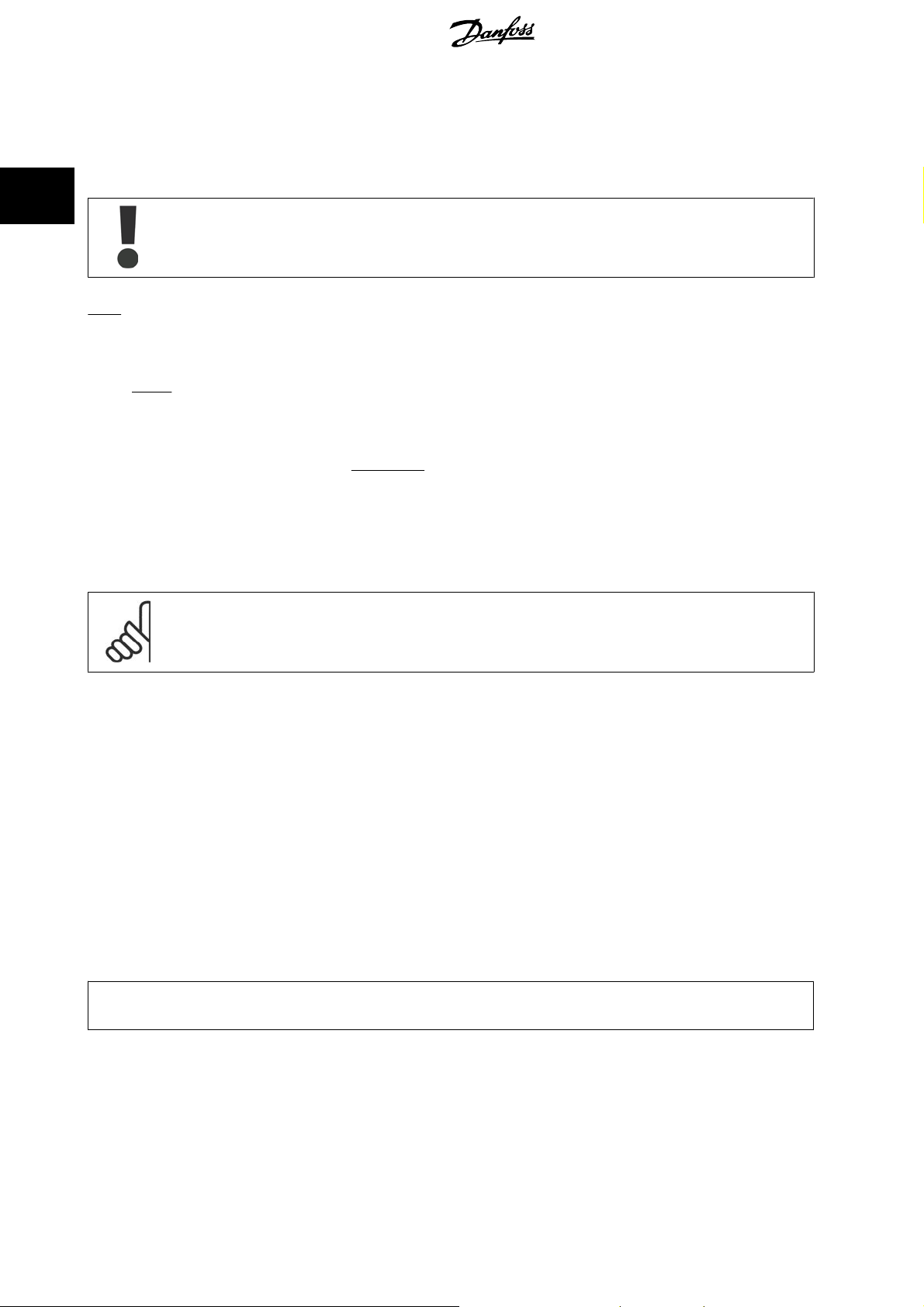

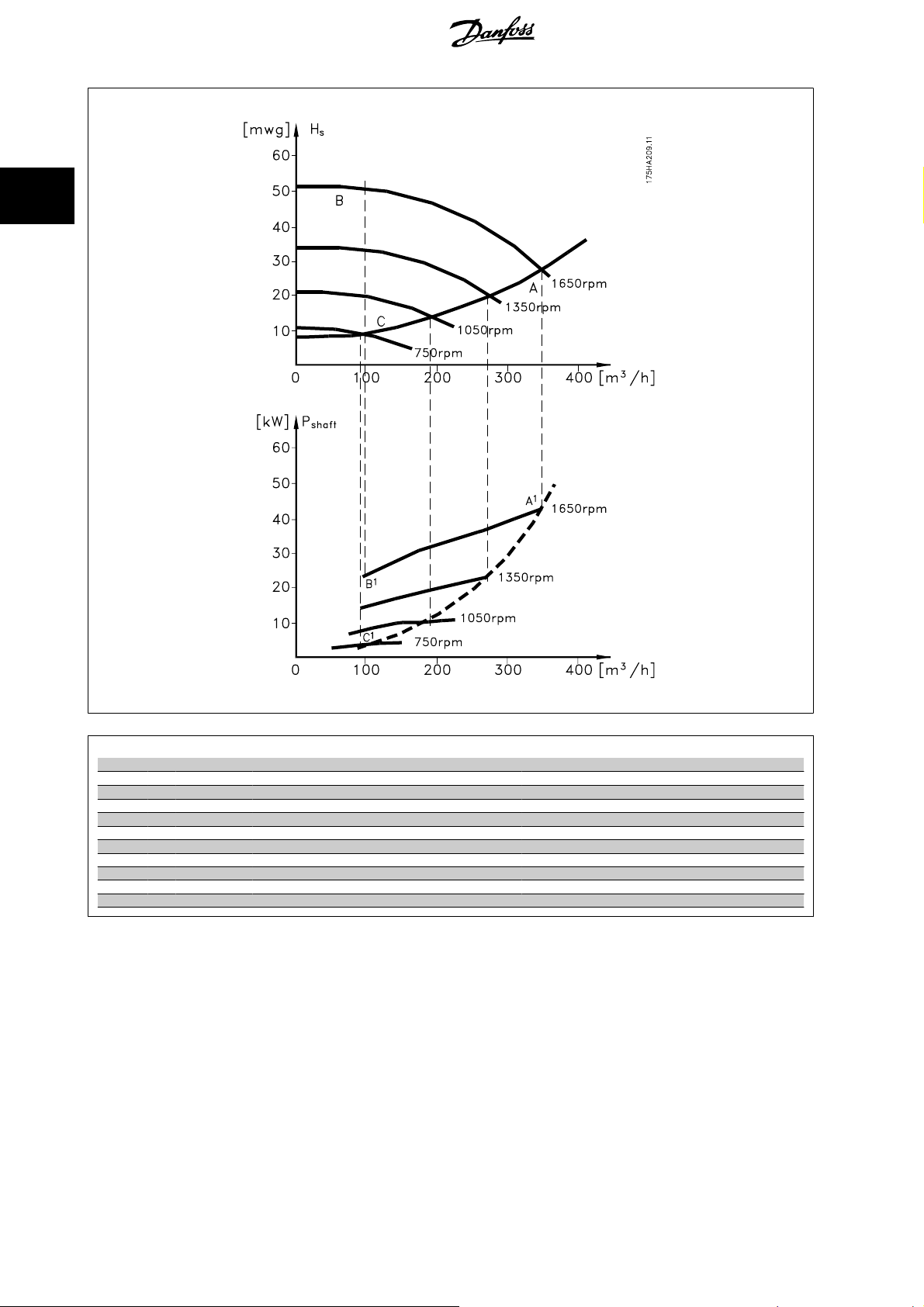

Illustration 2.1: The graph is showing fan curves (A, B and C) for re-

duced fan volumes.

2

Illustration 2.2: When using a frequency converter to reduce fan ca-

pacity to 60% - more than 50% energy savings may be obtained in

typical applications.

2.6.3. Example of energy savings

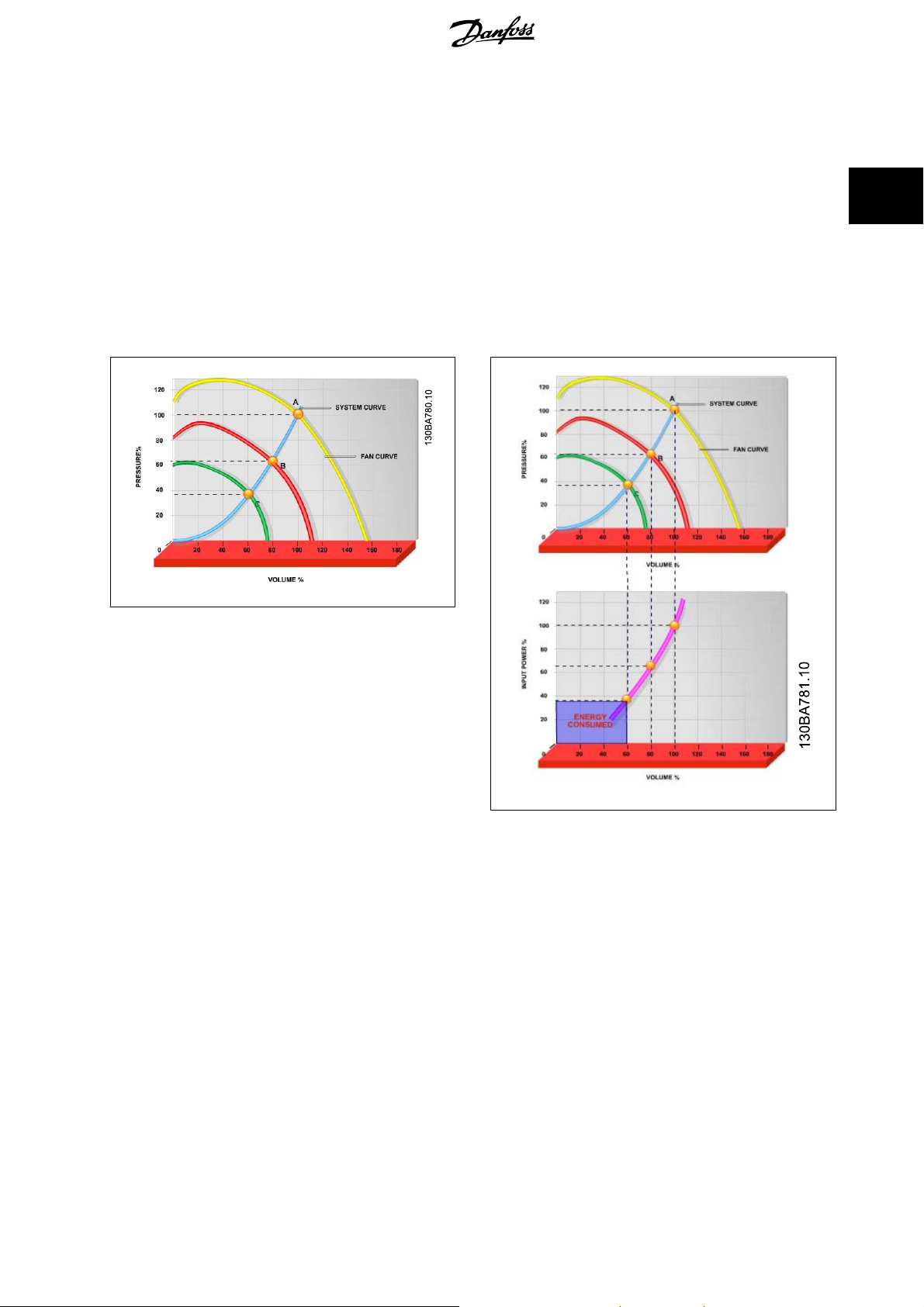

As can be seen from the figure (the laws of proportionality), the flow is controlled by changing the rpm. By reducing the speed only 20% from the rated

speed, the flow is also reduced by 20%. This is because the flow is directly proportional to the rpm. The consumption of electricity, however, is reduced

by 50%.

If the system in question only needs to be able to supply a flow that corresponds to 100% a few days in a year, while the average is below 80% of the

rated flow for the remainder of the year, the amount of energy saved is even more than 50%.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

15

Page 16

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

The laws of proportionality

The figure below describes the dependence of flow, pressure and power consumption on rpm.

Q = Flow P = Power

Q1 = Rated flow P1 = Rated power

Q

= Reduced flow P2 = Reduced power

2

H = Pressure n = Speed regulation

H1 = Rated pressure n1 = Rated speed

H

= Reduced pressure n2 = Reduced speed

2

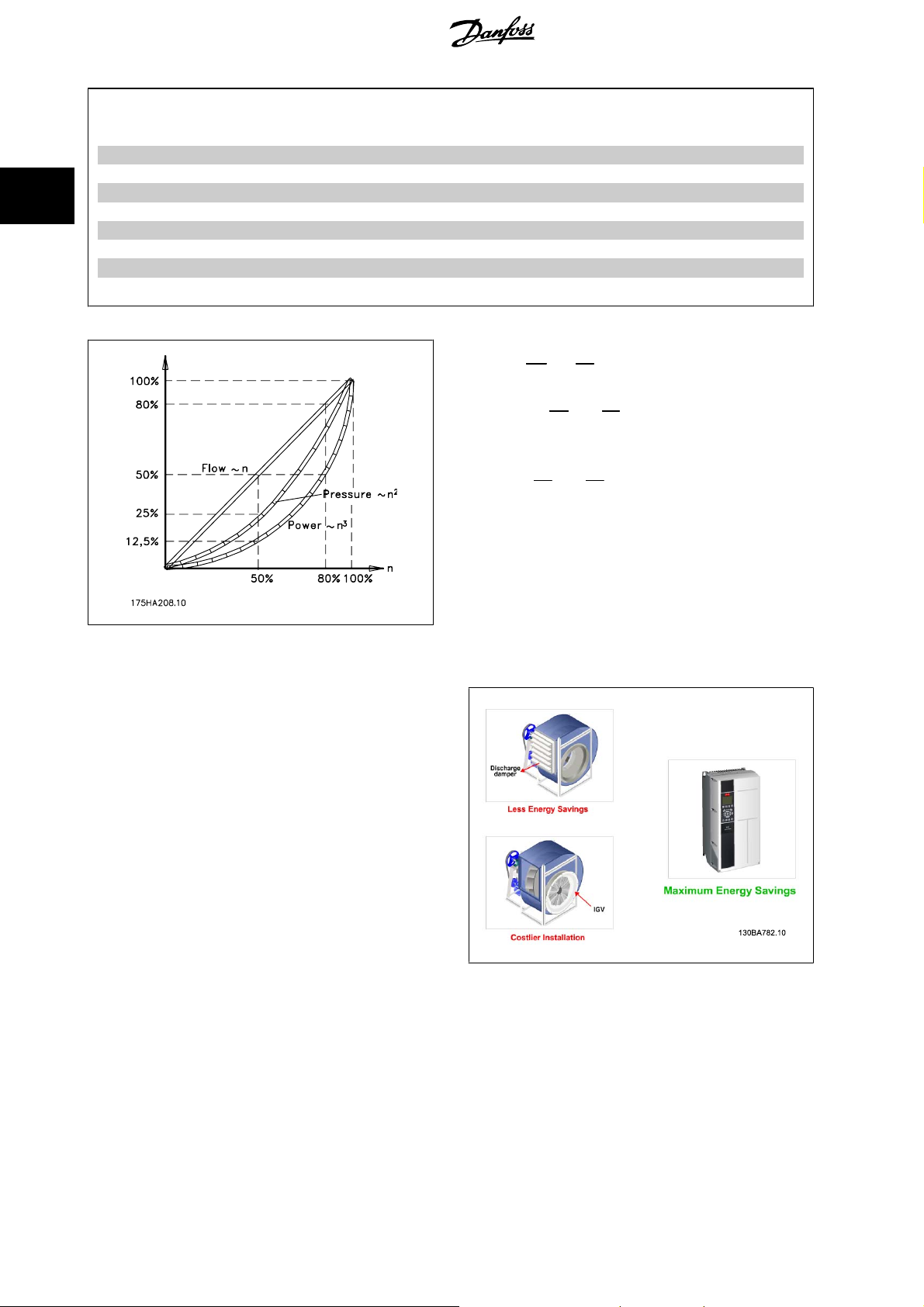

2.6.4. Comparison of energy savings

The Danfoss frequency converter solution offers major savings compared

with traditional energy saving solutions. This is because the frequency

converter is able to control fan speed according to thermal load on the

system and the fact that the frequency converter has a build-in facility

that enables the frequency converter to function as a Building Manage-

ment System, BMS.

Flow

:

Pressure

Power

Q

Q

:

:

n

1

2

P

P

1

=

n

2

H

H

1

2

n

(

2

1

(

)

n

2

n

3

1

)

n

2

1

=

2

=

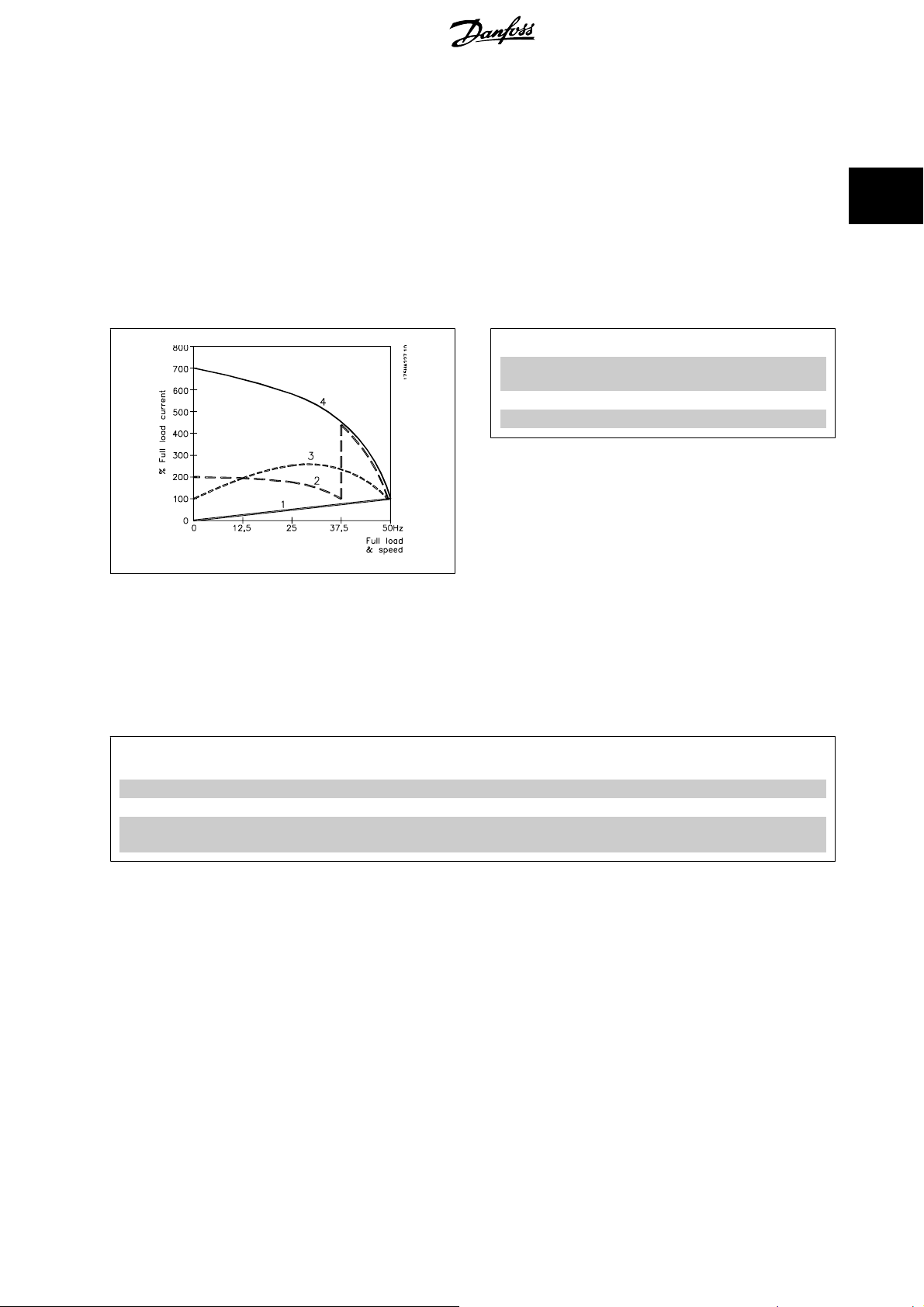

The graph below illustrates typical energy savings obtainable with 3 well-

known solutions when fan volume is reduced to i.e. 60%.

As the graph shows, more than 50% energy savings can be achieved in

typical applications.

16

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Illustration 2.3: The three common energy saving systems.

Page 17

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2

Illustration 2.4: Discharge dampers reduce power consumption somewhat. Inlet Guide Vans offer a 40% reduction but are expensive to install. The

Danfossfrequency converter solution reduces energy consumption with more than 50% and is easy to install.

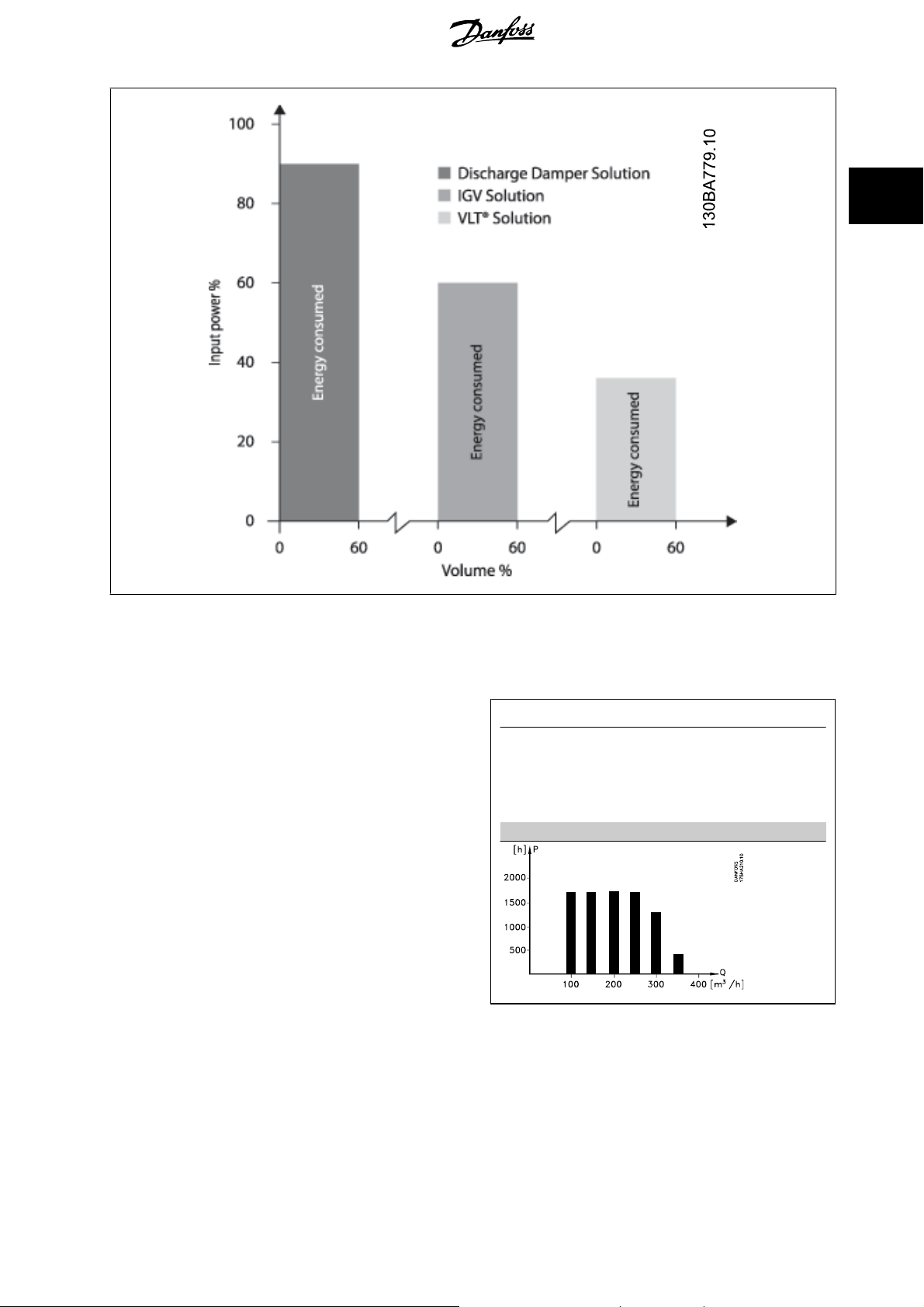

2.6.5. Example with varying flow over 1 year

The example below is calculated on the basis of pump characteristics ob-

tained from a pump datasheet.

The result obtained shows energy savings in excess of 50% at the given

flow distribution over a year. The pay back period depends on the price

per kwh and price of frequency converter. In this example it is less than

a year when compared with valves and constant speed.

Energy savings

P

shaft=Pshaft output

Flow distribution over 1 year

MG.11.B7.02 - VLT® is a registered Danfoss trademark

17

Page 18

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

m3/h

Distribution Valve regulation Frequency converter control

% Hours Power Consumption Power Consumption

A1 - B

350 5 438 42,5 18.615 42,5 18.615

300 15 1314 38,5 50.589 29,0 38.106

250 20 1752 35,0 61.320 18,5 32.412

200 20 1752 31,5 55.188 11,5 20.148

150 20 1752 28,0 49.056 6,5 11.388

100 20 1752 23,0 40.296 3,5 6.132

Σ 100 8760 275.064 26.801

1

kWh A1 - C

1

2.6.6. Better control

If a frequency converter is used for controlling the flow or pressure of a system, improved control is obtained.

A frequency converter can vary the speed of the fan or pump, thereby obtaining variable control of flow and pressure.

Furthermore, a frequency converter can quickly adapt the speed of the fan or pump to new flow or pressure conditions in the system.

Simple control of process (Flow, Level or Pressure) utilizing the built in PID control.

kWh

18

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 19

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2.6.7. Cos φ compensation

Generally speaking, a frequency converter with a cos φ of 1 provides power factor correction for the cos φ of the motor, which means that there is no

need to make allowance for the cos φ of the motor when sizing the power factor correction unit.

2.6.8. Star/delta starter or soft-starter not required

When larger motors are started, it is necessary in many countries to use equipment that limits the start-up current. In more traditional systems, a star/

delta starter or soft-starter is widely used. Such motor starters are not required if a frequency converter is used.

As illustrated in the figure below, a frequency converter does not consume more than rated current.

1 = VLT HVAC Drive

2 = Star/delta starter

3 = Soft-starter

4 = Start directly on mains

2.6.9. Using a frequency converter saves money

The example on the following page shows that a lot of equipment is not required when a frequency converter is used. It is possible to calculate the cost

of installing the two different systems. In the example on the following page, the two systems can be established at roughly the same price.

2

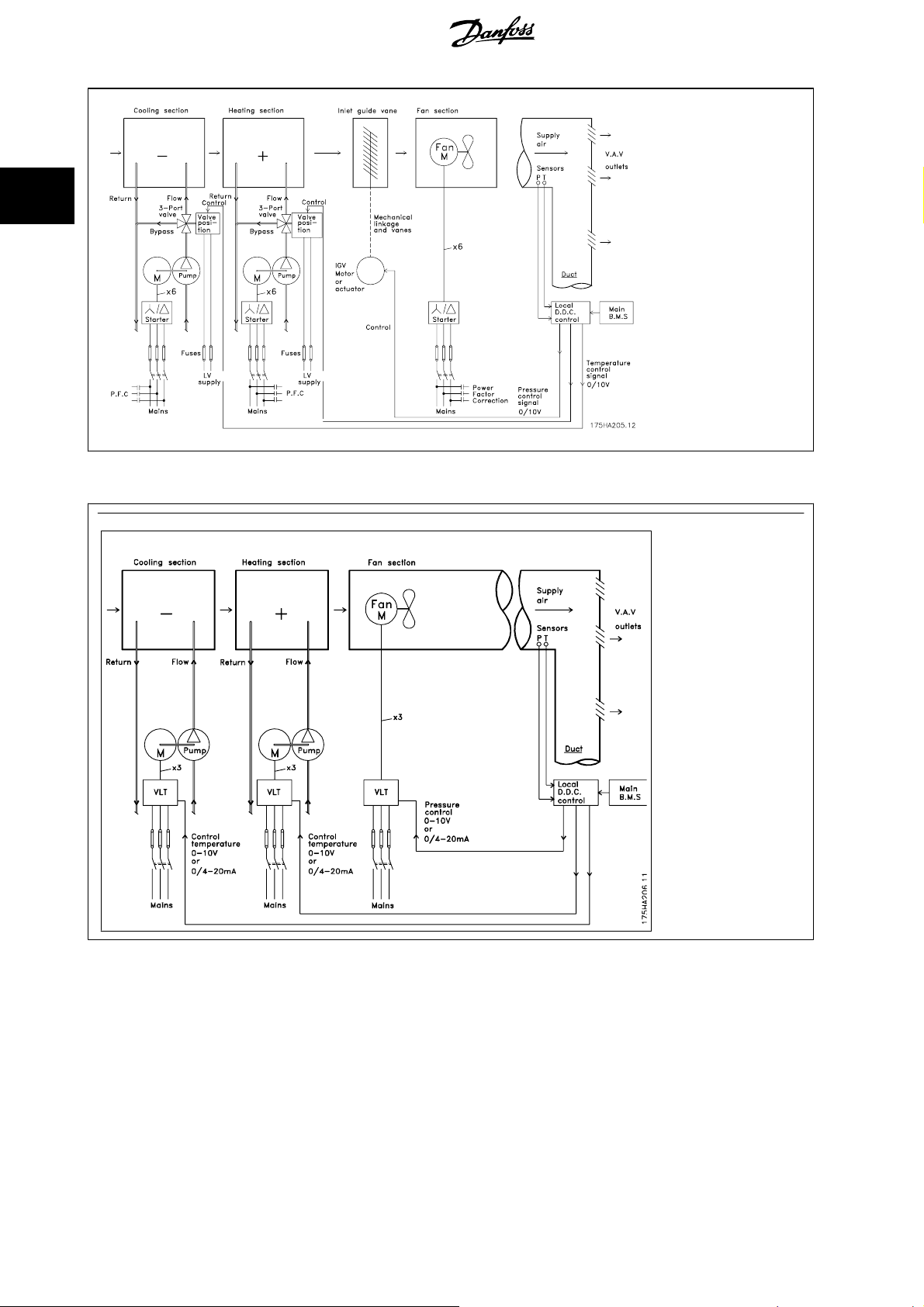

2.6.10. Without a frequency converter

The figure shows a fan system made in the traditional way.

D.D.C. = Direct Digital Control E.M.S. = Energy Management system

V.A.V. = Variable Air Volume

Sensor P = Pressure Sensor T = Temperature

MG.11.B7.02 - VLT® is a registered Danfoss trademark

19

Page 20

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

2.6.11. With a frequency converter

The figure shows a fan system controlled by frequency converters.

20

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 21

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2.6.12. Application examples

The next few pages give typical examples of applications within HVAC.

If you would like to receive further information about a given application, please ask your Danfoss supplier for an information sheet that gives a full

description of the application.

Variable Air Volume

Ask for The Drive to...Improving Variable Air Volume Ventilation Systems MN.60.A1.02

Constant Air Volume

Ask for The Drive to...Improving Constant Air Volume Ventilation Systems MN.60.B1.02

Cooling Tower Fan

Ask for The Drive to...Improving fan control on cooling towers MN.60.C1.02

Condenser pumps

Ask for The Drive to...Improving condenser water pumping systems MN.60.F1.02

Primary pumps

Ask for The Drive to...Improve your primary pumping in primay/secondary pumping systems MN.60.D1.02

Secondary pumps

Ask for The Drive to...Improve your secondary pumping in primay/secondary pumping systems MN.60.E1.02

2

MG.11.B7.02 - VLT® is a registered Danfoss trademark

21

Page 22

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

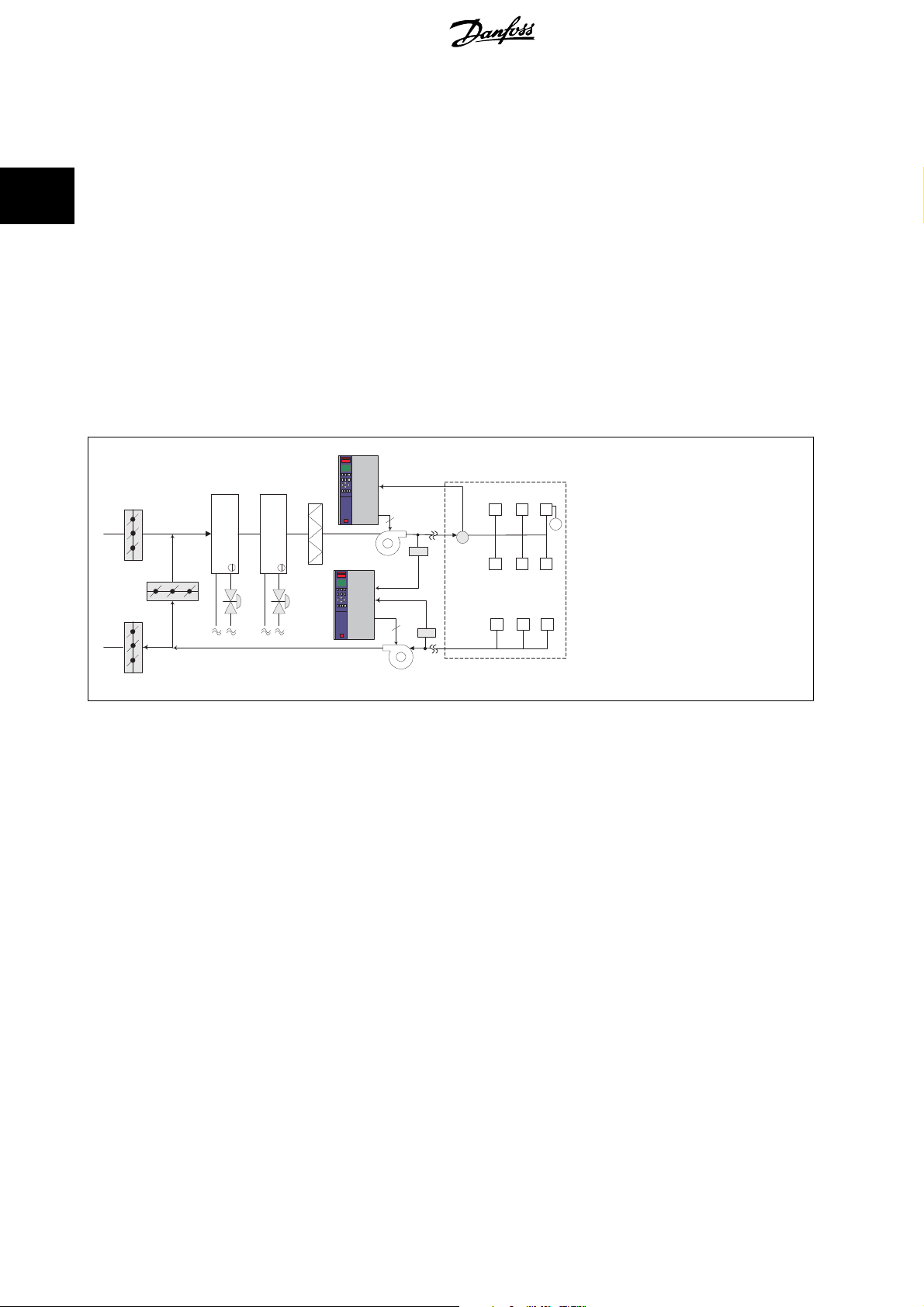

2.6.13. Variable Air Volume

VAV or Variable Air Volume systems, are used to control both the ventilation and temperature to satisfy the requirements of a building. Central VAV

systems are considered to be the most energy efficient method to air condition buildings. By designing central systems instead of distributed systems, a

greater efficiency can be obtained.

The efficiency comes from utilizing larger fans and larger chillers which have much higher efficiencies than small motors and distributed air-cooled chillers.

Savings are also seen from the decreased maintenance requirements.

2.6.14. The VLT solution

While dampers and IGVs work to maintain a constant pressure in the ductwork, a frequency converter solution saves much more energy and reduces

the complexity of the installation. Instead of creating an artificial pressure drop or causing a decrease in fan efficiency, the frequency converter decreases

the speed of the fan to provide the flow and pressure required by the system.

Centrifugal devices such as fans behave according to the centrifugal laws. This means the fans decrease the pressure and flow they produce as their

speed is reduced. Their power consumption is thereby significantly reduced.

The return fan is frequently controlled to maintain a fixed difference in airflow between the supply and return. The advanced PID controller of the HVAC

frequency converter can be used to eliminate the need for additional controllers.

Pressure

Cooling coil

D1

D2

Heating coil

Filter

signal

Supply fan

3

Flow

Pressure

transmitter

VAV boxes

T

Return fan

D3

Flow

3

22

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 23

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

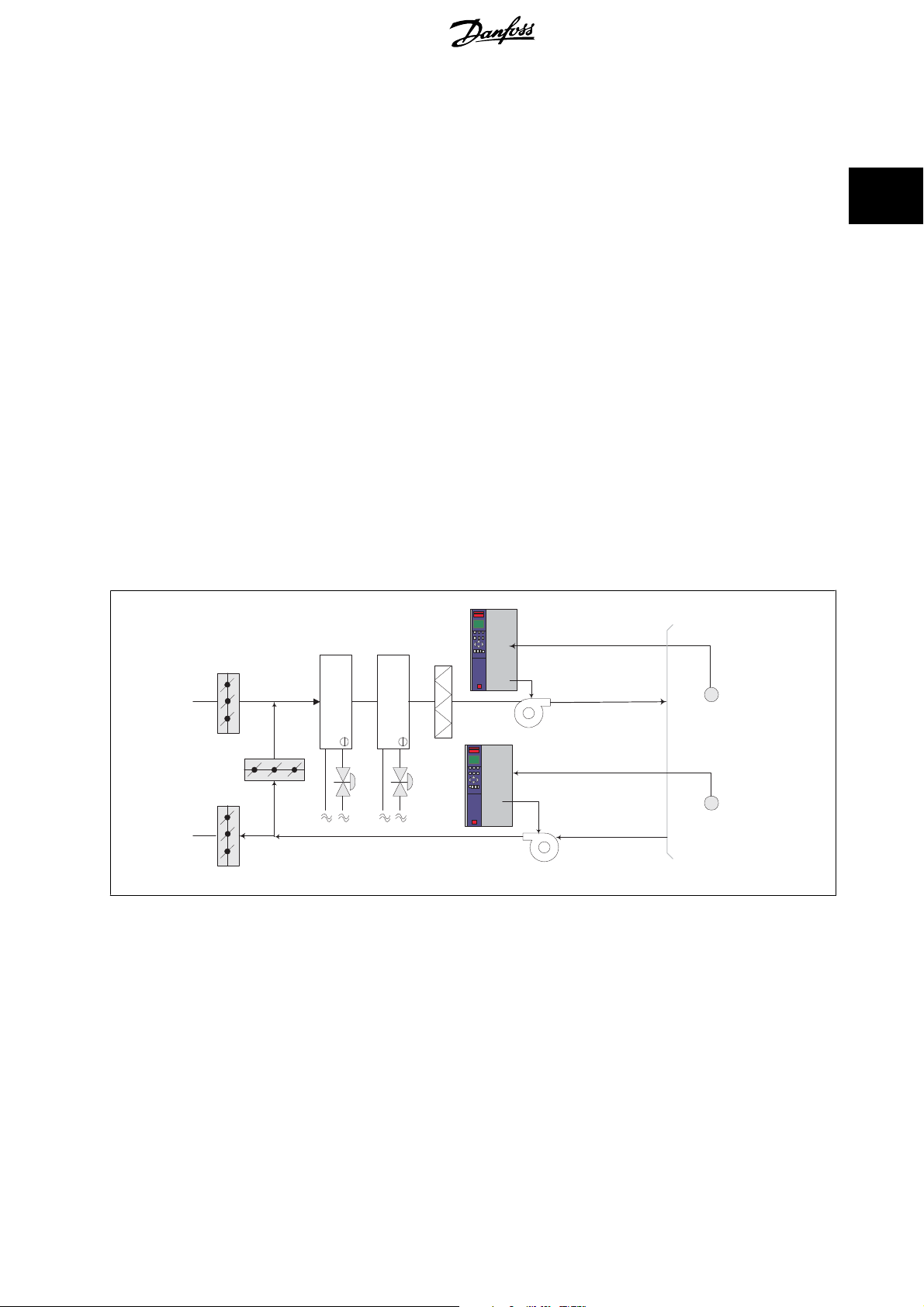

2.6.15. Constant Air Volume

CAV, or Constant Air Volume systems are central ventilation systems usually used to supply large common zones with the minimum amounts of fresh

tempered air. They preceded VAV systems and therefore are found in older multi-zoned commercial buildings as well. These systems preheat amounts

of fresh air utilizing Air Handling Units (AHUs) with a heating coil, and many are also used to air condition buildings and have a cooling coil. Fan coil units

are frequently used to assist in the heating and cooling requirements in the individual zones.

2.6.16. The VLT solution

2

With a frequency converter, significant energy savings can be obtained while maintaining decent control of the building. Temperature sensors or CO

sensors can be used as feedback signals to frequency converters. Whether controlling temperature, air quality, or both, a CAV system can be controlled

to operate based on actual building conditions. As the number of people in the controlled area decreases, the need for fresh air decreases. The CO

sensor detects lower levels and decreases the supply fans speed. The return fan modulates to maintain a static pressure setpoint or fixed difference

between the supply and return air flows.

With temperature control, especially used in air conditioning systems, as the outside temperature varies as well as the number of people in the controlled

zone changes, different cooling requirements exist. As the temperature decreases below the set-point, the supply fan can decrease its speed. The return

fan modulates to maintain a static pressure set-point. By decreasing the air flow, energy used to heat or cool the fresh air is also reduced, adding further

savings.

Several features of the Danfoss HVAC dedicated frequency converter can be utilized to improve the performance of your CAV system. One concern of

controlling a ventilation system is poor air quality. The programmable minimum frequency can be set to maintain a minimum amount of supply air

regardless of the feedback or reference signal. The frequency converter also includes a 3-zone, 3 setpoint PID controller which allows monitoring both

temperature and air quality. Even if the temperature requirement is satisfied, the frequency converter will maintain enough supply air to satisfy the air

quality sensor. The controller is capable of monitoring and comparing two feedback signals to control the return fan by maintaining a fixed differential

air flow between the supply and return ducts as well.

Temperature

Cooling coil

D1

Heating coil

Filter

signal

Supply fan

Temperature

transmitter

2

2

D2

D3

Pressure

signal

Return fan

Pressure

transmitter

MG.11.B7.02 - VLT® is a registered Danfoss trademark

23

Page 24

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

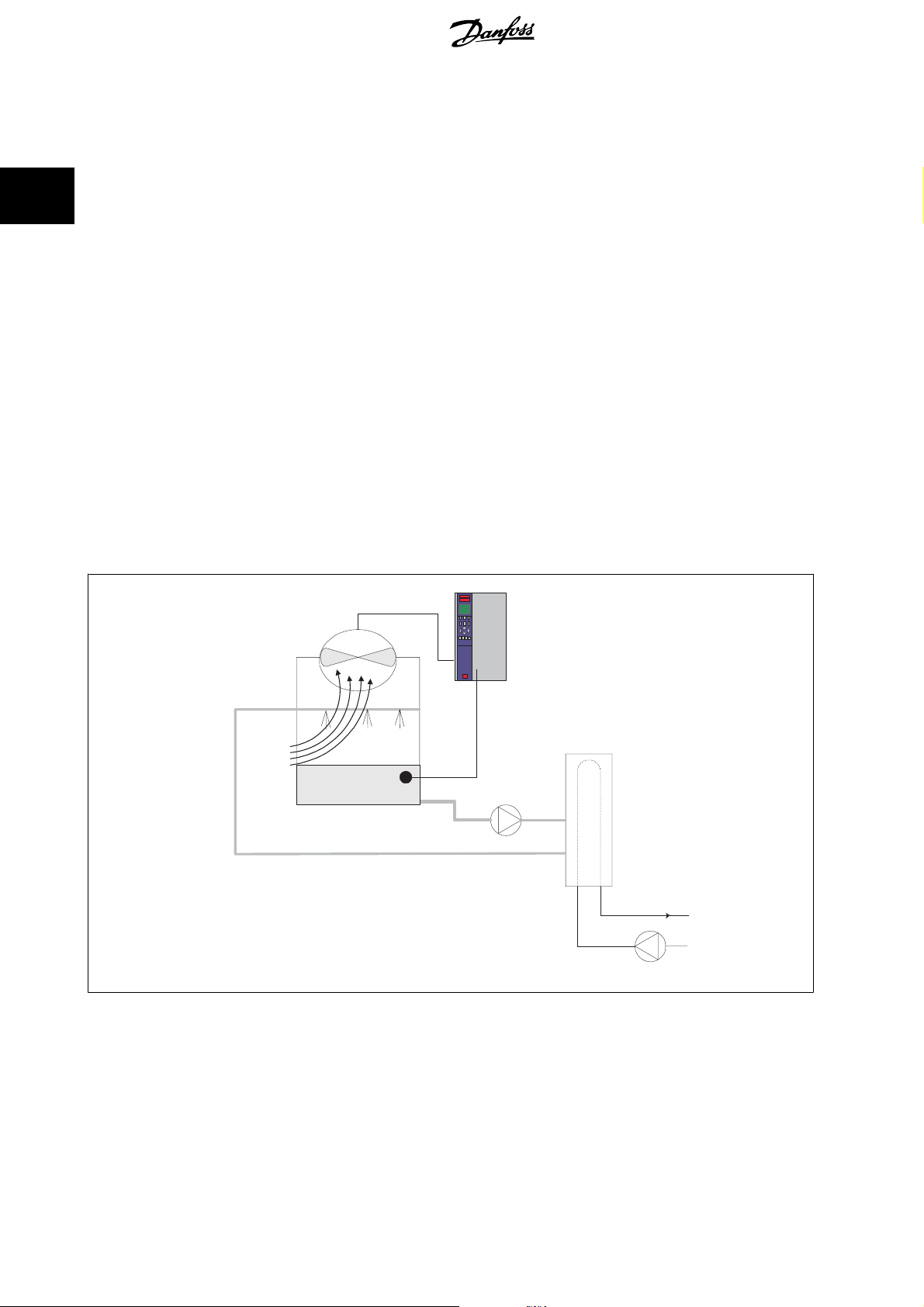

2.6.17. Cooling Tower Fan

Cooling Tower Fans are used to cool condenser water in water cooled chiller systems. Water cooled chillers provide the most efficient means of creating

chilled water. They are as much as 20% more efficient than air cooled chillers. Depending on climate, cooling towers are often the most energy efficient

method of cooling the condenser water from chillers.

They cool the condenser water by evaporation.

The condenser water is sprayed into the cooling tower onto the cooling towers “fill” to increase its surface area. The tower fan blows air through the fill

and sprayed water to aid in the evaporation. Evaporation removes energy from the water dropping its temperature. The cooled water collects in the

cooling towers basin where it is pumped back into the chillers condenser and the cycle is repeated.

2.6.18. The VLT solution

With a frequency converter, the cooling towers fans can be controlled to the required speed to maintain the condenser water temperature. The frequency

converters can also be used to turn the fan on and off as needed.

Several features of the Danfoss HVAC dedicated frequency converter, the HVAC frequency converter can be utilized to improve the performance of your

cooling tower fans application. As the cooling tower fans drop below a certain speed, the effect the fan has on cooling the water becomes small. Also,

when utilizing a gear-box to frequency control the tower fan, a minimum speed of 40-50% may be required.

The customer programmable minimum frequency setting is available to maintain this minimum frequency even as the feedback or speed reference calls

for lower speeds.

Also as a standard feature, you can program the frequency converter to enter a “sleep” mode and stop the fan until a higher speed is required. Additionally,

some cooling tower fans have undesireable frequencies that may cause vibrations. These frequencies can easily be avoided by programming the bypass

frequency ranges in the frequency converter.

Water Inlet

Temperature

Sensor

BASIN

Water Outlet

Conderser

Water pump

CHILLER

Supply

24

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 25

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

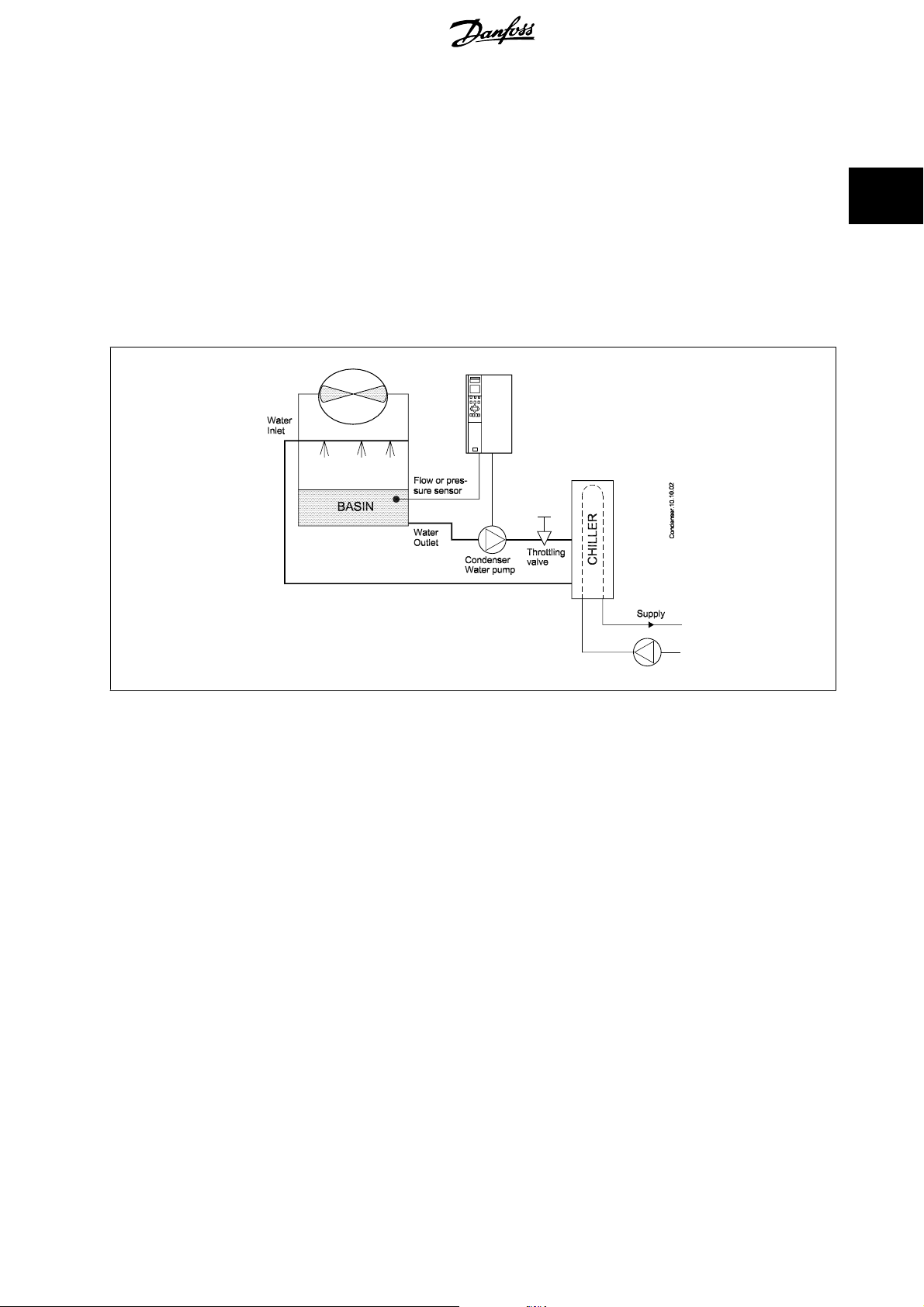

2.6.19. Condenser pumps

Condenser Water pumps are primarily used to circulate water through the condenser section of water cooled chillers and their associated cooling tower.

The condenser water absorbs the heat from the chiller's condenser section and releases it into the atmosphere in the cooling tower. These systems are

used to provide the most efficient means of creating chilled water, they are as much as 20% more efficient than air cooled chillers.

2.6.20. The VLT solution

Frequency converters can be added to condenser water pumps instead of balancing the pumps with a throttling valve or trimming the pump impeller.

Using a frequency converter instead of a throttling valve simply saves the energy that would have been absorbed by the valve. This can amount to savings

of 15-20% or more. Trimming the pump impeller is irreversible, thus if the conditions change and higher flow is required the impeller must be replaced.

2

MG.11.B7.02 - VLT® is a registered Danfoss trademark

25

Page 26

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

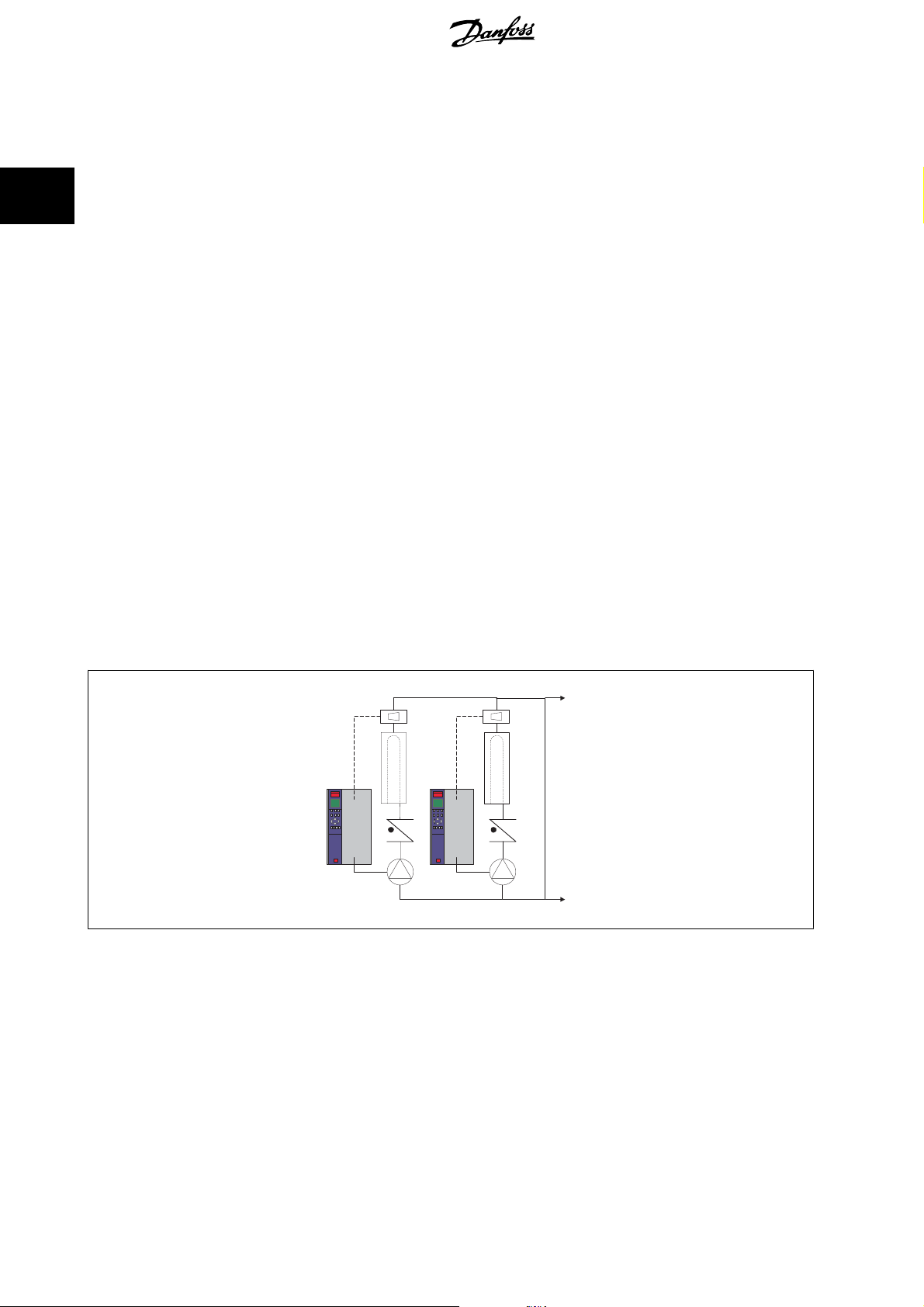

2.6.21. Primary pumps

Primary pumps in a primary/secondary pumping system can be used to maintain a constant flow through devices that encounter operation or control

difficulties when exposed to variable flow. The primary/ secondary pumping technique decouples the “primary” production loop from the “secondary”

distribution loop. This allows devices such as chillers to obtain constant design flow and operate properly while allowing the rest of the system to vary in

flow.

As the evaporator flow rate decreases in a chiller, the chilled water begins to become over-chilled. As this happens, the chiller attempts to decrease its

cooling capacity. If the flow rate drops far enough, or too quickly, the chiller cannot shed its load sufficiently and the chiller’s low evaporator tempera-

ture safety trips the chiller requiring a manual reset. This situation is common in large installations especially when two or more chillers in parallel are

installed if primary/ secondary pumping is not utilized.

2.6.22. The VLT solution

Depending on the size of the system and the size of the primary loop, the energy consumption of the primary loop can become substantial.

A frequency converter can be added to the primary system, to replace the throttling valve and/or trimming of the impellers, leading to reduced operating

expenses. Two control methods are common:

The first method uses a flow meter. Because the desired flow rate is known and is constant, a flow meter installed at the discharge of each chiller, can

be used to control the pump directly. Using the built-in PID controller, the frequency converter will always maintain the appropriate flow rate, even

compensating for the changing resistance in the primary piping loop as chillers and their pumps are staged on and off.

The other method is local speed determination. The operator simply decreases the output frequency until the design flow rate is achieved.

Using a frequency converter to decrease the pump speed is very similar to trimming the pump impeller, except it doesn’t require any labor and the pump

efficiency remains higher. The balancing contractor simply decreases the speed of the pump until the proper flow rate is achieved and leaves the speed

fixed. The pump will operate at this speed any time the chiller is staged on. Because the primary loop doesn’t have control valves or other devices that

can cause the system curve to change and the variance due to staging pumps and chillers on and off is usually small, this fixed speed will remain

appropriate. In the event the flow rate needs to be increased later in the systems life, the frequency converter can simply increase the pump speed

instead of requiring a new pump impeller.

Flowmeter

F

CHILLER

Flowmeter

F

CHILLER

26

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 27

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

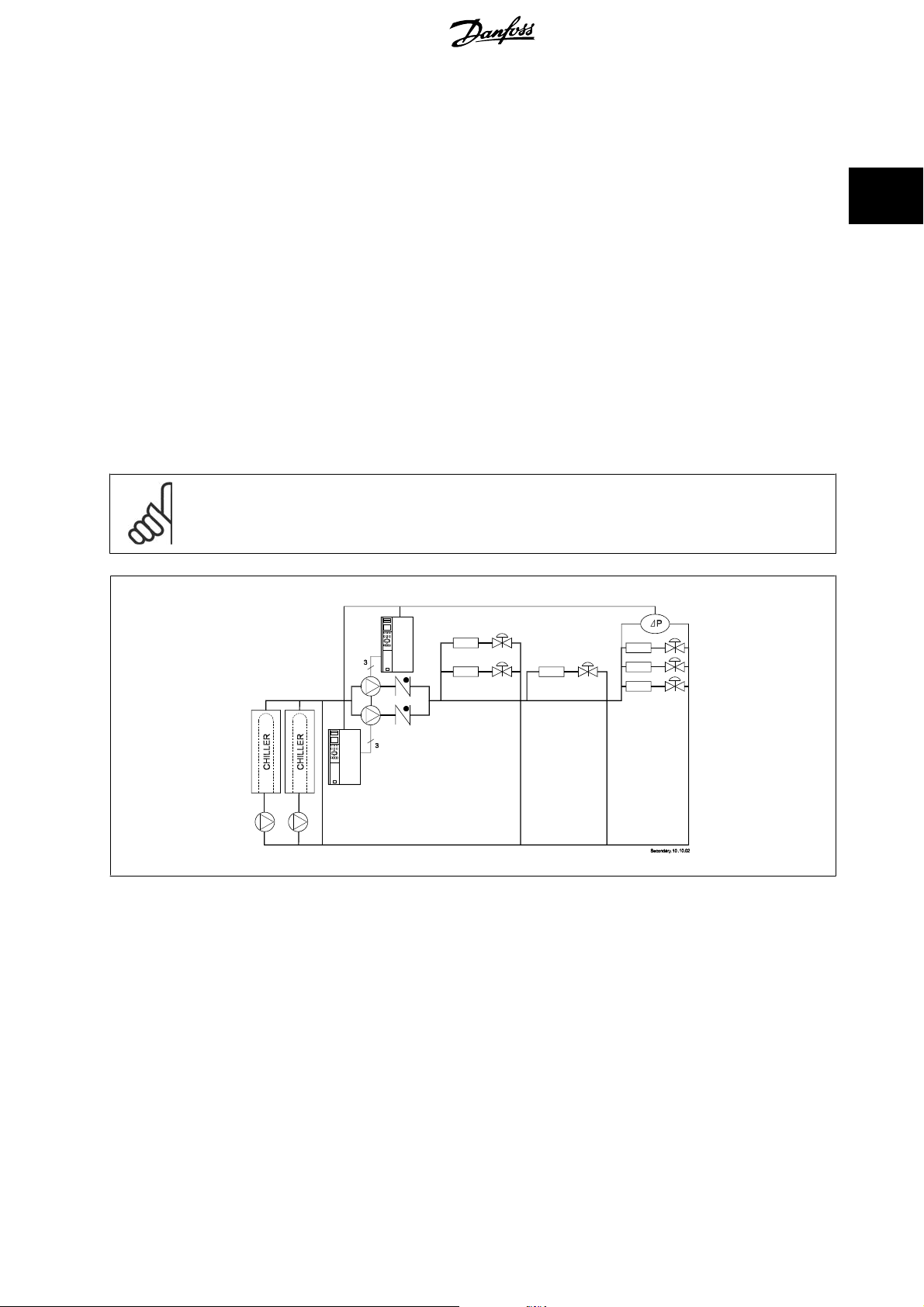

2.6.23. Secondary pumps

Secondary pumps in a primary/secondary chilled water pumping system are used to distribute the chilled water to the loads from the primary production

loop. The primary/secondary pumping system is used to hydronically de-couple one piping loop from another. In this case. The primary pump is used to

maintain a constant flow through the chillers while allowing the secondary pumps to vary in flow, increase control and save energy.

If the primary/secondary design concept is not used and a variable volume system is designed, when the flow rate drops far enough or too quickly, the

chiller cannot shed its load properly. The chiller’s low evaporator temperature safety then trips the chiller requiring a manual reset. This situation is

common in large installations especially when two or more chillers in parallel are installed.

2.6.24. The VLT solution

While the primary-secondary system with two-way valves improves energy savings and eases system control problems, the true energy savings and

control potential is realized by adding frequency converters.

With the proper sensor location, the addition of frequency converters allows the pumps to vary their speed to follow the system curve instead of the

pump curve.

This results in the elimination of wasted energy and eliminates most of the over-pressurization, two-way valves can be subjected too.

As the monitored loads are reached, the two-way valves close down. This increases the differential pressure measured across the load and two-way

va lv e. A s t his di ffe re ntia l p res su re sta rt s to r is e , the p um p is slowed to maintain the control head also called setpoint value. This set-point value is calculated

by summing the pressure drop of the load and two way valve together under design conditions.

2

NB!

Please note that when running multiple pumps in parallel, they must run at the same speed to maximize energy savings, either with

individual dedicated drives or one frequency converter running multiple pumps in parallel.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

27

Page 28

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

2.7. VLT HVAC Drive Controls

2.7.1. Control Principle

2

A frequency converter rectifies AC voltage from mains into DC voltage, after which this DC voltage is converted into a AC current with a variable amplitude

and frequency.

The motor is supplied with variable voltage / current and frequency, which enables infinitely variable speed control of three-phased, standard AC motors.

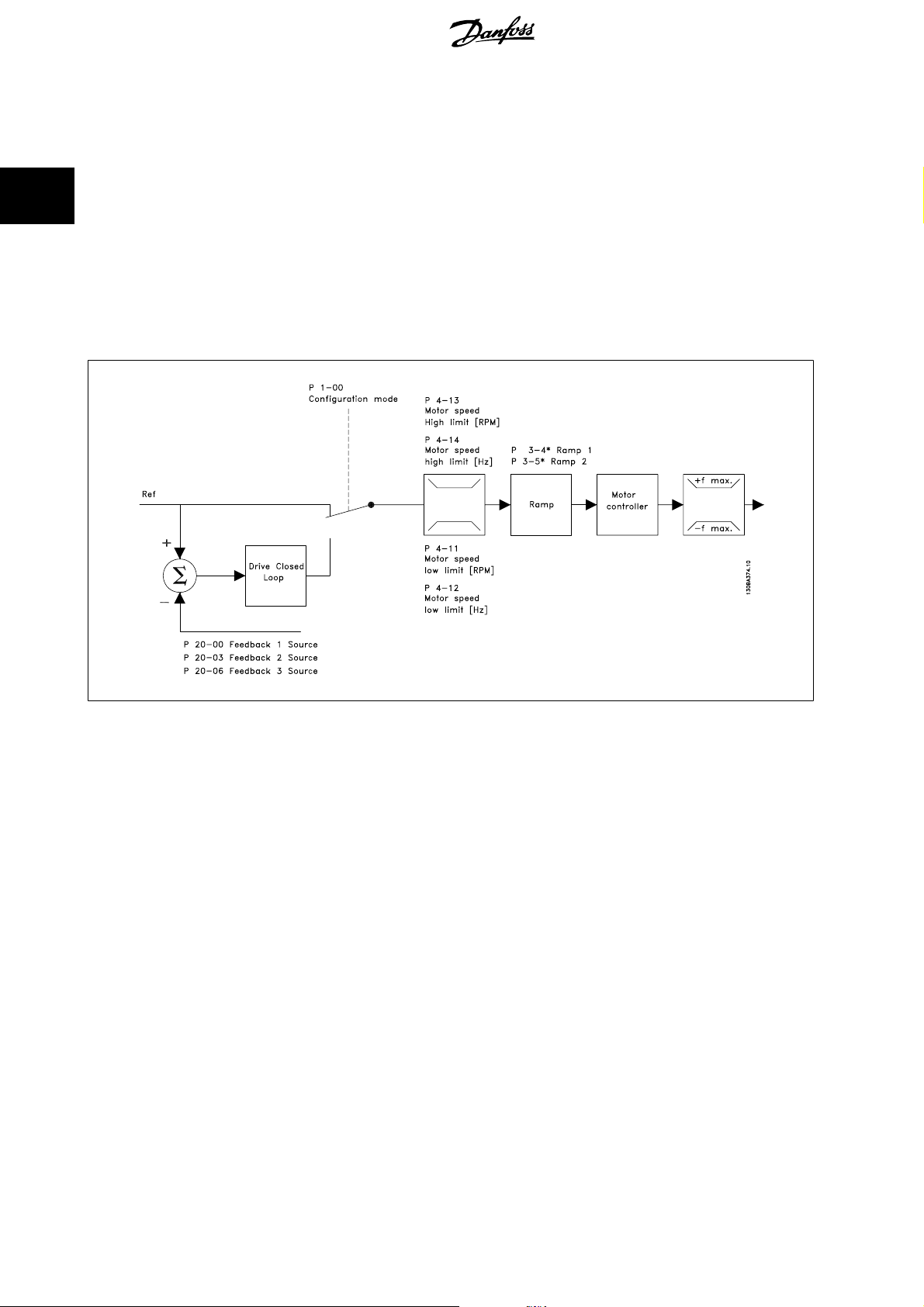

2.7.2. Control Structure

Control structure in open loop and closed loop configurations:

In the configuration shown in the illustration above, par. 1-00 is set to

received and fed through the ramp limitation and speed limitation before being sent to the motor control. The output of the motor control is then limited

by the maximum frequency limit.

Closed loop

Select

parameters are located in par. group 20-**.

[3] in par. 1-00 to use the PID controller for closed loop control of e.g. flow, level or pressure in the controlled application. The PID

Open loop

[0]. The resulting reference from the reference handling system is

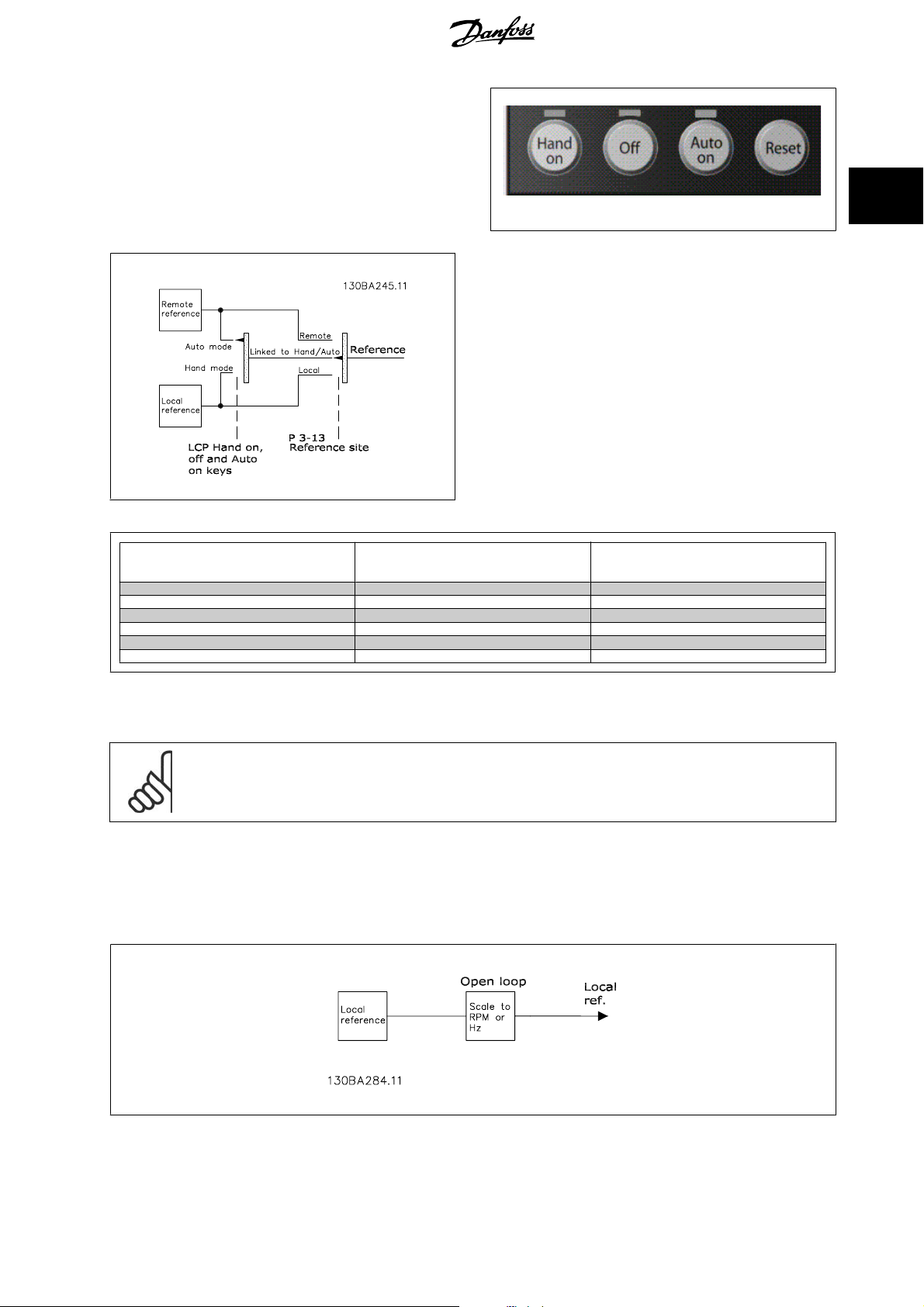

2.7.3. Local (Hand On) and Remote (Auto On) Control

The frequency converter can be operated manually via the local control panel (LCP) or remotely via analog and digital inputs and serial bus.

If allowed in par. 0-40, 0-41, 0-42, and 0-43, it is possible to start and stop the frequency converter via the LCP using the [Hand ON] and [Off] keys.

Alarms can be reset via the [RESET] key. After pressing the [Hand On] key, the frequency converter goes into Hand Mode and follows (as default) the

Local reference set by using the LCP arrow keys.

28

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 29

0

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

After pressing the [Auto On] key, the frequency converter goes into Auto

mode and follows (as default) the Remote reference. In this mode, it is

possible to control the frequency converter via the digital inputs and var-

ious serial interfaces (RS-485, USB, or an optional fieldbus). See more

about starting, stopping, changing ramps and parameter set-ups etc. in

par. group 5-1* (digital inputs) or par. group 8-5* (serial communica-

tion).

130BP046.1

Active Reference and Configuration Mode

The active reference can be either the local reference or the remote ref-

erence.

2

In par. 3-13

lected by selecting

To permanently select the remote reference select

lecting

on which mode is active. (Hand Mode or Auto Mode).

Hand Off

Auto

LCP Keys

Hand Linked to Hand / Auto Local

Hand -> Off Linked to Hand / Auto Local

Auto Linked to Hand / Auto Remote

Auto -> Off Linked to Hand / Auto Remote

All keys Local Local

All keys Remote Remote

The table shows under which conditions either the Local reference or the Remote reference is active. One of them is always active, but both can not be

active at the same time.

NB!

Local Ref. will be restored at power-down.

Reference Site

Par. 3-13

Reference Site

Linked to Hand/Auto

the local reference can be permanently se-

Local

[2].

Remote

[0] (default) the reference site will depend

Active Reference

[1]. By se-

Par. 1-00

is active (see table above for the conditions).

Reference Handling - Local Reference

Configuration Mode

determines what kind of application control principle (i.e. Open Loop or Closed loop) is used when the Remote reference

MG.11.B7.02 - VLT® is a registered Danfoss trademark

29

Page 30

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

2.8. PID

2.8.1. Closed Loop (PID) Controller

2

The frequency converter’s Closed Loop Controller allows the frequency converter to become an integral part of the controlled system. The frequency

converter receives a feedback signal from a sensor in the system. It then compares this feedback to a setpoint reference value and determines the error,

if any, between these two signals. It then adjusts the speed of the motor to correct this error.

For example, consider a ventilation system where the speed of the supply fan is to be controlled so that the static pressure in the duct is constant. The

desired static pressure value is supplied to the frequency converter as the setpoint reference. A static pressure sensor measures the actual static pressure

in the duct and supplies this to the frequency converter as a feedback signal. If the feedback signal is greater than the setpoint reference, the frequency

converter will slow down to reduce the pressure. In a similar way, if the duct pressure is lower than the setpoint reference, the frequency converter will

automatically speed up to increase the pressure provided by the fan.

NB!

While the default values for the frequency converter’s Closed Loop Controller will often provide satisfactory performance, the control

of the system can often be optimized by adjusting some of the Closed Loop Controller’s parameters.

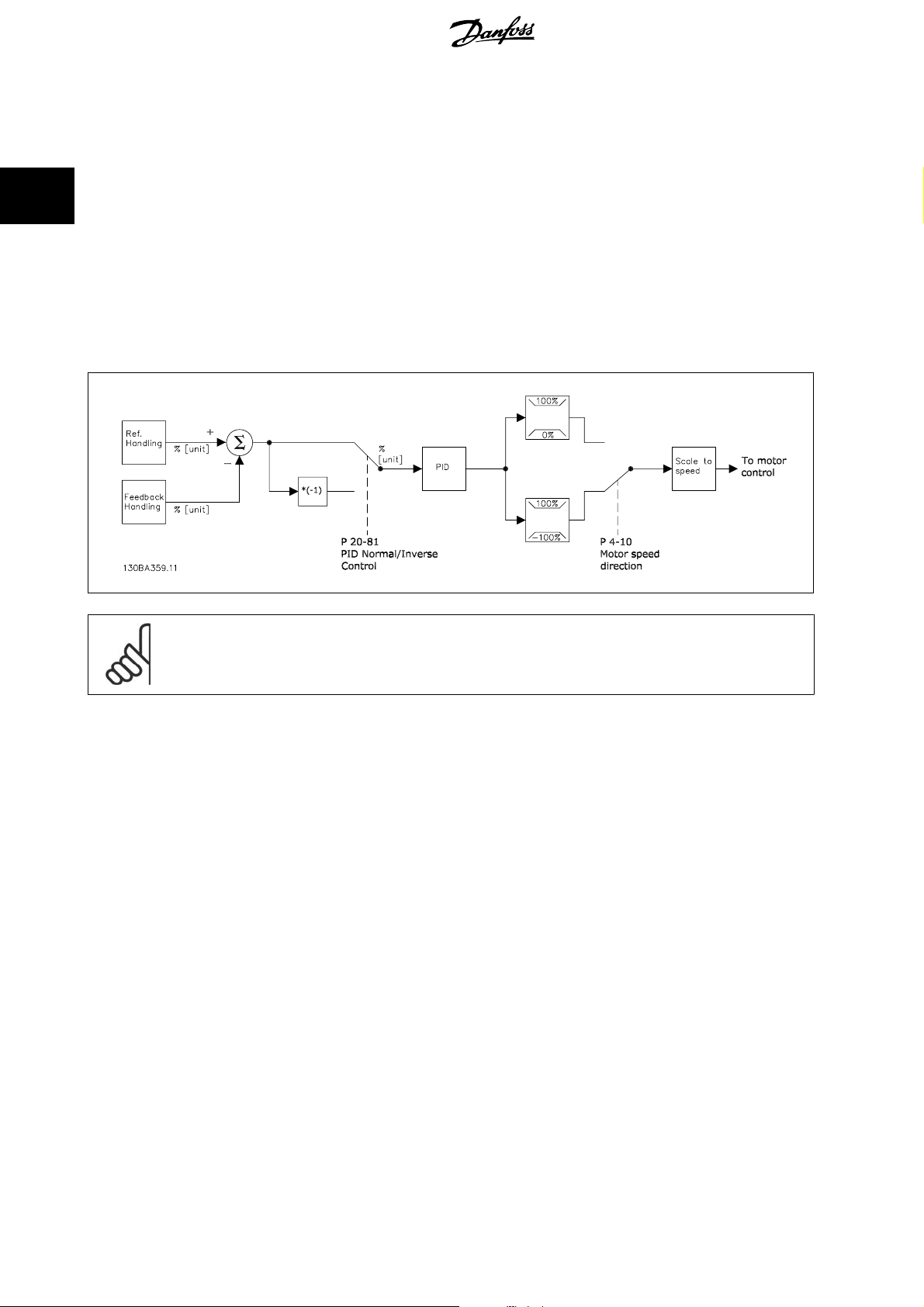

The figure is a block diagram of the frequency converter’s Closed Loop Controller. The details of the Reference Handling block and Feedback Handling

block are described in their respective sections below.

The following parameters are relevant for a simple PID control application:

30

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 31

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

Parameter Description of function

Feedback 1 Source par. 20-00 Select the source for Feed back 1 . This is most commonl y an analog inpu t, but other sources are

also available. Use the scaling of this input to provide the appropriate values for this signal. By

default, Analog Input 54 is the default source for Feedback 1.

Reference/Feedback Unit par 20-12 Select the unit for the setpoint referenceand feedback for the frequency converter’s Closed Loop

Controller. Note: Because a conversion can be applied to the feedback signal before it is used

by the Closed Loop Controller, the Reference/Feedback Unit (par. 20-12) may not be the same

as the Feedback Source Unit (par. 20-02, 20-05 and 20-08).

PID Normal/Inverse Control par. 20-81 Select

PID Proportional Gain par. 20-93 This parameter adjusts the output of the frequency converter’s closed loop controlled based on

PID Integral Time par. 20-94 The integrator adds over time (integrates) the error between the feedback and the setpoint

This table summarizes the parameters that are needed to set up the frequency converter’s Closed Loop Controller when a single feedback signal with no

conversion is compared to a single setpoint. This is the most common type of Closed Loop Controller.

Normal

[0] if the motor’s speed should decrease when the feedback is greater than the

Inverse

setpoint reference. Select

is greater than the setpoint reference.

the error between the feedback and the setpoint reference. Quick controller response is obtained

when this value is large. However, if too large of a value is used, the frequency converter’s output

frequency may become unstable.

reference. This is required to ensure that the error approaches zero. Quick controller response

is obtained when this value is small. However, if too small of a value is used, the frequency

converter’s output frequency may become unstable. A setting of 10000 s disables the integrator.

[1] if the motor’s speed should increase when the feedback

2

2.8.2. Closed Loop Control Relevant Parameters

The frequency converter’s Closed Loop Controller is capable of handling more complex applications, such as situations where a conversion function is

applied to the feedback signal or situations where multiple feedback signals and/or setpoint references are used. The below table summarizes the

additional parameters than may be useful in such applications.

Parameter

Feedback 2 Source

Feedback 3 Source

Feedback 1 Conversion

Feedback 2 Conversion

Feedback 3 Conversion

Feedback 1 Source Unit

Feedback 2 Source Unit

Feedback 3 Source Unit

Feedback Function par. 20-20 When multiple feedbacks or setpoints are used, this determines how they will be pro-

Setpoint 1

Setpoint 2

Setpoint 3

Refrigerant par. 20-30 If any Feedback Conversion (par. 20-01, 20-04 or 20-07) is set to

par. 20-03

par. 20-06

par. 20-01

par. 20-04

par. 20-07

par. 20-02

par. 20-05

par. 20-08

par. 20-21

par. 20-22

par. 20-23

Description of function

Select the source, if any, for Feedback 2 or 3. This is most commonly a frequency con-

verter analog input, but other sources are also available. Par. 20-20 determines how

multiple feedback signals will be processed by the frequency converter’s Closed Loop

Controller. By default, these are set to

These are used to convert the feedback signal from one type to another, for example

from pressure to flow or from pressure to temperature (for compressor applications).

If

Pressure to temperature

Group 20-3*, Feedback Adv. Conv. By default, these are set to

Select the unit for a feedback source, prior to any conversions. This is used for display

purposes only. This parameter is only available when using

feedback conversion.

cessed by the frequency converter’s Closed Loop Controller.

These setpoints can be used to provide a setpoint reference to the frequency converter’s

Closed Loop Controller. Par. 20-20 determines how multiple setpoint references will be

processed. Any other references that are activated in par. group 3-1* will add to these

values.

[2] is selected, the refrigerant must be specified in par.

No function

[0].

Linear

Pressure to Temperature

[0].

Pressure to Temper-

ature

[2], the refrigerant type must be selected here. If the refrigerant used is not listed

here, select

20-31, 20-32 and 20-33.

User defined

[7] and specify the characteristics of the refrigerant in par.

MG.11.B7.02 - VLT® is a registered Danfoss trademark

31

Page 32

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

Parameter Description of function

Custom Refrigerant A1

Custom Refrigerant A2

Custom Refrigerant A3

PID Start Speed [RPM]

PID Start Speed [Hz]

On Reference Bandwidth par. 20-84 This determines how close the feedback must be to the setpoint reference for the fre-

PID Anti Windup par. 20-91

PID Differentiation Time par. 20-95 This controls the output of the frequency converter’s Closed Loop Controller based on

PID Diff. Gain Limit par. 20-96 Because the differentiator responds to the rate of change of the feedback, a rapid

Lowpass Filter Time :

Analog Input 53

Analog Input 54

Digital (pulse) input 29

Digital (pulse) input 33

par. 20-31

par. 20-32

par. 20-33

par. 20-82

par. 20-83

par. 6-16

par. 6-26

par. 5-54

par. 5-59

When par. 20-30 is set to

value of coefficients A1, A2 and A3 in the conversion equation:

Temperature

The parameter that is visible will depend on the setting of par. 0-02, Motor Speed Unit.

In some applications, after a start command it is important to quickly ramp the motor

up to some pre-determined speed before activating the frequency converter’s Closed

Loop Controller. This parameter defines that starting speed.

quency converter to indicate that the feedback is equal to the setpoint.

On

[1] effectively disables the Closed Loop Controller’s integral function when it is not

possible to adjust the output frequency of the frequency converter to correct the error.

This allows the controller to respond more quickly once it can again control the system.

Off

[0] disables this function, making the integral function stay active continuously.

the rate of change of feedback. While this can provide fast controller response, such

response is seldom needed in HVAC systems. The default value for this parameter is

Off, or 0.00 s.

change can cause a large, undesired change in the output of the controller. This is used

to limit the maximum effect of the differentiator. This is not active when par. 20-95 is

set to Off.

This is used to filter out high frequency noise from the feedback signal. The value en-

tered here is the time constant for the low pass filter. The cut-off frequency in Hz can

be calculated as follows:

F

cut

Variations in the feedback signal whose frequency is below F

frequency converter’s Closed Loop Controller, while variations at a higher frequency are

considered to be noise and will be attenuated. Large values of Lowpass Filter Time will

provide more filtering, but may cause the controller to not respond to actual variations

in the feedback signal.

=

−

off

=

(

ln(pressure

T

2π

lowpass

User defined

1

[7], these parameters are used to define the

A

2

+1)−A1

−

A

3

)

will be used by the

cut-off

2.8.3. Example of Closed Loop PID Control

The following is an example of a Closed Loop Control for a ventilation system:

32

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 33

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

In a ventilation system, the temperature is to be maintained at a constant

value. The desired temperature is set between -5 and +35°C using a 0-10

volt potentiometer. Because this is a cooling application, if the tempera-

ture is above the setpoint value, the speed of the fan must be increased

1. Start/Stop via switch connected between terminals 12 (+24 V) and 18.

2. Temperature reference via a potentiometer (-5 to +35°C, 0 10 V)

connected to terminals 50 (+10 V), 53 (input) and 55 (common).

3. Temperature feedback via transmitter (-10-40°C, 4-20 mA) connected

to terminal 54. Switch S202 behind the Local Control Panel set to ON

(current input).

to provide more cooling air flow. The temperature sensor has a range of

-10 to +40°C and uses a two-wire transmitter to provide a 4-20 mA signal.

The output frequency range of the frequency converter is 10 to 50 Hz.

2

MG.11.B7.02 - VLT® is a registered Danfoss trademark

33

Page 34

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

2.8.4. Programming Order

Function Par. no. Setting

1) Make sure the motor runs properly. Do the following:

Set the frequency converter to control the motor

based on frequency converter output frequency.

Set the motor parameters using nameplate data. 1-2* As specified by motor name plate

Run Automatic Motor Adaptation. 1-29

2) Check that the motor is running in the right direction.

Pressing [Hand On] starts the motor at 5Hz in forward

direction and the display shows: “Motor is running.

Check if motor rotation direction is correct.

3) Make sure the frequency converter limits are set to safe values

Check that the ramp settings are within capabilities

of the frequency converter and allowed application

operating specifications.

Prohibit the motor from reversing (if necessary) 4-10

Set acceptable limits for the motor speed. 4-12

Switch from open loop to closed loop. 1-00

4) Configure the feedback to the PID controller.

Set up Analog Input 54 as a feedback input. 20-00

Select the appropriate reference/feedback unit. 20-12

5) Configure the setpoint reference for the PID controller.

Set acceptable limits for the setpoint reference.

Set up Analog Input 53 as Reference 1 Source. 3-15

6) Scale the analog inputs used for setpoint reference and feedback.

Scale Analog Input 53 for the temperature range of

the potentiometer (-5 to +35°C, 0-10 V).

Scale Analog Input 54 for the temperature range of

the temperature sensor (-10 to +40°C, 4-20 mA)

7) Tune the PID controller parameters.

Select inverse control because motor’s speed should

increase when the feedback is greater than the setpoint reference.

Adjust the frequency converter’s Closed Loop Controller, if needed.

8) Finished!

Save the parameter setting to the LCP for safe keeping

0-02

If motor rotation direction is incorrect, two motor

3-41

3-42

4-14

4-19

3-02

3-03

6-10

6-11

6-14

6-15

6-22

6-23

6-24

6-25

20-81

20-93

20-94

0-50

Hz

[1]

Enable complete AMA

function.

phase cables should be interchanged.

60 sec.

60 sec.

Depends on motor/load size!

Also active in Hand mode.

Clockwise

10 Hz

50 Hz

50 Hz

Closed Loop

[0]

[3]

Analog input 54

°C

[60]

-5 °C

35 °C

Analog input 53

0 V

10 V (default)

-5 °C

35 °C

4 mA

20 mA (default)

-10 °C

40 °C

Inverse

[1]

See Optimization of the PID Controller, below.

All to LCP

[1]

[1] and then run the AMA

[2] (default)

[1] (default)

34

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 35

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

2.8.5. Tuning the Drive's Closed Loop Controller

Once the frequency converter’s Closed Loop Controller has been set up, the performance of the controller should be tested. In many cases, its performance

may be acceptable using the default values of PID Proportional Gain (par. 20-93) and PID Integral Time (par. 20-94). However, in some cases it may be

helpful to optimize these parameter values to provide faster system response while still controlling speed overshoot. In many situations, this can be done

by following the procedure below.

1. Start the motor

2. Set par. 20-93 (PID Proportional Gain) to 0.3 and increase it until the feedback signal begins to oscillate. If necessary, start and stop the frequency

converter or make step changes in the setpoint reference to attempt to cause oscillation. Next reduce the PID Proportional Gain until the feedback

signal stabilizes. Then reduce the proportional gain by 40-60%.

3. Set par. 20-94 (PID Integral Time) to 20 sec. and reduce it until the feedback signal begins to oscillate. If necessary, start and stop the frequency

converter or make step changes in the setpoint reference to attempt to cause oscillation. Next, increase the PID Integral Time until the feedback

signal stabilizes. Then increase of the Integral Time by 15-50%.

4. Par. 20-95 (PID Differentiation Time) should only be used for very fast-acting systems. The typical value is 25% of the PID Integral Time (par.

20-94). The differentiator should only be used when the setting of the proportional gain and the integral time has been fully optimized. Make

sure that oscillations of the feedback signal are sufficiently dampened by the lowpass filter for the feedback signal (par 6 16, 6 26, 5 54 or 5 59,

as required).

2.8.6. Ziegler Nichols Tuning Method

2

In general, the above procedure is sufficient for HVAC applications. However, other, more sophisticated procedures can also be used. The Ziegler Nichols

tuning method is a technique which was developed in the 1940s, but is still commonly used today. It generally provides acceptable control performance

using a simple experiment and parameter calculation.

NB!

This method must not be used on applications that could be damaged by oscillations created by marginally stable control settings.

2. Increase the value of the PID Proportional Gain (par 20-93) until

the point of instability is reached, as indicated by sustained os-

cillations of the feedback signal. The PID Proportional Gain that

Illustration 2.5: Marginally stable system

1. Select proportional control only. That is, PID Integral Time (par.

20-94) is set to Off (10000 s) and PID Differentiation Time (par.

20 95) is also set to Off (0 s, in this case).

causes sustained oscillations is called the critical gain, K

3. Measure the period of oscillation, P

NOTE: P

should be measured when the amplitude of oscillation

u

is relatively small. The output must not saturate (i.e., the max-

imum or minimum feedback signal must not be reached during

the test).

4. Use the table below to calculate the necessary PID control pa-

rameters.

.

u

.

u

Type of Control Proportional Gain Integral Time Differentiation Time

PI-control 0.45 *

PID tight control 0.6 *

PID some overshoot 0.33 *

Ziegler Nichols tuning for regulator, based on a stability boundary

Experience has shown that the control setting according to Ziegler Nichols rule provides a good closed loop response for many systems. If necessary,

the operator can do the final tuning of the control iteratively to modify the response of the control loop.

K

u

K

u

K

u

MG.11.B7.02 - VLT® is a registered Danfoss trademark

0.833 *

0.5 *

P

0.5 *

P

P

u

u

u

-

0.125 *

0.33 *

P

u

P

u

35

Page 36

2

2. Introduction to VLT HVAC Drive VLT® HVAC Drive Design Guide

2.8.7. Reference Handling

A block diagram of how the drive produces the Remote Reference is shown below.

36

MG.11.B7.02 - VLT® is a registered Danfoss trademark

Page 37

VLT® HVAC Drive Design Guide 2. Introduction to VLT HVAC Drive

The Remote Reference is comprised of:

• Preset references.

• External references (analog inputs, pulse frequency inputs, digital potentiometer inputs and serial communication bus references).

• The Preset relative reference.

•Feedback controlled setpoint.

Up to 8 preset references can be programmed in the drive. The active preset reference can be selected using digital inputs or the serial communications

bus. The reference can also be supplied externally, most commonly from an analog input. This external source is selected by one of the 3 Reference

Source parameters (par. 3-15, 3-16 and 3-17). Digipot is a digital potentiometer. This is also commonly called a Speed Up/Speed Down Control or a

Floating Point Control. To set it up, one digital input is programmed to increase the reference while another digital input is programmed to decrease the

reference. A third digital input can be used to reset the Digipot reference. All reference resources and the bus reference are added to produce the total

External Reference. The External Reference, the Preset Reference or the sum of the two can be selected to be the active reference. Finally, this reference

can by be scaled using the Preset Relative Reference (par. 3-14).

The scaled reference is calculated as follows:

Reference=X+X

Where X is the external reference, the preset reference or the sum of these and Y is the Preset Relative Reference (par. 3-14) in [%].

Y

×

(

)

100

2

NB!

If Y, the Preset Relative Reference (par. 3-14) is set to 0%, the reference will not be affected by the scaling

2.8.8. Feedback Handling

A block diagram of how the frequency converter processes the feedback signal is shown below.

Feedback handling can be configured to work with applications requiring advanced control, such as multiple setpoints and multiple feedbacks. Three

types of control are common.

Single Zone, Single Setpoint

Single Zone Single Setpoint is a basic configuration. Setpoint 1 is added to any other reference (if any, see Reference Handling) and the feedback signal

is selected using par. 20-20.