Page 1

MAKING MODERN LIVING POSSIBLE

Programming Guide

VLT® HVAC Basic Drive

Page 2

Page 3

Contents

Contents

VLT® HVAC Basic Drive Programming Guide

1 Introduction

1.1.1 Copyright, Limitation of Liability and Revision Rights 1-1

1.1.2 Symbols 1-1

1.1.3 Abbreviations 1-2

1.1.5 Definitions 1-2

1.1.8 Electrical Overview 1-7

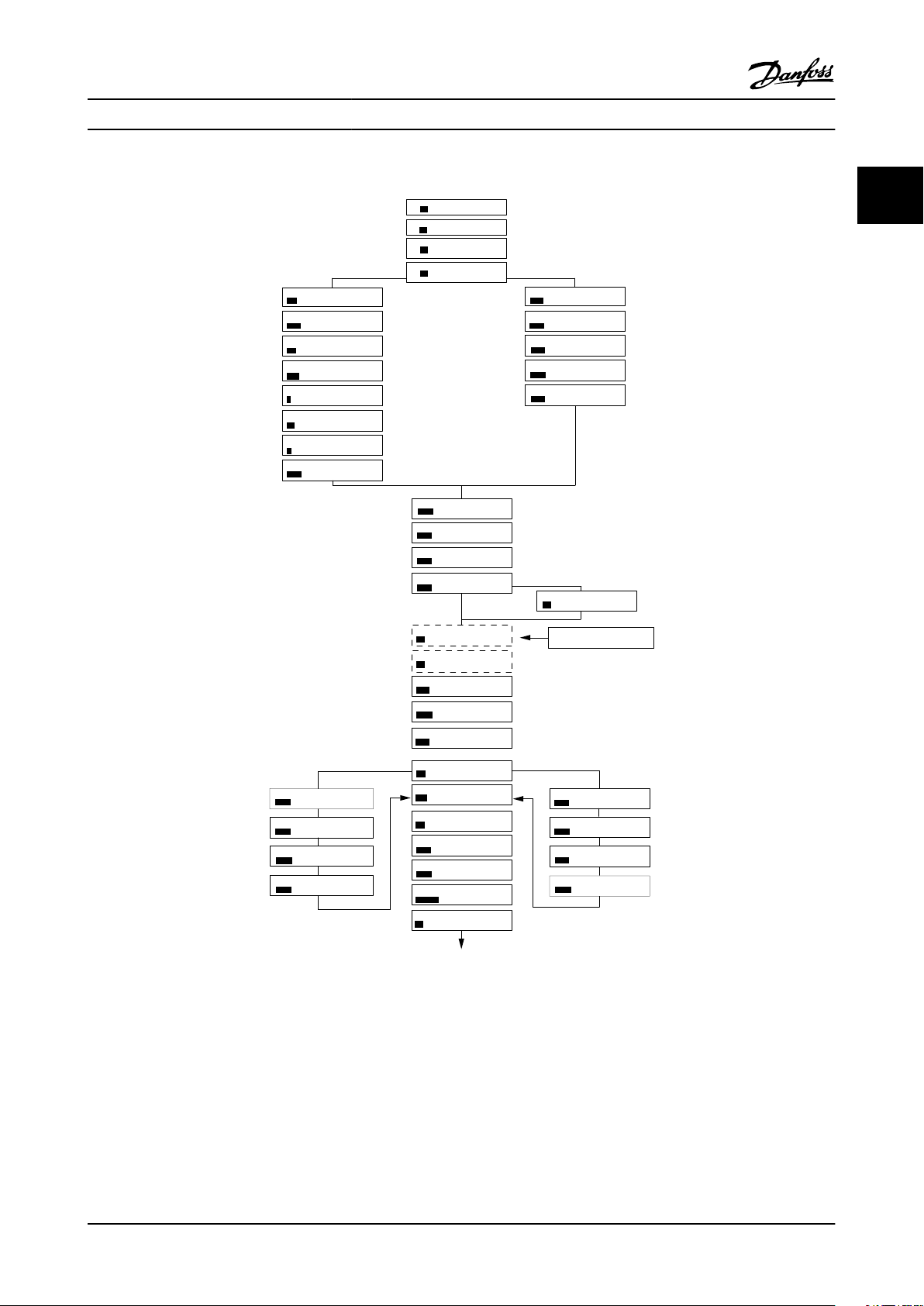

2 How to Program

2.1 Programming with MCT-10 Setup Software

2.2 Local Control Panel (LCP)

2.3 Menus

2.3.1 Status 2-2

2.3.2 Quick Menu 2-2

2.3.3 The FC101 Start-up Wizard for Open-loop Applications 2-2

2.3.4 Main Menu 2-11

2.4 Quick Transfer of Parameter Settings between Multiple Adjustable Frequency

Drives

2.5 Read-out and Programming of Indexed Parameters

1-1

2-1

2-1

2-1

2-2

2-12

2-12

2.6 Initialize the Adjustable Frequency Drive to Default Settings in Two Ways

3 Parameters

3.1 Main Menu - Operation and Display - Group 0

3.1.1 0-0* Basic Settings 3-1

3.1.2 0-1* Define and set-up Operations 3-2

3.1.3 0-3* LCP Custom Readout 3-3

3.1.4 0-4* LCP 3-4

3.1.5 0-5* Copy/Save 3-4

3.1.6 0-6* Password 3-5

3.2 Main Menu - Load and Motor - Group 1

3.2.1 1-0* General Settings 3-6

3.2.2 1-10 - 1-13 Motor Selection 3-6

3.2.5 1-2* Motor Data 3-8

3.3 Main Menu - Brakes - Group 2

3.3.1 2-1* Overvoltage Control 3-13

3.4 Main Menu - Reference/Ramps - Group 3

3.4.1 3-0* Reference Limits 3-14

2-12

3-1

3-1

3-6

3-13

3-14

3.4.2 3-1* References 3-14

3.4.3 3-4* Ramp 1 3-15

MG18B222 - VLT® is a registered Danfoss trademark

Page 4

Contents

VLT® HVAC Basic Drive Programming Guide

3.4.4 3-5* Ramp 2 3-15

3.4.5 3-8* Other Ramps 3-16

3.5 Main Menu - Limits/Warnings - Group 4

3.5.1 4-1* Motor Limits 3-17

3.5.3 4-5* Adj. Warnings 3-17

3.5.4 4-6* Speed Bypass 3-18

3.6 Main Menu - Digital In/Out - Group 5

3.6.1 5-0* Digital I/O Mode 3-20

3.6.2 5-1* Digital Inputs 3-20

3.6.4 5-4* Relays 3-26

3.6.6 5-9* Bus Controlled 3-30

3.7 Main Menu - Analog In/Out - Group 6

3.7.1 6-0* Analog I/O Mode 3-31

3.7.2 6-1* Analog Input 53 3-31

3.7.3 6-2* Analog Input 54 3-32

3.7.4 6-7* Analog/Digital Output 45 3-32

3.7.5 6-9* Analog/Digital Output 42 3-34

3.8 Main Menu - Communications and Options - Group 8

3.8.1 8-0* General Settings 3-36

3-17

3-20

3-31

3-36

3.8.2 8-3* FC Port Settings 3-36

3.8.3 8-5* Digital/Bus 3-37

3.8.4 8-7* BACnet 3-38

3.8.5 8-8* FC Port Diagnostics 3-39

3.8.6 8-9* Bus Feedback 3-39

3.9 Main Menu - Smart Logic - Group 13

3.9.1 13-** Prog. Features 3-40

3.9.2 13-0* SLC Settings 3-40

3.9.3 13-1* Comparators 3-42

3.9.4 13-2*Timers 3-43

3.9.5 13-4* Logic Rules 3-43

3.9.6 13-5* States 3-46

3.10 Main Menu - Special Functions - Group 14

3.10.1 14-0* Inverter Switching 3-49

3.10.2 14-1* >Mains Power On/Off 3-49

3.10.3 14-2* Trip Reset 3-49

3.10.4 14-4*Energy Optimizing 3-50

3-40

3-49

3.10.5 14-5* Environment 3-50

3.11 Main Menu - Drive Information - Group 15

MG18B222 - VLT® is a registered Danfoss trademark

3-52

Page 5

Contents

VLT® HVAC Basic Drive Programming Guide

3.11.1 15-0* Operating Data 3-52

3.11.2 15-3* Alarm Log 3-52

3.11.3 15-4* Drive Identification 3-52

3.12 Main Menu - Data Readouts - Group 16

3.12.1 16-0* General Status 3-54

3.12.2 16-1* Motor Status 3-54

3.12.3 16-3* Drive Status 3-55

3.12.4 16-5* Ref. & Feedb. 3-55

3.12.5 16-6* Inputs and Outputs 3-55

3.12.6 16-8* Fieldbus & FC Port 3-57

3.12.7 16-9* Diagnosis Readouts 3-57

3.13 Main Menu - Data Readouts 2 - Group 18

3.13.1 18-1* Fire Mode Log 3-58

3.14 Main Menu - Adjustable Frequency Drive Closed-loop - Group 20

3.14.1 20-0* Feedback 3-59

3.14.2 20-8* PI Basic Settings 3-59

3.14.3 20-9* PI Controller 3-59

3.15 Main Menu - Application Functions - Group 22

3.15.1 22-4* Sleep Mode 3-60

3.15.2 22-6* Broken Belt Detection 3-61

3-54

3-58

3-59

3-60

3.16 Main Menu - Application Functions 2 - Group 24

3.16.1 24-0* Fire Mode 3-62

3.16.2 24-1* Drive Bypass 3-63

4 Troubleshooting

4.1.2 Alarm Words 4-3

4.1.3 Warning Words 4-3

4.1.4 Extended Status Words 4-4

4.1.5 Fault Messages 4-4

5 Parameter Lists

5.1 Parameter Options

5.1.1 Default settings 5-1

5.1.2 0-** Operation / Display 5-2

5.1.3 1-** Load and Motor 5-3

5.1.4 2-** Brakes 5-4

5.1.5 3-** Reference/Ramps 5-5

5.1.6 4-** Limits/Warnings 5-6

3-62

4-1

5-1

5-1

5.1.7 5-** Digital In/Out 5-7

MG18B222 - VLT® is a registered Danfoss trademark

Page 6

Contents

VLT® HVAC Basic Drive Programming Guide

5.1.8 6-** Analog In/Out 5-8

5.1.9 8-** Comm. and Options 5-9

5.1.10 13-** Smart Logic 5-10

5.1.11 14-** Special Functions 5-11

5.1.12 15-** Drive Information 5-12

5.1.13 16-** Data Readouts 5-13

5.1.14 18-** Info & Readouts 5-14

5.1.15 20-** Drive Closed Loop 5-14

5.1.16 22-** Appl. Functions 5-15

5.1.17 24-** Appl. Functions 2 5-15

6 Index

6-1

MG18B222 - VLT® is a registered Danfoss trademark

Page 7

Introduction

1 Introduction

VLT® HVAC Basic Drive Programming Guide

1 1

VLT HVAC Basic Drive

FC 100 Series

Table 1.1

This guide can be used with all VLT

HVAC Basic Drive adjustable

frequency drives with software

version 2.0X.

The actual software version

number can be read from

15-43 Software Version.

Table 1.2

Copyright, Limitation of Liability and

1.1.1

Revision Rights

the use, or the inability to use information contained in

this manual, even if advised of the possibility of such

damages. In particular, Danfoss is not responsible for any

costs, including but not limited to those incurred as a

result of lost profits or revenue, loss or damage of

equipment, loss of computer programs, loss of data, the

costs to substitute these, or any claims by third parties.

Danfoss reserves the right to revise this publication at any

time and to make changes to its contents without prior

notice or any obligation to notify former or present users

of such revisions or changes.

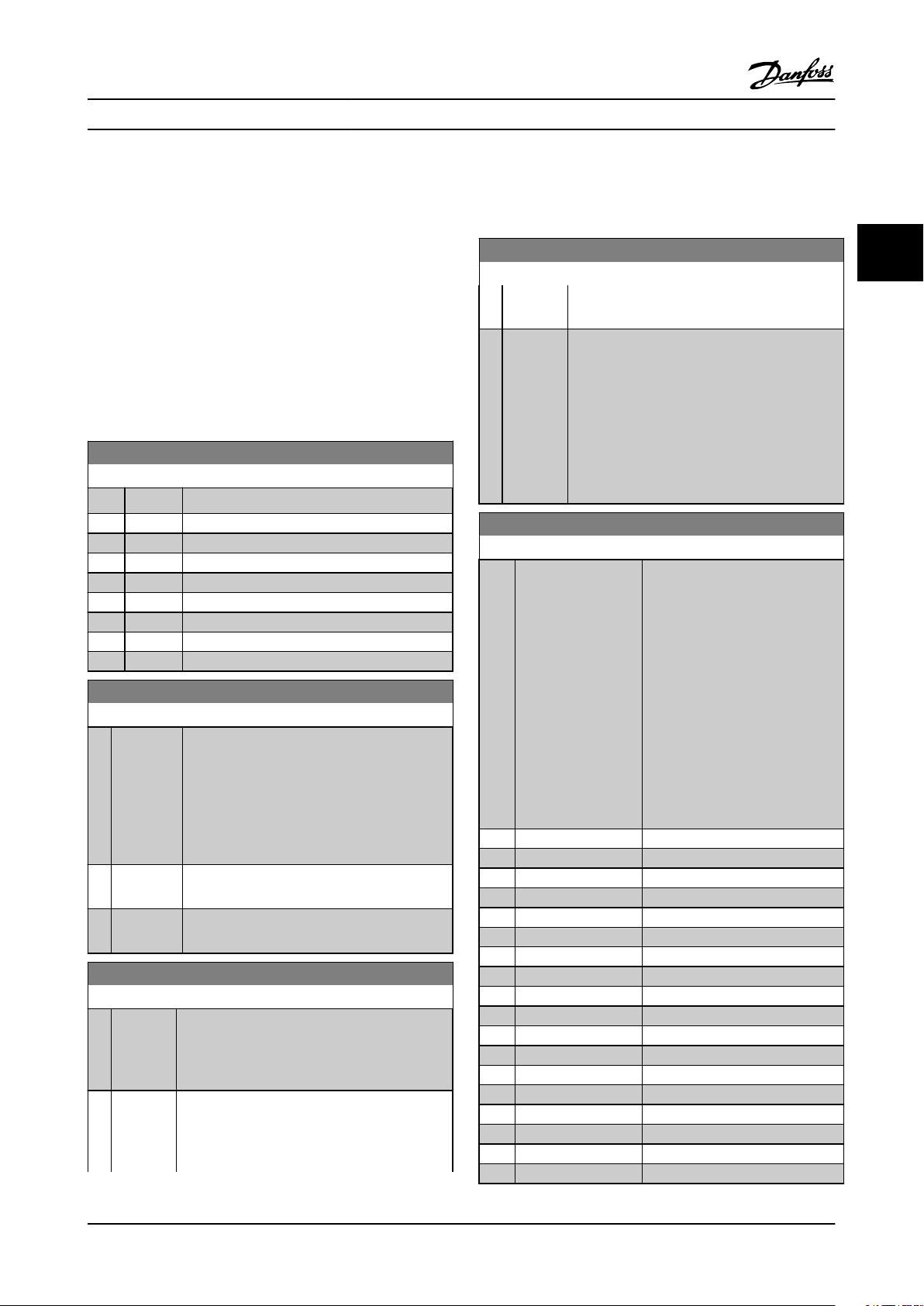

Symbols

1.1.2

Symbols used in this guide.

NOTE!

Indicates something to be noted by the reader.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury or

equipment damage.

This publication contains information proprietary to

Danfoss. By accepting and using this manual, the user

agrees that the information contained herein will be used

solely for operating equipment from Danfoss or equipment

from other vendors provided that such equipment is

intended for communication with Danfoss equipment over

a serial communication link. This publication is protected

under the copyright laws of Denmark and most other

countries.

Danfoss does not warrant that a software program

produced according to the guidelines provided in this

manual will function properly in every physical, hardware

or software environment.

Although Danfoss has tested and reviewed the documentation within this manual, Danfoss makes no warranty or

representation, neither expressed nor implied, with respect

to this documentation, including its quality, performance,

or fitness for a particular purpose.

In no event shall Danfoss be liable for direct, indirect,

special, incidental, or consequential damages arising out of

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates default setting

*

Table 1.3

MG18B222 - VLT® is a registered Danfoss trademark 1-1

Page 8

Introduction

VLT® HVAC Basic Drive Programming Guide

11

1.1.3 Abbreviations

Alternating current AC

American wire gauge AWG

Ampere/AMP A

Automatic Motor Adaptation AMA

Current limit I

Degrees Celsius

Direct current DC

Drive Dependent D-TYPE

Electro Magnetic Compatibility EMC

Electronic Thermal Relay ETR

Adjustable frequency drive FC

Gram g

Hertz Hz

Horsepower hp

Kilohertz kHz

Local Control Panel LCP

Meter m

Millihenry Inductance mH

Milliampere mA

Millisecond ms

Minute min

Motion Control Tool MCT

Nanofarad nF

Newton Meters Nm

Nominal motor current I

Nominal motor frequency f

Nominal motor power P

Nominal motor voltage U

Permanent Magnet motor PM motor

Protective Extra Low Voltage PELV

Printed Circuit Board PCB

Rated Inverter Output Current I

Revolutions Per Minute RPM

Regenerative terminals Regen

Second s

Synchronous Motor Speed n

Torque limit T

Volts V

The maximum output current I

The rated output current supplied by the

adjustable frequency drive

Table 1.4

LIM

°C

M,N

M,N

M,N

M,N

INV

s

LIM

VLT,MAX

I

VLT,N

1.1.4

Available Literature for VLT HVAC

Basic Drive

- Quick Guide MG18AXYY

- Programming Guide MG18BXYY provides

information on how to program and includes

complete parameter descriptions.

- Design Guide MG18CXYY provides all the

technical information about the adjustable

frequency drive and customer design and

applications.

- PC-based Configuration Tool MCT 10, MG10AXYY

enables the user to configure the adjustable

frequency drive from a Windows™-based PC

environment.

-

Danfoss VLT® Energy Box software at

www.danfoss.com/BusinessAreas/DrivesSolutions

then choose PC Software Download

VLT® Energy Box Software allows energy

consumption comparisons of HVAC fans and

pumps driven by Danfoss drives and alternative

methods of flow control. This tool may be used

to project, as accurately as possible, the costs,

savings, and payback of using Danfoss adjustable

frequency drives on HVAC fans and pumps.

X = Revision number

YY = Language code

Danfoss technical literature is available in print from your

local Danfoss Sales Office or online at:

www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations/Technical+Documentation.htm

Definitions

1.1.5

Adjustable Frequency Drive:

I

VLT,MAX

Maximum output current.

I

VLT,N

Rated output current supplied by the Adjustable frequency

drive.

U

VLT, MAX

Maximum output voltage.

Input:

Control command

Start and stop the connected motor by means of LCP and

digital inputs.

Functions are divided into two groups.

Functions in group 1 have higher priority than functions in

group 2.

1-2 MG18B222 - VLT® is a registered Danfoss trademark

Page 9

175ZA078.10

Pull-out

rpm

Torque

Introduction

VLT® HVAC Basic Drive Programming Guide

1 1

Group 1 Reset, Coasting stop, Reset and Coasting stop,

Quick stop, DC braking, Stop and the [OFF] key.

Group 2 Start, Latched start, Reversing, Start reversing, Jog

and Freeze output

Table 1.5

Motor:

Motor Running

Torque generated on output shaft and speed from zero

rpm to max. speed on motor.

f

JOG

Motor frequency when the jog function is activated (via

digital terminals).

f

M

Motor frequency.

f

MAX

Maximum motor frequency.

f

MIN

Minimum motor frequency.

f

M,N

Rated motor frequency (nameplate data).

I

M

Motor current (actual).

I

M,N

Rated motor current (nameplate data).

n

M,N

Rated motor speed (nameplate data).

n

s

Synchronous motor speed

2 ×

par

=

. 1 − 23 × 60

par

. 1 − 39

n

s

P

M,N

s

Rated motor power (nameplate data in kW or hp).

T

M,N

Rated torque (motor).

U

M

Instantaneous motor voltage.

U

M,N

Rated motor voltage (nameplate data).

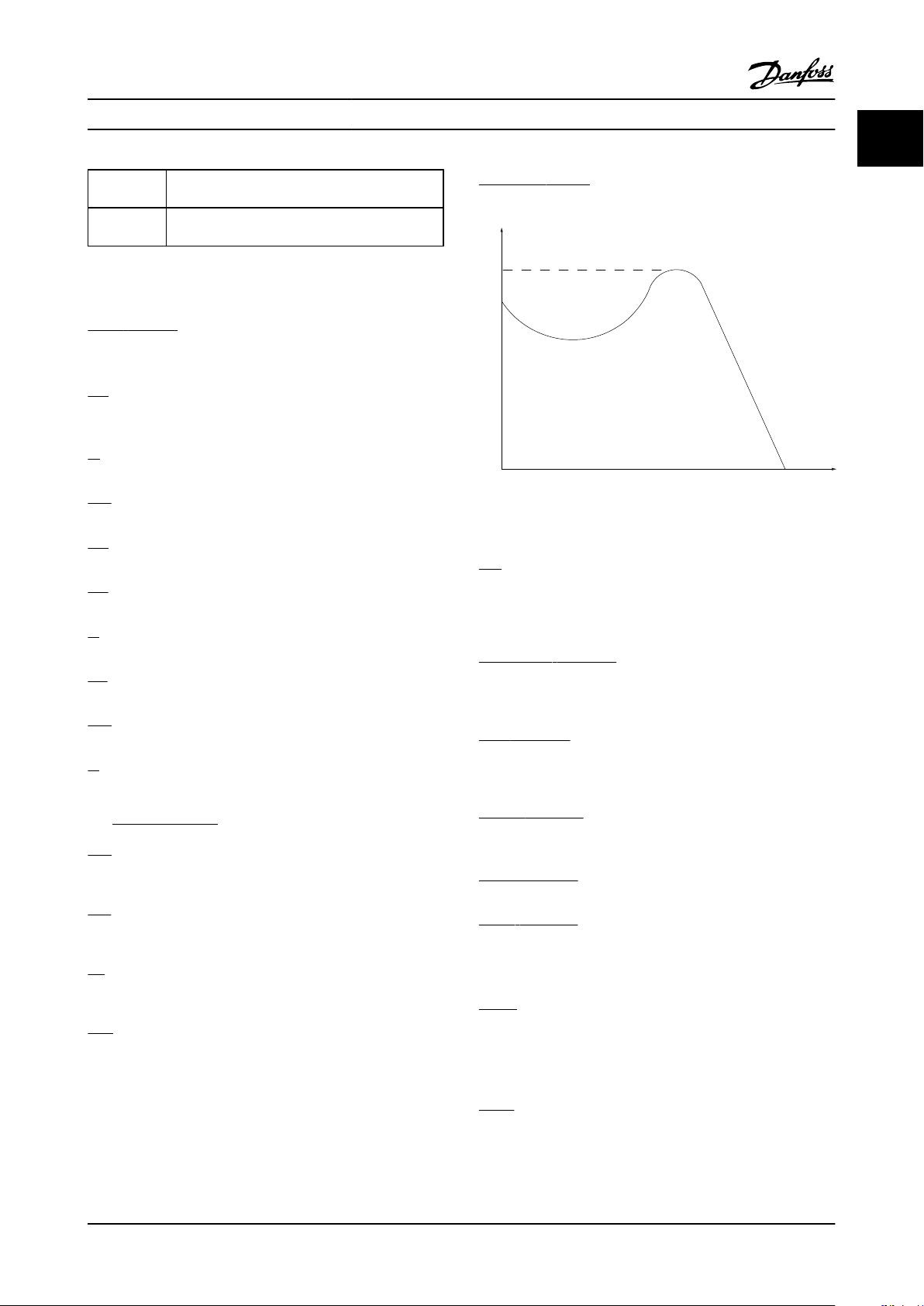

Break-away torque

Figure 1.1

η

VLT

The efficiency of the adjustable frequency drive is defined

as the ratio between the power output and the power

input.

Start-disable command

A stop command belonging to the group 1 control

commands - see this group.

Stop command

See Control commands.

References:

Analog Reference

A signal transmitted to the analog inputs 53 or 54, can be

voltage or current.

Binary Reference

A signal transmitted to the serial communication port.

Preset Reference

A defined preset reference to be set from -100% to +100%

of the reference range. Selection of eight preset references

via the digital terminals.

Ref

MAX

Determines the relationship between the reference input

at 100% full scale value (typically 10 V, 20 mA) and the

resulting reference. The maximum reference value set in

3-03 Maximum Reference.

Ref

MIN

Determines the relationship between the reference input

at 0% value (typically 0 V, 0 mA, 4 mA) and the resulting

reference. The minimum reference value set in

3-02 Minimum Reference.

MG18B222 - VLT® is a registered Danfoss trademark 1-3

Page 10

Introduction

VLT® HVAC Basic Drive Programming Guide

11

Miscellaneous:

Analog Inputs

The analog inputs are used for controlling various

functions of the Adjustable frequency drive.

There are two types of analog inputs:

Current input, 0-20 mA and 4-20 mA

Voltage input, 0-10 V

Analog Outputs

The analog outputs can supply a signal of 0–20 mA, 4–20

mA.

Automatic Motor Adaptation, AMA

AMA algorithm determines the electrical parameters for

the connected motor at standstill.

CTW

Control Word

Digital Inputs

The digital inputs can be used for controlling various

functions of the Adjustable frequency drive.

ETR

Electronic Thermal Relay is a thermal load calculation

based on present load and time. Its purpose is to estimate

the motor or Adjustable frequency drive temperature.

Initializing

If initialization is carried out (14-22 Operation Mode), the

Adjustable frequency drive returns to the default setting.

Intermittent Duty Cycle

An intermittent duty rating refers to a sequence of duty

cycles. Each cycle consists of an on-load and an off-load

period. The operation can be either periodic duty or nonperiodic duty.

LCP

The Local Control Panel makes up a complete interface for

control and programming of the adjustable frequency

drive. The control panel is detachable and can be installed

up to 10 ft [3 m] from the adjustable frequency drive, i.e.,

in a front panel by means of the installation kit option.

lsb

Least significant bit.

msb

Most significant bit.

MCM

Short for Mille Circular Mil, an American measuring unit for

cable cross-sections. 1 MCM = 0.5067 mm2.

Process PI

The PI control maintains the desired speed, pressure,

temperature, etc. by adjusting the output frequency to

match the varying load.

Power Cycle

Switch off line power until the display (LCP) is dark – then

turn power on again.

RCD

Residual Current Device.

Set-up

You can save parameter settings in two set-ups. Change

between the two parameter set-ups and edit one set-up,

while another set-up is active.

Slip Compensation

The adjustable frequency drive compensates for the motor

slip by giving the frequency a supplement that follows the

measured motor load, keeping the motor speed almost

constant.

Slip compensation is default set to off.

Smart Logic Control (SLC)

The SLC is a sequence of user-defined actions executed

when the associated user-defined events are evaluated as

true by the Smart Logic Controller. (Parameter group 13-**

Smart Logic Control (SLC).)

STW

Status Word

Adjustable Frequency Drive Standard Bus

Includes RS-485 bus with FC protocol. See 8-30 Protocol.

Thermistor

A temperature-dependent resistor placed where the

temperature is to be monitored (adjustable frequency drive

or motor).

Trip

A state entered in fault situations, e.g., if the adjustable

frequency drive is subject to an over-temperature or when

the adjustable frequency drive is protecting the motor,

process or mechanism. Restart is prevented until the cause

of the fault has disappeared and the trip state is canceled

by activating reset or, in some cases, by being

programmed to reset automatically. Trip may not be used

for personal safety.

Trip Lock

A state entered in fault situations when the adjustable

frequency drive is protecting itself and requiring physical

intervention, e.g., if the adjustable frequency drive is

subject to a short circuit on the output. A locked trip can

only be canceled by cutting off line power, removing the

cause of the fault, and reconnecting the adjustable

frequency drive. Restart is prevented until the trip state is

canceled by activating reset or, in some cases, by being

programmed to reset automatically. Trip may not be used

for personal safety.

VT Characteristics

Variable torque characteristics used for pumps and fans.

1-4 MG18B222 - VLT® is a registered Danfoss trademark

Page 11

Introduction

VLT® HVAC Basic Drive Programming Guide

1 1

plus

VVC

If compared with standard voltage/frequency ratio control,

Voltage Vector Control (VVC

plus

) improves the dynamics

and the stability, both when the speed reference is

changed and in relation to the load torque.

Power Factor

The power factor is the relation between I1 and I

3 x U x

I

cos

ϕ

Power factor

=

3 x U x

1

I

RMS

RMS

.

The power factor for 3-phase control:

=

I1 x cos

I

RMS

ϕ1

=

I

RMS

I

1

since cos

ϕ1 = 1

The power factor indicates to what extent the adjustable

frequency drive imposes a load on the line power supply.

The lower the power factor, the higher the I

RMS

for the

same kW [hp] performance.

2

2

I

=

I

RMS

+

1

2

I

+

I

+ .. +

5

7

2

I

n

In addition, a high power factor indicates that the different

harmonic currents are low.

The built-in DC coils in the adjustable frequency drive

produce a high power factor, which minimizes the

imposed load on the line power supply.

Safety Precautions

1.1.6

WARNING

The voltage of the adjustable frequency drive is dangerous

whenever connected to line power. Incorrect installation of

the motor, adjustable frequency drive or serial communication bus may cause death, serious personal injury or

damage to the equipment. Consequently, the instructions

in this manual, as well as national and local rules and

safety regulations, must be complied with.

Safety Regulations

1. The line power supply to the adjustable

frequency drive must be disconnected whenever

repair work is to be carried out. Make sure that

the line power supply has been disconnected and

that the necessary time has elapsed before

removing motor and line power supply plugs.

2. The [OFF] key on the control panel of the

adjustable frequency drive does not disconnect

the line power supply and consequently it must

not be used as a safety switch.

3. The equipment must be properly grounded, the

user must be protected against supply voltage

and the motor must be protected against

overload in accordance with applicable national

and local regulations.

4. The ground leakage current exceeds 3.5 mA.

5. Protection against motor overload is not included

in the factory setting. If this function is desired,

set 1-90 Motor Thermal Protection to data value [4]

ETR trip 1 or data value [3] ETR warning 1.

6. Do not remove the plugs for the motor and line

power supply while the adjustable frequency

drive is connected to line power. Make sure that

the line power supply has been disconnected and

that the necessary time has elapsed before

removing motor and line power plugs.

7. Please note that the adjustable frequency drive

has more voltage sources than L1, L2 and L3,

when load sharing (linking of DC intermediate

circuit) or external 24 V DC are installed. Make

sure that all voltage sources have been disconnected and that the necessary time has elapsed

before commencing repair work.

Safety Precautions - Continued

1.1.7

Warning against unintended start

1. The motor can be brought to a stop by means of

digital commands, bus commands, references or

a local stop, while the adjustable frequency drive

is connected to line power. If personal safety

considerations (e.g., risk of personal injury caused

by contact with moving machine parts following

an unintentional start) make it necessary to

ensure that no unintended start occurs, these

stop functions are not sufficient. In such cases,

the line power supply must be disconnected.

2. The motor may start while setting the

parameters. If this means that personal safety

may be compromised (e.g., personal injury caused

by contact with moving machine parts), motor

starting must be prevented, for instance by

secure disconnection of the motor connection.

3. A motor that has been stopped with the line

power supply connected, may start if faults occur

in the electronics of the adjustable frequency

drive, through temporary overload or if a fault in

the power supply grid or motor connection is

remedied. If unintended start must be prevented

for personal safety reasons (e.g., risk of injury

caused by contact with moving machine parts),

the normal stop functions of the adjustable

frequency drive are not sufficient.

MG18B222 - VLT® is a registered Danfoss trademark 1-5

Page 12

Introduction

VLT® HVAC Basic Drive Programming Guide

11

4. Control signals from, or internally within, the

adjustable frequency drive may in rare cases be

activated in error, be delayed or fail to occur

entirely. When used in situations where safety is

critical, these control signals must not be relied

on exclusively.

WARNING

High Voltage

Touching the electrical parts may be fatal - even after the

equipment has been disconnected from line power.

Also make sure that other voltage inputs have been

disconnected, such as load sharing (linkage of DC

intermediate circuit)

Systems where adjustable frequency drives are installed

must, if necessary, be equipped with additional monitoring

and protective devices according to the valid safety

regulations, e.g., law on mechanical tools, regulations for

the prevention of accidents, etc. Modifications on the

adjustable frequency drives by means of the operating

software are allowed.

NOTE!

Hazardous situations shall be identified by the machine

builder/integrator who is responsible for taking necessary

preventive means into consideration. Additional

monitoring and protective devices may be included, always

according to valid national safety regulations, e.g., law on

mechanical tools, regulations for the prevention of

accidents.

Protection Mode

Once a hardware limit on motor current or DC link voltage

is exceeded, the adjustable frequency drive will enter

Protection mode. Protection mode means a change of the

PWM modulation strategy and a low switching frequency

to minimize losses. This continues 10 sec after the last fault

and increases the reliability and the robustness of the

adjustable frequency drive while re-establishing full control

of the motor. Parameter 0-07 Auto DC Braking may cause

PWM when coasted.

1-6 MG18B222 - VLT® is a registered Danfoss trademark

Page 13

L1

L2

L3

3 Phase

power

input

PE

PE

+10Vdc

0-10Vdc-

0-10Vdc-

50 (+10V OUT)

54 (A IN)

53 (A IN)

55 (COM A IN/OUT)

0/4-20 mA

0/4-20 mA

42 0/4-20mA A OUT / DIG OUT

45 0/4-20mA A OUT / DIG OUT

18 (DIGI IN)

19 (DIGI IN)

27 (DIGI IN)

29 (DIGI IN)

12 (+24V OUT)

24V (NPN)

20 (COM D IN)

OV (PNP)

24V (NPN)

OV (PNP)

24V (NPN)

OV (PNP)

24V (NPN)

OV (PNP)

Bus ter.

Bus ter.

RS-485

Interface

RS-485

(N PS-485) 69

(P RS-485) 68

(Com RS-485) 61

(PNP) Source

(NPN) Sink

ON=Terminated

OFF=Unterminated

ON

1 2

240Vac 2A

Not present on all power sizes

Do not connect shield to

61 on 116, 117 and 118 units

01

02

03

relay1

relay2

UDC+

UDC-

Motor

U

V

W

130BB626.10

06

05

04

240Vac 2A

Introduction

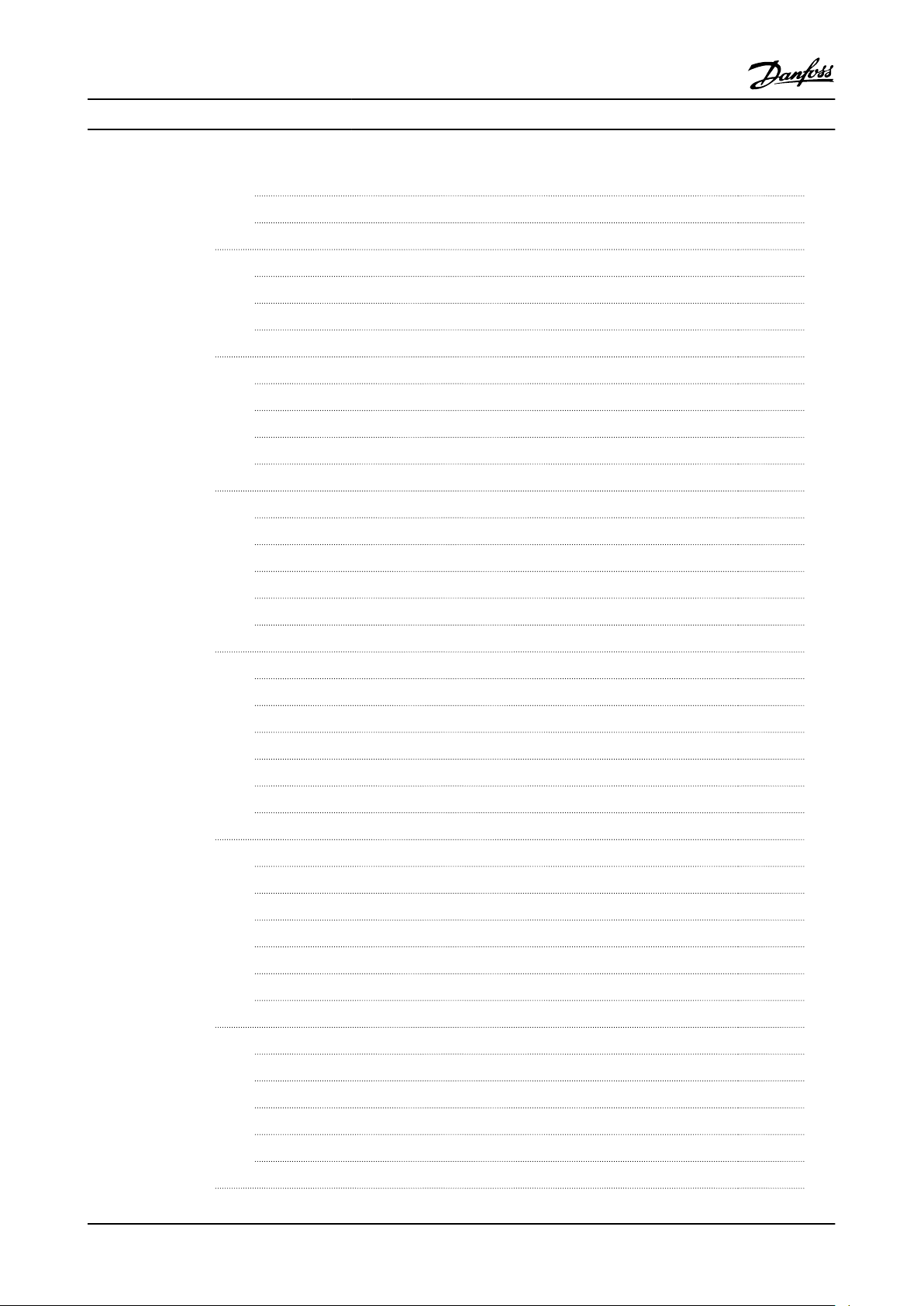

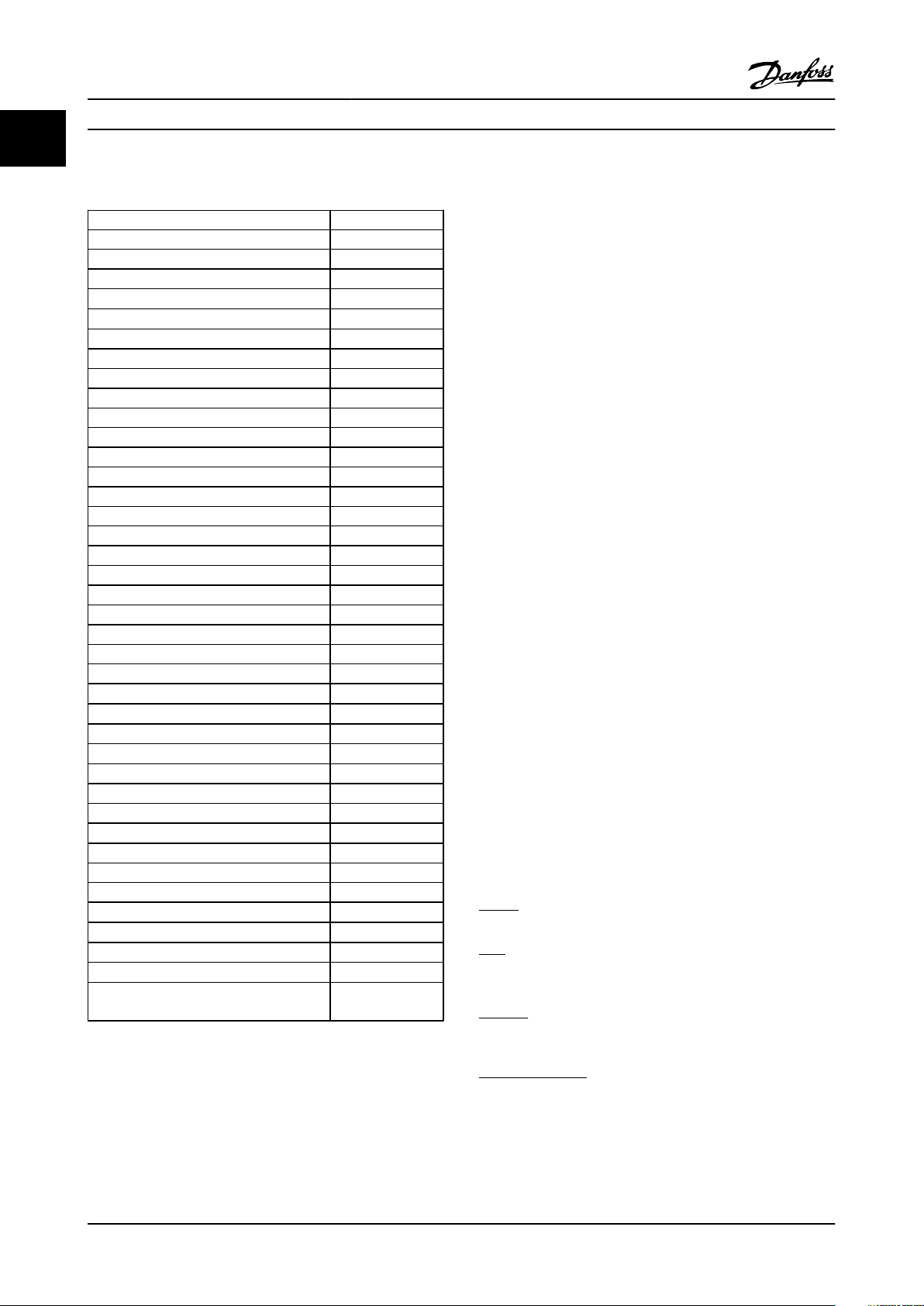

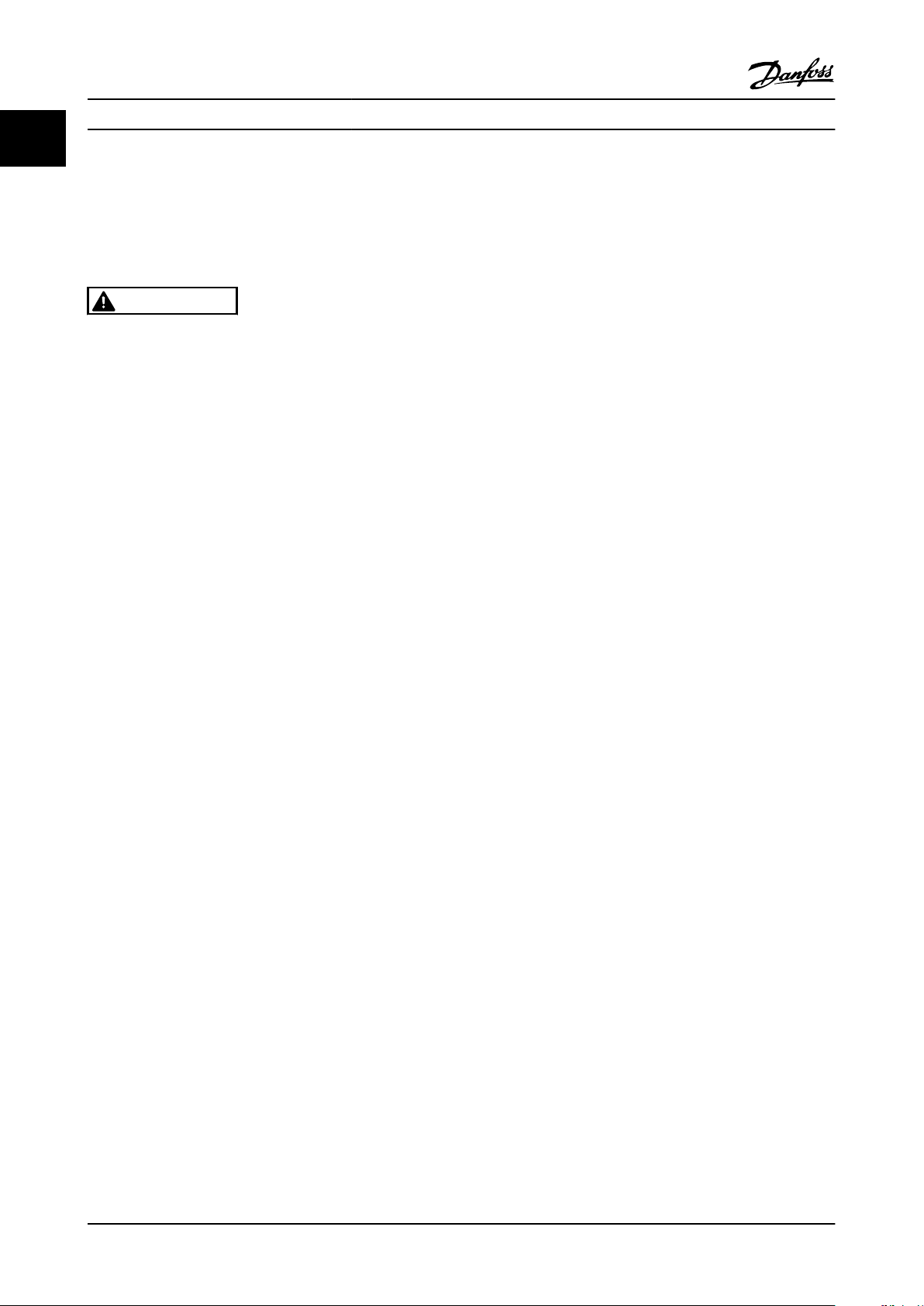

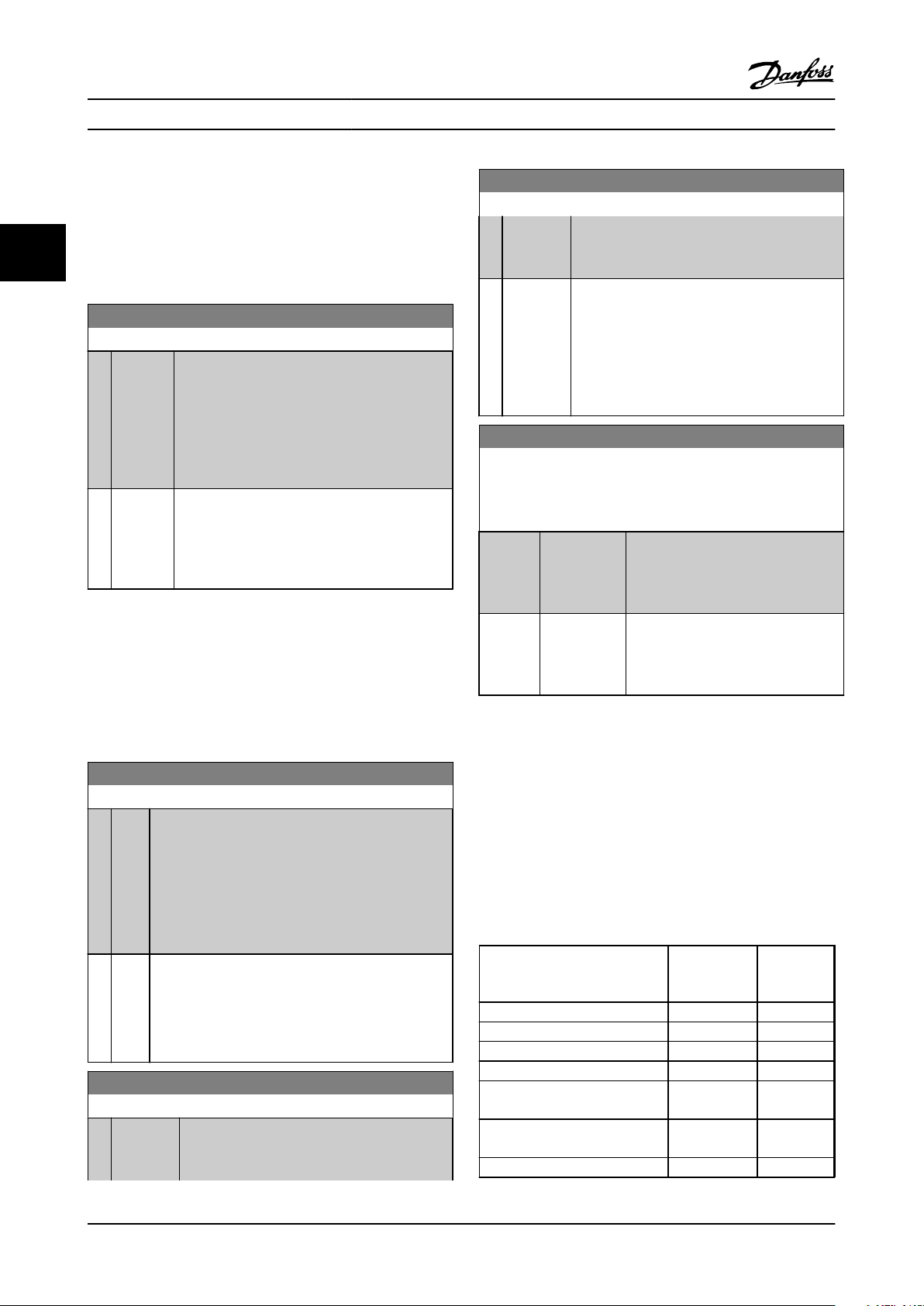

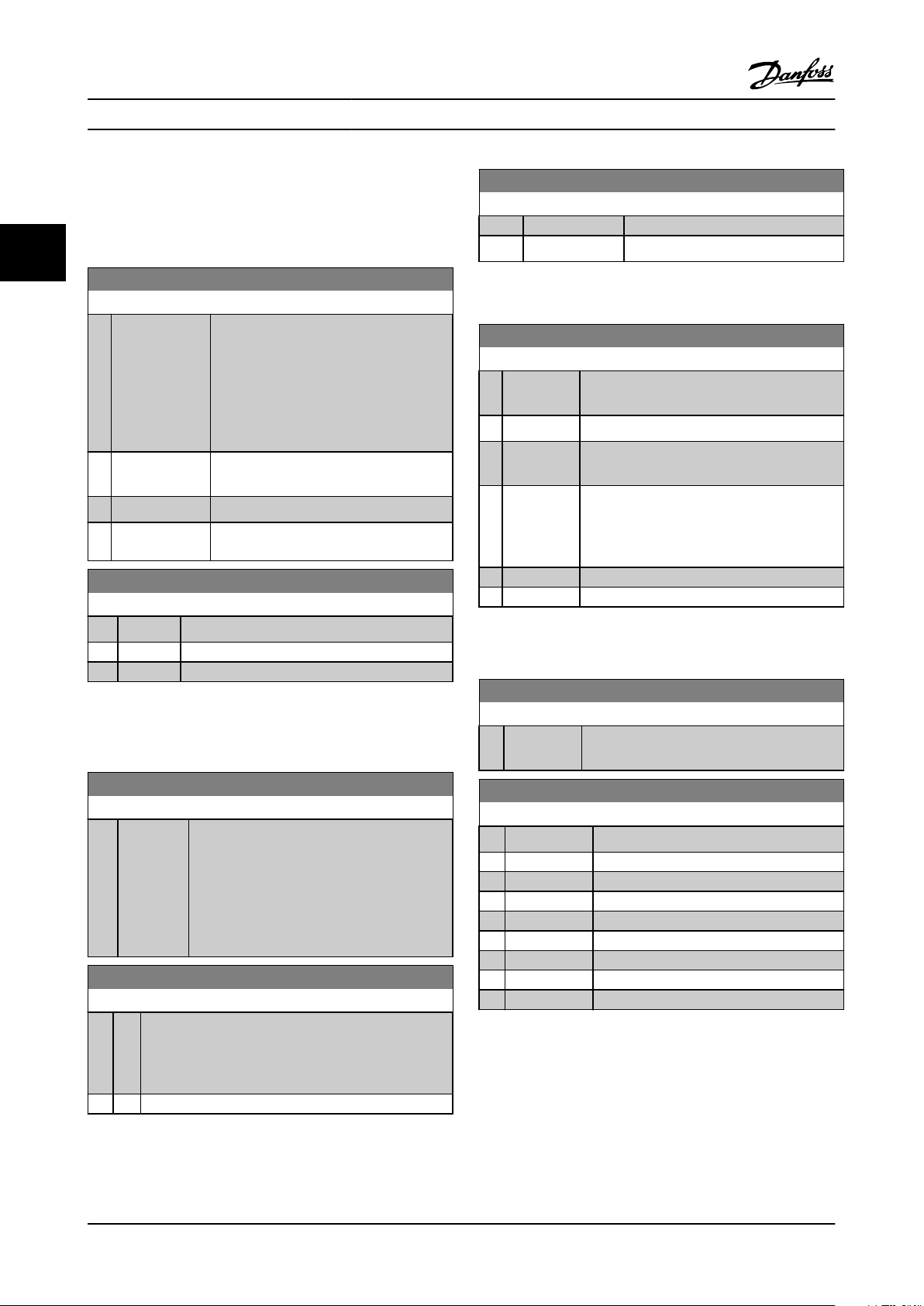

1.1.8 Electrical Overview

VLT® HVAC Basic Drive Programming Guide

1 1

Figure 1.2

NOTE!

Please note there is no access to UDC- and UDC+ on the following units:

IP20 380–480 V 40–125 hp [30–90 kW]

IP20 200–240 V 20–60 hp [15–45 kW]

IP20 525–600 V 3–125 hp [2.2–90 kW]

IP54 380–480 V 30–125 hp [22–90 kW]

MG18B222 - VLT® is a registered Danfoss trademark 1-7

Page 14

Introduction

VLT® HVAC Basic Drive Programming Guide

11

1-8 MG18B222 - VLT® is a registered Danfoss trademark

Page 15

130BB765.11

B

a

c

k

Com.

1-20 Motor Power

[5] 0.37kW - 0.5HP

Setup 1

A

B

1

12

13 14 15

11

11

10

9

8

7

6

5

4

3

2

C

D

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn.

On

11

How to Program

VLT® HVAC Basic Drive Programming Guide

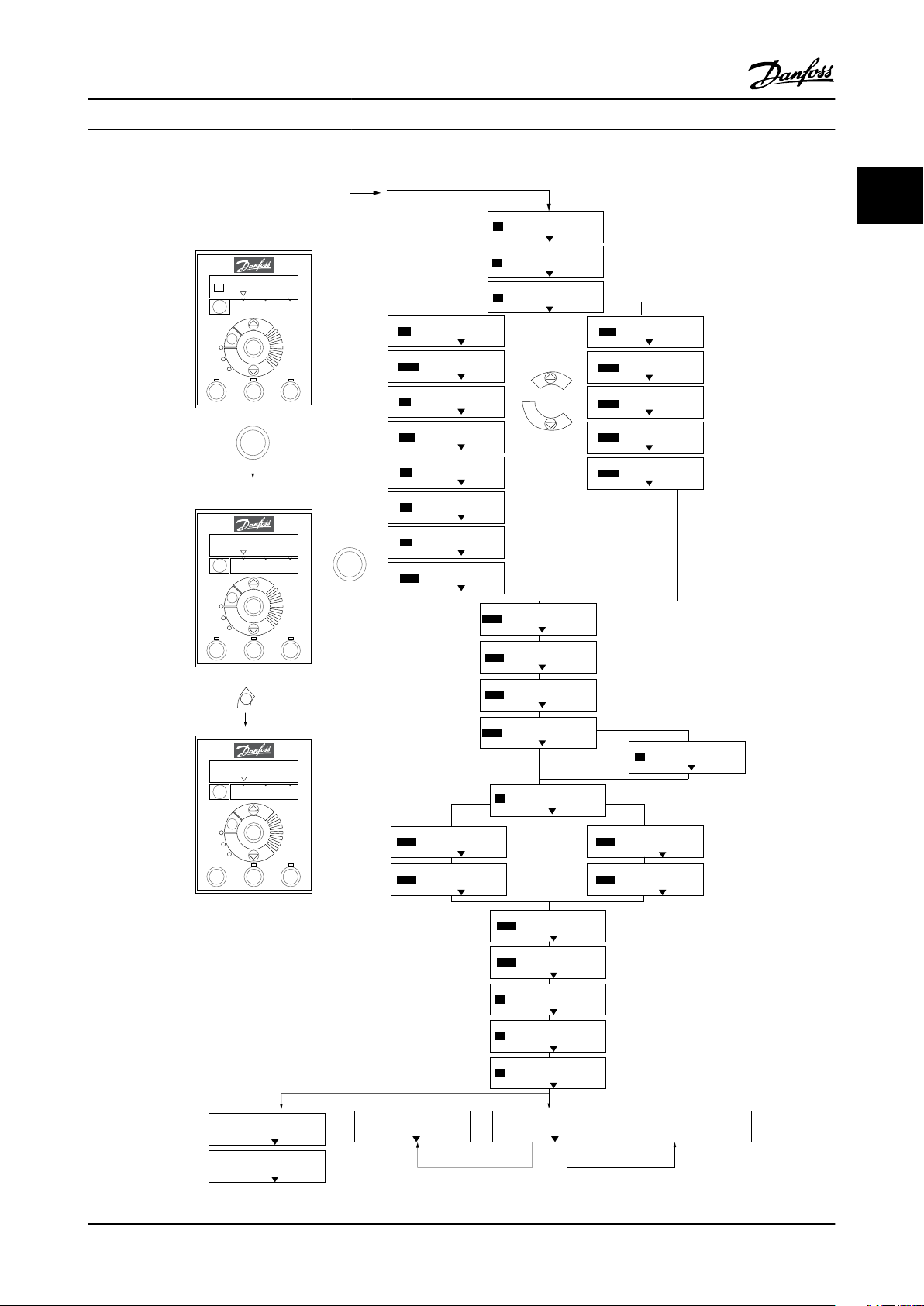

2 How to Program

2.1 Programming with MCT-10 Setup

Software

The adjustable frequency drive can be programmed from a

PC via RS-485 COM port by installing the MCT-10 Setup

Software. This software can either be ordered using code

number 130B1000 or downloaded from the Danfoss

Website: http://www.danfoss.com/BusinessAreas/DrivesSolutions/Softwaredownload/ Please refer to manual

MG10RXYY.

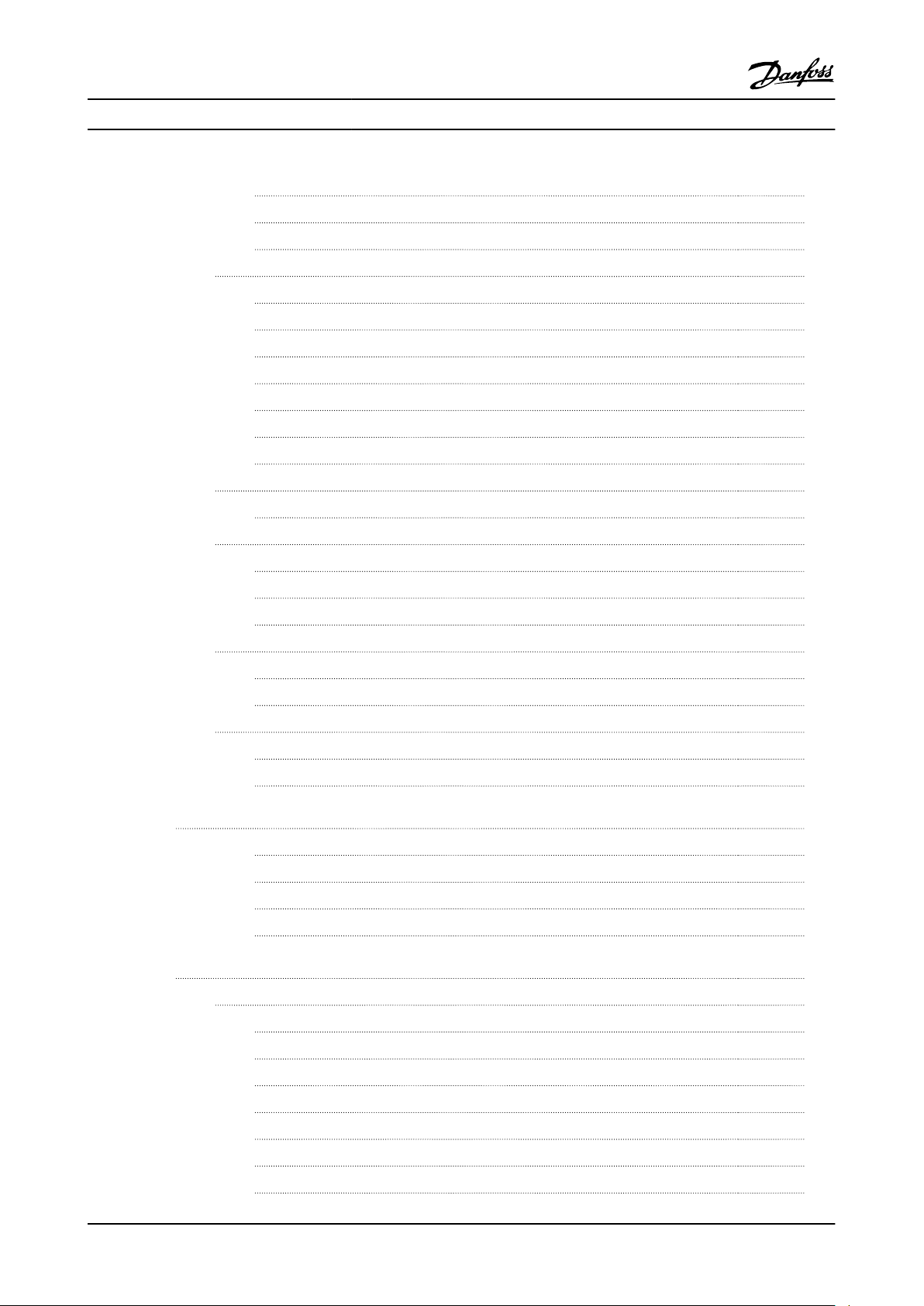

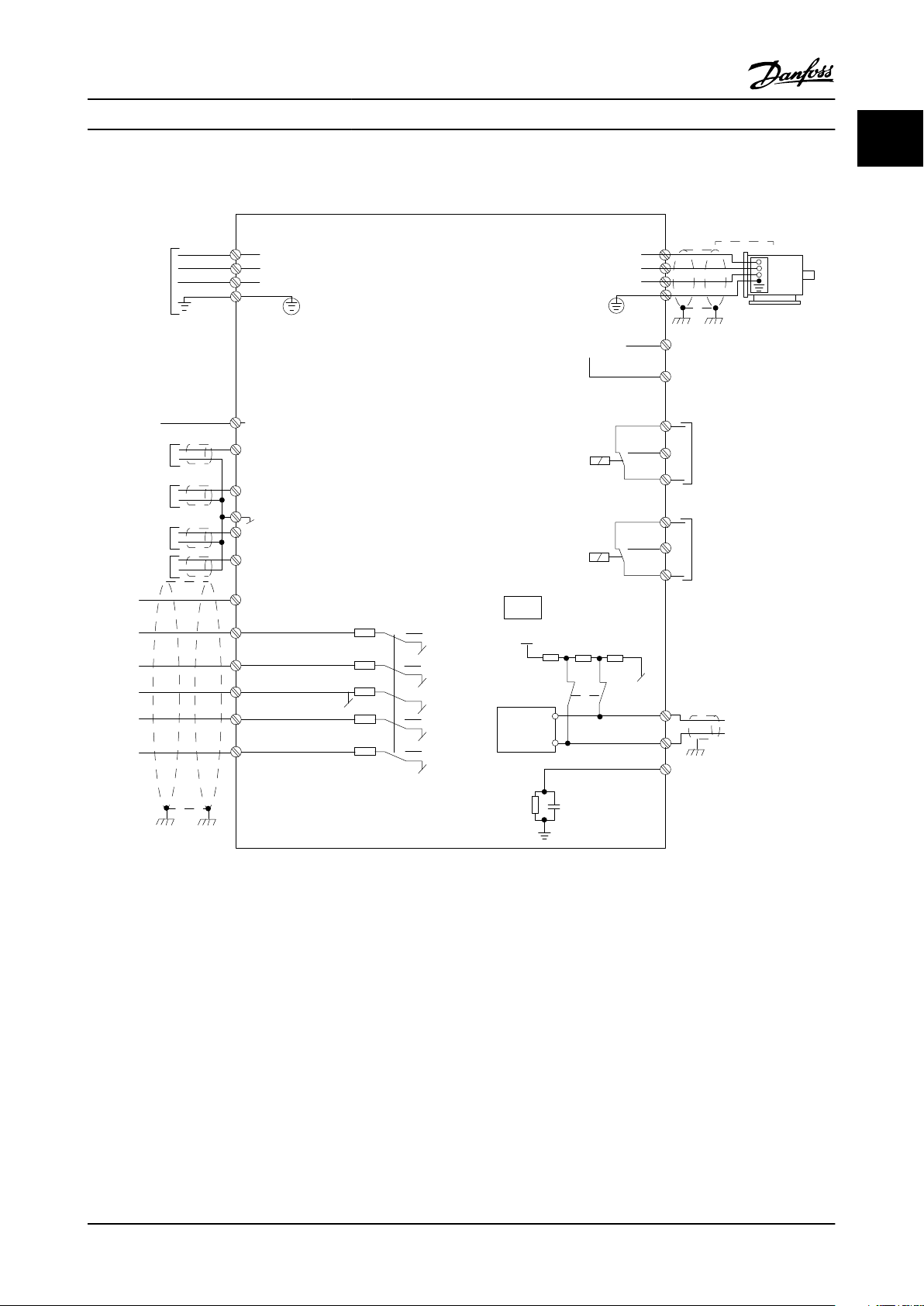

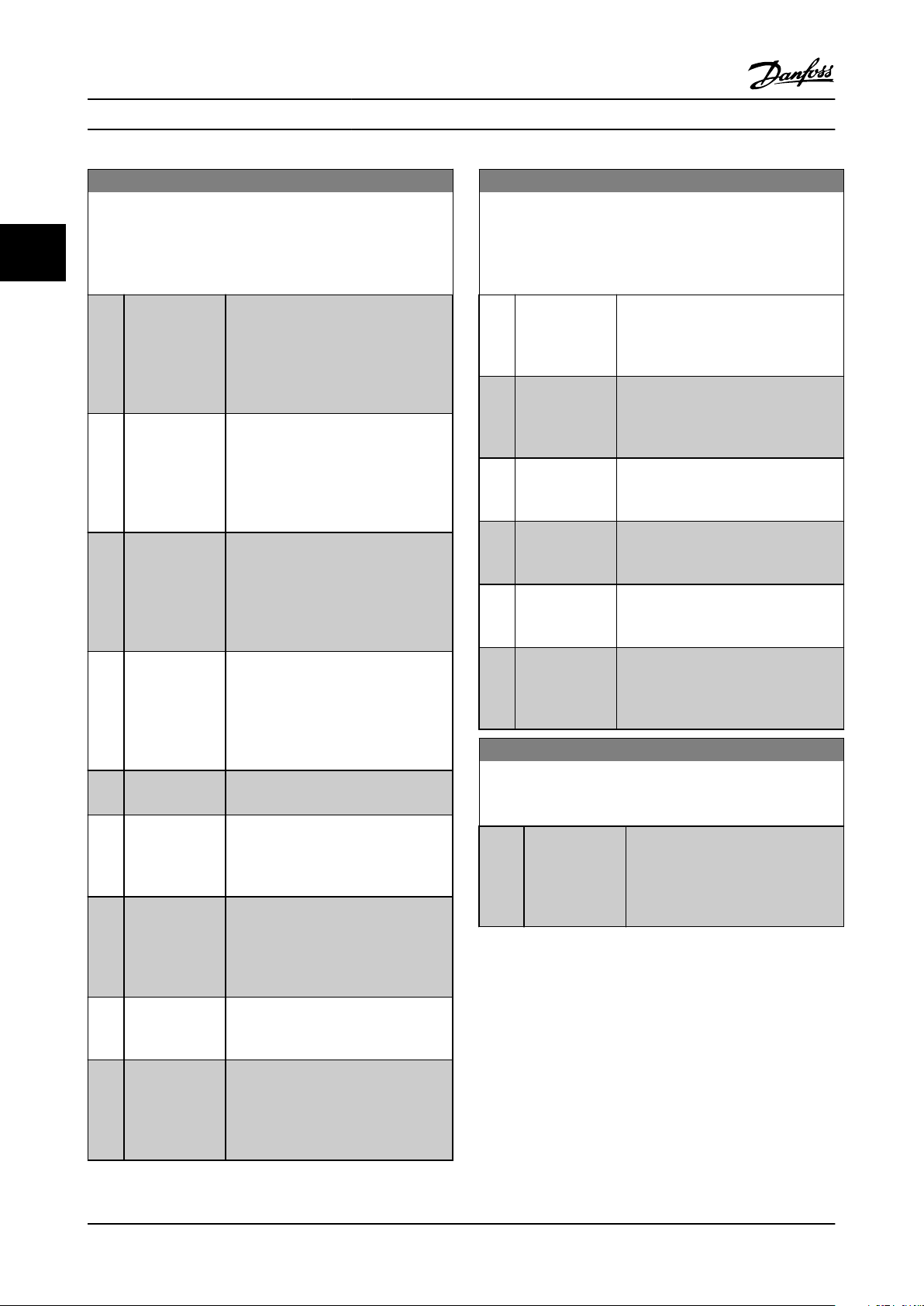

2.2 Local Control Panel (LCP)

The following instructions are valid for the FC 101 LCP. The

LCP is divided into four functional sections.

A. Alphanumeric display

B. Menu key

C. Navigation keys and LEDs

D. Operation keys and LEDs

Information can be read from the display.

1 Parameter number and name.

2 Parameter value.

3 Set-up number shows the active set-up and the edit set-

up. If the same set-up acts as both the active and edit setup, only that set-up number is shown (factory setting).

When the active and edit set-up differ, both numbers are

shown in the display (Set-up 12). The flashing number

indicates the edit set-up.

4 Motor direction is shown to the bottom left of the display

– indicated by a small arrow pointing either clockwise or

counter-clockwise.

5 The triangle indicates if the LCP is in status, quick menu or

main menu.

Table 2.1

B. Menu Key

Use the menu key to select between status, quick menu or

main menu.

C. Navigation keys and LEDs

6 Com led: Flashes when bus communication is communi-

cating.

7 Green LED/On: Control section is working.

8 Yellow LED/Warn.: Indicates a warning.

9 Flashing Red LED/Alarm: Indicates an alarm.

10 [Back]: For moving to the previous step or layer in the

navigation structure

11

Arrows [▲] [▼]: For navigating between parameter groups,

parameters and within parameters. Can also be used for

setting local reference.

12 [OK]: For selecting a parameter and for accepting changes to

parameter settings

2 2

Table 2.2

Figure 2.1

A. Alpha Numeric Display

The LCD display is backlit with two alpha-numeric lines. All

data is displayed on the LCP.

MG18B222 - VLT® is a registered Danfoss trademark 2-1

Page 16

130BB628.10

Select Language

[ 0 ] English

Set-up 1

FC

+24V

DIG IN

DIG IN

DIG IN

DIG IN

COM DIG IN

A OUT / D OUT

A OUT / D OUT

18

19

27

29

42

55

50

53

54

20

12

01

02

03

04

05

06

R2

R1

0-10 V

Reference

Start

+10V

A IN

A IN

COM

130BB674.10

45

+

-

130BB629.10

Press OK to start Wizard

Push Back to skip it

Set-up 1

How to Program

VLT® HVAC Basic Drive Programming Guide

D. Operation keys and LEDs

22

13 [Hand On]: Starts the motor and enables control of the

adjustable frequency drive via the LCP.

NOTE!

2.3.2

Quick Menu

Use the quick setup of the adjustable frequency drive to

program the most common VLT HVAC Basic Drive

functions. The [Quick Menu] consists of:

Terminal 27 Digital Input (5-12 Terminal 27 Digital

Input) has coast inverse as default setting. This

means that [Hand On] will not start the motor if

there is no 24 V to terminal 27. Connect terminal 12

to terminal 27.

14 [Off/Reset]: Stops the motor (off). If in alarm mode the

alarm will be reset.

15 [Auto On]: The adjustable frequency drive is controlled

either via control terminals or serial communication.

Table 2.3

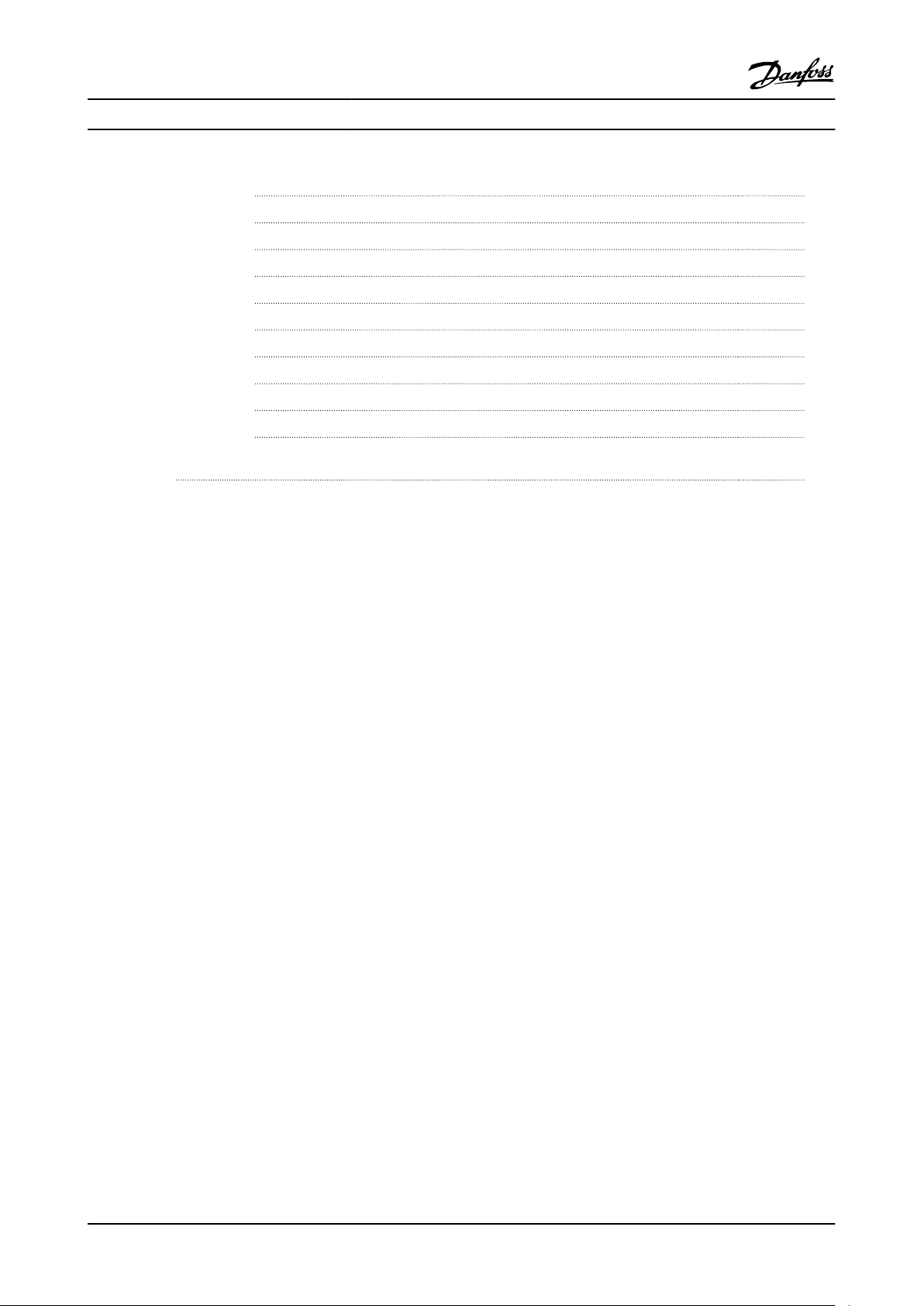

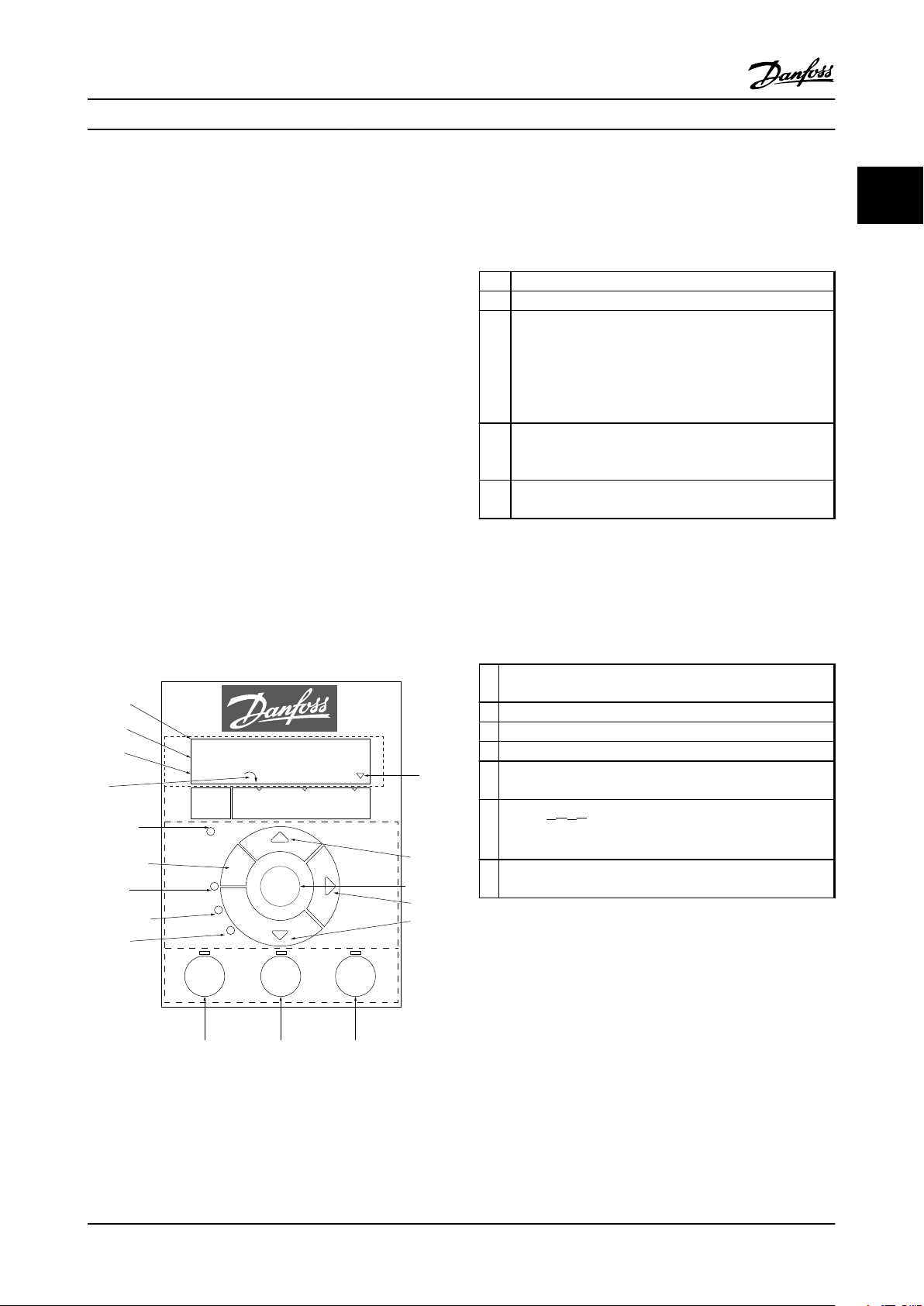

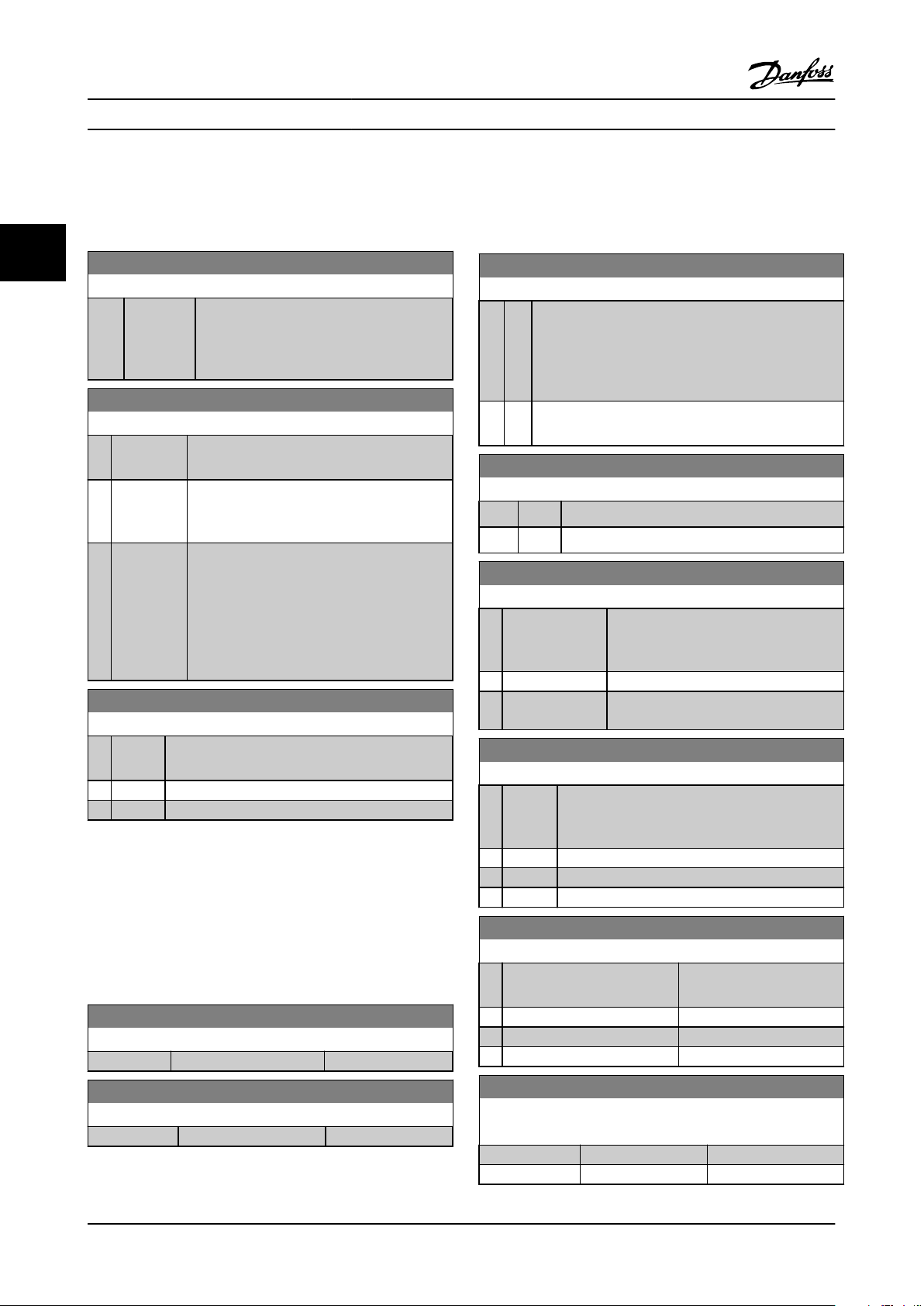

2.3.3 The FC101 Start-up Wizard for Open-

The built-in wizard menu guides the installer through the

Wizard for open-loop applications

•

Closed-loop set-up wizard

•

Motor set-up

•

Changes made

•

loop Applications

set up of the adjustable frequency drive in a clear and

At power-up

At the first power-up, the user is asked to choose the

preferred language. Once selected, this screen will never

be shown again in the following power-ups, but the

language can still be changed in 0-01 Language.

structured manner in order to set up an open-loop

application. An open-loop application is here an

application with a start signal, analog reference (voltage or

current) and optionally also relay signals (but no feedback

signal from the process applied).

Figure 2.2

2.3 Menus

2.3.1 Status

When choosing the [Status] menu it is possible to choose

between the following:

Motor Frequency (Hz), 16-13 Frequency;

•

Motor Current (A), 16-14 Motor Current;

•

Motor Speed Reference in Percentage (%),

•

16-02 Reference %;

Feedback, 16-52 Feedback [Unit];

•

Motor Power (kW) (if 0-03 Regional Settings is set

•

to [1] North America, Motor Power will be shown

in the unit of hp instead of kW), 16-10 Power [kW]

for kW, 16-11 Power [hp] for hp;

Custom Readout 16-09 Custom Readout;

•

Figure 2.3

The wizard will initially be shown after power-up until any

parameter has been changed. The wizard can always be

accessed again through the Quick Menu. Press [OK] to start

the wizard. If [Back] is pressed, the FC 101 will return to

the status screen.

Figure 2.4

2-2 MG18B222 - VLT® is a registered Danfoss trademark

Page 17

130BC401.10

Value

Setup 1

Power kW/50 Hz

Setup 1

Set Motor Speed low Limit

Hz

Setup 1

Set Motor Speed high Limit

Hz

Setup 1

Set Ramp 1 ramp-up time

s

Setup 1

Set Ramp 1 ramp-down Time

s

Setup 1

Active Flying start?

Disable

OK

OK

B

a

c

k

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn

On

Status Screen

The Wizard can always be

reentered via the Quick Menu!

Power Up Screen

At power up the user is

asked to choose the

prefered language.

Select language

[1] English

0.0 Hz

0.0 kW

Setup 1

Setup 1

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn

On

Press OK to start Wizard

Press Back to skip it

Setup 1

Status

Main

Menu

Quick

Menu

Hand

On

OK

Menu

O

Reset

Auto

On

Alarm

Warn

On

The next screen will be

the Wizard screen.

Wizard Screen

5

Setup 1

Set Motor Power

7

Setup 1

Set Motor Voltage

8

Setup 1

Set Motor frequency

9

Setup 1

Set Motor current

10

Setup 1

Set Motor nominal speed

11

1

2

if

if

3

17

20

21

22

B

a

c

k

B

a

c

k

B

a

c

k

Select Regional Settings

... the HVAC FC 101 Wizard starts

Setup 1

200-240V/50Hz/Delta

Grid Type

4

Asynchronous Motor

Setup 1

Asynchronous

Select Motor Type

6

Setup 1

Set Motor current

12

Setup 1

Select Motor nominal speed

13

Setup 1

Set Motor Cont. Rated Torque

14

Setup 1

Stator resistance

15

Setup 1

Motor poles

16

Setup 1

Back EMF at 1000 rpm

18

Setup 1

d-axis inductance

19

Setup 1

Set Max Output Frequency

23

24

Setup 1

Setup 1Setup 1

Setup 1

Set T53 low Voltage

V

Set T53 high Voltage

V

Set T53 Low Current

A

Set T53 High Current

A

Current

Voltage

28

29

26

27

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

Setup 1

AMA Failed

0.0 Hz

0.0 kW

Wizard completed

Press OK to accept

Automatic Motor Adaption

O

Auto Motor Adapt OK

Press OK

Select Function of Relay 2

No function

Select Function of Relay 1

[0] No function

Set Max Reference

Hz

Set Min Reference

Hz

AMA running

-----

AMA failed

Do AMA

(Do not AMA)

AMA OK

30

31

32

33

34

37

38

39

35 36

[0]

[0]

[0]

Setup 1

Select T53 Mode

Current

25

[0]

[0]

3.8

A

3000

RPM

5.4

Nm

0.65

Ohms

8

57

V

5

mH

0065

Hz

1.50

kW

0050

V

0050

Hz

04.66

A

1420

RPM

[0]

PM motor

Motor Type = Asynchronous

Motor Type = PM Motor

0000

0050

0003

0003

[0]

[0]

04.66

13.30

0050

0220

0000

0050

How to Program

VLT® HVAC Basic Drive Programming Guide

2 2

Figure 2.5

MG18B222 - VLT® is a registered Danfoss trademark 2-3

Page 18

How to Program

VLT® HVAC Basic Drive Programming Guide

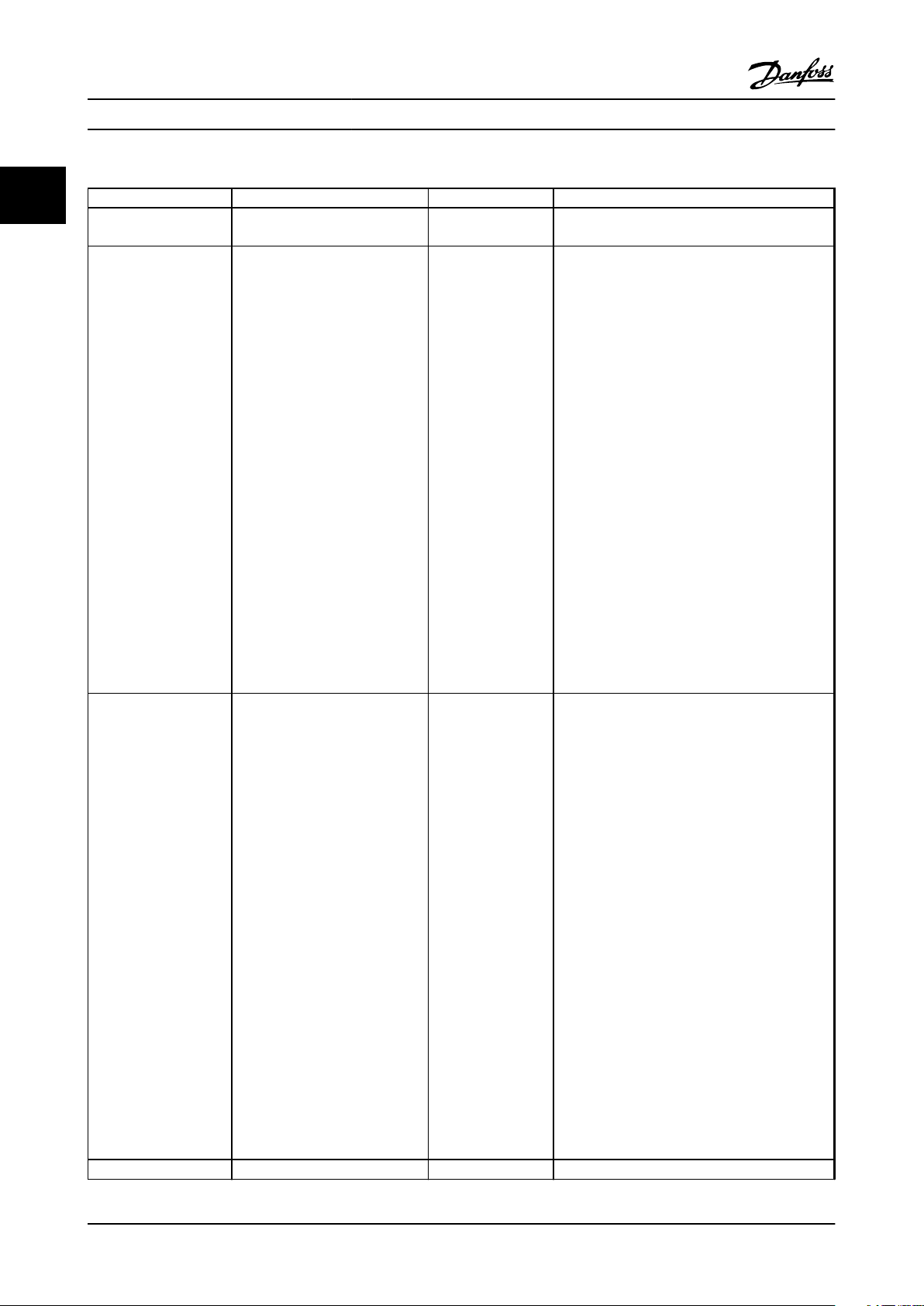

The FC 101 Start-up Wizard for Open-loop Applications

22

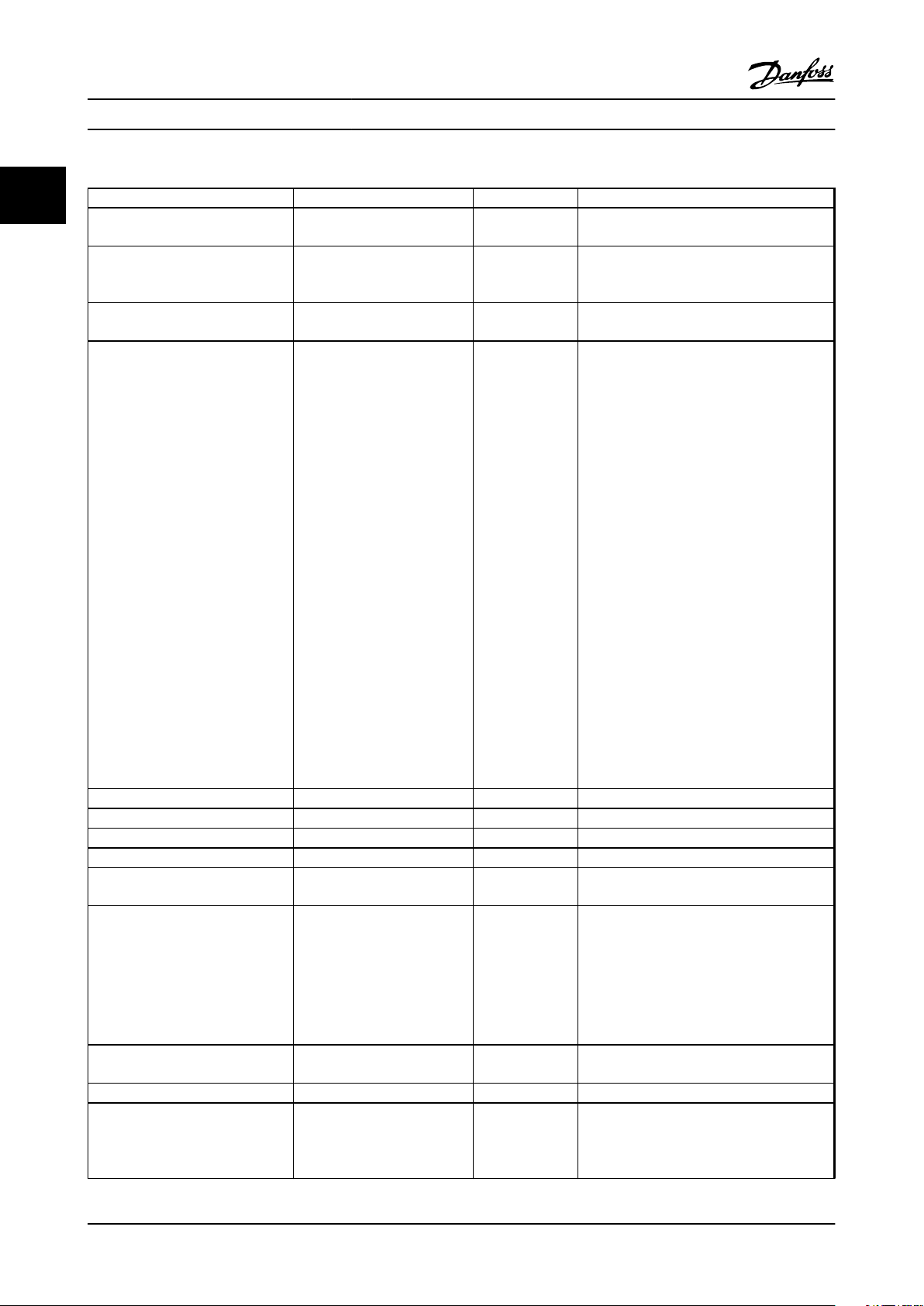

No & Name Range Default Function

0-03 Regional Settings [0] International

[1] US

0-06 GridType [0] 200–240 V/50 Hz/IT grid

[1] 200–240 V/50 Hz/Delta

[2] 200–240 V/50 Hz

[10] 380–440 V/50 Hz/IT grid

[11] 380–440 V/50 Hz/Delta

[12] 380–440 V/50 Hz

[20] 440–480 V/50 Hz/IT grid

[21] 440–480 V/50 Hz/Delta

[22] 440–480 V/50 Hz

[30] 525–600 V/50 Hz/IT grid

[31] 525–600 V/50 Hz/Delta

[32] 525–600 V/50 Hz

[100] 200–240 V/60 Hz/IT grid

[101] 200–240 V/60 Hz/Delta

[102] 200–240 V/60 Hz

[110] 380–440 V/60 Hz/IT grid

[111] 380–440 V/60 Hz/Delta

[112] 380–440 V/60 Hz

[120] 440–480 V/60 Hz/IT grid

[121] 440–480 V/60 Hz/Delta

[122] 440–480 V/60 Hz

[130] 525–600 V/60 Hz/IT grid

[131] 525–600 V/60 Hz/Delta

[132] 525–600 V/60 Hz

1-10 Motor Construction *[0] Asynchron

[1] PM, non-salient SPM

1-20 Motor Power

0.12–110 kW/0.16–150 hp Size related Enter motor power from nameplate data

0

Size related

[0] Asynchron Setting the parameter value might change these

Select operating mode for restart upon

reconnection of the drive to AC line voltage after

power-down

parameters:

1-01 Motor Control Principle

1-03 Torque Characteristics

1-14 Damping Gain

1-15 Low Speed Filter Time Const.

1-16 High Speed Filter Time Const.

1-17 Voltage filter time const.

1-20 Motor Power [kW]

1-22 Motor Voltage

1-23 Motor Frequency

1-24 Motor Current

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Torque

1-30 Stator Resistance (Rs)

1-33 Stator Leakage Reactance (X1)

1-35 Main Reactance (Xh)

1-37 d-axis Inductance (Ld)

1-39 Motor Poles

1-40 Back EMF at 1000 RPM

1-66 Min. Current at Low Speed

1-72 Start Function

1-73 Flying Start

4-19 Max Output Frequency

4-58 Missing Motor Phase Function

2-4 MG18B222 - VLT® is a registered Danfoss trademark

Page 19

How to Program

VLT® HVAC Basic Drive Programming Guide

No & Name Range Default Function

1-22 Motor Voltage 50.0–1,000.0 V Size related Enter motor voltage from nameplate data

1-23 Motor Frequency 20.0–400.0 Hz Size related Enter motor frequency from nameplate data

1-24 Motor Current 0.01–10,000.00 A Size related Enter motor current from nameplate data

1-25 Motor Nominal

Speed

1-26 Motor Cont. Rated

Torque

100.0–9,999.0 RPM Size related Enter motor nominal speed from nameplate data

0.1–1,000.0 Size related This parameter is available only when 1-10 Motor

Construction Design is set to [1] PM, non-salient

SPM.

NOTE!

Changing this parameter will affect settings

of other parameters

2 2

1-29 Automatic Motor

Adaption (AMA)

1-30 Stator Resistance

(Rs)

1-37 d-axis Inductance

(Ld)

1-39 Motor Poles 2-100 4 Enter the number of motor poles

1-40 Back EMF at 1000

RPM

1-73 Flying Start When PM is selected, Flying Start is enabled and

1-73 Flying Start [0] Disabled

3-02 Minimum Reference -4,999-4,999 0 The minimum reference is the lowest value

3-03 Maximum Reference -4,999–4,999 50 The maximum reference is the lowest obtainable

3-41 Ramp 1 Ramp Up

Time

3-42 Ramp 1 Ramp

Down Time

4-12 Motor Speed Low

Limit [Hz]

4-14 Motor Speed High

Limit [Hz]

4-19 Max Output

Frequency

5-40 Function Relay [0]

Function relay

5-40 Function Relay [1]

Function relay

See 1-29 Automatic Motor Adaption

(AMA)

0.000–99.990 Size related Set the stator resistance value

0–1000 Size related Enter the value of the d-axis inductance.

10–9,000 Size related Line-Line RMS back EMF voltage at 1000 RPM

[1] Enabled

0.05–3,600.0 s Size related Ramp-up time from 0 to rated 1-23 Motor

0.05–3,600.0 s Size related Ramp-down time from rated 1-23 Motor

0.0–400 Hz 0 Hz Enter the minimum limit for low speed

0.0–400 Hz 65 Hz Enter the maximum limit for high speed

0–400 Size related Enter the maximum output frequency value

See 5-40 Function Relay Alarm Select the function to control output relay 1.

See 5-40 Function Relay Drive running Select the function to control output relay 2.

Off Performing an AMA optimizes motor performance.

Obtain the value from the permanent magnet

motor data sheet. The de-axis inductance cannot

be found by performing an AMA.

cannot disable

0

Select [1] Enable to enable the drive to catch a

motor spinning due to line drop-out. Select [0]

Disable if this function is not required. When is

enabled 1-71 Start Delay and 1-72 Start Function

have no function. is active in VVC+ mode only.

obtainable by summing all references.

by summing all references.

Frequency if Asynchron motor is selected; ramp-up

time from 0 to 1-25 Motor Nominal Speed if PM

motor is selected

Frequency to 0 if Asynchron motor is selected;

ramp-down time from 1-25 Motor Nominal Speed

to 0 if PM motor is selected

MG18B222 - VLT® is a registered Danfoss trademark 2-5

Page 20

How to Program

VLT® HVAC Basic Drive Programming Guide

No & Name Range Default Function

22

6-10 Terminal 53 Low

Voltage

6-11 Terminal 53 High

Voltage

6-12 Terminal 53 Low

Current

6-13 Terminal 53 High

Current

6-19 Terminal 53 mode [0] Current

Table 2.4

0–10 V 0.07 V Enter the voltage that corresponds to the low

reference value.

0–10 V 10 V Enter the voltage that corresponds to the high

reference value.

0-20 mA 4 Enter the current that corresponds to the low

reference value.

0-20 mA 20 Enter the current that corresponds to the high

reference value.

1 Select if terminal 53 is used for current or voltage

[1] Voltage

input.

2-6 MG18B222 - VLT® is a registered Danfoss trademark

Page 21

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is forced to be set to

[1] Analog input 54

27

28

29

30

31

32

33

34

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Asynchronous Motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

0050

V

1-24 Motor current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0003

s

3-42 Ramp1 ramp-down time

0003

s

5

6

7

8

9

18

19

20

21

22

22a

23

24

25

26

35

36

37

38

39

40

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-13 Motor speed high limit

0050

Hz

130BC402.10

1-20 Motor Power

1.10

kW

1-23 Motor frequency

0050

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

O

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

1-00 Conguration Mode

[3]

Closed Loop

3

0-03 Regional Settings

[0]

Power kW/50 Hz

1

3-16 Reference Source 2

[0]

No Operation

22b

1-10 Motor Type

[0]

Asynchronous

4

2

[0]

200-240V/50Hz/Delta

1-30 Stator resistance

0.65

Ohms

1-25 Motor nominal speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-37 d-axis inductance(Ld)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 rpm

57

V

10

11

12

13

14

15

16

17

PM motor

1-39 Motor poles

8

%

04.66

Hz

MotorType = Asynchronous

MotorType = PM Motor

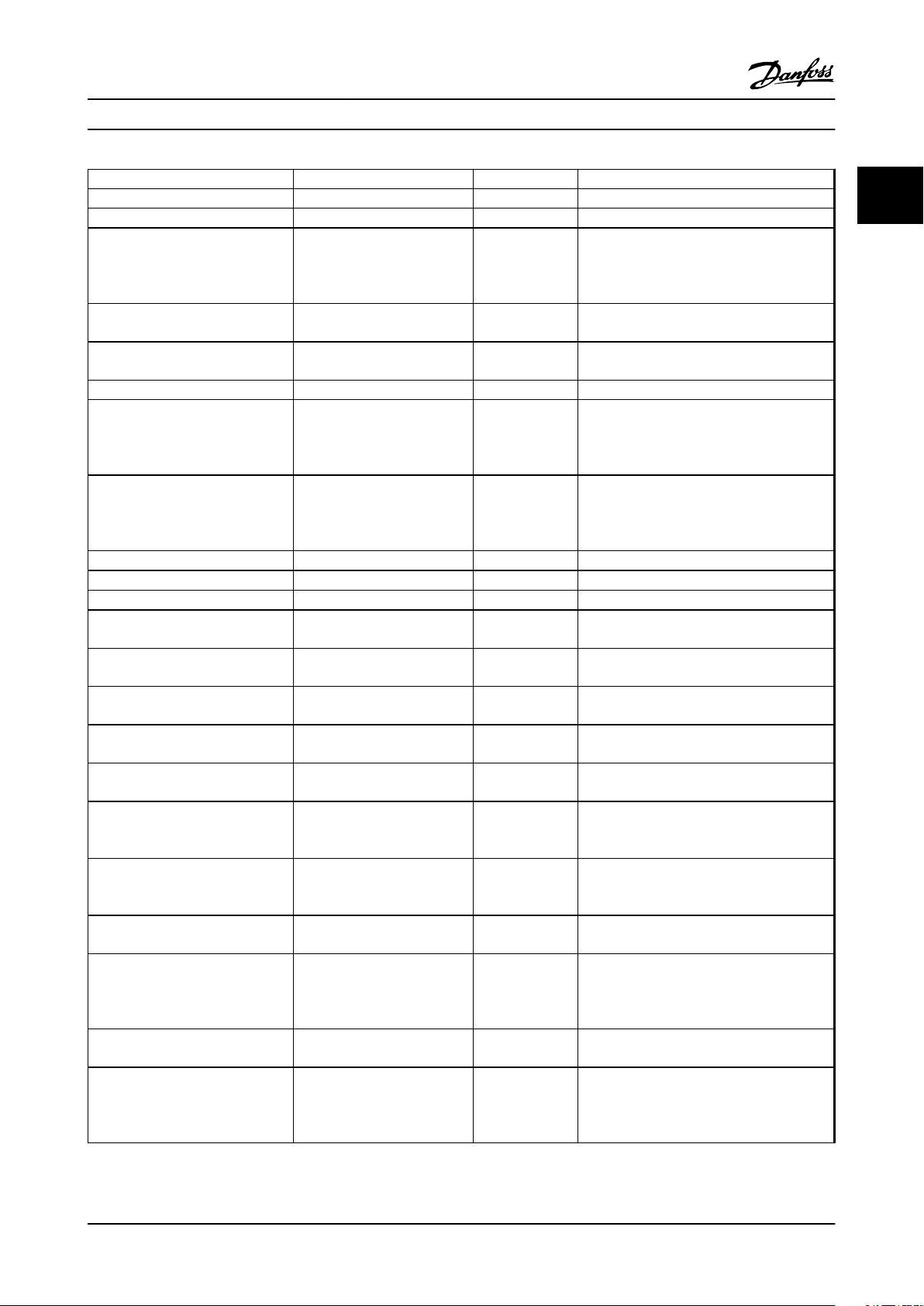

How to Program

Closed-loop Set-up Wizard

VLT® HVAC Basic Drive Programming Guide

2 2

Figure 2.6

MG18B222 - VLT® is a registered Danfoss trademark 2-7

Page 22

How to Program

VLT® HVAC Basic Drive Programming Guide

Closed-loop Set-up Wizard

22

No & Name Range Default Function

0-03 Regional Settings [0] International

[1] US

0-06 GridType [0] -[[132] please see start-up

wizard for open-loop

application

1-00 Configuration Mode [0] Open-loop

[3] Closed-loop

1-10 Motor Construction *[0] Motor construction

[1] PM, non-salient SPM

1-20 Motor Power

1-22 Motor Voltage 50.0–1,000.0 V Size related Enter motor voltage from nameplate data

1-23 Motor Frequency 20.0–400.0 Hz Size related Enter motor frequency from nameplate data

1-24 Motor Current 0.0–10,000.00 A Size related Enter motor current from nameplate data

1-25 Motor Nominal Speed 100.0–9,999.0 RPM Size related Enter motor nominal speed from nameplate

1-26 Motor Cont. Rated Torque 0.1–1,000.0 Size related This parameter is available only when

0.125–150 hp [0.09–110 kW] Size related Enter motor power from nameplate data

0

Size selected Select operating mode for restart upon

reconnection of the adjustable frequency

drive to AC line voltage after power-down.

0 Change this parameter to Closed-loop

[0] Asynchron Setting the parameter value might change

these parameters:

1-01 Motor Control Principle

1-03 Torque Characteristics

1-14 Damping Gain

1-15 Low Speed Filter Time Const.

1-16 High Speed Filter Time Const.

1-17 Voltage filter time const.

1-20 Motor Power [kW]

1-22 Motor Voltage

1-23 Motor Frequency

1-25 Motor Nominal Speed

1-26 Motor Cont. Rated Torque

1-30 Stator Resistance (Rs)

1-33 Stator Leakage Reactance (X1)

1-35 Main Reactance (Xh)

1-37 d-axis Inductance (Ld)

1-39 Motor Poles

1-40 Back EMF at 1000 RPM

1-66 Min. Current at Low Speed

1-72 Start Function

1-73 Flying Start

4-19 Max Output Frequency

4-58 Missing Motor Phase Function

data

1-10 Motor Construction Design is set to [1]

PM, non-salient SPM.

NOTE!

Changing this parameter will affect

settings of other parameters

1-29 Automatic Motor Adaption

(AMA)

1-30 Stator Resistance (Rs) 0.000–99.990 Size related Set the stator resistance value

1-37 d-axis Inductance (Ld) 0–1000 Size related Enter the value of the d-axis inductance.

2-8 MG18B222 - VLT® is a registered Danfoss trademark

Off Performing an AMA optimizes motor

performance.

Obtain the value from the permanent magnet

motor data sheet. The de-axis inductance

cannot be found by performing an AMA.

Page 23

How to Program

VLT® HVAC Basic Drive Programming Guide

No & Name Range Default Function

1-39 Motor Poles 2-100 4 Enter the number of motor poles

1-40 Back EMF at 1000 RPM 10–9,000 Size related Line-Line RMS back EMF voltage at 1000 RPM

1-73 Flying Start [0] Disabled

[1] Enabled

3-02 Minimum Reference -4,999-4,999 0 The minimum reference is the lowest value

3-03 Maximum Reference -4,999-4,999 50 The maximum reference is the highest value

3-10 Preset Reference -100–100% 0 Enter the setpoint.

3-41 Ramp 1 Ramp Up Time 0.05–3,600.0 s Size related Ramp-up time from 0 to rated 1-23 Motor

3-42 Ramp 1 Ramp Down Time 0.05–3,600.0 s Size related Ramp-down time from rated 1-23 Motor

4-12 Motor Speed Low Limit [Hz] 0.0–400 Hz 0.0 Hz Enter the minimum limit for low speed

4-14 Motor Speed High Limit [Hz] 0–400 Hz 65 Hz Enter the minimum limit for high speed

4-19 Max Output Frequency 0–400 Size related Enter the maximum output frequency value

6-29 Terminal 54 mode [0] Current

[1] Voltage

6-20 Terminal 54 Low Voltage 0–10 V 0.07 V Enter the voltage that corresponds to the low

6-21 Terminal 54 High Voltage 0–10 V 10 V Enter the voltage that corresponds to the low

6-22 Terminal 54 Low Current 0-20 mA 4 Enter the current that corresponds to the high

6-23 Terminal 54 High Current 0-20 mA 20 Enter the current that corresponds to the high

6-24 Terminal 54 Low Ref./Feedb.

Value

6-25 Terminal 54 High Ref./Feedb.

Value

6-26 Terminal 54 Filter Time

Constant

20-81 PI Normal/ Inverse Control [0] Normal

20-83 PI Start Speed [Hz] 0–200 Hz 0 Enter the motor speed to be attained as a

20-93 PI Proportional Gain 0–10 0.01 Enter the process controller proportional gain.

-4,999-4,999 0 Enter the feedback value that corresponds to

-4,999–4,999 50 Enter the feedback value that corresponds to

0–10 s 0.01 Enter the filter time constant.

[1] Inverse

0

1 Select if terminal 54 is used for current or

0

Select [1] Enable to enable the adjustable

frequency drive to catch a spinning motor,

e.g., in fan applications. When PM is selected,

Flying Start is enabled.

obtainable by summing all references.

obtainable by summing all references.

Frequency if Asynchron motor is selected;

ramp-up time from 0 to 1-25 Motor Nominal

Speed if PM motor is selected.

Frequency to 0 if Asynchron motor is selected;

ramp-down time from 1-25 Motor Nominal

Speed to 0 if PM motor is selected.

voltage input

reference value.

high reference value.

reference value.

reference value.

the voltage or current set in 6-20 Terminal 54

Low Voltage/6-22 Terminal 54 Low Current

the voltage or current set in 6-21 Terminal 54

High Voltage/6-23 Terminal 54 High Current

Select [0] Normal to set the process control to

increase the output speed when the process

error is positive. Select [1] Inverse to reduce

the output speed.

start signal for commencement of PI control.

Quick control is obtained at high amplification. However, if amplification is too great,

the process may become unstable

2 2

MG18B222 - VLT® is a registered Danfoss trademark 2-9

Page 24

How to Program

VLT® HVAC Basic Drive Programming Guide

No & Name Range Default Function

22

20-94 PI Integral Time 0.1–999.0 s 999.0 s Enter the process controller integral time.

Obtain quick control through a short integral

time, though if the integral time is too short,

the process becomes unstable. An excessively

long integral time disables the integral action.

Table 2.5

Motor Set-up

The Quick Menu Motor Set-up guides you through the

needed motor parameters.

No & Name Range Default Function

0-03 Regional

Settings

0-06 GridType [0] -[132]

1-10 Motor

Construction

1-20 Motor

Power

1-22 Motor

Voltage

1-23 Motor

Frequency

1-24 Motor

Current

1-25 Motor

Nominal

Speed

[0] International

[1] US

please see

start-up wizard

for open-loop

application

*[0] Motor

construction

[1] PM, nonsalient SPM

0.12–110 kW/

0.16–150 hp

50.0–1,000.0 V Size related Enter motor

20.0–400.0 Hz Size related Enter motor

0.01–10,000.00ASize related Enter motor

100.0–9,999.0

RPM

0

Size selected Select operating

mode for restart

upon

reconnection of

the drive to AC

line voltage after

power-down

[0]

Asynchron

Size related Enter motor

Size related Enter motor

power from

nameplate data

voltage from

nameplate data

frequency from

nameplate data

current from

nameplate data

nominal speed

from nameplate

data

No & Name Range Default Function

1-26 Motor

Cont. Rated

Torque

0.1–1,000.0 Size related This parameter is

available only

when 1-10 Motor

Construction

Design is set to

[1] PM, nonsalient SPM.

NOTE!

Changing this

parameter will

affect settings

of other

parameters

1-30 Stator

Resistance (Rs)

1-37 d-axis

Inductance

(Ld)

1-39 Motor

Poles

1-40 Back EMF

at 1000 RPM

1-73 Flying

Start

0.000–99.990 Size related Set the stator

resistance value

0–1000 Size related Enter the value

of the d-axis

inductance.

Obtain the value

from the

permanent

magnet motor

data sheet. The

de-axis

inductance

cannot be found

by performing an

AMA.

2-100 4 Enter the number

of motor poles

10–9,000 Size related Line-Line RMS

back EMF voltage

at 1000 RPM

[0] Disabled

[1] Enabled

0 Select Enable to

enable the

Adjustable

frequency drive

to catch a

spinning motor

2-10 MG18B222 - VLT® is a registered Danfoss trademark

Page 25

How to Program

VLT® HVAC Basic Drive Programming Guide

No & Name Range Default Function

3-41 Ramp 1

Ramp Up

Time

3-42 Ramp 1

Ramp Down

Time

4-12 Motor

Speed Low

Limit [Hz]

4-14 Motor

Speed High

Limit [Hz]

4-19 Max

Output

Frequency

Table 2.6

0.05–3,600.0 s Size related Ramp-up time

from 0 to rated

1-23 Motor

Frequency

0.05–3,600.0 s Size related Ramp-down time

from rated

1-23 Motor

Frequency to 0

0.0–400 Hz 0.0 Hz Enter the

minimum limit

for low speed

0.0–400 Hz 65 Enter the

maximum limit

for high speed

0–400 Size related Enter the

maximum output

frequency value

Changes Made

Changes Made lists all parameters changed since factory

setting. Only the changed parameters in current edit-setup

are listed in changes made.

If the parameter's value is changed back to the factory

settings from another different value, the parameter will

NOT be listed in Changes Made.

1. Press [Menu] key to enter the Quick Menu until

indicator in display is placed above Quick Menu.

2.

Press [▲] [▼] to select either FC 101 wizard,

closed-loop setup, motor setup or changes made,

then press [OK].

3.

Press [▲] [▼] to browse through the parameters

in the Quick Menu.

4. Press [OK] to select a parameter.

5.

Press [▲] [▼] to change the value of a parameter

setting.

6. Press [OK] to accept the change.

7. Press either [Back] twice to enter “Status”, or

press [Menu] once to enter “Main Menu”.

simplest and quickest access to the typical required

parameters.

The Main Menu accesses all parameters.

1. Press [Menu] key until indicator in display is

placed above “Main Menu”.

2.

Use [▲] [▼] to browse through the parameter

groups.

3. Press [OK] to select a parameter group.

4.

Use [▲] [▼] to browse through the parameters in

the specific group.

5. Press [OK] to select the parameter.

6.

Use [▲] [▼] to set/change the parameter value.

[Back] is used to go one level back.

2 2

2.3.4

Main Menu

[Main Menu] is used for programming all parameters. The

Main Menu parameters can be accessed immediately

unless a password has been created via 0-60 Main Menu

Password. For the majority of VLT HVAC Basic Drive

applications, it is not necessary to access the Main Menu

parameters but instead the Quick Menu provides the

MG18B222 - VLT® is a registered Danfoss trademark 2-11

Page 26

How to Program

VLT® HVAC Basic Drive Programming Guide

22

2.4 Quick Transfer of Parameter Settings

between Multiple Adjustable Frequency

Drives

Once the set-up of an adjustable frequency drive is

complete, Danfoss recommends that you store the data in

the LCP or on a PC via MCT-10 Setup Software tool.

Data storage in LCP.

WARNING

Stop the motor before performing this operation.

1.

Go to 0-50 LCP Copy

2. Press the [OK] key

3. Select “All to LCP”

4. Press the [OK] key

Connect the LCP to another adjustable frequency drive

and copy the parameter settings to this adjustable

frequency drive as well.

Data transfer from LCP to adjustable frequency drive:

NOTE!

Stop the motor before performing this operation.

1.

Go to 0-50 LCP Copy

2. Press the [OK] key

3. Select “All from LCP”.

4. Press the [OK] key

2.5

Read-out and Programming of Indexed

Parameters

Use as an example.

Choose the parameter, press [OK], and use [▲/▼] to scroll

through the indexed values. To change the parameter

value, select the indexed value and press [OK]. Change the

value by using the up/down keys. Press [OK] to accept the

new setting. Press [Cancel] to abort. Press [Back] to leave

the parameter.

2.6

Initialize the Adjustable Frequency

Drive to Default Settings in Two Ways

Recommended initialization (via 14-22 Operation Mode)

1.

Select 14-22 Operation Mode.

2. Press [OK].

3.

Select Initialization and Press [OK].

4. Cut off the line power supply and wait until the

display turns off.

5. Reconnect the line power supply - the adjustable

frequency drive is now reset. Except the following

parameters.

8-30 Protocol

8-31 Address

8-32 Baud Rate

8-33 Parity / Stop Bits

8-35 Minimum Response Delay

8-36 Maximum Response Delay

8-37 Maximum Inter-char delay

8-70 BACnet Device Instance

8-72 MS/TP Max Masters

8-73 MS/TP Max Info Frames

8-74 "I am" Service

8-75 Intialisation Password

15-00 Operating hours to 15-05 Over Volt's

15-03 Power Up's

15-04 Over Temp's

15-05 Over Volt's

15-30 Alarm Log: Error Code

15-4* Drive identification parameters

1-06 Clockwise Direction

Two-finger initialization:

1. Power off the adjustable frequency drive.

2. Press [OK] and [Menu].

3. Power up the adjustable frequency drive while

still pressing the keys above for 10 s.

4. The adjustable frequency drive is now reset,

except the following parameters:

2-12 MG18B222 - VLT® is a registered Danfoss trademark

Page 27

How to Program

15-00 Operating hours

15-03 Power Up's

15-04 Over Temp's

15-05 Over Volt's

15-4* Drive identification parameters

Initialization of parameters is confirmed by AL80 in the

display after the power cycle.

VLT® HVAC Basic Drive Programming Guide

2 2

MG18B222 - VLT® is a registered Danfoss trademark 2-13

Page 28

How to Program

VLT® HVAC Basic Drive Programming Guide

22

2-14 MG18B222 - VLT® is a registered Danfoss trademark

Page 29

Parameters

3 Parameters

VLT® HVAC Basic Drive Programming Guide

3.1 Main Menu - Operation and Display Group 0

Parameters related to the fundamental functions of the

adjustable frequency drive, function of the LCP buttons

and configuration of the LCP display.

3.1.1 0-0* Basic Settings

0-01 Language

Option: Function:

Defines the language to be used in the display.

[0] English

[1] Deutsch

[2] Francais

[3] Dansk

[4] Spanish

[5] Italiano

[28] Bras.port

[255] No Text

0-03 Regional Settings

Option: Function:

This parameter cannot be adjusted while the

motor is running. In order to meet the needs

for different default settings in different parts of

the world, 0-03 Regional Settings is implemented

in the adjustable frequency drive. The selected

setting influences the default setting of the

motor nominal frequency.

[0] Interna-

tional

[1] North

America

0-04 Operating State at Power-up

Option: Function:

[0] Resume Resumes operation of the adjustable frequency

Sets default value of 1-23 Motor Frequency [50

Hz].

Sets the default value of 1-23 Motor Frequency

to 60 Hz.

Select the operating mode upon reconnection of

the adjustable frequency drive to AC line voltage

after power-down when operating in Hand (local)

mode.

drive maintaining the same local reference and

the same start/stop condition (applied by [Hand

On]/[Off] on the LCP or Hand Start via a digital

0-04 Operating State at Power-up

Option: Function:

input as before the adjustable frequency drive

was powered down).

[1] Forced

stop,

ref=old

Uses saved reference [1] to stop the adjustable

frequency drive but at the same time retains the

local speed reference in memory prior to powerdown. After AC line voltage is reconnected and

after receiving a start command (using the LCP

[Hand On] button or Hand Start command via a

digital input) the adjustable frequency drive

restarts and operates at the retained speed

reference.

0-06 GridType

Option: Function:

Select the grid type of the supply

voltage/frequency.

NOTE!

Not all choices are supported in

all power sizes.

The IT grid is a line power source

where there are no connections to

ground.

Delta is a line power source where

the secondary part of the

transformer is delta connected and

one phase is connected to ground.

[0] 200-240V/50Hz/IT-grid

[1] 200-240V/50Hz/Delta

[2] 200-240V/50Hz

[10] 380-440V/50Hz/IT-grid

[11] 380-440V/50Hz/Delta

[12] 380-440V/50Hz

[20] 440-480V/50Hz/IT-grid

[21] 440-480V/50Hz/Delta

[22] 440-480V/50Hz

[30] 525-600V/50Hz/IT-grid

[31] 525-600V/50Hz/Delta

[32] 525-600V/50Hz

[100] 200-240V/60Hz/IT-grid

[101] 200-240V/60Hz/Delta

[102] 200-240V/60Hz

[110] 380-440V/60Hz/IT-grid

[111] 380-440V/60Hz/Delta

[112] 380-440V/60Hz

3

3

MG18B222 - VLT® is a registered Danfoss trademark 3-1

Page 30

Parameters

VLT® HVAC Basic Drive Programming Guide

3

0-06 GridType

Option: Function:

[120] 440-480V/60Hz/IT-grid

[121] 440-480V/60Hz/Delta

[122] 440-480V/60Hz

[130] 525-600V/60Hz/IT-grid

[131] 525-600V/60Hz/Delta

[132] 525-600V/60Hz

0-07 Auto DC Braking

Option: Function:

Protective function against overvoltage at coast.

WARNING

Can cause PWM when coasted.

[0] Off Function is not active.

[1] On Function is active.

3.1.2 0-1* Define and set-up Operations

Define and control the individual parameter set-ups. Userdefined parameters and miscellaneous external inputs (e.g.,

bus, LCP, analog/digital inputs, feedback, etc.) control the

functionality of the adjustable frequency drive.

A complete set of all parameters controlling the adjustable

frequency drive is called a set-up. The adjustable frequency

drive contains 2 set-ups, Set-up 1 and Set-up 2.

Furthermore, a fixed set of factory settings can be copied

into one or more set-ups.

Some of the advantages of having more than one set-up

in the adjustable frequency drive are:

Run motor in one set-up (Active Set-up) while

•

updating parameters in another set-up (Edit Setup)

Connect various motors (one at a time) to the

•

adjustable frequency drive. Motor data for various

motors can be placed in different set-ups.

Rapidly change settings of adjustable frequency

•

drive and/or motor, for example, while the motor

is running. Ramp time or preset references) via

bus or digital inputs.

The Active Set-up can be set as Multi Set-up where the

active set-up is selected via input on a digital input

terminal and/or via the bus control word.

0-10 Active Set-up

Option: Function:

Select the set-up in which the adjustable

frequency drive is to operate.

Use 0-51 Set-up Copy to copy a set-up to one or all

other set-ups. To avoid conflicting settings of the

same parameter within two different set-ups, link

the set-ups together using 0-12 Link Setups. Stop

the adjustable frequency drive before switching

between set-ups, where parameters marked ‘not

changeable during operation’ have different

values.

Parameters which are ‘not changeable during

operation’ are marked FALSE in the parameter lists

in 5 Parameter Lists.

[1] Set-up 1 Set-up 1 is active.

[2] Set-up 2 Set-up 2 is active.

[9] Multi

Set-up

Is used for remote selection of set-ups using

digital inputs and the serial communication port.

This set-up uses the settings from 0-12 Link Setups.

0-11 Programming Set-up

Option: Function:

Select the set-up to be edited (i.e.,

programmed) during operation: either the

active set-up or the inactive set-up. The set-up

number being edited is displayed in the LCP

flashing.

[1] Set-up 1

[2] Set-up 2

[9] Active Set-up(i.e., the set-up in which the adjustable

Set-up 1 [1] to Set-up 2 [2] can be edited freely

during operation, independently of the active

set-up.

frequency drive is operating) can also be edited

during operation.

0-12 Link Setups

Option: Function:

The link ensures synchronizing of the “not

changeable during operation” parameter values

enabling shift from one set-up to another during

operation.

If the set-ups are not linked, a change between

them is not possible while the motor is running.

Thus the set-up change does not occur until the

motor is coasted.

[0] Not

linked

Leaves parameters unchanged in both set-ups

and cannot be changed while the motor is

running.

3-2 MG18B222 - VLT® is a registered Danfoss trademark

Page 31

0

Custom Readout (Value)

P 16-09

Custom Readout

Unit P 0-30

Max value

P 0-32

Min value

Liniar

units only

P 0-31

Motor Speed

130BB779.10

Motor Speed

High limit

P 4-14 (Hz)

Linear Unit (e.g. Speed and ow)

Quadratic Unit (Pressure)

Cubic Unit (Power)

Parameters

VLT® HVAC Basic Drive Programming Guide

0-12 Link Setups

Option: Function:

[20] Linked Copies “not changeable during operation”

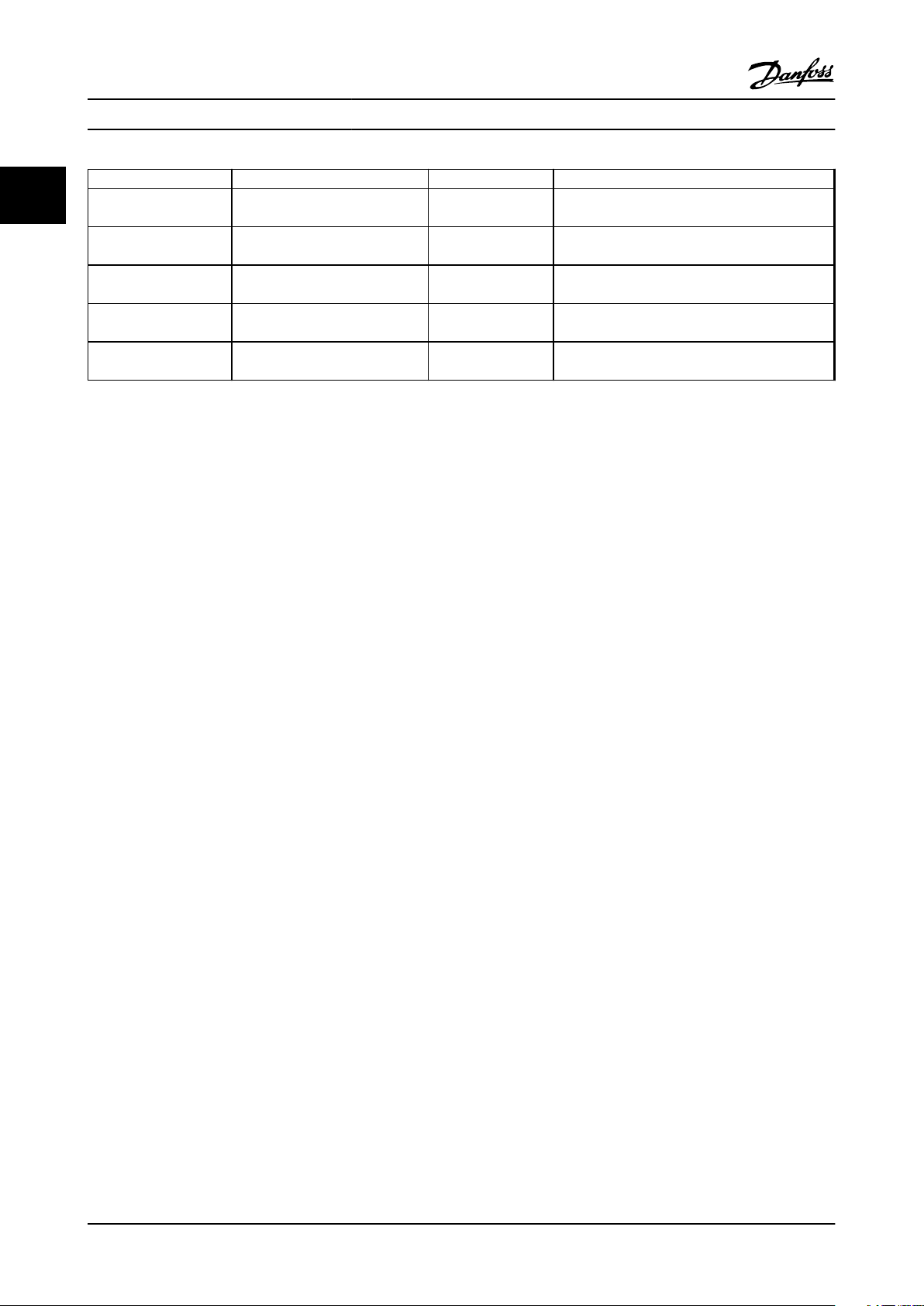

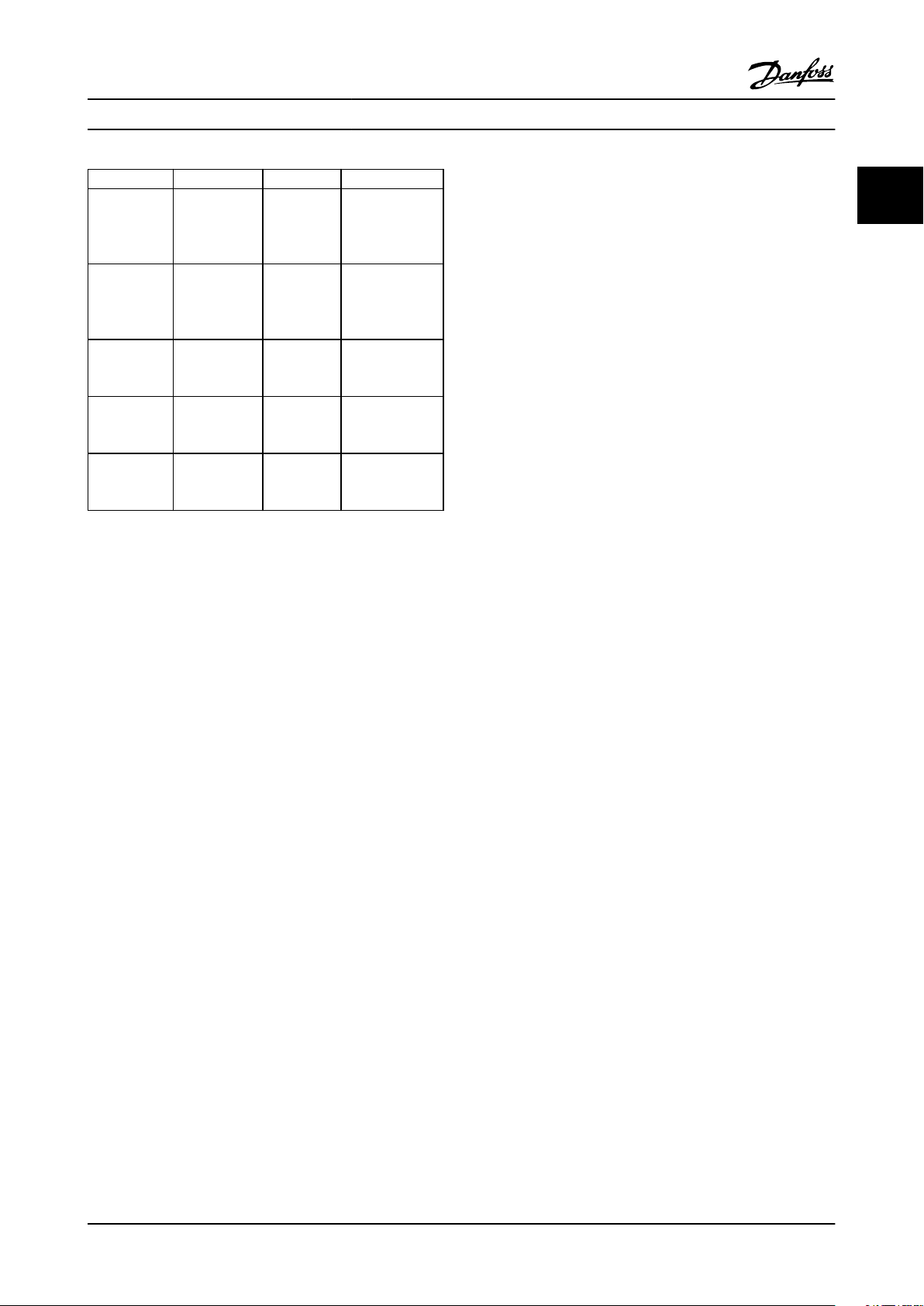

3.1.3 0-3* LCP Custom Readout

It is possible to customize the display elements for various

purposes: *Custom Readout. Value proportional to speed

(linear, squared or cubed depending on unit selected in

0-30 Custom Readout Unit) *Display Text. Text string stored

in a parameter.

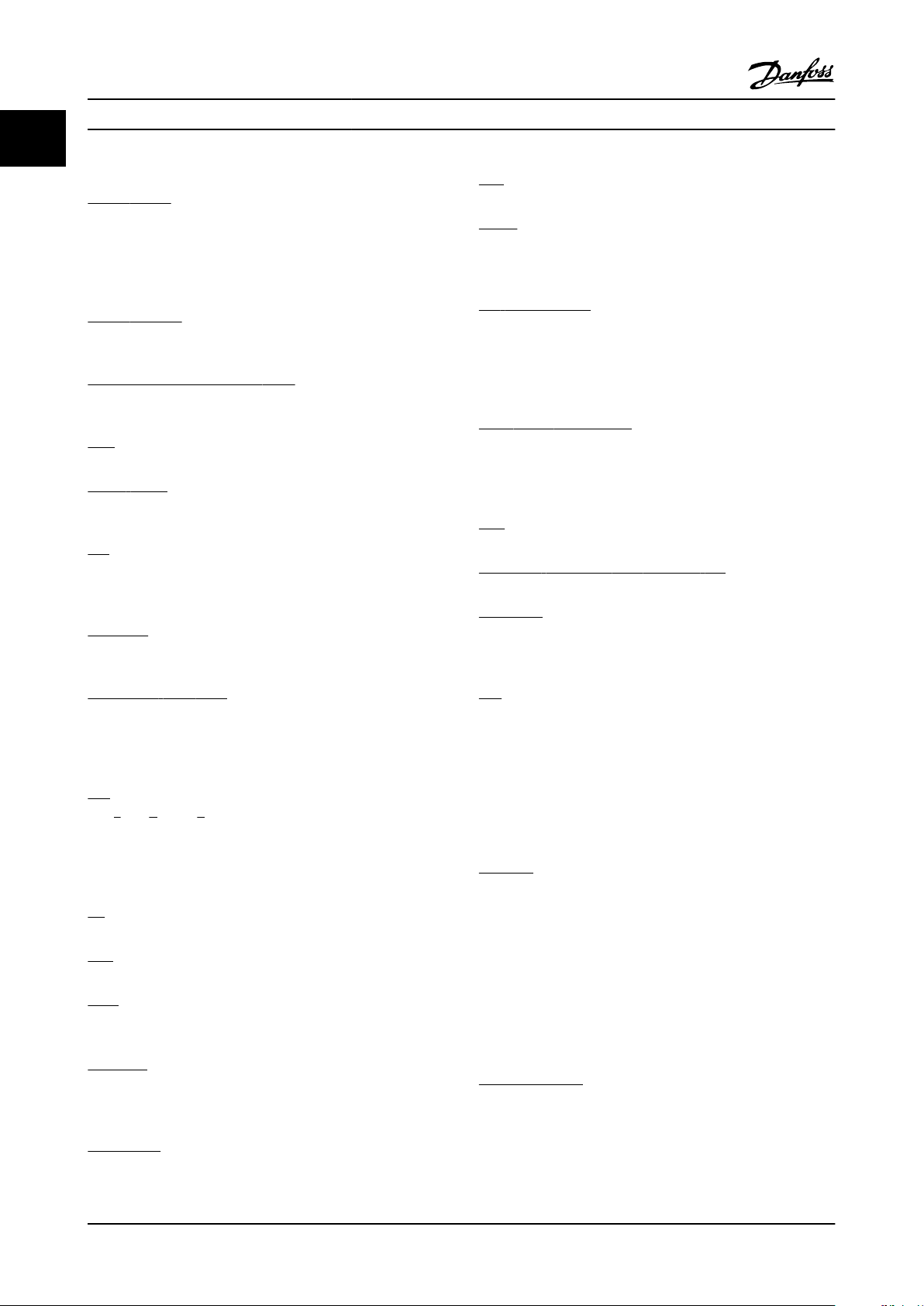

Custom Readout

The calculated value to be displayed is based on settings

in 0-30 Custom Readout Unit, 0-31 Custom Readout Min

Value (linear only), 0-32 Custom Readout Max Value,

4-14 Motor Speed High Limit [Hz] and actual speed.

Figure 3.1

The relation will depend on the type of unit selected in

0-30 Custom Readout Unit:

parameters from one set-up to the other, so they

are identical in both set-ups.

MG18B222 - VLT® is a registered Danfoss trademark 3-3

Unit Type

Dimensionless Linear

Speed

Flow, volume

Flow, mass

Velocity

Length

Temperature

Pressure Quadratic

Power Cubic

Table 3.1

Speed Relation

0-30 Custom Readout Unit

Option: Function:

Program a value to be shown in the

display of the LCP. The value has a linear,

squared or cubed relation to speed. This

relation depends on the unit selected (see

table above). The actual calculated value

can be read in 16-09 Custom Readout.

[0] None

[1] %

[5] PPM

[10] l/Min

[11] RPM

[12] Pulse/s

[20] l/s

[21] l/min

[22] l/h

[23] m3/s

[24] m3/min

[25] m3/h

[30] kg/s

[31] kg/min

[32] kg/h

[33] t/min

[34] t/h

[40] m/s

[41] m/min

[45] m

[60] Degree Celsius

[70] mbar

[71] bar

[72] Pa

[73] kPa

[74] m Wg

[80] kW

[120] GPM

[121] gal/s

[122] gal/min

[123] gal/h

3

3

Page 32

Parameters

VLT® HVAC Basic Drive Programming Guide

3

0-30 Custom Readout Unit

Option: Function:

[124] CFM

[127] ft3/h

[140] ft/s

[141] ft/min

[160] Degree Fahr

[170] psi

[171] lb/in2

[172] in WG

[173] ft WG

[180] hp

0-31 Custom Readout Min Value

Range: Function:

0 CustomReadoutUnit*

[ 0 - 999999.99

CustomReadoutUnit]

This parameter allows the

choice of the min. value of

the custom defined readout

(occurs at zero speed). It is

only possible to select a value

different to 0 when selecting

a linear unit in 0-30 Custom

Readout Unit. For quadratic

and cubic units, the minimum

value will be 0.

3.1.4 0-4* LCP

Enable, disable and password protect individual keys on

the LCP.

0-40 [Hand on] Key on LCP

Option: Function:

[0] Disabled

[1] Enabled [Hand on] key is enabled.

Select [0] Disabled to avoid accidental start of the

adjustable frequency drive in Hand mode.

0-42 [Auto on] Key on LCP

Option: Function:

[0] Disabled

[1] Enabled [Auto on] key is enabled.

Select [0] Disabled to avoid accidental start of the

adjustable frequency drive from LCP.

0-44 [Off/Reset] Key on LCP

Option: Function:

[0] Disabled

[1] Enabled

[7] Enable Reset Only

3.1.5 0-5* Copy/Save

0-32 Custom Readout Max Value

Range: Function:

100 CustomReadoutUnit*

[ 0.0 - 999999.99

CustomReadoutUnit]

This parameter sets the

max value to be shown

when the speed of the

motor has reached the set

value for 4-14 Motor Speed

High Limit [Hz].

0-37 Display Text 1

Range: Function:

[0 - 0 ] In this parameter it is possible to write an individual

text string to be read via serial communication.

Only used when running BACnet.

0-38 Display Text 2

Range: Function:

[0 - 0 ] In this parameter it is possible to write an individual

text string to be read via serial communication.

Only used when running BACnet.

0-39 Display Text 3

Range: Function:

[0 - 0 ] In this parameter it is possible to write an individual

text string to be read via serial communication.

Only used when running BACnet.

Copy parameter settings between set-ups and to/from the

LCP.

0-50 LCP Copy

Option: Function:

[0] No copy

[1] All to LCP Copies all parameters in all set-ups from the

adjustable frequency drive memory to the LCP

memory. For service purposes, it is

recommended to copy all parameters to the

LCP after commissioning.

[2] All from

LCP

[3] Size indep.

from LCP

Copies all parameters in all set-ups from the

LCP memory to the adjustable frequency drive

memory.

Copies only the parameters that are

independent of the motor size. The latter

selection can be used to program several

adjustable frequency drives with the same

function without disturbing motor data that are

already set.

3-4 MG18B222 - VLT® is a registered Danfoss trademark

Page 33

Parameters

0-51 Set-up Copy

Option: Function:

[0] No copy No function

[1] Copy from setup1Copy from set-up 1 to set-up 2.

[2] Copy from setup2Copy from set-up 2 to set-up 1.

VLT® HVAC Basic Drive Programming Guide

3

3

[9] Copy from

Factory setup

Copy factory setting to programming setup (chosen in 0-11 Programming Set-up).

3.1.6 0-6* Password

0-60 Main Menu Password

Range: Function:

0 * [0 - 999 ] Define the password for access to the main

menu via the [Main Menu] key. Setting value to

0 disables the password function.

MG18B222 - VLT® is a registered Danfoss trademark 3-5

Page 34

Parameters

VLT® HVAC Basic Drive Programming Guide

3

3.2 Main Menu - Load and Motor - Group 1

Parameters related to the motor nameplate load compensations and application load type.

3.2.1 1-0* General Settings

1-00 Configuration Mode

Option: Function:

[0] Open

Loop

[3] Closed

Loop

Motor speed is determined by applying a speed

reference or by setting desired speed when in

Hand mode.

Open-loop is also used if the adjustable frequency

drive is part of a closed-loop control system

based on an external PI controller providing a

speed reference signal as output.

Motor Speed will be determined by a reference

from the built-in PI controller varying the motor

speed as of a closed-loop control process (e.g.,

constant pressure or flow). The PI controller must

be configured in parameter group20-**.

NOTE!

This parameter cannot be changed when the motor is

running.

NOTE!

When set for Closed-Loop, the commands Reversing and

Start Reversing will not reverse the direction of the motor.

1-03 Torque Characteristics

Option: Function:

(e.g., multiple condenser fans or cooling tower

fans). Provides a voltage which is optimized for a

squared torque load characteristic of the motor.

[3] Auto

Energy

Optim.

For optimum energy efficient speed control of

centrifugal pumps and fans. Provides a voltage

which is optimized for a squared torque load

characteristic of the motor but in addition the

AEO feature will adapt the voltage exactly to the

current load situation, thereby reducing energy

consumption and audible noise from the motor.

1-06 Clockwise Direction

This parameter defines the term “Clockwise” corresponding to

the LCP direction arrow. Used for easy change of direction of

shaft rotation without swapping motor wires.

Option: Function:

[0] Normal Motor shaft will turn in clockwise

direction when adjustable frequency

drive is connected U -> U; V -> V, and