Page 1

Description

The bus bar kit is designed for the specic VLT® HVAC Drive FC

102, VLT

®

AQUA Drive FC 202, and VLT® AutomationDrive FC

302 D4h-size VLT

®

Common AC Drive Modules mounted in a

Rittal TS8 enclosure. The bus bars in this kit link 2 drive

modules in parallel.

Kit Part Number

Part number Kit description

176F6487

Bus bar kit for the VLT

®

Common AC Drive

Modules (6-pulse, 2-drive system)

Table 1.1 Part Number for the VLT® Common AC Drive Modules

Bus Bar Kit

Items Supplied

The kit contains the following parts:

•

Nut with integrated washer, M5 (10)

•

Nut with integrated washer, M8 (10)

•

Nut with integrated washer, M10 (12)

•

Screw, M5 x 12 mm (40)

•

Screw with integrated washer, M10 x 30 (12)

•

Stand-o, M5 x 25 (24)

•

Ground bus bar, 800 mm (1)

•

Ground plate (1)

•

Ground jumper plate (2)

•

Ground jumper bus bar (2)

•

Ground clamp (1)

•

EMI/EMC bracket, left (2)

•

EMI/EMC bracket, right (2)

•

EMI/EMC bracket, front (2)

•

EMI/EMC shield, lower (1)

DC bus assembly

•

L-brackets (2)

•

DC-link jumper bus bar (-) (2)

•

Jumper bus bar (+) (2)

•

DC bus support plate (1)

•

DC-link bus bar (2)

AC bus bar assembly

•

Brake terminal, left (2)

•

Brake terminal, right (2)

•

Brake terminal bracket (2)

•

Solid AC bus bar, (6)

•

Mains bus bar support bracket (1)

•

AC bus bar assembly bracket (1)

•

Mains bus bar S-bracket (1)

•

Flexible AC bus bars (12)

•

Support for brake terminals (1)

•

Side support (2)

Safety

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the unit is o. High voltage

can be present even when the warning indicator lights are

o. Failure to wait 20 minutes after power has been

removed before performing service or repair work, could

result in death or serious injury.

•

Stop the motor.

•

Disconnect the AC mains, permanent magnet type

motors, and remote DC-link supplies, including

battery back-ups, UPS, and DC-link connections to

other frequency converters.

•

Wait 20 minutes for the capacitors to discharge fully,

before performing any service or repair work.

•

Measure the voltage level to verify full discharge.

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

Danfoss A/S © 02/2016 All rights reserved. MI92I102

Page 2

Installation

NOTICE

If both a bus bar kit and a back-channel cooling kit are

being installed in the cabinet, install the back-channel

cooling kit rst.

NOTICE

APPROVALS AND CERTIFICATIONS

This VLT® Common AC Drive Modules bus bar kit is UL 508 C

compliant. These installation instructions describe how to

install Danfoss-supplied bus bars which, if followed, meet

specic agency approvals and certications. Seek agency

approvals or

certications

apart from Danfoss if designing

and building other congurations.

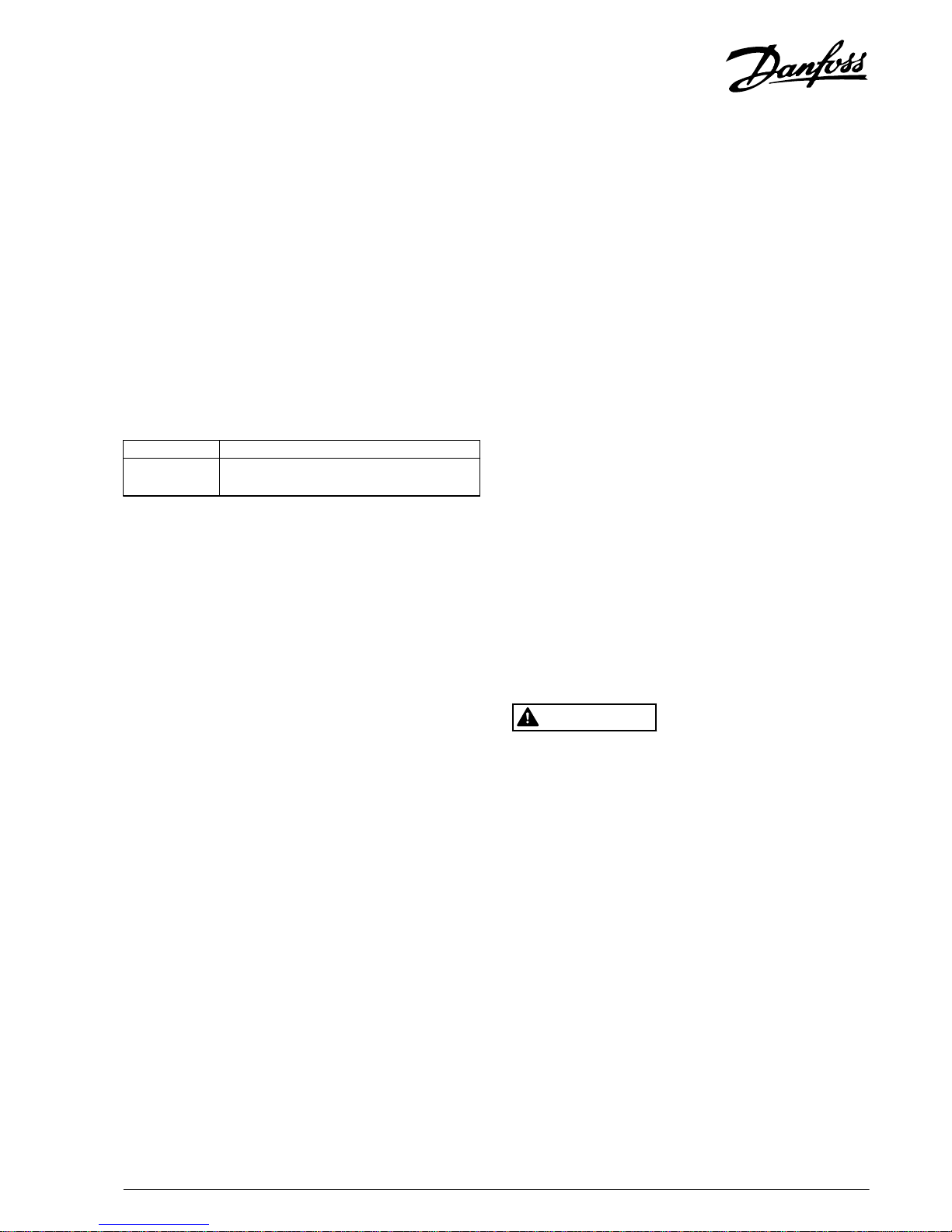

Installing DC-link Bus Bars

1. Install 1 L-bracket inside the top of the enclosure on

each side. Secure each bracket with 3 M5 nuts and

torque to 2.3 Nm (20 in-lb). See Illustration 1.1.

1 L-brackets 2 DC fuse with microswitch

Illustration 1.1 Installation of DC Bus Bar L-brackets above the

DC Fuses

2. Install the 6

stand-os

onto the support plate. Torque

to 2.3 Nm (20 in-lb). Refer to Illustration 1.2.

3. Install the 2 DC-link bus bars onto the support plate

using 3 M5 nuts per bus bar. Torque to 2.3 Nm

(20 in-lb).

1 Support plate 3 DC-link bus bars

2 Stand-os 4 M5 nut

Illustration 1.2 Installing DC-link Bus Bars onto Support Plate

4. With the DC-link bus bars facing downward, slide the

support plate onto the L-brackets. Secure the support

plate with 6 M5 screws and torque to 2.3 Nm (20 inlb). Refer to Illustration 1.3.

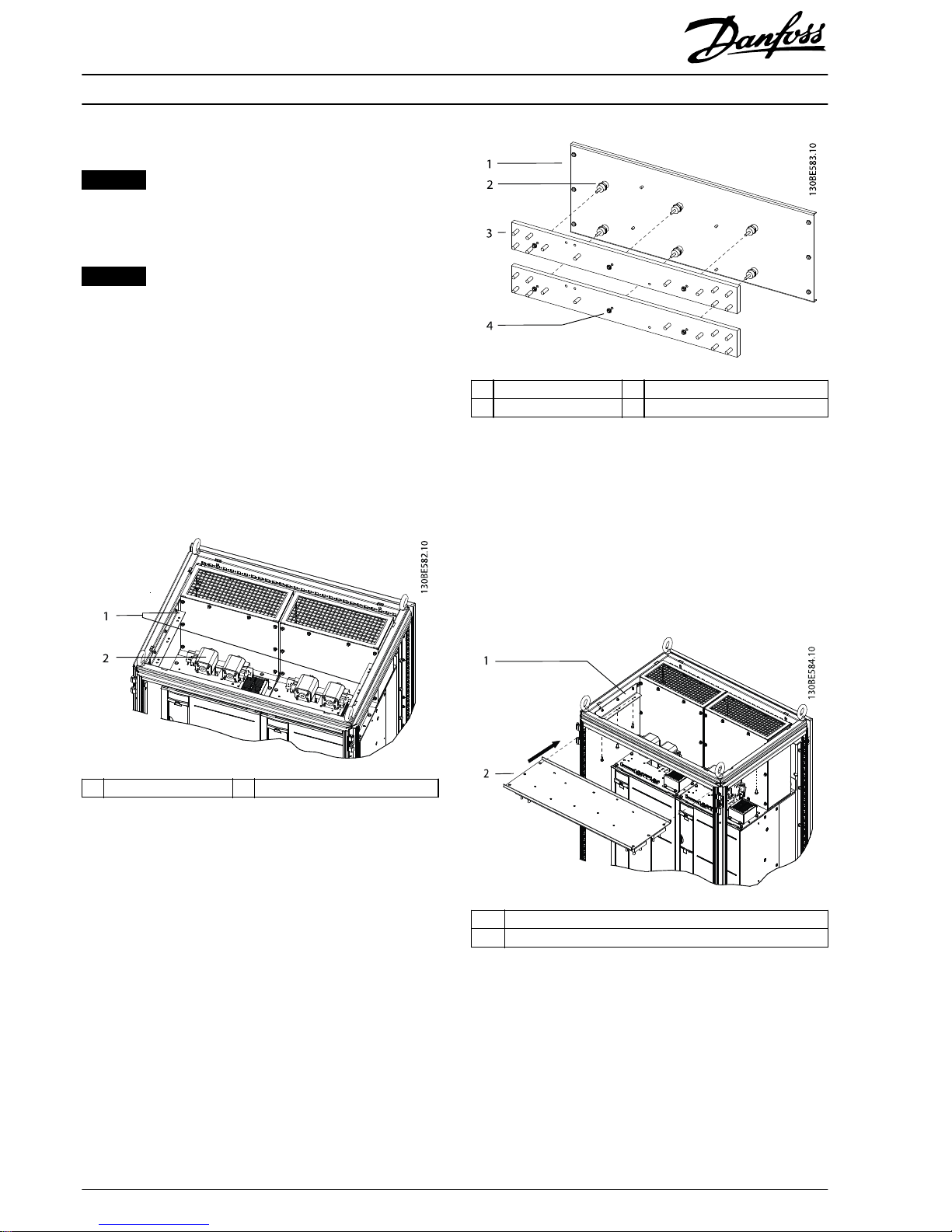

5. Install the DC+ and DC- jumper bus bars between

the DC fuses and the DC bus bars. Refer to

Illustration 1.4.

1L-brackets

2 DC-link bus bar assembly (support plate and bus bars)

Illustration 1.3 Installation of DC Bus Bars onto L-brackets

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

2

Danfoss A/S © 02/2016 All rights reserved. MI92I102

Page 3

1 DC-link jumper bus bars (+/- indicated in drawing) 3 Microswitch

2 DC-link bus bar 4 DC fuse

Illustration 1.4 Installation of DC Jumper Bus Bars

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

MI92I102 Danfoss A/S © 02/2016 All rights reserved.

3

Page 4

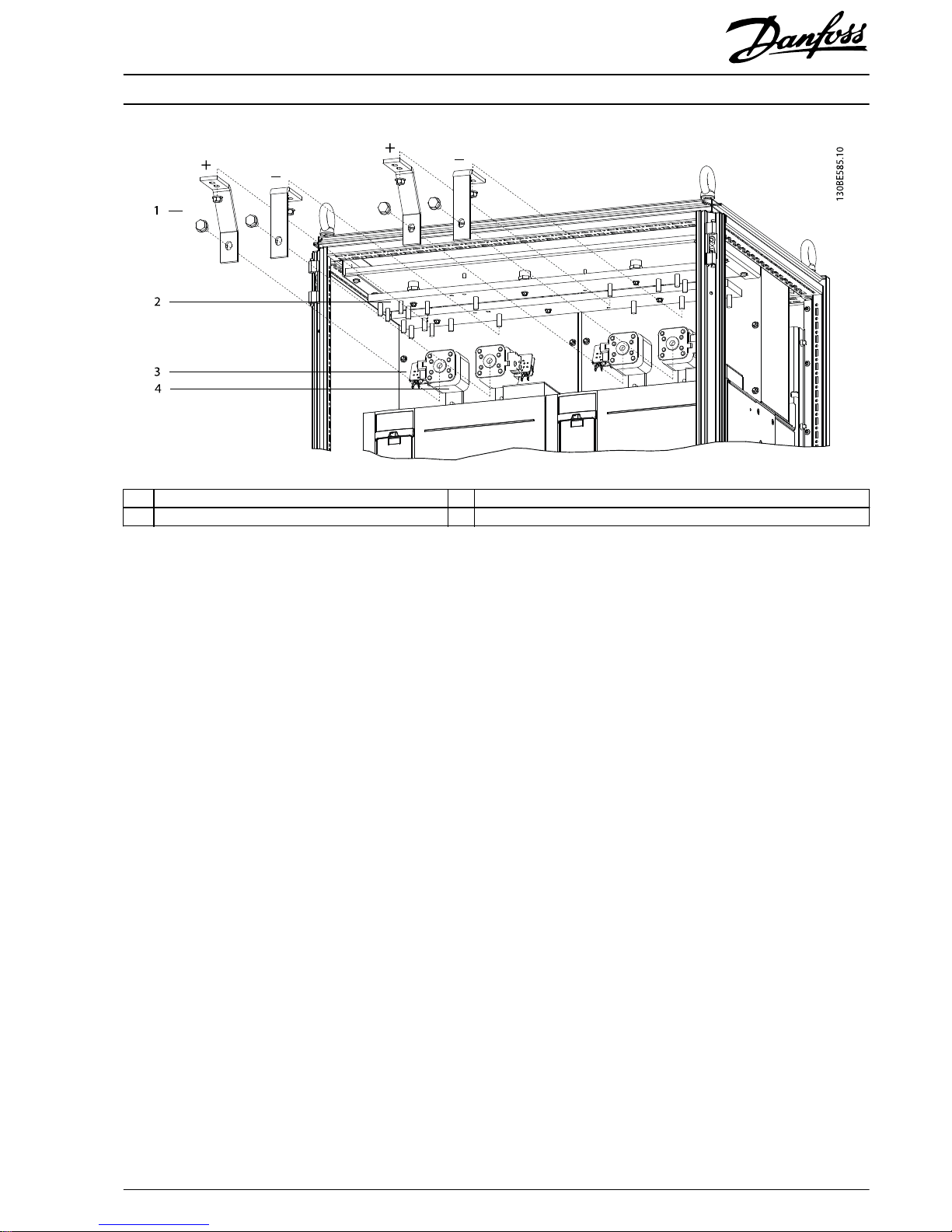

Assembling the AC Bus Bar Subassemblies

The AC bus bar assembly consists of the following 3 subassemblies, as shown in Illustration 1.5:

•

Support subassembly consisting of 3 components

•

Motor bus bar subassembly consisting of 3 components

•

Mains bus bar subassembly consisting of 5 components

1 AC bus bar subassembly bracket 3 Mains bus bar subassembly

2 Motor bus bar subassembly – –

Illustration 1.5 Exploded View of the AC Bus Bar Assembly

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

4

Danfoss A/S © 02/2016 All rights reserved. MI92I102

Page 5

1. Install the left and right brake terminals onto the brake terminal bracket using 4 M5 nuts. Torque to 2.3 Nm (20 in-lb).

2. Secure the brake terminal assembly to the AC bus bar assembly support with 2 M8 nuts. Torque to 9.6 Nm (85 in-lb). Refer

to Illustration 1.6.

3. Install the mains bus bar S-bracket to the AC bus bar assembly support bracket using 2 M5 nuts. Torque to 2.3 Nm

(20 in-lb).

1 AC bus bar assembly support bracket 4 M5 nut

2 Mounting point for lower EMI/EMC shield 5 Mains bus bar S-bracket

3 Brake terminal assembly (terminals and bracket) 6 Studs that insert into the side support bracket

Illustration 1.6 Assembling the AC Bus Bar Subassembly Bracket

4. Assemble the motor bus bar subassembly using 9 stand-os and 9 M5 nuts. Torque to 2.3 Nm (20 in-lb).

Refer to Illustration 1.7.

1 Slotted opening for M10 screw 3 M5 nut

2 Stand-os (front and back side of bus bar), indicated by an S in

the drawing

4 Solid motor bus bars

Illustration 1.7 Assembling the Motor Bus Bar Subassembly

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

MI92I102 Danfoss A/S © 02/2016 All rights reserved.

5

Page 6

5. Install the left and right brake terminals onto the brake terminal bracket using 4 M5 nuts. Torque to 2.3 Nm (20 in-lb).

6. Secure the brake terminal assembly to the mains bus bar support with 2 M8 nuts. Torque to 9.6 Nm (85 in-lb). Refer to

Illustration 1.6.

7. Assemble the mains bus bar subassembly using 9

stand-os

and 9 M5 nuts. Torque to 2.3 Nm (20 in-lb).

Refer to Illustration 1.8.

1 Mains bus bar support bracket 4 M5 nut

2 Stand-os (front and back side of bus bar), indicated by an S in

the drawing

5 Brake terminal assembly (terminals and bracket)

3 Slotted opening for M10 screw 6 Solid mains bus bars

Illustration 1.8 Assembling the Mains Bus Bar Subassembly

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

6

Danfoss A/S © 02/2016 All rights reserved. MI92I102

Page 7

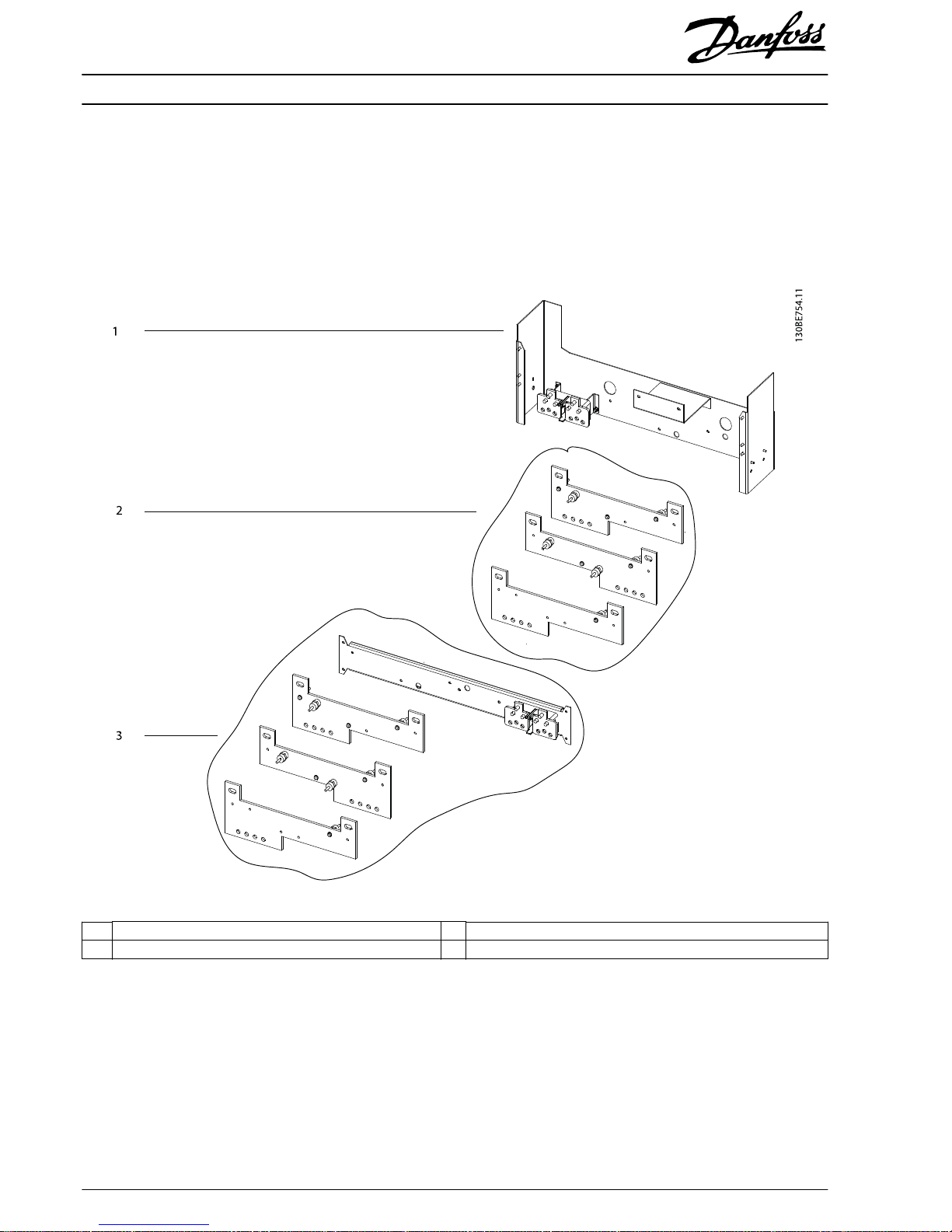

Installing the AC Bus Bar Assembly

1. Install 1 side support bracket inside the enclosure on

each side. Secure each side support bracket with 4

M5 screws and torque to 2.3 Nm (20 in-lb). See

Illustration 1.9.

2. Install ground plate assembly. See Illustration 1.9.

2a Attach the ground support bracket to the

inside of the enclosure. Secure with 4 M5

screws and torque to 2.3 Nm (20 in-lb).

2b Install the ground plate onto the 5 studs on

the ground support bar.

2c Secure the bottom of the ground plate to

the enclosure using 8 M5 screws. Torque to

2.3 Nm (20 in-lb).

2d Install the ground bus bar onto the ground

plate. Secure with 5 M8 nuts and torque to

to 9.6 Nm (85 in-lb).

2e Install the 1 ground jumper plate per drive

module. Secure the bottom of the ground

jumper plate to the top of the ground plate

using 1 M5 nut. Torque to 2.3 Nm (20 in-lb).

2f Secure the top of the ground jumper plate

to the bottom of the drive module reusing

the 2 existing M10 nuts. Torque to 19 Nm

(169 in-lb).

3. Install the ground jumper bus bars. Perform this step

for each drive module.

3a Secure the bottom of the ground jumper

bus bar to the ground bus bar using 1 M5

nut. Torque to 2.3 Nm (20 in-lb). See

Illustration 1.9 for the mounting attachment

points on the ground bus bar.

3b Secure the other end of the ground jumper

bus bar to the drive module ground

terminal using 1 M5 nut. Torque to 2.3 Nm

(20 in-lb).

4. Secure the motor bus bar subassembly (see

Illustration 1.7) to the AC bus bar assembly bracket

(Illustration 1.6) using 3 M5 nuts. Torque to 2.3 Nm

(20 in-lb).

5. Install the AC bus bar bracket/motor bus bar

subassembly to the side support brackets. Secure

each side with 2 M5 nuts and torque to 2.3 Nm

(20 in-lb).

6. Fasten the mains bus bar subassembly (see

Illustration 1.8) to the motor bus bar subassembly

using 4 M5 nuts. Torque to 2.3 Nm (20 in-lb).

7. Shape the

exible

bus bars to

t.

8. Install the motor

exible

bus bars for each drive

module. Refer to Illustration 1.10.

8a Insert 1 M10 screw into each of the slotted

holes in the motor bus bar subassembly,

with the screw shaft facing the front.

8b Install 3

exible

motor bus bars per drive

module, securing 1 end to the screw and

the other end to the drive module terminal.

Secure with 2 M10 nuts per bus bar. Torque

to 19 Nm (169 in-lb).

8c Verify that the proper R, S, T connections

are made. Refer to the Terminal Dimensions

section in the VLT

®

Common AC Drive

Modules Installation Guide.

9. Assemble the front EMI/EMC bracket assembly.

9a Attach the left EMI/EMC bracket to the front

EMI/EMC bracket using 3 M5 screws. Torque

to 2.3 Nm (20 in-lb).

9b Attach the right EMI/EMC bracket to the

front EMI/EMC bracket using 3 M5 screws.

Torque to 2.3 Nm (20 in-lb).

10. Install the front EMI/EMC bracket assembly over each

set of

exible

motor bus bars. Secure with 4 M5 nuts

and torque to 2.3 Nm (20 in-lb). Refer to

Illustration 1.11.

11. Install the exible mains bus bars for each drive

module. Refer to Illustration 1.12.

11a Insert 1 M10 screw into each of the slotted

holes in the mains bus bar subassembly,

with the screw shaft facing the front.

11b Install 3 exible mains bus bars per drive

module, securing 1 end to the screw and

the other end to the drive module mains

terminal. Secure with 2 M10 nuts per bus

bar. Torque to 19 Nm (169 in-lb).

11c Verify the proper U, V, W connections are

made. Refer to the Terminal Dimensions

section in the VLT

®

Common AC Drive

Modules Installation Guide.

12. Install the lower EMI/EMC shield to the AC bus bar

subassembly bracket. Secure with 2 M5 nuts. Torque

to 2.3 Nm (20 in-lb). See Illustration 1.13.

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

MI92I102 Danfoss A/S © 02/2016 All rights reserved.

7

Page 8

1 Screw at the bottom of the drive module that connects

to the top of the ground jumper plate

6 Ground bus bar

2 M10 nut 7 Ground jumper bus bar

3 Ground jumper plate 8 Side support bracket

4 M5 nut 9 Ground support bracket

5Ground plate ––

Illustration 1.9 Installation of Side Support Brackets and Ground Bus Bar Assembly

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

8

Danfoss A/S © 02/2016 All rights reserved. MI92I102

Page 9

1 Motor bus bar screws for drive module 1 4 M10 nuts

2 Motor bus bar subassembly 5 Flexible motor bus bars

3 Motor bus bar screws for drive module 2 – –

Illustration 1.10 Installation of Flexible Motor Bus Bars

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

MI92I102 Danfoss A/S © 02/2016 All rights reserved.

9

Page 10

1 Left EMI/EMC bracket (shown on drive module 1) 4 Ground plate

2 Front EMI/EMC bracket (shown on drive module 1) 5 Right EMI/EMC bracket (shown on drive module 1)

3 Flexible motor bus bars – –

Illustration 1.11 Installation of Front EMI/EMC Bracket Assembly

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

10

Danfoss A/S © 02/2016 All rights reserved. MI92I102

Page 11

1 Mains bus bar screws for drive module 1 4 Front EMI/EMC bracket assembly

2 Flexible mains bus bars 5 Mains bus bar screws for drive module 2

3 M10 Nuts 6 Mains bus bar subassembly

Illustration 1.12 Installation of Flexible Mains Bus Bars and Lower EMI/EMC Shield

Installation Instructions

Bus Bar Kit for 6-pulse, 2-drive System

VLT® Series FC 102, FC 202, and FC 302

MI92I102 Danfoss A/S © 02/2016 All rights reserved.

11

Page 12

1 DC-link bus bars (under mesh screen) 7 Flexible motor bus bars for drive module 2

2 Solid mains bus bars 8 Front EMI/EMC bracket assembly for drive module 2

3 Ground bar support bracket 9 Flexible mains bus bars for drive module 2

4 Ground bus bar 10 Solid motor bus bars for drive module 2

5 Ground plate 11 Lower EMI/EMC shield

6 Drive module 2 – –

Illustration 1.13 Installing Lower EMI/EMC Shield on an Assembled 2-Drive System canceled

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

*MI92I102*

MI92I102130R0689 02/2016

Loading...

Loading...