Page 1

Fact Sheet: VLT® Enclosed Drives

Extended functionality and real LHD for

high-performance operation

VLT® Enclosed Drives have been designed to meet the most demanding requirements for flexibility, robustness,

compactness and service-friendliness, making them a smart choice for diverse applications. They are ideal for low

harmonic drive (LHD) usage, with outstanding harmonic mitigation performance.

VLT® Enclosed Drives are

configurable with input/output filters,

control and enclosure options to meet

practically all requirements of the

application, eliminating the need for an

extra enclosure.

Selectable input/output filters ensure

highest quality of the voltage on

motor terminals, as well as the lowest

harmonics content of mains currents –

TDD <3% and it is a best choice, when

harmonics frequencies above 2 kHz in

the power supply network is a concern

to fulfil the IEC 61000-2-4 requirements

for harmonics up to 9 kHz.

<3%

Total harmonic

distortion, even

up to 9 kHz

Real LHD

Available for enclosure sizes

D and E

n VLT® AutomationDrive FC 302

n VLT® AQUA Drive FC 202

n VLT® HVAC Drive FC 102

n VLT® Refrigeration Drive FC 103

Protection ratings

n IP21 (Type 1)

n IP54 (Type 12)

Back-channel cooling

A unique ducted back-channel passes

cooling air over heat sinks with minimal

air passing through the electronics area.

There is an IP54/Type 12 seal between

the back-channel cooling duct and

the electronics area of the VLT® drive.

This allows 90% of the heat losses to

be exhausted directly outside of the

enclosure, improving reliability and

prolonging life by dramatically reducing

temperature rise and contamination

of the electronic components. Input/

output filters also use the IP54/ Type 12

-rated back-channel for cooling.

Supply voltage

and power ranges

n 380-480/500 V……90 kW-500 kW

n 525-690 V…….90 kW-710 kW

with 150% overload

drives.danfoss.com

Page 2

Feature Benefit

Built-in options

Back-channel cooling

Variable speed cooling fans Improve efficiency of the drive and reduce audible noise.

VLT® drives family with

common graphical LCP

Integrated selectable input/output filters

Door-mounted control compartment Safe accessibility to control terminals, also during operation of the drive.

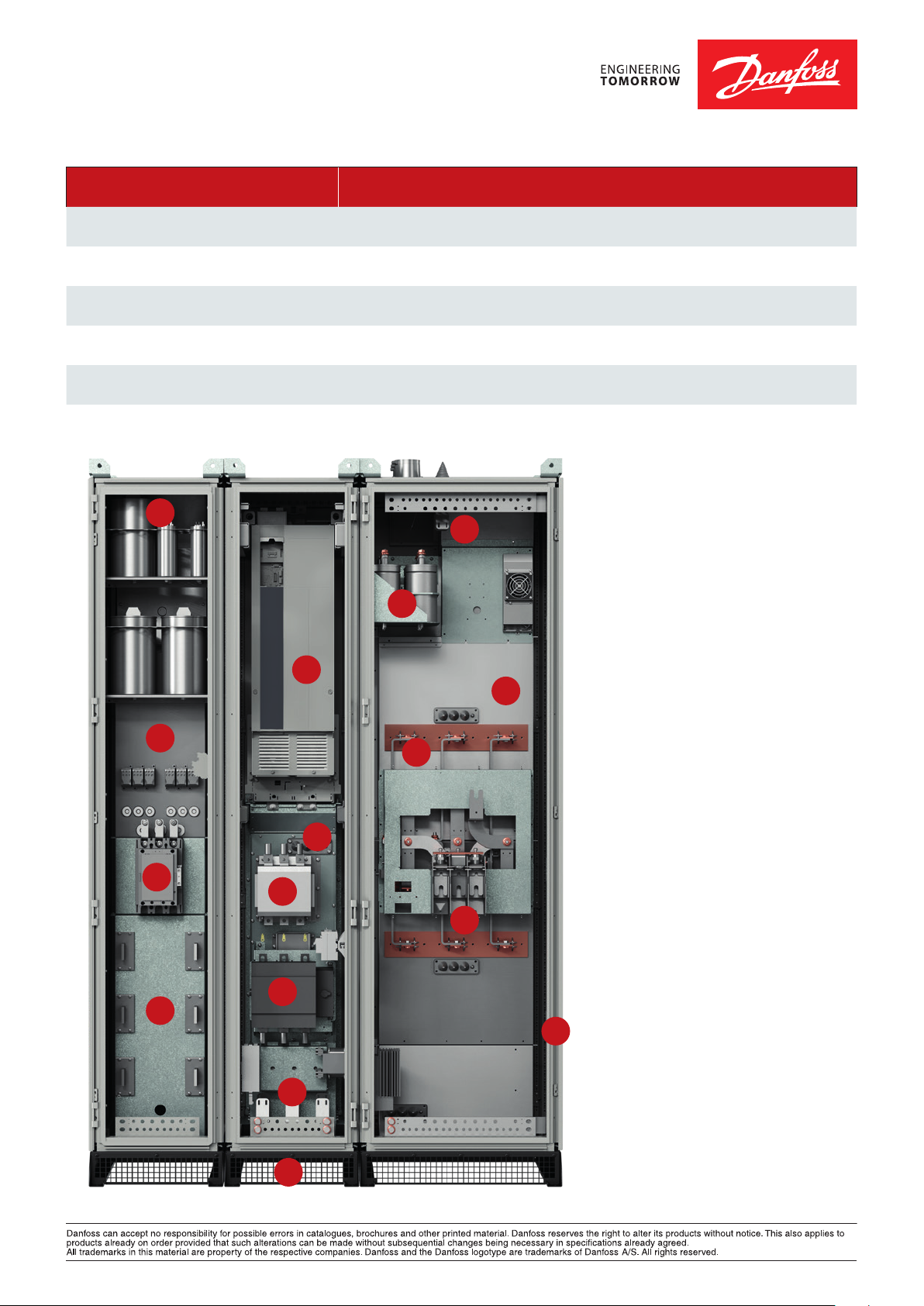

10

9

8

3

4

7

5

6

Eliminate the need for an extra cabinet when options are required. Save cost on equipment and

reduce space requirements.

Reduce the scale of air conditioning required for the room, and even reduce the room size, for savings

in up-front cost and operating expenses.

Know one drive, know them all. Save time and cost for training, service, ordering and spare parts

logistics.

Ensure highest quality of the voltage on motor terminals, as well as the lowest harmonics content of

the mains currents.

1 VLT® drive: Drives with enclosure size

D and E with selectable control options

cards.

11

12

1

13

14

2

15

16

2 Back-channel cooling assembly

ensures utilization of the drive’s backchannel cooling concept in the cabinet.

3 Mains contactor is a selectable mains

power option.

4 Mains switch disconnect is a

selectable mains power option

5 Bottom entry establishment ensures

IP54/NEMA12 connections to the power

supply.

6 Plinth is available as an option in

100 mm, 200 mm, and 400 mm sizes.

7 Magnetics of the input filter

assembly

ensures the low harmonics content of

mains currents - TDD<3%.

8 Contactor to control the harmonics

filter of the drive.

9 Back-channel cooling assembly for

input harmonic filter ensures efficient

cooling of magnetics.

10 Capacitors assembly of the input

harmonics filter.

11 Top-exit establishment ensures

IP54/NEMA12 connections of motor cables

from the top.

12 Capacitors assembly of the output

sine-wave filter.

13 Back-channel cooling assembly for

magnetics of the output sine-wave filter.

14 Sine-wave filter magnetics of the

output filter, as a selectable power option.

15 Motor connection terminals are

placed in the sine-wave filter cabinet of the

enclosed drive.

16 Enclosed drive cabinet utilizes Rittal

TS8 baying system.

DKDD.PFP.416.A1.02 © Copyright Danfoss Drives | 2019.09

Loading...

Loading...