Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® DriveMotor FCP 106/FCM 106

vlt-drives.danfoss.com

Page 2

Page 3

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Product Overview

1.3.1 Intended Use 5

1.3.2 Electrical Overview 6

1.4 Approvals

1.5 Disposal Instruction

2 Safety

2.1 Qualied Personnel

2.2 Safety Precautions

3 Mechanical Installation

3.1 Unpacking

3.1.1 Items Supplied, FCP 106 11

3.1.2 Further Items Required, FCP 106 11

3.1.3 Items Supplied, FCM 106 11

4

4

5

5

7

7

8

8

8

11

11

3.1.4 Identication of Unit 11

3.1.5 Nameplates 11

3.1.6 Lifting 12

3.2 Installation Environment

3.3 Mounting

3.3.1 Introduction 13

3.3.2 Prepare Gasket 13

3.3.3 Prepare Adapter Plate 14

3.3.4 Mount the DriveMotor 15

3.3.5 Shaft Alignment 15

3.3.6 Bearing Life and Lubrication 16

4 Electrical Installation

4.1 Safety Instructions

4.2 IT Mains

4.3 EMC-compliant Installation

4.4 Cable Requirements

4.5 Grounding

12

13

18

18

19

20

22

22

4.6 Motor Connection

4.6.1 Connect FCP 106 to Motor 22

4.6.2 Thermistor Input from Motor 24

4.7 AC Mains Connection

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 1

22

24

Page 4

Contents VLT® DriveMotor FCP 106/FCM 106

4.8 Control Wiring

4.8.1 Control Terminals and Relays 2 25

4.8.2 Control Terminals and Relays 3 25

4.8.3 Load Sharing 26

4.8.4 Brake 26

4.9 Installation Checklist

4.9.1 Recommendations for UL-listed PRGY Systems 28

5 Commissioning

5.1 Applying Power

5.2 Local Control Panel Operation

5.3 Memory Module MCM 101

5.3.1 Conguring with the VLT® Memory Module MCM 101 31

5.4 Basic Programming

5.4.1 Conguration for Open-loop Applications 32

5.4.2 Set-up Wizard for Closed-loop Applications 34

5.4.3 Quick Menu Motor Set-up 35

5.4.4 Changing Parameter Settings 36

25

27

29

29

29

31

31

5.4.5 Thermistor Set-up 36

6 Maintenance, Diagnostics and Troubleshooting

6.1 Maintenance

6.2 List of Warnings and Alarms

7 Specications

7.1 Clearances, Dimensions and Weights

7.1.1 Clearances 40

7.1.2 FCP 106 Dimensions 41

7.1.3 FCM 106 Dimensions 42

7.1.4 Weight 45

7.2 Electrical Data

7.2.1 Mains Supply 3x380–480 V AC Normal and High Overload 46

7.3 Mains Supply

7.4 Protection and Features

7.5 Ambient Conditions

7.6 Cable Specications

37

37

37

40

40

46

48

48

48

49

7.7 Control Input/Output and Control Data

7.8 Connection Tightening Torques

7.9 FCM 106 Motor Specications

7.10 Fuse and Circuit Breaker Specications

8 Appendix

2 Danfoss A/S © 11/2015 All rights reserved. MG03L302

49

51

51

52

54

Page 5

Contents Operating Instructions

8.1 Abbreviations and Conventions

8.2 Parameter Menu Structure

Index

54

54

57

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 3

Page 6

195NA447.10

195NA419.10

Introduction VLT® DriveMotor FCP 106/FCM 106

11

1 Introduction

1.1 Purpose of the Manual

This manual provides information required to install and

commission the frequency converter.

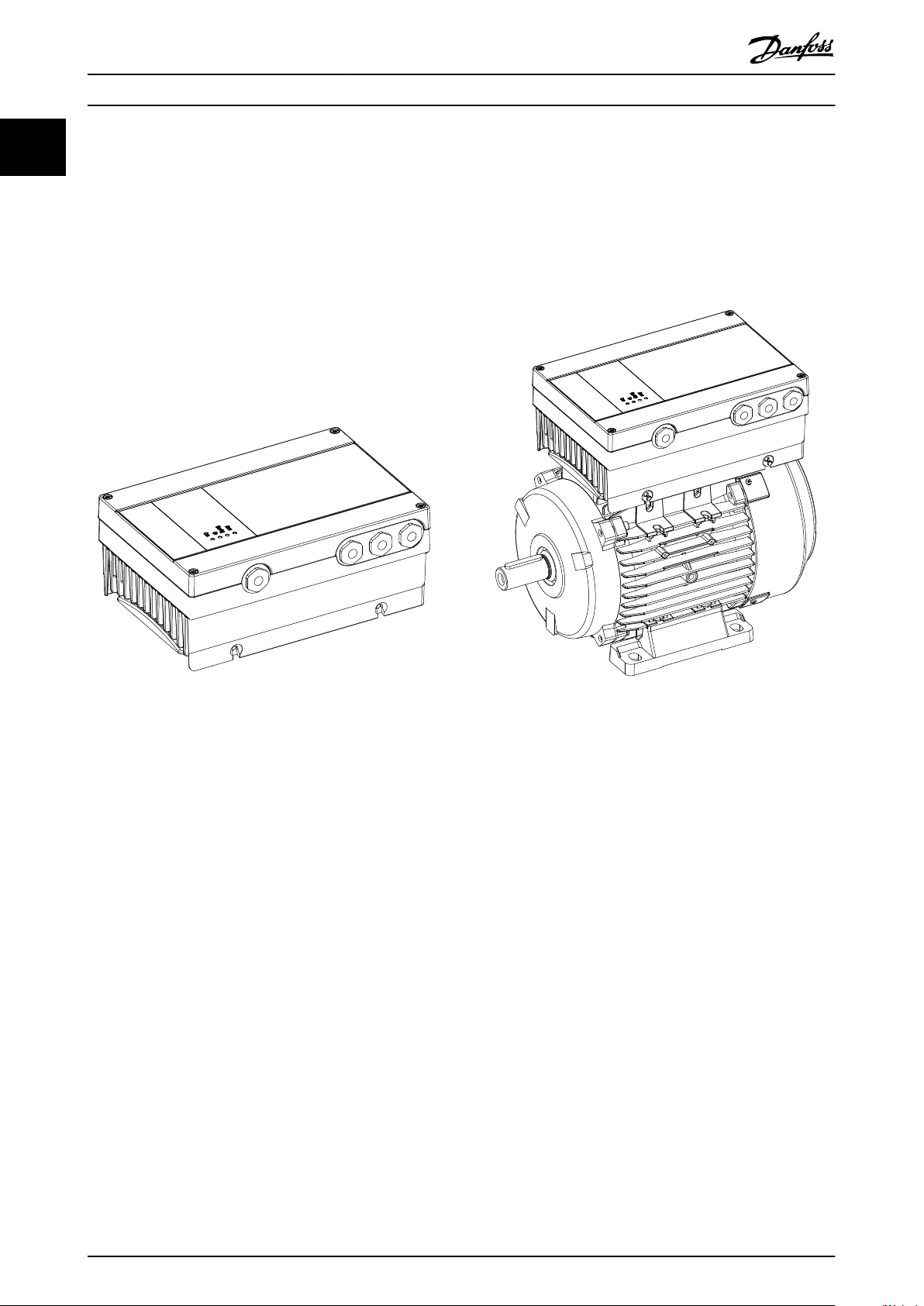

VLT® DriveMotor FCP 106

The delivery comprises the frequency converter only. A

wall mount adapter plate, or motor adapter plate and

power crimp terminals are also required for installation.

Order the wall mount kit or adapter plate and power crimp

terminals separately.

VLT® DriveMotor FCM 106

The frequency converter is mounted onto the motor at

delivery. The combined FCP 106 and motor is known as

the VLT® DriveMotor FCM 106.

Illustration 1.1 FCP 106

Illustration 1.2 FCM 106

4 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 7

Introduction Operating Instructions

1.2 Additional Resources

Available literature:

VLT® DriveMotor FCP 106/FCM 106 Operating

•

Instructions, for information required to install and

commission the frequency converter.

®

DriveMotor FCP 106/FCM 106 Design Guide

VLT

•

provides information required for integration of

the frequency converter into a diversity of

applications.

VLT® DriveMotor FCP 106/FCM 106 Programming

•

Guide, for how to program the unit, including

complete parameter descriptions.

®

LCP Instruction, for operation of the local

VLT

•

control panel (LCP).

VLT® LOP Instruction, for operation of the local

•

operation pad (LOP).

Modbus RTU Operating Instructions and VLT

•

DriveMotor FCP 106/FCM 106 BACnet Operating

Instructions for information required for

controlling, monitoring, and programming of the

frequency converter.

The VLT® PROFIBUS DP MCA 101 Installation Guide

•

provides information about installing the

PROFIBUS and troubleshooting.

The VLT® PROFIBUS DP MCA 101 Programming

•

Guide provides information about conguring the

system, controlling the frequency converter,

accessing the frequency converter, programming,

and troubleshooting. It also contains some typical

application examples.

Technical literature and approvals are available online at

vlt-drives.danfoss.com/Support/Service/.

Danfoss VLT® Energy Box software is available at

www.danfoss.com/BusinessAreas/DrivesSolutions, PC software

download area.

1 1

1.3 Product Overview

1.3.1 Intended Use

The frequency converter is an electronic motor controller

intended for:

Regulation of motor speed in response to system

•

feedback or to remote commands from external

controllers. A power drive system consists of:

- The frequency converter.

- The motor.

- Equipment driven by the motor.

®

The frequency converter can also be used for motor

overload protection. The frequency converter is allowed for

use in residential, industrial, and commercial environments

in accordance with local laws and standards.

Depending on conguration, the frequency converter can

be used in standalone applications or form part of a larger

application or installation.

When using a motor with thermal protection, the

frequency converter is allowed for use in residential,

industrial, and commercial environments in accordance

with local laws and standards.

System and motor status surveillance.

•

VLT® Motion Control Tool MCT 10 enables congu-

•

ration of the frequency converter from a

Windows™-based PC environment.

Danfoss VLT® Energy Box software, for energy

•

calculation in HVAC applications.

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 5

Foreseeable misuse

Do not use the frequency converter in applications which

are non-compliant with

environments. Ensure compliance with the conditions

specied in chapter 7 Specications.

specied operating conditions and

Page 8

195NA507.11

L1

L2

L3

PE

3-phase

power

input

+10 V DC

0–10 V DC 0/4–20 mA

0/4–20 mA

0–10 V DC -

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN/OUT)

42 0/4–20 mA A OUT/DIG OUT

45 0/4–20 mA A OUT/DIG OUT

12 (+24 V OUT)

18 (DIGI IN)

19 (DIGI IN)

20 (COM D IN)

27 (DIGI IN)

29 (DIGI IN)

PROFIBUS

MCM

24 V (NPN)

0 V (PNP)

24 V (NPN)

0 V (PNP)

24 V (NPN)

0 V (PNP)

24 V (NPN)

0 V (PNP)

Bus ter.

RS485

Interface

(N RS485) 69

(P RS485) 68

(Com RS485) 61

RS485

(PNP)-Source

(NPN)-Sink

Bus ter.

1 2

ON

ON=Terminated

OFF=Unterminated

03

02

01

relay 1

240 V AC 3A

06

05

04

relay 2

240 V AC 3A

UDC+

UDC-

PE

Motor

U

V

W

T1

T2

Thermistor

located in

motor

Group 5-*

Located in

motor block

Introduction VLT® DriveMotor FCP 106/FCM 106

11

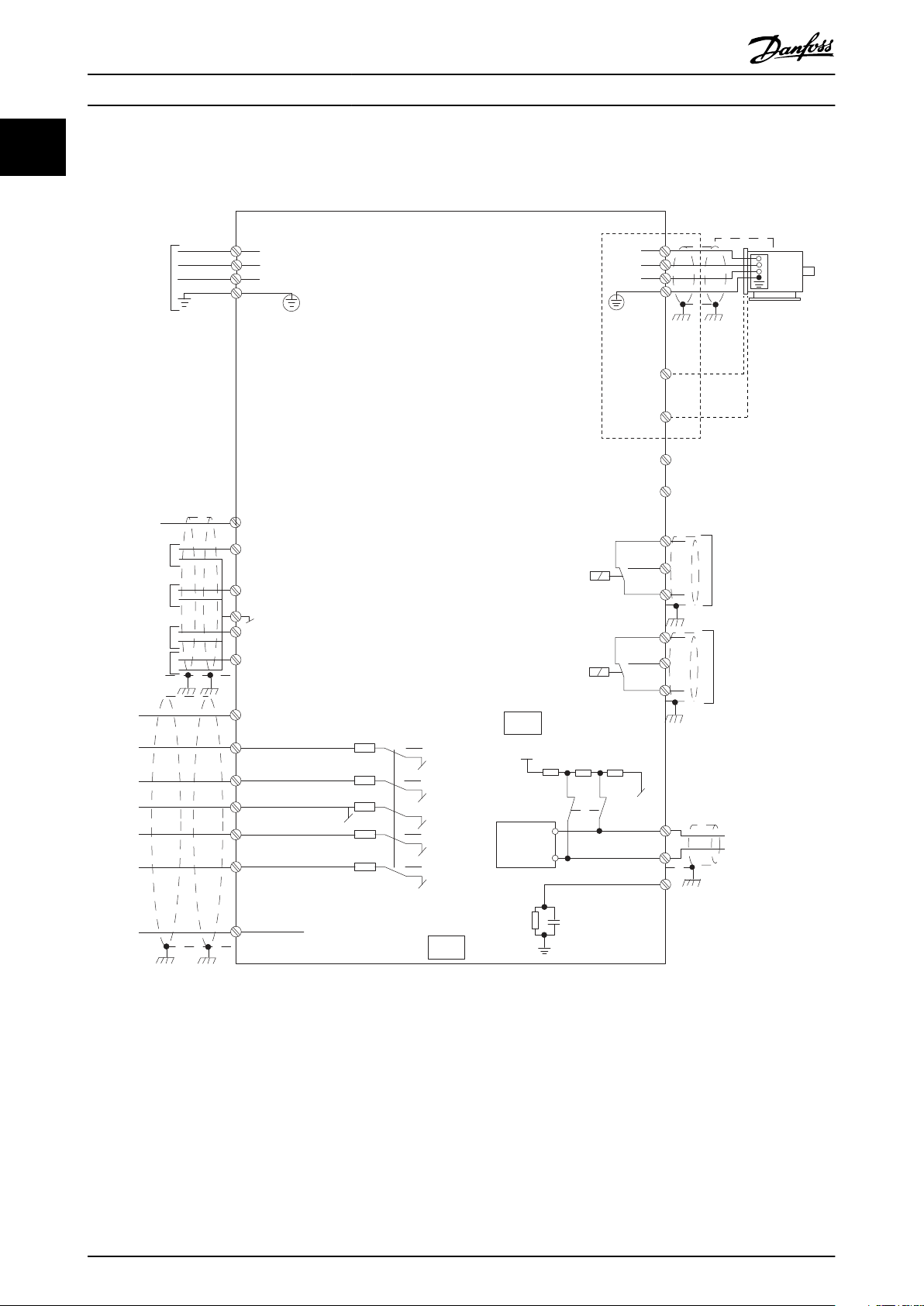

1.3.2 Electrical Overview

Illustration 1.3 Electrical Overview

6 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 9

Introduction Operating Instructions

1.4 Approvals

Certication FCP 106 FCM 106

EC Declaration of

Conformity

UL listed –

UL recognized

C-tick

The EC declaration of conformity is based on the following

directives:

Low Voltage Directive 2006/95/EC, based on EN

•

61800-5-1 (2007).

EMC Directive 2004/108/EC, based on EN 61800-3

•

(2004).

UL listed

Product evaluation is complete and the product can be

installed in a system. The system must also be UL listed by

the appropriate party.

UL recognized

More evaluation is required before the combined

frequency converter and motor can be operated. The

system in which the product is installed must also be UL

listed by the appropriate party.

The frequency converter complies with UL 508C thermal

memory retention requirements. For more information,

refer to the section Motor Thermal Protection in the

product-specic design guide.

✓ ✓

✓

✓ ✓

✓

–

1 1

Disposal Instruction

1.5

Equipment containing electrical components

must not be disposed of together with domestic

waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 7

Page 10

Safety VLT® DriveMotor FCP 106/FCM 106

2 Safety

22

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.1 Qualied Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualied personnel are allowed to install and operate this

equipment.

Qualied personnel are dened as trained sta, who are

authorized to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the qualied personnel must be

familiar with the instructions and safety measures

described in these operating instructions.

Safety Precautions

2.2

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input power. Failure to perform

installation, start-up, and maintenance by qualied

personnel could result in death or serious injury.

Only qualied personnel are permitted to

•

perform installation, start-up, and maintenance.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC supply, or load sharing, the motor can start at any

time. Unintended start during programming, service, or

repair work can result in death, serious injury, or

property damage. The motor can start with an external

switch, a eldbus command, an input reference signal

from the LCP or LOP, via remote operation using a

software tool, or after a cleared fault condition.

To prevent unintended motor start:

Disconnect the frequency converter from mains.

•

Press [O/Reset] on the LCP before

•

programming parameters.

Ensure that the frequency converter, motor, and

•

any driven equipment are fully wired and

assembled when the frequency converter is

connected to AC mains, DC supply, or load

sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. High voltage can be present

even when the warning LED indicator lights are o.

Failure to wait the specied time after power has been

removed before performing service or repair work can

result in death or serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum duration of waiting time is specied

in Table 2.1.

Before performing any service or repair work,

•

use an appropriate voltage measuring device to

make sure that the capacitors are fully

discharged.

8 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 11

Safety Operating Instructions

Voltage

[V]

3x400 0.55–7.5 (0.75–10) 4

Table 2.1 Discharge Time

1) Power ratings relate to normal overload (NO).

Power range

[kW (hp)]

1)

Minimum waiting

time

(minutes)

WARNING

RISK OF DEATH OR SERIOUS INJURY

According to UL 508C, the VLT® DriveMotor FCP 106 and

VLT® DriveMotor FCM 106 do not support the use of

delta grounded grid.

Using the VLT® DriveMotor FCP 106 or VLT® DriveMotor

FCM 106 on a delta grounded grid may cause death or

serious injury.

To avoid the risk:

Do not install VLT® DriveMotor FCP 106 and

•

VLT® DriveMotor FCM 106 on a delta grounded

grid.

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

perform installation, start-up, and maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this guide.

•

WARNING

LEAKAGE CURRENT HAZARD

Follow national and local codes regarding protective

earthing (PE) of equipment with a leakage current

exceeding 3.5 mA. Frequency converter technology

implies high frequency switching at high power. This

switching generates a leakage current in the ground

connection. A fault current in the frequency converter at

the output power terminals can contain a DC

component. The DC component can charge the lter

capacitors and cause a transient ground current. The

ground leakage current depends on various system

congurations including RFI ltering, screened motor

cables, and frequency converter power. EN/IEC 61800-5-1

(Power Drive System Product Standard) requires special

care because the leakage current exceeds 3.5 mA. See EN

60364-5-54 section 543.7 for further information.

Ensure correct grounding of the equipment by a

•

certied electrical installer.

Grounding must be reinforced in one of the

•

following ways:

- Ensure that the ground wire has a

cross-section of at least 10 mm2 (7

AWG).

- Ensure that 2 separate ground wires

are used, both complying with the

dimensioning rules.

NOTICE

HIGH ALTITUDES

For installation at altitudes above 2000 m (6562 ft),

contact Danfoss regarding PELV.

2 2

WARNING

UNINTENDED MOTOR ROTATION

WINDMILLING

Unintended rotation of permanent magnet motors

creates voltage and can charge the unit, resulting in

death, serious injury, or equipment damage.

Ensure that permanent magnet motors are

•

blocked to prevent unintended rotation.

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 9

WARNING

DC CURRENT RISK

This product can cause a DC current in the protective

conductor. Failure to follow the precautions can lead to

personal injury or property damage.

Take the following precautions:

When using a residual current device (RCD) for

•

extra protection, use only an RCD of Type B

(time delayed) on the supply side of this

product.

Protective earthing (PE) of the frequency

•

converter and the use of RCDs must always

follow national and local regulations.

Page 12

Safety VLT® DriveMotor FCP 106/FCM 106

WARNING

GROUNDING HAZARD

22

For operator safety, it is important to ground the

frequency converter properly in accordance with national

and local electrical codes, as well as the instructions in

this manual. Ground currents are higher than 3.5 mA.

Failure to ground the frequency converter properly could

result in death or serious injury.

It is the responsibility of the user, or certied electrical

installer, to ensure correct grounding of the equipment

according to national, and local electrical codes and

standards.

Follow all local and national electrical codes to

•

ground electrical equipment properly.

Establish proper protective grounding for

•

equipment with current higher than 3.5 mA.

A dedicated ground wire is required for input

•

power, motor power, and control wiring.

Use the clamps provided on the equipment for

•

proper ground connections.

Do not ground one frequency converter to

•

another in a daisy chain fashion.

Keep the ground wire connections as short as

•

possible.

Use high-strand wire to reduce electrical noise.

•

Follow the motor manufacturer’s wiring

•

requirements.

10 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 13

1

2 3

456

Enclosure: IP66 , Tamb. 40

C / 104 F

V LT

MADE IN

DENMARK

R

P/N: 134G2844 S/N: 010400G253

4.0kW(400V) / 5.0HP(460V)

IN: 3x380-480V 50/60Hz , 8.3/6.8A

OUT: 3x0-Vin 0-400Hz , 9.0/8.2A

o

*1 3 1U3 9 3 0 0 1 0 1 0 2 G 2 9 0 *

Drive Motor

www.danfoss.com

T/C: FCP106P4K0T4C66H1FSXXAXX

Enclosure rating: See manual

E134261 Ind. Contr. Eq.

o

7

8

9

10

11

195NA484.11

Mechanical Installation Operating Instructions

3 Mechanical Installation

3.1 Unpacking

NOTICE

INSTALLATION - EQUIPMENT DAMAGE RISK

Incorrect installation can result in equipment damage.

Before installation, check for fan cover damage,

•

shaft damage, foot or mounting damage, and

loose fasteners.

Check nameplate details.

•

Ensure level mounting surface, balanced

•

mounting. Avoid misalignment.

Ensure that gaskets, sealants, and guards are

•

correctly tted.

Ensure correct belt tension.

•

3.1.1 Items Supplied, FCP 106

Check that all items are included:

1 FCP 106 frequency converter.

•

1 accessory bag.

•

1 VLT® Memory Module MCM 101.

•

Operating instructions.

•

3.1.3 Items Supplied, FCM 106

Check that all items are included:

1 FCM 106 frequency converter with motor.

•

1 accessory bag.

•

Operating Instructions.

•

3.1.4 Identication of Unit

Items supplied may vary according to product congu-

ration.

Make sure the items supplied and the information

•

on the nameplate correspond to the order conrmation.

Check the packaging and the frequency converter

•

visually for damage caused by inappropriate

handling during shipment. File any claim for

damage with the carrier. Retain damaged parts

for clarication.

3.1.5 Nameplates

3 3

3.1.2 Further Items Required, FCP 106

1 adapter plate (wall mount adapter plate or

•

motor adapter plate).

1 gasket, used between motor adapter plate and

•

frequency converter.

1 motor connector.

•

4 screws for fastening frequency converter to

•

adapter plate.

4 screws for fastening motor adapter plate to

•

motor.

Crimp terminals:

•

- AMP standard power timer contacts

female, see chapter 4.6.1 Connect FCP

106 to Motor for ordering numbers.

- 3 pieces for motor terminals, U, V, and

W.

- 2 pieces for thermistor (optional).

- 1 piece for grounding terminal.

2 guiding pins (optional).

•

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 11

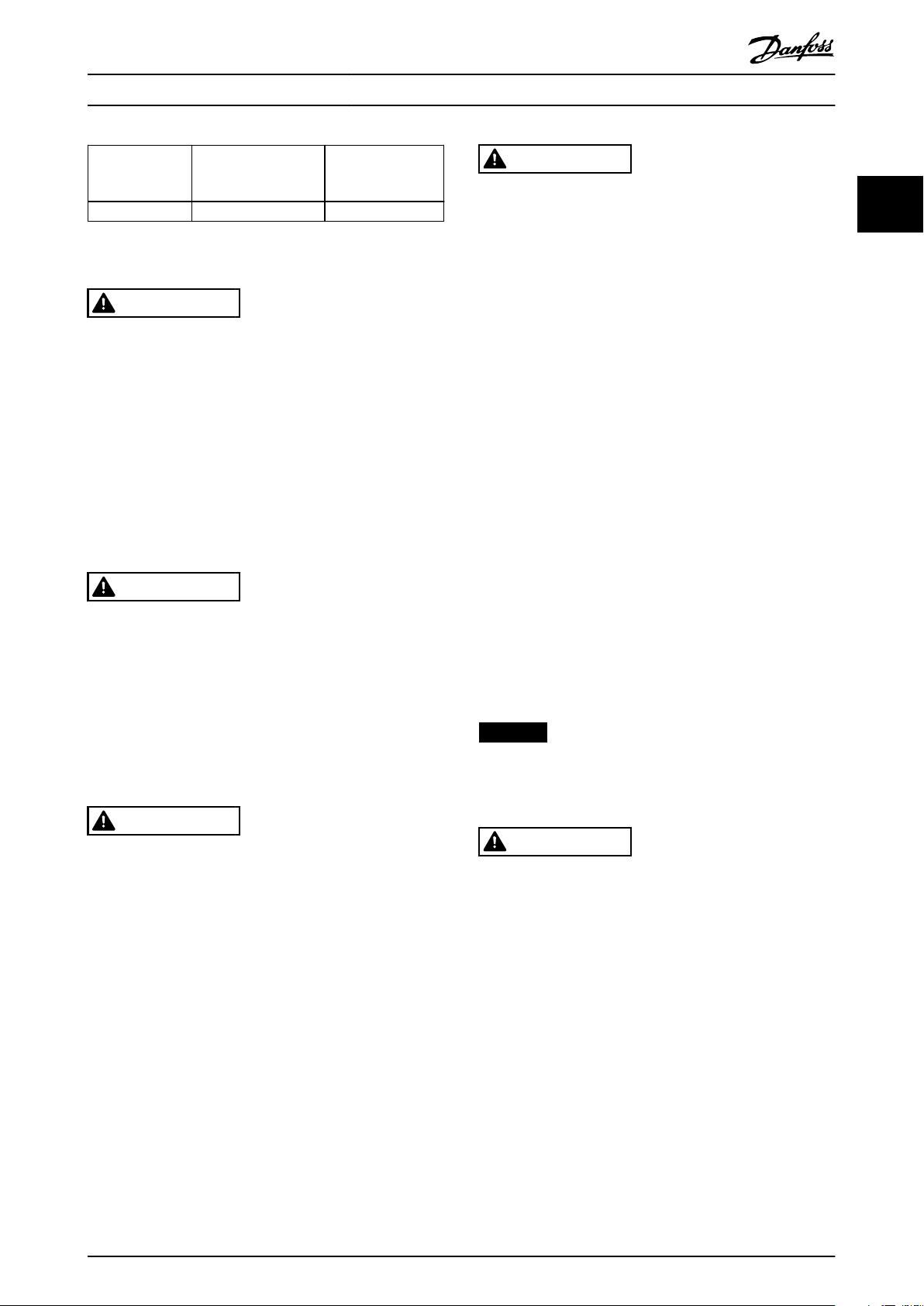

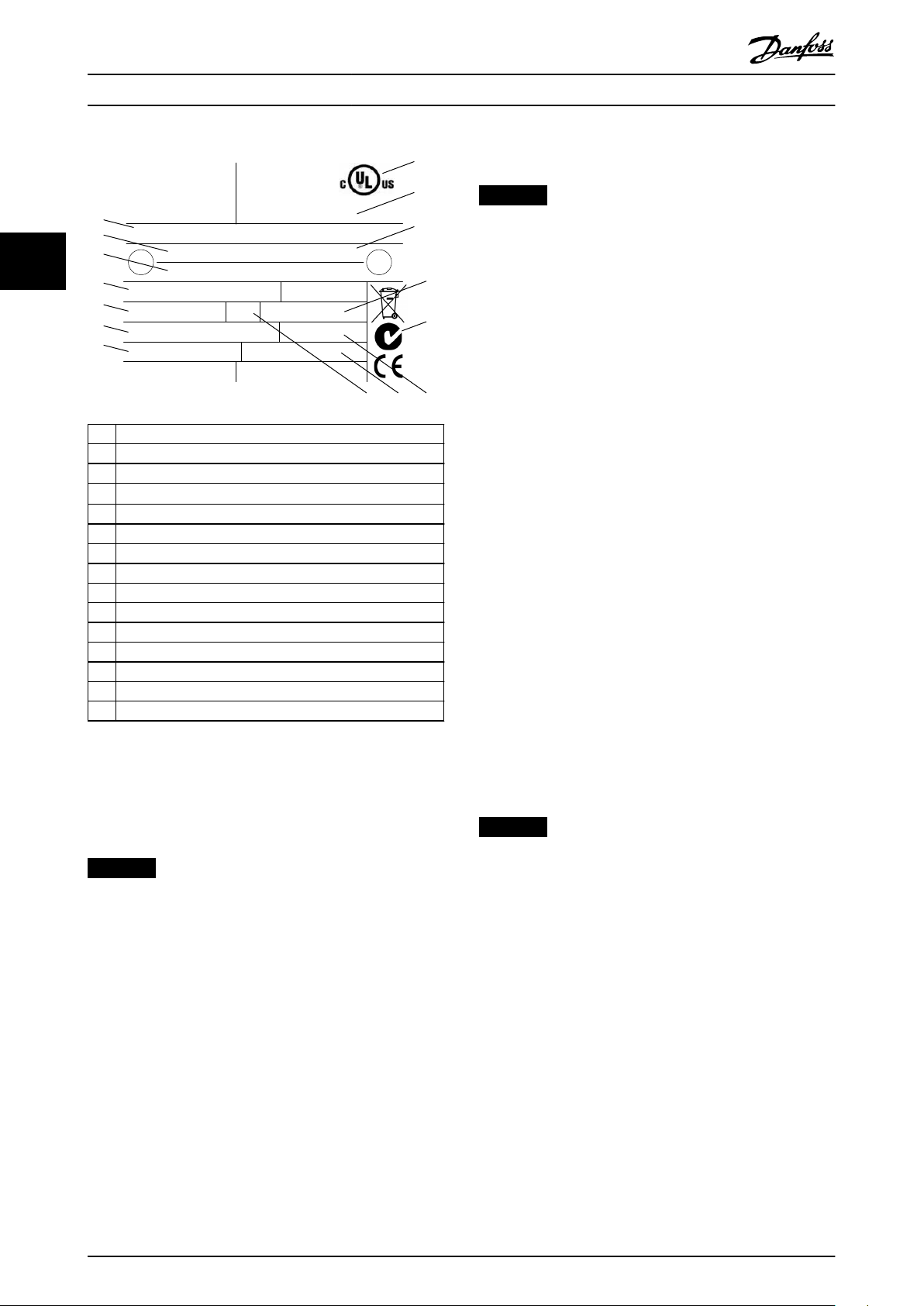

1 Type code

2 Certications

3 Enclosure rating

4 Bar code for manufacturer use

5 Certications

6

Serial number

Enclosure type and IP rating, maximum ambient

7

temperature without derating

Output voltage, frequency, and current (at low/high

8

voltages)

9 Input voltage, frequency, and current (at low/high voltages)

10 Power rating

11 Ordering number

Illustration 3.1 FCP 106 Nameplate (Example)

1) Example of format: Serial number ‘xxxxx253’ indicates

manufacture in week 25, year 2013.

1)

Page 14

195NA483.10

V LT

MOTOR REF: HPS112 1500 159

Drive Motor

www.danfoss.com

T/C: FCM106P7K5T4C55H1FSXXAXXE4N7K5150B03000

Listed E347257

EP Motors for Ind. Use

Enclosure rating Type 12

Tamb. 40

C/104 F

o

o

1

MADE IN DENMARK

P/N: 134L4306 S/N: 000000G000

IN: 3X380-480V, 50-60Hz, 15/13A

Out: 7.5kW(400V) / 10HP(460V)

Cos /PF: 0.98 / 0.96

ϕ

MSV: &OEM4&

DUTY Class S1IP55

0-1500 min /50Hz

-1

Wt 14.5 kg

5

2

3

4

6

789

10

11

12

13

14

15

DBV: &OEM3&

Mechanical Installation VLT® DriveMotor FCP 106/FCM 106

3.1.6 Lifting

NOTICE

LIFTING - EQUIPMENT DAMAGE RISK

Incorrect lifting can result in equipment damage.

Use both lifting lugs when provided.

33

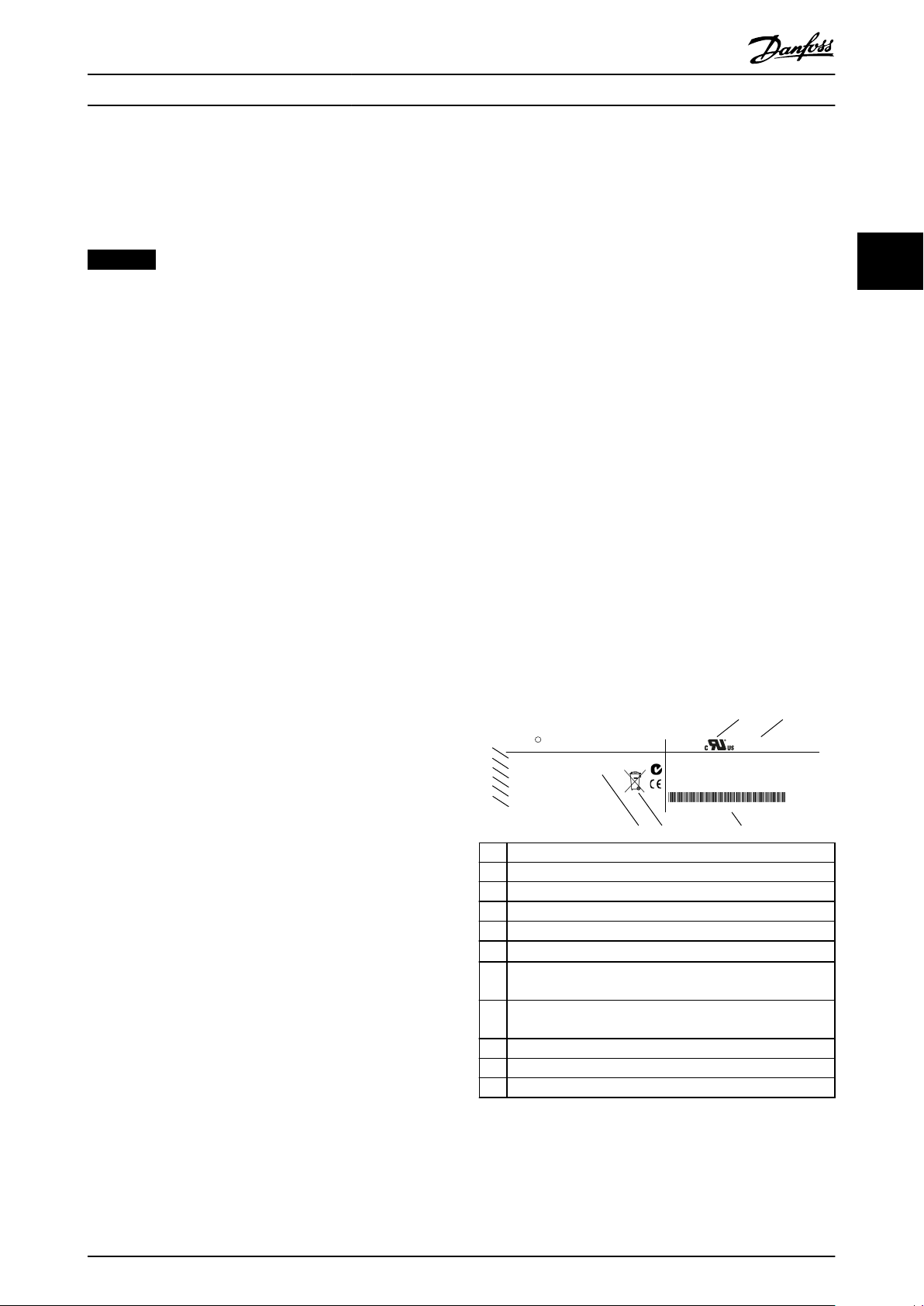

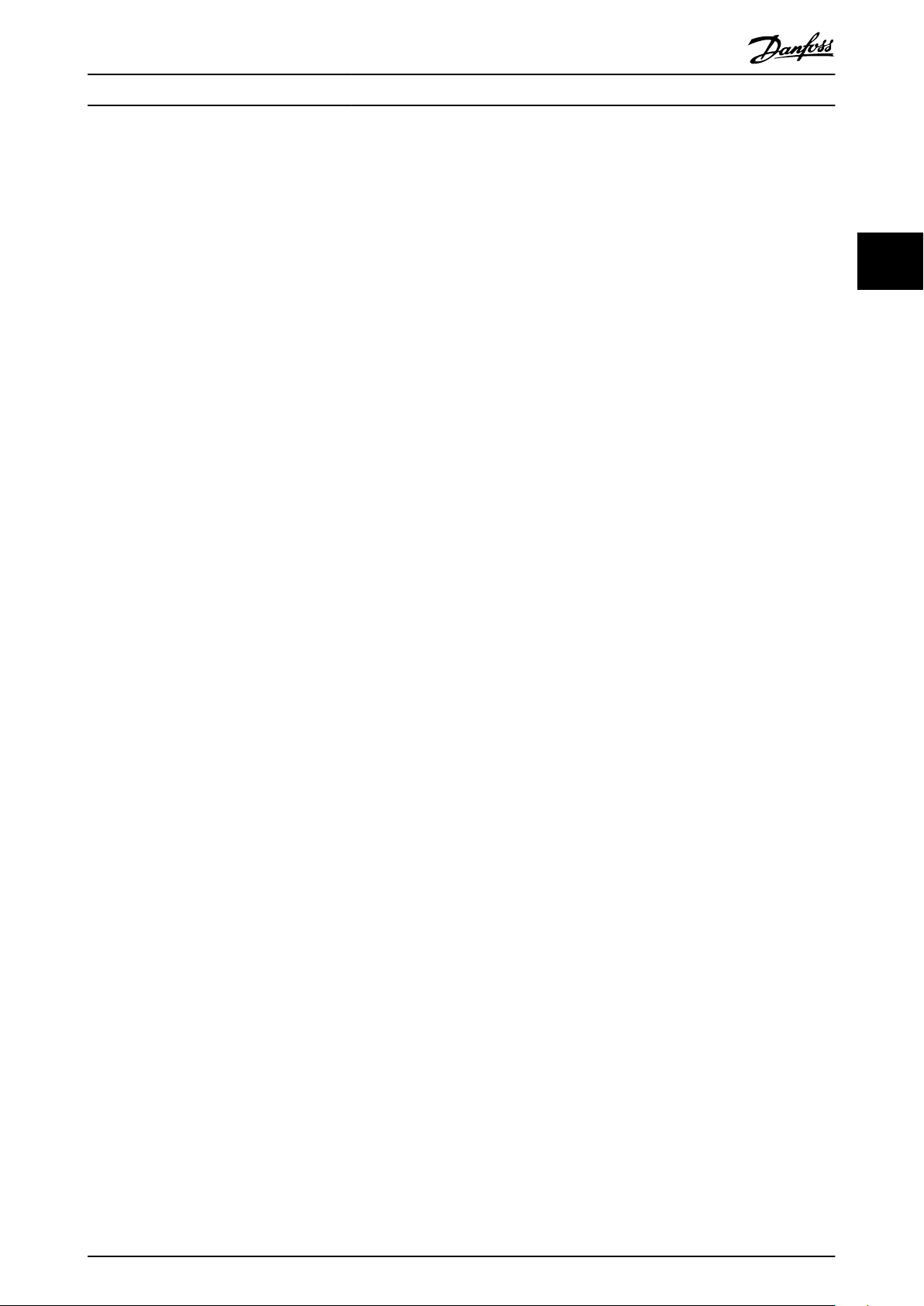

1 Type code

2 Certications

3 Enclosure rating

4

Serial number

5 Motor duty class

6 Certications

7 Weight

8 Motor power factor

9 Enclosure rating - ingress protection (IP) class

10 Frequency range

11 Motor reference

12 Maximum ambient temperature without derating

13 Power rating

14 Input voltage, current, and frequency (at low/high voltages)

15 Ordering number

1)

•

For vertical lift, prevent uncontrolled rotation.

•

For lift machine, do not lift other equipment

•

with motor lifting points only.

Only qualied personnel must undertake handling and

lifting of the unit. Ensure:

Availability of full product documentation,

•

together with tools and equipment necessary for

safe working practice.

Cranes, jacks, slings, and lifting beams are rated

•

to bear the weight of the equipment to be lifted.

For weight of unit, see chapter 7.1.4 Weight.

When using an eyebolt, that the shoulder of the

•

eyebolt is tightened

stator frame, before lifting.

Eyebolts or lifting trunnions supplied with the unit are

rated to bear the weight of the unit only, not the

additional weight of ancillary equipment attached.

3.1.7 Storage

rmly against the face of the

Illustration 3.2 FCM 106 Nameplate (Example)

1) Example of format: Serial number ‘xxxxx253’ indicates

manufacture in week 25, year 2013.

NOTICE

LOSS OF WARRANTY

Do not remove the nameplate from the frequency

converter.

12 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Ensure that the requirements for storage are fullled. Refer

to chapter 7.5 Ambient Conditions for further details.

Installation Environment

3.2

NOTICE

In environments with airborne liquids, particles, or

corrosive gases, ensure that the IP/type rating of the

equipment matches the installation environment. Failure

to meet requirements for ambient conditions can reduce

the lifetime of the frequency converter. Ensure that

requirements for air humidity, temperature, and altitude

are met.

Vibration and shock

The frequency converter complies with requirements for

units mounted on the walls and oors of production

premises, as well as in panels bolted to walls or oors.

For detailed ambient conditions specications, refer to

chapter 7.5 Ambient Conditions.

Page 15

Mechanical Installation Operating Instructions

3.3 Mounting

3.3.1 Introduction

There are several mounting alternatives.

FCM 106

The frequency converter is mounted onto the motor at

delivery. The combined unit is known as the

DriveMotor.Installation procedure:

1. Mount the DriveMotor, see chapter 3.3.4 Mount

the DriveMotor.

2. Perform the electrical installation, starting with

chapter 4.7.1 Connecting to Mains.

Go directly to chapter 3.3.4 Mount the DriveMotor.

FCP 106

Mount the frequency converter onto the adapter plate,

which is:

Fastened to a at surface beside the motor, or

•

Mounted directly onto the motor. When

•

assembled, the combined frequency converter

and motor is known as the DriveMotor.

Installation procedure:

1. Prepare the gasket and adapter plate, see

chapter 3.3.2 Prepare Gasket and

chapter 3.3.3 Prepare Adapter Plate.

2. Connect the frequency converter to the motor.

See chapter 4.6.1 Connect FCP 106 to Motor. The

combined unit is then known as the DriveMotor.

3. Mount the DriveMotor, see chapter 3.3.4 Mount

the DriveMotor.

4. Perform the remaining electrical installation, see

chapter 4.7.1 Connecting to Mains.

3.3.2 Prepare Gasket

Preparation of a gasket applies only when mounting an

FCP 106 onto a motor.

Mounting of FCP 106 onto a motor requires tting a

customised gasket. The gasket ts between the motor

adapter plate and the motor.

No gasket is supplied with the FCP 106.

Therefore, before installation, design and test a gasket to

full the ingress protection requirement (for example IP55,

IP54, or Type 3R).

Requirements for gasket:

Maintain the ground connection between

•

frequency converter and motor. The frequency

converter is grounded to the motor adapter plate.

Use a wire connection between motor and

frequency converter and ensure metallic contact

between the motor adapter plate and motor.

Use a UL recognised material for the gasket,

•

when UL listing or recognition is required for the

assembled product.

3 3

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 13

Page 16

195NA414.10

Mechanical Installation VLT® DriveMotor FCP 106/FCM 106

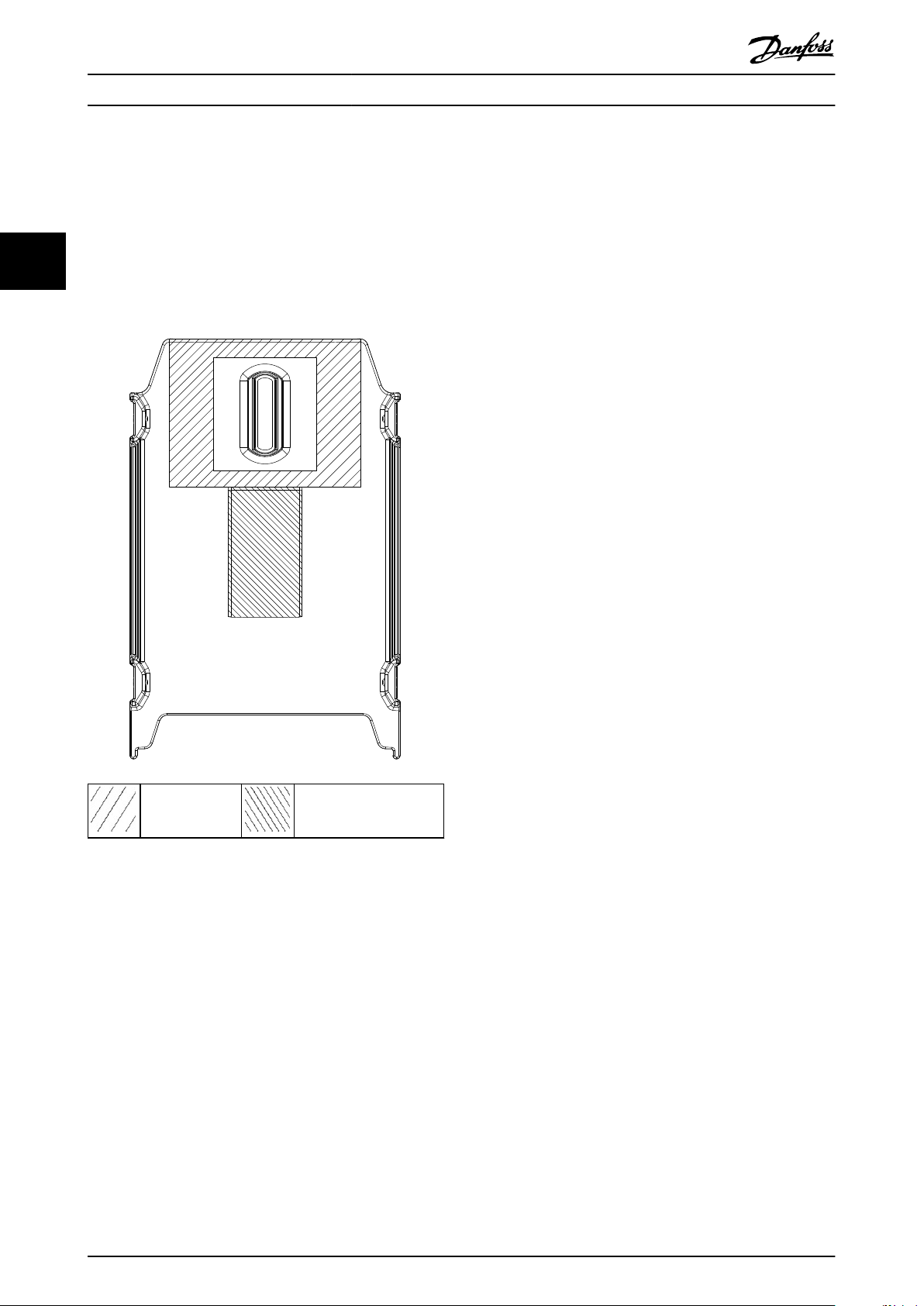

3.3.3 Prepare Adapter Plate

The adapter plate is available with or without pre-drilled

holes.

33

For adapter plate with no pre-drilled holes, refer to

Illustration 3.3.

When the adapter plate has no holes, drill them as follows:

4 holes within area 1, for fastening adapter plate

•

to motor (required).

1 hole within area 2, for a lifting lug (optional).

•

Make allowance for countersunk screws.

•

For adapter plate with pre-drilled holes, no extra holes are

required. Pre-drilled holes are specic for FCM 106 motors

only.

Area 1 Area 2

Illustration 3.3 Adapter Plate, Guide for Drilling Holes

14 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 17

195NA411.12

Mechanical Installation Operating Instructions

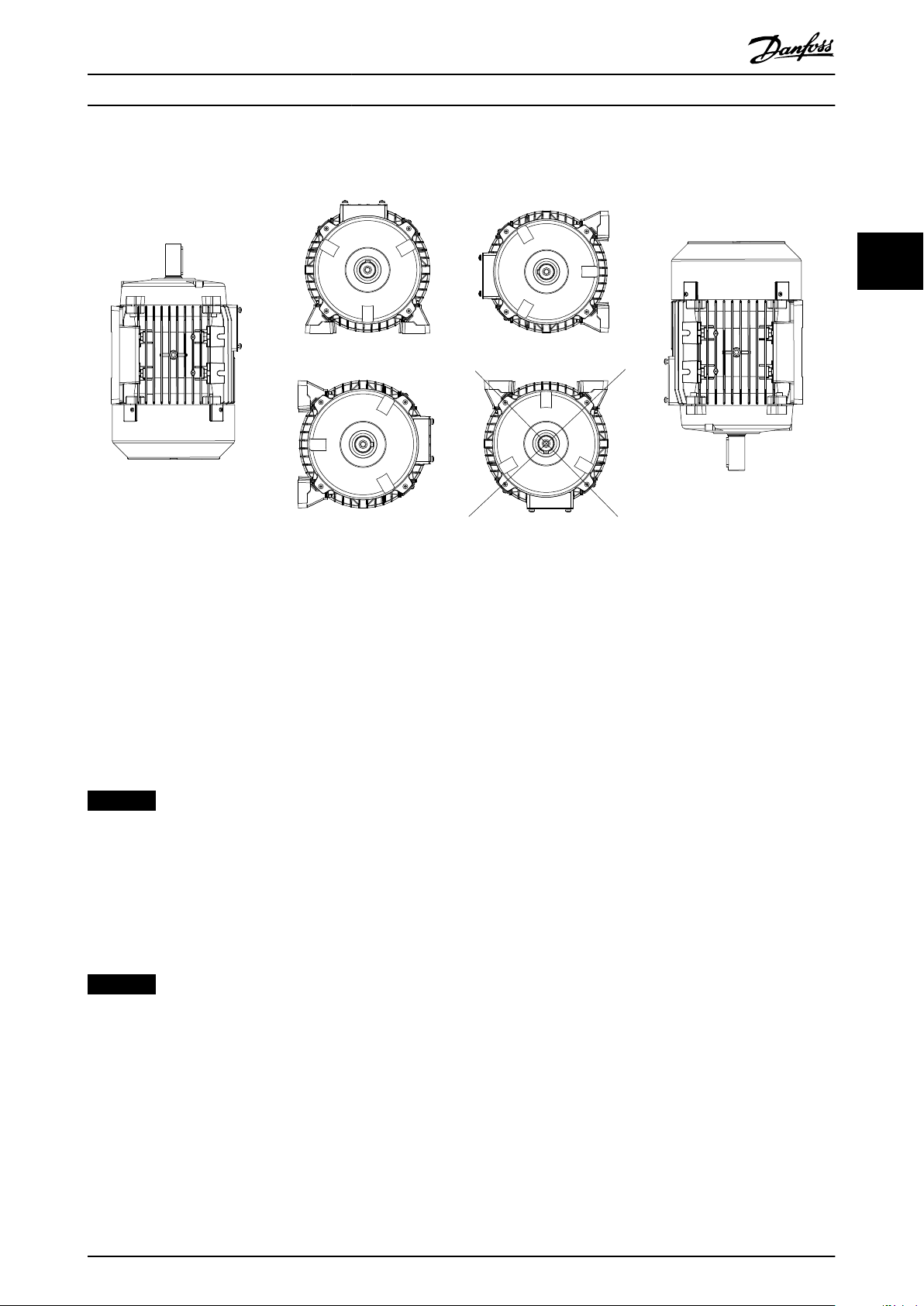

3.3.4 Mount the DriveMotor

3 3

Illustration 3.4 Installation Orientation, IP54/UL Type 3R

Mount the DriveMotor with adequate access for routine

maintenance. Observe the recommended clearances, see

chapter 7 Specications. A minimum of 0.75 m clearance

around the motor is recommended, both for working

access and adequate airow at the motor fan inlet. See

also chapter 7.1 Clearances, Dimensions and Weights.

Where more than 1 DriveMotor are mounted close by,

ensure that there is no recirculation of exhausted warm air.

Foundations must be solid, rigid, and level.

NOTICE

Electrical installation

Do not remove the top foil on the frequency converter,

as this foil is a part of the protective arrangements.

Fitting pinions, pulleys, and couplings

Drill pinions, pulleys, and couplings to standard limits and

t on the shaft with a screwing motion. Ensure correct

guarding of all moving parts.

NOTICE

Tapping of ttings onto the motor shaft, with a hammer

or mallet, causes bearing damage. This damage results in

an increase in bearing noise and a signicant reduction

in bearing life.

3.3.5 Shaft Alignment

When the application requires direct coupling, the shafts

must be correctly aligned in all 3 planes. Incorrect

alignment can be a major source of noise, vibration, and

reduced bearing life.

Make allowance for shaft end

in both axial and vertical planes. Flexible drive couplings

are preferred.

oat and thermal expansion

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 15

Page 18

Mechanical Installation VLT® DriveMotor FCP 106/FCM 106

3.3.6 Bearing Life and Lubrication

The life expectancy of the ball bearings is according to Table 3.1 and Table 3.2, when the following conditions are fullled:

Temperature of 80 °C (176 °F).

•

Radial forces in load point corresponding to half-shaft extension do not exceed the values specied in Table 3.1

•

33

and Table 3.2.

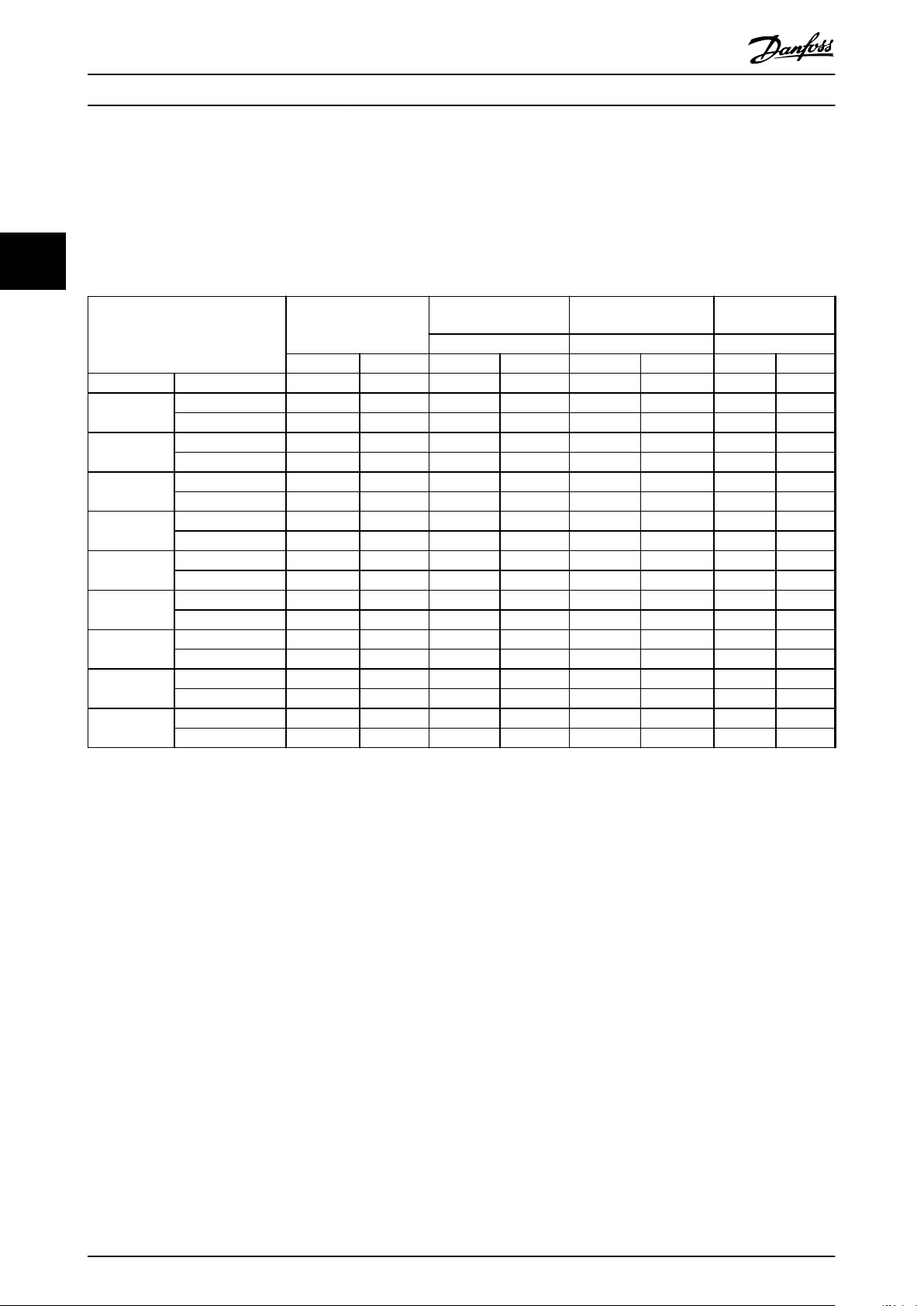

Permissible radial forces Permissible axial forces

IE2 50 Hz 3-phase motors

20000 h 40000 h 20000 h 40000 h 20000 h 40000 h 20000 h 40000 h

Motor size Number of poles F rad [N] F rad [N] F ax [N] F ax [N] F ax [N] F ax [N] F ax [N] F ax [N]

71

80

90

100

112

132 S

132 M

160 M

160 L

2 460 370 230 175 260 205 210 170

4 580 465 330 250 350 275 300 240

2 590 475 320 255 340 280 290 220

4 830 665 440 350 470 380 410 310

2 670 535 340 260 380 315 310 235

4 940 750 480 365 470 385 440 330

2 920 735 480 360 540 460 430 325

4 1290 1030 680 530 740 620 620 465

2 930 745 480 380 560 475 400 300

4 1300 1040 680 540 750 630 600 450

2 1350 1080 800 625 1000 845 610 460

4 1900 1520 1130 880 1320 1095 930 700

2 1400 1120 780 610 990 835 580 435

4 1970 1575 1090 850 1300 1080 890 670

2 1550 1240 840 685 1180 975 500 395

4 2170 1735 1180 950 1520 1245 830 640

2 1580 1265 820 675 1180 980 460 365

4 2220 1775 1150 925 1510 1245 790 610

(IMB3)

Both directions Force upwards Force downwards

Permissible axial forces

(IMV1)

Permissible axial

forces (IMV1)

Table 3.1 Permissible Forces, IE2 50 Hz 3-phase Motors

Permissible radial forces: Load point corresponding to half-shaft extension, 0 axial force assumed.

Permissible axial forces: 0 radial force assumed.

Permissible loads of simultaneous radial and axial forces can be supplied on request.

16 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 19

Mechanical Installation Operating Instructions

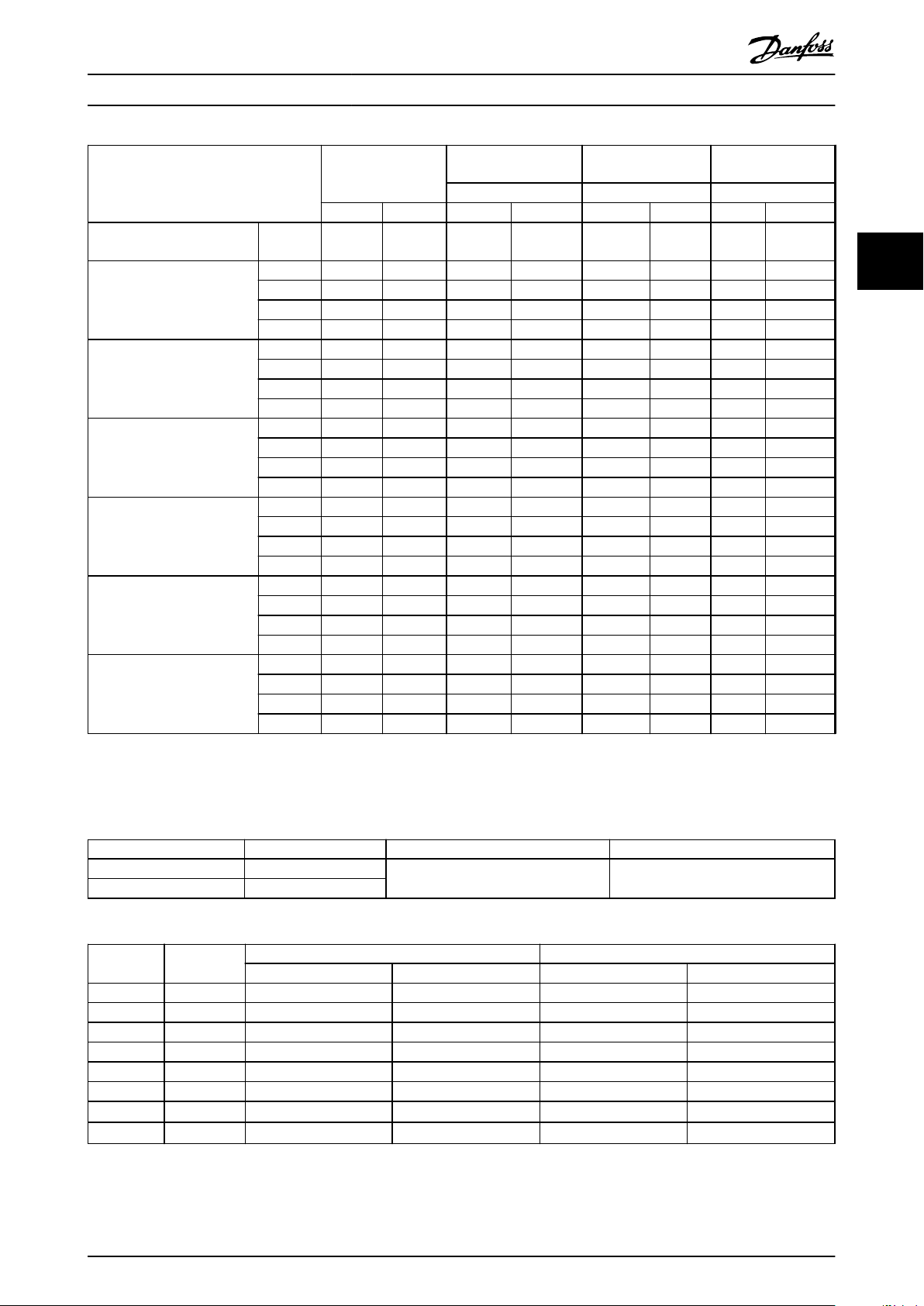

HPS motors

Motor size

71

90

112

132 M

132 XL

132 XXL

Permissible radial

forces

20000 h 40000 h 20000 h 40000 h 20000 h 40000 h 20000 h 40000 h

Speed

[RPM]

1500 580 465 330 250 350 275 300 240

1800 520 420 295 225 315 250 270 215

3000 460 370 230 175 260 205 210 170

3600 415 335 205 155 235 185 190 150

1500 940 750 480 365 470 385 440 330

1800 845 675 430 330 420 345 395 300

3000 670 535 340 260 380 315 310 235

3600 600 480 305 235 340 285 280 210

1500 1300 1040 680 540 750 630 600 450

1800 1170 935 610 485 675 565 540 405

3000 930 745 480 380 560 475 400 300

3600 835 670 430 340 505 430 360 270

1500 – – – – – – – –

1800 1710 1370 1015 790 1190 985 835 630

3000 1350 1080 800 625 1000 845 610 460

3600 1215 970 720 565 900 760 550 415

1500 1970 1575 1090 850 1300 1080 890 670

1800 – – – – – – – –

3000 1400 1120 780 610 990 835 580 435

3600 1260 1010 700 550 890 750 520 390

1500 1970 1575 1090 850 1300 1080 890 670

1800 1770 1415 980 765 1170 970 800 600

3000 1400 1120 780 610 990 835 580 435

3600 1260 1010 700 550 890 750 520 390

F rad [N] F rad [N] F ax [N] F ax [N] F ax [N] F ax [N] F ax [N] F ax [N]

Permissible axial forces

(IMB3)

Both directions Force upwards Force downwards

Permissible axial

forces (IMV1)

Permissible axial

forces (IMV1)

3 3

Table 3.2 Permissible Forces, HPS Motors

Permissible radial forces: Load point corresponding to half-shaft extension, 0 axial force assumed.

Permissible axial forces: 0 radial force assumed.

Permissible loads of simultaneous radial and axial forces can be supplied on request.

Motor type Motor frame size Lubrication type Temperature range

Asynchronous 80–180

PM 71–160

Table 3.3 Lubrication

Motor frame

size

71 1500/3000 – – 6205 2ZC3 6303 2ZC3

80 1500/3000 6204 2ZC3 6204 2ZC3 – –

90 1500/3000 6205 2ZC3 6205 2ZC3 6206 2ZC3 6205 2ZC3

100 1500/3000 6206 2ZC3 6206 2ZC3 – –

112 1500/3000 6306 2ZC3 6306 2ZC3 6208 2ZC3 6306 2ZC3

132 1500/3000 6208 2ZC3 6208 2ZC3 6309 2ZC3 6208 2ZC3

160 1500/3000

180 1500/3000

Table 3.4 Standard Bearing References and Oil Seals for Motors

1) Data available at future release.

Speed

[RPM]

Bearing type, asynchronous motors Bearing type, PM motors

Drive end Non-drive end Drive end Non-drive end

1) 1)

1) 1)

Lithium basis

-40 to +140 °C (-40 to +280 °F)

– –

– –

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 17

Page 20

195NA516.10

1

Electrical Installation VLT® DriveMotor FCP 106/FCM 106

4 Electrical Installation

4.1 Safety Instructions

See chapter 2 Safety for general safety instructions.

44

WARNING

INDUCED VOLTAGE

Induced voltage from output motor cables that run

together can charge equipment capacitors, even with the

equipment turned o and locked out. Failure to run

output motor cables separately or use screened cables

could result in death or serious injury.

Run output motor cables separately, or

•

Use screened cables.

•

CAUTION

1 PCB area

SHOCK HAZARD

The frequency converter can cause a DC current in the

PE conductor. Failure to follow the recommendation

means that the RCD may not provide the intended

protection.

When a residual current-operated protective

•

device (RCD) is used for protection against

electrical shock, only an RCD of Type B is

permitted on the supply side.

CAUTION

EQUIPMENT HAZARD

The PCB area is sensitive to electrostatic discharge.

Touching the PCB area can cause equipment damage.

Do not touch the PCB area.

•

Illustration 4.1 Avoid Touching the PCB Area

Overcurrent protection

Extra protective equipment, such as short-circuit

•

protection or motor thermal protection between

frequency converter and motor, is required for

applications with multiple motors.

Input fusing is required to provide short-circuit

•

and overcurrent protection. If not factorysupplied, the installer must provide fuses. See

maximum fuse ratings in Table 7.15, Table 7.16,

and Table 7.17.

Wire type and ratings

NOTICE

Insulation requirements, MH1

For control card and relay card wires, the minimum

required insulation is 300 V and 75 °C (167 °F).

All wiring must comply with local and national

•

regulations regarding cross-section and ambient

temperature requirements.

Power connection wire recommendation:

•

Minimum 75 °C (167 °F) rated copper wire.

See chapter 7 Specications and chapter 7.6 Cable Speci-

cations for recommended wire sizes and types.

18 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 21

195NA403.11

1

Electrical Installation Operating Instructions

4.2 IT Mains

CAUTION

IT MAINS

Installation on isolated mains source, that is, IT mains.

Maximum supply voltage allowed when connected to

mains: 440 V (3x380–480 V units).

For IT mains operation only:

Disconnect power and wait until discharged. See

•

discharge time in Table 2.1.

Remove cover, see Illustration 4.7.

•

Disable the RFI lter by removing the RFI switch/

•

screw. For location, see Illustration 4.2.

In this mode, the internal RFI lter capacitors between

housing and the mains RFI lter circuit are disabled, to

reduce the ground capacity currents.

4 4

1 RFI switch/screw

Illustration 4.2 Location of RFI Switch/Screw

CAUTION

To reinsert, use an M3.5x20 screw only.

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 19

Page 22

195NA420.10

L1

L2

L3

PE

7

1

2

3

4

56

Electrical Installation VLT® DriveMotor FCP 106/FCM 106

4.3 EMC-compliant Installation

4.3.1 EMC-compliant Electrical Installation

44

1 PLC 5 Control cables

2 Motor 6 Mains, 3-phase, and reinforced PE

3 Frequency converter 7 Cable insulation (stripped)

4 Minimum 200 mm (7.87 in) clearance between control cable, mains cable, and mains motor cable.

Illustration 4.3 EMC-compliant Electrical Installation, FCP 106

20 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 23

195NA407.10

L1

L2

L3

PE

1

6

2

5 4

3

Electrical Installation Operating Instructions

4 4

1 PLC 4 Control cables

2 DriveMotor 5 Mains, 3-phase, and reinforced PE

3 Minimum 200 mm (7.87 in) clearance between control

cable and mains cable.

6 Cable insulation (stripped)

Illustration 4.4 EMC-compliant Electrical Installation, FCM 106

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 21

Page 24

Electrical Installation VLT® DriveMotor FCP 106/FCM 106

To ensure EMC-compliant electrical installation, observe

these general points:

Use only screened motor cables and screened

•

control cables.

Connect the screen to ground at both ends.

•

Avoid installation with twisted screen ends

•

(pigtails), since this type of installation ruins the

44

screen eect at high frequencies. Use the cable

clamps provided instead.

Ensure the same potential between frequency

•

converter and ground potential of the PLC.

Use star washers and galvanically conductive

•

installation plates.

4.4 Cable Requirements

All cabling must comply with national and local regulations

on cable cross-sections and ambient temperature. Copper

or aluminium conductors are required (75 °C (167 °F)

(recommended). For cable specications, refer to

chapter 7.6 Cable Specications.

Grounding

4.5

When connecting the FCP 106 to a third-party motor,

ensure protective bonding:

Ensure metal contact between the frequency

•

converter and the motor, see Illustration 4.5.

Mount an extra ground wire on the adapter plate.

•

Mount an extra ground wire on the motor.

•

Motor Connection

4.6

Step Description

1 Mount motor phases and thermistor wires in crimp

terminals.

Crimp ordering numbers (AMP standard power timer

contacts)1):

134B0495 (0.2–0.5 mm2) [AWG 24–20].

•

134B0496 (0.5–1 mm2) [AWG 20–17].

•

134B0497 (1–2.5 mm2) [AWG 17–13.5].

•

134B0498 (2.5–4 mm2) [AWG 13–11].

•

134B0499 (4–6 mm2) [AWG 12-10].

•

2 Mount PE clamp to motor connector and connect crimp

PE terminal to wire.

3 Mount the gasket between the motor and adapter plate.

See chapter 3.3.2 Prepare Gasket.

4 Pull motor phases and thermistor wires through the neck

of the adapter plate.

5 Mount the adapter plate onto the motor using 4 screws.

Insert guide pins into 2 of the screw holes, before

•

lowering the adapter plate into position. Remove the

guide pins when mounting screws.

Ensure that metallic contact is established between

•

the adapter plate and the motor, via the screws.

6 Mount motor connector gaskets onto the neck of the

adapter plate.

7 Click the terminals into the motor connector.

Mount the 3 motor phases.

•

Mount the 2 thermistor wires.

•

Mount PE connector.

•

For correct installation, refer to terminal numbers

•

printed on the motor connector.

NOTICE

4.6.1 Connect FCP 106 to Motor

NOTICE

To avoid damage to equipment, before mounting the

FCP 106 on the motor:

Observe cooling clearances specied in

•

Table 7.1.

Observe screw clearances listed in Table 7.2.

•

NOTICE

RISK OF DAMAGE

Screws extending too far into the enclosure or too far

above the adapter plate pose a risk of damage to motor

or frequency converter.

The thermistor is not galvanically isolated.

Interchanging the thermistor wires with the motor

wires may permanently damage the frequency

converter.

8 Click motor connector into the neck of the adapter plate.

9 Position the FCP 106 on adapter plate.

10 Fasten the FCP 106 to adapter plate using 4 screws.

Table 4.1 Installation Steps as Shown in Illustration 4.5

1) Contacts from other manufacturers, and contacts made with equal

or better electrical conductivity and plating, are also suitable if they

full the mechanical and electrical requirements.

The FCP 106 is now mounted onto the motor. The

combined unit is known as the DriveMotor.

To connect the FCP 106 to the motor, follow the installation steps shown in Table 4.1 and Illustration 4.5.

22 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 25

195NA415.11

6

9

1

10

8

5

4

3

T1

M

M

T2

U

V

W

PE

2

7

Electrical Installation Operating Instructions

4 4

1 U, V, W (motor phases) 6 Adapter plate

2 MT1, MT2 (motor thermistor wires) 7 Motor connector gasket

3 PE 8 Motor connector

4 Gasket between motor and motor bracket 9 Frequency converter

5 Motor cables 10 Fastening screw

Illustration 4.5 Connecting FCP 106 to Motor

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 23

Page 26

1

2

3

4

195NA413.10

195NA408.11

Electrical Installation VLT® DriveMotor FCP 106/FCM 106

4.6.2 Thermistor Input from Motor

Connect the motor thermistor to the terminals located in

the motor connector, as shown in chapter 4.6.1 Connect FCP

106 to Motor.

Set parameter 1-90 Motor Thermal Protection according to

guidelines in chapter 5.4.5 Thermistor Set-up. For more

®

44

detailed information, refer to the VLT

and FCM 106 Programming Guide.

DriveMotor FCP 106

NOTICE

The thermistor is not galvanically isolated. Interchanging

the thermistor wires with the motor wires may

permanently damage the frequency converter.

4.7 AC Mains Connection

4.7.1 Connecting to Mains

The frequency converter is designed to operate all

standard 3-phased asynchronous motors and PM motors.

For maximum cross-section on wires, see

chapter 7.2.1 Mains Supply 3x380–480 V AC Normal and High

Overload.

FCP 106 wall mount

To comply with EMC emissions requirements:

•

- Use screened motor cable, maximum

length 0.5 m (1.64 ft).

- Connect this cable to the metal housing

of both the frequency converter and the

motor.

See also chapter 4.3 EMC-compliant Installation.

•

Procedure for connection of mains power

1. Observe safety precautions, see chapter 2.2 Safety

Precautions.

2. Loosen front cover screws.

3. Remove the front cover, see Illustration 4.7.

4. Mount cable glands fullling the requirements for

the needed enclosure integrity.

5. Connect the ground wires to the ground

terminals via the cable glands, see Illustration 4.8.

6. Connect the mains cable to terminals L1, L2, and

L3, and tighten the screws. See Illustration 4.8.

7. Reassemble cover and tighten screws.

8. For tightening torques, see chapter 7.8 Connection

Tightening Torques.

1 LCP extension cable entry

2, 3 Entries for other cables: Control, RS485, and relay

cables

4 Mains cable entry

Illustration 4.6 Location of Cable Entries, MH1–MH3

Illustration 4.7 Remove Front Cover

24 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 27

195NA405.12

5 6

1

2

3

4

195NA458.12

5

7

1

2

4

3

6

Electrical Installation Operating Instructions

1 Control terminals

2 Relays

3 Mains (L3, L2, L1)

4 PE

5 RS485

6 Spring clamp for PROFIBUS cable

Control Wiring

4.8

4.8.1 Control Terminals and Relays 2

Procedure:

1. Connect the terminal and cables at the locations

shown in Illustration 4.9 and Illustration 4.10.

2. For more terminal details, refer to

chapter 4.8.2 Control Terminals and Relays 3.

3. Mount the front cover and tighten the screws.

4. The frequency converter is now ready. For startup, go to chapter 5.1.2 Start-up.

4.8.2 Control Terminals and Relays 3

4 4

Illustration 4.8 Cabling, MH1–MH3

1 Control terminals

2 Relay terminals

3 UDC+, UDC-, Line (L3, L2, L1)

4 PE

5 LCP connector

6

7

Illustration 4.9 Location of Terminals and Relays, MH1

VLT® PROFIBUS DP MCA 101

VLT® Memory Module MCM 101

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 25

Page 28

195NA409.12

1

2

3

4

8

5

6

7

130BB625.11

12 20 55

202729 42 45 55

50 53 54

GND

GND

DIGI IN/OUT

DIGI IN/OUT

61 68 69

N

P

COMM. GND

+24 V

DIGI IN

DIGI IN

10 V/20 mA IN

10 V/20 mA IN

0/4-20m A A OUT/DIG OUT

0/4-20 mA A OUT/DIG OUT

10 V OUT

BUS TER.

OFF ON

Electrical Installation VLT® DriveMotor FCP 106/FCM 106

Terminal

number

12 +24 V output – –

18 Digital input *PNP/NPN Start

19 Digital input *PNP/NPN No operation

20 Com – –

27 Digital input/

29 Digital input/

44

50 +10 V output – –

53 Analog input *0–10 V/0–20 mA/

54 Analog input *0–10 V/0–20 mA/

1 Control terminals

2 Relay terminals

3 UDC+, UDC-, Line (L3, L2, L1)

4 PE

5 LCP connector

6

7

8 Spring clamp for PROFIBUS cable

VLT® PROFIBUS DP MCA 101

VLT® Memory Module MCM 101

55 Com – –

42 10 bit *0–20 mA/4–20 mA/DO Analog

45 10 bit *0–20 mA/4–20 mA/DO Analog

1, 2, 3 Relay 1 1, 2 NO 1, 3 NC [9] Alarm

4, 5, 6 Relay 2 4, 5 NO 4, 6 NC [5] Drive

Table 4.2 Control Terminal Functions

* Indicates default setting.

Function Conguration Factory

setting

*PNP/NPN Coast inverse

output

*PNP/NPN Jog

output/pulse

input

Ref1

4–20 mA

Ref2

4–20 mA

running

Illustration 4.10 Location of Terminals and Relays, MH2–MH3

Control terminals

Illustration 4.11 Control Terminals

NOTICE

PNP/NPN is common for terminals 18, 19, 27, and 29.

4.8.3 Load Sharing

Load sharing is not allowed.

4.8.4 Brake

The frequency converter has no internal brake. An external

brake can be connected between the UDC+ and UDCterminals. Limit the voltage between these terminals to

maximum 768 V.

NOTICE

Increasing voltage beyond the limit decreases life, and

may permanently damage the frequency converter.

26 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 29

Electrical Installation Operating Instructions

4.9 Installation Checklist

Before completing installation of the unit, inspect the entire installation as detailed in Table 4.3. Check and mark the items

when completed.

Inspect for Description

Auxiliary equipment•Look for auxiliary equipment, switches, disconnects, or input fuses/circuit breakers, residing on the input

power side of the frequency converter, or output side to the motor. Ensure that they are ready for full-

speed operation.

Check the function and installation of any sensors used for feedback to the frequency converter.

•

Remove any power factor correction caps on the motor.

•

Adjust any power factor correction caps on the mains side and ensure that they are dampened.

•

Cable routing

Control wiring

Cooling clearance

Ambient conditions•Check that requirements for ambient conditions are met.

Fusing and circuit

breakers

Grounding

Input and output

power wiring

Panel interior

Switches

Vibration

Ensure that the motor wiring and control wiring are separated, screened, or in 3 separate metallic conduits

•

for high frequency interference isolation.

Check for broken or damaged wires and loose connections.

•

Check that the control wiring is isolated from power and motor wiring for noise immunity.

•

Check the voltage source of the signals, if necessary.

•

The use of screened cable or twisted pair is recommended. Ensure that the screen is terminated correctly.

Ensure that the top and bottom clearance is adequate to ensure proper air ow for cooling, see

•

chapter 7.1 Clearances, Dimensions and Weights.

Check for proper fusing or circuit breakers.

•

Check that all fuses are inserted rmly and are in operational condition, and that all circuit breakers are in

•

the open position.

Check for sucient ground connections and ensure that those connections are tight and free of oxidation.

•

Grounding to conduit, or mounting the back panel to a metal surface, is not a suitable grounding.

•

Check for loose connections.

•

Check that the motor and mains cables are in separate conduit or separated screened cables.

•

Inspect that the unit interior is free of dirt, metal chips, moisture, and corrosion.

•

Check that the unit is mounted on an unpainted, metal surface.

•

Ensure that all switch and disconnect settings are in the proper positions.

•

Check that the unit is mounted solidly, or that shock mounts are used, as necessary.

•

Check for an unusual amount of vibration.

•

☑

4 4

Table 4.3 Installation Check List

CAUTION

POTENTIAL HAZARD IN THE EVENT OF INTERNAL FAILURE

Risk of personal injury if the frequency converter is not properly closed.

Before applying power, ensure that all safety covers are in place and securely fastened.

•

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 27

Page 30

Electrical Installation VLT® DriveMotor FCP 106/FCM 106

4.9.1 Recommendations for UL-listed PRGY

Systems

WARNING

FIRE HAZARD

For VLT® DriveMotor FCM 106 with either asynchronous

or permanent magnet motors listed under UL PRGY

systems, conduct a locked rotor temperature test and a

44

running overload test to avoid motor overtemperature.

The need for conducting the tests is determined by the

end product standard where the VLT® DriveMotor FCM

106 is used. Failure to complete/pass the locked rotor

temperature test and the running overload test could

prevent the frequency converter from functioning.

Check and set the following parameters before

•

test:

- Parameter 1-90 Motor Thermal

Protection.

- Parameter 4-18 Current Limit.

- Parameter 14-20 Reset Mode.

- Parameter 14-21 Automatic Restart

Time.

- Parameter 14-90 Fault Level.

- Parameter 30-22 Locked Rotor Detection.

Do not exceed the temperature limits stated in

•

the motor data provided by the motor

manufacturer.

28 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 31

130BB628.10

Select Language

[ 0 ] English

Setup 1

130BD512.10

Auto

on

Reset

Hand

on

O

Status

Quick

Menu

Main

Menu

Alarm

Log

Back

Cancel

Info

OK

Status

1(1)

0.00 kW

O Remote Stop

0.0Hz

On

Alarm

Warn.

A

0.00 A

0.0 %

B

C

D

2605 kWh

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21

Commissioning Operating Instructions

5 Commissioning

5.1 Applying Power

5.1.1 Turn on Mains Power

Turn on mains power to power up the frequency converter.

5.1.2 Start-up

Start the frequency converter.

5 5

At the rst power-up with LCP connected, select the

preferred language. Once selected, this screen does not

appear again in the following power-ups. To change

language at a later stage, go to parameter 0-01 Language.

Illustration 5.1 Select Language

5.2 Local Control Panel Operation

NOTICE

The frequency converter can also be programmed from a

PC via the RS485 COM port by installing the MCT 10 Setup Software.

The LCP is divided into 4 functional sections.

A. Alphanumeric display.

B. Menu selection.

D. Operation keys and indicator lights (LEDs).

C. Navigation keys and indicator lights (LEDs).

Illustration 5.2 Local Control Panel (LCP)

A. Display area

The display area is activated when the frequency converter

receives power from mains voltage, a DC bus terminal, or a

24 V DC external supply.

The information shown on the LCP can be customized for

user application. Select options in the Quick Menu Q3-13

Display settings.

Call-

Display Parameter

out

1 1.1 0-20 Reference %

2 1.2 0-21 Motor current

3 1.3 0-22 Power [kW ]

4 2 0-23 Frequency

5 3 0-24 kWh counter

number

Default setting

Table 5.1 Legend to Illustration 5.2

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 29

Page 32

195NA422.11

1

2

42 mm

Commissioning VLT® DriveMotor FCP 106/FCM 106

B. Display menu key

Menu keys are used for menu access for parameter set-up,

D. Operation keys and indicator lights (LEDs)

Operation keys are at the bottom of the LCP.

toggling through status display modes during normal

operation, and viewing fault log data.

Callout Key Function

6 Status Shows operational information.

7 Quick Menu Allows access to programming

parameters for initial set-up

instructions and many detailed

application instructions.

8 Main Menu Allows access to all programming

55

9 Alarm Log Shows a list of current warnings,

Table 5.2 Legend to Illustration 5.2

parameters.

the last 10 alarms, and the

maintenance log.

Callout Key Function

18 Hand On Starts the frequency converter in local

control.

An external stop signal by control

•

input or serial communication

overrides the local hand on.

19 O Stops the motor but does not remove

power to the frequency converter.

20 Auto On Puts the system in remote operational

mode.

Responds to an external start

•

command by control terminals or

serial communication.

21 Reset Resets the frequency converter manually

after a fault has been cleared.

C. Navigation keys and indicator lights (LEDs)

Navigation keys are used for programming functions and

Table 5.5 Legend to Illustration 5.2

moving the display cursor. The navigation keys also

provide speed control in local operation. There are also 3

frequency converter status indicator lights in this area.

NOTICE

To adjust the display contrast, press [Status] and [▲]/[▼].

Callout Key Function

10 Back Reverts to the previous step or list in

the menu structure.

11 Cancel Cancels the last change or command

as long as the display mode has not

changed.

12 Info Press for a denition of the function

shown.

13 Navigation keys Press to move between items in the

menu.

14 OK Press to access parameter groups or

to enable a selection.

Table 5.3 Legend to Illustration 5.2

Call-

out

15 ON Green The ON light activates when the

16 WARN Yellow When warning conditions are

17 ALARM Red A fault condition causes the red

Indicator Light Function

frequency converter receives

power from mains voltage, a DC

bus terminal, or a 24 V external

supply.

met, the yellow WARN light

turns on, and text appears in

the display area identifying the

problem.

alarm light to ash, and an

alarm text is shown.

Table 5.4 Legend to Illustration 5.2

5.2.1 Connect LCP Cable

1 Control panel

2 Panel door

Illustration 5.3 LCP Remote Mounting

To view or change the frequency converter settings, attach

the LCP using the LCP cable. See Illustration 5.3.

After use, remove the LCP cable from the frequency

converter to maintain the ingress protection class of the

enclosure.

30 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 33

195NA501.10

1

Commissioning Operating Instructions

5.3 Memory Module MCM 101

The VLT® Memory Module MCM 101 is a small memory

plug containing data such as:

Firmware.

•

SIVP le.

•

Pump table.

•

Motor database.

•

Parameter lists.

•

The frequency converter comes with the module installed

from the factory.

5.3.1

Conguring with the VLT® Memory

Module MCM 101

When replacing or adding a frequency converter to a

system, it is easy to transfer existing data to the new

frequency converter. However, the frequency converters

must be of the same power size and with compatible

hardware.

WARNING

DISCONNECT POWER BEFORE SERVICING!

Before performing repair work, disconnect the frequency

converter from AC mains. After mains has been discon-

nected, wait 4 minutes for the capacitors to discharge.

Failure to follow these steps can result in death or

serious injury.

1. Remove the lid from a frequency converter

containing a memory module.

2. Unplug the memory module.

3. Place and tighten the lid.

4. Remove the lid from the new frequency

converter.

5. Insert the memory module in the new/other

frequency converter and leave it in.

6. Place and tighten the lid on the new frequency

converter.

7. Power up the frequency converter.

5 5

1

VLT® Memory Module MCM 101

Illustration 5.4 Location of Memory Module

If the memory module becomes defect, it does not prevent

the frequency converter from working. The warning LED

on the lid ashes, and a warning shows in the LCP (if

installed).

Warning 206, Memory module indicates that either a

frequency converter runs without a memory module, or

that the memory module is defect. To see the exact reason

for the warning, refer to parameter 18-51 Memory Module

Warning Reason.

A new memory module can be ordered as a spare part.

Ordering number: 134B0791.

NOTICE

The rst power-up takes approximately 3 minutes.

During this time, all data is transferred to the new

frequency converter.

5.4 Basic Programming

This manual explains initial set-up only. For full parameter

lists, refer to the VLT® DriveMotor FCP 106 and FCM 106

Programming Guide.

At initial start-up, the frequency converter enters the startup wizard for open-loop applications, see

chapter 5.4.1

Once the start-up wizard has completed, the following

extra set-up wizards and instructions are available:

•

•

•

For general instructions on how to change parameter

settings, refer to chapter 5.4.4 Changing Parameter Settings.

Conguration for Open-loop Applications.

Chapter 5.4.2 Set-up Wizard for Closed-loop

Applications.

Chapter 5.4.3 Quick Menu Motor Set-up.

Chapter 5.4.5 Thermistor Set-up.

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 31

Page 34

FC

+24 V (OUT)

DIG IN

DIG IN

DIG IN

DIG IN

COM DIG IN

A OUT / D OUT

A OUT / D OUT

18

19

27

29

42

55

50

53

54

20

12

01

02

03

04

05

06

R2

R1

+

0–10 V

Start

+10 V (OUT)

A IN

A IN

COM IN/OUT

130BB674.11

45

Reference

Commissioning VLT® DriveMotor FCP 106/FCM 106

5.4.1 Conguration for Open-loop Applications

This section guides the installer through the set-up of the frequency converter in a clear and structured manner to set up

an open-loop application. An open-loop application does not utilize a feedback signal from the process.

55

Illustration 5.5 Principle Wiring for Open-loop Applications

32 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 35

195NA416.11

International

4-12

Motor Speed low Limit

Hz

4-14

Motor Speed high Limit

Hz

3-41

Ramp 1 ramp-up time

s

3-42

Ramp 1 ramp-down Time

s

1-73 Active

Flying start?

Disable

1-20

Motor Power

1-22

Motor Voltage

1-23

Motor frequency

1-24

Motor current

1-25

Motor nominal speed

0-03

Regional Settings

380-440V/50Hz

Grid Type

Asynchronous motor

Asynchronous

1-10

Motor Type

1-24

Motor current

1-25

Motor nominal speed

1-26

Motor Cont. Rated Torque

1-30

Stator resistance

1-39

Motor poles

1-40

Back EMF at 1000 rpm

1-37

d-axis inductance

6 - 10 T53 low Voltage

V

6 - 11 T53 high Voltage

V

6 - 12 T53 Low Current

A

6 - 13 T53 High Current

A

Current

Voltage

AMA Failed

0.0 Hz

0.0 kW

Wizard completed

Press OK to accept

1-29

Automatic Motor Adaption

O

Auto Motor Adapt OK

Press OK

5 - 40 Function of Relay 2

No function

5 - 40 Function of Relay 1

[0] No function

3-03

Max Reference

Hz

3-02

Min Reference

Hz

AMA running

-----

AMA failed

Perform AMA

(Do not perform AMA)

AMA OK

6 - 19 T53 Mode

Current

3.8

A

3000

RPM

5.4

Nm

0.65

Ohms

8

57

V

5

mH

1.50

kW

0050

V

0050

Hz

04.66

A

1420

RPM

[0]

Motor type = Asynchronous

Motor type = PM motor

0000

0050

0003

0003

04.66

13.30

0050

0220

0000

0050

[12]

[0]

[0]

[0]

[0]

[1]

[0]

0-06

PM motor

1-38 q-axis Inductance (Lq)

5

mH

1-44 Current at Min Inductance for d-axis

100

%

Current at Min Inductance for q-axis

100

%

1-70 PM Start Mode

Rotor Detection

[0]

1-46 Position Detection Gain

%

O

100

30-22 Locked Rotor Detection

[0]

s

30-23 Locked Rotor Detection Time[s]

0.10

4-19 Max Output Frequency

65

Hz

Motor Type = IPM

IPM Type = Sat.

IPM Type = non-Sat.

Commissioning Operating Instructions

5 5

Illustration 5.6 Conguration for Open-loop Applications

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 33

Page 36

6-29 Terminal 54 Mode

[1]

Voltage

6-25 T54 high Feedback

0050

Hz

20-94 PI integral time

0020.00

s

Current

Voltage

This dialog is set to

[1] Analog input 54

20-00 Feedback 1 source

[1]

Analog input 54

3-10 Preset reference [0]

0.00

3-03 Max Reference

50.00

3-02 Min Reference

0.00

Asynchronous Motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

400

V

1-24 Motor Current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0003

s

3-42 Ramp1 ramp-down time

0003

s

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-13 Motor speed high limit

0050

Hz

195NA417.11

1-20 Motor Power

1.10

kW

1-23 Motor Frequency

50

Hz

6-22 T54 Low Current

A

6-24 T54 low Feedback

0016

Hz

6-23 T54 high Current

13.30

A

6-25 T54 high Feedback

0050

0.01

s

20-81 PI Normal/Inverse Control

[0]

Normal

20-83 PI Normal/Inverse Control

0050

Hz

20-93 PI Proportional Gain

00.50

1-29 Automatic Motor Adaption

[0]

O

6-20 T54 low Voltage

0050

V

6-24 T54 low Feedback

0016

Hz

6-21 T54 high Voltage

0220

V

6-26

T54 Filter time const.

1-00 Conguration Mode

[3]

Closed Loop

0-03 Regional Settings

[0]

Power kW/50 Hz

3-16 Reference Source 2

[0]

No Operation

1-10 Motor Type

[0]

Asynchronous

[12]]

1-30 Stator Resistance

0.65

Ohms

1-25 Motor Nominal Speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-38 q-axis inductance(Lq)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 RPM

57

V

PM Motor

1-39 Motor Poles

8

%

04.66

Hz

MotorType = Asynchronous

MotorType = PM Motor

Motor Type = IPM

IPM Type = Sat.

IPM Type = non-Sat.

1-44 d-axis Inductance Sat. (LdSat)

(1-70) PM Start Mode

Rotor Detection

[0]

1-46 Position Detection Gain

%

O

100

30-22 Locked Rotor Detection

[0]

s

30-23 Locked Rotor Detection Time[s]

0.10

5

mH

(1-45) q-axis Inductance Sat. (LqSat)

5

mH

(1-48) Current at Min Inductance for d-axis

100

%

1-49 Current at Min Inductance for q-axis

100

%

380-440V/50Hz

This dialog is set to

[0] No Operation

Commissioning VLT® DriveMotor FCP 106/FCM 106

5.4.2 Set-up Wizard for Closed-loop Applications

55

Illustration 5.7 Closed-loop Set-up Wizard

34 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 37

Asynchronous Motor

1-73 Flying Start

[0]

No

1-22 Motor Voltage

400

V

1-24 Motor Current

04.66

A

1-25 Motor nominal speed

1420

RPM

3-41 Ramp 1 ramp-up time

0003

s

3-42 Ramp1 ramp-down time

0003

s

0-06 Grid Type

4-12 Motor speed low limit

0016

Hz

4-13 Motor speed high limit

0050

Hz

195NA462.11

1-20 Motor Power

1.10

kW

1-23 Motor Frequency

50

Hz

1-00

[3]

Closed Loop

0-03 Regional Settings

[0]

International

1-10 Motor Type

[0]

Asynchronous

[12]]

1-30 Stator Resistance

0.65

Ohms

1-25 Motor Nominal Speed

3000

RPM

1-24 Motor Current

3.8

A

1-26 Motor Cont. Rated Torque

5.4

Nm

1-38 q-axis inductance(Lq)

5

mH

4-19 Max Ouput Frequency

0065

Hz

1-40 Back EMF at 1000 RPM

57

V

PM Motor

1-39 Motor Poles

8

MotorType = Asynchronous

MotorType = PM Motor

Motor Type = IPM

IPM Type = Sat.

IPM Type = non-Sat.

1-44 d-axis Inductance Sat. (LdSat)

(1-70) PM Start Mode

Rotor Detection

[0]

1-46 Position Detection Gain

%

100

30-22 Locked Rotor Det ection

[0]

s

30-23 Locked Rotor Det ection Time[s]

0.10

5

mH

(1-45) q-axis Inductan ce Sat. (LqSat)

5

mH

(1-48) Current at Min Inductance for d-axis

100

%

1-49 Current at Min In ductance for q-axis

100

%

380-440V/50Hz

Commissioning Operating Instructions

5.4.3 Quick Menu Motor Set-up

The Quick Menu Motor Set-up guides the installer through setting of the required motor parameters.

NOTICE

MOTOR OVERLOAD PROTECTION

Thermal protection of the motor is recommended. Especially when running at low speed, the cooling from the

integrated motor fan is often not sucient.

Use PTC or Klixon, see chapter 4.6.2 Thermistor Input from Motor, or

•

Enable motor thermal protection by setting parameter 1-90 Motor Thermal Protection to [4] ETR trip 1.

•

5 5

Illustration 5.8 Quick Menu Motor Set-up

MG03L302 Danfoss A/S © 11/2015 All rights reserved. 35

Page 38

Commissioning VLT® DriveMotor FCP 106/FCM 106

5.4.4 Changing Parameter Settings

Quick access to change parameter settings:

1. To enter the Quick Menu, press [Menu] until the

indicator in the display reaches Quick Menu.

2.

Press [▲] [▼] to select wizard, closed-loop set-up,

motor set-up, or changes made, then press [OK].

3.

Press [▲] [▼] to browse through the parameters in

the Quick Menu.

4. To select a parameter, press [OK].

55

5.

Press [▲] [▼] to change the value of a parameter

setting.

6.

Press [►] to shift digit when a decimal parameter

is in the editing state.

7. To accept the change, press [OK].

8. Press either [Back] twice to enter Status, or press

[Menu] once to enter Main Menu.

The Main Menu accesses all parameters:

1. Press [Menu] until the indicator in the display

reaches Main Menu.

2.

Press [▲] [▼] to browse through the parameter

groups.

3. To select a parameter group, press [OK].

4.

Press [▲] [▼] to browse through the parameters in

the

specic group.

5. To select the parameter, press [OK].

6.

Press [▲] [▼] to set/change the parameter value.

Changes made:

1. Press [Menu] until the indicator in the display

reaches Quick Menu.

2.

Press [▲] [▼] to browse through the quick menus.

3. To select 05 Changes Made, press [OK].

Changes Made lists all parameters changed from

•

default settings.

The list shows only parameters which have been

•

changed in the current edit set-up.

Parameters which have been reset to default

•

values are not listed.

The message Empty indicates that no parameters

•

have been changed.

5.4.5 Thermistor Set-up

Set parameter 1-90 Motor Thermal Protection to [1]

Thermistor warning or [2] Thermistor trip. For details, refer to

VLT® DriveMotor FCP 106 and FCM 106 Programming Guide.

36 Danfoss A/S © 11/2015 All rights reserved. MG03L302

Page 39

Maintenance, Diagnostics an... Operating Instructions

6 Maintenance, Diagnostics and Troubleshooting

6.1 Maintenance

3. Disconnect the frequency converter from external

DC supply, if present.

Under normal operating conditions and load proles, the

frequency converter is maintenance-free throughout its

designed lifetime. To prevent breakdown, danger, and

damage, examine the frequency converter at regular

intervals depending on the operating conditions. Replace

worn or damaged parts with original spare parts or

standard parts. For service and support, contact the local

Danfoss supplier.

4. Disconnect the frequency converter from the

motor as it can generate voltage when turned, for

example by windmilling.

5. Wait for discharge of the DC link. For discharge

time, see Table 2.1.

6. Remove the frequency converter from the motor

adapter plate or wall mount plate.

1. Read the safety warnings in chapter 2 Safety.

2. Disconnect the frequency converter from mains.

6.2 List of Warnings and Alarms

Alarm/

warning

number

2 Live zero error X X

3 No motor X A motor has not been connected to the frequency converter.

4 Mains ph. loss X X X

7 DC over volt X X DC-link voltage exceeds limit.

8 DC under volt X X DC-link voltage is lower than voltage warning low-limit.

9

10 Motor ETR over X X

11 Motor th over X X

13 Over Current X X X Inverter peak current limit is exceeded.

14 Earth Fault X X X Discharge from output phases to ground.

16 Short Circuit X X Short circuit in motor or on motor terminals.

17

24 Fan fault X X External fans have failed either due to defect hardware, or due to

25 Brake resistor

27 Short circuited X X Brake chopper fault: The brake transistor is short-circuited, or the brake

28 Brake check X X Brake checked and failure detected.

Fault text Warning Alarm Trip lock Cause of problem

Signal on terminal 53 or 54 is less than 50% of value set in:

Parameter 6-10 Terminal 53 Low Voltage.

•

Parameter 6-12 Terminal 53 Low Current.

•

Parameter 6-20 Terminal 54 Low Voltage.

•

Parameter 6-22 Terminal 54 Low Current.

•

See also parameter group 6-0* Analog In/Out.

Missing phase on supply side or excess voltage imbalance. Check

supply voltage. See parameter 14-12 Function at Mains Imbalance.

Inverter

overload

Control word

timeout

short

X X More than 100% load for too long.

Motor is overheated due to more than 100% load for too long. See

parameter 1-90 Motor Thermal Protection.

Thermistor or thermistor connection is disconnected. See