Page 1

Programming Guide

VLT® Condition-based Monitoring

VLT® FC Series

vlt-drives.danfoss.com

Page 2

Page 3

VLT® Condition-based Monitoring

Programming Guide

Contents

1

Before you begin 5

1.1

Introduction to the Programming Guide 5

Reading the parameter table 5

1.2

2

Introduction to Condition-based monitoring 7

2.1

System Requirements and Compatibility 7

2.2

Ordering Condition-based Monitoring in drives 9

2.2.1

Ordering Condition-based monitoring License From Factory 9

2.2.2

Ordering Condition-based Monitoring in Existing VLT Drive Using MCT-10 9

2.2.3

Enabling Condition-based Monitoring Features 11

2.3

Overview on Condition-based Monitoring 11

2.4

Condition-based Monitoring Workow 12

2.4.1

Step 1: Baseline Conguration 12

Contents

2.4.2

Step 2: Sensor Conguration (Optional) 13

2.4.3

Step 3: Threshold Calculation 13

2.4.4

Step 4: Alarms and Warnings 13

3

Examples of Condition-based Monitoring Functions 15

3.1

Example 1: Motor Stator Winding Monitoring 15

3.2

Example 2: Load Envelope 15

3.3

Example 3: Vibration Monitoring 16

4

Commissioning of Condition-based Monitoring 17

4.1

Commissioning Overview 17

4.2

Commissioning using MCT-10 Condition-based Monitoring Plug-in 17

4.3

Recommended Parameter Set-up using LCP or MCT-10 22

4.4

Threshold Conguration Guidelines 24

5

Fieldbus Integration for Condition-based Monitoring 25

5.1

Fieldbus Integration - Options and Parameters 25

6

Parameter Descriptions 29

6.1

Parameter Group 45 -** Condition-based Monitoring 29

6.2

Parameter Group 46-** CBM Monitoring Conguration 39

6.3

Parameter Group 47 -** CBM Baseline Data 45

7

Appendix 49

7.1

Motor Stator Windings 49

7.1.1

Alarm 510, Motor Stator Winding Alarm 49

AU310741645108en-000201/130R0901 | 3Danfoss A/S © 2020.10

Page 4

VLT® Condition-based Monitoring

Programming Guide

7.1.2

Warning 510, Motor Stator Winding Warning 1 49

7.1.3

Warning 500, Motor Stator Winding Warning 2 49

7.2

Vibration Monitoring 49

7.2.1

Alarm 512, Vibration Monitoring Alarm 49

7.2.2

Warning 512, Vibration Monitoring Warning 1 49

7.2.3

Warning 502, Vibration Monitoring Warning 2 49

7.3

Load Envelope 49

7.3.1

Alarm 511, Load Envelope Alarm 49

7.3.2

Warning 511, Load Envelope Warning 1 50

7.3.3

Warning 501, Load Envelope Warning 2 50

Contents

AU310741645108en-000201/130R09014 | Danfoss A/S © 2020.10

Page 5

2

5

6

1

3

4

e30bu346.10

VLT® Condition-based Monitoring

Programming Guide

Before you begin

1 Before you begin

1.1 Introduction to the Programming Guide

Introduction

This chapter describes the purpose of the programming guide, intended audience, disclaimer, safety conventions and additional

resources.

Purpose of this Programming Guide

This programming guide provides information on working with Condition-based monitoring parameters on the VLT® FC series.

It provides an overview of parameters and value ranges for operating the drive. Installation and operating instructions are not in

scope of this programming guide.

Intended Audience

The intended audience of the programming guide is trained personnel, automation engineers and programmers with experience in

operating with parameters and basic knowledge of Danfoss AC drives.

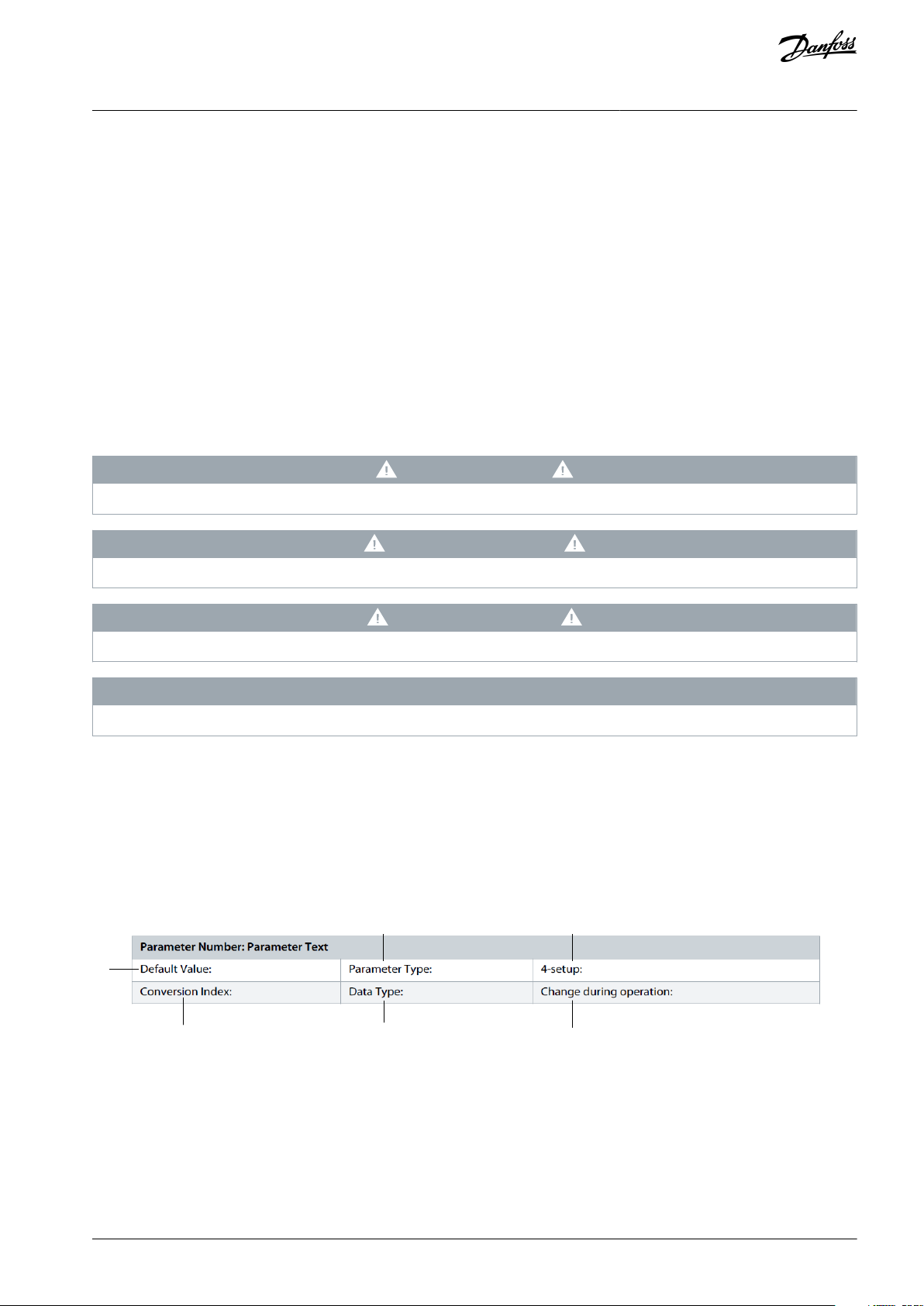

Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Additional Resources

Additional resources are available to help you understand related information.

Technical documentation for various product options is available via the Danfoss home page in the Service and Support/Documen-

tation section.

1.2 Reading the parameter table

This programming guide includes parameter and options tables. These descriptions explain how to read the parameter and options

tables.

Illustration 1: Parameter Table

1 indicates the value set in factory.

2 indicates whether the parameter type is option or range.

3 indicates the manner of parameter set-ups. All setups means that the parameter can be set individually in each of the 4 setups. For

example, 1 single parameter can have 4 dierent data values. 1 setup indicates that the data value is the same in all setups.

4 refers to the conversion index. Parameter values are transferred as whole numbers only. Conversion factors are therefore used to

transfer decimals. If a value is transferred as 100 and a conversion index of -1, the real value is 10.0.

5 indicates the dierent data types for the parameters.

AU310741645108en-000201 / 130R0901 | 5Danfoss A/S © 2020.10

Page 6

Conversion index

Conversion factor

100175

3600000

74

36007060671/6061000000

5

100000

4

10000

3

1000210011001-10.1-20.01-30.001

-4

0.0001

-5

0.00001

-6

0.000001

Data type

Description

Type2Integer 8

Int83Integer 16

Int164Integer 32

Int325Unsigned 8

Uint8

6

Unsigned 16

Uint16

7

Unsigned 32

Uint32

9

Visible string

VisStr

33

Normalized value 2 bytes

N235Bit sequence of 16 boolean variables

V254Time dierence w/o date

TimD

VLT® Condition-based Monitoring

Programming Guide

6 indicates whether the parameter value can be changed while the frequency converter is in operation. False indicates that the

frequency converter must be stopped before a change can be made.

Table 1: Conversion Table

Before you begin

Table 2: Data type

AU310741645108en-000201 / 130R09016 | Danfoss A/S © 2020.10

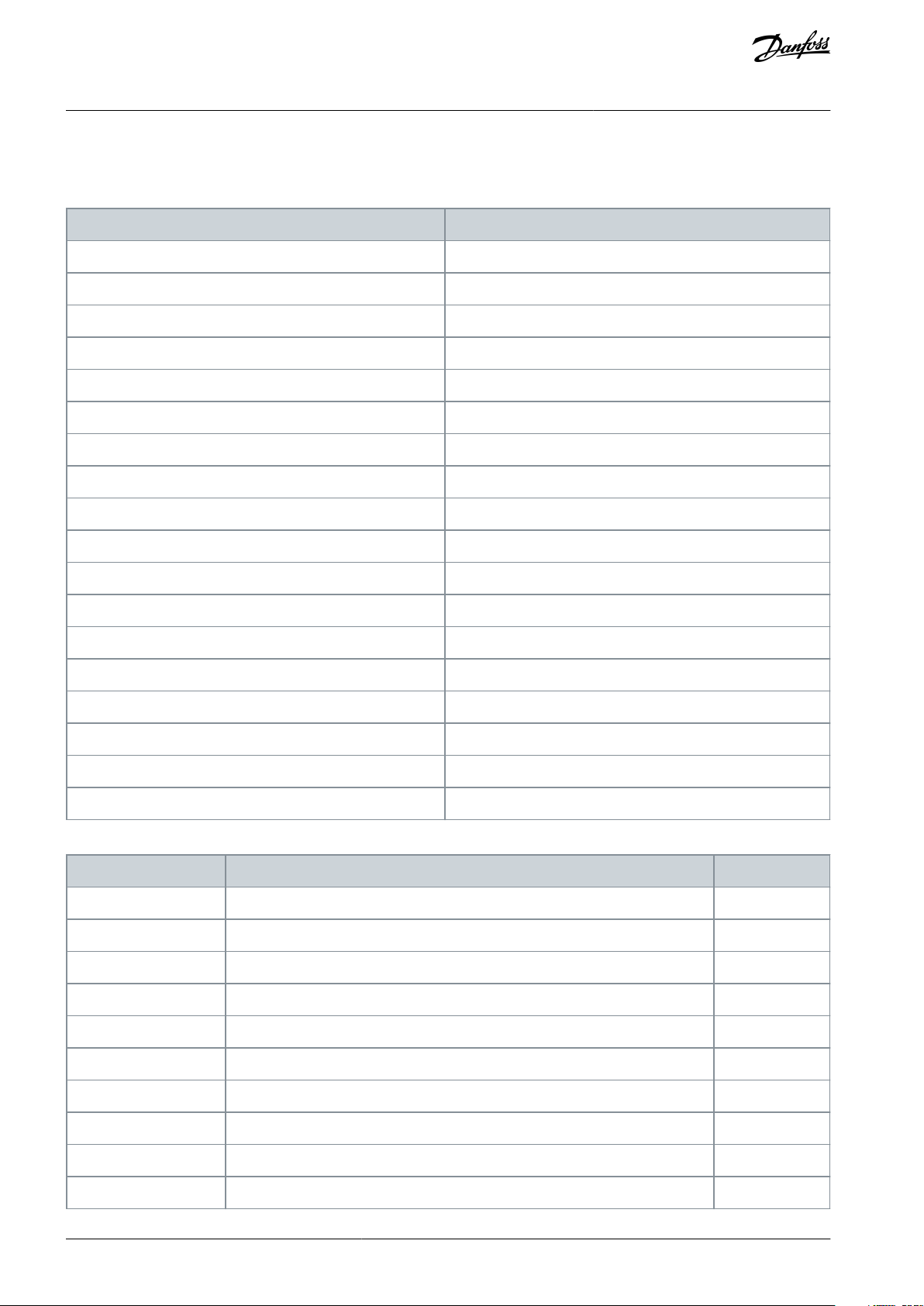

Page 7

VLT® Product

Minimum Software Compatibility Version

VLT® HVAC Drive FC 102

5.70

VLT® Refrigeration Drive FC 103

2.70

VLT® AQUA Drive FC 202

3.80

VLT® Automation Drive FC 302

8.60

VLT® Motion Control Tool MCT 10

5.11

Control card version

Compatibility

Identication of control card version

MKII

Yes

White USB

MKINoBlack USB

Control mode

Compatibility

VVC+

Yes

U/fNoFluxNoMotor type

Compatibility

Asynchronous

Yes

PM, non salient SPM

(1)

No

PM, salient IPM

(1)

No

SynRM

No

PMaSynRM

No

Filter name

Compatibility

Description

VLT® dU/dt Filter MCC 102

Yes

Baseline needs to be run with the lter.

When the lter is installed later, make sure a new baseline is generated.

VLT® Sine-Wave Filter MCC 101

Yes

VLT® All-Mode Filter MCC 201

Yes

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

monitoring

2 Introduction to Condition-based monitoring

2.1 System Requirements and Compatibility

In order to enable Condition-based monitoring and eectively function, verify the following software compatibilty and system-requirements.

VLT® Products and Software compatibility for Condition-based monitoring

Control card compatibility for Condition-based monitoring

MKII control card is required to enable license code functions.

Contact local Danfoss Sales partner to determine the possibility of upgrading VLT® product with new control card, inorder to acti-

vate license code.

Stator Winding Monitoring Compatibilities

1

Ongoing implementation

Filters for stator winding monitoring function

Table 3: Compatible Filters for stator winding function

AU310741645108en-000201 / 130R0901 | 7Danfoss A/S © 2020.10

Page 8

Option type

Number of AI

Name of AI on the board

VLT® General Purpose I/O MCB 101

2

30/11, 30/12

VLT® Analog I/O MCB109

3

42/1, 42/3, 42/5

VLT® Sensor Input MCB 114

1

48/2

VLT(R) Programmable I/O MCB 115

3

X49/7+8, X49/9+10, X49/11+12

Option name

Status of Condition-based

monitoring support

Slot

FC 102

FC 103

FC 202

FC 302

FCD 302

Modbus RTU

Yes

RS485

xxxxx

BACNet MS/TP

No

RS485

x----

Metasys N2

Yes

RS485

x----

VLT® Probus DP MCA 101

Yes, with basic PDC value exchange.

AxxxxxVLT® Devicenet MCA 104

Yes, with basic PDC value exchange.

Ax-xx-VLT® CANOpen MCA 105

Yes, with basic PDC value exchange.

A---x

AK-LonWorks MCA 107 for ADAP-Kool

NoA-x---

LonWorks MCA 108

NoAxx---

VLT® BACNet MCA 109

NoAx----

VLT® Pronet MCA 120

Yes, with basic PDC value exchange.

Axxxx

x

VLT® Ethernet/IP MCA 121

YesAx-xxx

VLT® Modbus TCP MCA 122

YesAx-xxx

VLT® POWERLINK MCA 123

NoA---xx

VLT® EtherCAT MCA 124

YesA---xx

VLT® BACNet/IP MCA 125

YesAx----

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

Sensor Congurations and Additional Analog Inputs

Condition-based programming use external sensors to obtain data. These external sensors are connected to AC Drive via Analog

Inputs (AI).

By default, the software enables the use of 2 sensors which is used for vibration monitoring in 2 directions. The software also allows

the addition of more sensors. Contact your local sales oce for more information.

To facilitate the addition of more sensors or when embedded analog inputs are used, congure the following options to extend the

analog inputs.

Table 4: Options and Analog Input Congurations

Fieldbus support in Condition-based Monitoring

Table 5: Fieldbus and Product Compatibility for Condition-based Monitoring

monitoring

In the above table:

•

x indicates the VLT® product supports the eldbus protocol.

•

- indicates the VLT® product does not support the eldbus protocol.

AU310741645108en-000201 / 130R09018 | Danfoss A/S © 2020.10

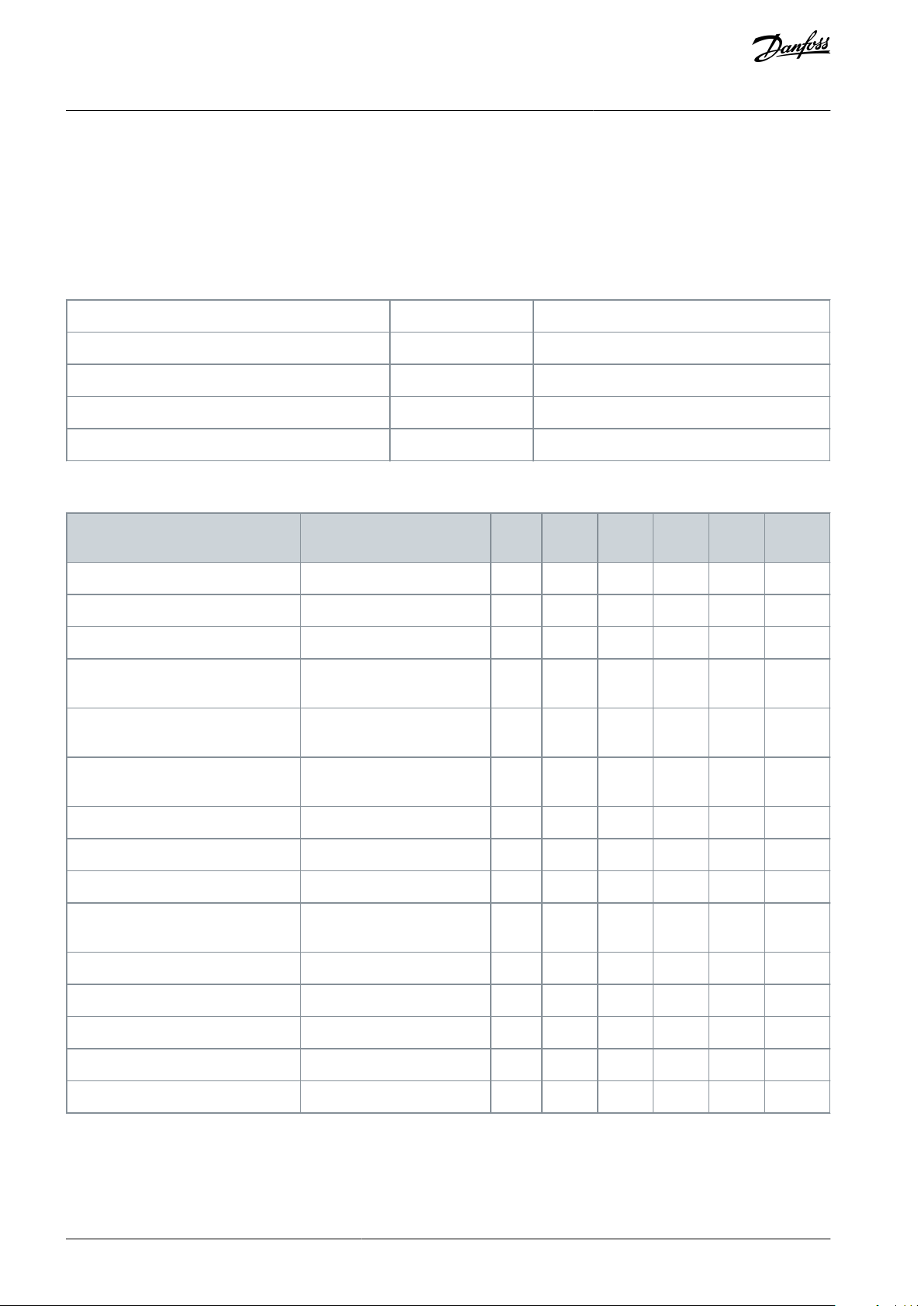

Page 9

Parameter number and name

License enabled from factory

License activated by customer (retrot)

Parameter 15-44 Ordered Typecode String

LX1X

SXXX

Parameter 15-45 Actual Typecode String

LX1X

LX1X

Parameter 50-00 License Installed

CBM

CBM

e30bi288.10

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

For more information on eldbus integration with condition-based monitoring, see 5 Fieldbus Integration for Condition-based

Monitoring

For more information on the slots, see the VLT® product design guide

monitoring

2.2 Ordering Condition-based Monitoring in drives

Condition-based monitoring can be activated from the factory when ordering a new drive. The user can also activate conditionbased monitoring on existing VLT product using a license code.

When a license code is activated, parameters in parameter groups 45-**, 46-**, and 47-** reect the acceptance of license code.

These parameters are visible in LCP, MCT-10 or eld bus when license code is activated. For further information on specic license

codes for each VLT product, refer to Selection Guide.

Identifying License code information

Using the parameter group 15, the user can identify license code information.

2.2.1 Ordering Condition-based monitoring License From Factory

For the license code to be activated from the factory,the information has to be entered during product selection in the congurator.

Procedure

1.

Go to Danfoss Drives Congurator.

2.

Click the symbol corresponding to Software Release to open software release selections.

3.

Select LX1X Condition Based Monitoring CBM.

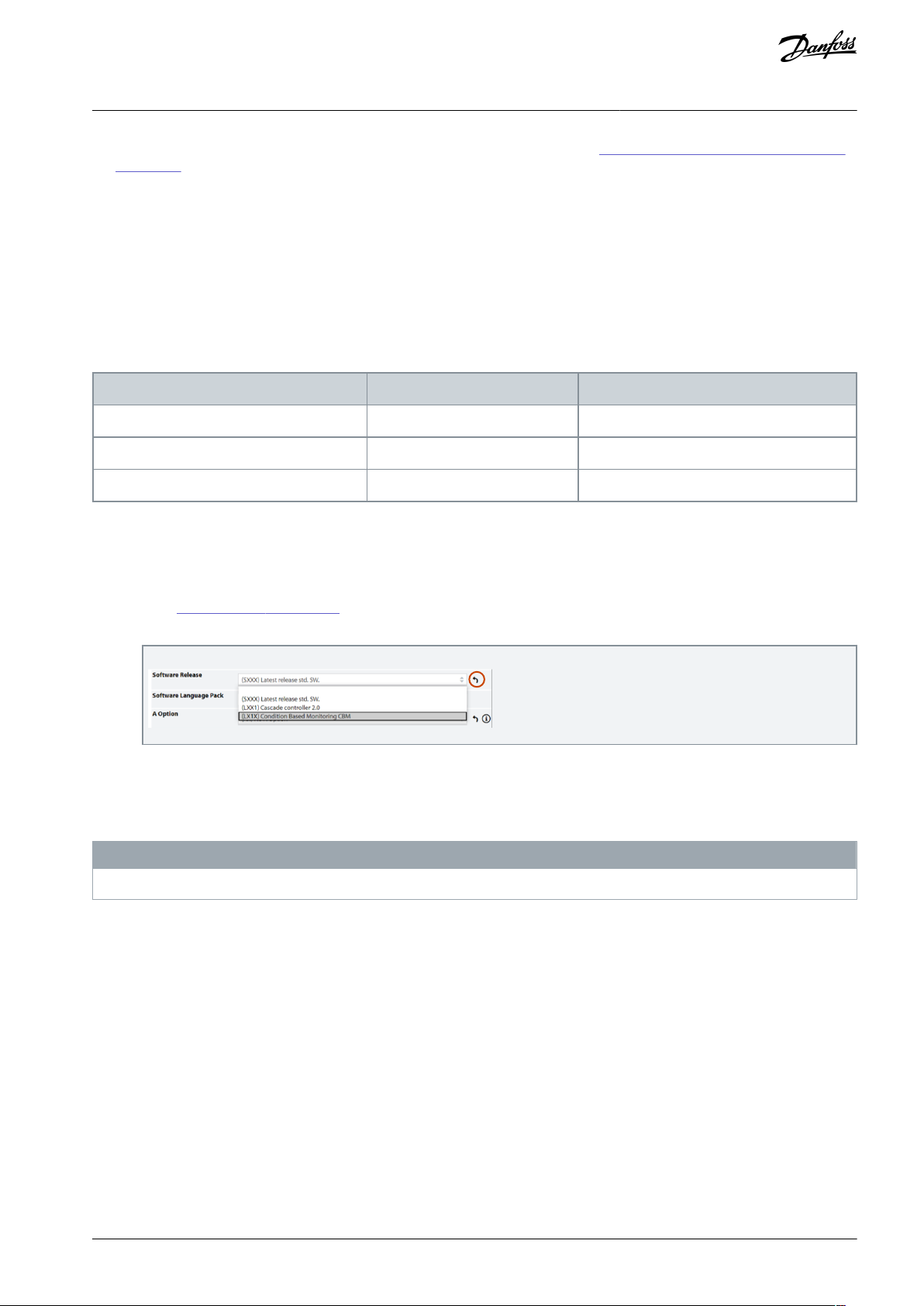

2.2.2 Ordering Condition-based Monitoring in Existing VLT Drive Using MCT-10

For retrot, licenses can be ordered from the regional sales oce. See Product Compatibility.

N O T I C E

License codes are unique to a single drive. The license code cannot be used on multiple drives.

The license code comprises of 16 alphanumeric characters in the format (XXXX-XXXX-XXXX-XXXX).

Procedure After receiving the license code, perform the following steps:

1.

Go to parameter group 50-** License group.

AU310741645108en-000201 / 130R0901 | 9Danfoss A/S © 2020.10

Page 10

e30bi438.10

e30bi439.10

e30bi440.10

e30bi287.10

VLT® Condition-based Monitoring

Programming Guide

2.

Stop polling. Press the button as shown in the gure.

Introduction to Condition-based

monitoring

Illustration 2: Stop Polling

3.

Go to parameter 50-01 License Code using the LCP or MCT-10.

4.

Enter the license code in parameter 50-01 License Code, instead of 0000-0000-0000-0000.

After entering the license code using the LCP, parameter 50-01 License Code shows the following information.

AU310741645108en-000201 / 130R090110 | Danfoss A/S © 2020.10

Page 11

e30bi286.10

ID

Name

Value

Description

45-00.0

Function

[1] Warning

Set the value for enabling stator monitoring.

45-00.1

Function

[1] Warning

Set the value for enabling load envelope.

45-00.2

Function

[1] Warning

Set the option for enabling vibration monitoring sensor 1.

45-00.3

Function

[0] O

Set the option for enabling vibration monitoring sensor 2.

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

When the license is accepted by the drive, the LCP displays as shown below.

5.

Restart the drive and MCT-10 to activate the features.

The parameter groups 45, 46, and 47 are now available in LCP and in MCT-10.

monitoring

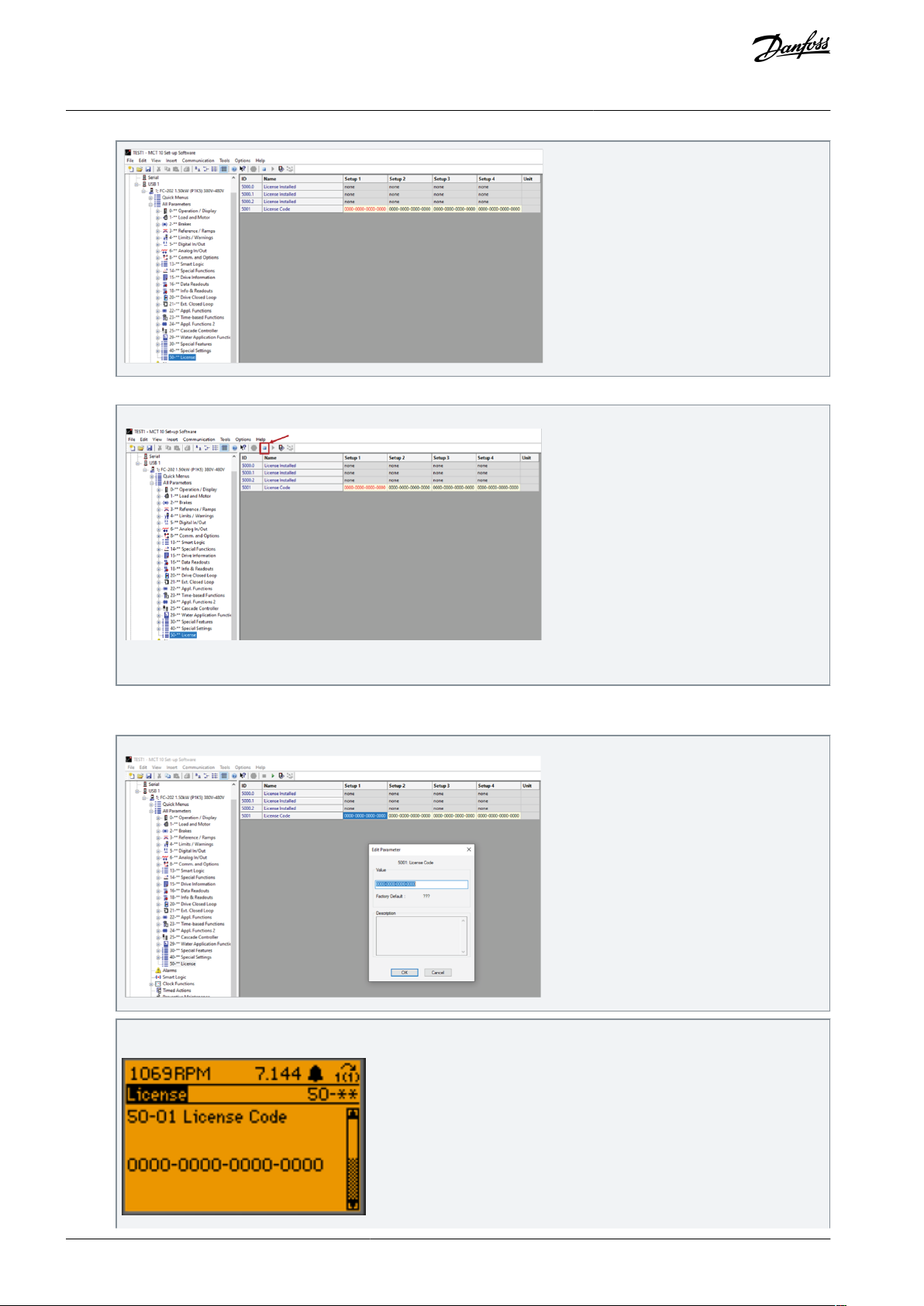

2.2.3 Enabling Condition-based Monitoring Features

In this recommendation, the scenario considered is to enable condition-based monitoring, when one sensor is installed on the

drive.

Procedure

1.

Go to Parameter Group 45 -** Condition-based Monitoring.

2.

Set the values to raise warnings for condition-based monitoring features, as described in the table.

N O T I C E

Make sure to congure parameter 45-00 Function inorder to generate [1] Warnings or [2] Warnings & Alarms, for proper

functioning of condition-based monitoring features.

The recommendation is to set [1] Warnings in parameter 45-00 Function. Setting [2] Warnings & Alarms in the param-

-

eter can cause the AC drive to trip, as alarms stops the drive.

2.3 Overview on Condition-based Monitoring

Condition-based monitoring in Danfoss VLT® drives enables to regularly check the condition and performance of the machine when

the drive is in service, and detects potential mechanical, motor, or application failures before the occurrence of an actual failure.

Benets of installing the condition-based monitoring rmware are as follows:

•

Reduces unexpected downtime

•

Eliminates unexpected halts in production

•

Optimizes maintenance

•

Reduction of spare part stock inventory

•

Optimizes production processes

Condition-based monitoring functions

Following are the 3 functions introduced in Condition-based monitoring. All the functions can be enabled at the same time for

monitoring the drive.

•

Motor stator winding monitoring: For this type of monitoring capability, an additional equipment is not required. The motor

current signature (inter-turn short circuit or unbalance in motor winding) is detected in drive. Damages caused by motor stator

AU310741645108en-000201 / 130R0901 | 11Danfoss A/S © 2020.10

Page 12

AC drive is installed

and commissioned

Baseline

Configuration

Threshold

Calculation

Threshold

Calculation

Monitoring

Monitoring

Initiate Baseline

(Measurement)

Sensor

Configuration

(optional)

Sensor

Configuration

(optional)

Baseline

Configuration

Initiate Baseline

(Measurement)

A

B

e30bu344.20

duration from few minutes upto 6 months

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

winding isolation occurs over a period of time. When more winding turns are impacted, the overcurrent protection is activated

due to extensive heating and stops the motor

•

Load envelope: For this type of monitoring capability, an additional equipment is not required. Mechanical load of an application is monitored by comparing current load curve with expected load curve based on data gathered during commissioning.

During monitoring, overload and under-load deviations, which occur in applications, are detected.

•

Vibration monitoring: For this type of monitoring capability, the installation of vibration sensor(s) is required. Speed related

vibration (RMS) monitoring via external vibration sensor, detecting early signs of motor misalignments.

monitoring

N O T I C E

ISO10816 standard provides guidance for evaluating vibration severity for machines operating within 10–200 Hz of frequency

range. The standard shall be complied with before commissioning of vibration monitoring function.

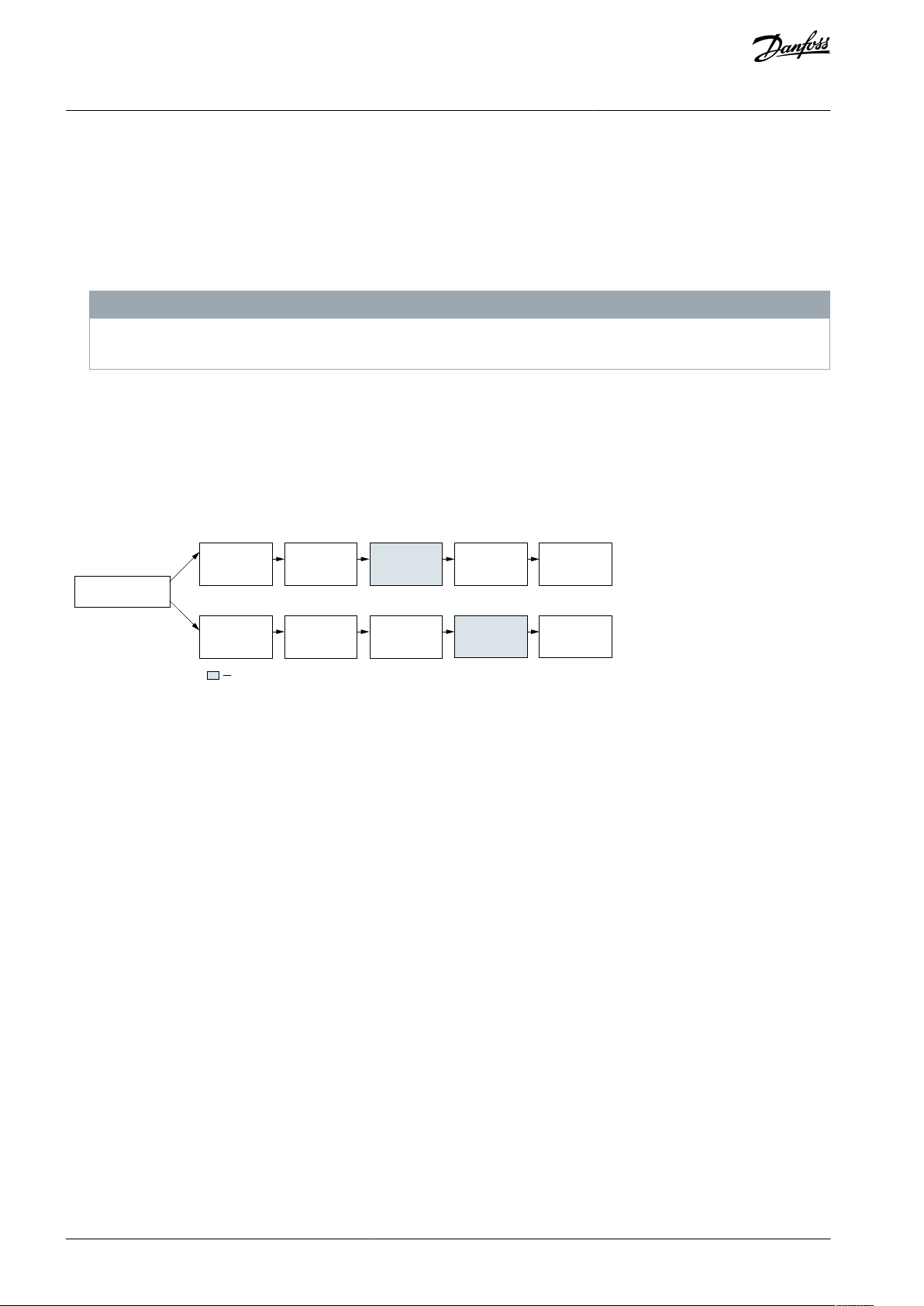

2.4 Condition-based Monitoring Workow

Before starting the commissioning of condition-based monitoring, make sure that the system is congured (installed and commissioned) for normal operation of the drive.

Depending on the user's requirement, commissioning condition-based monitoring allows the possibility to congure thresholds before or after initiating the baseline measurement. The process of obtaining baseline measurements after initiation takes upto 6

months.

The following illustration depicts the two ways to commission condition-based monitoring in a drive.

Illustration 3: Condition-based Monitoring Workow Overview

2.4.1 Step 1: Baseline Conguration

Baseline conguration is the 1st step and essential when commissioning a drive for condition-based monitoring. A baseline signature is required to determine any deterioration in the stator winding, load operating point, or vibration level of the application. The

baseline is recorded for each of the activated condition-based monitoring functions.

Following are the dierent ways to congure baseline:

•

Baseline Run: The drive takes control of the motor speed and creates a certain congurable speed prole and measures the

relevant signals. Depending on the load conditions, it is not always possible to execute the baseline run when the load does not

allow.

•

Online Baseline: In this method, the baseline is created by the drive without interrupting the operation of the drive and application. For the user-specied period of time, the relevant signals are gathered by the drive. This method provides a better representation of normal variation in the application.

•

Manual Baseline: In this method, the baseline values are manually congured into the drive.This method is relevant when the

baseline values are dened using prior experience and the values are congured in the drive.

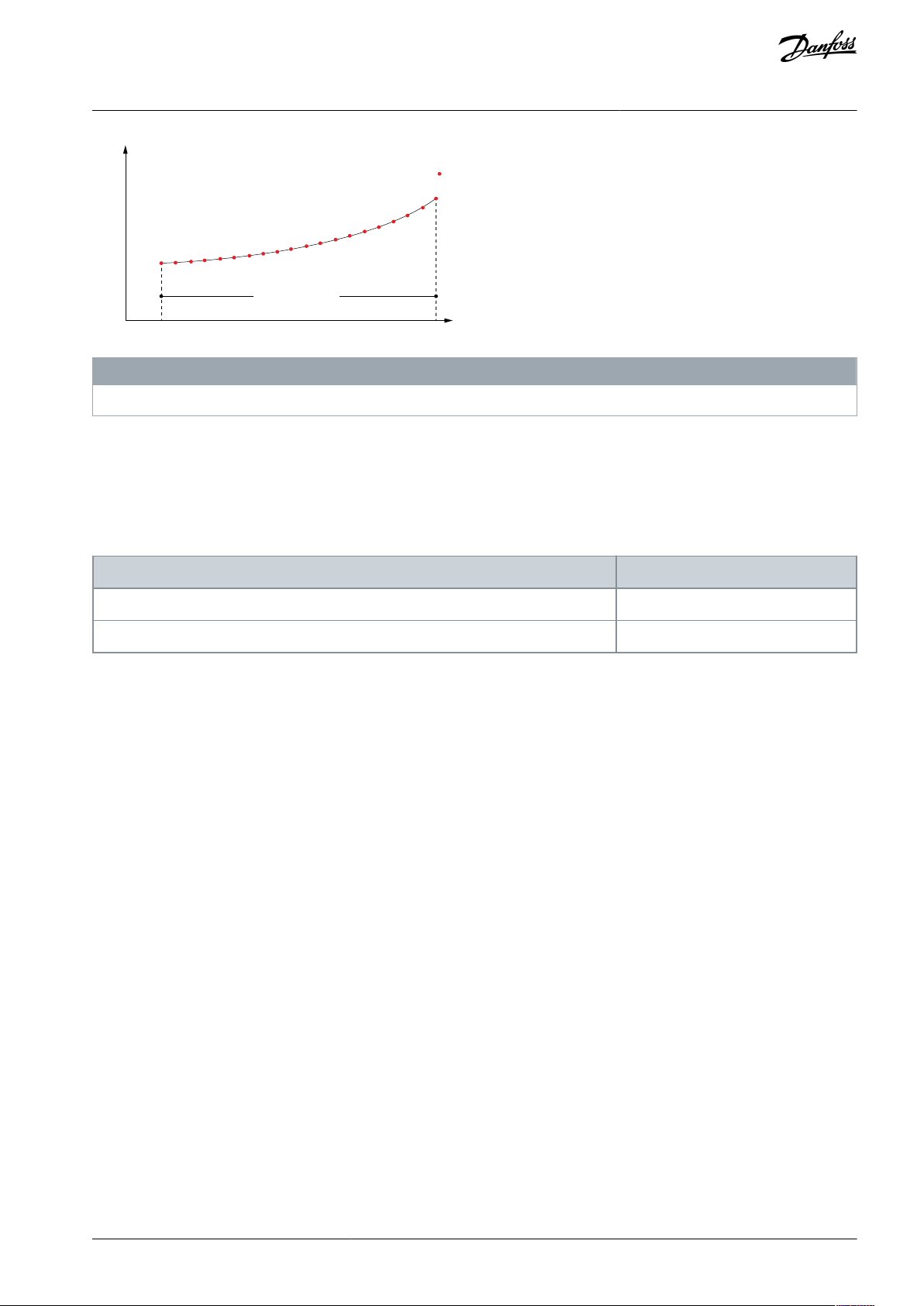

As illustrated in the graph below, a baseline consists of 20 speed points which are captured based on the user-dened minimum

and maximum observation interval.

AU310741645108en-000201 / 130R090112 | Danfoss A/S © 2020.10

Page 13

Speed point x 20

Value depending on feature

(vibration, load envelope, stator winding)

Observation area

Minimum

Frequency Maximum

e30bi292.10

Parameter ID and name

Example Values

Parameter 6-12 Terminal 53 Low Current

4 mA

Parameter 6-13 High Current

20 mA

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

monitoring

N O T I C E

For new installations, ISO 20816 recommends a wear-in period before taking a baseline measurement.

2.4.2 Step 2: Sensor Conguration (Optional)

Vibration monitoring requires installation of an external vibration transmitter. The sensor is connected via analog input using for

example terminal 53 or terminal 54. When using these terminals make sure to scale correctly. For AI53 S201 to ON = mA and for AI54

switch S202 to ON = mA.

Make sure to congure the correct scaling using parameters in Parameter Group 6-1* Analog Input 1.

For example when terminal AI53 is used, congure the following:

If these terminals are in use for other equipment, it is possible to extend the analog input with extension options. For information on

extension options, see the Selection Guide.

2.4.3 Step 3: Threshold Calculation

Dening or setting the threshold values

In this step, the thresholds are dened. There are 3 methods of threshold calculation.

•

Absolute: This is the common method when the equipment values are already known. The threshold has a xed value irrespec-

tive of the measured baseline value. For example, when the operator knows the absolute limit for the equipment, an absolute

value is set for the alarm threshold. In case of vibration monitoring, the limit values described in standards such as ISO

10816/20816 can be used for the alarm threshold as an absolute value.

•

Oset: This method of setting threshold values requires understanding of the application and baseline values. The threshold

depends on the baseline value to which a user-dened oset is considered in the threshold conguration. Setting a very low or

high value leading to false positives is a risk when using this method. False settings can cause irresponsive monitoring, even in

the case of faults.

•

Factor: This method is easier to use when compared to oset, because it does not require in-depth application knowledge. The

threshold depends on the baseline value which is multiplied by a factor. For example, the threshold value may be 150% of the

baseline. Setting a very high threshold is a risk when using this method of threshold calculation.

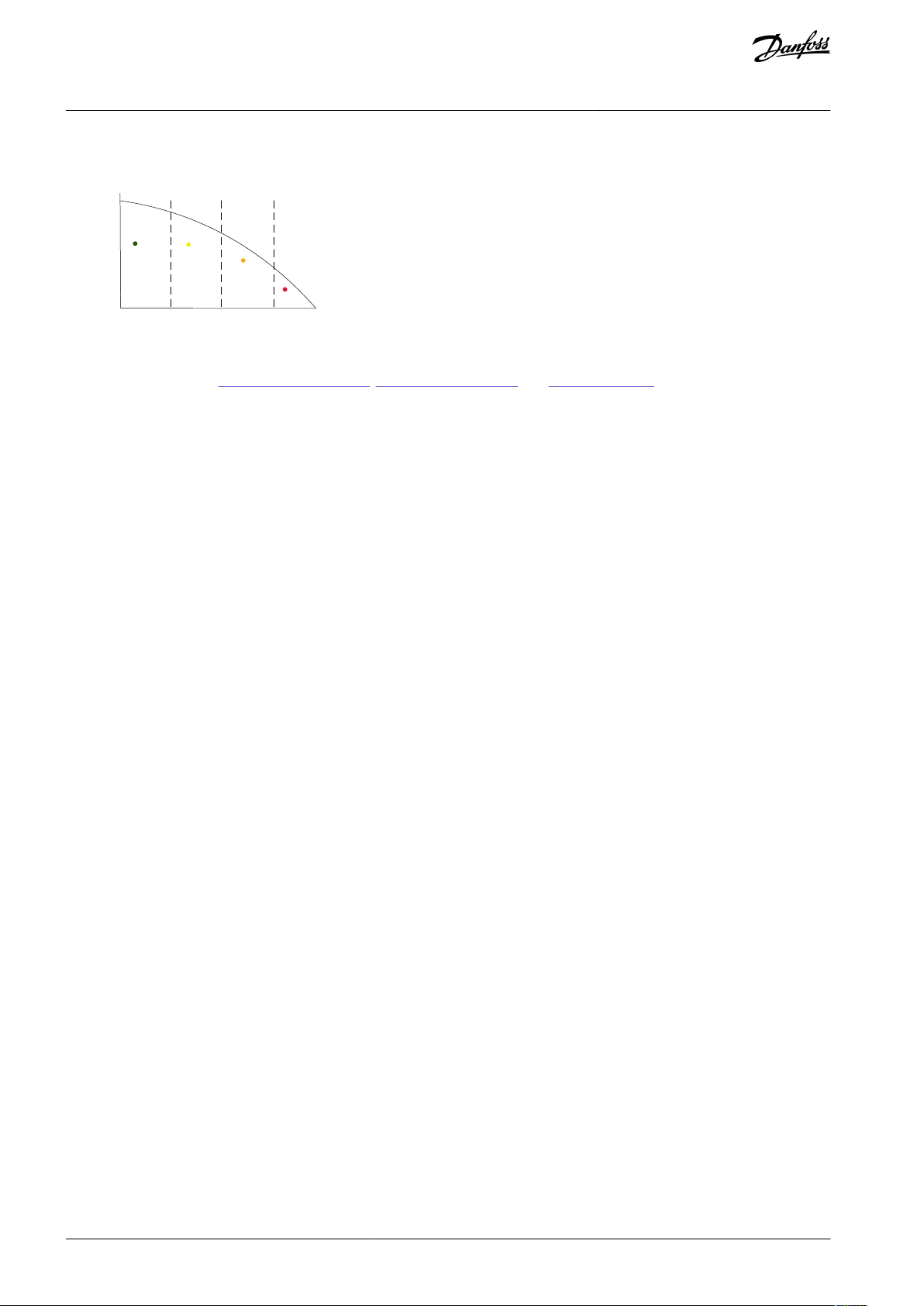

2.4.4 Step 4: Alarms and Warnings

In condition-based monitoring, for each feature, the user can dene activation stages for warnings and alarms. The interpretation of

alarm and warning color codes are as follows:

Green: No alarms are indicated. Condition-based monitoring operations continue.

Yellow: First indication of warning-stage 1 alarm is visible. Stage 1 warning fault are also shown as Stage 1 Warning (S1). Notication

to users to plan for maintenance operations. In this stage, condition-based monitoring operations continue.

Orange: Clear indication of warning-stage 2 alarm is visible. Stage 2 warning fault are also shown as Stage 2 Warning (S2). Notica-

tion to users to act as soon as possible before the fault becomes critical.

Red: A critical alarm has occurred and condition-based monitoring operations has stopped.

AU310741645108en-000201 / 130R0901 | 13Danfoss A/S © 2020.10

Page 14

Threshold

Time

No Faults

Warning

Stage 1

Fault

Warning

Stage 2

Fault

Critical

Fault

e30bu345.10

VLT® Condition-based Monitoring

Introduction to Condition-based

Programming Guide

Illustration 4: Alarm and Warning Stages

For more information, see 7.1 Motor Stator Windings, 7.2 Vibration Monitoring, and 7.3 Load Envelope.

monitoring

AU310741645108en-000201 / 130R090114 | Danfoss A/S © 2020.10

Page 15

Current spectrum

Voltage spectrum

Machine

status

e30bi294.10

Current (A)

Frequency (Hz)

Upper threshold

Lower threshold

Baseline

-0.5

1

0.5

1.5

2

0

0 10 20 30 40 50

e30bi293.10

VLT® Condition-based Monitoring

Examples of Condition-based

Programming Guide

Monitoring Functions

3 Examples of Condition-based Monitoring Functions

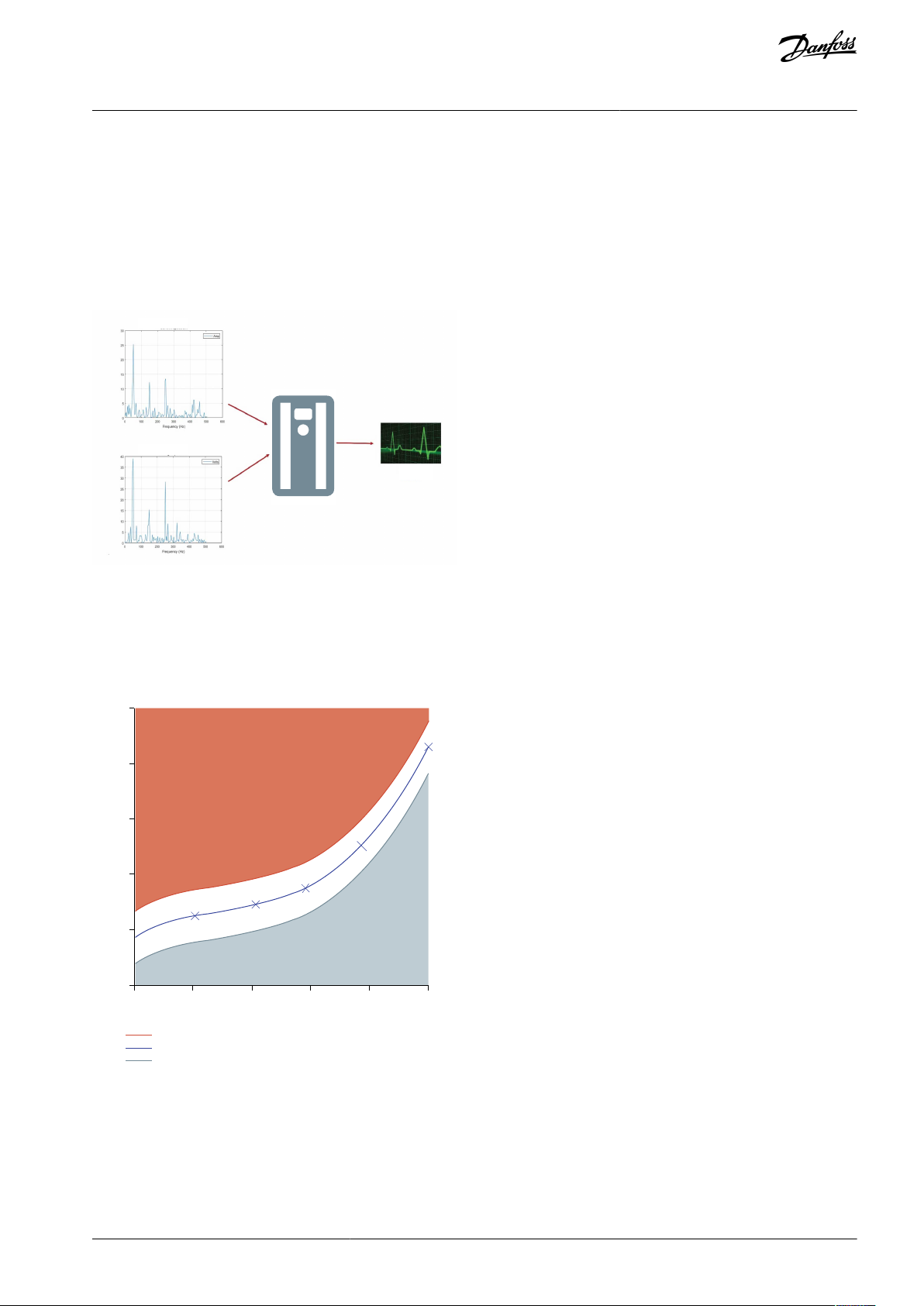

3.1 Example 1: Motor Stator Winding Monitoring

The AC drive provides variable magnitude of voltage and frequency to the stator terminal of connected 3-phase induction motors.

During healthy conditions of the motor with good stator winding insulation between inter-turn, the electrical signature shows consistency on the measurement. The electrical signature repeats the baseline value for repeated measurement.

However, in case of weakened insulation or inter-turn short circuit condition, the electrical signatures deviate from its original baseline values. The function withstands false positive in case of AC mains unbalance.

Illustration 5: Example of Motor Stator Winding Monitoring

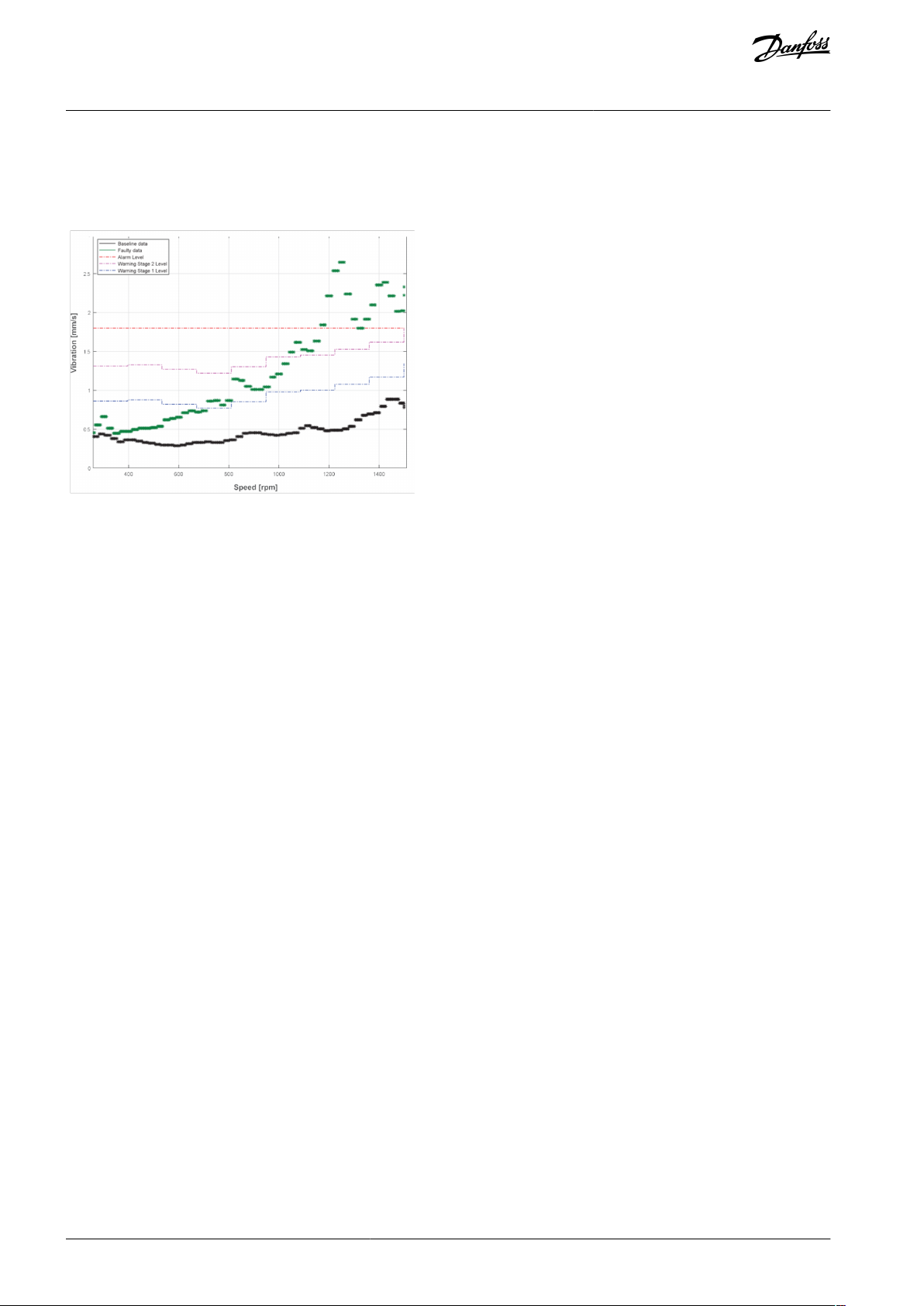

3.2 Example 2: Load Envelope

The function monitors torque and speed prole of the application which is measured during the baseline measurement. The threshold conguration works similar to the other functions. Condition-based monitoring can detect underload and overload situations.

Hence, there are 2 warning stages for high side (overload scenario) and 2 warning stages for underload scenario.

Illustration 6: Load Envelope Example

AU310741645108en-000201 / 130R0901 | 15Danfoss A/S © 2020.10

Page 16

e30bi328.10

VLT® Condition-based Monitoring

Examples of Condition-based

Programming Guide

Monitoring Functions

3.3 Example 3: Vibration Monitoring

The standard ISO 10816/20816 is the recommendation for vibration monitoring. The advantage, VLT® condition-based monitoring

provides, is the speed reference to the vibration level instead of an absolute level. The absolute level can mislead in lower levels of

the speed reference.

Illustration 7: Vibration Monitoring Example

AU310741645108en-000201 / 130R090116 | Danfoss A/S © 2020.10

Page 17

e30bi314.10

e30bi315.10

VLT® Condition-based Monitoring

Commissioning of Condition-based

Programming Guide

Monitoring

4 Commissioning of Condition-based Monitoring

4.1 Commissioning Overview

This chapter describes the commissioning of condition-based monitoring from baseline creation to monitoring the system. Before

performing commissioning steps, the assumption is the drive is installed and the license code for condition-based monitoring is

activated in the drive.

Danfoss Drives recommends to use MCT-10 Condition-based monitoring plug-in for commissioning of condition-based monitoring.

It is also possible to perform the commissioning using LCP. The following sections in this chapter, contain the following:

•

Commissioning using MCT-10 condition-based monitoring plug-in

•

Commissioning using LCP

•

Threshold Conguration Guidelines

Based on your MCT-10 version and activated license code, the plug-in is shown below.

Illustration 8: Condition-based Monitoring Plugin

4.2 Commissioning using MCT-10 Condition-based Monitoring Plug-in

Perform the following steps to set up conditiion-based monitoring in the drive.

•

Ensure MCT-10 version 5.11 or later is installed.

•

Ensure the desktop or laptop is connected to a powered-on AC drive with activated license code.

Note: The red highlight in the gure correspond to Danfoss recommended selections, and the blue highlight in the gure corre-

spond to application values. These values can vary based on application.

Procedure: The following are recommended steps to set-up condition-based monitoring:

1.

Select Online Baseline.

AU310741645108en-000201 / 130R0901 | 17Danfoss A/S © 2020.10

Page 18

e30bi316.10

e30bi317.10

Online baseline

Baseline run

2 Hours

1 Minute

4 Hours

2 Minutes

8 Hours

4 Minutes

1 Day

10 Minutes

2 Days

30 Minutes

5 Days

1 Hour

1 Week

2 Hours

2 Weeks

1 Month

2 Months

4 Months

6 Months

VLT® Condition-based Monitoring

Programming Guide

2.

Select minimum and maximum speed range using the slider or specify values in the textboxes.

The recommendation is to congure a speed window which relates to motor limitations. The motor speed is congured in

Parameter 4-11 Motor Speed Low Limit [RPM] and Parameter 4-13 Motor Speed High Limit [RPM].

Commissioning of Condition-based

Monitoring

Note: For advanced baseline settings, the minimum speed can be set as 30% of nominal speed as failures in low speed

measurement ranges are dicult to detect.

3.

Specify duration to capture baseline in Duration eld.

It is recommended to specify atleast 1 Week or more in the Duration eld.

Some of the duration options and corresponding baseline run values are specied below:

4.

Specify the speed band in the Speed step band, % eld.

AU310741645108en-000201 / 130R090118 | Danfoss A/S © 2020.10

Page 19

e30bi318.10

e30bi319.10

e30bi320.10

VLT® Condition-based Monitoring

Programming Guide

Note: Do not set speed band to 0%. 0% is for niche applications.

5.

Congure vibration sensor information in Sensor source and Sensor unit elds.

By default, no value is selected in the elds. If vibration sensors are not congured, press Next.

6.

Congure the minimum and maximum reference values in AI53 minimum input, AI53 maximum input, AI54 minimum input,

and AI54 maximum input. Press Next.

The recommended minimum and maximum values are 0 and 100 respectively, providing a reference from 0% to 100%.

Commissioning of Condition-based

Monitoring

Make sure to provide the correct scaling either 0-20 mA or 4-20 mA. See Sensor Conguration (Optional).

7.

Select an option to set method of baseline conguration. Press Next.

Note:

•

Duration to nish online baseline execution can occur within a period of 2 hours, 6 months, or one week.

•

Creating a baseline before conguring monitoring settings, requires an additional on-site visit to congure the threshold settings.

8.

To congure stator thresholds, congure settings in Stator tab.

9.

Select the Danfoss recommended options (highlight in red).

10.

Specify application values in Alarm and Warnings elds (highlight in blue).

Note: The values in the gure do not imply specic application values. Ensure to enter values which suit the application.

Following are the recommended application specic values for monitoring motor stator winding. See

4.4 Threshold Con-

guration Guidelines.

AU310741645108en-000201 / 130R0901 | 19Danfoss A/S © 2020.10

Page 20

e30bi321.10

e30bi322.10

e30bi323.10

VLT® Condition-based Monitoring

Programming Guide

11.

To congure load envelope threshold settings, press Load tab.

12.

Select the Danfoss recommended options (highlight in red).

13.

Specify the application-specic values in Alarms and Warnings elds (highlight in blue).

Note: The values in the gure does not imply specic application values. Ensure to enter values which suit the application.

Commissioning of Condition-based

Monitoring

14.

To congure vibration monitoring threshold congurations, pressVibration 1 tab.

15.

Select Danfoss recommended options (highlight in red).

16.

Specify application specic values in Alarm and Warnings eld (highlight in blue).

17.

Click Create Baseline.

AU310741645108en-000201 / 130R090120 | Danfoss A/S © 2020.10

Page 21

e30bi324.10

e30bi325.10

e30bi326.10

e30bi327.10

VLT® Condition-based Monitoring

Programming Guide

Commissioning of Condition-based

Monitoring

The progress bar indicates the remaining time for completion.

18.

To modify the duration during baseline creation, select required timeline from the Duration eld.

19.

To stop the baseline creation, click Stop Baseline Creation.

A timestamp is displayed in Started and Stopped eld, when parameter 0-70 Date and Time is congured.

AU310741645108en-000201 / 130R0901 | 21Danfoss A/S © 2020.10

Page 22

•••

•

ID

Name

Value

Parameter 45-00.0

Function (Stator Winding Monitoring)

Select [1] Warning to congure warning for stator winding monitoring.

Parameter 45-00.1

Function (Load Envelope)

Select [1] Warning to congure warning for load envelope.

Parameter 45-00.2

Function (Vibration Sensor 1)

Select [1] Warning to congure warning for vibration monitoring.

Parameter 45-00.3

Function (Vibration Sensor 2)

Select [0] Oto disable warnings or alarms for vibration sensor 2.

Parameter 45-24

Duration

Select [36] 1 week. This selection must be based on application.

Parameter 45-25

Online Speed Band

Select 5. This selection is application specic.

Parameter 45-26

Minimum Speed

Congure the same value as specied in Parameter 4-11

Parameter 45-27

Maximum Speed

Congure the same value as specied in Parameter 4-13

Parameter 45-20

Type

Select [2] Online Baseline.

Parameter number

Parameter name

Description and setting

Parameter 45-30.0

Baseline Statistics

Set [3] Mean +/-3 Standard Deviation

Parameter 45-31.0

Warning mode

[1] Oset

Parameter 45-34.0

Warning S2

For motor sizes 0 - <22 kW, specify 4.00.

For motor sizes >22kW, specify 2.00

Parameter 45-35.0

Warning S1

For motor sizes 0 - <22 kW, specify 2.00.

For motor sizes >22kW, specify 1.00

Parameter 46-11.0

Warning S2 time

Specify 10.00

Parameter 46-12.0

Warning S1 time

Specify 10.00

Parameter 45-60

Active Threshold

Specify 0.05

Parameter 45-61

Load Mode

For constant torque, specify [0] Absolute. For variable torque, specify [1] Oset.

Parameter 46-62

Load Threshold

For constant torque, specify 160. For variable torque, specify 2.

Parameter number

Parameter name

Description and setting

Parameter 45-32.0

Alarm Mode

Set [1] Oset.

VLT® Condition-based Monitoring

Programming Guide

4.3 Recommended Parameter Set-up using LCP or MCT-10

Step 1: Baseline Conguration

Commissioning of Condition-based

Monitoring

Result:

•

Parameter 45-21 shows the baseline status.

•

Parameter 45-22 shows the baseline progress.

Step 2: Threshold Conguration for Stator Winding Monitoring

To congure warnings, set parameter 45-00.0 to [1] Warning.

To congure alarms, set parameter 45-0.0 to [2] Alarm & Warning.

AU310741645108en-000201 / 130R090122 | Danfoss A/S © 2020.10

Page 23

•

•

•

Parameter number

Parameter name

Description and setting

Parameter 45-33.0

Alarm High

For motor sizes 0 - <22 kW, specify 6.00.

For motor sizes 22kW - <90kW, specify 4.00.

For motor sizes 90KW and above, specify 3.00.

Parameter 46-10.0

Alarm time

Specify 10.00

Parameter number

Parameter name

Description and setting

Parameter 45-30.1

Baseline Statistics

Set [3] Mean +/-3 Standard Deviation

Parameter 45-31.1

Warning mode

[1] Oset

Parameter 45-34.1

Warning S2 High

Specify 30. The value in this parameter is based on the application.

Parameter 45-35.1

Warning S1 High

Specify 20. The value in this parameter is based on the application.

Parameter 45-36.1

Warning S1 Low

Specify 20. The value in this parameter is based on the application.

Parameter 45-37.1

Warning S2 Low

Specify 30. The value in this parameter is based on the application.

Parameter 46-11.1

Warning S2 Time

Specify 10.00.

Parameter 46-12.1

Warning S1 Time

Specify 10.00.

Parameter 46-13.1

Interpolation Type

Specify [0] Linear.

Parameter number

Parameter name

Description and setting

Parameter 45-00.1

Function (Load Envelope)

Set [2] Alarm & Warning

Parameter 45-32.1

Alarm mode

[1] Oset

Parameter 45-33.1

Alarm high

Specify 60.

Parameter 45-38.1

Alarm low

Specify 60.

Parameter 46-10.1

Alarm time

Specify 10.00.

Parameter number

Parameter name

Description and setting

Parameter 45-30.2

Baseline Statistics

Set [3] Mean+/- Standard Deviation

Parameter 45-31.2

Warning mode

[1] Oset

Parameter 45-34.2

Warning S2 High

Specify 1.52.

Parameter 45-35.2

Warning S1 High

Specify 1.12.

Parameter 46-11.2

Warning S2 time

Specify 10.00.

Parameter 46-12.2

Warning S1 time

Specify 10.00.

Parameter 46-13.2

Interpolation Type

Set [1] Linear.

VLT® Condition-based Monitoring

Commissioning of Condition-based

Programming Guide

Step 3: Threshold Conguration for Load Envelope

To congure warnings, set parameter 45-00.1 to [1] Warning. Following are the recommended settings.

Monitoring

To congure alarm, set parameter 45-00.1 to [2] Alarm & Warnings. Following are the recommended settings. When alarms are raised,

the system operation is stopped.

Step 4: Vibration Threshold Conguration

AU310741645108en-000201 / 130R0901 | 23Danfoss A/S © 2020.10

Page 24

Parameter number

Parameter name

Description and setting

Parameter 45-00.1

Function (Load Envelope)

Set [2] Alarm & Warning

Parameter 45-32.1

Alarm mode

[1] Oset

Parameter 45-33.1

Alarm high

Specify 60.

Parameter 45-38.1

Alarm low

Specify 0.

Parameter 46-10.1

Alarm time

Specify 10.00.

Parameter

Alarm or Warning

Motor Size <

22kW

Motor Size 22kW to

<90 kW

Motor Size 90kW to

<355 kW

Motor Size 355kW

and higher

Parameter 45-33[0]

Alarm

(*)

6.00

4.00

3.00

3.00

Parameter 45-34[0]

Warning 2

4.00

2.00

2.00

2.00

Parameter 45-35[0]

Warning 1

2.00

1.00

1.00

1.00

Zone

Part 3 (Industrial Machines >15kW)

Part 7 (Pumps)

Part 1 (Rest)

Rigid

Flexible

Category 1 (critical)

Category 2 (less critical)

Small /

Rigid

Large /

Flexible

<300kW

>300kW

<300kW

>300kW

<200kW

>200kW

<200kW

>200kW

Zone C limit

(mm/s)

4.5

7.1

7.1116.6

7.6

8.5

9.5

4.5

14.7

Zone B limit

(mm/s)

2.8

4.5

4.5

7.145

5.1

6.1

1.8

9.3

Zone A limit

(mm/s)

1.4

2.3

2.3

3.5

2.5

3.5

3.2

4.2

0.71

4.5

Vibration

Warning

Oset

(mm/2)

0.7

1.125

1.125

1.775

1

1.25

1.275

1.525

0.45

2.325

O-set %

for level 1

Example

(1))

2.8

4.5

4.5

7.145

5.1

6.1

1.8

9.3

VLT® Condition-based Monitoring

Commissioning of Condition-based

Programming Guide

When parameter 45-00.1 is set to [2] Alarm & Warnings, following are the recommended settings. When alarms are raised, the system

operation is stopped.

Monitoring

4.4 Threshold Conguration Guidelines

Application specic input for monitoring Motor Stator Winding

Following are the recommendation congurations for dierent motor sizes to monitor motor stator winding.

*

By default, the setting should be disabled, as it stops system operation, when the event occurs.

Application specic input for Vibration Monitoring

Following are the recommendation congurations for dierent motor sizes to monitor motor stator winding.

Table 6: Recommendation for Vibration Monitoring

1)

sensor range 25mm/s

AU310741645108en-000201 / 130R090124 | Danfoss A/S © 2020.10

Page 25

Alarm or Warning overview

Alarm

number

(Parameter 18-55)

Warning

number

(Parameter 18-56)

Alarm

Word 3

(Parameter 16-97)

Warning

Word 3

(Parameter 16-98)

Description

Stator

Alarm

51031Warning S2

50030Warning S1

510

31

Max/min thresholds exceed

520

Congure the bit to show the alarm when maximum or

minimum threshold value is exceeded during automatic generation or manual change.

Load Envelope

Alarm high

51130Congure the bit to show load envelope high alarm.

Warning S2 high

50128Congure the bit to show load envelope high stage 2

warning.

Warning S1 high

51129Congure the bit to show load envelope high stage 1

warning.

Warning S1 low

51129Congure the bit to show load envelope low stage 1

warning.

Warning S2 low

50128Congure the bit to show load envelope low stage 2

warning.

Alarm Low

51130Congure the bit to show low alarm.

Max/min thresholds exceed

521

Congure the bit to show an alarm when the minimum

or maximum threshold value is exceeded during automatic generation or manual change.

Sensor 1

Alarm

51229Congure the bit to show an alarm for sensor 1.

Warning S2

50226Congure the bit to show a warning stage 2 for sensor

1.

VLT® Condition-based Monitoring

Fieldbus Integration for Condition-

Programming Guide

based Monitoring

5 Fieldbus Integration for Condition-based Monitoring

5.1 Fieldbus Integration - Options and Parameters

The parameter 16-03 Status Word indicates the overall alarm or warning which is triggered due to condition-based monitoring. Specic alarms and warnings are congured using parameter 16-97 Alarm Word 3 and parameter 16-98 Warning Word 3. To make sure

that the eldbus is integrated for viewing the alarms and warnings in condition-based monitoring, congure the following:

Alarm and Warning number with associated bits

The bit for each alarm and warning number is congured in parameter 18-55 Active Alarm Number, parameter 18-56 Active Warning

Numbers, parameter 16-97 Alarm Word 3, and parameter 16-98 Warning Word 3, as shown in the table. The alarm and warning number

is reected in the LCP.

N O T I C E

Parameter 18-55 Active Alarm Numbers and Parameter 18-56 Active Warning Numbers is only available in VLT® Automation Drive FC

302.

Table 7: Bits for conguring alarm and warning number

AU310741645108en-000201 / 130R0901 | 25Danfoss A/S © 2020.10

Page 26

Alarm or Warning overview

Alarm

number

(Parameter 18-55)

Warning

number

(Parameter 18-56)

Alarm

Word 3

(Parameter 16-97)

Warning

Word 3

(Parameter 16-98)

Description

Warning S1

51227Congure the bit to show a warning stage 1 for sensor

1.

Max/min thresholds exceed

522

Congure the bit to show an alarm when maximum or

minimum threshold values is exceeded during automatic generation or manual change

Sensor 2

Alarm

51328Congure the bit to show an alarm for sensor 2.

Warning S2

50324Congure the bit to show a warning stage 2 for sensor

2.

Warning S1

51325Congure the bit to show a warning stage 1 for sensor

2.

Max/min thresholds exceed

523

Congure the bit to show a warning when maximum

or minimum threshold values exceed during automatic

generation or manual change.

Sensor 3

Alarm

51427Congure the bit to show an alarm for sensor 3.

Warning S2

50422Congure the bit to show a warning stage 2 for sensor

3.

Warning S1

51423Congure the bit to show a warning stage 1 for sensor

3.

Max/min thresholds exceed

524

Congure the bit to show an alarm when maximum or

minimum threshold values is exceeded during automatic generation or manual change.

Sensor 4

Alarm

51526Congure the bit to show an alarm for sensor 4.

Warning S2

50520Congure the bit to show a warning stage 2 for sensor

4.

Warning S1

51521Congure the bit to show a warning stage 1 for sensor

4.

Max/min thresholds exceed

525

Congure the bit to show an alarm when maximum or

minimum threshold value is exceeded during automatic generation or manual change.

Bit

Hex

Dec

Alarm Word 3 in parameter 16-97

Warning Word 3 in parameter 16-98

011

Temperature input error

Temperature input error

122

Memory Modele Fault

VLT® Condition-based Monitoring

Programming Guide

Fieldbus Integration for Condition-

based Monitoring

Alarm and Warning Conversion

In the following table, the conversion for bit, hexadecimal, and decimal are listed for parameter 16-97 Alarm Word 3 and parameter

16-98 Warning Word 3.

Table 8: Alarm and Warning Conversion Table

AU310741645108en-000201 / 130R090126 | Danfoss A/S © 2020.10

Page 27

Bit

Hex

Dec

Alarm Word 3 in parameter 16-97

Warning Word 3 in parameter 16-98

244

Internal Fan Error

Internal Fan Warning

388

Sync. Fault

41016

ORM Fault

52032

Test MOC Function

64064

Probus Converter Invalid

Probus Converter time warning

7801288100

2569200

51210400

102411800

2048121000

4096132000

8192144000

16384

15

8000

32768

16

10000

65536

17

20000

131072

18

40000

262144

19

80000

524288

20

100000

1048576

Sensor 4 S2

21

200000

2097152

Sensor 4 S1

22

400000

4194304

Sensor 3 S2

23

800000

8388608

Sensor 3 S1

24

1000000

16777216

Sensor 2 S2

25

2000000

33554432

Sensor 2 S1

26

4000000

67108864

CBM Sensor 4 Alarm

Sensor 1 S2

27

8000000

134217728

CBM Sensor 3 Alarm

Sensor 1 S1

28

10000000

268435456

CBM Sensor 2 Alarm

CBM Load Envelope High/Low S2

29

20000000

536870912

CBM Sensor 1 Alarm

CBM Load Envelope High/Low S1

30

40000000

1073741824

CBM Load High/Low Alarm

CBM Motor Stator Winding S2

31

80000000

2147483648

CBM Motor Stator Winding Alarm

CBM Motor Stator Winding S1

VLT® Condition-based Monitoring

Programming Guide

Fieldbus Integration for Condition-

based Monitoring

PCD Parameters

In the section, the parameters relevant for conguring the dierent eldbus options are described. Within the array index of the

parameter, make sure to congure the option in order to setup condition-based monitoring via eldbus.

AU310741645108en-000201 / 130R0901 | 27Danfoss A/S © 2020.10

Page 28

Parameter 8-43

Parameter 8-43.0

Parameter 8-43.2

Parameter 8-43.3

FC

[1603] Status word

[1697] Alarm Word 3

[1698] Warning Word 3

Modbus RTU

Metasys N2

Parameter 9-16

Parameter 9-16.0

Parameter 9-16.2

Parameter 9-16.3

VLT Probus DP MCA 101

[1603] Status word

[1697] Alarm Word 3

[1698] Warning Word 3

VLT Pronet MCA 120

Parameter 10-12

Paramter 10-12.0

Paramter 10-12.2

Parameter 10-12.3

VLT Devicenet MCA 104

[1603] Status word

[1697] Alarm Word 3

[1698] Warning Word 3

Parameter 10-51

Parameter 10-51.0

Parameter 10-51.2

Parameter 10-51.3

VLT CANOpen MCA 105

[1603] Status word

[1697] Alarm Word 3

[1698] Warning Word 3

Parameter 12-22

Parameter 12-22.0

Parameter 12-22.2

Parameter 12-22.3

VLT Ethernet/IP MCA 121

[1603] Status word

[1697] Alarm Word 3

[1698] Warning Word 3

VLT Modbus TCP MCA 122

VLT POWERLINK MCA 123

VLT® Condition-based Monitoring

Programming Guide

Table 9: Fieldbus option using parameter 8-43 PCD Read Conguration

Table 10: Fieldbus option using parameter 9-16 PCD Read Conguration

Table 11: Fieldbus

Fieldbus Integration for Condition-

based Monitoring

Table 12: Fieldbus option using Parameter 10-51 Process Data Cong Read

Table 13: Fieldbus option using Parameter 12-22 Process Data Cong Read

AU310741645108en-000201 / 130R090128 | Danfoss A/S © 2020.10

Page 29

45-00: Function

Default Value:O

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: False

Options

Option

Name

Description

[0]ONotication is disabled.

[1]

Warning

Warning notications are triggered.

[2]

Alarm & Warning

Both alarm and warning notications are triggered.

Parameter ID

Description

45-00.0

Select the required option to enable stator winding monitoring.

45-00.1

Select the required option to enable load envelope

45-00.2

Select the required option to enable sensor 1 vibration.

45-00.3

Select the requred option to enable sensor 2 vibration.

Default Value: O

Parameter Type: Option

4-setup: 2setup

Conversion Index: -

Data Type: Uint8

Change during operation: False

Option

Name

Description

[0]*OStatus is disabled.

[1]OnShows current monitoring status.

[2]

Waiting For Baseline

Baseline computation is in progress.

45-10: Alarm High Threshold

Default Value:0%

Parameter Type: Range

4-setup: All set-up

VLT® Condition-based Monitoring

Programming Guide

Parameter Descriptions

6 Parameter Descriptions

6.1 Parameter Group 45 -** Condition-based Monitoring

In this parameter group, you can enable condition-based monitoring, dene units, baseline computation, input sources, view baseline status, and progress.

Parameter 45-00: Function

Table 14: Parameter 45-00

Set type of notication level and to enable monitoring of the drive.

Table 15: Options

Table 16: Parameter Index

Parameter 45-01: Status

Set the parameter to view current monitoring status.

Parameter 45-10: Alarm High Threshold

Table 17: Parameter 45-10

AU310741645108en-000201 / 130R0901 | 29Danfoss A/S © 2020.10

Page 30

45-10: Alarm High Threshold

Conversion Index: -

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-10.0

Stator Winding

45-10.1

Stator Winding Active

45-10.2

Stator Winding Load

45-10.3

Load Envelope

45-10.4

Sensor 1 Vibration

45-10.5

Sensor 2 Vibration

45-11: Warning S2 High Threshold

Default Value: 0

Parameter Type: Range [0 - 655.35 %]

4-setup: All setups

Conversion Index:

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-11.0

Stator Winding

45-11.1

Stator Winding Active

45-11.2

Stator Winding Load

45-11.3

Load Envelope

45-11.4

Sensor 1 Vibration

45-11.5

Sensor 2 Vibration

45-12: Warning S1 High Threshold

Default Value: 0

Parameter Type: Range [0 - 655.35 %]

4-setup: All setups

Conversion Index: -2

Data Type: Uint8

Change during operation: True

VLT® Condition-based Monitoring

Programming Guide

Set the maximum threshold limit. The drive triggers a notication when threshold limit is exceeded.

Table 18: Options

Parameter 45-11: Warning S2 High Threshold

Parameter Descriptions

Table 19: Parameter 45-11

Set the maximum threshold limit for warning stage 2 for the index. The drive triggers a warning notication when threshold limit is

exceeded.

Table 20: Parameter Index

Parameter 45-12: Warning S1 High Threshold

Table 21: Parameter 45-12

Set the maximum threshold limit for warning stage 1, in the parameter index. The drive triggers a warning notication when threshold limit is exceeded. Entering a value in the parameter indicates a user specied threshold limit.

AU310741645108en-000201 / 130R090130 | Danfoss A/S © 2020.10

Page 31

Parameter ID

Description

45-12.0

Stator Winding

45-12.1

Stator Winding Active

45-12.2

Stator Winding Load

45-12.3

Load Envelope

45-12.4

Sensor 1 Vibration

45-12.5

Sensor 2 Vibration

45-13: Actual Monitor Value

Default Value:0%

Parameter Type: N/A

4-setup: All setups

Conversion Index: -2

Data Type: Uint16

Change during operation: True

Parameter ID

Description

45-13.0

Stator Winding

45-13.1

Stator Winding Active

45-13.2

Stator Winding Load

45-13.3

Load Envelope

45-13.4

Sensor 1 Vibration

45-13.5

Sensor 2 Vibration

45-14: Warning S1 Low Threshold

Default Value:0%

Parameter Type: Range [0 - 655.35 %]

4-setup: All set up

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-14.0

Stator Winding

45-14.1

Stator Winding Active

45-14.2

Stator Winding Load

VLT® Condition-based Monitoring

Programming Guide

Table 22: Parameter Index

Parameter 45-13: Actual Monitor Value

Table 23: Parameter 45-13

Parameter Descriptions

Shows the current value of selected signal.

Table 24: Parameter Index

Parameter 45-14: Warning S1 Low Threshold

Table 25: Parameter 45-14

Set the minimum threshold limit for warning stage 1 notication in the parameter index. The drive triggers a notication when the

actual monitoring value falls below the minimum threshold limit.

Table 26: Parameter Index

AU310741645108en-000201 / 130R0901 | 31Danfoss A/S © 2020.10

Page 32

45-14.3

Load Envelope

45-14.4

Sensor 1 Vibration

45-14.5

Sensor 2 Vibration

45-15: Warning S2 Low Threshold

Default Value:0%

Parameter Type: Range [0 - 655.35 %]

4-setup: All setups

Conversion Index: -

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-15.0

Stator Winding

45-15.1

Stator Winding Active

45-15.2

Stator Winding Load

45-15.3

Load Envelope

45-15.4

Sensor 1 Vibration

45-15.5

Sensor 2 Vibration

45-16: Alarm Low Threshold

Default Value:0

Parameter Type: Range ()

4-setup: All setups

Conversion Index: -

Data Type: Uint16

Change during operation: True

Parameter ID

Description

45-16.0

Stator Winding

45-16.1

Stator Winding Active

45-16.2

Stator Winding Load

45-16.3

Load Envelope

45-16.4

Sensor 1 Vibration

45-16.5

Sensor 2 Vibration

VLT® Condition-based Monitoring

Programming Guide

Parameter Descriptions

Parameter 45-15: Warning S2 Low Threshold

Table 27: Parameter 45-15

Set the minimum threshold limit for warning stage 2 notication, in the parameter index. The drive triggers a warning stage 2 notication when the actual monitoring value falls below the threshold limit specied in the parameter.

Table 28: Parameter Index

Parameter 45-16: Alarm Low Threshold

Table 29: Parameter 45-16

Set the minimum threshold limit, in the parameter index. The drive triggers an alarm notication when the actual falls below the

minimum threshold limit.

Table 30: Parameter Index

Parameter 45–20: Type

AU310741645108en-000201 / 130R090132 | Danfoss A/S © 2020.10

Page 33

Default Value: O

Parameter Type: Option

4-setup: All setups

Conversion Index: -

Data Type: Uint8

Change during operation: True

Option

Name

Description

[0]*OBaseline computation type is not set.

[1]

Baseline

Run

Select the option when the application can operate from minimum to maximum speed in one sweep. On

enabling this option, the condition-based monitoring function sets speed points. On completion of baseline computation, the motor is ramped down to 0. The option can only operate when Hand On mode is set

via control panel.

[2]

Online

Baseline

Select the option in applications where baseline run cannot be utilized. In this type of baseline computation, the drive is controlled by the application baseline and speed points are recorded and saved during

the duration specied in Parameter 45-24 Duration. The option can only operate when Auto On mode is set

via control panel.

Default Value: Not Started

Parameter Type: Option

4-setup: All setups

Conversion Index: -

Data Type: Uint16

Change during operation: True

Option

Name

Description

[0]*

Not Started

-

[1]

Baseline Run running

-

[2]

Online Baseline running

-

[3]

Baseline Completed

-

[4]

Baseline Failed

-

Default Value: 0%

Parameter Type: [0-100%]

4-setup: All setups

Conversion Index: -

Data Type: Uint8

Change during operation: True

Default Value: Size related

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: False

Option

Name

Description

[0]

1 Min

-

[1]

2 Mins

-

VLT® Condition-based Monitoring

Programming Guide

Use the parameter to select type of baseline computation.

Parameter 45–21: Status

Parameter Descriptions

Shows the current status of baseline computation.

Parameter 45–22: Progress

Shows the progress of baseline computation. 0% indicates that the baseline computation is not started and 100% indicates that

baseline computation is completed.

Parameter 45–24: Duration

Select a suitable duration for baseline computation. If a value is not selected, by default, the system considers 2 minutes for baseline

run and 1 hour for online baseline.

AU310741645108en-000201 / 130R0901 | 33Danfoss A/S © 2020.10

Page 34

Option

Name

Description

[2]

4 Mins

-

[6]

10 Mins

-

[9]

30 Mins

-

[13]

1 Hour

-

[16]

2 Hours

-

[19]

4 Hours

-

[23]

8 Hours

-

[27]

1 Day

-

[30]

2 Days

-

[33]

5 Days

-

[36]

1 Week

-

[40]

2 Weeks

-

[43]

1 Month

-

[46]

2 Months

-

[49]

4 Months

-

[52]

6 Months

-

Default Value: 2%

Parameter Type: [0–5%]

4-setup: 2 setup

Conversion Index: 0

Data Type: Uint8

Change during operation: True

Default Value: Size Related

Parameter Type: Range [parameter 4-11 – 3600 RPM]

4-setup: 2 setup

Conversion Index: 67

Data Type: Uint16

Change during operation: False

Default Value: Size Related

Parameter Type: [0 – parameter 4-13]

4-setup: 2 setup

Conversion Index: 67

Data Type: Uint16

Change during operation: False

Default Value: Size related

Parameter Type: Range [parameter 45-26 – parameter 45-27RPM]

4-setup: 2 setup

VLT® Condition-based Monitoring

Programming Guide

Parameter Descriptions

Parameter 45–25: Online Speed Band

Use this parameter to dene a window to capture the baseline data for dierent speed points when the speed of drive is within the

specied band percentage. Setting the parameter increases a chance to capture all speed points in online baseline mode.

Parameter 45–26 Min. Speed

Use this parameter to set the minimum speed of the drive to begin condition-based monitoring functions. Ensure to set a value

which exceeds the minimum speed limit of motor. The minimum limit of motor speed corresponds to the setting in parameter 4-11

Motor Speed Low Limit [RPM]. For more information, refer to VLT® AutomationDrive FC 301/302 Programming Guide.

Parameter 45–27: Max.Speed

Use this parameter to set the maximum speed of the drive for condition-based monitoring functions. Setting the minimum and

maximum speed denes the speed range for condition-based monitoring functions to perform eectively. Ensure to set a value

which does not exceed the maximum limit of motor speed. The maximum limit of motor speed corresponds to the setting in param-

eter 4-13 Motor Speed High Limit [RPM]. For more information, refer to the corresponding VLT® Product Programming Guide.

Parameter 45–28: Speed Points

AU310741645108en-000201 / 130R090134 | Danfoss A/S © 2020.10

Page 35

Conversion Index: 67

Data Type: Uint16

Change during operation: False

Default Value: Mean

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: True

Option

Name

Description

[1]*

Mean

Average of the baseline data is shown.

[2]

Maximum/Minimum

Maximum and minimum of the baseline data is shown.

[3]

Mean +/- 3 Standard Deviation

Mean and +/-3 standard deviations of the baseline data is shown.

Parameter ID

Description

45-30.0

Stator Winding

45-30.1

Load Envelope

45-30.2

Sensor 1 Vibration

45-30.3

Sensor 2 Vibration

Default Value: Absolute

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: True

Option

Name

Description

[0]*

Absolute

Absolute value is considered as threshold limit.

[1]

Oset

Calculates threshold as a sum of the computed baseline data and the oset values.

[2]

Factor

Calculates threshold as baseline data * factor.

Parameter ID

Description

45-31.0

Stator Winding

45-31.1

Load Envelope

45-31.2

Sensor 1 Vibration

45-31.3

Sensor 2 Vibration

VLT® Condition-based Monitoring

Programming Guide

Shows the baseline speed points calculated within the range dened in parameter 45-26 Min.Speed and parameter 45-27 Max.speed.

Parameter 45–30: Baseline Statistics

Select type of baseline statistical data for visualizing calculated threshold limits for each parameter index. The calculated threshold

is used for monitoring purposes.

Table 31: Parameter Index

Parameter Descriptions

Parameter 45–31: Warning Mode

Select a mode to dene threshold limit for warnings.

The values can be specied in Parameter 45-34 Warning S2 High , Parameter 45-35 Warning S1 High, Parameter 45-36 Warning S1 Low,

and Parameter 45-37 Warning S2 Low. For example, if you select Absolute as the option and an warning S2 low and warning S1 high

value as 200 and 300 respectively. The threshold limit for warning stage 2 ranges from 200 to 300.

Table 32: Parameter Index

Parameter 45–32: Alarm Mode

AU310741645108en-000201 / 130R0901 | 35Danfoss A/S © 2020.10

Page 36

Default Value: Absolute

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: True

Option

Name

Description

[0]*

Absolute

Absolute value is considered as threshold.

[1]

Oset

Calculates threshold as a sum of the computed baseline data and the oset values.

[2]

Factor

Calculates threshold as baseline data * factor.

Parameter ID

Description

45-32.0

Stator Winding

45-32.1

Load Envelope

45-32.2

Sensor 1 Vibration

45-32.3

Sensor 2 Vibration

Default Value: Size Related

Parameter Type: Range [0–100%]

4-setup: 2 setup

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-33.0

Stator Winding

45-33.1

Load Envelope

45-33.2

Sensor 1 Vibration

45-33.3

Sensor 2 Vibration

Default Value: Size Related

Parameter Type: Range [0–100%]

4-setup: 2 setup

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-34.0

Stator Winding

VLT® Condition-based Monitoring

Programming Guide

Parameter Descriptions

Select a mode to dene the threshold limits for alarms.

The values can be specied in Parameter 45-33 Alarm High and Parameter 45-38 Alarm Low. For example, if you select Absolute and

set an alarm low and alarm high value as 200 and 300 respectively. The threshold limit for alarms ranges from 200 to 300.

Table 33: Parameter Index

Parameter 45–33: Alarm High

Type the threshold value for high alarm notication. Based on the type of alarm mode selected by the user, a high alarm threshold is

calculated.

Table 34: Options

Parameter 45–34: Warning S2 High

Type the threshold value for computing a warning S2 high notication. Based on the type of warning mode selected by the user, a

warning S2 high threshold is calculated.

Table 35: Options

AU310741645108en-000201 / 130R090136 | Danfoss A/S © 2020.10

Page 37

45-34.1

Load Envelope

45-34.2

Sensor 1 Vibration

45-34.3

Sensor 2 Vibration

Default Value: Size Related

Parameter Type: Range [0–100%]

4-setup: 2 setup

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-35.0

Stator Winding

45-35.1

Load Envelope

45-35.2

Sensor 1 Vibration

45-35.3

Sensor 2 Vibration

Default Value: Size Related*

Parameter Type: Range [0–100%]

4-setup: 2 setup

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-36.0

Stator Winding

45-36.1

Load Envelope

45-36.2

Sensor 1 Vibration

45-36.3

Sensor 2 Vibration

Default Value: Size Related

Parameter Type: Range [0–100%]

4-setup: 2 setup

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-37.0

Stator Winding

45-37.1

Load Envelope

VLT® Condition-based Monitoring

Programming Guide

Parameter Descriptions

Parameter 45–35: Warning S1 High

Type the threshold value for computing a warning S1 high notication. Based on the type of warning mode selected by the user, a

warning S1 high threshold is calculated.

Table 36: Options

Parameter 45–36: Warning S1 Low

Type the threshold value for computing a warning S1 low notication. Based on the type of warning mode selected by the user, a

warning S1 low threshold is calculated.

Table 37: Options

Parameter 45–37: Warning S2 Low

Type the threshold value for computing a warning S2 low notication. Based on the type of warning mode selected by the user, a

warning S2 low threshold is calculated.

Table 38: Options

AU310741645108en-000201 / 130R0901 | 37Danfoss A/S © 2020.10

Page 38

45-37.2

Sensor 1 Vibration

45-37.3

Sensor 2 Vibration

Default Value: Size Related

Parameter Type: Range [0–100%]

4-setup: 2 setup

Conversion Index: -2

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-38.0

Stator Winding

45-38.1

Load Envelope

45-38.2

Sensor 1 Vibration

45-38.3

Sensor 2 Vibration

Default Value: 2

Parameter Type: Range [0–65535]

4-setup: 2 setup

Conversion Index: 0

Data Type: Uint8

Change during operation: True

Parameter ID

Description

45-39.0

Stator Winding

45-39.1

Load Envelope

45-39.2

Sensor 1 Vibration

45-39.3

Sensor 2 Vibration

Default Value: None

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: False

Option

Name

Description

[0]*

None

-

[1]

Analog Input 53

-

[2]

Analog Input 54

-

[3]

Analog Input X30/11

-

VLT® Condition-based Monitoring

Programming Guide

Parameter 45–38: Alarm Low

Type the threshold value for computing a low alarm notication. Based on the type of alarm mode selected by the user, a low alarm

threshold is calculated.

Table 39: Options

Parameter Descriptions

Parameter 45–39: Online Baseline Counter

Type the minutes during which monitoring values are captured for a speed point during baseline generation. Speed points are captured for dierent types of condition-based monitoring during the minutes specied in this parameter.

Table 40: Option

Parameter 45–50: Sensor 1 Source

Select an analog input source for receiving sensor signals. Scaling of analog inputs is performed as dened in parameter group 6. For

more information on parameter group 6, refer to VLT® Automation Drive FC 301/302 Programming Guide.

AU310741645108en-000201 / 130R090138 | Danfoss A/S © 2020.10

Page 39

Option

Name

Description

[4]

Analog Input X30/12

-

[5]

Analog Input X42/1

-

[6]

Analog Input X42/3

-

[7]

Analog Input X42/5

-

[8]

Analog Input X48/2

-

Parameter ID

Description

45-50.0

Sensor 1 Vibration

45-50.1

Sensor 2 Vibration

Default Value: mm/s

Parameter Type: Option

4-setup: 2 setup

Conversion Index: -

Data Type: Uint8

Change during operation: True

Option

Name

Description

[0]*

mm/s

-

[1]

inch/s

-

[2]

m/s2-[3]g-

45-60: Active Threshold

Default Value: 2*

Parameter Type: Range [0-100%]

4-setup: 2 set-ups

Conversion Index:-2

Data Type: Uint8

Change during operation: True

46-09: Monitoring Speeds

Default Value: Size Related*

Parameter Type: Range [par 45-46 - par 45-47 RPM]

4-setup: All set up

Conversion Index: 67

Data Type: Uint16

Change during operation: True

VLT® Condition-based Monitoring

Programming Guide

Table 41: Option

Parameter 45–51: Sensor 1 Unit

Parameter Descriptions

Use the parameter to set unit of monitoring signals from the sensor. The unit is specied on the vibration sensor.

Parameter 45-60: Active Threshold

Table 42: Parameter 45-60 Active Threshold

6.2 Parameter Group 46-** CBM Monitoring Conguration

Parameter 46-09: Monitoring Speeds

Table 43: Parameter 46-09

This parameter shows the 20 speed points in RPM. By default, the baseline minimum speed is considered.

Parameter 46-10: Alarm Time

AU310741645108en-000201 / 130R0901 | 39Danfoss A/S © 2020.10

Page 40

46-10: Alarm Time

Default Value: 10s*

Parameter Type: Range [0 - 60000s]

4-setup: All set up

Conversion Index: -2

Data Type: Uint32

Change during operation: True

Parameter ID

Description

46-10.0

Stator Winding

46-10.1

Load Envelope

46-10.2

Sensor 1 Vibration

46-10.3

Sensor 2 Vibration

46-11: Warning S2 Time

Default Value: 10s*

Parameter Type: Range [0 - 60000s]

4-setup: All set up

Conversion Index: -2

Data Type: Uint32

Change during operation: True

Parameter ID

Description

46-11.0

Stator Winding

46-11.1

Load Envelope

46-11.2

Sensor 1 Vibration

46-11.3

Sensor 2 Vibration

46-12: Warning S1 Time

Default Value: 10s*

Parameter Type: Range [0 - 60000s]

4-setup: All set up

Conversion Index: -2

Data Type: Uint32

Change during operation: True

Parameter ID

Description

VLT® Condition-based Monitoring

Programming Guide

Table 44: Parameter 46-10

Parameter Descriptions

Set the time in seconds to dene duration during which the alarm is not triggered. When the value which is monitored exceeds or

falls below the alarm threshold for more than the time specied in the parameter, an alarm is triggered. Alarm time is the amount of

time in seconds a monitoring state should be over alarm threshold before triggering an alarm.

Table 45: Parameter Index

Parameter 46-11: Warning S2 Time

Table 46: Parameter 46-11

Set the time in seconds to dene duration during which the warning S2 is not triggered. When the value which is monitored exceeds or falls below the warning S2 threshold for more than the time specied in the parameter, a warning S2 is triggered.

Table 47: Parameter Index

Parameter 46-12: Warning S1 Time

Table 48: Parameter 46-12

Set the time in seconds to dene duration during which the warning S1 is not triggered. When the value which is monitored exceeds or falls below the warning S1 threshold for more than the time specied in the parameter, a warning S1 is triggered.

Table 49: Parameter Index

AU310741645108en-000201 / 130R090140 | Danfoss A/S © 2020.10

Page 41

46-12.0

Stator Winding

46-12.1

Load Envelope

46-12.2

Sensor 1 Vibration

46-12.3

Sensor 2 Vibration

46-13: Interpolation Type

Default Value:Linear *

Parameter Type: Option

4-setup: 2 set-up

Conversion Index: -

Data Type: Uint8

Change during operation: True

Parameter ID

Description

46-13.0

Stator Winding

46-13.1

Load Envelope

46-13.2

Sensor 1 Vibration

46-13.3

Sensor 2 Vibration

Options

Option

Name

Description

[0]*

Linear

Select this option for stator and load monitoring.

[1]

Staircase

Select this option for vibration monitoring.

46-20: Alarm High

Default Value: 0%*

Parameter Type: Range [0 - 200%]

4-setup: All setups

Conversion Index: -2

Data Type: Uint16

Change during operation: True

46-21: Warning S2 High

Default Value: 0%*

Parameter Type: Range [0 - 200%]

4-setup: All set up

Conversion Index: -2

Data Type: Uint16

Change during operation: True

VLT® Condition-based Monitoring

Programming Guide

Paramter 46-13: Interpolation Type