Page 1

MAKING MODERN LIVING POSSIBLE

Design Guide

VLT® Brake Resistor MCE 101

VLT® Frequency Converters • FC 51 • FC 102 • FC 202 • FC 301

FC 302 • FC 360 • FCD 302 • VLT® 2800

www.danfoss.com/drives

Page 2

Page 3

Contents Design Guide

Contents

1 Introduction

1.1 How to Read this Design Guide

1.2 Conformity

1.3 Safety Precautions

1.4 Disposal

2 Product Overview

2.1 Description of the Brake System

2.2 Horizontal or Vertical Load

2.3 Aluminium-housed Brake Resistors

2.3.1 Aluminium-housed Flat-pack Brake Resistors 6

2.3.2 Aluminium-housed Compact Brake Resistor 6

2.4 Steel Grid Brake Resistors

3 Installation

3.1 Mechanical Installation

3.1.1 Aluminium-housed Compact Brake Resistors and Flat-pack Brake Resistors 7

3.1.2 Steel Grid Brake Resistors 10

4

4

4

4

4

5

5

5

6

6

7

7

3.1.3 Accessories 11

3.2 Electrical Installation

3.2.1 EMC Precautions 12

3.2.2 Cable Connection 12

3.2.3 Brake Cable 13

3.3 Protective Functions

3.3.1 Overtemperature Protection 13

3.3.2 Brake Resistor and Brake IGBT 14

4 System Integration

4.1 Brake Resistor Calculation

4.1.1 Brake Set-up 15

4.1.2 Calculation of Brake Resistor Resistance 15

4.1.3 Calculation of Braking Power 16

4.1.4 Calculation of the Brake Resistor Peak Power 17

4.1.5 Calculation of the Brake Resistor Average Power 17

4.1.6 Braking of Inertia 17

12

13

15

15

5 Programming

5.1 Parameters for VLT® Micro Drive FC 51

5.2 Parameters for VLT® HVAC Drive FC 102 and VLT® AQUA Drive FC 202

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 1

18

18

18

Page 4

Contents Design Guide

5.3 Parameters for VLT® AutomationDrive FC 301/FC 302 and ® Decentral Drive FCD

302

21

5.4 Parameters for VLT® AutomationDrive FC 360

5.5 Parameters for VLT® 2800

6 Application Examples

6.1 Conveyor Belt

6.2 Centrifuge

6.3 Continuous Braking

7 Special Conditions

7.1 Alternative Braking Methods

7.1.1 DC Injection Braking 30

7.1.2 AC-braking 30

7.1.3 Mechanical Holding Brake 30

7.1.4 DC Braking 31

8 Selection Guide

8.1 Selection Flow Chart

8.2 Selection Tables for Recommended Brake Resistors

24

25

27

27

29

29

30

30

32

32

33

8.2.1 Abbreviations used in the Brake Resistor Tables 33

8.2.2 VLT® Micro Drive FC 51 33

8.2.3 VLT® HVAC Drive FC 102 35

8.2.4 VLT® AQUA Drive FC 202 41

8.2.5 VLT® AutomationDrive FC 301 48

8.2.6 VLT® AutomationDrive FC 302 51

8.2.7 VLT® AutomationDrive FC 360 57

8.2.8 VLT® Decentral Drive FCD 302 59

8.2.9 VLT® 2800 60

8.3 Selection Tables for Alternative Brake Resistors

8.3.1 Abbreviations used in the Brake Resistor Tables 62

8.3.2 VLT® HVAC Drive FC 102, T2 62

8.3.3 VLT® HVAC Drive FC 102, T4 62

8.3.4 VLT® AQUA Drive FC 202, T2 63

8.3.5 VLT® AQUA Drive FC 202, T4 63

8.3.6 VLT® AutomationDrive FC 301, T2 64

62

8.3.7 VLT® AutomationDrive FC 302, T2 64

8.3.8 VLT® AutomationDrive FC 301, T4 65

8.3.9 VLT® AutomationDrive FC 302, T5 65

9 Specifications

2 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

66

Page 5

Contents Design Guide

9.1 Ambient Conditions

9.2 General Electrical Specifications

9.3 Electrical Data: MCE 101 Product Types 9xx

9.4 Mechanical Data: MCE 101 Product Types 9xx

9.5 Electrical Data: Product Types BWD and BWG

9.6 Mechanical Data: Product Types BWD and BWG

9.7 Mechanical Drawings

9.7.1 Figure 1 - 914CBT-HxxxDHT 83

9.7.2 Figure 2 - 914CBT-HxxxCHT 87

9.7.3 Figure 3 - 914CBT-HxxxBHT 90

9.7.4 Figure 4 - 914CBR-VxxxDT 93

9.7.5 Figure 5 - 914CBR-VxxxCT 96

9.7.6 Figure 6 - 914CBR-VxxxBT 98

9.7.7 Figure 7 - 914CCHxxxCT 101

9.7.8 Figure 8 - 917CM13 103

9.7.9 Figure 9 - 917CM15 105

9.7.10 Figure 10 - 917CM17 107

66

66

67

74

81

82

83

9.7.11 Figure 11 - 917CM25 109

9.7.12 Figure 12 - 917CM27 111

9.7.13 Figure 13 - 917CM37 113

9.7.14 Figure 14 - 917CMD27 115

9.7.15 Figure 15 - 917CMD37 117

9.7.16 Figure 16 - 929CBT-VxxxGHT 119

9.7.17 Figure 17 - 929CBT-VxxxBGHT 122

9.7.18 Figure 18 - 930CBT-VxxxGHT 125

9.7.19 Figure 19 - 930CBT- VxxxBGHT 128

9.7.20 Figure 20 - BWD250xxx 131

9.7.21 Figure 21 - BWD500xxx 132

9.7.22 Figure 22 - BWD600xxx 133

9.7.23 Figure 23 - BWG250xxx 135

9.7.24 Figure 24 - BWG500xxx 136

9.8 Mechanical Drawings: Accessories

9.8.1 Mounting Brackets: L Profile 137

9.8.2 Mounting Brackets: Footprint 139

137

Index

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 3

142

Page 6

Introduction Design Guide

1

1 Introduction

1.1 How to Read this Design Guide

Danfoss VLT® Brake Resistors MCE 101 are optimised for:

VLT® Micro Drive FC 51

•

VLT® HVAC Drive FC 102

•

VLT® AQUA Drive FC 202

•

VLT® AutomationDrive FC 300

•

VLT® AutomationDrive FC 360

•

VLT® Decentral Drive FCD 302

•

VLT® 2800

•

General versions for horizontal and vertical applications are

available.

The Design Guide provides the information required to

select and plan installation of the right brake resistor for

an application:

Selection of the correct brake resistor

•

Pre-installation considerations

•

Programming.

•

As an alternative to using a brake resistor, other braking

methods can be applied depending on the braking profile

of the application, see chapter 7 Special Conditions.

1.2

Conformity

Table 1.1 Approval

1) See Table 9.2 and Table 9.4 for UL conformity.

What is CE Conformity and Labelling

The purpose of CE labelling is to avoid technical trade

obstacles within EFTA and the EU. The EU has introduced

the CE label as a simple way of showing whether a

product complies with the relevant EU directives. The CE

label says nothing about the specifications or quality of

the product. Brake resistors are regulated by the following

EU directive:

The low-voltage directive (2006/95/EC)

Brake resistors must be CE labelled in accordance with the

low-voltage directive of December 12, 2006. The directive

applies to all electrical equipment and appliances used in

the 50-1000 V AC and the 75-1500 V DC voltage ranges.

Danfoss CE-labels in accordance with the directive and

issues a declaration of conformity upon request.

1.3

Safety Precautions

1)

Additional technical literature is also available online at

www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations/Technical+Documentation.

WARNING

When in use, the brake resistor surface temperature

rises. DO NOT touch the brake resistor during operation.

WARNING

Never work on a brake resistor in operation.

NOTICE

Never attempt to repair a defective brake resistor.

1.4 Disposal

Equipment containing electrical components

may not be disposed of together with

domestic waste.

It must be separately collected with electrical

and electronic waste according to local and

currently valid legislation.

4 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 7

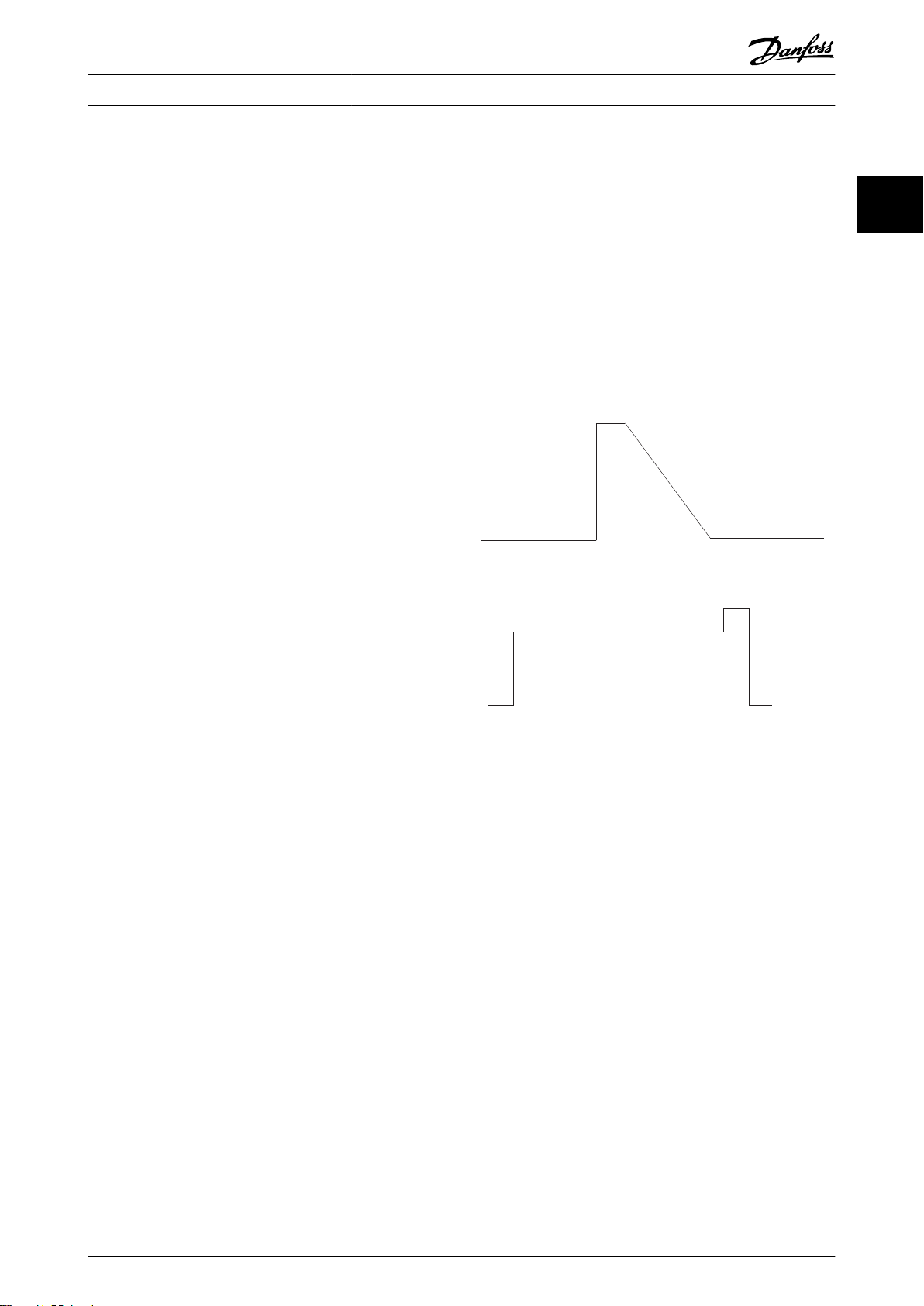

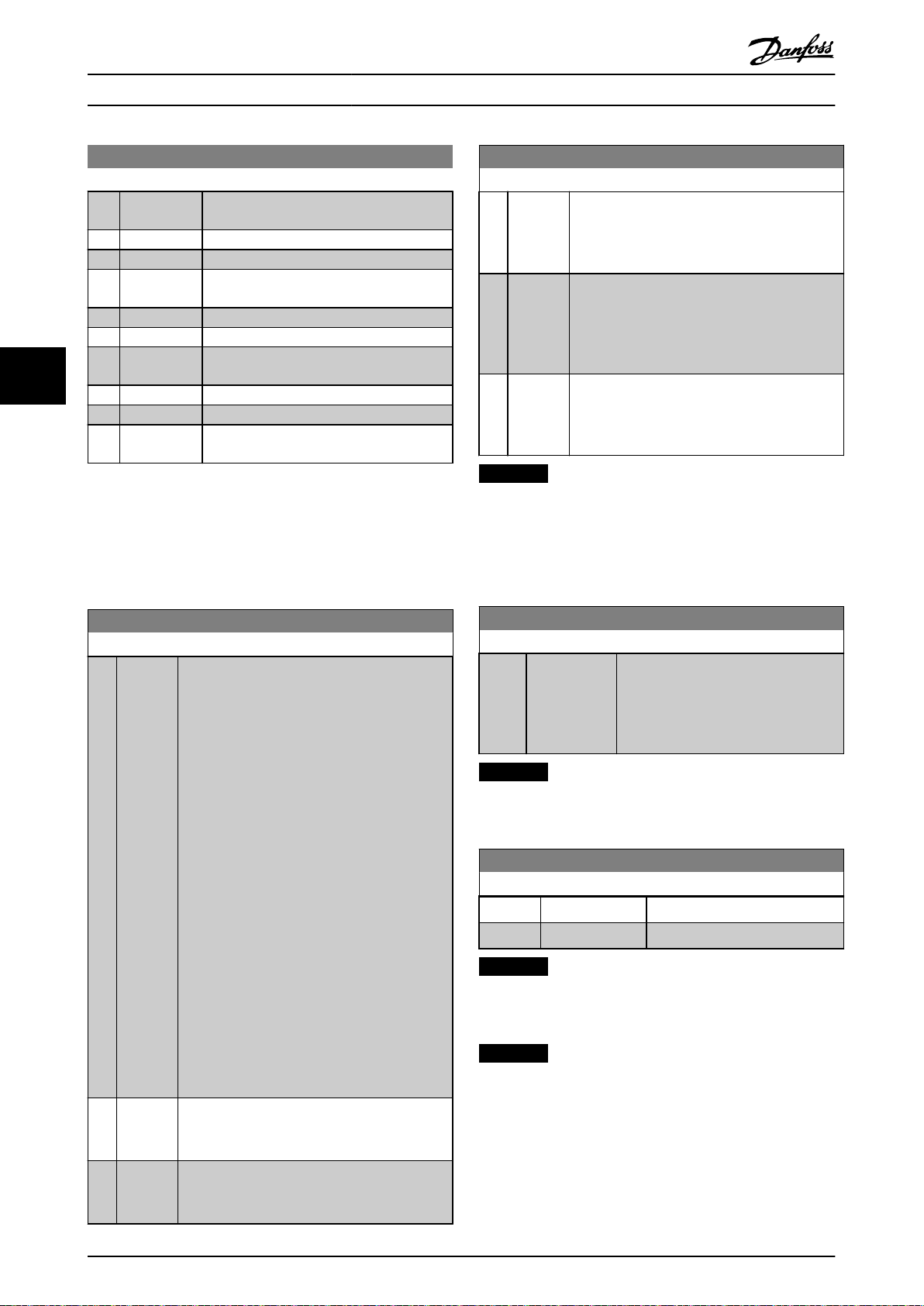

150/160%

175UA067.10

100%

150/160%

175UA068.10

Product Overview Design Guide

2 Product Overview

2.1 Description of the Brake System

2.2

Horizontal or Vertical Load

2 2

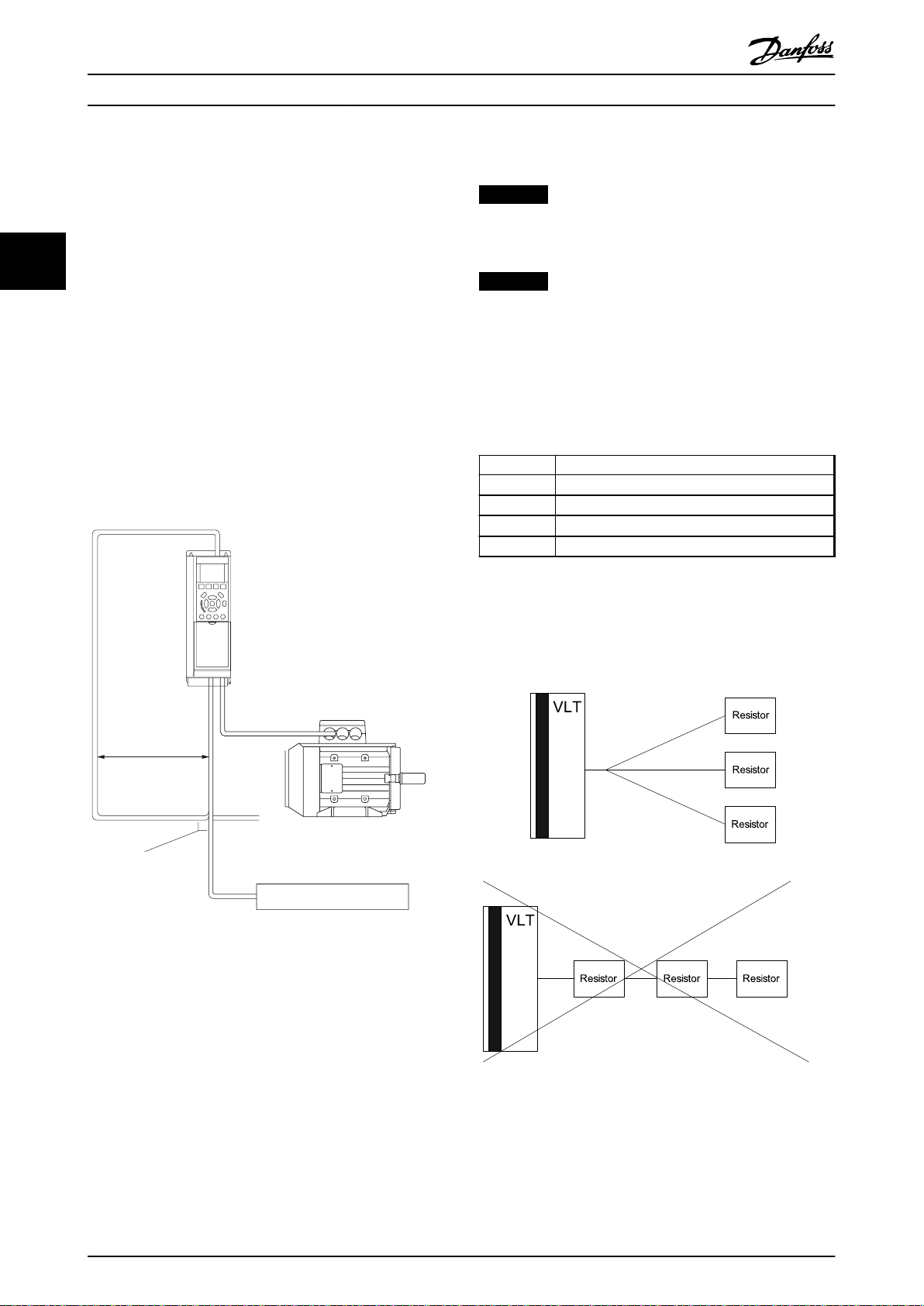

When the speed reference of a frequency converter is

reduced, the motor acts as a generator and the frequency

converter brakes. When a motor acts as a generator, it

supplies energy to the frequency converter which is

collected in the DC link. The function of the brake resistor

is to provide a load on the DC link during braking, thereby

ensuring that the braking power is absorbed by the brake

resistor.

If a brake resistor is not used, the DC-link voltage of the

frequency converter continues to increase, until disconnecting for protection. The advantage of using a brake

resistor is that it enables braking of a heavy load quickly,

e.g. on a conveyor belt.

The brake resistors in this series are all external

components. Therefore, the brake resistor does not form

an integral part of the frequency converter.

The external brake resistor provides the following

advantages:

The resistor time cycle can be selected as

•

required.

The heat developed during braking can be

•

conveyed beyond the panel cabinet to allow the

energy to be used.

The electronic components do not overheat, even

•

when the brake resistor is overloaded.

The brake resistor series is suitable for Danfoss frequency

converters

VLT® Micro Drive FC 51

•

VLT® HVAC Drive FC 102

•

VLT® AQUA Drive FC 202

•

VLT® AutomationDrive FC 300

•

VLT® AutomationDrive FC 360

•

VLT® Decentral Drive FCD 302

•

VLT® 2800

•

.

2.2.1 How to Select

The Danfoss brake resistor range consists of 2 groups:

Brake resistors for horizontal loads (conveyors,

•

trolleys, gantry cranes, etc.), see Illustration 2.1;

Brake resistors for vertical loads (cranes, hoists,

•

elevators), see Illustration 2.2.

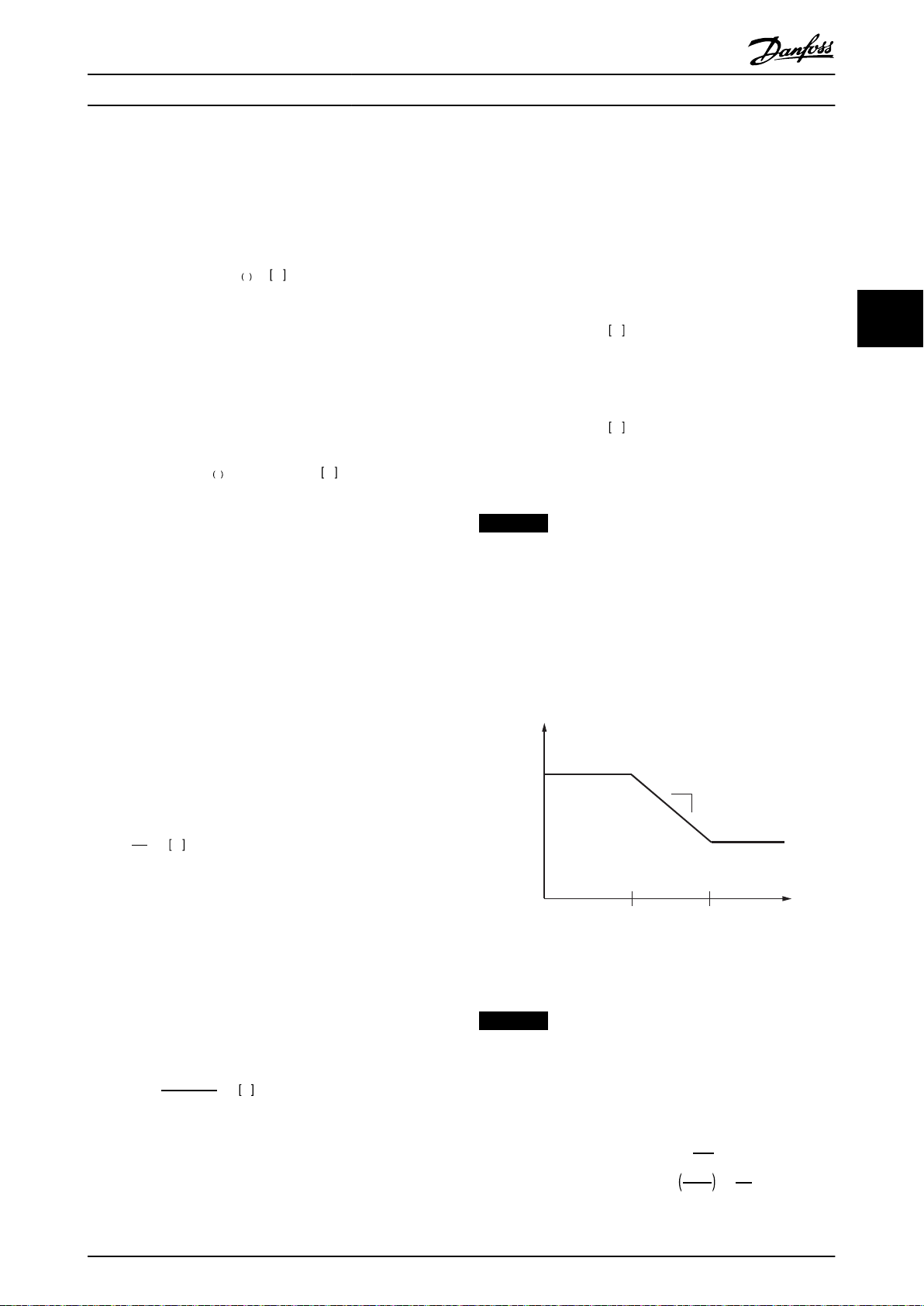

Illustration 2.1 Horizontal Loads

Illustration 2.2 Vertical Loads

The brake resistor range is intended to cover the general

braking requirements for horizontal and vertical brake

applications.

To select the best brake resistor for an application, refer to

chapter 8.1 Selection Flow Chart. The flow chart links to

further information, either selection tables or calculations

of inertia or duty cycle.

To cater for both the horizontal and vertical ranges, 3

types of brake resistors are available:

Aluminium-housed flat-pack brake resistors

•

Aluminium-housed compact brake resistors

•

Steel grid brake resistors

•

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 5

Page 8

130BD245.12

1

130BD646.10

130BD228.10

130BD217.10

130BD586.10

Product Overview Design Guide

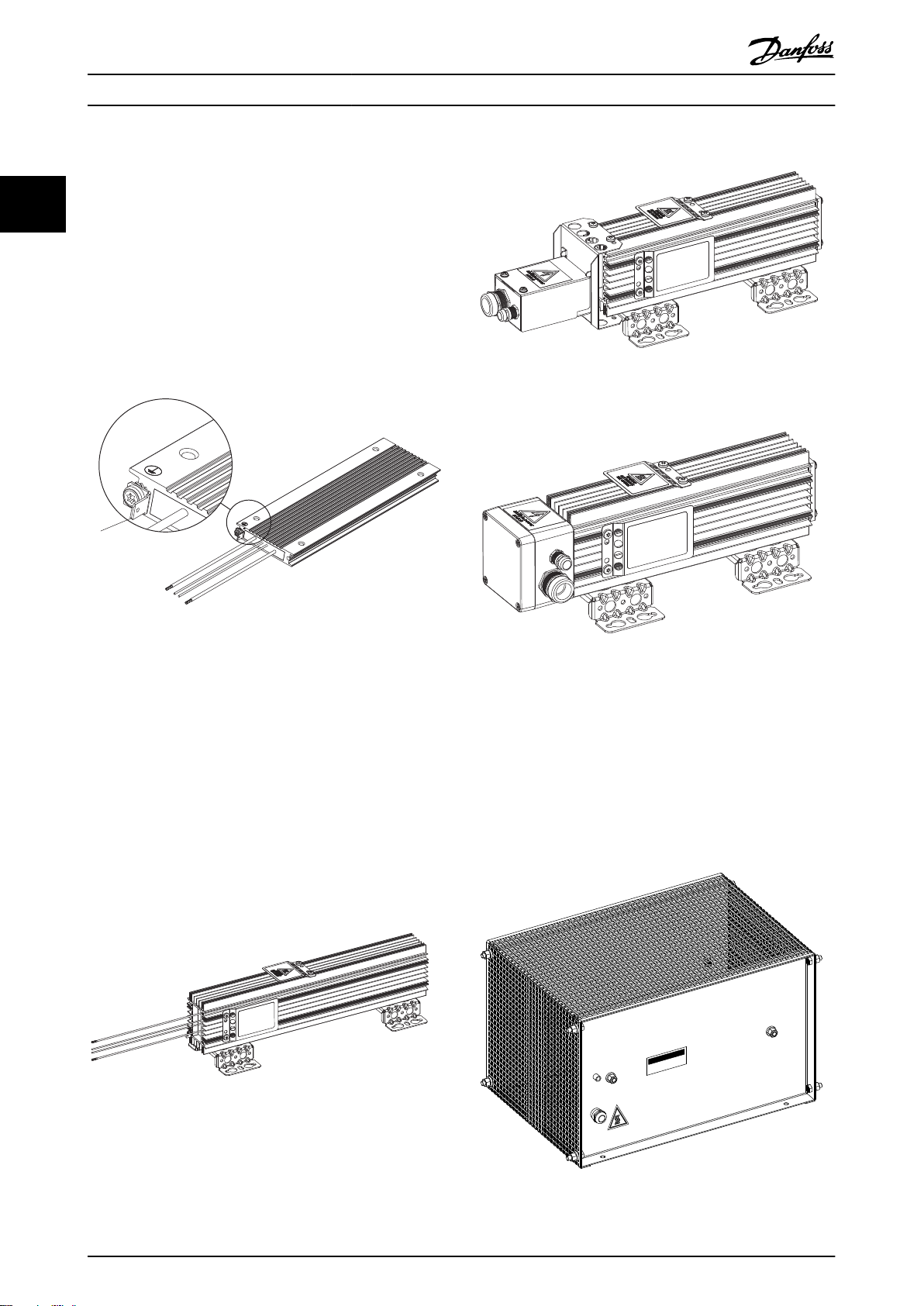

2.3 Aluminium-housed Brake Resistors

2.3.1 Aluminium-housed Flat-pack Brake

22

Resistors

The flat-pack brake resistor is an anodized aluminiumhoused resistor suitable for wall mounting or on a

footprint or an L-profile bracket. The L-profile bracket is

used for rear mounting. The brake resistor is designed for

high pulse loads of up to 40 times the nominal load and is

therefore suitable for both vertical and horizontal

applications. The enclosure protection is IP54 or IP65.

Illustration 2.5 CBR-V-DT IP21

Illustration 2.3 Flat-pack IP54

Aluminium-housed Compact Brake

2.3.2

Resistor

The compact brake resistor is housed in aluminium profiles

with pre-mounted brackets for wall mounting. It is

designed for high pulse loads of up to 60 times the

nominal load and is therefore used for both horizontal and

vertical loads. The enclosure protection class is either IP21,

IP54 or IP65. The brake resistor IP classes IP21 and IP65 are

equipped with a connection box containing cable glands

and cable connection to the resistor and the temperature

switch. IP54 versions have fixed unscreened cables.

Illustration 2.6 CBR-V-BT IP65

2.4 Steel Grid Brake Resistors

The steel grid brake resistor is steel grid housed and

consists of multiple elements. This brake resistor is suitable

for pulse loads between 10 and 20 times the nominal load,

suitable for frequent braking applications such as cranes,

hoists and elevators. It is supplied in an IP20 enclosure

with cable glands and has a built-in temperature switch.

Illustration 2.4 CBR-V-CT IP54

6 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Illustration 2.7 Steel Grid House IP20

Page 9

130BD900.10

200 mm

Installation Design Guide

3 Installation

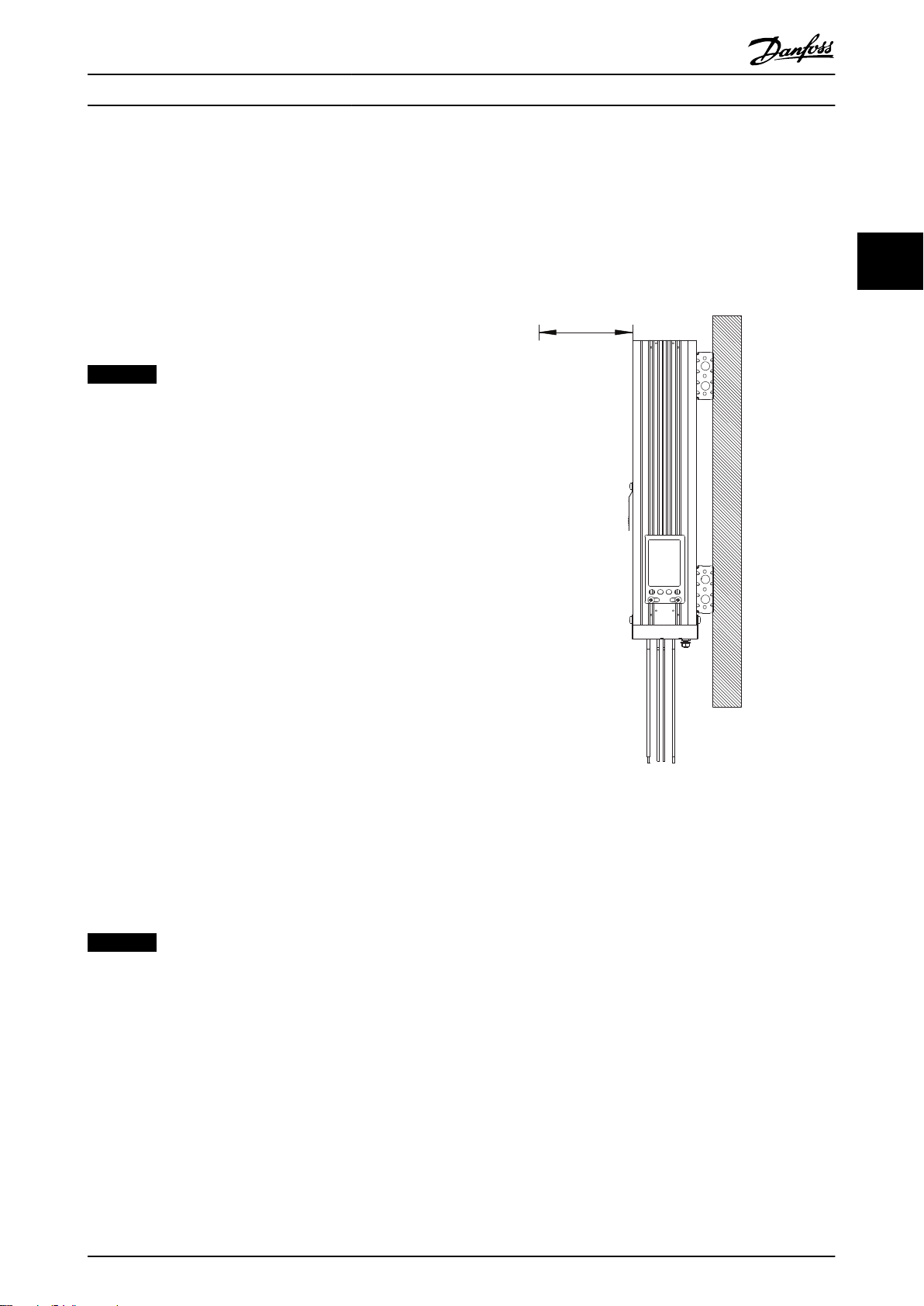

3.1 Mechanical Installation

The brake resistors are cooled by natural convection, and

the specified minimum clearances must be observed to

ensure efficient ventilation. The ventilation must be

efficient enough to dispatch the regenerative power in the

brake resistor.

NOTICE

When installing the brake resistor, ensure all precautions

are in place to avoid the risk of overloading. Overloading

can lead to a fire hazard due to the heat generated in

the brake resistor.

The brake resistor is very hot during or after braking.

The brake resistor must be located in a secure

environment to avoid fire risk.

Mount the brake resistor free of any combustible

•

materials at a well ventilated location.

The MCE 101 brake resistors product type 9xx

•

contain a built-in temperature switch (for

overtemperature protection purposes. See

chapter 3.3 Protective Functions).

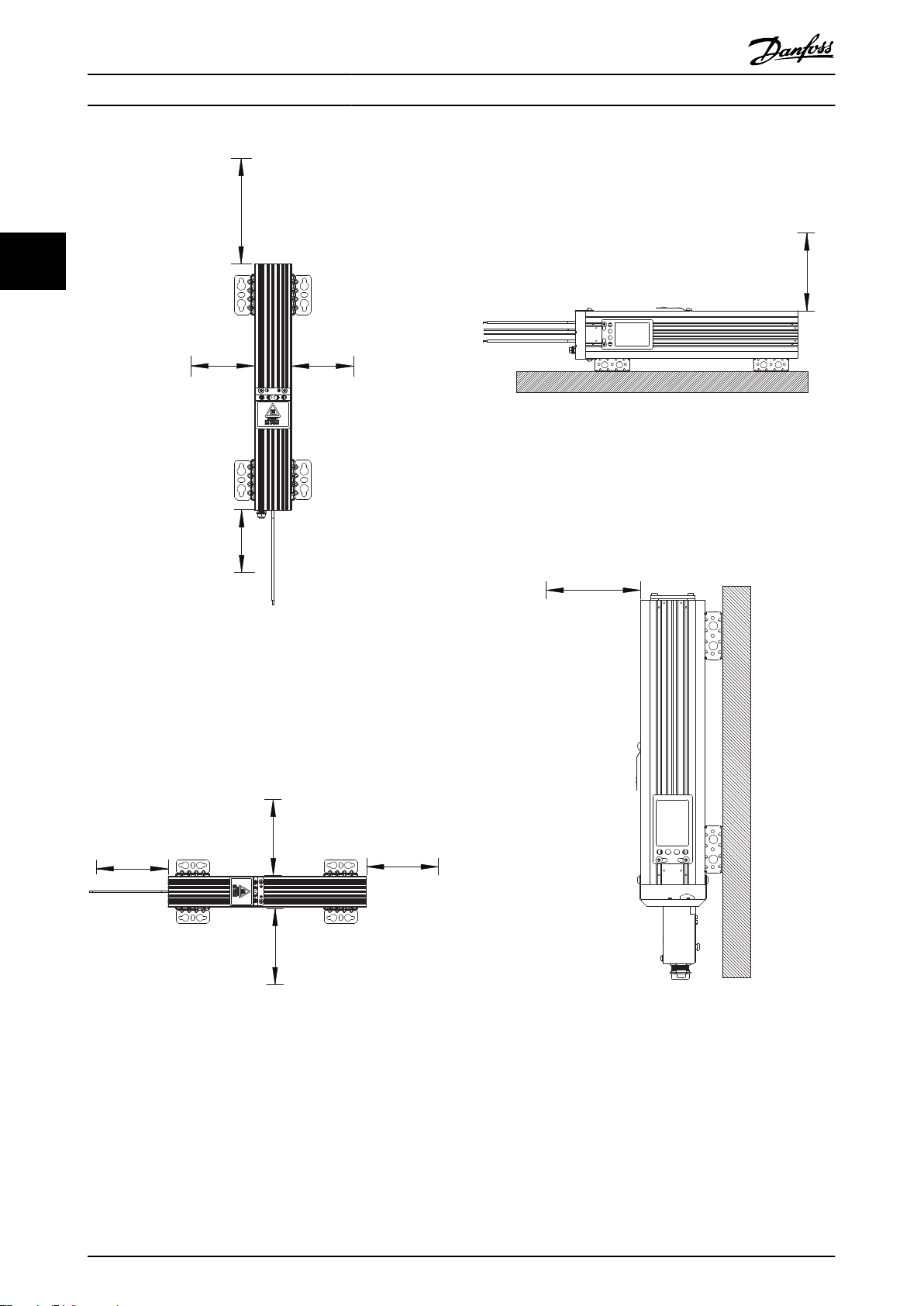

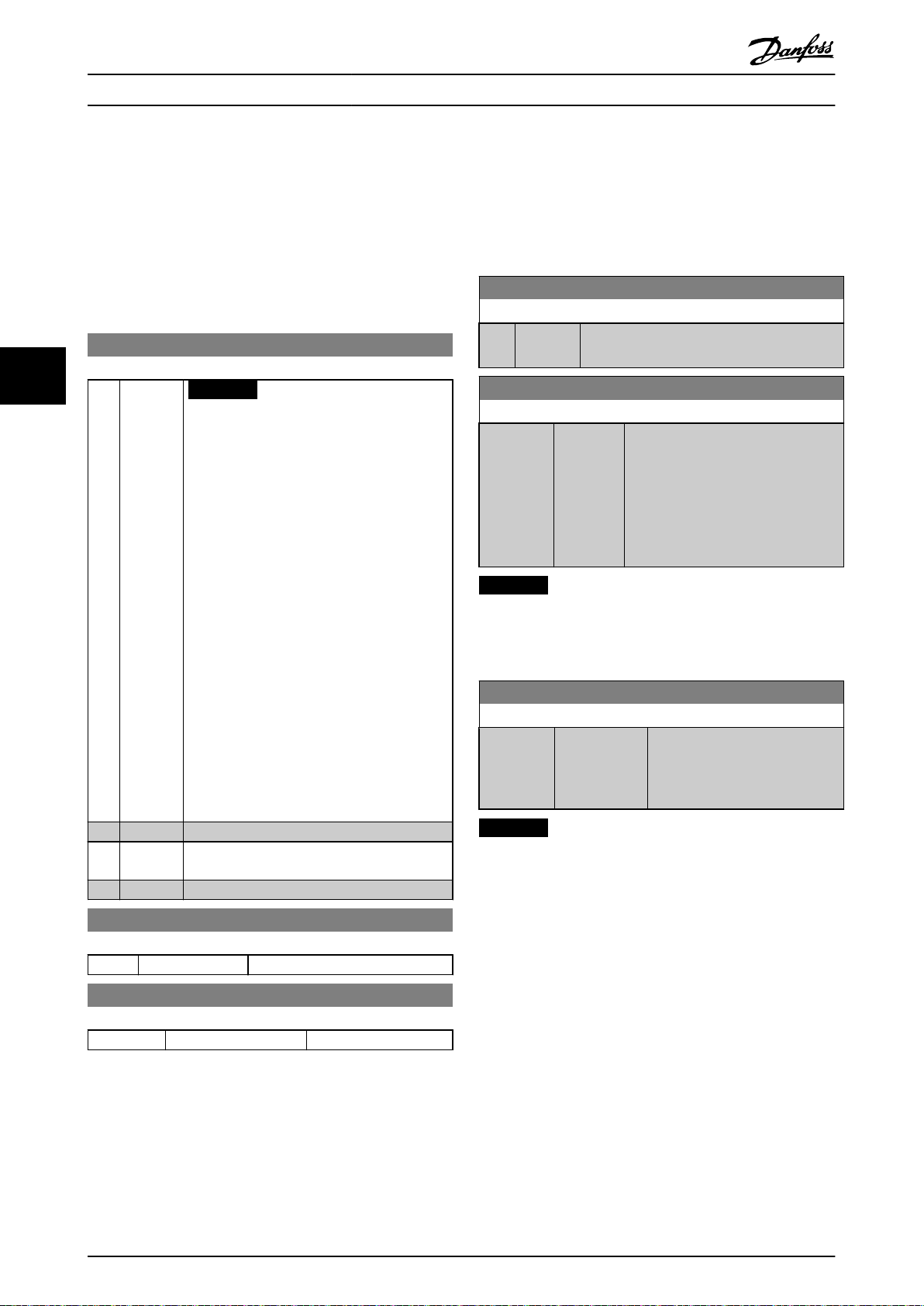

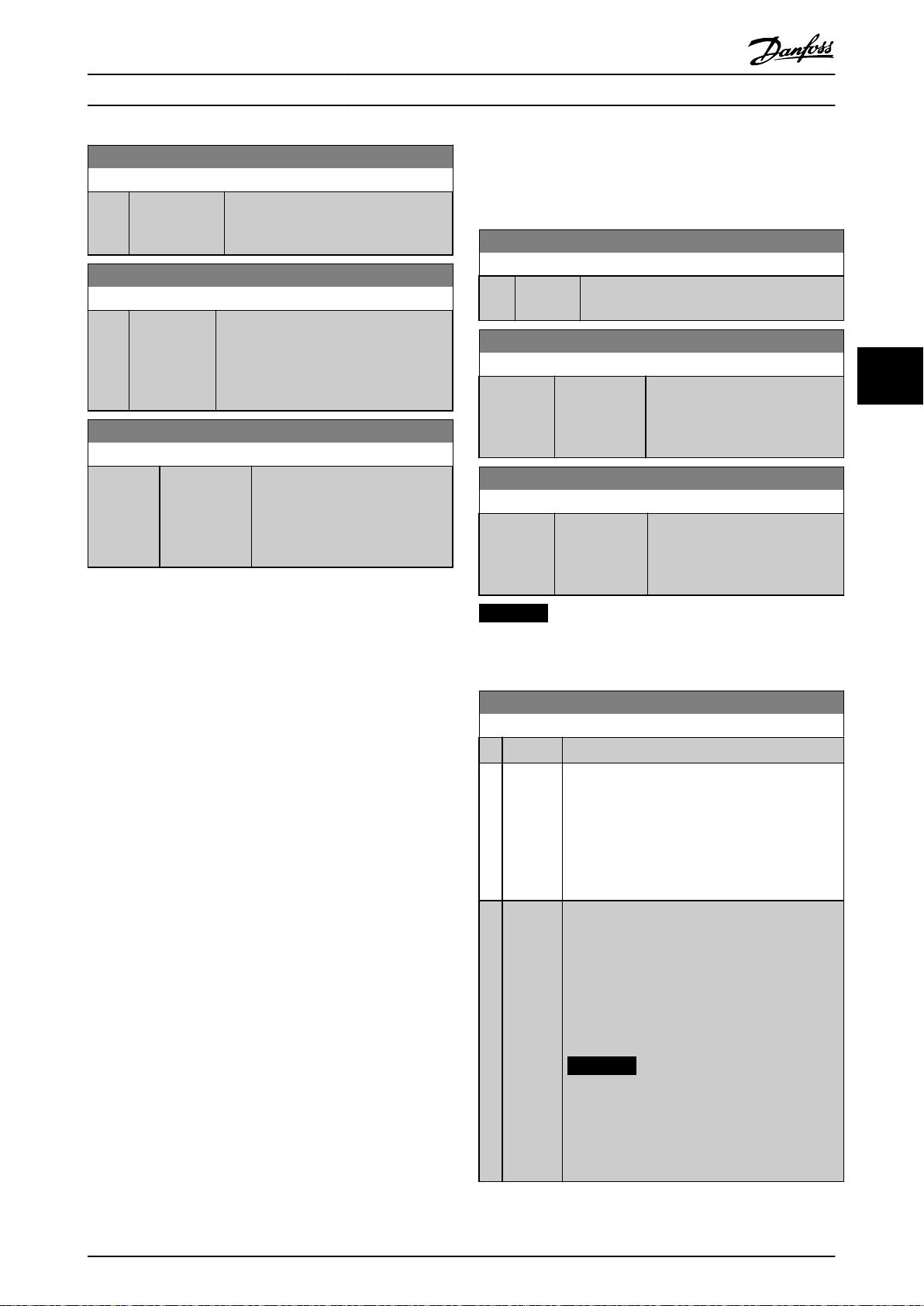

Vertical Mounting, IP54

For minimum clearances for vertical mounting for all

aluminium-housed compact and flat-pack brake resistors,

see Illustration 3.1 and Illustration 3.2.

3 3

Aluminium-housed Compact Brake

3.1.1

Resistors and Flat-pack Brake

Resistors

The aluminium-housed compact and flat-pack brake

resistors are designed for vertical mounting for optimum

cooling performance. However, horizontal mounting is

possible for both flat-pack and compact brake resistors.

Derating with 20% is required when mounting the

compact brake resistors horizontally. No derating for flatpacks are required. The enclosure protection of the IP21

types is reduced to IP20 when mounted horizontally.

NOTICE

All resistors are cooled by natural convection. To ensure

sufficient airflow and cooling, follow minimum clearance

in Illustration 3.1 to Illustration 3.8.

Illustration 3.1 Vertical Mounting, IP54

Versions with Fixed Cables

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 7

Page 10

130BD901.10

200 mm

500 mm

200 mm

200 mm

200 mm

200 mm

200 mm200 mm

130BD902.10

130BD903.10

500 mm

130BD904.10

200 mm

Installation Design Guide

For minimum clearances for horizontal mounting for all

aluminium-housed compact and flat-pack brake resistors,

IP54 versions (versions with fixed cables), see Illustration 3.4

(side view).

33

Illustration 3.4 Horizontal mounting, IP54

Versions with Fixed Cables

Vertical mounting, IP21 and IP65

For minimum clearances for vertical mounting for all

aluminium-housed compact brake resistors, see

Illustration 3.5 and Illustration 3.6.

Illustration 3.2 Vertical Mounting, IP54

Versions with Fixed Cables

Horizontal mounting, IP54

For minimum clearances for horizontal mounting for all

aluminium-housed compact and flat-pack brake resistors,

see Illustration 3.3 (top view).

Illustration 3.3 Horizontal mounting, IP54

Versions with Fixed Cables

Illustration 3.5 Vertical Mounting, IP21 and IP65

Versions with Connection Box

8 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 11

200 mm

200 mm

500 mm

100 mm

130BD905.10

200 mm

100 mm

200 mm

200 mm

130BD906.10

130BD907.10

500 mm

130BD227.11

Installation

Design Guide

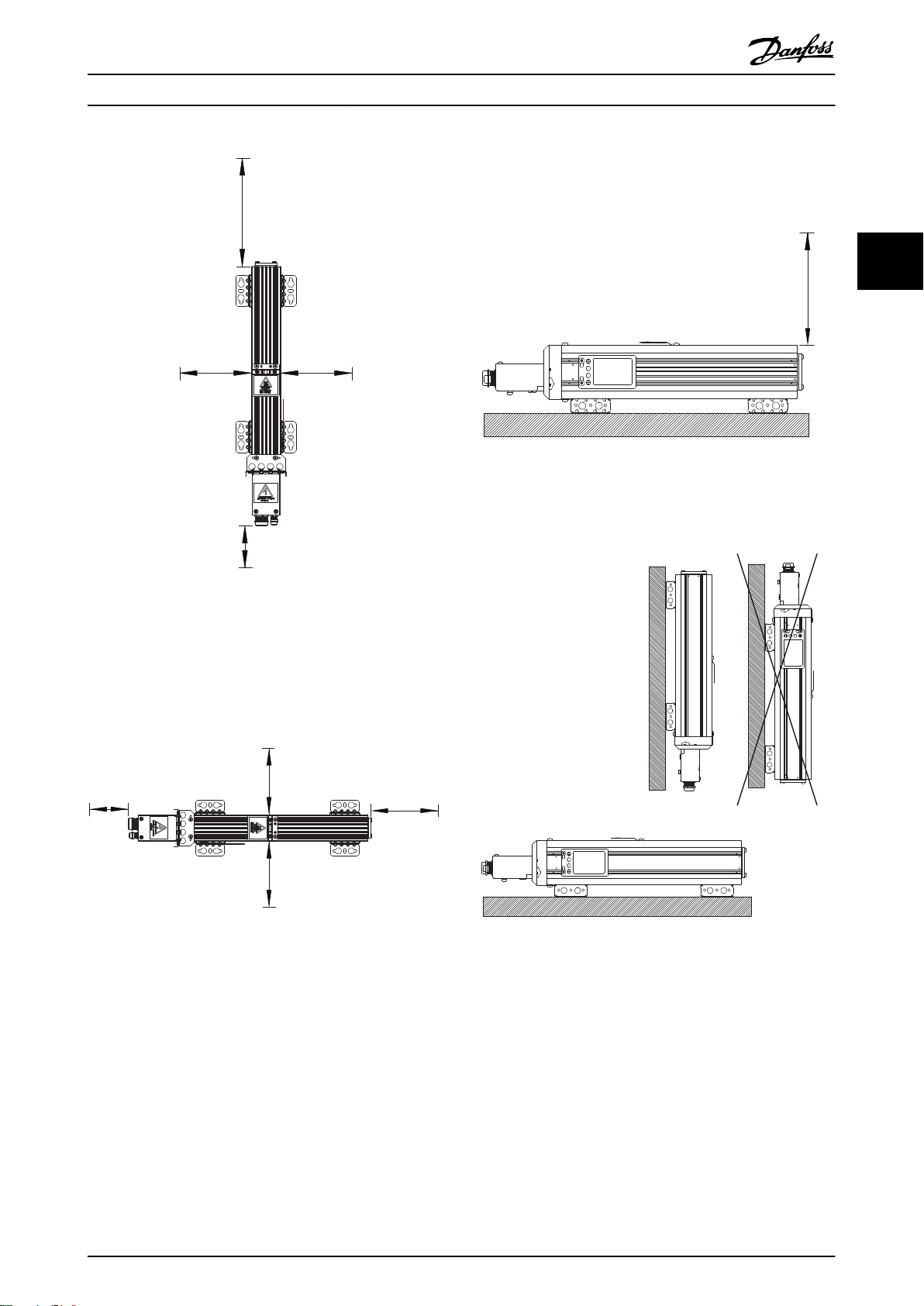

Horizontal mounting, IP21 and IP65

For minimum clearances for horizontal mounting for all

aluminium housed compact brake resistors, see

Illustration 3.8 (side view).

3 3

Illustration 3.8 Horizontal Mounting, IP21 and IP65

Versions with Connection Box

Orientation, compact and flat-pack brake resistors

Illustration 3.6 Vertical Mounting, IP21 and IP65

Versions with Connection Box

Horizontal mounting, IP21 and IP65

For minimum clearances for horizontal mounting for all

aluminium-housed compact brake resistors, see

Illustration 3.7 (top view).

Illustration 3.7 Horizontal Mounting, IP21 and IP65

Versions with Connection Box

Illustration 3.9 Orientation of Compact and Flat-pack Brake

Resistors

Derating with 20% is required when mounting the

compact brake resistors horizontally. The enclosure

protection of the IP21 types is reduced to IP20 when

mounted horizontally.

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 9

Page 12

130BD708.12

150 mm

150 mm

150 mm

150 mm

500 mm

175Uxxxx

130BD884.10

175Uxxxx

130BD709.11

Installation Design Guide

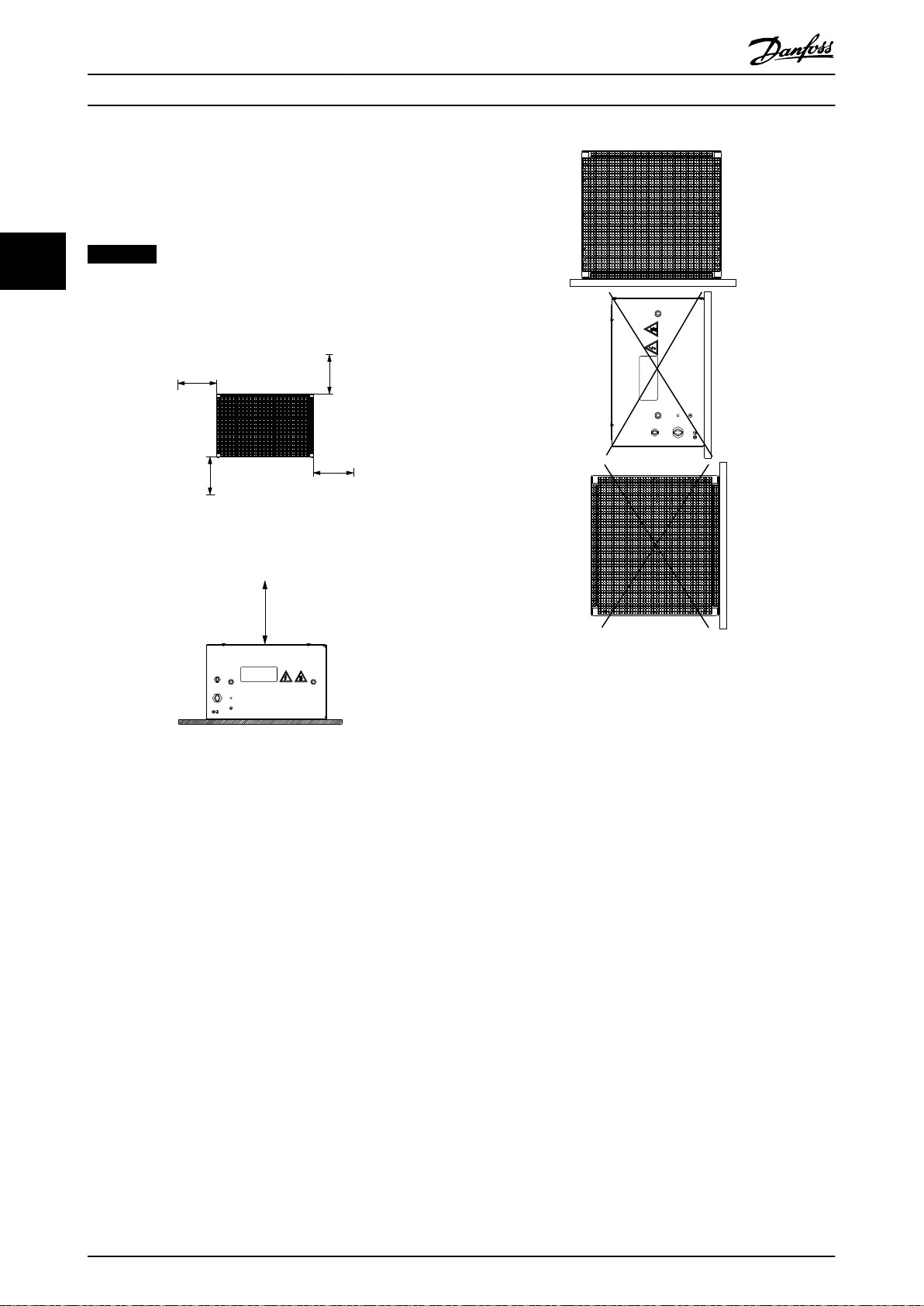

3.1.2 Steel Grid Brake Resistors

The steel grid brake resistors are designed for horizontal

mounting only.

33

NOTICE

All resistors are cooled by natural convection. To ensure

sufficient airflow and cooling, follow minimum

clearances in Illustration 3.10 and Table 3.3.

Illustration 3.10 Minimum Clearances of all Steel Grid Brake

Resistors - Top View

Illustration 3.12 Orientation of Steel Grid Brake Resistors

Illustration 3.11 Minimum Clearances of all Steel Grid Brake

Resistors - Side View

10 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 13

1

2

3

130BD595.10

130BD838.10

Installation

Design Guide

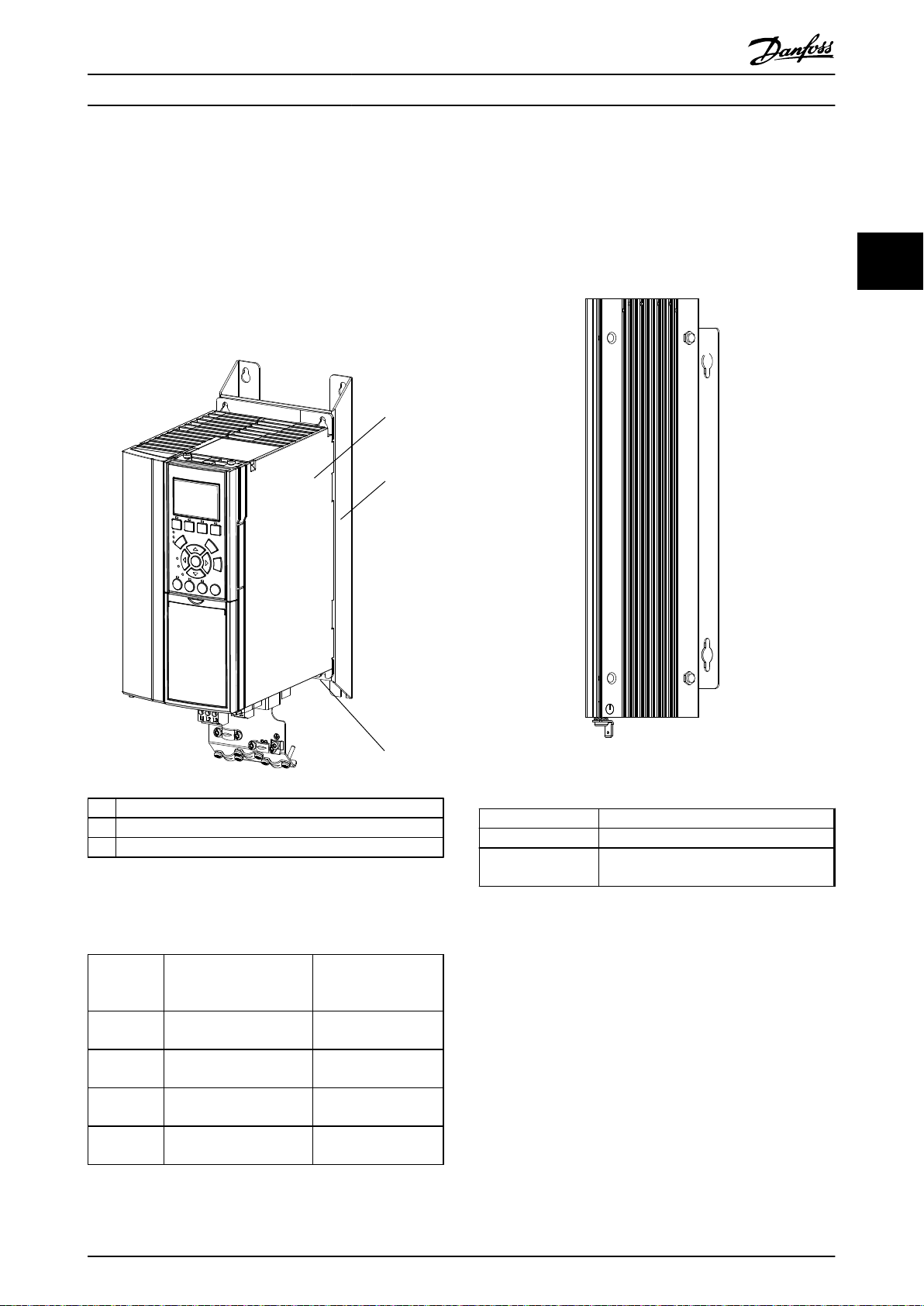

3.1.3 Accessories

Footprint brackets

The footprint bracket is an accessory used for mounting

flat-pack brake resistors.

Use the footprint bracket to mount the brake resistor at

the rear of the frequency converter. Once mounted, the

combined brake resistor and frequency converter occupy

the same space in the cabinet as the frequency converter

alone.

For mechanical dimensions for footprint brackets, see

chapter 9.8.2 Mounting Brackets: Footprint.

L profile brackets

The L profile bracket is an accessory used for mounting

flat-pack brake resistors. The L profile brackets support

both horizontally and vertically mounting on a fixed

surface optimising the required footprint.

3 3

1 Frequency converter

2 Footprint mounting bracket

3 Flat-pack brake resistor

Illustration 3.13 Flat-pack Brake Resistor mounted at Rear of

Frequency Converter

Part number Compatible brake resistor Compatible frequency

175U0085

175U0087

175U0086

175U0088

Table 3.1 Selection Table

1x100 W flat-pack

1x200 W flat-pack

2x100 W flat-pack

2x200 W flat-pack

2x100 W flat-pack

2x200 W flat-pack

1x100 W flat-pack

1x200 W flat-pack

converter enclosure

size

A2

A2

A3

A3

Illustration 3.14 L Profile Bracket

Part number Compatible brake resistor

175U0009 1x200 W flat-pack

175U0011

Table 3.2

1) Order 2x175U0011 for 300 W flat-pack brake resistors.

1)

1x100 W flat-pack

1x300 W flat-pack

For mechanical dimensions for L profile brackets, see

chapter 9.8.1 Mounting Brackets: L Profile

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 11

Page 14

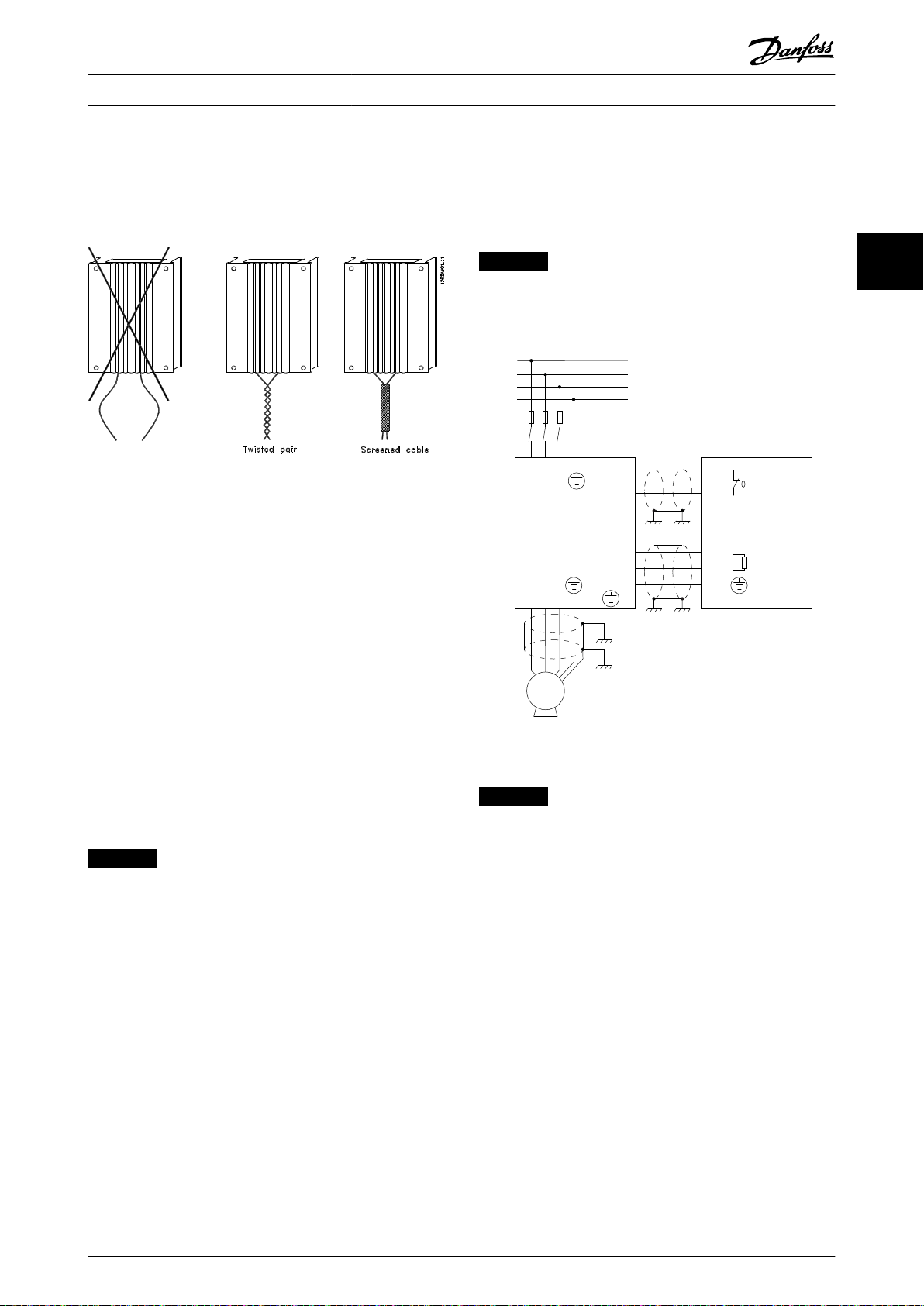

Fieldbus cable

Min. 200 mm

90° crossing

Brake resistor

130BD507.11

130BB154.12

Installation Design Guide

3.2 Electrical Installation

Cable Connection

3.2.2

3.2.1 EMC Precautions

The following EMC precautions are recommended to

achieve interference-free operation of fieldbus cable(s) and

33

digital and analog inputs and outputs.

NOTICE

To comply with EMC emission specifications, screened/

armoured cables are recommended.

NOTICE

Observe relevant national and local regulations, for

example regarding protective earth connection. Keep the

fieldbus cable(s) away from motor and brake resistor

cables to avoid coupling of high frequency noise from one

cable to another. Normally, a distance of 200 mm (8

inches) is sufficient, but keeping the greatest possible

distance between the cables is recommended, especially

where cables run in parallel over long distances. When

crossing is unavoidable, the fieldbus cable(s) must cross

motor and brake resistor cables at an angle of 90°, see

Illustration 3.15.

Cables General: All cabling must comply with national

and local regulations on cable cross-sections and

ambient temperature.

See Table 3.3 for recommended temperature ratings for all

cables and conductors connected to the brake resistor as

ground connection, thermal switch and brake power.

IP class Recommended cables

IP20

IP21

IP54

IP65

Table 3.3 Cable Temperature Ratings

1) For ground connection

How to connect more than one resistor

Star parallel connection to ensure load is shared evenly

between 2 or more resistors.

≥80 °C

≥80 °C

≥90 °C

≥90 °C

1)

Illustration 3.15 Cable Routing

Illustration 3.16 Connection of Several Brake Resistors

12 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 15

81

82

99

91 92 93 95

96 97 98 99

12

18

L1 L2 L3 PE

U V W PE

VLT

MCE 101

Brake resistor

T1

T2

RB1

RB2

L1

L2

L3

PE

F1

PE

R-

R+

PE

+24V

D-in

M

3~

130BD553.11

Installation

Design Guide

Brake resistors with fixed cables

To reduce the electrical noise from the wires between the

brake resistor and the frequency converter, twist the wires.

For enhanced EMC performance a metal screen can be

used.

Illustration 3.17 Twisted Cables

Brake Cable

3.2.3

Max. length: 20 m shielded cable.

Automatic restart after enabling of the temperature

switch:

Select coast inverse for the selected digital input.

Prevent automatic restart:

Select latched start for the selected digital input.

NOTICE

Coast does not terminate the brake function.

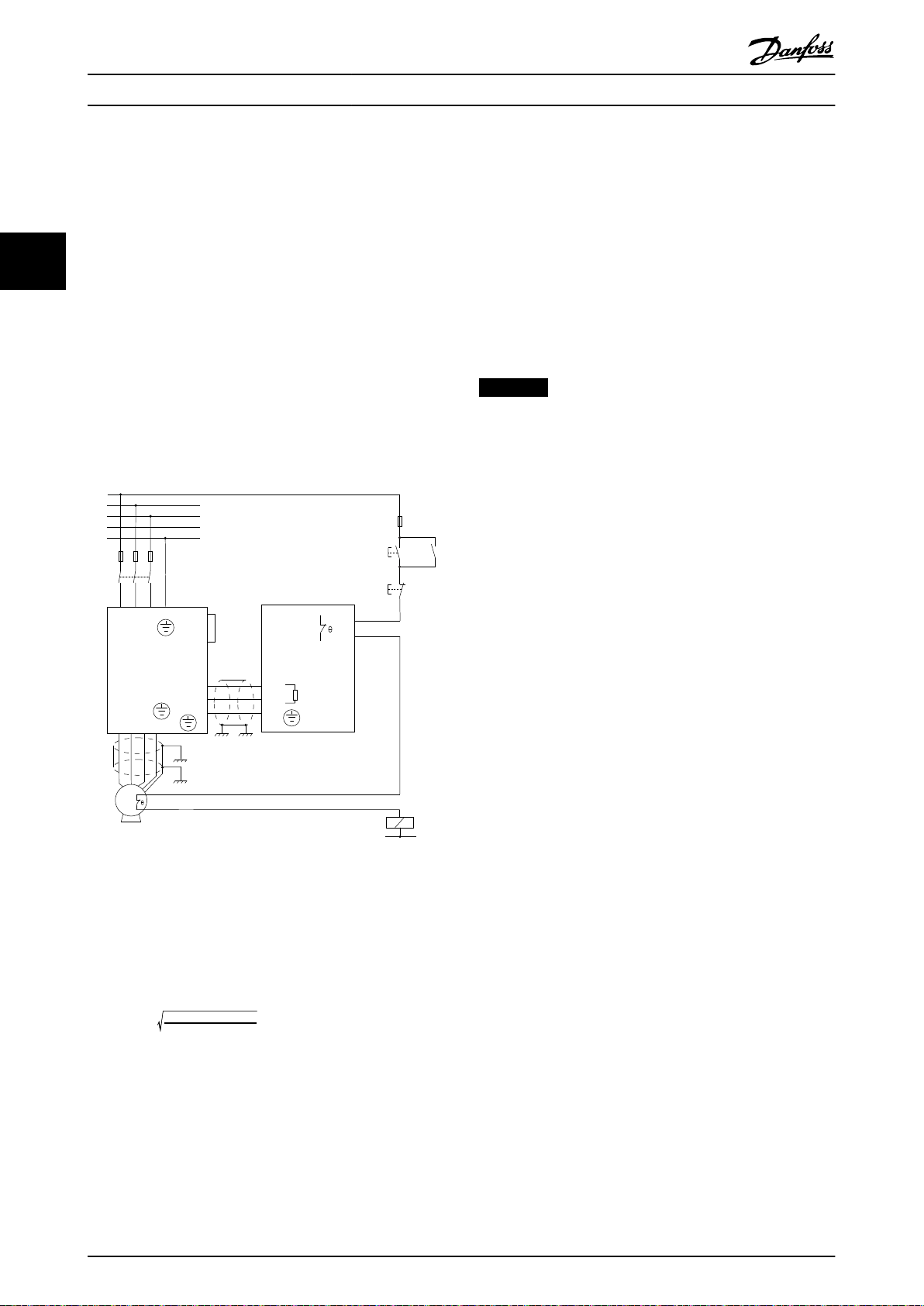

Example 1

3 3

Ensure the connection cable to the brake resistor is

shielded. Connect the shielding to the conductive back

plate of the frequency converter and to the brake resistor

metal cabinet, using cable clamps.

3.3

Protective Functions

3.3.1 Overtemperature Protection

The Danfoss brake resistor MCE 101 is equipped with a

galvanic isolated temperature switch (PELV) that is closed

under normal operating conditions and open if the brake

resistor is overheated.

NOTICE

Use the temperature switch as overtemperature

protection feature to prevent damage of the brake

resistor caused by overtemperature. To prevent damage

to the brake resistor, perform an immediate stop or a

ramp down.

There are several ways the temperature switch can be

used:

The temperature switch as digital input to frequency

converter

Example 1

1. Connect terminal T1 of the brake resistor to the

frequency converter terminal 12 or 13.

2. Connect terminal T2 of the brake resistor to a

digital input e.g. terminal 18.

Illustration 3.18 Temperature Switch in Brake Resistor

NOTICE

The temperature switch as input to the frequency

converter cannot be considered a primary safety

function.

In case of a malfunction in the brake IGBT, the frequency

converter and brake resistor are only protected by

disconnecting the mains supply to the frequency

converter. The temperature switch must be connected

disabling the mains supply to the frequency converter by

a contactor preventing dangerous overtemperatures.

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 13

Page 16

91 92 93 95

96 97 98 99

M

3~

12

27

L1 L2 L3 PE

VLT

MCE 101

Brake resistor

T1

T2

RB1

RB2

99

PE

81

R -

82R+

PE

L1

L2

L3

N

PE

F1

S1 K1

F2

S2

K1

K1

U V W PE

130BD554.11

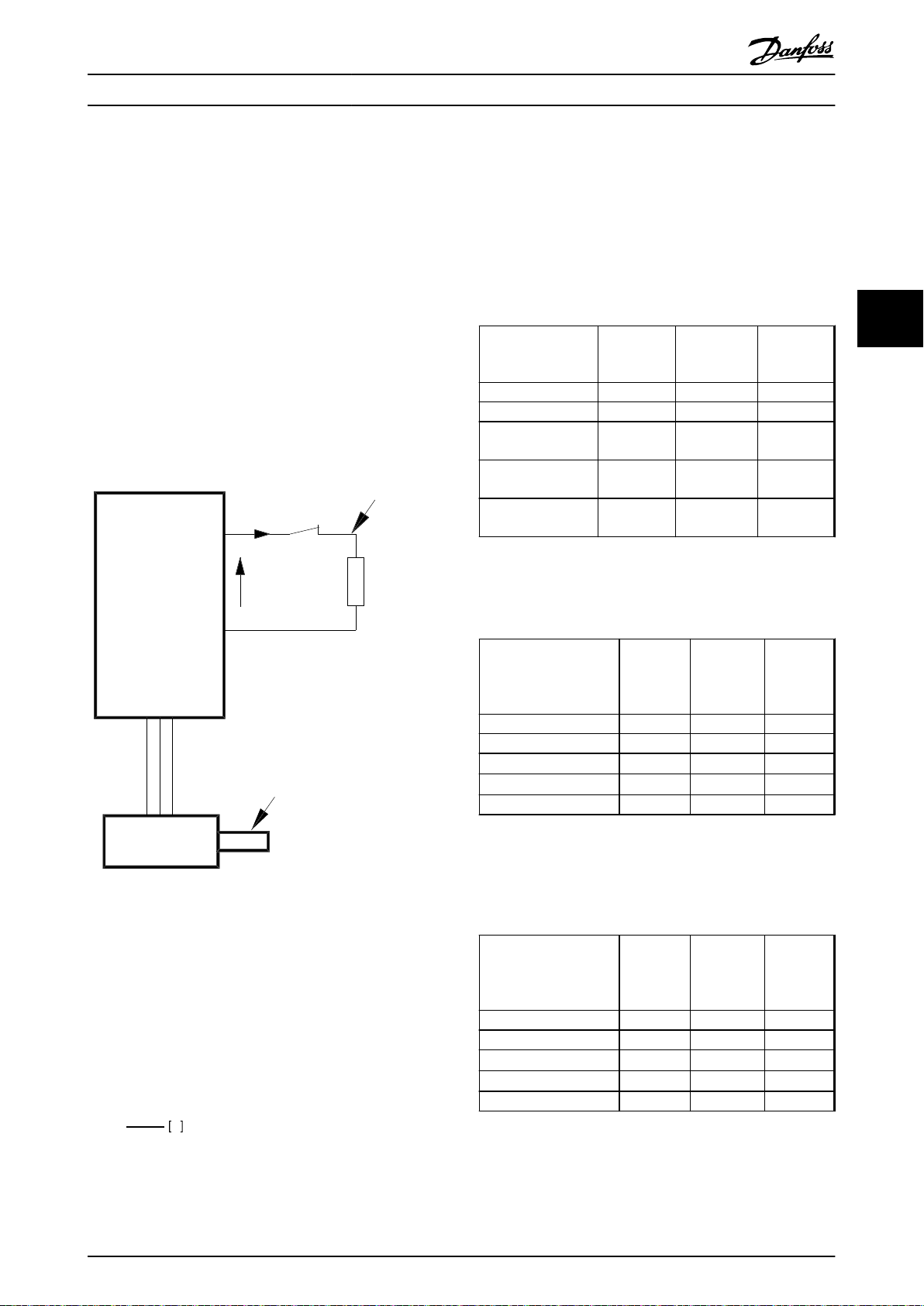

Installation Design Guide

The temperature switch disabling the mains supply to

3.3.2

Brake Resistor and Brake IGBT

VLT by a contactor

Example 2

1. Connect the brake resistor built-in thermal switch

as controlling an input contactor. In this example,

the thermal switch within the brake resistor is

33

connected in series with the thermal switch

within the motor.

2. Connect start and stop push buttons in series

with the thermal switches.

3. Connect to a contactor in the mains supply in

front of the frequency converter.

Thermal overheating in brake resistor or motor disables

the mains supply to the frequency converter.

Example 2

Brake resistor power monitor

In addition, the brake power monitor function makes it

possible to read out the momentary power and the mean

power for a selected time period. The brake can also

monitor the power energising and make sure it does not

exceed a limit selected in parameter 2-12 Brake Power Limit

(kW). In 2-13 Brake Power Monitoring, select the function to

carry out when the power transmitted to the brake resistor

exceeds the limit set in parameter 2-12 Brake Power Limit

(kW).

NOTICE

Monitoring the brake power does not fulfil a safety

function. The brake resistor circuit is not ground leakage

protected.

The brake is protected against short-circuiting of the brake

resistor, and the brake transistor is monitored to ensure

that short-circuiting of the transistor is detected. Use a

relay or digital output to protect the brake resistor against

overloading in the event of a fault in the frequency

converter, see chapter 3.3.1 Overtemperature Protection.

Illustration 3.19 Temperature Switch in both Motor and Brake

Resistor disabling Mains Supply by an Input Contactor

Thermo relay disabling the brake resistor

Example 3

Calculate the brake current (I

thermo relay

) setting of the

temperature switch as follows:

P

I

thermo relay

brake resistor max

=

R

br

Rbr is the current brake resistor value calculated in

chapter 4.1.2 Calculation of Brake Resistor Resistance.

Look up the brake current setting of the thermo relay for

Danfoss brake resistors in chapter 8 Selection Guide.

Overvoltage control (OVC) can be selected as an alternative

brake function in parameter 2-17 Over-voltage Control. If the

DC-link voltage increases, this function is active for all

units. The function ensures that a trip can be avoided. This

is done by increasing the output frequency to limit the

voltage from the DC link. It is a useful function, e.g. if the

ramp-down time is too short since tripping of the

frequency converter is avoided. In this situation the rampdown time is extended.

14 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 17

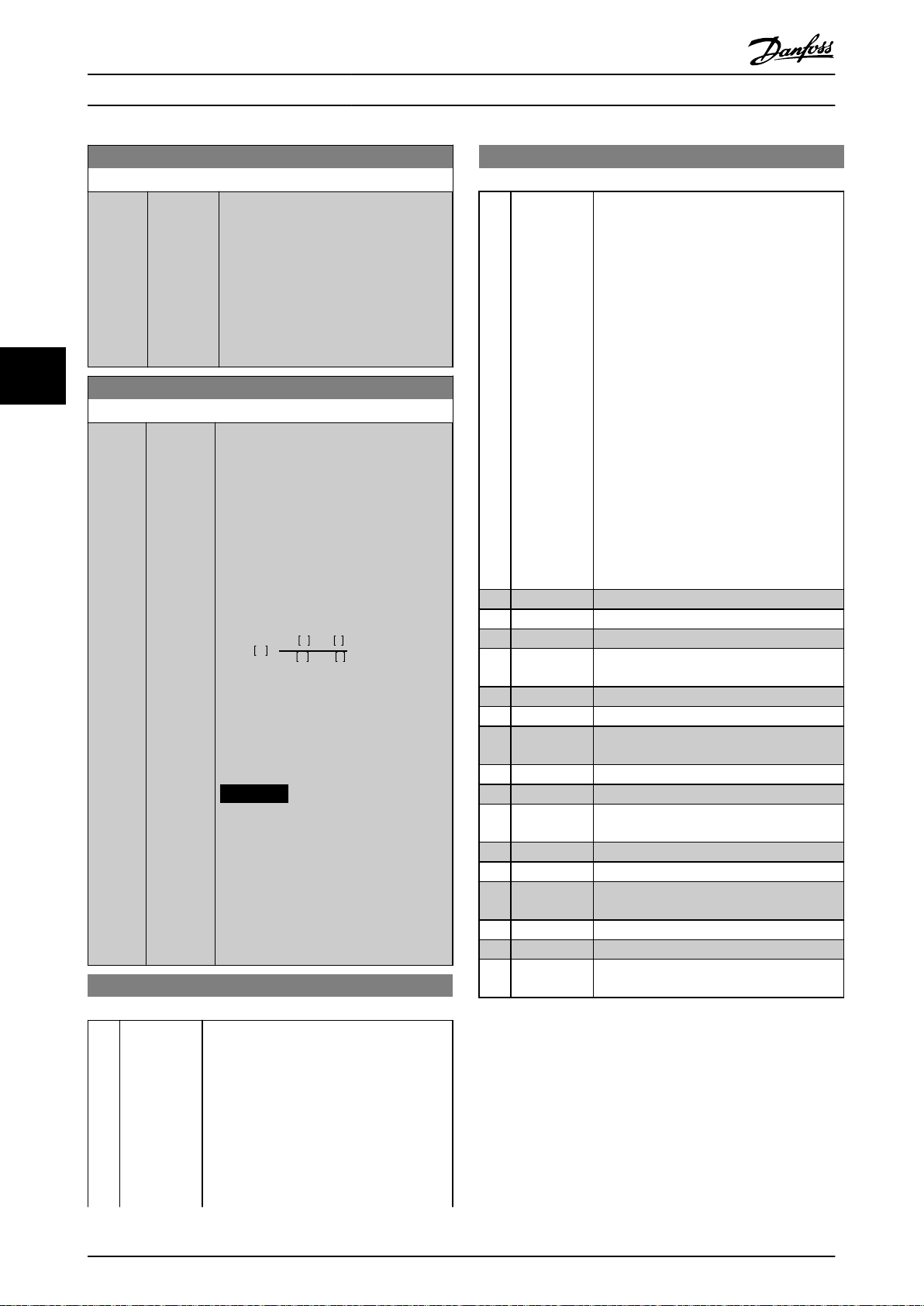

P

peak,mec.

175ZA096.14

VLT

U

DC

I

termo

P

peak

P

avg

R

br

P

b, max

P

motor

η

INV

= 0.98

η

motor

= 0.9

System Integration

4 System Integration

Design Guide

4.1 Brake Resistor Calculation

To ensure the optimal selection of brake resistor for a

given application, its inertia and braking profile

calculations are required.

This chapter explains the calculations required to obtain

values for optimal selection of brake resistor for a given

application.

4.1.1 Brake Set-up

The following sections use expressions and abbreviations

related to the brake set-up in Illustration 4.1.

Udc is the voltage, where the brake is activated. The FCseries brake function is settled depending on the mains

supply.

DC-link Voltage (Udc), FC 51

Size [V] Brake active

[V]

FC 51 1x200-240 390 410 410

FC 51 3x200-240 390 410 410

FC 51 3x380-480,

1.5-4.0 kW

FC 51 3x380-480,

5.5-15 kW

FC 51 3x380-480,

18.5-22 kW

Table 4.1 DC-link Voltage (Udc), FC 51

1) Adjustable with 2-14 Brake Voltage Reduce

770 800 800

705-770

770 800 800

1)

Warning

before cut

out [V]

800 800

Cut out

(trip) [V]

DC-link Voltage (Udc), FC 102

Brake

Size [V]

FC 102 3x200-240 390 405 410

FC 102 3x380-480 778 810 820

FC 102 3x525-600

FC 102 3x525-600

FC 102 3x525-690 1099 1109 1130

1)

2)

active

[V DC]

943 965 975

1099 1109 1130

High

voltage

warning

[V DC]

Over

voltage

alarm

[V DC]

4 4

Table 4.2 DC-link Voltage (Udc), FC 102

1) Enclosure types A, B, C

2) Enclosure types D, E, F

Illustration 4.1 Brake Set-up

Calculation of Brake Resistor

4.1.2

Resistance

To prevent the frequency converter from cutting out for

protection when the motor brakes, select resistor values on

the basis of the peak braking power and the intermediate

circuit voltage:

2

Udc

R

=

br

P

peak

Ω

The brake resistor performance depends on the DC-link

voltage (Udc).

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 15

DC-link Voltage (Udc), FC 202

Brake

Size [V]

FC 202 3x200-240 390 405 410

FC 202 3x380-480 778 810 820

FC 202 3x525-600

FC 202 3x525-600

FC 202 3x525-690 1099 1109 1130

Table 4.3 DC-link Voltage (Udc), FC 202

1) Enclosure types A, B, C

2) Enclosure types D, E, F

1)

2)

active

[V DC]

943 965 975

1099 1109 1130

High

voltage

warning

[V DC]

Over

voltage

alarm

[V DC]

Page 18

P

[W]

P

peak

P

avg

T

p

T

b

t [s]

175ZA094.13

System Integration Design Guide

DC-link Voltage (Udc), FC 301/FC 302

Use the brake resistance R

, to ensure that the frequency

rec

converter is able to brake at the highest braking torque

High

voltage

warning

[V DC]

Size [V]

FC 301 3x200-240

FC 301 3x200-240

Brake

active

[V DC]

1)

2)

365 405 410

390 405 410

FC 302 3x200-240 390 405 410

44

FC 301 3x380-480

FC 301 3x380-480

FC 302 3x380-500

FC 302 3x380-500

FC 302 3x525-600

FC 302 3x525-600

1)

2)

3)

4)

3)

4)

728 810 820

778 810 820

810 840 855

810 828 855

943 965 975

1099 1109 1130

FC 302 3x525-690 1099 1109 1130

Table 4.4 DC-link Voltage (Udc), FC 301/FC 302

1) Enclosure type A

2) Enclosure types B, C

3) Enclosure types A, B, C

4) Enclosure types D, E, F

DC-link Voltage (Udc), FC 360

1)

High

voltage

warning

[V DC]

800 800

800 800

Size [V]

FC 360 3x380-480,

0.37-22 kW

FC 360 3x380-480, 30-75

kW

Brake

active

[V DC]

700-770

N/A

2)

Over

voltage

alarm

[V DC]

Over

voltage

alarm

[V DC]

(M

) (e.g. 160%). The formula is written as:

br(%)

2

U

x 100

R

Ω =

η

η

rec

motor

VLT

P

motor

is typically at 0.90

is typically at 0.98

x

dc

M

x η

br

%

VLT

x η

motor

When a higher brake resistor resistance is selected, 160%/

150%/110% braking torque cannot be obtained, and there

is a risk that the frequency converter cuts out of DC-Link

overvoltage for protection.

For braking at lower torque, for example 80% torque, it is

possible to install a brake resistor with lower power rating.

Calculate size using the formula for calculating R

Calculation of Braking Power

4.1.3

rec

.

When calculating the braking power, ensure that the brake

resistor is scaled for the average power as well as the peak

power.

The average power is determined by the process

•

period time, i.e. the length of the braking time in

relation to the process period time.

The peak power is determined by the braking

•

torque, which means that as braking progresses,

the brake resistor must be able to dissipate the

energy input.

Illustration 4.2 shows the relation between the average

Table 4.5 DC-link Voltage (Udc), FC 360

1) Adjustable with 2-14 Brake voltage reduce

2) No built-in brake option

power and the peak power.

DC-link Voltage (Udc), FCD 302

High

voltage

warning

[V DC]

Size [V]

Brake

active

[V DC]

FCD 302 3x380-480 778 810 820

Table 4.6 DC-link Voltage (Udc), FCD 302

DC-link Voltage (Udc), VLT 2800

Brake

Size [V]

active

[V DC]

VLT 2800 3x200-240 385 400 410

VLT 2800 3x380-480 770 800 820

Table 4.7 DC-link Voltage (Udc), VLT 2800

16 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

High

voltage

warning

[V DC]

Over

voltage

alarm

[V DC]

Over

voltage

alarm

[V DC]

T

p

T

b

Process period time in s

Braking time in s

Illustration 4.2 Relation between Average Power and Peak

Power

Page 19

ω Start

ω Stop

∆t

∆ω/∆t

175ZA863.11

System Integration

Design Guide

4.1.4 Calculation of the Brake Resistor Peak

Power

P

the motor shaft. Calculate P

P

P

when the motor brakes.

P

the efficiencies of the motor and the frequency converter.

Calculate P

P

When the brake resistor recommended by Danfoss is

selected (R

chapter 8 Selection Guide, the brake resistor is certain to

provide a braking torque of 160%/150%/110% on the

motor shaft.

is the peak power by which the motor brakes on

peak, mec

as follows:

peak, mec

=

P

×

M

peak, mec

is the braking power dissipated to the brake resistor

peak

is lower than P

peak

=

peak

motor

peak,mec

as follows:

peak

P

×

M

motor

) on the basis of the tables in

rec

BR %

×

W

BR %

since the power is reduced by

η

×

η

W

VLT

motor

Danfoss offers brake resistors with a duty-cycle of max.

10% and 40%. If a 10% duty-cycle is applied, the brake

resistors are able to absorb P

for 10% of the period

peak

time. The remaining 90% of the period time is used on

deflecting excess heat.

Calculate the average power with 10% duty-cycle as

follows:

P

=

P

avg

peak

× 10 %

W

Calculate the average power with 40% duty-cycle as

follows:

P

=

P

avg

peak

× 40 %

W

The calculations apply to intermittent braking using a

period time of 30 s.

NOTICE

Exceeding the specified intermittent braking period time

may result in overheating the resistor.

4 4

Calculation of the Brake Resistor

4.1.5

Average Power

The average power is determined by the length of the

braking time in relation to the process period time.

When the kinetic energy (Eb) transferred to the resistor in

each braking sequence is known (see chapter 6.1 Conveyor

Belt and chapter 6.2 Centrifuge), calculate the average

power of the brake resistor as follows:

E

avg

b

=

W

T

p

T

× 100

b

%

T

p

Tp = process period time in s

Tb = braking time in s

P

Tp = period time in s, see Illustration 4.2.

When the kinetic energy transferred to the resistor in each

braking sequence is not known, calculate the average

power on the basis of the process period time and the

braking time.

Calculate the duty-cycle for the braking sequence as

follows:

Duty cycle =

where

4.1.6 Braking of Inertia

When braking high inertia values on the motor shaft, base

the brake resistor values on the inertia, Δω, Δt, see

Illustration 4.3.

Illustration 4.3 Braking of High Inertia

Δt is determined by the ramp-down time.

NOTICE

The ramp-down time goes from the rated motor

frequency to 0 Hz.

P

can be calculated as:

peak

P

=

η

×

η

×

ω

VLT

η

×

n

start

VLT

P

peak

peak

=

motor

η

motor

×

j is the motor shaft inertia.

start

×

× j ×

j

×

2 ×

Δω

60

Δt

Δn

π

2

×

Δt

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 17

Page 20

Programming Design Guide

5 Programming

For descriptions of all available parameters, see the

product specific Programming Guide, www.danfoss.com/

BusinessAreas/DrivesSolutions/Documentations/VLT+Technical

+Documentation.htm.

5.1

Parameters for VLT® Micro Drive FC 51

2-10 Brake Function

55

Option: Function:

NOTICE

Resistor brake is only functional in

frequency converters with integrated

dynamic brake. An external resistor must

be connected.

Resistor Brake

The resistor brake limits voltage in the

intermediate circuit when the motor acts as

generator. Without brake resistor, the frequency

converter eventually trips.

The resistor brake consumes surplus energy

resulting from motor braking. A frequency

converter with brake, stops a motor faster than

without a brake, which is used in many

applications. Requires connection of external

brake resistor.

An alternative to the resistor brake is the AC

brake.

AC Brake

The AC brake consumes surplus energy by

creating power loss in the motor.

It is important to keep in mind that an increase

in power loss causes motor temperature to rise.

* Off No brake function.

[0]

[1] Resistor

Brake

[2] AC Brake AC brake is active.

Resistor brake is active.

5.2

Parameters for VLT® HVAC Drive FC 102

and VLT® AQUA Drive FC 202

2-02 DC Braking Time

Range: Function:

10 s* [0 - 60 s] Set the duration of the DC braking current set

in 2-01 DC Brake Current, once activated.

2-03 DC Brake Cut In Speed [RPM]

Range: Function:

Size

related*

[ 0 - 0

RPM]

Set the DC brake cut-in speed to

activate the DC braking current set in

2-01 DC Brake Current, upon a stop

command.

When 1-10 Motor Construction is set to

[1] PM non-salient SPM this value is

limited to 0 RPM (OFF)

NOTICE

Parameter 2-03 DC Brake Cut In Speed [RPM] does not

have effect when 1-10 Motor Construction=[1] PM, nonsalient SPM.

2-04 DC Brake Cut In Speed [Hz]

Range: Function:

Size related* [ 0 - 1000.0

Hz]

Set the DC brake cut-in speed for

activation of the DC braking

current set in 2-01 DC Brake

Current, upon a stop command.

NOTICE

Parameter 2-04 DC Brake Cut In Speed [Hz] has no effect

when 1-10 Motor Construction[1] PM, non-salient SPM.

2-11 Brake Resistor (Ohm)

Range: Function:

5 Ω* [5-5000 Ω] Set brake resistor value.

2-14 Brake Voltage Reduce

Range: Function:

0 V* [ 0 - 0 V]

18 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 21

Programming Design Guide

2-10 Brake Function

Option: Function:

Available selections depend on 1-10 Motor

Construction:

[0] Asynchron:

[0] Off

•

[1] Resistor brake

•

[2] AC brake

•

[1] PM non-salient:

[0] Off

•

[1] Resistor brake

•

[0] Off No brake resistor installed.

[1] Resistor

brake

[2] AC brake AC Brake only works in Compressor Torque mode

Brake resistor incorporated in the system, for

dissipation of surplus brake energy as heat.

Connecting a brake resistor allows a higher DClink voltage during braking (generating

operation). The resistor brake function is only

active in frequency converters with an integral

dynamic brake.

in 1-03 Torque Characteristics.

2-11 Brake Resistor (ohm)

Range: Function:

Size

related*

[ 5.00 -

65535.00

Ohm]

Set the brake resistor value in Ω. This

value is used for monitoring the power

to the brake resistor in 2-13 Brake Power

Monitoring. This parameter is only active

in frequency converters with an integral

dynamic brake.

Use this parameter for values without

decimals. For a selection with 2 decimals,

use parameter 30-81 Brake Resistor (ohm).

2-12 Brake Power Limit (kW)

Range: Function:

Size

related*

[ 0.001 -

2000.000

kW]

Parameter 2-12 Brake Power Limit (kW) is

the expected average power dissipated in

the brake resistor over the time period

selected within 2-13 Brake Power

Monitoring. It is used as the monitoring

limit for 16-33 Brake Energy /2 min and

thereby specifies when a warning/alarm is

to be given.

To calculate parameter 2-12 Brake Power

Limit (kW), the following formula can be

used.

2

U

V×tbrs

P

br,avg

P

br,avg

the brake resistor, Rbr is the resistance of

the brake resistor. tbr is the active

breaking time within the 120 s period, Tbr.

br

W

=

RbrΩ×Tbrs

is the average power dissipated in

2-12 Brake Power Limit (kW)

Range: Function:

Ubr is the DC voltage where the brake

resistor is active.

NOTICE

If values are unknown, or if Tbr is

different from 120 s, the practical

approach is to run the brake

application, readout 16-33 Brake

Energy /2 min and then enter this

+20% in 2-12 Brake Power Limit

(kW).

2-13 Brake Power Monitoring

Option: Function:

This parameter is only active in frequency

converters with an integral dynamic brake.

This parameter enables monitoring of the

power to the brake resistor. The power is

calculated on the basis of the resistance

(parameter 2-11 Brake Resistor (ohm)), the

DC-link voltage, and the resistor duty time.

The time periode can be selected in this

parameter.

The functions are as follows:

Off:

•

Brake power monitoring disabled.

Default setting.

Warning (time period):

•

Activates a warning on the display

when the power transmitted over

the selected time period exceeds

100% of the monitoring limit

(parameter 2-12 Brake Power Limit

(kW)). The warning disappears

when the transmitted power falls

below 80% of the monitoring limit.

Trip (time period);

•

Trips frequency converter and

displays an alarm when the

calculated power exceeds 100% of

the monitoring limit.

Warning & trip (time period):

•

Activates both of the above,

including warning, trip and alarm.

* Disabled Brake power monitoring disabled.

[0]

[1] Warning 120s Warning based on 120 s time periode.

[2] Trip 120s Trip based on 120 s time periode.

[3] Warning &

trip 120s

[4] Warning 30s Warning based on 30 s time periode.

[5] Trip 30s Trip based on 30s time periode

Warning and trip based on 120 s time

periode.

5 5

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 19

Page 22

Programming Design Guide

2-13 Brake Power Monitoring

Option: Function:

[6] Warning &

trip 30s

[7] Warning 60s Warning based on 60 s time periode.

[8] Trip 60s Trip based on 60 s time periode.

[9] Warning &

trip 60s

[10] Warning 300s Warning based on 300 s time periode.

[11] Trip 300s Trip based on 300 s time periode.

[12] Warning &

55

trip 300s

[13] Warning 600s Warning based on 600s time periode.

[14] Trip 600s Trip based on 600 s time periode.

[15] Warning &

trip 600s

Warning and trip based on 30 s time

periode.

Warning and trip based on 60 s time

periode.

Warning and trip based on 300 s time

periode.

Warning and trip based on 600 s time

periode.

If power monitoring is disabled or Warning is selected, the

brake function remains active, even if the monitoring limit

is exceeded. This may lead to thermal overload of the

resistor. It is also possible to generate a warning via a

relay/digital outputs. The measuring accuracy of the power

monitoring depends on the accuracy of the resistance of

2-15 Brake Check

Option: Function:

[2] Trip Monitors for a short-circuit or disconnection of

the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the frequency converter

cuts out while displaying an alarm (trip locked).

[3] Stop and

trip

[4] AC brake Monitors for a short-circuit or disconnection of

Monitors for a short-circuit or disconnection of

the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the frequency converter

ramps down to coast and then trips. A trip lock

alarm is displayed.

the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the frequency converter

performs a controlled ramp-down.

NOTICE

Remove a warning arising in connection with [0] Off or

[1] Warning by cycling the mains supply. The fault must

be corrected first. For [0] Off or [1] Warning, the

frequency converter keeps running even if a fault is

located.

the resistor (better than ±20%).

2-15 Brake Check

Option: Function:

Select type of test and monitoring function to

check the connection to the brake resistor, or

whether a brake resistor is present, and then

display a warning or an alarm in the event of a

fault. The brake resistor disconnection function is

tested during power-up. However, the brake

IGBT test is performed when there is no braking.

A warning or trip disconnects the brake function.

The testing sequence is as follows:

1. The DC-link ripple amplitude is

measured for 300 ms without braking.

2. The DC-link ripple amplitude is

measured for 300 ms with the brake

turned on.

3. If the DC-link ripple amplitude while

braking is lower than the DC-link ripple

amplitude before braking +1%. Brake

check failed, return a warning or alarm.

4. If the DC-link ripple amplitude while

braking is higher than the DC-link

ripple amplitude before braking +1%.

Brake check OK.

Off Monitors brake resistor and brake IGBT for a

[0]

*

[1] Warning Monitors brake resistor and brake IGBT for a

short-circuit during operation. If a short-circuit

occurs, a warning appears.

short-circuit, and runs a test for brake resistor

disconnection during power-up.

2-16 AC brake Max. Current

Range: Function:

100 %* [ 0 - 1000.0%]Enter the maximum permissible current

when using AC brake to avoid

overheating of motor windings. The AC

brake function is available in Flux mode

only.

NOTICE

Parameter 2-16 AC brake Max. Current has no effect when

1-10 Motor Construction=[1] PM, non-salient SPM.

2-17 Over-voltage Control

Option: Function:

[0] Disabled No OVC required.

[2] * Enabled Activates OVC.

NOTICE

Parameter 2-17 Over-voltage Control has no effect when

1-10 Motor Construction[1] PM, non-salient SPM.

NOTICE

The ramp time is automatically adjusted to avoid

tripping of the frequency converter.

20 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 23

Programming Design Guide

16-32 Brake Energy /s

Range: Function:

0 kW* [0 - 10000 kW] View the brake power transmitted to an

external brake resistor, stated as an

instantaneous value.

16-33 Brake Energy /2 min

Range: Function:

0 kW* [0 - 10000

kW]

View the brake power transmitted to an

external brake resistor. The mean power is

calculated on an average level based on

the selected time period within 2-13 Brake

Power Monitoring.

30-81 Brake Resistor (ohm)

Range: Function:

Size

related*

[ 0.01 -

65535.00 Ohm]

Set the brake resistor value in Ω

with 2 decimals. This value is used

for monitoring the power to the

brake resistor in 2-13 Brake Power

Monitoring.

5.3

Parameters for VLT® AutomationDrive

FC 301/FC 302 and ® Decentral Drive

FCD 302

2-02 DC Braking Time

Range: Function:

10 s* [0 - 60 s] Set the duration of the DC braking current set

in 2-01 DC Brake Current, once activated.

2-03 DC Brake Cut In Speed [RPM]

Range: Function:

Size related* [ 0 - 60000

RPM]

2-04 DC Brake Cut In Speed [Hz]

Range: Function:

Size related* [ 0 - 1000.0

Hz]

Set the DC brake cut-in speed for

activation of the DC braking

current set in 2-01 DC Brake

Current, upon a stop command.

Set the DC brake cut-in speed for

activation of the DC braking

current set in 2-01 DC Brake

Current, upon a stop command.

5 5

NOTICE

Parameter 2-04 DC Brake Cut In Speed [Hz] has no effect

when 1-10 Motor Construction[1] PM, non-salient SPM.

2-10 Brake Function

Option: Function:

[0] Off No brake resistor is installed.

[1] Resistor

brake

[2] AC brake Is selected to improve braking without using a

A brake resistor is incorporated in the system, for

dissipation of surplus brake energy as heat.

Connecting a brake resistor allows a higher DClink voltage during braking (generating operation).

The resistor brake function is only active in

frequency converters with an integral dynamic

brake.

brake resistor. This parameter controls an

overmagnetisation of the motor when running

with a generatoric load. This function can improve

the OVC-function. Increasing the electrical losses

in the motor allows the OVC function to increase

the braking torque without exceeding the over

voltage limit.

NOTICE

The AC brake is not as efficient as dynamic

braking with resistor.

AC brake is for VVC+ mode in both open

and closed loop.

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 21

Page 24

Programming

Design Guide

2-11 Brake Resistor (ohm)

Range: Function:

Size

related*

55

2-12 Brake Power Limit (kW)

[ 5.00 -

65535.00

Ohm]

Set the brake resistor value in Ω. This

value is used for monitoring the power

to the brake resistor in 2-13 Brake Power

Monitoring. This parameter is only active

in frequency converters with an integral

dynamic brake.

Use this parameter for values without

decimals. For a selection with 2 decimals,

use parameter 30-81 Brake Resistor (ohm).

Range: Function:

Size

related*

[ 0.001 -

2000.000

kW]

Parameter 2-12 Brake Power Limit (kW) is

the expected average power dissipated in

the brake resistor over the time period

selected within 2-13 Brake Power

Monitoring. It is used as the monitoring

limit for 16-33 Brake Energy /2 min and

thereby specifies when a warning/alarm is

to be given.

To calculate parameter 2-12 Brake Power

Limit (kW), the following formula can be

used.

2

U

V×tbrs

P

br,avg

P

br,avg

the brake resistor, Rbr is the resistance of

the brake resistor. tbr is the active

breaking time within the 120 s period, Tbr.

Ubr is the DC voltage where the brake

resistor is active.

br

W

=

RbrΩ×Tbrs

is the average power dissipated in

NOTICE

If values are unknown, or if Tbr is

different from 120 s, the practical

approach is to run the brake

application, readout 16-33 Brake

Energy /2 min and then enter this

+20% in 2-12 Brake Power Limit

(kW).

2-13 Brake Power Monitoring

Option: Function:

This parameter is only active in frequency

converters with an integral dynamic brake.

This parameter enables monitoring of the

power to the brake resistor. The power is

calculated on the basis of the resistance

(parameter 2-11 Brake Resistor (ohm)), the

DC-link voltage, and the resistor duty time.

The time periode can be selected in this

parameter.

The functions are as follows:

2-13 Brake Power Monitoring

Option: Function:

Off:

•

Brake power monitoring disabled.

Default setting.

Warning (time period):

•

Activates a warning on the display

when the power transmitted over

the selected time period exceeds

100% of the monitoring limit

(parameter 2-12 Brake Power Limit

(kW)). The warning disappears

when the transmitted power falls

below 80% of the monitoring limit.

Trip (time period);

•

Trips frequency converter and

displays an alarm when the

calculated power exceeds 100% of

the monitoring limit.

Warning & trip (time period):

•

Activates both of the above,

including warning, trip and alarm.

[0] * Disabled Brake power monitoring disabled.

[1] Warning 120s Warning based on 120 s time periode.

[2] Trip 120s Trip based on 120 s time periode.

[3] Warning &

trip 120s

[4] Warning 30s Warning based on 30 s time periode.

[5] Trip 30s Trip based on 30s time periode

[6] Warning &

trip 30s

[7] Warning 60s Warning based on 60 s time periode.

[8] Trip 60s Trip based on 60 s time periode.

[9] Warning &

trip 60s

[10] Warning 300s Warning based on 300 s time periode.

[11] Trip 300s Trip based on 300 s time periode.

[12] Warning &

trip 300s

[13] Warning 600s Warning based on 600s time periode.

[14] Trip 600s Trip based on 600 s time periode.

[15] Warning &

trip 600s

Warning and trip based on 120 s time

periode.

Warning and trip based on 30 s time

periode.

Warning and trip based on 60 s time

periode.

Warning and trip based on 300 s time

periode.

Warning and trip based on 600 s time

periode.

If power monitoring is disabled or Warning is selected, the

brake function remains active, even if the monitoring limit

is exceeded. This may lead to thermal overload of the

resistor. It is also possible to generate a warning via a

relay/digital outputs. The measuring accuracy of the power

monitoring depends on the accuracy of the resistance of

the resistor (better than ±20%).

22 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 25

Programming Design Guide

2-15 Brake Check

Option: Function:

Parameter 2-15 Brake Check is only active in

frequency converters with an integral dynamic

brake.

Select type of test and monitoring function to

check the connection to the brake resistor, or

whether a brake resistor is present, and then

display a warning or an alarm in the event of a

fault.

NOTICE

The brake resistor disconnection function

is tested during power-up. However, the

brake IGBT test is performed when there is

no braking. A warning or trip disconnects

the brake function.

The testing sequence is as follows:

1. The DC-link ripple amplitude is

measured for 300 ms without braking.

2. The DC-link ripple amplitude is

measured for 300 ms with the brake

turned on.

3. If the DC-link ripple amplitude while

braking is lower than the DC-link ripple

amplitude before braking + 1%: Brake

check has failed by returning a warning

or alarm.

4. If the DC-link ripple amplitude while

braking is higher than the DC-link ripple

amplitude before braking + 1%: Brake

check is OK.

Off Monitors brake resistor and brake IGBT for a

[0]

*

[1] Warning Monitors brake resistor and brake IGBT for a

[2] Trip Monitors for a short-circuit or disconnection of

[3] Stop and

trip

[4] AC brake Monitors for a short-circuit or disconnection of

short-circuit during operation. If a short-circuit

occurs, warning 25 appears.

short-circuit, and runs a test for brake resistor

disconnection during power-up.

the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the frequency converter

cuts out while displaying an alarm (trip locked).

Monitors for a short-circuit or disconnection of

the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the frequency converter

ramps down to coast and then trips. A trip lock

alarm is displayed (e.g. warning 25, 27 or 28).

the brake resistor, or a short-circuit of the brake

IGBT. If a fault occurs, the frequency converter

performs a controlled ramp-down. This option is

available for FC 302 only.

2-15 Brake Check

Option: Function:

[5] Trip Lock

NOTICE

Remove a warning arising in connection with [0] Off or

[1] Warning by cycling the mains supply. The fault must

be corrected first. For [0] Off or [1] Warning, the

frequency converter keeps running even if a fault is

located.

2-16 AC brake Max. Current

Range: Function:

100 %* [ 0 - 1000.0 %] Enter the maximum permissible current

when using AC brake to avoid

overheating of motor windings.

NOTICE

Parameter 2-16 AC brake Max. Current has no effect when

1-10 Motor Construction[1] PM, non salient SPM.

2-17 Over-voltage Control

Option: Function:

Overvoltage control (OVC) reduces the risk

of the frequency converter tripping due to

an overvoltage on the DC-link caused by

generative power from the load.

[0] * Disabled No OVC required.

[1] Enabled (not

at stop)

[2] Enabled Activates OVC.

Activates OVC except when using a stop

signal to stop the frequency converter.

NOTICE

Do not enable OVC in hoisting applications.

2-18 Brake Check Condition

Range: Function:

[0] * At Power Up Brake check is performed at power

up.

[1] After Coast Situations Brake check is performed after coast

situations.

16-32 Brake Energy /s

Range: Function:

0 kW* [0 - 10000 kW] View the brake power transmitted to an

external brake resistor, stated as an

instantaneous value.

5 5

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 23

Page 26

Programming Design Guide

16-33 Brake Energy /2 min

Range: Function:

0 kW* [0 - 10000

kW]

View the brake power transmitted to an

external brake resistor. The mean power is

calculated on an average level based on

the selected time period within 2-13 Brake

Power Monitoring.

30-81 Brake Resistor (ohm)

Range: Function:

Size

55

related*

[ 0.01 -

65535.00

Ohm]

Set the brake resistor value in Ω. This

value is used for monitoring the

power to the brake resistor in

2-13 Brake Power Monitoring. This

parameter is only active in frequency

converters with an integral dynamic

brake.

5.4

Parameters for VLT® AutomationDrive

FC 360

2-10 Brake Function

Option: Function:

[0]*Off No brake resistor is installed.

[1] Resistor

brake

[2] AC brake Improves braking without using a brake resistor.

A brake resistor is incorporated in the system for

dissipation of surplus brake energy as heat.

Connecting a brake resistor allows a higher DClink voltage during braking (generating

operation). The brake resistor function is only

active in frequency converters with an integral

dynamic brake.

This parameter controls an overmagnetisation of

the motor when running with a generatoric load.

This function can improve the OVC-function.

Increasing the electrical losses in the motor

allows the OVC-function to increase braking

torque without exceeding the voltage limit.

NOTICE

The AC brake is not as efficient as

dynamic braking with resistor.

AC brake is for VVC+ mode in both open

and closed loop.

2-11 Brake Resistor (ohm)

Range: Function:

Size

related*

[ 0 65535

Ohm]

Set the brake resistor value in Ω. This

value is used for monitoring the power to

the brake resistor. Parameter 2-11 Brake

Resistor (ohm) is only active in frequency

converters with an integral dynamic brake.

Use this parameter for values without

decimals.

2-12 Brake Power Limit (kW)

Range: Function:

Size

related*

[0.001

- 2000

kW]

Parameter 2-12 Brake Power Limit (kW) is the

expected average power dissipated in the

brake resistor over a period of 120 s. It is

used as the monitoring limit for 16-33 Brake

Energy /2 min and thereby specifies when a

warning/alarm is to be given.

To calculate parameter 2-12 Brake Power

Limit (kW), the following formula can be

used.

P

W

=

br,avg

P

is the average power dissipated in the

br,avg

brake resistor, Rbr is the resistance of the

2

U

V×tbrs

br

RbrΩ×Tbrs

24 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 27

Programming Design Guide

2-12 Brake Power Limit (kW)

Range: Function:

brake resistor. tbr is the active breaking time

within the 120 s period, Tbr.

Ubr is the DC voltage where the brake

resistor is active. This depends on the unit

as follows:

T4 units: 778 V

NOTICE

If Rbr is not known or if Tbr is different

from 120 s, the practical approach is

to run the brake application, readout

16-33 Brake Energy /2 min and then

enter this + 20% in 2-12 Brake Power

Limit (kW).

2-16 AC Brake, Max current

Range: Function:

100 %* [0 - 160%]Enter the maximum permissible current

when using AC brake to avoid overheating

of motor windings.

NOTICE

Parameter 2-16 AC Brake, Max current

has no effect when 1-10 Motor

Construction is set to [1] PM, nonsalient SPM.

2-17 Over-voltage Control

Option: Function:

Overvoltage control (OVC) reduces the risk of

the frequency converter tripping due to an

overvoltage on the DC-link caused by

generative power from the load.

[0] * Disabled No OVC required.

[1] Enabled

(not at

stop)

[2] Enabled Activates OVC

Activates OVC except when using a stop signal

to stop the frequency converter.

WARNING

Do NOT enable OVC in hoisting

applications.

5.5

Parameters for VLT® 2800

126 DC brake time

Range: Function:

10 sec* [0 - 60 sec.] The DC brake time is set at which

parameter 132 DC brake voltage is to be

active.

127 DC brake cut-in frequency

Range: Function:

0.00 OFF* [0.0 (OFF) par. 202]

Set the DC brake cut-in frequency at

which the DC brake is to be

activated in connection with a stop

command.

132 DC brake voltage

Range: Function:

0%* [0 - 100% of

max. DC

brake

voltage]

Set the DC brake voltage to be activated at

stop when the DC brake frequency set in

parameter 127 DC brake cut-in frequency is

reached, or if DC braking inverse is active via

a digital input or via serial communication.

Subsequently, the DC brake voltage is active

for the time set in parameter 126 DC brake

time.

400 Brake function

Option: Function:

[0] Off

[1] Resistor

brake

[4] AC brake

[5] Load

sharing

Select [1] Resistor brake if the frequency

converter has an integral brake transistor, and a

brake resistor is connected to terminals 81, 82.

A higher DC-link voltage is permitted during

braking (generated operation) when a brake

resistor is connected.

Select [4] AC brake to improve braking without

using brake resistors. Note that [4] AC brake is

not as effective as [1] Resistor brake.

NOTICE

Disconnected and reconnect mains voltage to activate a

change of selection.

5 5

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 25

Page 28

Programming Design Guide

456 Brake Voltage Reduce

Range: Function:

0*0* [0-25 V if 200 V

device]

[0-50 V if 400 V

device]

Set the voltage by which the level for

resistor braking is reduced. It is only

active when [1] Resistor is selected in

parameter 400 Brake function.

NOTICE

The greater the reduction value, the faster the reaction

to a generator overload. Should only be used if there are

problems with overvoltage in the DC-link voltage.

55

26 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 29

Application Examples Design Guide

6 Application Examples

6.1 Conveyor Belt

Illustration 6.1 shows the relation between the braking

power and the acceleration/braking of a conveyor belt.

Note:

The motor power during braking is negative,

•

since the torque on the motor shaft is negative.

The motor power is time-dependent.

•

The braking power (the power to be dissipated to the

brake resistor) corresponds almost exactly to the negative

motor power plus losses in the motor and the frequency

converter.

Kinetic energy (E) in conveyor belt + motor:

E

= 0. 5 × m ×

where

m = mass with linear movement [kg]

v = speed of mass with linear movement [m/s]

j = inertia of motor and gear box [kgm2]

ω = motor speed [rad/s]

2

v

+ 0 .5 × j × ω

2

Ws

Insert:

n

× 2π

ω

=

60

The result is:

E

= 0 .5×

b

2

m v

+ 0 .0055 ×

2

j

×

n

− 0 .052 × n ×

M

×

η

Ws

f

M

6 6

n

ω

= motor speed =

× 2π

60

rad /

s

This formula is also expressed as follows:

E

= 0. 50 × m ×

2

v

+ 0 .0055 × j ×

n2Ws

However, not all of the energy is dissipated in the brake

resistor. The friction of the conveyor belt and the power

loss of the motor also contribute to the braking function.

So, the formula for energy dissipation (Eb) to the brake

resistor is as follows:

E

= 0 .5×

b

m v

2

+ 0 .5

jω

2

− 0 .5 ×

Mfω

×

η

M

Ws

where

Mf = Friction torque [Nm]

ŋM = Motor efficiency

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 27

Page 30

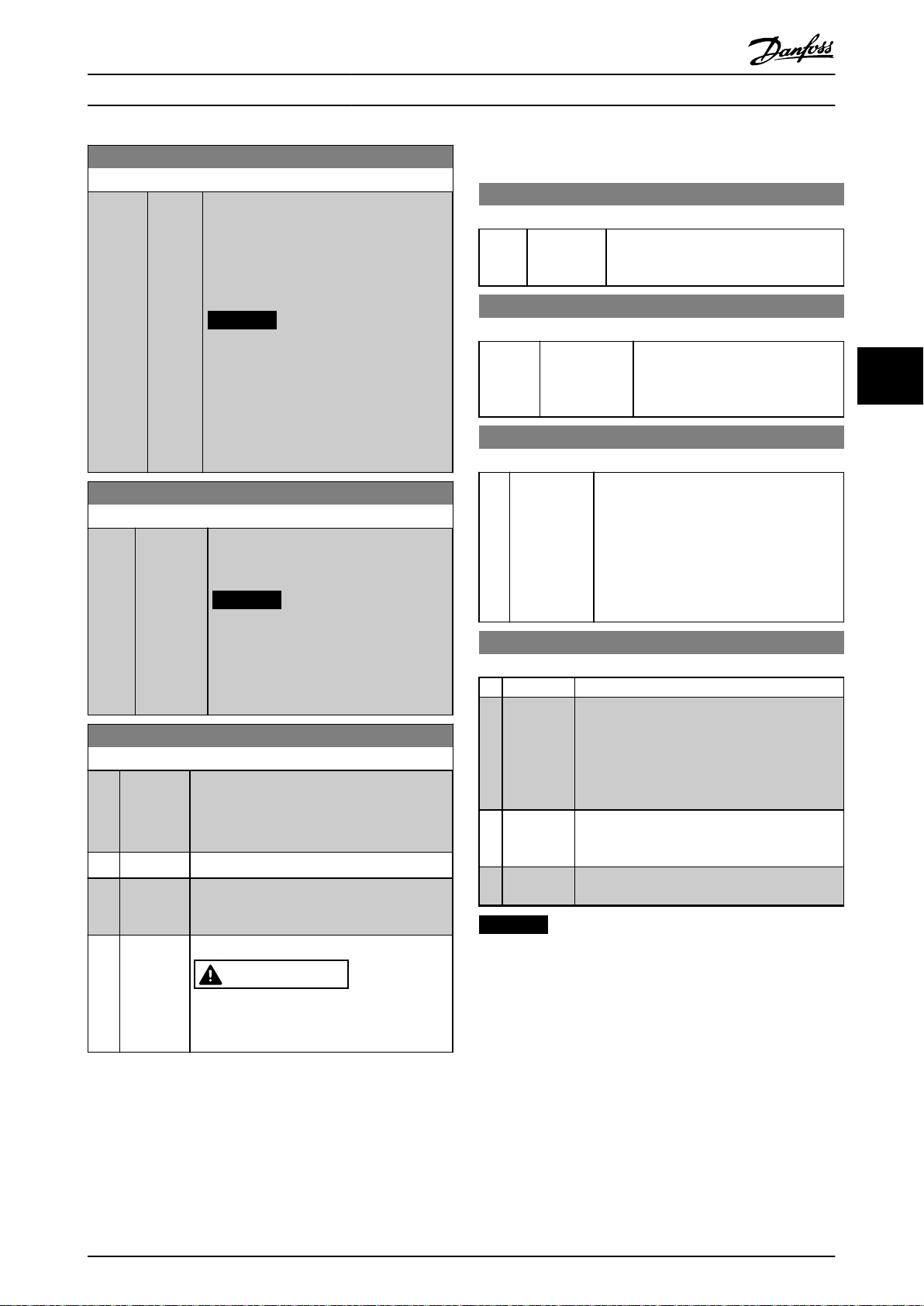

P

average

Time [s]

Time [s]

Time [s]

Time [s]

Length [m]

175ZA397.14

Acceleration

Braking

P

braking, avg.

P

[W]

Motor power

P

[W]

Brake power

M

[Nm]

Torque

V

[m/s]

Speed

VLT®

M

V

[m/s]

Speed

m v

T

p

m

ϖ

[m/s]

T

p

Application Examples

Design Guide

66

Illustration 6.1 Conveyor Belt: Relation between Braking Power and Acceleration/Deceleration

28 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 31

Application Examples Design Guide

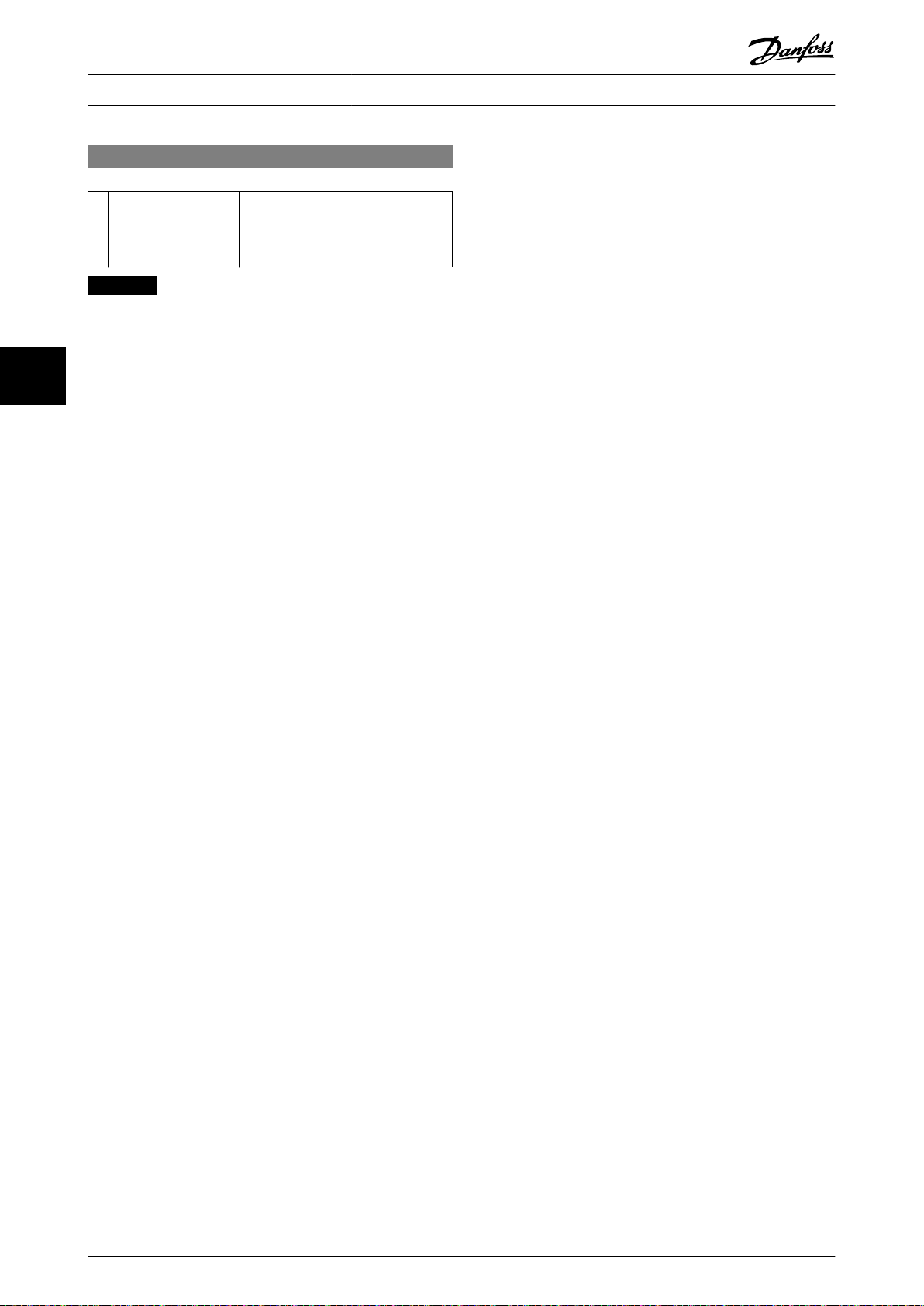

6.2 Centrifuge

Illustration 6.2 Centrifuge with Brake Resistor

Braking of a centrifuge is a typical application of brake

resistors, shown in Illustration 6.2.

The formula for energy dissipation (Eb) to the brake resistor

is:

6 6

E

= 0. 0055 ×

b

j

× n22 + 0. 0055 ×

c

j

× n12 × ηM

M

Ws

where

m = weight of the centrifuge content [kg]

jC = centrifuge inertia [kgm2] = 0.5 x m (r

2

+ r

1

jM = gear motor inertia [kgm2]

ηM = gear motor efficiency

n1 = max. motor speed [rpm]

n2 = max. centrifuge speed [rpm]

Rb = brake resistor

6.3

Continuous Braking

To achieve continuous braking, select a brake resistor in

which the constant braking power does not exceed the

average power P

of the brake resistor.

avg

NOTICE

Contact the Danfoss distributor for further information.

2

)

2

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 29

Page 32

Special Conditions Design Guide

7 Special Conditions

7.1 Alternative Braking Methods

7.1.1 DC Injection Braking

If the 3-phase winding of the stator is fed with direct

current, a stationary magnetic field Φ is set up in the

stator bore causing a voltage to be induced in the bars of

the cage rotor as long as the rotor is in motion. Since the

electrical resistance of the rotor cage is very low, even

small induced voltages can create a high rotor current.

This current produces a strong braking effect on the bars

and hence on the rotor. As the speed decreases, the

frequency of the induced voltage decreases and with it the

inductive impedance. The ohmic resistance of the rotor

77

gradually becomes dominant and so increases the braking

effect as the speed comes down. The braking torque

generated decreases steeply just before standstill and

finally ceases when there is no further movement. Direct

current injection braking is therefore not suitable for

holding a load at rest.

FC 102, 202, 301 and 302-Series

An over-modulated DC current added to the AC current

works as an eddy current brake (parameter 2-02 DC Braking

Time ≠ 0 s).

AC-braking

7.1.2

When the motor acts as a brake, the DC-link voltage

increases because energy is fed back to the DC-link. The

principle in AC-brake is to increase the magnetisation

during the braking and thereby increase the thermal losses

of the motor.

VLT 2800

By using parameter 144 in VLT 2800, it is possible to adjust

the size of the generator torque that can be applied to the

motor without the intermediate circuit voltage exceeding

the warning level.

The braking torque depends on the speed. With the ACbrake function enabled and parameter 144=1.3 (factory

setting) it is possible to brake with about 50% of rated

torque below 2/3 of rated speed and with about 25 % at

rated speed. The function is not working at low speed

(below 1/3 of nominal motor speed). It is only possible to

run for about 30 s with parameter 144 greater than 1.2.

NOTICE

If the value in parameter 144 is increased, the motor

current simultaneously increases significantly when

generator loads are applied. The parameter should

therefore only be changed if it is guaranteed during

measurement that the motor current in all operating

situations never exceeds the maximum permitted current

in the motor. Note: The current cannot be read out from

the display.

7.1.3 Mechanical Holding Brake

A mechanical holding brake mounted directly on the

motor shaft normally performs static braking. In some

applications, the static holding torque is working as static

holding of the motor shaft (usually synchronous

permanent motors). A holding brake is either controlled by

a PLC or directly by a digital output from the frequency

converter (relay or solid state).

NOTICE

FC 102, 202, 301 and 302-Series

The brake energy is distributed in the motor by changing

the loss conditions in the motor. The AC brake function

cannot be used in applications with high cycling frequency

since this overheats the motor (parameter 2-10 Brake

Function=[2] AC Brake). By using factory settings it is

possible to brake with about 50% of rated torque below

2/3 of rated speed and with about 25% at rated speed.

The function is not working at low speed (below 1/3 of

nominal motor speed).

When the holding brake is included in a safety chain:

A frequency converter cannot provide a safe control of a

mechanical brake. A redundancy circuitry for the brake

control must be included in the total installation.

30 Danfoss A/S © Rev. 05/2014 All rights reserved. MG90O202

Page 33

Special Conditions Design Guide

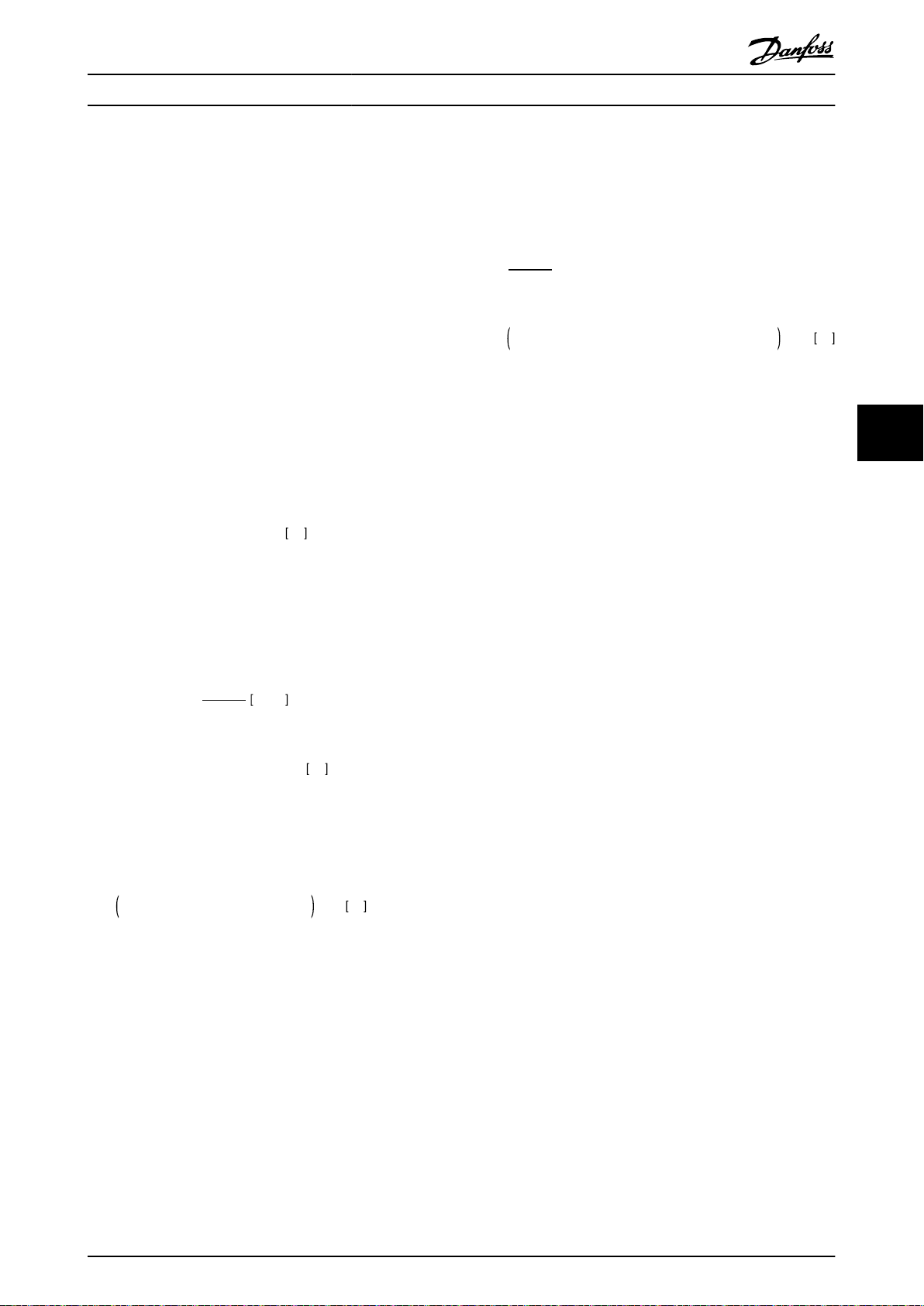

7.1.4 DC Braking

Resistor brake is useful from max. speed down to a certain

frequency. Below this frequency DC braking is to be

applied as required. The most efficient way of doing this is

to use a combination of dynamic and DC braking. See

Illustration 7.1. The parameters can be found in

chapter 5 Programming.

7 7

Illustration 7.1 Optimum Braking

How to calculate optimum DC-brake cut in frequency:

n

−

n

0

Slip

s

=

Synchronous speed

n

0

n

× 100 %

f

× 60

n

=

0

p

[1/min]

f = frequency supplied to motor

p = no. of pole pairs

nn = speed of the rotor

s

×

DC-brake cut in frequency = 2 ×

100

f

Hz

MG90O202 Danfoss A/S © Rev. 05/2014 All rights reserved. 31

Page 34

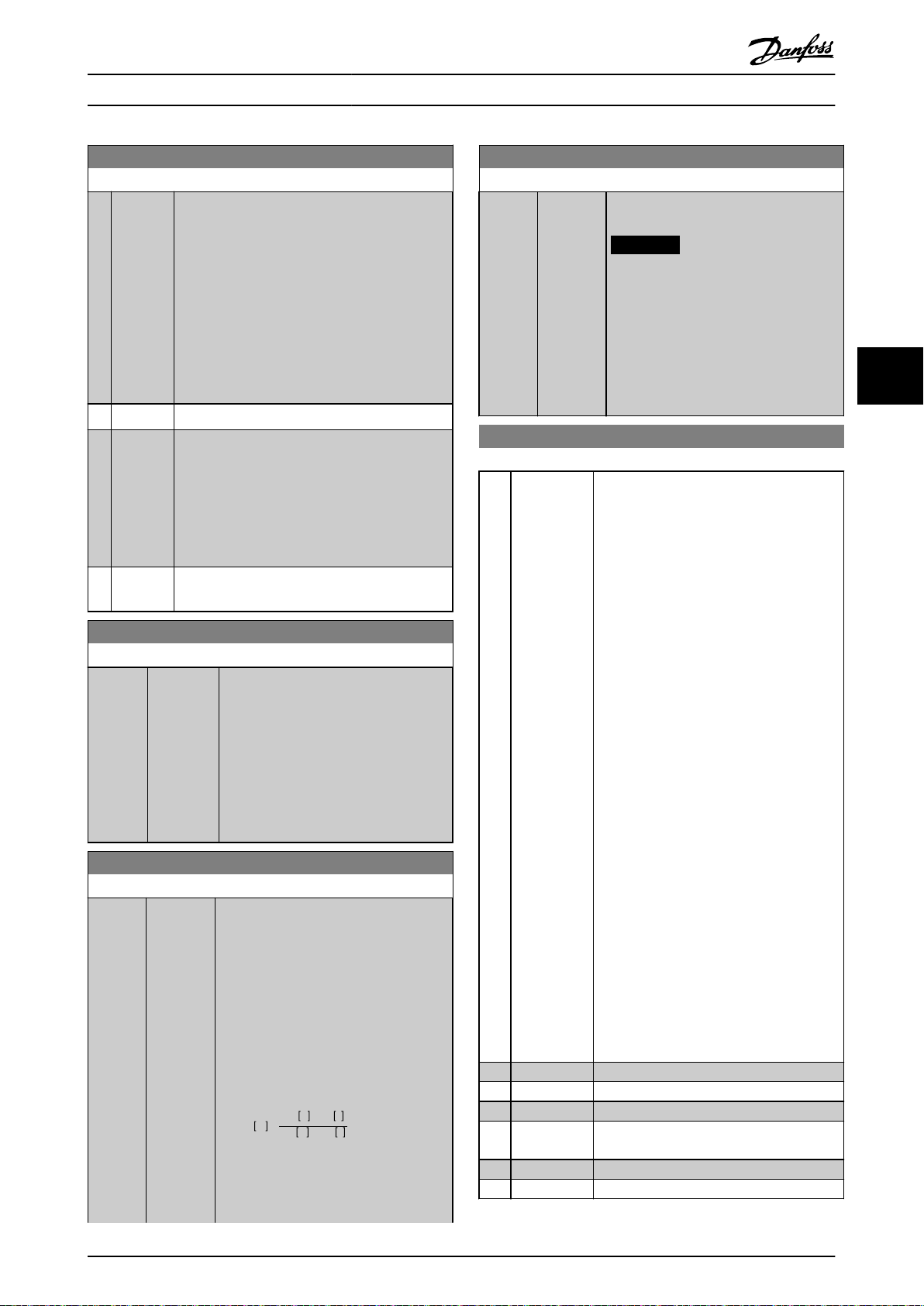

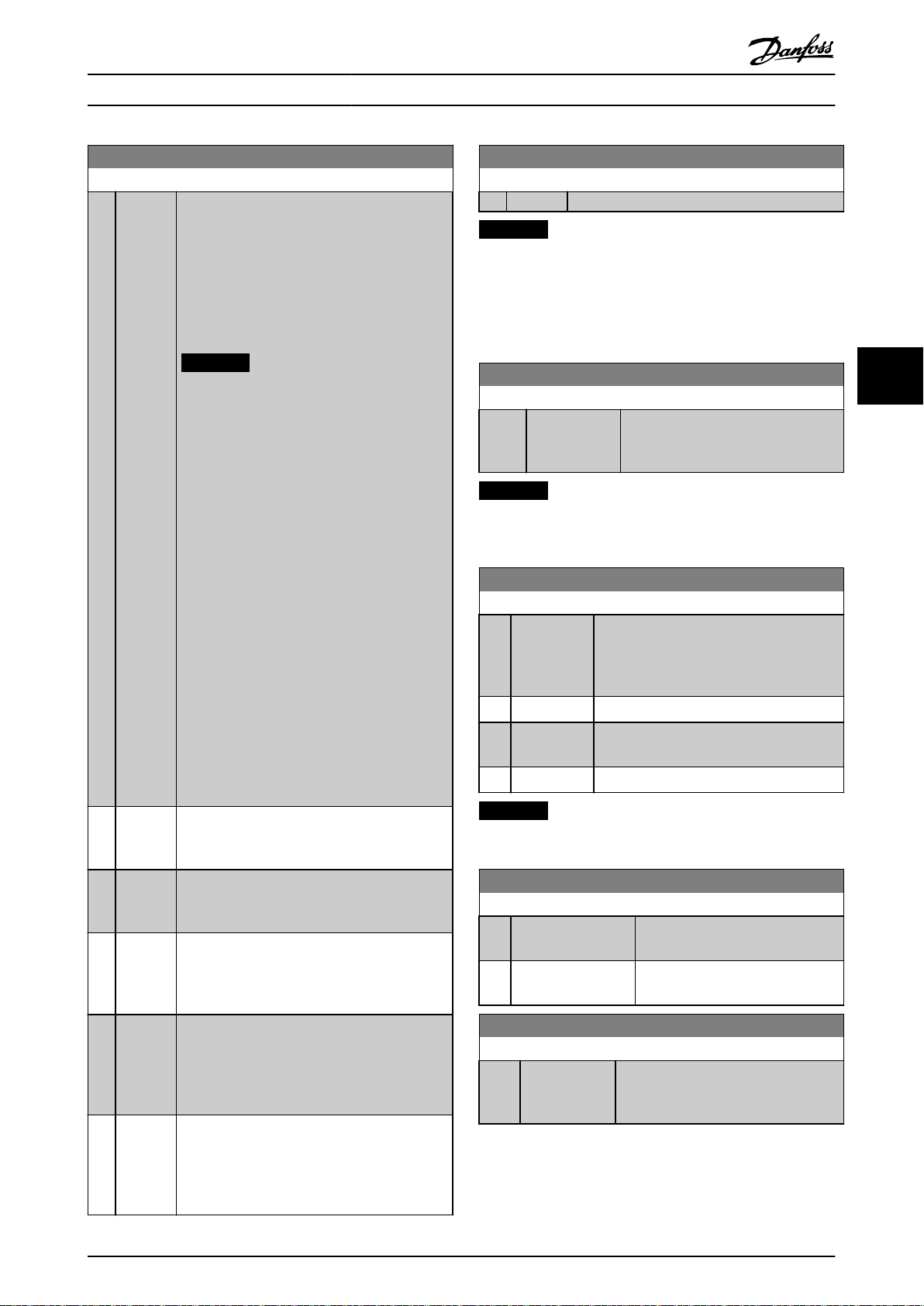

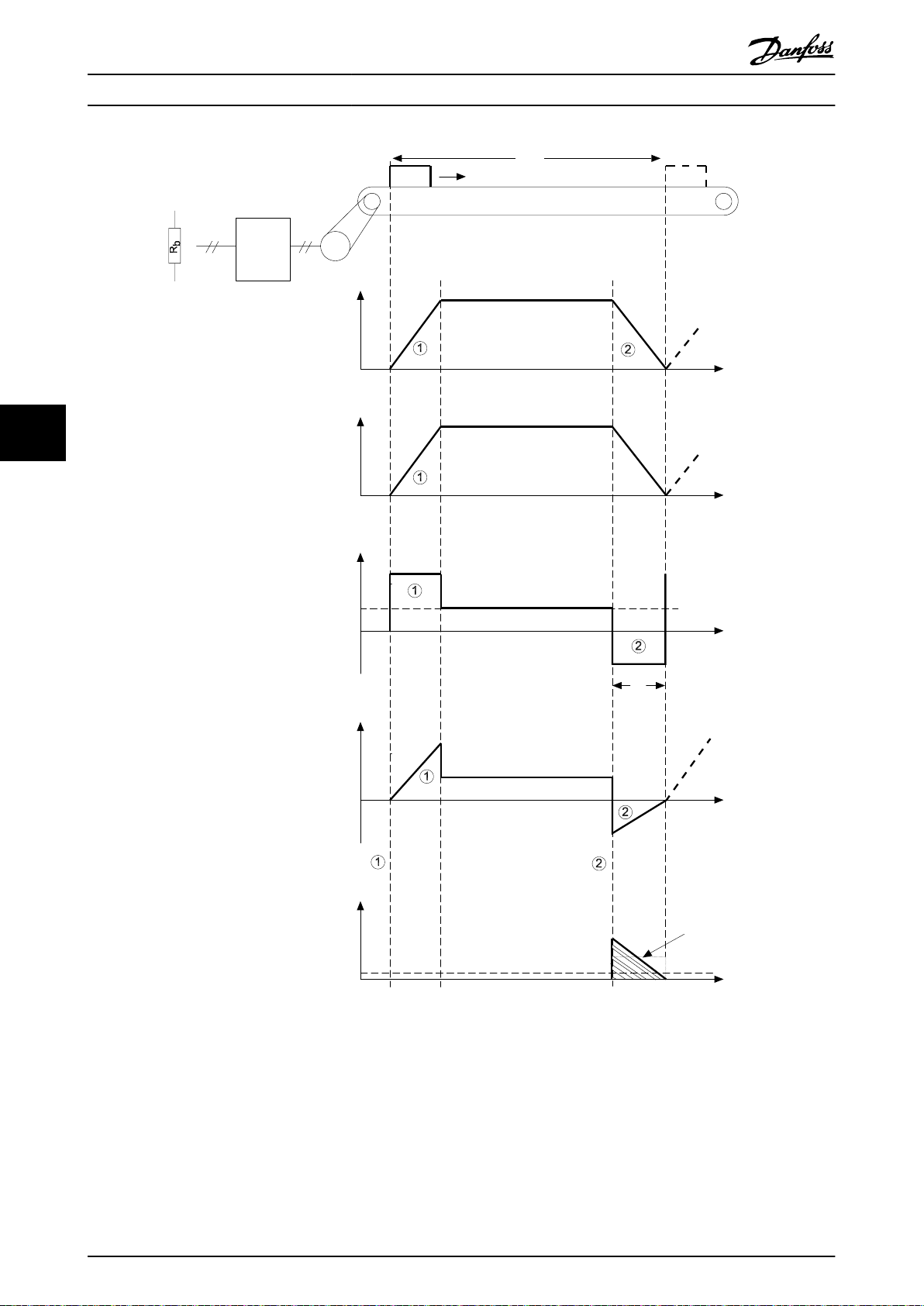

Select a 10%

duty cycle brake

resistor from the

selection tables

Select a 10%

duty cycle brake

resistor from the

selection tables

Select a 40%

duty cycle brake

resistor from the

selection tables

Please contact

Danfoss

1)

Please contact

Danfoss

1)

130BB148.13

Low intertia

ramp down>15 s

Low or high

intertia?

Horizontal

Vertical

Horizontal or

vertical movement?

Determine braking

time of the

application

Braking time<

brake resistor period

Braking time>

brake resistor period

Calculate duty

cycle