Page 1

Intelligence

to empower

your industrial

applications

Versatile, reliable and

consistently awesome

Selection Guide | VLT® AutomationDrive FC 300 Series

drives.danfoss.com

Page 2

Seamlessly into the future ........................................................................... 4

Consistently awesome ................................................................................... 5

Designed for easy integration in any application ......................... 6

Designed with fast and easy start-up in mind ................................

Extensive functionality for high-performance operation ......... 8

Leveraging digitalization to reduce maintenance costs ........... 9

Flexible, modular and adaptable. Built to last .................................. 10

Stand-alone drives, enclosed drives, modules ................................ 12

Application flexibility to boost your business ................................. 13

Integrated motion controller – for positioning

and synchronization applications ........................................................... 14

Increase precision, accuracy and speed .............................................. 16

Tailored safety ...................................................................................................... 17

Free to connect ................................................................................................... 18

Customized commissioning experience ............................................ 19

Modular simplicity – A, B and C enclosures ...................................... 20

VLT® Wireless Communication Panel LCP 103 ................................. 21

High-power modularity – D, E and F enclosures ........................... 22

Engineered for cost savings via intelligent heat

management, compactness and protection ................................... 24

Ruggedized for extra protection .............................................................. 24

Optimize performance and grid protection ..................................... 26

DrivePro® Life Cycle service products ................................................... 27

Connection example ....................................................................................... 28

Technical data ...................................................................................................... 29

Electrical data – A, B, and C enclosures ................................................ 30

Dimensions enclosure sizes A, B and C ................................................ 34

Ordering typecode for A, B and C enclosures ................................. 35

Content

2 Danfoss Drives · DKDD.PB.302.A8.02

Page 3

Chosen for its versatility, respected for its

reliability, the VLT® AutomationDrive has

been providing consistently awesome

performance for almost half a century.

It may have been around for a while. But that

doesn’t mean it hasn’t evolved. Far from it.

The VLT® AutomationDrive is now tougher and more

intelligent than it has ever been before.

Built to last, this robust drive operates effectively and

reliably even with the most demanding applications and

in the most challenging environments. Read on to find

out about the new generation E-frames and the lower

temperature rating.

As with all Danfoss drives, the VLT® AutomationDrive is

motor independent giving you the power to choose the

motor that best suits your application.

Packed with innovation, it features both hardware and

software enhancements that maximize performance, and

a new Ethernet platform for improved communication.

VLT® AutomationDrive takes full advantage of all that the

new digital age has to offer to ensure it completely fulfills

the requirements of your applications and optimizes your

processes throughout the entire lifecycle.

Consistency,

reliability,

versatility.

And all the power

you need.

Electrical data – D, E and F enclosures ................................................. 36

Dimensions enclosure sizes D, E and F ................................................ 38

Electrical data and dimensions – VLT® 12-Pulse ............................. 39

Ordering typecode for D, E and F enclosures .................................. 42

Electrical data – VLT® Low Harmonic Drive

and VLT® Advanced Active Filters ............................................................ 44

A options: Fieldbuses ...................................................................................... 46

B options: Functional extensions ............................................................. 47

C options: Motion control and relay card ........................................... 49

D option: 24 V back-up power supply .................................................. 49

Accessories ............................................................................................................ 50

Power options ..................................................................................................... 51

Accessory compatibility with enclosure size ................................... 52

Loose kits for enclosure sizes D, E and F.............................................. 54

3Danfoss Drives · DKDD.PB.302.A8.02

Page 4

4 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Seamlessly into the future

The fourth Industrial Revolution, or

Industry 4.0, builds on the progress of

automation by introducing elements

of interconnectivity, data acquisition,

machine learning and intelligent

applications of analytics. AC drives play

an important and powerful part in

this transition by being the first point

of interaction between sensors from

the process, the motor in operation

and communicating this information

via communications bus to a central

control location.

At Danfoss Drives, we live and

breathe Industry 4.0, with the VLT®

AutomationDrive representing the

latest and best technologies in the

drives industry. When you choose the

VLT® AutomationDrive, you can count

on the intelligent drive functions,

application know-how, proven quality

and reliability, and the support you

need to make a seamless transition into

Industry 4.0 and beyond.

The VLT® AutomationDrive offers:

Web-based configuration, Electronic

Data Interchange (EDI), transparent

order management

Access to drawings, engineering

diagrams, and ePlan macros

Simulation tools such as Danfoss

HCS for harmonic calculation and

Danfoss ecoSmart™ for motor-drive

system efficiency calculations

Compatibility with all industry-

leading motor and fieldbus

technologies

Embedded intelligence for

adaptability to evolving application

needs

Flexible interface to the drive

data from multiple access points

including: directly at the drive, via

mobile applications, through an

integrated web server and via cloud

connectivity

Page 5

It’s easy to sum up the qualities of

the VLT® AutomationDrive in just two

words – consistently awesome.

Throughout the entire lifecycle of your

application, the VLT® AutomationDrive

provides benefits that not only save

you time and money, but also help

optimize your process while providing

the flexibility and reliability to meet

your current and future demands.

Awesome versatility

Modular and adaptable, the

VLT® AutomationDrive fits into any

environment. It can be relied on to

meet all your needs whether you have

a single application or a variety of

different ones.

Its cutting-edge thermal design

and unique back-channel cooling

for drives above 90 kW make

VLT® AutomationDrive one of the

most compact and cost-efficient

drives in the market.

Consistently awesome

Simple start-up

VLT® AutomationDrive is robust and

intelligent, but at the same time quick

and easy to install and provides years of

reliable operation.

Intelligent operation

VLT® AutomationDrive has a big brain

ready to be put to work to control your

applications effectively, efficiently and

reliably.

High availability

Once installed, you can trust

VLT® AutomationDrive to provide

troublefree operation. New intelligent

maintenance features and a range of

DrivePro® services proactively improve

productivity, performance and uptime.

5| Content | Danfoss Drives · DKDD.PB.302.A8.02

Do it differently

Know-how and experience

Proven quality

DrivePro® services

A

w

e

s

o

m

e

v

e

r

s

a

t

i

l

i

t

y

S

i

m

p

l

e

s

t

a

r

t

-

u

p

O

p

t

i

m

i

z

e

d

p

e

r

f

o

r

m

a

n

c

e

I

n

t

e

l

l

i

g

e

n

t

o

p

e

r

a

t

i

o

n

Page 6

Before any wires are connected or power is applied,

your expectations of an AC drive determine whether

or not it is the correct fit for your application. An awesome

combination of functionality, suitability for your

environment and the availability of comprehensive

engineering tools make the VLT® AutomationDrive FC 300

Series an AC drive you can feel absolutely confident

selecting no matter your needs.

Designed for easy

integration in any

application

Fits in any environment

VLT® AutomationDrive can be installed

wherever it best suits your application

– close to the motor, located centrally

in an electrical panel or outdoors.

Its wide variety of enclosure class,

conformal coating and ruggedization

options reduce maintenance costs and

ensure reliable operation in a range

of challenging environments. A wide

operating temperature range of -25

°C to +50 °C adds additional peace of

mind when your applications take your

drive to the extremes.

Modular and adaptable

The VLT® AutomationDrive is built on a

flexible, modular design concept that

provides an extraordinarily versatile

motor control solution. The drive

is equipped with a wide range of

industry features that enables optimal

process control, higher quality output

and reduced costs related to spare

parts and service. The book-style

mounting takes advantage of this

modular construction principle,

allowing for more drives to fit into less

space.

Application flexibility

When you have a variety of

applications, it’s best to select an AC

drive that you can count on to meet

all your needs. Whether operating

pumps, conveyors, palletizers or

material treatment equipment, the VLT®

AutomationDrive delivers the optimum

control you want for reliable operation,

all day long.

Reduced harmonic impact

The ability to predict the impact of

adding AC drives to your facility is

critical to keeping costs low. The

Danfoss HCS tool allows you to

calculate how much harmonic content

to expect before you install your drive

and avoid additional costs of harmonics

and harmonic mitigation equipment

on your facility. The availability of low

harmonic drives, 12-pulse drives and

low harmonic power options further

minimizes harmonic impact.

Compact and efficient

When your application requires more

power, you don’t want to have to

increase the space needed for an

AC drive. Thanks to its cutting-edge

thermal design, VLT® AutomationDrive

is one of the most compact air-cooled

drives on the market in the range of

90 kW to 800 kW at 500 V. Combining

this best-in-class power density with

unique back-channel cooling further

reduces costs associated with cooling

while keeping the space required to a

minimum.

5

Awesome versatility

reasons to choose

the VLT® AutomationDrive

1. Fits in any environment

2. Modular and adaptable

3. Application flexibility

4. Reduced harmonic impact

5. Compact and efficient

6 DKDD.PB.302.A8.02 | Content |

Page 7

Your choice of AC drive should reduce the time it takes

to get your application up and running without sacrificing

any features or functionality. The VLT® AutomationDrive

FC 300 Series is designed to simplify every step in the startup process – from wiring to programming to operation –

and reliably deliver what you need for your application.

Designed with fast

and easy start-up in mind

Easy installation

All I/O terminals are pluggable and

spring-loaded and each has dualconnector configuration making wiring

easy and flexible. Drives with high

environmental enclosure ratings can

also be ordered with pre-threaded

cable gland openings to allow for an

easy and reliable way to install your

drive in harsh environments.

Dedicated application

functionality

A versatile drive doesn’t have to mean

that your drive is complicated to

commission. Application-dedicated

functions in the VLT® AutomationDrive

perfectly balance ease and robustness

to deliver reliable performance

regardless of the application. Features

such as droop functionality for load

sharing, integrated brake control

for the safe operation of hoists and

the integrated process controller for

demand-based pumping help to save

time and money during start-up.

Optimized motor control

Automatic Motor Adaptation (AMA)

is a powerful algorithm that tests

and adjusts the drive to the unique

traits of your motor, improving overall

control and operating efficiency.

Enhancements to the AMA for both

asynchronous and PM motors means

the process takes place in just a few

milliseconds without spinning the

motor. This enhanced AMA II, running

before every start, ensures that the

motor parameters are always calibrated

to the specific operating conditions

increasing motor control accuracy.

Tailored and tested

Every VLT® AutomationDrive is delivered

from the factory exactly as you have

configured it. Every drive is built with

care and completely tested at full load

against an AC motor prior to shipping,

with your selected options already

installed, which ensures that your drive

will operate just as you expect it to.

Powerful PC tools

The VLT® Motion Control Tool MCT 10

is a PC tool designed with your drive

in mind. Powerful features, like the

Motor Setup and Functional Safety

Setup tools, allow fast and easy

commissioning of your application.

MCT 10 includes the VLT® Software

Customizer. Use it to create tailored

Smart Assisted Startup wizards for

accurate commissioning of your drive;

or to define a unique set of customerspecific initial values for common

parameters that can be loaded in your

drive to replace factory default values.

5

Simple start-up

reasons to choose

the VLT® AutomationDrive

1. Easy installation

2. Dedicated application

functionality

3. Optimized motor control

4. Tailored and tested

5. Powerful PC tools

7| Content | DKDD.PB.302.A8.02

Page 8

The VLT® AutomationDrive FC 300 Series is installed in a

wide variety of demanding applications and environments.

Regardless of your application’s needs, you can count on

the VLT® AutomationDrive to deliver the capabilities for

long, worry-free operation in even the most sensitive of

environments.

Extensive functionality for

high-performance operation

Integrated Motion Controller

The performance of the VLT®

AutomationDrive FC 302 is enhanced

without complexity thanks to the

Integrated Motion Controller (IMC).

Providing motion functionality,

high-precision scaled positioning

and synchronizing tasks are simple

to perform with or without encoder

feedback, and commissioning is

fast and safe. IMC is configurable by

parameters – no special programming

language is required. No additional

modules or hardware are necessary.

Robust four-quadrant control

Applications, such as extruders

and separators, place heavy

demands on your AC drive. The

VLT® AutomationDrive can meet

your demands by providing reliable

operation in both motoring and

generating phases of operation.

Accurate torque controls, especially

through zero speed where the key

challenges lie, result in smooth and

continuous operation, saving both time

and money.

Low noise operation

Unfiltered AC drives produce

electromagnetic interference (EMI)

– both conducted and and emitted.

This interference can negatively impact

sensitive equipment. Built-in EMC/

RFI protection with screened motor

cables to Residential Category C1 (to

50 m) and C2 (to 150 m) provides the

ability to operate without additional

and expensive filters, further increasing

reliability and reducing interference

with sensitive electronics.

Easy PLC integration

VLT® AutomationDrive is compatible

with PROFINET, PROFIBUS DP-V1,

DeviceNet, EtherNet/IP, EtherCAT,

POWERLINK, CANopen and Modbus

TCP protocols. All Ethernet options

feature dual-ports with a built-in switch

or HUB (POWERLINK). Some of the

Ethernet technologies also support ring

topology for higher availability and fast

installation. Fieldbus configuration files,

pretested function blocks and add-on

instructions are available for easy, lowrisk, integration into your PLC system.

High-efficiency operation

New standards in Ecodesign have

been published focusing on energy

efficiency of AC drives and drive-motor

systems. As these standards increase

the focus on the efficiency of AC drives

worldwide, it’s important to know

that, with the VLT® AutomationDrive,

you can count on having a foundation

to meet these coming requirements.

Using Danfoss ecoSmart™, you can

quickly determine the IE class of your

AC drive, the IES class of your specific

motor-drive system and the part-load

efficiency of your drive.

5

Intelligent operation

reasons to choose

the VLT® AutomationDrive

1. Integrated Motion Controller

2. Robust four-quadrant control

3. Low noise operation

4. Easy PLC integration

5. High-efficiency operation

8 DKDD.PB.302.A8.02 | Content |

Page 9

Unplanned downtime can be costly – both in terms of

maintenance and lost production. Enhancements in the

VLT® AutomationDrive provide more information about

your devices and their performance, and a range of services

optimizes their availability.

Leveraging digitalization

to reduce maintenance costs

Intelligent troubleshooting

When something goes wrong with

your process, the more data you have,

the easier it is to pinpoint and quickly

resolve the cause. New, intelligent

maintenance features utilize the VLT®

AutomationDrive’s various sensors to

record and store 2-3 seconds of realtime information around an Alarm,

Warning or other defined trigger. This

data from up to the last 20 events

is then stored in the memory of the

drive from where it can be retrieved

and inspected within MCT 10. The

addition of the Real Time Clock option

allows the events to be time and

date stamped, providing even more

actionable data than ever before.

Wireless connectivity

The new VLT® Wireless Communication

Panel LCP 103 provides wireless

connectivity to your VLT® AutomationDrive using the MyDrive® Connect app

for iOS and Android devices. It allows

full and secure access to the drive for

easy commissioning, operation and

maintenance on your smart devices.

Use the advanced LCP copy function to

back up parameters to the storage of

the LCP 103 or your smart device.

Remote access

Offsite accessibility allows for easier

and faster access to both remote

facilities or to large numbers of installed

drives. Utilizing the integrated and

modernized interface of the web server

in the Ethernet-based communication

options, each drive can be remotely

accessed and monitored for operation

and diagnostics purposes saving time

and costs.

Intuitive maintenance

The Danfoss VLT® AutomationDrive

features both preventive and predictive

maintenance functions that provide for

worry-free operation while reducing

maintenance costs and unplanned

downtime. Preventive maintenance

functions can be used to schedule

proactive maintenance alerts based

on running time of the drive and

triggering alerts, visible on the LCP and

transferable over fieldbus. Predictive

maintenance functions turn your drive

into a configurable smart sensor that

continuously monitors the condition

of your motor and application based

on standards and guidelines such as

the ISO 13373 standard for Condition

Monitoring and Diagnostics of

Machines or the VDMA 24582 guideline

for condition monitoring.

DrivePro® services

Danfoss Drives’ comprehensive

portfolio of services spans the entire

lifecycle of your drives. As well as

traditional service functions that

improve productivity, performance and

uptime, digitalization and the Internet

of Things play valuable roles in our

range of support and value-adding

services. The drives themselves interact

closely with their surrounding systems

and processes. Built-in functionality

allows them to collect and share

data that is visible to maintenance

personnel, Danfoss service teams, and

3rd-party service providers for fast and

remote monitoring purposes.

5

Optimized

performance

reasons to choose

the VLT® AutomationDrive

1. Intelligent troubleshooting

2. Wireless connectivity

3. Remote access

4. Intuitive maintenance

5. DrivePro® services

9| Content | DKDD.PB.302.A8.02

Page 10

Speaks your language

When it comes to working with

advanced technologies, such as AC

drives, it is fairly easy to feel lost while

navigating through hundreds of

parameters. Using a graphical interface

makes this process much easier;

especially when it lists parameters

in your native language. As many as

28 language options are available,

including several Cyrillic, Arabic (right

to left) and Asian options.

Additionally, the ability to save up

to 50 user-selectable parameters

further simplifies interactions with key

parameter settings for your unique

application.

motor and remain confident that the

system will perform to the highest

possible standards.

As an independent manufacturer of AC

drive solutions, you can count on

Danfoss to support all commonly used

motor types and foster ongoing

development as new technologies

emerge.

Flexible, modular and adaptable

Built to last

Free to equip

The VLT® AutomationDrive can

optimally control nearly all standard

industrial motor technologies,

including Asynchronous, IPM, SPM,

Synchronous Reluctance and PM

assisted Synchronous Reluctance

motors. This means that system

designers, OEMs and end users are free

to connect the drive to their selected

A VLT® AutomationDrive is built on a flexible, modular

design to provide an extraordinarily versatile motor

control solution. The drive is equipped with a wide range

of industry features that enable optimal process control,

higher quality output and reduce costs related to spare

parts and service.

10 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 11

Power range

200-240 V

High overload

208 V ........................1.8-143 A IN, 0.25-37 kW,

230 V .........................1.8-170 A IN, 0.34-50 Hp

Normal overload

208 V ........................ 1.8-170 A IN, 0.25-45 kW

230 V .........................1.8-170 A IN, 0.34-60 Hp

380-500 V

High overload

400 V .................. 1.3-1460 A IN, 0.37-800 kW,

460 V ................... 1.2-1380 A IN, 0.5-1200 Hp

Normal overload

400 V ................ 1.3-1720 A IN, 0.37-1000 kW

460 V ................... 1.2-1530 A IN, 0.5-1350 Hp

525-600 V

High overload

575 V .............................1.7-100 A IN, 1-100 Hp

Normal overload

575 V .............................1.7-131 A IN, 1-120 Hp

525-690 V

High overload

575 V ................... 1.6-1260 A IN, 1.5-1350 Hp

690 V ...................1.6-1260 A IN, 1.1-1200 kW

Normal overload

575 V ................... 1.6-1415 A IN, 1.1-1550 Hp

690 V ...................1.6-1415 A IN, 1.1-1400 kW

Ingress protection ratings

IEC: IP00, IP20, IP21, IP54, IP55, IP66

UL: Chassis, Type 1, Type 12, Type 4X

690 V

The 690 V versions of VLT®

AutomationDrive FC 302 units for

the power range from 1.1 kW up

to 1400 kW can control motors

down to 0.37 kW without stepdown transformer. This enables you

to choose from a broad variety of

compact, reliable and efficient drives

for demanding production facilities

operating from 690 V mains networks.

Reduce costs with

compact drives

A compact design and efficient heat

management enable the drives to take

up less space in control rooms and

panels, thereby reducing initial costs.

Compact dimensions are also an

advantage in applications where

drive space is restricted, making it

possible for designers to develop

smaller applications without being

forced to compromise on protection

and grid quality. For example, VLT®

AutomationDrive FC 302 in a D or E

enclosure size is 25-68% smaller than

equivalent drives.

Despite the compact dimensions,

all units are nevertheless equipped

with integrated DC link chokes and

EMC filters, which help to reduce grid

pollution and reduce cost and efforts

for external EMC components and

wiring.

The IP20 version is optimized for

side-by-side mounting in cabinets to

50 °C without derating and features

covered power terminals to prevent

accidental contact. The AC drive can

also be ordered with an optional brake

chopper in the same package size.

Control and power cables are fed in

separately at the bottom.

The AC drives combine a flexible

system architecture that allows them

to be adapted to specific applications,

with a uniform user interface across all

FC 301 FC 302

Power range [kW] 200-240 V 0.25-37 0.25-37

Power range [kW] 380-(480) 500 V 0.37-75 (480 V ) 0.37-800 (500 V )

Power range [kW] 525-600 V – 0.75-75

Power range [kW] 525-690 V – 1.1-1400

Flux vector control –

Cable length – screened/unscreened

25/50m (A1 only),

50/75m

150/300 m

Permanent magnet motor operation

(w/wo feedback)

–

Safety function Safe Torque Off (STO – EN 61800-5-2) Optional (A1 only)

Scan interval/response time ms 5 1

Output frequency (OL) 0.2-590 Hz

0-590 Hz,

(600-1000 Hz)*

Max load (24 V DC) for analog output and

control card [mA]

130 200

Programmable digital input 5 (4) 6 (4)

Programmable digital output changeable 1 2

Programmable relay output 1 2

* For frequency up to 1000 Hz please contact your local Danfoss partner.

Choose the adequate performance level

Special needs require special features and performance

power classes. This allows you to adapt

the drive to the exact needs of your

specific application. As a result, project

work and costs are subsequently

reduced. The easy-to-use interface

reduces training requirements. The

integrated SmartStart guides users

quickly and efficiently through the setup process, resulting in fewer faults due

to configuration and parameterization

errors.

11| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 12

Stand-alone drives

No need to compromise

Can’t make space for a cabinet? Now

there is no need. VLT® drives are so

robust that you can mount them

virtually anywhere, even right beside

the motor. Equipped for the toughest

of environments, they suit your

application, no matter the requirement.

More uncompromising features:

Enclosure types rated up to

IP66/UL Type 4X

Full EMC compliance according

to international standards

Ruggedized and coated PCBs

Wide temperature range, operating

from -25 °C to +50 °C without

derating

Motor cable lengths up to 150 m

as standard, with uncompromised

performance

Enclosed drives

Win time

VLT® drives are designed with the

installer and operator in mind to save

time on installation, commissioning

and maintenance.

VLT® enclosed drives are designed for

full access from the front. Just open the

cabinet door and all components can

be reached without removing the drive,

even when mounted side by side.

More time-saving features:

An intuitive user interface with an

award-winning Local Control Panel

(LCP) and common control platform

that streamlines start-up and

operating procedures

Robust design and advanced

controls make VLT® drives virtually

maintenance free

Modules

Win space

The compact design of high-power

VLT® drives makes them easy to fit

even in small spaces. Integrated filters,

options and accessories provide

additional capabilities and protection

without increasing the enclosure size.

More space-saving features:

Built-in DC link reactors for harmonic

suppression eliminate the need for

higher loss external AC line reactors

Optional built-in RFI filters are

available throughout the power

range

Optional input fuses and loadshare

terminals are available within

standard enclosures

In addition to the many valuable

features that VLT® drives offer as

standard, there are numerous other

control, monitoring and power

options available in pre-engineered

factory configurations

12 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 13

The VLT® AutomationDrive is optimized to create value for you, enabling maximum

performance in all major applications irrespective of industry.

Application flexibility to boost your business

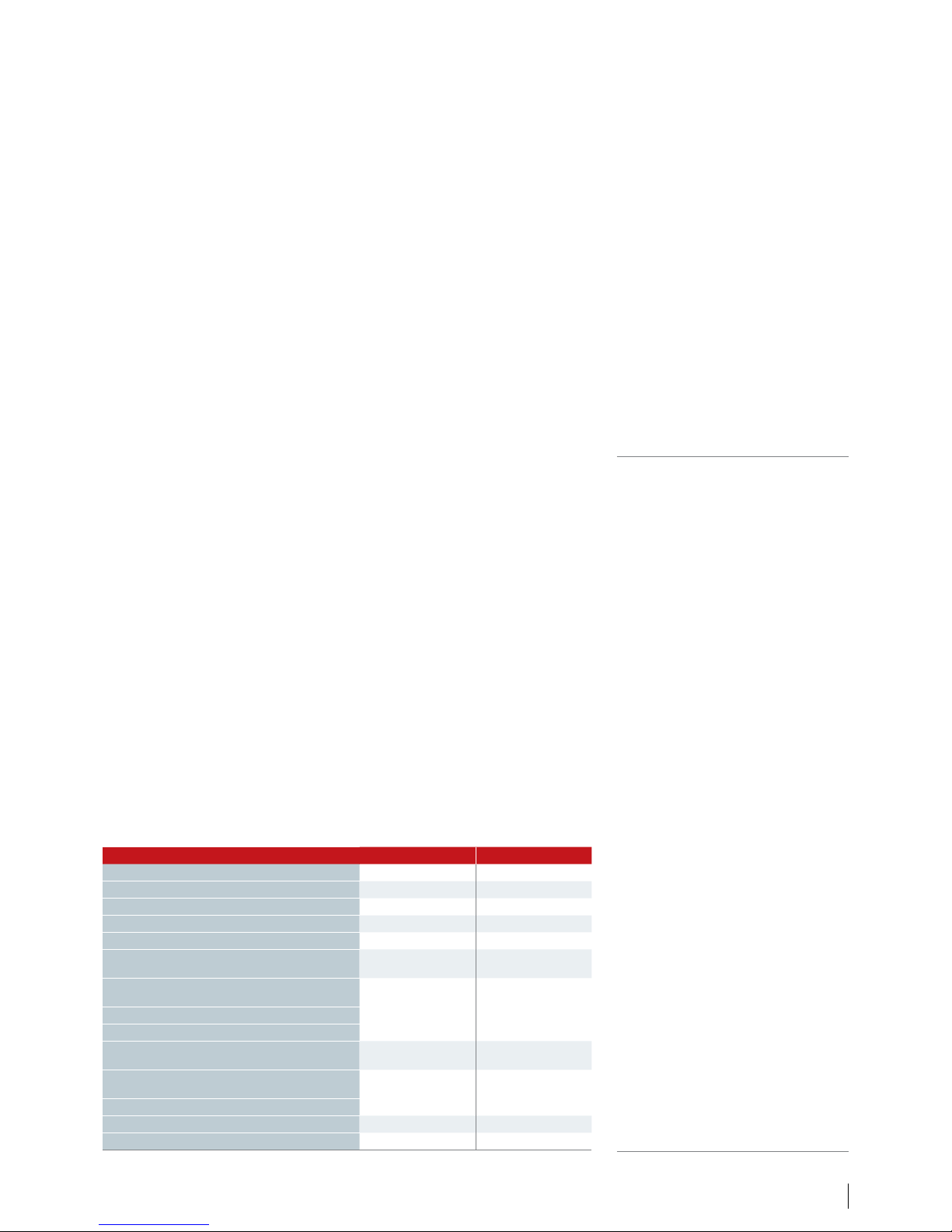

Applications Industries

HVAC

Food and Beverage,

Packaging

Water and Wastewater

Refrigeration

Marine and Offshore

Mining and Minerals

Metals

Chemical

Cranes and Hoists

Elevators and

Escalators

Material handling

Oil and Gas

Textile

Pumps

Fans

Compressors

Conveyors

Process, material treatment

Mills, drums, kilns

Winding, unwinding

Drilling

Propulsion, thrusters

Winches

Vertical and horizontal movement

Power conversion generation, smart grids

Positioning, synchronization

13| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 14

Perform high-precision positioning

and synchronization, simply using an

AC drive. With the Integrated Motion

Controller (IMC) functionality, the

VLT® AutomationDrive FC 302

replaces more complex positioning

and synchronization controllers, to save

time and cost.

Positioning and synchronization

operations are typically performed

using a servo drive or a motion

controller. However, many of these

applications do not actually require

the dynamic performance available

from a servo drive.

Therefore the FC 302 with IMC is a costeffective, high-performance alternative

to servo in single-axis positioning and

synchronizing applications.

Use IMC for many applications that

have been solved with servo drives

until now, such as:

n Rotary tables

n Cutting machines

n Packaging machines

Encoderfree

to save costs and

reduce complexity

Use FC 302 to run an induction or PM

motor with or without motor feed-

back – with no need for additional

hardware. With sensorless control (no

motor feedback) best performance is

achieved with a PM motor. The performance of sensorless control of induction motors is however sufficient for

less-demanding applications.

With IMC you save time and cost:

n No advanced programming and

fewer components means fewer

hours needed for engineering,

installation and commissioning

n Save further cost for a feedback

device, cabling and installation by

using sensorless control

n To save cost for a home sensor and

cabling, use the “homing on torque

limit” function

The IMC solution provides

easy and safe set-up:

n Configuration via parameters, with

no advanced programming required.

Reduced complexity will minimize

the risk of errors

n To add more functionality, use the

Smart Logic Controller (SLC), which

is fully compatible with IMC

n To realign the home position

during operation, use the “home

synchronizing” function

Integrated motion controller – for positioning

and synchronization applications

14 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 15

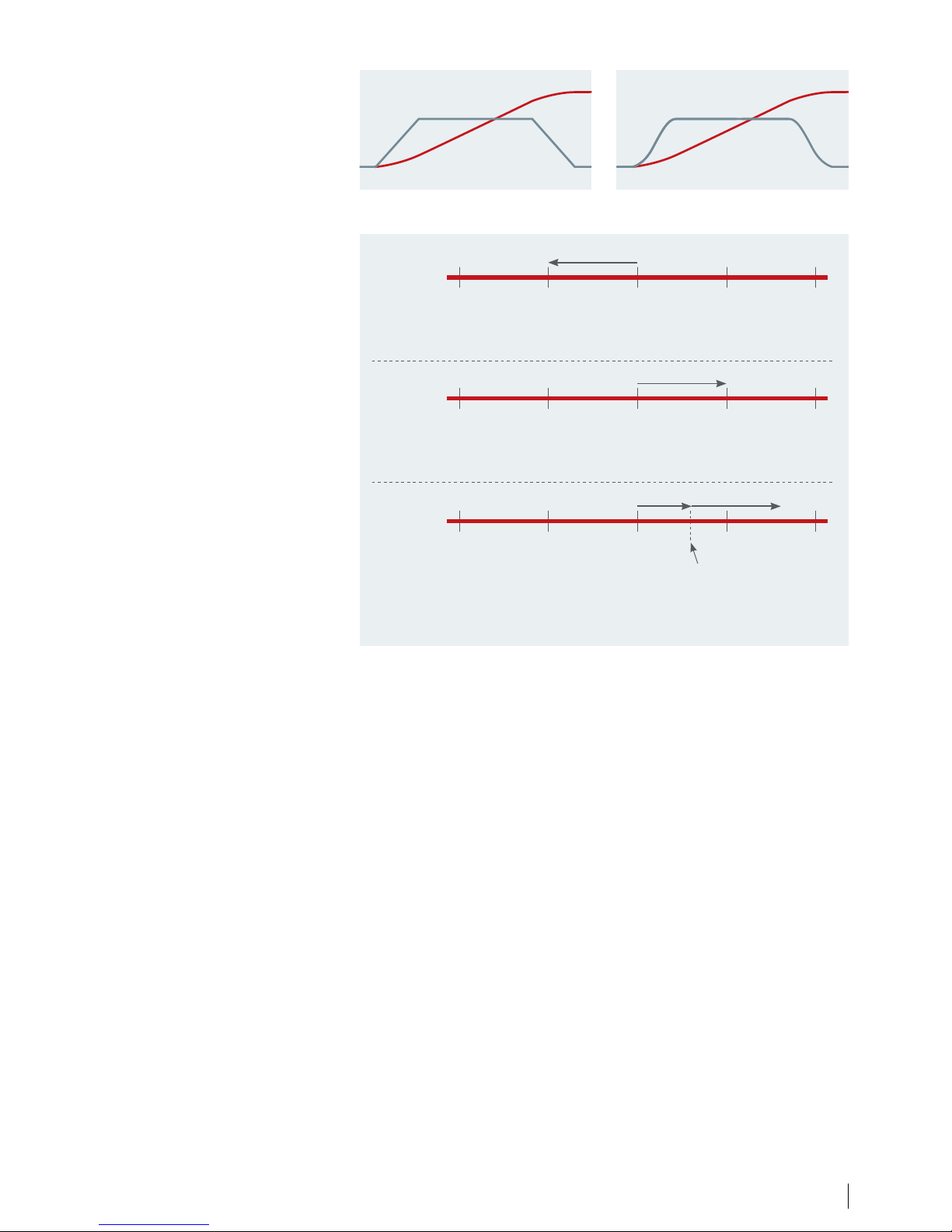

Positioning

In positioning mode, the drive controls

movement over a specific distance

(relative positioning) or to a specific

target (absolute positioning). The drive

calculates the motion profile based on

target position, speed reference and

ramp settings (see the examples in Fig. 1

and Fig. 2 on the right).

There are 3 positioning types using

different references for defining the

target position:

n Absolute positioning

Target position is relative to the

defined zero point of the machine.

n Relative positioning

Target position is relative to

the actual position of the machine.

n Touch probe positioning

Target position is relative to a signal

on a digital input

This illustration (Fig. 3) shows the

different resulting target with a set

target position (reference) of 1000 and

starting position of 2000 for each of the

positioning types.

Synchronizing

In synchronizing mode, the drive follows the position of a master; multiple

drives can follow the same master. The

master signal can be an external signal,

for example, from an encoder, a virtual

master signal generated by a drive or

master positions transferred by fieldbus.

Gear ratio and position offset is adjustable by parameter.

Homing

With sensorless control and closed

loop control with an incremental

encoder, homing is required to create

a reference for the physical position of

0 1000 2000 3000 4000

With absolute positioning, the drive moves backwards from the starting position

of 2000 to the absolute position of 1000 related to 0.

0 1000 2000 3000 4000

With relative positioning, the drive moves a distance of 1000 forward from

the starting position of 2000 ending at position 3000.

0 1000 2000 3000 4000

With touch probe positioning, the drive starts moving forward from the starting

position of 2000, detects the touch probe sensor and moves a distance of 1000

forward from the position of the touch probe sensor.

Absolute

Relative

Touch probe

Touch probe sensor

Fig. 3. IMC supports 3 positioning modes

Fig. 1. Motion profile with linear ramps Fig. 2. Motion profile with S-ramps

the machine after power up. There are

several home functions with and without sensor to choose from. The home

synchronizing function can be used to

continuously realign the home position

during operation when there is some

sort of slip in the system. For example

in case of sensorless control with an

induction motor or in case of slip in the

mechanical transmission.

Position Position

SpeedSpeed

15| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 16

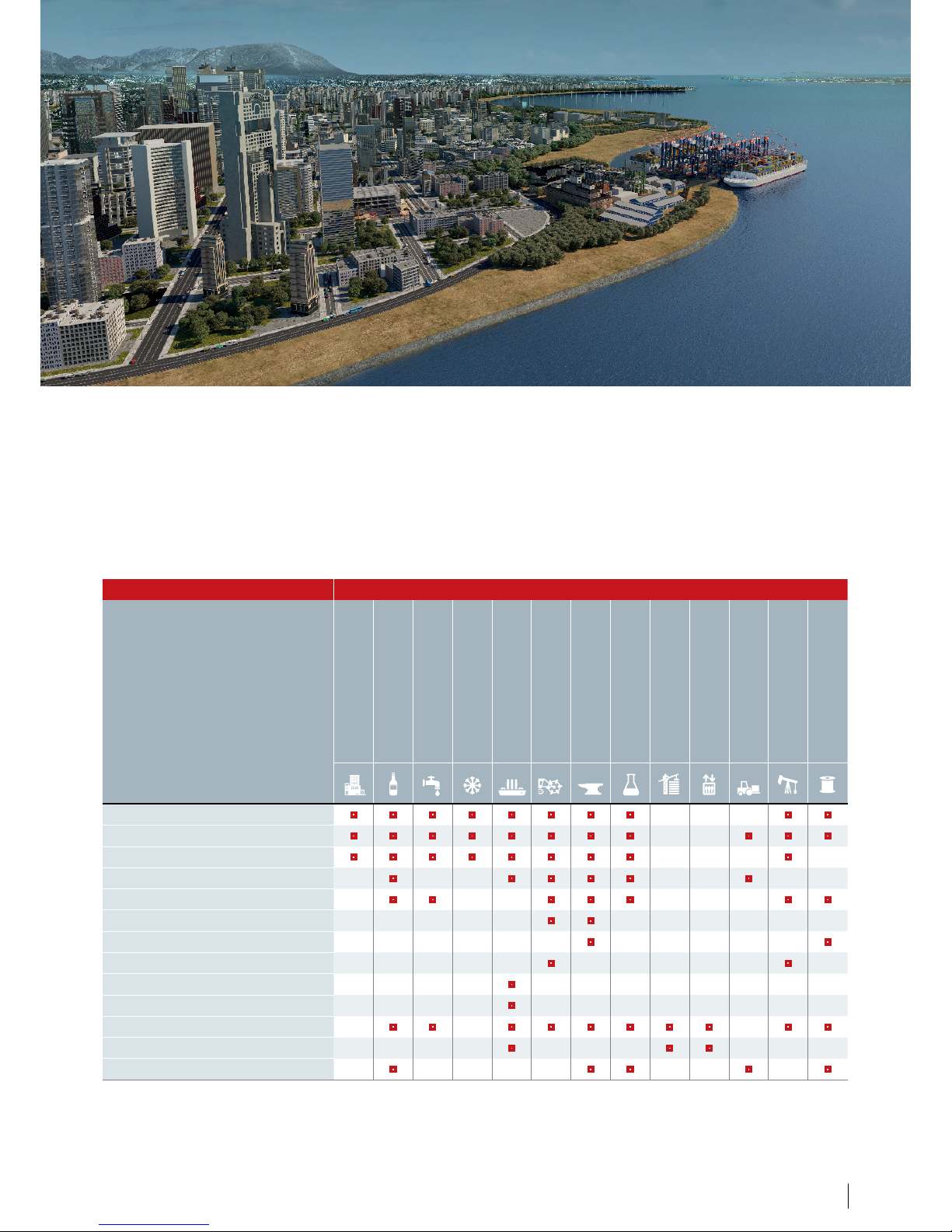

Expand the standard functionality of a VLT® AutomationDrive

with energy-enhancing motion control options.

Increase productivity

and performance

Replacing mechanical controls with

intelligent, energy-saving electronic

solutions is an effective way to reduce

both installation and daily running

costs.

The ability to set and control the

packaging application with greater

precision also reduces packaging errors

and equipment breakdowns.

The result is a reliable, highquality process that increases

both productivity and bottom line

performance.

Reduce installation costs

Replacing mechanics by electronic

synchronizing or cam control increases

flexibility while reducing costs. For

example, electronic cam control, a

standard feature in the VLT® Motion

Control Option MCO 305, both adds

Increase precision, accuracy and speed

new functionalities and removes the

need for mechanical cam discs and

boxes.

Increase capacity

In other cases, manufacturers might

want to increase the capacity of their

packaging application. This can be

achieved with the VLT® Synchronizing

Controller MCO 350, which offers

unparalleled synchronizing control

and can be set up easily via the userfriendly control panel on the VLT®

AutomationDrive.

As well as increasing the performance,

the controller adds extra value by

being an intelligent way to simplify the

control system.

No matter which option you choose,

the benefits of freedom of control and

operational efficiency will provide a fast

return on your investment.

Add flexibility to

applications such as

Printing lines

Bottle washers

Conveyor belts

Packaging systems

Material-handling systems

Palletizers

Indexing tables

Storage systems

Pick-and-place systems

Positioning on the fly

Foil wrapping

Flow packing

Filling and sealing

Crane, lift and hoist applications

Product-rejection systems

Winder applications

16 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 17

safety fieldbus. This interconnection

enables activation of Safe Torque Off

(STO) irrespective of where a hazard

occurs. The safety functions of the MCB

152 are implemented according to EN

IEC 61800-5-2.

The MCB 152 supports PROFIsafe

functionality to activate integrated

safety functions of the VLT®

AutomationDrive from any PROFIsafe

host, up to Safety Integrity Level SIL

2 according to EN IEC 61508 and EN

IEC 62061, Performance Level PL d,

Category 3 according to EN ISO

13849-1.

Quick commissioning

Parameter configuration is fully

integrated into the VLT® Motion

Control Tool MCT 10 and enables

simple start-up and easy maintenance.

Visual instructions in MCT 10 ensure

both fault-free wiring and that safety

parameters are correctly transferred

from the PC to the drive.

The software also offers easy diagnosis

and a dynamic commissioning report

which can be used for supplying

certification documentation necessary

for safety acceptance tests.

module is certified according to ISO

13849-1 up to PL d as well as IEC 61508/

IEC 62061 up to SIL 2 and provides

SS1 and SLS (SMS) functionality. The

option can be used in low and high

demand applications. SS1 offers ramp

and time based functionality. SLS can

be configured both with and without

ramp down on activation.

VLT® Safety Option MCB 152

The VLT® Safety Option MCB 152

operates the safety functions of an

AC drive via the PROFIsafe fieldbus in

combination with the VLT® PROFINET

MCA 120 fieldbus option. Central

and decentral drives located at

different machinery cells can easily

be interconnected with the PROFIsafe

Protect both equipment

and operators

The VLT® AutomationDrive FC 302

is delivered as standard with the

STO (Safe Torque Off ) function in

compliance with ISO 13849-1 PL d and

SIL 2, according to IEC 61508/IEC 62061.

This safety function can be extended

to include SS1, SLS, SMS, safe jog

mode, etc. with the VLT® Safety Option

MCB 150 Series. The speed monitoring

functions are available both with and

without speed feedback.

VLT® Safety Option

MCB 150 and MCB 151

The MCB 150 and MCB 151 can be

integrated directly in the AC drive

and is prepared for future connection

to common safety bus systems. The

Tailored safety

Before

AC drive

without STO

Safety

module

Contactors

Actuator

After

AC drive

with STO (FC 302)

Actuator

17| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 18

networks are easier to maintain,

while providing improved systems

performance.

User friendly and fast setup

Danfoss fieldbuses can be configured

via the drive’s local control panel, which

features a user-friendly interface with

support for many user languages.

Real-time information is becoming

increasingly important in industrial

automation and control systems as

we progress further into Industry 4.0.

Immediate access to data increases

transparency in production facilities,

while making it possible to optimize

system performance, collect and

analyze system data and provide

remote support around the clock from

anywhere in the world.

Regardless of your application or your

preferred communication protocol, AC

drives have an extremely wide variety

of communication protocols to select

from. In this way you can ensure that

the AC drive integrates seamlessly into

your chosen system providing you the

freedom to communicate however you

see fit.

Increase productivity

Fieldbus communication reduces

capital costs in production plants. In

addition to the initial savings achieved

through the significant reduction in

wiring and control boxes, fieldbus

Web server dashboard

Free to connect

The drive and fieldbus can also be

configured using the software tools

that support each drive family. Danfoss

Drives offers fieldbus drivers and PLC

examples for free from the Danfoss

Drives website to make integration to

your system even easier.

18 DKDD.PB.302.A8.02 | Content |

Page 19

VLT® Software Customizer

VLT® Software Customizer allows you

to customize the commissioning

experience to best fit your needs. It is

a tool that enables you to simply and

quickly create and test your desired

setup using the simulator before

uploading it to a real drive.

The VLT® Software Customizer consists

of three main features:

SplashScreen allows you to create

a custom splash screen for when the

drive starts up. You can use the builtin editor to create an image from

blank or import an existing image

from a library or from your computer

and adapt it to the VLT®.

InitialValues allows you to set a

new default value for virtually any

parameter.

SmartStart allows you to create

a custom start-up wizard to go

through exactly the parameters you

need.

The VLT® Motion Control Tool MCT 10

is an interactive tool for quick and easy

online/offline configuration of a VLT®

drive or soft starter using a PC. You

can also use the tool to configure the

communication network and to back

up all your relevant parameter settings.

With MCT 10, you can control and

configure your system simultaneously

and monitor your entire system more

effectively for faster monitoring,

diagnosis, troubleshooting (alarms/

warnings) and better preventive

maintenance. Starting with version

4.00, MCT 10 includes even more

features that enhance usability.

Status plug-in

The readouts for various status and

control words, relay inputs and outputs

that are available over the fieldbus

have been greatly improved. We have

combined these signals into a single

plug-in that shows you much more

information. You’ll be able to see right

away if a certain relay or bit is on or off,

and what exact command the drive has

been configured with, saving you time.

Motor plug-in

The motor plug-in makes it easier to

select the needed motor type and to

parameterize the drive accordingly.

Simply select the required motor type,

and the corresponding parameters

are listed together with a description

guiding you on how to set the correct

value. The motor types supported by

the motor plug-in are:

Asynchronous

PM, non-salient SPM

PM, salient IPM

Synchronous Reluctance (SynRM)

Customized commissioning experience

19| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 20

1. Enclosure

The drive meets requirements for

enclosure class IP20/Chassis. IP21/

UL Type 1, IP54/UL Type 12, IP55/UL

Type 12 or IP66/UL Type 4X.

2. EMC and Network effects

All versions of VLT® AutomationDrive

comply as standard with EMC

limits B, A1 or A2 according to the

EN 55011 norm and IEC618003 Category C1, C2 and C3. The

standard integrated DC coils ensure

low harmonic load on the network

according to EN 61000-3-12 and

increase the lifetime of the DC link

capacitors.

3. Protective coating

The electronic components are,

as standard, coated as per

IEC 60721-3-3, class 3C2. For harsh

and aggressive environments,

coating as per IEC 60721-3-3, class

3C3 is available.

4. Removable fan

Like most of the elements, the

fan can be quickly removed and

remounted for easy cleaning.

5. Control terminals

Specially developed removable

spring-loaded cage clamps add

to reliability and facilitate easy

commissioning and service.

6. Fieldbus option

All major industrial fieldbuses are

supported. See complete list of

available fieldbus options on

page 41.

Delivered fully assembled and tested to meet your specific requirements

Modular simplicity – A, B and C enclosures

7. I/O options

The general purpose I/O, relay,

safety and thermistor expands the

flexibility of the drives.

8. Display option

Danfoss drives’ renowned

removable Local Control Panel (LCP)

has an improved user interface.

Choose between 28 built-in

languages (including Chinese) or

have it customized with your own.

Languages can be changed by the

user. Wireless version available.

Alternatively the drive can be

commissioned via the built-in USB/

RS485 connection or through

fieldbus options with the VLT®

Motion Control Tool MCT 10 PC tool.

4

8

2

3

9

5

7

6

1

20 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 21

9. 24 V supply or RTC

A 24 V supply option to keep the

control section and any installed

option functioning during power

failure. An extended version

combines a Real-time Clock with

a battery in one D-option.

10. Mains switch

This switch interrupts the mains

supply and has a free useable

auxiliary contact.

Safety

Extended range of integrated

functional safety. Please see chapter

“Tailored safety” on page 17.

4

3

9

6

7

5

8

10

2

1

The VLT® Wireless Communication

Panel LCP 103 (8) communicates

with MyDrive® Connect – an app

which can be downloaded to iOSand Android-based smart devices.

MyDrive® Connect offers full access

to the drive making it easier to

perform commissioning, operation,

monitoring and maintenance tasks.

Utilizing the active point-to-point

wireless connection, maintenance

personnel can receive real-time error

messages via the app to ensure a

quick response to potential issues

and reduce downtime.

VLT® Wireless Communication Panel LCP 103

21| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 22

1. Display options

Danfoss drives’ renowned removable

Local Control Panel (LCP) has an

improved user interface. Choose

between 28 built-in languages

(including Chinese) or have it

customized with your own. Languages

can be changed by the user.

2. Hot pluggable LCP

The LCP can be plugged in or

unplugged during operation. Settings

are easily transferred via the control

panel from one drive to another or

from a PC with MCT 10 set-up software.

3. Integrated manual

The info button makes the printed

manual virtually redundant. Users

have been involved throughout

development to ensure optimum

overall functionality of the drive. The

user group has significantly influenced

the design and functionality of the LCP.

The Automatic Motor Adaptation

(AMA), the Quick Set-Up menu

and the large graphic display make

commissioning and operation a breeze.

4. Fieldbus options

See complete list of available fieldbus

options on page 46.

5. I/O options

The general purpose I/O, relay and

thermistor expands the flexibility of the

drives.

6. Control terminals

Specially developed removable springloaded cage clamps add to reliability

and facilitate easy commissioning and

service.

7. 24 V supply

A 24 V supply keeps the VLT® drives

logically “alive” in situations when the

AC power supply is removed.

Is available in an extended version

with RTC. Real Time Clock parameters’

settings will be supported.

8. RFI filter suitable for IT grids

All high-power drives come standard

with RFI filtering according to EN

61800-3 Cat. C3/EN 55011 class A2.

A1/C2 RFI filters according to IEC 61000

and EN 61800 standards as integrated

options.

9. Modular construction

and ease of maintenance

All components are easily accessible

from the front of the drive, allowing

for ease of maintenance and side-byside mounting of drives. The drives are

constructed using a modular design

that allows for the easy replacement of

modular sub-assemblies.

10. Programmable options

A freely programmable motion

control option for user-specific control

algorithms and programs allows the

integration of PLC programs.

11. Conformally coated and

ruggedized circuit boards

All high-power drive circuit boards are

conformal coated to withstand the salt

mist test. Meets IEC 60721-3-3

Class 3C3. The conformal coating

complies with ISA (International Society

of Automation) standard S71.04 1985,

class G3. Additionally, drives in D and E

enclosures can be further ruggedized

to withstand the higher vibration needs

of certain applications.

12. Back-channel cooling

The unique design uses a back channel

to pass cooling air over heat sinks.

This design allows up to 90% of the

heat losses to be exhausted directly

outside of the enclosure with minimal

air passing through the electronics

area. This reduces temperature rise

and contamination of the electronic

components for improved reliability

and increased functional life.

As an option, the back-channel cooling

duct can be supplied in stainless

steel to provide a degree of corrosion

resistance against conditions such as

those found in salt-air environments

near the ocean.

13. Enclosure

The drive meets relevant requirements

for all possible installation conditions.

Enclosure class IP00/chassis, IP20/

chassis, IP21/UL Type 1, and IP54/UL

Type 12. A kit is available to increase

the enclosure class on enclosure size D

drives to UL Type 3R.

14. DC-link reactor

The built-in DC-link reactor ensures low

harmonic disturbance of the power

supply in accordance with IEC-610003-12. The result is a more compact

design with higher efficiencies than

competitive systems with externalmounted AC chokes.

15. Input mains option

Various input configurations are

available, including fuses, mains

disconnect switch, or RFI filter.

High-power modularity – D, E and F enclosures

The high-power VLT® AutomationDrive modules are all built on a modular

platform allowing for highly customized drives which are mass produced,

tested, and delivered from the factory.

Upgrades and further options dedicated to your industry are a matter of

plug-and-play. Once you know one, you know them all.

22 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 23

2

1

3

9

8

6

5

4

10

12

13

11

14

7

Efficiency is vital

for high-power drives

Efficiency is essential in the design

of the high-power VLT® drive series.

Innovative design and exceptionally

high-quality components have resulted

in unsurpassed energy efficiency.

VLT® drives pass more than 98% of

the supplied electrical energy on to

the motor. Only 2% or less is left in

the power electronics as heat to be

removed.

Energy is saved and electronics last

longer because they are not exposed

to high temperatures within the

enclosure.

Safety

Extended range of integrated

functional safety. Please see chapter

“Tailored safety” on page 17.

15

23| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 24

Engineered for cost savings

via intelligent heat management,

compactness and protection

Ruggedized for

extra protection

All Danfoss VLT® drives follow the same design principle for fast,

flexible and fault-free installation, and efficient cooling.

The AC drives are available in a broad

range of enclosure sizes and protection

ratings from IP20 to IP66 to enable

easy installation in all environments:

mounted in panels, switch rooms or

as stand-alone units in the production

area.

Cost-saving heat management

In AC drives, there is total separation

between the back-channel cooling

air and the internal electronics.

This separation greatly reduces the

airflow over the sensitive electronics,

minimizing the exposure to

In order to reduce the potential

negative effects of vibration, the drives

have been ‘ruggedized’. It is a process

that ensures that critical components

on the PCB have increased protection,

significantly reducing the risk of

malfunction while at sea.

The printed circuit boards in the drives

are also all coated in accordance with

IEC 60721-3-3 class 3C3, providing

additional protection against moisture

and dust.

Reliable operation at

engine room temperatures

up to 55 °C

VLT® drives can operate at full load in

engine rooms with 50 °C temperature

and 55 °C at reduced power close to,

for example, pumps and thrusters.

There is no need for installation in airconditioned control rooms with long

motor cables.

contaminants. At the same time, it

removes heat efficiently which helps

to prolong product life, increase

the overall availability of the system

and reduce faults related to high

temperatures.

For example, by exhausting heat

directly outside, it is possible to reduce

the size of the cooling system in the

panel or switch room. This can be

achieved with Danfoss’ extremely

efficient back-channel cooling concept,

allowing heat to be vented outside the

control room.

Spark-free design

The VLT® drives conform to the Limited

Explosion Risk requirements in The

European Agreement concerning the

International Carriage of Dangerous

Goods by Inland Waterways, as they do

not create any sparks durings normal

operation and the temperature does

not exceed 200 °C.

In daily use, the benefits are equally

clear as the energy consumption

related to cooling can be reduced

significantly. This means that designers

can reduce the size of the air

conditioning system, or even eliminate

it entirely.

Coated circuit boards

The AC drive conforms as standard to

class 3C3 (IEC 60721-3-3) to ensure long

lifetime even in harsh environments.

24 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 25

Back-channel

cooling gives up to

90%

reduction

in investment for air

cooling systems

Back-channel cooling

By directing air through a rear cooling

channel, up to 90% of the drive’s heat

loss is removed directly outside the

installation room.

Minimal airflow over electronics

Complete separation between backchannel cooling air and the internal

electronics ensures efficient cooling.

Panel-through cooling

An accessory mounting kit for small and

mid-range drives enables heat losses to be

directed directly outside the panel room.

25| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 26

Optimize performance

and grid protection

Built-in protection

The AC drive contains all the modules

necessary for compliance with EMC

standards.

A built-in, scalable RFI filter minimizes

electromagnetic interference, and

the integrated DC link chokes reduce

the harmonic distortion in the mains

network, in accordance with

IEC 61000-3-12. Furthermore, they

increase the lifetime of the DC link

capacitors and therefore the overall

efficiency of the drive.

These built-in components save

cabinet space, as they are integrated

in the drive from the factory. Efficient

EMC mitigation also enables the use

of cables with smaller cross-sections,

which reduces installation costs.

26 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Page 27

Use motor cables up to 300 m

The design of the AC drive makes it

a perfect choice in applications that

require long motor cables. Without

needing additional components, the

drive provides trouble-free operation

with cable lengths of up to 150 m

shielded or 300 m unshielded. This

allows the drive to be installed in a

central control room, away from the

application without affecting motor

performance.

Expand grid and motor

protection with filter solutions

Danfoss’ wide range of solutions for

harmonic mitigation ensures a clean

power supply and optimal equipment

protection, and includes:

VLT® Advanced Harmonic Filter AHF

VLT® Advanced Active Filter AAF

VLT® Low Harmonic Drives

VLT® 12-pulse Drives

Provide extra motor protection with:

VLT® Sine-wave Filter

VLT® dU/dt Filter

VLT® Common Mode Filters

Achieve optimum performance for

your application, even where the grid is

weak or unstable.

Optimized harmonic performance

Efficient harmonic mitigation protects electronics

and increases efficiency.

Harmonic distortion

Electrical interference reduces efficienc y and risks

harming equipment.

EMC Standards Conducted emission

Standards and

requirements

EN 55011

Facility operators must

comply with EN 55011

Class B

Housing

and light industries

Class A Group 1

Industrial

environment

Class A Group 2

Industrial

environment

EN/IEC 61800-3

Converter manufacturers

must conform to EN 61800-3

Category C1

First

environment, home

and office

Category C2

First

environment, home

and office

Category C3

Second

environment

Compliance

1)

1)

Compliance to mentioned EMC classes depends on the selected filter.

For further details see the design guides.

300

150

0

-150

-300

[V]

8 16 24 32 ms

300

150

0

-150

-300

[V]

8 16 24 32 ms

Discover more at drivepro.danfoss.com

Pre-sales

support

Training

DrivePro®

Services

Higher performance

More uptime

Healthier budget

Stay calm. You’re covered.

DrivePro® Retrofit

DrivePro® Extended Warranty

DrivePro® Exchange DrivePro® Remote Expert Support

DrivePro® Spare Parts

DrivePro® Preventive Maintenance

DrivePro® Start-up

DrivePro® Upgrade

DrivePro® Life Cycle

You’re covered

with DrivePro® Life Cycle service products

Get the most out of your systems, with the help of DrivePro® services

for Danfoss VLT® and VACON® drives. You get services that go beyond

simple troubleshooting, maintenance, repairs and replacements.

They also proactively improve productivity, performance and uptime.

DrivePro® app

Use the DrivePro app for fast

access to the DrivePro® services,

for improved productivity,

performance and uptime of

your systems. Find your closest

service partner, place a service

request, and register your VLT®

and VACON® drives. You can also

look up product information,

specifications and manuals for

your specific VLT® or VACON® drive

based on the nameplate product

code, or the product name.

27| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 28

28 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

Connection example

This diagram shows a typical installation

of the VLT® AutomationDrive. Power

is connected to the terminals 91 (L1),

92 (L2) and 93 (L3) and the motor is

connected to 96 (U), 97 (V) and 98 (W).

Terminals 88 and 89 are used for load

sharing between drives.

Analog inputs can be connected to

the 53 (V or mA), and for 54 (V or mA)

terminals.

These inputs can be set up as either

reference, feedback or thermistor

inputs.

There are 6 digital inputs to be

connected to terminals 18, 19, 27, 29,

32, and 33. Two digital input/output

terminals (27 and 29) can be set up

as digital outputs to show an actual

status or warning or can be used as a

pulse reference signal. The terminal 42

analog output can show process

values such as 0 - Imax.

On the 68 (P+) and 69 (N-) terminals’

RS 485 interface, the drive can be

controlled and monitored via serial

communication.

3 Phase

power

input

DC bus

Switch Mode

Power Supply

Motor

Analog Output

Interface

relay1

* relay2

ON=Terminated

OFF=Open

Brake

resistor

130BC931.10

91 (L1)

92 (L2)

93 (L3)

PE

88 (-)

89 (+)

50 (+10 V OUT)

53 (A IN)

54 (A IN)

55 (COM A IN)

0/4-20 mA

12 (+24V OUT)

13 (+24V OUT)

37 (D IN)

18 (D IN)

20 (COM D IN)

10Vdc

15mA 130/200mA

+ - + -

(U) 96

(V) 97

(W) 98

(PE) 99

(COM A OUT) 39

(A OUT) 42

(P RS-485) 68

(N RS-485) 69

(COM RS-485) 61

0V

5V

S801

0/4-20 mA

RS-485

RS-485

03

+10Vdc

0/-10Vdc -

+10Vdc

+10Vdc

0/4-20 mA

0/-10Vdc -

240Vac, 2A

24Vdc

02

01

05

04

06

240Vac, 2A

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

19 (D IN)

24V (NPN)

0V (PNP)

27

24V

0V

(D IN/OUT)

0V (PNP)

24V (NPN)

(D IN/OUT)

0V

24V

29

24V (NPN)

0V (PNP)

0V (PNP)

24V (NPN)

33 (D IN)

32 (D IN)

1 2

ON

S201

ON

21

S202

ON=0/4-20mA

OFF=0/-10Vdc +10Vdc

95

400Vac, 2A

P 5-00

21

ON

S801

(R+) 82

(R-) 81

*

*

: Chassis

: Earth

**

The numbers represent the terminals on the drive

Page 29

Technical data

Basic unit without extensions

Main supply (L1, L2, L3)

Supply voltage

200-240 V AC

380-500 V AC

525-600 V AC

525-690 V AC

Supply frequency 50/60 Hz

Displacement power factor

(cos ф) near unity

> 0.98

Switching on input supply

L1, L2, L3

1-2 times/min.

Output data ( T1, T2, T3)

Output voltage 0-100% of supply voltage

Output frequency 0-590 Hz

Switching on output Unlimited

Ramp times 0.01-3600 s

Digital inputs

Programmable digital inputs 6*

Changeable to digital output 2 (terminal 27, 29)

Logic PNP or NPN

Voltage level 0-24 V DC

Maximum voltage on input 28 V DC

Input resistance, Ri Approx. 4 kΩ

Scan interval 5 ms

* Two of the inputs can be used as digital outputs

Analog inputs

Analog inputs 2

Modes Voltage or current

Voltage level 0 to +10 V (scaleable)

Current level 0/4 to 20 mA (scaleable)

Accuracy of analog inputs Max. error: 0.5% of full scale

Pulse inputs

Programmable pulse inputs 2*

Voltage level 0-24 V DC (PNP positive logic)

Pulse input accuracy

(0.1-1 kHz)

Max. error: 0.1% of full scale

* Two of the digital inputs can be used for pulse inputs.

Digital outputs

Programmable

digital/pulse outputs

2

Voltage level at

digital/frequency output

0-24 V DC

Max. output current

(sink or source)

40 mA

Maximum output frequency 0-32 kHz

Accuracy on frequency output Max. error: 0.1% of full scale

Analog outputs

Programmable

analog outputs

1

Current range at

analog output

0/4-20 mA

Max. load to common at

analog output (clamp 30)

500 Ω

Accuracy on analog output Max. error: 0.5 % of full scale

Control card

USB interface 1.1 (Full Speed)

USB plug Type “B”

RS485 interface Up to 115 kBaud

Max. load (10 V) 15 mA

Max. load (24 V) 200 mA

Relay outputs

Programmable relay outputs 2

Max. terminal load (AC)

on 1-3 (NC), 1-2 (NO),

4-6 (NC) power card

240 V AC, 2 A

Max. terminal load (AC -1) on

4-5 (NO) power card

400 V AC, 2 A

Min. terminal load on

1-3 (NC), 1-2 (NO),

4-6 (NC), 4-5 (NO)

power card

24 V DC 10 mA, 24 V AC 20 mA

Surroundings/external

Ingress protection class

IP: 00/20/21/54/55/66

UL Type: Chassis/1/12/3R/4X

Vibration test 0.7 g

Max. relative humidity

5-95% (IEC 721-3-3); Class 3K3

(non-condensing) during operation

Ambient temperature Max. 50 °C without derating

Galvanic isolation of all I/O supplies according to PELV

Aggressive environment Designed for 3C3 (IEC 60721-3-3)

Ambient temperature

– Operating temperature range is -25 °C to 50 °C without derating

Max 55 °C with derating

Fieldbus communication

Standard built-in:

FC Protocol

N2 Metasys

FLN Apogee

Modbus RTU

Optional:

VLT® PROFIBUS DP V1 MCA 101

VLT® DeviceNet MCA 104

VLT® CANopen MCA 105

VLT® 3000 PROFIBUS Converter MCA 113

VLT® 5000 PROFIBUS Converter MCA 114

VLT® PROFINET MCA 120

VLT® EtherNet/IP MCA 121

VLT® Modbus TCP MCA 122

VLT® POWERLINK MCA 123

VLT® EtherCAT MCA 124

VLT® 5000 DeviceNet Converter MCA 194

Protection mode for longest possible up-time

– Electronic motor thermal protection against overload

– Protection against overtemperature

– The AC drive is protected against short circuits

on motor terminals R, S, T

– The AC drive is protected against ground faults

on motor terminals U, V, W

– Protection against mains phase loss

– Real-Time Clock with battery backup

– Advanced data logging using real-time stamps

– Predictive maintenance

– Preventive maintenance

– D-option VLT® Real-time Clock Option MCB 117

Agency approvals

29| Content | Danfoss Drives · DKDD.PB.302.A8.02

Page 30

30 Danfoss Drives · DKDD.PB.302.A8.02 | Content |

[T2] 3 x 200-240 V AC – high overload

High overload (160% 1 min/10 min) Enclosure size

Type

code

Output current

(3 x 200-240 V)

Typical shaft

output power

Conti nuous

input current

Estimated

power loss

Protection rating [IEC/UL]

IP20/21 IP21 IP55 IP66

FC-302 Con. I

N

Inter. I

MAX

(60 s)

kW @

208 V

Hp @

230 V

[A] [W] Chassis Type 1 Type 12 Type 4X

PK25 1.8 2.9 0.25 0.34 2.6 21 A1*/A2 A2 A4/A5 A4/A5

PK37 2.4 3.8 0.37 0.5 3.5 29 A1*/A2 A2 A4/A5 A4/A5

PK55 3.5 5.6 0.55 0.75 5.1 42 A1*/A2 A2 A4/A5 A4/A5

PK75 4.6 7.4 0.75 1 6.6 54 A1*/A2 A2 A4/A5 A4/A5

P1K1 6.6 10.6 1.1 1.5 9.4 63 A1*/A2 A2 A4/A5 A4/A5

P1K5 7.5 12 1.5 2 10.9 82 A1*/A2 A2 A4/A5 A4/A5

P2K2 10.6 17 2.2 3 15.2 116 A2 A2 A4/A5 A4/A5

P3K0 12.5 20 3 4 18.1 155 A3 A3 A5 A5

P3K7 16.7 26.7 3.7 5 24 185 A3 A3 A5 A5

P5K5 24.2 38.7 5.5 7.5 35.2 239 B3 B1 B1 B1

P7K5 30.8 49.3 7.5 10 44.8 371 B3 B1 B1 B1

P11K 46.2 73.9 11 15 67.2 463 B4 B2 B2 B2

P15K 59.4 89.1 15 20 81 624 B4 C1 C1 C1

P18K 74.8 112 18.5 25 102 740 C3 C1 C1 C1

P22K 88 132 22 30 120 874 C3 C1 C1 C1

P30K 115 173 30 40 156 1143 C4 C2 C2 C2

P37K 143 215 37 50 195 1400 C4 C2 C2 C2

*A1 enclosure is only available as FC 301

[T2] 3 x 200-240 V AC – normal overload

Normal overload (110% 1 min/10 min) Enclosure size

Type

code

Output current

(3 x 200-240 V)

Typical shaft

output power

Conti nuous

input current

Estimated

power loss

Protection rating [IEC/UL]

IP20/21 IP21 IP55 IP66

FC-302 Con. I

N

Inter. I

MAX

(60 s)

kW @

208 V

Hp @

230V

[A] [W] Chassis Type 1 Type 12 Type 4X

PK25 1.8 2.9 0.25 0.34 2.6 21 A1*/A2 A2 A4/A5 A4/A5

PK37 2.4 3.8 0.37 0.5 3.5 29 A1*/A2 A2 A4/A5 A4/A5

PK55 3.5 5.6 0.55 0.75 5.1 42 A1*/A2 A2 A4/A5 A4/A5

PK75 4.6 7.4 0.75 1 6.6 54 A1*/A2 A2 A4/A5 A4/A5

P1K1 6.6 10.6 1.1 1.5 9.4 63 A1*/A2 A2 A4/A5 A4/A5

P1K5 7.5 12 1.5 2 10.9 82 A1*/A2 A2 A4/A5 A4/A5

P2K2 10.6 17 2.2 3 15.2 116 A2 A2 A4/A5 A4/A5

P3K0 12.5 20 3 4 18.1 155 A3 A3 A5 A5

P3K7 16.7 26.7 3.7 5 24 185 A3 A3 A5 A5

P5K5 30.8 33.9 7.5 10 30.8 310 B3 B1 B1 B1

P7K5 46.2 50.8 11 15 46.2 514 B3 B1 B1 B1

P11K 59.4 65.3 15 20 59.4 602 B4 B2 B2 B2

P15K 74.8 82.3 18.5 25 74.8 737 B4 C1 C1 C1

P18K 88 96.8 22 30 88 845 C3 C1 C1 C1

P22K 115 127 30 40 114 1140 C3 C1 C1 C1

P30K 143 157 37 50 143 1353 C4 C2 C2 C2

P37K 170 187 45 60 169 1636 C4 C2 C2 C2

*A1 enclosure is only available as FC 301

Electrical data – A, B, and C enclosures

Page 31

31| Content | Danfoss Drives · DKDD.PB.302.A8.02

[T5] 3 x 380-500 V AC – high overload

High overload (160% 1 min/10 min) Enclosure size

Type

code

Output current

Typical shaft

output power

Continuous

input

current

Estimated

power

loss

Protection rating [IEC/UL]

(3 x 380-440 V) (3 x 441-500 V) IP20/21 IP21 IP55 IP66

FC-302 Con. I

N

Inter. I

MAX

(60 s)

Con. I

N

Inter. I

MAX

(60 s)

kW @

400 V

Hp @

460 V

[A] [W] Chassis Type 1 Type 12 Type 4X

PK37 1.3 2.1 1.2 1.9 0.37 0.5 1.9 35 A1*/A2 A2 A4/A5 A4/A5

PK55 1.8 2.9 1.6 2.6 0.55 0.75 2.6 42 A1*/A2 A2 A4/A5 A4/A5

PK75 2.4 3.8 2.1 3.4 0.75 1 3.5 46 A1*/A2 A2 A4/A5 A4/A5

P1K1 3 4.8 2.7 4.3 1.1 1.5 4.3 58 A1*/A2 A2 A4/A5 A4/A5

P1K5 4.1 6.6 3.4 5.4 1.5 2 5.9 62 A1*/A2 A2 A4/A5 A4/A5

P2K2 5.6 9 4.8 7.7 2.2 3 8 88 A2 A2 A4/A5 A4/A5

P3K0 7.2 11.5 6.3 10.1 3 4 10.4 116 A2 A2 A4/A5 A4/A5

P4K0 10 16 8.2 13.1 4 5 14.4 124 A2 A2 A4/A5 A4/A5

P5K5 13 20.8 11 17.6 5.5 7.5 18.7 187 A3 A3 A5 A5

P7K5 16 25.6 14.5 23.2 7.5 10 23 255 A3 A3 A5 A5

P11K 24 38.4 21 33.6 11 15 35.2 291 B3 B1 B1 B1

P15K 32 51.2 27 43.2 15 20 46.4 379 B3 B1 B1 B1

P18K 37.5 60 34 54.4 18.5 25 54.4 444 B4 B2 B2 B2

P22K 44 70.4 40 64 22 30 64 547 B4 B2 B2 B2

P30K 61 91.5 52 78 30 40 82.5 570 B4 C1 C1 C1

P37K 73 110 65 97.5 37 50 99 697 C3 C1 C1 C1

P45K 90 135 80 120 45 60 123 891 C3 C1 C1 C1

P55K 106 159 105 158 55 75 144 1022 C4 C2 C2 C2

P75K 147 221 130 195 75 100 200 1232 C4 C2 C2 C2

*A1 enclosure is only available as FC 301

[ T5] 3 x 380-500 V AC – normal overload

Normal overload (110% 1 min/10 min) Enclosure size

Type

code

Output current

Typical shaft

output power

Continuous

input

current

Estimated

power

loss

Protection rating [IEC/UL]

(3 x 380-440 V) (3 x 441-500 V) IP20/21 IP21 IP55 IP66

FC-302 Con. I

N

Inter. I

MAX

(60 s)

Con. I

N

Inter. I

MAX

(60 s)

kW @

400 V

Hp @

460 V

[A] [W] Chassis Type 1 Type 12 Type 4X

PK37 1.3 2.1 1.2 1.9 0.37 0.5 1.9 35 A1*/A2 A2 A4/A5 A4/A5

PK55 1.8 2.9 1.6 2.6 0.55 0.75 2.6 42 A1*/A2 A2 A4/A5 A4/A5

PK75 2.4 3.8 2.1 3.4 0.75 1 3.5 46 A1*/A2 A2 A4/A5 A4/A5

P1K1 3 4.8 2.7 4.3 1.1 1.5 4.3 58 A1*/A2 A2 A4/A5 A4/A5

P1K5 4.1 6.6 3.4 5.4 1.5 2 5.9 62 A1*/A2 A2 A4/A5 A4/A5

P2K2 5.6 9 4.8 7.7 2.2 3 8 88 A2 A2 A4/A5 A4/A5

P3K0 7.2 11.5 6.3 10.1 3 4 10.4 116 A2 A2 A4/A5 A4/A5

P4K0 10 16 8.2 13.1 4 5 14.4 124 A2 A2 A4/A5 A4/A5

P5K5 13 20.8 11 17.6 5.5 7.5 18.7 187 A3 A3 A5 A5

P7K5 16 25.6 14.5 23.2 7.5 10 23 255 A3 A3 A5 A5

P11K 32 35.2 27 29.7 15 20 31.9 392 B3 B1 B1 B1

P15K 37.5 41.3 34 37.4 18.5 25 37.4 465 B3 B1 B1 B1

P18K 44 48.4 40 44 22 30 44 525 B4 B2 B2 B2