Page 1

Installation Instructions

VLT® Encoder Option MCB 102

®

VLT

AutomationDrive FC 301/FC 302

Introduction

The VLT® Encoder Option MCB 102 can be used as feedback

source for closed-loop control or as master source for synchronizing control. Congure the encoder option in parameter

group 17-** Feedback Option, see the VLT

301/FC 302 Programming Guide.

Signal type 5 V TTL, RS422 1 Vpp, SinCos

Maximum resolution 16.384 pulses/revolution

Maximum frequency 410 kHz

Table 1.1 Supported Incremental Encoder Types

SSI without incremental track

SSI with SinCos

SSI with TTL

Hiperface with incremental track Resolution 8192–1.073.741.824

EnDat 2.1 and 2.2 without

incremental track

EnDat 2.1 and 2.2 with SinCos

EnDat 2.1 and 2.2 with TTL

Table 1.2 Supported Absolute Single and Multi-turn Encoder Types

Maximum cross-section, exible/rigid wire

without cable end sleeves

Maximum cross-section, exible wire with cable

end sleeves with collar

Minimum cross-section

Table 1.3 Supported Wire Dimensions

Data length 13–32 bits, clock rate

100–260 kHz

positions/revolution, multiturn 1–

16,777,216 revolutions, Baudrate

600–38400

Maximum data length 64 bit,

Clock rate 100–260 kHz

®

AutomationDrive FC

2

1.5 mm

/16 AWG

2

0.75 mm

0.2 mm

/18 AWG

2

/26 AWG

Items Supplied

Safety

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. High voltage can be present even when the

warning LED indicator lights are

specied time after power has been removed before

performing service or repair work can result in death or

serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and DClink connections to other frequency converters.

Disconnect or lock PM motor.

•

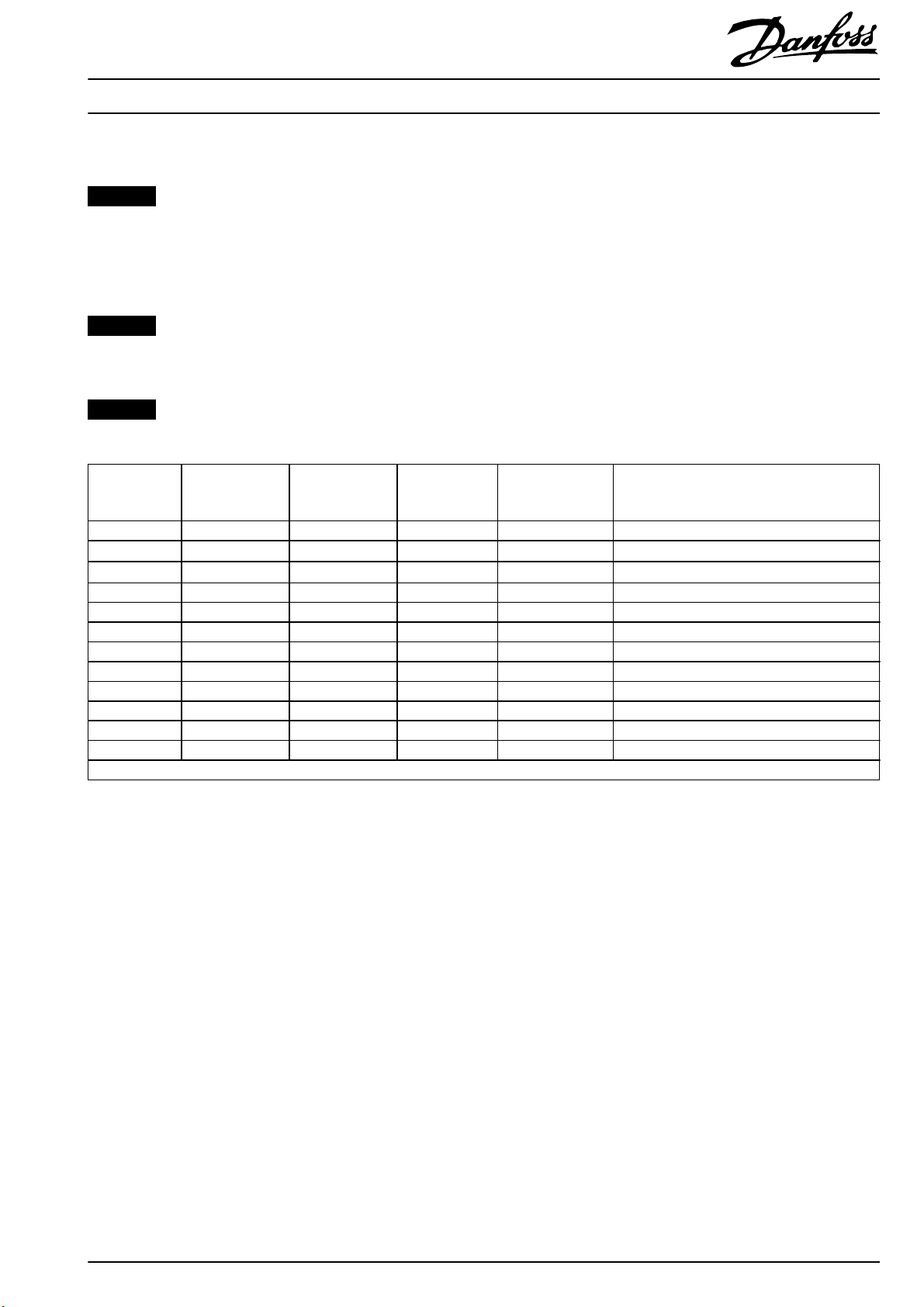

Wait for the capacitors to discharge fully. The

•

minimum duration of waiting time is specied in

Tabl e 1.4 and is also visible on the product label on

top of the frequency converter.

Before performing any service or repair work, use

•

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

Voltage [V] Minimum waiting time (minutes)

4715

200–240 0.25–3.7 kW

(0.34–5 hp)

380–500 0.25–7.5 kW

(0.34–10 hp)

525–600 0.75–7.5 kW

(1–10 hp)

525–690 – 1.5–7.5 kW

Failure to wait the

o.

–5.5–37 kW

(7.5–50 hp)

– 11–75 kW

(15–100 hp)

– 11–75 kW

(15–100 hp)

11–75 kW

(2–10 hp)

(15–100 hp)

VLT® Encoder Option MCB 102

•

Ordering numbers

130B1115 (uncoated)

•

130B1203 (coated)

•

Tab le 1. 4 D ischa rge Time

Danfoss A/S © 06/2017 All rights reserved. MI33F402

Page 2

Installation Instructions

Mounting

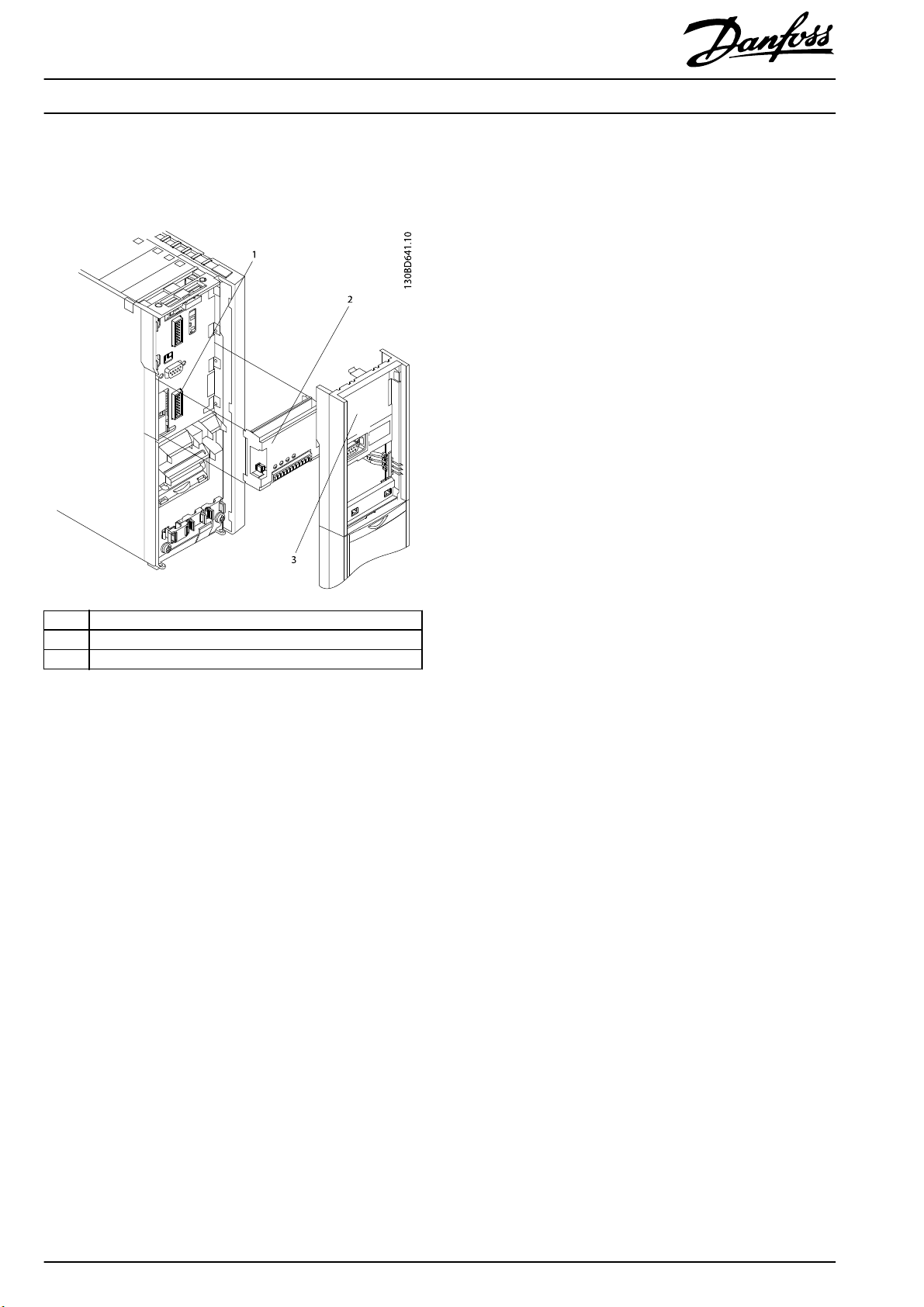

Mount the option according to Illustration 1.1.

®

VLT

Encoder Option MCB 102

®

AutomationDrive FC 301/FC 302

VLT

1Slot B

2Option

3LCP frame

Illustration 1.1 Mounting

2

Danfoss A/S © 06/2017 All rights reserved. MI33F402

Page 3

®

VLT

Installation Instructions

Encoder Option MCB 102

®

AutomationDrive FC 301/FC 302

VLT

Electrical Installation

NOTICE

Supply the encoder through the VLT® Encoder Option MCB 102. Avoid using external supply for the encoder.

Encoder monitor

The 4 encoder channels (A, B, Z, and D) are monitored, open, and short circuits can be detected. There is a green LED for each

channel which lights up when the channel is OK.

NOTICE

To view the LEDs on the option, remove the cover. Select response to encoder errors in parameter 17-61 Feedback Signal

Monitoring.

NOTICE

Maximum cable length for incremental encoder 150 m [492 ft].

Connector

designation

X31

1 – – – – 24 V output (21–25 V, I

2–

3

4 GND GND GND GND GND

5 A input A input A input A input A input

6 A inv input A inv input A inv input A inv input A inv input

7 B input B input B input B input B input

8 B inv input B inv input B inv input B inv input B inv input

9 Z input +Data RS485 Clock out Clock out Z input OR +Data RS485 OR clock

10 Z inv input -Data RS485 Clock out inv. Clock out inv. Z input OR -Data RS485 OR clock-

11 NC NC Data in Data in Data

12 NC NC Data in inv. Data in inv. Data-

Maximum 5 V on X31.5-12

Table 1.5 Encoder Connections

1) Typical supply voltage for the encoder: Check encoder data.

Incremental

(TTL and SinCos)

1)

5 V

Hiperface

8 V

–

®

1)

EnDat SSI Description

– – 8 V output (7–12 V, I

5 V

1)

5 V

1)

5 V output (5 V ±5%, I

max

: 200 mA)

max

max

: 125 mA)

: 200 mA)

MI33F402 Danfoss A/S © 06/2017 All rights reserved.

3

Page 4

Installation Instructions

Set-up and Connection

®

VLT

Encoder Option MCB 102

®

AutomationDrive FC 301/FC 302

VLT

VLT® AutomationDrive FC 301/FC 302 with VLT® Encoder Option MCB 102 supports multiple encoder

congurations

which can be

used as speed and/or position feedback for closed-loop ux motor control, closed-loop speed control, and closed-loop position

control:

Select [2] MCB 102 as “Flux Motor Feedback Source” in parameter 1-02 Flux Motor Feedback Source.

•

Select [0] Motor feedb. P1-02 or [2] MCB 102 as “Speed PID Feedback Source” in parameter 7-00 Speed PID Feedback Source.

•

Select [0] Motor feedb. P1-02 or [2] MCB 102 as “Position PI Feedback Source” in parameter 7-90 Position PI Feedback Source

•

Incremental Encoders

With TTL and SinCos Incremental encoder, the actual position is 0 after power-up and encoder pulses are counted to increment/

decrement actual position. For improved resolution with TTL encoders, both the positive and negative edges of A and B pulses are

detected giving 4 quad counts per encoder pulse. With SinCos encoders, the signal is sampled 1024 times per sine-cosine period

meaning that the resulting resolution is 1024 times periods per revolution.

Connection Parameter Description

Parameter 17-10 Signal Type Select the signal type for the encoder:

[1] RS 422 (5V TTL)

[2] Sinusoidal 1Vpp

Parameter 17-11 Resolution

(PPR)

Parameter 17-60 Feedback

Direction

Parameter 17-61 Feedback

Signal Monitoring

Illustration 1.2 Incremental Encoder

Parameter groups 4-3* Motor

Speed Monitoring and 4-4*

Speed Monitoring

Set the resolution of the encoder. Pulses per

revolution for TTL or periods per revolution for

SinCos.

Select [1] Counter clockwise if actual position

(parameter 16-06 Actual Position) counts

negative when the frequency converter is

running forward. Alternative is to swap A and B

track on the encoder connection.

The signal level is monitored by hardware when

using TTL encoders. Select the reaction when a

problem is detected:

[0] Disabled = No reaction

[1] Warning = Warning 90, Feedback monitor is

issued when the signal level is too high or too

low.

[2] Trip = The frequency converter trips with

alarm 90, Feedback monitor when the signal

level is too high or too low. There is no

hardware monitoring of SinCos encoders.

Oer possibility to activate and adjust further

monitoring of speed tracking.

4

Danfoss A/S © 06/2017 All rights reserved. MI33F402

Page 5

®

VLT

Installation Instructions

Encoder Option MCB 102

®

AutomationDrive FC 301/FC 302

VLT

SSI Encoders

Absolute position is read from the encoder and used to set the actual position after power-up. Thereafter, the absolute position is

read every 1 ms and used to track any movements. If the absolute position read from the encoder changes more than half an

encoder revolution from the previous position, it is considered to be invalid and the position value is not used. Up to 4 consecutive

invalid positions are skipped, 5 consecutive invalid positions trigger an error, the reaction to this error depends on the setting of

parameter 17-61 Feedback Signal Monitoring. If no reaction or only warning is selected, up to 10 consecutive invalid positions are

skipped where after the position is considered valid and thus used.

When an incremental track is added, it is used for tracking movements while the absolute position readings are used to monitor,

and if needed, correct any deviations between the 2 tracks. A warning is issued when the actual position based on the incremental

track deviates more than 3 qc from the absolute position.

Connection Parameter Description

Parameter 17-10 Signal Type Select the incremental signal type for the

encoder:

[0] None = no incremental track

[1] RS 422 (5V TTL)

[2] Sinusoidal 1Vpp

Parameter 17-11 Resolution

(PPR)

Parameter 17-20 Protocol

Selection

Parameter 17-21 Resolution

(Positions/Rev)

Parameter 17-22 Multiturn

Revolutions

Parameter 17-24 SSI Data

Lengt h

Parameter 17-25 Clock Rate Set the frequency for the clock signal

Illustration 1.2 SSI Absolute only

Parameter 17-26 SSI Data

Form at

Parameter 17-60 Feedback

Direction

Parameter 17-61 Feedback

Signal Monitoring

Illustration 1.2 SSI Absolute and Incremental

Parameter groups 4-3* Motor

Speed Monitoring and 4-4*

Speed Monitoring

Set the incremental resolution of the encoder.

Pulses per revolution for TTL or periods per

revolution for SinCos.

Select [4] SSI

Set the absolute resolution in positions per

revolution.

Set number of multi turn revolutions.

Set the data length for the absolute position in

number of bits.

®

generated by the VLT

102. Default is 260 kHz. It should be reduced in

case of long encoder cable or electrical noise

issues.

Select the SSI data format:

[0] Gray code

[1] Binary code

Select [1] Counter clockwise if the actual

position (parameter 16-06 Actual Position)

counts negative when the frequency converter

is running forward.

The signal level is monitored by hardware

when using TTL encoders. Select the reaction

when a problem is detected:

[0] Disabled = No reaction

[1] Warning = Warning 90, Feedback monitor is

issued when the signal level is too high or too

low.

[2] Trip = The frequency converter trips with

alarm 90, Feedback monitor when the signal

level is too high or too low. There is no

hardware monitoring of SinCos encoders.

Oer possibility to activate and adjust further

monitoring of speed tracking.

Encoder Option MCB

MI33F402 Danfoss A/S © 06/2017 All rights reserved.

5

Page 6

®

VLT

Installation Instructions

Encoder Option MCB 102

®

AutomationDrive FC 301/FC 302

VLT

Hiperface Encoders

Absolute position is read from the encoder and used to set the actual position after power-up. Thereafter, the incremental track is

used for tracking movements while the absolute position readings are used to monitor and if needed correct any deviations

between the 2 tracks. A warning is issued when the actual position based on the incremental track deviates more than 3 qc from

the absolute position.

Connection Parameter Description

Parameter 17-10 Signal Type Select [2] Sinusoidal 1Vpp

Parameter 17-11 Resolution (PPR) Set the incremental resolution of the

encoder in sine – cosine periods per

revolution.

Parameter 17-20 Protocol

Selection

Parameter 17-21 Resolution

(Positions/Rev)

Parameter 17-22 Multiturn

Revolutions

Parameter 17-34 HIPERFACE

Baudrate

Parameter 17-60 Feedback

Direction

Parameter groups 4-3* Motor

Speed Monitoring and 4-4*

Speed Monitoring

Select [1] HIPERFACE

Set the absolute resolution in positions per

revolution.

Set number of multi turn revolutions.

Set the baud rate for the Hiperface data

channel. Default is 9600 and there is

normally no reason to change it.

Select [1] Counter clockwise if actual position

(parameter 16-06 Actual Position) counts

negative when the frequency converter is

running forward.

Oers possibility to activate and adjust

further monitoring of speed tracking.

6

Danfoss A/S © 06/2017 All rights reserved. MI33F402

Page 7

®

VLT

Installation Instructions

Encoder Option MCB 102

®

AutomationDrive FC 301/FC 302

VLT

EnDat Encoders

Absolute only

Absolute position is read from the encoder and used to set the actual position after power-up. Thereafter, the absolute position is

read every 1 ms and used to track any movements.

Absolute and incremental

Absolute position is read from the encoder and used to set the actual position after power-up. Thereafter, the incremental track Is

used for tracking movements while the absolute position readings are used to monitor, and if needed, correct any deviations

between the 2 tracks. A warning is issued when the actual position based on the incremental track deviates more than 3 qc from

the absolute position.

Connection Parameter Description

Parameter 17-10 Signal Type Select the incremental signal type for the

encoder:

[0] None = no incremental track

[1] RS 422 (5V TTL)

[2] Sinusoidal 1Vpp

Illustration 1.2 EnDat Absolute

Parameter 17-11 Resolution

(PPR)

Parameter 17-20 Protocol

Selection

Parameter 17-22 Multiturn

Revolutions

Parameter 17-25 Clock Rate Set the frequency for the clock signal

Parameter 17-60 Feedback

Direction

Parameter 17-61 Feedback

Signal Monitoring

Parameter groups 4-3* Motor

Speed Monitoring and 4-4*

Speed Monitoring

Set the resolution of the encoder. Pulses per

revolution for TTL or periods per revolution for

SinCos.

Select [2] EnDat

Set number of multi turn revolutions.

®

generated by the VLT

102. Default is 260 kHz. It should be reduced in

case of long encoder cable or electrical noise

issues.

Select [1] Counter clockwise if the actual

position (parameter 16-06 Actual Position) counts

negative when the frequency converter is

running forward.

The signal level is monitored by hardware when

using TTL encoders. Select the reaction when a

problem is detected:

[0] Disabled = No reaction.

[1] Warning = Warning 90, Feedback monitor is

issued when the signal level is too high or too

low.

[2] Alarm = The frequency converter trips with

alarm 90, Feedback monitor when the signal

level is too high or too low. There is no

hardware monitoring of SinCos encoders.

Oer possibility to activate and adjust further

monitoring of speed tracking.

Encoder Option MCB

Illustration 1.2 EnDat Absolute and Incremental

MI33F402 Danfoss A/S © 06/2017 All rights reserved.

7

Page 8

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this mate rial are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI33F402130R0309 06/2017

*MI33F402*

Loading...

Loading...