Page 1

Installation guide

VCM 86 Non-return valve

1. Identication &

introduction

180R9413

Check valve

Type VCM 86

Code no. 180H0056

Serial no. XXXXXX03-XXX

180R9413

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

The non-return valve is designed for use in Seawater

Reverse Osmosis (SWRO) membrane systems. In case the

high-pressure pump stops momentarily, the volume of

water in the membrane vessel may work as an accumulator and will send ow backwards.

When using multiple pumps in parallel, the

non-return valve prevents the water from one

pump to run into the parallel-coupled pumps at

start-up. The valve is prepared for easy installation on the high-pressure outlet of APP 53-86

series 07 or lower.

Use only Style 77DX coupling or equivalent.

Typ e Outlet

Connection

VCM 86 3" Victaulic

OSG

1)

The check valve is mounted directly in the outlet port with a ange with 6 bolts (M10 x 25)

2)

Wetted parts materials: Super Duplex, PEEK, PP, Hastelowy, FKM, NBR

3)

The installation instruction for Style 77DX is located in the Victaulic document I-100 Field Installation

3)

Diameter

1)

mm (inch)

87. 7

(3.45)

Length

mm (inch)

175.5

(6.90)

Material

Super

Duplex

2)

Max.

pressure

barg (psig)

80

(1,160)

Flow

continuoulu

m3/h (gpm)

90

(396)

Code

number

180H0056

Handbood (http://static.victaulic.com)

© Danfoss | DCS (im) | 2019.10

180R9413 | AN315326401211en-000101 | 1

Page 2

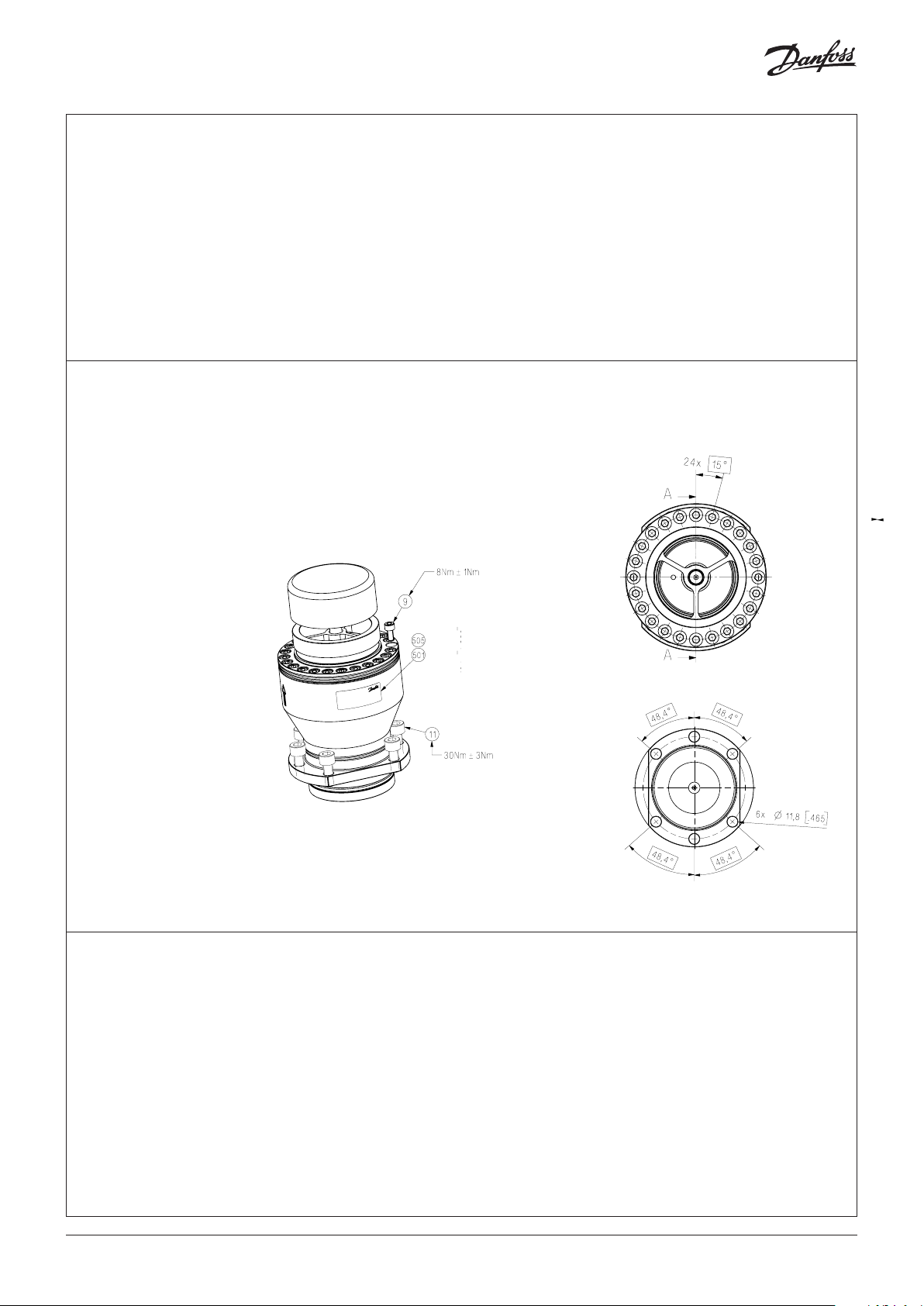

2. Installation

2.1 Mounting holes and torque

The VCM 86 check valve comes with a ange

connection that is easily mounted directly on the

pumps high pressure outlet port (outlet

connection is not required).

When installing the valve, lubricate the O-ring at

the ange before pushing it into the outlet of the

pump.

Note: Bolts must be tightened with torque

30Nm ± 3 Nm.

Now 24 screws

© Danfoss | DCS (im) | 2019.10

180R9413 | AN315326401211en-000101 | 2

Loading...

Loading...