Page 1

Service guide

Non-return valve

VCM 46

Disassembling and Assembling

The Service guide covers the instruction for

disassembling and assembling the VCM 46 Nonreturn valve.

IMPORTANT:

It is essential that the VCM 46 is serviced in

conditions of absolute cleanliness.

WARNING:

Do not use silicone when assembling the VCM

46. Do not reuse disassembled O-rings; they

might be damaged.

Always use new O-rings.

For a better understanding of the VCM 46, please

see the sectional view.

Tools needed:

• Snap ring pliers or nylon mandrel

• Screwdriver

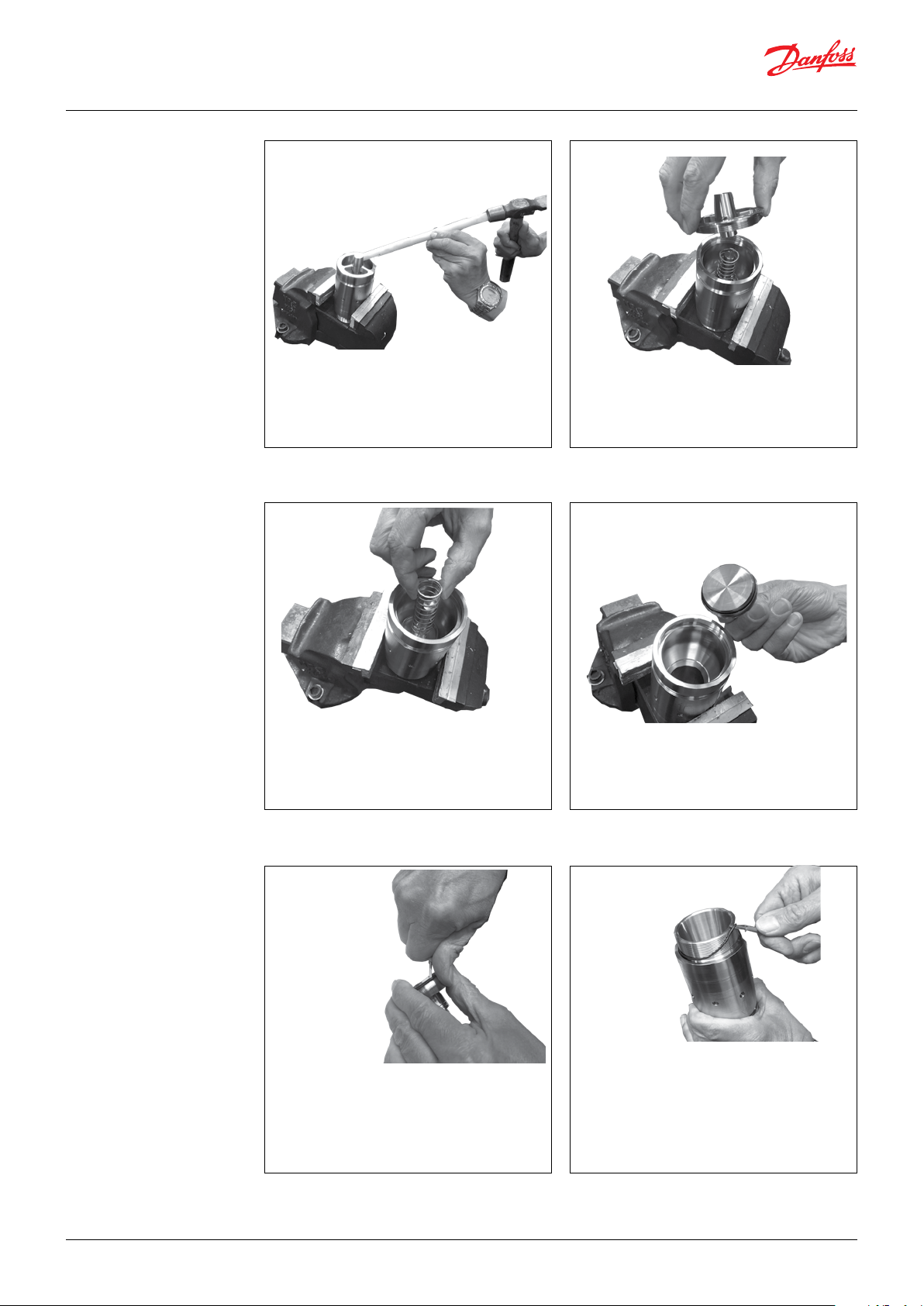

Disassembling

1. Mount the VCM 46 into a vice with

aluminum trays.

2. Turn the nut CCW with snap ring pliers.

© Danfoss | DCS (im) | 2021.03

180R9420 | AX323840049566en-000201 | 1

Page 2

Service guide | Disassembling and Assembling VCM 46

3. Alternatively use a mandrel made of nylon.

5. Remove the spring.

4. Remove the nut.

6. Remove the valve cone.

© Danfoss | DCS (im) | 2021.03

7. Remove the O-ring at the cone with a small

screw driver.

2. Remove the O-ring at the thread end of the

valve with a small screw driver.

180R9420 | AX323840049566en-000201 | 2

Page 3

Service guide | Disassembling and Assembling VCM 46

Assembling

1. Lubrication:

• To prevent seizing-up, lubricate threads

with PTFE lubrication type.

• O-ring inside VCM 46 may be lubricated

only with clean ltered water.

• O-rings at the thread end must be

lubricated.

• It is important to lubricate ALL parts to

be assembled with clean ltered water.

2. Mount the lubricated O-ring at the thread

end of the valve.

3. Mount the water lubricated O-ring on the

cone. Ensure the O-ring is pushed fully into

the O-ring groove.

5. Mount the spring on the rod of the cone. 6. Lubricate the threads of the nut.

4. Mount the the cone.

© Danfoss | DCS (im) | 2021.03

180R9420 | AX323840049566en-000201 | 3

Page 4

Service guide | Disassembling and Assembling VCM 46

7. Screw in the nut.

9. Alternatively use a plasitc mandrel.

8. Tighten the nut with a snap ring pliers.

© Danfoss | DCS (im) | 2021.03

Testing valve function:

Verify free movement of valve cone.

180R9420 | AX323840049566en-000201 | 4

Page 5

Spare part list and

sectional drawing

Spare part list

Service interval

Pos. Qty. Designation Material Seal set

180H4000

4 1 O-ring 35.00 x 3.00 NBR x

6 1 O-ring 58.00 x 2.00 NBR x

4 years for inspection and exchanging O-rings as

needed.

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2021.03

180R9420 | AX323840049566en-000201 | 5

Loading...

Loading...