Page 1

User Guide

VACON® OPTEA/OPTE9 Ethernet Board

Page 2

Page 3

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Contents

1

Introduction 10

1.1

Purpose of the Manual 10

Additional Resources 10

1.2

Manual and Software Version 10

1.3

1.4

Type Approvals and Certications 11

1.5

Trademarks 11

1.6

Product Overview 12

1.6.1

Ethernet Networks with VACON® AC drives 12

1.6.2

Fieldbus Protocols 12

1.6.2.1

1.6.2.2

1.6.2.3

Redundancy Protocols 17

1.6.3

Modbus TCP/Modbus UDP 12

PROFINET I/O 16

EtherNet/IP 17

Contents

1.6.3.1

1.6.3.2

1.6.3.3

1.6.3.4

1.6.4

PROFINET Shared Device (OPTEA) 23

1.6.5

Address Conict Detection (ACD) 24

1.6.6

Technical Data 24

1.6.7

VACON® PC Tools 24

1.7

AC Drive Support 25

1.7.1

VACON® OPTEA Advanced Dual Port Ethernet Drive Support 25

1.7.2

VACON® OPTE9 Dual Port Ethernet Drive Support 25

1.8

Symbols and Abbreviations 26

2

Safety 29

2.1

Safety Symbols 29

2.2

Danger and Warnings 29

2.3

Cautions and Notices 30

Rapid Spanning Tree Protocol (RSTP) 17

Media Redundancy Protocol (MRP) 19

Device Level Ring (DLR) 20

PROFINET System Redundancy (OPTEA) 22

2.4

Grounding 32

3

Commissioning 34

3.1

Before Commissioning 34

3.1.1

Installing VACON® PC Tools 34

3.1.2

Downloading Fieldbus Option Firmware 34

3.1.3

Downloading Function Blocks for PLC 34

BC346130105092EN-US-000101/DPD01583 | 3Danfoss A/S © 2020.06

Page 4

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

3.2

Commissioning with VACON® PC tools 35

3.2.1

Updating Fieldbus Firmware with VACON® Loader 35

3.2.2

Updating Firmware over Ethernet with VACON® Loader 36

3.2.3

Conguring with VACON® NCIPCong 39

3.2.4

Setting the Drive Parameters 40

3.2.4.1

3.2.4.2

3.3

OPTCx Emulation Mode (OPTEA) 43

4

Control Interface and Communication 46

4.1

Ethernet Communication Overview 46

4.2

Fieldbus Option Board Communication Modes 46

4.2.1

Requirements for Communication Modes 46

4.2.2

Fieldbus Communication Mode Features and Limitations 47

4.2.3

Normal Fieldbus Communication 47

Setting the Drive Parameters with VACON® NCDrive 40

Setting the Drive Parameters with VACON® Live 42

Contents

4.2.4

Fast Fieldbus Communication 48

4.2.5

Fast Safety Fieldbus Communication 49

4.2.6

Normal Extended Mode 49

4.3

Drive Control with Modbus TCP/UDP 49

4.3.1

Modbus Communication Overview 49

4.3.2

Quick Setup for Modbus Connection 49

4.3.3

Data Addresses and Modbus Memory Map 49

4.3.4

Coil Registers 50

4.3.5

Resettable Trip Counters 50

4.3.6

Input Discrete Registers 51

4.3.7

Input Registers 51

4.3.8

Holding Registers 51

4.3.8.1

4.3.8.2

4.3.8.3

4.3.8.4

VACON® Application IDs 52

FB Process Data In 52

FB Process Data Out 54

ID Map 55

4.3.8.5

4.3.8.6

4.3.8.7

4.3.8.8

4.3.8.9

4.3.8.10

4.3.8.11

Operation Day Counter 56

Resettable Operation Day Counter 57

Energy Counter 57

Resettable Energy Counter 58

Fault History 59

Fault History with 16-bit Error Codes 59

Reset Fault History 59

BC346130105092EN-US-000101/DPD015834 | Danfoss A/S © 2020.06

Page 5

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

4.4

Contents

4.3.8.12

4.3.9

Connection Timeout in Modbus Communication 60

4.3.10

Example Messages 61

4.3.10.1

4.3.10.2

4.3.10.3

Drive Control with PROFINET 63

4.4.1

PROFINET Communication Overview 63

4.4.2

Quick Setup for PROFINET Connection 64

4.4.3

PROFIdrive 4.1 Prole Overview 64

4.4.4

PROFIdrive 4.1 State Machine 64

4.4.5

Telegram Types 66

4.4.5.1

4.4.5.2

Reset Fault with Time Stamps 59

Write Process Data 61

Read Process Data 62

Exception Response 63

Standard Telegram 1 and Variants 67

VACON®-specic Telegram 1 and Variants 68

4.4.5.3

4.4.5.4

4.4.5.5

4.4.5.6

4.4.5.7

4.4.6

Telegram Building Blocks 74

4.4.6.1

4.4.6.2

4.4.6.3

4.4.6.4

4.4.7

PROFIdrive Signal Numbers 77

4.4.8

User-specic Record Data 80

4.4.9

Connection Timeout in PROFINET 80

4.4.10

Examples with Siemens Controller 81

4.4.10.1

4.4.10.2

VACON®-specic Telegram 2 and Variants 69

VACON®-specic Telegram 3 and Variants 70

VACON®-specic Telegram 4 and Variants 71

VACON®-specic Telegram 5 and Variants 72

VACON®-specic Telegram Vendor PPO and Variants 72

PROFIdrive 4.1 Control Word (STW1) 74

PROFIdrive 4.1 Status Word (ZSW1) 75

Setpoint Value 76

Actual Speed Value 77

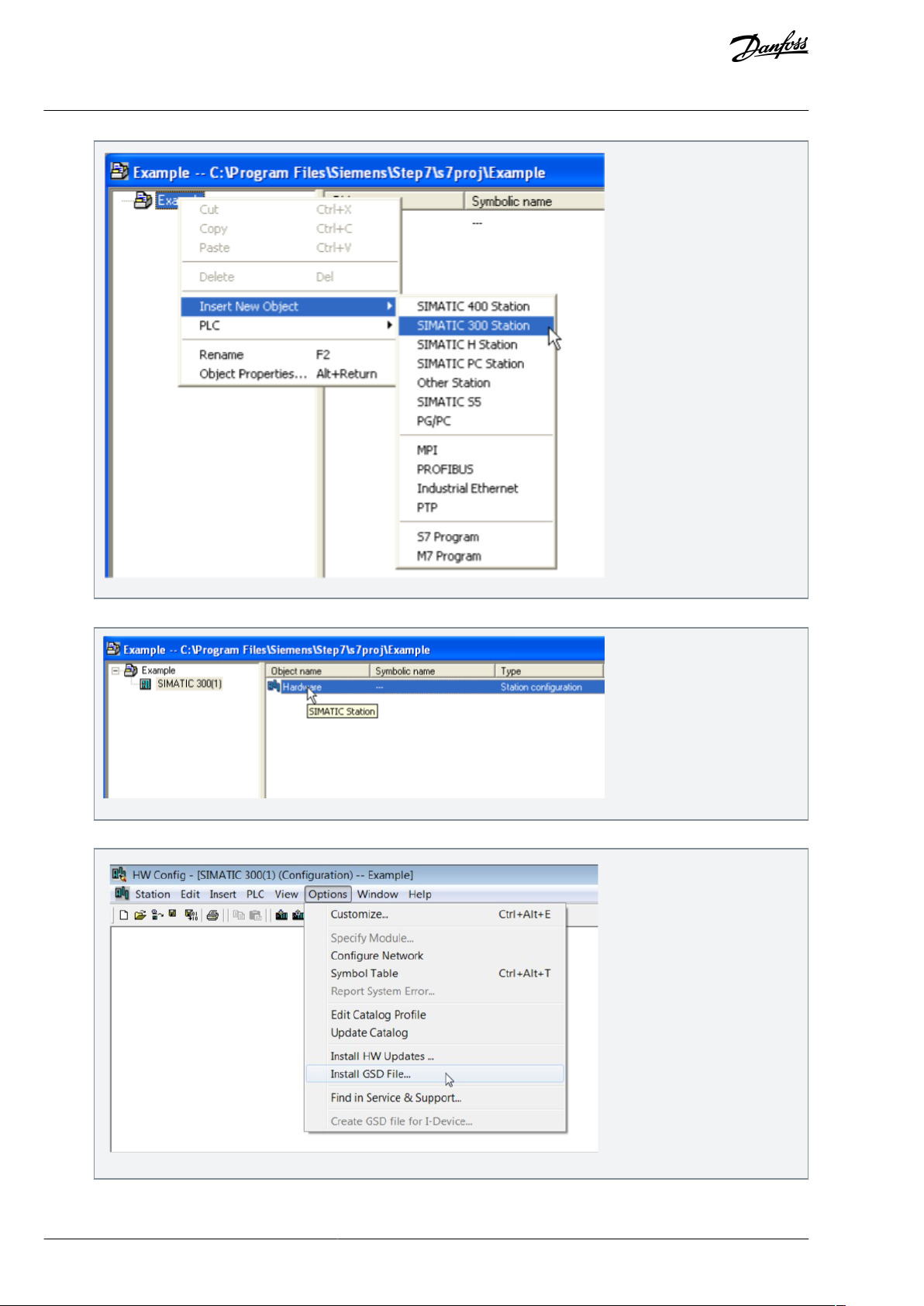

Conguring with Step 7 81

Conguring with TIA Portal 90

4.4.10.3

4.5

PROFIsafe (OPTEA) 102

4.5.1

Introduction to PROFIsafe 102

4.5.2

PROFIdrive on PROFIsafe 103

4.6

Drive Control with EtherNet/IP 103

4.6.1

EtherNet/IP Communication Overview 103

4.6.2

Quick Setup for EtherNet/IP Connection 104

4.6.3

AC/DC Drive Prole 105

Conguring with SIMATIC PDM 97

BC346130105092EN-US-000101/DPD01583 | 5Danfoss A/S © 2020.06

Page 6

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

4.6.4

EDS File 105

4.6.5

CIP Objects 105

4.6.5.1

4.6.5.2

4.6.5.3

4.6.5.4

4.6.5.5

4.6.5.6

4.6.5.7

4.6.5.8

4.6.5.9

4.6.6

Vendor-specic Objects 126

4.6.6.1

4.6.6.2

Identity Object, Class 0x01 105

Message Router Object, Class 0x02 108

Connection Manager Object, Class 0x06 109

TCP/IP Interface Object, Class 0xF5 110

Ethernet Link Object, Class 0xF6 115

Assembly Object, Class 0x04 118

Motor Data Object, Class 0x28 119

Control Supervisor Object, Class 0x29 120

AC/DC Drive Object, Class 0x2A 123

Vendor Parameters Object, Class 0xA0 126

Assembly Instance Selector Object, Class 0xBE 127

Contents

4.6.6.3

4.6.6.4

4.6.7

Supported Assembly Instances Overview 132

4.6.8

CIP I/O Assembly Instances for AC/DC Drive 133

4.6.8.1

4.6.8.2

4.6.9

Vendor-specic I/O Assembly Instances 137

4.6.9.1

4.6.9.2

4.6.10

Mapping of Standard Output Assemblies onto VACON® Data 149

4.6.11

Mapping of VACON® Data onto Standard Input Assemblies 150

4.6.12

Special Assembly Instances 150

4.6.13

Connection Timeout in EtherNet/IP Communication 150

4.7

VACON® Process Data Description 151

4.7.1

Control Word Overview 151

4.7.2

Status Word Overview 155

Motor Control Mode Object, Class 0xA1 129

Fault History Object, class 0xA2 131

CIP Output Instances 135

CIP Input Instances 136

Vendor Output Instances 137

Vendor Input Instances 143

4.7.3

Control and Status Word Monitoring Values 158

4.7.4

Speed Reference and Actual Speed 159

4.7.5

Process Data 159

4.7.6

Fieldbus Process Data 159

4.8

Time Synchronization 162

4.8.1

System Time Update with ID 2551 162

4.8.2

Simple Network Time Protocol (SNTP) 162

BC346130105092EN-US-000101/DPD015836 | Danfoss A/S © 2020.06

Page 7

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

5

Parameter Access 163

Parameter Access with PROFINET 163

5.1

5.1.1

Parameter Access Sequence 163

Parameter Requests 163

5.1.2

5.1.2.1

5.1.2.2

5.1.2.3

5.1.3

Parameter Responses 165

5.1.3.1

5.1.3.2

5.1.3.3

5.1.3.4

5.1.3.5

5.1.3.6

Request Header 164

Parameter Address 164

Parameter Value 165

Error Response 166

PROFIdrive 4.1 Error Classes and Codes 166

PROFIdrive Parameter Access Errors 167

Response Header 169

Parameter Values 169

Parameter Description Elements 169

Contents

Drive Parameter Access Using Application ID 170

5.1.4

5.1.5

PROFINET Parameters 170

5.1.5.1

5.1.5.2

5.1.5.3

5.1.6

Parameter Channel Examples 173

5.1.6.1

5.1.6.2

5.1.6.3

5.1.6.4

5.1.6.5

5.1.6.6

5.2

Parameter Access with EtherNet/IP 179

5.2.1

Explicit Messaging 179

5.2.2

List of Data Types 179

5.2.3

General CIP Error Codes 180

PROFIdrive Parameters 170

Vendor-specic PROFIdrive Parameters 171

Safety Parameters 173

Request First Element of PNU964 Value 174

Request All Elements of Parameter PNU964 175

Request the Value of Parameter ID 103 176

Change the Value of Drive Parameter ID 103 (Successful) 176

Change the Value of Drive Parameter ID 103 (Unsuccessful) 177

Change the Values of Multiple Drive Parameters (ID 103 and ID 104) 178

5.2.4

Connection Manager Object Error Codes 181

5.2.5

Supported CIP and Vendor Objects 182

6

Parameters 184

6.1

Option Board Parameters 184

6.1.1

Comm. Protocol 186

6.1.2

Comm. Timeout 186

6.1.3

Mode/Emulation 187

BC346130105092EN-US-000101/DPD01583 | 7Danfoss A/S © 2020.06

Page 8

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

6.2

Contents

6.1.4

IP Address Mode 187

6.1.5

Speed and Duplex 188

6.1.6

IP Port Filtering 188

6.1.7

EIP Output Instance 189

6.1.8

EIP Input Instance 189

6.1.9

EIP Product Code Oset 189

6.1.10

Modbus Unit Identier 189

6.1.11

PNIO Name of Station 190

6.1.12

SNTP Mode 190

6.1.13

SNTP IP Address 190

6.1.14

SNTP Port 190

6.1.15

Time Interval 190

6.1.16

Time Oset 190

AC Drive Parameters 191

6.2.1

AC Drive Parameters for Fieldbus Control and Reference Selection 191

6.2.2

Protocol-related ID Reading and Writing 191

6.2.3

Fieldbus Parameters for VACON® 100 Family Standard Application 191

6.2.4

Fieldbus Parameters for VACON® 20 Standard Application 192

6.2.5

Fieldbus Parameters for VACON® 20 X Multipurpose Application 192

6.2.6

Fieldbus Parameters for VACON® NXP Multipurpose Application 192

6.2.7

Torque Control Parameterization 193

6.3

VACON® NXP System Software Parameters for Application Developers 193

6.3.1

System Software Variables for Selecting Communication Modes 194

6.3.2

System Software Variables for Monitoring Supported Communication Modes 194

6.3.3

System Software Variables for Selecting the Input Process Data Slot 194

7

Monitoring Values 195

7.1

Option Board Monitoring Values 195

7.1.1

MAC Address 197

7.1.2

Media Redundancy 197

7.1.3

System Redundancy (OPTEA) 198

7.1.4

SNTP Status 198

7.1.5

SNTP Server IP 198

7.1.6

Last Update Time 198

7.2

Monitoring Values of Control and Status Words 198

8

Fault Tracing 200

8.1

LED Indications on VACON® OPTEA/OPTE9 Option Boards 200

8.2

LED Indications with EtherNet/IP 201

BC346130105092EN-US-000101/DPD015838 | Danfoss A/S © 2020.06

Page 9

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

8.3

8.4

8.5

8.6

8.7

8.8

Contents

PROFINET Alarm System 203

Fault Handling 205

Gathering Diagnostic Data 205

Typical Fault Conditions 205

Other Fault Conditions 206

Fieldbus Fault Codes 207

BC346130105092EN-US-000101/DPD01583 | 9Danfoss A/S © 2020.06

Page 10

•

•

•

•

•

•

•••••

•

NOTE! Download the English and French product manuals with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'ensemble des informations de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

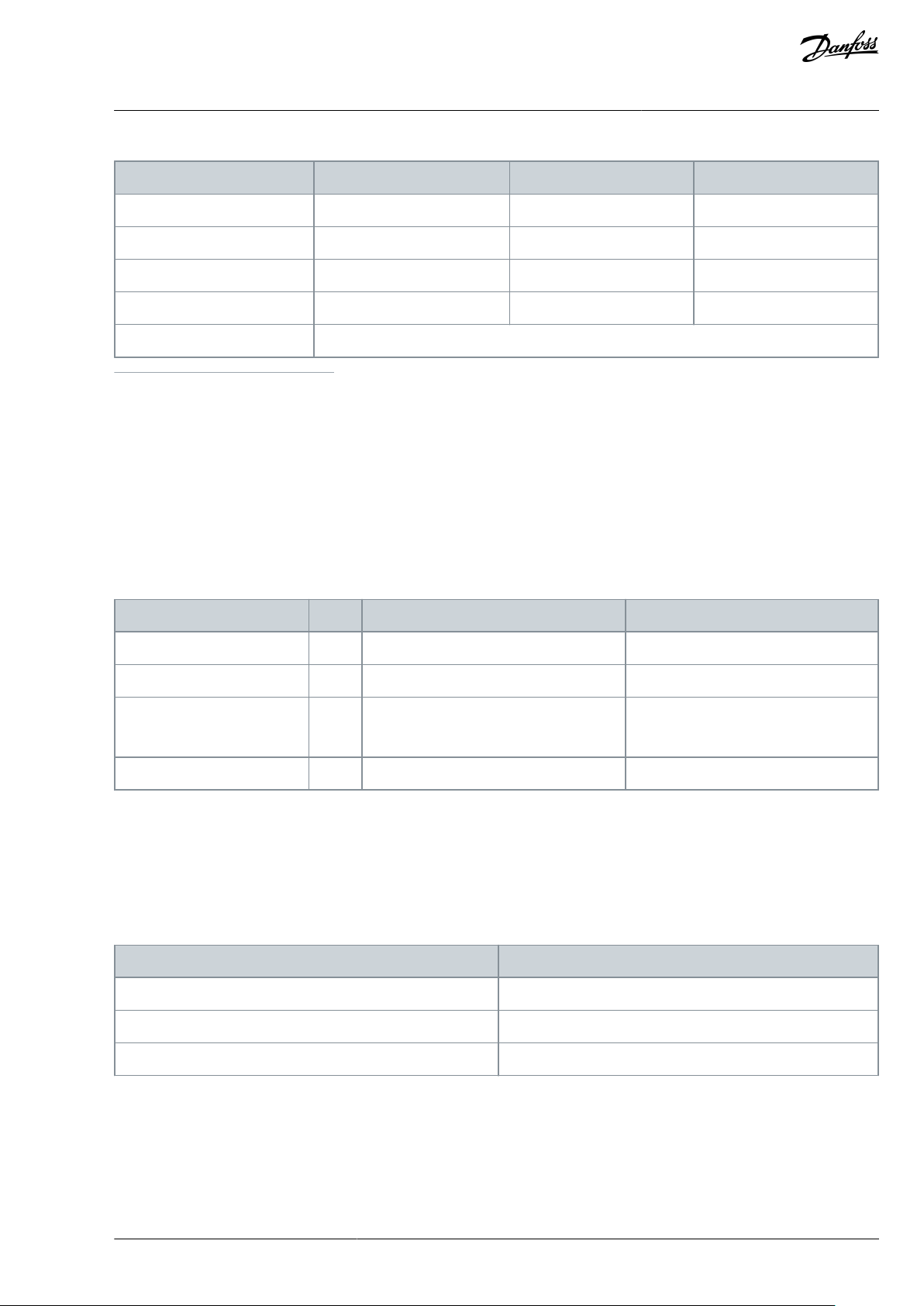

Manual version

New features

Firmware

version

DPD01583C (for

OPTE9)

EtherNet/IP protocol

Ethernet ring support (RSTP)

Address Conict Detection (ACD)

V004

(OPTE9)

DPD01583D (for

OPTE9)

Media Redundancy Protocol (MRP)

Simple Network Management Protocol (SNMP)

LLDP-MIB, LLDP-EXT-DOT3-MIB, LLDP-EXT-PNO-MIB

EDD les SIMATIC PDM

V006

(OPTE9)

DPD01583E (for

OPTE9)

Fast communication modes in VACON® NXP

PROFINET Alarms.

V007

(OPTE9)

DPD01583F (for

OPTE9)

Simple Network Time Protocol (SNTP).

Fast MRP support veried

V008

(OPTE9)

Device Level Ring (DLR)

V009

(OPTE9)

DPD01583G (for

OPTEA/OPTE9)

PROFINET + PROFIsafe for VACON® NXP

V001 (OPTEA)

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

1 Introduction

1.1 Purpose of the Manual

The EtherNet/IP user guide provides information about conguring the system, controlling the drive, accessing parameters, programming, troubleshooting, and some typical application examples.

The user guide is intended for use by qualied personnel, who are familiar with the VACON® drives, EtherNet/IP technology, and

with the PC or PLC that is used as a master in the system.

Read the instructions before commissioning and programming and follow the procedures in this manual.

1.2 Additional Resources

Resources available for the drive and optional equipment are:

•

VACON® Ethernet Installation Guide provides the necessary information to install the option board to the AC drive.

•

The Operating Guide of the AC drive provides the necessary information to get the drive up and running.

•

The Application Guide of the AC drive provides more details on working with parameters and many application examples.

Supplementary publications and manuals are available from drives.danfoss.com/knowledge-center/technical-documentation/.

For US and Canadian markets:

1.3 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Manual and Software Version

BC346130105092EN-US-000101 / DPD0158310 | Danfoss A/S © | 2020.06

Page 11

•

•

•

•

•

Manual version

New features

Firmware

version

Support for all features supported by OPTE9 board including EtherNet/IP and Modbus

TCP/UDP protocols

Improved emulation mode with OPTCP, OPTCQ, and OPTCI boards when installed to VACON® NXP

PROFINET System Redundancy "S2"

V002 (OPTEA)

DPD01583H (for

OPTEA/OPTE9)

The structure of the manual updated. Installation information removed (see VACON

®

Ethernet Installation Guide).

Support for 32-bit process data items with VACON® 100 family AC drives.

V003 (OPTEA)

Shared Device

V005 (OPTEA)

089

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

1.4 Type Approvals and Certications

The following list is a selection of possible type approvals and certications for Danfoss drives:

Introduction

N O T I C E

The specic approvals and certication for the drive are on the nameplate of the drive. For more information, contact the local

Danfoss oce or partner.

1.5 Trademarks

EtherNet/IP© is a trademark of ODVA, Inc.

License for LWIP

Copyright (c) 2001, 2002 Swedish Institute of Computer Science.

All rights reserved.

BC346130105092EN-US-000101 / DPD01583 | 11Danfoss A/S © 2020.06

Page 12

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Redistribution and use in source and binary forms, with or without modication, are permitted provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in

the documentation and/or other materials provided with the distribution.

3. The name of the author may not be used to endorse or promote products derived from this software without specic prior written permission.

THIS SOFTWARE IS PROVIDED BY THE AUTHOR “AS IS” AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED

TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT

SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

(INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE

Introduction

1.6 Product Overview

1.6.1 Ethernet Networks with VACON® AC drives

The VACON® AC drives can be connected to the Ethernet networks using the VACON® OPTEA Advanced Dual Port Ethernet eldbus

option board (OPTEA), or the VACON® OPTE9 Dual Port Ethernet eldbus option board (OPTE9).

OPTEA supports all the features described in this manual. Features that are not supported by OPTE9, are marked with extra (OPTEA)

on the title.

The option boards support PROFINET I/O, EtherNet/IP, Modbus TCP, and Modbus UDP eldbus protocols. In addition, the Advanced

Dual Port Ethernet board (OPTEA) supports PROFINET I/O with PROFIsafe when the OPTBL/OPTBM/OPTBN option board is also installed. OPTEA also supports advanced features such as PROFINET System Redundancy "S2".

OPTEA can be used alone as PROFINET I/O device. However, PROFIsafe always requires OPTBL/OPTBM/OPTBN option board and VACON® NXP control, too.

The drives can be daisy chained by utilizing two Ethernet ports. The following network topologies are supported. See details in

Ethernet Board Installation Guide.

•

Star

•

Daisy chain

•

Ring

Every appliance connected to an Ethernet network has two identiers: a MAC address and an IP address. The MAC address (Address

format: xx:xx:xx:xx:xx:xx) is unique for each appliance and cannot be changed. The MAC address of the Ethernet board can be found

on the sticker attached to the board.

In a local network, the user can dene the IP addresses as long as all the units connected to the network are given the same network

portion of the address. Overlapping IP addresses cause conicts between appliances. For more information about setting IP addresses, see 3.2.3 Conguring with VACON® NCIPCong, 3.2.4.1 Setting the Drive Parameters with VACON® NCDrive, or 3.2.4.2 Set-

ting the Drive Parameters with VACON® Live.

1.6.2 Fieldbus Protocols

1.6.2.1 Modbus TCP/Modbus UDP

Modbus is a communication protocol developed by Modicon systems. In simple terms, it is a way of sending information between

electronic devices. The device requesting the information is called the Modbus Master (or the Client in Modbus TCP/UDP) and the

devices supplying information are Modbus Slaves (in Modbus TCP/UDP servers).

In a standard Modbus network, there is one Master and up to 247 Slaves, each with a unique Slave Address from 1 to 247. The

Master can also write information to the Slaves. Modbus is typically used to transmit signals from instrumentation and control devices back to the main controller or data gathering system.

The Modbus communication interface is built around messages. The format of these Modbus messages is independent of the type

of physical interface used.

The same protocol can be used regardless of the connection type. Because of it, Modbus gives the possibility to upgrade easily the

hardware structure of an industrial network, without the need for large changes in the software. A device can also communicate

with several Modbus nodes at once, even if they are connected with dierent interface types. There is no need to use a dierent

protocol for every connection.

BC346130105092EN-US-000101 / DPD0158312 | Danfoss A/S © | 2020.06

Page 13

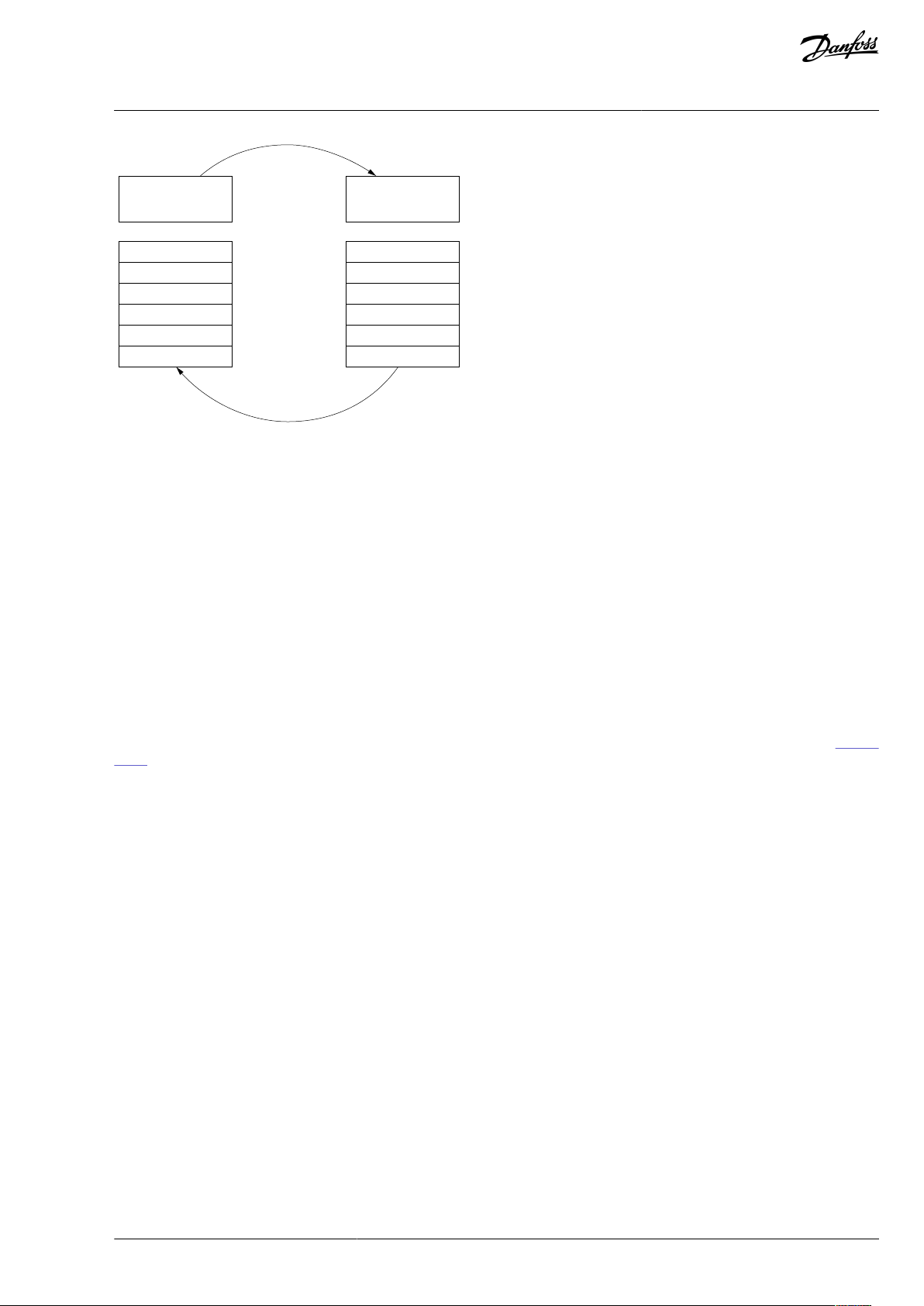

Master´s

message

Slave response

Start

Address

Function

Data

CRC

End

Start

Address

Function

Data

CRC

End

e30bh904.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Illustration 1: Basic Structure of Modbus Frame

Introduction

On simple interfaces like RS485, the Modbus messages are sent in plain form over the network. In this case, the network is dedicated

to Modbus. When using more versatile network systems like TCP/IP over Ethernet, the Modbus messages are embedded in packets

with the format necessary for the physical interface. In that case Modbus and other types of connections can co-exist at the same

physical interface at the same time. Although the main Modbus message structure is peer-to-peer, Modbus is able to function on

both point-to-point and multidrop networks.

Each Modbus message has the same structure. Four basic elements are present in each message. The sequence of these elements is

the same for all messages, to make it easy to parse the content of the Modbus message. In the Modbus network, the master always

starts the conversation. A Modbus master sends a message and depending on the contents of the message, a slave reacts to it.

There can be more than one master in a Modbus network. Addressing in the message header is used to dene which device must

respond to a message. If the address eld does not match their own address, all other nodes on the Modbus network ignore the

message.

Modbus UDP vs TCP

In addition to TCP, the option boards also support UDP (from OPTE9 rmware version V006). We recommend using UDP when reading and writing rapidly and repetitively (cyclically) same data as with process data. Use TCP for single operations, like service data

(for example, reading or writing parameter values).

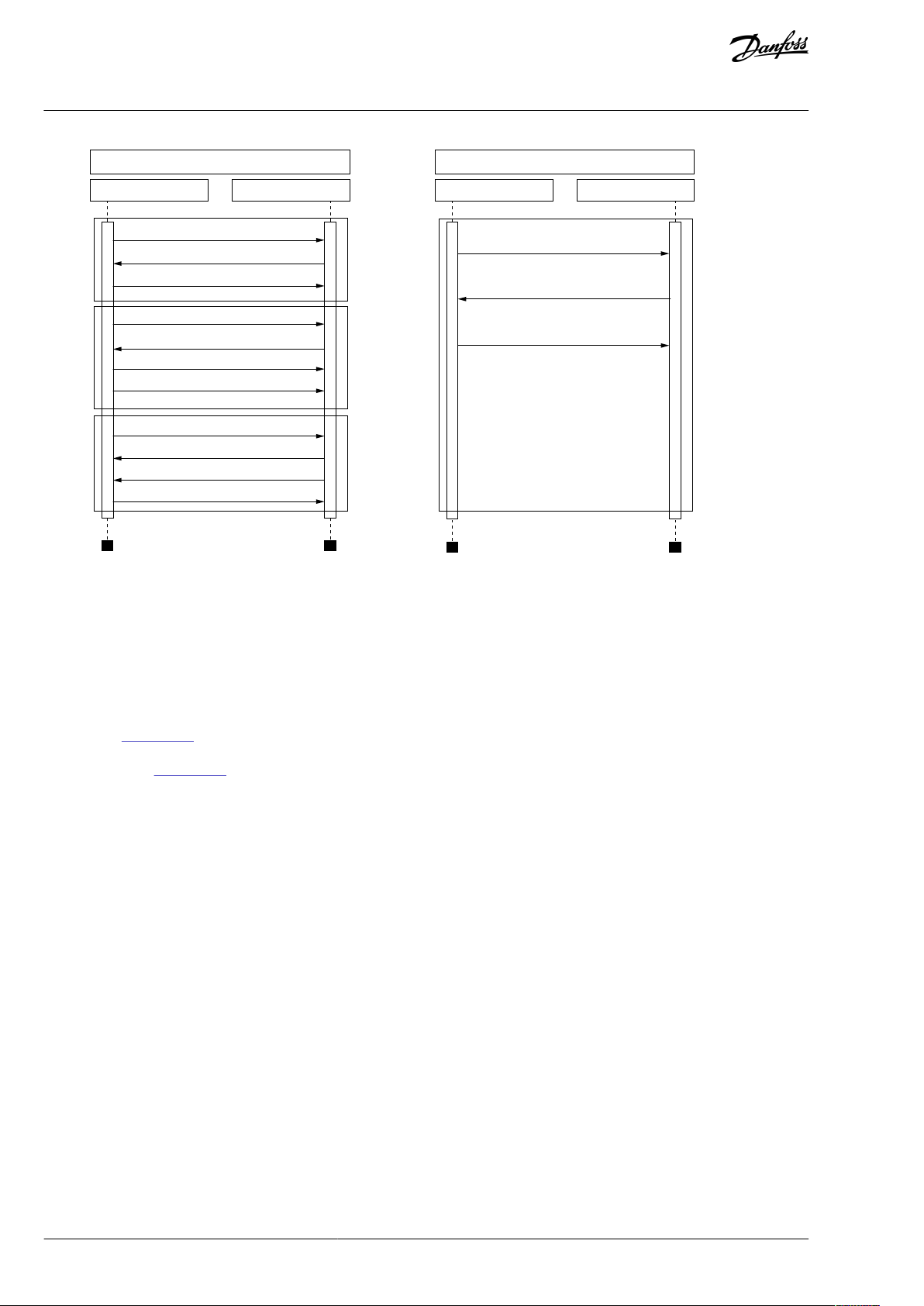

The main dierence between UDP and TCP is that when using TCP, the receiver must acknowledge every Modbus frame (see Illustra-

tion 2). It adds extra trac to the network and more load to the system (PLC and drives) because software must follow sent frames

to make sure that they have reached their destination.

BC346130105092EN-US-000101 / DPD01583 | 13Danfoss A/S © 2020.06

Page 14

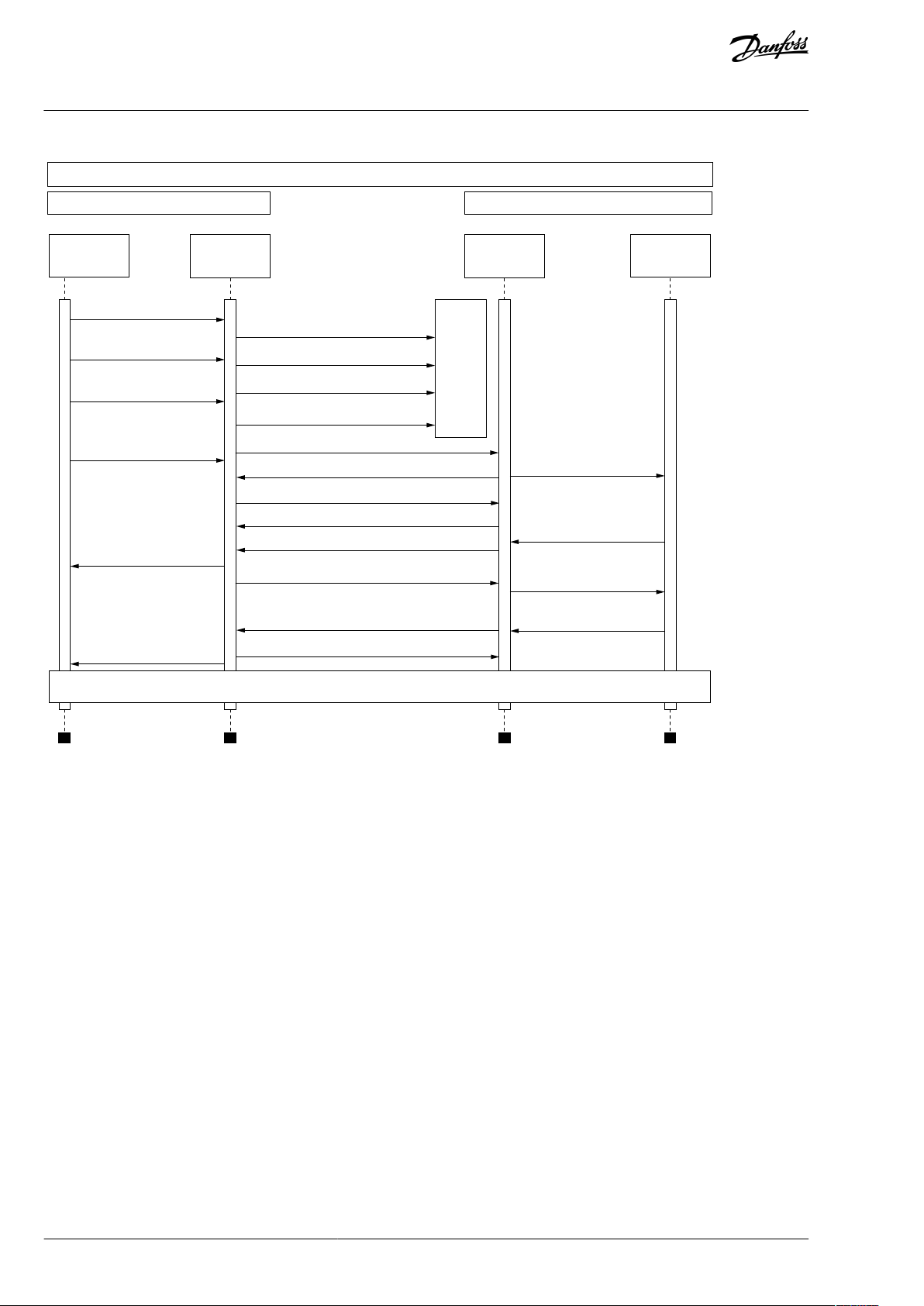

Modbus TCP Communication

PLC

Open

Connection

Communicate

Communicate

Close

Connection

Drive

TCP, SYN

TCP, SYN, ACK

TCP, ACK

Modbus Query

Modbus Query

Modbus Response, TCP, ACK

TCP, ACK

TCP, ACK

TCP, ACK

TCP, ACK

TCP, FIN, ACK

Modbus UDP Communication

PLC Drive

Modbus Query

Modbus Response

Modbus Query

e30bh930.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

Illustration 2: Modbus TCP and UDP Communication Comparison

Another dierence between TCP and UDP is that UDP is connectionless. TCP connections are always opened with TCP SYN messages and closed with TCP FIN or TCP RST. With UDP, the rst packet is already a Modbus query. The option board treats IP address and

port combination as a connection. If port changes, it is considered as a new connection or as a second connection if both stay active.

When using UDP, it is not guaranteed that the sent frame reaches is destination. PLC must follow the Modbus requests by using the

Modbus transaction id-eld. It actually must do it also when using TCP. If PLC does not receive response in time from drive in UDP

connection, it must send the query again. When using TCP, the TCP/IP stack keeps resending the request until receiver has acknowledged it (see Illustration 3). If PLC sends new queries during this time, some of them can not be sent to network (by TCP/IP stack)

until previous sent package(s) has been acknowledged. It can cause small packet storms when the connection is resumed between

PLC and drive (See Illustration 4).

BC346130105092EN-US-000101 / DPD0158314 | Danfoss A/S © | 2020.06

Page 15

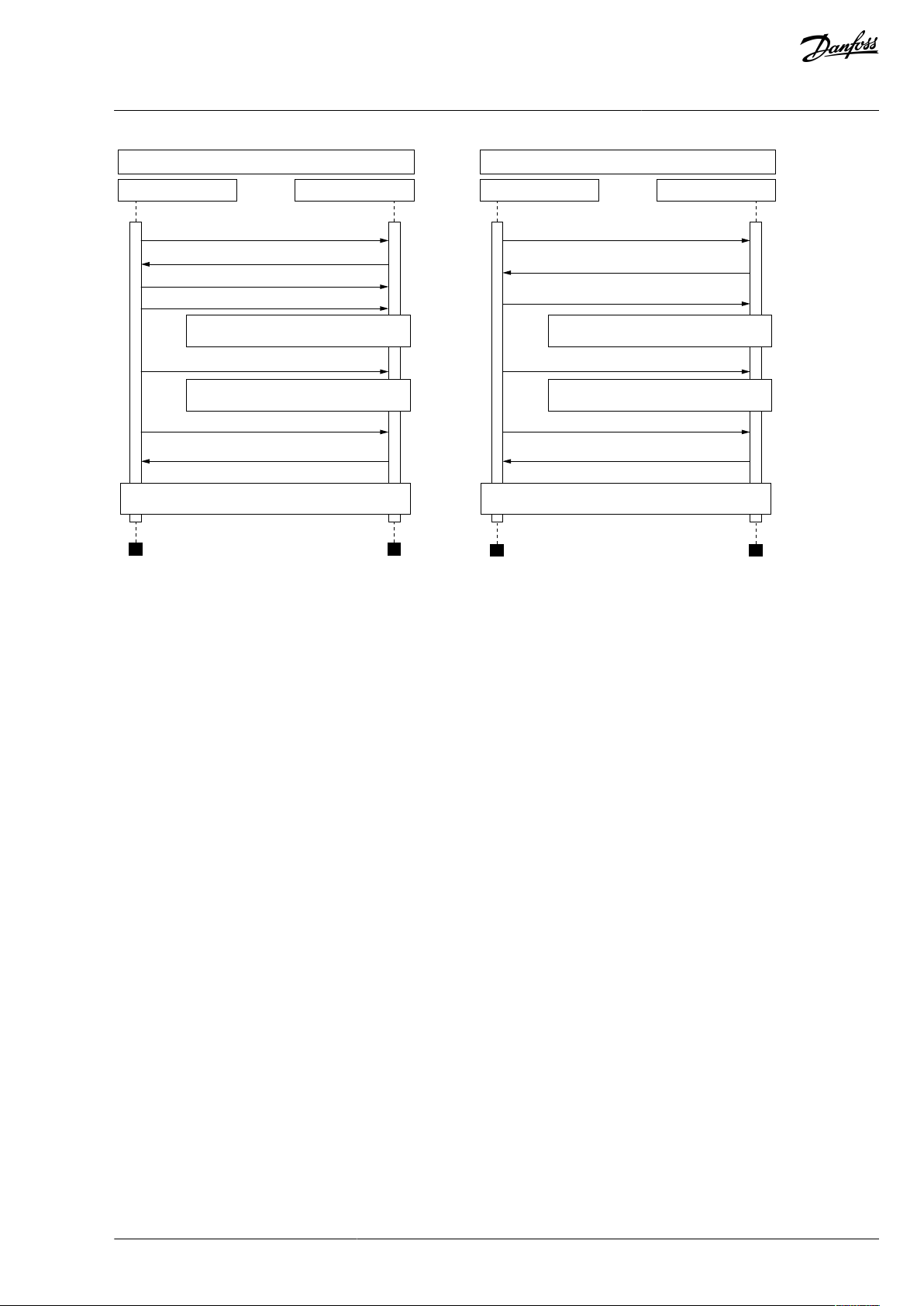

Modbus TCP Communication

PLC Drive

Modbus Query (1)

Modbus Query (2)

Modbus Response (1), TCP, ACK

Modbus Response (2), TCP, ACK

TCP, ACK

TCP retransmission, Modbus Query (2)

TCP retransmission, Modbus Query (2)

Normal communication continues

Packet lost, no response

Packet lost, no response

Modbus Query (1)

Modbus Response (1)

Modbus Response (4)

Modbus Query (2)

Modbus Query (3)

Modbus Query (4)

Packet lost, no response

Packet lost, no response

Normal communication continues

Modbus UDP Communication

PLC Drive

e30bh931.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

Illustration 3: Modbus TCP and UDP Communication Errors Comparison

BC346130105092EN-US-000101 / DPD01583 | 15Danfoss A/S © 2020.06

Page 16

e30bh932.10

Modbus TCP Communication

PLC Drive

Modbus Modbus

TCP

stack

TCP

stack

Modbus Query (1)

Modbus Query (2)

Modbus Query (3)

Modbus Query (4)

Modbus Query

(1,2,3)

Modbus Query (4)

Modbus Response (1,2,3)

Modbus Response (4)

TCP Modbus Query

TCP, ACK

TCP, ACK

TCP, ACK

TCP, ACK

TCP, Modbus Response (1,2,3)

TCP, Modbus Response (4)

TCP, Modbus Query (4)

Retransmission

Modbus Query (1,2,3)

Retransmission Modbus Query (1,2,3)

Retransmission

Modbus Query (1,2)

Retransmission

Modbus Query (1)

Modbus

Response (1,2,3)

Modbus

Response (4)

Normal communication continues

Packet lost

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

Illustration 4: Modbus TCP Retransmissions

Losing one packet is not a fatal because the same request can be sent again after timeout. In TCP, the packages always reach their

destination but if network congestion causes retransmissions, those packages contain most likely old data or instructions when they

reach their destination.

1.6.2.2 PROFINET I/O

PROFINET is the Ethernet-based automation standard of PROFIBUS International for the implementation of an integrated and consistent automation solution based on Industrial Ethernet. PROFINET supports the integration of simple distributed eld devices and

time-critical applications in (switched) Ethernet communication. It also supports the integration of component-based distributed

automation systems for vertical and horizontal integration of networks.

The option boards implement the following features:

•

PROFINET I/O version 2.4

•

PROFINET RT

•

Conformance class B (PA)

•

Highest netload class (class III)

•

Standard diagnosis for VACON® AC drive faults and alarms

The Advanced Dual Port Ethernet option board (OPTEA) implements also

BC346130105092EN-US-000101 / DPD0158316 | Danfoss A/S © | 2020.06

Page 17

PLC

Managed switch with RSTP support

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

OPTE9-8

1 2

DP AP

3 4 5 6 7 8

Power

e30bh922.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

•

PROFINET system redundancy (S2)

•

PROFIsafe over PROFINET

•

OPTCP-emulation (OPTCx) mode when installed to VACON® NXP

•

Shared Device

Introduction

1.6.2.3 EtherNet/IP

The EtherNet/IP© is an industrial Ethernet network solution available for manufacturing automation. The CIP© (Common Industrial

Protocol) encompasses a comprehensive suite of messages and services for various manufacturing automation applications, including control, safety, synchronization, motion, conguration, and information. The CIP provides users with a unied communication

architecture throughout the manufacturing enterprise.

More information on the EtherNet/IP can be found at http://www.odva.org.

1.6.3 Redundancy Protocols

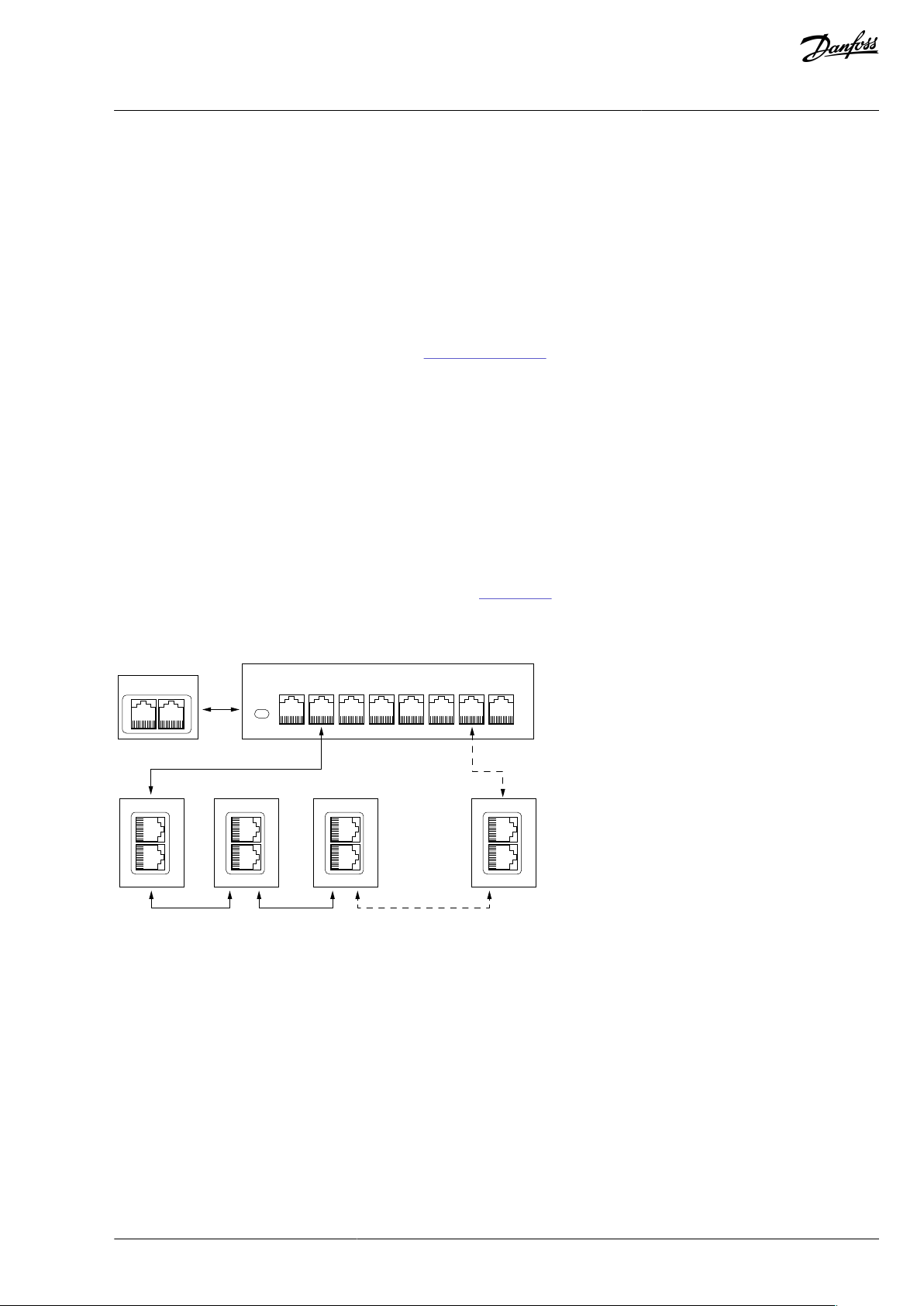

1.6.3.1 Rapid Spanning Tree Protocol (RSTP)

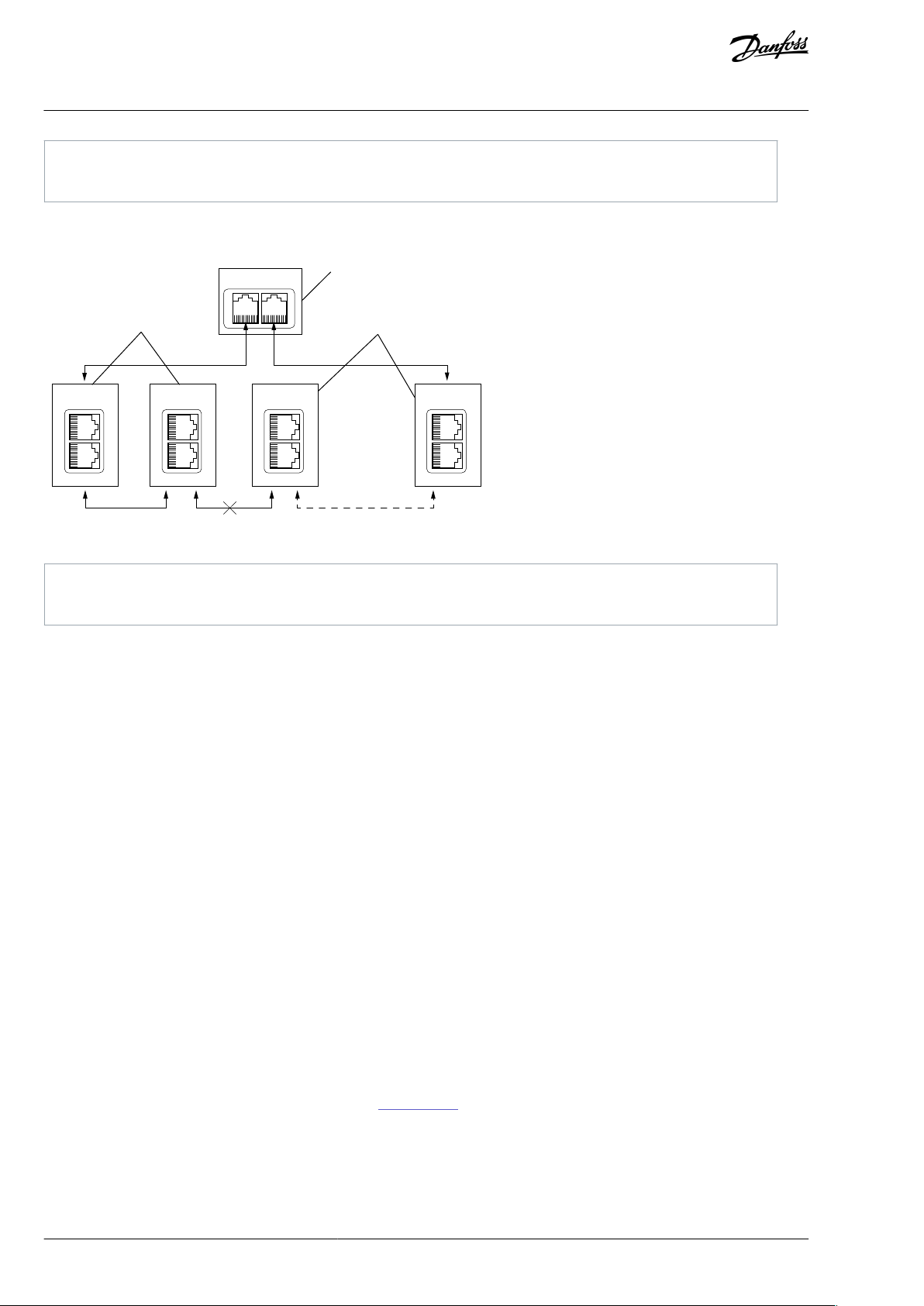

To use the RSTP protocol, add a managed Ethernet switch that supports the RSTP protocol. If a single link is broken, the RSTP switch

notices it and start sending data from the PLC to both directions eectively creating two daisy chains. When the link has been repaired, the switch notices it, too, and reverts to normal operating mode. Compared to the star topology, the ring topology adds

more network trac to almost all drives. Damage to two cables always creates an isolated subnetwork.

In the RSTP conguration, one of the ports in the switch is "Designated Port" (DP) and the other "Alternative Port" (AP). When the

network is functioning properly, the trac ows through the designated port. Only the BPDU (Bridge Protocol Data Unit) packets

are transferred through the AP port. The BPDU packets are used by the switch to determine if the network is working properly. If it

detects that the BPDU packets do not go through the ring, it changes the alternative port to a second designated port. Now the

switch sends packets to both directions in the broken ring (see Illustration 6).

Each designated port has a list of MAC addresses which are behind that port. Only frames directed to the device in the MAC list are

forwarded into that designated port. The broadcast and multicast frames are sent to all designated ports.

Illustration 5: Ring Topology

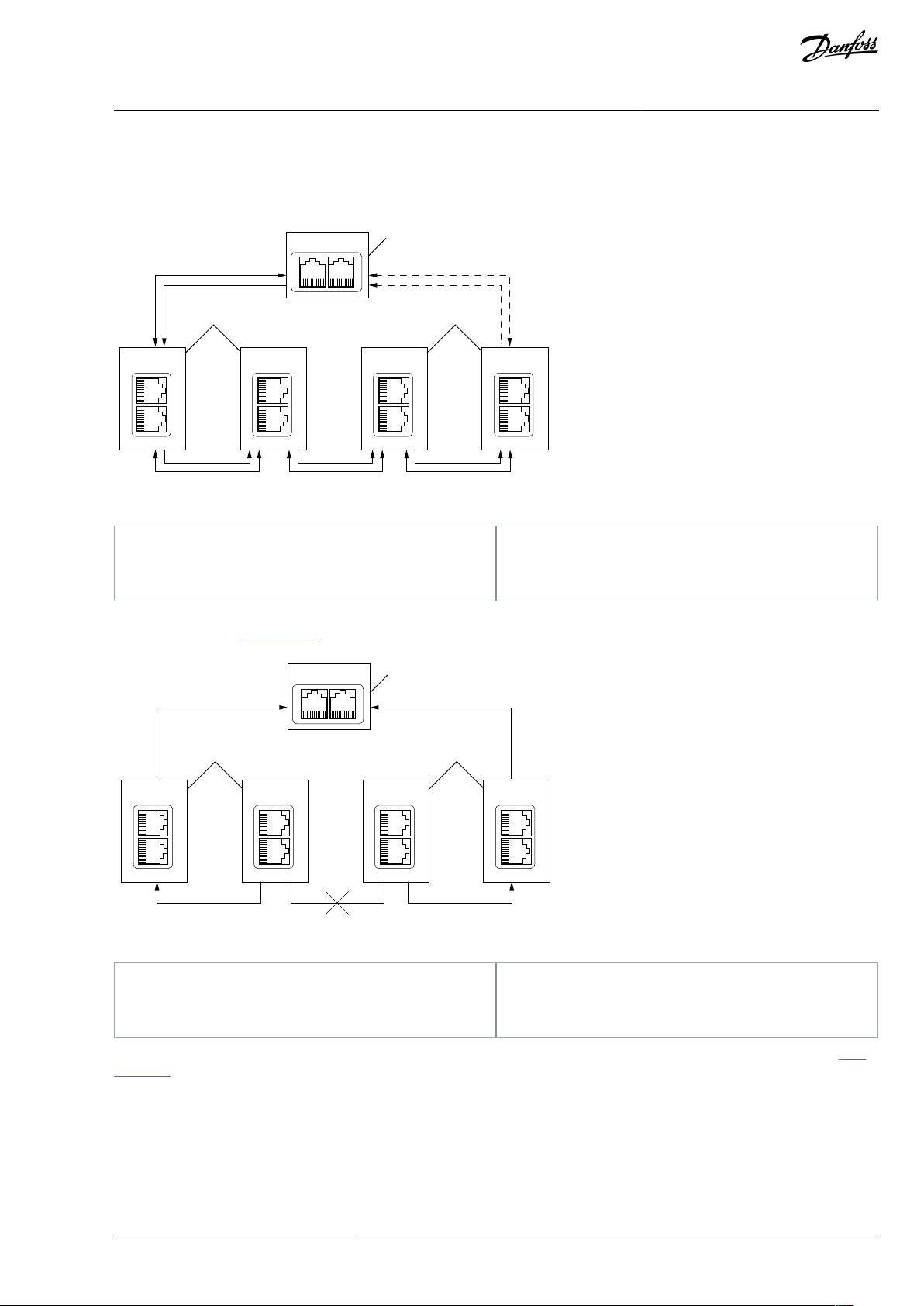

In the example below, the Ethernet communication is interrupted to device number 3 and other devices after that when the link is

broken. The Fieldbus communication maybe faulted when the link is broken, but when the switch enables the second designated

port, the connections can be reopened. In the RSTP protocol, it generally takes few seconds before the second designated port is

activated. The time depends on the BPDU exchange cycle, which is 2 seconds by default.

BC346130105092EN-US-000101 / DPD01583 | 17Danfoss A/S © 2020.06

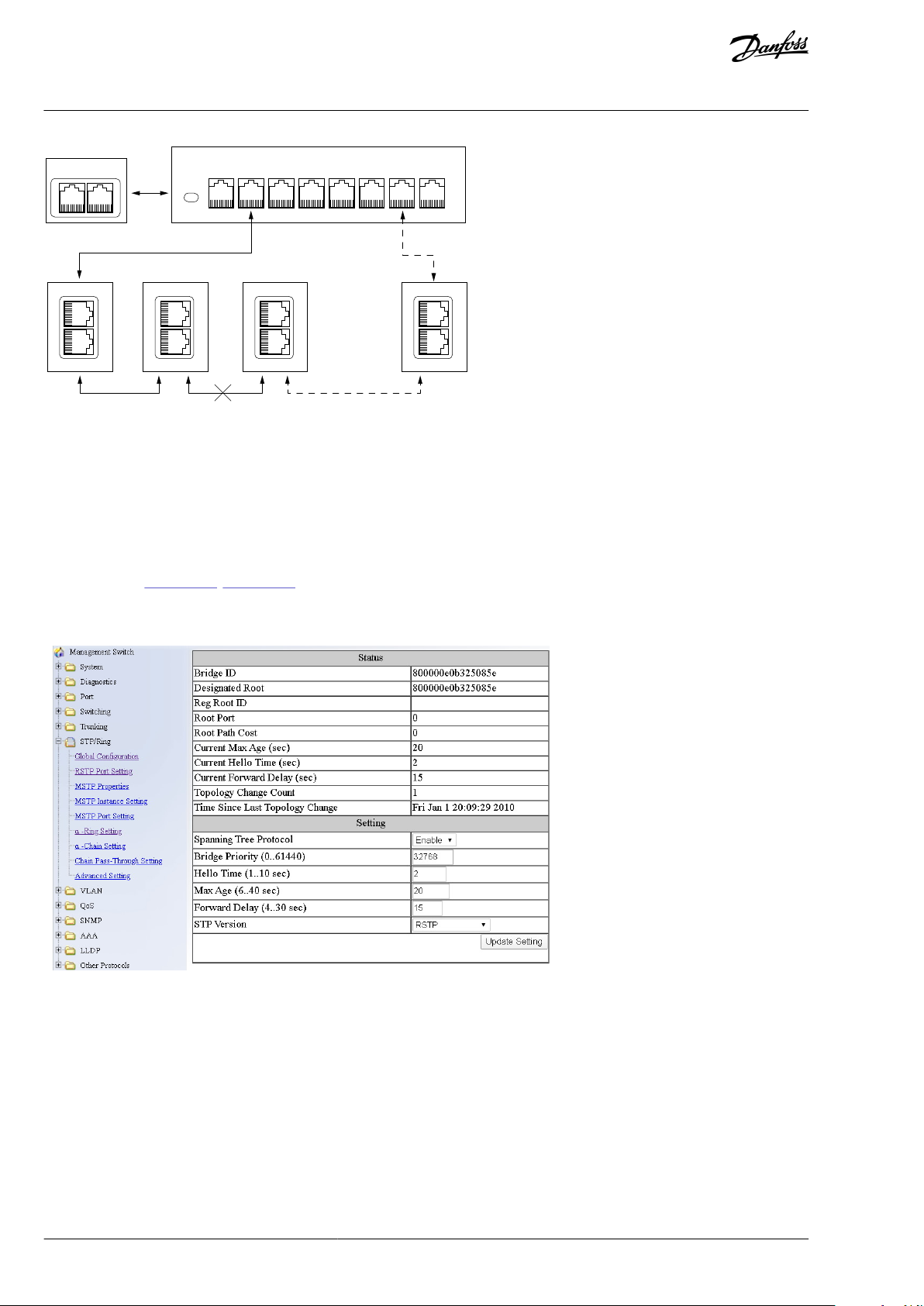

Page 18

PLC

Managed switch with RSTP support

DRIVE

OPTE9-1

DRIVE

...

OPTE9-2

DRIVE

OPTE9-3

DRIVE

OPTE9-8

1 2

DP DP

3 4 5 6 7 8

Power

e30bh923.10

e30bh924.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

Illustration 6: Ring Topology: Error in Network

NOTE! The switch itself in Ethernet boards does not implement the RSTP protocol, so the network always needs a third party switch

to support it.

NOTE! Do not use RSTP together with PROFIsafe. Recovery time in RSTP network can be several seconds, and recovery time in STP

network can be several tens of seconds. To compensate the recovery time, the PROFIsafe watchdog time must be set long enough

so that slow recovery time of RSTP network can be tolerated. However, for example, in Siemens TIA portal, the longest PROFIsafe

watchdog time setting is 1920 ms, and it is too short for RSTP.

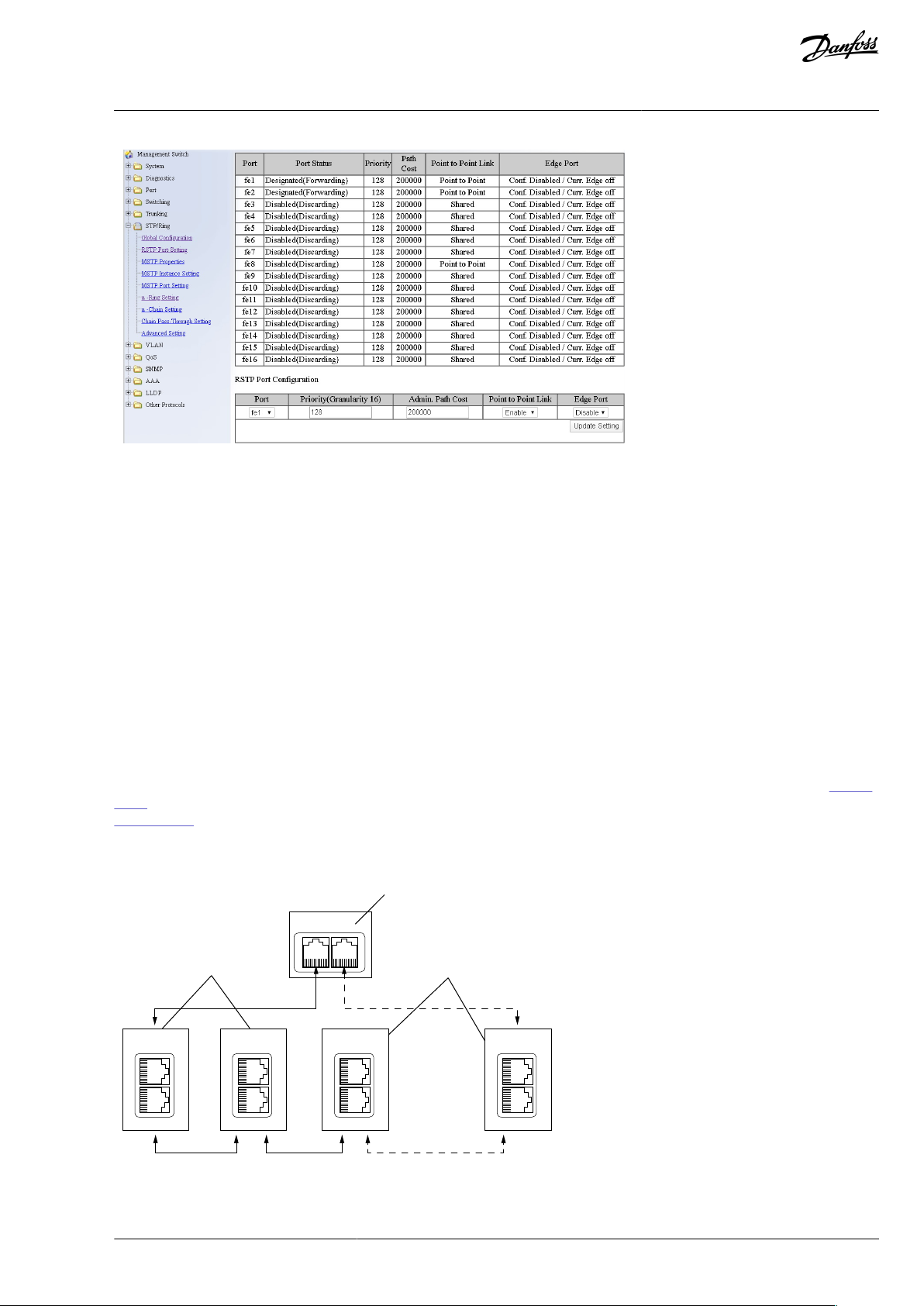

Conguration Example

The screenshots (

Illustration 7, Illustration 8) show one example of conguring the RSTP in the switch (in this case an EtherWAN

switch). Port two is the designated port and port one is the alternative port. The PLC was connected to port nine (the laptop taking

the screenshots was in port 16). When conguring your switch, refer to the manual of the switch manufacturer.

Illustration 7: EtherWAN Switch RSTP Conguration Example

BC346130105092EN-US-000101 / DPD0158318 | Danfoss A/S © | 2020.06

Page 19

e30bh925.10

OPTE9-1

...

OPTE9-2 OPTE9-3 OPTE9-8

1

2

2

e30bh927.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Illustration 8: EtherWAN Switch RSTP Conguration Example - Port Settings

Introduction

1.6.3.2 Media Redundancy Protocol (MRP)

The MRP is designed to react deterministically on a cable failure. It makes it suitable to be used in process automation. One of the

nodes in the network has the role of Media Redundancy Master (MRM), which observes and controls the ring topology to react to

network faults. Usually this device is PLC or network switch.

Other nodes in the network are called Media Redundancy Clients (MRC), and they react on received conguration frames from the

MRM and can detect link changes on its ring ports. OPTEA and OPTE9 boards support only MRC functionality.

The MRM and MRC have two ring ports, which take one of the following states:

•

DISABLED - All frames are dropped

•

BLOCKING - All frames are dropped, except the following frames:

-

MRP frames (for example, MRP_test and MRP_TopologyChange)

-

Frames specied to pass ports in "Discarding" state, for example, LLDP frames

•

FORWARDING - All frames are forwarded according to normal behavior

The MRM sends MRP_Test frames in a congured time period to monitor the state of the ring topology. If the MRM receives its own

MRP_Test frames (network is closed), one of the ring ports is set to FORWARDING state and the other to BLOCKED state (see Illustra-

tion 9). If the MRM does not receive the MRP_Test frames (network is open), it sets both of its ring ports to FORWARDING state (see

Illustration 10).

The following gure shows an example of an MRP network, where the PLC acts as an MRM. The dotted line shows Blocked connection.

Illustration 9: MRP Ring: Closed Network

BC346130105092EN-US-000101 / DPD01583 | 19Danfoss A/S © 2020.06

Page 20

1

PLC/MRM

2

Drive/MRC

OPTE9-1

...

OPTE9-2 OPTE9-3 OPTE9-8

e30bh928.10

1

2

2

1

PLC/MRM

2

Drive/MRC

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

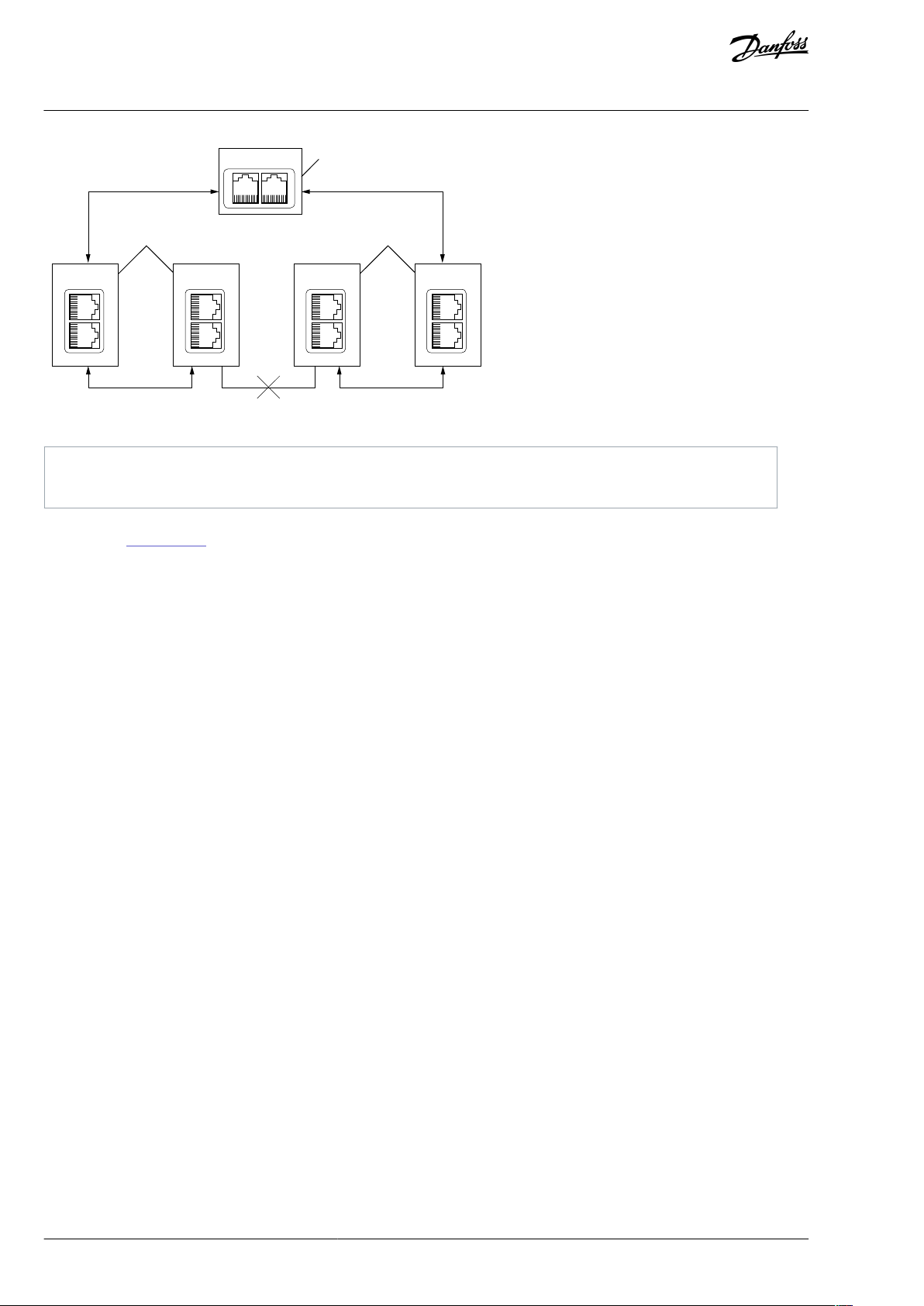

In the example below, the Ethernet communication is interrupted to device number 3 and other devices after that when the link is

broken.

Illustration 10: MRP Ring: Error in Network

NOTE! MRP (as MRC) can only be used when PROFINET is the selected protocol. MRP is available in all versions of OPTEA board and

in OPTE9 since V006 rmware.

MRP Recovery Times and Fast MRP

MRP can be congured to send test frames with dierent time periods, depending on the maximum allowed recovery time for the

network. These times are set as the guaranteed time for a network of 50 nodes to recover from a ring error.

Typically, in PROFINET systems the recovery time is dened as 200 ms. However, the MRP specication allows for recovery times of

500, 200, 30, and 10 ms. OPTEA and OPTE9 boards can be used in systems with the lowest recovery time of 10 ms. It is often called

“Fast MRP”.

When using MRP in a PROFINET network, the recommendation is to set the watchdog time of each device in the ring to the maximum recovery time, usually 200 ms. It guarantees that a cable failure does not interrupt the eldbus connection.

1.6.3.3 Device Level Ring (DLR)

Device Level Ring (DLR) protocol provides a way to detect, manage, and recover from faults in a ring-based network. It supports a

single-ring topology. Multiple or overlapping rings are not supported. Other features include "Sign on process" used to identify all

ring participants, and "Neighbor check process" which allows nodes to check the health of their adjacent nodes.

One device acts as a ring supervisor, monitoring the state of the ring while other devices act as DLR nodes. Only one device can act

as an active supervisor, although back-up supervisors are possible. Nodes can be divided into Beacon- and Announce-based nodes

depending on which frames the nodes process. OPTEA and OPTE9 boards support Announce-based functionality.

DLR nodes have three states:

•

IDLE_STATE: indicating linear topology for non-supervisor nodes

•

FAULT_STATE: initial state for enabled ring supervisor, or when ring fault has been detected

•

NORMAL_STATE: normal function in ring topology mode

The active ring supervisor sends Beacon frames from both its ring ports once per beacon interval (400 μs by default) to monitor the

state of the ring. It also sends an Announce frame once per s. If the Beacon frames are received back at the supervisor, one of its

ports is set to blocking and the other to forwarding state (Illustration 11). Only the following packets are processed from the blocked

port:

BC346130105092EN-US-000101 / DPD0158320 | Danfoss A/S © | 2020.06

Page 21

e30bh975.10

1

2 2

3

3

4

4

OPTE9-1 OPTE9-2

OPTE9-3 OPTE9-4

1

Ring Supervisor

2

DLR Node

3

Beacon

4

Announce

OPTE9-1 OPTE9-2

OPTE9-3 OPTE9-4

e30bh976.10

2

3

3

2

1

1

Active Ring Supervisor

2

DLR Node

3

Link Status

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

•

Beacon frames from self and other supervisors

•

Link_Status/Neighbor_Status frames

•

Neighbor_Check request or response and Sign_On frames

Illustration 11: DLR Ring: Network Conguration when Ring is Closed (NORMAL_STATE)

Introduction

If a network error occurs to DLR-capable nodes, the nodes send Link_Status frames to inform the ring supervisor immediately which

port(s) have a failure (Illustration 12).

Illustration 12: DLR Ring: Failure in Network

A Link_Status frame triggers an error response in active ring supervisor, which unblocks trac on its previously blocked port (Illus-

tration 13). If there is an uncommon failure (for example, if a cable breaks between two non-DLR capable devices), the error is no-

ticed from Beacon timeout value, and not from Link_Status frames. Therefore, a recovery in a network with non-DLR capable devices

can take longer.

BC346130105092EN-US-000101 / DPD01583 | 21Danfoss A/S © 2020.06

Page 22

OPTE9-1 OPTE9-2

OPTE9-3 OPTE9-4

1

2 2

e30bh977.10

1

Active Ring Supervisor

2

DLR Node

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Illustration 13: DLR Ring: Network Conguration after Failure (FAULT_STATE)

Introduction

The ring recovers after Beacon frames again are received from both of the active ring supervisors ring ports. Ring recovers back to its

original state (Illustration 11).

NOTE! DLR is active only when EtherNet/IP is the selected protocol. DLR is available since V002 rmware for OPTEA and since V009

rmware for OPTE9 board.

DLR Recovery Times

DLR allows setting of the beacon interval and the beacon timeout values, with lower beacon interval providing faster ring recovery

performance. With default values (400 μs interval and 1960 μs timeout), DLR can reach much faster ring recovery times than, for

example, Media Redundancy Protocol. Typically, these times are around 3 ms for Beacon-based and 4 ms for Announce-based nodes.

When using DLR, we recommend that the watchdog time is set to a value greater than 4 ms. It ensures that a properly congured

ring network recovers from a network failure within the watchdog time.

1.6.3.4 PROFINET System Redundancy (OPTEA)

Redundancy is a requirement in process automation systems for high availability and reduced production downtimes. PROFINET

System Redundancy provides a solution to build a system with redundant PN controllers, devices, and communication.

PROFINET System Redundancy fullls among others the following requirements:

Highly reliable communication

•

Short take over time

•

Bumpless I/O data during fault recovery

•

Monitoring of the back-up connection

•

System redundancy implements two redundant PN controllers, one working as primary and other as back-up. These controllers can

be connected via a redundant network to PN devices. It is, however, not mandatory as system redundancy has dierent levels which

are independent from each other. Thus, PN controller, Ethernet media, and PN device can have dierent redundancy congurations.

BC346130105092EN-US-000101 / DPD0158322 | Danfoss A/S © | 2020.06

Page 23

1

2

3

45

e30bh978.10

1

Primary

2

Back-up

3

Redundant network

4

Device with redundant connectivity

5

Device with singular connectivity

Host

NAP IO

IOC

PROFINET

SR-ARa

Single NAP

S2

SR-ARb

IOC

Host

e30bh979.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

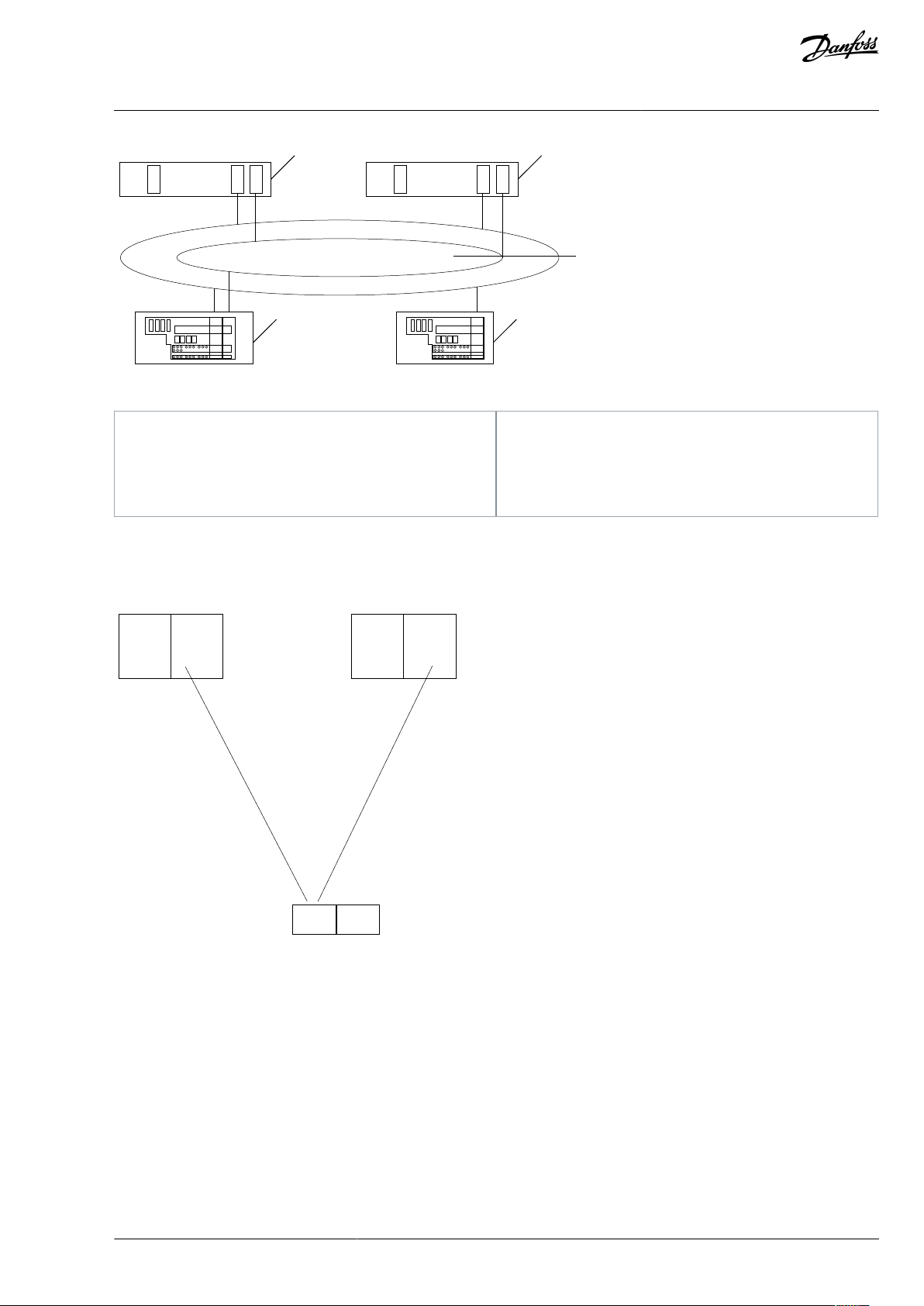

Illustration 14: System Redundancy Overview

Introduction

OPTEA supports "S2" level of System Redundancy and Media Redundancy Protocol (MRP) for redundant connectivity.

S2 uses a single PROFINET interface (NAP = Network Access Point), and two SR-ARs (System Redundancy Application Relations =

connections), one to each PN controller. Redundant PN controllers have parallel access to an SR PN device, but only one AR acts as a

primary (SR-ARa) and the other is back-up (SR-ARb).

Illustration 15: NAP S2, Connected to 2 IOCs

In case the primary AR fails, the IOC initiates a switch for the back-up SR-AR to become primary. This switchover cannot take longer

than the Redundancy Data Hold Time (RDHT) congured by the IOC. During the transition, the input data is hold and the output

data frozen to ensure a bumpless transition. OPTEA does not create a fault during this time when a back-up connection is available.

A fault is created after this time elapses and no Primary is available.

NOTE! System Redundancy is available in OPTEA version V002 or later and requires the use of GSDML le dated 21.06.2018 or later.

1.6.4 PROFINET Shared Device (OPTEA)

OPTEA supports Shared Device feature where multiple PLCs can connect to same device. PLC A can connect to PROFIdrive module

and PLC B can connect to PROFIsafe module. It is also possible to have System Redundancy connections (two PLCs) and PROFIsafe

from third PLC at the same time.

This kind of setup generates up to three times more Ethernet trac than connecting with single PLC, so consider the cycle times

and number of devices in the system. Connections to multiple PROFIdrive or PROFIsafe modules are not supported.

BC346130105092EN-US-000101 / DPD01583 | 23Danfoss A/S © 2020.06

Page 24

Technical item or function

Technical data

General

Board name

OPTEA/OPTE9

Ethernet connections

Interface

Two RJ-45 connectors

Transfer cable

Shielded Twisted Pair (STP) CAT5e

(1)

Communications

Speed

10 / 100 Mb

Duplex

half / full

Default IP-address

By default the board is in DHCP mode.

Protocol

Modbus TCP, Modbus UDP, Pronet I/O, EtherNet/IP

Environment

Ambient operating temperature

-10°C…50° C

Storing temperature

-40°C…70° C

Humidity

<95%, no condensation allowed

Altitude

Maximum 1000 m

Vibration

0.5 G at 9…200 Hz

Safety

Fullls EN 50178 standard

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Shared device feature also enables adding of PROFIsafe to existing systems. Notice that PROFIsafe has its own conguration requirements (see 4.5 PROFIsafe (OPTEA)).

Introduction

1.6.5 Address Conict Detection (ACD)

The OPTEA and OPTE9 option boards implement ACD algorithm (IETF RFC 5227). The implementation includes requirements from

the EtherNet/IP protocol.

The ACD algorithm tries to detect actively if another device is using the IP address in the same network. The ACD sends 4 ARP request packets when the Ethernet interface of the device activates, or when its IP address changes.

ACD prevents the use of the Ethernet interface until the ARP probing nishes. This delays the start-up of eldbus protocols about 1

s. During the delay or after it, the ACD passively checks incoming ARP messages for use of the IP address of the device.

If another device with the same IP address is detected, the ACD tries to defend its IP address with a single ARP message. If the other

device with the same IP address also supports ACD, it must stop using the address. If it does not, the ACD closes the Ethernet connection and indicates the situation with LEDs. This is done according the "DefendWithPolicyB". Other policies are not supported.

If the eldbus protocol has been active, it can activate a eldbus fault (depends on the eldbus and drive application conguration).

1.6.6 Technical Data

Table 2: OPTEA/OPTE9 Option Board Technical Data

1

For connecting the eldbus Ethernet boards, use only Ethernet cables that meet at least the requirements of category 5 (CAT5) according to EN

50173 or ISO/IEC 11801.

1.6.7 VACON® PC Tools

With VACON® PC tools, it is possible to do following operations for OPTEA/OPTE9 Ethernet board:

Update rmware into OPTEA/OPTE9 board (with VACON® Loader), see

•

•

Set parameters for OPTEA/OPTE9 Ethernet board (with VACON® NCDrive or VACON® Live), see 3.2.4.1 Setting the Drive Parame-

ters with VACON® NCDrive and 3.2.4.2 Setting the Drive Parameters with VACON® Live

•

Read monitor values of OPTEA/OPTE9 Ethernet board (with VACON® NCDrive or VACON® Live)

For instructions on downloading and installing the tools, see 3.1.1 Installing VACON® PC Tools.

The following table describes what PC tools are supported in each AC drive type.

3.2.1 Updating Fieldbus Firmware with VACON® Loader

BC346130105092EN-US-000101 / DPD0158324 | Danfoss A/S © | 2020.06

Page 25

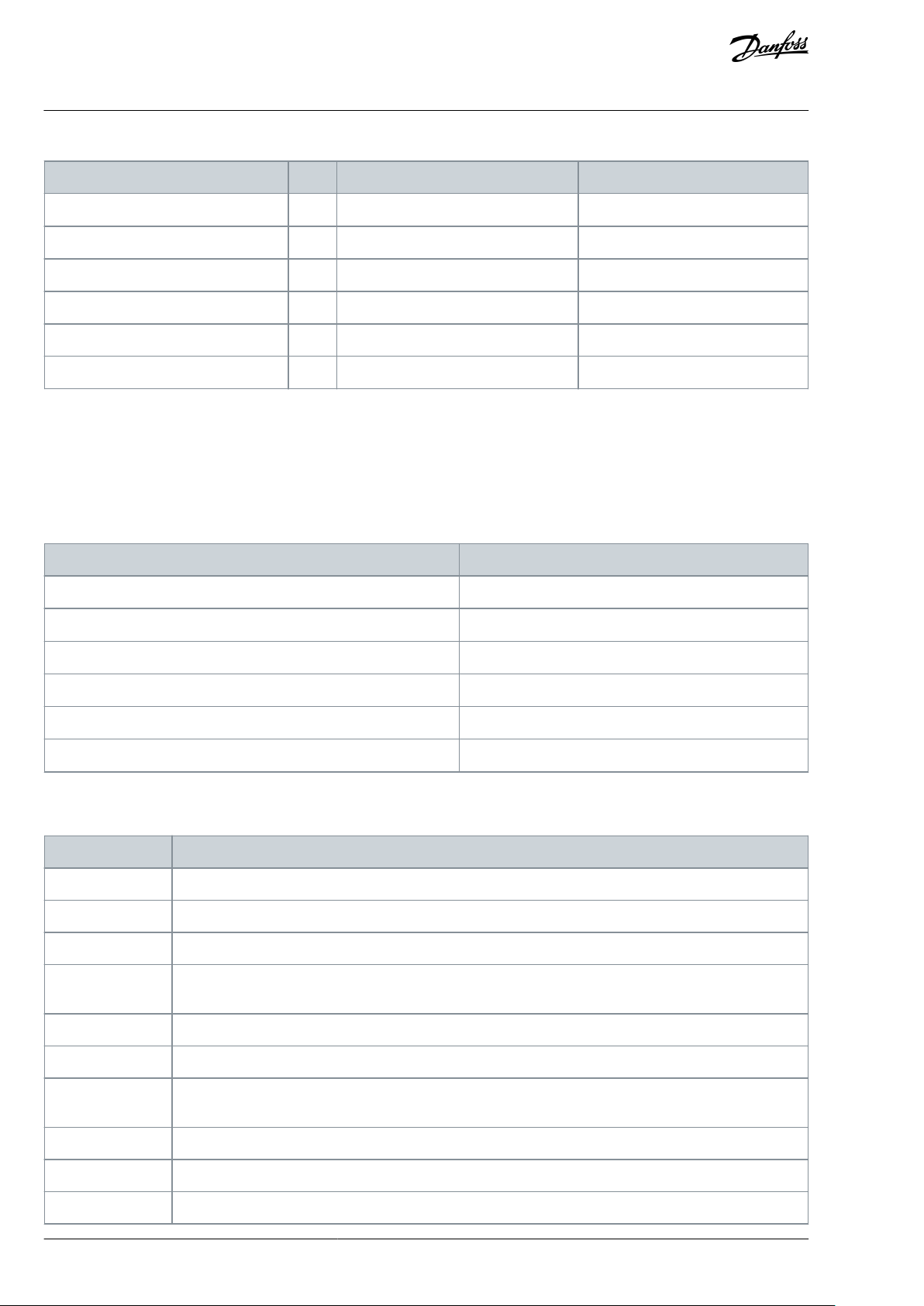

Tool

VACON® 100 family

VACON® NXS/NXP

VACON® 20 family

VACON® Loader

Serial

(1)

Serial

(1)

Serial

(1)

VACON® Live

Serial

(1)

, Ethernet

(2)

-

Serial

(1)

VACON® NCIPCong

Ethernet

(2)

Ethernet

(2)

Ethernet

(2)

VACON® NCDrive

-

Ethernet

(2)

-

VACON® NCLoad

Not supported; use VACON® Loader.

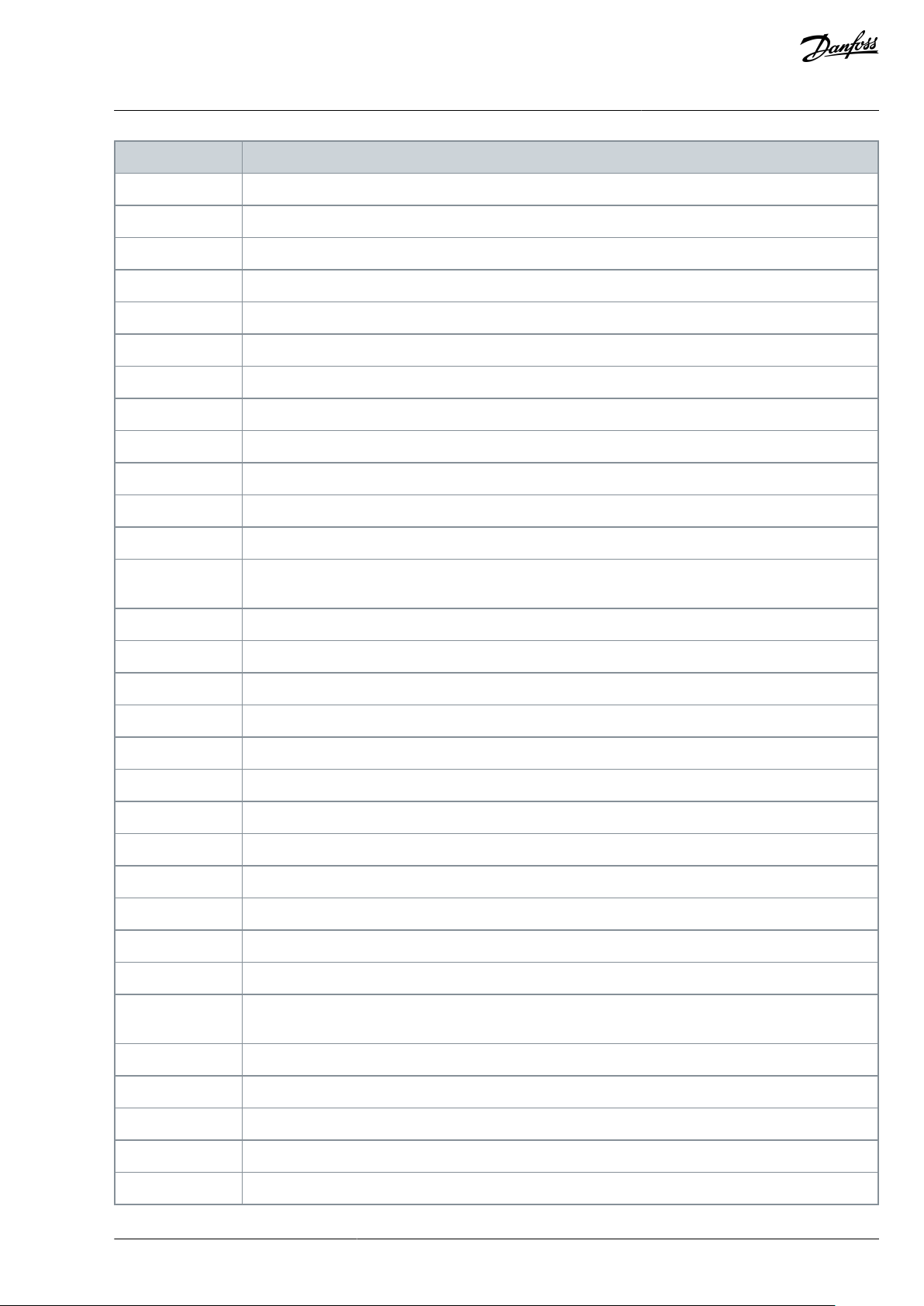

AC drive

Slots

From AC drive software version on

From OPTEA software version on

VACON® NXP

D, E

NXP00002V196

V001

VACON® NXS

D, E

NXS00002V184

V003

VACON® 100 INDUSTRIAL

and 100 X

D, E

FW0072V028

V002

VACON® 100 FLOW

D, E

FW0159V018

V002

AC Drive

From AC drive software version on

VACON® NXP

NXP00002V197

VACON® 100 INDUSTRIAL and 100 X

FW0072V028

VACON® 100 FLOW

FW0159V018

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Table 3: The Supported PC Tools with Dierent AC Drives

1

The connection type "serial" is a direct serial connection to the AC drive.

2

The connection type "Ethernet" is an Ethernet connection, for example, VACON® 100 family built-in Ethernet interface, or a connection via OPTEA/

OPTE9 Dual Port Ethernet option board.

Introduction

1.7 AC Drive Support

1.7.1 VACON® OPTEA Advanced Dual Port Ethernet Drive Support

The VACON® OPTEA Advanced Dual Port Ethernet option board can be used with the following VACON® AC drives. Option board

can be used for PROFINET with PROFIsafe communication in slot E, when OPTBL/OPTBM/OPTBN is installed to slot D. If PROFIsafe is

not used, then OPTEA can be installed to slot D too.

Table 4: OPTEA-supported AC Drives and Slots

VACON® 100 Family Support

The VACON® 100 family AC drives are supported from the OPTEA rmware version V002. The process data in VACON® 100 family AC

drives is 32 bit. PROFIsafe features are supported only in VACON® NXP drives.

EtherNet/IP and Modbus TCP/UDP Support

Support for EtherNet/IP, Modbus TCP/UDP, and other features which were in OPTE9, were added to OPTEA rmware V002. Table

below shows required minimum AC drive rmware version.

Table 5: Required Minimum AC Drive Firmware Versions

1.7.2 VACON® OPTE9 Dual Port Ethernet Drive Support

The VACON® OPTE9 Dual Port Ethernet option board can be used with the following VACON® AC drives.

BC346130105092EN-US-000101 / DPD01583 | 25Danfoss A/S © 2020.06

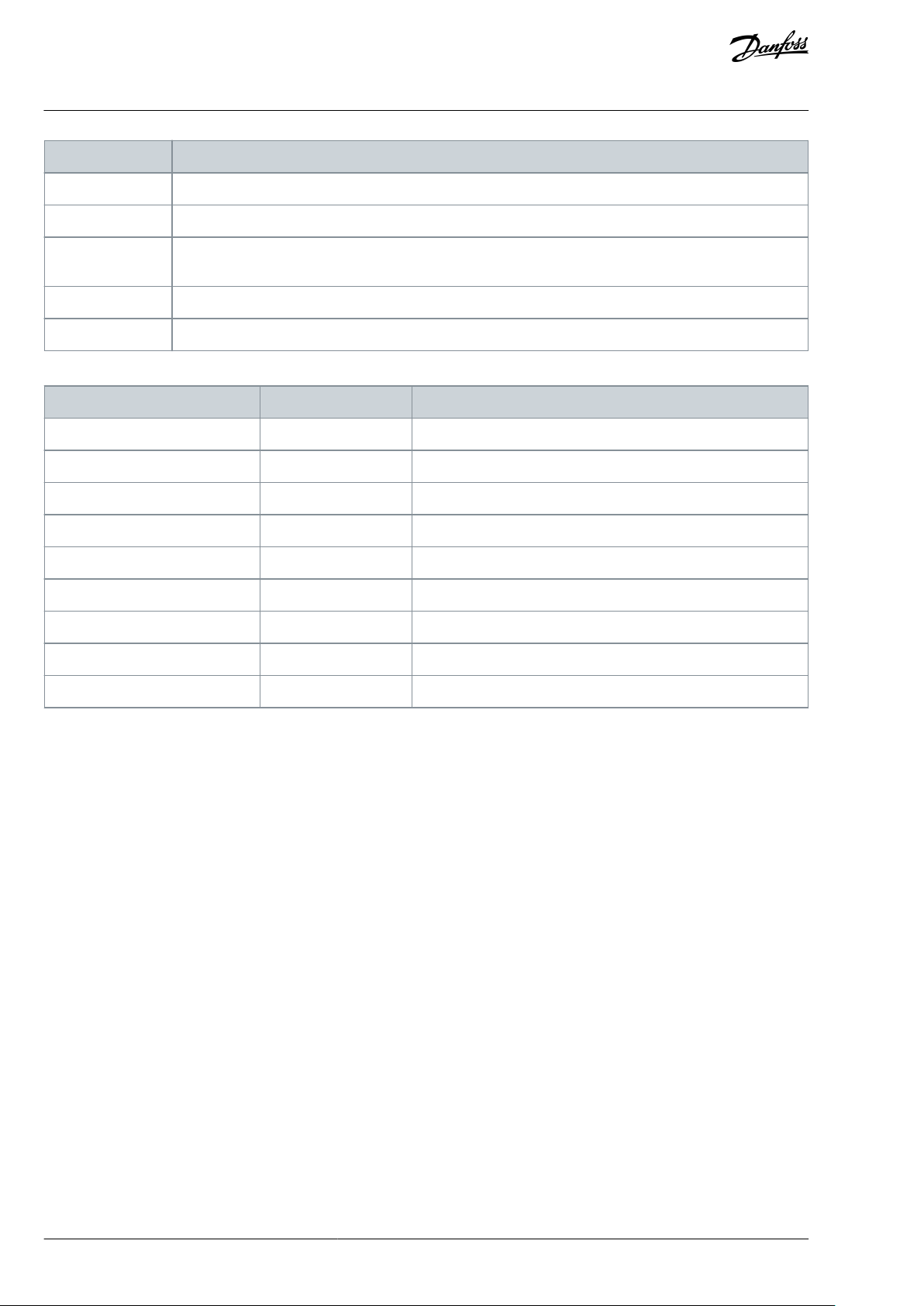

Page 26

AC drive

Slots

From AC drive software version on

From OPTE9 software version on

VACON® NXP

D, E

NXP00002V188

V001

VACON® NXS

D, E

NXS00002V179

V001

VACON® 100 INDUSTRIAL and 100 X

D, E

FW0072V018

V003

VACON® 100 FLOW

D, E

FW0159V012

V003

VACON® 20

-

FW0107V011

V002

VACON® 20 X and CP

-

FW0117V007

V002

AC Drive

From AC drive SW version on

VACON® NXP

NXP00002V191

VACON® NXS

NXS00002V181

VACON® 100 INDUSTRIAL and 100 X

FW0072V018

VACON® 100 FLOW

FW0159V012

VACON® 20

FW0107V012

VACON® 20 X and CP

FW0117V009

Abbreviation

Denition

ACD

Address Conict Detection

ARP

Address Resolution Protocol

CIP

Common Industrial Protocol

CRC

Cyclic Redundancy Check is an error-detecting code commonly used in eldbusses to detect accidental

changes to raw data.

CW

Control word

DCP

Discovery and Basic Conguration Protocol

DHCP

Dynamic Host Conguration Protocol is used for dynamical resolving of network conguration parameters

like an IP address.

DLR

Device Level Ring

DU

Data unit

EDD

Electronic Device Description

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Table 6: OPTE9-supported AC Drives and Slots

VACON® 100 Family Support

The VACON® 100 family AC drives are supported from the OPTE9 rmware version V003. The process data in VACON® 100 family AC

drives is 32 bit.

EtherNet/IP and Modbus TCP/UDP Support

EtherNet/IP protocol was added to OPTE9 rmware version V004. The following table shows required minimum AC drive rmware

version.

Table 7: Required Minimum AC Drive Firmware Versions

Introduction

1.8 Symbols and Abbreviations

Table 8: Symbols and Abbreviations

BC346130105092EN-US-000101 / DPD0158326 | Danfoss A/S © | 2020.06

Page 27

Abbreviation

Denition

EDS

Electronic Data Sheet

EMC

Electromagnetic compatibility

FB

Fieldbus

FD

Full Duplex

GSDML

General Station Description Markup Language

GW

Gateway

HD

Half Duplex

HI

Upper 8/16 bits in a 16/32-bit value.

LED

Light emitting diode

LLDP

Link Layer Discovery Protocol

LO

Lower 8/16 bits in a 16/32-bit value.

MIB

Management Information Base

Modbus TCP /

Modbus UDP

Simple and vendor-neutral communication protocol intended for monitoring and controlling of eld devices.

MRC

Media Ring Client

MRM

Media Ring Master

MRP

Media Ring Protocol

NSOLL

Sollwert (German for reference value)

NIST

Istwert (German for actual value)

PC

Personal computer

PDI

Process Data In

PDO

Process Data Out

PHY(X)

Ethernet physical interface X, where X shows the number of interfaces

PLC

Programmable logic controller

PNU

Parameter number

PPO

Process parameter object

PROFINET I/O

PROFINET is a standard for industrial automation in Ethernet network. PROFINET I/O describes the exchange of data between controllers and eld devices.

RDHT

Redundancy Data Hold Time

RPM

Revolutions per minute

RSTP

Rapid Spanning Tree Protocol

SNMP

Simple Network Management Protocol

SNTP

Simple Network Time Protocol

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Introduction

BC346130105092EN-US-000101 / DPD01583 | 27Danfoss A/S © 2020.06

Page 28

Abbreviation

Denition

STW1

Steuerwort 1 (German for control word 1)

SW

Status word

TCP

Transmission Control Layer provides reliable, ordered, and error-checked delivery of data streams between

computers that are connected to a local area network.

UTC

Coordinated Universal Time

ZSW1

Zustandwort 1 (German for status word 1)

Type name

Bit size

Explanation

INT88Signed short integer

UINT8

8

Unsigned short integer

INT16

16

Signed integer

UINT16

16

Unsigned integer

INT32

32

Signed long integer

UINT32

32

Unsigned long integer

FLOAT32

32

32-bit oating point

STRING3

24

3 byte string

STRING5

40

5 byte string

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Table 9: Data Types

Introduction

BC346130105092EN-US-000101 / DPD0158328 | Danfoss A/S © | 2020.06

Page 29

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Danger and Warnings

D A N G E R

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. A contact with this voltage can lead to death or seri-

ous injury.

Do not touch the components of the power unit when the drive is connected to mains. Before connecting the drive to mains,

-

make sure that the covers of the drive are closed.

D A N G E R

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, the brake resistor terminals, or the DC terminals are live when the drive is connected to mains, also

when the motor does not operate. A contact with this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, the brake resistor terminals, or the DC terminals when the drive is connected to

-

mains. Before connecting the drive to mains, make sure that the covers of the drive are closed.

D A N G E R

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live 5 minutes after the drive is disconnected from the mains

and the motor has stopped. Also the load side of the drive can generate voltage. A contact with this voltage can lead to death or

serious injury.

Before doing electrical work on the drive:

-

Disconnect the drive from the mains and make sure that the motor has stopped.

Lock out and tag out the power source to the drive.

Make sure that no external source generates unintended voltage during work.

Wait 5 minutes before opening the cabinet door or the cover of the AC drive.

Use a measuring device to make sure that there is no voltage.

BC346130105092EN-US-000101 / DPD01583 | 29Danfoss A/S © 2020.06

Page 30

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Safety

W A R N I N G

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this voltage

can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

W A R N I N G

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the pulse

control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions (including the

start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic fault reset. See

the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start can result in

personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to operate

-

under any condition.

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certied electrical installer.

-

W A R N I N G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B or

a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and therefore

can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

2.3 Cautions and Notices

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT MEASUREMENTS

Doing measurements on the AC drive when it is connected to mains can damage the drive.

Do not do measurements when the AC drive is connected to mains.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identied with the PE symbol.

BC346130105092EN-US-000101 / DPD0158330 | Danfoss A/S © | 2020.06

Page 31

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

C A U T I O N

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

C A U T I O N

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Remember to use ESD protection always when working with electronic components of the AC drive. Do not touch the com-

-

ponents on the circuit boards without proper ESD protection.

Safety

N O T I C E

DAMAGE TO THE AC DRIVE FROM MOVEMENT

Movement after installation can damage the drive.

Do not move the AC drive during operation. Use a xed installation to prevent damage to the drive.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

N O T I C E

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

N O T I C E

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

BC346130105092EN-US-000101 / DPD01583 | 31Danfoss A/S © 2020.06

Page 32

Cross-sectional area of the phase conductors (S) [mm2]

The minimum cross-sectional area of the protective earthing conductor in question [mm2]

S ≤ 16

S

16 < S ≤ 35

16

35 < S

S/2

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

N O T I C E

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

2.4 Grounding

Ground the AC drive in accordance with applicable standards and directives.

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identied with the PE symbol.

W A R N I N G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certied electrical installer.

-

Safety

The standard EN 61800-5-1 tells that 1 or more of these conditions for the protective circuit must be true.

The connection must be xed.

•

The protective earthing conductor must have a cross-sectional area of minimum 10 mm2 Cu or 16 mm2 Al. OR

•

There must be an automatic disconnection of the mains, if the protective earthing conductor breaks. OR

•

There must be a terminal for a second protective earthing conductor in the same cross-sectional area as the rst protective

earthing conductor.

The values of the table are valid only if the protective earthing conductor is made of the same metal as the phase conductors. If this

is not so, the cross-sectional area of the protective earthing conductor must be determined in a manner that produces a conductance equivalent to that which results from the application of this table.

The cross-sectional area of each protective earthing conductor that is not a part of the mains cable or the cable enclosure, must be a

minimum of:

•

2.5 mm2 if there is mechanical protection, and

•

4 mm2 if there is not mechanical protection. With cord-connected equipment, make sure that the protective earthing conductor

in the cord is the last conductor to be interrupted, if the strain-relief mechanism breaks.

Obey the local regulations on the minimum size of the protective earthing conductor.

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

BC346130105092EN-US-000101 / DPD0158332 | Danfoss A/S © | 2020.06

Page 33

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Safety

N O T I C E

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

W A R N I N G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B or

a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and therefore

can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

BC346130105092EN-US-000101 / DPD01583 | 33Danfoss A/S © 2020.06

Page 34

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Commissioning

3 Commissioning

3.1 Before Commissioning

VACON® OPTEA/OPTE9 Ethernet can be commissioned through the control panel of the AC drive or by using the VACON® PC tools.

Before starting the commissioning, check the following:

•

When using the control panel of the AC drive for commissioning: for instructions on how to use the control panel, see the Operating Guide for VACON® NXP products or the Application Guide for the VACON® 100 family.

•

When using VACON® PC tool for commissioning: the correct tool installed.

-

For a list of supported PC tools, see 1.6.7 VACON® PC Tools.

-

For instructions on installing the tools, see 3.1.1 Installing VACON® PC Tools.

•

VACON® AC drive in which OPTEA/OPTE9 Ethernet option board installed. See Ethernet Boards Installation Guide for instructions.

•

The IP addresses of the Ethernet option board are set according to the network. By default, the option board uses a DHCP Server

to get an IP address. If your network does not have a DHCP Server, set an IP address manually and change the "IP Mode" to

"static". See instructions in 3.2.3 Conguring with VACON® NCIPCong.

For more information about IP addresses or a DHCP Server, contact your network administrator.

•

Ethernet cable is connected to the Ethernet interface of the option board.

The PC can also be connected directly to the device using a crossover cable. This option can be needed if your PC does not

support Automatic crossover function.

With VACON® 100 family AC drive, Ethernet cable can also be connected to the Ethernet port of the control board. The instruc-

tions are the same for both connections. Another option is to use the serial cable converter and the panel connector for commissioning.

3.1.1 Installing VACON® PC Tools

Prepare for commissioning by installing the needed VACON® PC Tools.

Procedure

1.

Go to www.danfoss.com/.

2.

Select Downloads from Service and Support drop-down menu.

3.

Select Drives as business unit.

4.

Download the VACON® PC tool depending on the used AC drive.

•

VACON® 100 family AC drive: VACON® Loader and VACON® Live

•

VACON® 20 AC drive: VACON® Loader and VACON® Live

•

VACON® NXP AC drive: VACON® NCDrive and VACON® Loader

5.

Start the installation program and follow the on-screen instructions.

6.

After installation, launch VACON® PC tool from Windows Start menu.

7.

For more information about software features, go to Help drop-down menu and select Contents.

3.1.2 Downloading Fieldbus Option Firmware

Prepare for commissioning by downloading the Fieldbus Option Firmware.

Procedure

Go to

1.

2.

3.

4.

www.danfoss.com/.

Select Downloads from Service and Support drop-down menu.

Select Drives as business unit.

Download le Fieldbus rmware.

3.1.3 Downloading Function Blocks for PLC

Danfoss provides samples of function blocks and add-on-instructions to support commissioning of drive eldbus interfaces. They

are published with source code.

Procedure

BC346130105092EN-US-000101 / DPD0158334 | Danfoss A/S © | 2020.06

Page 35

e30bh634.10

e30bh635.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

1.

Go to www.danfoss.com/.

2.

Select Downloads from Service and Support drop-down menu.

3.

Select Drives as business unit.

4.

Select Fieldbus conguration les for VLT® and VACON® drives.

5.

Download le VACON® TIA Portal Function Blocks, VACON® TIA PORTAL PROFIsafe Funct. Block, or VACON® OPTE9/EA

EtherNet/IP AOI.

Commissioning

3.2 Commissioning with VACON® PC tools

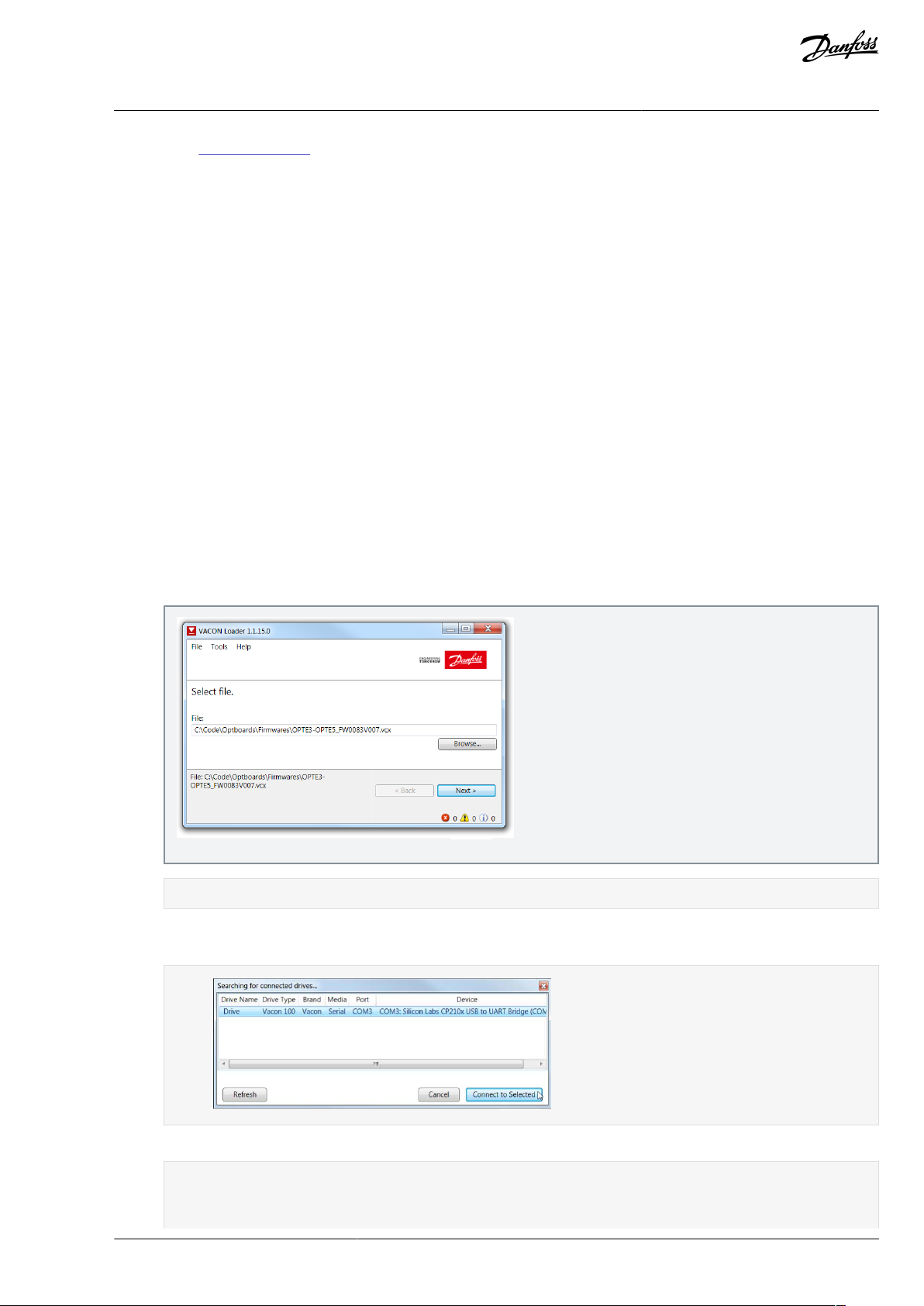

3.2.1 Updating Fieldbus Firmware with VACON® Loader

Use these instructions to upload the eldbus rmware with VACON® Loader.

NOTE! Screenshots in these instructions are examples only. The product information shown in them is dierent depending on

which option board is used.

Check the list in Before commissioning.

Adjust the baud rate if needed:

•

With VACON® 20, use the baud rate 9600.

•

With VACON® 20 X and VACON® 20 CP, the following baud rates are supported: 9600, 19200, 38400 or 57600.

•

With VACON® 100 family and VACON® NXP drives, VACON® Loader selects a correct baud rate automatically.

Procedure

1.

2.

3.

4.

Connect your PC to the controller by using the serial cable.

Open the File Explorer and select the rmware le to be updated to the option board and double-click it.

VACON® Loader software opens.

Press Next and wait for the loader to nd the network drives.

Select a drive from the list and press Connect to Selected.

5.

Select the modules to be updated, and press Next.

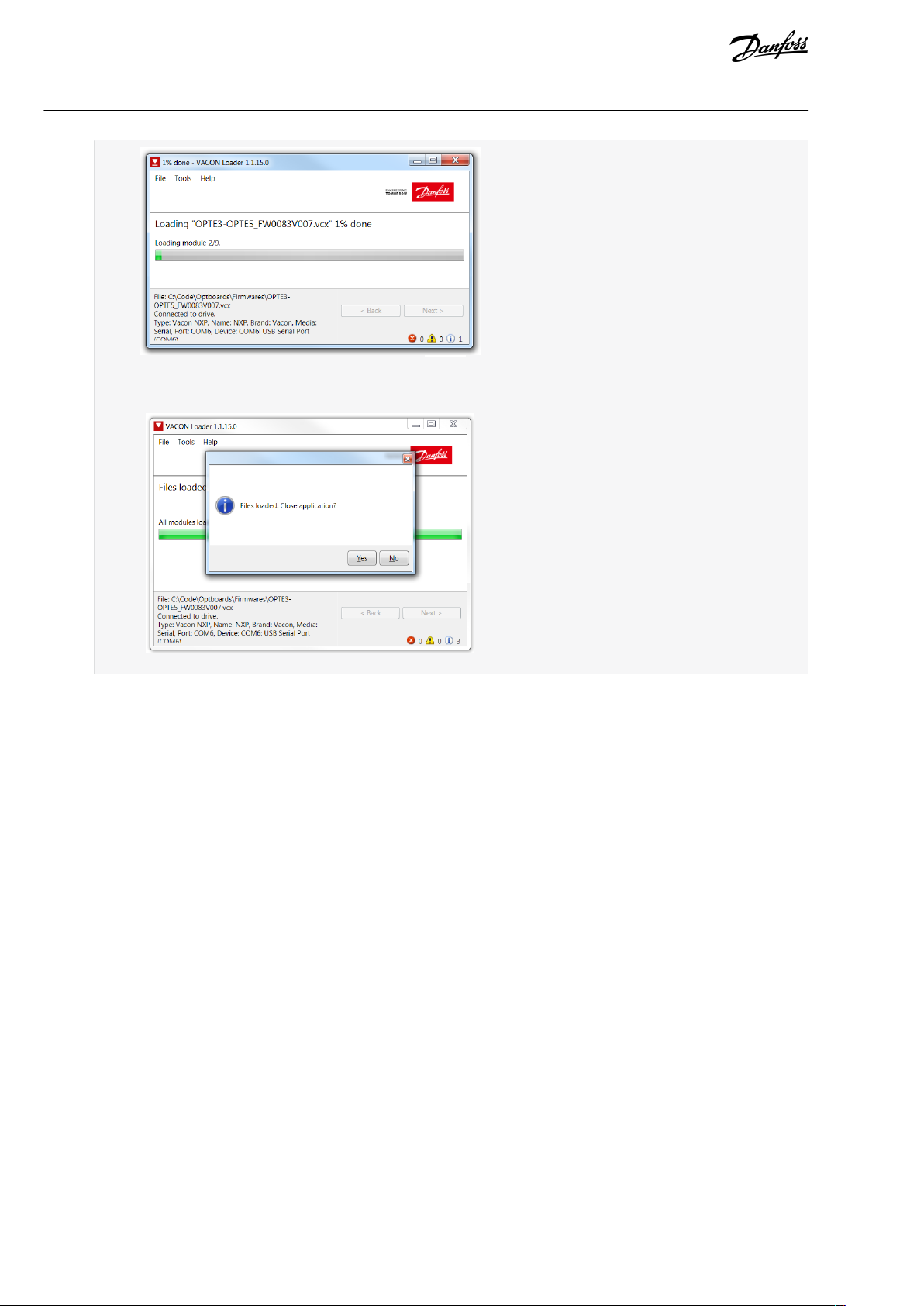

Firmware starts to load:

BC346130105092EN-US-000101 / DPD01583 | 35Danfoss A/S © 2020.06

Page 36

e30bh636.10

e30bh637.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Commissioning

Loading is nished:

3.2.2 Updating Firmware over Ethernet with VACON® Loader

Use these instructions to upload the eldbus or VACON® control rmware over Ethernet with VACON® Loader.

OPTEA and OPTE9 boards enable updating VACON® 100 control and option board rmware over Ethernet with VACON® Loader. The

option board works as gateway for the rmware update. It means that it is not possible to update the rmware of the option board

which is being used as the update gateway.

If the rmware loading fails (for example, network is lost during update), the option board remembers used Ethernet settings and

remains in state waiting for reconnection and rmware update.

Procedure

1.

Start VACON® Loader and select the rmware le to be updated.

BC346130105092EN-US-000101 / DPD0158336 | Danfoss A/S © | 2020.06

Page 37

e30bi240.10

e30bi241.10

e30bi242.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Commissioning

2.

Press Next. VACON® Loader starts to scan for serial connections. At this point press Cancel.

3.

From the communication settings, change connection type to Ethernet.

VACON® Loader starts to scan drives from Ethernet networks.

4.

When the drive is found, select it and press Connect to selected. From this point on, load prosess is identical with serial connection.

BC346130105092EN-US-000101 / DPD01583 | 37Danfoss A/S © 2020.06

Page 38

e30bi243.10

e30bh636.10

e30bh637.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Commissioning

Firmware starts to load:

Loading is nished:

5.

If the scan does not nd the device but the IP address of the drive is available, press cancel to scan dialog and enter the

correct IP address in the IP eld. Then press Next.

BC346130105092EN-US-000101 / DPD0158338 | Danfoss A/S © | 2020.06

Page 39

e30bi244.10

e30bh917.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Commissioning

3.2.3 Conguring with VACON® NCIPCong

Use these instructions to set the IP addresses for the option board with VACON® NCIPCong. To nd more information about the

software features, select Help --> Manual.

Check the list in 3.1 Before Commissioning.

Procedure

1.

To launch the VACON® NCIPCong, go to the Windows Start menu and select VACON® NCIPCong.

2.

Select Conguration --> Scan and wait until the devices connected to the bus display on the left side of the screen in the

tree structure.

NOTE! The VACON® NCIPCong uses broadcast messages for scanning devices. Some network switches can block the

broadcast messages. In this case, each network node must be scanned separately.

3.

Set the option board settings.

•

To change the board name, select the cell in the column Node and enter the name of the node. Notice that it changes

the name seen only in VACON® PC tools. PROFINET I/O Name Of Station value must be changed via protocol settings

or over PROFINET I/O DCP protocol.

•

To change the node IP settings, select the cell in the right column and enter the value according to the network IP

settings. The program reports conicts with a red color in table cells.

•

To change the IP Mode, click the cell and select the correct mode from the drop-down list.

BC346130105092EN-US-000101 / DPD01583 | 39Danfoss A/S © 2020.06

Page 40

e30bh918.10

e30bh919.10

e30bh920.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

•

4.

To change the currently active protocol, select the setting from the tree structure and click OK.

Commissioning

To commit the changes, mark the checkbox and select Conguration --> Congure from the menu.

5.

To change other settings, edit the information in the tree structure.

See 6.1 Option Board Parameters for more information about the settings.

3.2.4 Setting the Drive Parameters

3.2.4.1 Setting the Drive Parameters with VACON® NCDrive

Use these instructions to set the drive parameters with VACON® NCDrive.

Also option board parameters can be congured with VACON® NCDrive (except for the PROFINET NameOfStation parameter). However, we recommend using the VACON® NCIPCong tool to congure the option board in the VACON® NXS/P AC drives.

Check the list in 3.1 Before Commissioning.

BC346130105092EN-US-000101 / DPD0158340 | Danfoss A/S © | 2020.06

Page 41

e30bh900.10

e30bh901.10

e30bh639.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

Commissioning

Make sure that the option board IT settings are congured with VACON®NCIPCong. See instructions in 3.2.3 Conguring with VA-

CON® NCIPCong.

NOTE! The VACON® NCDrive software is recommended to be used in LAN (Local Area Network) only.

Procedure

1.

To nd drives for connections, press the Drive Select button to scan the network drives.

2.

In the Select the active drive dialog, select the drive for the connection, press the Set Active Drive button and press Close.

The IP information presented in the dialog comes from the option board, other information comes from the drive.

3.

Press the ON-LINE button.

The NCDrive connects to the drive and starts loading parameter information.

BC346130105092EN-US-000101 / DPD01583 | 41Danfoss A/S © 2020.06

Page 42

e30bh902.10

e30bh903.10

VACON® OPTEA/OPTE9 Ethernet Board

User Guide

4.

To change the option board settings, navigate to the M7 Expander boards menu, and select the slot to which OPTEA/OPTE9

is connected.

It is possible to change parameters dened in 6.1 Option Board Parameters. If the IP address, network mask, and default

gate address are changed, "IP Mode" must be changed to "Fixed IP" to activate the settings.

Commissioning

3.2.4.2 Setting the Drive Parameters with VACON® Live

Use these instructions to set the Drive Parameters with VACON® Live.

With VACON® Live, it is possible to modify OPTEA/OPTE9 Ethernet parameters and view monitor values.

Check the list in 3.1 Before Commissioning.

NOTE! VACON® 20, VACON® 20 X, and VACON® 20 Cold Plate do not support VACON® Live connection over the OPTE9 Ethernet port.

OPTEA does not support VACON® 20, VACON® 20 X, and VACON® 20 CP drives.

Procedure

1.