Page 1

vacon nxp

®

ac drives

arfiff30

generator application

user manual

Page 2

Page 3

arfiff30 Generator VACON® • 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

VACON® GENERATOR APPLICATION MANUAL

INDEX

Document code: DPD01916B

Software code: ARFIFF30V122

Date: 2.6.2021

1. Generator Application ............................................................................................................................................ 7

2. Generator Versions compatibility issues ................................................................................................................ 8

3. Power Take Modes ................................................................................................................................................. 9

3.1 Power Take Out modes ................................................................................................................................... 9

3.1.1 Induction motor ......................................................................................................................................... 9

3.1.2 Permanent Magnet Synchronous Motor ..................................................................................................... 9

3.2 Synchronous machine ................................................................................................................................... 10

3.3 Power Take In modes ................................................................................................................................... 11

3.3.1 Induction Motor – Boosting ...................................................................................................................... 11

3.3.2 Induction Motor- Take Me Harbour. ......................................................................................................... 11

3.3.3 Permanent Magnet Synchronous Motor - Boosting ................................................................................... 11

3.3.4 Permanent Magnet Synchronous Motor – Take Me Harbour .................................................................... 12

3.3.5 Synchronous machine - Boosting .............................................................................................................. 12

3.3.6 Synchronous machine – Take Me Harbor .................................................................................................. 13

4. Main contactor control ........................................................................................................................................ 14

5. Control I/O ........................................................................................................................................................... 15

6. Monitoring signals................................................................................................................................................ 16

6.1 Monitoring ................................................................................................................................................... 16

6.1.1 Monitoring 1 Values ................................................................................................................................. 16

6.1.2 Monitoring 2 Values ................................................................................................................................. 17

6.1.3 Fieldbus Monitoring values ....................................................................................................................... 18

6.1.4 IO Monitoring values ................................................................................................................................ 18

6.1.5 Master Follower values ............................................................................................................................ 19

6.1.6 License code activation............................................................................................................................. 19

6.1.7 Line synch ................................................................................................................................................ 19

6.2 Monitoring Signal Descriptions ..................................................................................................................... 20

6.2.1 Monitoring 1 values.................................................................................................................................. 20

6.2.2 Monitoring 2 values.................................................................................................................................. 23

6.2.3 Fieldbus monitoring values ....................................................................................................................... 26

6.2.4 IO Monitoring values ................................................................................................................................ 31

6.2.5 Master Follower monitoring values .......................................................................................................... 33

7. ARFIFF30– Parameter list ..................................................................................................................................... 35

7.1 Basic Parameters (G2.1) ................................................................................................................................ 35

7.2 Reference Handling (G2.2) ............................................................................................................................ 36

7.2.1 PTM handling ........................................................................................................................................... 36

7.2.2 PTO handling ............................................................................................................................................ 36

7.2.3 PTI-Boost handling ................................................................................................................................... 37

7.2.4 PTI 0-Speed .............................................................................................................................................. 37

7.2.5 Regen Motor Mode .................................................................................................................................. 37

7.2.6 Commissioning ......................................................................................................................................... 38

Page 4

4 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

7.2.7 DC Voltage Reference Handling ................................................................................................................ 38

7.2.8 Speed / Frequency Ref handling ............................................................................................................... 39

7.2.9 Torque Control ......................................................................................................................................... 39

7.2.10 Motor Potentiometer reference ........................................................................................................... 39

7.3 Ramp Control (G2.3) ..................................................................................................................................... 39

7.3.1 Ramp Control ........................................................................................................................................... 39

7.4 Input Signals (G2.4)....................................................................................................................................... 40

7.4.1 Basic settings............................................................................................................................................ 40

7.4.2 Digital Inputs ............................................................................................................................................ 41

7.4.3 Analogue Input 1 ...................................................................................................................................... 42

7.4.4 Analogue Input 2 ...................................................................................................................................... 42

7.4.5 Analogue Input 3 ...................................................................................................................................... 43

7.4.6 Analogue Input 4 ...................................................................................................................................... 43

7.5 Output Signals (G2.5) .................................................................................................................................... 44

7.5.1 Dig Out Signals ......................................................................................................................................... 44

7.5.2 Delayed DO 1 ........................................................................................................................................... 45

7.5.3 Delayed DO 2 ........................................................................................................................................... 45

7.5.4 Analog Output 1 ....................................................................................................................................... 47

7.5.5 Analog Output 2 ....................................................................................................................................... 47

7.5.6 Analog Output 3 ....................................................................................................................................... 48

7.5.7 Options .................................................................................................................................................... 48

7.5.8 Supervision limits ..................................................................................................................................... 48

7.6 Limit Settings (G2.6) ..................................................................................................................................... 49

7.6.1 Current Limit ............................................................................................................................................ 49

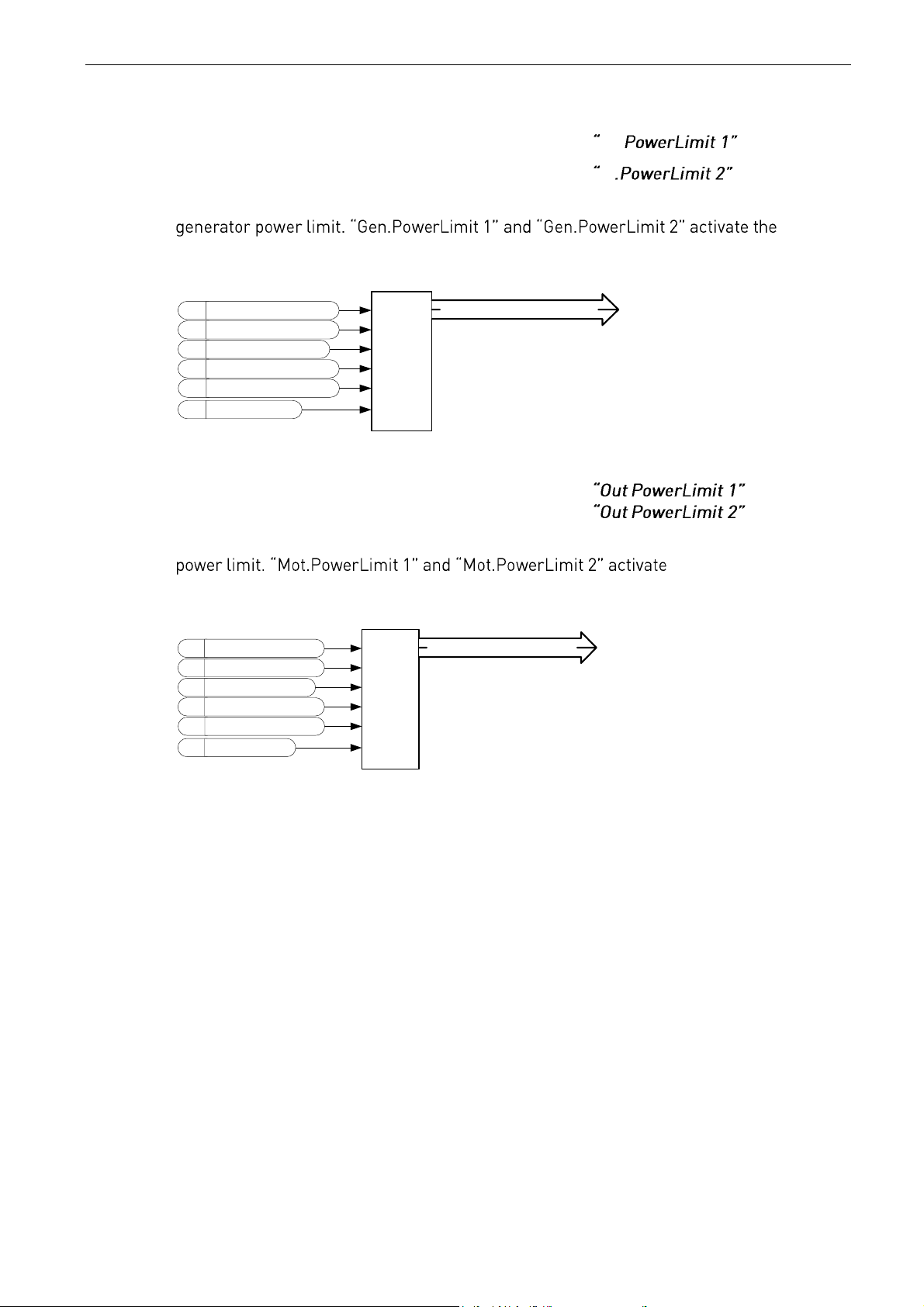

7.6.2 Power Limit .............................................................................................................................................. 49

7.6.3 Frequency Limit ........................................................................................................................................ 49

7.6.4 Voltage..................................................................................................................................................... 49

7.6.5 DC Voltage ............................................................................................................................................... 50

7.6.6 Torque ..................................................................................................................................................... 50

7.6.7 Active Current .......................................................................................................................................... 51

7.7 Flux and DC Current handling CL Settings (G2.7) ............................................................................................ 51

7.8 Motor Control (G2.8) .................................................................................................................................... 52

7.8.1 Motor Control Basic Settings .................................................................................................................... 52

7.8.2 U/f Settings .............................................................................................................................................. 52

7.8.3 PMSM Control settings ............................................................................................................................. 53

7.8.4 Stabilators ................................................................................................................................................ 54

7.8.5 Identification parameters ......................................................................................................................... 55

7.8.6 Tuning parameters ................................................................................................................................... 55

7.8.7 Flying Start Tuning parameters ................................................................................................................. 56

7.9 Speed Control (G2.9) .................................................................................................................................... 56

7.10 Drive Control (G2.10) .................................................................................................................................... 57

7.11 Master Follower (G2.11) ............................................................................................................................... 57

7.12 Protection (G 2.12) ....................................................................................................................................... 58

7.12.1 General ................................................................................................................................................ 58

7.12.2 Temperature Board parameters ........................................................................................................... 59

7.12.3 Earth fault ............................................................................................................................................ 59

7.12.4 External Fault ....................................................................................................................................... 59

7.12.5 Generator Voltage ................................................................................................................................ 60

7.12.6 Generator Frequency ........................................................................................................................... 60

7.12.7 Motor thermal protections ................................................................................................................... 60

7.12.8 Fieldbus protection .............................................................................................................................. 61

7.12.9 Cooling Monitoring .............................................................................................................................. 61

7.12.10 Options ................................................................................................................................................ 61

7.13 Fieldbus (G 2.13)........................................................................................................................................... 62

Page 5

arfiff30 Generator VACON® • 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

7.14 ID Control Functions (G2.14) ......................................................................................................................... 63

7.14.1 Value Control ....................................................................................................................................... 63

7.14.2 DIN ID Control 1 ................................................................................................................................... 63

7.14.3 DIN ID Control 2 ................................................................................................................................... 63

7.14.4 DIN ID Control 3 ................................................................................................................................... 64

7.15 Curve 1 definition (G2.15) ............................................................................................................................. 64

7.16 Curve 2 definition (G2.16) ............................................................................................................................. 65

7.17 Curve 3 definition (G2.17) ............................................................................................................................. 66

7.18 Line Synch (G2.18) ........................................................................................................................................ 67

7.19 Keypad control (Control keypad: Menu M3) .................................................................................................. 67

7.20 System menu (Control keypad: Menu M6) .................................................................................................... 67

7.21 Expander boards (Control keypad: Menu M7) ............................................................................................... 67

8. Parameter Descriptions ........................................................................................................................................ 68

8.1 Basic parameters .......................................................................................................................................... 68

8.2 Reference Handling ...................................................................................................................................... 74

8.2.1 PTM Handling ........................................................................................................................................... 74

8.2.2 PTO Handling ........................................................................................................................................... 74

8.2.3 PTI-Boost.................................................................................................................................................. 79

8.2.4 PTI 0-Speed .............................................................................................................................................. 81

8.2.5 Regen Motor ............................................................................................................................................ 82

8.2.6 Commissioning ......................................................................................................................................... 83

8.2.7 DC Voltage Reference ............................................................................................................................... 85

8.2.8 Speed and Frequency ............................................................................................................................... 86

8.2.9 Torque Control ......................................................................................................................................... 87

8.2.10 Ramp Control ....................................................................................................................................... 88

8.3 Input Signals ................................................................................................................................................. 89

8.3.1 Basic Settings ........................................................................................................................................... 89

8.3.2 Digital input signals .................................................................................................................................. 90

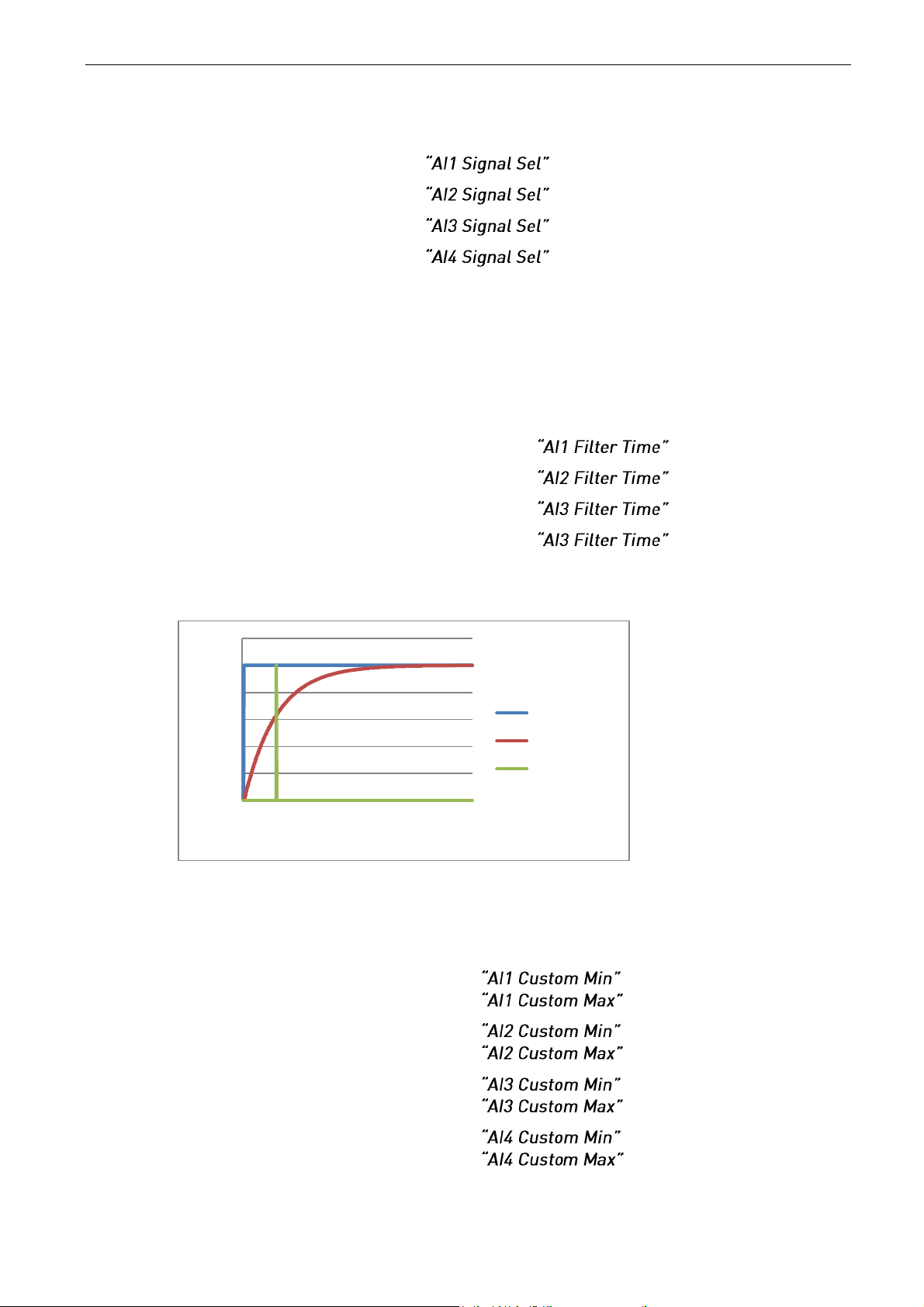

8.3.3 Analogue Inputs 1-4 ................................................................................................................................. 95

8.4 Output Signals .............................................................................................................................................. 98

8.4.1 Digital output signals ................................................................................................................................ 98

8.4.2 Delayed digital output 1 & 2 ................................................................................................................... 100

8.4.3 Analogue output 1 & 2 & 3 .................................................................................................................... 101

8.4.4 Options .................................................................................................................................................. 105

8.4.5 Supervision limits ................................................................................................................................... 107

8.5 Limit settings .............................................................................................................................................. 108

8.5.1 Current Limits......................................................................................................................................... 108

8.5.2 Power Limits .......................................................................................................................................... 108

8.5.3 Frequency limits ..................................................................................................................................... 110

8.5.4 Voltage................................................................................................................................................... 111

8.5.5 DC Voltage limit regulators ..................................................................................................................... 112

8.5.6 Torque ................................................................................................................................................... 114

8.5.7 Active Current ........................................................................................................................................ 114

8.6 Flux Control ................................................................................................................................................ 115

8.7 Motor Control ............................................................................................................................................ 116

8.7.1 U/f Settings ............................................................................................................................................ 117

8.7.2 Close Loop Settings ................................................................................................................................ 124

8.7.3 Permanent magnet synchronous motor settings ..................................................................................... 126

8.7.4 Stabilization settings............................................................................................................................... 132

8.7.5 Identification settings ............................................................................................................................ 136

8.7.6 Flying Start ............................................................................................................................................. 138

8.8 Speed Control settings ................................................................................................................................ 139

8.9 Drive Control .............................................................................................................................................. 141

Page 6

6 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

8.10 Master Follower ......................................................................................................................................... 148

8.10.1 Master Follower: DriveSynch system .................................................................................................. 148

8.10.2 Master follower configuration ............................................................................................................ 151

8.11 Protections ................................................................................................................................................. 153

8.11.1 General settings ................................................................................................................................. 153

8.11.2 Temperature Board ............................................................................................................................ 156

8.11.3 Earth Fault ......................................................................................................................................... 158

8.11.4 External Fault ..................................................................................................................................... 158

8.11.5 Generator Voltage OPT-D7 ................................................................................................................. 159

8.11.6 Generator Frequency OPT- D7 ............................................................................................................ 160

8.11.7 Motor Protection ............................................................................................................................... 161

8.11.8 Over Load Protection ......................................................................................................................... 163

8.11.9 Fieldbus communication .................................................................................................................... 165

8.11.10 Cooling protection.............................................................................................................................. 165

8.11.11 Protection Options ............................................................................................................................. 166

8.12 Fieldbus ...................................................................................................................................................... 167

8.12.1 Signals from drive to Fieldbus ............................................................................................................. 167

8.12.2 Signals from fieldbus to drive ............................................................................................................. 167

8.13 ID Functions ............................................................................................................................................... 169

8.13.1 Value Control ..................................................................................................................................... 169

8.13.2 DIN ID Control .................................................................................................................................... 172

8.14 Curve 1 Definition ....................................................................................................................................... 173

8.15 Curve 2 Definition ....................................................................................................................................... 173

8.16 Curve 3 Definition ....................................................................................................................................... 173

8.17 Line synch .................................................................................................................................................. 174

9. Keypad control parameters ................................................................................................................................ 175

10. Status and control words in detail.................................................................................................................. 176

10.1 Basic In ByPass (0) ...................................................................................................................................... 176

10.2 FB Control Word ......................................................................................................................................... 177

10.2.1 Standard (1) ....................................................................................................................................... 177

10.2.2 Vacon Generator 1 profile (2) ............................................................................................................. 178

10.2.3 Vacon AFE 2 Profile (Not Implemented as of 1.7.2014) ....................................................................... 180

10.3 FB Status Word ........................................................................................................................................... 182

10.4 Status Word (Application) ID 43 .................................................................................................................. 184

11. Problem solving ............................................................................................................................................. 186

12. FAULT CODES ................................................................................................................................................. 187

Page 7

arfiff30 Generator VACON® • 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

1. Generator Application

Software ARFIFF30, Generator application

The VACON® Generator application is an application that can be used to keep constant DC Voltage

regardless of input power source. The application supports Synchronous Generator (LCL Needed),

Permanent Magnet Synchronous Motor (Absolute Encoder needed) and asynchronous motor

(Incremental Encoder needed).

VACON® Generator application also support PTI operations. However, this manual does include

details on related hardware selections. We recommend you read the Grid Converter technical

documentation and contact VACON® technical support for more details.

The basic I/O-configuration of the AC drive consists of OPT-A1, OPT-A2 and if needed OPT-D7 or

OPT-A5 option cards depending of what type of generator is used. Also, for commissioning purposes

it is recommended to use OPT-D2 board. The basic I/O configuration has been described in table 2-1.

As a default the control place (P3.1) of the Generator drive is Keypad.

This application requires NXP3 control board 761 or newer.

Page 8

8 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

2. Generator Versions compatibility issues

V095

• Frequency Reference monitoring signal ID number changed from ID1752 to ID25

o 1752 is reserved for P 2.8.7.4 DeadTieContCurL

V101

• P2.2.4.5 TorqueRefRampTime is removed and internally forced to zero.

• New parameter for new ramp handling

o P2.2.4.5 TRefRampUpRate ID1934

o P2.2.4.6 TRefRampDownRate ID1935

• P2.2.4.5 TorqueRefRampTime was ramping regardless of Run state. With long

ramp time torque reference did not ramp to new reference fast enough e.g. when

changing between PTO and PTI-Boost modes.

• TRefRampUpRate is ramp rate when absolute value is increasing.

• TRefRampDownRate is ramp rate when negative or positive value is going toward

zero.

Note 1: When updating application, it is not recommended to use VACON® NCDrive parameter

download function. Instead, upload the parameters from the unit and make comparison to the old

parameter file. Application is constantly developed; this includes changing parameter default values.

If parameters are directly downloaded to drive, the improved default values will be lost.

Page 9

arfiff30 Generator VACON® • 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

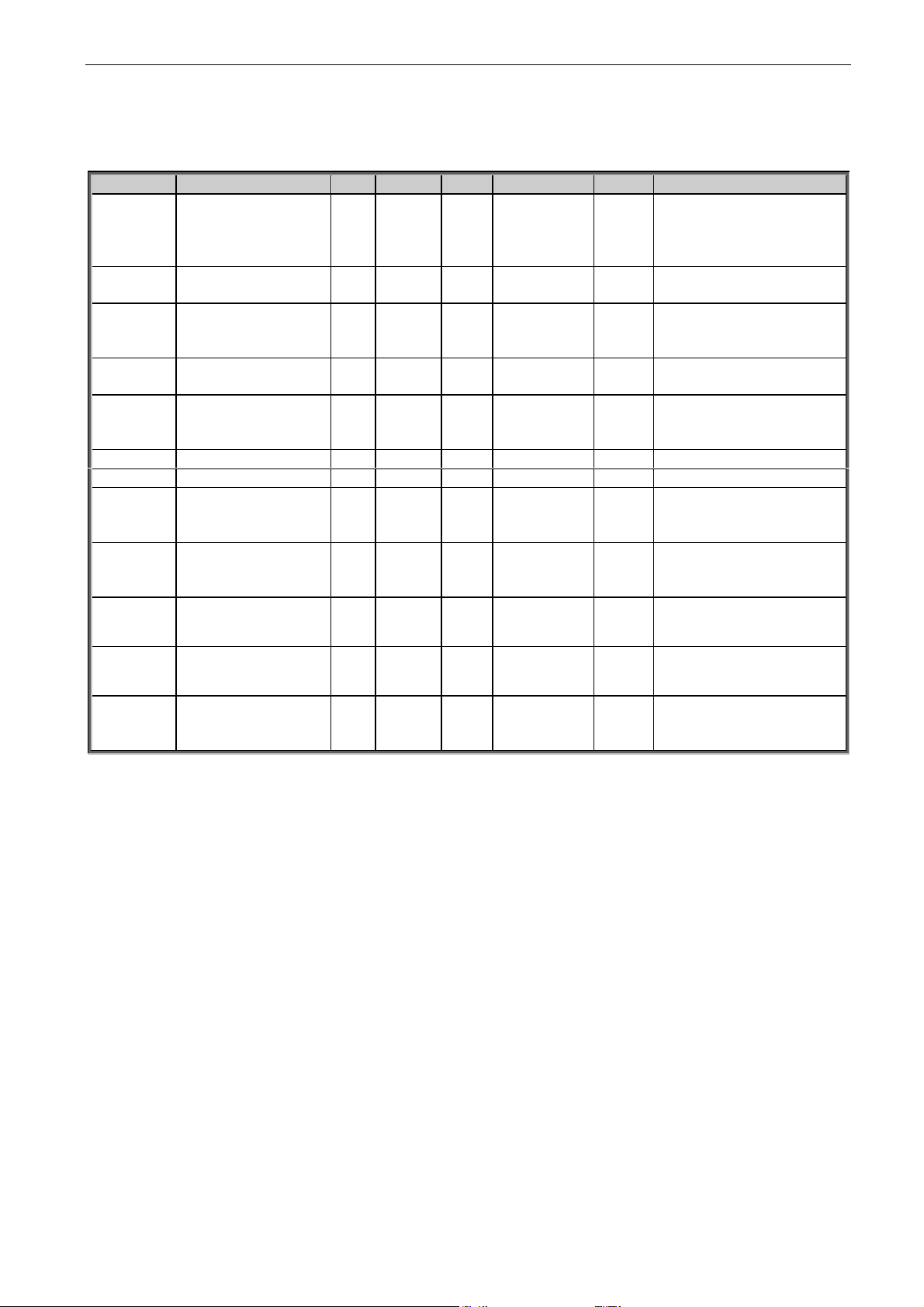

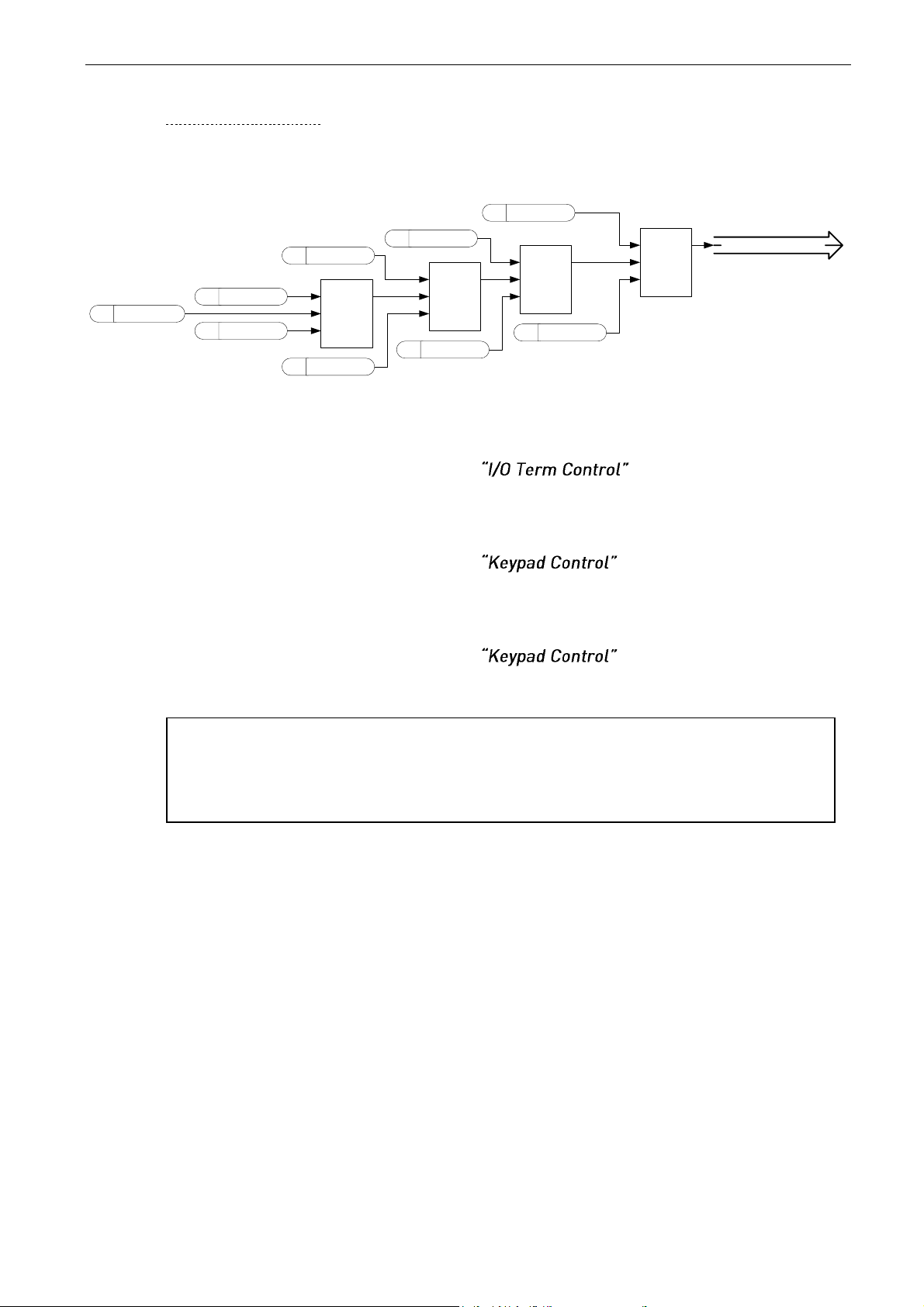

3. Power Take Modes

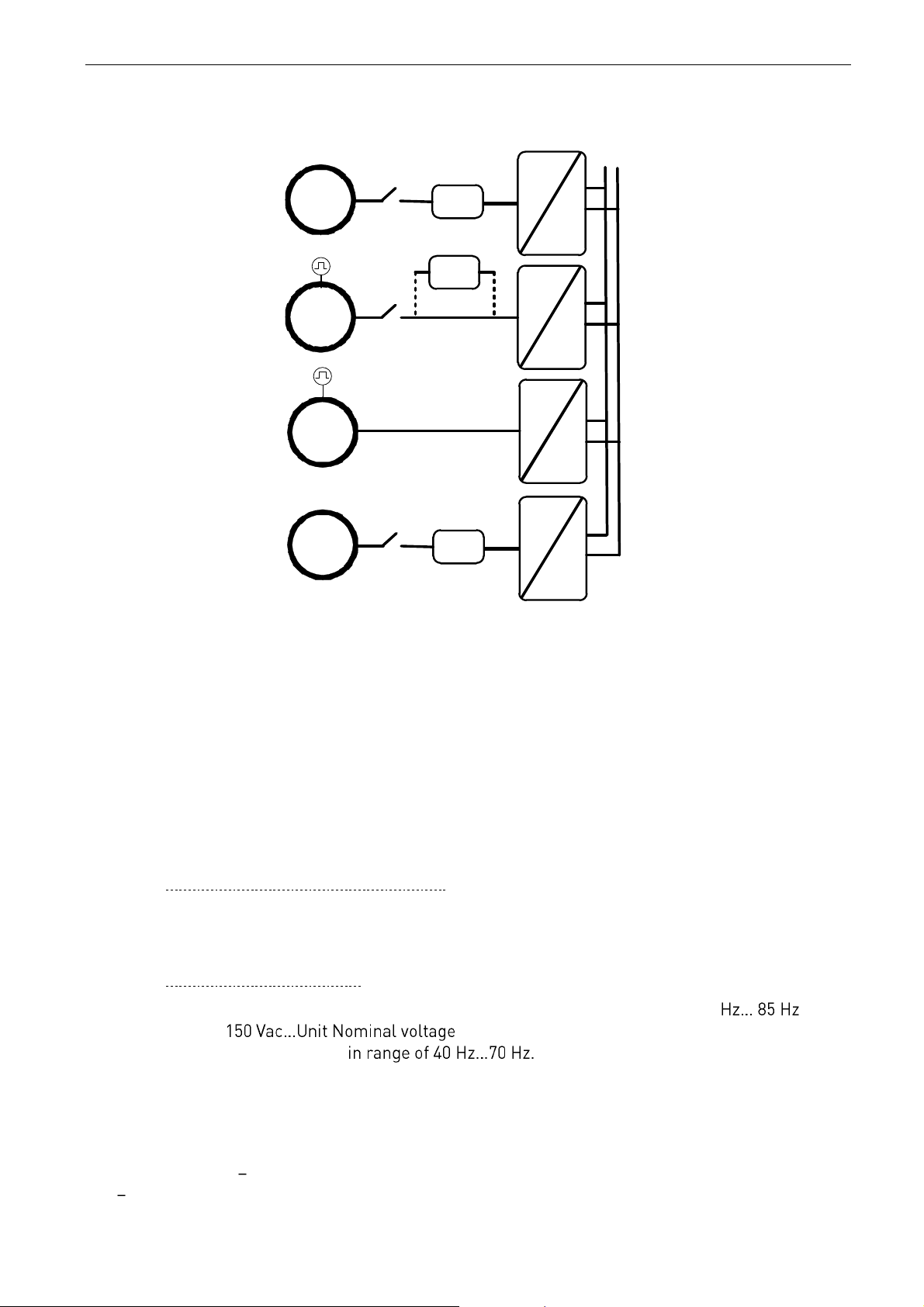

U2

=

~

Filter

SG

U1

Q2

=

~

Filter

PMG

U1

Q2

U2

=

~

IMG

U2

=

~

Filter

SM

U1

Q2

UDC

U2

Figure 3-1.

3.1 Power Take Out modes

3.1.1 Induction motor

AC drive is operated in closed loop control. Closed Loop is needed to have good response to power

demand changes. AC drive will be set to operate in DC Reference mode with negative torque

reference, which can be handled in G2.2.1.6 PTO group, when Power Take mode is PTO. Torque

reference can be handled by using curve reference mode or with direct control from upper system.

3.1.1.1

Induction motor in open loop control.

Pure open loop control can be used on cases were generator drive is not required to keep the DC

stable, e.g. when grid side drive can be kept in AFE mode.

3.1.1.2

Regenerative Motor Mode

This mode can be used in open loop mode but involve limits for frequency range: 30 and

for voltage range: . When starting this operation mode, the

recommended generator speed is This mode requires licence code. To

get the licence, provide the technical details beforehand to VACON® Finland for approval.

3.1.2 Permanent Magnet Synchronous Motor

Depending on the system requirements, the PMSM can be controlled in normal motor control modes

or AFE mode. If PTI TMH is also needed, we recommend the normal motor control mode. If only

PTI Boosting is needed, the system may be possible to operate in AFE mode.

Page 10

10 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

PMSM in normal motor control modes needs to be operated in closed loop control to have a good

response time to the changes in power demand.

AFE mode can be used without filter if motor can be run with unity power factor. AFE can

compensate if inductor size is programmed according to stray inductance of PM motor and stray

inductance voltage is over half of BEM voltage, if not, LC filter is enough. When paralleling, LCL is

needed

3.2 Synchronous machine

This is normal AFE operation.

Page 11

arfiff30 Generator VACON® • 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

3.3 Power Take In modes

PTI needs to be separated to two different modes. In all modes the DC Voltage needs to be kept

constant with the Grid side drive (or otherwise have suitable DC Voltage available). When using the

Grid Converter application on grid side, change the operation mode to AFE operation mode. Constant

DC Voltage can be also kept with the uGrid operation mode when special care of references and limit

values in PMS has been take care of.

PTI - Boosting.

In this mode the generator (motor) is already rotating when more power is started to be fed to the

generator (motor). When the PTI is started, we recommend a minimum frequency limit of ~20 Hz for

the drive is. Above this limit, the operation is considered to be boosting.

PTI TMH (Take Me Harbour)

In this mode, the generator (motor) needs to be started from zero speed. You can do this for

example so that the main engine is not running and the propeller power is taken from the diesel

generator using existing shaft generator system.

3.3.1 Induction Motor – Boosting

3.3.1.1

In DC Voltage Reference mode

While in PTO mode, the AC drive is operated in the torque reference mode. When you change the

operation mode to boosting, you can simply put the AC drive torque reference to positive direction.

3.3.1.2

In Speed Reference Mode

In this mode, the AC drive will follow the speed reference of the PMS. Usually the power capacity of

the Shaft Generator system is only a fraction of the main engine power capacity. Therefore, you need

to check the power, torque and current limitations.

3.3.2 Induction Motor- Take Me Harbour.

In this mode, the AC drive will follow the speed reference of the PMS Usually the power capacity of

the Shaft Generator system is only a fraction of the main engine power capacity. Therefore, you need

to check the power, torque and current limitations.

3.3.3 Permanent Magnet Synchronous Motor - Boosting

Depending on the system requirements, the PMSM can be controlled in normal motor control modes

or AFE mode. If PTI TMH is also needed, we recommend the normal motor control mode. If only

PTI Boosting is needed and there is space for sine filter, the system can be operated in AFE mode.

3.3.3.1

Operating in AFE Mode, DC Voltage Reference Mode

Change is made only between PTO and PTI Boosting mode.

When the AC drive is operating in PTO mode, the constant DC Voltage in maintained. When you

change to the Boosting mode, the constant DC Voltage needs to be kept with grid side drive. When

the grid side drive keeps the constant DC Voltage, the DC Voltage Reference can be set lower on the

generator side drive thus changing the power flow direction. To be able to control the power flow,

the PMS needs to control the Output Power.

Page 12

12 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

3.3.3.2

Operating in AFE Mode, Speed Reference Mode

This operation mode is not possible.

3.3.3.3

Operating in normal motor control mode, DC Voltage Reference Mode

While in PTO mode, the AC drive is operated in the torque reference mode. When you change the

operation mode to boosting, you can simply put the AC drive torque reference to positive direction.

With this selection, the PMS will control the positive torque reference thus defining boosting torque.

3.3.3.4

Operating in normal motor control mode. Speed Reference Mode

In this mode, the AC drive will follow the speed reference of the PMS. Usually the power capacity of

the Shaft Generator system is only a fraction of the main engine power capacity. Therefore, you need

to check the power, torque and current limitations.

3.3.4 Permanent Magnet Synchronous Motor – Take Me Harbour

This control can be made only by using the normal motor control modes. AFE mode cannot start

from below 25 Hz.

3.3.4.1

Operating in normal motor control mode, DC Voltage Reference Mode

While in PTO mode, the AC drive is operated in the torque reference mode by using selection 1 /

Curve in P2.2.9.1 Torque Ref Select. When you change the operation mode to boosting, you need to

set the reference to positive direction. With this selection, the PMS will control the positive torque

reference thus defining torque to be used for propulsion.

3.3.4.2

Operating in normal motor control mode. Speed Reference Mode

In this mode, the AC drive will follow the speed reference of the PMS. Usually the power capacity of

the Shaft Generator system is only a fraction of the main engine power capacity. Therefore, you need

to check the power, torque and current limitations.

3.3.5 Synchronous machine - Boosting

3.3.5.1

Operating in AFE Mode, DC Voltage Reference Mode

Change is made only between PTO and PTI Boosting mode.

While the AC drive is operating in the PTO mode, the constant DC Voltage is maintained. When you

change to the Boosting mode, the constant DC Voltage needs to be kept with grid side drive. When

the grid side drive keeps the constant DC Voltage, the DC Voltage Reference can be set lower in the

generator side thus changing power flow direction. To be able to control power flow, the PMS needs

to control the Output Power limit P2.6.2.1 OutputPowerLim.

3.3.5.2

Operating in AFE Mode, Speed Reference Mode

This operation mode is not possible.

3.3.5.3

Operating in normal motor control mode, DC Voltage Reference Mode

Not supported nor recommended.

3.3.5.4

Operating in normal motor control mode. Speed Reference Mode

Not supported nor recommended.

Page 13

arfiff30 Generator VACON® • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

3.3.6 Synchronous machine – Take Me Harbor

This operation mode is only possible in the normal motor control modes.

3.3.6.1

Operating in normal motor control mode, DC Voltage Reference Mode

Not supported nor recommended

3.3.6.2

Operating in normal motor control mode. Speed Reference Mode

Change is made only between PTO and PTI TMH.

While the AC drive is operating in PTO mode, the constant DC Voltage is maintained. When you

change to PTI - TMH mode, the constant DC Voltage needs to be kept with grid side drive.

In this mode the AC drive will follow the speed reference of the PMS Usually the power capacity of

the Shaft Generator system is only a fraction of the main engine power capacity. Therefore, you need

to check the power, torque and current limitations.

Page 14

14 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

4. Main contactor control

The Generator application controls the MCB (Main Circuit Breaker) of the system with selectable

Relay Output. When charging of the DC bus is ready, the MCB will be closed. The status of the MCB

is monitored via digital input. Digital input used for monitoring is chosen with parameter P2.4.2.4.

When a fault occurs, the MCB will be opened after one second so the drive will go to stop state

first. In case of F1 Over Current, F2 Over Voltage or F31 and F41 IGBT faults, the breaker is opened

immediately. If the charging is on when the fault is acknowledged the MCB will be closed.

An external charging circuit is needed to charge the DC bus.

Page 15

arfiff30 Generator VACON® • 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

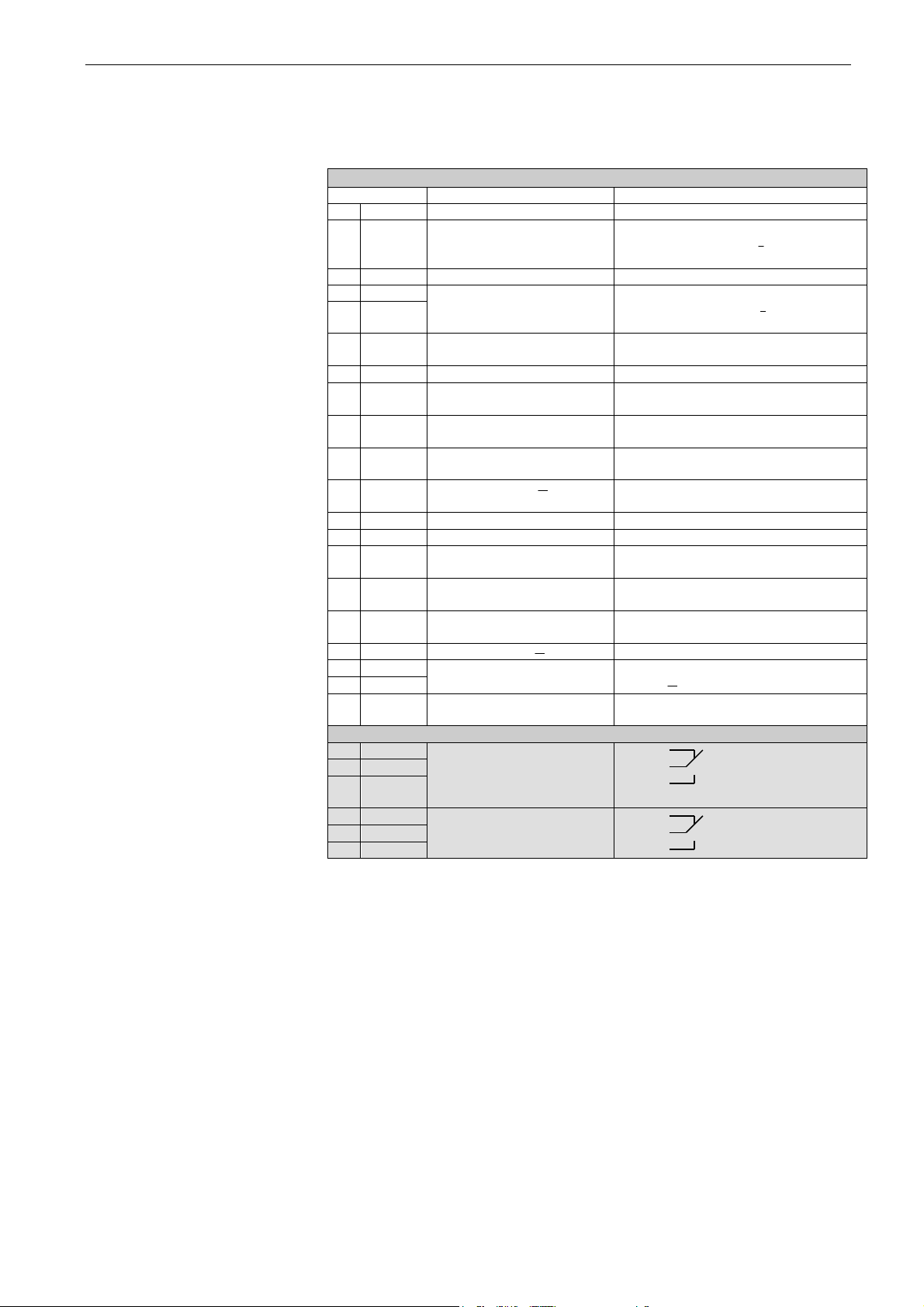

5. Control I/O

OPT-A1

Terminal

Signal

Description

1

+10Vref

Reference voltage output

Voltage for potentiometer, etc.

2

AI1+

Analogue input 1.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Input range selected by jumpers.

Default range: Voltage 0 10 V

3

AI1-

I/O Ground

Ground for reference and controls

4

AI2+

Analogue input 2.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Input range selected by jumpers.

Default range: Current 0 20 mA

5

AI2-

6

+24V

Control voltage output

Voltage for switches, etc. max 0.1 A

7

GND

I/O ground

Ground for reference and controls

8

DIN1

Start

Programmable G2.2.1

0=Stop,

1=Run

9

DIN2

Programmable G2.2.1

No function defined at default

10

DIN3

Programmable G2.2.1

No function defined at default

11

CMA

Common for DIN 1 DIN 3

Connect to GND or +24V

12

+24V

Control voltage output

Voltage for switches (see #6)

13

GND

I/O ground

Ground for reference and controls

14

DIN4

Main contactor supervision

Programmable G2.2.1

0 = contactor open

1 = contactor closed

15

DIN5

Programmable G2.2.1

No function defined at default

16

DIN6

Fault reset

Programmable G2.2.1

Rising edge will reset active faults

17

CMB

Common for DIN4 DIN6

Connect to GND or +24V

18

AO1+

Analogue output 1

Programmable

Range 0 20 mA/RL, max. 500

19

AO1-

20

DO1

Digital output

READY

Programmable P2.3.1.1

Open collector, I50mA, U48 VDC

OPT-A2

21

RO1

Relay output 1

Programmable P2.3.1.2

Switching capacity

24 VDC / 8 A

22

RO1

23

RO1

250 VAC / 8A

125 VDC / 0.4 A

24

RO2

Relay output 2

Main contactor control

This RO is not programmable.

Fixed for Main Contactor Control

25

RO2

26

RO2

Table 5-1 Default I/O configuration.

Reference

Page 16

16 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6. Monitoring signals

Menu M1 (Monitoring) holds all the monitoring values. Values are only for monitoring, and cannot be

altered by the panel.

6.1 Monitoring

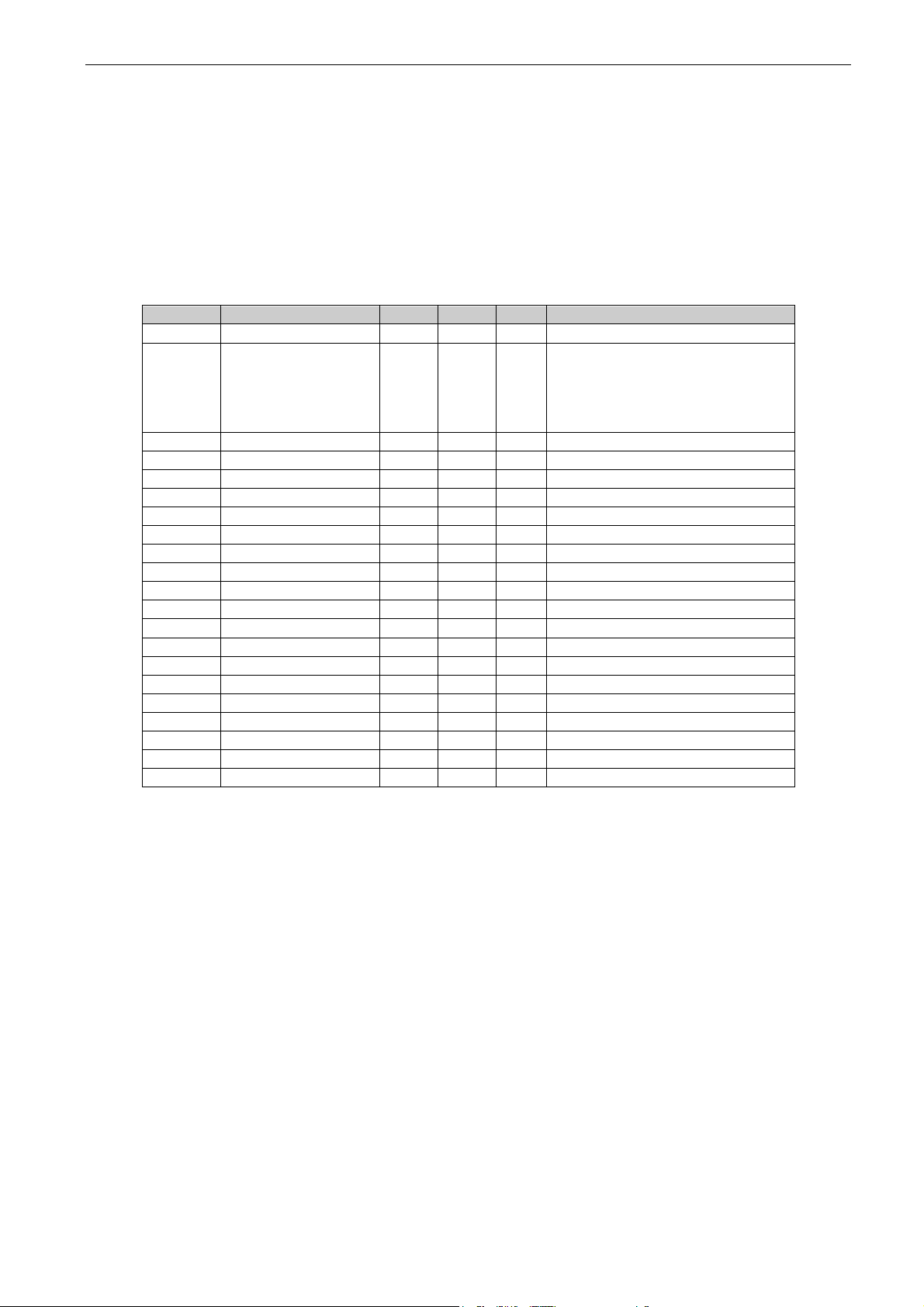

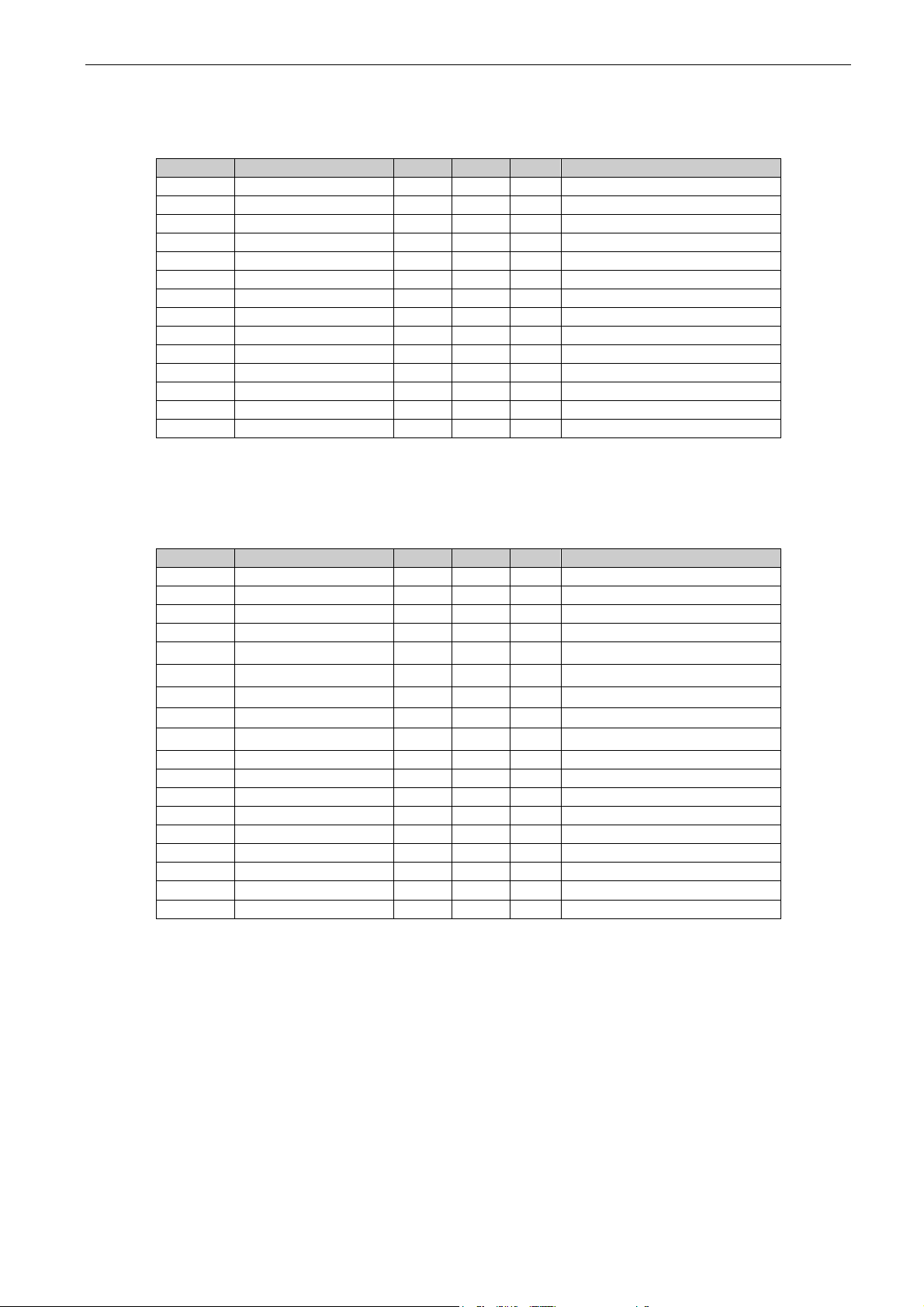

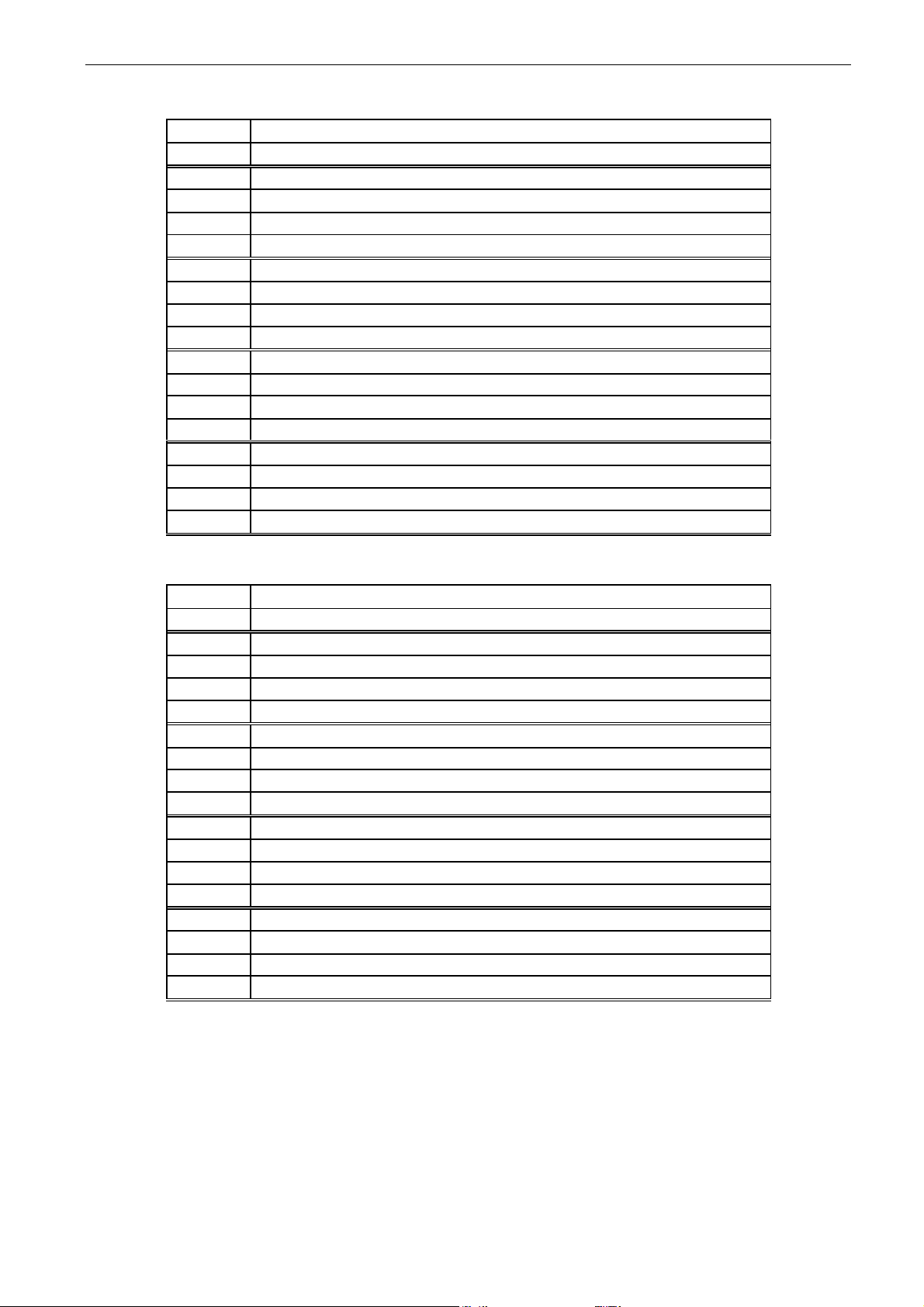

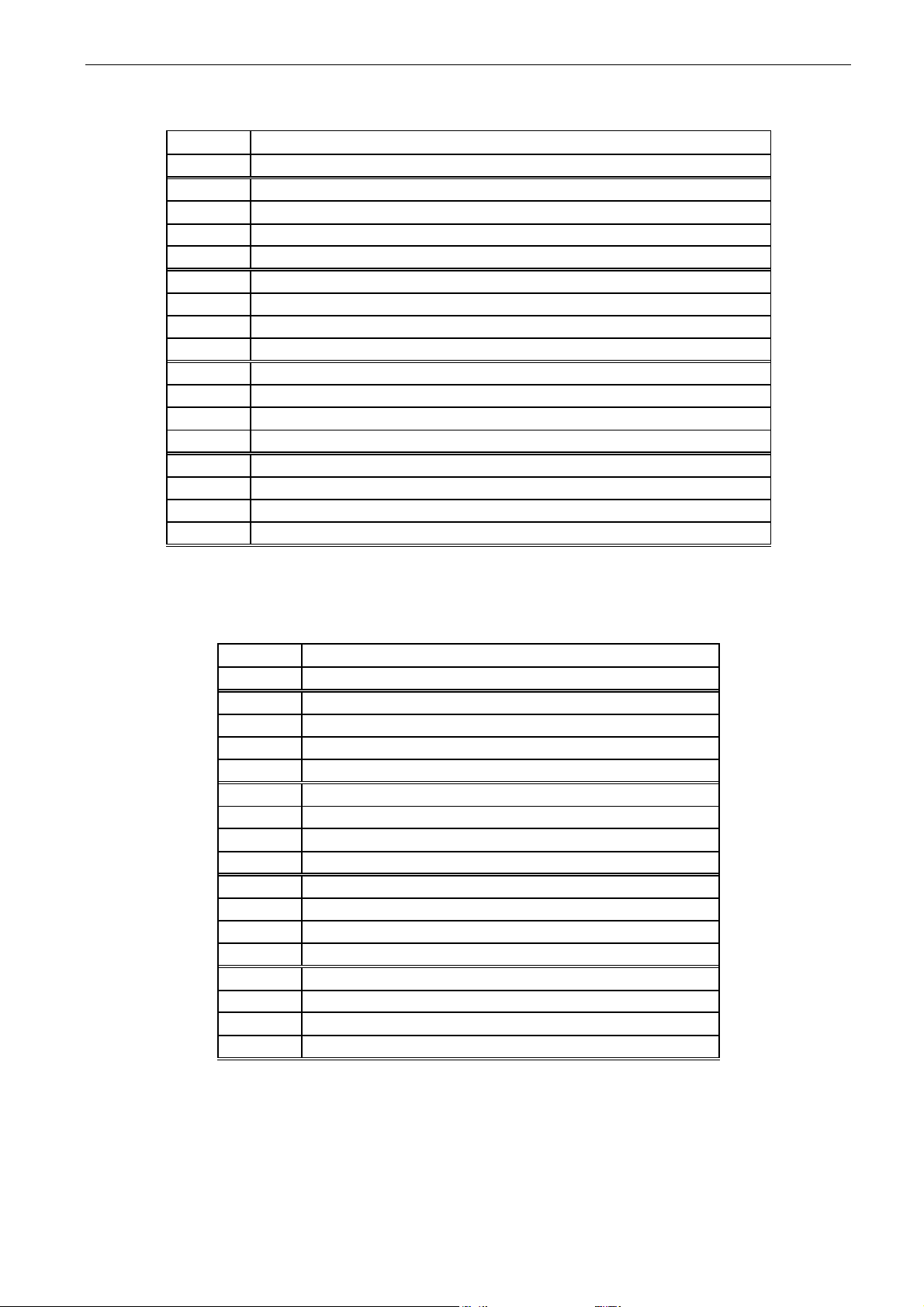

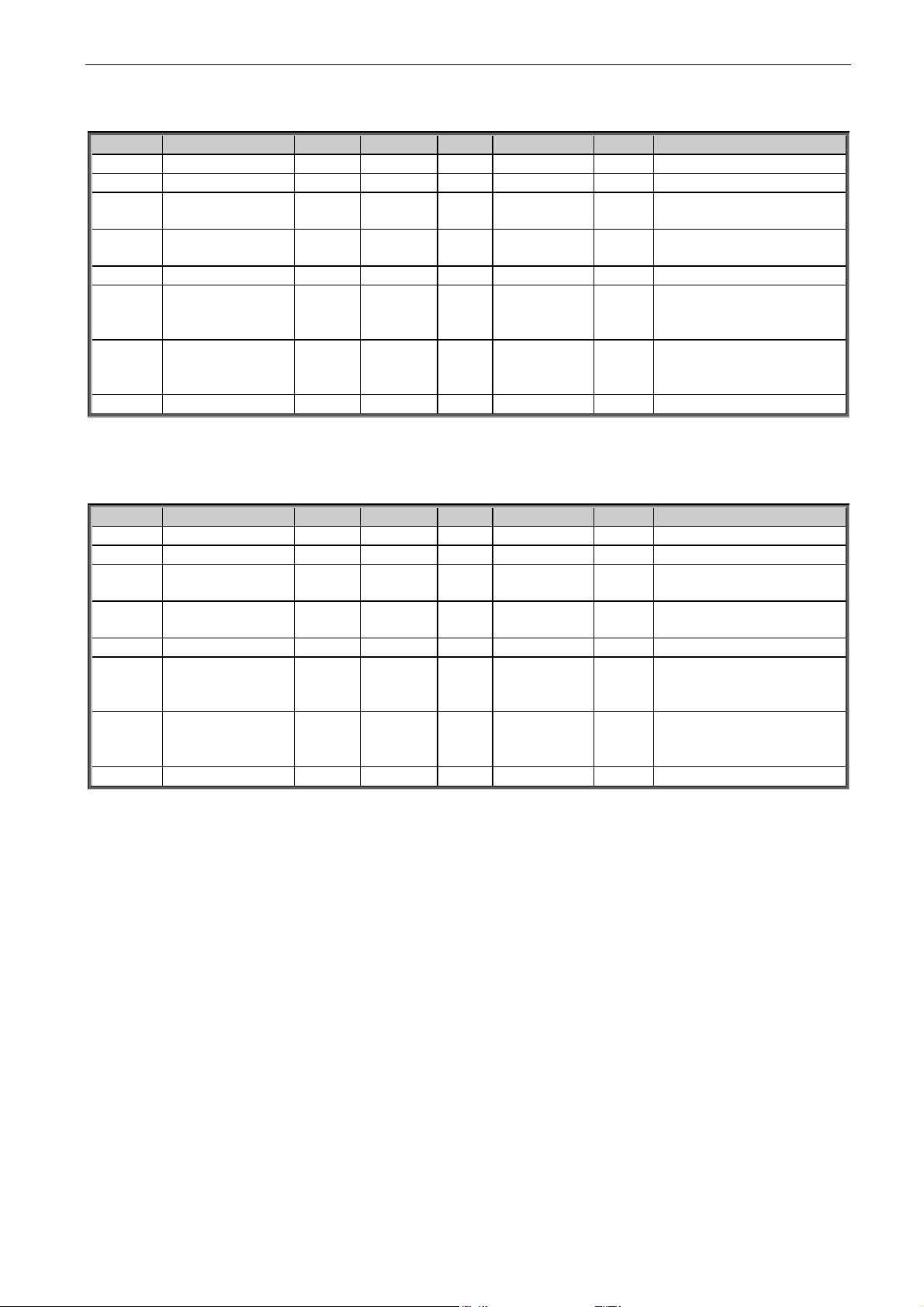

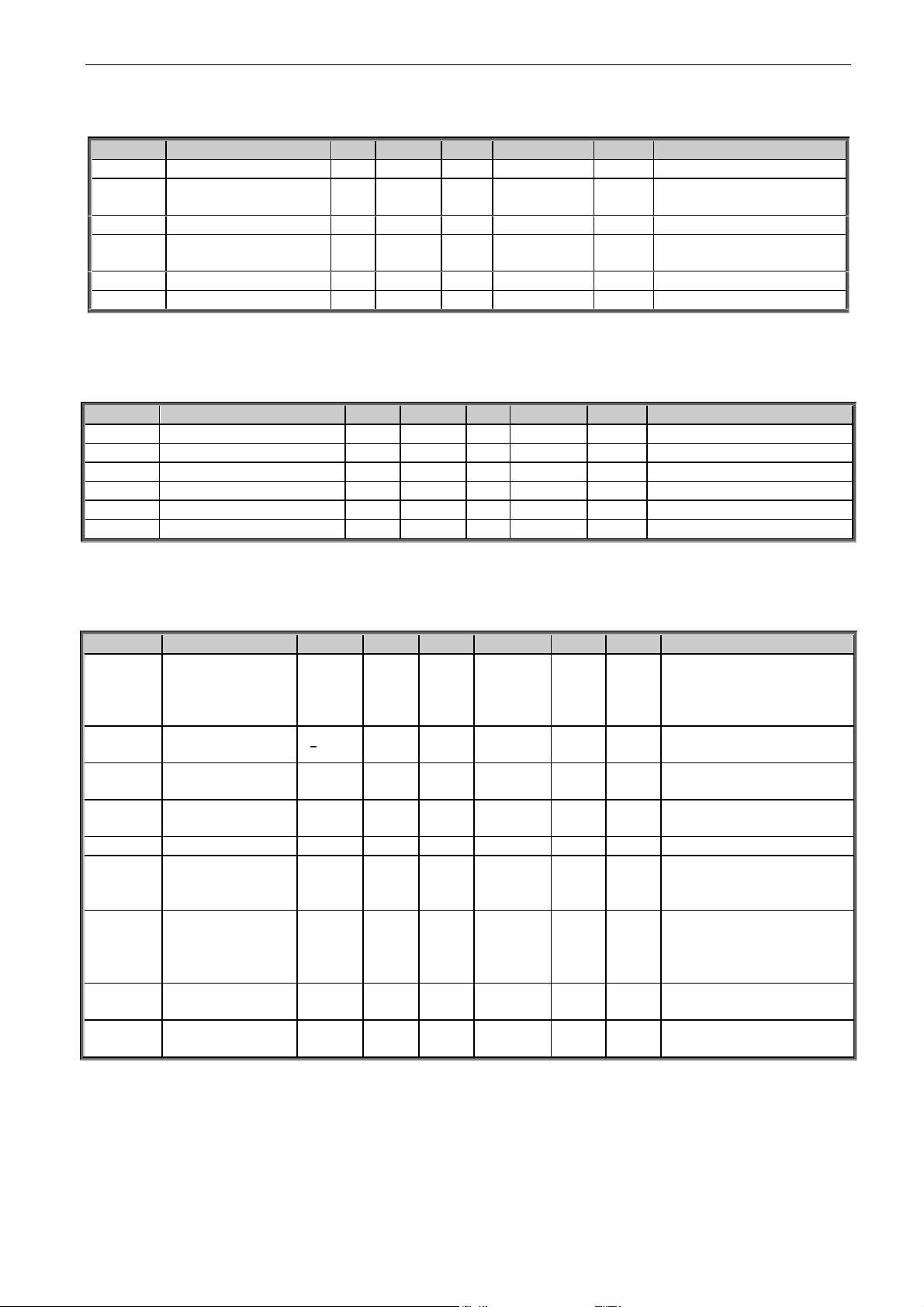

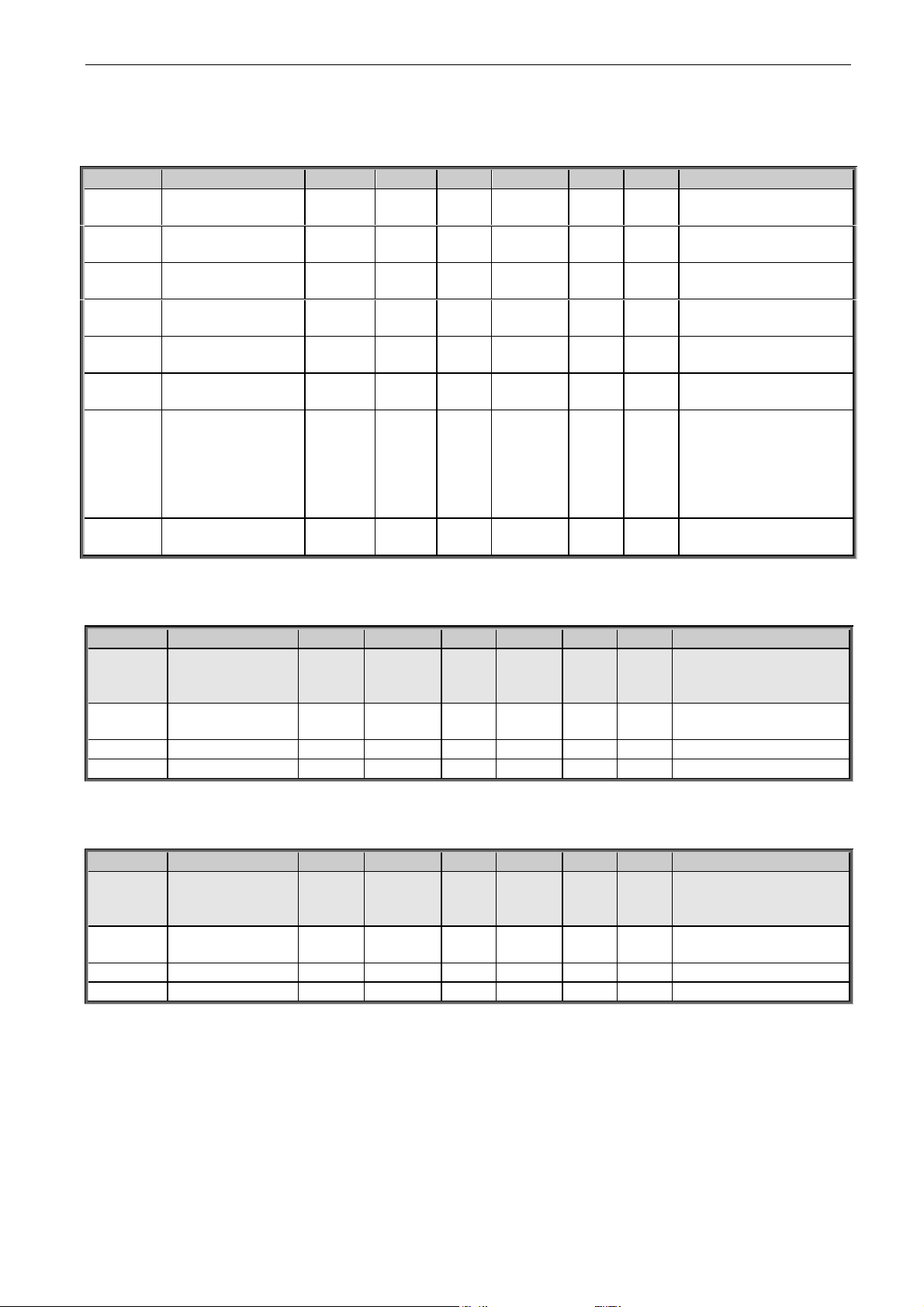

6.1.1 Monitoring 1 Values

Code

Parameter

Unit

Form.

ID

Description

V1.1.1

DC-Link Voltage

V # 1108

DC Voltage filtered

V1.1.2

DC Voltage Ref.

%

#,##

1200

Used DC voltage reference by the

regenerative unit in % of Nominal DC

Voltage.

Nominal DC voltage = 1.35 * Supply

voltage

V1.1.3

DC Voltage Actual

%

#,##

7

Same scaling as DC Voltage Ref.

V1.1.4

Total Current

A

Varies

1104

Filtered current

V1.1.5

Active Current

%

#,#

1125 V1.1.6

Reactive Current

%

#,#

1157 V1.1.7

Power kW

kW

Varies

1508 V1.1.8

Power %

%

#,#

5 V1.1.9

Status Word

# 43 V1.1.10

Supply Frequency

Hz

#,##

1

Drive output frequency

V1.1.11

Supply Voltage

V

#,#

1107

Drive output voltage

V1.1.12

LineFrequency D7

Hz

#,##

1654

Measured line frequency

V1.1.13

Line Voltage D7

V # 1650

Measured line voltage

V1.1.14

AC Voltage Reference

V # 1556 V1.1.15

DC Ref Max Lim

%

#,##

1606 V1.1.16

Encoder 1 Freq.

Hz

#,##

1164 V1.1.17

Torque Reference

%

#,#

18 V1.1.18

Final Torque Reference

%

#,#

1145 V1.1.19

Actual Torque Reference

%

#,#

1180 V1.1.20

Motor Torque

%

#,#

4

Filtered

V1.1.21

Motor Speed

rpm # 2

Table 6-1, Monitoring 1

Page 17

arfiff30 Generator VACON® • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

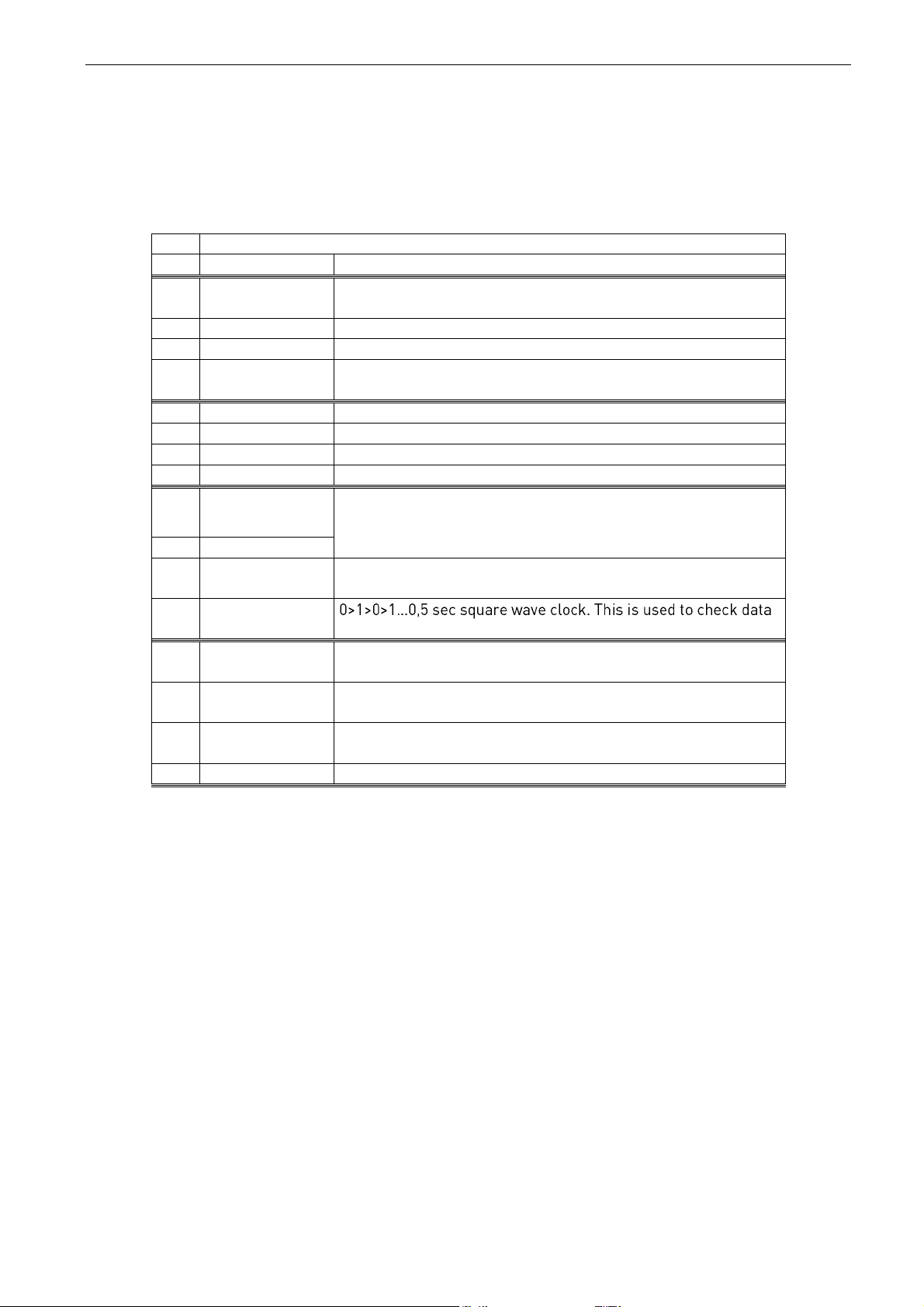

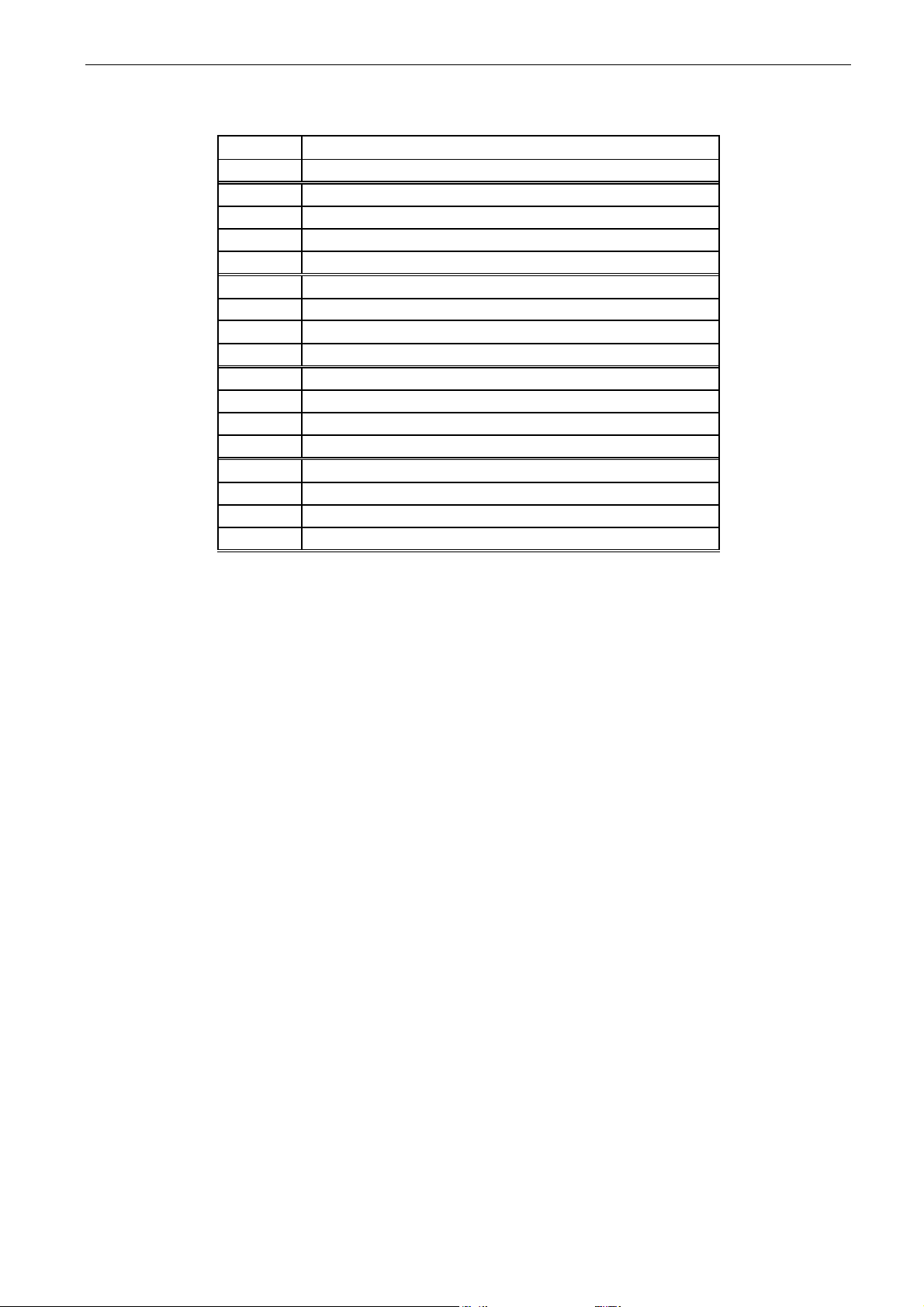

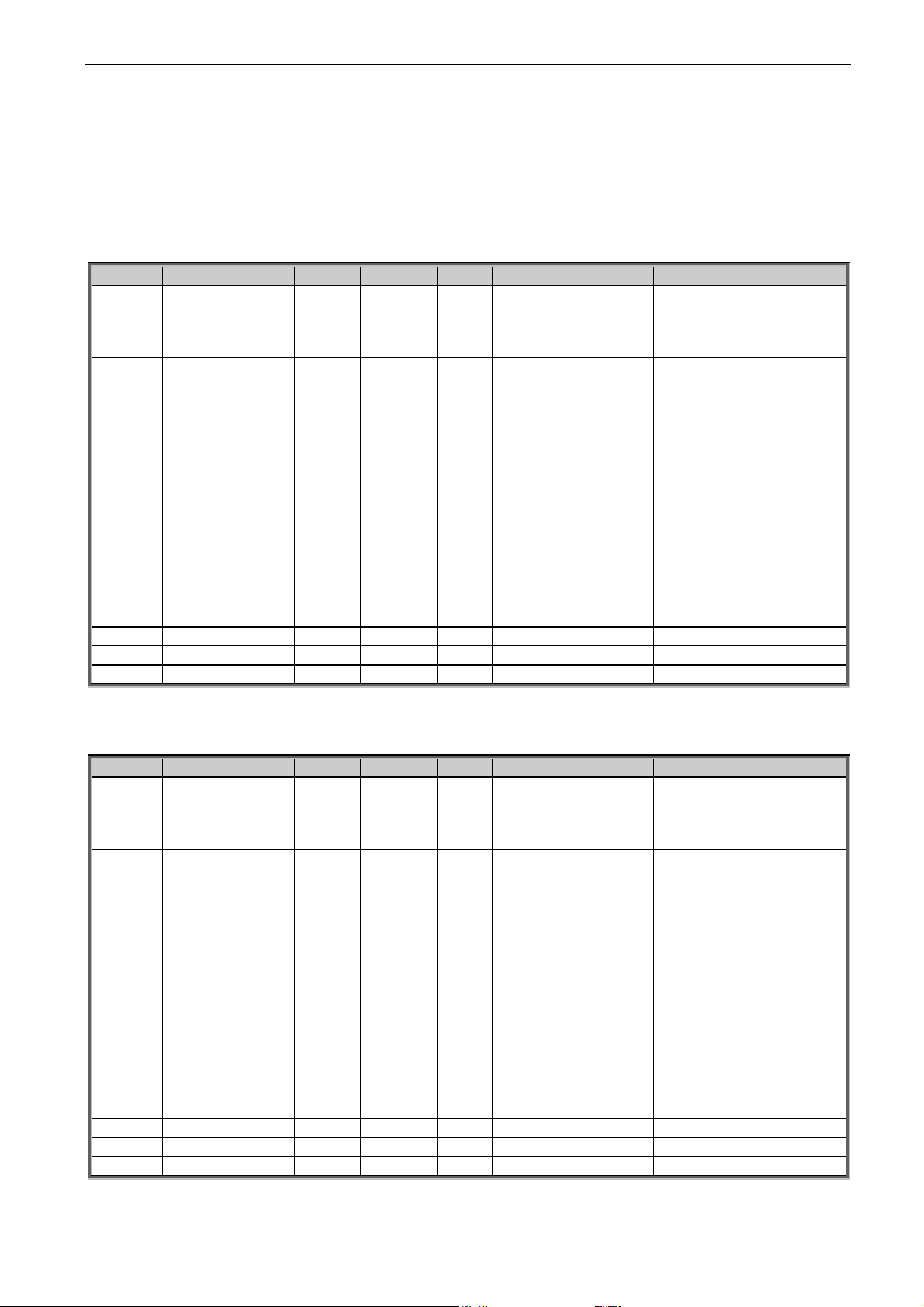

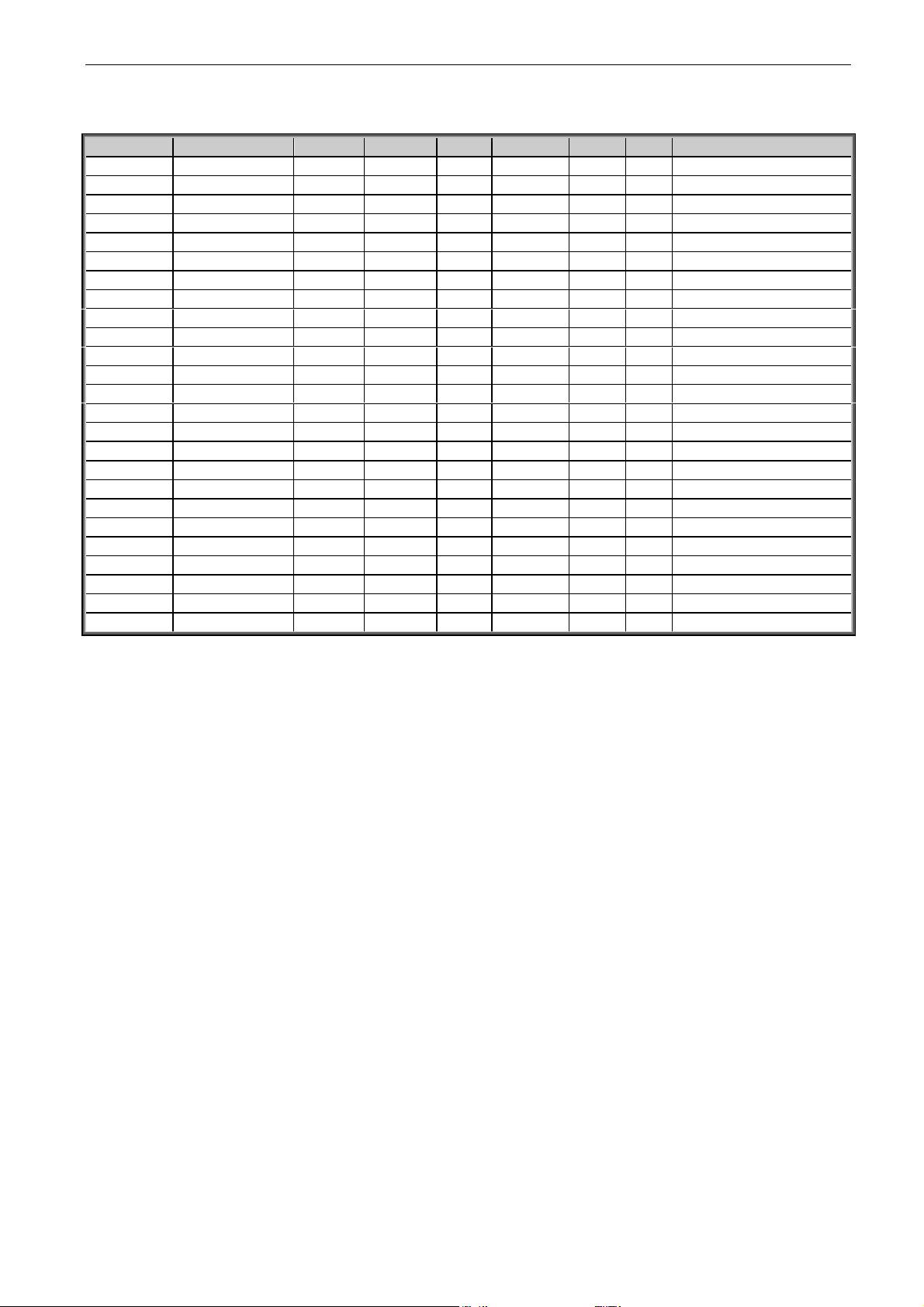

6.1.2 Monitoring 2 Values

Code

Parameter

Unit

Form.

ID

Description

V1.2.1

DC Voltage

V # 44

Measured DC Link voltage in

Volts, unfiltered.

V1.2.2

Cos Phii Actual

#,###

1706 V1.2.3

Unit Temperature

°C # 1109 V1.2.4

Freq Reference

Hz

#,##

25

Used line frequency reference

V1.2.5

Current

A

Varies

1113

Unfiltered current

V1.2.6

Operation Hours

h

#,#

1856

V1.2.7

Reactive Current

Reference

%

#,#

1389

V1.2.8

Power Take Mode

# 1925 V1.2.9

Torque

%

#,#

1134

Unfiltered

V1.2.10

Limit & Regulators

# 77 V1.2.11

Shaft Frequency

Hz

#,##

1124 V1.2.12

U Phase Current

A

Varies

39 V1.2.13

V Phase Current

A

Varies

40 V1.2.14

W Phase Current

A

Varies

41

V1.2.15

Fault Word 10

1202

V1.2.16

Warning Word 10

1269

Table 6-2, Monitoring 2

Page 18

18 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

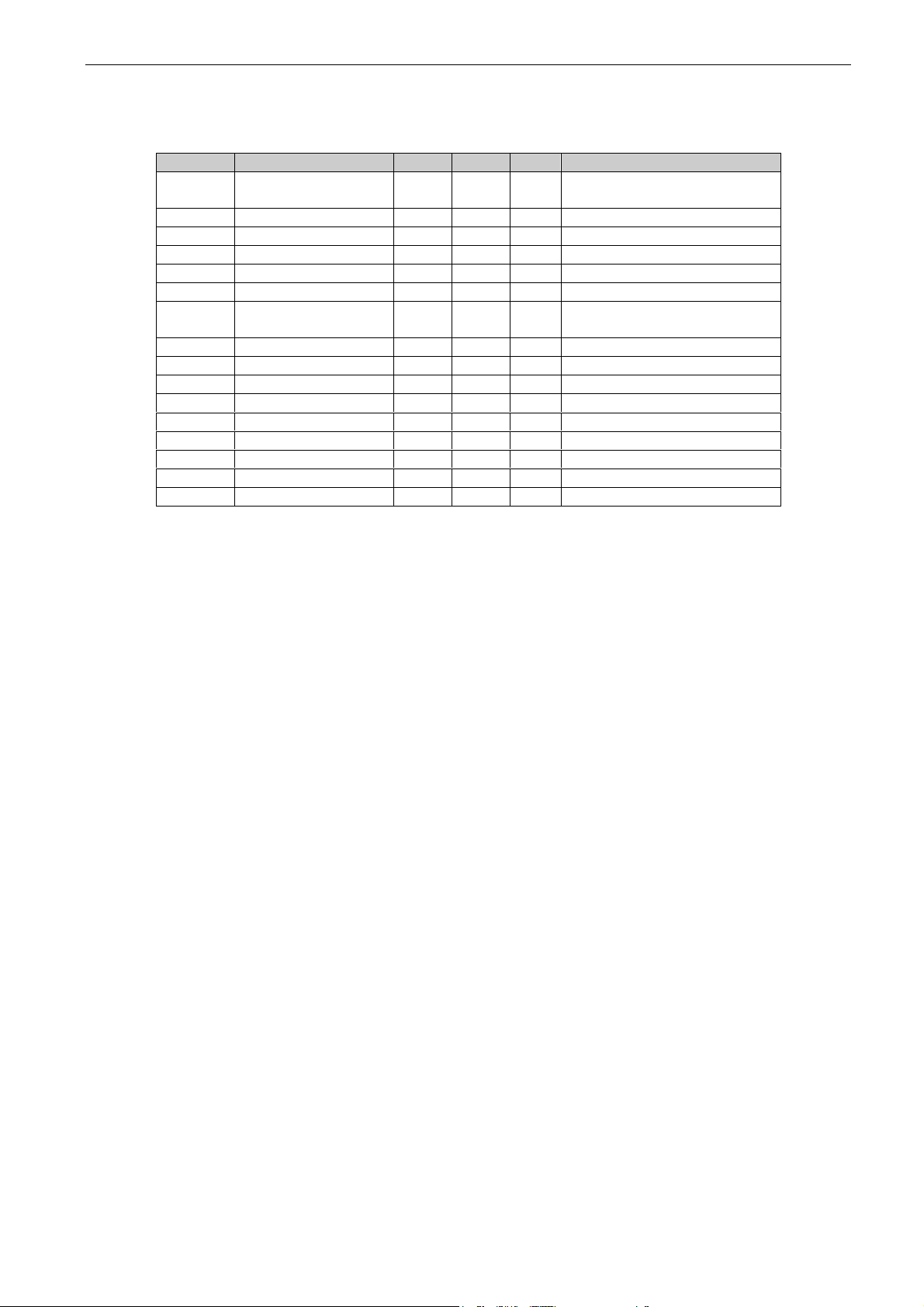

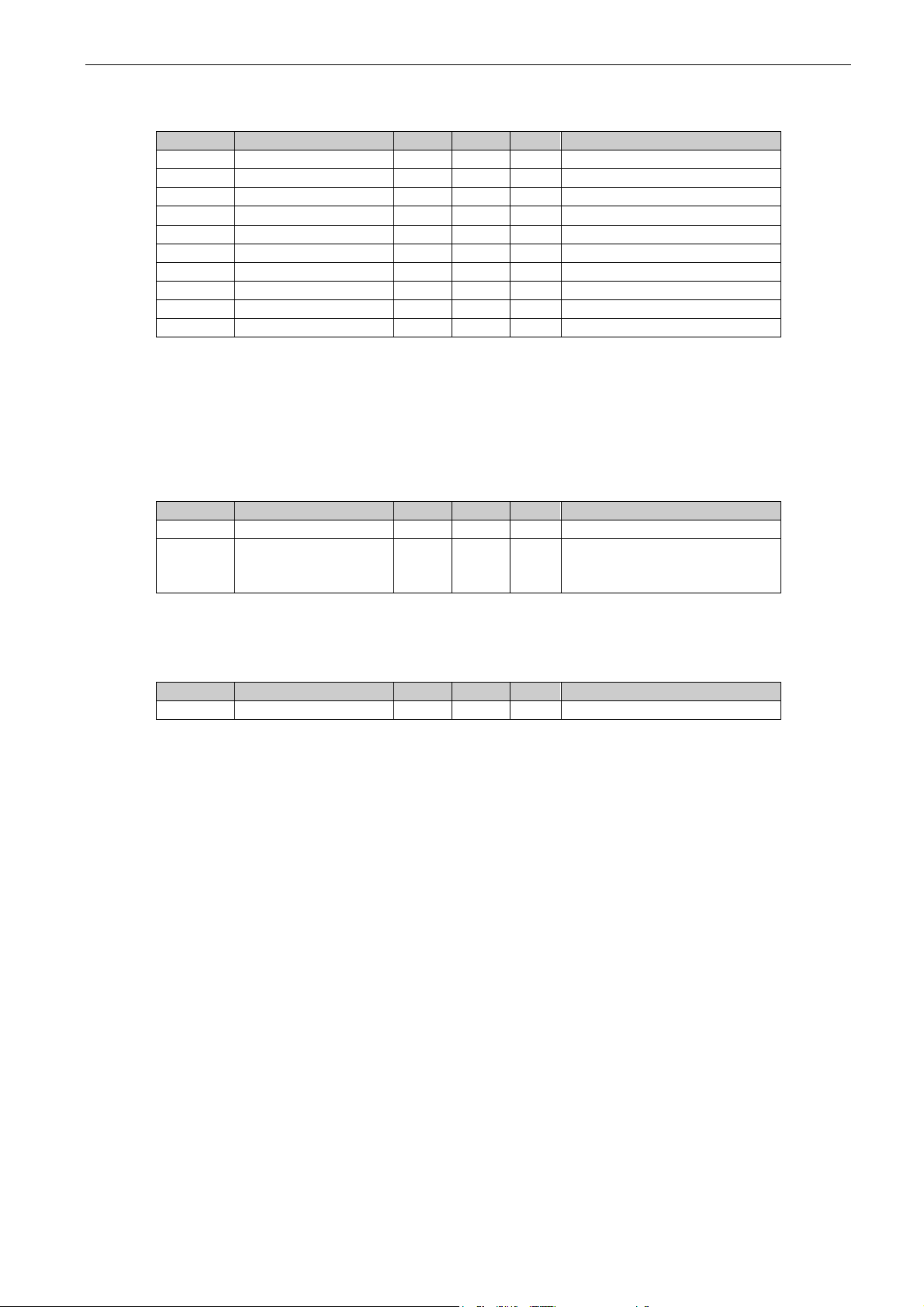

6.1.3 Fieldbus Monitoring values

Code

Parameter

Unit

Form.

ID

Description

V1.3.1

FB Control Word

# 1160

Control word from fieldbus

V1.3.2

FB Status Word

# 68

Status word to fieldbus

V1.3.3

FB Actual Value

# 865 V1.3.4

FB Speed Ref

# 875 V1.3.5

FB Torque Ref

#,#

1140 V1.3.6

Generator CW

# 1700 V1.3.7

Generator SW

# 1701 V1.3.8

Fault Word 1

# 1172 V1.3.9

Fault Word 2

# 1173 V1.3.10

Warning Word 1

# 1174 V1.3.11

Last Active Warning

# 74 V1.3.12

Last Active Fault

# 37 V1.3.13

Speed FB Scaled

#,##

1907 V1.3.14

FB Analog Out

%

#,##

48

Table 6-3, Fieldbus

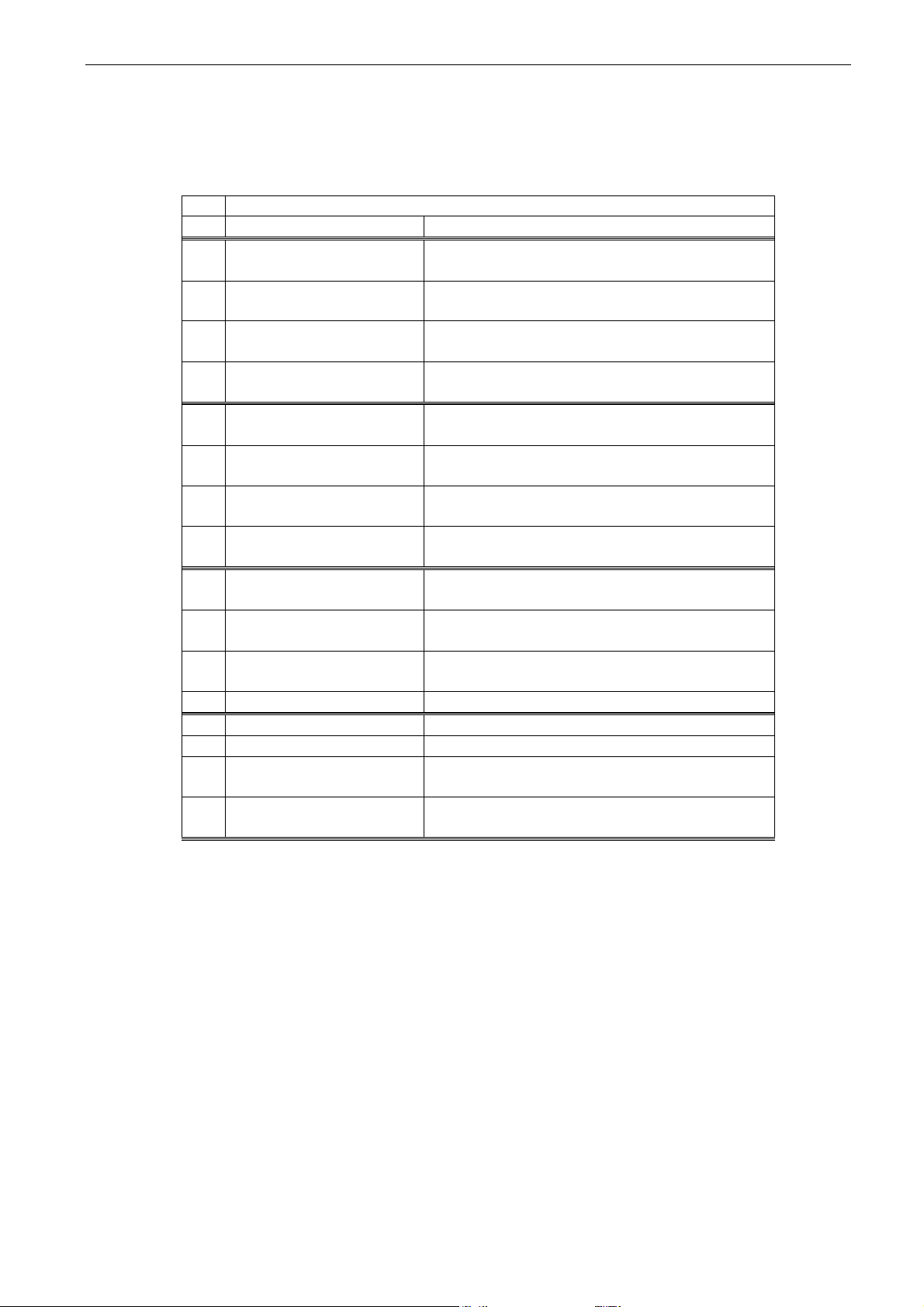

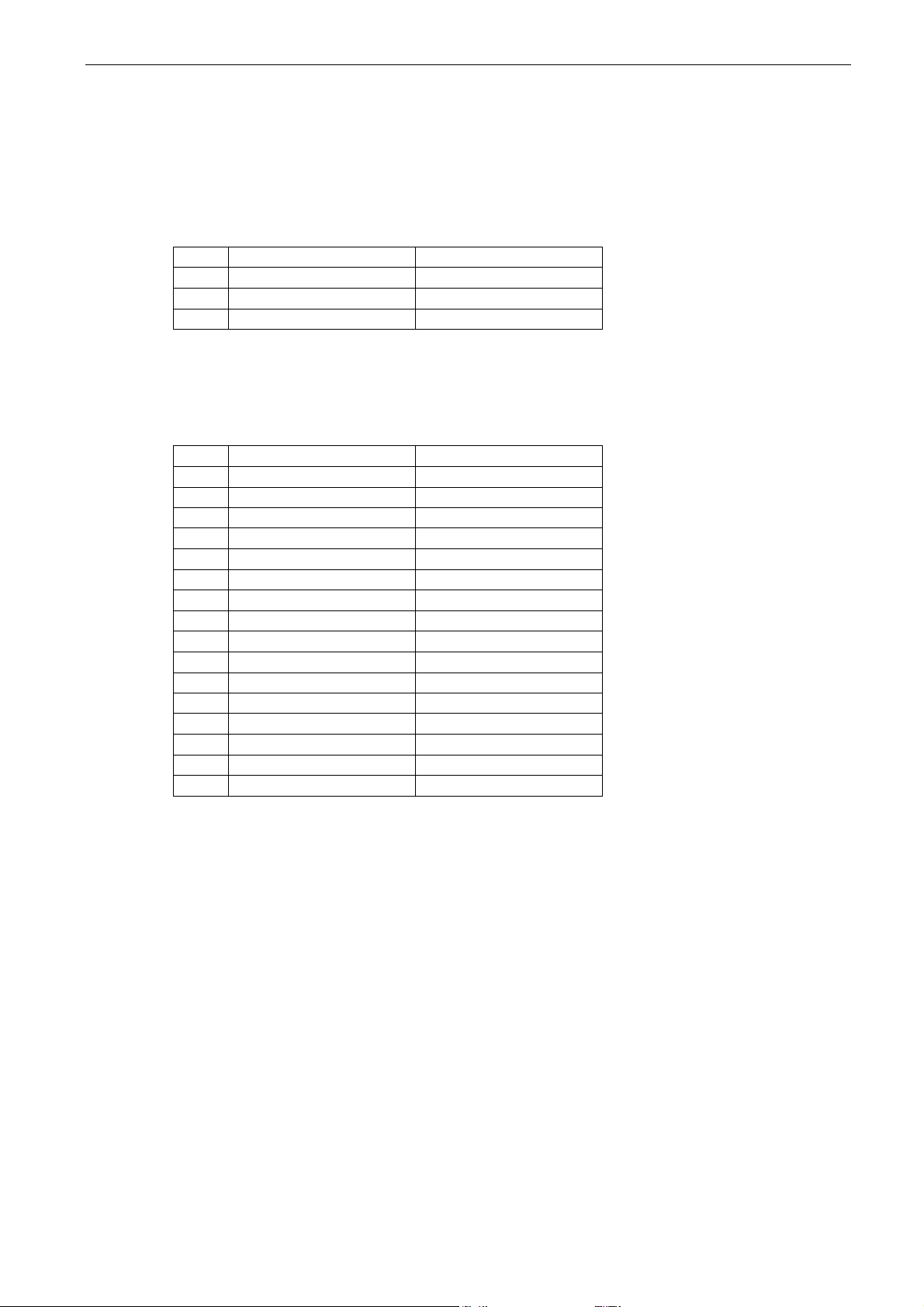

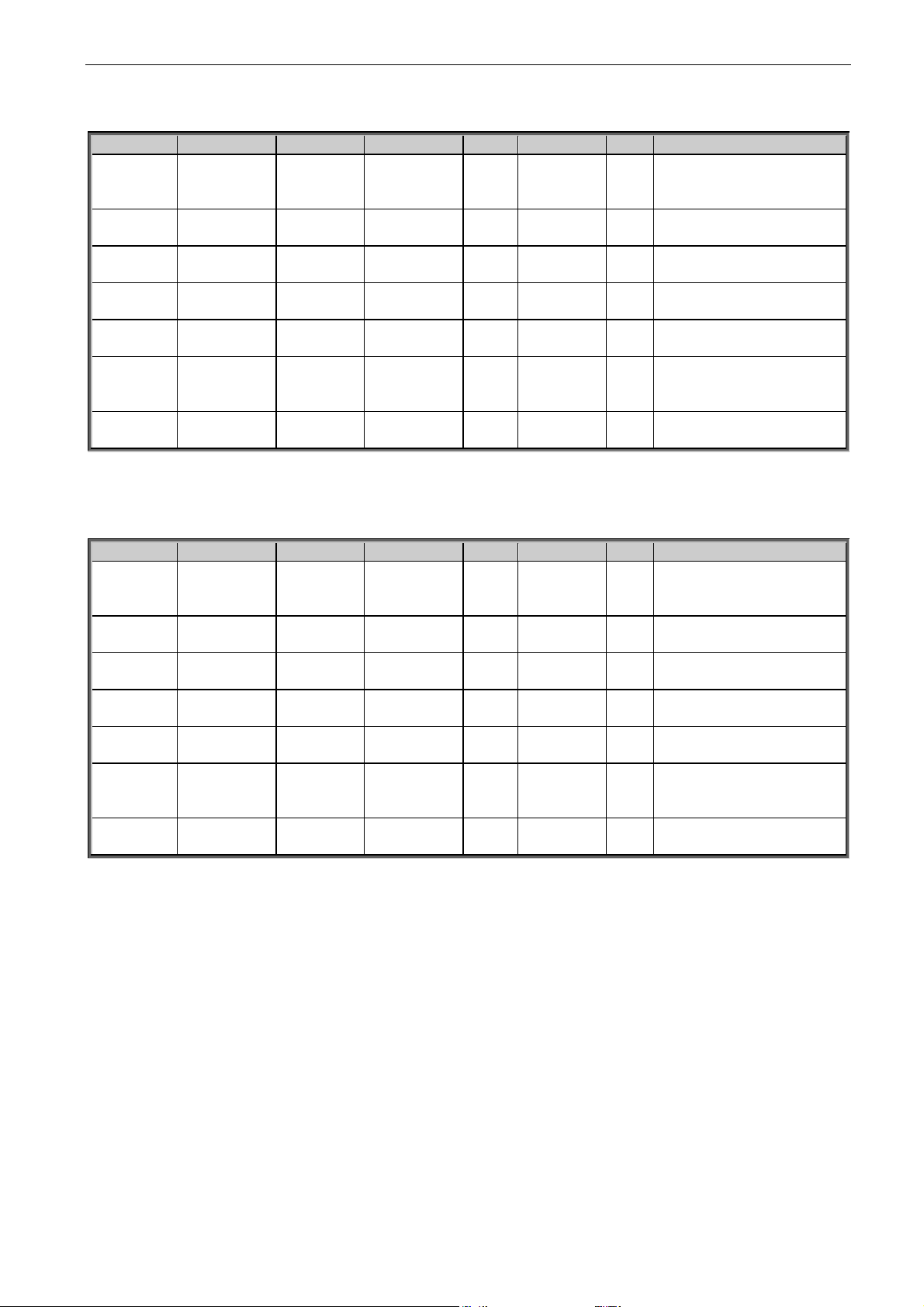

6.1.4 IO Monitoring values

Code

Parameter

Unit

Form.

ID

Description

V1.4.1

DIN1, DIN2, DIN3

# 15 V1.4.2

DIN4, DIN5, DIN6

# 16

V1.4.3

DIN Status 1

# 56

V1.4.4

DIN Status 2

# 57

V1.4.5

Analogue Input 1

%

#,##

13

V1.4.6

Analogue Input 2

%

#,##

14

V1.4.7

Analogue input 3

%

#,##

27

AI3, unfiltered.

V1.4.8

Analogue input 4

%

#,##

28

AI4, unfiltered.

V1.4.9

Analogue Out 1

%

#,##

26

V1.4.10

Analogue Out 2

%

#,##

50

AO2

V1.4.11

Analogue Out 3

%

#,##

51

AO3

V1.4.12

PT100 Temp. 1

°C

#,#

50 V1.4.13

PT100 Temp. 2

°C

#,#

51 V1.4.14

PT100 Temp. 3

°C

#,#

52 V1.4.15

PT100 Temp. 4

°C

#,#

69 V1.4.16

PT100 Temp. 5

°C

#,#

70

V1.4.17

PT100 Temp. 6

°C

#,#

71

V1.4.18

PT100 Max Temperature

°C

#,#

42

Table 6-4, IO monitoring

Page 19

arfiff30 Generator VACON® • 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6.1.5 Master Follower values

Code

Parameter

Unit

Form.

ID

Description

V1.5.1

SB System Status

# 1800 V1.5.2

System Current

A

Varies

80 V1.5.3.1

Current D1

Varies

1820 V1.5.3.2

Current D2

Varies

1821 V1.5.3.3

Current D3

Varies

1822 V1.5.3.4

Current D1

Varies

1823 V1.5.4.1

Status Word D1

# 1828 V1.5.4.2

Status Word D2

# 1829 V1.5.4.3

Status Word D3

# 1830 V1.5.4.4

Status Word D4

# 1831

Table 6-5, Master follower

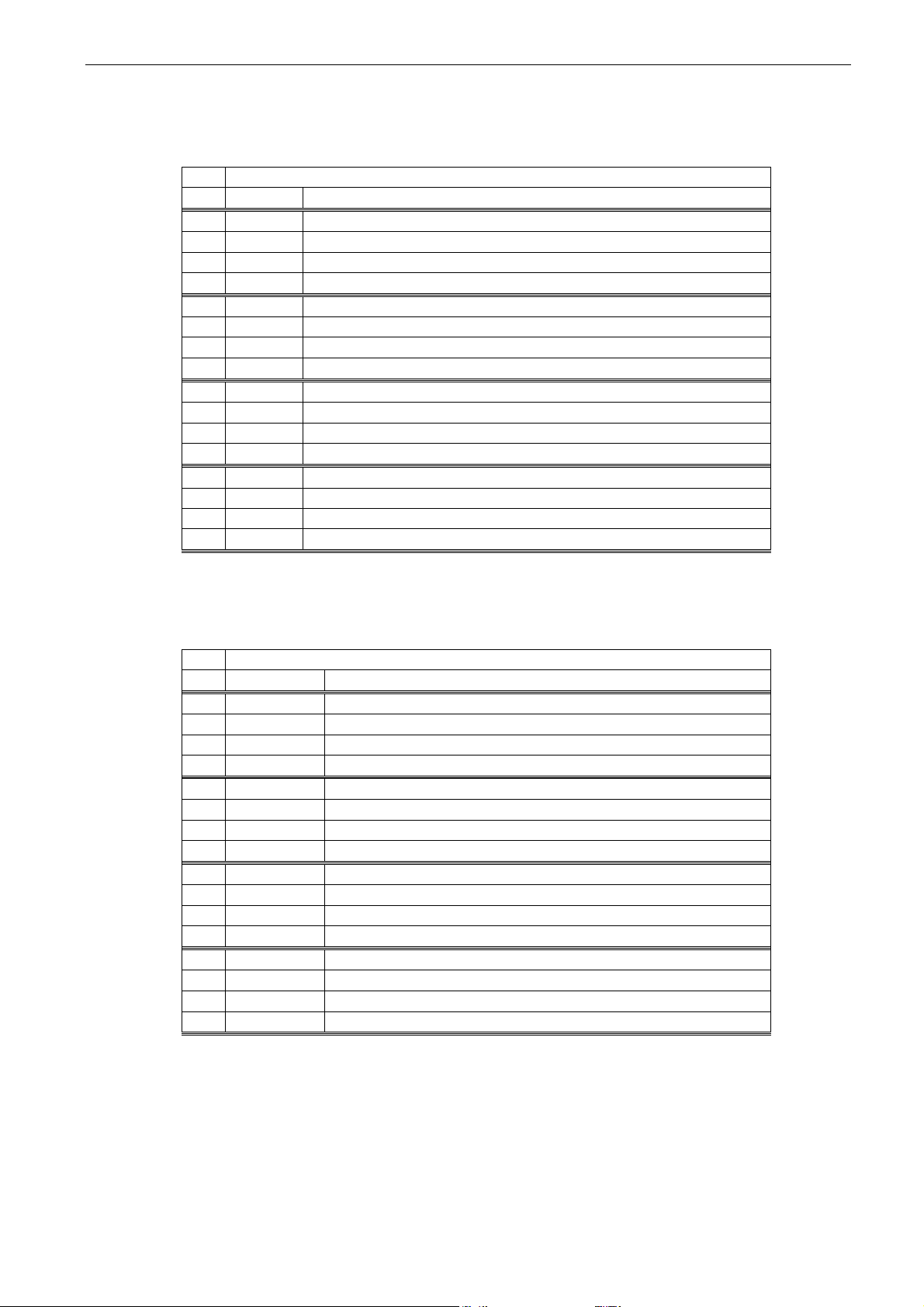

6.1.6 License code activation

Code

Parameter

Unit

Form.

ID

Description

V1.6.1

License Status

# 1996

V1.6.2

Serial Number Key

# 1997

Give this number to VACON®

technical support in case of

License Key problems.

Table 6-6, Activation

6.1.7 Line synch

Code

Parameter

Unit

Form.

ID

Description

V1.7.1

Line Synch Error

#,#

1659

Table 6-7, Line synch

Page 20

20 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6.2 Monitoring Signal Descriptions

6.2.1 Monitoring 1 values

V1.1.1 DC Voltage V ID1108

Measured DC voltage, filtered.

V1.1.2 DC Voltage Ref. % ID1200

DC voltage reference. Compared to given supply voltage.

1.35 * Supply Voltage * DC Voltage Ref = DC Voltage

V1.1.3 DC Voltage Actual % ID7

DC voltage actual in same scale as V1.1.2 DC Voltage Reference.

V1.1.4 Total Current A ID 1113

Filtered current of the drive.

V1.1.5 Active Current % ID 1125

Active current in % of System Rated Current.

Active Current > 0: Current flow from Drive DC-Link to AC-Side.

Active Current < 0: Current flow from AC-Side to Drive DC-Link.

V1.1.6 Reactive Current % ID 1157

Reactive current of the regenerative drive in % of System Rated Current.

V1.1.7 Power kW [kW] ID 1508

Drive output power in kW.

AFE control modes:

Power kW > 0: Current flow from AC-Side to Drive DC-Link.

Power kW < 0: Current flow from Drive DC-Link to AC-Side.

Motor control modes:

Power kW > 0: Current flow from Drive DC-Link to AC-Side.

Power kW < 0: Current flow from AC-Side to Drive DC-Link.

V1.1.8 Power % % ID 5

Drive output power in %.

Negative value means that current is flowing to AC side from DC side.

Page 21

arfiff30 Generator VACON® • 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

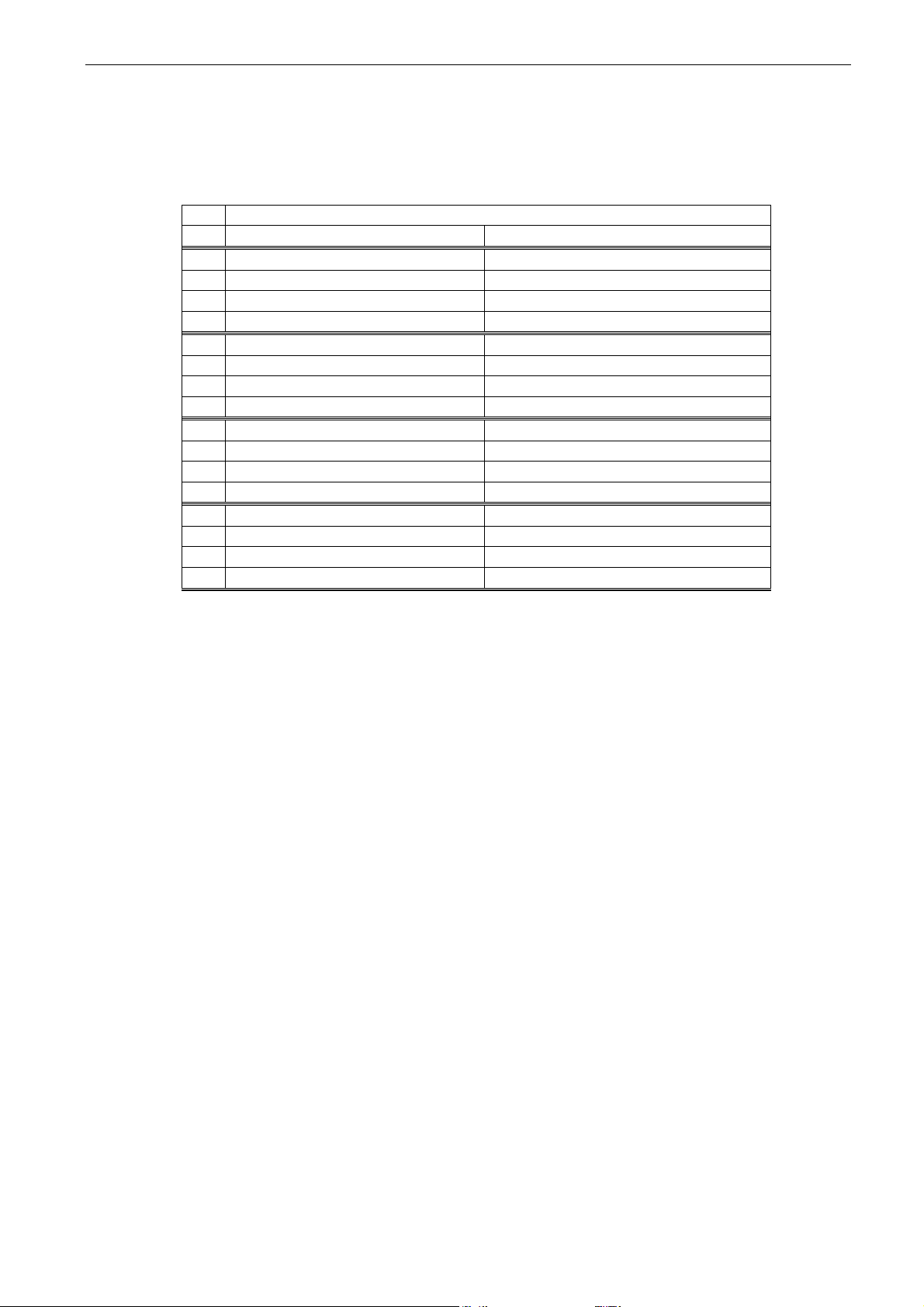

V1.1.9 Status Word (Application) ID 43

Application Status Word combines different drive statuses to one data word.

Application Status Word ID43

FALSE

TRUE

b0

No Charge Command

Charge Command Active

b1

Not in Ready state

Ready

b2

Not Running

Running

b3

No Fault

Fault

b4

No Start Request

Start Request Active

b5

Quick stop active

Quick stop not active

b6

Run Disabled

Run Enable

b7

No Warning

Warning

b8 Charging Switch closed (internal)

b9 Main Contactor Control (DO Final)

b10 Main Contactor Feedback

b11

b12

No Run Request

Run Request

b13 PTO

b14 PTI

b15 Regen

Table 6-8, Application status word

V1.1.10 Supply Frequency Hz ID 1

Drive output frequency. Updated in stop state when Regen Options B9 is activated.

V1.1.11 Supply Voltage V ID 1107

Drive output voltage.

V1.1.12 Line Frequency D7 Hz ID 1654

Measured Line Voltage Frequency when using OPT-D7 option board in slot C.

V1.1.13 Line Voltage D7 [V] ID 1650

Measured line voltage rms value when using OPT-D7 option board in slot C.

V1.1.14 AC Voltage Reference [V] ID1556

AC side voltage reference.

V1.1.15 DC Voltage max limit ID1606

Drive will limit DC Reference to inside drive specification but allows higher reference if

lover supply voltage. This shows the final limit of DC reference.

Page 22

22 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.1.16 Encoder 1 Frequency Hz ID 1164

Encoder frequency directly from encoder

V1.1.17 Torque reference % ID 18

Torque reference value before load share.

V1.1.18 Final Torque Ref % ID1145

Final torque reference in torque reference chain, before acceleration compensation

and speed controller output.

V1.1.19 Actual Torque Reference % ID1180

Final torque reference from speed control and torque control. Also includes torque step

and acceleration compensation factors.

V1.1.20 Motor torque % ID 4

In % of Motor nominal torque

Open loop

1 s linear filtering

Closed Loop

32 ms filtering

V1.1.21 Motor Speed rpm # ID2

Estimated motor speed.

Page 23

arfiff30 Generator VACON® • 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6.2.2 Monitoring 2 values

V1.2.1 DC Voltage V ID44

The measured DC voltage, unfiltered.

V1.2.2 CosPhiActual ID 1706

The calculated Cos Phi.

V1.2.3 Unit Temperature °C ID 1109

The heatsink temperature of the drive.

V1.2.4 Freq Reference Hz ID25

Used frequency reference. In AFE mode frequency reference is determined internally

when synchronization is made.

V1.2.5 Current A ID 1113

Unfiltered current of the drive.

V1.2.6 Operation Hours h ID1856

This shows operation hours of the drive. P2.7.19 is used to enter old value if software is

updated.

V1.2.7 Reactive Current Reference % ID1389

Final reactive current reference.

V1.2.8 Power Take Mode Used ID1925

0 = Commissioning.

1 = Power Take Out.

2 = Power Take In, Boost.

3 Power Take In, From Zero Speed.

V1.2.9 Torque % ID 1125

Unfiltered motor torque, recommended signal for NCDrive monitoring.

V1.2.10 Limits and Regulators ID77

Page 24

24 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

Limit & Regulators ID77

Bit

B0

Motoring Current Limit

B1

Generator Current Limit

B2

Motoring Torque Limit

B3

Generator Torque Limit

B4

Over Voltage Requlator

B5

Under Voltage Regulator

B6

Positive Speed Controller Limit

B7

Negative Speed Controller Limit

B8

Positive Iq Limit

B9

Negative Iq Limit

B10

Motoring Power Limit Active

B11

Generator Power Limit Active

B12

B13

B14

B15

Table 6-10, Limits and regulators

V1.2.11 Shaft Frequency ID1124

Shaft Frequency used by motor control

V1.2.12 U Phase Current A ID39

V1.2.13 V Phase Current A ID40

V1.2.14 W Phase Current A ID41

Phase current in rpm, 1 second linear filtering.

Page 25

arfiff30 Generator VACON® • 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.2.15 Fault Word 10 ID1202

Fault Word 10

Bit

Fault(s)

B0

B1

B2

F82 Overload Fault

B3

B4

F56 & F65 PT100 Temperature

B5

B6

B7

B8 B9 B10 B11 B12

B13

B14 B15

V1.2.15 Warning Word 10 ID1269

Warning Word 10

Bit

Fault(s)

B0 B1

W3 Earth Fault

B2

W82 Overload fault

B3

B4

W56 & W65 PT100 Temperature

B5 B6 B7

B8

B9 B10 B11 B12 B13 B14

B15

Page 26

26 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6.2.3 Fieldbus monitoring values

V1.3.1 FB Control Word ID 1160

Control word from fieldbus. The table below shows the bypass operation for such fieldbus boards

that natively support the bypass operation or can be parameterized to bypass mode.

FB Control Word ID1160

Signal

Comment

B00

DC Charge

0= Open MCB.

1= Close DC charge contactor, CB closed automatically.

B01

B02

B03

Run

0= AFE is stopped

1= AFE is started

B04

B05

B06

B07

Reset

0>1 Reset fault.

B08

B09

B10

Fieldbus Control

0= No control from fieldbus

1=Control from fieldbus

B11

Watchdog

communication between fieldbus master and the drive.

B12

FB DIN2

Can be used to control RO or directly parameter by ID number.

G2.4.1

B13

FB DIN3

Can be used to control RO or directly parameter by ID number.

G2.4.1

B14

FB DIN4

Can be used to control RO or directly parameter by ID number.

G2.4.1

B15

Reserved for future use.

Table 6-10, Fieldbus control word

Page 27

arfiff30 Generator VACON® • 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.3.2 FB Status Word ID 68

Status word to fieldbus. The table below shows the bypass operation for such fieldbus boards that

natively support the bypass operation or can be parameterized to bypass mode.

Signal

Comment

b0

Ready On

0=Drive not ready to switch on

1=Drive ready to start charging

b1

Ready Run

0=Drive not ready to run

1=Drive ready and MCB is ON

b2

Running

0=Drive not running

1=Drive in Run state (Modulating)

b3

Fault

0=No active fault

1=Fault is active

b4

Run Enable Status

0= Run Disabled. Drive in stop state

1= Run Enabled. Drive can be started.

b5

Quick Stop Active

0=Quick Stop Active

1=Quick Stop not Active

b6

CB Control OK

0= Status opposite of control

1= Status and control OK

b7

Warning

0= No active warnings

1= Warning active

b8

At Reference

0= DC Voltage Ref and Act DC Voltage are not

same.

b9

Fieldbus Control Active

0=Fieldbus control not active

1=Fieldbus control active

b10

Above Limit

0= DC Voltage is below P2.5.5.2 level

1=The DC Voltage is above the P2.5.5.2 level

b11

Reserved for future use.

b12

Reserved for future use.

b13

Reserved for future use.

b14

DC Charge DO Control

0= DC not charged

1= DC Charging Active

b15

Watchdog

Same as received on bit 11 of the main control

word.

Table 6-11, Fieldbus status word

V1.3.3 FB Actual Value ID865

Use Process data ID to drive this value.

V1.3.4 FB Speed Reference ID875

Use Process data ID to drive this value.

V1.3.5 FB Torque Reference ID1140

Use Process data ID to drive this value.

Page 28

28 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.3.6 Generator Control Word ID1700

FALSE

TRUE

b0

b1

b2

b3

b4

b5

b6

b7

b8

b9

b10

b11

b12

b13

b14

b15

Table 6-12, Generator control word

V1.3.7 Generator Status Word ID1701

FALSE

TRUE

b0 Generation Operation Selected

b1 DC Control Active

b2

b3

b4

b5

b6

b7

b8

b9

b10

b11

b12

b13

b14

b15

Table 6-13, Generator status word

Page 29

arfiff30 Generator VACON® • 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.3.8 Fault Word 1 ID 1172

Fault Word 1

Bit

Fault(s)

B0

F1 Over current, F31 IGBT, F41 IGBT

B1

F2 Over Voltage

B2

F9 Under Voltage

B3 B4

F3 Earth Fault

B5 B6

F14 Unit Over Temperature

B7

F16 Motor Temperature, F29 Thermistor, F56 PT100, F65 PT100

B8

F10 Line Synch fault (AFE), F10 Input line fault (INU)

B9 B10 B11

F52 Keypad or F52 PC communication fault

B12

F53 FieldBus fault

B13

F59 System Bus fault

B14

F54 Slot Communication fault

B15

F50 4mA fault

Table 6-14, Fault word 1

V1.3.9 Fault Word 2 ID 1173

Fault Word 2

Bit

Fault(s)

B0

B1

B2

F43 Encoder Fault

B3 B4 B5 B6

F51 External fault

B7 B8 B9

F31 IGBT, F41 IGBT

B10 B11 B12 B13

B14

F64 Main Switch State fault

B15

Table 6-15, Fault word 2

Page 30

30 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.3.10 Warning Word 1 ID 1174

Warning Word 1 ID1174

Bit

Warning(s)

B0

B1

B2 B3 B4 B5 B6

F53 FB Warning Slot D

B7

F67 FB Warning Slot E

B8

W14 Over Temperature

B9 B10 B11 B12 B13

B14

B15

Table 6-16, Warning word

V1.3.11 Warning ID74

Last active warning number.

V1.3.12 Last Active Fault ID37

Last active fault. number.

V1.3.13 Speed, FB Scaled ID1907

V1.3.14 FB Analog Out % ID48

Fieldbus value to control analogue output.

Page 31

arfiff30 Generator VACON® • 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6.2.4 IO Monitoring values

V1.4.1 DIN1, DIN2, DIN3 ID 15

V1.4.2 DIN4, DIN5, DIN6 ID 16

DIN1/DIN2/DIN3 status

DIN4/DIN5/DIN6 status

b0

DIN3

DIN6

b1

DIN2

DIN5

b2

DIN1

DIN4

Table 6-17, Digital input status word 1

V1.4.3 DIN Status 1 ID 56

V1.4.4 DIN Status 2 ID 57

DIN StatusWord 1

DIN StatusWord 2

b0

DIN: A.1

DIN: C.5

b1

DIN: A.2

DIN: C.6

b2

DIN: A.3

DIN: D.1

b3

DIN: A.4

DIN: D.2

b4

DIN: A.5

DIN: D.3

b5

DIN: A.6

DIN: D.4

b6

DIN: B.1

DIN: D.5

b7

DIN: B.2

DIN: D.6

b8

DIN: B.3

DIN: E.1

b9

DIN: B.4

DIN: E.2

b10

DIN: B.5

DIN: E.3

b11

DIN: B.6

DIN: E.4

b12

DIN: C.1

DIN: E.5

b13

DIN: C.2

DIN: E.6

b14

DIN: C.3

b15

DIN: C.4

Table 6-18, Digital input status word 2

V1.4.5 Analogue Input 1 % ID13

V1.4.6 Analogue Input 2 % ID14

V1.4.7 Analogue input 3 % ID 27

V1.4.8 Analogue input 4 % ID 28

Unfiltered analogue input level.

0% = 0 mA / 0 V, -100% = -10 V, 100% = 20 mA / 10 V.

Monitoring scaling is determined by the option board parameter.

It is possible to adjust this input value from fieldbus when the input terminal selection is

0.1. This way it is possible to adjust the free analogue input from fieldbus and have all

analogue input functions available for fieldbus process data.

Page 32

32 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.4.9 Analogue Out 1 % ID 26

V1.4.10 Analogue Out 2 % ID 50

V1.4.11 Analogue Out 3 % ID 51

Analogue Output value 0% = 0 mA / 0 V, 100% = 20 mA / 10 V

V1.4.12 PT100 Temp. 1 °C ID 50

V1.4.13 PT100 Temp. 2 °C ID 51

V1.4.14 PT100 Temp. 3 °C ID 52

V1.4.15 PT100 Temp. 4 °C ID 69

V1.4.16 PT100 Temp. 5 °C ID 70

V1.4.17 PT100 Temp. 6 °C ID 71

Separate measurement from two PT100 board. The signal has 4 s filtering time.

V1.4.18 PT-100 Temperature Cº ID 42

Highest temperature of OPTB8 board. 4 s filtering.

Page 33

arfiff30 Generator VACON® • 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

6.2.5 Master Follower monitoring values

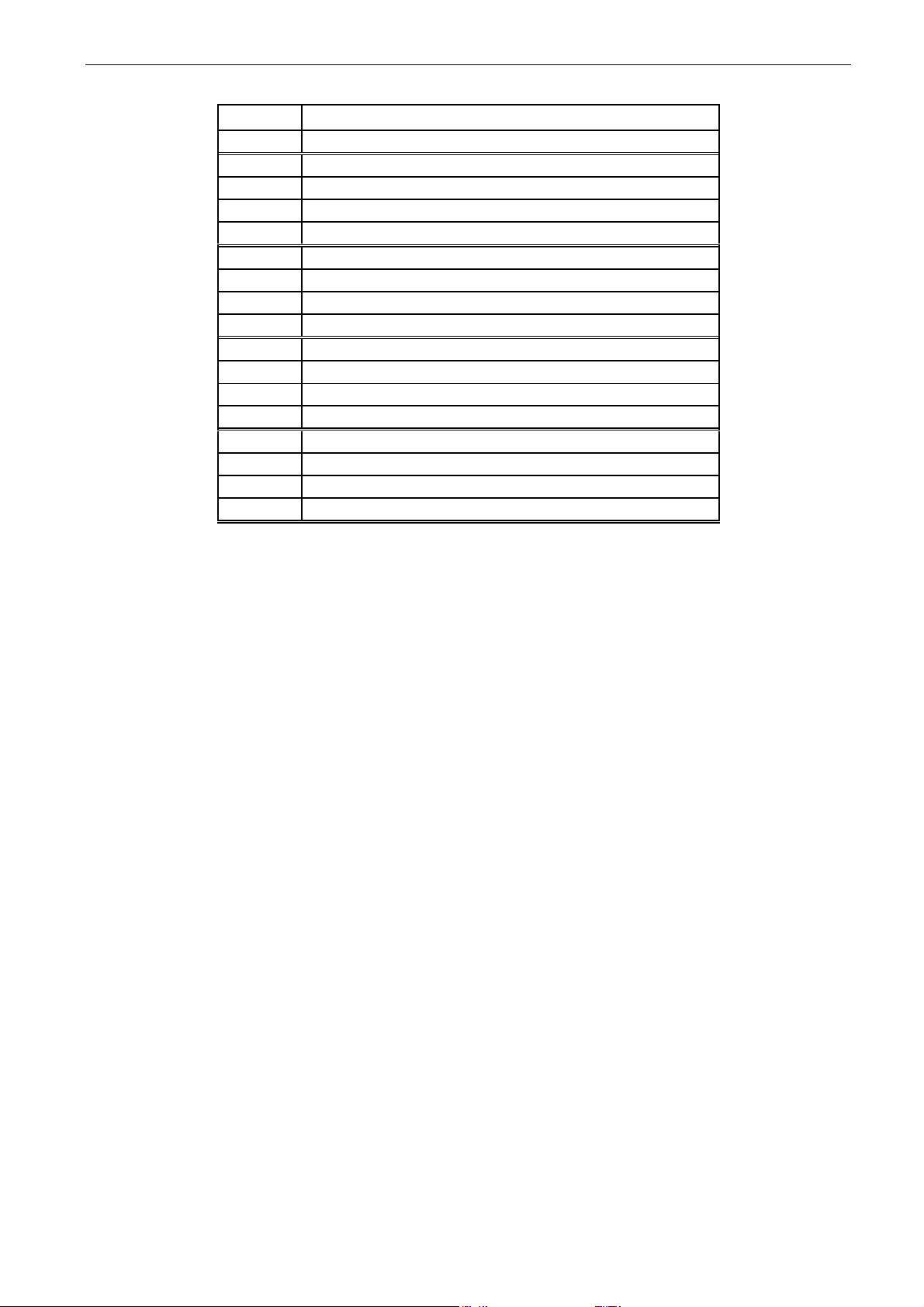

V1.5.1 SB System Status ID1800

System Bus Status Word ID1800

FALSE

TRUE

b0 Drive 1 System Bus in Synch

b1 Drive 1 Ready

b2 Drive 1 Running

b3 Drive 1 Fault

b4 Drive 2 System Bus in Synch

b5 Drive 2 Ready

b6 Drive 2 Running

b7 Drive 2 Fault

b8 Drive 3 System Bus in Synch

b9 Drive 3 Ready

b10 Drive 3 Running

b11 Drive 3 Fault

b12 Drive 4 System Bus in Synch

b13 Drive 4 Ready

b14 Drive 4 Running

b15 Drive 4 Fault

Table 6-19, System bus status word

V1.5.2 System Current ID80

Sum current of all drives in system bus

V1.5.3.1 Current D1 ID1820

V1.5.3.2 Current D2 ID1821

V1.5.3.3 Current D3 ID1822

V1.5.3.4 Current D4 ID1823

Page 34

34 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

V1.5.4.1 Status Word D1 # ID1828

V1.5.4.2 Status Word D2 # ID1829

V1.5.4.3 Status Word D3 # ID1830

V1.5.4.4 Status Word D4 # ID1831

Follower Drive Status Word

FALSE

TRUE

b0

b1

Not in Ready state

Ready

b2

Not Running

Running

b3

No Fault

Fault

b4

b5

b6

b7

b8

b9

b10

SB Not In Synch

SB In Synch

b11

b12

b13

b14

b15

Heard Beat Pulse

Heard Beat Pulse

Table 6-20, Follower drive status word

Page 35

arfiff30 Generator VACON® • 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

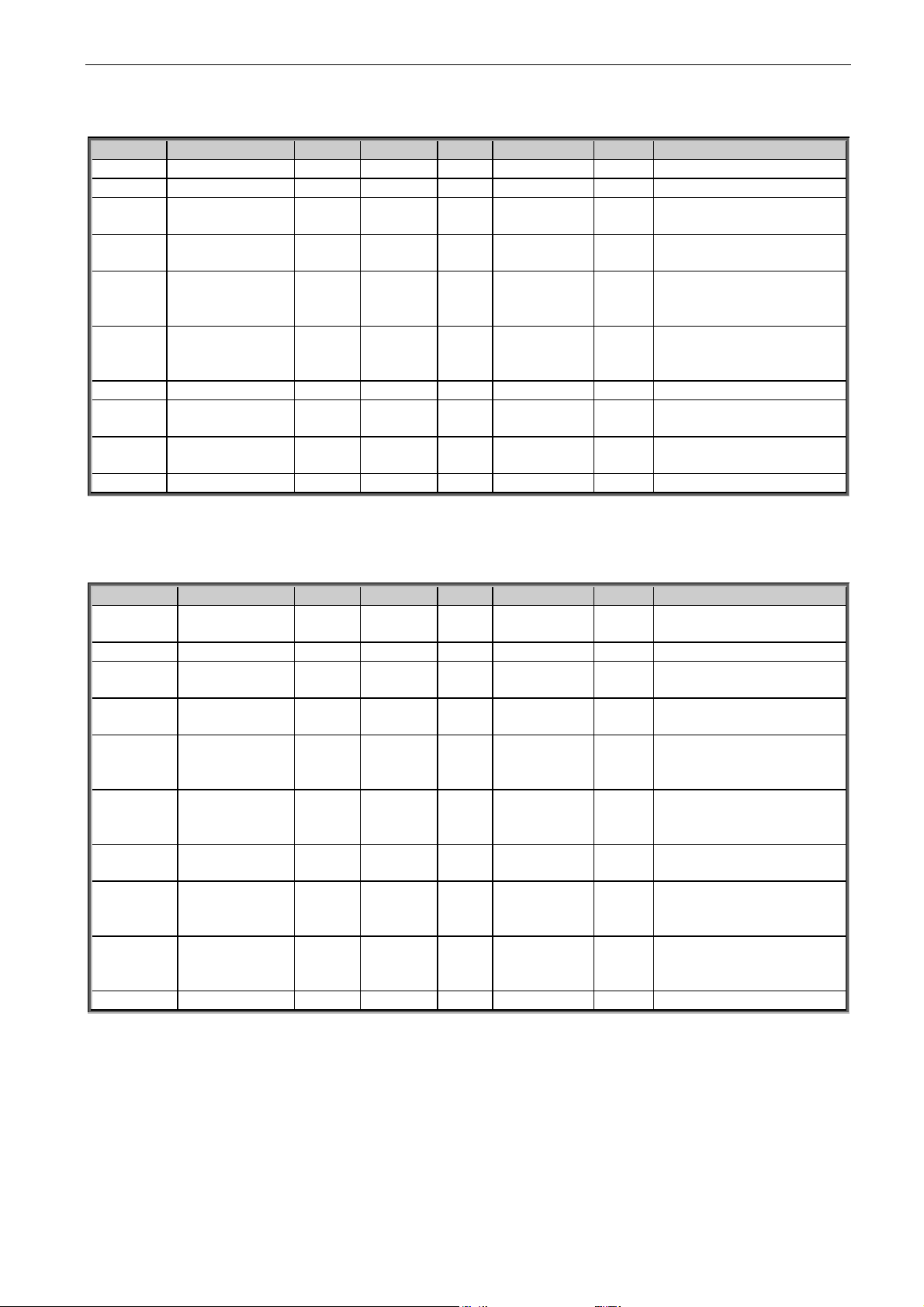

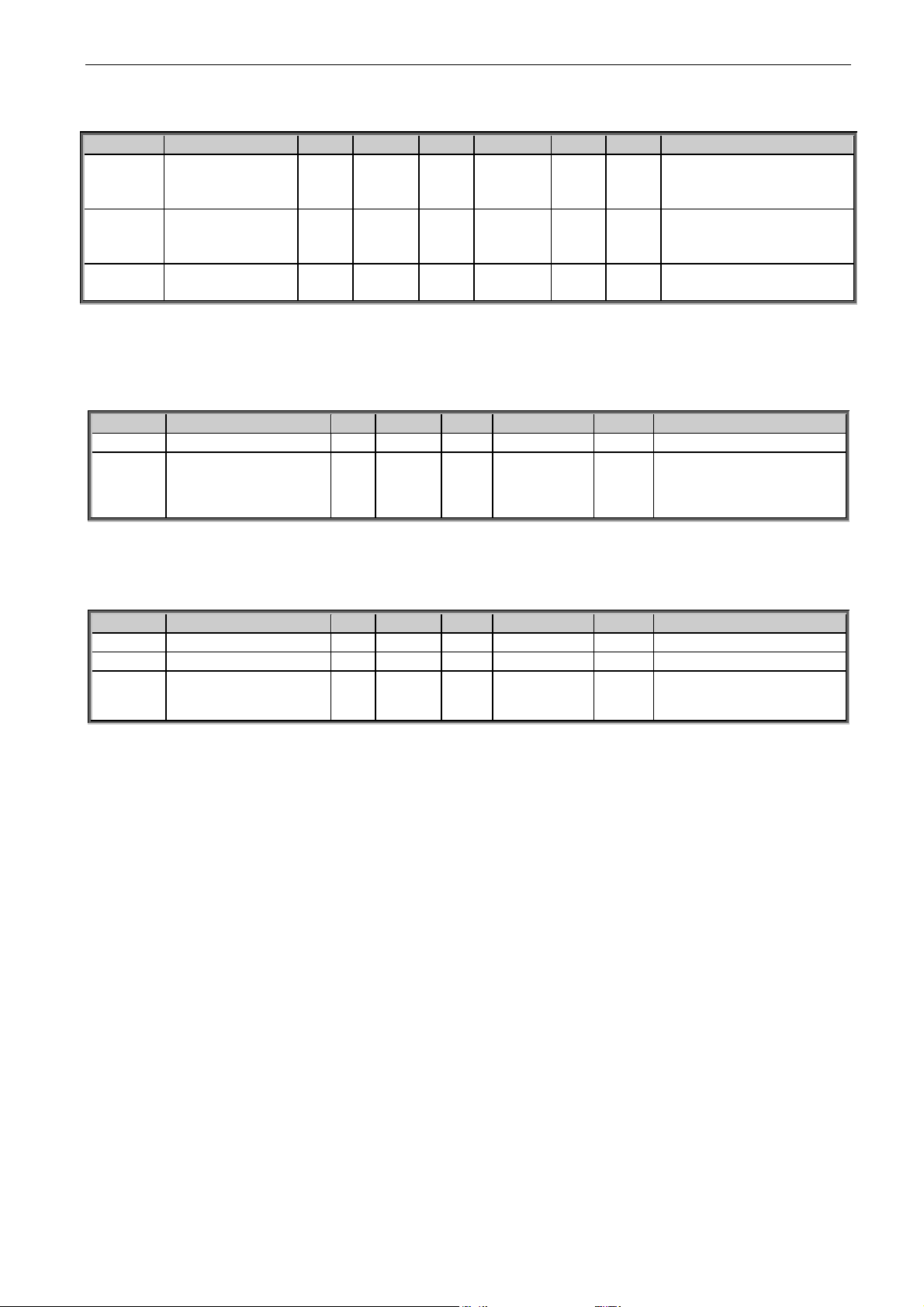

7. ARFIFF30– Parameter list

In this document you will find the lists of parameters and monitoring values which are available in

this application.

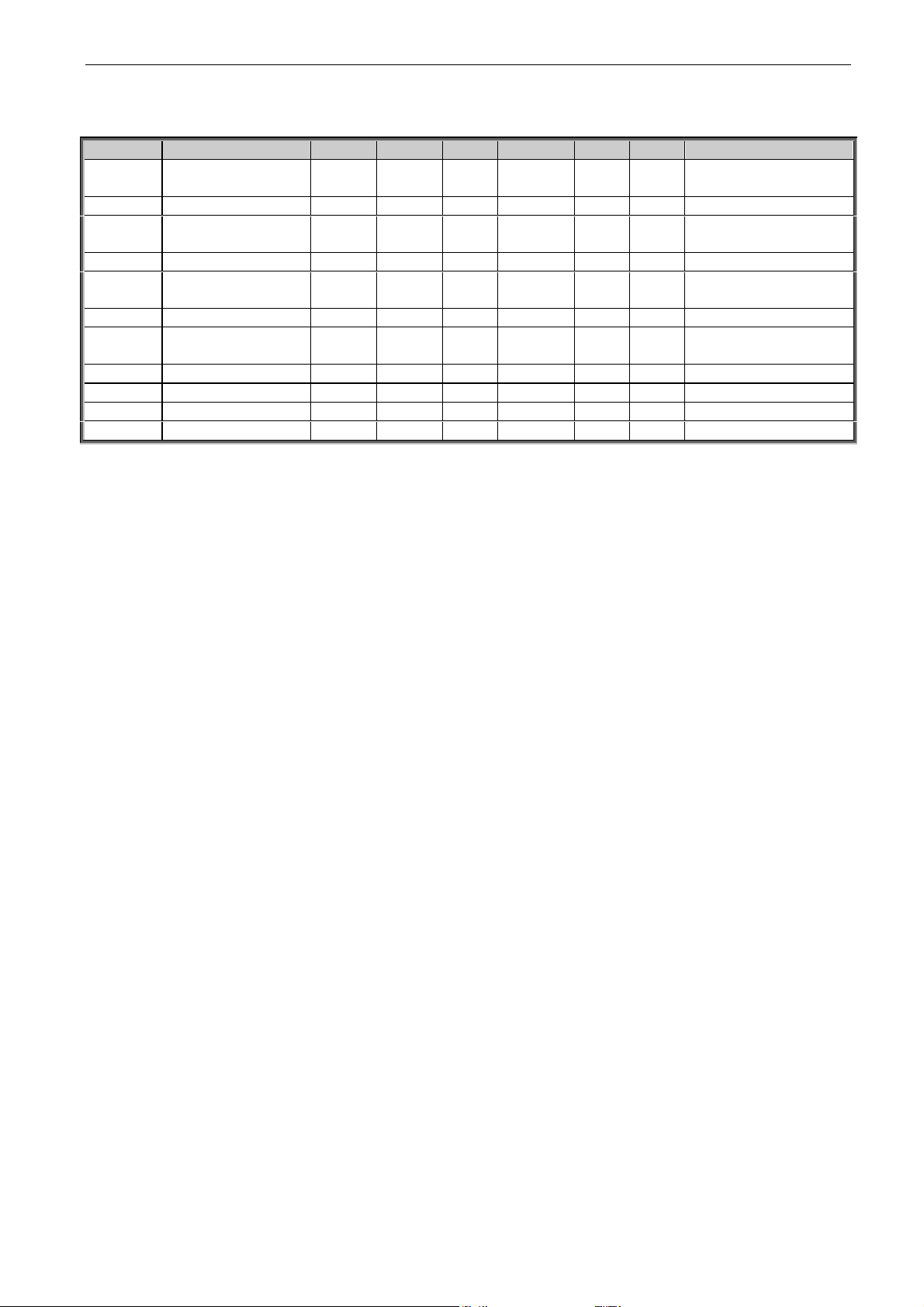

7.1 Basic Parameters (G2.1)

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.1.1

Mot/Gen Type

0 2 0 650

0 = Synchronous Machine

1 = PM Motor

2 = Asynchronous Motor

P2.1.2

Nominal Voltage

400V:

323V

690V:

446V

400V:

550V

690V:

758V

V

400

110

Set here the nominal voltage of

the generator.

P2.1.3

Nominal Frequency

0

125

Hz

50

1532

P2.1.4

Nominal Current

0.0 A 113 P2.1.5

Nominal Speed

24

20000

rpm

1440

112 P2.1.6

Nominal Cos Phi

0.30

1.00 0.85

120 P2.1.7

Nominal Power

0

32700

kW 0 116 P2..1.8

Magnetization Current

612

P2.1.9

Parallel Generator

0 1 0 1501

0 = Single Generator

1 = Parallel Generator

Activation will set DC Drooping

to 4%.

P2.1.10

Identification

0 8

0

631

0=No action

1=Identification w/o run

2=Identification with run

3=Encoder ID Run

4=Ident All

5=Absolute encoder, locked

rotor

6=U/f and Magn.Current

7=DTC ident.

8=Current Meas. Offset AFE.

NOTE: Set motor control mode

to Freq Control before

identification!

Table 7-1, Basic parameters

Page 36

36 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

7.2 Reference Handling (G2.2)

7.2.1 PTM handling

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.2.1.1

Power Take Mode 00

0 4 0 1910

0 = Commissioning

1 = PTO

2 = PTI-BOOST

3 = PTI- 0-Speed

4 = Regen Motor

P2.2.1.2

Power Take Mode 01

0 4 0 1902

0 = Commissioning

1 = PTO

2 = PTI-BOOST

3 = PTI- 0-Speed

4 = Regen Motor

P2.2.1.3

Power Take Mode 10

0 4 0 1903

0 = Commissioning

1 = PTO

2 = PTI-BOOST

3 = PTI- 0-Speed

4 = Regen Motor

P2.2.1.4

Power Take Mode 11

0 4 0 1904

0 = Commissioning

1 = PTO

2 = PTI-BOOST

3 = PTI- 0-Speed

4 = Regen Motor

P2.2.1.5

PTM Stop Time

0.00

30.00 s 3.00

1915

Table 7-2, Power take mode handling

7.2.2 PTO handling

Code

Parameter

Min

Max

Unit

Default

ID

Note

2.2.1.6.1

Torque Select

0 5 0 1931

0 = Speed

1 = Torque

2 = Ramp Out

3 = Min

4 = Max

5 = Window

2.2.1.6.2

Torque Reference

Select

0 6 0 1929

0 = Torque Ref Max

1 = Curve 1

2 = Analogue Input 1

3 = Analogue Input 2

4 = AI1 Joystick

5 = AI2 Joystick

6 = Fieldbus

7 = Curve 2

8 = Curve 3

2.2.1.6.3

Load Share

0.0

400.0 % 100.0

1248

Table 7-3, Power take out handling

Page 37

arfiff30 Generator VACON® • 37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

7.2.3 PTI-Boost handling

Code

Parameter

Min

Max

Unit

Default

ID

Note

2.2.1.7.1

Torque Select

0 5 0 1930

0 = Speed

1 = Torque

2 = Ramp Out

3 = Min

4 = Max

5 = Window

2.2.1.7.2

Torque Reference

Select

0 6 0 1928

0 = Torque Ref Max

1 = Curve 1

2 = Analogue Input 1

3 = Analogue Input 2

4 = AI1 Joystick

5 = AI2 Joystick

6 = Fieldbus

7 = Curve 2

8 = Curve 3

Table 7-4, Power Take in boost handling

7.2.4 PTI 0-Speed

Code

Parameter

Min

Max

Unit

Default

ID

Note

2.2.1.8.1

Torque Select

0 5 0 1933

0 = Speed

1 = Torque

2 = Ramp Out

3 = Min

4 = Max

5 = Window

2.2.1.8.2

Torque Reference

Select

0 6 0 1932

0 = Torque Ref Max

1 = Curve 1

2 = Analogue Input 1

3 = Analogue Input 2

4 = AI1 Joystick

5 = AI2 Joystick

6 = Fieldbus

7 = Curve 2

8 = Curve 3

Table 7-5, Power take in zero speed parameters

7.2.5 Regen Motor Mode

Code

Parameter

Min

Max

Unit

Default

ID

Note

2.2.1.9.1

License Key

0

65535 0

1995

2.2.1.9.2

Reserved

Table 7-6, Regenerative motor mode parameters

Page 38

38 • VACON® arfiff30 Generator

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

7.2.6 Commissioning

Code

Parameter

Min

Max

Unit

Default

ID

Note

2.2.1.10.1

MC Mode

0 4 0 1913

0 = AFE

1 = Freq. Control

2 = OL Torque Control

3 = CL Speed Control

4 = CL Torque Control

2.2.1.10.2

DC Control

0 1 0 1914

0 = No

1 = Yes

2.2.1.10.3

Torque Select

0 5 0 1278

0 = Speed

1 = Torque

2 = Ramp Out

3 = Min

4 = Max

5 = Window

2.2.1.10.4

Torque Reference

Select

0 6 1 641

0 = Torque Ref Max

1 = Curve 1

2 = Analogue Input 1

3 = Analogue Input 2

4 = AI1 Joystick

5 = AI2 Joystick

6 = Fieldbus

7 = Curve 2

8 = Curve 3

Table 7-7, Commissioning parameters

7.2.7 DC Voltage Reference Handling

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.2.2.1

System Nominal AC

400V:

323V

690V:

446V

400V:

550V

690V:

758V

V 0 1201

Keep zero if motor or

generator voltage is same as

grid voltage.

P2.2.2.2

System Nominal DC

0

1500 V 0

1809

P2.2.2.3

DC Voltage Ref.

500V:

105%

690V:

105%

500V:

130%

690V:

115%

%

110.00

1462

DC Voltage reference as % of

Nominal DC Voltage

Nominal DC voltage = 1.35 *

Supply voltage

P2.2.2.4

DC Voltage Drooping

0

100 % 0

620

AFE drooping DC-voltage.

Parallel 3.00%

P2.2.2.5

Reactive Current

Reference

-100

100 % 0

1459

Regenerative reactive

current reference 100,0 =

nominal current.

Positive =Inductive

Negative = Capacitive

P2.2.2.6

DC Voltage Filtering

time

0

15.00 s 0,03

1760

Table 7-8, DC voltage reference handling

Page 39

arfiff30 Generator VACON® • 39

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Business

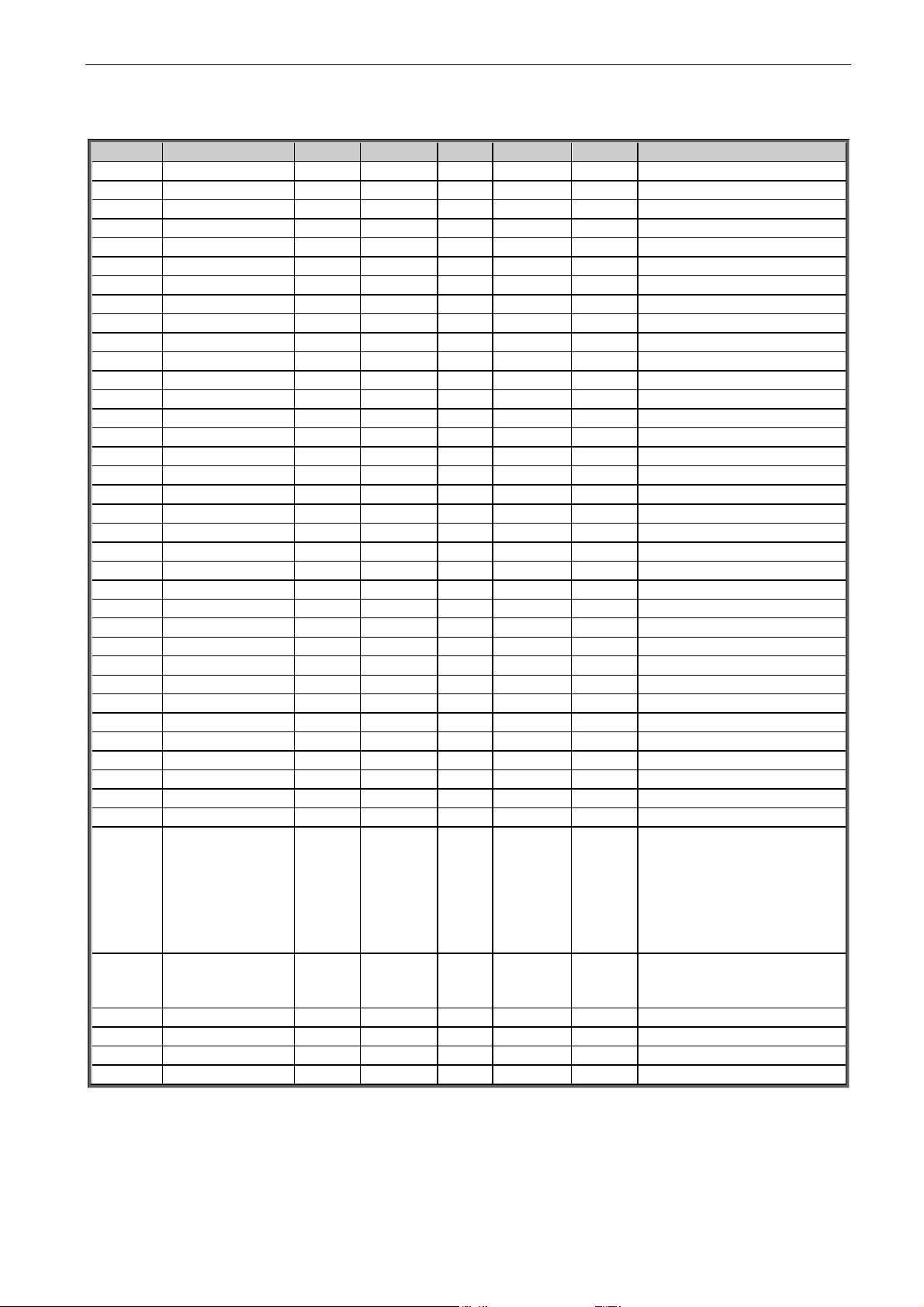

7.2.8 Speed / Frequency Ref handling

Code

Parameter

Min

Max

Unit

Default

ID

Note

P2.2.3.1

Speed Ref Select

0 5 0 117

0 = Keypad Reference

1 = Analogue Input 1

2 = Analogue Input 2

3 = AI1 Joystick

4 = AI2 Joystick

5 = Fieldbus

P2.2.3.2

Min Frequency

0

125 0

101

P2.2.3.3

Max Frequency

0

125 50

102

Table 7-9, Speed / frequency reference handling

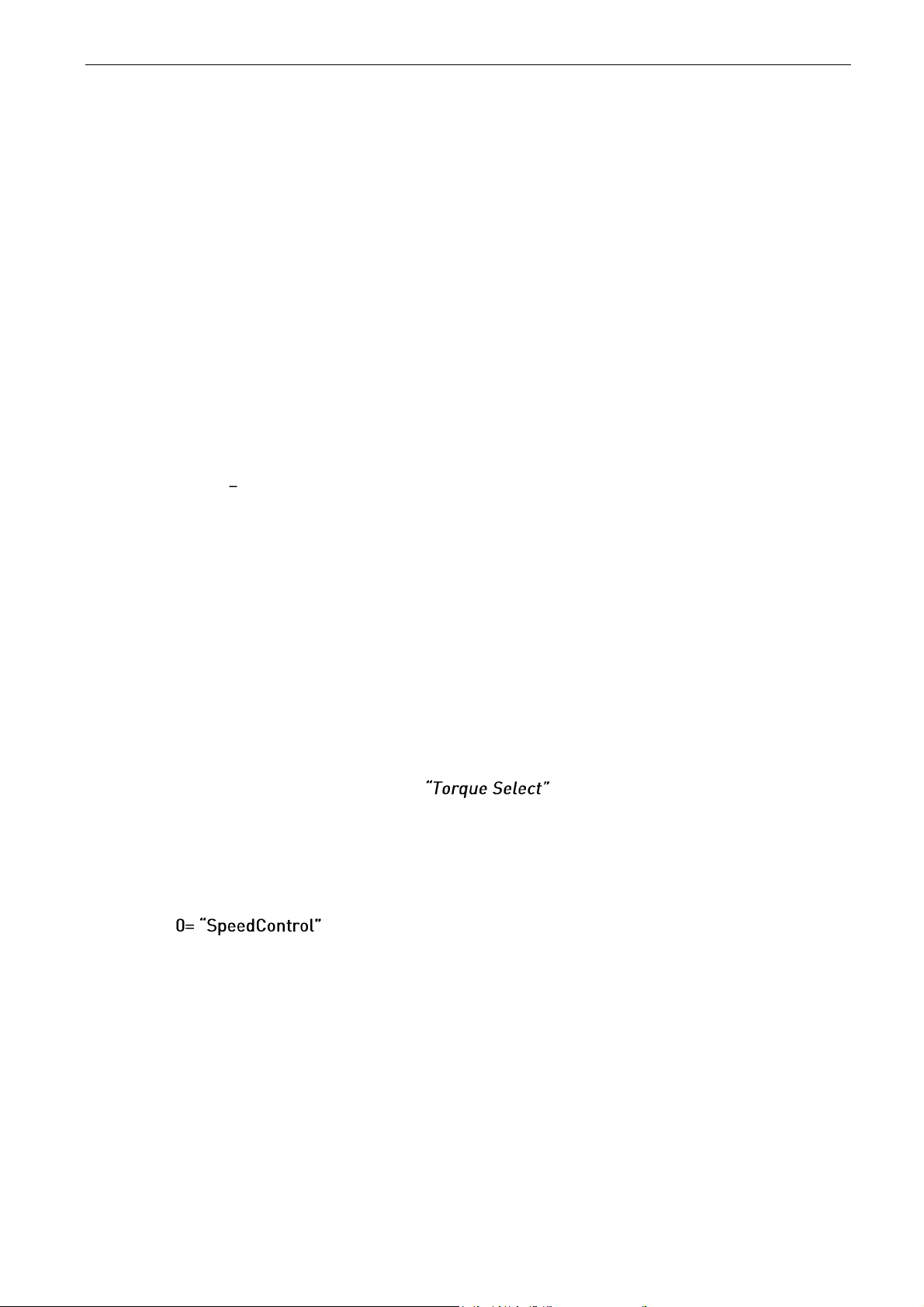

7.2.9 Torque Control

Code

Parameter

Min

Max

Unit

Default

ID