Page 1

vacon® nxp

ac drives

system drive

hardware manual

Page 2

Page 3

vacon • 3

TABLE OF CONTENTS

Document ID: DPD01365

Revision: C

Revision release date: 23.06.2020

1. Introduction ................................................................................................................ 5

1.1 Revision history ..................................................................................................................... 5

1.2 Scope of supply ..................................................................................................................... 5

1.3 Related brochures and manuals........................................................................................... 5

1.4 Definitions and abbreviations................................................................................................ 6

1.5 Project specifications............................................................................................................ 7

1.5.1 Parameters ............................................................................................................. 7

1.5.2 Sections and options ............................................................................................... 8

1.5.3 System layout and footprint drawings.................................................................... 8

1.6 Supplied documentation ....................................................................................................... 8

1.7 Storage .................................................................................................................................. 9

1.8 Lifting and moving the cabinet sections ............................................................................. 10

2. Safety........................................................................................................................ 11

2.1 Warnings ............................................................................................................................. 12

2.2 Cautions............................................................................................................................... 13

2.3 Grounding and ground fault protection .............................................................................. 14

3. Available sections ..................................................................................................... 15

3.1 Auxiliary device section....................................................................................................... 15

3.2 Main incoming section ........................................................................................................ 16

3.3 Non-regenerative front-end section................................................................................... 18

3.4 Active front-end section...................................................................................................... 20

3.5 Inverter unit section ............................................................................................................ 22

3.5.1 Drive sizes FR4-FR8 ............................................................................................. 22

3.5.2 Drive sizes FI9-FI14 .............................................................................................. 25

3.6 Dynamic brake section........................................................................................................ 28

3.7 Transport split unit.............................................................................................................. 29

4. Installation................................................................................................................ 30

4.1 Installation procedure......................................................................................................... 30

4.2 Preparing the installation site ............................................................................................ 31

4.2.1 Free space around the cabinet ............................................................................. 31

4.3 Mounting the cabinets......................................................................................................... 32

4.3.1 Fixing the cabinet to the floor and wall ................................................................ 32

4.3.2 Back-to-back installation ..................................................................................... 33

4.4 Connecting the busbars ...................................................................................................... 34

4.4.1 Side-by-side connection ....................................................................................... 34

4.4.2 Back-to-back connection...................................................................................... 35

4.5 Fixing the cabinet frames to each other ............................................................................. 36

4.6 Cabling................................................................................................................................. 37

4.6.1 Grounding.............................................................................................................. 37

4.6.2 Mains and motor connection ................................................................................ 37

4.6.3 EMC grounding ..................................................................................................... 42

4.6.4 Installation of ferrite rings (+OCM) on the motor cable ....................................... 42

4.6.5 Control connections .............................................................................................. 43

4.6.6 Auxiliary low-voltage connections........................................................................ 44

4.7 Screw tightening torques.................................................................................................... 45

5. Service ...................................................................................................................... 55

5.1 Warranty .............................................................................................................................. 55

5.2 Maintenance ........................................................................................................................ 55

5.3 Removing the drives from the cabinet................................................................................ 56

5.3.1 IUS_4 / IUS_6 ........................................................................................................ 56

5.3.2 IUS_7 / IUS_8 ........................................................................................................ 57

5.3.3 IUS_9 / IUS_10 ...................................................................................................... 58

5.3.4 IUS_12 ................................................................................................................... 61

5.3.5 IUS_13 / IUS_14 .................................................................................................... 64

6. Technical information ............................................................................................... 67

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 4

vacon • 4

6.1 Control and interface .......................................................................................................... 67

6.1.1 Control without speed feedback (open loop) ........................................................ 67

6.1.2 Control with speed feedback (closed loop) .......................................................... 67

6.2 Load definitions ................................................................................................................... 67

6.2.1 Pump and fan load ................................................................................................ 68

6.2.2 OL(

6.2.3 Starting torque >> OL(

6.2.4 OL(

6.2.5 OL(

n

n

n

base

base

base

) > OL(

) > OL(

) < OL(

n

) for constant torque load ..................................................... 69

max

n

) for constant torque load ......................................... 70

max

n

) for constant power load...................................................... 71

max

n

) for constant power load...................................................... 72

max

6.3 Technical specifications for VACON® drives ...................................................................... 73

6.3.1 NXN - Non-regenerative front end units.............................................................. 73

6.3.2 NXA - Active front-end units................................................................................. 75

6.3.3 NXI - Inverter units ............................................................................................... 77

6.3.4 NXB - Brake chopper units................................................................................... 82

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 5

Introduction vacon • 5

1. I

The VACON® NXP System Drive is a comprehensive configured common DC bus drive line up for

heavy-industry needs where round-the-clock activity is required leaving little time for maintenance.

All sections are grouped depending on their functionality, making it possible to plan each

installation phase according to your requirements. The engineered sections slot in alongside each

other allowing you to arrange integrated transport splits to save space. Alternatively, you can add

extra transport sections to speed up installation. All larger modules have slide-out mechanics for

easier set-up and maintenance.

The VACON® NXP System Drive is built to last. Items such as busbar systems and high/low power

devices are separated into individual compartments away from each other. This means that, if an

issue occurs, it is compartmentalized and doesn’t cause widespread failure helping to reduce

lifetime and maintenance costs.

NTRODUCTION

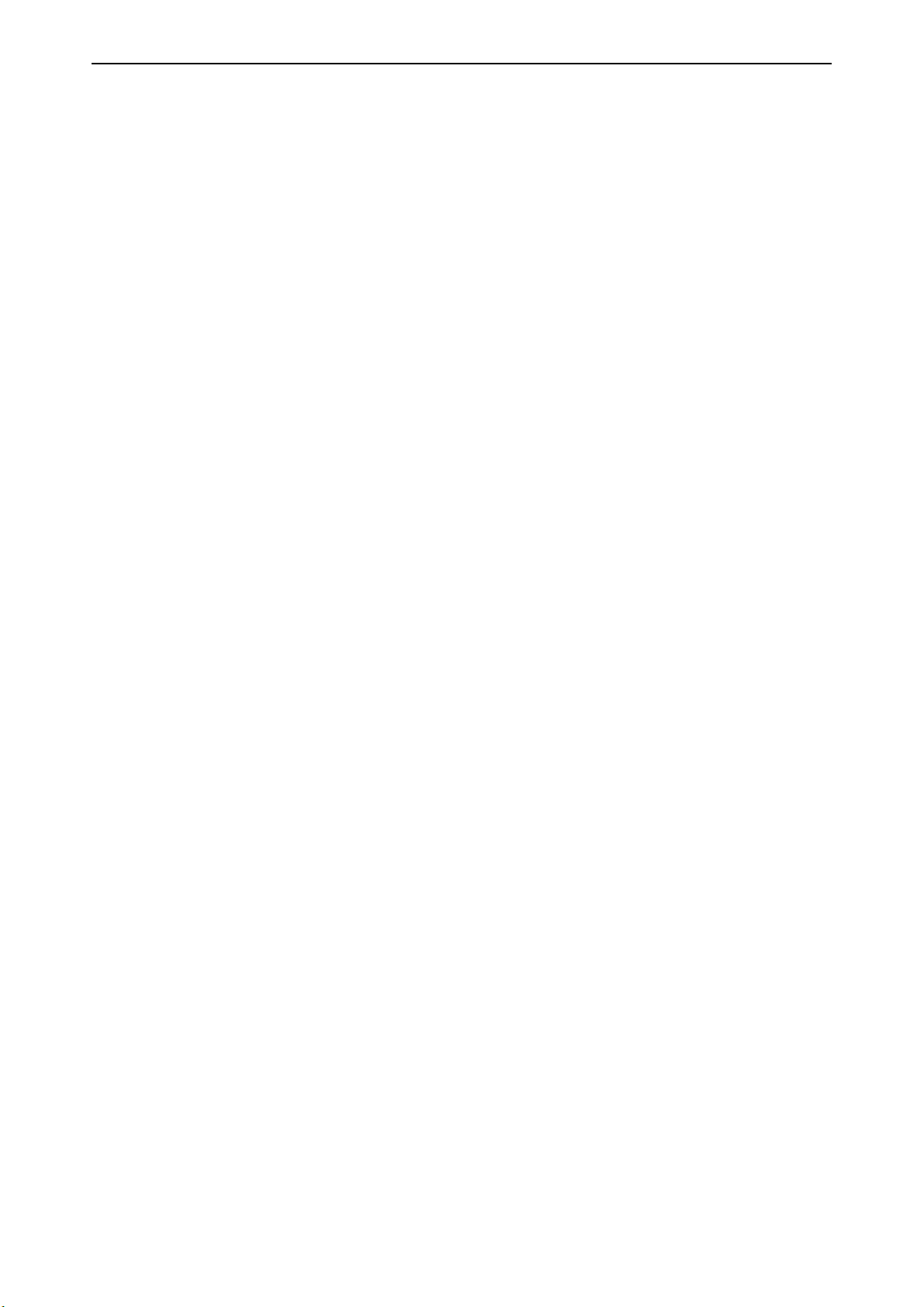

1.1 Revision history

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

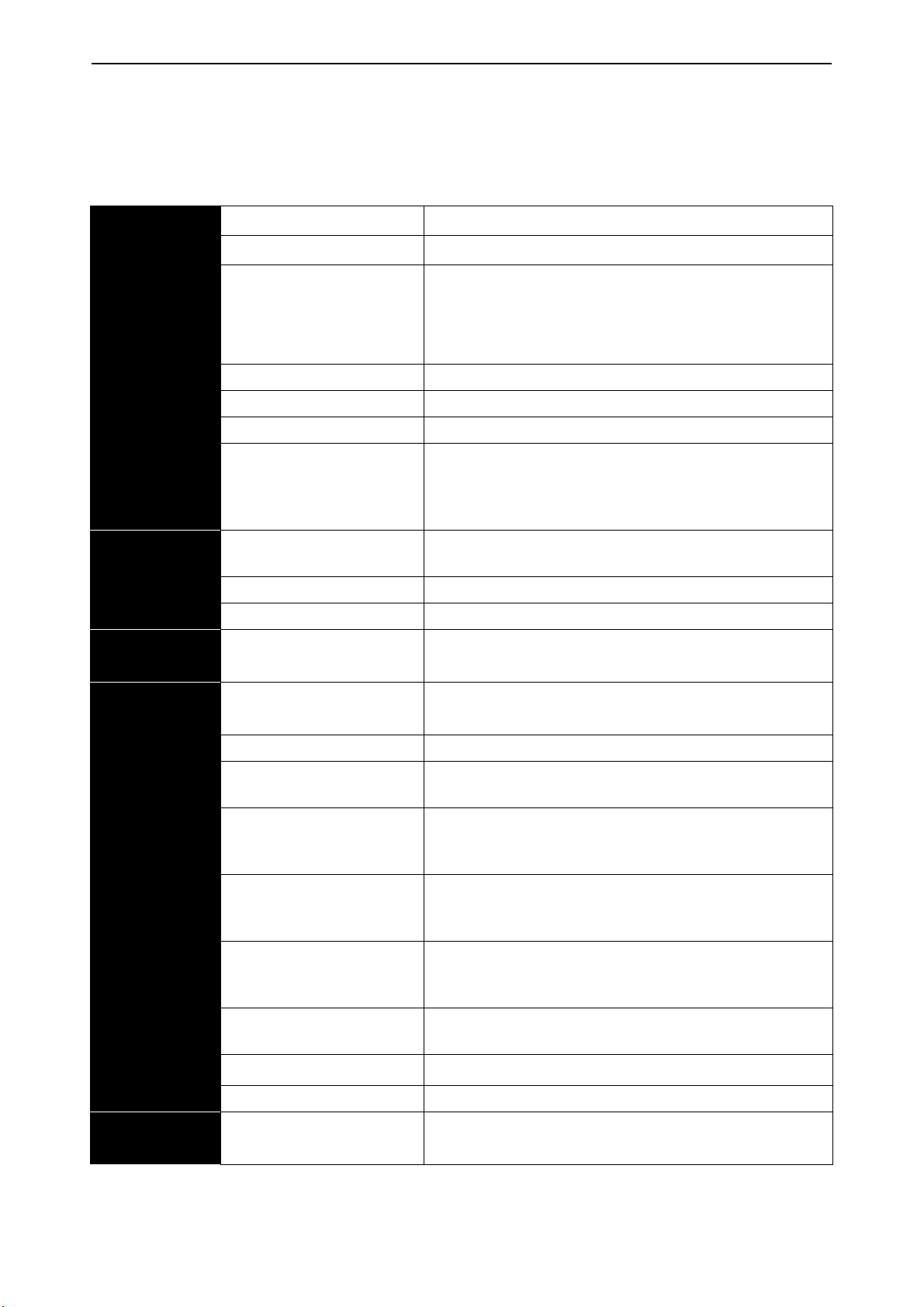

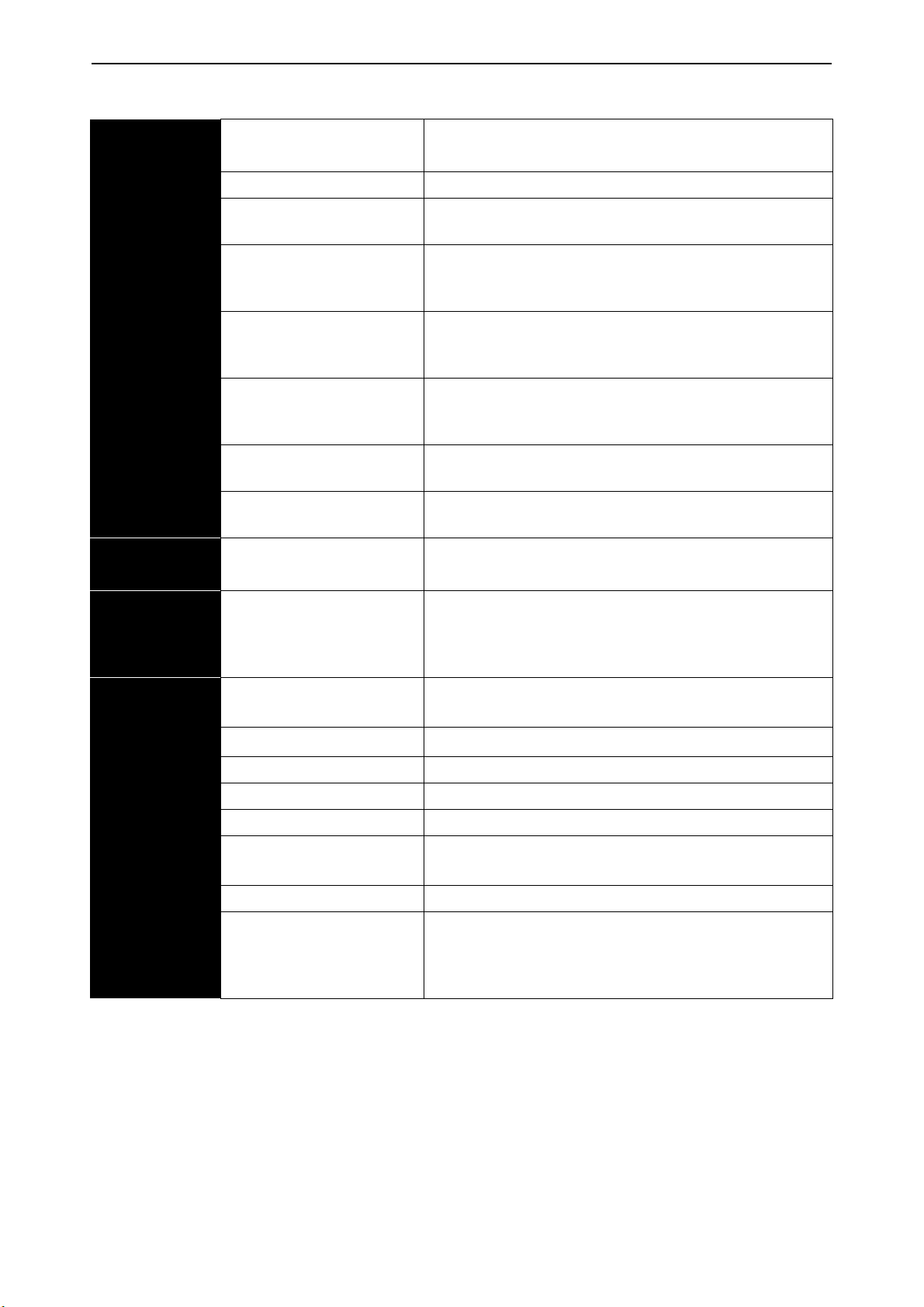

Table 1. Manual revision history

Rev.

Release

date

Changes/updates

A 17.12.2013 First version

B 07.01.2015

C 23.06.2020

Updated Chapter 2 “Available sections”.

Updated Chapter 4.3 “Removing the drives from the cabinet”.

Changes to the chapter structure of the manual.

Added Chapter 4.1 “Installation procedure”.

Updated Chapter 4.4 “Connecting the busbars”.

Added Chapter 4.6.3 “EMC grounding”.

Added Chapter 4.6.4 “Installation of ferrite rings (+OCM) on the motor cable”.

Added Chapter 4.6.6 “Auxiliary low-voltage connections”.

Added Chapter 4.7 “Screw tightening torques”.

1.2 Scope of supply

The scope of supply is limited to the drives listed in this manual. Process, machine or drive control

systems are not part of the scope of supply.

1.3 Related brochures and manuals

VACON® NX user manuals and brochures are available in PDF format on the Danfoss website at

www.danfoss.com.

• VACON® NXP Common DC Bus Selection Guide

• VACON® NXN NFE User manual

• VACON® NX Active Front End User Manual

• VACON® NX Inverters FI4-FI8 Operating Guide

• VACON® NX Inverters FI9-FI14 Operating Guide

Also manuals for different applications and option boards are available on the Danfoss website at

www.danfoss.com.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 6

vacon • 6 Introduction

1.4 Definitions and abbreviations

ADS Auxiliary Device Section

AFS Active Front-end Section

DBS Dynamic Brake Section

DRL Drive List

IUS Inverter Unit Section

LV Low Voltage

MIS Main Incoming Section

NFS Non-regenerative Front-end Section

SLD Single Line Diagram

TSU Transport Split Unit

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 7

Introduction vacon • 7

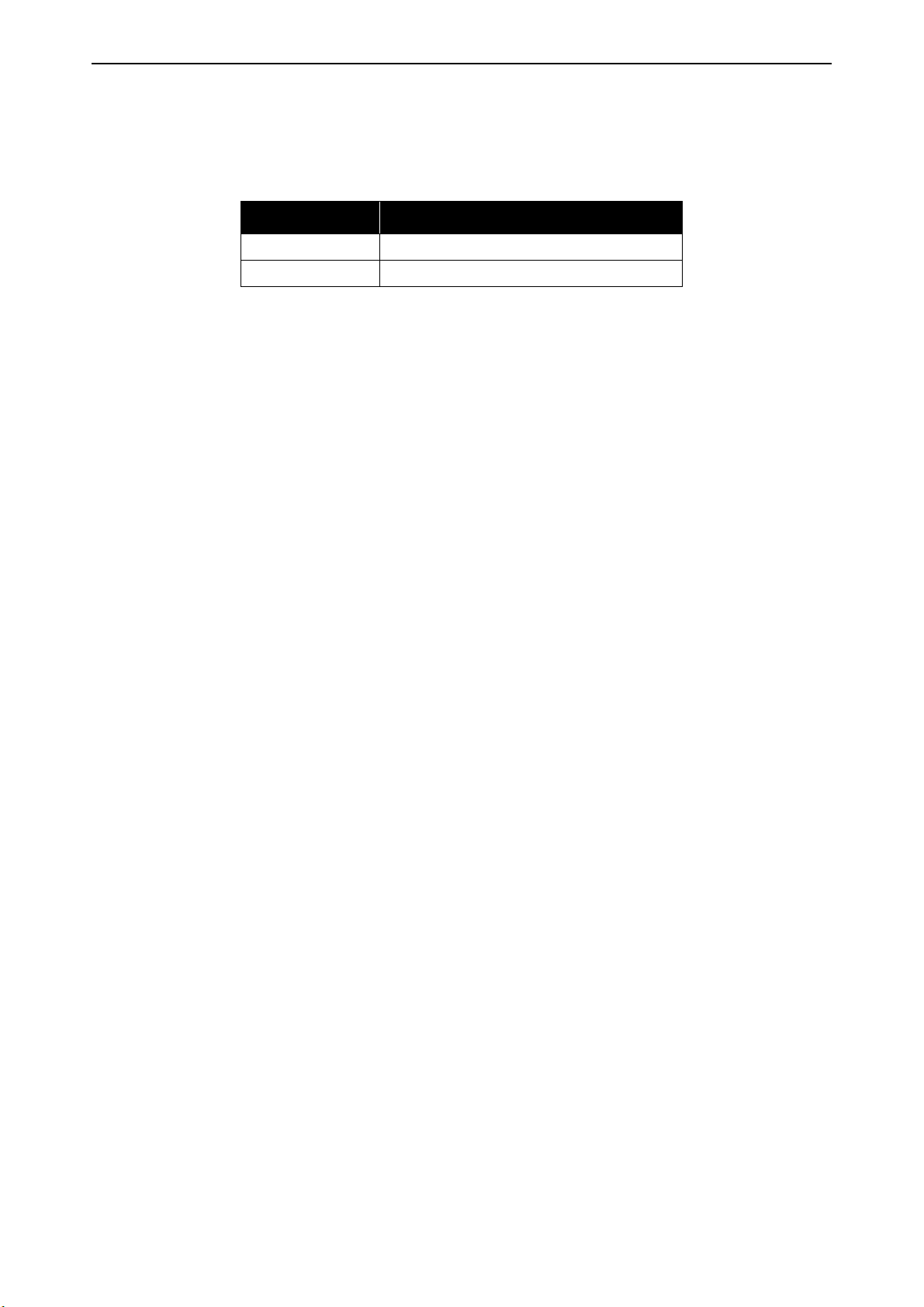

1.5 Project specifications

1.5.1 Parameters

Project parameters are selected with the line-up configuration tool. Table 2 shows an example of

parameters selected with the configuration tool.

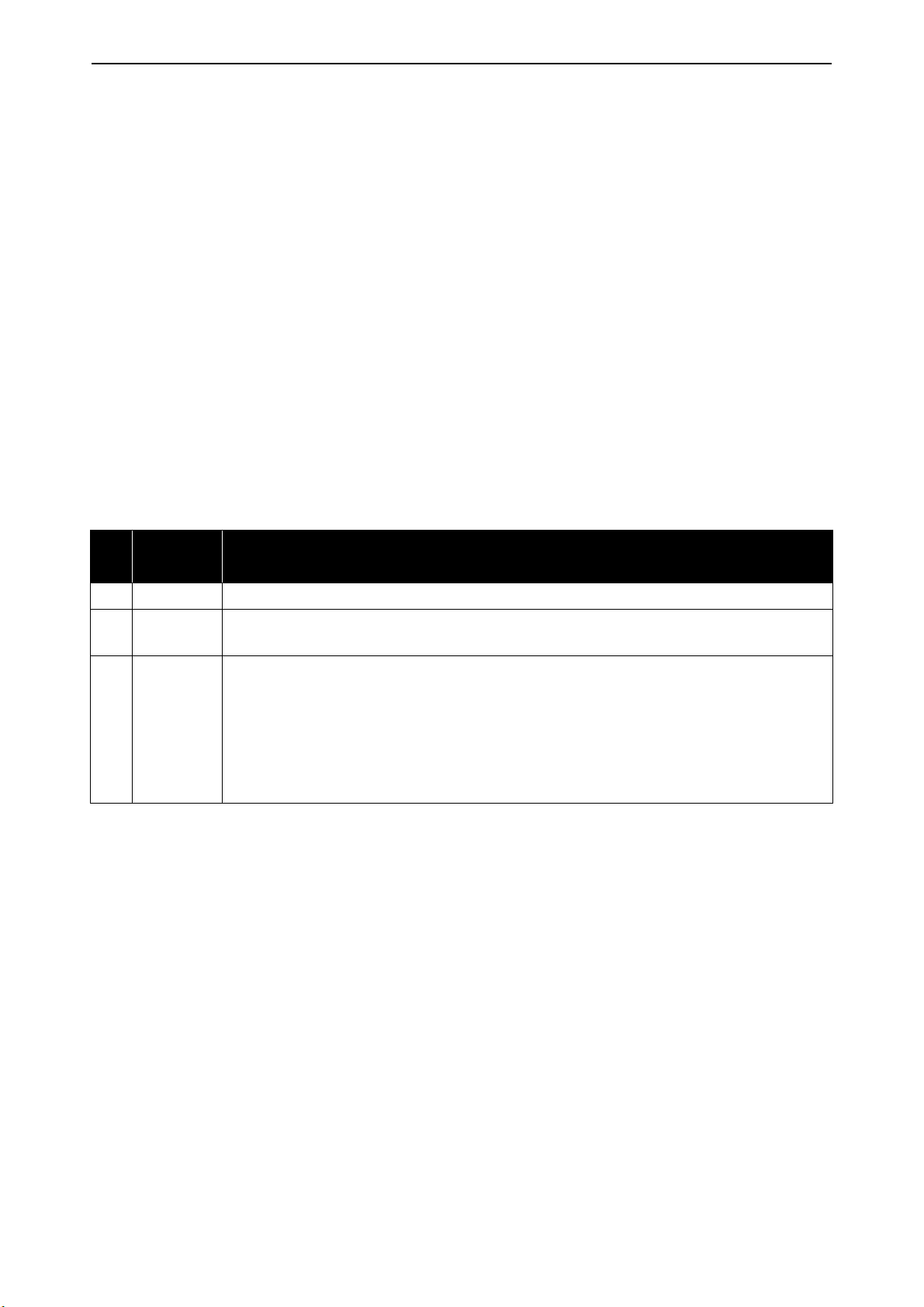

Table 2. Example of parameters selected from the configuration tool

Parameter Selection

Mains network type IT

Mains voltage 690 V AC

Frequency 50 Hz

Mains maximum current 2500 A

Busbar system DC+, DC-, PE

Busbar system voltage 1100 V DC

Busbar system maximum current 2500 A

Icw, 1 s

50 kA

PE design 50%

Busbars and flexibars Tinned

Cabinet type Rittal TS8

Height 2000 mm

Depth 600 mm

Cabinet material Powder coated steel

Sheet steel parts within the enclosure Without coating

Colour RAL 7035

Ingress protection of enclosure Protection against accidental touching of live parts

Protection barriers and covers IP 21

Ambient temperature 35°C

Halogen free wires and ducts No

Mimic diagram No

Type of packing Sea freight box

Application Industry

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 8

vacon • 8 Introduction

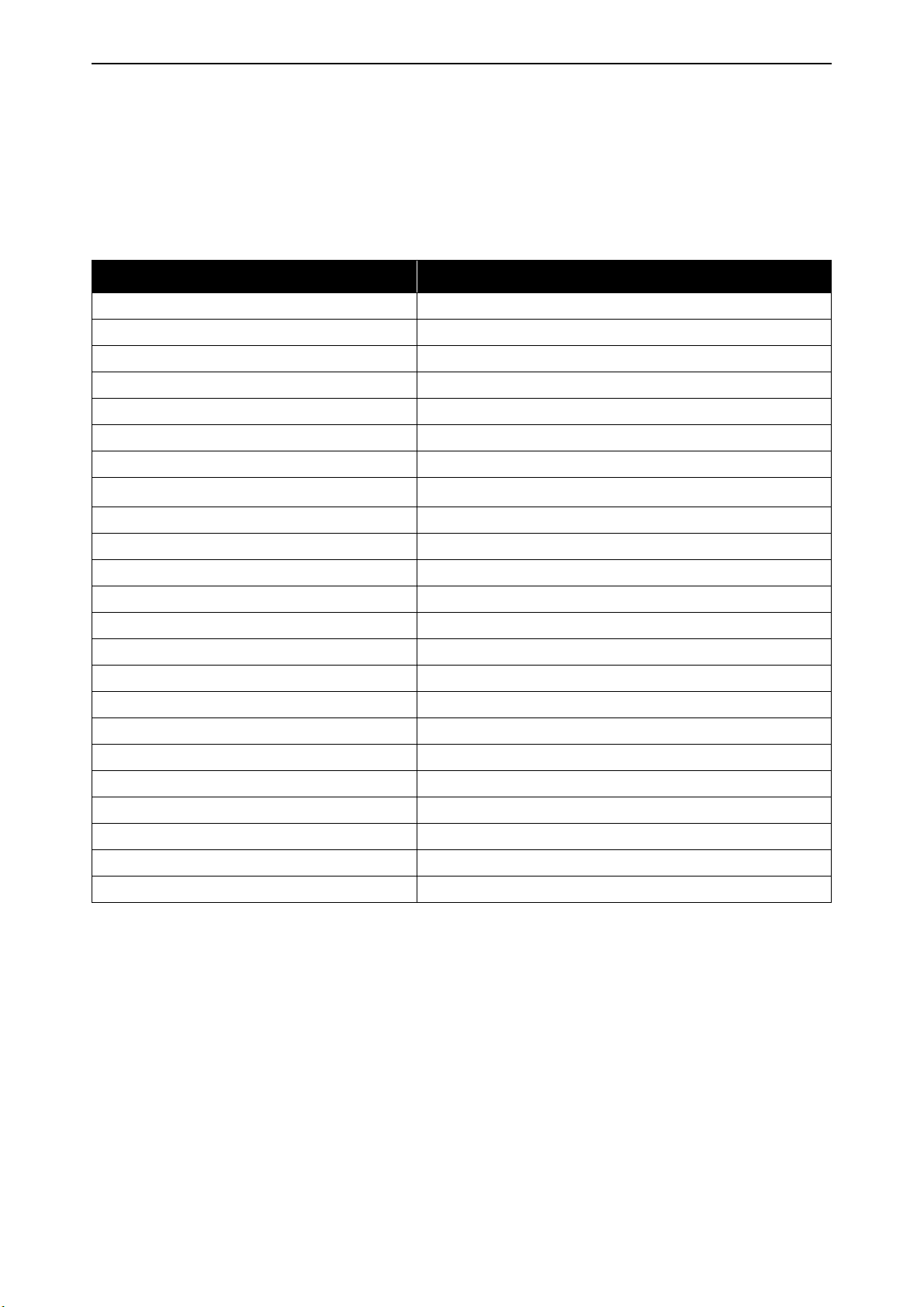

1.5.2 Sections and options

Sections and options are selected using the line-up configuration tool.

The available sections and options are introduced in Chapter 3.

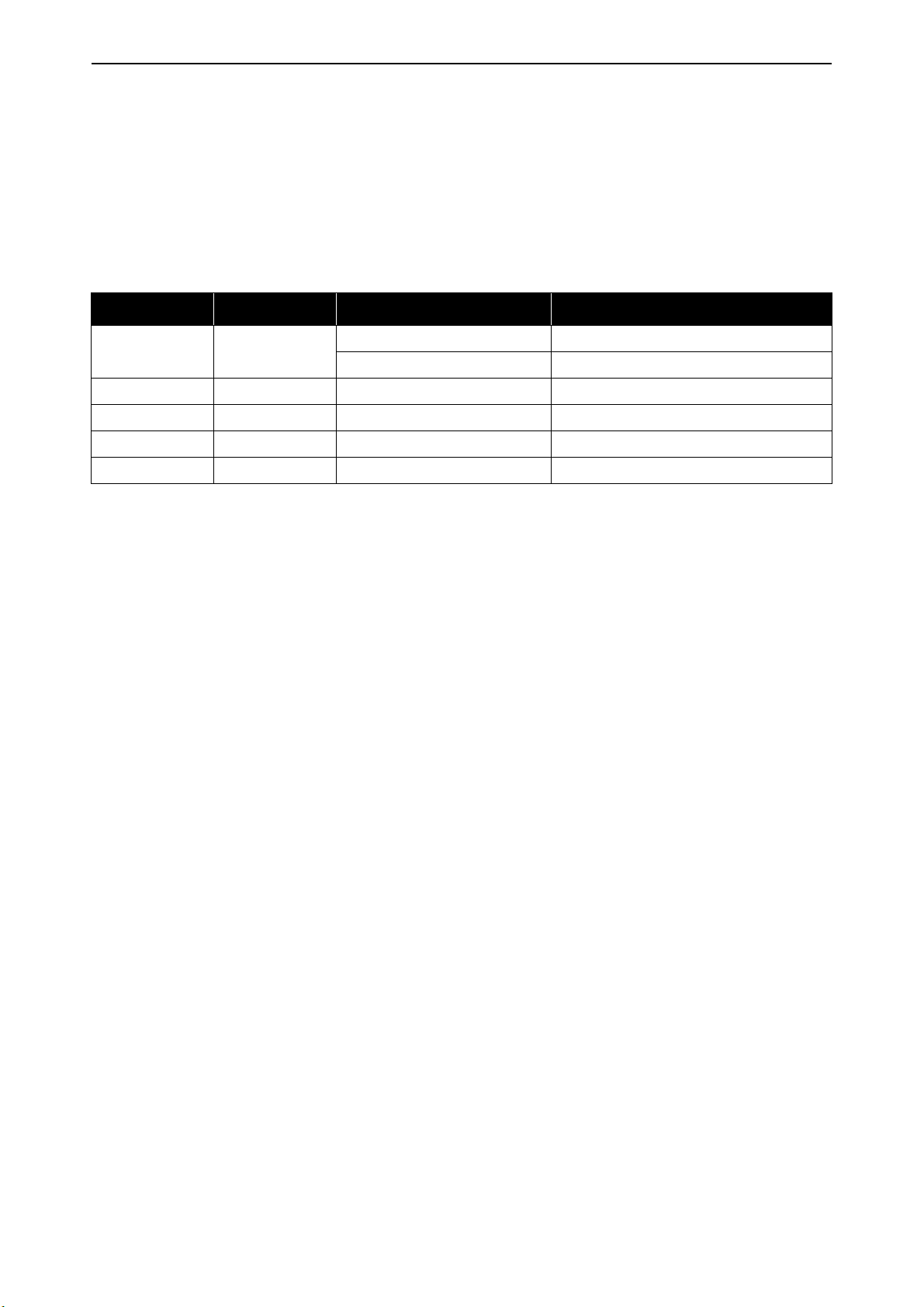

Table 3. Example of selected sections and options from the configuration tool

# Section type Section category Options

1 ADS_600 Control +PES

2 MIS_2500 Incoming power +ICB

3 AFS_13 Incoming power 4 IUS_4 Outgoing power +ODU

5 IUS_10 Outgoing power +ODU

6 IUS_10 Outgoing power +ODU

7 IUS_12 Outgoing power +ISC, +ODU

8 IUS_7 Outgoing power +ODU

9 IUS_12 Outgoing power +ISC, +ODU

1.5.3 System layout and footprint drawings

System layout and footprint drawings are created based on the sections and options selected with

the line-up configuration tool.

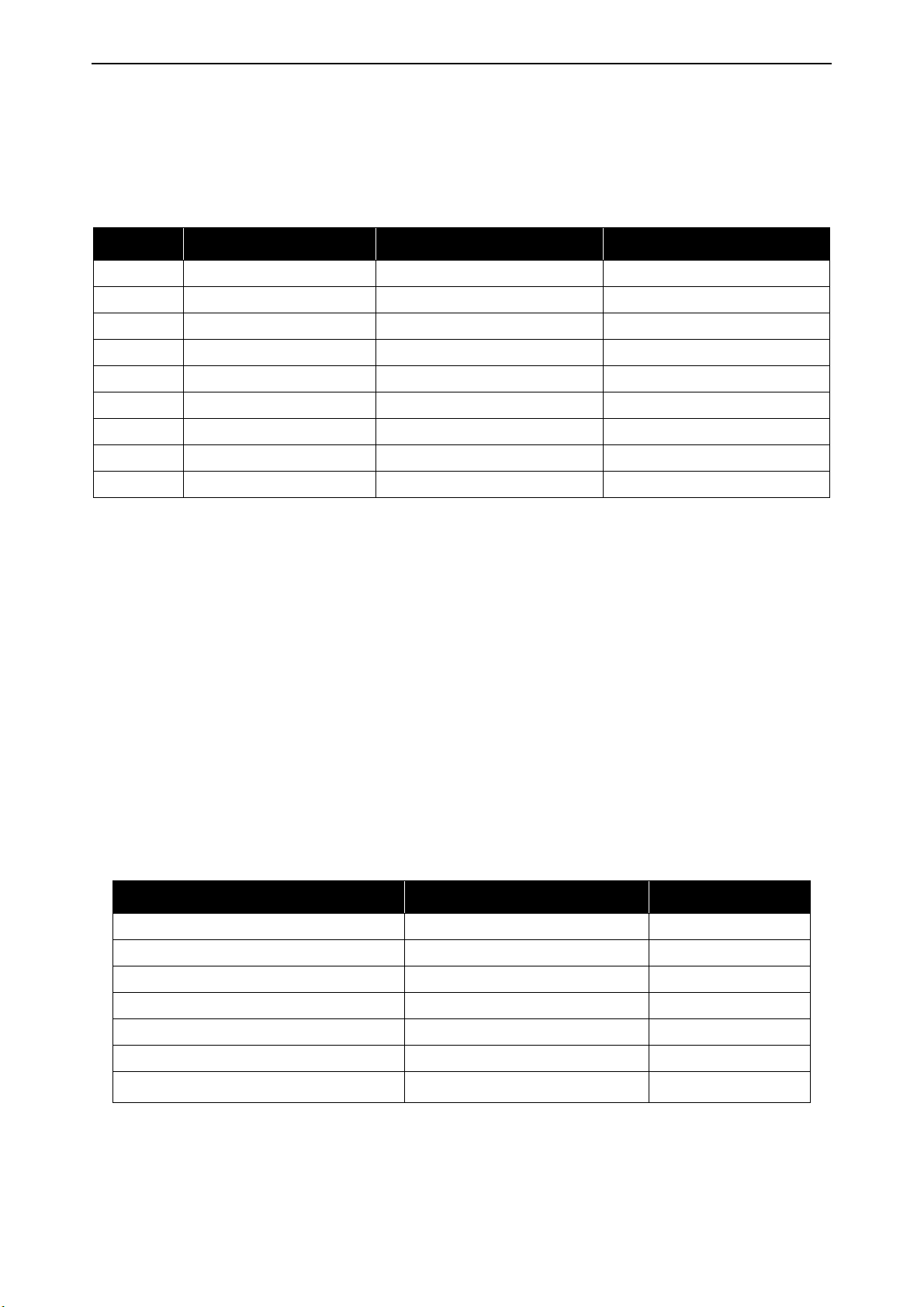

1.6 Supplied documentation

Danfoss delivers technical documentation for the switchgear assembled AC drives according to the

Danfoss design standard. The documentation is provided in english.

The scope of supply regarding documentation does not include:

• Special requirements

• Delivery specific requirements

• Customer specific requirements (e.g. marking, naming, coding etc.)

Table 4. Supplied documentation

Document type Electronic format Paper copies

Cable connection table dwg, dxf or pdf 3 sets

Parts list dwg, dxf or pdf 3 sets

Wiring list dwg, dxf or pdf 3 sets

Circuit diagram dwg, dxf or pdf 3 sets

Switchgear layout drawing dwg, dxf or pdf 3 sets

Device layout drawing dwg, dxf or pdf 3 sets

VACON® manuals (as applicable)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

pdf 3 sets

Page 9

Introduction vacon • 9

1.7 Storage

If the system drive is to be kept in store before use, make sure that the ambient conditions are

acceptable:

• Storing temperature –40…+70 °C

• Relative humidity <95%, no condensation

The environment should also be free from dust. If there is dust in the air, the drive should be well

protected to make sure dust does not get into the drive.

If the drive is to be stored during longer periods, the power should be connected to the drive once

in 24 months and kept on for at least 2 hours. If the storage time exceeds 24 months the electrolytic

DC capacitors need to be charged with caution. Therefore, such a long storage time is not

recommended.

If the storing time is much longer than 24 months, the recharging of the capacitors has to be carried

out so that the possible high leakage current through the capacitors is limited. The best alternative

is to use a DC power supply with adjustable current limit. The current limit has to be set for example

to 300-500 mA and the DC power supply has to be connected to the B+/B- terminals (DC supply

terminals).

DC voltage must be adjusted to nominal DC voltage level of the unit (1.35xUn AC) and supplied at

least for 1 hour.

If DC voltage is not available and the unit has been stored de-energized much longer than 1 year,

consult factory before connecting power.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 10

vacon • 10 Introduction

Min 60°

13858_00

13859_00

13006.emf

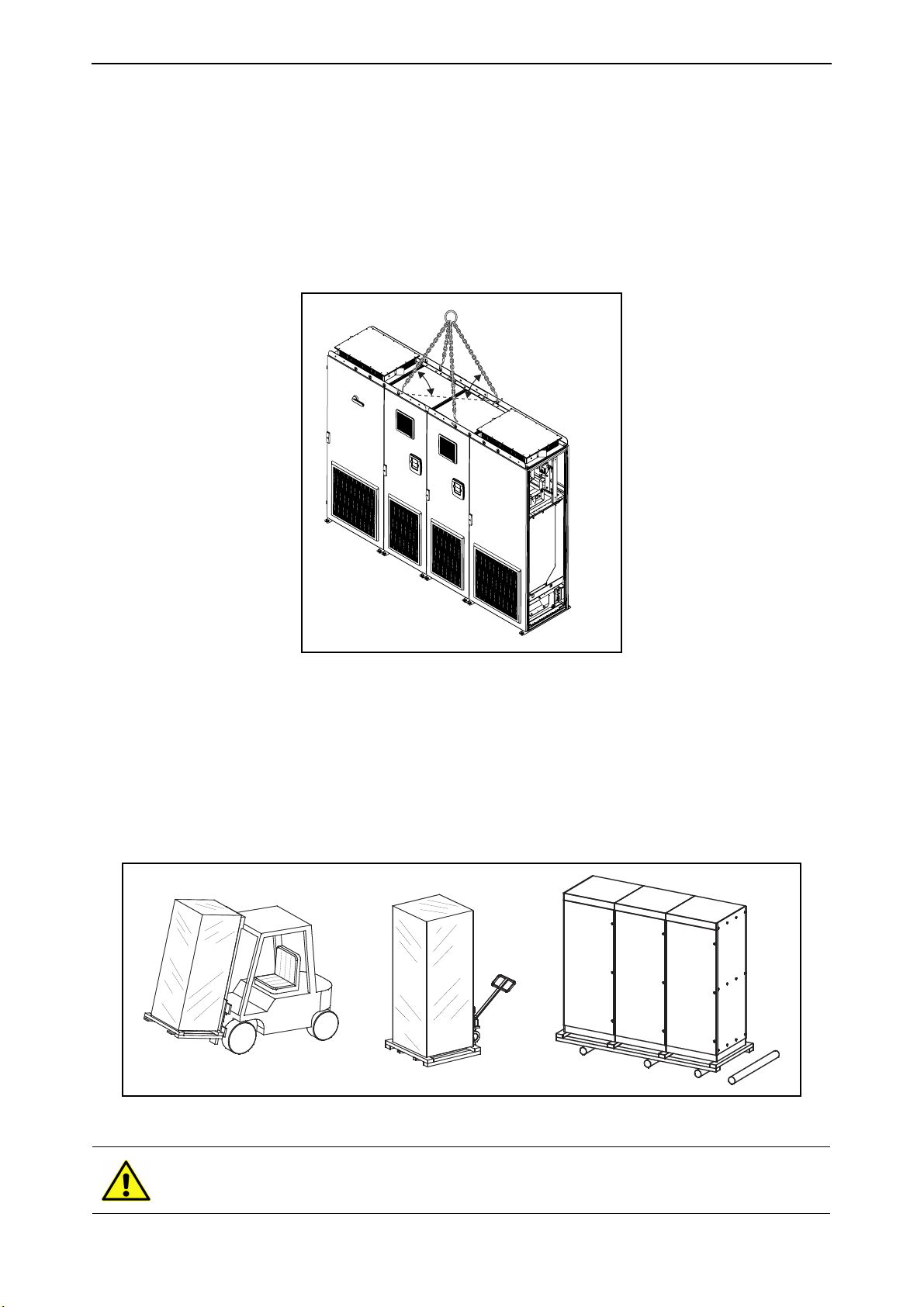

1.8 Lifting and moving the cabinet sections

For transport, the system drive is split into smaller sections. The cabinet sections are delivered

either in a wooden box or a wooden cage. The cabinets are transported vertically. Always refer to

shipping marks for more detailed information. To lift the cabinet sections, use lifting equipment

capable of handling the weight of the cabinets.

There are lifting beams on the top of the cabinets. Use the beams to lift and to move the cabinets to

the required location.

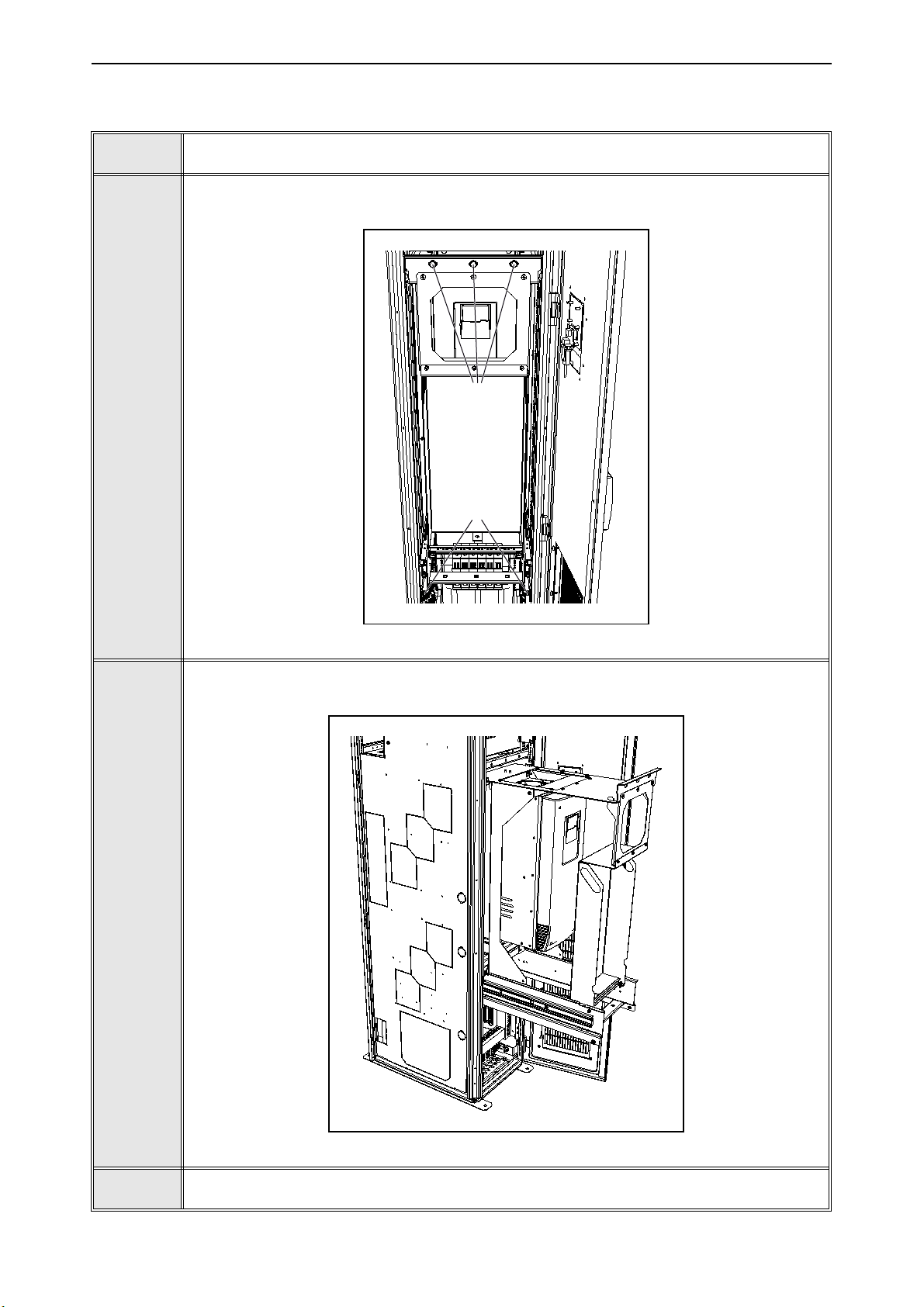

Figure 1. Lifting the cabinet sections

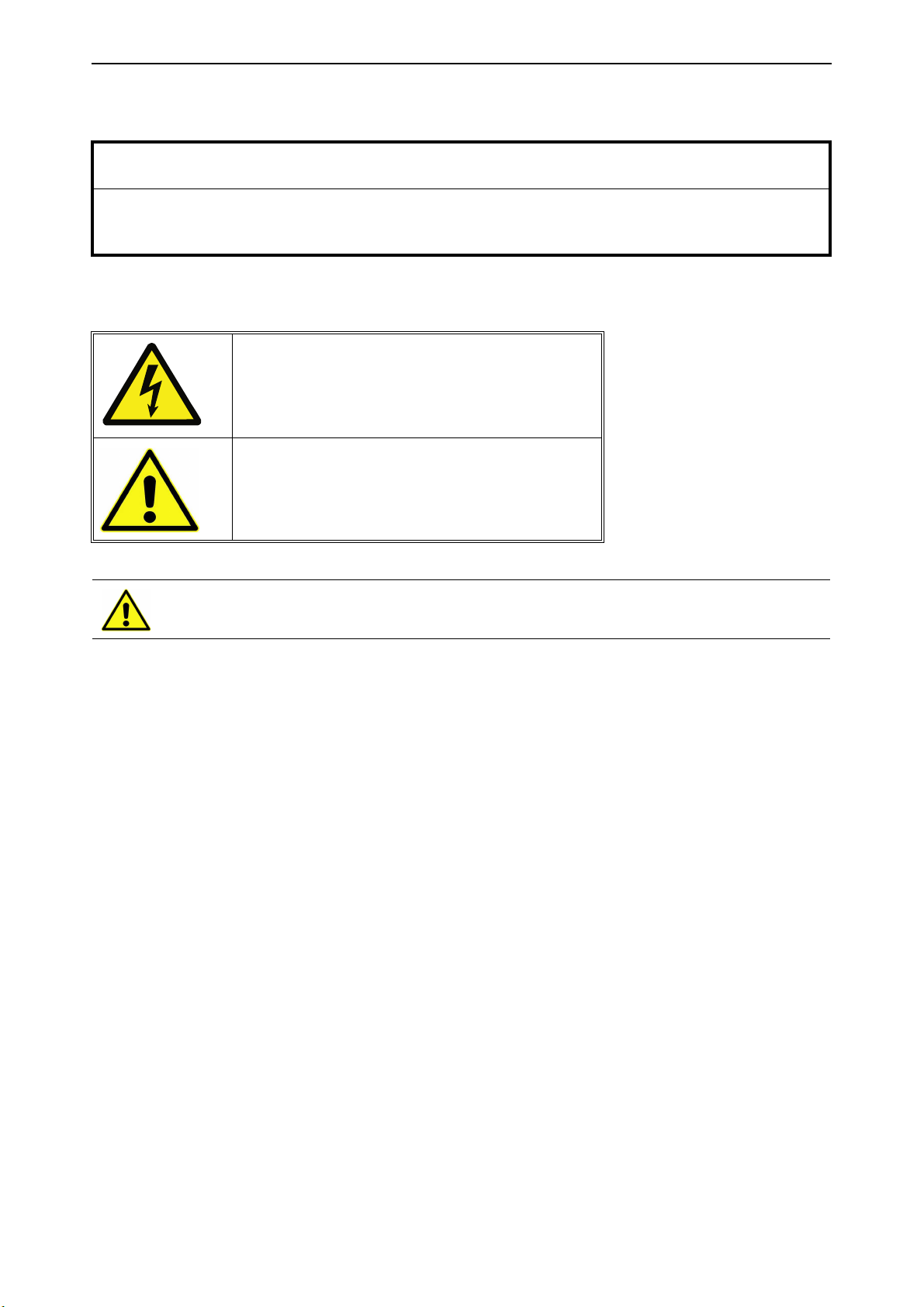

Moving of the cabinets on site can be carried out as follows by a forklift truck, a hoist or on rollers:

• Lower the package onto a level base

• Remove the package covering only at the site of installation

• Low, narrow or convoluted transport routes may require removal of the pallet prior to

movement

• Move packages in the upright position only

Figure 2. Moving the cabinet sections

Switchgear parts can easily topple backwards when manoeuvring on rollers or

manual trolleys because their centre of gravity is typically located high up at the rear

of the unit.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 11

Safety vacon • 11

9000.emf

13006.emf

13006.emf

2. S

AFETY

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from https://www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site https://www.danfoss.com/en/service-and-support/.

Please, read the information in cautions and warnings carefully.

The cautions and warnings are marked as follows:

= WARNING, dangerous voltage!

= CAUTION, possible damage to equipment!

Installation is only permitted to be carried out by a competent electrician!

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 12

vacon • 12 Safety

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

2.1 Warnings

The components of the power unit and all cabinet mounted devices are live when

the drive is connected to mains potential. Coming into contact with this voltage is

extremely dangerous and may cause death or severe injury.

The motor terminals U, V, W, the DC bus/brake resistor terminals and all other

mains devices are potentially live when the drive is connected to mains, even if the

motor is not running.

After disconnecting the AC drive from the mains, wait until the fan stops and the

indicators on the keypad go out (if no keypad is attached see the indicators on the

cover). Wait 5 more minutes before doing any work on the connections of the drive. Do

not open the cabinet door before this time has expired. After expiration of this time,

use measuring equipment to absolutely ensure that no voltage is present. Always

ensure the absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the relay

outputs and other I/O-terminals may have a dangerous control voltage present even

when the drive is disconnected from mains.

Before connecting the drive to mains make sure that the drive front and cable covers

as well as the cabinet doors are closed.

Wear protective gloves when you do mounting, cabling or maintenance operations.

There can be sharp edges in the AC drive that can cause cuts.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 13

Safety vacon • 13

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

2.2 Cautions

VACON® AC drives are meant for

fixed installations only

.

Do not perform any measurements when the AC drive is connected to mains.

The touch current of VACON® AC drives exceeds 3.5 mAAC. According to standard

EN61800-5-1, a reinforced protective ground connection must be ensured. See

Chapter 2.3.

If the drive is used as a part of a machine, the machine manufacturer is responsible

for providing the machine with a supply disconnecting device (EN60204-1).

Only spare parts delivered by Danfoss can be used.

At power-up, power brake or fault reset the motor will start immediately if the start

signal is active, unless the pulse control for Start/Stop logic has been selected.

Futhermore, the I/O functionalities (including start inputs) may change if parameters,

applications or software are changed. Disconnect, therefore, the motor if an

unexpected start can cause danger.

The motor starts automatically after automatic fault reset if the autoreset function is

activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor cable

from the drive.

Do not touch the components on the circuit boards. Static voltage disharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of the

supply network.

Make sure that the cooling is sufficient. If the AC drive becomes frequently too hot, the

lifetime of the drive will be shorter than usually.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 14

vacon • 14 Safety

13006.emf

13006.emf

2.3 Grounding and ground fault protection

CAUTION!

The AC drive must always be grounded with a grounding conductor connected to the grounding terminal marked with:

The touch current of the AC drive exceeds 3.5 mA AC. According to EN61800-5-1, one or more of the

following conditions for the associated protective circuit shall be satisfied:

A fixed connection and

• the protective grounding conductor shall have a cross-sectional area of at least 10 mm2 Cu

or 16 mm2 Al, or

• an automatic disconnection of the supply in case of discontinuity of the protective grounding

conductor, or

• provision of an additional terminal for a second protective grounding conductor of the same

cross-sectional area as the original protective grounding conductor.

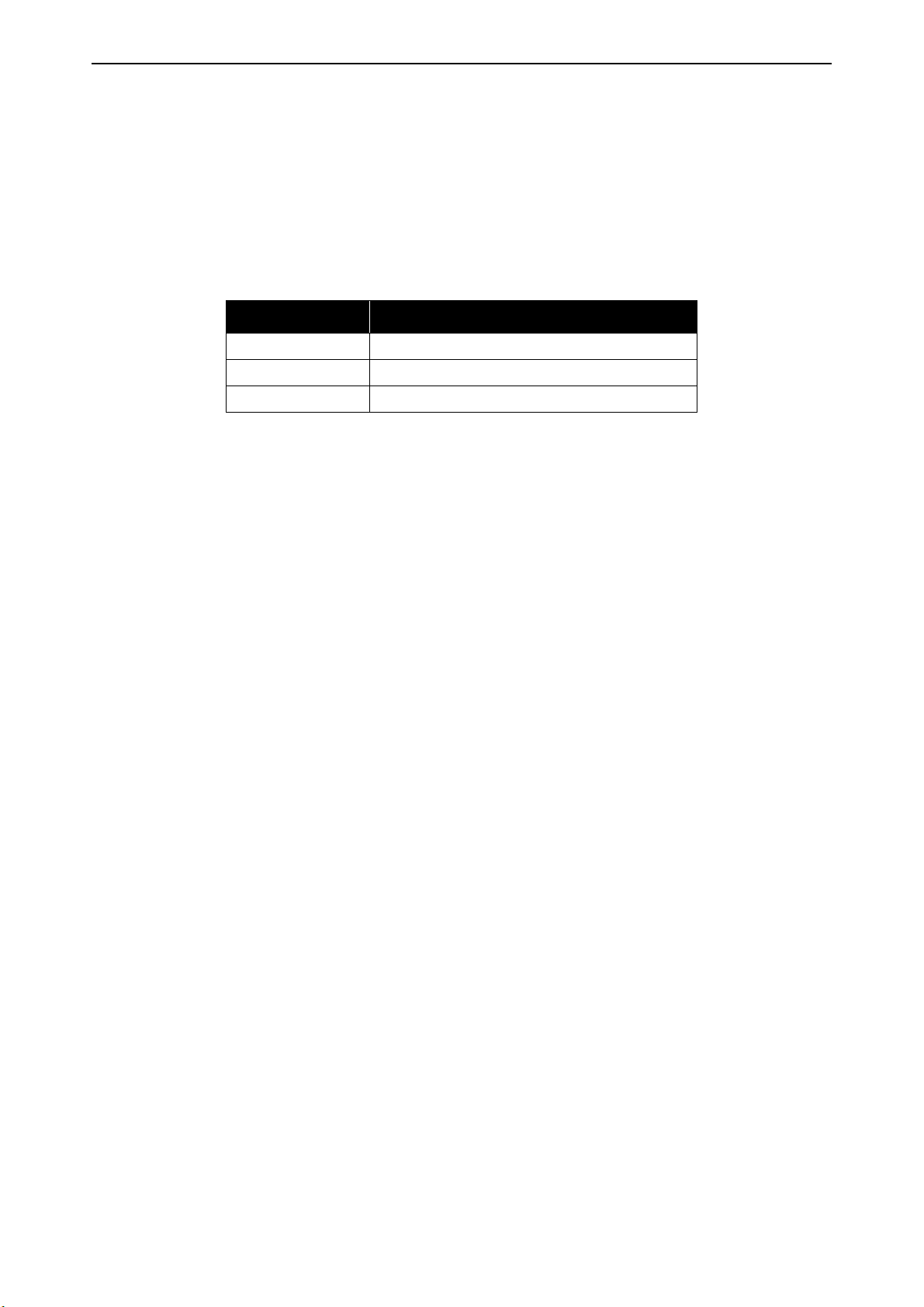

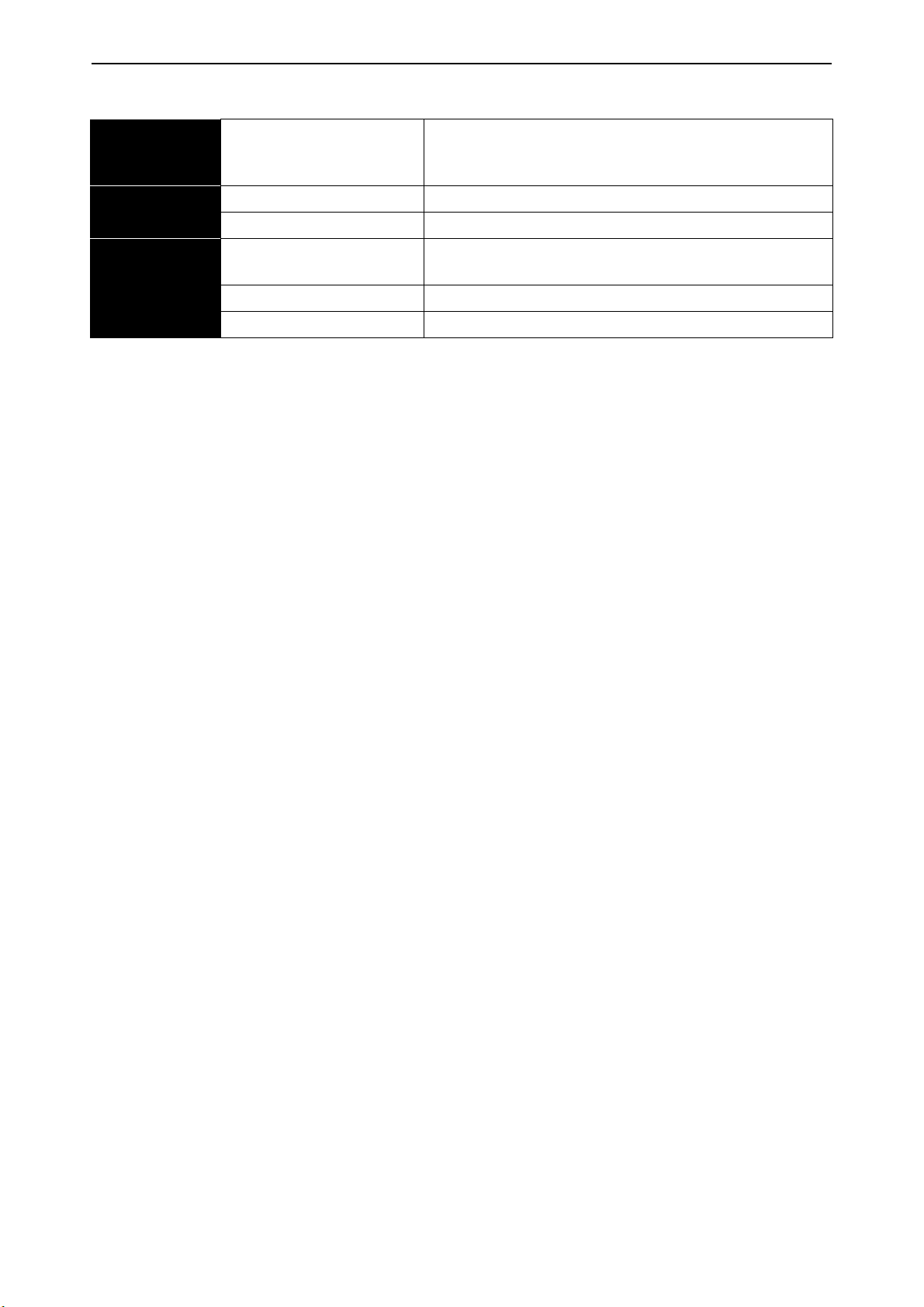

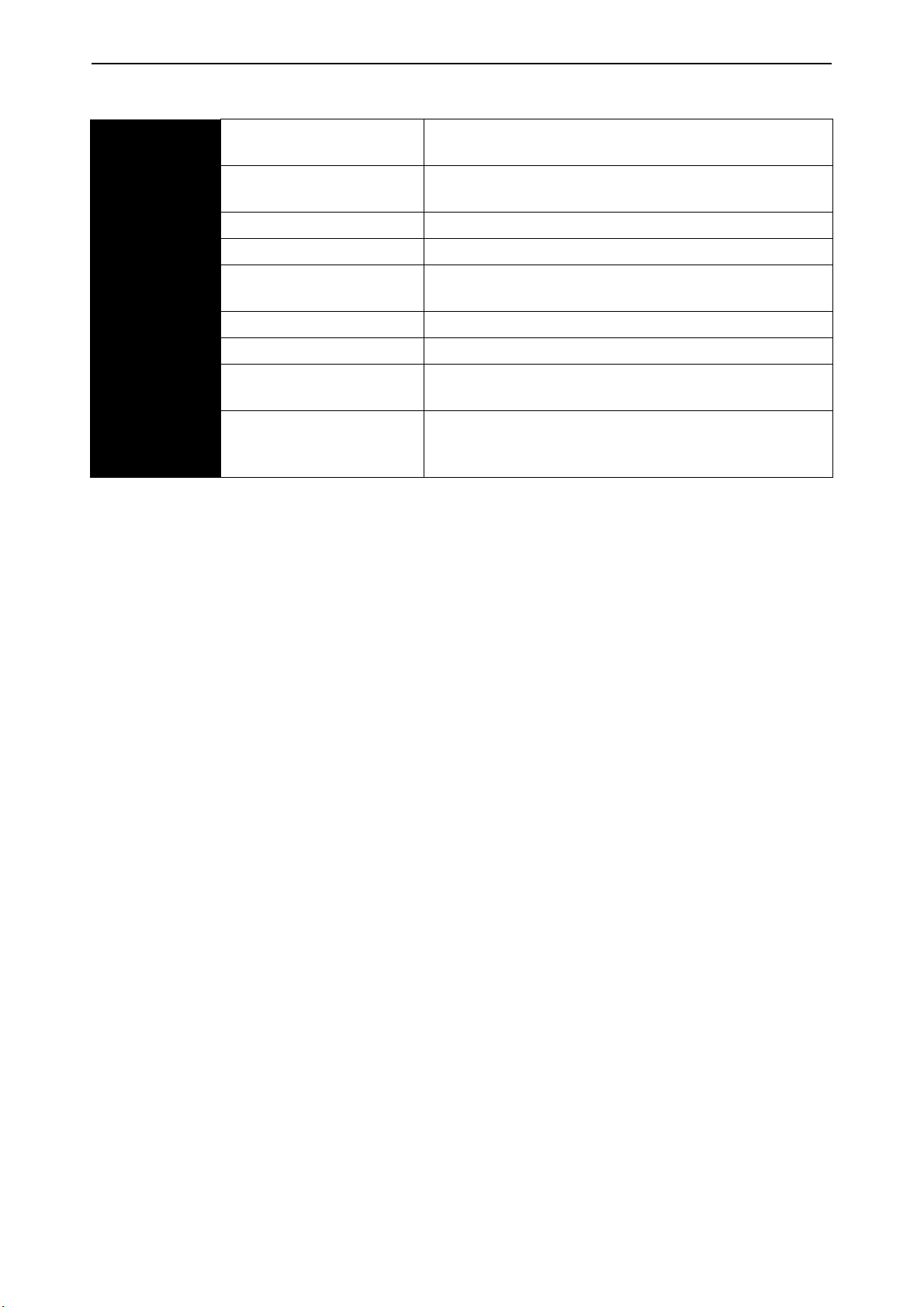

Table 5. Protective grounding conductor cross-section

Cross-sectional area of phase conductors (S)

[mm2]

S

≤16

16<S≤35

35<

S

Minimum cross-sectional area of the corre-

sponding protective grounding conductor

[mm2]

S

16

S

/2

The values above are valid only if the protective grounding conductor is made of the same metal

as the phase conductors. If this is not so, the cross-sectional area of the protective grounding

conductor shall be determined in a manner which produces a conductance equivalent to that

which results from the application of this table.

The cross-sectional area of every protective grounding conductor which does not form part of the

supply cable enclosure shall, in any case, be no less than:

• 2.5 mm2 if mechanical protection is provided or

• 4 mm2 if mechanical protection is not provided. For cord-connected equipment, provisions

shall be made so that the protective grounding conductor in the cord shall, in the case of

failure of the strain-relief mechanism, be the last conductor to be interrupted.

However, always follow the local regulations for the minimum size of the protective grounding

conductor.

NOTE! Due to the high capacitive currents present in the AC drive, fault current protective switches

may not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is a

certain procedure according to which the test shall be performed. Ignoring this

procedure may result in a damaged product.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 15

Available sections vacon • 15

3. A

VAILABLE SECTIONS

3.1 Auxiliary device section

The auxiliary device section (ADS) includes the common line-up controls. This section can be

customized for all application and segment needs. There are three ADS sizes available.

Table 6. ADS section size

ADS type Width x Height x Depth (mm)

ADS_400 400 x 2000 x 605

ADS_600 600 x 2000 x 605

ADS_800 800 x 2000 x 605

As standard the ADS section has the following equipment:

1. Control for the circuit breaker with +ICB selected

2. Indication of the mains status (fault, pre-charging and ON)

3. Auxiliary power supply 24 V, 5 A

4. Auxiliary Transformer, 2500 VA 1-phase supply (in bottom of cabinet)

5. Terminals for control and monitoring

As pre-engineered standard options, we can provide the following:

• Emergency stop CAT0 (+PES)

• Emergency stop CAT1 (+PED)

• Insulation fault sensor (+PIF)

• Arc protection relay (+PAP)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

• Auxiliary voltage transformer 4000 VA (+AT4)

• Auxiliary voltage 110 V AC (+AT1)

• Auxiliary power supply 24 V, 10 A (+ADC)

• Cabling from the top (+CIT)

• Empty auxiliary 600 mm cabinet with door (+G60)

• UL approved design and components (+NAR)

• Customer specific option (+CSO)

+PAP will have sub units in selected sections if needed, please refer to the circuit diagrams.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 16

vacon • 16 Available sections

3.2 Main incoming section

The main incoming section (MIS) includes the main incoming device. The main incoming device and

size is dependent on the required current of the complete line-up.

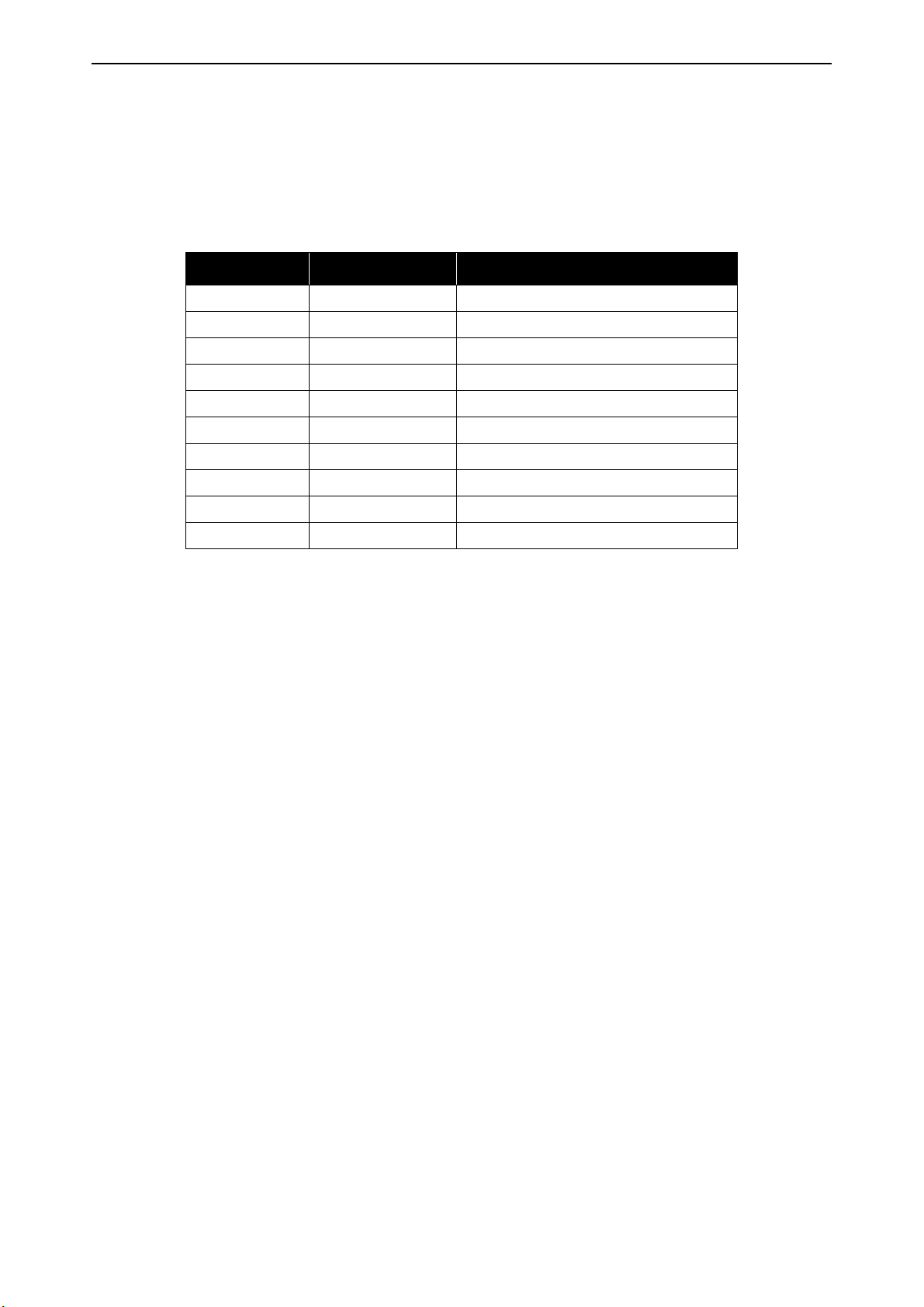

Table 7. Available MIS sizes

MIS type Input current Width x Height x Depth (mm)

MIS_630 630 A 400 x 2000 x 605

MIS_800 800 A 600 x 2000 x 605

MIS_1000 1000 A 600 x 2000 x 605

MIS_1250 1250 A 600 x 2000 x 605

MIS_1600 1600 A 600 x 2000 x 605

MIS_2000 2000 A 600 x 2000 x 605

MIS_2500 2500 A 600 x 2000 x 605

MIS_3200 3200 A 800 x 2000 x 605

MIS_4000 4000 A 800 x 2000 x 605

MIS_5000 5000 A 800 x 2000 x 605

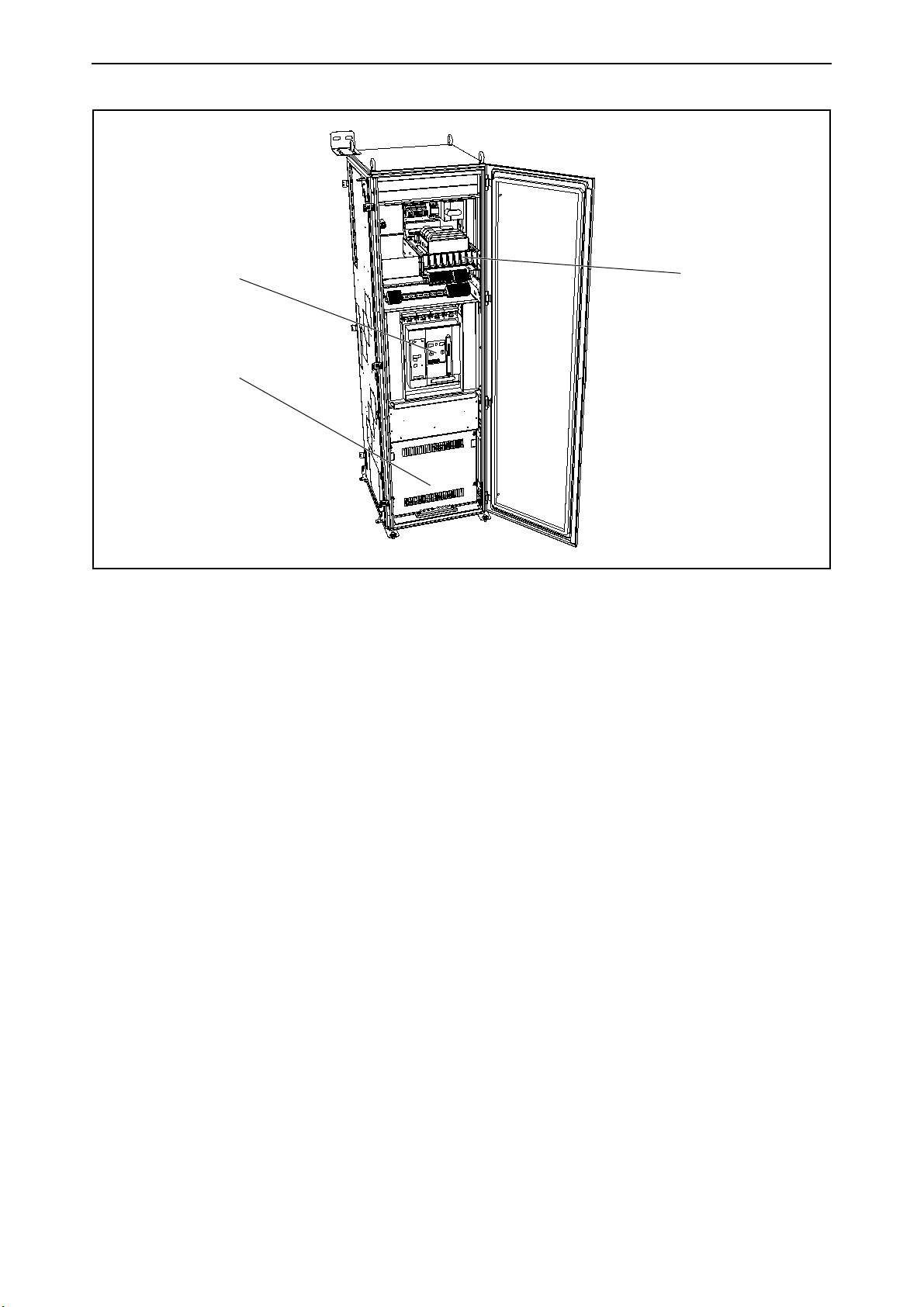

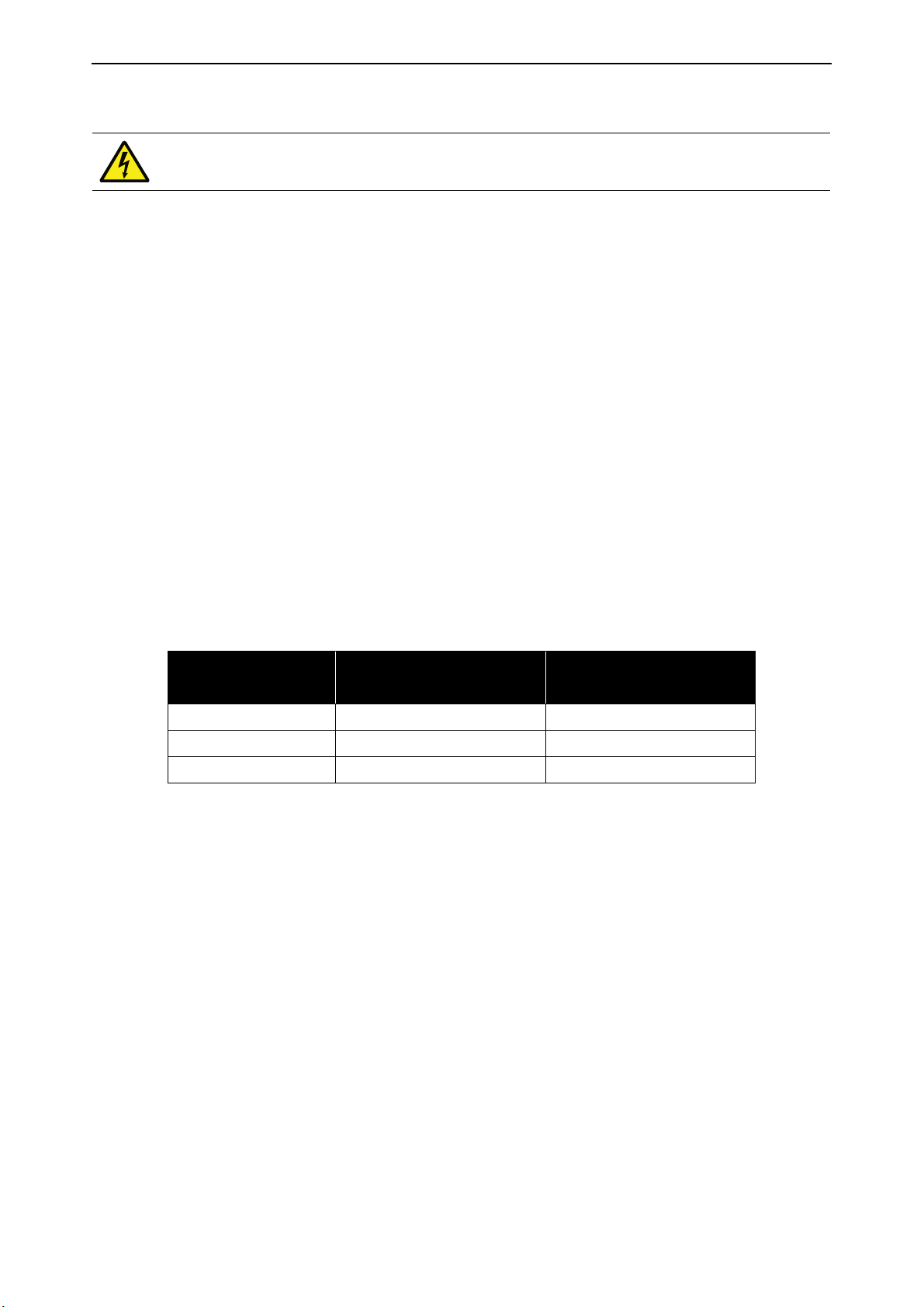

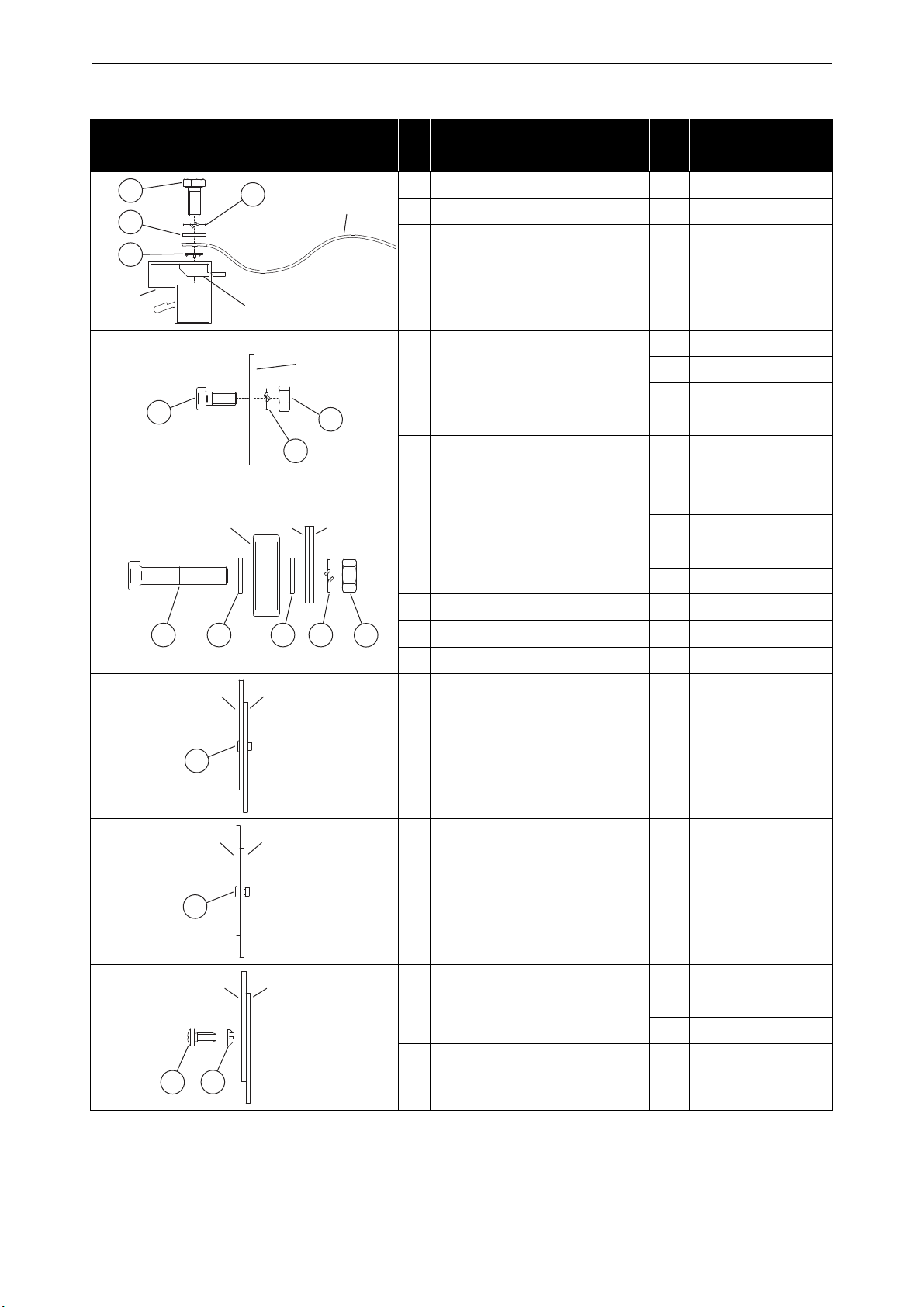

As standard the MIS section has the following equipment (see Figure 3):

1. Air circuit breaker

2. Mains connections

3. Digital multi instrument with field bus connection

4. Pre-charging components for AFE

As pre-engineered standard options we can provide the following:

• Cabling from the top (+CIT)

• Ground Switch (+ILE)

• Current transducers (+ITR)

• UL approved design and components (+NAR)

• Arc detection (+ADU)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

+ILE requires an additional section.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 17

Available sections vacon • 17

1

2

4

13849_00

Figure 3. Example of main incoming section MIS_1600

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 18

vacon • 18 Available sections

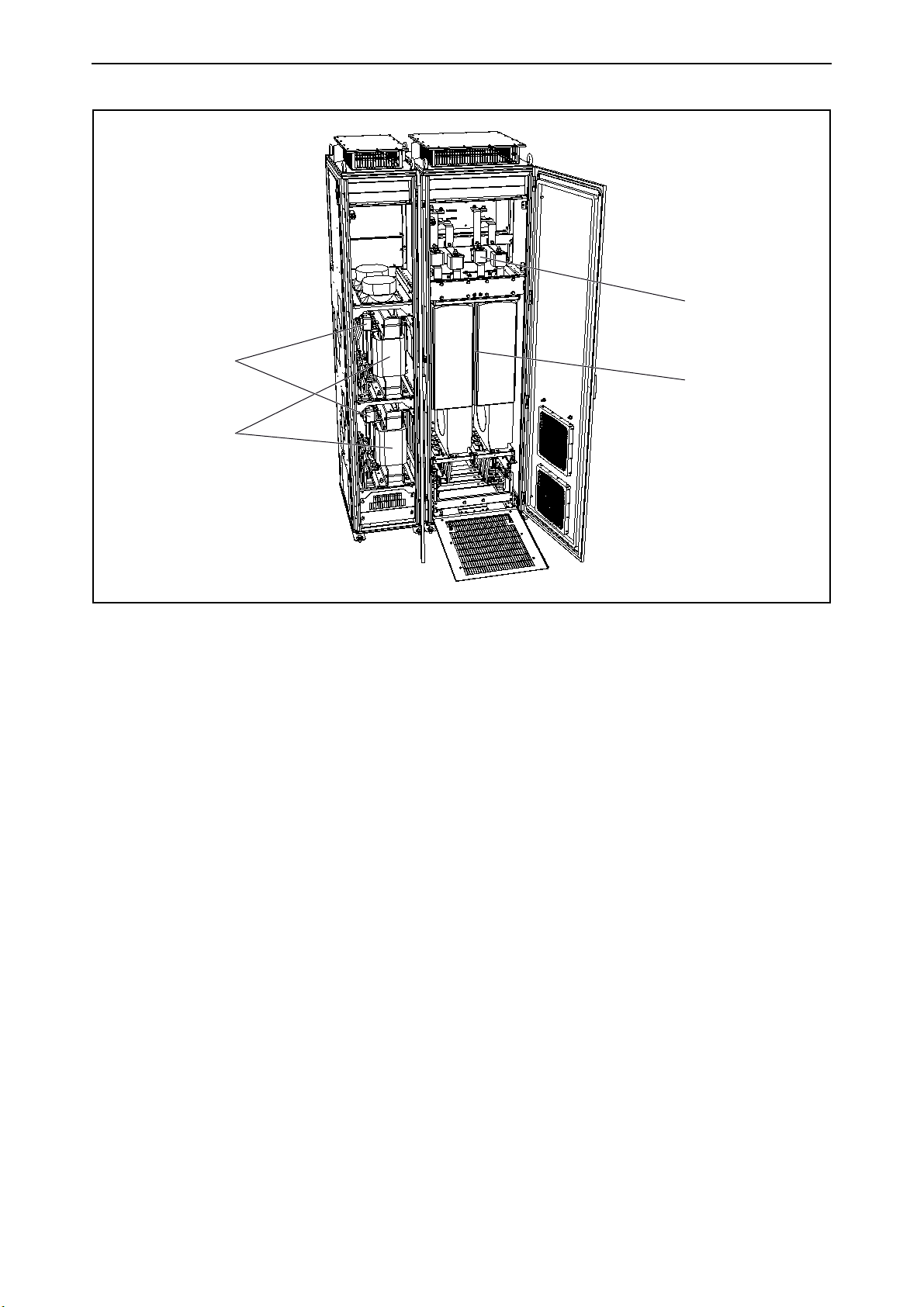

3.3 Non-regenerative front-end section

The non-regenerative front-end section (NFS) includes one or multiple NXN units from the VACON®

NXP product series. The NXN is a non-regenerative supply unit that can be utilized in 6-pulse, 12pulse, 18-pulse and 24-pulse systems.

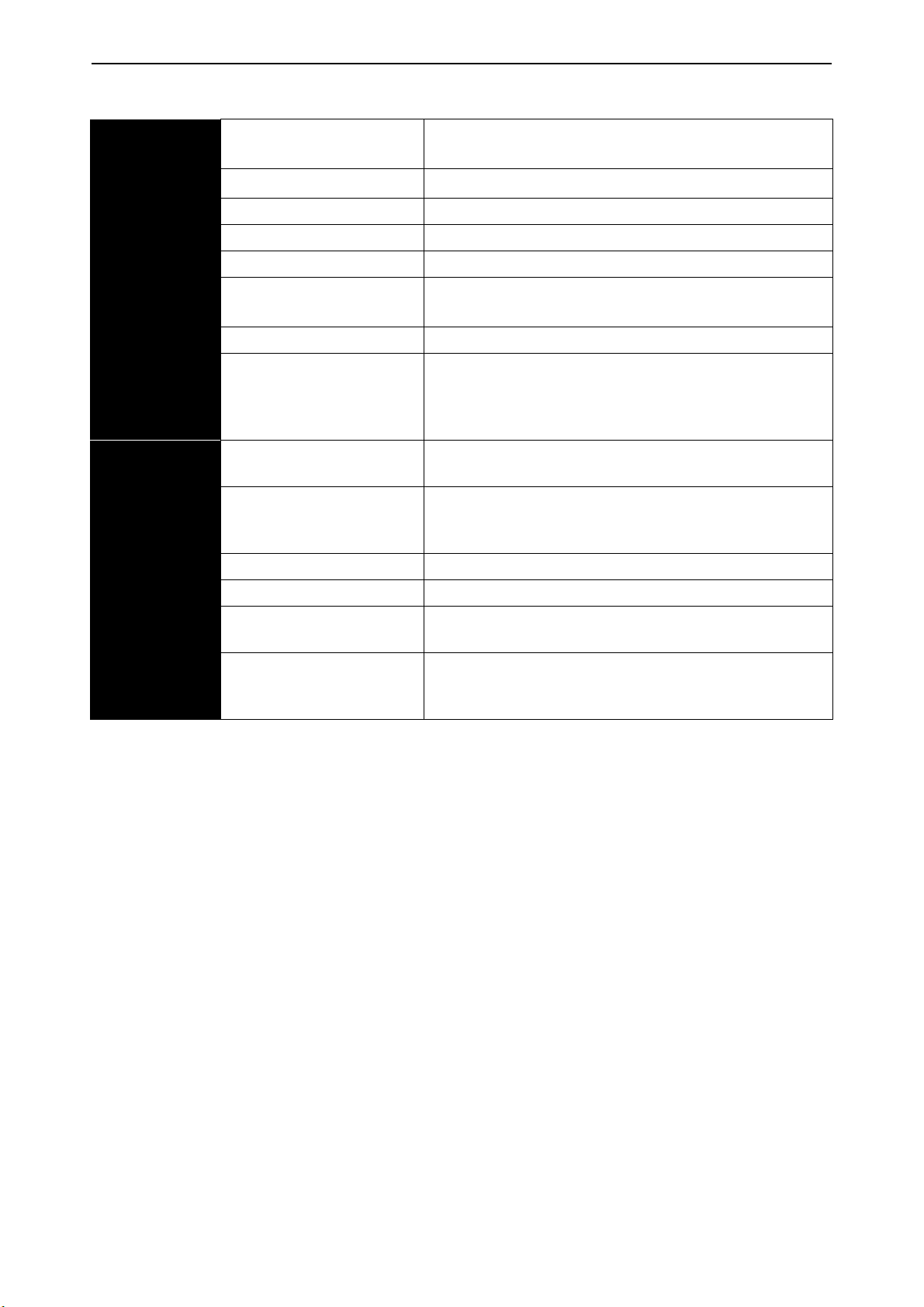

Table 8. Available NFS sections

NFS type Number of NXN units Width x Height x Depth (mm)

NFS_1x* 1 800 x 2100 x 605

NFS_2x* 2 800 x 2100 x 605

* _M selection for mirrored design.

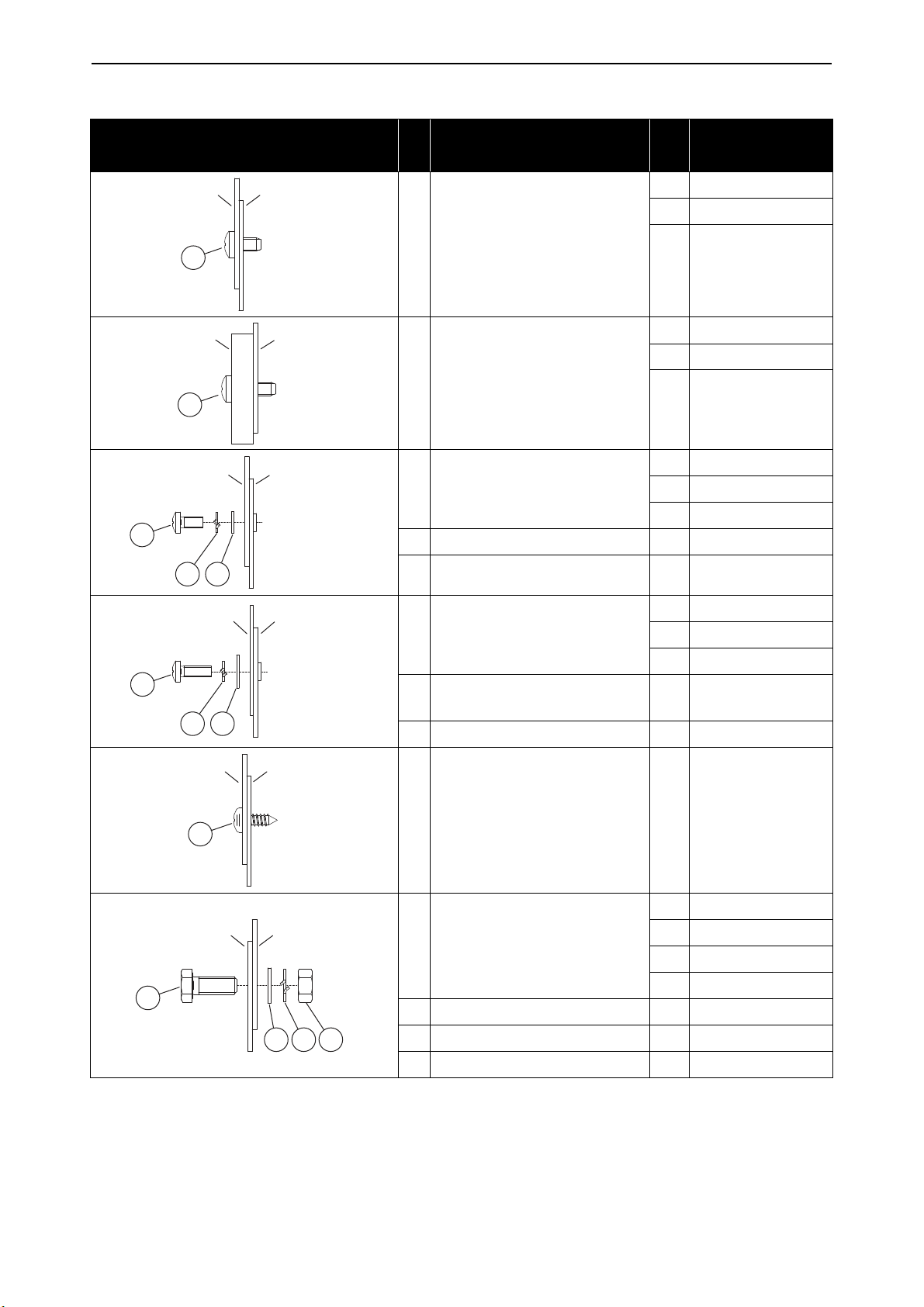

As standard the NFS section includes the following (see Figure 4):

1. The NXN unit(s)

2. Chokes

3. Terminals for control and indication signals (installed in MIS or ADS section)

4. DC fuses for the Supply Unit

5. AC fuses for the filter

As pre-engineered standard options we can provide the following:

• UL approved design and components (+NAR)

• Arc detection (+ADU)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 19

Available sections vacon • 19

2

4

5

1

13850_00

Figure 4. Example of non-regenerative front-end section NFS_2x

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 20

vacon • 20 Available sections

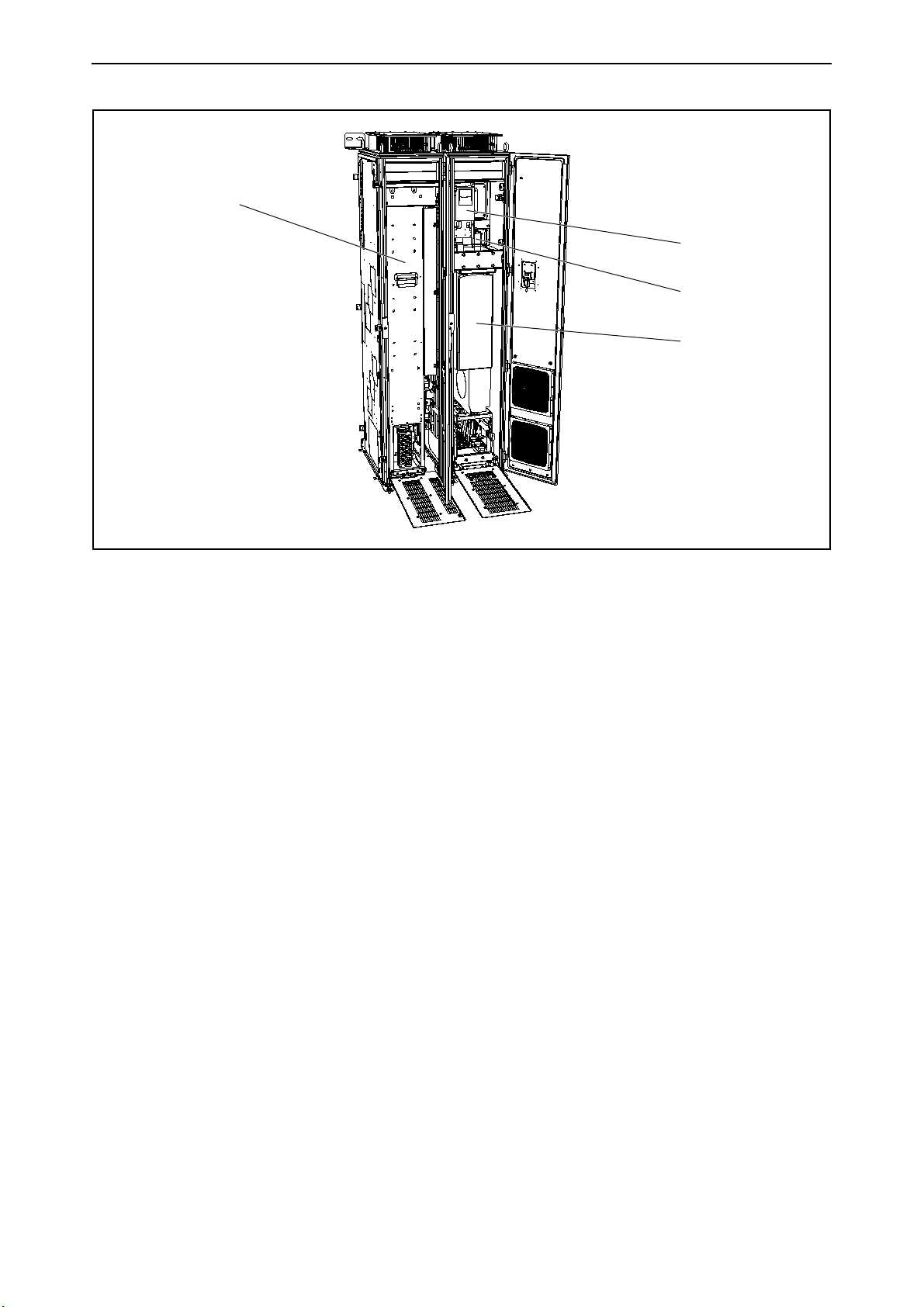

3.4 Active front-end section

The active front-end section (AFS) includes an LCL-filter and an NXA unit from the VACON® NXP

product series. The active front-end provides low THD(I) and several units can be connected in

parallel providing full or reduced redundancy.

Table 9. Available AFS sections

AFS type Drive size Width x Height x Depth (mm)

AFS_9*/**

AFS_10*/**

AFS_13*/**

AFS_13_2x*/**

* _M selection for mirrored design.

** +AC, AC busbars for two or more AFS sections after the MIS section, limited to 2600 A per side of

the MIS.

*** Dimensions including LCL.

FI9 800 x 2100 x 605***

FI10 800 x 2100 x 605***

FI13 1400 x 2100 x 605***

FI13 3200 x 2100 x 605***

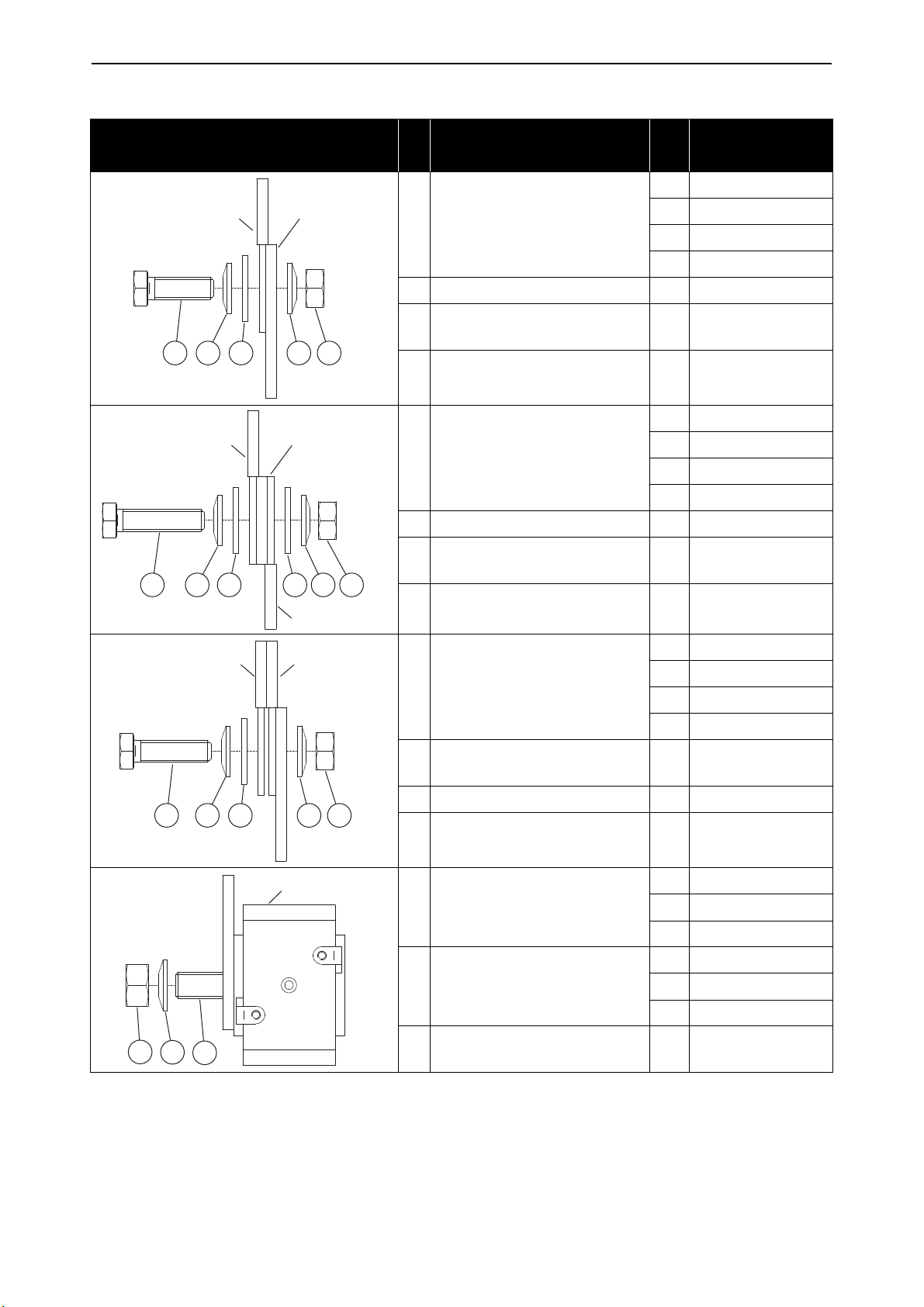

As standard the AFS sections include the following (see Figure 5):

1. LCL Filter

2. The NXA unit

3. Control unit

4. Pre-charging components (installed in MIS section)

5. Terminals for control and indication signals (installed in MIS or ADS section)

6. DC fuses for the Supply Unit

7. AC fuses for the filter (installed in MIS section)

As pre-engineered standard options we can provide the following:

• UL approved design and components (+NAR)

• Arc detection (+ADU)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 21

Available sections vacon • 21

1

2

3

6

13851_00

Figure 5. Example of active front-end section AFS_9

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 22

vacon • 22 Available sections

3.5 Inverter unit section

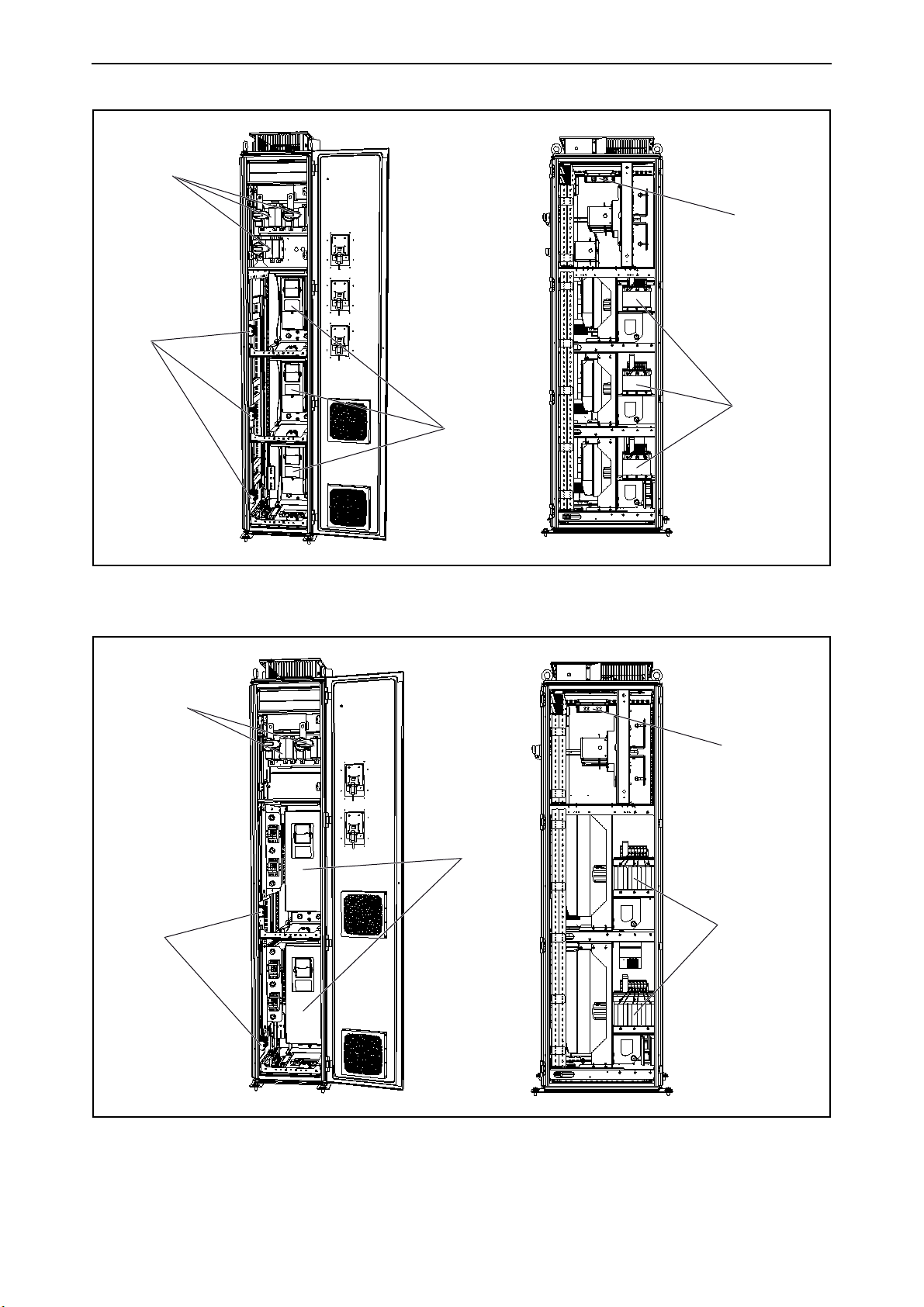

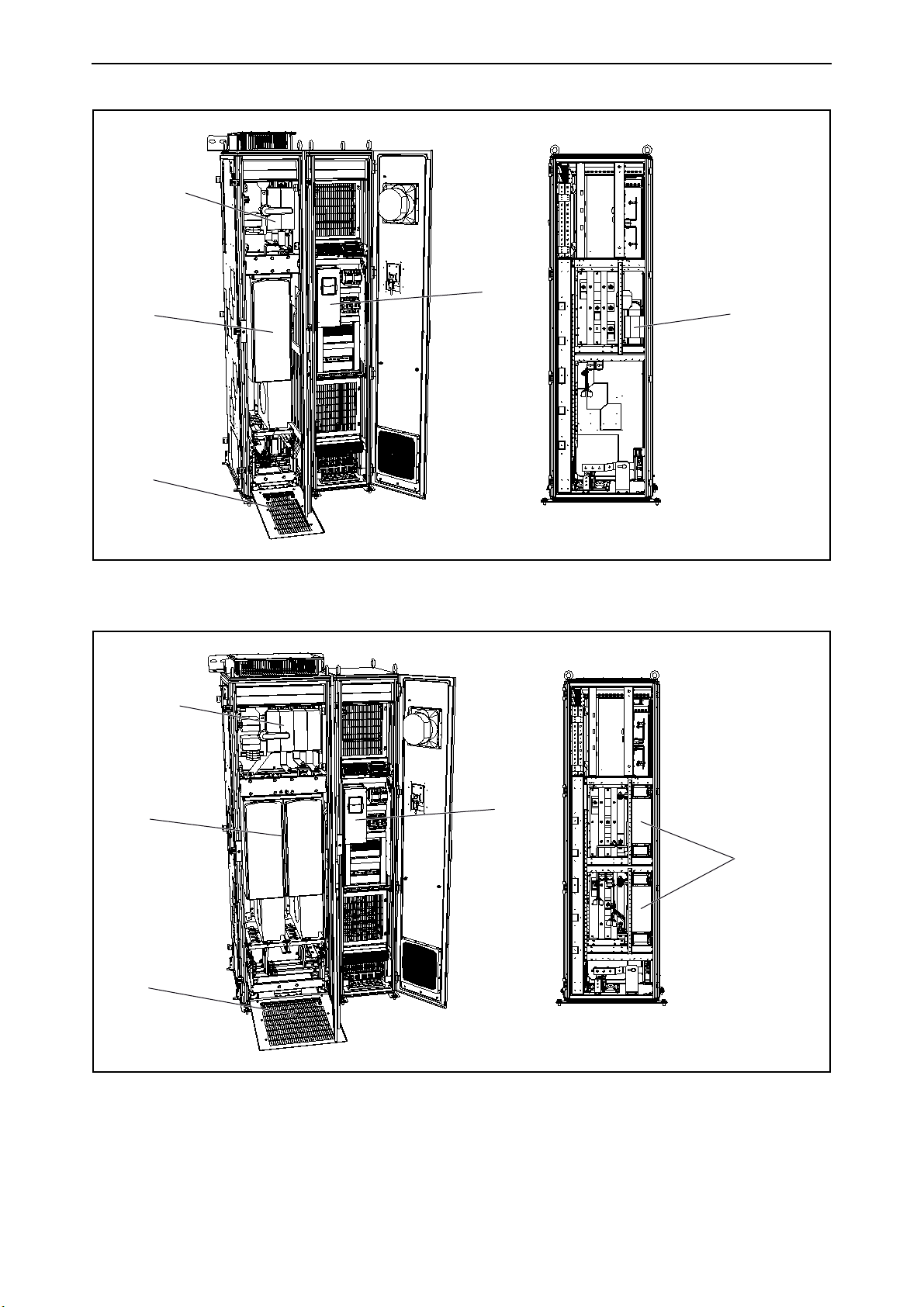

3.5.1 Drive sizes FR4-FR8

The inverter unit section (IUS) includes one or several smaller NXI drives from the VACON® NXP

product series. The inverter units are all VACON® NXP premium drives.

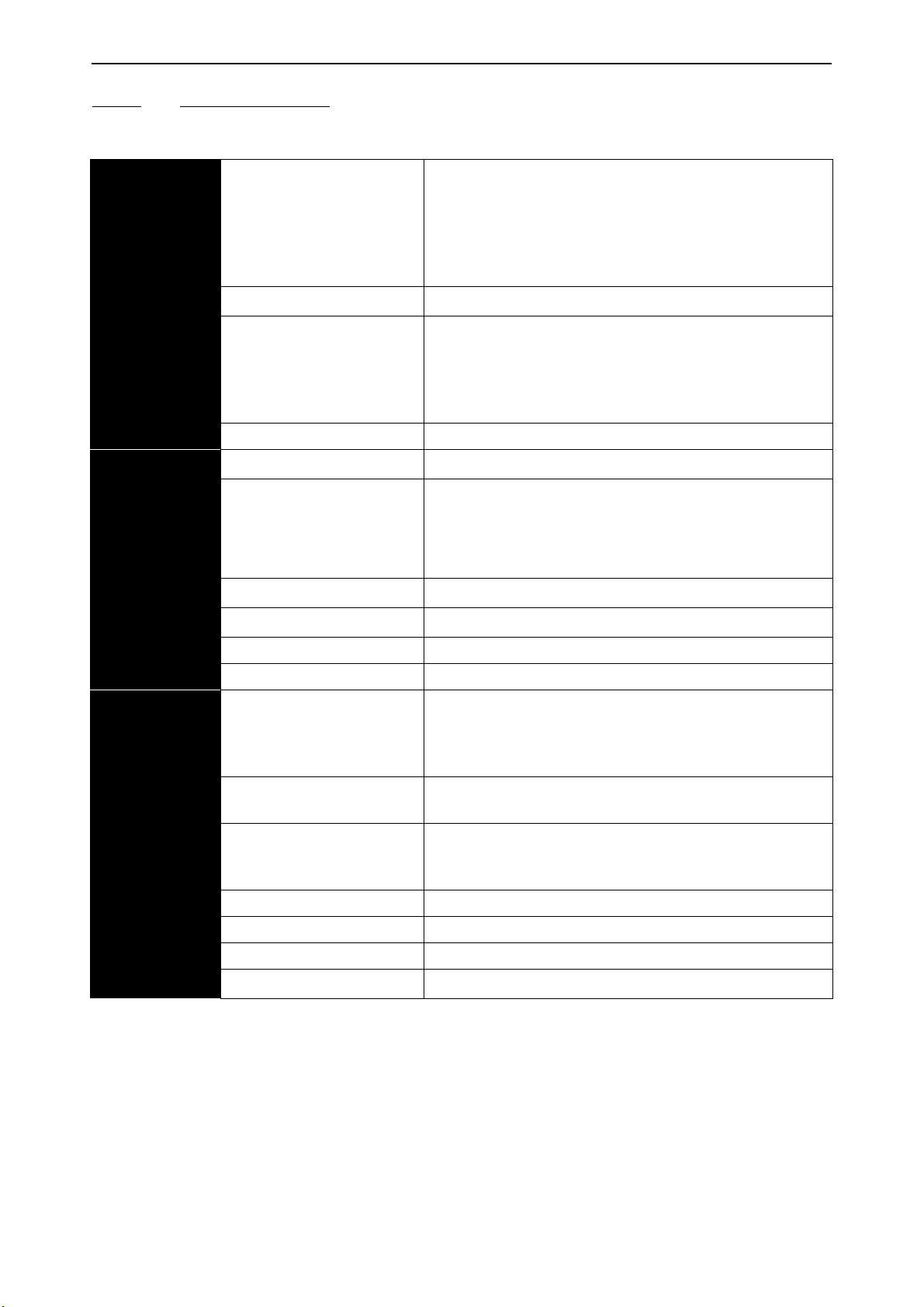

Table 10. Available IUS section sizes FR4-FR8

IUS type Drive size Number of drives/ section Width x Height x Depth (mm)

IUS_4_x FR4*

1-3 400 x 2100 x 605**

4-14 1200 x 2100 x 605**

IUS_6_x FR6 1-2 400 x 2100 x 605**

IUS_7 FR7 1 400 x 2100 x 605**

IUS_8 FR8 1 400 x 2100 x 605**

COT_4-8*** - - 400 x 2000 x 605

* Only option board and fieldbus options

**Top exit +400 mm can be shared between two sections

*** Section for cabling with top cabling option (+COT)

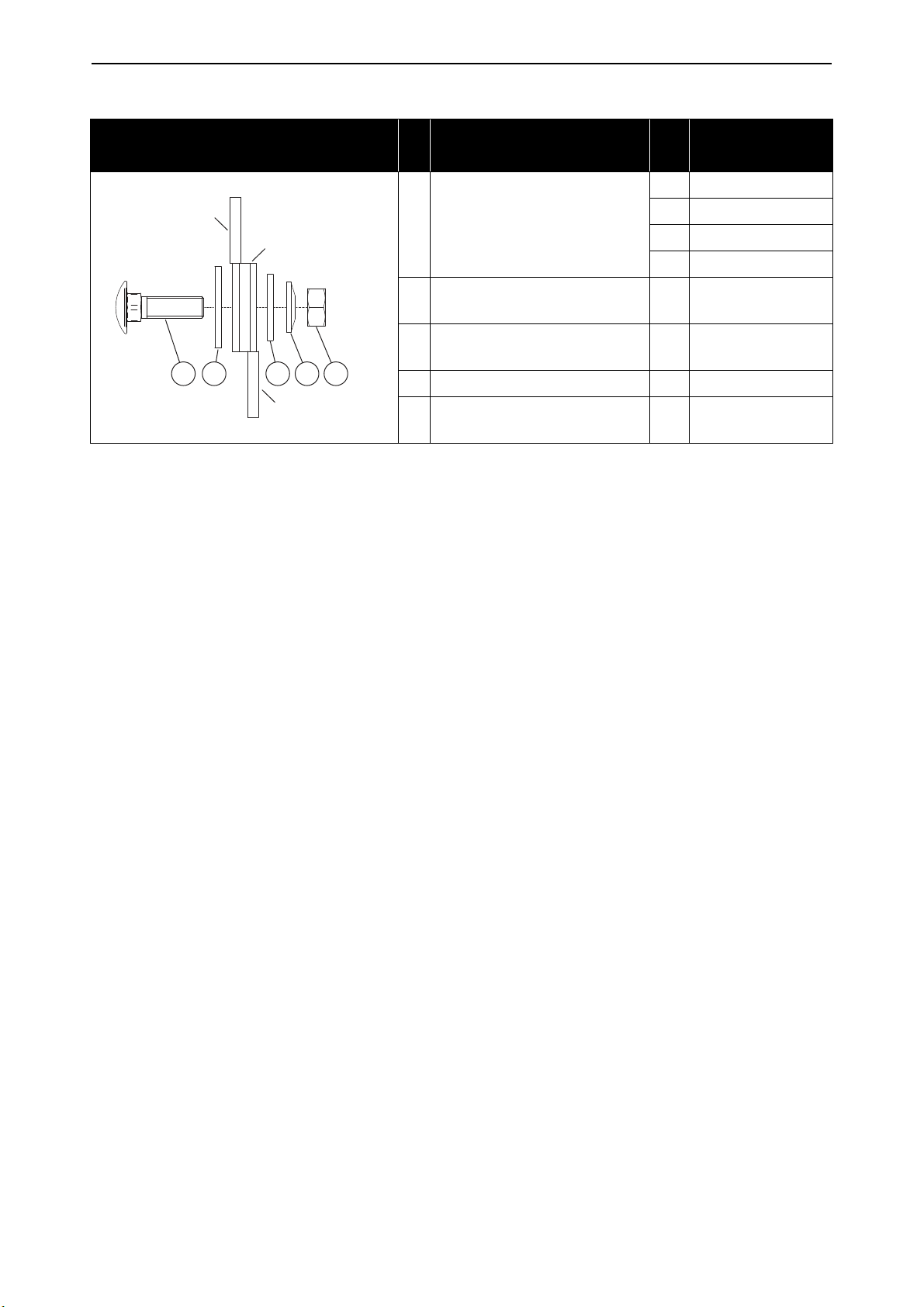

As standard the IUS section includes the following (see Figure 6):

1. Input fuses (DC fuses)

2. Fuse switch (IEC FR4-FR6)

3. The NXI drive(s)

4. Control box (integrated into the module)

5. Terminals for control and indication signals

As pre-engineered standard options we can provide the following:

• dU/dt (+ODU)

• Input Switch, DC disconnect (+ISD)

• Arc detection (+ADU)

• Motor fan control (+AMF)

• Motor heater feeder (+AMH)

• Mechanical break control (+AMB)

• Top cabling (+COT)

• UL approved design and components (+NAR)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 23

Available sections vacon • 23

1+2

5

3+4

+ODU

+ACL

13852_00

1+2

5

3+4

+ODU

13853_00

+ACL

Figure 6. Example of inverter unit IUS_4

Figure 7. Example of inverter unit IUS_6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 24

vacon • 24 Available sections

1

+ODU

3+4

5

13854_00

Figure 8. Example of inverter unit IUS_8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 25

Available sections vacon • 25

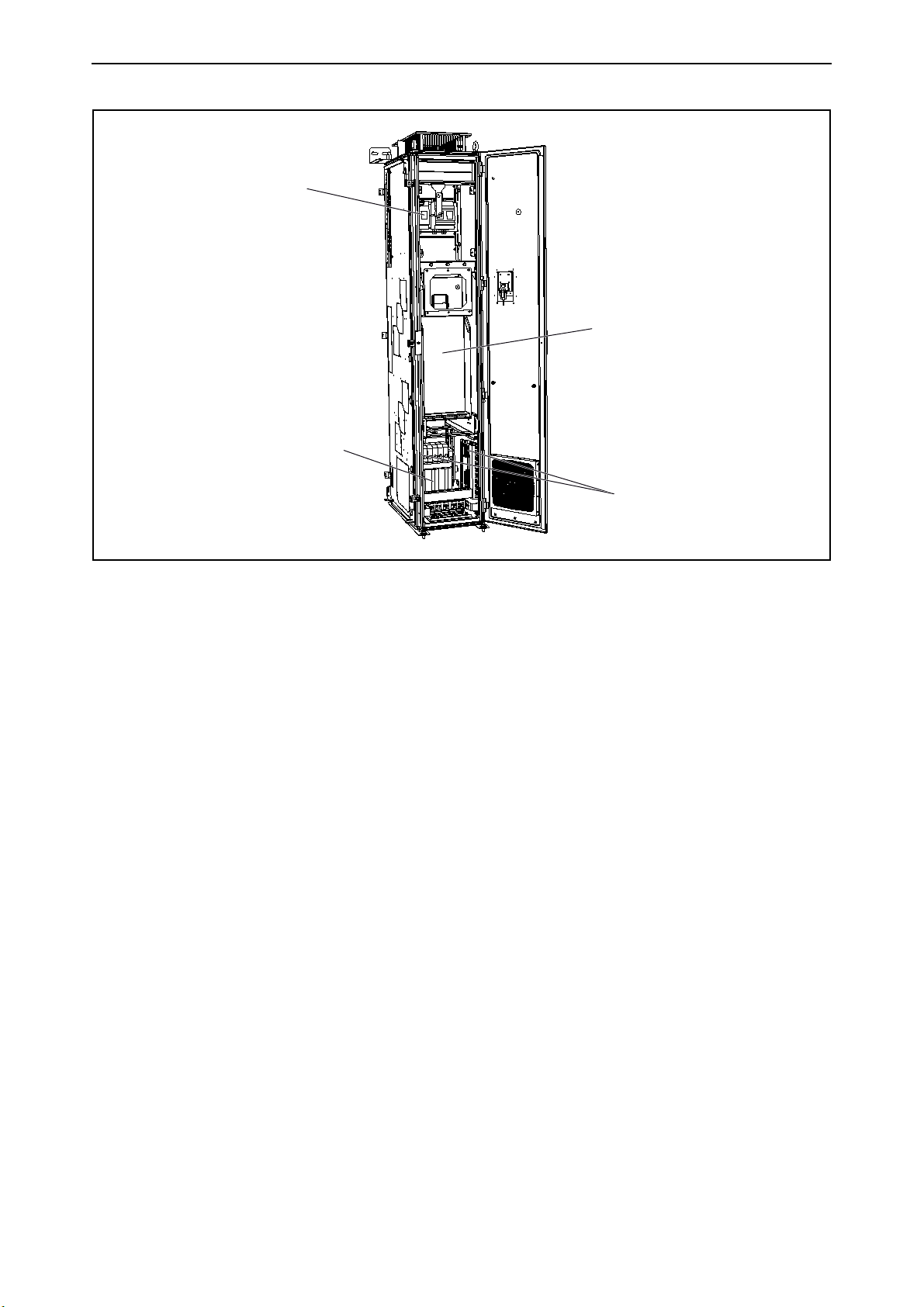

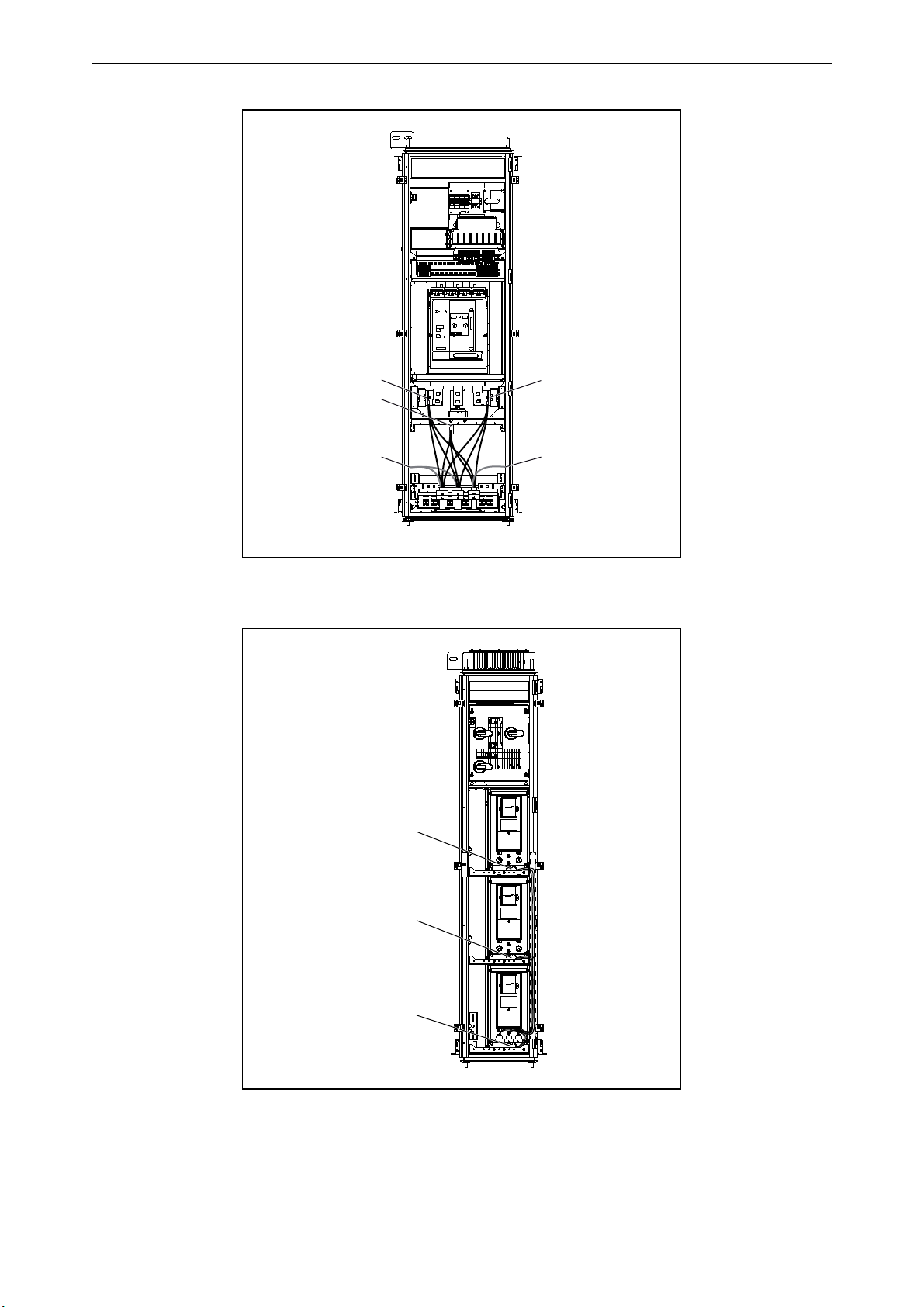

3.5.2 Drive sizes FI9-FI14

The inverter unit section (IUS) includes the largest NXI drives from the VACON® product series. The

inverter units are all VACON® NXP premium drives.

Table 11. Available IUS section sizes FI9-FI14

IUS type Drive size Width x Height x Depth (mm)

Width x Height x Depth (mm),

with +ODU

IUS_9 FI9 800 x 2100 x 605 800 x 2100 x 605

IUS_9_2x FI9 1200 x 2100 x 605 1200 x 2100 x 605

IUS_10 FI10 800 x 2100 x 605 800 x 2100 x 605

IUS_10_2x FI10 1200 x 2100 x 605 1200 x 2100 x 605

IUS_12 FI12 1000 x 2100 x 605 1000 x 2100 x 605

IUS_12_2x FI12 1800 x 2100 x 605 Not available

IUS_13 FI13 1400 x 2100 x 605 1400 x 2100 x 605

IUS_14 FI14 2800 x 2100 x 605 2800 x 2100 x 605

As standard the IUS section includes the following (see Figure 9):

1. Input fuses (DC fuses)

2. The NXI drive

3. Service platform/module removal

4. Control section and fixed external terminals, 70 pcs

As pre-engineered standard options we can provide the following:

• dU/dt (+ODU)

• Common mode filter (+OCM)

• Input Switch with charging (+ISC)

• Arc detection (+ADU)

• Motor fan control (+AMF)

• Motor heater feeder (+AMH)

• Mechanical break control (+AMB)

• Top cabling (+COT)

• UL approved design and components (+NAR)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 26

vacon • 26 Available sections

+ISC

2

3

+ODU

4

13855_00

+ISC

2

3

4

+ODU

13856_00

Figure 9. Example of inverter unit IUS_9

Figure 10. Example of inverter unit IUS_12

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 27

Available sections vacon • 27

+ISC

2

3

4

+ODU

13857_00

Figure 11. Example of inverter unit IUS_13

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 28

vacon • 28 Available sections

3.6 Dynamic brake section

The dynamic brake section (DBS) includes the largest NXI drives from the VACON® NXP product

series. The brake units are all VACON® NXP premium drives.

As standard the DBS section includes the following:

1. Input fuses (DC fuses)

2. The NXI brake chopper

3. Service platform/module removal

4. Control section and fixed external terminals, 70 pcs

As pre-engineered standard options we can provide the following:

• Input Switch (with charging) (+ISC)

• Input Switch (DC-disconnect) (+ISD)

• Arc detection (+ADU)

• Top cabling (+COT)

• UL approved design and components (+NAR)

• Cabinet heater (+ACH)

• Cabinet light (+ACL)

The dynamic brake sections are similar to the inverter unit sections. See the dimensions and

example figures in Chapter 3.5.2.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 29

Available sections vacon • 29

3.7 Transport split unit

Transport Split Units are available for easy access to main bus joints between sections.

Table 12. Available TSU section sizes

TSU type Width x Height x Depth (mm)

TSU_200 200 x 2000 x 605

TSU_300 300 x 2000 x 605

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 30

vacon • 30 Installation

4. I

4.1 Installation procedure

Each VACON® NXP System Drive delivery is project specific. The following installation sequence is

a general description of the process of connecting the cabinet sections and installing the system

drive.

As each installation is project specific, the instructions and illustrations in the following chapters

are general examples. More detailed instructions, such as layout drawings, dimensions and wiring

diagrams, are included in the project delivery.

1

2

3

4

NSTALLATION

Before starting the installation, read the safety instructions in Chapter 2 carefully.

Make sure that the ambient conditions at the installation site are according to the

specifications. See the specifications in Chapter 6.3.

Remove the package covering from the product only at the installation site and in the

specified ambient conditions.

Before moving the cabinets to the installation site, make sure that the space is

properly prepared for the installation. See Chapter 4.2.

Move the cabinets to the installation site. See the instructions in Chapter 1.8.

5

6

7

8

9

10

11

12

13

14

15

16

17

Make sure that there is enough free space around the cabinets. See Chapter 4.2.1.

Lift the first cabinet section into the desired installation location. See Chapter 4.3.

Fix the first cabinet section to the floor or wall. See Chapter 4.3.

Lift the second cabinet section next to the first section, in a position from which it can

be pushed into place.

Before pushing the cabinets together, loosen the nuts and bolts on the ends of the

busbars to be connected. See Chapter 4.4.

Push the cabinets together, make sure that the busbars come together properly.

Connect the busbars by tightening the nuts and bolts on the busbars. See Chapter 4.4.

Mount the cabinet frames to each other. See Chapter 4.5.

Mount the second section to the floor or wall.

Install the rest of the sections following the same procedure.

Once all the cabinets are connected, remove the lifting beams from the top of the

cabinets, so that they do not block the air flow. After the beams are removed, mount

the bolts back on the cabinet roof.

Do the cabling between cabinets (auxiliary low-voltage connections, fiber

connections, etc.). See the project specific wiring diagrams, which are included in the

delivery.

Connect the motor and mains cables to the system drive. Pay attention to grounding

of the cables. See Chapter 4.6.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 31

Installation vacon • 31

200 mm

1000 mm

13860_00

4.2 Preparing the installation site

Before starting the installation work make sure that the level of the floor is within acceptable limits.

The maximum deviation from the basic level can be no more than 5 mm over a 3 m distance. The

maximum acceptable height difference between cabinet front and rear edges should be within

+2/-0 mm limit.

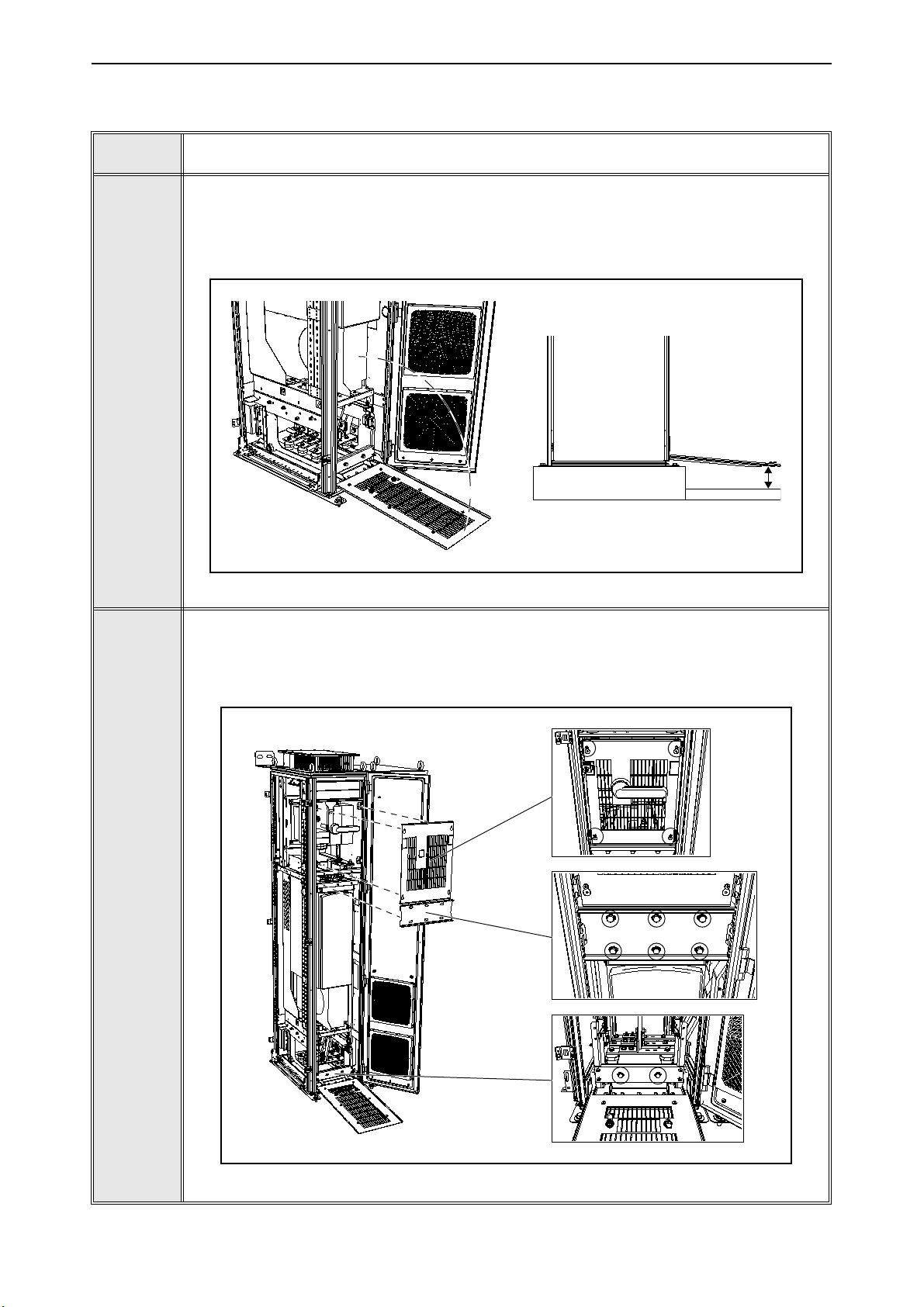

4.2.1 Free space around the cabinet

Enough space must be left above and in front of the cabinet to ensure sufficient cooling and space

for maintenance.

It is recommended to leave at least 200 mm above and 1000 mm in front of the cabinets.

Also make sure that the temperature of the cooling air does not exceed the maximum ambient

temperature of the drives.

Figure 12. Required space around the cabinet

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 32

vacon • 32 Installation

2 2 2

11

1

2

3

13861_00

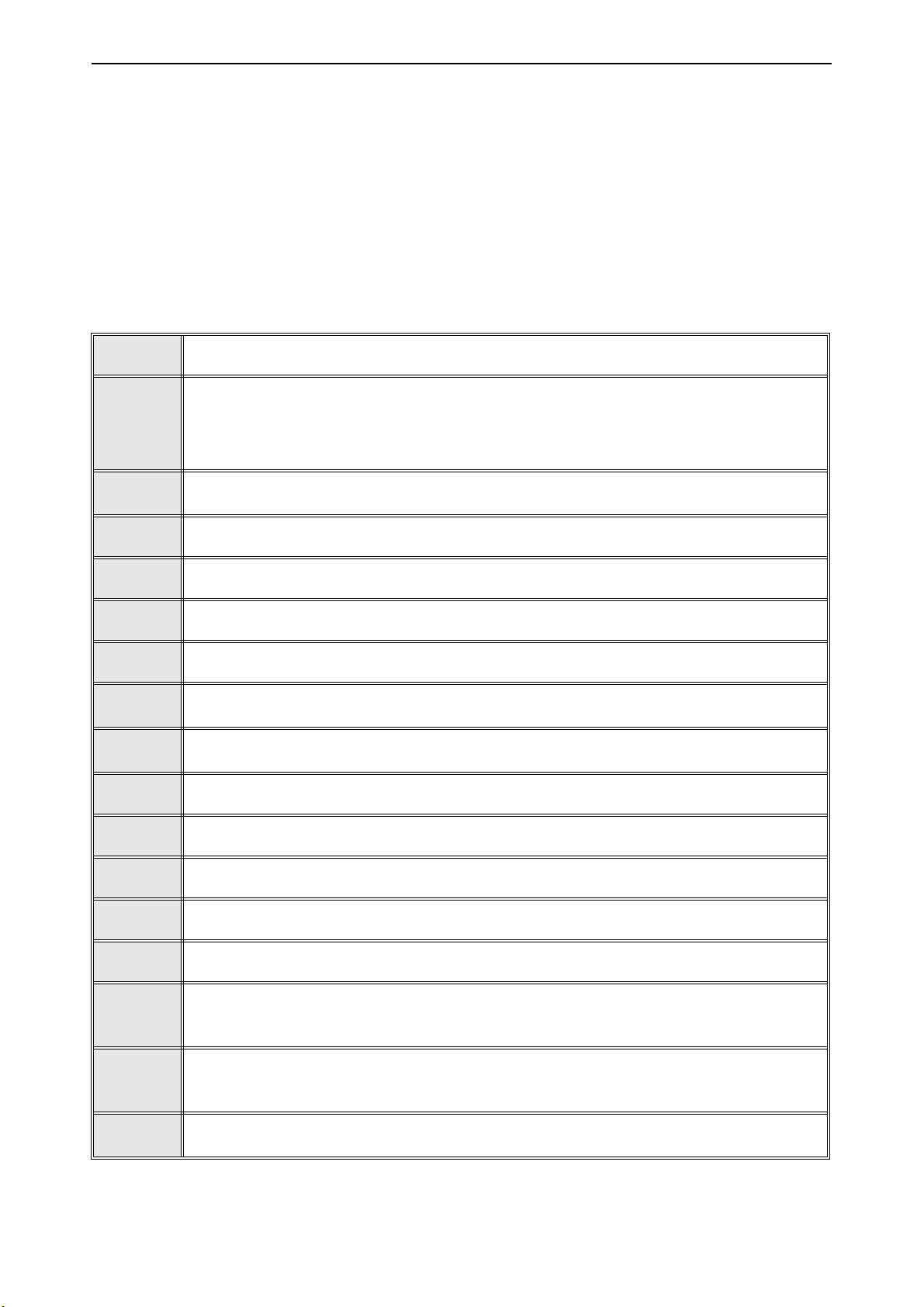

4.3 Mounting the cabinets

The cabinet should always be fixed to the floor or to the wall. Depending on installation conditions,

the cabinet sections can be fixed in different ways. There are holes in the front and back corners

which can be used for fixing. Additionally, the rails on the top of the cabinet have fixing lugs for fixing

the cabinet to the wall or to another cabinet.

4.3.1 Fixing the cabinet to the floor and wall

If the cabinet is installed against a wall, fix the top of the cabinet to the wall (1) and the front corners

to the floor (2) with bolts.

If bottom-only fixing is used, fix the cabinet to the floor in the front (2) and in the back (3) with bolts.

Fix all the cabinet sections in the same way.

Figure 13. Fixing the cabinet to the wall and floor

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 33

Installation vacon • 33

2 2

1

13862_00

4.3.2 Back-to-back installation

The sections can also be installed back-to-back. In this case, fix the top parts of the cabinets

together (1) and the front corners to the floor (2) with bolts.

Leave a gap between the backs of the cabinets. Check the correct dimensions from the documents

included in the delivery.

Figure 14. Fixing the cabinets back-to-back

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 34

vacon • 34 Installation

13864_00

DC

AC

PE

4.4 Connecting the busbars

The busbars are located in the back of the cabinets. To access them, it might be necessary to take

out the drives. See the instructions in Chapter 5.3.

Join together the DC, AC and PE busbars by bolting them together with baying brackets. The

mounting bolts, nuts and washers are delivered in place.

The busbars, size of the nuts and bolts differ case-by-case. See the correct tightening torque values

for different size bolts and different types of connections in Chapter 4.7.

4.4.1 Side-by-side connection

Figure 15. Connecting the common DC, AC and PE busbars

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 35

Installation vacon • 35

15599_00

15600_00

Figure 16. Connecting the common AC busbars in UL cabinets

4.4.2 Back-to-back connection

Figure 17. Connecting the common DC and PE busbars in back-to-back cabinet installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 36

vacon • 36 Installation

1

2

1

1

2

1

2

1

1

2

1

2

1

1

2

1

2

13863_00

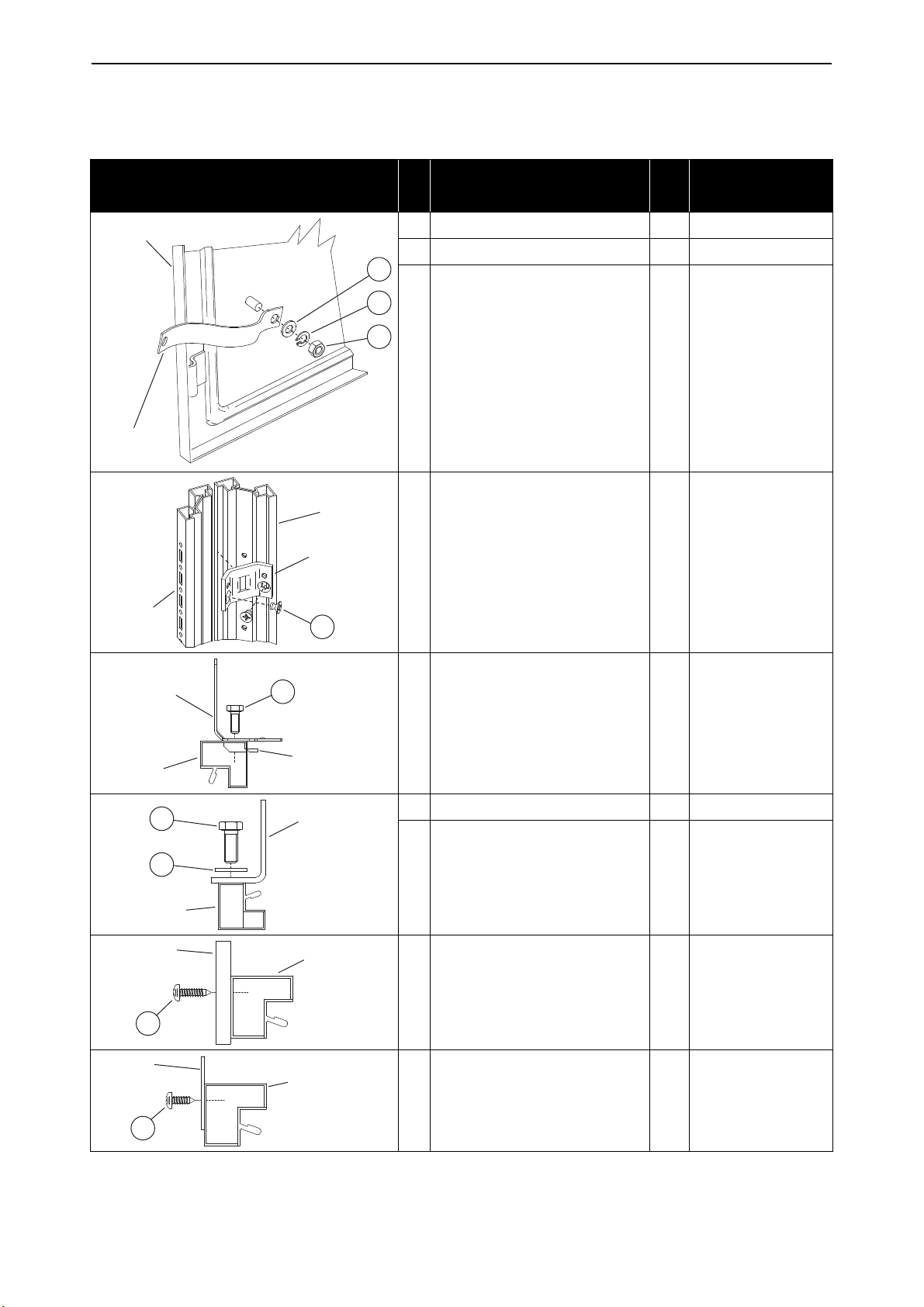

4.5 Fixing the cabinet frames to each other

All the necessary parts for fixing the cabinet frames to each other are included in the delivery.

To join two cabinet sections to each other you need six quick-fit baying clamps (1 in figure below)

and four angular baying brackets (2 in figure). The four angular baying brackets are installed in the

top and bottom corners on the inside of the cabinet. Three of the quick-fit baying brackets are

installed in the front and three in the back on the outside of the cabinet.

Figure 18. Quick-fit baying clamps

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 37

Installation vacon • 37

9000.emf

4.6 Cabling

Before connecting any cables, use a multimeter to check that the cables to be

connected are not live.

4.6.1 Grounding

PE conductors are connected to the PE busbar. The PE busbars in each section are connected (see

Figure 15 on page 34) and the PE busbars must be connected to ground.

See the grounding and ground fault protection instructions in Chapter 2.3.

4.6.2 Mains and motor connection

The power supply terminals can be reached through the bottom part of the cabinet. The mains

cables are connected to terminals L1, L2 and L3 on the main input section (see Figure 19 on

page 38). The motor cables are connected to inverter section terminals marked with U, V and W.

Make openings for the cables in the grommets on the bottom of the cabinet and lead through the

cables. Use cable clamps to fix the cables.

Use cables with a temperature rating of at least +70°C. As a rule of thumb, cables and fuses can be

dimensioned according to the frequency converter nominal output current, which you can find on

the rating plate. Dimensioning according to the output current is recommended because the

frequency converter input current never significantly exceeds the output current.

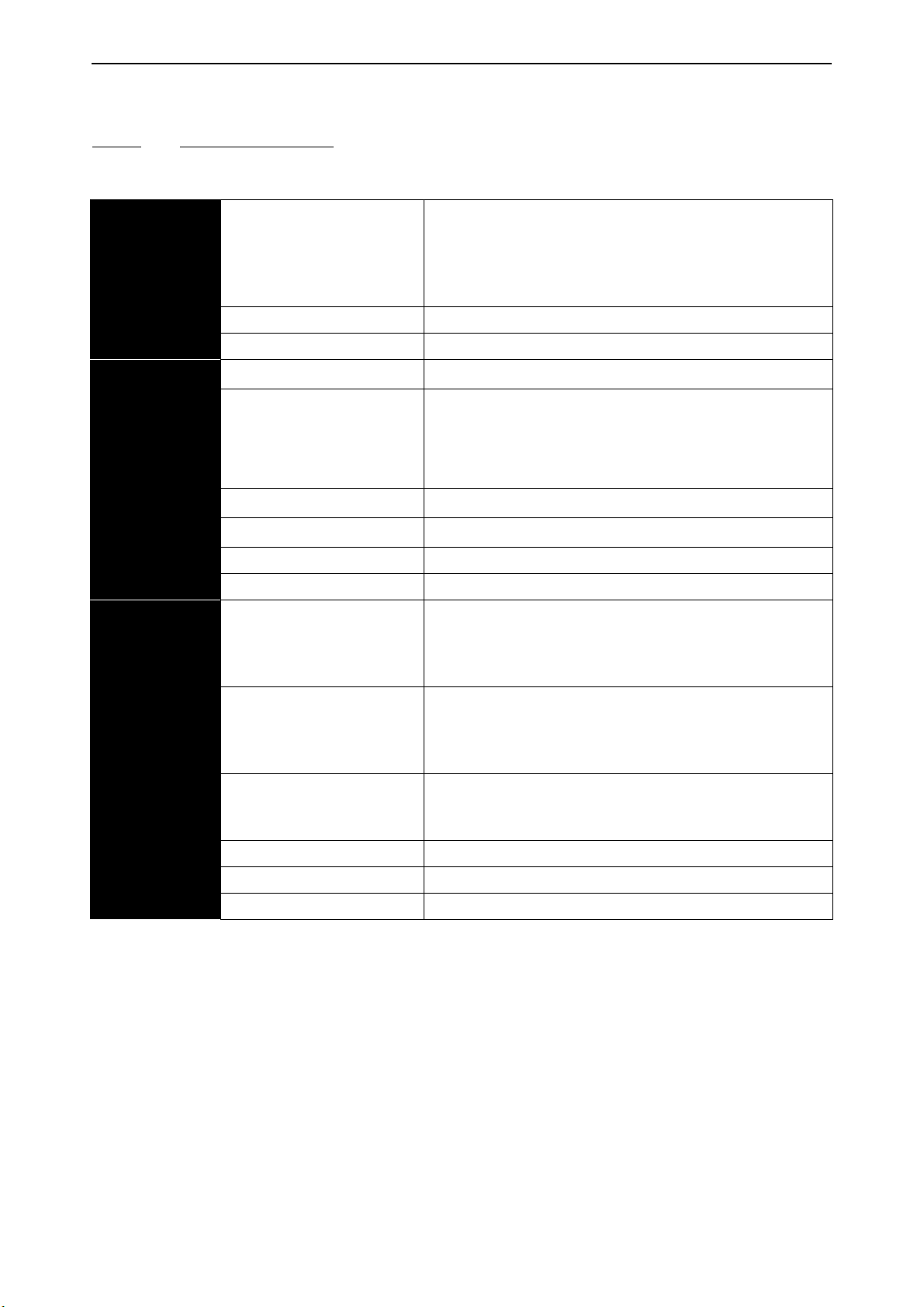

Table 13. Cable types required to meet standards

Cable type

Level L

(2nd environment)

Level T

Mains cable 1 1

Motor cable 2 1/2*

Control cable 4 4

* Recommended

Level L =

EN61800-3, 2nd environment

Level T = For IT networks

1 =

Power cable intended for fixed installation and the specific mains voltage. Shielded

cable not required (DRAKA NK CABLES - MCMK or similar recommended).

Symmetrical power cable equipped with concentric protection wire and intended

2 =

for the specific mains voltage (DRAKA NK CABLES - MCMK or similar

recommended).

4 =

Screened cable equipped with compact low-impedance shield (DRAKA NKCABLES

- JAMAK, SAB/ÖZCuY-O or similar).

See the more detailed cabling and fuse selection instructions in the corresponding user manual

(see Chapter 1.5).

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 38

vacon • 38 Installation

L1

L2

L3

PE

PE

13865_00

U2, V2, W2

U1, V1, W1

PU1

PU2

PU3

U3, V3, W3

13866_00

Figure 19. Cabling of the main incoming section (MIS)

Figure 20. Cabling of inverter section IUS_4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 39

Installation vacon • 39

U2, V2, W2

U1, V1, W1

PU1

PU2

13867_00

U

V

W

PE

13868_00

Figure 21. Cabling of inverter section IUS_6

Figure 22. Cabling of inverter section IUS_8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 40

vacon • 40 Installation

U

V

W

PE

13869_00

U2

PU1 PU2

V2

W2

U1

V1

W1

PE

13870_00

Figure 23. Cabling of inverter sections IUS_9 and IUS_10

Figure 24. Cabling of inverter section IUS_12

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 41

Installation vacon • 41

U

V

W

PE

13871_00

Figure 25. Cabling of inverter section IUS_13

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 42

vacon • 42 Installation

15598_00

PE

+OCM

15601_00

U V W

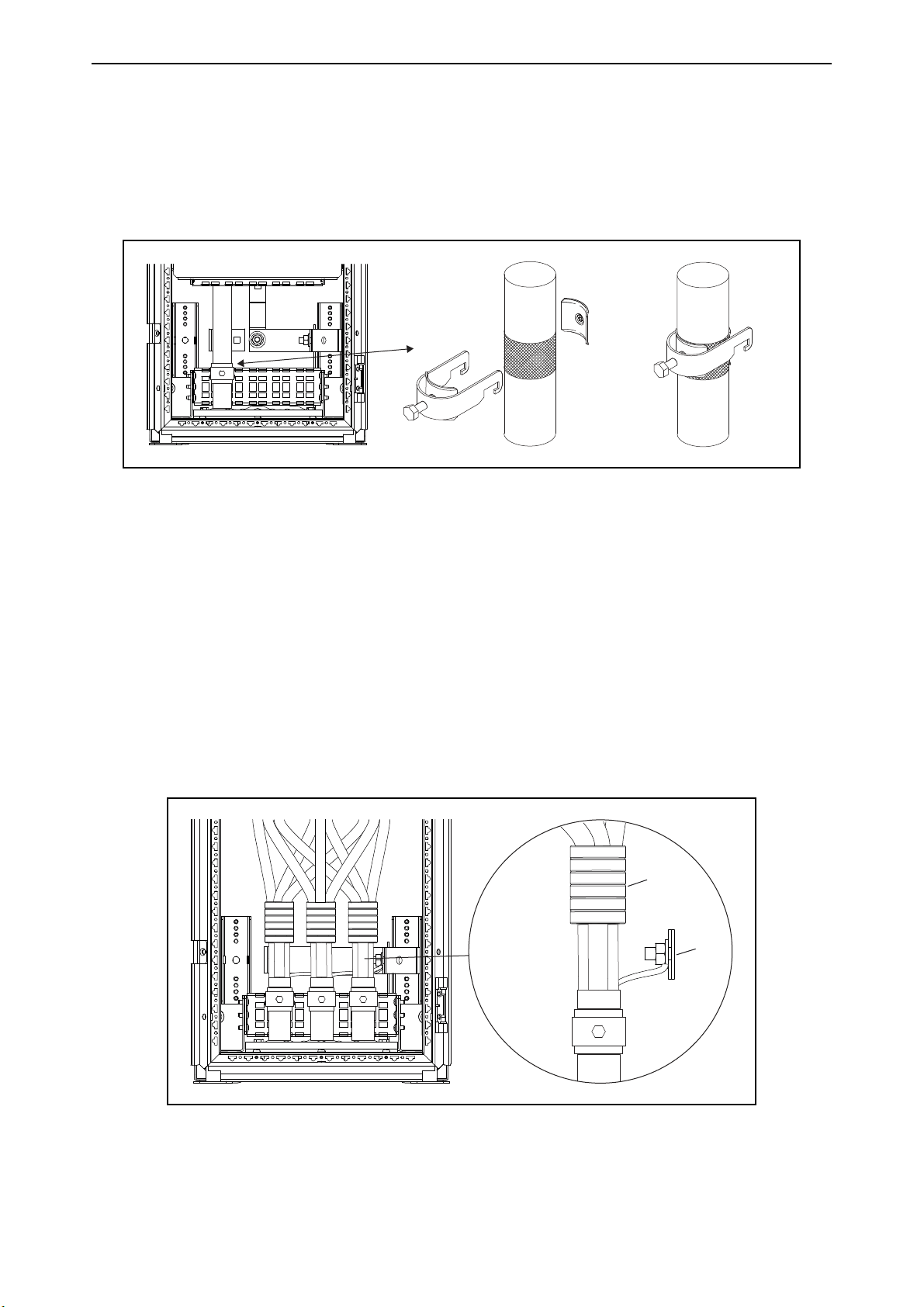

4.6.3 EMC grounding

For the EMC levels C1 and C2, it is necessary to have a 360º grounding of the shield on both ends of

the motor cable. The EMC grounding clamps must be suited to the output cable diameter to give a

360º contact with the cables. To make a 360° connection with the grounding clamp, expose the

shield of the motor cables.

Figure 26. 360º grounding

4.6.4 Installation of ferrite rings (+OCM) on the motor cable

Route only the motor phase conductors through the ferrite rings. Do not route the PE/ground wire

through the ferrite rings. Leave the cable screen below and outside the rings. Mount the PE/ground

wire or pigtail on the ground busbar.

In case of parallel motor cables, reserve an equal amount of ferrite ring sets for each cable. Route

all the phase conductors of one cable through one set of rings.

The delivery consists of fixed sets of ferrite rings (option). When ferrite rings are used to attenuate

the risk of bearing damage, always use two ferrite ring sets per motor cable.

NOTE! The ferrite rings are only additional protection. The basic protection against bearing currents

is an insulated bearing.

Figure 27. Installation of ferrite rings on motor cables

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 43

Installation vacon • 43

A BBCCDDE

E

A

13872_00

4.6.5 Control connections

The control unit of the AC drive consists roughly of the control board and additional boards

connected to the five slot connectors (A to E) of the control board. The control board is connected to

the power unit through a D-connector or fibre optic cables.

Usually, when the frequency converter is delivered from the factory, the control unit includes at least

the standard compilation of two basic boards (I/O board and relay board) which are normally

installed in slots A and B.

The control board can be powered externally (+24 V, ±10%) by connecting the external power source

to either of the bidirectional terminals. This voltage is sufficient for parameter setting and for

keeping the fieldbus active.

The tightening torques for the control unit terminals:

• Relay and thermistor terminals (screw M3): 0.5 Nm.

• Other terminals (screw M2.6): 0.2 Nm.

For more detailed cabling instructions, see the corresponding user manual (see Chapter 1.5).

Figure 28. Control unit, control board (right) and option boards (A-E)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 44

vacon • 44 Installation

15604_00

4.6.6 Auxiliary low-voltage connections

The auxiliary low-voltage connections between cabinets can be done with wiring or with busbars.

For transport, the wires between two separately transported cabinets are disconnected from the

terminals. The wiring diagrams for the connections are delivered with the system drive.

Auxiliary low-voltage busbars (Auxigaine) are available as an option. In this case, the busbars of two

cabinets are connected with quick-connect bridge connectors. The bridge connectors are installed

by simply pressing them into place.

Figure 29. Installing the bridge connectors on the auxiliary low-voltage busbars

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 45

Installation vacon • 45

1

Grounding

braid

Rittal door

15553_UK

2

3

Rittal

frame

Rittal

8800490

Rittal

frame

1

15554_UK

Rittal

8800430

Rittal

frame

Rittal

M8 4163

1

15555_UK

Rittal

frame

Lifting

bar

1

2

15556_UK

Rittal

frame

UPGM

1

15557_UK

Rittal

frame

Fe

1

15558_UK

4.7 Screw tightening torques

Table 14. Tightening torques

Detail # Part Size

1 Plain washer, DIN 125 2 Spring washer, DIN 128 -

3 Nut, DIN 934 M8 10

Rittal tapered thread form-

1

ing screw M6x8

M6 9

Tightening torque

(Nm), ±15%

Rittal hex head bolt 8x16

1

with toothed neck

1 Hex head bolt, DIN 933 M12 20

2 Rittal IP rubber washer -

Self tapping screw,

1

DIN7049

Self tapping screw,

1

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

DIN7049

M8 9

ST 5.5

5

ST 5.5

5

Page 46

vacon • 46 Installation

Grounding

braid

Rittal

Rittal

M8 4163

1

2

3

4

15559_UK

1

Fe

Hinge

2

3

15560_00

1

SKF

2 234

FeFe

15561_00

Bearing

1

FeFe

15562_00

1

FePVC

15563_00

2

Fe (painted)Fe (painted)

1

15564_UK

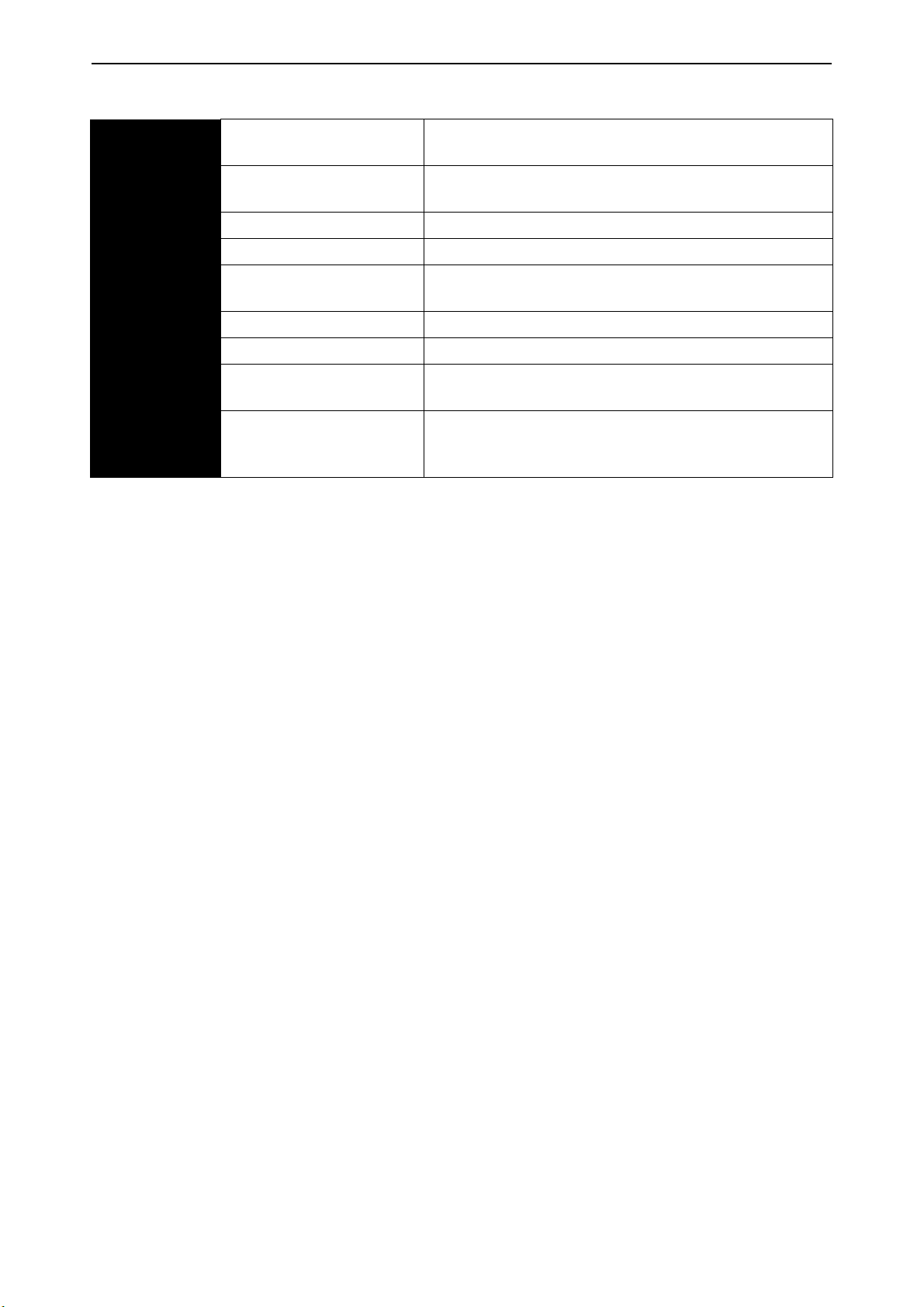

Table 14. Tightening torques

Detail # Part Size

1 Plain washer, DIN 125 2 Hex head bolt, DIN 933 M8 9

3 Toothed washer, DIN 6797 -

4 Spring washer, DIN 128 -

M6 6

M8 20

1 Socket head bolt, DIN 912

M10 40

M12 70

2 Spring washer, DIN 128 3 Nut, DIN 934 -

M6 6

M8 20

1 Socket head bolt, DIN 7984

M10 40

M12 70

Tightening torque

(Nm), ±15%

2 Plain washer, DIN 125 3 Nut, DIN 934 4 Spring washer, DIN 128 -

1 Rivet -

1 Rivet -

M4 1.5

Self-tapping screw,

1

DIN7500

M5 3

M6 6

2 Toothed washer, DIN 6797 -

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 47

Installation vacon • 47

1

FeFe

15565_00

1

FeUPGM

15566_00

1

23

Fe (holder)Fe

15567_UK

1

23

Fe (holder)PVC

15568_UK

1

FeFe

15569_00

1

2 4 3

FeFe

15570_00

Table 14. Tightening torques

Detail # Part Size

M4 1.5

M5 3

Self-tapping screw,

1

DIN7500

M6 6

M4 1.5

M5 3

Self-tapping screw,

1

DIN7500

M6 6

M4 1.5

1 Screw, DIN 7045

M5 3

M6 6

2 Plain washer, DIN 125 -

3 Spring washer, DIN 128 -

Tightening torque

(Nm), ±15%

M4 1.5

1 Screw, DIN 7045

M5 3

M6 6

Plain washer large,

2

DIN9021

3 Spring washer, DIN 128 -

Self-tapping screw,

1

DIN7049

ST 5.5

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Plain washer, DIN 125 3 Nut, DIN 934 -

-

5

4 Spring washer, DIN 128 -

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 48

vacon • 48 Installation

1 3 44 3 2

FeFe

15571_00

1 4 2

FeFe

3

15572_00

1 4

5 3 2

FeCable gland

15573_UK

1

1

Socomec

SB205

15574_00

1 2 4 3

FeSocomec

SB205

15575_00

Table 14. Tightening torques

Detail # Part Size

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Nut, DIN 934 3 Plain washer, DIN 125 4 Spring washer, DIN 128 -

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Plain washer, DIN 125 3 Press nut 4 Spring washer, DIN 128 1 Hex head bolt, DIN 933 M8 2

2 Nut, DIN 934 3 Plain washer, DIN 125 -

Tightening torque

(Nm), ±15%

Plain washer large,

4

DIN9021

-

5 Spring washer, DIN 128 -

1 Hex head bolt, DIN 933 M8 10

1 Hex head bolt, DIN 933 M8 10

2 Plain washer, DIN 125 3 Nut, DIN 934 -

4 Spring washer, DIN 128 -

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 49

Installation vacon • 49

1

Socomec SB205

15576_00

132

Socomec

SB205

Cu

15577_00

21

IS40-8SCu

15578_00

IS40-8SFe

21

15579_00

IC20Cu

21

15580_00

Table 14. Tightening torques

Detail # Part Size

1 Hex head bolt, DIN 933 M8 10

1 Hex head bolt, DIN 933 M8 10

2 Nut, DIN 934 -

Conical spring washer,

3

DIN6796

Tightening torque

(Nm), ±15%

-

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

Conical spring washer,

2

DIN6796

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Spring washer, DIN 128 -

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

Conical spring washer,

2

DIN6796

-

-

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 50

vacon • 50 Installation

IC20Fe

1 2

15581_00

31

Cu Cu

23

15582_00

Cu Fe

31 23

15583_00

Cu UPGM

41 5 32

15584_00

Table 14. Tightening torques

Detail # Part Size

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Spring washer, DIN 128 -

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Nut, DIN 934 -

Conical spring washer,

3

DIN6796

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

Tightening torque

(Nm), ±15%

-

M12 70

2 Nut, DIN 934 -

Conical spring washer,

3

DIN6796

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Plain washer, DIN 125 3 Nut, DIN 934 -

Conical spring washer,

4

DIN6796

5 Spring washer, DIN 128 -

-

-

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 51

Installation vacon • 51

Flexibar Cu

341 24

15585_UK

Flexibar Cu

Flexibar

341 4 23

15586_UK

Flexibar Flexibar

241 34

15587_UK

3

1

2

Ferraz 33 TTF

15588_00

Table 14. Tightening torques

Detail # Part Size

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Nut, DIN 934 -

Plain washer large,

3

DIN9021

Conical spring washer,

4

DIN6796

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

2 Nut, DIN 934 -

Plain washer large,

3

DIN9021

Tightening torque

(Nm), ±15%

-

-

-

Conical spring washer,

4

DIN6796

M6 6

M8 20

1 Hex head bolt, DIN 933

M10 40

M12 70

Plain washer large,

2

DIN9021

3 Nut, DIN 934 -

Conical spring washer,

4

DIN6796

M8 10

1 Stud, DIN 913

M10 15

M12 15

M8 13.5

2 Nut, DIN 934

M10 26

M12 46

Conical spring washer,

3

DIN6796

-

-

-

-

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 52

vacon • 52 Installation

44 TTQF

3

1

2

15589_00

83 TTQ

3 12

15590_00

84 TTQF

3

1

2

15591_00

3 21

CuCu

15592_00

Table 14. Tightening torques

Detail # Part Size

M8 10

1 Stud, DIN 913

M10 15

M12 15

M8 13.5

2 Nut, DIN 934

M10 26

M12 46

Conical spring washer,

3

DIN6796

M8 10

1 Stud, DIN 913

M10 15

M12 15

M8 13.5

2 Nut, DIN 934

M10 26

M12 46

Conical spring washer,

3

DIN6796

Tightening torque

(Nm), ±15%

-

-

M8 10

1 Stud, DIN 913

M10 15

M12 15

M8 13.5

2 Nut, DIN 934

M10 26

M12 46

Conical spring washer,

3

DIN6796

M6 6

Cup square neck bolt,

1

DIN603

M8 20

M10 40

M12 70

2 Nut, DIN 934 -

Conical spring washer,

3

DIN6796

-

-

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 53

Installation vacon • 53

CuCu

2 4 31

Cu

15593_00

FeCu

3 21

15594_00

UPGM

Cu

2 4 31

15595_00

Cu

Flexibar

4 231

15596_UK

Table 14. Tightening torques

Detail # Part Size

M6 6

Cup square neck bolt,

1

DIN603

M8 20

M10 40

M12 70

Plain washer large,

2

DIN9021

3 Nut, DIN 934 -

Conical spring washer,

4

DIN6796

M6 6

Cup square neck bolt,

1

DIN603

M8 20

M10 40

M12 70

2 Nut, DIN 934 -

Tightening torque

(Nm), ±15%

-

-

Conical spring washer,

3

DIN6796

M6 6

Cup square neck bolt,

1

DIN603

M8 20

M10 40

M12 70

2 Plain washer, DIN 125 3 Nut, DIN 934 4 Spring washer, DIN 128 -

M6 6

Cup square neck bolt,

1

DIN603

M8 20

M10 40

M12 70

2 Nut, DIN 934 -

Plain washer large,

3

DIN9021 (1 size bigger)

Conical spring washer,

4

DIN6796

-

-

-

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 54

vacon • 54 Installation

Cu

Flexibar

Flexibar

3 5 421

15597_UK

Table 14. Tightening torques

Detail # Part Size

M6 6

Cup square neck bolt,

1

DIN603

M8 20

M10 40

M12 70

Plain washer large,

2

DIN9021 (1 size bigger)

Plain washer large,

3

DIN9021

4 Nut, DIN 934 -

Conical spring washer,

5

DIN6796

Tightening torque

(Nm), ±15%

-

-

-

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 55

Service vacon • 55

5. S

ERVICE

5.1 Warranty

Only manufacturing defects are covered by the warranty. The manufacturer assumes no

responsibility for damages caused during or resulting from transport, receipt of the delivery,

installation, commissioning or use.

The manufacturer shall in no event and under no circumstances be held responsible for damages

and failures resulting from misuse, wrong installation, unacceptable ambient temperature, dust,

corrosive substances or operation outside the rated specifications.

Neither can the manufacturer be held responsible for consequential damages.

The Manufacturer's warranty period is 18 months from the delivery or 12 months from the

commissioning whichever expires first (Danfoss general terms and conditions of sale).

The local distributor may grant a warranty time different from the above. This warranty time shall

be specified in the distributor's sales and warranty terms. Danfoss assumes no responsibility for

any other warranties than that granted by Danfoss itself.

In all matters concerning the warranty, please contact your distributor first.

5.2 Maintenance

All technical devices, drives as well, need a certain amount of care-taking and failure preventive

maintenance. To maintain trouble-free operation of the VACON® drives, environmental conditions,

as well as load, line power, process control, etc. have to be within specifications, determined by

manufacturer.

If all conditions are in accordance with the manufacturer's specifications, there are no other

concerns, but to provide a cooling capacity high enough for the power- and control circuits. This

requirement can be met by making sure, that the cooling system works properly. Operation of

cooling fans and cleanness of the heat sink should be verified regularly.

Regular maintenance is recommended to ensure trouble free operation and long lifetime of the

VACON® drives. At least the following things should be included in the regular maintenance.

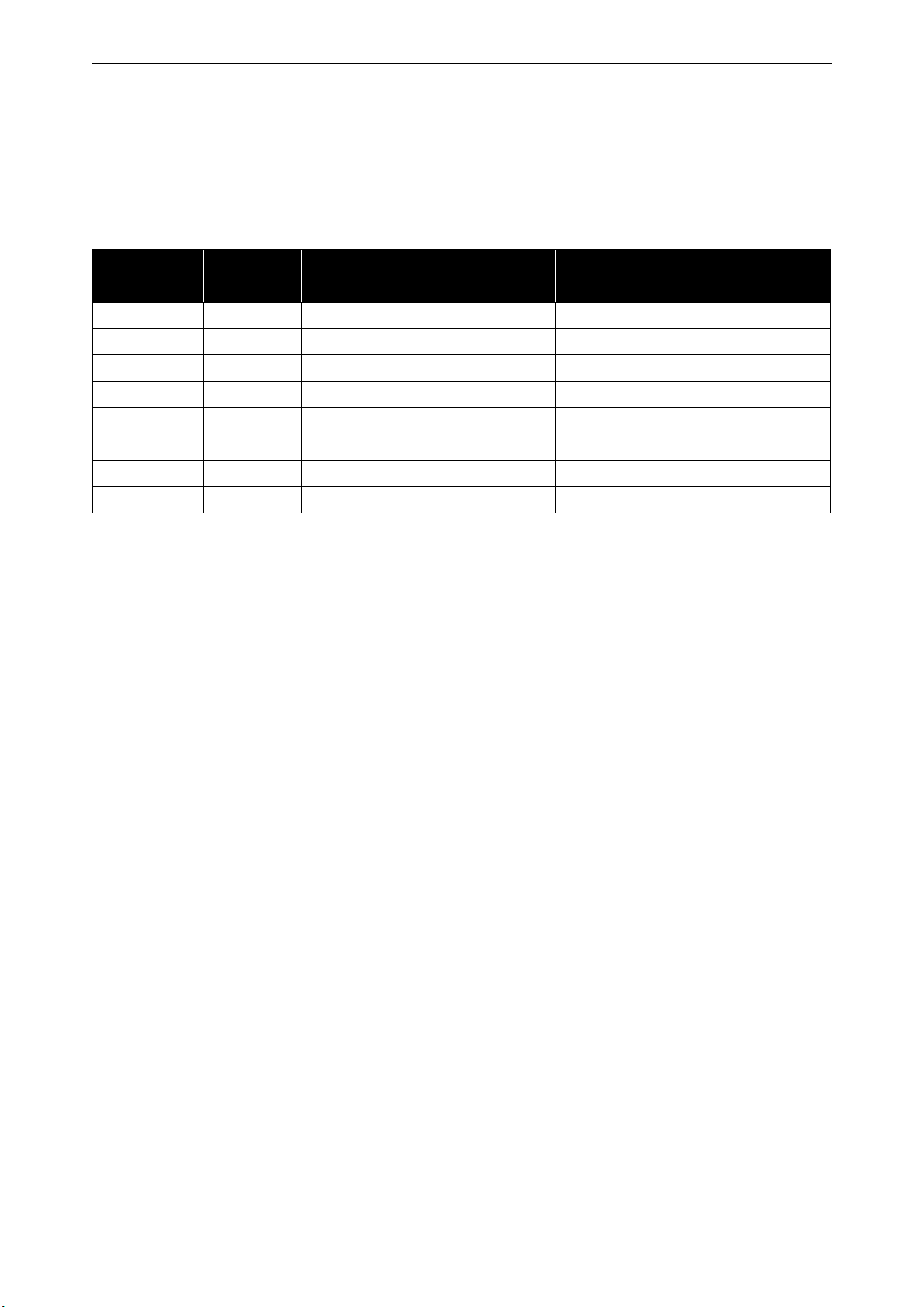

Table 15. Maintenance schedule

Interval Maintenance

12 months (if unit is stored) Reform the capacitors

Check the tightening torques of the input and output terminals

6-24 months (depending on

environment)

5-7 years

and I/O terminals.

Clean the cooling tunnel.

Check operation of the cooling fan, check for corrosion on terminals, busbars and other surfaces.

Change the cooling fans:

• Cabinet fans

• Drive fans

• LCL filter fans

5-10 years Change the DC-link capacitors if DC voltage ripple is high.

It is also recommended to record all actions and counter values with dates and time for follow up of

maintenance.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 56

vacon • 56 Service

13006.emf

13929_00

X

X

X

X

13930_00

5.3 Removing the drives from the cabinet

Servicing is only permitted to be carried out by Danfoss-trained service personnel!

5.3.1 IUS_4 / IUS_6

1

2

3

Open the cabinet door.

Disconnect all cables from the drive. See Chapter 4.6.

Release the drive assembly. Remove the four M8x20 bolts (tightening torque 20Nm).

Figure 30. Drive assembly mounting bolts (X) in IUS_4 (left) and IUS_6 (right)

Pull out the drive assembly.

4

Figure 31. Pulling the drive assembly in IUS_4 (left) and IUS_6 (right)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 57

Service vacon • 57

13931_00

X

X

13932_00

5.3.2 IUS_7 / IUS_8

1

2

Open the cabinet door.

Release the drive assembly. Remove the five M8x20 bolts (tightening torque 20Nm).

3

Figure 32. Drive assembly mounting bolts (X)

Pull out the drive assembly.

Figure 33. Pulling the drive assembly out of the cabinet

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Disconnect all cables from the drive. See Chapter 4.6.

Page 58

vacon • 58 Service

13877_00

±5mm

3

2

1

13878_00

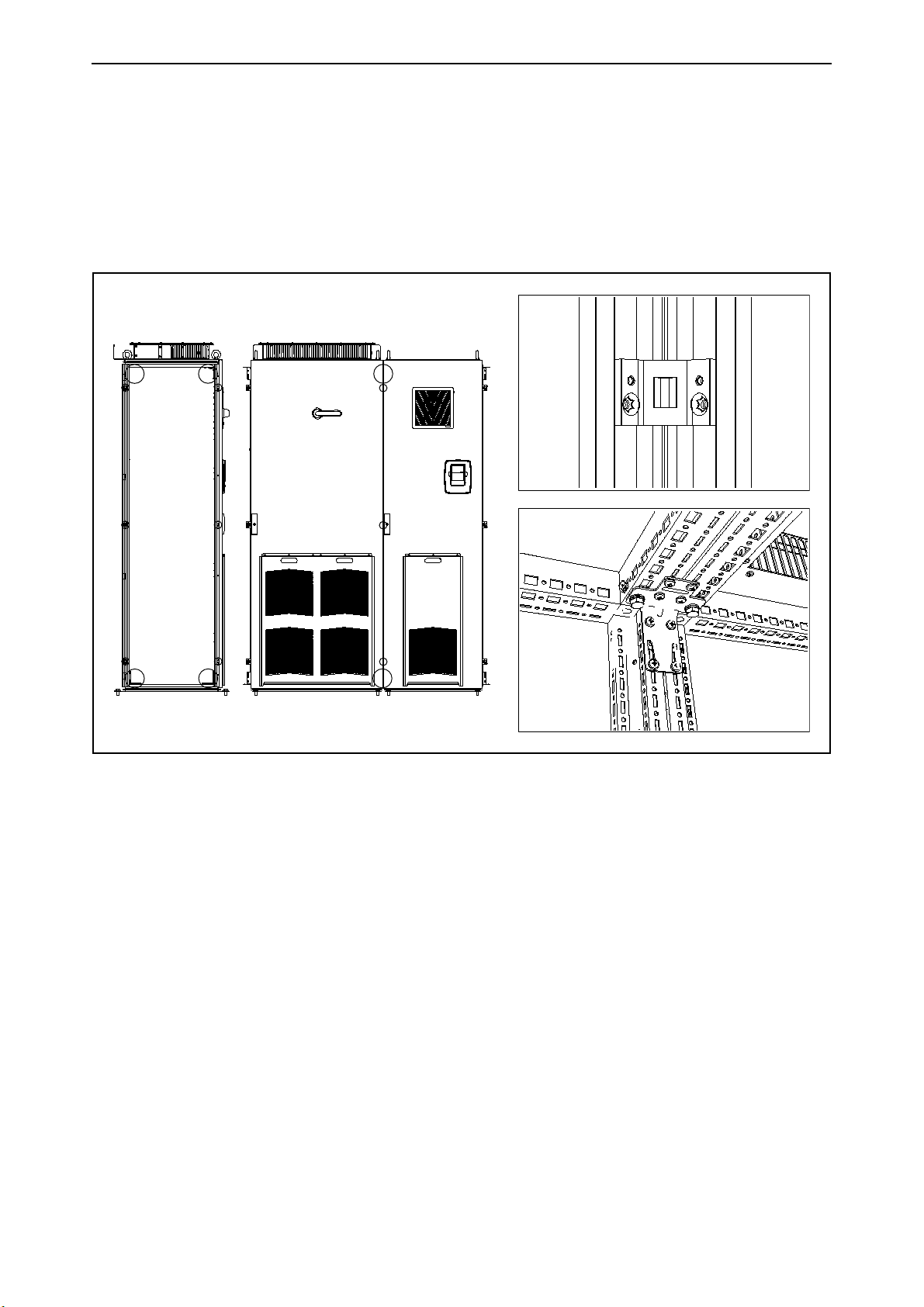

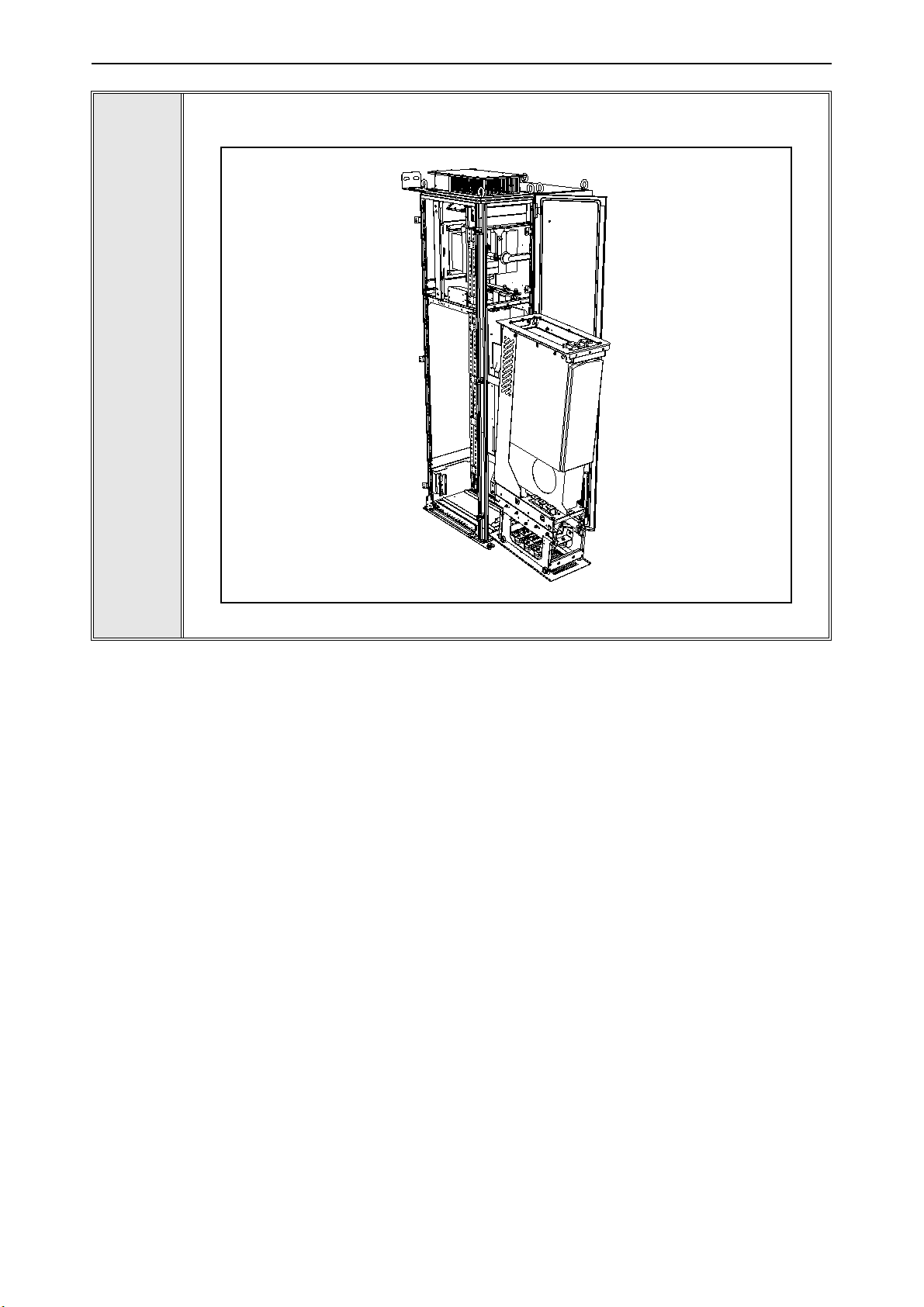

5.3.3 IUS_9 / IUS_10

1

2

Open the cabinet door.

Release the service ramp and turn it down in front of the drive.

NOTE! The height of the surface in front of the cabinet should not differ more than

5mm from the level of the cabinet installation.

Figure 34. Lowering the service ramp

3

1. Loosen the four M5 screws (tightening torque 3Nm) and remove the touch cover.

2. Remove the six M8 screws (torque 20 Nm) and remove the upper holder plate.

3. Remove the two M8 screws (torque 20 Nm) from the drive bottom holder plate.

Figure 35. Removing the drive touch cover and holder plates

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 59

Service vacon • 59

13912_00

1

3 3

2

13879_00

Release the input busbar assemblies. Remove:

1. two M10 nuts and M10x30 bolts (torque 40 Nm) from the upper busbars,

2. two M12 nuts and M12x40 bolts (torque 70 Nm) from the lower busbars,

3. two M8x20 screws (torque 20 Nm) from the back plate.

Take out the busbar assemblies, including the fuses.

4

5

Figure 36. Releasing the input busbar assembly

Release the output busbars. Remove three M10 nuts/bolts (tightening torque 40Nm).

Figure 37. Busbar mounting screws

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 60

vacon • 60 Service

13880_00

Pull the drive out on the service ramp.

6

Figure 38. Pulling the drive out of the cabinet

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 61

Service vacon • 61

13933_00

±5mm

13934_00

3

2

1

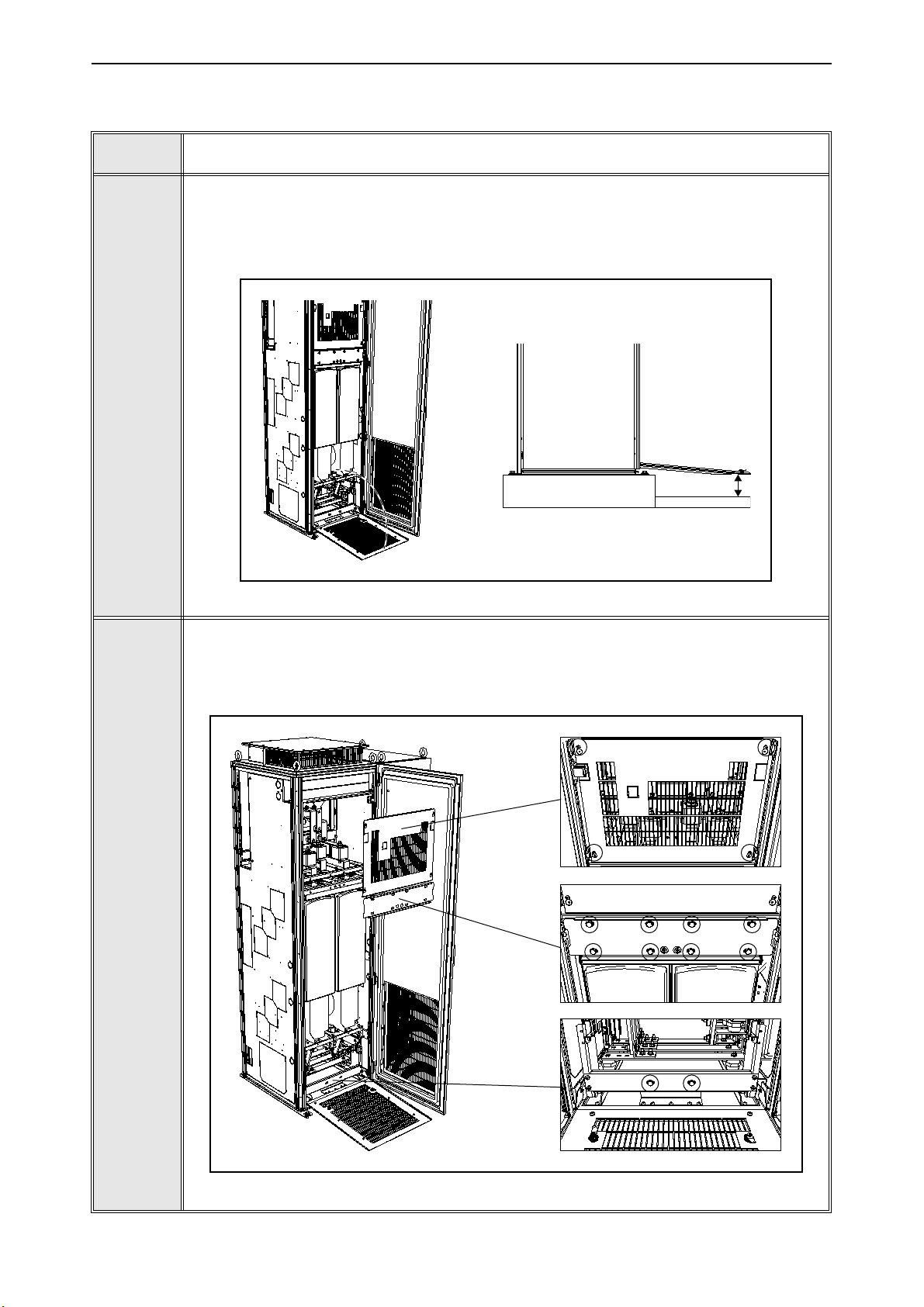

5.3.4 IUS_12

1

2

Open the cabinet door.

Release the service ramp and turn it down in front of the drive.

NOTE! The height of the surface in front of the cabinet should not differ more than

5mm from the level of the cabinet installation.

Figure 39. Lowering the service ramp

3

1. Loosen the four M5 screws (tightening torque 3 Nm) and remove the touch cover.

2. Remove the eight M8 screws (torque 20 Nm) and remove the upper holder plate.

3. Remove the two M8 screws (torque 20 Nm) from the drive bottom holder plate.

Figure 40. Removing the drive touch cover and holder plates

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 62

vacon • 62 Service

13935_00

1

3

3

1

2

2

13936_00

Release the input busbar assembly. Remove:

1. four M10 nuts and M10x30 bolts (torque 40 Nm) from the upper busbars,

2. four M12 nuts and M12x40 bolts (torque 70 Nm) from the lower busbars,

3. two M8x20 screws (torque 20 Nm) from the back plate.

Take out the busbar assemblies, including the fuses.

4

5

Figure 41. Releasing the input busbar assembly

Release the output busbars. Remove six M10 nuts/bolts (tightening torque 40 Nm).

Figure 42. Output busbar mounting screws

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 63

Service vacon • 63

13937_00

Pull the drive out on the service ramp.

6

Figure 43. Pulling the drive out of the cabinet

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 64

vacon • 64 Service

13938_00

±5mm

13939_00

3

2

1

5.3.5 IUS_13 / IUS_14

1

2

Open the cabinet door.

Release the service ramp and turn it down in front of the drive.

NOTE! The height of the surface in front of the cabinet should not differ more than

5mm from the level of the cabinet installation.

Figure 44. Lowering the service ramp

1. Loosen the four M5 screws (tightening torque 3 Nm) and remove the touch cover.

2. Remove the eight M8 screws (torque 20 Nm) and remove the upper holder plate.

3. Remove the four M8 screws (torque 20 Nm) from the drive bottom holder plate.

3

Figure 45. Removing the drive touch cover and holder plates

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 65

Service vacon • 65

13940_00

1

3

1

1

2

2

2

3

13941_00

Release the input busbar assembly. Remove:

1. six M10 nuts and M10x30 bolts (torque 40 Nm) from the upper busbars,

2. six M12 nuts and M12x40 bolts (torque 70 Nm) from the lower busbars,

3. two M8x20 screws (torque 20 Nm) from the back plate.

Take out the busbar assemblies, including the fuses.

4

5

Figure 46. Releasing the input busbar assembly

Release the output busbars. Remove three M12 nuts/bolts (tightening torque 70Nm).

Figure 47. Output busbar mounting screws

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 66

vacon • 66 Service

13942_00

Pull the drive out on the service ramp.

6

Figure 48. Pulling the drive out of the cabinet

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 67

Technical information vacon • 67

6. T

ECHNICAL INFORMATION

6.1 Control and interface

Speed and/or torque control functions are available in the drive. Speed and/or torque reference as

well as command word is generated by the overriding line control system and individually

transmitted to each drive either via fieldbus or hardwired signals. The drive transmits selected

actual values as well as status words back to the line control system.

6.1.1 Control without speed feedback (open loop)

• Speed error in steady state typically <0.5%

• Torque rise time <10 ms

• Torque error in steady state typically <3%

• Suitable also for multimotor configuration

6.1.2 Control with speed feedback (closed loop)

Full torque control at zero speed cannot be maintained without speed feedback. When a speed error

of less than 0.5% or full torque control at all speeds is required, motor control based on feedback

from an encoder is a necessity. This capability is incorporated into the VACON® NXP drive. In

addition to the current measurement system used, the NXP drive utilizes feedback values from the

encoder to determine the motor state. The enhanced microprocessor provided with the NXP drive

is capable of calculations every 150 microseconds. This control can be used for applications

requiring high precision, such as sectional drives.

• Speed error in steady state typically <0.01% (pulse encoder type dependent)

• Pulse encoder: 250-5000 ppr at 5, 12 or 24 V (option board dependent)

• Torque rise time <10 ms

• Torque error in steady state typically <3%

6.2 Load definitions

The drives are normally selected based on the load definition shown in the drive list, where:

•

n

= minimum speed [RPM], beginning of the continuous constant torque load speed

min

range

•

n

= base speed [RPM], end of the continuous constant torque load speed range (and

base

beginning of the continuous constant power load speed range)

•

n

= maximum speed [RPM], end of the continuous constant power load speed range (also

max

maximum allowed motor speed)

•P [

n

] = base power [kW], motor shaft power at the end of the continuous constant torque

base

load speed range (also motor shaft power of the continuous constant power load speed

range)

•T [

n

] = base torque [Nm], motor shaft torque of the continuous constant torque load

base

speed range (also motor shaft torque at the beginning of the continuous constant power

load speed range)

•

OL

= overload [%], short time maximum load, 1 min. / 10 min. (100% = no overload)

NOTE! Load is defined based on the information received. Danfoss is not responsible for verifying

that the information is sufficient and accurate.

There are various possibilities to define the load curve. Below are some examples.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 68

vacon • 68 Technical information

0

100

200

300

400

500

600

700

800

0 200 400 600 800 1000 1200 1400 1600

cont. load

max load

Speed [rpm]

Tor que [Nm ]

13886_UK

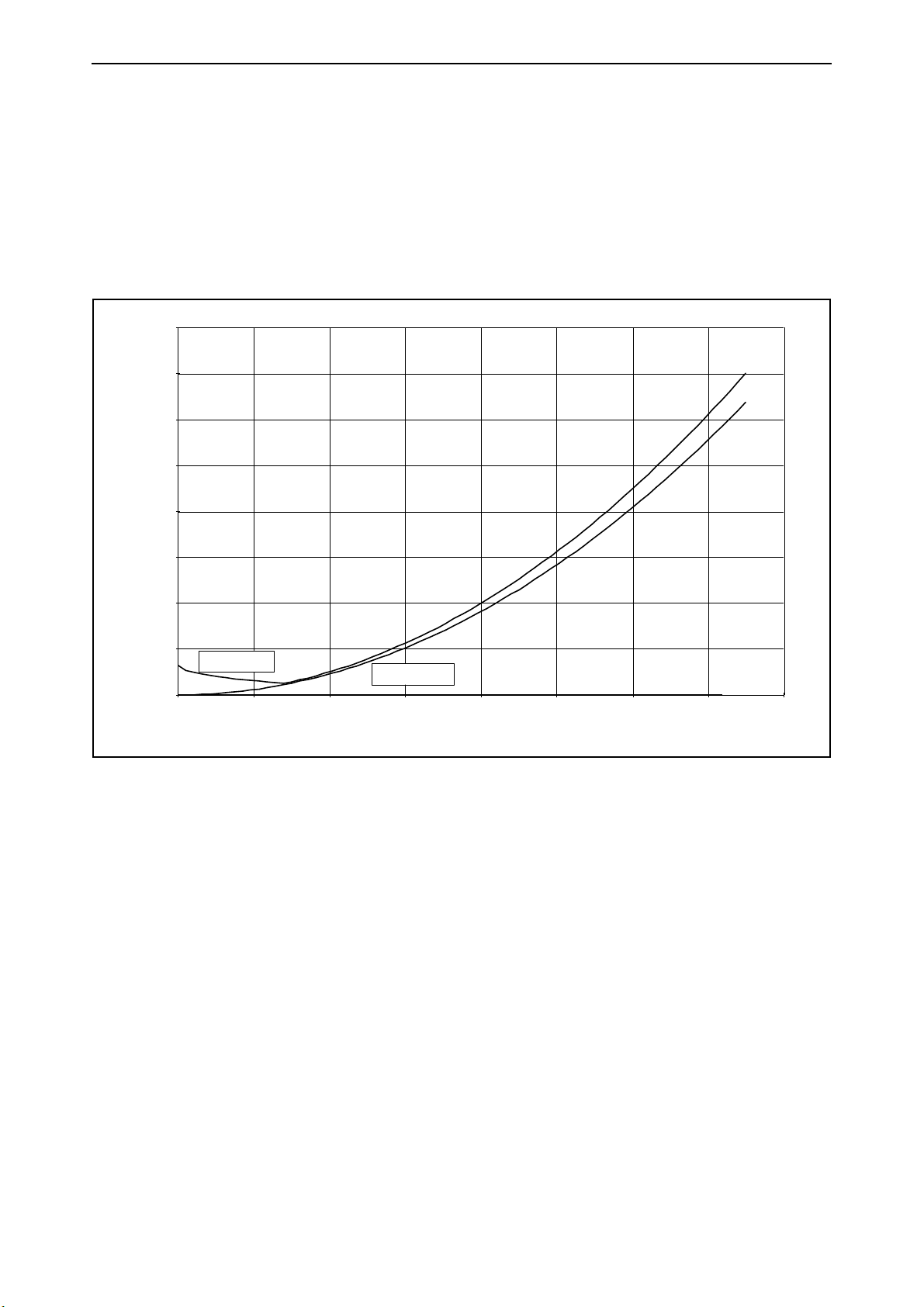

6.2.1 Pump and fan load

Set all speeds to the same value (

n

min

=

n

base

=

n

) to have the typical pump and fan curve, i.e.

max

quadratically increasing load.

The overload is now set as starting torque and as OL at maximum speed (the overload is now defined

as percent of torque at maximum speed).

The calculation of current is also here done assuming nominal flux in the motor from 0 to field

weakening point (current calculation according to ”optimized flux curve” is not available).

Figure 49. Example: pump and fan load

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 69

Technical information vacon • 69

0

200

400

600

800

1000

1200

0 200 400 600 800 1000 1200 1400 1600

cont. load

max load

Speed [rpm]

Tor que [Nm ]

13887_UK

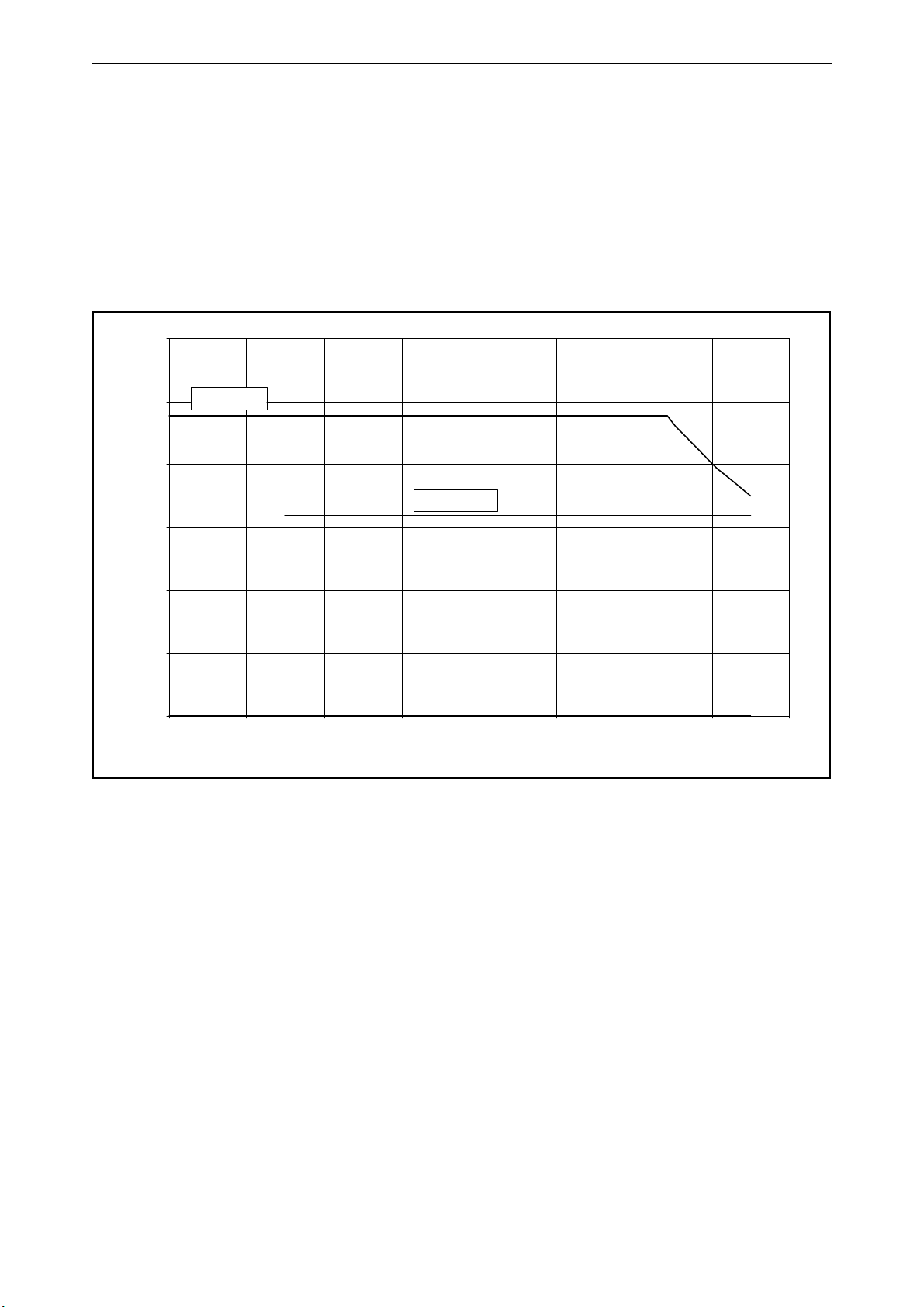

6.2.2 OL(

n

base

) > OL(

n

) for constant torque load

max

It is possible to set the overload at base speed smaller than the overload at maximum speed, i.e.

OL(

n

base

) < OL(

n

max

).

This can be useful when selecting the correct AC drive for constant torque drives where the overload

demand at low speeds is higher than at high speeds.

This possibility is usually used when the field weakening point is higher than base speed.

The benefit from this can be the possibility to use a size smaller AC drive.

Figure 50. Example: OL(n

base

) > OL(n

) for constant torque load

max

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 70

vacon • 70 Technical information

0

200

400

600

800

1000

1200

0 200 400 600 800 1000 1200 1400 1600

cont. load

max load

Speed [rpm]

Tor que [Nm ]

13888_UK

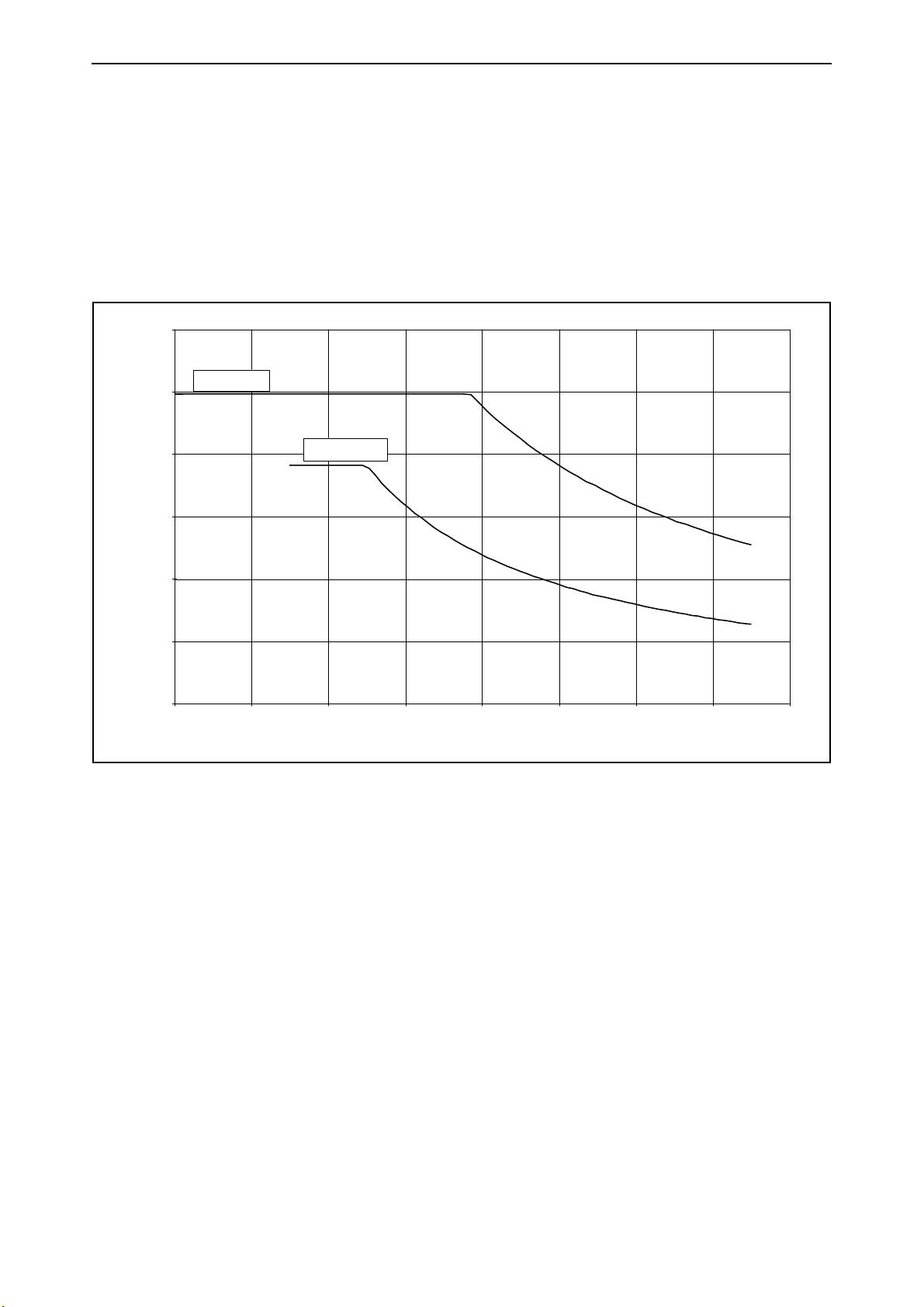

6.2.3 Starting torque >> OL(

It is possible to set the starting torque higher than the overload at maximum speed, i.e. OL(

OL(

n

).

max

n

) for constant torque load

max

n

base

) <

This can be useful when selecting the correct AC drive for constant torque drives where the starting