Page 1

vacon nx

ac drives

optcj

bacnet option board

user manual

Page 2

INDEX

Document code: DPD00901A

Date edited: 19.01.2012

1. General info ........................................................................................................................ 3

2. BACnet Option Board Technical data ................................................................................. 4

2.1 System Software versions ........................................................................................................ 5

3. BACnet FIELDBUS BOARD LAYOUT AND CONNECTIONS ................................................... 6

4. Grounding cable shield ...................................................................................................... 7

4.1 Grounding by clamping the cable to the converter frame (recommended)............................. 7

4.2 Grounding only one point on the net ........................................................................................ 8

4.3 Bus terminal resistors ............................................................................................................. 9

4.4 Bus Biasing ............................................................................................................................. 10

5. LED indications ................................................................................................................ 11

6. INSTALLATION OF VACON NX BACnet BOARD ................................................................. 12

7. COMMISSIONING .............................................................................................................. 14

7.1 Fieldbus board parameters .................................................................................................... 14

7.2 Expander board menu (M7) .................................................................................................... 14

7.3 BACnet parameters ................................................................................................................ 14

7.3.1 MS/TP MAC address (P7.x.1.1) ....................................................................................... 15

7.3.2 Baud rate (P7.x.1.2) ........................................................................................................ 15

7.3.3 Instance number (P7.x.1.3)............................................................................................. 15

7.3.4 Communication status (V7.x.2.1) .................................................................................... 16

7.3.5 Baud Rate (V7.x.2.2) ........................................................................................................ 16

7.3.6 Fault (V7.x.2.3) ............................................................................................................... 16

7.3.7 Index Nr. (V7.x.2.4) ......................................................................................................... 16

7.4 ANNEX - PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT (NORMATIVE) ...... 17

7.5 Object Map .............................................................................................................................. 19

7.5.1 Binary Value Object ........................................................................................................ 20

7.5.2 Analog Value Object ........................................................................................................ 21

8. FAULT TRACKING ............................................................................................................. 23

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 3

general vacon • 3

1

WARNING!

1. GENERAL INFO

Instead of sending and receiving information to and from frequency converters through I/O, you can

connect them to a fieldbus.

Vacon NX frequency converters can be connected to the RS-485 bus using a fieldbus board. The

converter can then be controlled, monitored and programmed from the host system.

BACnet is also known by names Direct Digital Control Systems and Building Management Systems.

BACnet technology is used mostly in building automation, lightning control, air conditioning and in

heating automation. The protocol is an upper level net protocol suitable for large building

automation projects.

BACnet stands for

protocol communication standard conceived by a consortium of building management, system users

and manufacturers.

If you purchase your BACnet option board separately, please note that it shall be installed in

on the control board of the frequency converter.

Building Automation and Control Network. BACnet is a true non-propriatery open

slot E

Internal components and circuit boards are at high potential when the frequency

converter is connected to the power source. This voltage is extremely dangerous

and may cause death or severe injury if you come into contact with it.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 4

4 • vacon technical data

Connections

OPT-CJ

Communications

Environment

Safety

2. BACNET OPTION BOARD TECHNICAL DATA

Interface

Data transfer

method

Transfer cable Twisted pair (1 pair and shield)

Electrical isolation 500 VDC

BACnet MS/TP As described in ANSI/ASHRAE Standards 135-2004

Baud rate 9600, 19200, 38400 and 76800 baud (supports autobaud

MAC Addresses 1 to 127

Ambient operating

temperature

Storing

temperature

Humidity <95%, no condensation allowed

Altitude Max. 1000 m

Vibration 0.5 G at 9…200 Hz

Fulfils EN50178 standard

Table 2-1. BACnet technical data

: Pluggable connector (5.08mm)

RS-485 MS/TP, half-duplex

detection)

–10°C…55°C

–40°C…60°C

2

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 5

layout and connections vacon • 5

2.1 System Software versions

OPT-CJ BACnet option board is supported from system software versions:

• NXL NXL00005V149.VCN

• NXS NXS00001V161.VCN

• NXP NXP00002V160.VCN

Autobaud detection and BACnet specific fault codes (readable from panel) are added from system

software versions:

• NXL NXL00005V248.VCN

• NXS NXS00001V163.VCN

• NXP NXP00002V162.VCN

Communication timeout is available from system SW versions. When not supported, the default is 10

seconds.

• NXL NXL00005V254.VCN

• NXS NXS00001V167.VCN

• NXP NXP00002V168.VCN

OPT-CJ software version

New baud rate 76800 from software versions:

• NXL: NXL00005V257.VCN

• NXS: NXS00001V170.VCN

• NXP: NXP00002V171.VCN

OPTCJ_10522V009 and newer:

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 6

6 • vacon technical data

Signal

Connector

Description

VP 2 Supply voltage – plus (5V)

X4

X1

Bus connector

Jumpers Interface board connector

Grounding plate

1

2

3

4

5

3. BACNET FIELDBUS BOARD LAYOUT AND CONNECTIONS

Vacon BACnet option board is connected to the fieldbus through a 5-pin pluggable bus connector.

The communication with the control board of the frequency converter takes place through the

standard Vacon Interface Board Connector.

Figure 3-1. Vacon BACnet option board OPT-CJ

NC* 1* No connection

RxD/TxD –N 3 Receive/Transmit data – A

RxD/TxD –P 4 Receive/Transmit data – B

DGND 5 Data ground (reference potential for VP)

*You can use this pin (1) to bypass the cable shield to the next slave

Table 3-1. OPT-CJ bus connector signals

3

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 7

grounding cable shield vacon • 7

Cut here

Strip this part

1 2 3 4 5

B

A

4. GROUNDING CABLE SHIELD

4.1 Grounding by clamping the cable to the converter frame (recommended)

This manner of grounding is the most effective and especially recommended when the distances

between the devices are relatively short or if the device is the last device on

the net.

Note: Normally, the option board has already been installed in slot D or slot E of the control board. It

is not necessary to detach the whole board for the grounding of the bus cable shield. Just detach the

terminal block.

1 Strip about 5 cm of the cable and cut off the grey cable shield.

Remember to do this for both bus cables (except for the last device). See pictures below.

2 Leave no more than 1 cm of the cable outside the terminal block and strip the data cables

at about 0.5 cm to fit in the terminals. See pictures below.

Note: Do this for both bus cables.

Figure 4-1.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Figure 4-2.

4

Page 8

8 • vacon grounding cable shield

1 2 3 4 5

B

A

Shield

3 Insert the data cables of both cables into terminals #3 (Line B) and #4 (Line A).

4 Strip the cable at such a distance from the terminal that you can fix it to the frame with the

grounding clamp. See pictures below:

Figure 4-3.

4.2 Grounding only one point on the net

In this manner of grounding, the shield is connected to ground only at the last device on the net in

the same way as described in chapter 4.1. Other devices of the net just pass the shield.

We recommend you to use an Abico connector to fit the shields into the terminal.

1. Strip about 5 cm of the cable and cut off the grey cable shield. Remember to do this for

both bus cables (except for the last device).

2. Leave no more than 1 cm of the cable outside the terminal block and strip the data cable

at about 0.5 cm to fit in the terminals. See Figure 4-4.

4

Figure 4-5.

Note! Do this for both cables.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Page 9

grounding cable shield vacon • 9

3. Fix both the cables on the frame with the clamp. See Figure 4-5.

Figure 4-6.

4.3 Bus terminal resistors

Figure 4-8. Using jumper X4 to set the bus termination.

If Vacon is the last device of the fieldbus line the bus termination must be set. Use jumper X4 (ON

position). See Figure 4-7.

Note: Jumper X1 is only used when D9 type connector is assembled (Not used with BACnet protocol)

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 10

10 • vacon grounding cable shield

31-40

27 kohm

DAT A A

DAT A B

1

2

3

4

5

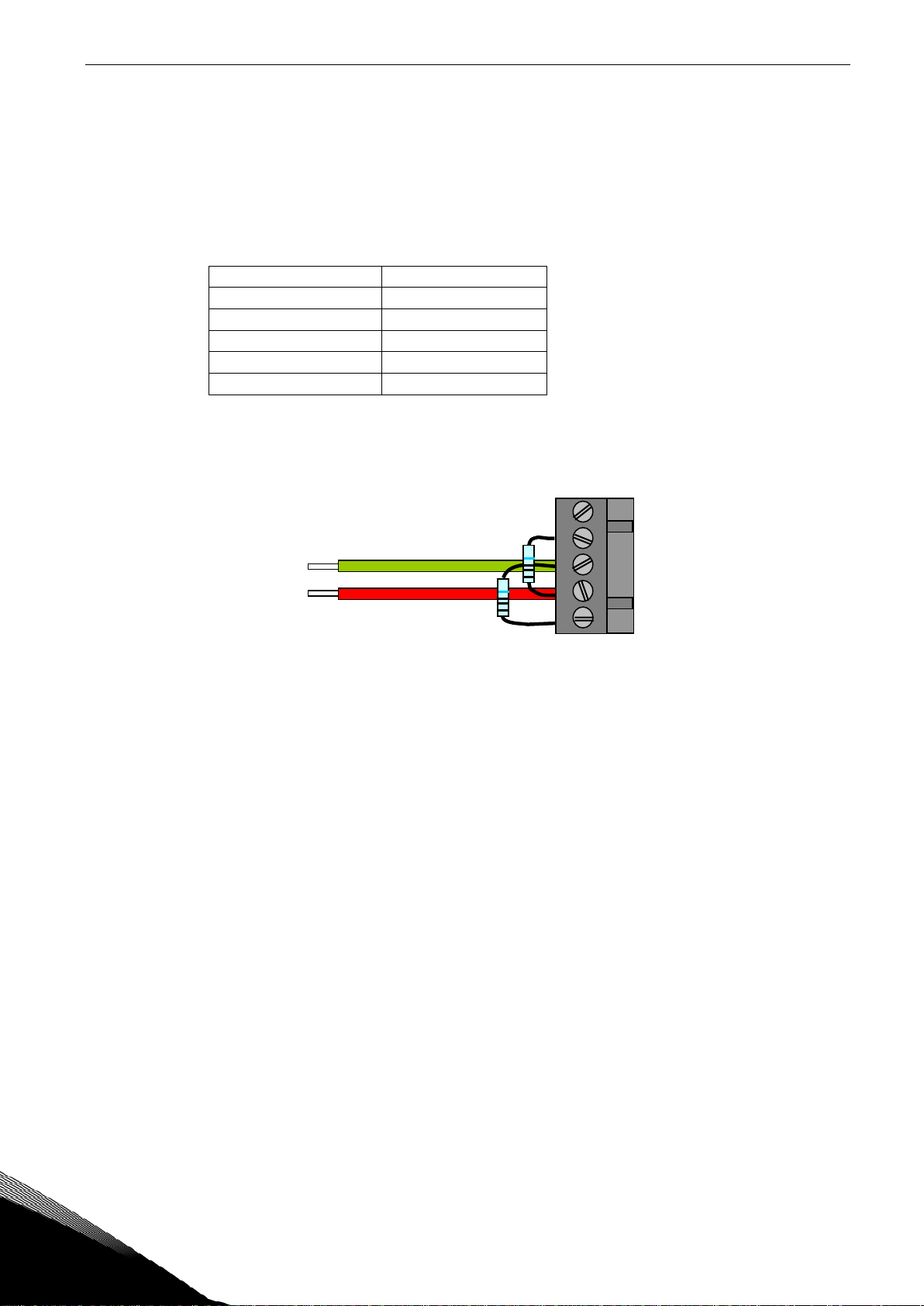

4.4 Bus Biasing

Bus biasing is required to ensure faultless communication between devices at RS-485 bus. Bus

biasing makes sure that the bus state is at proper potential when no device is transmitting. Without

biasing, faulty messages can be detected when the bus is in idle state. RS-485 bus state should be

neather +0,200..+7V or –0,200..-7V. Illegal bus state is <200mV..-200mV.

Number of nodes Bias resistance

2-5 1.8 kohm

5-10 2.7 kohm

11-20 12 kohm

21-30 18 kohm

Table 4-1. Bias resistor size vs number of node

Fail safe

biasing in OPT-CJ option board

Connect resistor biasing resistors between pins #2 and #4 as well as pins #3 and #5 as shown in

picture.

Matters related to this are discussed in the application note

Failsafe Biasing of Differential Buses

(an-847.pdf) published by National Semiconductor (www.national.com).

4

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

Loading...

Loading...