Page 1

vacon® nxn

ac drives

non-regenerative front end unit (nfe)

user manual

Page 2

AT LEAST THE 11 FOLLOWING STEPS OF THE

START-UP QUICK GUIDE

MUST BE PERFORMED DUR-

ING THE INSTALLATION AND COMMISSIONING.

IF ANY PROBLEMS OCCUR, PLEASE CONTACT YOUR LOCAL DISTRIBUTOR.

Start-up Quick Guide

1. Check that the delivery corresponds to your order, see Chapter 3

2. Before taking any commissioning actions, read carefully the safety instructions

in Chapter 1.2

3. Before the mechanical installation, check the minimum clearances around the

unit and check the ambient conditions in Chapter 5

4. Check the size of the supply cable/bus bar, DC output cable/bus bar, and mains

fuses, DC fuses and check the cable connections.

5. Follow the installation instructions, see Chapter 5.

6. The sizes and grounding of control connections are explained in Chapter 5.

7. All parameters have factory default values. No any changes need to make for

proper operation.

8. The VACON

®

NX Non-Regenerative Front End is now ready for use.

Vacon Ltd is not responsible for the use of the Non-Regenerative Front End against

the instructions.

Page 3

vacon 2

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

CONTENTS

VACON® NXN USER MANUAL

INDEX

1 SAFETY

2 EU DIRECTIVE

3 RECEIPT OF DELIVERY

4 Non-REGENERATIVE FRONT END UNIT (NFE)

5 INSTALLATION

6 CONTROL KEYPAD

7 APPENDICES

Page 4

vacon 3

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

ABOUT THE VACON® NXN USER'S MANUAL

Congratulations for choosing VACON® NX Non-Regenerative Front End!

The User's Manual will provide you with the necessary information about the installation, commissioning

and operation of VACON® NX Non-Regenerative Front End. We recommend that you carefully study these

instructions before powering up the Non-Regenerative Front End for the first time.

In the Non-Regenerative Front End Application Manual you will find information about the Nonregenerative Front End application. Should that application not meet the requirements of your process,

please contact the manufacturer for information on special application.

This manual is available in both paper and electronic editions. We recommend you to use the electronic

version if possible. If you have the electronic version at your disposal, you will be able to benefit from the

following features:

The manual contains several links and cross-references to other locations in the manual, which makes it

easier to move around in the manual. The reader can thus easily find and check things.

The manual also contains hyperlinks to web pages. To visit these web pages through the links, you must

have an internet browser installed on your computer.

This manual is applicable only for Non-Regenerative Front End unit, AC choke and optional components

that are introduced in this manual.

Page 5

vacon 4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

VACON® NX N User Manual

Table of contents

Document code: DPD01172C

Date edited: 30.01.2019

1. Safety ............................................................................................................................ 6

1.1 Warnings ........................................................................................................................................ 6

1.2 Safety Instructions ........................................................................................................................ 6

1.3 Grounding ...................................................................................................................................... 6

1.4 Warning symbols ........................................................................................................................... 7

2. EU directive ................................................................................................................... 8

2.1 CE marking .................................................................................................................................... 8

2.2 EMC directive ................................................................................................................................. 8

2.2.1 Introduction........................................................................................................................... 8

2.2.2 Technical criteria .................................................................................................................. 8

2.2.3 VACON® Non-Regenerative Front End EMC classification ............................................... 8

2.2.4 .......................................................................... 8

3. Receipt of delivery ................................ ....................................................................... 10

3.1 Type designation code for the NFE unit ..................................................................................... 10

3.2 Type designation code for the AC choke .................................................................................... 12

3.3 Storage ......................................................................................................................................... 12

3.4 Maintenance ................................................................................................................................ 12

3.5 Lifting the modules ..................................................................................................................... 13

3.6 Lifting the AC choke .................................................................................................................... 14

3.7 Warranty ...................................................................................................................................... 14

4. Non-Regenerative Front End (NFE) .............................................................................. 15

4.1 Introduction ................................................................................................................................. 15

4.2 Non-Regenerative Front End enclosure sizes .......................................................................... 17

4.3 Non-Regenerative Front End unit technical data ..................................................................... 18

4.4 Application ................................................................................................................................... 19

4.5 Diagrams...................................................................................................................................... 19

4.5.1 Connection between control unit and power unit ............................................................ 19

4.6 Non-Regenerative Front End power ratings ............................................................................. 20

4.6.1 VACON® NXN; DC voltage 460 800V ................................................................................. 20

4.6.2 VACON® NXN; DC voltage 640 1100V ............................................................................... 20

4.7 Non-Regenerative Front End unit Dimensions ...................................................................... 20

4.8 AC choke Dimensions .............................................................................................................. 20

4.9 Non-Regenerative Front End Fuse selection ......................................................................... 21

4.9.1 Introduction......................................................................................................................... 21

4.9.2 Fuses; mains voltage 380 690V ........................................................................................ 21

4.9.2.1 AC fuses........................................................................................................................ 21

4.9.2.2 DC fuses ....................................................................................................................... 21

4.10 Non-Regenerative Front End unit Circuit breaker selection ................................................ 21

4.11 Non-Regenerative Front End unit Main contactor ................................................................. 22

4.12 Pre-Charging and start up.......................................................................................................... 22

Page 6

vacon 5

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

4.13 Paralleling ................................................................................................................................... 22

4.14 12-pulse solution ......................................................................................................................... 23

4.15 Derating ....................................................................................................................................... 23

4.15.1 As the Ambient Temperature ............................................................................................ 23

4.15.2 As the Installation altitude ................................................................................................. 25

5. Installation .................................................................................................................. 27

5.1 Mounting ...................................................................................................................................... 27

5.1.1 Non-Regenerative Front End Unit..................................................................................... 27

5.1.2 AC choke ............................................................................................................................. 28

5.1.3 Control Box ......................................................................................................................... 29

5.2 Cooling ......................................................................................................................................... 29

5.2.1 Non-Regenerative Front End unit .................................................................................... 29

5.2.2 AC choke ............................................................................................................................. 31

5.2.3 Arranging ventilation of the enclosure ............................................................................. 32

5.2.4 Steering air flow ................................................................................................................. 34

5.3 Power connection ........................................................................................................................ 35

5.3.1 AC connection ..................................................................................................................... 35

5.3.2 DC connection ..................................................................................................................... 36

5.4 Cable installation and the UL standards ................................................................................... 36

5.5 I/O terminals and I/O signals ...................................................................................................... 37

6. Control keypad ............................................................................................................. 40

6.1 Navigation .................................................................................................................................... 41

6.1.1 Monitoring menu ................................................................................................................ 41

6.1.2 Parameter menu ................................................................................................................ 42

6.1.3 Fault history menu ............................................................................................................. 44

6.1.4 System menu ...................................................................................................................... 46

7. Appendices .................................................................................................................. 47

Page 7

Safety vacon 6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

1. SAFETY

1.1 Warnings

WARNING

1

The components of the power unit circuit are live when the NonRegenerative Front End is connected to AC supply. Coming into contact

with this voltage is extremely dangerous and may cause death or severe

injury. The control unit is isolated from mains potential.

2

The control I/O-terminals are isolated from the mains potential. However, the relay outputs and other I/O-terminals may have dangerous control

voltage present even when the Non-Regenerative Front End is disconnected from the AC supply.

3

Do not touch the components on the circuit boards. Static voltage discharge may damage the components.

1.2 Safety Instructions

1

The Non-Regenerative Front End, AC choke and optional components are

meant for fixed installations only.

2

Do not perform any measurements when the Non-Regenerative Front

End is connected to the AC supply.

3

After having disconnected the Non-Regenerative Front End from the AC

supply, wait until the fan stops. Wait 5 more minutes before doing any

work on the Non-Regenerative Front End connections. Do not even open

the cover before this time has expired.

4

Do not perform any voltage withstand tests on any part of the NonRegenerative Front End. There is a certain procedure according to which

the tests must be performed. Ignoring this procedure may result in damaged product.

5

Before connecting the Non-Regenerative Front End to AC supply, make

sure that the Non-Regenerative Front End front and cable covers are

closed.

6

Before doing any work on Common DC bus, system must be grounded.

1.3 Grounding

The Non-Regenerative Front End unit and AC choke must always be grounded with an grounding

conductor connected to the grounding terminal.

ONLY A COMPETENT ELECTRICIAN MAY CARRY OUT

THE ELECTRICAL INSTALLATION

!

Page 8

vacon 7 Safety

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

1.4 Warning symbols

For your own safety, please pay special attention to the instructions marked with the following symbols:

=

Dangerous voltage

WARNING

=

General warning

HOT SURFACE

=

Hot surface Risk of burn

NOTE! You can download the English and French product manuals with applicable safety, warning

and caution information from https://www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

sur le site https://www.danfoss.com/en/service-and-support/.

Page 9

EU directive vacon 8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

2

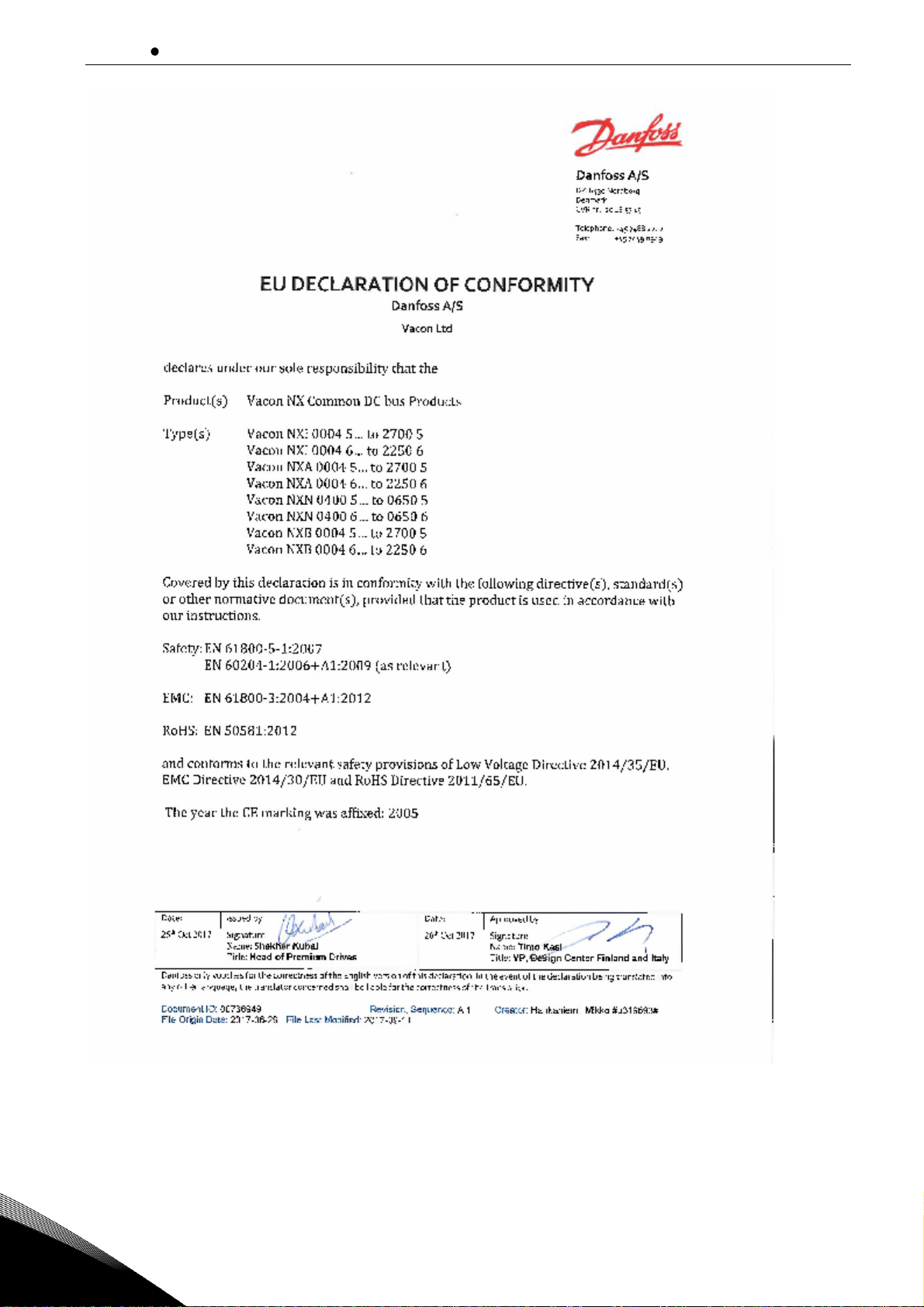

2. EU DIRECTIVE

2.1 CE marking

The CE marking on the product guarantees the free movement of the product within the EEA (European Economic Area). It also guarantees that the product complies with applicable directives (for

example, the EMC directive and other possible so-called new method directives). VACON® NX NonRegenerative Front End carries the CE label as a proof of compliance with the Low Voltage Directive

(LVD) and the Electro Magnetic Compatibility (EMC) directive. SGS FIMKO has acted as the Notified

Body.

2.2 EMC directive

2.2.1

Introduction

The EMC Directive provides that the electrical apparatus must not excessively disturb the environment it is used in, and, on the other hand, it must have an adequate level of immunity toward other

disturbances from the same environment.

The compliance of VACON® NX Non-Regenerative Front End with the EMC directive is verified with

Technical Construction Files (TCF) and checked and approved by SGS FIMKO, which is a Notified

Body. The Technical Construction Files are used to authenticate the conformity of VACON® NX Non-

Regenerative Front End with the Directive because it is impossible to test such a large product family in a laboratory environment and because the combinations of installation vary greatly.

2.2.2

Technical criteria

Our basic idea was to develop a range of VACON® NX Non-Regenerative Front End offering the best

possible usability and cost efficiency. EMC compliance was a major consideration from the outset of

the design.

2.2.3

VACON® Non-Regenerative Front End EMC classification

Factory delivered VACON® NX Non-Regenerative Front End are Class T equipment, which fulfills all

EMC immunity requirements (standard EN 61800-3).

Class T:

Class T equipment have a small earth leaking current and can be used with floating DC input.

2.2.4

The following page presents the photocopy of the Manufacturer's Declaration of Conformity assuring

the compliance of VACON® NX Non-Regenerative Front End with the EMC-directives.

Warning: This product is of the restricted sales distribution class according to IEC 61800-3. In residential areas, this product may cause radio interference in which case the user may be required to

take adequate measures.

Page 10

vacon 9 EU directive

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

2

Page 11

Receipt of delivery vacon 10

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

3

3. RECEIPT OF DELIVERY

VACON® NX Non-Regenerative Front End has undergone scrupulous tests and quality checks at the

factory before they are delivered to the customer. However, after unpacking the product, check that

no signs of transportation damage are to be found on the product and that the delivery is complete

(compare the type designation of the product to the codes below, see Figure 3-1 and Figure 3-2).

Should the product have been damaged during the shipping, please contact primarily the cargo insurance company or the carrier.

If the delivery does not correspond to your order, contact the supplier immediately.

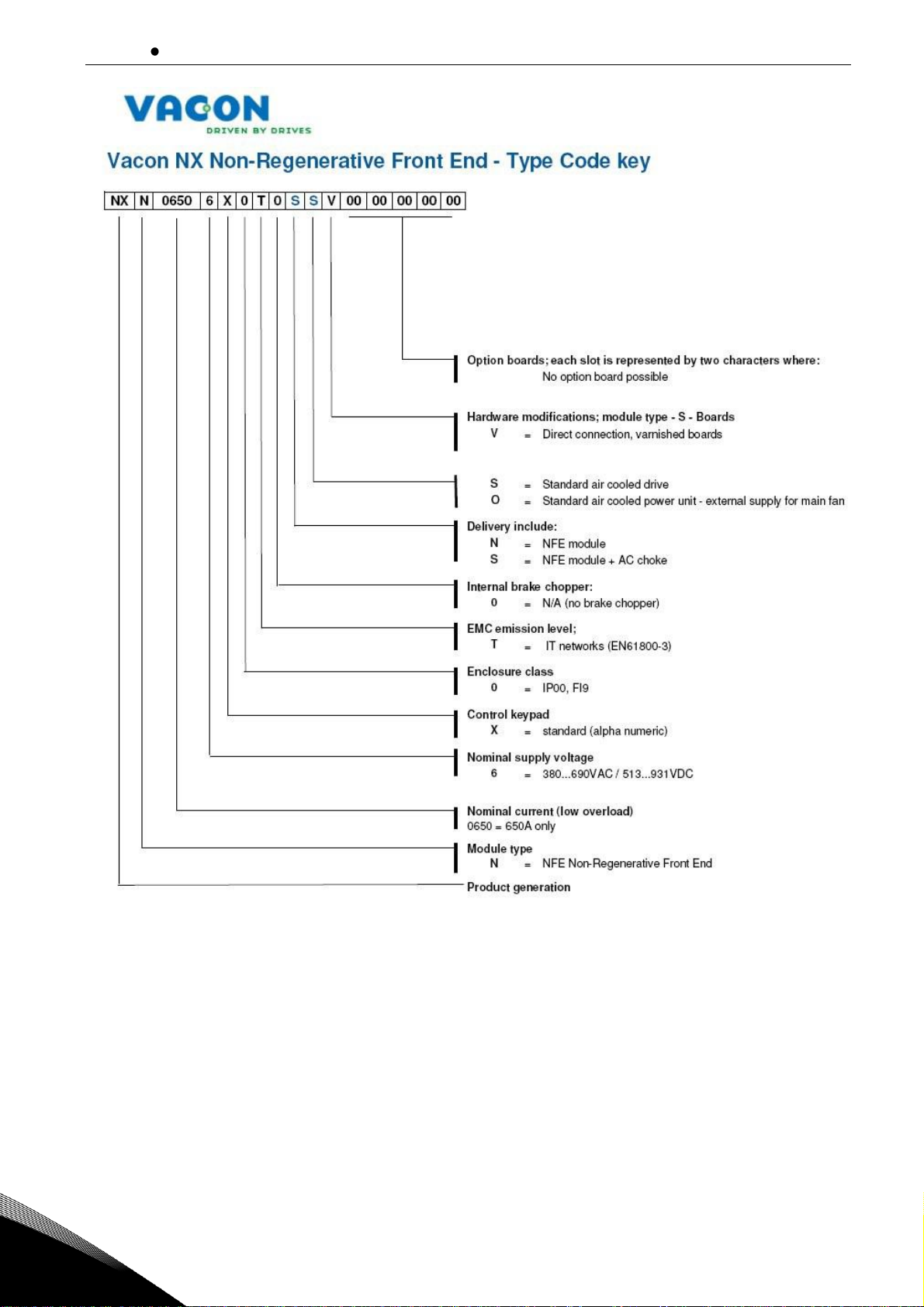

3.1 Type designation code for the NFE unit

In VACON® type designation code for Common DC Bus components, the Non-Regenerative Front End

Unit is characterized by letter N and letter N or S. If the Non-Regenerative Front End unit is ordered

by letter N delivery is not include anything else than the unit itself. If letter S is used delivery include

the unit, the AC choke.

NOTE! Delivery does NOT include any auxiliary devices which are needed for proper operation (the

AC or DC fuses, the fuses bases, the main contactor or circuit breaker etc.) The customer must take

care of them.

Page 12

vacon 11 Receipt of delivery

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

3

Figure 3-1. Type designation code for the Non-Regenerative Front End.

Page 13

Receipt of delivery vacon 12

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

3

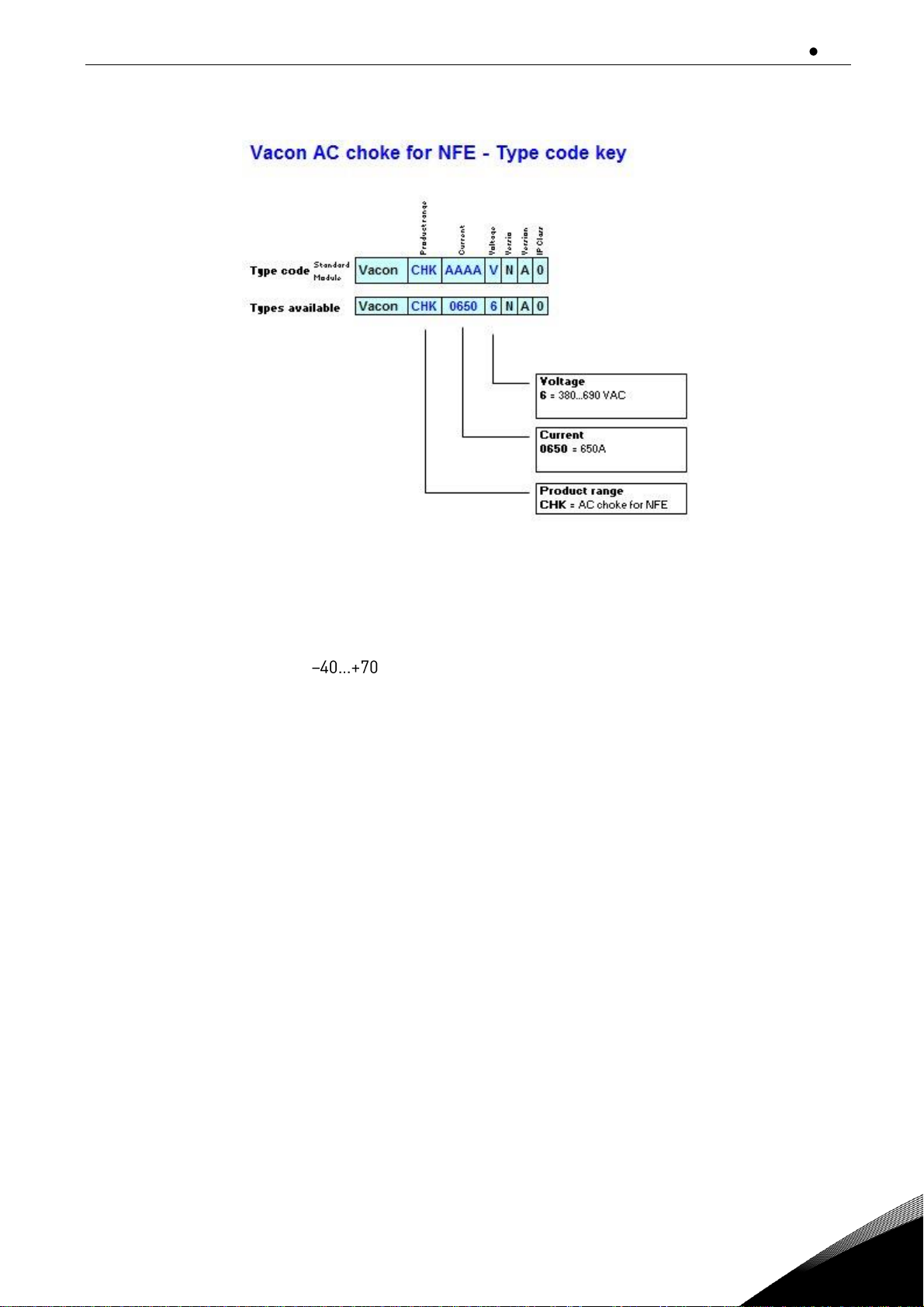

3.2 Type designation code for the AC choke

AC choke has one version which is suitable for 380-500V and 525-690V voltages.

Figure 3-2. Type designation code for the AC choke.

3.3 Storage

If VACON® NX Non-Regenerative Front End is to be stored before use, make sure that the ambient

conditions are acceptable:

Storage temperature °C

Relative humidity <95%, no condensation

3.4 Maintenance

All technical devices, drives as well, need a certain amount of care-taking and failure preventive

maintenance. To maintain trouble-free operation of the VACON® NX Non-Regenerative Front End,

environmental conditions, as well as load, line power, process control, etc. have to be within specifications, determined by manufacturer.

If all conditions are in accordance with the manufacturer's specifications, there are no other concerns, but to provide a cooling capacity high enough for the power- and control circuits. This requirement can be met by making sure, that the cooling system works properly. Operation of cooling

fans and cleanness of the heat sink should be verified regularly.

Regular maintenance is recommended to ensure trouble free operation and long lifetime of VACON®

NX Non-Regenerative Front End. At least the following things should be included in the regular

maintenance.

Page 14

vacon 13 Receipt of delivery

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

3

Table 3-1. Maintenance interval

It may also be necessary to check the tightening torques of terminals at certain intervals.

It is also recommended to record all actions and counter values with dates and time for follow up of

maintenance. It may also be necessary to check the tightening torques of terminals at certain intervals.

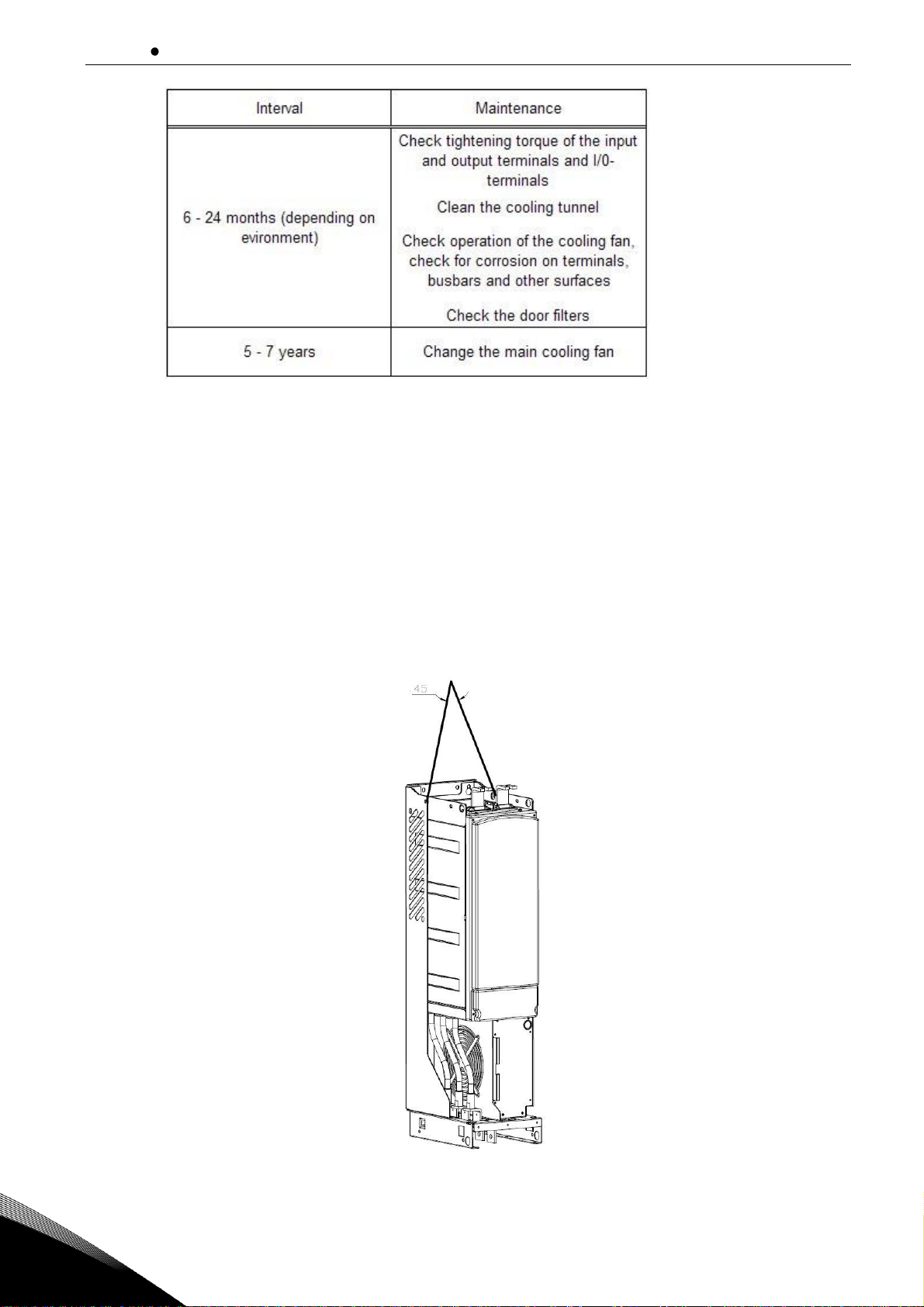

3.5 Lifting the modules

The modules can be lifted by the holes on top. Place the lifting hooks symmetrically in at least four

holes. The maximum allowed lifting angle is 45 degrees. For enclosures FI9, see Figure 3-3.

The lifting equipment must be able to carry the weight of the module.

Figure 3-3. Lifting points for FI9 module.

Page 15

Receipt of delivery vacon 14

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

3

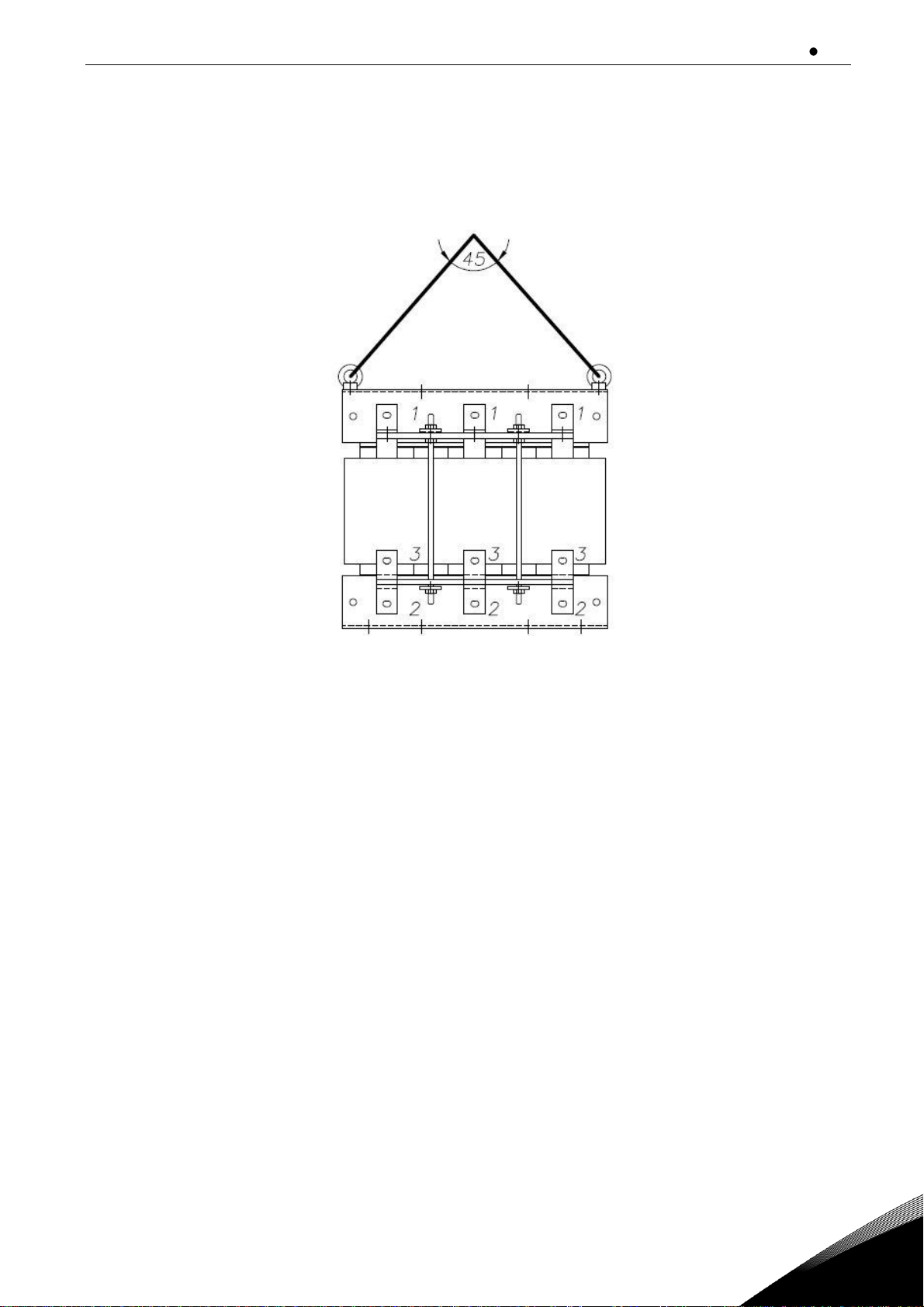

3.6 Lifting the AC choke

The AC choke can be lifted by the holes on top. Place the lifting hooks symmetrically in two holes.

The maximum allowed lifting angle is 45 degrees. Lifting points for the AC choke, see Figure 3-4.

Figure 3-4. Lifting points for AC choke.

3.7 Warranty

Only manufacturing defects are covered by the warranty. The manufacturer assumes no responsibility for damages caused during or resulting from transport, receipt of the delivery, installation, commissioning or use.

The manufacturer shall in no event and under no circumstances be held responsible for damages

and failures resulting from misuse, wrong installation, unacceptable ambient temperature, dust,

corrosive substances or operation outside the rated specifications.

Neither can the manufacturer be held responsible for consequential damages.

The Manufacturer's warranty period is 18 months from the delivery or 12 months from the commis-

sioning whichever expires first (General delivery terms NL92/Orgalime S92).

The local distributor may grant a warranty time different from the above. This warranty time shall be

specified in the distributor's sales and warranty terms. The manufacturer assumes no responsibility

for any other warranties than that granted by the manufacturer itself.

In all matters concerning the warranty, please contact your distributor first.

Page 16

vacon 15 Non-Regenerative Front End (NFE)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

4. NON-REGENERATIVE FRONT END (NFE)

4.1 Introduction

The VACON® NX Non-Regenerative Front End is used to transfer power between the AC input and

intermediate DC circuit. The VACON® NX Non-Regenerative Front End has only a one-way function.

This means that power can only be transferred from the AC input to the intermediate DC circuit. If

braking is needed, brake chopper has to be connected to the intermediate DC circuit.

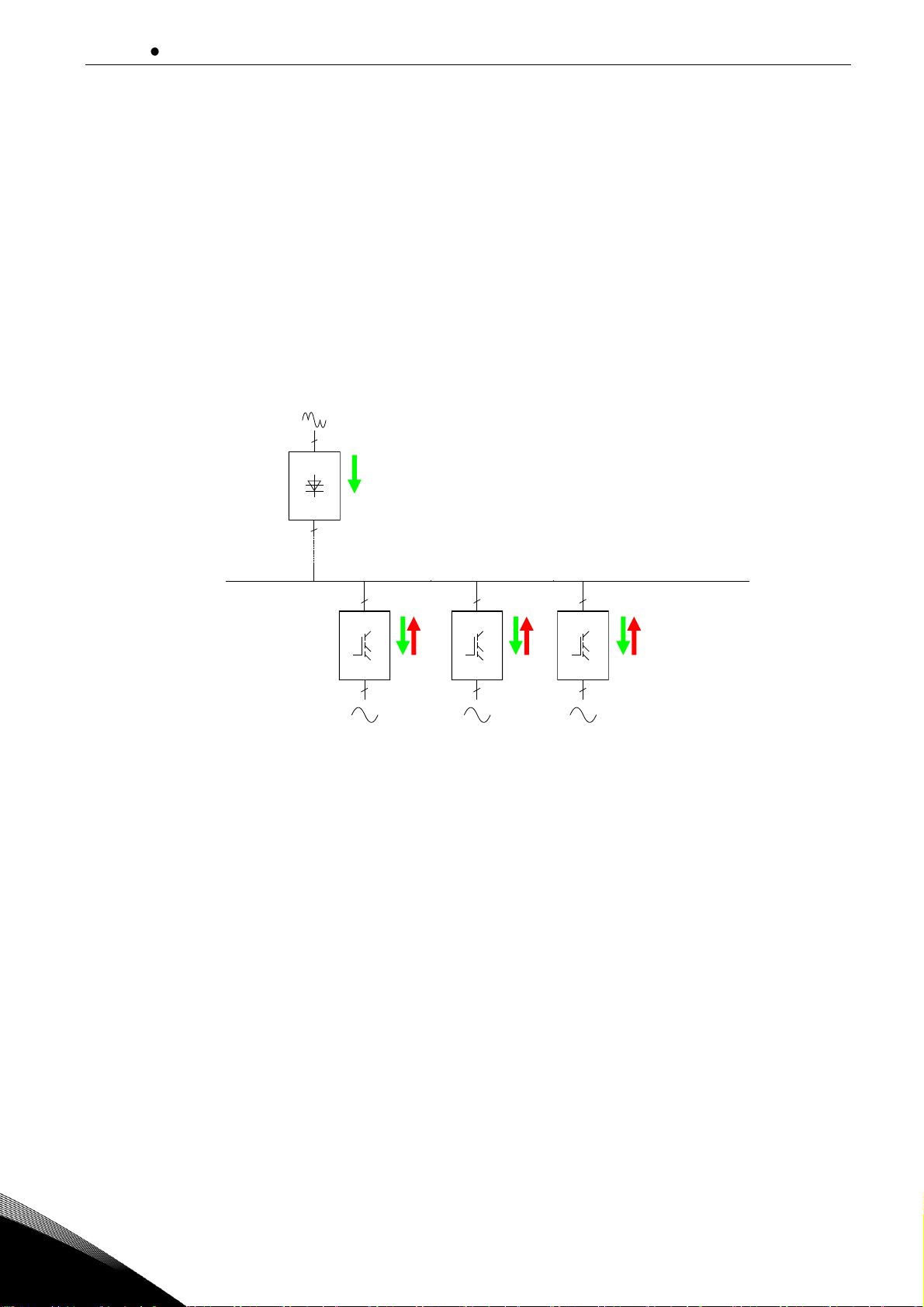

In a typical VACON® NX Non-Regenerative Front End configuration, the desired number of Inverters,

Figure 4-1, are connected to the intermediate DC circuit.

The Non-Regenerative Front End configuration consists of the unit itself, AC choke, AC fuses, main

contactor and DC fuses, Figure 4-2.

Figure 4-1. Typical Non-Regenerative Front End configuration.

NFE*

3

FFE*

3

2

3

INU

2

3

INU

2

3

INU

2

2

BCU

AFE*

Common DC bus

* alternative

2 2 2

Page 17

Non-Regenerative Front End (NFE) vacon 16

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Figure 4-2. VACON® Non-Regenerative Front End Single Unit connections

CLOSE

-RO2

26

24

25

Page 18

vacon 17 Non-Regenerative Front End (NFE)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

4.2 Non-Regenerative Front End enclosure sizes

Figure 4-3. VACON® NXN, FI9. Protection class IP00

Page 19

Non-Regenerative Front End (NFE) vacon 18

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

4.3 Non-Regenerative Front End unit technical data

Mains connection

Input voltage Uin

380 - 690 Vac; -15%...+10%, EN 60204-1

Input frequency

45…66 Hz

Continuous input current

IH: Ambient temperature max. +40°C,

overload 1.5 x IH (1 min./10 min.)

IL: Ambient temperature max. +40°C,

overload 1.1 x IL (1 min./10 min.)

Connection to mains

Unlimited (internal overload protections)

Current THD

Depend on additional chokes ( normal case < 40%)

Starting delay

Depend on dc bus capacitance (max 10 s)

Unexpected input power

break

Shorter breaks than 40ms works normally if DC does not drop

remarkably. Longer break means normal starting operation

(charging current varies according to load).

DC

connection

Output voltage Uout

465...800Vdc ( 380-500 Vac);

640...1100Vdc ( 525-690 Vac);

Efficiency

>98%

DC bank capasitance

6.8µF (included 10 M discharging resistor)

Control characteristics

Control method

NFE is an independent power unit. Charging and protections

controlled by NFE itself.

Ambient conditions

Ambient operating temperature

H

L

Storage temperature

–40°C…+70°C

Relative humidity

0 to 95% RH, non-condensing, non-corrosive,

no dripping water

Air quality:

- chemical vapours

- mechanical particles

IEC 721-3-3, unit in operation, class 3C2

IEC 721-3-3, unit in operation, class 3S2

Altitude

100% load capacity (no derating) up to 1,000 m

1-% derating for each 100m above 1000.; max. 2000m

Vibration

EN50178/EN60068-2-6

Displacement amplitude 0.

Shock

EN50178, EN60068-2-27

UPS Drop Test (for applicable UPS weights)

Storage and shipping: max 15 G, 11 ms (in package)

Cooling air required

1150 m3/h

Enclosure class

IP00/Open type standard size in the kW/HP range

EMC

(at default settings)

Immunity

Fulfil all EMC immunity requirements. Can be chosen N-, L- or

T-level.

Safety

CE, UL, CUL

EN 61800-5-1 (2003); (see unit nameplate for more detailed

approvals)

Control connections

Display

LCD

Trip information

Relay I/O

Auxiliary voltage

+24 V, +/- 20%, max. load 50 mA

Analogue output

0(4)-20 mA, RL=500 Ohm

Digital output

Open collector, max. Load 48V/50 mA

Relay outputs

Max switching load: 250Vac/2A or 250Vdc/0.4 A

Protections

Unit over temperature protection

Trips if temperature rising over trip level (default)

Current measurement

Trips if current over trip level (default)

Supply phase supervision

Trips if any of the output phases is missing (default)

Table 4-1. Technical specification for VACON® NX Non-Regenerative Front End unit

Page 20

vacon 19 Non-Regenerative Front End (NFE)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

4.4 Application

The VACON® NX Non-Regenerative Front End needs a special application. The unit is delivered with

that application. If application code is needed please contact please contact the manufacturer. More

information about application can be found from this manual.

4.5 Diagrams

4.5.1

Connection between control unit and power unit

The communication connections between the Non-Regenerative Front End power unit and the

con-

trol unit

is established using serial cable, Figure 4-4. The control unit is located under the front cov-

er of the power unit. The control unit cannot place outside of the power unit.

Figure 4-4. NFE power and control connections.

Page 21

Non-Regenerative Front End (NFE) vacon 20

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

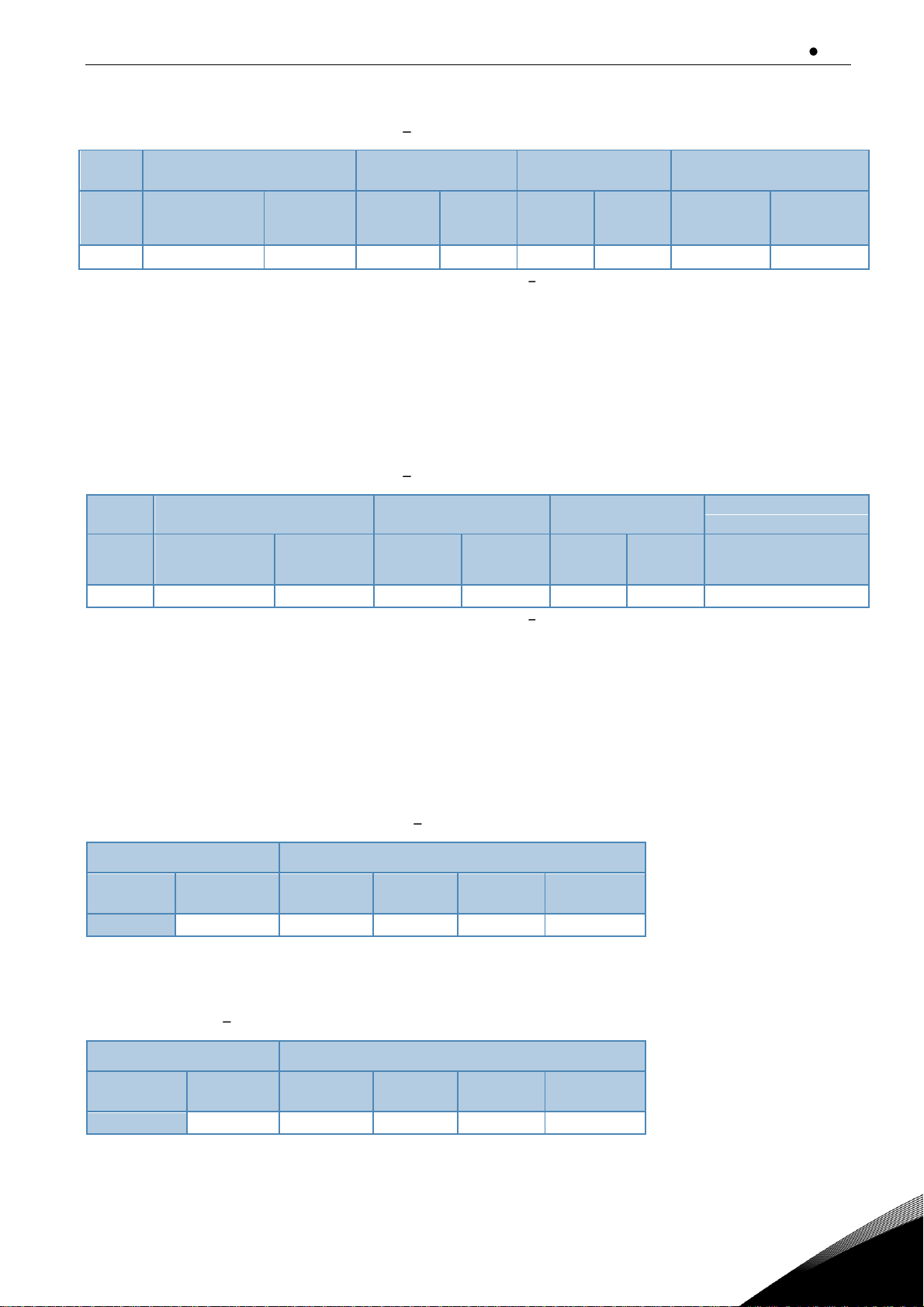

4.6 Non-Regenerative Front End power ratings

4.6.1

VACON® NX N; DC voltage 460 800V

Unit

Low oveload

(AC current)

High oveload

(AC current)

DC Power

(continuous)

Type

Code

Enclosure

I

L-cont [A]

I

1min [A]

I

H-cont [A]

I

1min [A]

400V mains

500 V mains

P [kW]

P [kW]

NFE

NXN_0650 6

FI9

650

715

507

793

410

513

Table 4-2. Power ratings of VACON® NXN, supply voltage 460 800Vdc

For dimensions of NXN units, see Table 4-4 and AC choke Table 4-5.

Note: The rated currents in given ambient (+40°C).

Note: The motor output power: Pout=Pdc x (Eff.INU x Eff.Motor).

Pdc =NFEs DC power

Eff.INU=efficiency of the inverter

Eff.Motor=efficiency of the motor

4.6.2

VACON® NX N; DC voltage 640 1100V

Unit

Low oveload

(AC current)

High oveload

(AC current)

DC Power

(continuous)

Type

Code

Enclosure

I

L-cont [A]

I

1min [A]

I

H-cont [A]

I

1min [A]

690V mains

P [kW]

NFE

NXN_0650 6

FI9

650

715

507

793

708

Table 4-3. Power ratings of VACON® NXN, supply voltage 640 1100Vdc

For dimensions of NXN unit, see Table 4-4 and AC choke Table 4-5.

Note: The rated currents in given ambient (+40°C).

Note: The motor output power: Pout=Pdc x (Eff.INU x Eff.Motor).

Pdc =NFEs DC power

Eff.INU=efficiency of the inverter

Eff.Motor=efficiency of the motor

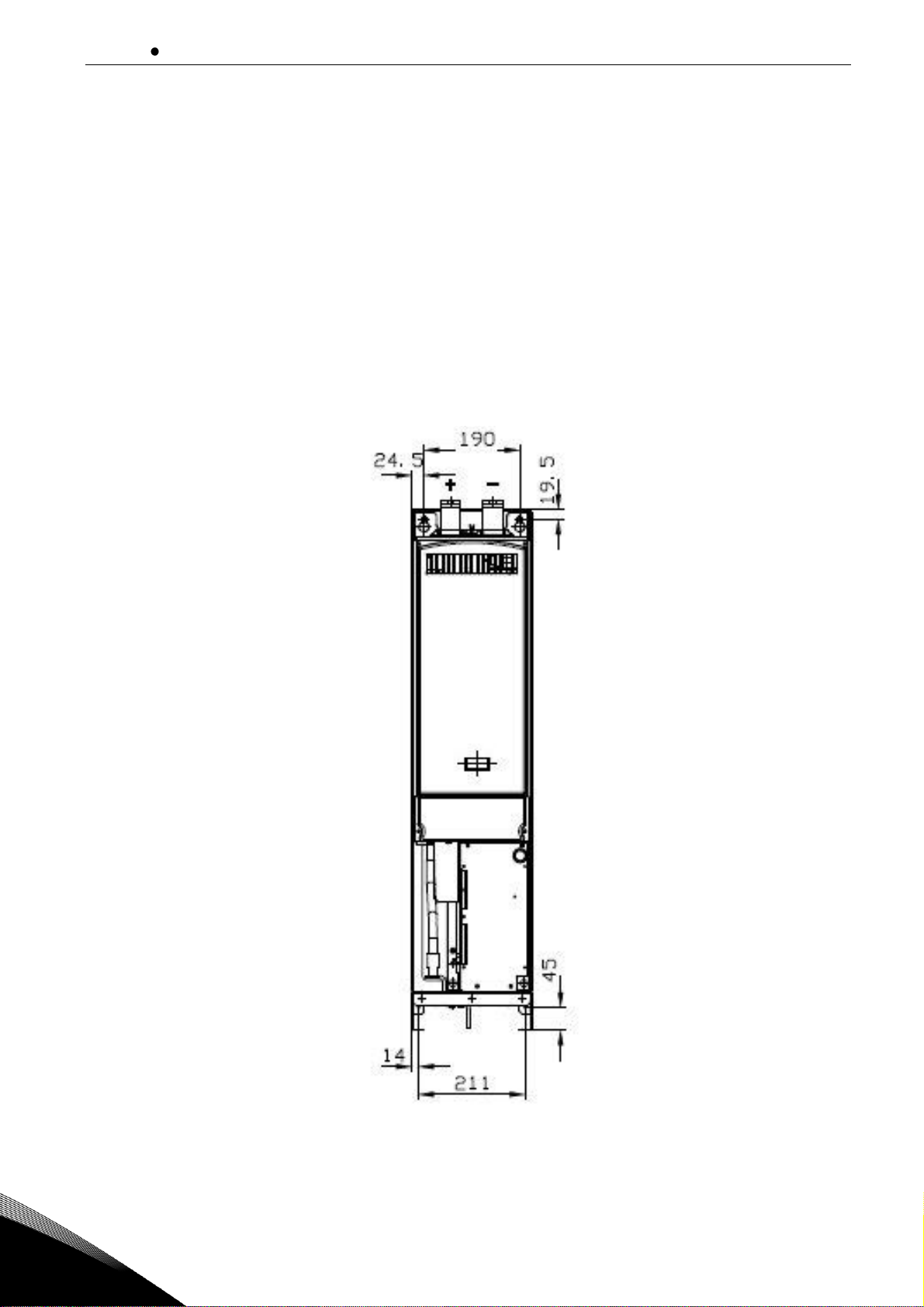

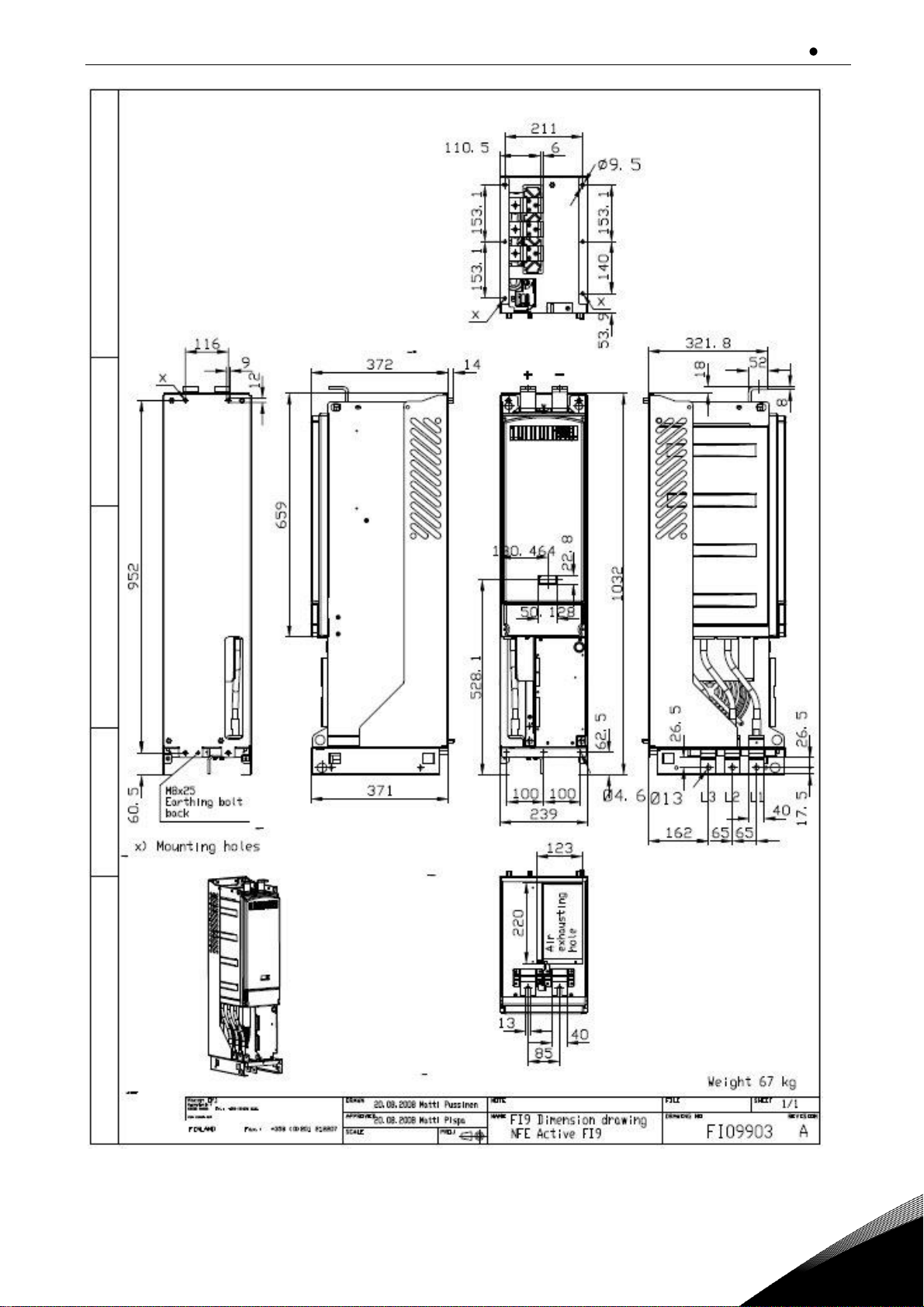

4.7 Non-Regenerative Front End unit Dimensions

Module

Module Dimension

Type

Enclosure

Height

Width

Depth

Weight

[mm]

[mm]

[mm]

[kg]

NFE

FI9

1030

239

372

67

Table 4-4. The NXN unit dimensions

Note: More detailed dimensions can be found in Appendix 7-4.

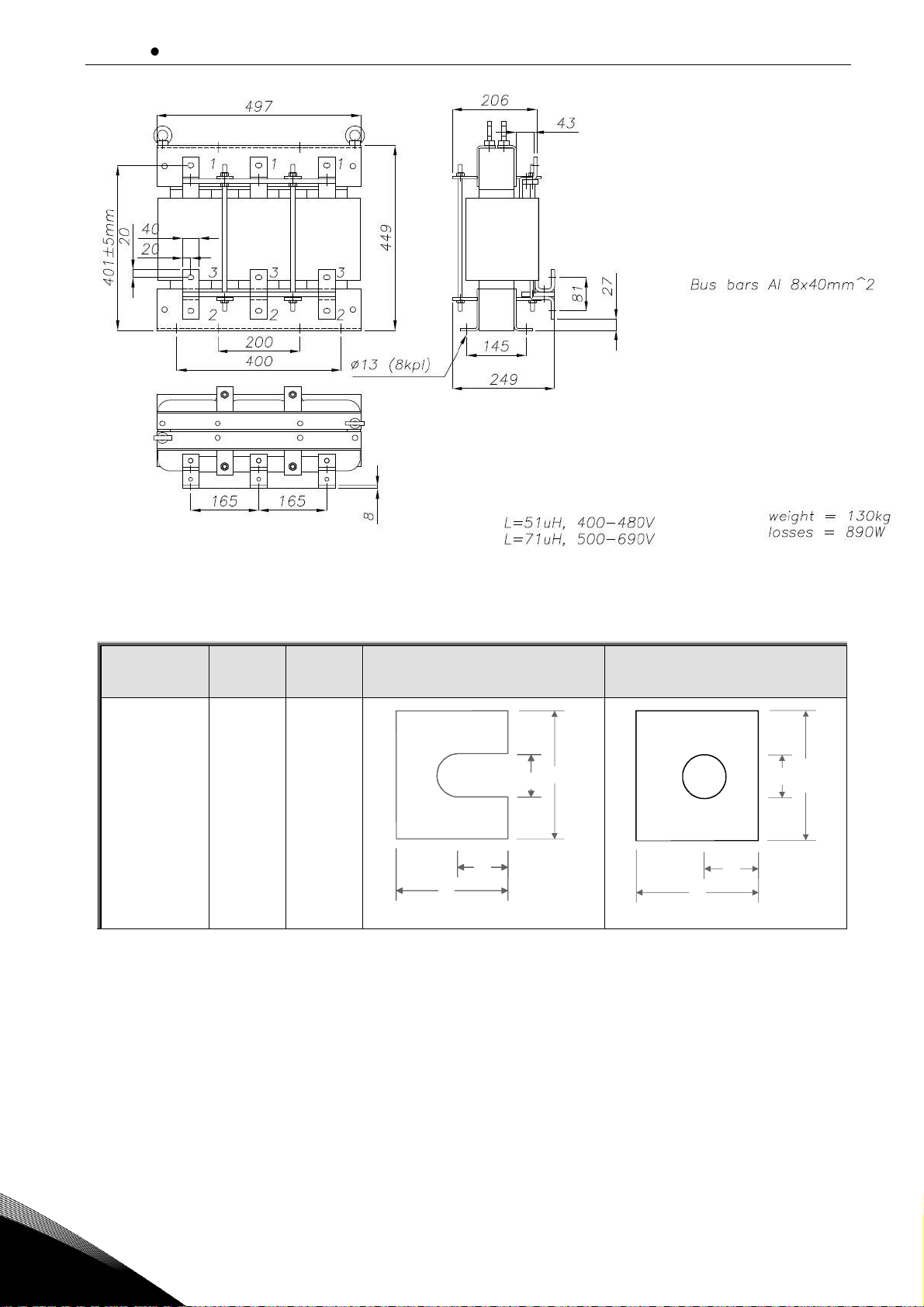

4.8 AC choke Dimensions

Module

Module Dimension

Type

Enclosure

Height

Width

Depth

Weight

[mm]

[mm]

[mm]

[kg]

AC choke

CHK-650

449

497

249

130

Table 4-5. AC choke dimensions

Note: More detailed dimensions can be found Appendix 7-5.

Page 22

vacon 21 Non-Regenerative Front End (NFE)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

4.9 Non-Regenerative Front End Fuse selection

4.9.1

Introduction

AC fuses are used to protect the input network in case the Non-Regenerative Front End unit or the

AC choke is faulty. DC fuses are used to protect the Non-Regenerative Front End unit and the AC

choke in case there is a short circuit in the DC buses. If DC fuses are not used, short-circuit in the

DC buses will cause a loading of the Non-Regenerative Front End unit. Vacon Ltd will not assume

any responsibility for damages caused by insufficient protection.

4.9.2

Fuses; mains voltage 380 690V

4.9.2.1 AC fuses

Module

AC fuses

Type

Code

Enclosure

Ferraz Shawmut

UN

[V]

IN [A]

Size

Q'ty

type [aR]*

NFE

NXN_0650 6

FI9

NH3UD69V1000PV

690

1000

3

3

Table 4-6. Ferraz Shawmut AC fuse selection, mains voltage 380 690Vac

Module

AC fuses

Type

Code

Enclosure

Bussman

UN

[V]

IN [A]

Size

Q'ty

type [aR]*

NFE

NXN_0650 6

FI9

170M6466

690

1250

3BKN/50

3

Table 4-7. Bussman AC fuse selection, mains voltage 380 690Vac

Note: All fuses are blade type. If some other type is needed please contact your nearest distributor.

4.9.2.2 DC fuses

Module

DC fuses

Type

Code

Enclosure

Ferraz Shawmut

UN

[V]

IN [A]

Size

Q'ty

type [aR]*

NFE

NXN_0650 6

FI9

PC73UD11C13CTF

1100

1250

73(LR)

2

Table 4-8. Ferraz Shawmut DC fuse selection, mains voltage 465 1100Vdc

Module

DC fuses

Type

Code

Enclosure

Bussman

UN

[V]

IN [A]

Size

Q'ty

type [aR]*

NFE

NXN_0650 6

FI9

170M8610

1000

1000

3BKN/75

2

Table 4-9. Bussman DC fuse selection, mains voltage 465 1100Vdc

Note: All fuses are flush-end type. If some other type is needed please contact your nearest distributor.

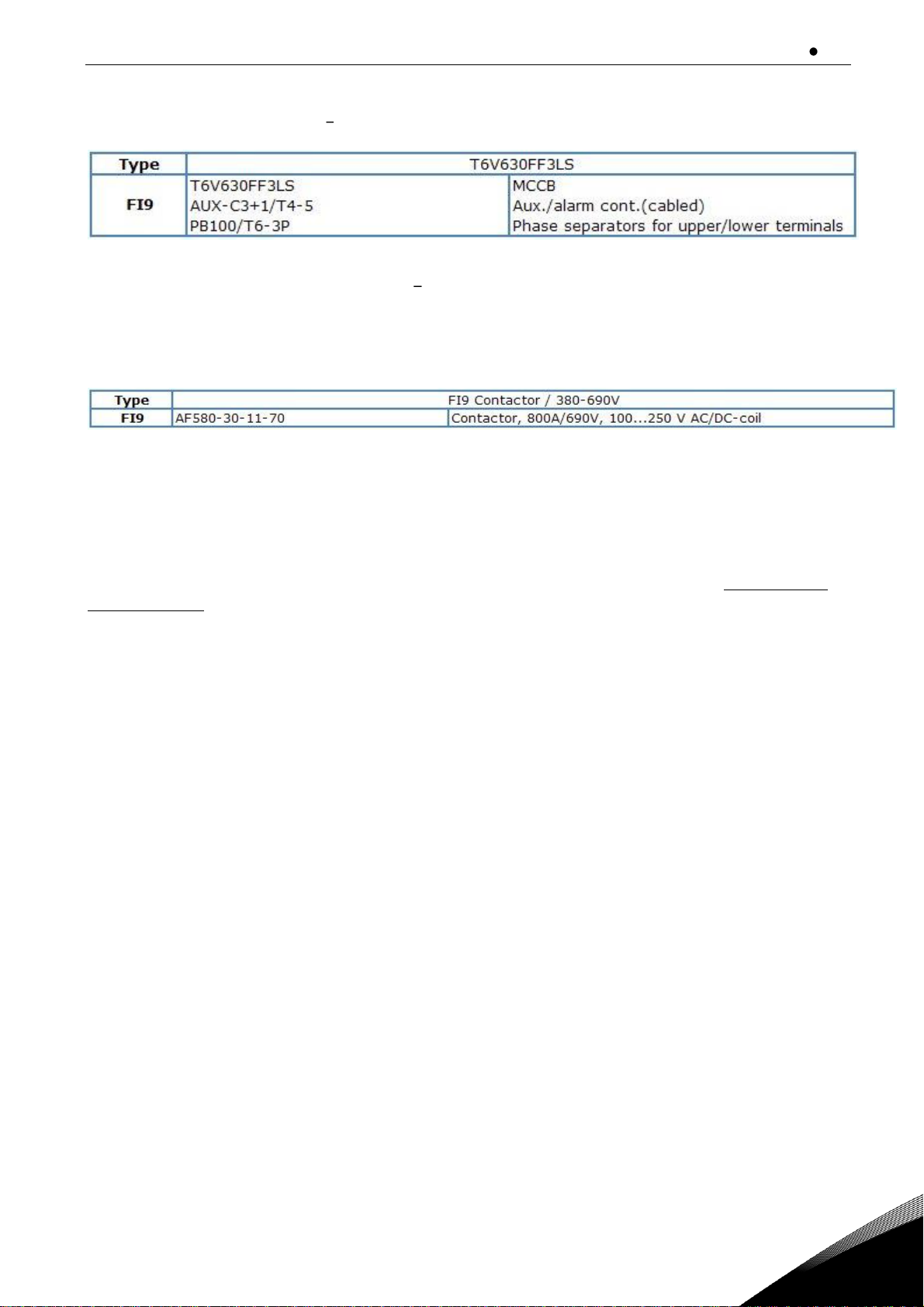

4.10 Non-Regenerative Front End unit Circuit breaker selection

The Non-Regenerative Front End can also be protected by a circuit-breaker. The recommended type

of circuit-breaker is shown in Table 4-10. If a circuit-breaker from another manufacturer is used, it

must be equivalent to the circuit-breaker shown. Further information on the circuit-breaker shown

is available from the manufacturer. Circuit-breaker does not provide the same level of protection as

Page 23

Non-Regenerative Front End (NFE) vacon 22

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

fuses. A circuit-breaker can be used without a main contactor. The circuit-breakers shown are suitable for equipment rated at 380 690 V.

Table 4-10. Circuit breaker for VACON® NXN

4.11 Non-Regenerative Front End unit Main contactor

If a main contactor is to be used, the type shown in Table 4-11 are recommended. If a contactor from

another manufacturer is used, it must be equivalent to the types shown. Further information on the

contactor shown is available from the manufacturer.

Table 4-11. Recommended main contactor type.

4.12 Pre-Charging and start up

External pre-charging circuit is not needed with the Non-Regenerative Front End. Pre-charging is

done by controlling thyristors and the DC link voltage is charged smoothly. Pre-charging is current

limit controlled. Due to this, the charging time varies depending on DC link capacitance. The NonRegenerative Front End performs charging when the main contactor is closed and a start signal is

applied to DIN1. The NFE goes into run mode after successful charging. If Non-regenerative Front

Ends are connected in parallel, each module charges DC link voltage independently. Parallel connected modules can be connected to the supply simultaneously or one module at a time. See Appendix 7-2 for the circuit diagram of parallel connected NFE modules.

The Non-Regenerative Front End monitors the pre-charging process. If the time of charging is over

the adjustable pre-charging monitoring time (default 10s) a fault is indicated. If the DC link capacitance is so high that the default value for charging monitoring is not enough, the value can be increased.

4.13 Paralleling

The power of the input group can be increased by connecting several Non-Regenerative Front End

units in parallel. No communication between the units is required; they work independently.

Each Non-Regenerative Front End unit connected in parallel must have its own short-circuit protection on AC and DC sides. The fuses are selected in accordance with Section 4.9. When paralleling,

attention must be paid to the sufficient short-circuit capacity of the system.

The derating of Non-Regenerative Front End units connected in parallel is 5% of the DC power; this

should be taken into account when selecting the input unit.

If a device is to be isolated from the AC and DC voltages, and other Non-Regenerative Front End

units connected in parallel are also to be used, separate isolators are required in the AC input and

DC output. The AC input can be isolated using a compact circuit-breaker, an ordinary circuit-breaker

or a fuse switch. Contactors are not suitable for isolating the AC input because they cannot be locked

in the safe position. The DC output can be isolated using a fuse switch. A load isolation switch or

safety isolation switch can be used for this. The device can also be connected to mains even when

the other devices connected in parallel are already connected and running. After this, the device can

be connected to the intermediate circuit.

Page 24

vacon 23 Non-Regenerative Front End (NFE)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Note: Parallel connection means that the AC supply of more than one units connected together from DC link is

coupled with the same supply transformer.

4.14 12-pulse solution

In 12-pulse solution the supply transformer has two galvanically separated secondary circuits, see

Appendix 7-3. The 12-pulse solution can reduce the effect of harmonic waves of the current in the

supply network. In order to reduce the effect of harmonics, there must be a phase displacement of

30º between the secondary circuits of the transformer. The phase displacement is implemented by

connecting one secondary circuit to triangle and the other to star. In 12-pulse solution there must be

an equal number of non-regenerative units connected to the both secondary coils of the supply

transformer.

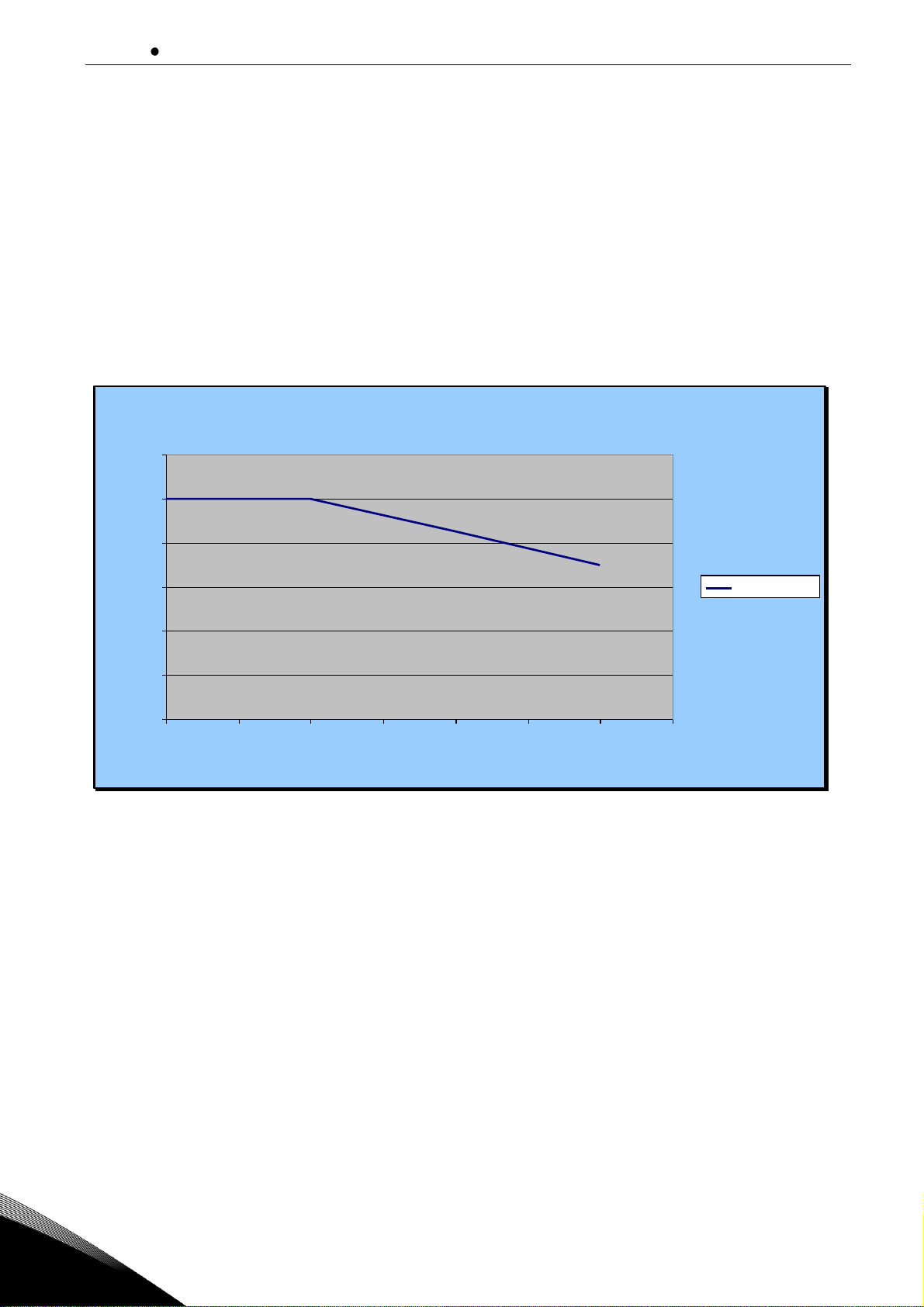

4.15 Derating

The output power has to be derated if one of following cases:

• Ambient temperature is more than 40ºC

• Installation altitude is more than 1000 m

4.15.1 As the Ambient Temperature

The power rating of the Non-Regenerative Front End unit is valid for an ambient temperature of

40ºC. If the device is to be used in higher ambient temperatures, its power rating must be subjected

to derating. The derating coefficient is 1.5%/1ºC, for ambient temperatures not exceeding 50ºC. The

reduced power is calculated using the formula:

x)/100)*C)º40(%100((* −−= tPP

nde

Pn = nominal power of the unit

t = ambient temperature

x = derating coefficient

Page 25

Non-Regenerative Front End (NFE) vacon 24

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Derating as a function of ambient temperature

50

60

70

80

90

100

110

0 10 20 30 40 50 60

Ambient temperature, ºC

Loadability, %

Loadability %

Figure 4-5. Derating as the ambient temperature.

Page 26

vacon 25 Non-Regenerative Front End (NFE)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

4.15.2 As the Installation altitude

The power rating of the Non-Regenerative Front End unit is valid for a maximum installation altitude

of 1,000 m (380-690 V). If the device is to be used in higher installation altitudes, its power rating

must be subjected to derating. The derating coefficient is 1.5%/100m. The power rating of the device

can be reduced to a maximum installation altitude of 3,000 m (380V-500V) or of 2000 m (525V-690V).

The reduced power is calculated using the formula:

x)/100)*)(%100((*

baseinstnde

hhPP −−=

Pn = nominal power of the unit

hinst = intended installation altitude

hbase = 1,000 m

x = derating coefficient

Derating as a function of installation altitude

0

20

40

60

80

100

120

0 500 1000 1500 2000 2500 3000 3500

Installation altitude, m

Loadability, %

Loadability %

Figure 4-6. Derating as the installation altitude 380-500V.

Page 27

Non-Regenerative Front End (NFE) vacon 26

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Derating as a function of installation altitude

84

86

88

90

92

94

96

98

100

102

0 500 1000 1500 2000 2500

Installation altitude, m

Loadability, %

Loadability %

Figure 4-7. Derating as the installation altitude 525-690V.

Note: If higher installation altitude than 3,000 m is required please contacts your nearest distributor to get

more information.

Page 28

vacon 27 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

5. INSTALLATION

5.1 Mounting

The equipment mounting must be sturdy enough to carry the weight of the equipment. The enclosure class of the equipment will depend on the mounting and solutions to be used. The equipment

mounting must provide sufficient shielding for contact of the live parts (IP2x). The installation and

mounting must comply with local laws and regulations.

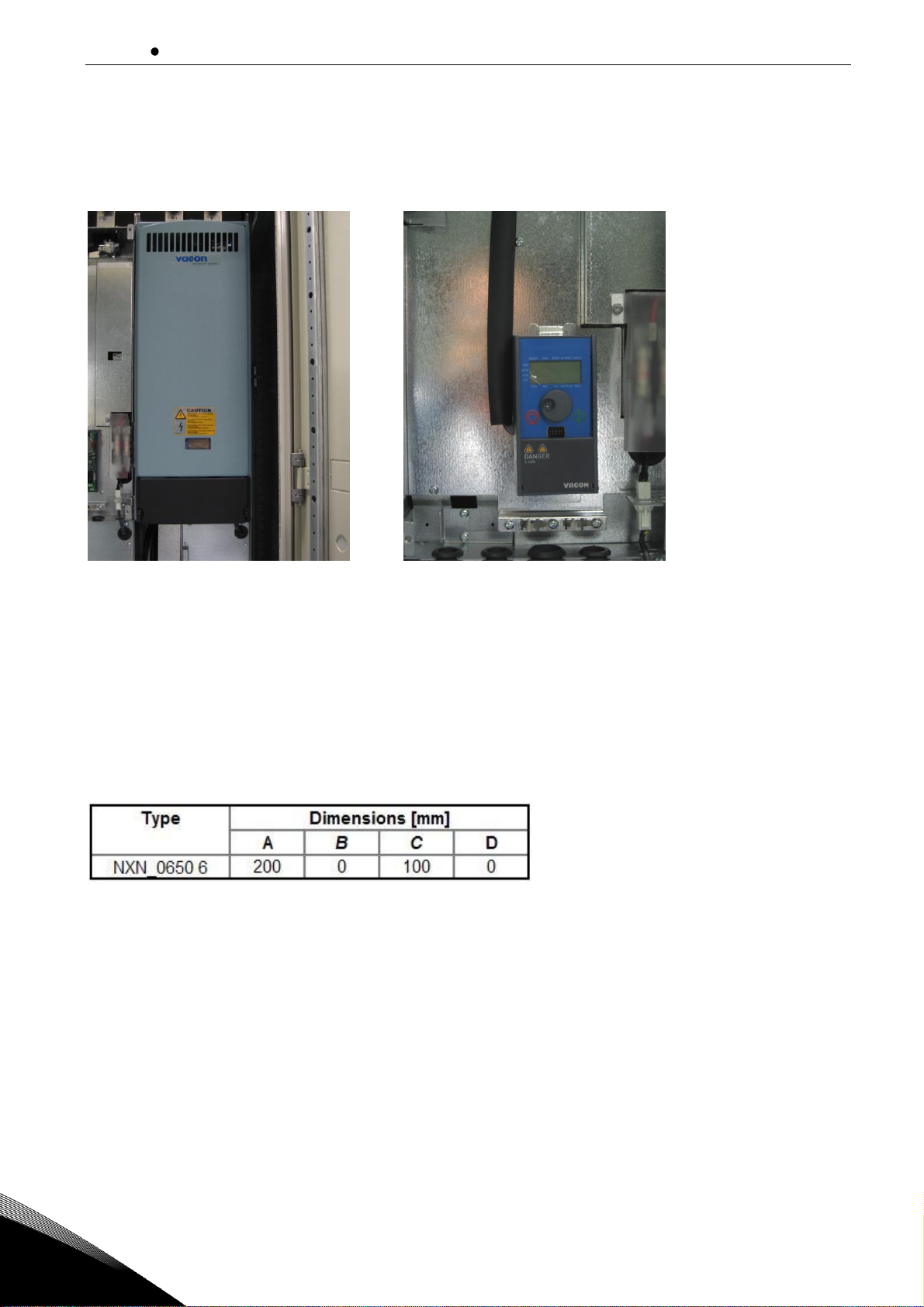

5.1.1

Non-Regenerative Front End Unit

The Non-Regenerative Front End can be mounted in a vertical position on the back plane of a cubicle. Enough space must be reserved around the Non-Regenerative Front End to ensure sufficient

cooling, see Figure 5-5. Follow the minimum dimensions for installation, see Table 5-1. Required

cooling air capacity and minimum air holes on the switchgear, see Table 5-2. Also make sure that

the mounting plane is relatively even. The Non-Regenerative Front End is fixed with four bolts, Figure 5-1.

Figure 5-1. Mounting points of FI9 NFE unit.

Page 29

Installation vacon 28

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

5.1.2

AC choke

The AC choke can only be mounted in a vertical position on the floor of a cubicle. Enough space must

be reserved around the AC choke to ensure sufficient cooling, see Figure 5-7. Follow the minimum

dimensions for installation, see Table 5-3. Required cooling air capacity and minimum air holes on

the switchgear, see Table 5-4. Also make sure that the floor is relatively even. AC choke must be attached properly so that it will not be able to move.

AC choke can be mounted so that the connectors face forward or so that they face to the side. Figure

5-2 presents a mounting where the connectors face forward. Figure 5-3 presents a mounting where

the connectors face to the side. This mounting is recommended if the Non-Regenerative Front End

units are parallel connected. In this case it must be assured that the connectors face to the same

direction and that there is enough space between the connectors and the AC choke.

Figure 5-2. Mounting of AC choke.

Figure 5-3. Mounting of parallel connected AC chokes.

Page 30

vacon 29 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

5.1.3

Control Box

The Control unit of the Non-Regenerative Front End unit is mounted under the front cover of module, see Figure 5-4. VACON® alphanumeric display and the navigation wheel can be used for parameterization and monitoring of the Non-Regenerative Front End unit.

Figure 5-4. Mounting of the control unit.

5.2 Cooling

5.2.1

Non-Regenerative Front End unit

Enough free space must be left around the Non-Regenerative Front End unit to ensure sufficient air

circulation and cooling. You will find the required dimensions for free space in the table below. You

will find the required cooling air, minimum air holes and heat dissipation in the Table 5-2.

When planning the cooling for the space, take into consideration that the Non-Regenerative Front

End unit heat loss is approx. 1% of the nominal capacity. Air flow, see Figure 5-6.

Table 5-1. Mounting space dimensions.

A = free space above the unit

B

= distance between inverter and cabinet wall

C = free space underneath of the units

D

= distance between two units

Page 31

Installation vacon 30

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Figure 5-5. Installation space for FI9.

Figure 5-6. Cooling airflow for FI9 NFE unit.

Type

Heat dissi-

pation (W)

Cooling air required

(m3/h)

Minimum air holes on

switchgear (mm2)

NXN_0650 6

2450

1150

65000

Table 5-2. Required cooling air for the Non-Regenerative Front End unit.

Page 32

vacon 31 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

5.2.2

AC choke

Enough free space must be left around the AC choke to ensure sufficient air circulation and cooling.

You will find the required dimensions for free space in the table below. You will find the required

cooling air, minimum air holes and heat dissipation in the Table 5-4.

When planning the cooling for the space, take into consideration that the AC choke heat loss is approx. 0.5% of the nominal capacity.

Table 5-3. Mounting space dimensions.

A = free space above the AC choke

B

= distance between AC choke and cabinet wall

C

= free space under the AC choke

D

= distance between AC choke and cabinet wall

E

= distance between AC choke and cabinet wall

Figure 5-7. Installation space.

Type

Heat dissi-

pation

(W)

Minimum air holes on

switchgear (mm2)

CHK-0650-6

890

30000

Table 5-4. Required cooling air for the AC choke.

Page 33

Installation vacon 32

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

5.2.3

Arranging ventilation of the enclosure

The enclosure door must be provided with air gaps for air intake. To achieve sufficient cooling inside

the cabinet, the dimensions for the total area of free openings for incoming air given in Table 5-2 and

Table 5-4 must be followed. For instance, there could be two screened gaps as presented in Figure

5-8 ( s recommendation). This layout ensures a sufficient air flow to the module fans

as well as cooling of the additional components.

Air outlet gaps must be situated on top of the cabinet. The minimum effective air outlet area per unit

frame is given in Table 5-2 and Table 5-4. The cooling arrangements inside the cabinet must be such

that they prevent hot output air from mixing with the incoming fresh air (see Chapter 5.2.4).

The ventilation gaps must fulfill the requirements set by the selected IP class. The examples in this

manual apply to protection class IP21.

During operation, air is sucked in and circulated by a fan blower at the bottom of the power unit. If

the power unit is placed in the upper part of the cabinet, the fan blower will be in the mid of the cabinet, at the height of the upper ventilation grid. In case of the AC choke is installed below the NonRegenerative Front End unit air inlet 1.1 in Figure 5-8 cannot be used.

Page 34

vacon 33 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Figure 5-8. Cabinet openings for cooling.

1. Cooling air inlets

2. Hot air exhaust

1.1

2

2

1.2

Page 35

Installation vacon 34

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

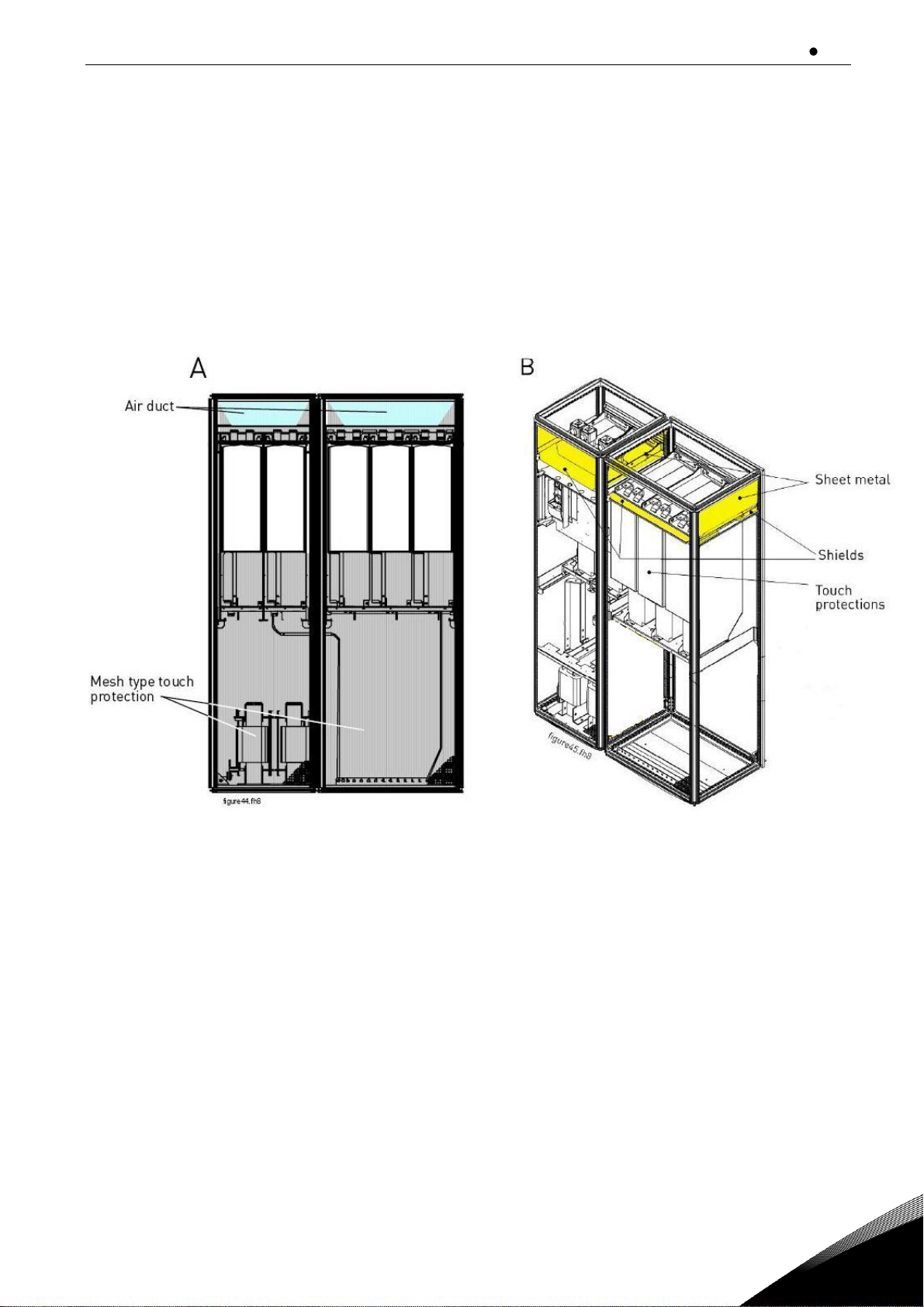

5.2.4

Steering air flow

Cooling air must be taken in through the ventilation gaps on the door and blown out at the top of the

enclosure. To steer the hot air from the power unit to the outlet at the top of the enclosure and prevent it from circulating back to the fan blower, use either of the following arrangements:

A. Install a closed air duct from the power unit to the outlet on top of the enclosure (A in

figures below).

B. Install shields in the gaps between the power unit and the cabinet walls (B in figures

below). Place the shields above the air outlet gaps at the sides of the module.

Figure 5-9. Cabinet cooling airflow guides.

The sheet metal airflow guides (deflectors) prevents air circulation between different sections of the

equipment. The shield guides in prevent air circulation inside a section. The exhaust air holes must not

be covered, nor must anything be placed above them to stop the free exit of warm air from inside the

equipment. The cooling air intake holes must not be blocked in any way.

The materials used for preventing the circulation of air inside the equipment must be fire-restraining.

The edges must be sealed to prevent the formation of gaps. When the deflectors are made according to

the instructions, no separate cooling fan is required.

NOTE! The deflectors must be installed above the air intake holes on the top (in the front) of the unit.

NOTE! If a flat roof is used, mount a V-shaped air guide on the underside of the roof to direct the air

flow horizontally. See Figure 5-10.

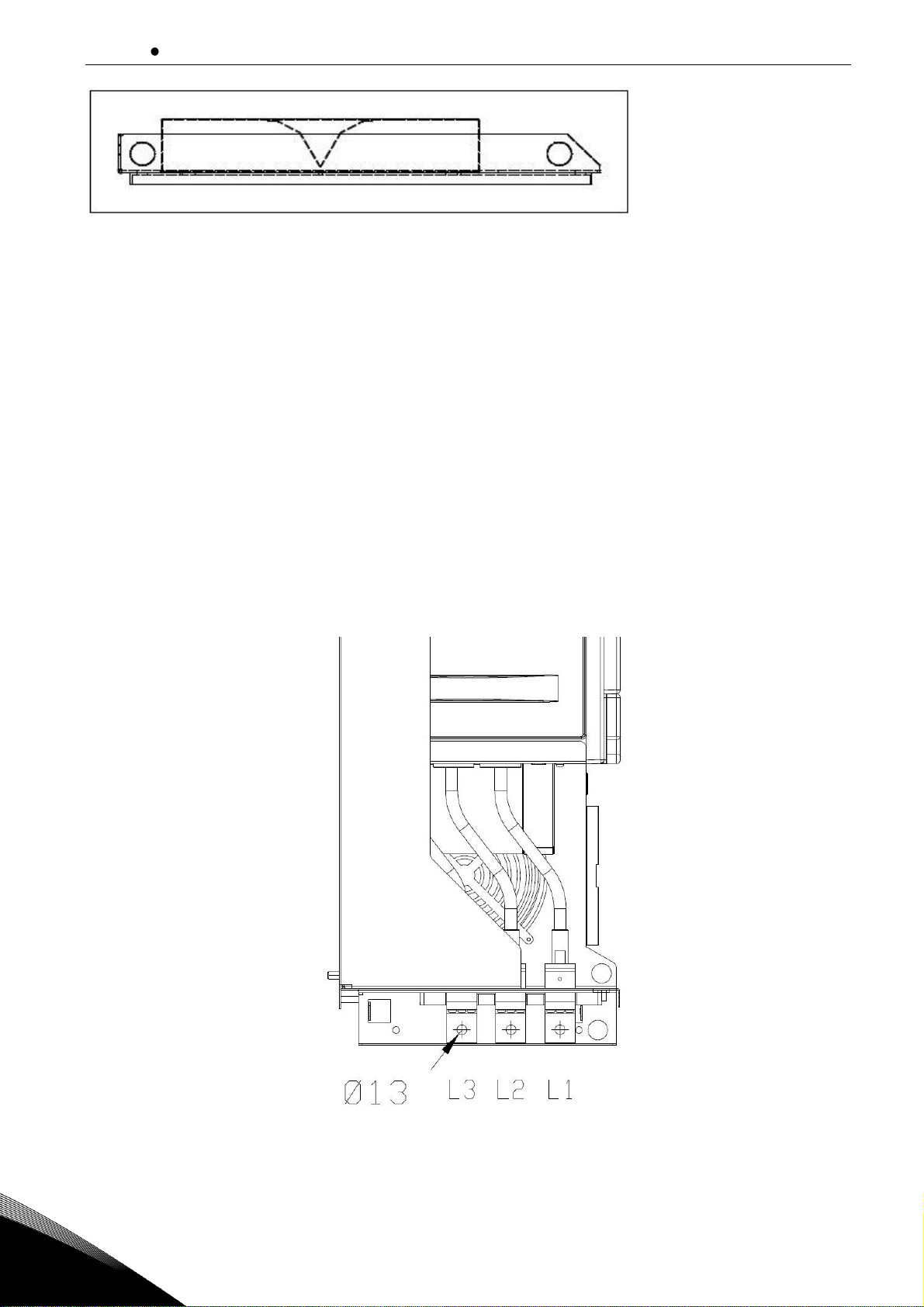

Page 36

vacon 35 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Figure 5-10. Roof structure seen from the side

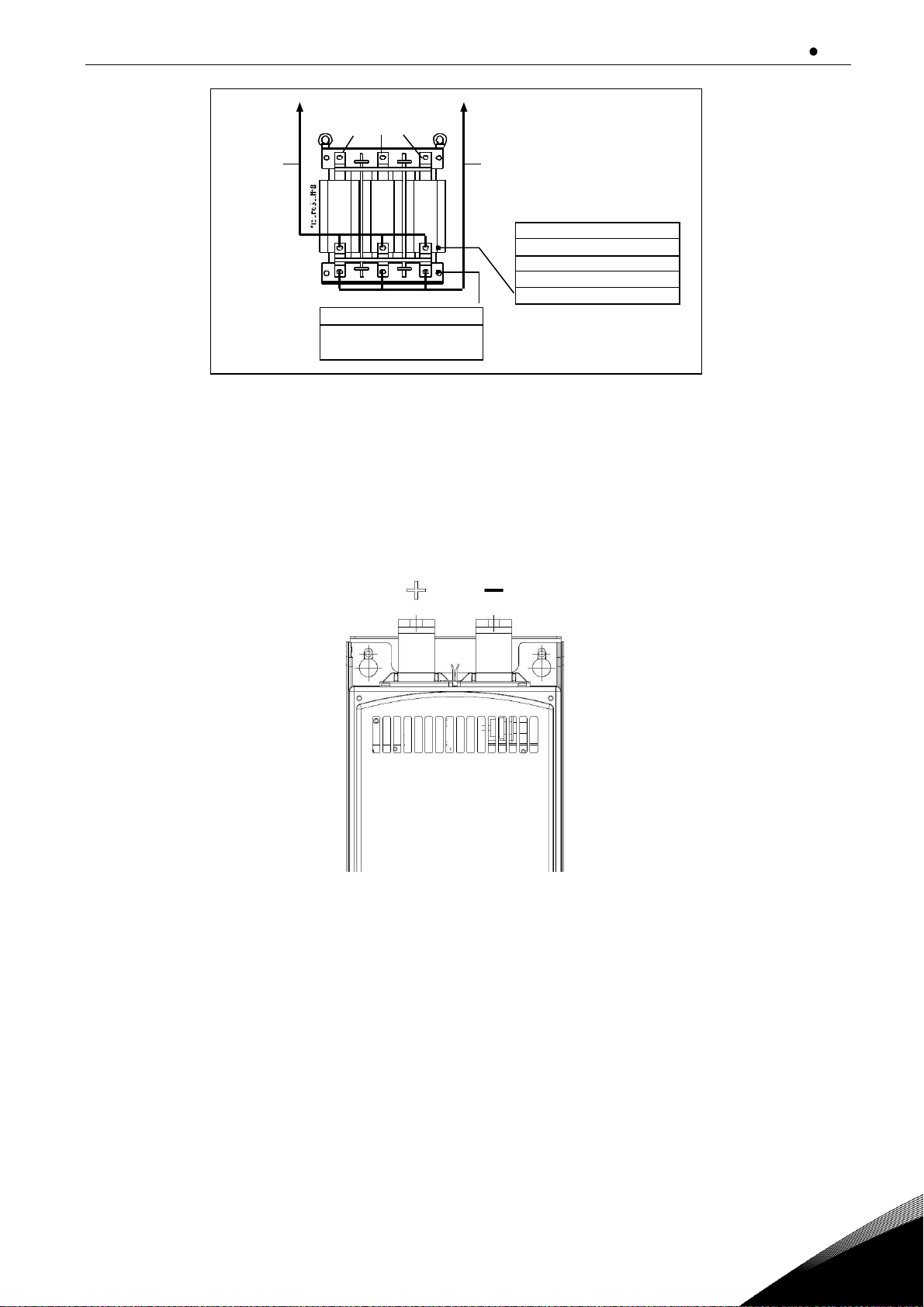

5.3 Power connection

5.3.1

AC connection

The 3-phase input is connected to the input terminals of the AC choke (L1, L2 and L3), see Figure

5-12. Used input terminal are selected by supply voltage. The output terminals of the AC choke (L1,

L2 and L3) are connected to the input terminals of the NFE unit (L1, L2 and L3), see Figure 5-11. The

AC input of the NFE input group must be protected against short circuit. The fuses suitable for protection are shown in Section 4.9. A circuit breaker can also be used for protection, see Section 4.10.

The best short-circuit protection is achieved by using fuses. The short-circuit protection must be on

the input side when seen from the AC choke, Figure 4-2.

A cable or busbar designed for the purpose must be used to make the connection. The connection

must be dimensioned according to the nominal current rating of the Non-Regenerative Front End.

The necessary overloading allowance must also be used. The connection must also have the same

short-circuit capacity as the whole system. The connecting cable or busbar may be of copper or aluminium. When aluminium is used, steps must be taken to prevent corrosion. The dimensions of the

terminals in the unit are indicated in Appendix 7-6.

Figure 5-11. FI9 unit AC connection.

Page 37

Installation vacon 36

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Figure 5-12. AC choke connections.

5.3.2

DC connection

The DC connection of the Non-Regenerative Front End unit is connected to the terminals at the top,

see Figure 5-13. The terminals are marked as B+ for connection to DC+ and B- for connection to DC. The DC connection must be protected using DC fuses, see Section 4.9. The terminal dimensions are

shown in Appendix 7-6.

Figure 5-13. FI9 unit DC connection.

5.4 Cable installation and the UL standards

To meet the UL (Underwriters Laboratories) regulations, a UL-approved copper cable with a minimum heat-resistance of +60/75C must be used.

Use Class 1 wire only.

The units are suitable for use on a circuit capable of delivering not more than 100,000 rms

symmetrical amperes, 600 V maximum, or equivalent when protected by class J, T or

Semiconductor fuses.

The tightening torques of the terminals are given below in Table 5-1.

L 1 L 2 L 3 V o l t a g e / F r e q u e n c y V o l t a g

e / F r e q u e n c y 5 0 0 V / 5 0 H z 5 7 5 V / 6 0 H z 6 9 0 V / 5 0 H z 4 0 0 V / 5 0 H z 4 8 0 V / 6 0 H z 5 2 5 V / 5 0 H z C a b l e s / b u s b a r s t o N F E u n i t C a b l e s / b u s b a r

s t o N F E u n i t T e r m i n a l s f o r s u p p l y c a b l e

s

Page 38

vacon 37 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Type

DC terminals

Tightening torque [Nm]

AC terminals

Tightening torque [Nm]

Bolt Ø

Min

Nom

Max

Bolt Ø

Min

Nom

Max

NXN_0650 6

M12

65

70

75

M10

35

40

45

Table 5-1. Tightening torques of terminals

5.5 I/O terminals and I/O signals

I/O terminals can be found under the cover of Control box, see Figure 5-14 and 5-15. Descriptions of

I/O signals see Figure 5-16.

NOTE! Digital signal out is open collector type.

Figure 5-14. Open the cover.

Page 39

Installation vacon 38

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Strip the plastic

cable coating for

360°earthing

Control cable

tightening

torque: 0.4 Nm

Figure 5-15. Cabling.

Page 40

vacon 39 Installation

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Terminal

Signal

Factory preset

Description

1

+10Vre

Ref. Voltage out

Not used

2

AI1

Analog signal in 1

Not used

3

GND

I/O signal ground

6

24Vout

24V output for DI's

7

GND

I/O signal ground

8

DI1

Digital input 1

0 = STOP

1 = START

9

DI2

Digital input 2

Not used

10

DI3

Digital input 3

1 = RESET

A A RS485 signal A

Not used

B B RS485 signal B

Not used

4

AI2

Analog signal in 2

Not used

5

GND

I/O signal ground

13

GND

I/O signal ground

14

DI4

Digital input 4

Not used

15

DI5

Digital input 5

Not used

16

DI6

Digital input 6

Not used

18

AO

Analog signal out

0 = Not used

1 = DC voltage

2 = Current

20

DO

Digital signal out

0 = Not used

1 = Ready

2 = Running

3 = Fault

4 = Fault inverted

5 = Warning

22

RO11

Relay out 1

0 = Not used

1 = Ready

2 = Running

3 = Fault

4 = Fault inverted

5 = Warning

23

RO12

24

RO21

Relay out 2

0 = Not used

1 = Ready

2 = Running

3 = Fault

4 = Fault inverted

5 = Warning

25

RO22

26

RO23

Figure 5-16. I/O signals.

Page 41

Control keypad vacon 40

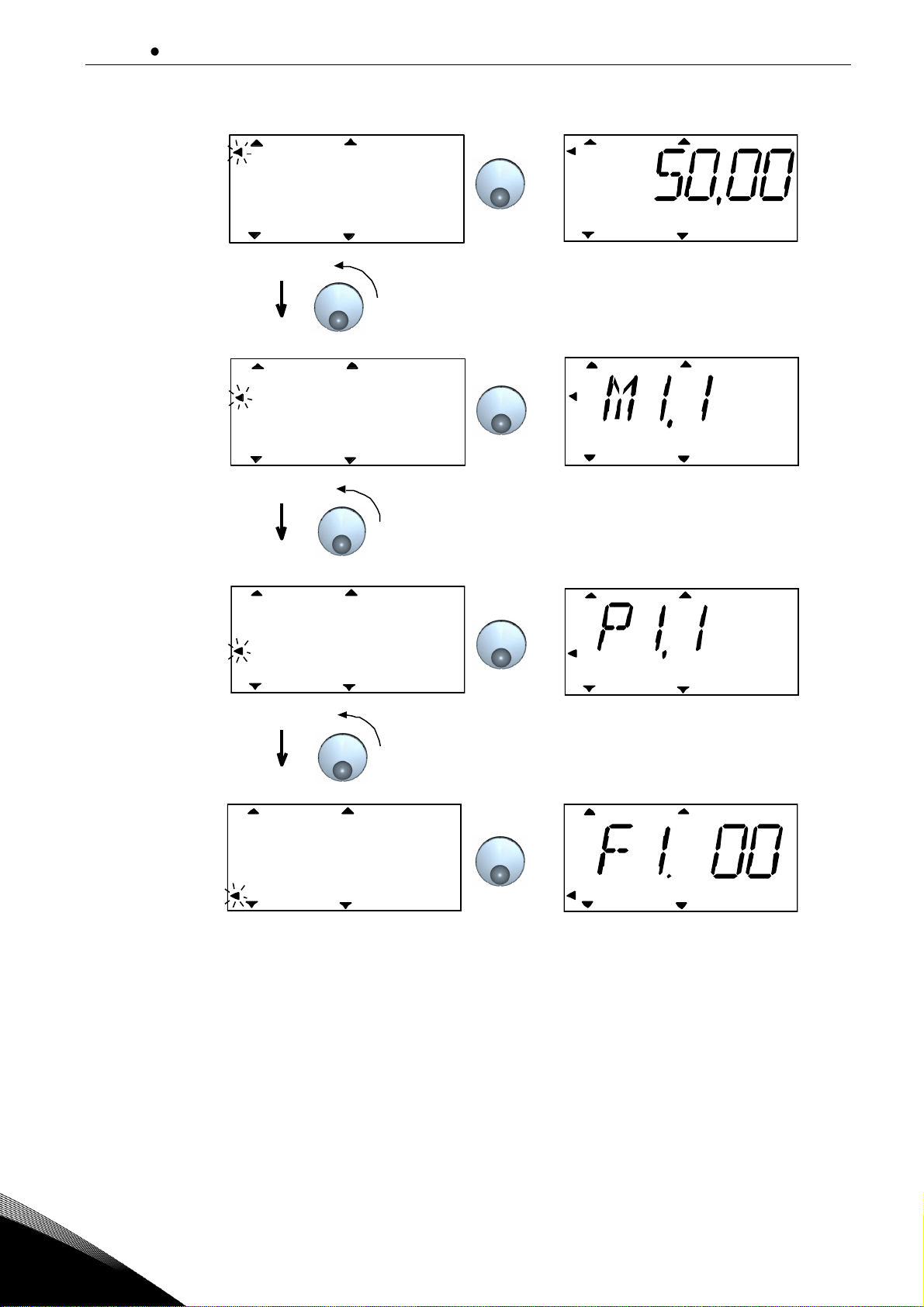

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

6. CONTROL KEYPAD

The control keypad is the link between VACON® NX Non-Regenerative Front End and the user. The

control keypad features an alphanumeric display and indicators for the status (READY, RUN, STOP,

ALARM, FAULT) and four indicators for the active menu (REF, MON, PAR, FLT). There are also three

Status Indica green red).

The control information, i.e. the menu number, description of the menu or the displayed value and

the numeric information are presented on three text lines.

The navigation wheel is used for navigating on the panel display. The wheel has two separate functions;

- rotating the wheel e.g. for changing parameter value (12 steps / round)

- pressing the wheel e.g. for accepting the new value.

Page 42

vacon 41 Control keypad

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

6.1 Navigation

Hz Hz

FWD REV I/O KEYPAD BUS

REF

MON

PAR

FLT

FAULTALARMSTOPREADY RUN

FWD REV I/O KEYPAD BUS

REF

PAR

FLT

FAULTALARMSTOPREADY RUN

MON

PUSH

FWD REV I/O KEYPAD BUS

REF

PAR

FLT

FAULTALARMSTOPREADY RUN

MON

FWD REV I/O KEYPAD BUS

REF

PAR

FLT

FAULTALARMSTOPREADY RUN

MON

PUSH

FWD REV I/O KEYPAD BUS

REF

PAR

FLT

FAULTALARMSTOPREADY RUN

MON

FWD REV I/O KEYPAD BUS

REF

PAR

FLT

FAULTALARMSTOPREADY RUN

MON

PUSH

FWD REV I/O KEYPAD BUS

REF

PAR

FLT

FAULTALARMSTOPREADY RUN

MON

ROTATE

ROTATE

ROTATE

REFERENCE

MENU

Displays the

keypad reference

value

regardless of

the selected

control place.

MONITORING MENU

In this menu

you can

browse the

monitoring

values.

PARAMETER

MENU

In this menu

you can

browse and

edit the

parameters.

FAULT MENU

Here you will

be able

to browse

through the

faults occurred.

PUSH

FWD REV I/O KEYPAD BUS

REF

MON

PAR

FLT

FAULTALARMSTOPREADY RUN

Figure 6-1. Navigation

6.1.1

Monitoring menu

Monitoring values mean actual values of measured signals as well as statuses of some control settings. Monitoring values are listed in Table 6-1.

Pushing the navigation wheel once in this menu takes the user to the next level, where the monitoring value, e.g. M1.1 and value is visible (see Figure 6-2). The monitoring values can be browsed by

rolling the navigation wheel clockwise.

Page 43

Control keypad vacon 42

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Hz

FAULTALARMSTOPREADY RUN

REF

MON

PAR

FLT

FWD REV I/O KEYPAD BUS

Alternates

in the display

Browse

M1.1 - M1.20

Figure 6-2. Monitoring menu

Code

Parameter

Scale

Unit

Description

M1.1

U_DCLINK

1 V DC voltage

M1.2

IL1 1 A

Current of phase 1

M1.3

IL2 1 A

Current of phase 2

M1.4

IL3 1 A

Current of phase 3

M1.5

UL12

1 V Voltage between phases L1-L2

M1.6

UL23

1 V Voltage between phases L2-L3

M1.7

UL31

1 V Voltage between phases L3-L1

M1.8

Isum

1 A Total average AC current

M1.9

Temp

1

˚C

Unit Temperature

Table 6-1. Monitoring signals.

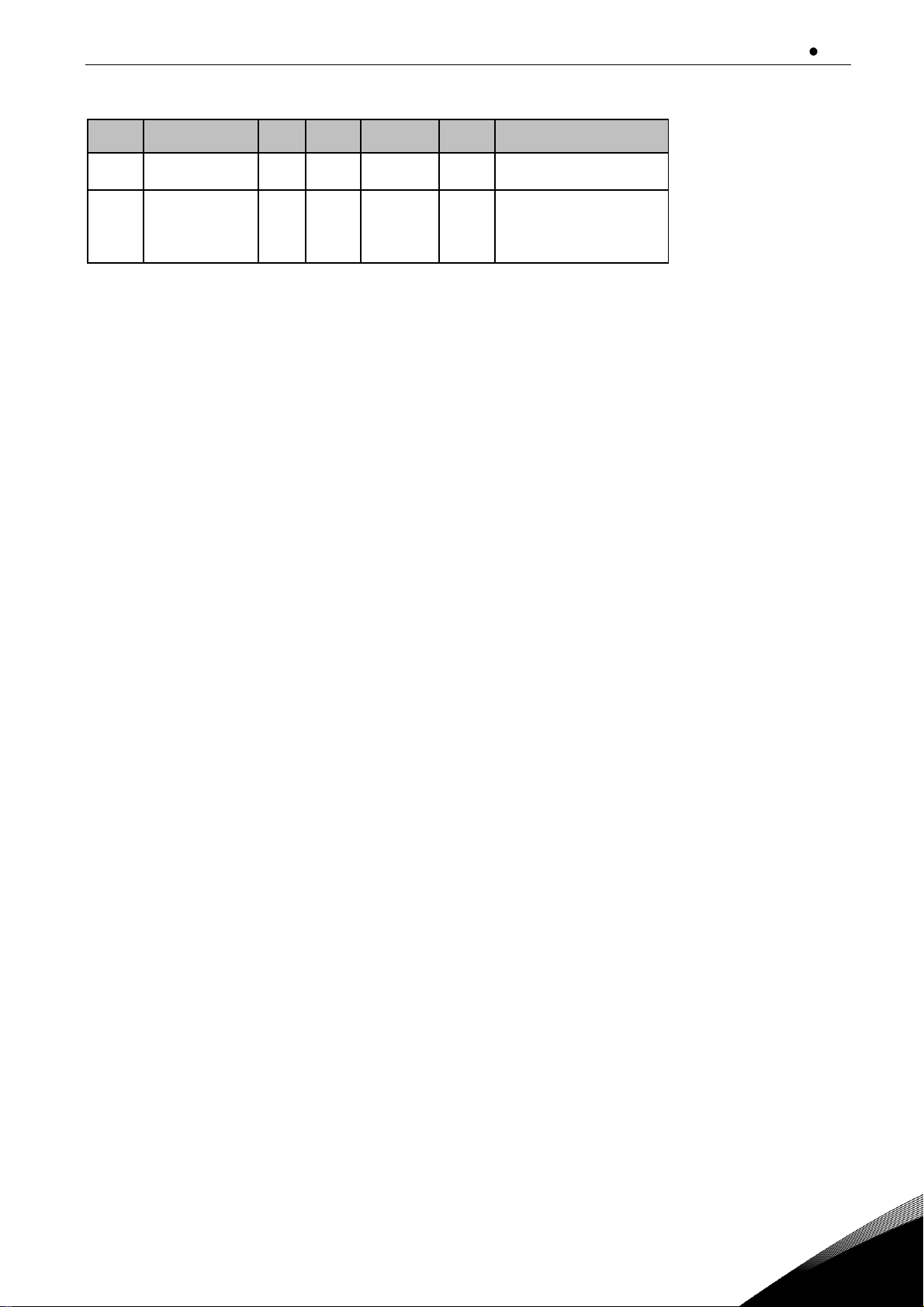

6.1.2

Parameter menu

In Parameter menu all settable parameters are visible. The parameters can be browsed by rolling

the navigation wheel clockwise. Pushing the navigation wheel once in this menu takes the user to

the next level, where the parameter value, e.g. P3.1 and value is visible (see Figure 6-3). Parameters

are listed below.

The following figure shows the parameter menu view:

Page 44

vacon 43 Control keypad

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Hz

FAULTALARMSTOPREADY RUN

REF

MON

PAR

FLT

FWD REV I/O KEYPAD BUS

Alternates

in the display

Browse

P1.1 ->

Push to enter

edit mode

Change

value

Push to

confirm

Figure 6-3. Parameter menu

Digital outputs

Code

Parameter

Min

Max

Default

Unit

Description

P1.1

Relay output 1

0 5 0

0 = Not used

1 = Ready

2 = Running

3 = Fault active

4 = Fault inverted

5 = Warning active

P1.2

Relay output 2

0 5 0

0 = Not used

1 = Ready

2 = Running

3 = Fault active

4 = Fault inverted

5 = Warning active

P1.3

Digital output 1

0 5 0

0 = Not used

1 = Ready

2 = Running

3 = Fault active

4 = Fault inverted

5 = Warning active

Analog outputs

Code

Parameter

Min

Max

Default

Unit

Description

P2.1

Analog output

funtion

0 2 0

0 = Not used

1 = DC voltage

2 = Current

P2.2

Analog output

minimum

0 1 0

0 = 0mA

1 = 4mA

P2.1 Analog output function

If the DC voltage is selected scaling is 0/4mA = 0VDC and 20mA = 1000VDC. If the current is

selected scaling is 0/4mA = 0A and 20mA = 650A.

Page 45

Control keypad vacon 44

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

NFE parameters

Code

Parameter

Min

Max

Default

Unit

Description

P3.1

Load time

limit

1

20

10

s

P3.2

Over voltage

limit

440

1300

1300

V

P3.3

Over current

limit

51

1014

780

A

P3.1 Load time limit

If the pre-charging is longer than the level set by this parameter then loading time fault is

triggered.

P3.2 Over voltage limit

If the DC link voltage is higher than the level set by this parameter then over voltage fault is

triggered.

P3.3 Over current limit

If the input current is higher than the level set by this parameter then over current fault is

triggered.

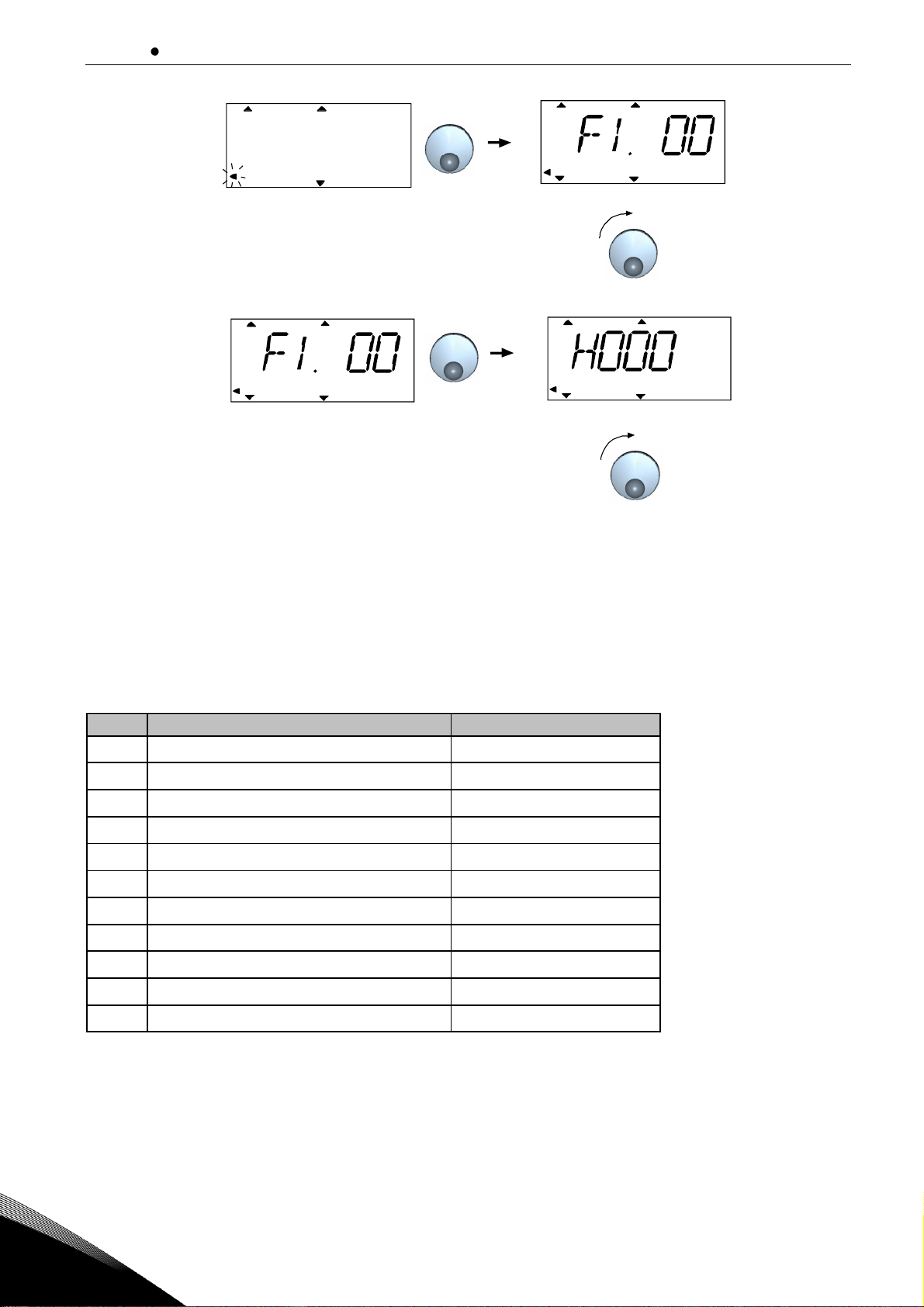

6.1.3

Fault history menu

In Fault history menu you can browse through 9 latest faults (see Figure 6-4). If a fault is active, the

relevant fault number (e.g. F2) alternates in the display with main menu. When you browse between

the faults, the fault codes of active faults are blinking. The active faults can be reset by pressing the

STOP button for 1 second. If the fault cannot be reset, the blinking continues. It is possible to navigate in the menu structure also when there are active faults present, but the display returns automatically to the fault menu if buttons or navigation wheel are not pressed or navigation is not rotated. The operating hour, minute and second values at the fault instant are shown in the value menu

(operating hours = displayed reading x 1000 h). Fault codes are listed in Table 6-2.

Page 46

vacon 45 Control keypad

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

FAULTALARMSTOPREADY RUN

REF

MON

PAR

FLT

FWD REV I/O KEYPAD BUS

FAULTALARMSTOPREADY RUN

REF

MON

PAR

FLT

FWD REV I/O KEYPAD BUS

FAULTALARMSTOPREADY RUN

REF

MON

PAR

FLT

FWD REV I/O KEYPAD BUS

FAULTALARMSTOPREADY RUN

REF

MON

PAR

FLT

FWD REV I/O KEYPAD

Browse

faults 1-9

Push

Push

Browse

for hours (H),

minutes (M)

and seconds (S)

Figure 6-4. Fault history menu

Note! The whole fault history can be cleared by pressing STOP button for 5 sec time

when the drive is stopped and fault history menu is selected in the display.

Note! If STOP button is pressed for 5 sec and no any menu is selected in the display fac-

tory reset is done. Factory reset set all parameters to default values!

Fault

Description

Default limit value

F1

Over current

780 A

F2

Over voltage

1300 Vdc

F4

Loading time fault

10 s

F8

System Fault

F9

Under voltage

(Supply voltage * 0.8*1.35)

F11

Input phase loss

F13

Under temperature

<-10 / ˚C

F14

Over temperature

>80 / ˚C

F22

EEPROM fault

F32

Fan/Inverter fault

F99

Communication interrupted API/Power

Table 6-2. Fault codes.

Page 47

Control keypad vacon 46

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

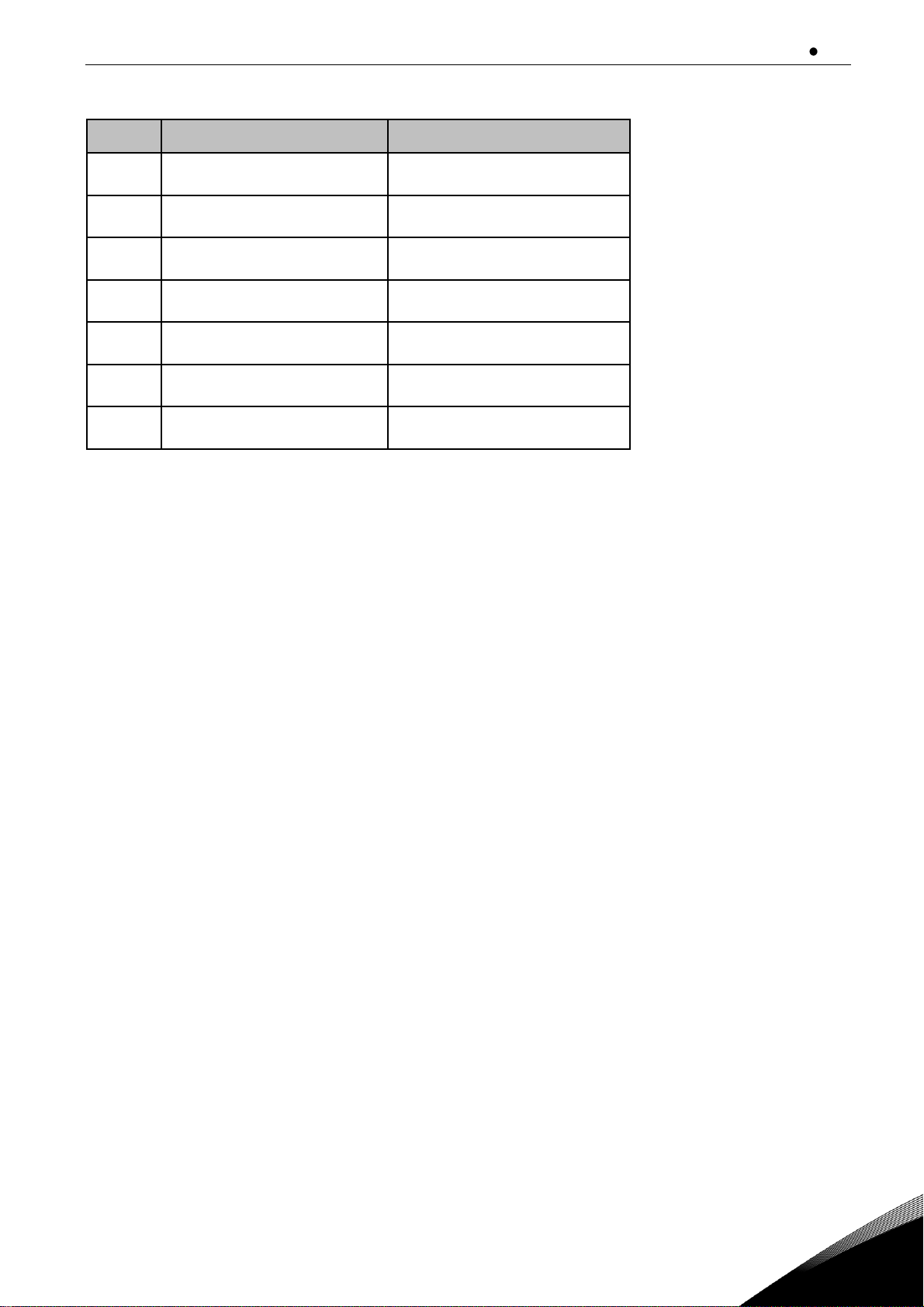

6.1.4

System menu

Code

Parameter

Description

S1.1

API SW ID

S1.2

API SW Version

S1.3

Power SW ID

S1.4

Power SW Version

S1.5

Application SW ID

S1.6

Application SW Version)

S1.7

CPU Load

Table 6-3. System menu signals.

Page 48

vacon 47 Appendices

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

7

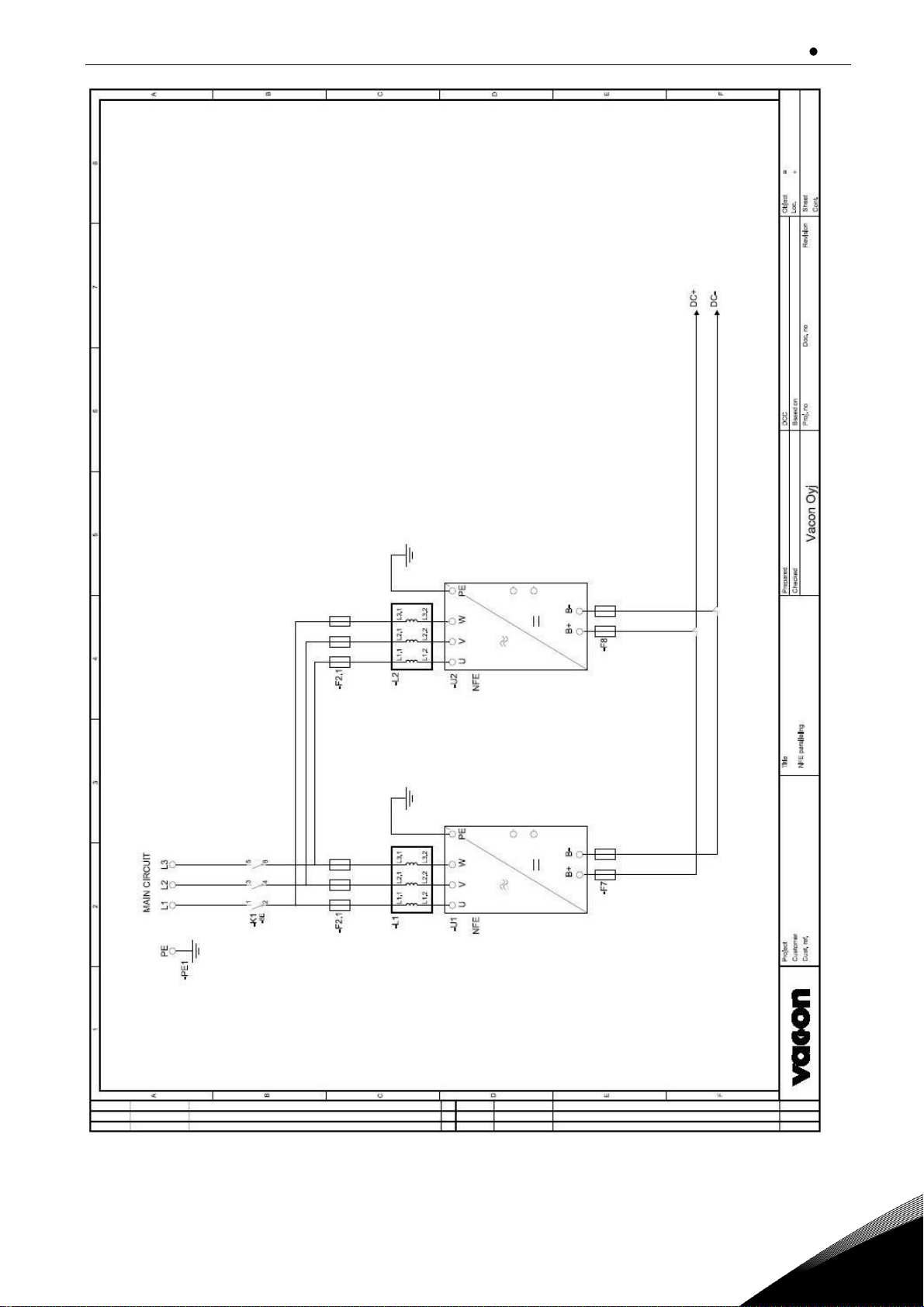

7. APPENDICES

Appendix 7-1. Circuit diagram for NFE.

Page 49

Appendices vacon 48

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

7

Appendix 7-2. Circuit diagram for parallel connected NFE.

Page 50

vacon 49 Appendices

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

7

Appendix 7-3. Circuit diagram for 12- pulse solution with NFE.

Page 51

Appendices vacon 50

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

7

Appendix 7-4. FI9 Dimensions

Page 52

vacon 51 Appendices

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

7

Appendix 7-5. AC choke dimensions

Enclosure

Type

IL

[A]

DC terminal

AC Terminal

NXN_0650 6

FI9

650

PE: M8×25

Appendix 7-6.Terminal sizes for VACON

®

NX Non-regenerative Front End unit.

40

13

35

16

6 x 40

13

38

17

Page 53

www.danfoss.com

Vacon Ltd

Member of the Danfoss Group

Runsorintie 7

65380 Vaasa

Finland

Document ID:

DPD01172C

Rev. C

Sales code: DOC-USERNXNNFE+DLUK

Loading...

Loading...