Page 1

vacon

®

nx

ac drives

apfiff10 sia-i

System Interface

application manual

Page 2

Page 3

apfiff10 sia-i VACON® • 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

System Interface Application

INDEX

Document code: ud01079

Software Code: APFIFF10V244

Date: 24.4.2019

1. INTRODUCTION .............................................................................................................. 5

2. CONTROL I/O ................................................................................................................. 6

3. SYSTEM INTERFACE APPLICATION PARAMETER LISTS ................................................ 7

3.1 Monitoring Values .......................................................................................................................... 7

3.1.1 Monitor Page 1 ....................................................................................................................... 8

3.1.2 Monitor Page 2 ....................................................................................................................... 8

3.1.3 PI-Controller Monitoring ...................................................................................................... 9

3.2 Basic Parameters ........................................................................................................................ 10

3.3 Input Signals ................................................................................................................................ 11

3.3.1 Digital Input .......................................................................................................................... 11

3.3.2 Analogue Input ..................................................................................................................... 12

3.4 Output Signals .............................................................................................................................. 13

3.4.1 Digital Output ....................................................................................................................... 13

3.4.2 Analogue Output .................................................................................................................. 14

3.5 Reference Handling ..................................................................................................................... 14

3.6 Ramp Functions ........................................................................................................................... 16

3.7 Drive Control ................................................................................................................................ 17

3.7.1 Drive Control/Open Loop Ctrl ............................................................................................. 18

3.7.2 Drive Control/UV/OV CTRL stab ......................................................................................... 19

3.8 Motor Control ............................................................................................................................... 20

3.8.1 PMSM Control ...................................................................................................................... 21

3.9 Limit Settings ............................................................................................................................... 22

3.10 Speed Control............................................................................................................................... 23

3.11 Oscillation Damp .......................................................................................................................... 24

3.12 Brake & Fan Control .................................................................................................................... 25

3.13 Master Follower ........................................................................................................................... 26

3.14 Protections ................................................................................................................................... 27

3.15 Flux Reference Handling ............................................................................................................. 29

3.16 Startup Torque ............................................................................................................................. 29

3.17 Monitor Settings ........................................................................................................................... 29

3.18 Data Mapping ............................................................................................................................... 30

3.19 PI Control Parameters ................................................................................................................ 30

3.19.1 Connect DIN -> ID 1 ......................................................................................................... 31

3.19.2 Connect DIN -> ID 2 ......................................................................................................... 31

3.19.3 Connect DIN -> ID 3 ......................................................................................................... 31

3.19.4 Value Control ................................................................................................................... 32

3.20 Keypad Control ............................................................................................................................. 32

3.21 Expander Boards ......................................................................................................................... 32

Page 4

4 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4. DESCRIPTION OF THE SYSTEM INTERFACE APPLICATION PARAMETERS ..................... 33

4.1 Input Signals ................................................................................................................................ 35

4.1.1 Digital Input .......................................................................................................................... 35

4.1.2 Analogue Input ..................................................................................................................... 39

4.1.3 Digital Output ....................................................................................................................... 41

4.1.4 Analogue output................................................................................................................... 41

4.2 Reference Handling ..................................................................................................................... 42

4.3 Ramp Functions ........................................................................................................................... 44

4.4 Drive Control ................................................................................................................................ 46

4.4.1 Open Loop Control ............................................................................................................... 51

4.4.2 Undervoltage/Overvoltage Control, Stabilator .................................................................. 53

4.5 Motor Control ............................................................................................................................... 55

4.6 PMSM Control .............................................................................................................................. 59

4.7 Limit Settings ............................................................................................................................... 60

4.8 Speed control ............................................................................................................................... 62

4.9 Oscillation Damp .......................................................................................................................... 67

4.10 Brake and fan control .................................................................................................................. 67

4.11 Master Follower ........................................................................................................................... 68

4.12 Protections ................................................................................................................................... 71

4.13 Flux Reference Handling ............................................................................................................. 79

4.14 Startup Torque ............................................................................................................................. 80

4.15 Monitor Settings ........................................................................................................................... 81

4.16 Data Mapping ............................................................................................................................... 81

4.17 PI Control...................................................................................................................................... 82

4.18 ID Functions ................................................................................................................................. 83

4.18.1 Value Control ................................................................................................................... 84

5. FIELDBUS PROFILE ...................................................................................................... 86

5.1 PD Signals from the Overriding system to the Vacon Drive. .................................................... 86

5.2 PD Signals from the Vacon Drive to the Overriding System ..................................................... 86

5.3 Main Control Word ID1160 .......................................................................................................... 87

5.4 Main Status Word ID1162 ............................................................................................................ 88

5.5 Auxiliary Control Word ID1161 .................................................................................................... 89

5.6 Auxiliary Status Word ID1163 ...................................................................................................... 90

5.7 Fault Word 1 ID1172 .................................................................................................................... 91

5.8 Fault Word 2 ID1173 .................................................................................................................... 92

5.9 Alarm Word 1 ID1174 ................................................................................................................... 93

5.10 Digital Input Status 1 and 2: ID15 and ID16 ................................................................................ 94

6. BLOCK DIAGRAMS ................................................................ ........................................ 95

7. FAULT TRACING ......................................................................................................... 100

Page 5

apfiff10 sia-i VACON® • 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

System Interface Application (apfiff10 sia-i)

1. INTRODUCTION

The System Interface Application is typically used in coordinated drives with overriding control

system. The recommended interface to control the system is a fieldbus communication through

hardwired analogue and digital signals as well as keypad and PC control can be used.

Note! When the drive is controlled through fieldbus, the fieldbus card must be set to Bypass mode.

The System Interface Application utilises most advanced functions in NXP motor control software

and is suitable for demanding drive systems like paper machines and drives in metal industry and

processing lines. It can also be used for any other standard applications. Following applications are

working with this application.

• Pulp and paper machine drives like dryer, press section, wire section, pope reel, winder and

unwinder.

• Drives in metal industry like casting machine, melt shop or preparing line

• Standard drives like pump and fan, lifts, cranes, conveyors, etc.

Additional functions:

• Flexible speed and torque reference chains.

• Advanced drive control profile for fieldbus communication

• Flexible fieldbus data connections.

• Adaptive speed controller.

• Inertia compensation and oscillation damping features.

• System Bus support for master follower applications with speed/torque follower.

• Fast and multi drive monitoring tool (NCDrive) support.

• Programmable U/f curve and flux curve.

• Speed /torque-selector options, window control

• Automatic identification run

• Support to permanent magnet motors and multiple winding motors.

Page 6

6 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

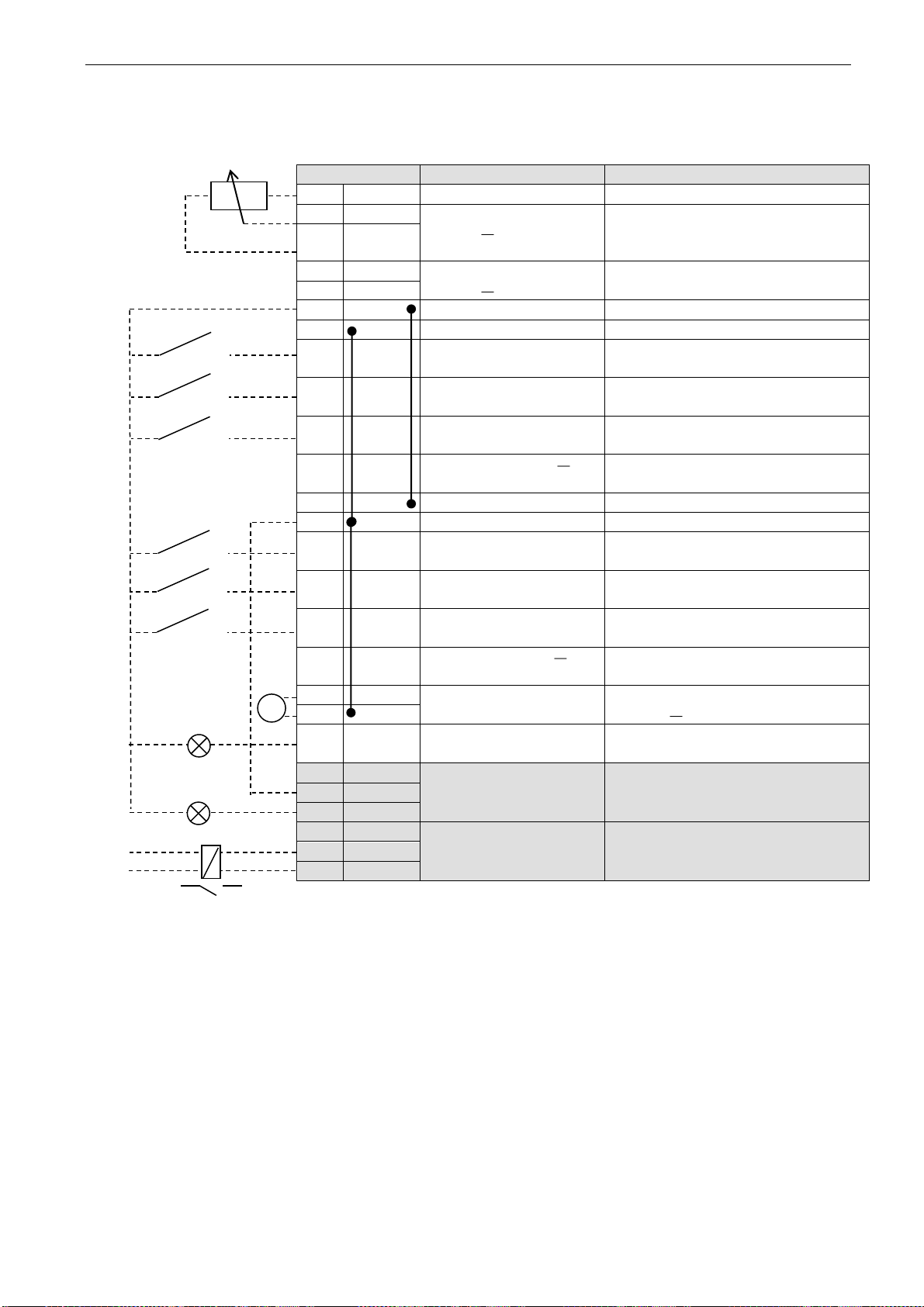

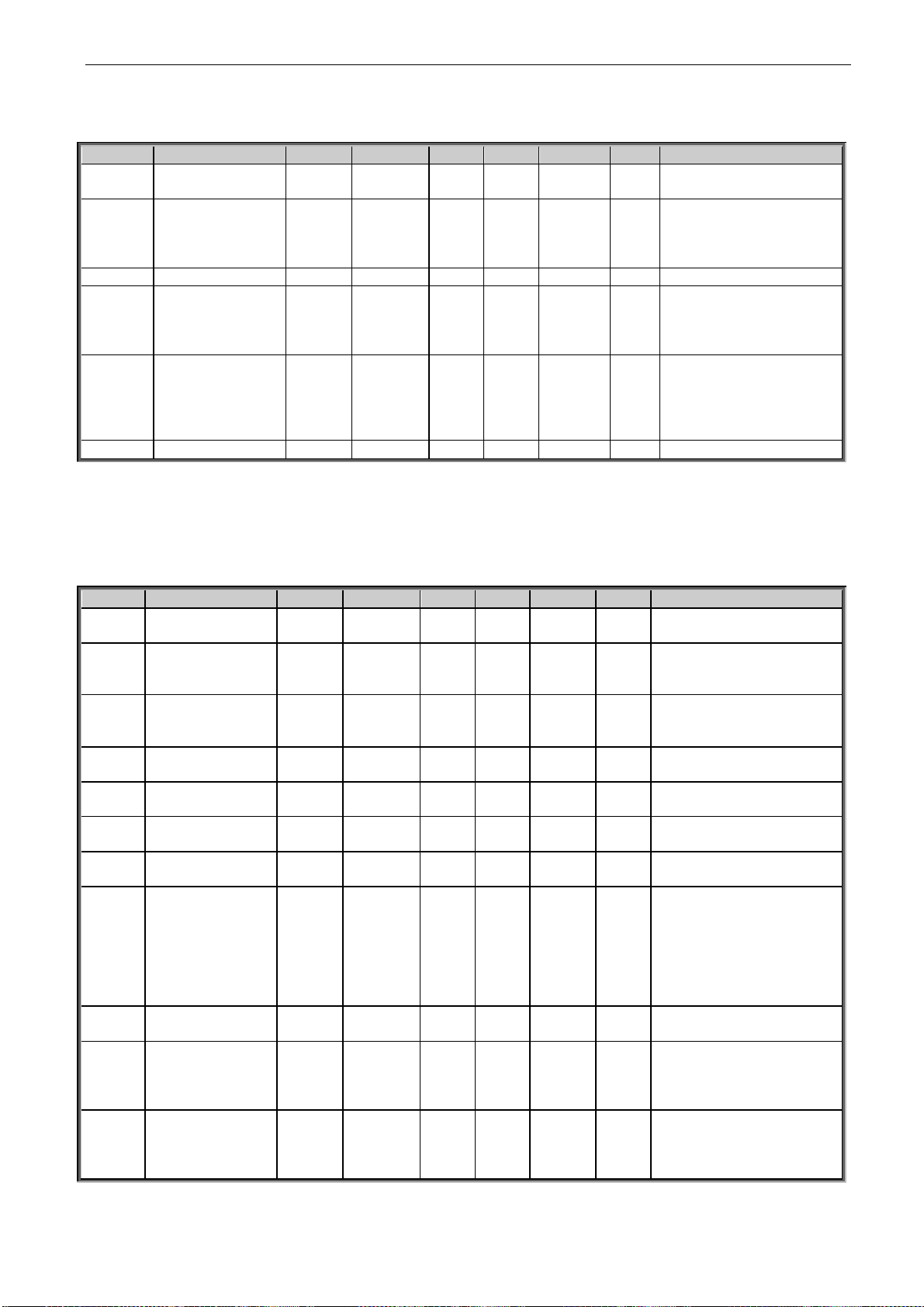

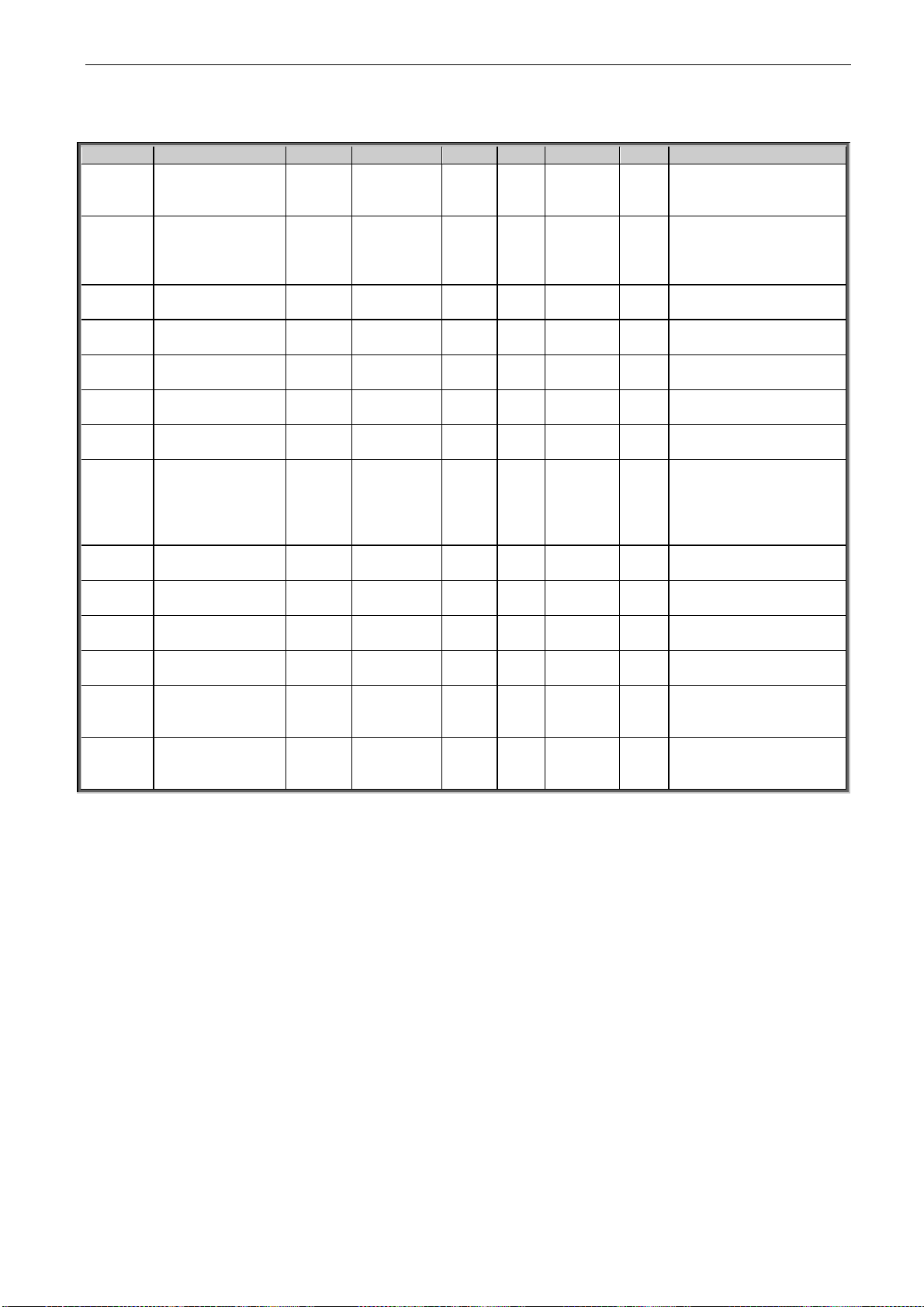

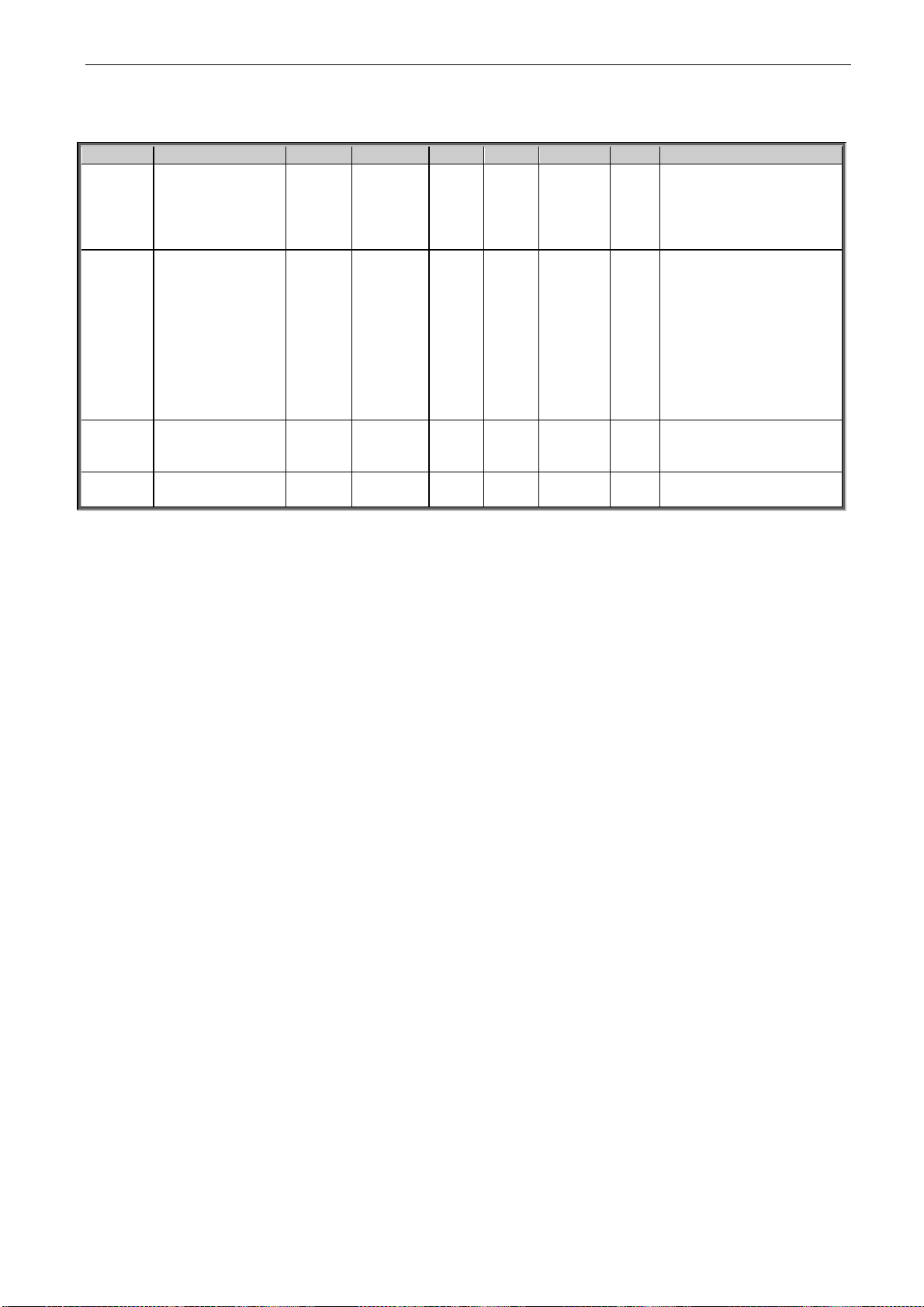

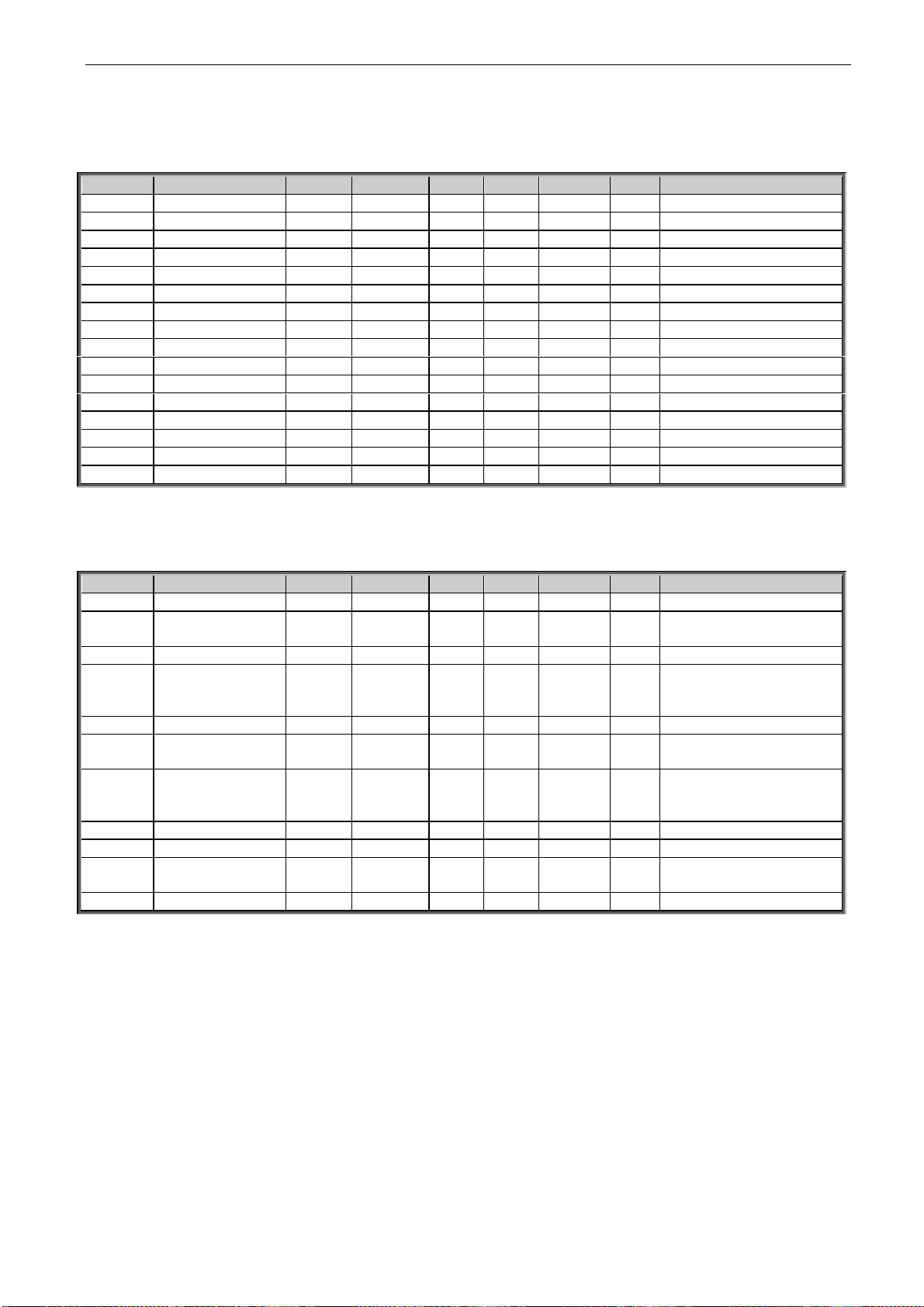

2. CONTROL I/O

Terminal

Signal

Description

1

+10V

Reference output

Voltage for potentiometer, etc.

2

AI1+

Analogue input, voltage

range 0 10V DC

Voltage input frequency reference

3

AI1-

4

AI2+

Analogue input, current

range 0 20mA

Current input frequency reference

5

AI2-

6

+24V

Control voltage output

Voltage for switches, etc. max 0.1 A

7

GND

I/O ground

Ground for reference and controls

8

DIN1

Digital input 1

(Programmable)

9 DIN2

Digital input 2

(Programmable)

10

DIN3

Digital input 3

(programmable)

11

CMA

Common for DIN 1

DIN 3

Connect to GND or +24V

12

+24V

Control voltage output

Voltage for switches (see #6)

13

GND

I/O ground

Ground for reference and controls

14

DIN4

Digital input 4

Run Enable

Contact closed = Run Enable

Contact open =Run Disable

15

DIN5

Digital input 5

Main Switch Ack.

Contact closed = Switch is closed.

Contact open= Switch is open.

16

DIN6

Digital input 6

Emergency Stop

Contact open= EmstopActive.

Contact closed = Emstop not active.

17

CMB

Common for DIN4

DIN6

Connect to GND or +24V

18

AOA1+

Programmable

Programmable

Range 0 20 mA/RL, max. 500

19

AOA1-

20

DOA1

Digital output

READY

Programmable

Open collector, I50mA, U48 VDC

21

RO1

Relay output 1

RUN

Programmable

22

RO1

23

RO1

24

RO2

Relay output 2

DC bus Charging OK

Programmable

25

RO2

26

RO2

Table 1. System Interface Application default I/O configuration.

mA

READY

RUN

220

Page 7

apfiff10 sia-i VACON® • 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

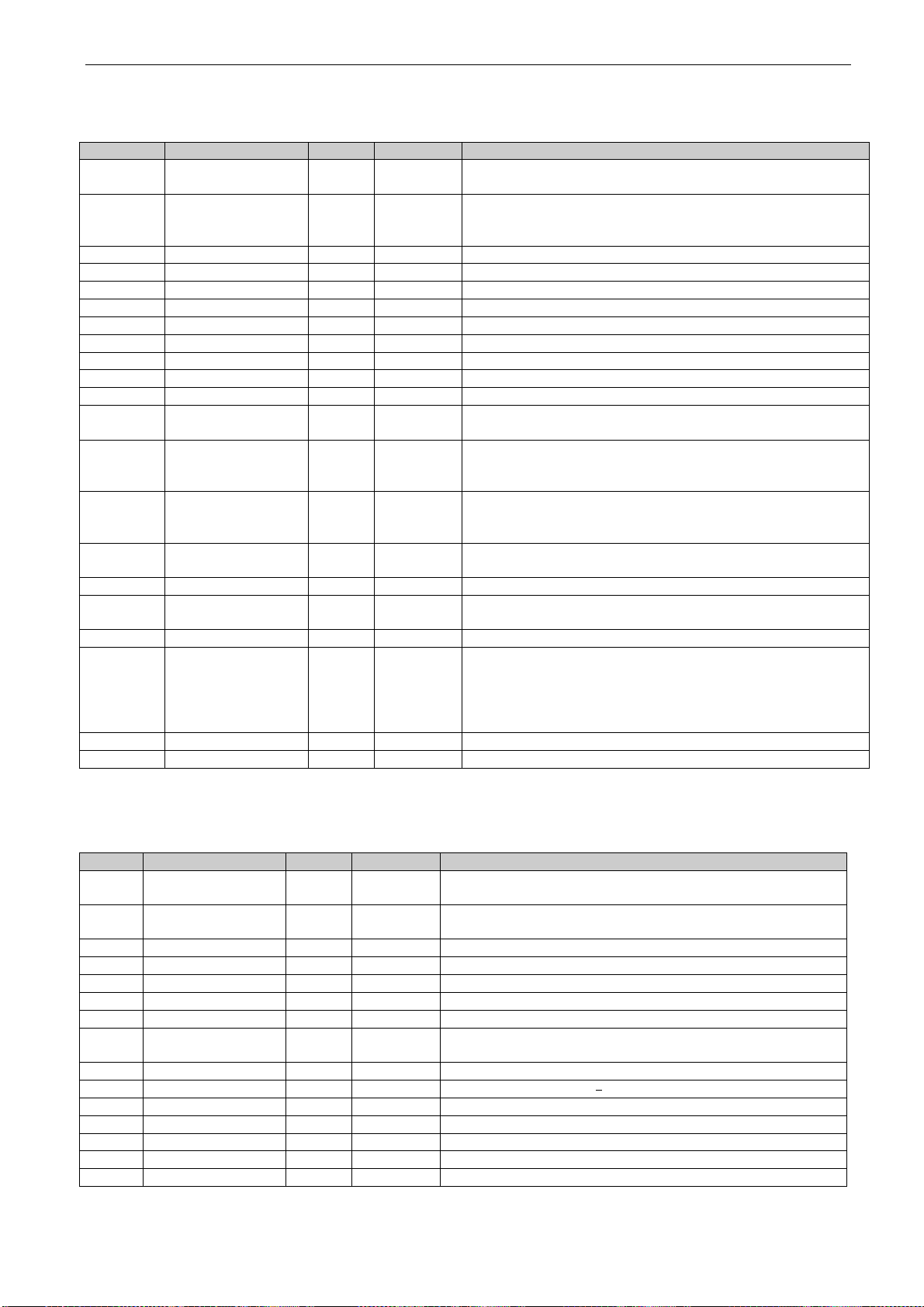

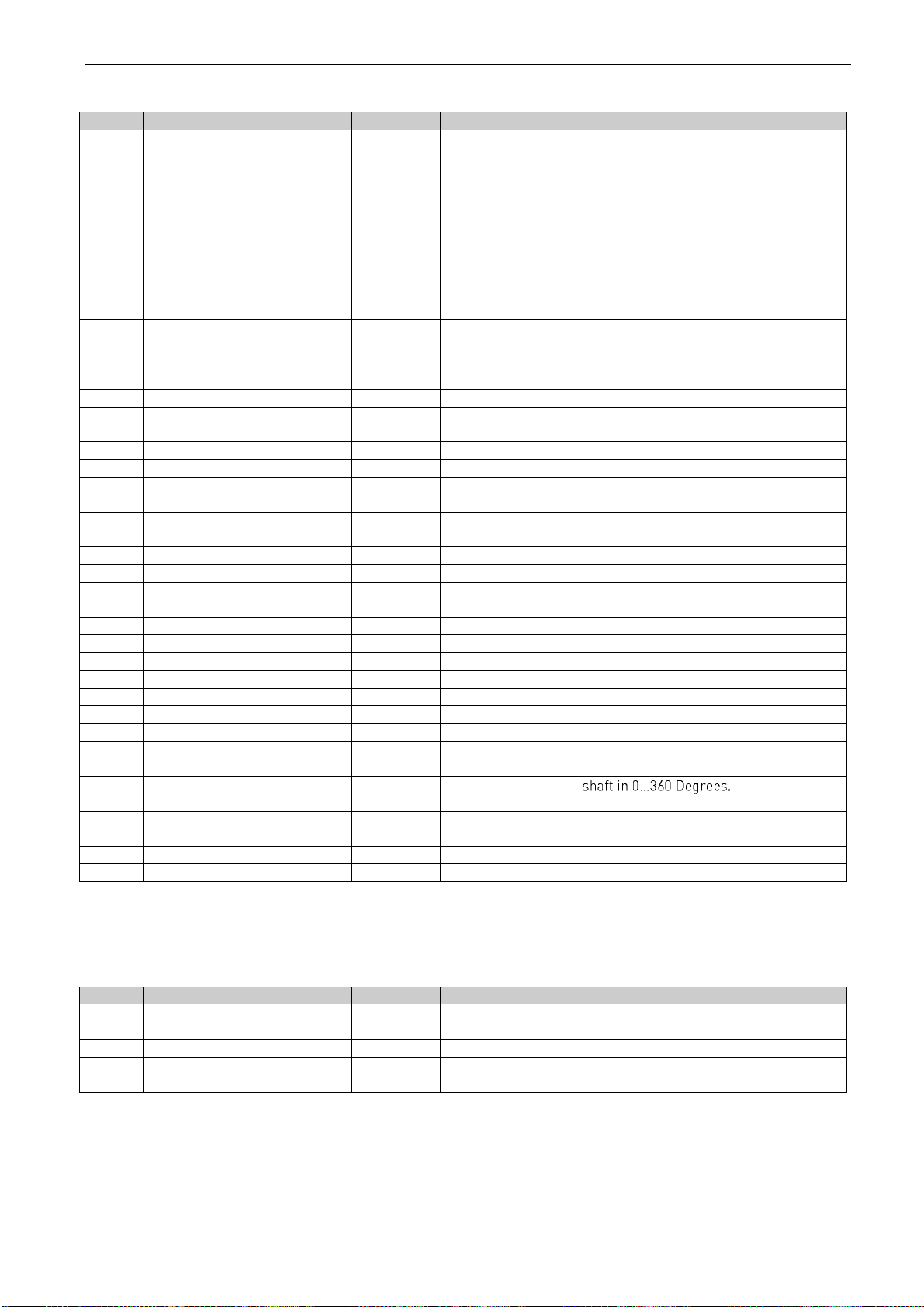

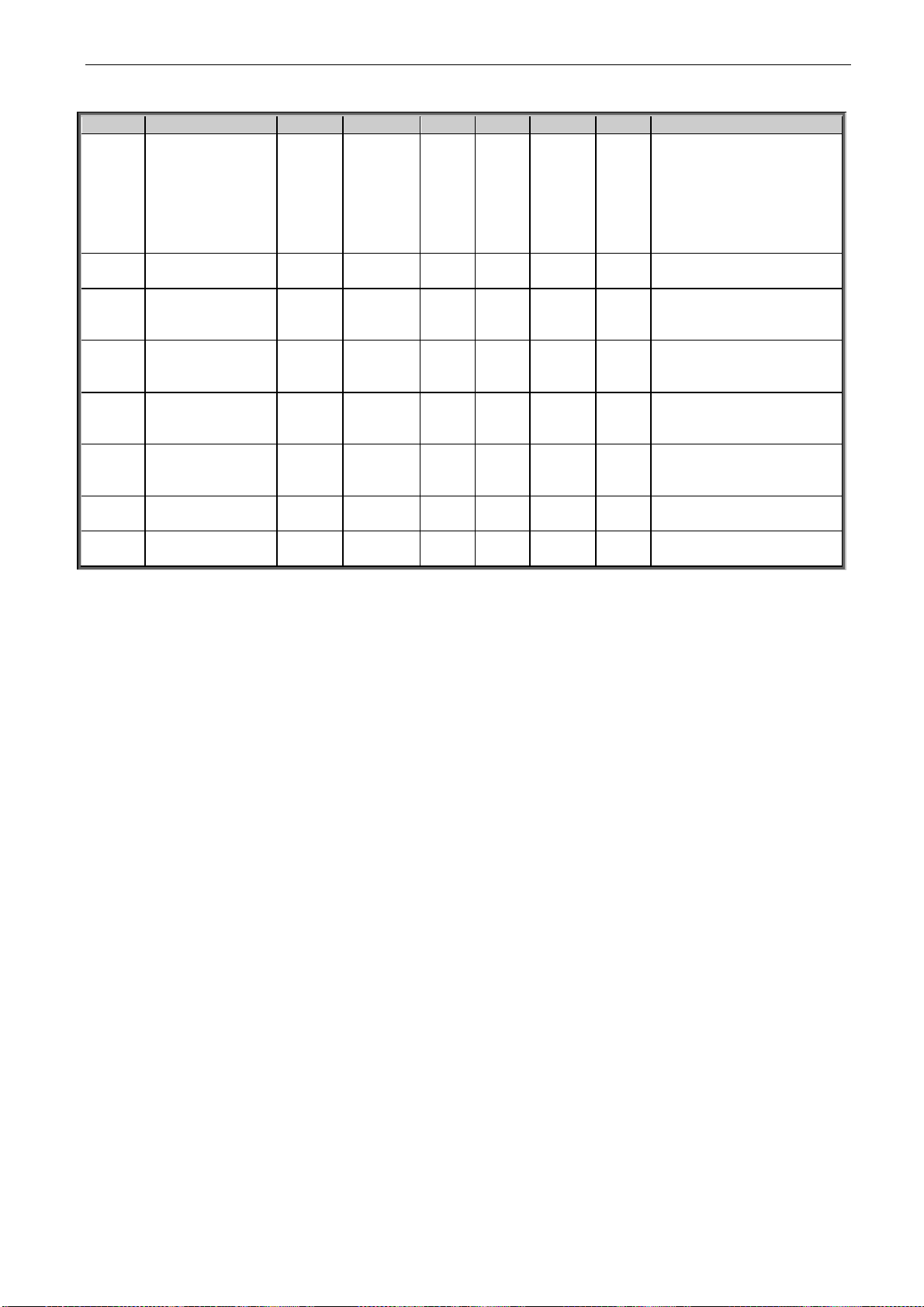

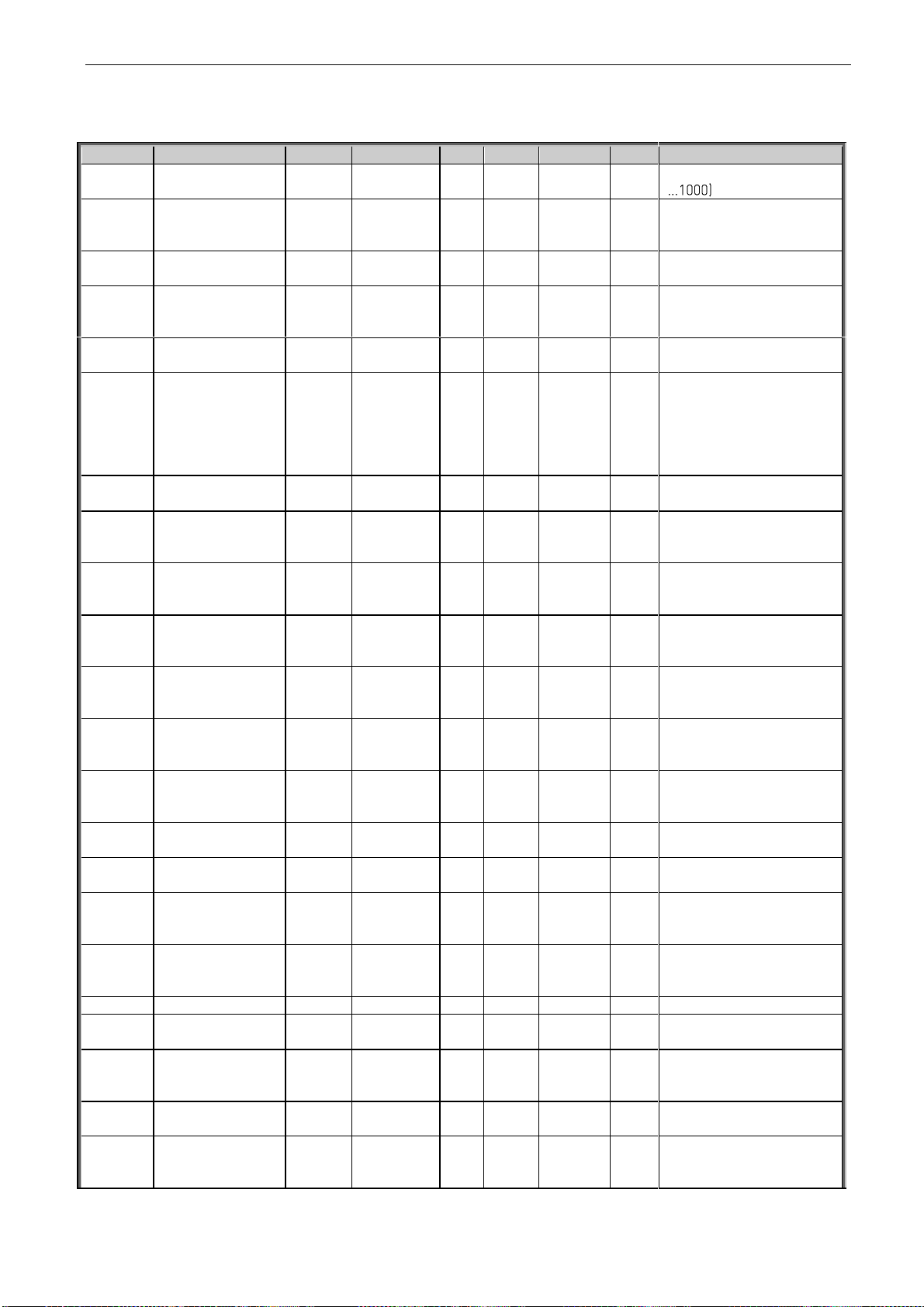

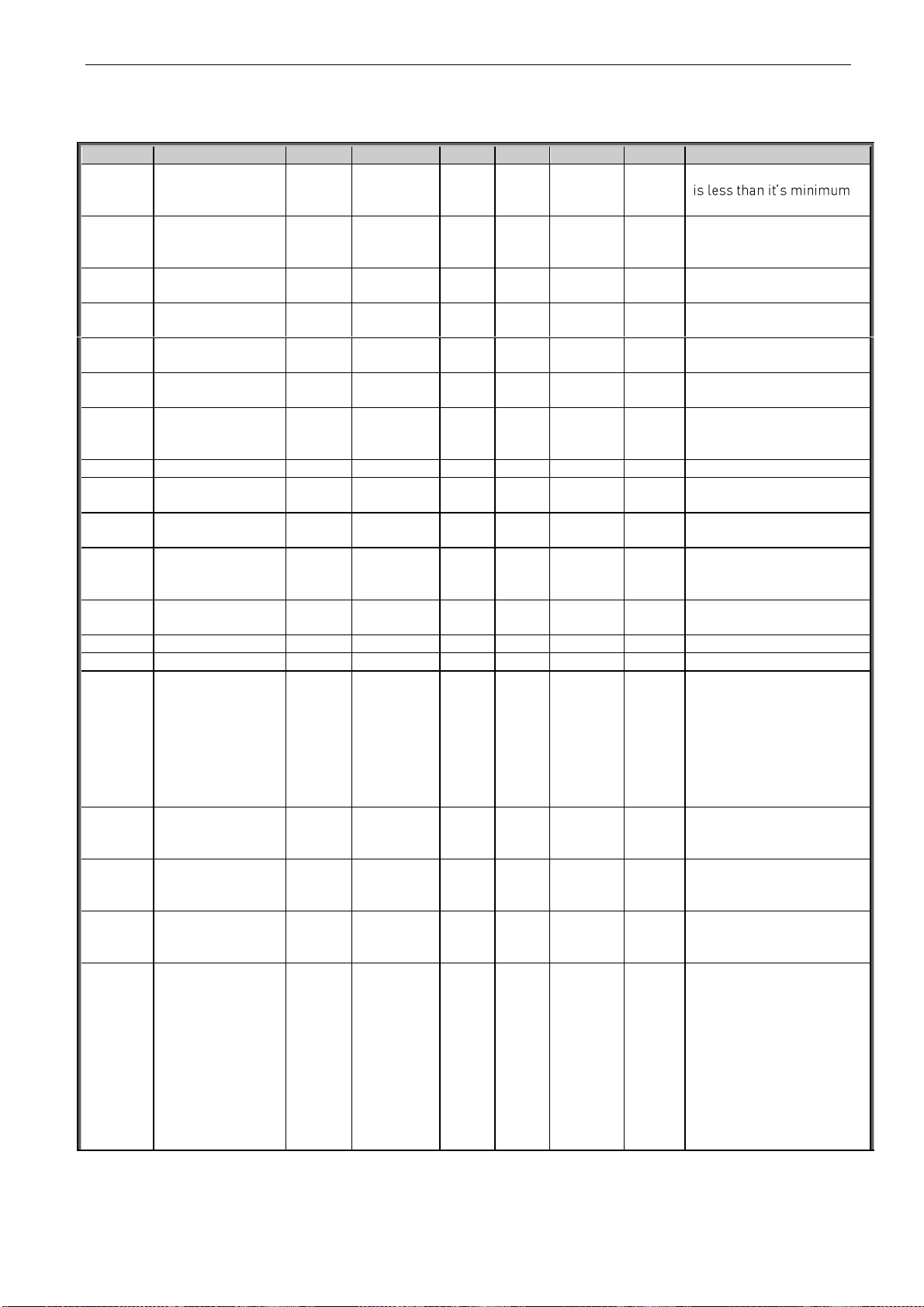

3. SYSTEM INTERFACE APPLICATION PARAMETER LISTS

On the next pages you will find the lists of monitoring signals and parameters. The parameter

descriptions are given on pages 33 to 81.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter

number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; given if available

Step = Accuracy of smallest possible change of value

Default = Value preset by factory

ID = ID number of the parameter (used with PC tools)

3.1 Monitoring Values

The monitoring values are the actual values of parameters and signals as well as statuses and

measurements. See Vacon NX User's Manual, Chapter 7 for more information.

Page 8

8 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.1.1 Monitor Page 1

Code

Parameter

Unit

ID

Description

V1.1.1

Output frequency

Hz

1

Frequency output from the drive to the motor.

V1.1.2

Speed

Rpm

2

Motor speed in rpm. In open loop this is the calculated speed

of the motor and in closed loop this is the filtered value of the

speed measured from the encoder.

V1.1.3

Freq. Reference

Hz

25

Frequency reference to the ramp generator.

V1.1.4

Current A 3

Filtered motor current.

V1.1.5

Torque % 4

Filtered motor torque in percentage of motor nominal torque.

V1.1.6

Power % 5

Power in percentage of motor nominal power.

V1.1.7

Motor voltage

V

6

Motor terminal voltage.

V1.1.8

DC-link voltage

V

7

DC link voltage.

V1.1.9

Unit tempertaure

°C

8

Heat sink temperature.

V1.1.10

DIN Status Word1

15

See the chapter 5.10

V1.1.11

DIN Status Word2

16

See the chapter 5.10

V1.1.12

MotorTempCalc

%

9

Calculated motor temperature .

100.0% = nominal temperature of the motor.

V1.1.13

Temp sensor 1

°C

50

Temperature of the PT100 or KTY 84 type temperature sensor

1 connected to Analogue input. If OPT-B8 board is used then

this value shows temperature of channel 1.

V1.1.14

Temp sensor 2

°C

51

Temperature of the PT100 or KTY 84 type temperature sensor

2 connected to Analogue input. If OPT-B8 board is used then

this value shows temperature of channel 2.

V1.1.15

Temp sensor 3

°C

52

If OPT-B8 board is used for temperature measurement then

this value shows temperature of channel 3.

V1.1.16

Unit nom. voltage

V

1117

Nominal voltage rating of the drive unit.

V1.1.17

Unit nom. current

A

1118

Nominal current rating of the drive unit. This is same as IL

current rating of the unit.

V1.1.18

DC nom. voltage

V

1120

Nominal DC link voltage of the drive unit.

V1.1.19

ID Run status

49

Bitwise status of automatic identification after ID run.

B0= Stator resistance and U/f curve

B1= Reserved

B2= Magnetisation current.

B3= Flux linearization curve.

V1.1.20

Analogue Input 1

%

59

Filtered A.1

V1.1.21

Analogue Input 2

%

60

Filtered A.1

Table 2. Monitoring page 1

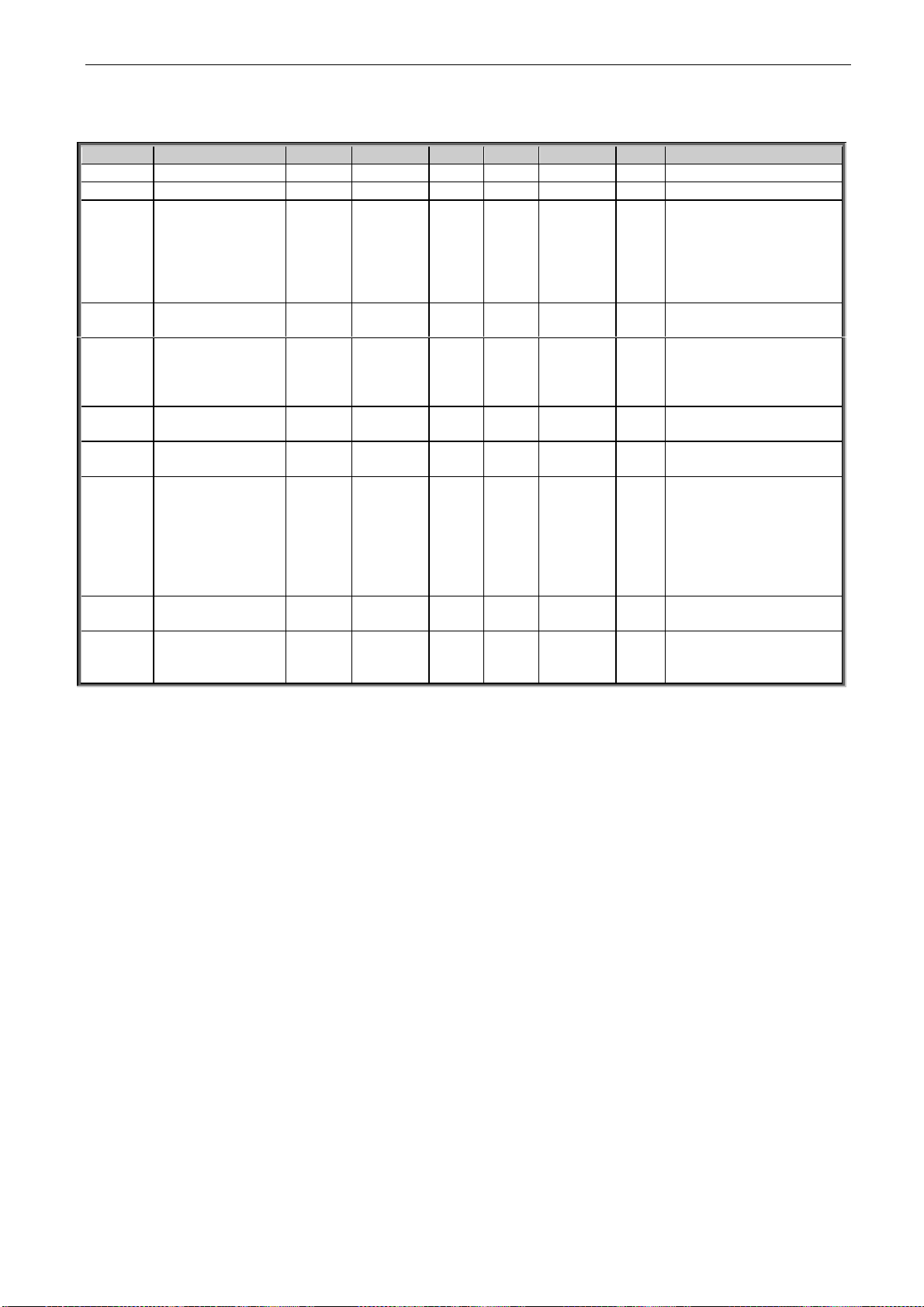

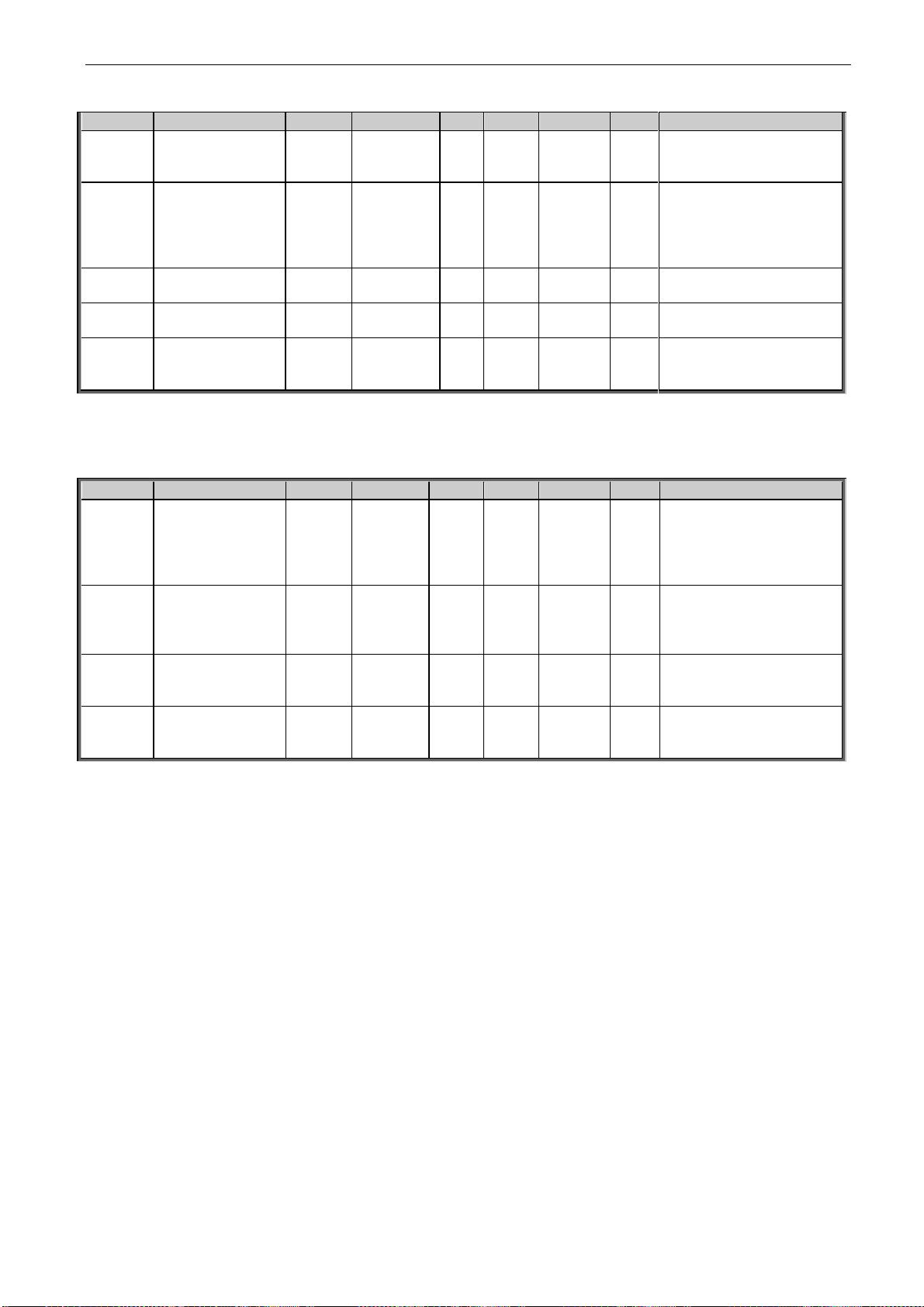

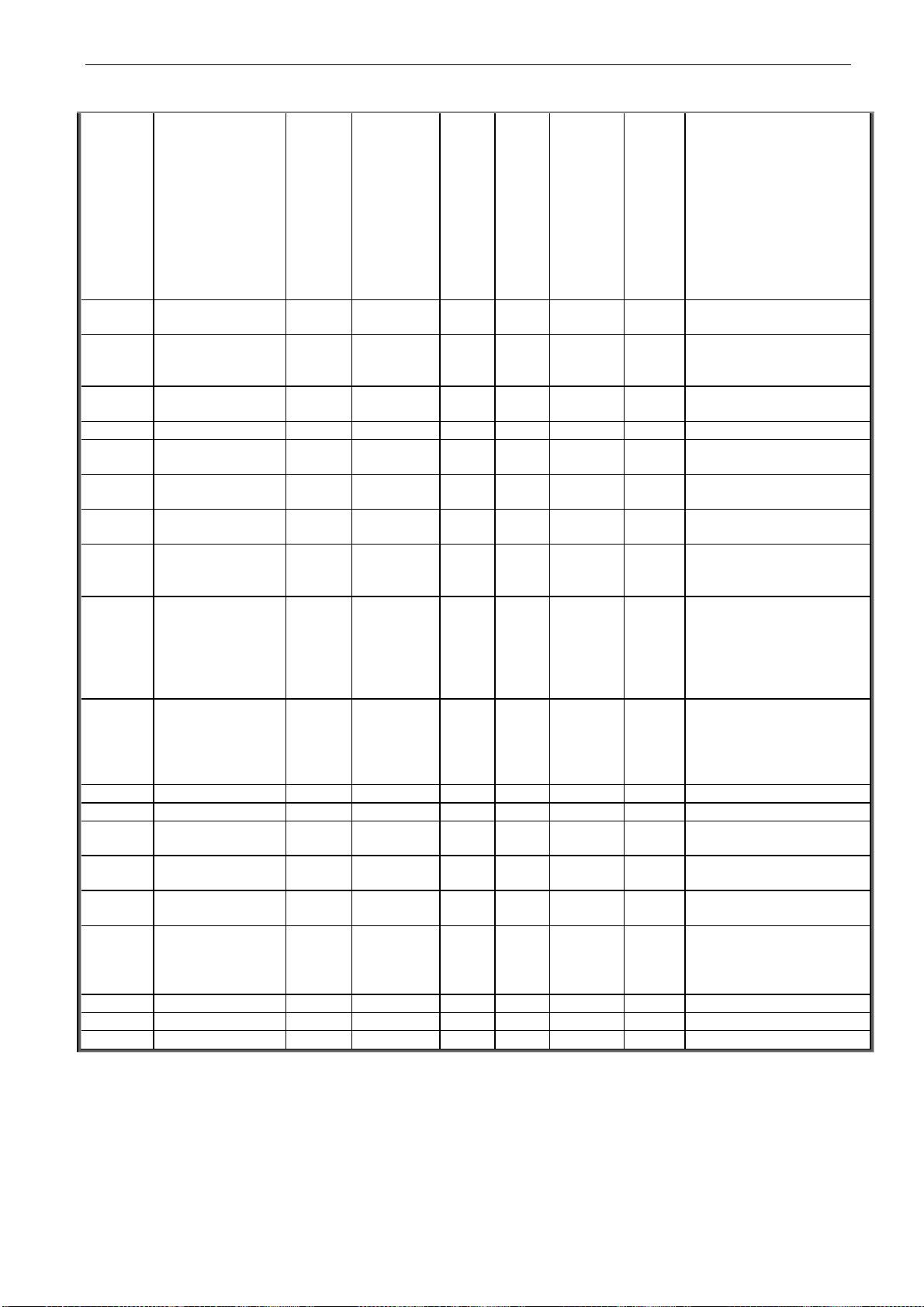

3.1.2 Monitor Page 2

Code

Parameter

Unit

ID

Description

V1.2.1

Speed Measured

rpm

1124

Speed measured from the encoder.

V1.2.2

Torque Unfilt.

%

1125

Unfiltered torque calculated by the drive.100% equals to motor

nominal torque.

V1.2.3

Current Unfilt.

%

1113

Unfiltered Motor current in Amperes.

V1.2.4

Speed Reference1

rpm

1126

Speed reference selected as per the control place selection.

V1.2.5

Speed Reference2

rpm

1127

Speed reference after speed share logic.

V1.2.6

Speed Reference3

rpm

1128

Speed reference at the input of the ramp generator.

V1.2.7

Speed Ramp Out

rpm

1129

Final speed reference after Ramp generator

V1.2.8

Speed Reference4

rpm

1130

Speed reference after the speed correction is added to the

Speed Ramp Out. 1)

V1.2.9

Used Speed Ref

rpm

1131

Final speed reference after the speed step logic. 1)

V1.2.10

Speed Error

rpm

1132

Speed error=Speed Act Speed Ref 1)

V1.2.11

SPC OUT

%

1134

Iq Reference from the speed controller output. 1)

V1.2.12

SPC Out P-part

%

1866

Speedcontroller monitoring P-part separately

V1.2.13

SPC Out I-part

%

1865

Speedcontroller monitoring I-part separately

V1.2.14

Speed Limit Pos

rpm

1135

Positive speed limit on the speed reference

V1.2.15

Speed Lim Neg

rpm

1136

Negative speed limit on the speed reference

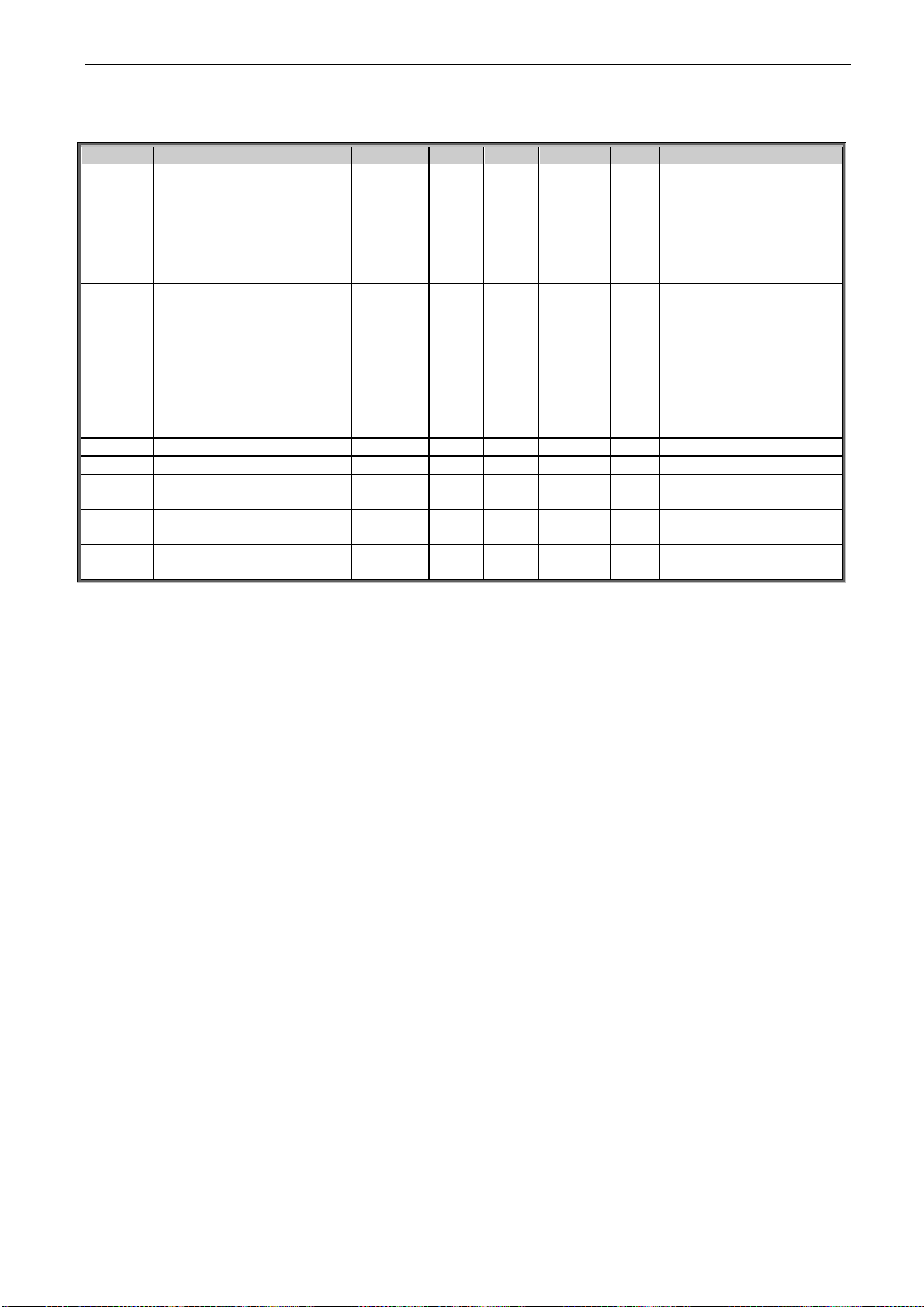

Page 9

apfiff10 sia-i VACON® • 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Code

Parameter

Unit

ID

Description

V1.2.16

TC Speed Lim Pos

rpm

1137

Positive speed limit when Torque Select is 2/3/4/5 and Motor

Ctrl Mode =3.

V1.2.17

TC Speed Lim Neg

rpm

1138

Negative speed limit when Torque Select is 2/3/4/5 and Motor

Ctrl Mode =3.

V1.2.18

Master TorqueRef

%

1139

Torque reference from Master Drive in case of master

Follower comm.

-300.0....+300.0% of the motor nominal torque

V1.2.19

FB Torque Ref

%

1140

Torque Reference from the Fieldbus.

-300.0...300.0%. of motor nominal torque

V1.2.20

I/0 Torque Ref

%

1141

Torque Reference from the analogue Input

-300.0...300.0%. of motor nominal torque

V1.2.21

Torque Ref1

%

1142

Torque reference after Torque Reference selector (Master,

Fieldbus, analogue I/P)

V1.2.22

Torque Ref2

%

1143

Scaled Torque Reference

V1.2.23

Torque Ref3

%

1144

Torque reference after Load Share logic.

V1.2.24

Used Torque Ref

%

1145

Final, limited torque reference for speed/torque controller

V1.2.25

Acc Comp Out

%

1146

Acceleration compensation used in terms of

IqReference.100.0% equals to motor nominal current. 1)

V1.2.26

Droop Speed RPM

rpm

1147

Speed droop used in rpm.

V1.2.27

Startup TorqAct

A

1148

startup torque in use, 100.0 %= motor nominal torque.

V1.2.28

Iq Current Lim +

%

1152

Final upper IqCurrentLimit 100.0 %= motor nominal current

(unsigned)

V1.2.29

Iq Current Lim -

%

1153

Final lower IqCurrentLimit 100.0 %= motor nominal current

(unsigned)

V1.2.30

Iq Reference

%

1154

Final IqReference, 100.0% = motor nominal current

V1.2.31

Iq Actual

%

1155

Measured Iq 100.0% = motor nominal current

V1.2.32

Id Reference

%

1156

Final IdReference 100.0% = motor nominal current

V1.2.33

Id Actual

%

1157

Measured Id 100.0 %= motor nominal current.

V1.2.34

Flux % 1158

Estimated rotor flux in percentage of the motor nominal flux.

V1.2.35

Rotor t Const

ms

1159

Rotor Time Constant in ms

V1.2.36

Main Control Word

1160

V1.2.37

Aux Control Word1

1161

See the chapter 5.5

V1.2.38

Main Status Word

1162

See the chapter 5.4

V1.2.39

Aux Status Word

1163

See the chapter 5.6

V1.2.40

Fault Word 1

1172

See the chapter 5.7

V1.2.41

Fault Word 2

1173

See the chapter 5.8

V1.2.42

Alarm Word 1

1174

See the chapter 5.9

V1.2.43

Shaft Position

1169

Position of the motor

V1.2.44

Shaft Rounds

1170

No. of rounds of the motor shaft.

V1.2.45

Pole Pair Number

58

Number of pole pairs in the motor estimated from the motor

data.

V1.2.46

Output power

1508

Drive output power

V1.2.47

Last active fault

37

Code of the last active fault

Table 3. Monitoring page 2

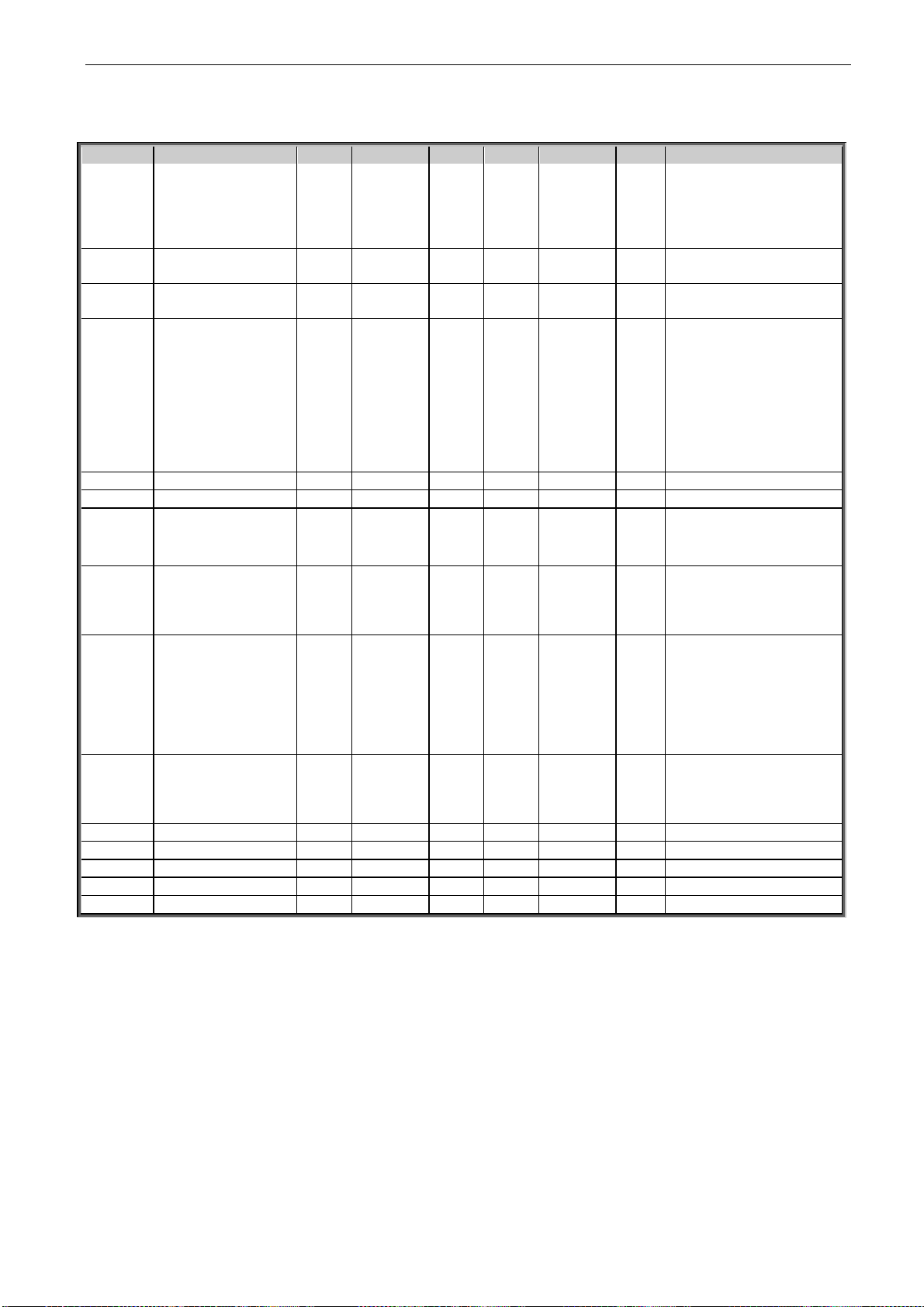

3.1.3 PI-Controller Monitoring

Code

Parameter

Unit

ID

Description

V1.3.1

PI Reference value

20

PI controller reference value

V1.3.2

PI Actual value

21

PI Controller actual value

V1.3.3

PI Controller output

23

PI Controller output before output scaling

V1.3.4

PI Controller output

scaled

1807

PI Controller output after output scaling. This is the value that

is written to values selected by P2.18.6

Table 4. PI-Controller monitoring page

Page 10

10 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

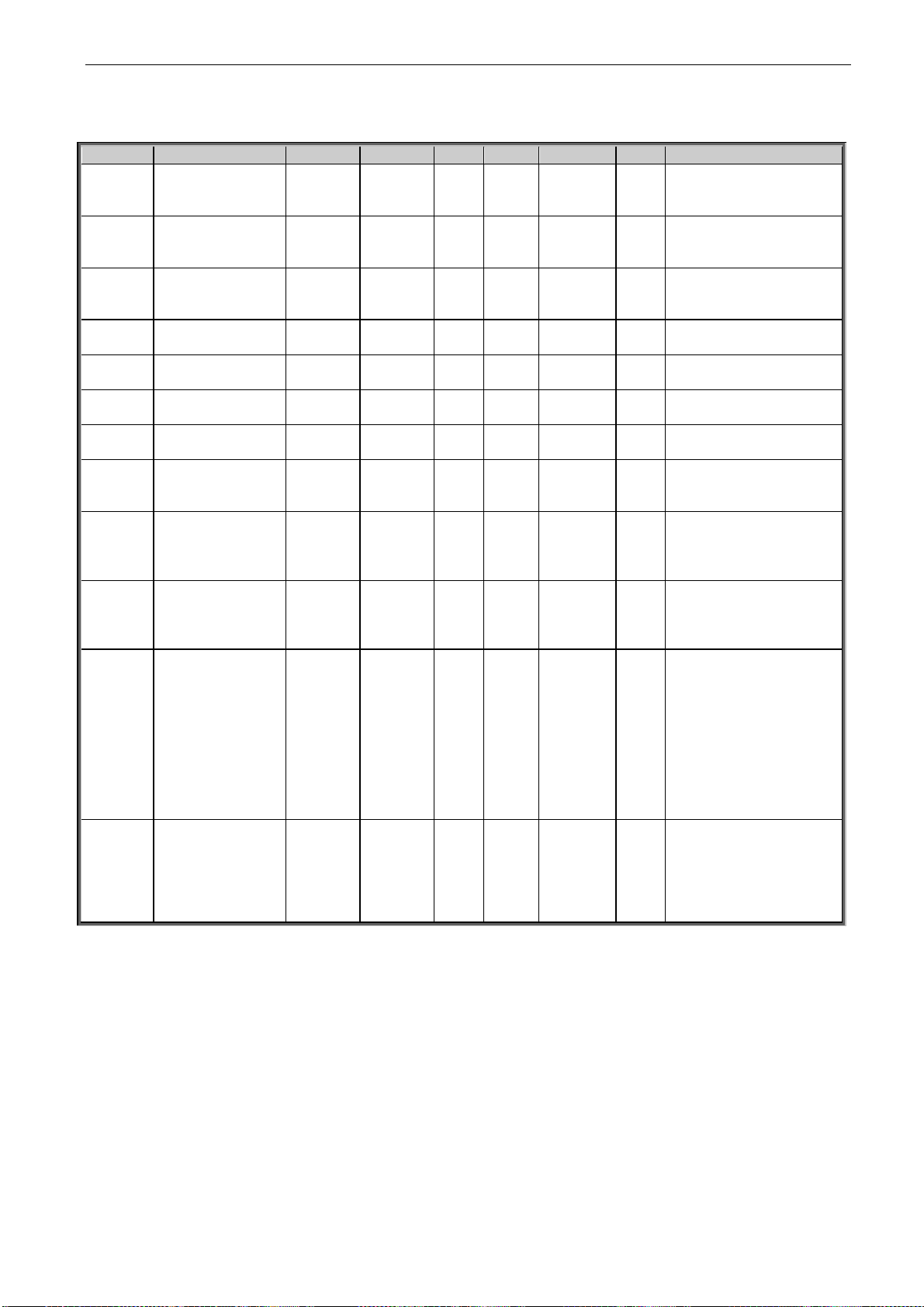

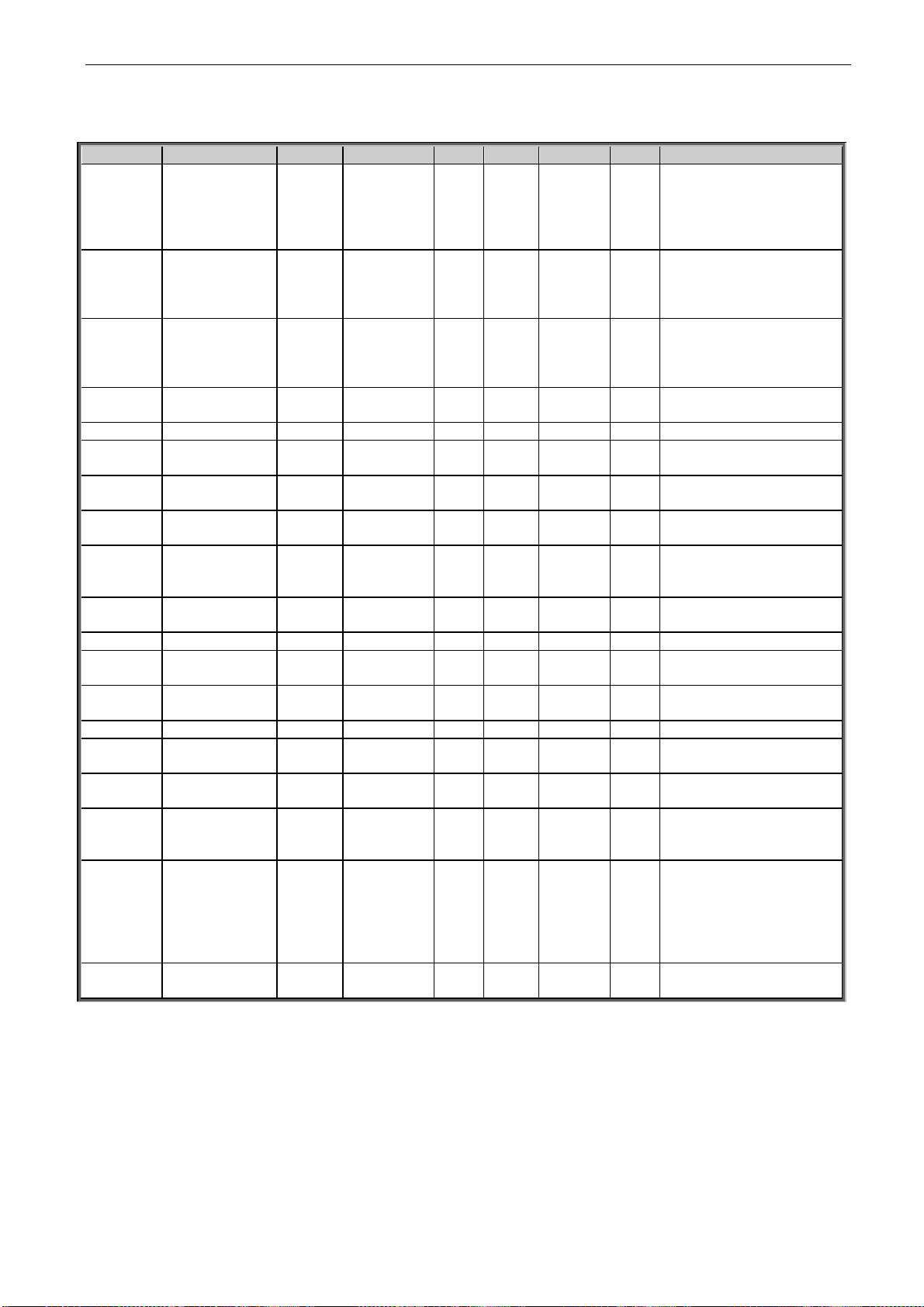

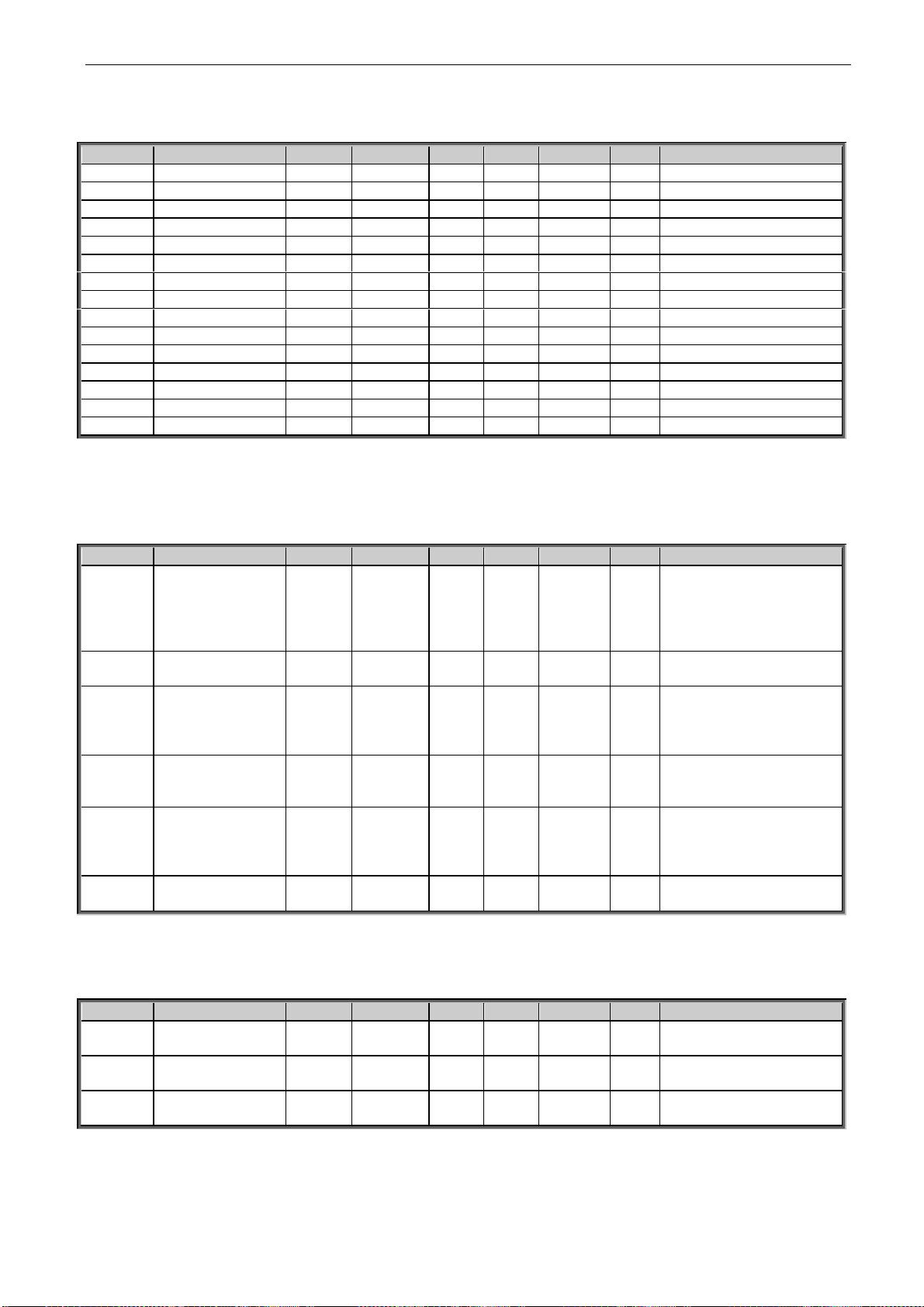

3.2 Basic Parameters

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.1.1

Supply Voltage

0

1000 V 1

500

1201

Supply Voltage in Volts. If

unknown then parameter

should be zero.

P2.1.2

Motor Nominal

Voltage

180

690 V 1

400

110

Nominal Voltage of the

Motor in volts as per

Rating Plate

P2.1.3

Motor Nominal

Frequency

30.00

320.00

Hz

0.01

50.00

111

Nominal Frequency of the

Motor ##. ## Hz as per

Rating Plate

P2.1.4

Motor Nominal

Current

0,01 * I

H

2 * IH

A

0.1

IH

113

Nominal Current of the

Motor. in ####.# A

P2.1.5

Motor Nominal

Speed

300

ns rpm 1 1440

112

Nominal Speed of the

Motor as per Rating Plate

P2.1.6

Motor Cos Phi

0.30

1.00

0.01

0.85

120

Rated value of cos phi as

per Rating Plate

P2.1.7

Process Speed

0.0

3200.0

rpm

0.1

14400

1203

Process Speed limit in

RPM scale

P2.1.8

Magn. Current

0.0

Motor

Nom

Current

A

0.1

0.5

612

Nominal magnetizing

current of the motor in

amps (Current Format)

P2.1.9

Field Weakng Pnt

8.00

320.00

Hz

0.01

50.00

602

Frequency at which Field

Weakening should start.

Applicable only in Open

Loop Control

P2.1.10

Voltage at FWP

5.00

200.00

%

0.01

100.00

603

Motor Voltage Limit in

Field weakening.

Applicable only in Open

Loop Control

P2.1.11

ID Run

0 4 1 0

631

Automatic Identification

run for the motor.

0 = None

1 = Identification without

motor running.

2 = Identification with

motor running.

3 = Encoder ID

4 = Magnetisation current

calculation

P2.1.12

Motor Type

0 3 1 0

650

Motor type

0= Induction motor

1= Not Used

2= Permanent magnet

motor

3= Not Used

Table 5. Basic parameters G2.1

Page 11

apfiff10 sia-i VACON® • 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

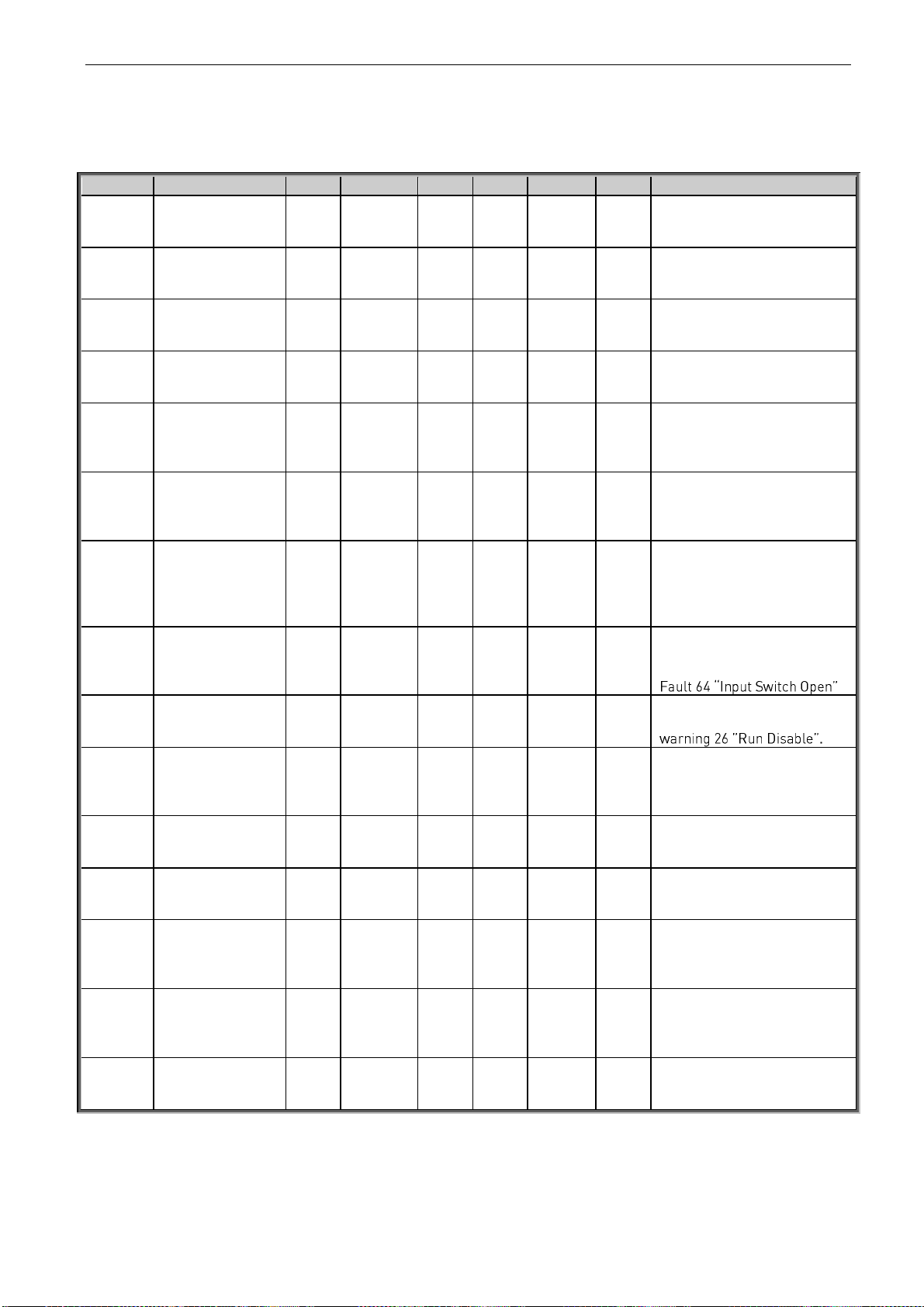

3.3 Input Signals

3.3.1 Digital Input

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.2.1.1

Run Forward

0

Max. No

of DIN

installed

1 0

1206

Digital input selection for the

Run Forward command when

the Control Place=IO control.

P2.2.1.2

Run Reverse

0

Max. No

of DIN

installed

1 0

1207

Digital input selection for Run

Reverse command when the

control place=IO control

P2.2.1.3

IO Ctrl

0

Max. No

of DIN

installed

1 0

1404

Digital input selection to

activate the IO control.

P2.2.1.4

Reset

0

Max. No

of DIN

installed

1 0

1208

Digital input Selection for

Fault Resetting.

P2.2.1.5

Brake Open

0

Max. No

of DIN

installed

1 0

1210

Input Selection for Acknowledgement of Motor Mechanical Brake. Off=Brake

Closed, On=Brake Opened.

P2.2.1.6

Brake Open Logic

0 1 1 0

1379

The connection type for brake

open acknowledgement.

0= Normally Open.

1= Normally closed.

P2.2.1.7

Motor Fan Ack.

0

Max. No

of DIN

installed

1 0

1211

Input selection for Motor Fan

Acknowledgement. If no

acknowledgement for 1 Sec

after Fan On command then

Alarm F56 ``Motor Fan``

P2.2.1.8

Input Switch Ack

0

Max. No

of DIN

installed

1 5

1209

Input selection for input

switch acknowledgement.

If not acknowledged then

P2.2.1.9

Run Enable

0

Max. No

of DIN

installed

1 4

1212

Input selection For Run Enable. If input is missing then

P2.2.1.10

Run Enable Logic

0 1 1 0

1380

Connection type for Run

Enable.

0= Normally Open

1= Normally closed.

P2.2.1.11

Emstop

0

Max. No

of DIN

installed

1 6

1213

Input For Emergency Stop.

Low=Emergency stop Active

P2.2.1.12

External Fault

0

Max. No

of DIN

installed

1 0

1214

Digital input selection for

External Fault signal

connection.

P2.2.1.13

Ext. Fault Logic

0 1 1 0

1381

Connection type for external

fault input connection.

0= Normally open

1= Normally closed.

P2.2.1.14

Motor 1 Or 2 Sel

0

Max. No

of DIN

installed

1 0

1215

Select parameter set for

Motor 1 or Motor 2 with the

selected digital input.

High=Motor2.Low=Motor1

P2.2.1.15

PI Activation

-1

Max. No

of DIN

installed

1 0

1804

When HIGH PI Controller is

activated.

-1 = Forced ON

Table 6. Digital Input parameters, G2.2.1

Page 12

12 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

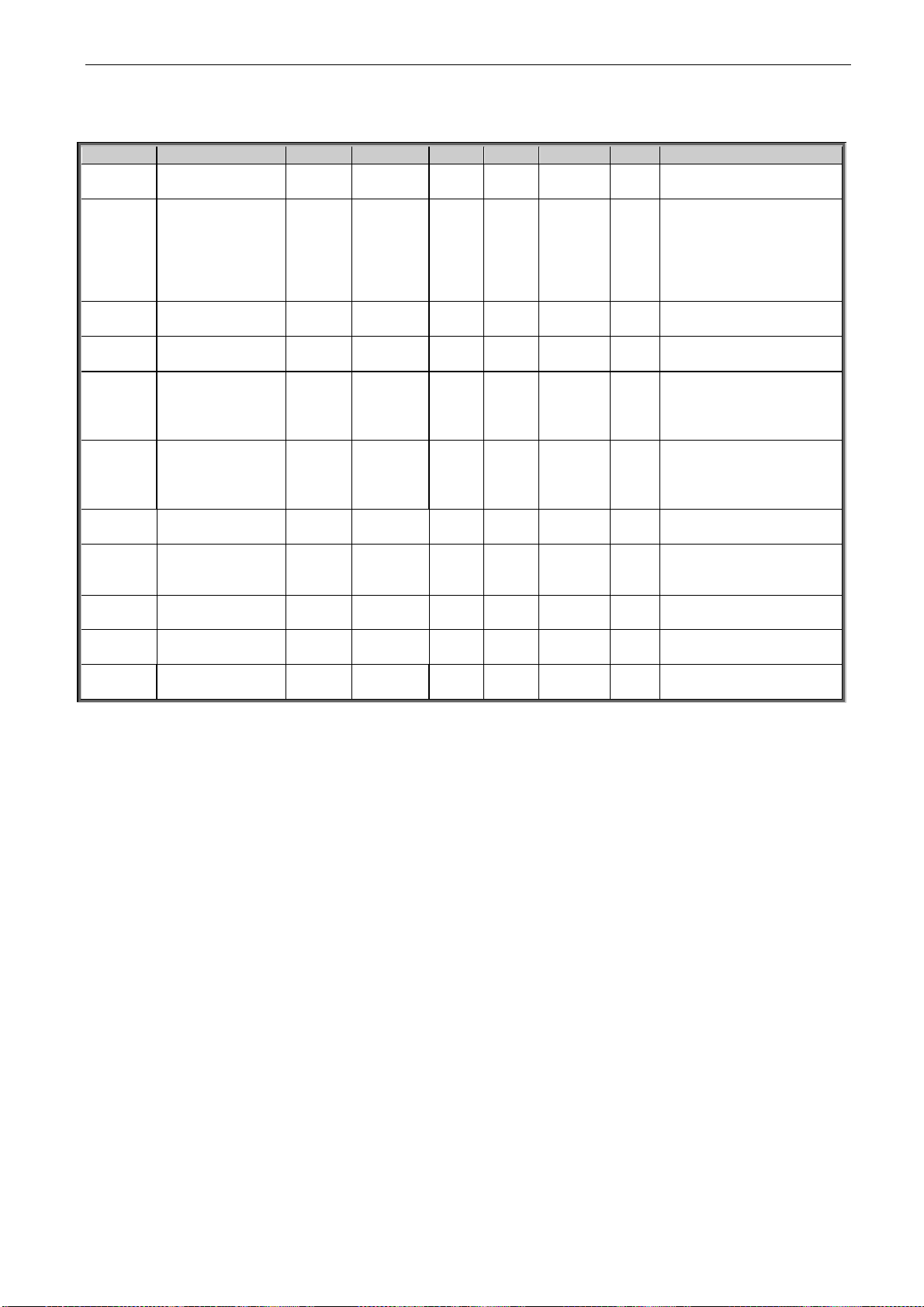

3.3.2 Analogue Input

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.2.2.1

I/O SpeedRef Sel

0 5 1 0

1219

Analogue Input selection

for Speed reference when

Control Place=1 (IO ctrl)

P2.2.2.2

I/O TorqRef Sel

0 3 1 0

1220

Analogue Input selection

for Torque reference

when Control Place=1

(Local IO Control)

P2.2.2.3

TS 1 AI Sel

0 2 1 0

1221

Analogue Input selection

for PT100 or KTY 84 type

temperature sensor 1.

P2.2.2.4

TS 1 Sel

0 2 1 0

1222

Number of PT100 or KTY

84 elements in series.

0=1*PT100,

1=2*PT100,

2=3*PT100.

3=1*KTY84-130

4=2*KTY84-130

5=3*KTY84-130

P2.2.2.5

TS 2 AI Sel

0 2 1 0

1223

Analogue Input selection

for PT100 or KTY 84 type

temperature sensor 2.

P2.2.2.6

TS 2 Sel

0 2 1 0

1224

Number of PT100

elements in series.

0=1*PT100,

1=2*PT100,

2=3*PT100.

3=1*KTY84-130

4=2*KTY84-130

5=3*KTY84-130

P2.2.2.7

AI1 Ref Scale

Min

-30000

30000

1 0

1226

Min. value of signal selected for AI1. This corresponds to

+0V/0mA/2V/4mA

P2.2.2.8

AI1 RefScale

Max

-30000

30000

1 1440

1225

Max. value of signal selected for AI1. This corresponds to +10V/20mA

P2.2.2.9

AI1 Minimum

0 1 1 0

1227

Minimum voltage or

Current at AI1.

0=0V/0mA, 1=4mA

P2.2.2.10

AI1 Filter Time

0.01

10.00

s

0.01

1

1228

Filter time for AI1 in ###.

## Sec

P2.2.2.11

AI2 RefScale Min

-30000

30000

1 0

1230

Min. Value of Signal selected for AI2.This corresponds to

+0V/0mA/2V/4mA

P2.2.2.12

AI2 RefScale

Max

-30000

30000

1 1000

1229

Max. Value of Signal selected for AI2.This corresponds to +10V/20mA

P2.2.2.13

AI2 Minimum

0 1 1 0

1231

Minimum Voltage or Current at AI2.0=0V/0mA,

1=4mA

P2.2.2.14

AI2 Filter Time

0.01

10.00

s

0.01

1

1232

Filter time for AI2 in ###.

## Sec.

Table 7. Analogue Input parameters, G2.2.2

Page 13

apfiff10 sia-i VACON® • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

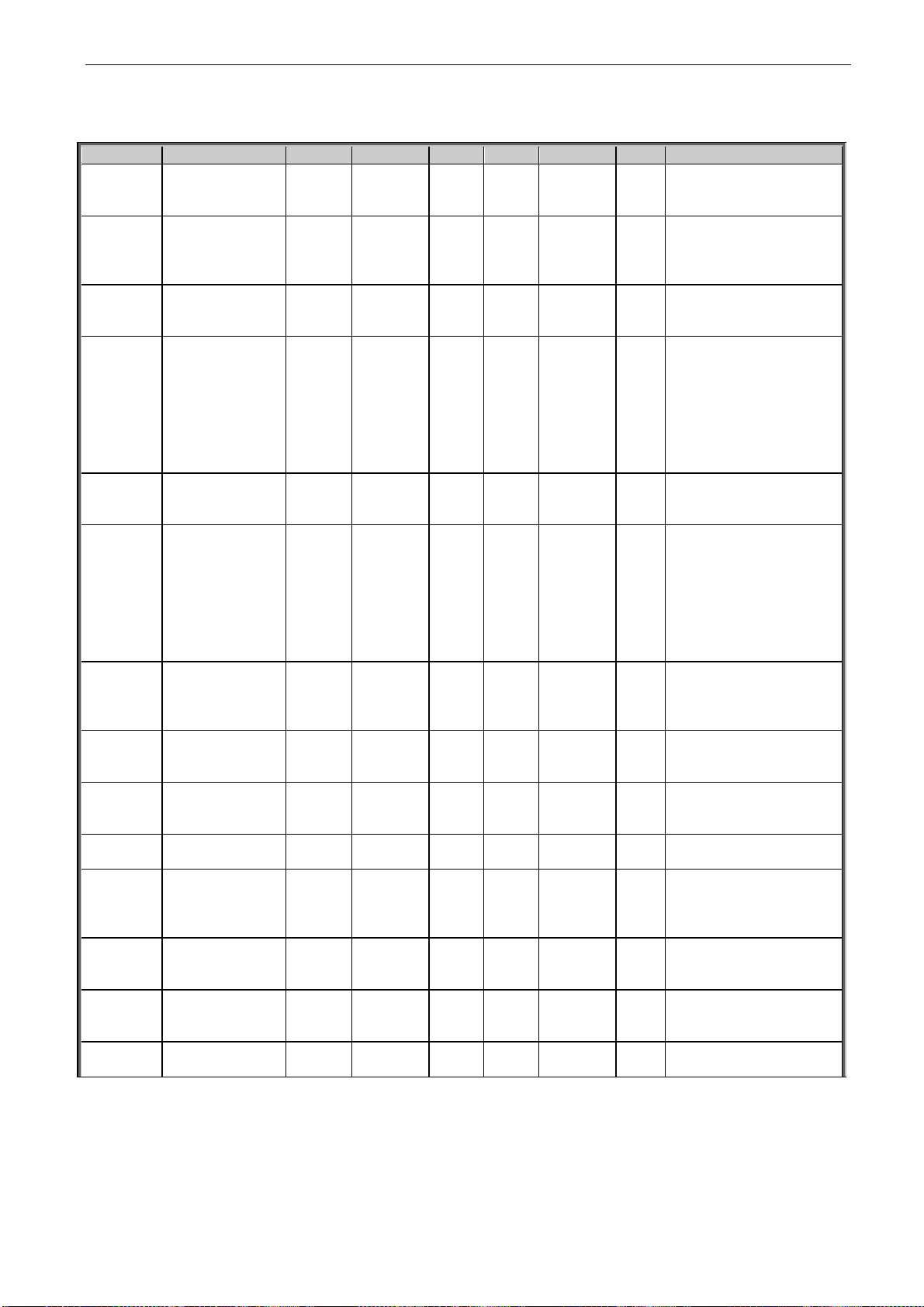

3.4 Output Signals

3.4.1 Digital Output

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.3.1.1

DO1 (ID.BitNo.)

0.00

2000.15

0.01

1162.00

1216

Select the signal for

controlling DO1.

P2.3.1.2

DO2 (ID.BitNo.)

0.00

2000.15

0.01

1162.00

1217

Select the signal for

controlling DO2

P2.3.1.3

DO3 (ID.BitNo.)

0.00

2000.15

0.01

1163.00

1218

Select the signal for

controlling DO3.

P2.3.1.4

DO4 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1385

Select the signal for

controlling DO4.

P2.3.1.5

DO5 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1386

Select the signal for

controlling DO5.

P2.3.1.6

DO6 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1390

Select the signal for

controlling DO6.

P2.3.1.7

DO7 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1391

Select the signal for

controlling DO7.

P2.3.1.8

DO8 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1395

Select the signal for

controlling DO8.

P2.3.1.9

DO9 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1396

Select the signal for

controlling DO9.

P2.3.1.10

DO10 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1423

Select the signal for

controlling DO10.

P2.3.1.11

DO11 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1427

Select the signal for

controlling DO11.

P2.3.1.12

DO12 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1428

Select the signal for

controlling DO12.

P2.3.1.13

DO13 (ID.BitNo.)

0.00

2000.15

0.01

0000.00

1429

Select the signal for

controlling DO13.

Table 8 Digital Output parameters, G2.3.1

Page 14

14 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

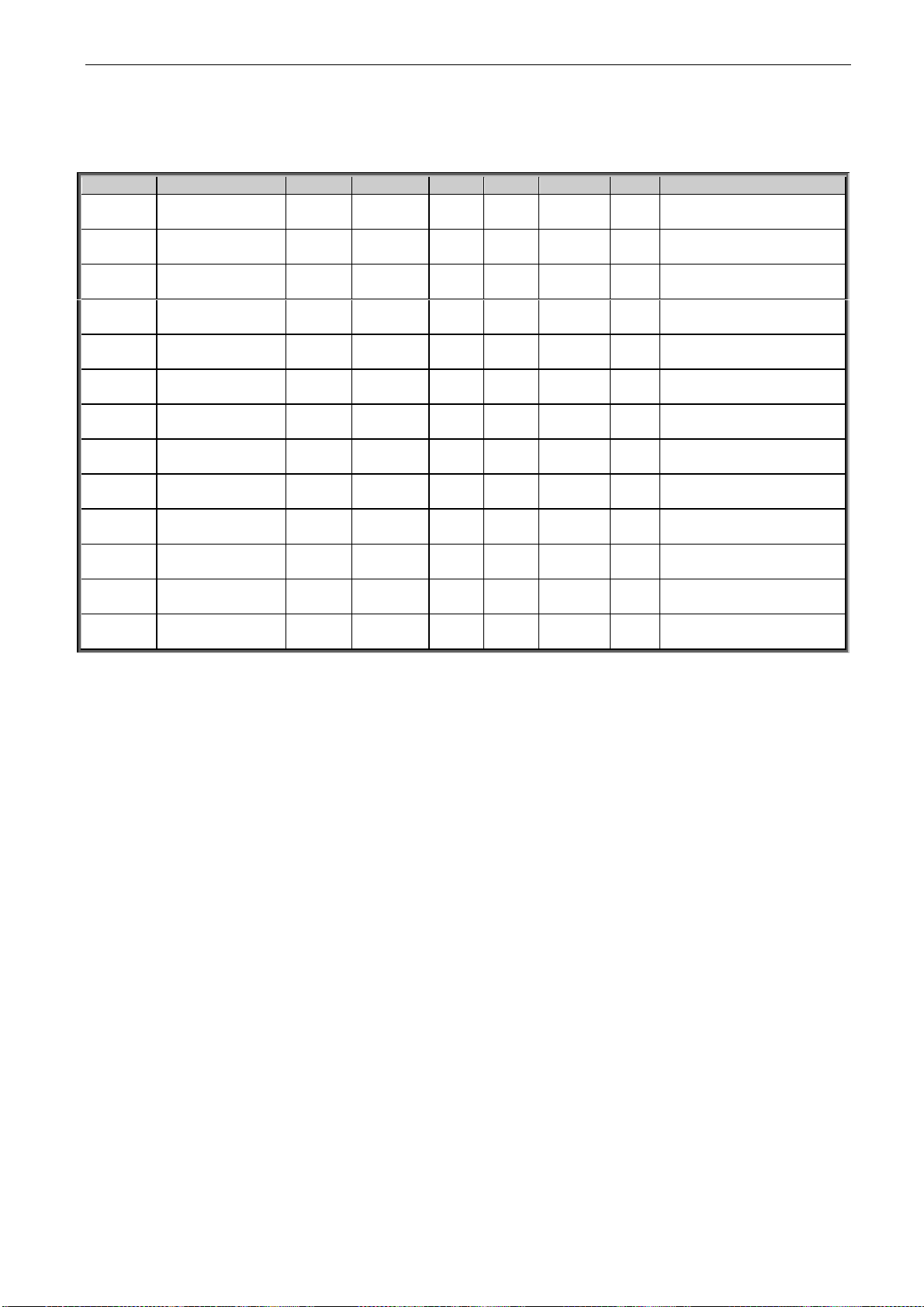

3.4.2 Analogue Output

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.3.2.1

AO1 Signal ID

0

2000

1 0

1233

Set the ID no. Of a signal

to be connected to AO1.

P2.3.2.2

AO1 Offset

0 1 1 0

1234

Minimum voltage or current at AO1.

0= OV/0mA.

1= 2V/4mA

P2.3.2.3

AO1 Filter

0.02

10.00

S

0.01

10.00

1235

Filter time for AO1

P2.3.2.4

AO1 Max Value

-30000

30000

1 1500

1236

Maximum value of the signal selected for AO1. This

will correspond to +10V/

20mA.

P2.3.2.5

AO1 Min Value

-30000

30000

1 0

1237

Minimum value of the signal selected for AO1. This

will correspond to 0V/0mA

or 2V/4mA depending on

AO1 Offset.

P2.3.2.6

AO1 Adjust

-200,00

200,00

0,01

0,00

375

Table 9 Analogue output parameters, G2.3.2

3.5 Reference Handling

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.4.1

Spd Ref Filter

0

5000

ms 1 0

324

Filter time for the speed

reference in ms

P2.4.2

Const Ref 1

P2.8.4

P2.8.3

rpm 1 0

1239

Constant speed reference 1.

Normally used for forward

inching

P2.4.3

Const Ref 2

P2.8.4

P2.8.3

rpm 1 0

1240

Constant speed reference 2.

Normally used for reverse

inching

P2.4.4

CriticalSpeedLow

0

Max_

Speed

Rpm 1 0

509

Low limit for critical speed

range

P2.4.5

CriticalSpeedHigh

0

Max_

Speed

Rpm 1 0

510

High limit for critical speed

range

P2.4.6

Speed Share

-300.00

300.00

%

0.01

100.00

1241

Speed share as percentage

of speed reference.

P2.4.7

FBRef Scale

10

30000

1 20000

1242

This will correspond to

P2.1.7 (Process Speed).

P2.4.8

Tref Source Sel

0 4 1 0

641

Source for the torque

reference.

0=None

1=Master

2=Fieldbus

3=Analogue I/P

4=Master SPC

P2.4.9

Tref Filter

0

5000

ms 1 0

1244

Filter time for the torque

reference in ms

P2.4.10

Tref Hysteresis

-300.0

300.0

%

0.1

0.0

1245

Hysteresis for the torque

reference in ####.#

%.100.0% ~motor nominal

torque.

P2.4.11

Tref Dead Zone

-300.0

300.0

%

0.1

0.0

1246

Dead zone in % where the

torque reference will be

considered as zero. 100.0%

~motor nominal torque.

Page 15

apfiff10 sia-i VACON® • 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.4.12

TorqueRef Scale

0 1 1 0

1247

The scale for the torque

reference chain and all

signals related to torque.

0 = 1000 corresponds to

motor nominal torque.

1 = 10000 corresponds to

motor nominal torque

P2.4.13

Load Share

0.0

400.0

%

0.1

100.0

1248

Load share for the torque

reference in %.

P2.4.14

Tref Ramp Time

0.0

30000

ms 1 0

1249

The ramp time in ms for

nominal torque reference

change.

P2.4.15

Flux Reference

10.0

150.0

%

0.1

100.0

1250

Flux reference in %.100%

equals rated flux of the

drive.

P2.4.16

Above Spd Limit

0

P2.8.3

rpm 1 0

1251

The speed limit above which

bit10 of the status word will

be TRUE

P2.4.17

Speed Step

-2000

2000

1 0

1252

Step speed ref. relative to

process speed. 20000 =

P2.1.7 Process speed

P2.4.18

Torque Step

-300.0

300.0

%

0.1

0.0

1253

Torque step in % of nom.

torque of the motor

P2.4.19

Speed Ref

Interpolator TC

0

32000

ms 1 10

1184

Table 10 Ref Handling parameters, G2.4

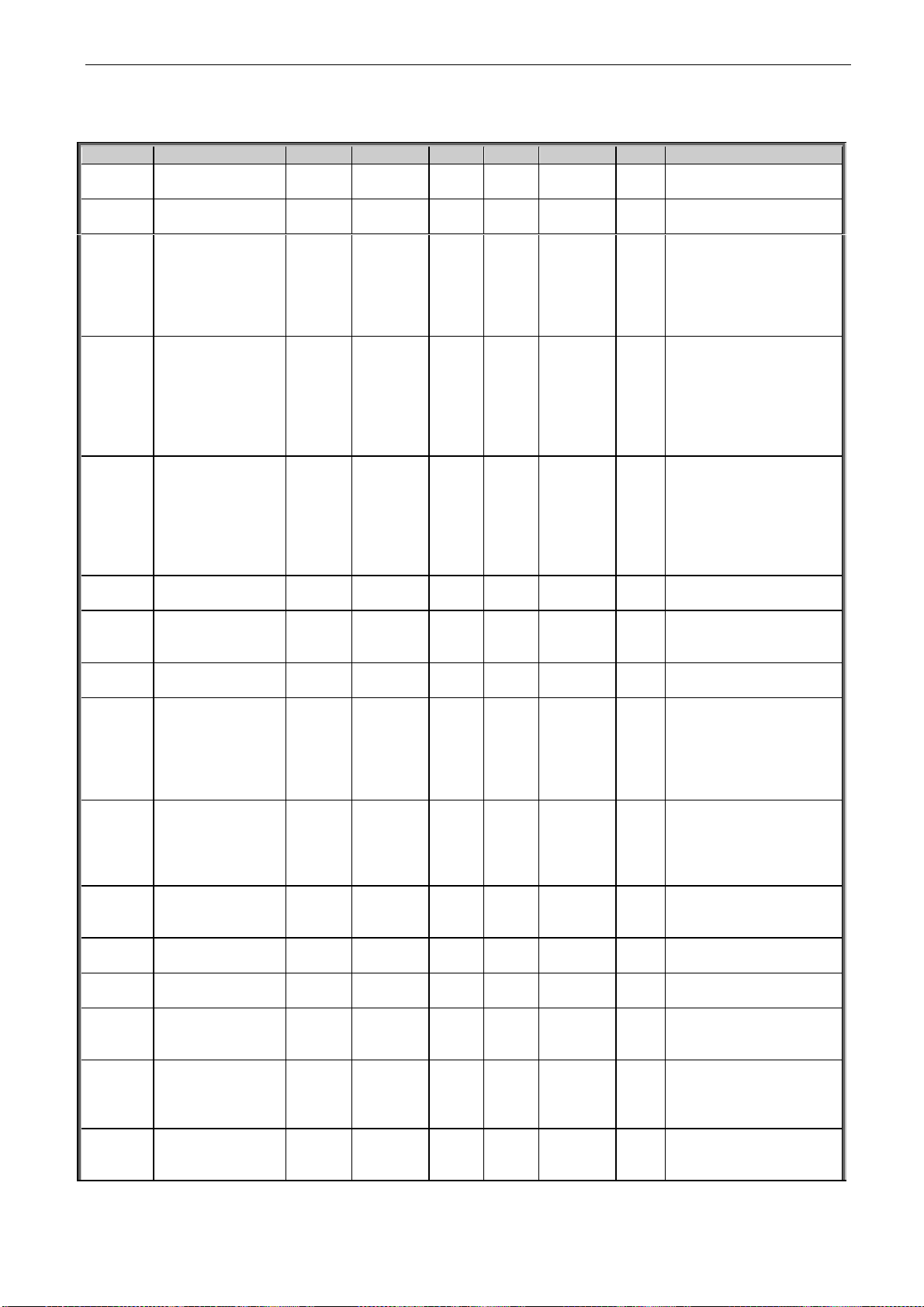

Page 16

16 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.6 Ramp Functions

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.5.1

Accel Time 1

0.0

3000.0

s

0.1

10.0

103

Acceleration Time in sec

P2.5.2

Decel Time 1

0.0

3000.0

s

0.1

10.0

104

Deceleration Time in sec

P2.5.3

S Ramp AccDec

0

100 % 1 0 500

Smooth ratio for S curves

for Acceleration and

Deceleration ramp.

0=Linear Ramps

100=Full Acc/Dec inc/dec

times.

P2.5.4

Emstop Ramp

0.0

3000.0

s

0.1

10.0

1256

Deceleration time in

Emergency Stop

P2.5.5

Emstop Delay

0.00

320.00

s

0.01

0

1254

Delay in activation of

emergency stop ramp

after emergency stop is

active

P2.5.6

ConstSpd

AccTime

0.0

3000.0

s

0.1

5.0

1257

Acceleration time for

Constant Speed 1 and 2

P2.5.7

ConstSpd

DecTime

0.0

3000.0

s

0.1

5.0

1258

Deceleration time for

Constant Speed 1 and 2

P2.5.8

S Ramp Const Spd

0

100 % 1 0 1259

Smooth ratio for S-curves

of Const Speed ramp

0=Linear ramps

100=Full Acc/Dec inc/dec

0=linear ramps

100=full acc/dec inc/dec

times

P2.5.9

Ramp Time

Reference

0 1 1 0

1132

P2.5.10

Open loop

emergency stop

limit ramp time

0

3000,0

s

0,1

1,0

1610

Table 11 Ramp Function parameters, G2.5

Page 17

apfiff10 sia-i VACON® • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.7 Drive Control

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.6.1

Control Place

0 2 1 1 2

125

Place to control the drive

operation.

0=FieldBus

1=IO

2=Panel/ PC Tool

P2.6.2

Brake Chopper

0 3 1 0

504 Brake chopper mode

selection.

P2.6.3

BrkChopper Level

0

1500

V

1

1.15*nom

DC Volt

1267

Brake chopper operation

level in volts

P2.6.4

Brk Res Load Lim

0.0

300.0

%

0.1

5.0

1268

Generator side torque

limit to avoid overheating

of the brake resistor during continuous braking.

This is active when Brake

Chopper is selected and

there is no emergency

stop active and drive is

not decelerating.

G2.6.5

Open Loop Control

See table on next page

G2.6.6

UV/OV Control

See table two pages down

P2.6.7

Restart Delay

0.000

60.000

s

0.001

1424

After coast stop the restarting of the drive is

disabled for this time.

P2.6.8

ControlOptions

0

65535

1 0

1084

This packed bit word is

made for enabling/

disabling different control

options.

P2.6.9

ControlSlotSel

0 8 1 0

1440

Selects which slot

process data is used

0 = All

4 = Slot D

5 = Slot E

6 = Fast comm. Slot D

7 = Fast comm. Slot E

P2.6.10

Modulator Type

0 3 1 1

1516

0 = Hardware

1 = Software 1

2 = Software 2 (DS)

3 = Software 3

P2.6.11

Advanced Options 1

0

65535

1 0

1560

P2.6.12

Advanced Options 2

0

65535

1 0

1561

P2.6.13

Advanced Options 4

0

65535

1 0

1563

P2.6.14

Advanced Options 5

0

65535

1 0

1564

P2.6.15

Advanced Options 6

0

65535

1 0

1565

Table 12 Drive Control parameters, G2.6

Page 18

18 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.7.1 Drive Control/Open Loop Ctrl

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.6.5.1

U/f Ratio Select

0 3 1 0

108

U/F ratio selection.

0=Linear

1=Squared

2=Programmable

3=Linear + Flux opt

P2.6.5.2

U/f Zero Point V

0.00

105.00

%

0.01

0.00

606

Motor voltage (%*Motor

Nominal Voltage) at programmable U/F curve zero

point .

P2.6.5.3

U/f Mid Point V

0.00

105.00

%

0.01

100.00

605

Motor voltage (%*Motor

Nominal Voltage) at programmable U/F curve

middle point

P2.6.5.4

U/f Mid Freq

0.00

320.00

Hz

0.01

50.00

604

Programmable U/F curve

middle point

P2.6.5.5

U/f Opt.

0 1 1 0

109

U/F opt. control

P2.6.5.6

DC Brake

Speed

0

MotorNom

Speed

rpm 1 0

515

Below this speed DC

braking will be active.

P2.6.5.7

DC Brake

Current

0

2 * IH

A

507

DC Braking current

P2.6.5.8

DC Brake Time

0

20000

ms 1 0

508

P2.6.5.9

Flux Brake

0 1 1 0

520

Flux braking control

0 = Disable

1 = Enable

P2.6.5.10

FluxBrakeCurr

ent

0

2 * IH

A 0

519

Flux braking current

P2.6.5.11

TorqStab Kp

0

1000

1

1412

Gain for torque stabilator

P2.6.5.12

TorqStab Damp

TC

0

1000

1

1413

Damping time constant for

torque stabilator

P2.6.5.13

TorqStab Kp

FWP

0

1000

1

1414

Gain for torque stabilator

at FWP

P2.6.5.14

Flux Stab Kp

0

32000

1

1410

Gain for flux stabilator

P2.6.5.15

Flux Stab Filt

0

32000

1

1411

Filter time constant for

flux stabilator

P2.6.5.16

Make Flux

Time

0.000

60.000

s

0.001

0.200

660

Time to magnetise the

motor

P2.6.5.17

MakeFluxVolta

ge

0.00

120.00

%

0.01

2.01

661

Magnetising voltage in

###.## % of motor

nominal voltage.

P2.6.5.18

MeasRsVolt

Drop

0

65535

1 0

662

Measured voltage drop at

stator resistance between

two phases with nominal

current of the motor. This

is estimated during ID

Run.

P2.6.5.19

Ir Add Zero

Point Voltage

0

30000

664

Table 13 Drive Control/Open Loop Ctrl parameters, G2.6.5

Page 19

apfiff10 sia-i VACON® • 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.7.2 Drive Control/UV/OV CTRL stab

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.6.6.1

Undervolt Ctrl

0 1 1 0

608

Under voltage controller

0=Off, 1=On.

P2.6.6.2

Uvolt Ref Sel

0 1 1 1

1260

Selection of under voltage

Reference for Undervoltage Controller.

0=UV ref min

1=0.8*

EstimatedDCNomVoltage

P2.6.6.3

Undervolt Kp

0

32767

1

1415

Gain for the P term of

Under voltage controller

P2.6.6.4

Undervolt Ti

0

32767

1

1416

Gain for I term of under

voltage controller

P2.6.6.5

Over volt Ctrl

0 2 1 0

607

Over voltage controller

0=Off,

1=On with no Ramp,

2=On with ramp.

P2.6.6.6

Overvolt Ref Sel

0 2 1 1

1262

Overvoltage reference

level depending on the

status of the brake

chopper

P2.6.6.7

OverVolt Kp

0

32767

1

1468

Gain for P term of overvoltage controller

P2.6.6.8

OverVolt Kp Add

0

32767

1

1425

Addition gain for P term of

overvoltage controller till

FWP.

P2.6.6.9

OverVolt Ti

0

32767

1

1409

Gain for I term of the overvoltage controller.

P2.6.6.10

VoltStab Kp

0

1000

1

1417

Gain for the voltage

stabilator

P2.6.6.11

VoltStab TC

0

1000

1

1418

Damping rate for the

voltage stabilator.

Table 14. Drive Control/UV/OV Ctrl, Stab Parameters, G2.6.6

Page 20

20 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.8 Motor Control

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.7.1

Start Function

0 1 1 0

505

0=Starts from 0-speed,

1=Flying start

P2.7.2

Stop Function

0 1 1 0

506

0=Coast stop

1=Ramp stop

P2.7.3

Emstop Mode

0 3 1 1

1276

Stop function in Emergency Stop

0=Coast Stop

1=Ramp stop

2=Torque limit Stop

3=Constant Power Stop

P2.7.4

Motor Ctrl Mode

0 3 1 0

600

0=Open Loop Freq ctrl,

1=Open Loop Speed crtl

2=Open Loop speed

/torque ctrl as per P2.7.5

3=Closed Loop speed/

torque Control as per

P2.7.5

P2.7.5

Torque Select

1 5 1 1

1278

1=Speed Control

2=Torque Control

3=Min of torque ref and

SPC Out

4=Max of torque ref and

SPC Out

5=Window Control

P2.7.6

CurrentControlKp

1

10000

1 4000

617

Current controller p-gain

(0 ... 10000)

P2.7.7

CurrentControlTi

0.1

100.0

ms

0.1

1.5

1400

Current controller

integrator time constant

(0 ... 1000) = 0...100.0 ms

P2.7.8

Switching Freq

1.0

Switching

FreqMax

KHz

0.1 601

Switching frequency.

P2.7.9

Dynamic Damp Kp

0.00

100.00

%

0.01

0

1406

Dynamic damping gain

when parameter 2.7.5

Torque Select is greater

than 1. 1.00 means nominal torque for nominal

speed difference.

P2.7.10

Dynamic Damp TC

0

32000

ms 1 0

1407

Bandpass filter time constant for dynamic damping. 0 means static damping proportional to frequency error.

P2.7.11

DC Magn Current

0.0

Motor

Nom

Current

A

627

Constant DC Magnetization Current

P2.7.12

DC Magn Time

0

10000

ms 1 0

628

Constant DC magn. time

[ms] in ramp start

P2.7.13

Start 0Speed Time

0

32000

ms 1 100

615

Time of zero speed ref at

start in ms, (0 ...32000)

P2.7.14

Stop 0SpeedTime

0

32000

ms 1 100

616

Time of zero speed ref at

ramp stop in ms, (0

...32000)

P2.7.15

Stop State Flux

0

150.0

% 1 100.0

1401

The % of rated flux maintained after the motor is

stopped for the time Flux

Off Delay.

P2.7.16

Flux Off Delay

-1

32000

s 1 0

1402

The time in seconds for

which the flux will be

maintained in the motor.

Page 21

apfiff10 sia-i VACON® • 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

Setting this value to 1

will keep the Stop State

Flux continuously.

P2.7.17

MotTempCompen

0 3 1 0

1426

Motor temperature

compensation.

0= Disabled

1= From TS1 temp

2= From TS2 temp.

3= Internal

P2.7.18

Modulation Index

0

200 % 1

100

655

Table 15. Motor control parameters, G2.7

3.8.1 PMSM Control

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.7.18.1

Flux Control Kp

0.00

320.00

%

0.01

5.00

651

Gain for the flux

controller in %.

P2.7.18.2

Flux Control Ti

0.0

100.0

ms

0.1

5.0

652

Integral time constant for

flux current controller in

ms.

P2.7.18.3

RsIdentification

0 1 1 0

654

Stator resistance

identification during every

start.

0 = Disabled

1 = Enabled.

P2.7.18.4

Modulation

Index

0

200 % 1

100

655

Modulation index in % for

closed loop operation.

P2.7.18.5

EncAngleOffset

0

65535

1 0

649

Low word of (endat) encoder angle corresponding to shaft 0 position.

This parameter is only for

monitoring and back up

purpose. It is used only

with absolute encoders .

P2.7.18.6

Encoder Zero

position

identification

mode

0 2 0

1691

0 = Automatic

1 = Forced

2 = On Power UP

P2.7.18.7

Start

positioning

current

0,0

200,0

% 50,0

1601

P2.7.18.8

Polarity pulse

current

0,0

200,0

% 0,0

1602

P2.7.18.9

Ls Voltage Drop

0

3000

512

673

P2.7.18.10

Motor BEM

Voltage

0,00

320,00

%

0,01

90,00

674

P2.7.18.11

Estimator Kp

0

3000

1 400

1781

Table 16. PMSM control parameters, G2.7.17

Page 22

22 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.9 Limit Settings

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.8.1

Zero Speed Level

0

Motor

NomSpeed

rpm 1 15

1283

Speed below which Bit 11

of Auxiliary Status Word

becomes TRUE

P2.8.2

Zero Speed Mon

0 1 1 1

1284

Monitoring of Zero speed

is based on

0=Speed Ref,

1=Speed Actual

P2.8.3

Speed Maximum

-10000

10000

rpm 1 1440

1285

Maximum limit of the

Speed reference

P2.8.4

Speed Minimum

-10000

10000

rpm 1 0

1286

Minimum Limit for the

Speed Reference

P2.8.5

Current Limit

0,01 * IH

2 * IH

A

0.1 107

Maximum Total Current

Limit.

P2.8.6

Torque Limit Mot

0.0

300.0

%

0.1

300.0

1287

Torque limit for the

motoring side.

P2.8.7

Torque Limit Gen

0.0

300.0

%

0.1

300.0

1288

Torque limit for the

generator side.

P2.8.8

SPC OUT Limit

0.0

300.0

%

0.1

300.0

1382

Absolute maximum limit

for the speed controller

output in closed loop

control in % of motor

nominal torque.

P2.8.9

Power Limit Mot

0.0

300.0

%

0.1

300.0

1289

Power limit for motor

side

P2.8.10

Power Limit Gen

0.0

300.0

%

0.1

300.0

1290

Power limit for generator

side

P2.8.11

PullOutTorque

0.0

1000.0

%

0.1

250.0

1291

Pull Out Torque limit of

the motor

P2.8.12

System Inertia

0

30000

kgm2 1 0

1292

Inertia of the system in

kgm2.

P2.8.13

Max Brake Power

0.000

30.000

kW

0.00

1

0.000

1293

Max Braking Power Limit

in Constant Power

Emergency Stop

P2.8.14

Max Braking Torq

1

30000

Nm 1 1

1294

Max Braking Torque of

the motor in Constant

Power Emergency Stop

Table 17 Limit setting parameters, G2.8

Page 23

apfiff10 sia-i VACON® • 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.10 Speed Control

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.9.1

SPC Kp

1

1000

1 30

613

Speed controller P gain (0

P2.9.2

SPC Ti

0

32000

ms 1 300

614

Speed controller integrator time constant

0...32000ms

P2.9.3

Kp Min

0

100

% 1 100

1295

Relative gain (%)of SPC Kp

if torque is below P2.9.4

P2.9.4

Min Point

0

100.0

%

0.1

0.0

1296

Torque Limit for adaptive

SpeedControl_Kp (1000 =

nominal)

P2.9.5

Min Filt

0

1000

ms 1 0

1297

Filtering TC for Speed

Control_Kp in ms

P2.9.6

SPC Kp FWP

1

200

% 1 100

1298

Relative final gain of speed

controller at field weakening in % of SPC Kp.

<100 reduces gain,

>100 increases gain above

FWP

P2.9.7

SPC Kp N0

0

100

% 1 100

1299

Relative gain (%) below

SPC Kp N0 Point Init:=100

P2.9.8

N0 Point

P2.8.4

P2.8.3

rpm 1 0

1300

Below this speed N0 the

speed controller gain will

be SPC Kp N0

P2.9.9

N1Point

P2.8.4

P2.8.3

rpm 1 0

1301

Above this speed N1 speed

controller gain will be SPC

Kp

P2.9.10

Mech AccComp

TC

0.00

300.00

s

0.01

0.00

1302

Mechanical time constant

for acceleration compensation in Sec (0...300 s)

P2.9.11

Accel Comp Filt

0

1000

ms 1 0

1303

Filter time constant for

Acceleration compensation in ms

P2.9.12

LoadDrooping

0.00

100.00

%

0.01

0.00

620

Load Drooping = 0 ...

100.00% of nominal speed

at nominal torque

P2.9.13

Drooping Time

0.00

327.67

s

0.01

0.00

656

Load drooping time in ms.

Value 0 means static or

continuous drooping.

P2.9.14

Window Pos RPM

0

P2.1.5

rpm 1 0

1304

Window width in RPM for

positive direction

P2.9.15

Window Neg RPM

0

P2.1.5

rpm 1 0

1305

Window width in RPM for

negative direction

P2.9.16

Window Off Pos

0

P2.9.14

rpm 1 0

1306

Window OFF limit in RPM

for hysteresis in Window

ctrl in positive direction

P2.9.17

Window Off Neg

0

P2.9.15

rpm 1 0

1307

Window OFF limit in RPM

for hysteresis in Window

ctrl in Negative direction

P2.9.18

Slip Adjust

0

500

% 1 100

619

Slip adjust 0...500%

P2.9.19

Speed Error Filt

0

1000

ms 1 0

1311

Filter time for the speed

error

P2.9.20

Speed Act Filter

0.0

250.0

ms

0.1

0.0

1308

Filter time for the measured speed from the

encoder.

P2.9.21

SpeedErrLowPass

F

-3200,0

3200,0

Hz

0,1

0,0

1185

Speed error LP filter cutoff

frequency.

P2.9.22

AntiSwinLowPasT

C

-32000

32000

ms 1 0

1186

Lowpass time constant for

second order Antiswing

lowpass filter.

Page 24

24 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.9.23

AntiSwingGain

-32000

32000

% 1 100

1187

Gain for Antiswing function

in % to optimize step

response

P2.9.24

AntiSwingTC

-32000

32000

ms 1 0

1188

BandStop/swinging time

constant in ms for

AntiSwing control to

reduce swinging and/or

speed overshoot.

P2.9.25

Speed controller

P gain (CL)

0

32767

3000

637 P2.9.26

Speed controller

I gain (OL)

0

32767

300 638

P2.9.27

Load Drooping

Removal

0 2

0 1534

0=Normal

1= At zero Freq Lim

2=Linear zero to Fnom

Table 18 Speed control parameters, G2.9

3.11 Oscillation Damp

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.10.1

Oscill Damp Sel

0 2 1 0

1310

Resonance damper

selector

0 = Not in Use

1 = BandPass

2 = BandStop + BandPass

P2.10.2

Oscill Freq

0.0

450.0

Hz

0.1

0.0

1313

Resonance damper

natural frequency

1.0...450.0 Hz

0 = Not in use

P2.10.3

Oscill Damp Gain

0.0

100.0

%

0.1

0.0

1314

Resonance damper damping gain at notch frequency 0 ... 100.0%

P2.10.4

Phase Shift

0

360

Deg 1 0

1315

Resonance Damper Phase

shift at Notch frequency

0...360 deg

Table 19. Oscillation damping parameters, G2.10

Page 25

apfiff10 sia-i VACON® • 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.12 Brake & Fan Control

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.11.1

Brake In Fault

0 1 1 0

1319

Selection of mechanical

brakes closing on fault in

drive

0=Brakes applied at zero

speed (par. 3.8.1)

1=brakes are applied immediately on Fault

P2.11.2

Brake In Emstop

0 1 1 0

1318

Selection of mechanical

brakes closing on emergency stop.

0=Brakes applied at zero

speed (P2.8.1)

1=brakes are applied immediately on emergency

stop

P2.11.3

Brake Open limit

0.0

3200.0

rpm

0.1

0.0

1535

P2.11.4

Brake Close Limit

0.0

3200.0

rpm

0.1

0.0

1539 P2.11.5

Brake Fault Delay

0.0

3200.0

s

0.1

1.0

352

P2.11.6

Brake mechanical

Delay

0.0

3200.0

s

0.1

0.0

1544 P2.11.7

Brake On/Off

current limit

0.0

Imax

A

0.1

0.0

1085 P2.11.8

Mot Fan OffDelay

0.00

300.00

s

0.01

20.00

1320

Motor fan off delay

###.## Seconds

Table 20. Brake and fan control parameters, G2.11

Page 26

26 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.13 Master Follower

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.12.1

M/F Mode

0 4 1 0

1324

0=None

1=Master

2=Follower

3= DriveSynch Master

4=DriveSynch Follower

P2.12.2

Follower SpRef

0 2 1 0

1327

Source of speed reference

for the drive if Par 2.12.1=2

Follower

0=Drive´s own reference

1=Master speed reference

before Ramp

2=Master speed reference

after Ramp.(Follower

Drive ramp is bypassed in

this case)

P2.12.3

Follower Start

Delay

0.00

327.67

s

0.10

0.00

1398

Delay in starting the multiple wind current follower

after the master is started.

P2.12.4

Follower phase

shift

0,0

360,0

Dec

0,0 1518

Table 21 Master Follower parameters, G2.12

Page 27

apfiff10 sia-i VACON® • 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.14 Protections

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.13.1

AI <4mA

0 2 1 0

700

If value of Analogue input

value

P2.13.2

Panel Commn.

1 2 1 1

1329

Operation in case Control

Place=2 and a keypad

stops communicating

P2.13.3

External Fault

0 2 1 2

701

Select the action in case of

External fault

P2.13.4

Input Ph. Superv

0 2 1 0

730

Operation in case of Input

Phase loss.

P2.13.5

Output Ph. Superv

0 2 1 0

702

Operation in case of motor

phase loss

P2.13.6

Earth Fault

0 1 1 0

703

Operation in case of Earth

Fault

P2.13.7

Earth Fault Curr

0.0

100.0

%

0.1

50.0

1333

Max. level for Earth

current in % of unit

current.

P2.13.8

Earth Fault Delay

0

5000

ms 1 800

1334

Earth fault wait time in ms

P2.13.9

Motor Stall

0 2 1 1

709

Operation in case of Motor

stall.

P2.13.10

Stall Current

0.0

2 * IH

A

0.1

10.0

710

Current limit of motor stall

protection

P2.13.11

Stall Freq Lim

0.00

P2.1.3

Hz

0.01

25.00

712

Max frequency for stall

protection, f[Hz] =

StallFrequency/FreqScale

P2.13.12

Stall Time Lim

1.00

120.00

s

0.01

15.00

711

Max time for stall

protection to operate.

P2.13.13

Thermistor

0 2 1 0

732

Action on thermistor fault

P2.13.14

Encoder Fault

0 3 1 0

1353

Encoder fault

P2.13.15

Mech Brake Fault

1 2 1 2

1316

Action on mechanical

brake fault. This fault is

enabled only if digital input

for mechanical brake

acknowledgement is

selected.

1= Warning

2= Fault

P2.13.16

Follower TimeOut

0.00

5.00

s

0.01

0.00

1352

Delay time for master

follower communication

Fault.

P2.13.17

FB

WatchdogDelay

0

5.00

s

0.01

1.05

1354

Profibus watchdog delay. If

set to 0 watchdog function

is disabled.

P2.13.18

PT100 Num In Use

0 5 1 0

739

Select the number of

PT100 channels used on

OPTB8 board.

P2.13.19

PT100 AlarmLimit

-30

200

C

1

110

1347

Select the temp. limit for

PT100 sensor above which

PT100 Temp. alarm is

generated.

Note that PT100 can be

connected through

analogue input as

explained in the manual or

through OPTB8 card for

PT100. The limit is

common for all.

Page 28

28 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

P2.13.20

PT100 Fault Limit

PT100

Alarm

Limit

200

C

1

120

1348

Select the temp. limit for

PT100 sensor above which

PT100 Temp. fault is

generated.

Note that PT100 can be

connected through

analogue input as

explained in the manual or

through OPTB8 card for

PT100. The limit is

common for all.

P2.13.21

Motor

CalcTempProt

0 2 1 0

704

Operation in case of Motor

thermal protection

P2.13.22

ThermalTime

Const

1

200

min 1 45

707

Motor Thermal Time

Constant in minutes, (1...

200)

P2.13.23

Zero Spd Cooling

0.0

100.0

%

0.1

40.0

706

Motor cooling ability at

zero speed unit in %

P2.13.24

Motor Duty Cycle

0

300

% 1 100

708

Motor Duty Cycle in %

P2.13.25

Underload Prot

0 2 1 0

713

Operation in case of

Underload.

P2.13.26

Speed Zero Load

0.0

300.0

%

0.1

0.0

714

Underload load curve at

zero freq,unit

P2.13.27

Speed Nom Load

0.0

300.0

%

0.1

0.0

1341

Underload load curve at

nominal freq,unit

P2.13.28

UnderLdSpeed

Nom

0

Motor

NomSpeed

Max

rpm 1 1440

1342

Speed limit value for

Underload protection

P2.13.29

Auto reset word 1

0

65535

1 0

1171

Select faults that you want

to autoreset

B0 +1 = Reserved

B1 +2 = Reserved

B2 +4 = AutoReset

Under Voltage Fault

P2.13.30

FB

Communication

fault response

1 4 2

733

0 = No Action

1 = Warning

2 = Warning; Prev.Freq.

3 = Warning; Preset Freq.

4 = Fault

P2.13.31

FB Fault delay

0,00

320,00

s 0

1430

P2.13.32

FB Fault speed

-30000

30000

Rpm 0

728

P2.13.33

Encoder Iq fault

limit

0

300 %

100

1800

P2.13.34

Encoder fast fault

freq limit

0,00

320,00

Hz 10,00

1801

P2.13.35

Parameter Lock

0 1 0

1086

0 = Disabled

1 = Enabled

P2.13.36

Speed Error Mode

0 3

0 752

0=No response

1=Warning

2=Fault,stop acc. to 2.4.7

3=Fault,stop by coasting

P2.13.37

Speed Error Limit

0,0

100,0

%

5,0 753

P2.13.38

Speed Fault Delay

0,00

100,00

S

0,1 754

P2.13.39

Follower Fault

0 1

1536

Table 22. Protection parameters, G2.13

Page 29

apfiff10 sia-i VACON® • 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.15 Flux Reference Handling

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.14.1

Flux Curve 10%

0.0

250.0

%

0.1

10.0

1355

Flux linearization point 1

P2.14.2

Flux Curve 20%

0.0

250.0

%

0.1

20.0

1356

Flux linearization point 2

P2.14.3

Flux Curve 30%

0.0

250.0

%

0.1

30.0

1357

Flux linearization point 3

P2.14.4

Flux Curve 40%

0.0

250.0

%

0.1

40.0

1358

Flux linearization point 4

P2.14.5

Flux Curve 50%

0.0

250.0

%

0.1

50.0

1359

Flux linearization point 5

P2.14.6

Flux Curve 60%

0.0

250.0

%

0.1

60.0

1360

Flux linearization point 6

P2.14.7

Flux Curve 70%

0.0

250.0

%

0.1

70.0

1361

Flux linearization point 7

P2.14.8

Flux Curve 80%

0.0

250.0

%

0.1

80.0

1362

Flux linearization point 8

P2.14.9

Flux Curve 90%

0.0

250.0

%

0.1

90.0

1363

Flux linearization point 9

P2.14.10

Flux Curve 100%

0.0

250.0

%

0.1

100.0

1364

Flux linearization point 10

P2.14.11

Flux Curve 110%

0.0

250.0

%

0.1

110.0

1365

Flux linearization point 11

P2.14.12

Flux Curve 120%

0.0

250.0

%

0.1

120.0

1366

Flux linearization point 12

P2.14.13

Flux Curve 130%

0.0

250.0

%

0.1

130.0

1367

Flux linearization point 13

P2.14.14

Flux Curve 140%

0.0

250.0

%

0.1

140.0

1368

Flux linearization point 14

P2.14.15

Flux Curve 150%

0.0

250.0

%

0.1

150.0

1369

Flux linearization point 15

Table 23. Flux reference handling parameters, G2.14

3.16 Startup Torque

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.15.1

Startup TorqueSel

0 3 1 0

621

0 = Not in use

1 = Torque Memory,

2 = Torque Reference

3 = Startup Torque

FWD/REV

P2.15.2

Startup Torque

Time

0

10000

ms 1 0

1371

Maximum time for startup

torque in ms, (0 ...10000)

P2.15.3

Startup Torque

FWD

-300.0

300.0

%

0.1

0.0

633

StartupTorqueReference

to forward direction -300.0

...300.0% of motor nominal

torque

P2.15.4

Startup Torque

REV

-300.0

300.0

%

0.1

0.0

634

StartupTorqueReference

to reverse direction -300.0

...300.0%.

P2.15.5

Torque Memory

Source

0 2 1 1

1374

Source for torque

memory. At the next start

the same startup torque

reference will be used.

P2.15.6

Torque Memory

Reference

-300.0

300.0

%

0.1

0.0

1375

Fixed reference for the

torque memory

Table 24. Start-up Torque parameters, G2.15

3.17 Monitor Settings

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.16.1

Speed Mon Filter

0

32000

ms 1 20

1376

Filter in ms for monitoring

signal V1.1.2 Motor Speed.

P2.16.2

Curr Mon Filter

20

2000

ms 1 20

1377

Filter in ms for monitoring

signal V1.1.4 Motor Curr

P2.16.3

Torq Mon Filter

20

2000

ms 1 20

1378

Filter in ms for monitoring

signal V1.1.5 Motor Torque

Table 25 DAC parameters, PG.16

Page 30

30 • VACON® apfiff10 sia-i

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3.18 Data Mapping

Code

Parameter

Min

Max

Unit

Step

Default

ID

Note

P2.17.1

PD IN1 ID

0

65535

1 0

876 P2.17.2

PD IN2 ID

0

65535

1 0

877 P2.17.3

PD IN3 ID

0

65535

1 0

878 P2.17.4

PD IN4 ID

0

65535

1 0

879

P2.17.5

PD IN5 ID

0

65535

1 0

880

P2.17.6

PD IN6 ID

0

65535

1 0

881

P2.17.7

PD IN7 ID

0

65535

1 0

882

P2.17.8

PD IN8 ID

0

65535

1 0

883

P2.17.9

PD OUT1 ID

0

65535

1 4

852

Torque

P2.17.10

PD OUT2 ID

0

65535

1 1163

853

Aux Control Word

P2.17.11

PD OUT3 ID

0

65535

1 1172

854

Fault Word 1

P2.17.12

PD OUT4 ID

0

65535

1 1173

855

Fault Word 2

P2.17.13

PD OUT5 ID

0

65535

1 15

856

DIN Status Word 1

P2.17.14

PD OUT6 ID

0

65535

1 1174

857

Alarm Word

P2.17.15

PD OUT7 ID

0

65535

1 1170

858

Motor Shaft Rounds

P2.17.16

PD OUT8 ID

0

65535

1 1169

859