Page 1

vacon

ac drives

®

nx

arfif106

Grid Converter

with General Grid Codes

Application manual

Page 2

Page 3

arfif106 Grid Converter + Grid Codes VACON® · 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

Table of contents

Document: DPD01978A

Software code: ARFIF106V128

Version release date: 4.6.2021

1. General ................................ ................................................................................................ .... 9

1.1 AFE Control ............................................................................................................................... 9

1.2 Island (Static Power Supply) .................................................................................................. 10

1.3 Micro Grid................................................................................................................................ 11

1.4 Acronyms ................................................................................................................................ 12

1.5 Compatibility issues in parameters between versions ........................................................ 13

2. Grid Codes ................................ ............................................................................................. 14

2.1 Grid Codes compliance .......................................................................................................... 15

3. Quick start and operation principles ..................................................................................... 17

3.1 Quick start instructions.......................................................................................................... 17

3.2 In case of parallel AFE: .......................................................................................................... 17

3.3 Pre-Charging of DC ................................................................................................................ 19

3.4 Main circuit breaker control (MCB) ....................................................................................... 20

3.5 Start Sequence ....................................................................................................................... 21

3.6 Stop sequence ........................................................................................................................ 22

3.7 Start Stop timing diagram ..................................................................................................... 23

3.8 Start Stop Timing Diagram with Grid Codes......................................................................... 24

3.9 Operation principle: Droop Speed Control Mode ................................................................. 25

3.10 Operation principle: Isochronous Control Mode .................................................................. 25

3.11 Voltage compensation ............................................................................................................ 26

3.12 OPT-D7 voltage measurement option board ........................................................................ 27

4. Control I/O ............................................................................................................................. 29

4.1 Slot A and Slot B terminals .................................................................................................... 29

4.2 Terminal To Function (TTF) ................................................................................................... 29

4.1 Defining inputs and outputs ................................................................................................... 30

4.1 Defining a terminal in NCDrive .............................................................................................. 31

5. Monitoring signals ................................................................................................................. 32

5.1 Monitoring value tables.......................................................................................................... 32

5.1.1 Monitoring values 1 .................................................................................................... 32

5.1.2 Monitoring values 2 .................................................................................................... 34

5.1.3 Fieldbus monitoring values ....................................................................................... 34

5.1.4 I/O monitoring values ................................................................................................. 35

5.1.5 Master / Follower ....................................................................................................... 35

5.1.6 Licence activation status ........................................................................................... 35

5.1.7 Grid Code .................................................................................................................... 36

5.1.8 PI Power Controller ................................................................................................... 36

5.1.9 Active Limits ............................................................................................................... 36

Page 4

4 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

5.1.10 Line Monitoring .......................................................................................................... 36

5.2 Description of monitoring values .......................................................................................... 37

5.2.1 Monitoring 1 values .................................................................................................... 37

5.2.2 Monitoring 2 values .................................................................................................... 39

5.2.3 Fieldbus monitoring values ....................................................................................... 41

5.2.4 I/O monitoring values ................................................................................................. 47

5.2.5 Master Follower ......................................................................................................... 48

5.2.5.1 Currents ..................................................................................................................................... 49

5.2.5.2 Statuses ..................................................................................................................................... 50

5.2.6 Licence activation status ........................................................................................... 51

5.2.7 Grid Code .................................................................................................................... 52

5.2.8 PI Power Controller ................................................................................................... 57

5.2.9 Active Limits ............................................................................................................... 57

5.2.10 Line Monitoring .......................................................................................................... 57

6. Parameter list ........................................................................................................................ 58

6.1 Basic parameters ................................................................................................................... 58

6.2 Reference handling ................................................................................................................ 58

6.2.1 DC Reference Tuning ................................................................................................. 59

6.2.2 Power / Frequency reference ................................................................................... 59

6.2.2.1 PID Power Controller for AFE ...................................................................................................... 60

6.2.2.2 High Frequency Power Reference ............................................................................................... 60

6.2.2.3 Low Frequency Power Reference ................................................................................................ 60

6.2.3 Reactive Reference .................................................................................................... 61

6.2.4 AC voltage reference ................................................................................................. 61

6.3 Ramp control .......................................................................................................................... 61

6.4 Input signals ........................................................................................................................... 62

6.4.1 Basic settings ............................................................................................................. 62

6.4.2 Digital inputs .............................................................................................................. 63

6.4.3 Analogue input 1 ........................................................................................................ 64

6.4.4 Analogue input 2 ........................................................................................................ 64

6.4.5 Analogue input 3 ........................................................................................................ 65

6.4.6 Analogue input 4 ........................................................................................................ 65

6.5 Output signals ......................................................................................................................... 66

6.5.1 Digital output signals ................................................................................................. 66

6.5.2 Delayed DO 1 .............................................................................................................. 67

6.5.3 Delayed DO 2 .............................................................................................................. 67

6.5.4 Analogue output 1 ...................................................................................................... 68

6.5.5 Analogue output 2 ...................................................................................................... 69

6.5.6 Analogue output 3 ...................................................................................................... 70

6.5.7 Options ........................................................................................................................ 70

6.6 Limit settings .......................................................................................................................... 71

6.6.1 Current limit ............................................................................................................... 71

6.6.2 Power limit ................................................................................................................. 71

6.6.3 Frequency limit .......................................................................................................... 71

6.6.4 Micro Grid ................................................................................................................... 71

6.6.5 DC voltage ................................................................................................................... 72

6.7 Drive control ........................................................................................................................... 72

6.7.1 AFE control ................................................................................................................. 72

6.7.2 Identification ............................................................................................................... 73

Page 5

arfif106 Grid Converter + Grid Codes VACON® · 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

6.7.3 Active Compensation ................................................................................................. 73

6.8 Master/Follower ..................................................................................................................... 73

6.9 Protections .............................................................................................................................. 74

6.9.1 General ....................................................................................................................... 74

6.9.2 PT-100 ......................................................................................................................... 75

6.9.3 Earth fault ................................................................................................................... 75

6.9.4 Fieldbus fault .............................................................................................................. 75

6.9.5 External fault .............................................................................................................. 76

6.9.6 Grid voltage D7 ........................................................................................................... 76

6.9.7 Grid frequency ............................................................................................................ 76

6.9.8 Supply Voltage ............................................................................................................ 76

6.9.9 Over Load .................................................................................................................... 77

6.9.10 opt-d7 protections ...................................................................................................... 77

6.9.11 Cooling protection ...................................................................................................... 77

6.9.12 Extra ............................................................................................................................ 77

6.10 Fieldbus ................................................................................................................................... 78

6.11 Micro Grid................................................................................................................................ 80

6.12 Synchronisation to external grid ........................................................................................... 81

6.13 Reserved ................................................................................................................................. 81

6.14 ID control functions ................................................................................................................ 82

6.14.1 Value control .............................................................................................................. 82

6.14.2 DIN ID control 1 .......................................................................................................... 82

6.14.3 DIN ID control 2 .......................................................................................................... 82

6.14.4 DIN ID control 3 .......................................................................................................... 83

6.14.5 DIN ID control 4 .......................................................................................................... 83

6.14.6 ID Controlled Digital Output 1 ................................................................................... 83

6.14.7 ID Controlled Digital Output 1 ................................................................................... 83

6.15 Auto Fault reset ...................................................................................................................... 83

6.16 Grid voltage PI ........................................................................................................................ 84

6.17 Grid Code parameters ............................................................................................................ 85

6.17.1 Anti-islanding ............................................................................................................. 85

6.17.2 FRT (Fault Ride-Through) .......................................................................................... 85

6.17.2.1 FRT Timer ................................................................................................................................... 85

6.17.3 Reconnection .............................................................................................................. 86

6.17.4 Line Voltage trip limits ............................................................................................... 87

6.17.5 Line Frequency trip limits ......................................................................................... 88

6.17.6 Dynamic reactive current injection ........................................................................... 89

6.17.6.1 Linear Under Voltage .................................................................................................................. 89

6.17.6.2 Linear Over Voltage .................................................................................................................... 89

6.17.6.3 Power Lock Under Voltage ......................................................................................................... 89

6.17.6.4 Power Lock In/Out Over Voltage ................................................................................................. 89

6.17.6.5 Dynamic Grid Support ................................................................................................................ 90

6.17.7 Reactive power control .............................................................................................. 91

6.17.7.1 Q(U) Power ................................................................................................................................ 91

6.17.7.2 Q(U) Curve ................................................................................................................................. 91

6.17.7.3 Q(P) curve .................................................................................................................................. 91

6.17.8 Power Limit/Reference.............................................................................................. 92

6.17.8.1 High Frequency Power Limit ....................................................................................................... 92

6.17.8.2 High Voltage Power Limit ........................................................................................................... 92

6.17.8.3 Low Voltage Charge Limit ........................................................................................................... 92

6.17.8.4 Low Frequency Charge Limit ....................................................................................................... 93

Page 6

6 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

6.17.9 Power Reference ........................................................................................................ 94

6.17.9.1 Low Frequency Power Reference ................................................................................................ 94

6.17.9.2 High Frequency Power Reference ............................................................................................... 94

6.17.9.3 High Voltage Power Reference ................................................................................................... 94

6.17.10 Cos Phii Control.......................................................................................................... 95

6.17.10.1 Voltage Log In Log Out................................................................................................................ 95

6.17.10.2 Active Current ............................................................................................................................ 95

6.17.11 External Input ............................................................................................................. 95

6.17.12 Limited Grid Support.................................................................................................. 95

6.17.13 Options ........................................................................................................................ 96

6.18 Keypad control (Control panel: menu M3) ............................................................................ 97

6.19 System menu (Control panel: menu M6) .............................................................................. 97

6.20 Expander boards (Control panel: menu M7) ........................................................................ 97

7. Description of parameters..................................................................................................... 98

7.1 Basic parameters ................................................................................................................... 98

7.1.1 Transformer parameters ........................................................................................ 100

7.2 Reference handling .............................................................................................................. 101

7.2.1 DC Reference Tuning ............................................................................................... 103

7.2.2 Power /frequency reference ................................................................................... 104

7.2.2.1 PID Power Controller ................................................................................................................ 108

7.2.2.2 High Frequency Power Reference AFE Operation ...................................................................... 111

7.2.2.3 Low Frequency Power Reference AFE operation ....................................................................... 113

7.2.3 Reactive Reference Tuning ...................................................................................... 115

7.2.4 AC Voltage Reference .............................................................................................. 116

7.3 Ramp control ........................................................................................................................ 119

7.4 Input signals ......................................................................................................................... 120

7.4.1 Basic settings ........................................................................................................... 120

7.4.2 Digital input signals ................................................................................................. 122

7.4.2.1 Synchronization to external grid ............................................................................................... 123

7.4.2.2 Forced control place ................................................................................................................. 125

7.4.3 Analogue inputs 1-4 ................................................................................................. 127

7.4.3.1 Analogue input to any parameter ............................................................................................. 129

7.5 Output signals ....................................................................................................................... 130

7.5.1 Digital output signals ............................................................................................... 130

7.5.1.1 Fieldbus digital inputs connection............................................................................................. 131

7.5.2 Delayed digital output 1 & 2 .................................................................................... 132

7.5.3 Analogue output 1 & 2 & 3 ....................................................................................... 134

7.5.4 Options ...................................................................................................................... 138

7.6 Limit settings ........................................................................................................................ 139

7.6.1 Current limits ........................................................................................................... 139

7.6.2 Power limits.............................................................................................................. 143

7.6.3 Frequency limits....................................................................................................... 144

7.6.4 Micro Grid limits ....................................................................................................... 145

7.6.5 DC voltage regulators .............................................................................................. 146

7.7 Drive control ......................................................................................................................... 148

7.7.1 AFE Control .............................................................................................................. 151

7.7.2 Identification ............................................................................................................. 153

7.7.3 Active Compensation ............................................................................................... 153

7.8 Master/Follower ................................................................................................................... 154

7.9 Protections ............................................................................................................................ 156

Page 7

arfif106 Grid Converter + Grid Codes VACON® · 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

7.9.1 General settings ....................................................................................................... 156

7.9.2 PT-100 ....................................................................................................................... 159

7.9.2.1 Individual channel monitoring .................................................................................................. 160

7.9.3 Earth fault ................................................................................................................. 161

7.9.4 Fieldbus .................................................................................................................... 161

7.9.5 External fault ............................................................................................................ 162

7.9.6 Grid voltage D7 ......................................................................................................... 163

7.9.7 Grid frequency .......................................................................................................... 165

7.9.8 Supply voltage .......................................................................................................... 166

7.9.9 Over Load Protection ............................................................................................... 168

7.9.10 D7 protections .......................................................................................................... 169

7.9.11 Cooling protection .................................................................................... 170

7.9.12 Extra .......................................................................................................................... 170

7.10 Fieldbus ................................................................................................................................. 172

7.11 Micro Grid (uGrid) ................................................................................................................. 174

7.11.1 Generator Simulation .............................................................................................. 176

7.11.2 AFE operation mode selection ................................................................................ 177

7.12 Synch to external grid .......................................................................................................... 178

7.13 Reserved ............................................................................................................................... 179

7.14 ID functions ........................................................................................................................... 179

7.14.1 Value control ............................................................................................................ 179

7.14.2 DIN ID control ........................................................................................................... 181

7.14.3 ID Controlled Digital Output .................................................................................... 183

7.15 Auto Fault Reset ................................................................................................................... 184

7.16 Grid voltage PI controller ..................................................................................................... 185

7.16.1 Grid voltage PI OPT-D7 limits ................................................................................. 185

7.17 Grid Code parameters .......................................................................................................... 186

7.17.1 Anti-Islanding ........................................................................................................... 187

7.17.2 FRT (Fault Ride-Through) ........................................................................................ 189

7.17.2.1 FRT Timer ................................................................................................................................. 191

7.17.3 Reconnection ............................................................................................................ 193

7.17.3.1 Line OK Limits........................................................................................................................... 193

7.17.4 Line Voltage trip limits ............................................................................................. 194

7.17.5 Line Frequency trip limits ....................................................................................... 198

7.17.6 Reactive current injection (dynamic) ...................................................................... 200

7.17.6.1 Linear reference under voltage ................................................................................................. 201

7.17.6.2 Linear reference over voltage ................................................................................................... 202

7.17.6.3 Power Lock In and Out Reference under voltage. ...................................................................... 204

7.17.6.4 Power Lock In and Out Reference over voltage. ........................................................................ 207

7.17.6.5 Dynamic Grid Support .............................................................................................................. 210

7.17.7 Reactive Power Control ........................................................................................... 212

7.17.7.1 Q(U) Power .............................................................................................................................. 212

7.17.7.2 Q(U) Curve ............................................................................................................................... 213

7.17.7.3 Q(P) Curve ................................................................................................................................ 214

7.17.8 Power Limit .............................................................................................................. 215

7.17.8.1 High Frequency Power Limit ..................................................................................................... 216

7.17.8.2 High Frequency Power Limit with absolute high frequency limit................................................ 218

7.17.8.3 High Voltage Power Limit ......................................................................................................... 219

7.17.8.4 Low Voltage Charge Limit ......................................................................................................... 221

7.17.8.5 Low Frequency Charge Limit ..................................................................................................... 222

7.17.9 Power Reference ...................................................................................................... 224

Page 8

8 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

7.17.9.1 Low Frequency Power Reference .............................................................................................. 224

7.17.9.2 High Frequency Power Reference ............................................................................................. 226

7.17.9.3 High Voltage Power Reference ................................................................................................. 228

7.17.10 Cos Phii Control........................................................................................................ 229

7.17.10.1 Lock In and Out control ............................................................................................................ 229

7.17.10.2 Cos Phii Active Current Control ................................................................................................. 230

7.17.11 External Input ........................................................................................................... 231

7.17.12 Limited Grid Support................................................................................................ 231

7.17.13 Grid Code Options .................................................................................................... 232

8. Keypad control parameters ................................................................................................. 234

9. FB Status and control in detail ............................................................................................ 235

9.1 FB DC Reference .................................................................................................................. 235

9.2 State machine: Basic............................................................................................................ 236

9.2.1 FB Control Word Basic ............................................................................................ 236

9.3 State Machine: Standard ...................................................................................................... 237

9.3.1 Control Word: Standard ........................................................................................... 237

9.4 State machine: Vacon AFE 1 ................................................................................................ 238

9.4.1 Control Word: Vacon AFE 1 ..................................................................................... 238

9.1 State machine: Vacon AFE 2 ................................................................................................ 239

9.1.1 Control Word: Vacon AFE 2 Profile (3) .................................................................... 239

9.2 FB Status Word ..................................................................................................................... 241

10. Problem solving ................................................................................................................... 243

11. Commissioning .................................................................................................................... 244

11.1 Open loop voltage compensation ........................................................................................ 244

11.1.1 Parameters affect .................................................................................................... 244

11.1.2 No load tuning .......................................................................................................... 244

11.1.3 Tuning on the fly ....................................................................................................... 244

11.1.4 Tuning with load bank .............................................................................................. 245

11.1.5 Tuning against strong grid ...................................................................................... 245

11.1.6 Closed Loop Voltage Control ................................................................................... 245

12. Fault codes .......................................................................................................................... 246

Page 9

arfif106 Grid Converter + Grid Codes VACON® · 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

1. General

This application is not kept backwards compatible. See chapter Compatibility issues before you

update the application. The Grid Converter application is used to make AC grids with a possibility to

operate in parallel with other power sources. The Grid Converter application has three different

operation modes and only AFE mode supports grid codes:

- AFE mode with and without grid codes activated.

- Island mode (no grid code support).

- Micro Grid mode (no grid code support).

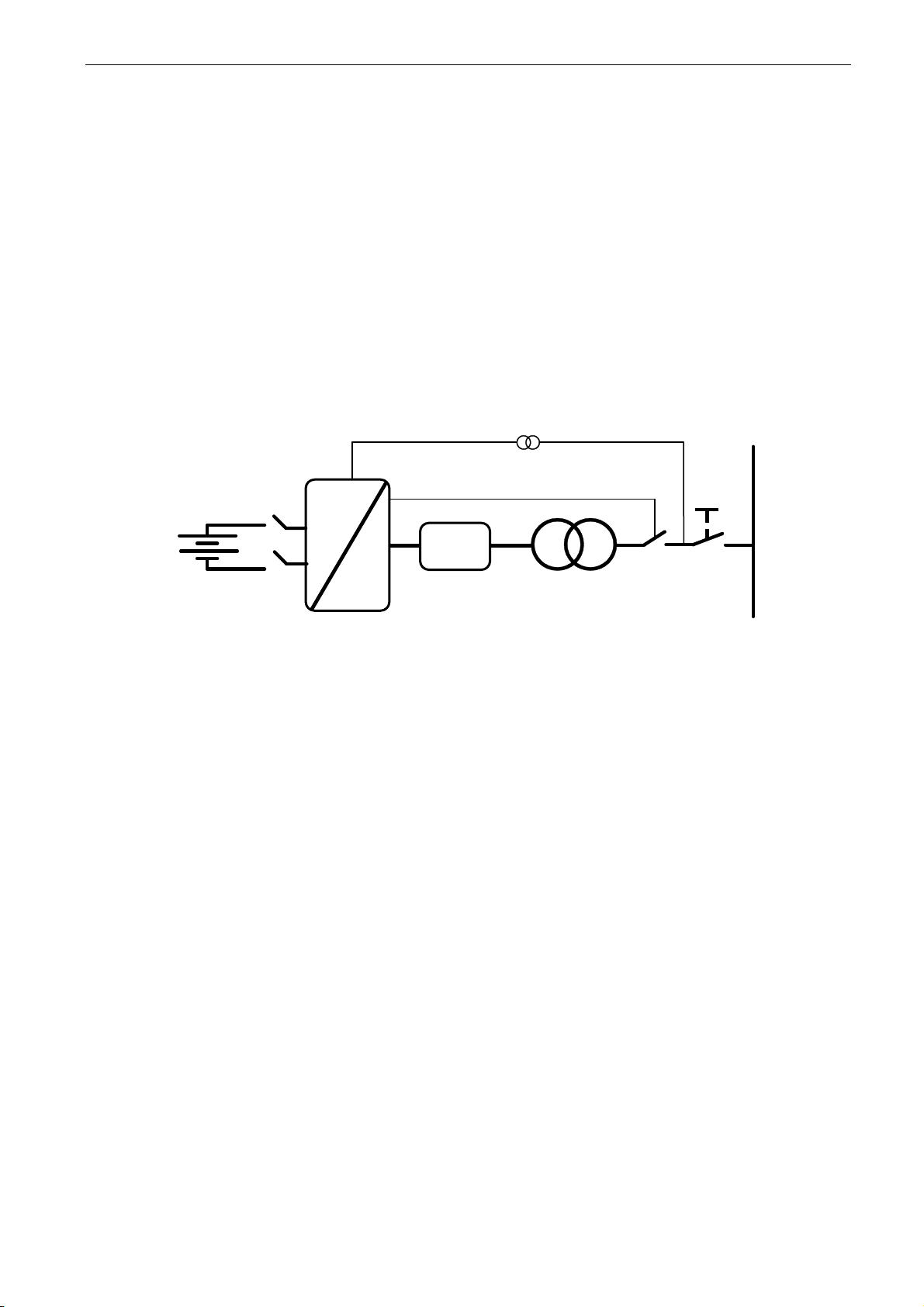

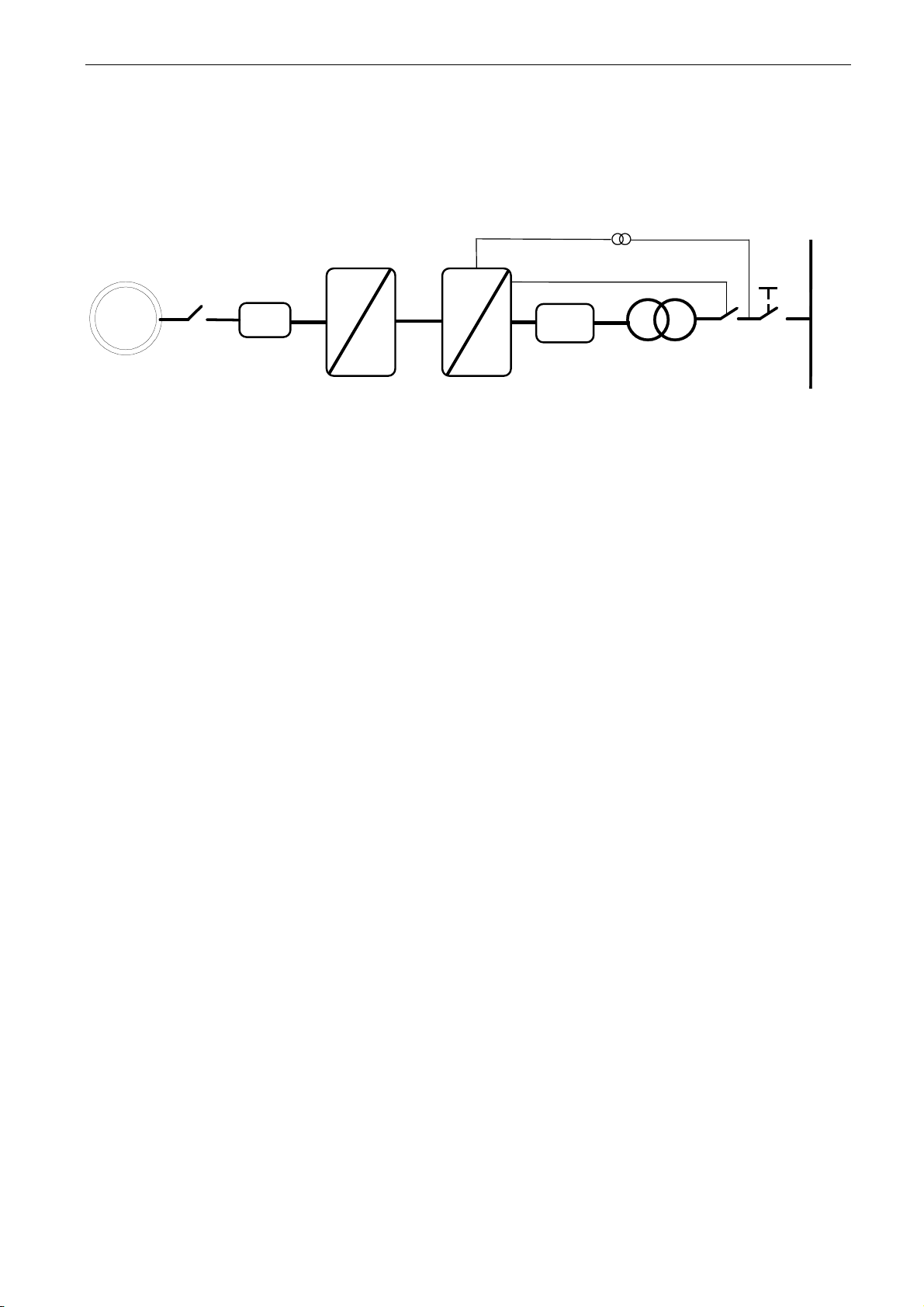

1.1 AFE Control

AFE function keeps constant DC voltage. AFE mode transfers power between DC and AC. AFE

cannot create grid by itself, it needs to be connected to existing grid.

Utility Grid

T1

Q1

U4

U3

U5

=

~

Filter

U4 = Transf. GC Side

U5 = Transf. Grid Side

D7

S1

D Y

T2

MCB Control

Figure 1.

Page 10

10 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

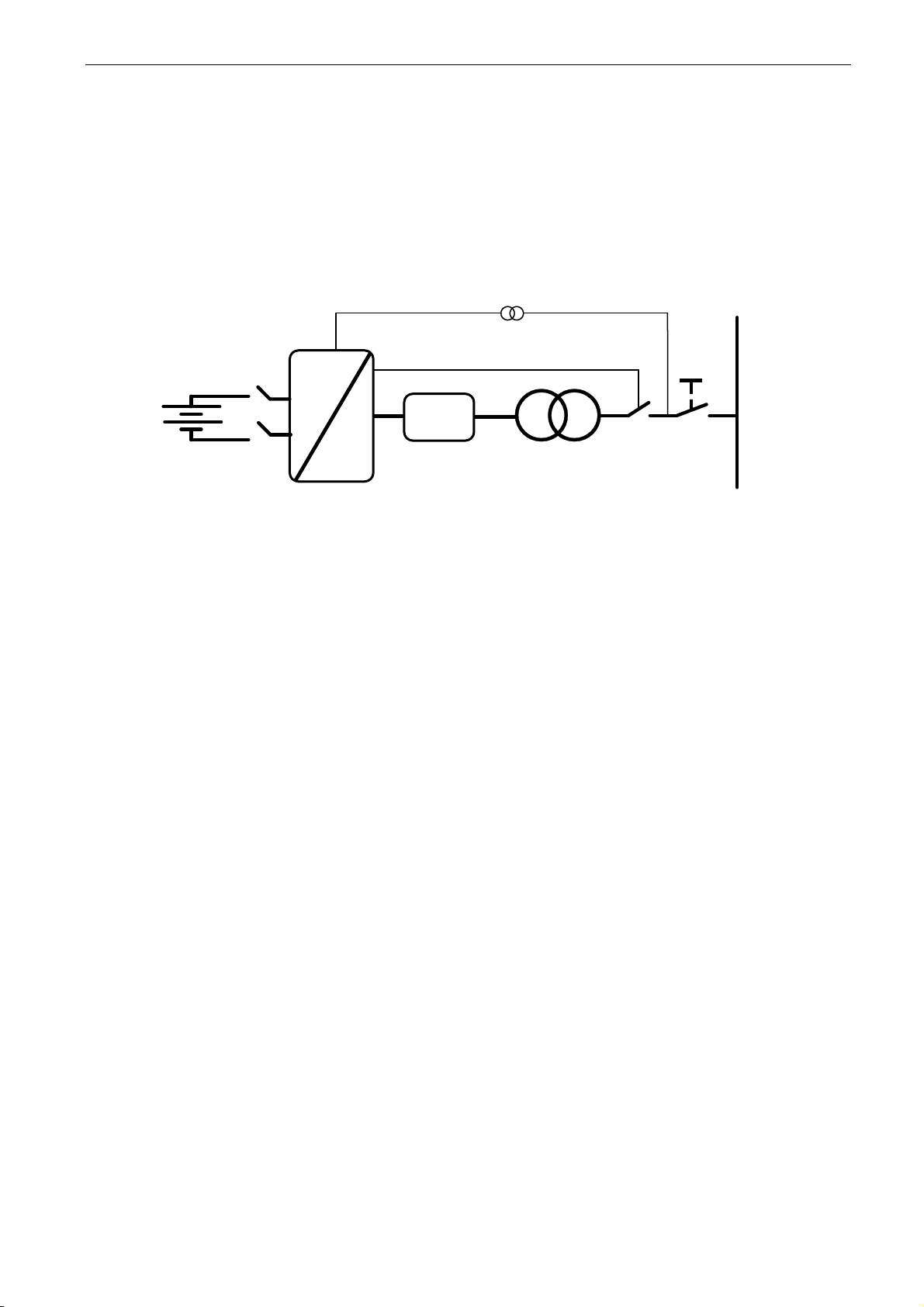

1.2 Island (Static Power Supply)

Island mode generates constant voltage and frequency. In island mode DC Voltage is not controlled.

Island mode cannot operate in parallel with other power sources in AC side, because the drive will

not balance reactive or active power with other power sources.

DC voltage level needs to be considered to have correct voltage on AC side in different load

situations, considering voltage losses in LCL filter and in transformer.

Utility Grid

T1

Q1

U4

U3

U5

=

~

Filter

U4 = Transf. GC Side

U5 = Transf. Grid Side

D7

S1

D Y

T2

MCB Control

Figure 2.

Page 11

arfif106 Grid Converter + Grid Codes VACON® · 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

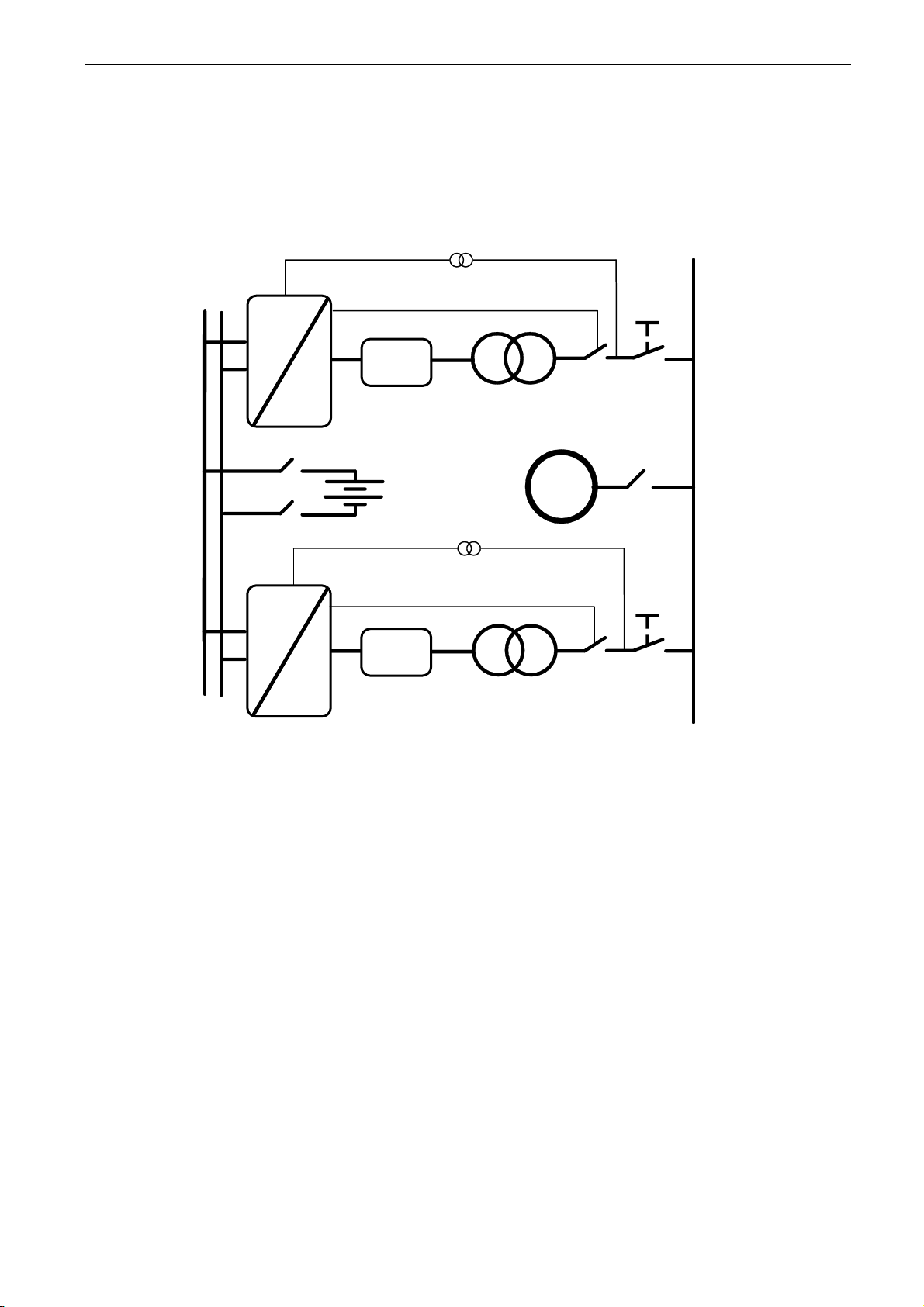

1.3 Micro Grid

Micro Grid mode controls the grid voltage and frequency. It functions like an ordinary generator.

Micro Grid mode does not control DC Voltage.

With the help of voltage droop and frequency droop, more than one Micro Grid and/or Generators

can work together.

Q1

Utility Grid

=

~

Filter

U4 = Transf. GC Side

U5 = Transf. Grid Side

T1

S1

Q1

U4

U3

U5

=

~

Filter

U4 = Transf. GC Side

U5 = Transf. Grid Side

D7

S1

G1

Q2

U4

U5

U3

T1

D7

D Y

T2

D Y

T2

MCB Control

MCB Control

Figure 3.

Page 12

12 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

1.4 Acronyms

AC = Alternating Current

AI = Analogue Input

AIO

=

All-In-One Applications

AM = Asynchronous Motor

ASIC

=

Application Specific Integrated Circuit

CL = Closed Loop

DC = Direct Current

DI = Digital Input

DO = Digital Output

DS = DriveSynch

FB = Field Bus

FFT

=

Function To Terminal

FW = Firmware

FWP

=

Field Weakening Point

FWPV

=

Field Weakening Point Voltage

GE = Greater or Egual

HW = Hardware

I/f

=

Current / Frequency

Id = Magnetization Current

IGBT

=

Insulated Gate Bipolar Transistor

INV

=

Inversion

Iq = Torque Producing Current

k-factor

=

Reactive relation to voltage. k = (Δiq/In)/(ΔU/Un)

LT = Less Than

MF = Master-Follower

OL = Open Loop

OV = Over Voltage

PID

=

Proportional Integral Derivative

PM = Permanent Magnet

PMS

=

Power Management System

PMSM

=

Permanent Magnet Synchronous Motor

PU = Per Unit

RO = Relay Output

RS = Reset Set

SB = System Bus

Sep.Ex SM

=

Separately Excitated Synchronous Motor

SM = Synchronous Machine

SPC

=

Speed Control

SQS

=

Safe Quick Stop

SR = Set Reset

SRM

=

Synchronous Reluctance Motor

SS1

=

Safe Stop 1

STO

=

Safe Torque Off

SW = Software

TC = Torque Control

TC = Time Constant

TTF

=

Terminal To Function

U/f

=

Voltage / Frequency

UV = Under Voltage

Page 13

arfif106 Grid Converter + Grid Codes VACON® · 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

1.5 Compatibility issues in parameters between versions

Update Note 1: This application parameters are not kept backwards compatible if new features or

improvements would be difficult to implement by doing so. Read this change note and chapter

“Compatibility issues in parameters between versions” from manual before updating the application.

Update Note 2: It’s recommended to use compare function for parameter changes when updating

application, especially in cases when version number change is considerably high.

Application is constantly developed; this includes changing parameter default values, and if

parameters are directly downloaded to drive improved default values may be lost.

V122

Page 14

14 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

2. Grid Codes

In AFE mode Grid Codes are available (Island mode and uGrid mode do not support Grid Codes).

To use Grid Codes, OPT-D7 is needed along with P2.17.1 Grid Code license.

Grid Codes are enabled with P2.17.3 EnableGridCode selection 2 / Enabled, whole parameter group

G2.17 is dedicated for grid code settings, by default, no grid code functionalises area active other

than unspecific frequency and voltage level tripping limits.

NOTE! Drive Grid Codes are compliant only when drive itself is controlling the MCB.

In case of upper system is controlling the breaker, the upper system will need certification.

Utility Grid

T1

Q1

U4

U3

U5

=

~

Filter

U4 = Transf. GC Side

U5 = Transf. Grid Side

D7

S1

D Y

T2

MCB Control

Page 15

arfif106 Grid Converter + Grid Codes VACON® · 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

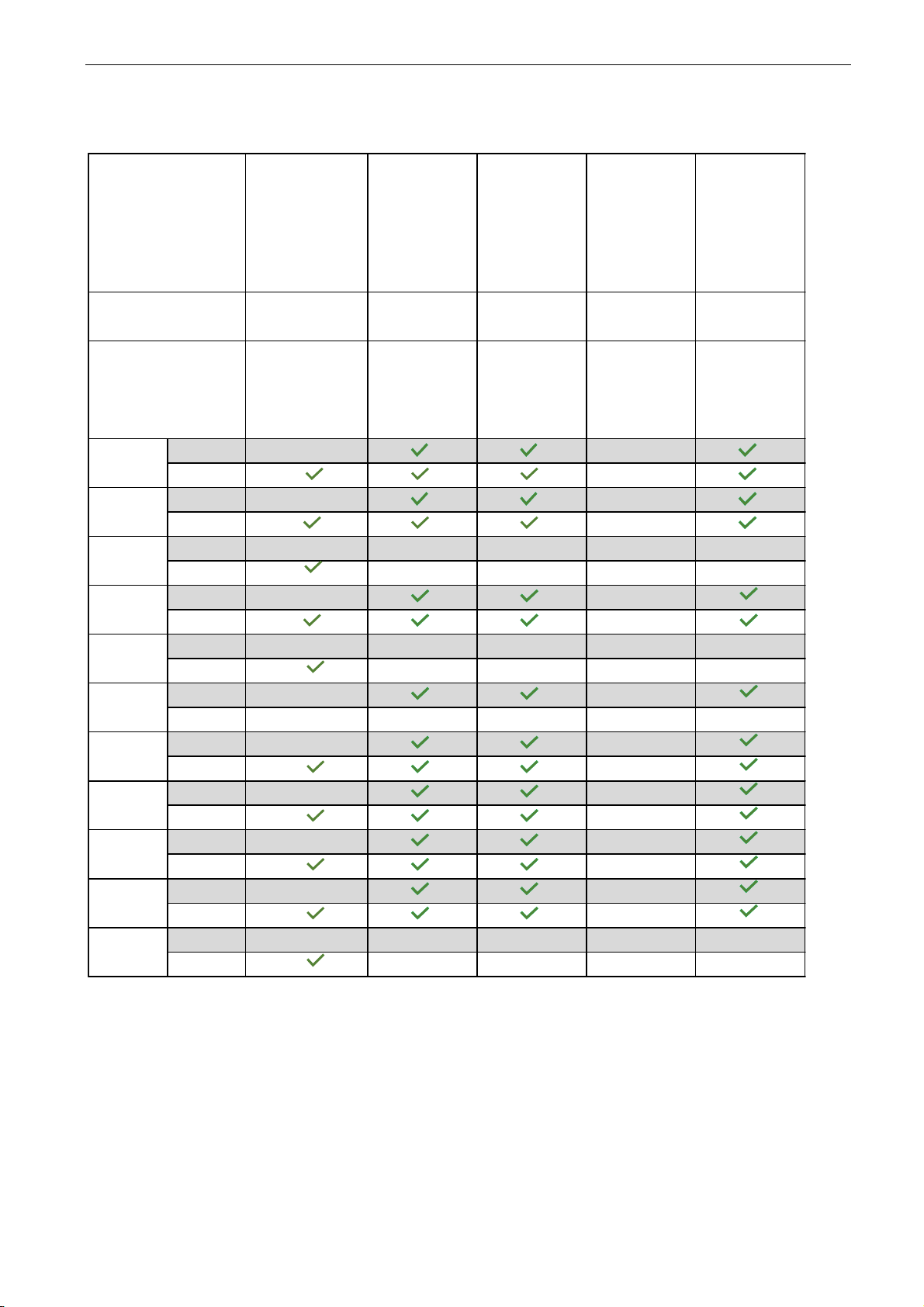

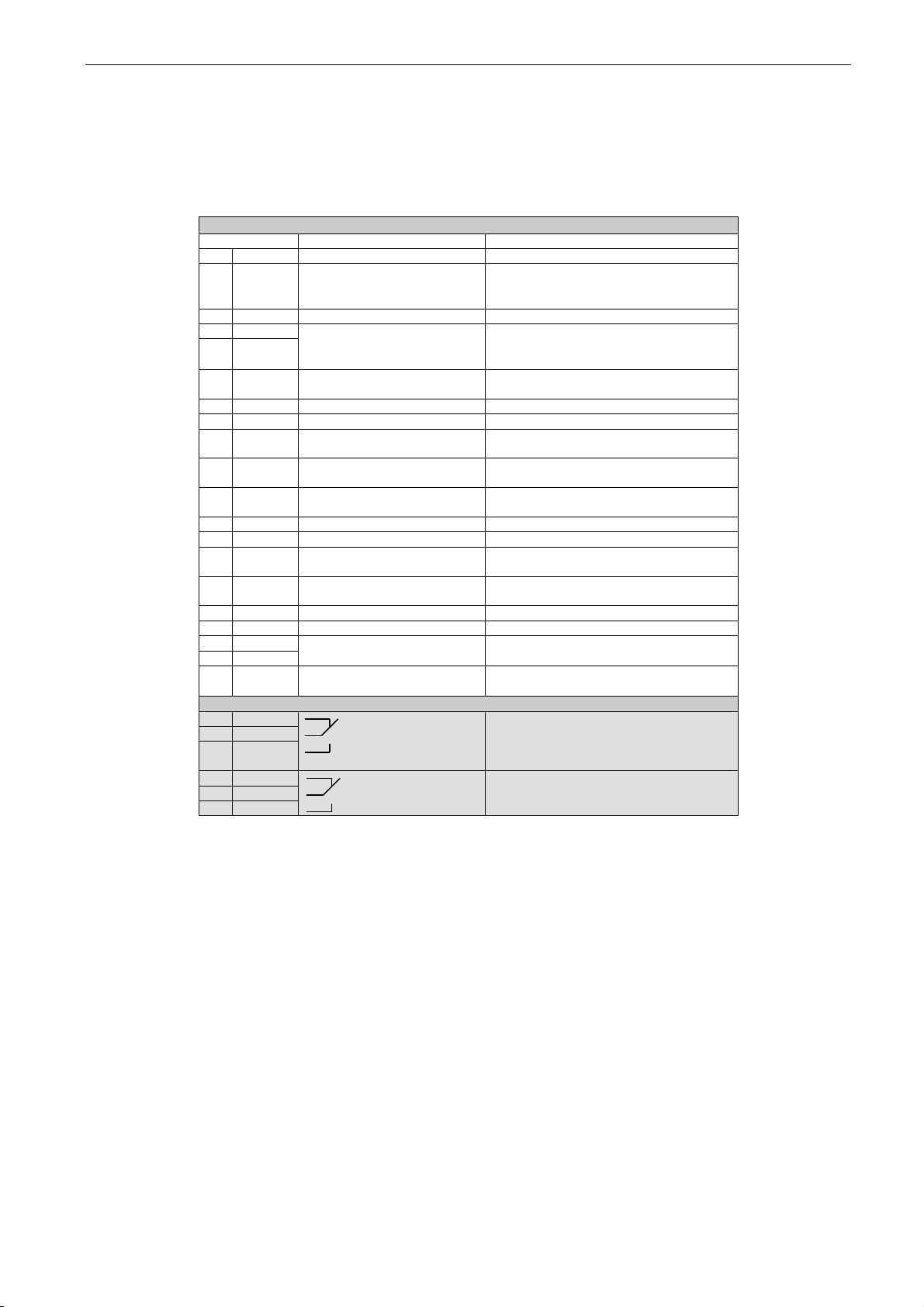

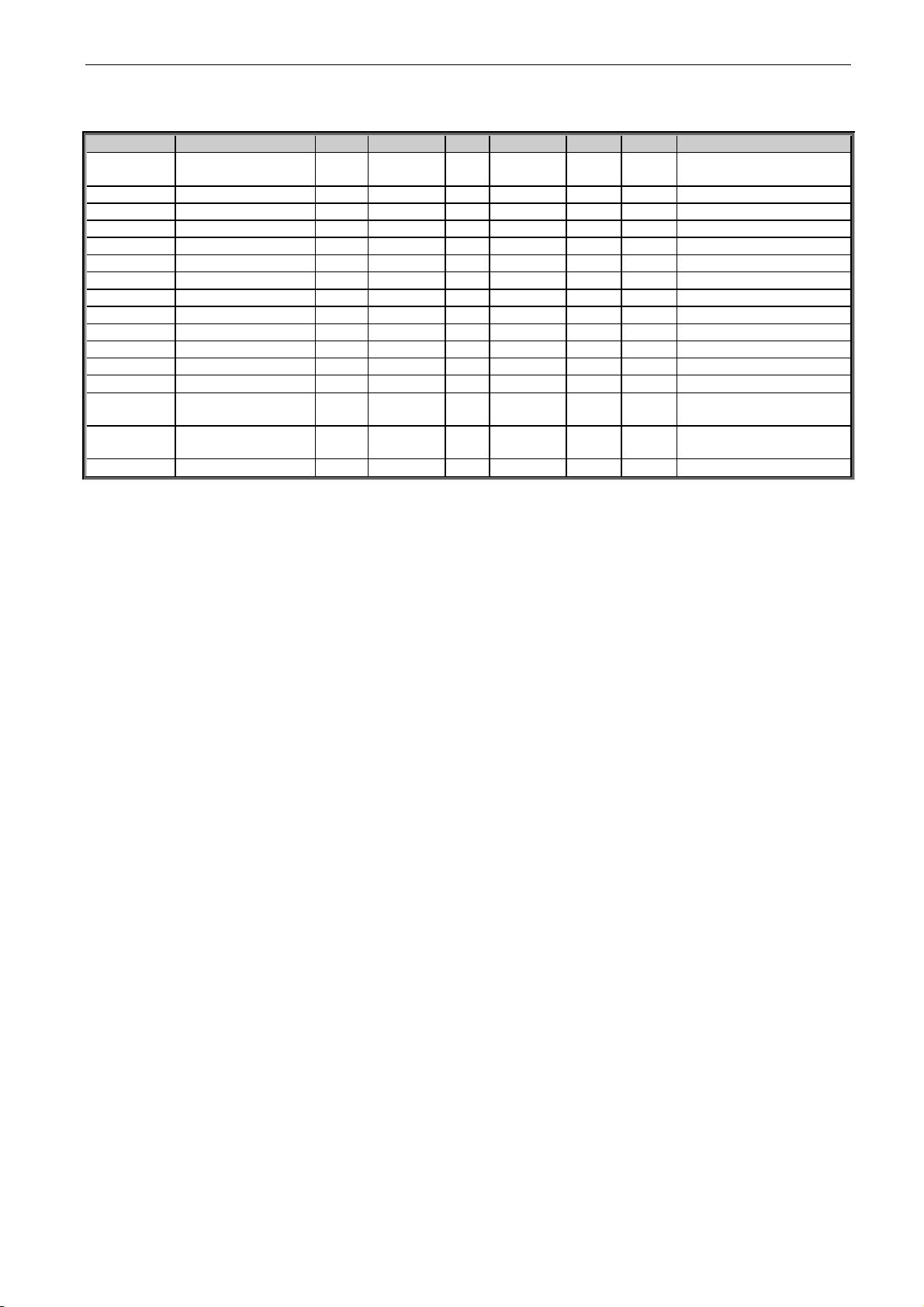

2.1 Grid Codes compliance

UL1741,

UL1741SA,

IEEE1547:2003,

IEEE1547.1:2005;

California Rule21,

Hawaii 14H

(USA/Canada)

ENTSO-e

Regulation

2016/031 of 14 of

April 2016

(Europe)

IEC62116:2014

(Anti-islanding)

(International)

EN50549-1:2019

EN50549-2:2019

(estimated April

2021)

(Europe)

VDE-AR-N-4105,

VDE-AR-N-

4110,

VDE-AR-N-4120

(Germany)

NXP2V200

NXP2V203

or later

NXP2V203

or later

NXP2V203

or later

NXP2V203

or later

ARFIF106 V103

ARFIF106

V121 or later

release

ARFIF106

V121 or later

release

ARFIF106

V121 or later

release

ARFIF106

V121 or later

release

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

CH63

CH64

2xCH64

FI12

FI13

FI14

CH5

CH61

CH62

Electric connection Grid

codes and Electrical

Safety standards

System software

Application software

FI9

FI10

Page 16

16 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

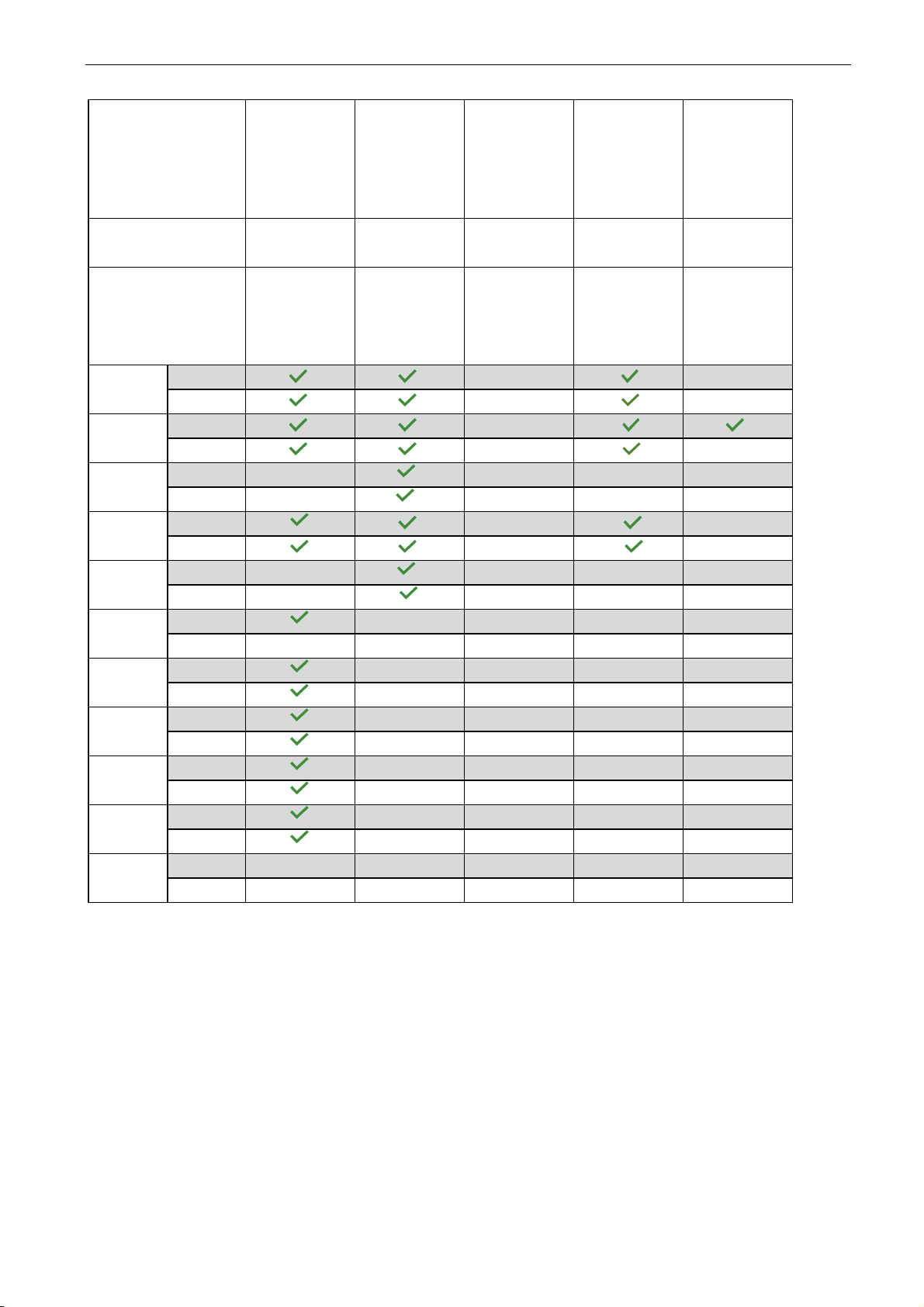

FGW TG3 rev

24,

FGW TG4 rev 8,

FGW TG8 rev 7

(Germany /

BDEW)

CEI 0-16: 04-

2019,

CEI 0-21: 04-

2019

(Italy)

Regulation

2016/631 of 14 of

April 2016;

(France)

IEC62109-1;

IEC62109-2;

AS/NZS

4777.2:2015

(PV)(Australia)

PEA (Thailand)

NXP2V203

or later

NXP2V203

or later

NXP2V203

or later

NXP2V200

or later

NXP2V203

or later

ARFIF106

V121 or later

release

ARFIF106

V121 or later

release

ARFIF106

V121 or later

release

ARFIF106

V104 or V121

or later release

ARFIF106

V121 or later

release

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

400VAC

600VAC

FI13

FI14

CH5

CH63

CH64

2xCH64

CH61

CH62

Electric connection Grid

codes and Electrical

Safety standards

System software

Application software

FI9

FI10

FI12

Page 17

arfif106 Grid Converter + Grid Codes VACON® · 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

3. Quick start and operation principles

NOTE! Before you start the commissioning, read the safety instructions in the user manual of your

product.

To use the Island, Micro Grid, or Shaft generator operation, you need a licence key. The AFE mode

is available without a licence.

This application requires an NXP3 control board VB761 or newer.

The control place (P3.1) of the Grid Converter drive is Keypad as a default.

The basic I/O configuration of the Grid Converter drive consists of OPT-A1, OPT-A2, and OPT-D7

option boards. The basic I/O configuration is described in Table 1.

OPT-D7 is required when the Grid Converter unit is needed to start with zero power to the grid. If

grid frequency is not monitored with OPT-D7, the unit may go generator side or directly to full power

because different reference frequency and grid frequency.

The Grid Converter is utilised by using AFE hardware with special software. An external LC(L)-filter

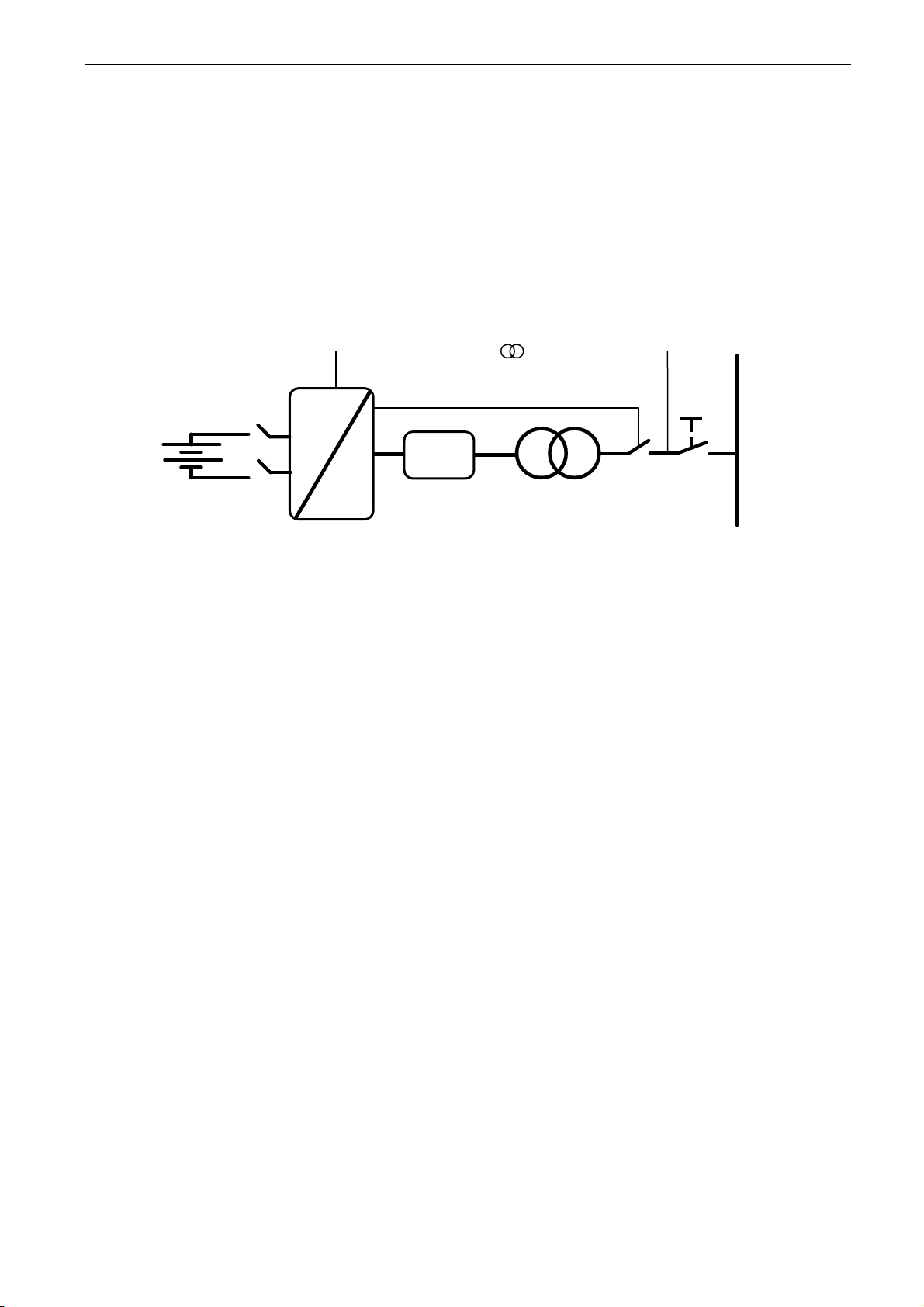

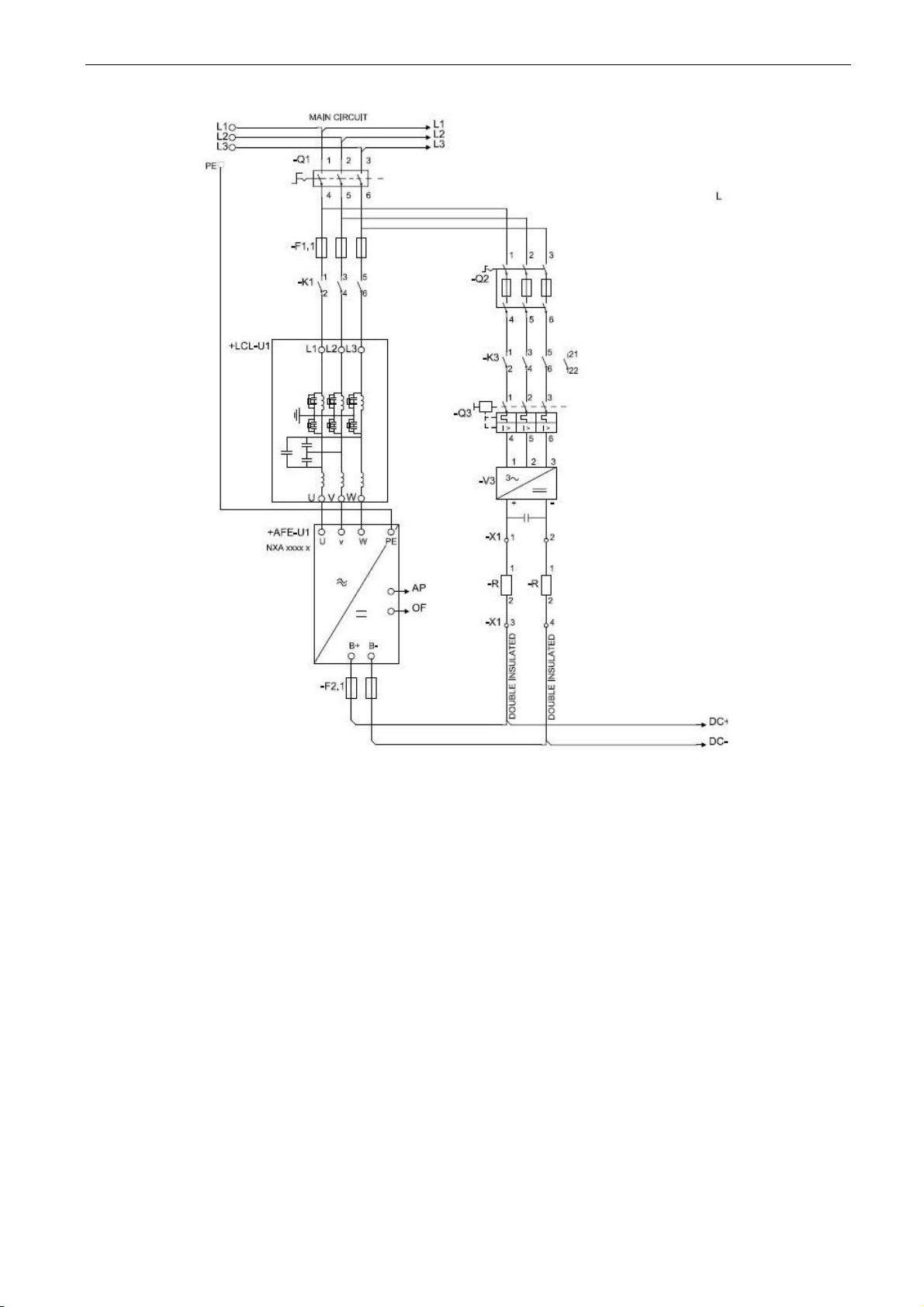

and charging circuit is needed. This unit is selected when low harmonics are required. The principle

connection of AFE drive has been described in Figure 4.

The external 24 Vdc is recommended for control board(s). It enables the setting of parameters even

when the power unit itself is not powered. This is important also when software updates are made.

Some default I/O configuration of the application can cause unexpected DO operation. When the

control board is powered, the drive can give information from the status of the system if, for example,

the drive I/O is used for an overall system monitoring.

The external 24 Vdc is required for the drives in cases where the start command starts the control

board-controlled precharging operation.

3.1 Quick start instructions

1. Connect the unit according to the Figure 4.

2. Power up the control unit with 24 Vdc.

3. Set the basic parameters (G2.1)

4. Check that the digital input parameters (G2.4.2) have been set according to the connections.

5. Change the control place according to the system requirements.

6. Charge the unit.

3.2 In case of parallel AFE:

1. Set P2.1.5 Parallel AFE to Yes. This will also set DC Drooping to 3.00% (Default).

Page 18

18 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

Figure 4. Connection

Page 19

arfif106 Grid Converter + Grid Codes VACON® · 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

3.3 Pre-Charging of DC

This AFE application has its own charging control, P2.5.1.13 DC Charge (24 Vdc required for control

board) and charging protection in case the external charging cannot get DC voltage to required level

within set time P2.9.1.6 Charge Max Time (provided that the DC Voltage reaches the under voltage

fault level).

The charging function is activated when P2.5.1.13 DC Charge is A.1 or higher. When the control

place is IO, Keypad or NCDrive, charging is started from the start command.

Charging is not started if:

- Drive is in fault state.

- P2.4.2.26 Enable CB Close is FALSE

- P2.4.2.8 Run Enable is FALSE

- P2.4.2.19 Quick Stop is FALSE

Charging is also stopped if above conditions occur during charging or if the start command is

removed.

For fieldbus control, charging is started with B0 of FB Control Word on the supporting FB profiles.

Charging is also stopped if B0 goes low. Also MCB is opened if already closed.

DC Charge (F80) is given if 85 % of DC Nominal is not reached within P2.9.1.6 Charge Max Time

and charging is stopped.

DC Charging is stopped when the drive receives feedback from P2.4.2.4 MCB Feedback.

NOTE! Use suitably sized DC Charging resistor. To select the correct size, check Pulse loadability

for time duration set in for Max Charge Time parameter.

Page 20

20 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

3.4 Main circuit breaker control (MCB)

The Grid Converter application controls the circuit breaker of the system with the relay output RO2.

When the DC bus is charged, the MCB will be closed. The status of the MCB is monitored via a

digital input. The digital input used for monitoring is selected with parameter P2.3.1.3. Faults can be

set to open the MCB by selecting a response to a fault to be 3=Fault, DC OFF.

An external charging circuit is necessary to charge the DC bus but drive can control this circuit if 24

Vdc is provided for the control board.

Closing limit is 85% of the nominal DC Voltage.

Opening limit is 75% of the nominal DC Voltage.

Nominal DC Voltage for the Grid Converter is adjusted with System Nominal DC parameter P2.1.7

ID1805.

Over Current (F1), Hardware IGBT (F31) and Software IGBT (F41) faults will open MCB immediately

to protect the drive.

For Grid Code use its recommended to have breaker that mechanical opening delay is less than 30

ms when clearing times are less than 200 ms also use early brake auxiliary contact as accessory to

breaker of contact.

NOTE! Drive Grid Codes are compliant only when drive itself is controlling the MCB.

NOTE! The MCB feedback is necessary for the correct operation of the Grid Converter application.

NOTE! Only the drive controls its own MCB. If additional interlocks or opening commands are

needed, these commands must go through the drive.

NOTE! UPS may be needed during short circuit situation to keep MCB closed if control voltage is

taken from the grid where the short circuit occurs.

NOTE! Missing feedback signal prevent drive going to ready state. MCB Feedback can be monitored

from Status Word B10.

NOTE! If feedback is not used there will be three second forced delay on internally generated MCB

feedback signal. MCB Feedback can be monitored from Status Word B10.

Page 21

arfif106 Grid Converter + Grid Codes VACON® · 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

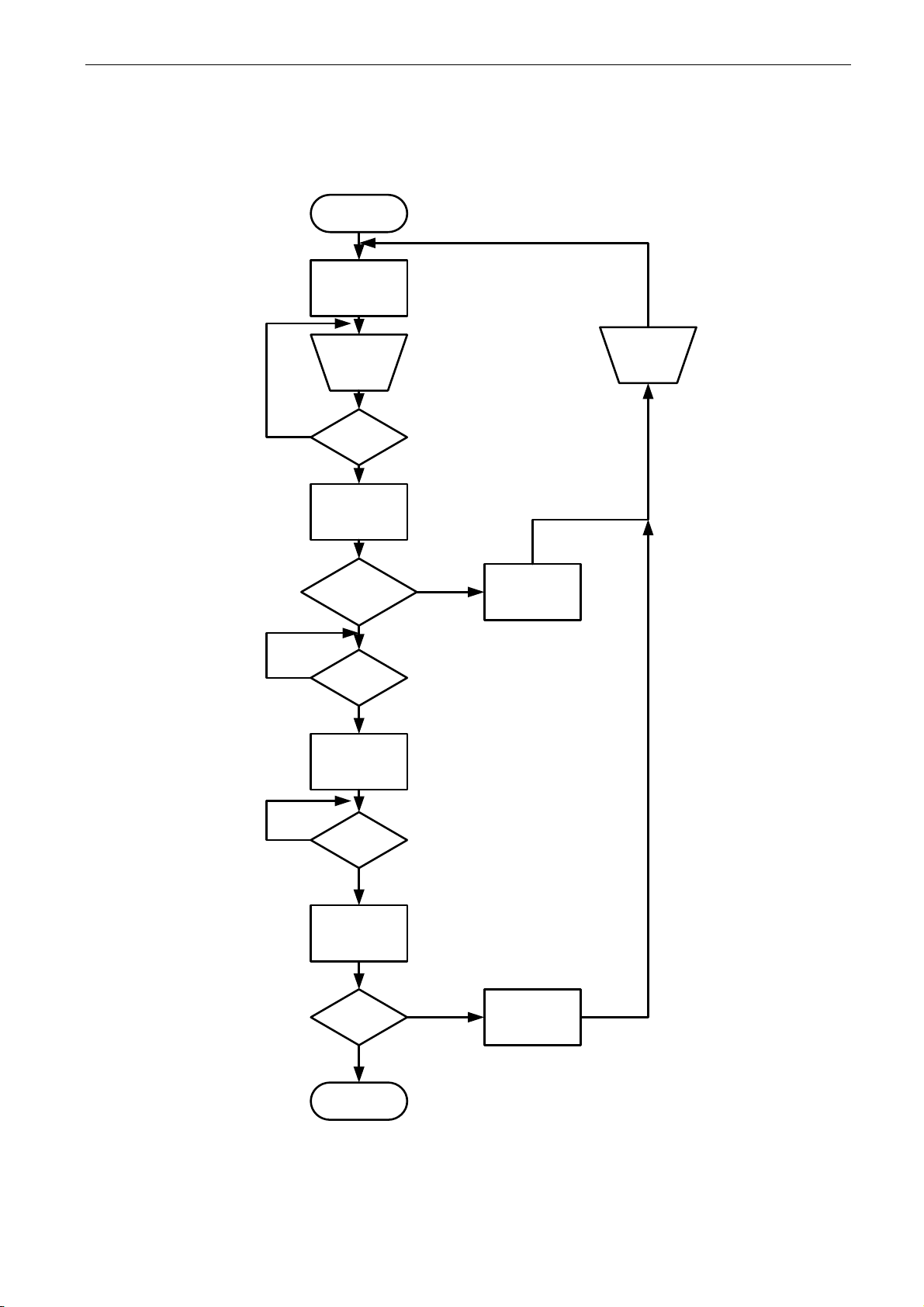

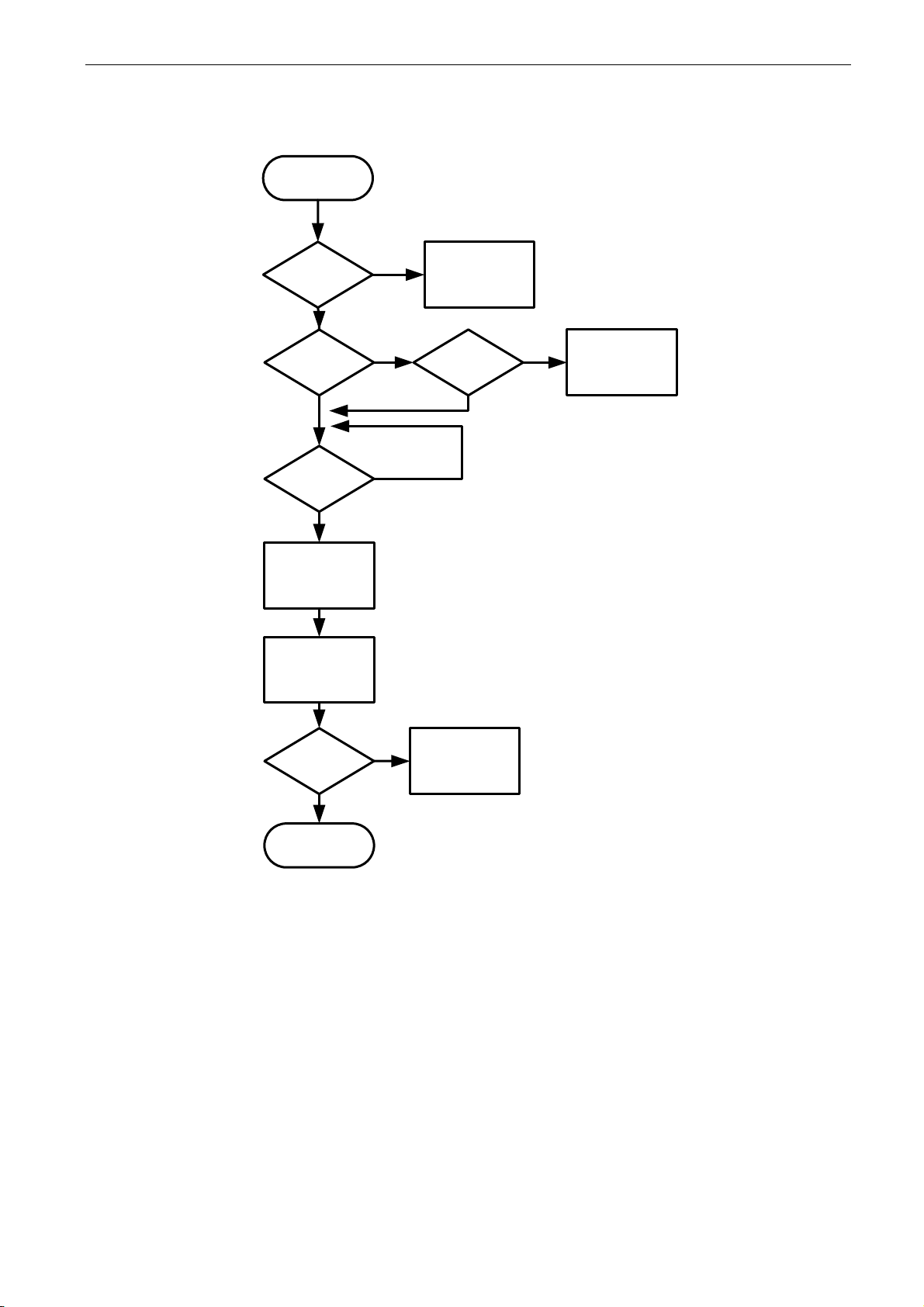

3.5 Start Sequence

In uGrid mode synchronization to main is done also but if grid is not found drive will make the grid. In

Island mode drive will make the grid immediately without synchronization to the grid.

Ready to switch on

Charge DC-

Link

DC-Link

> 85 %

NO

Close Main

Contactor

YES

Main Contactor

Closed

YES

NO

MCC Fault

Fault Rese t

Run Enable

Ready To Run

NO

Start Signal

YES

NO

Synchronize with

mains

Synch O K

NO

YES

Line Synch Fault

F10

Running

Start

Figure 5. AFE start sequence

Page 22

22 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

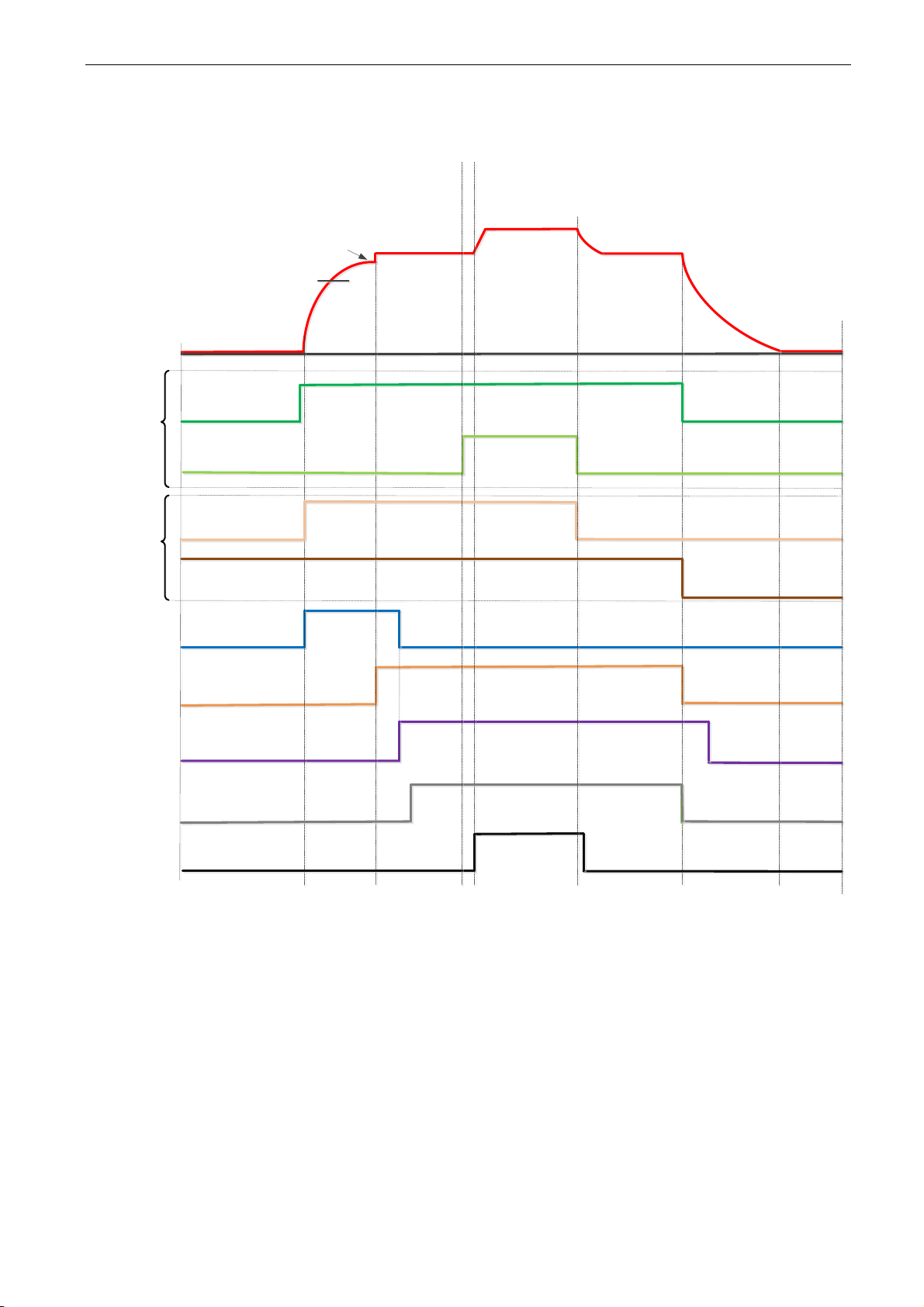

3.6 Stop sequence

Modulating

MCB Closed

No

F64 A4

Open MCB

No

Yes

Yes

Stop Modulation

(If Run State)

Open MCB

Stop Request MCB Closed

No

F64 A2

(If DC > 85 %)

(Delayed)

Yes

MCB Closed

No

Yes

F64 A3

(Delayed)

End

Figure 6. Stop sequence

Page 23

arfif106 Grid Converter + Grid Codes VACON® · 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

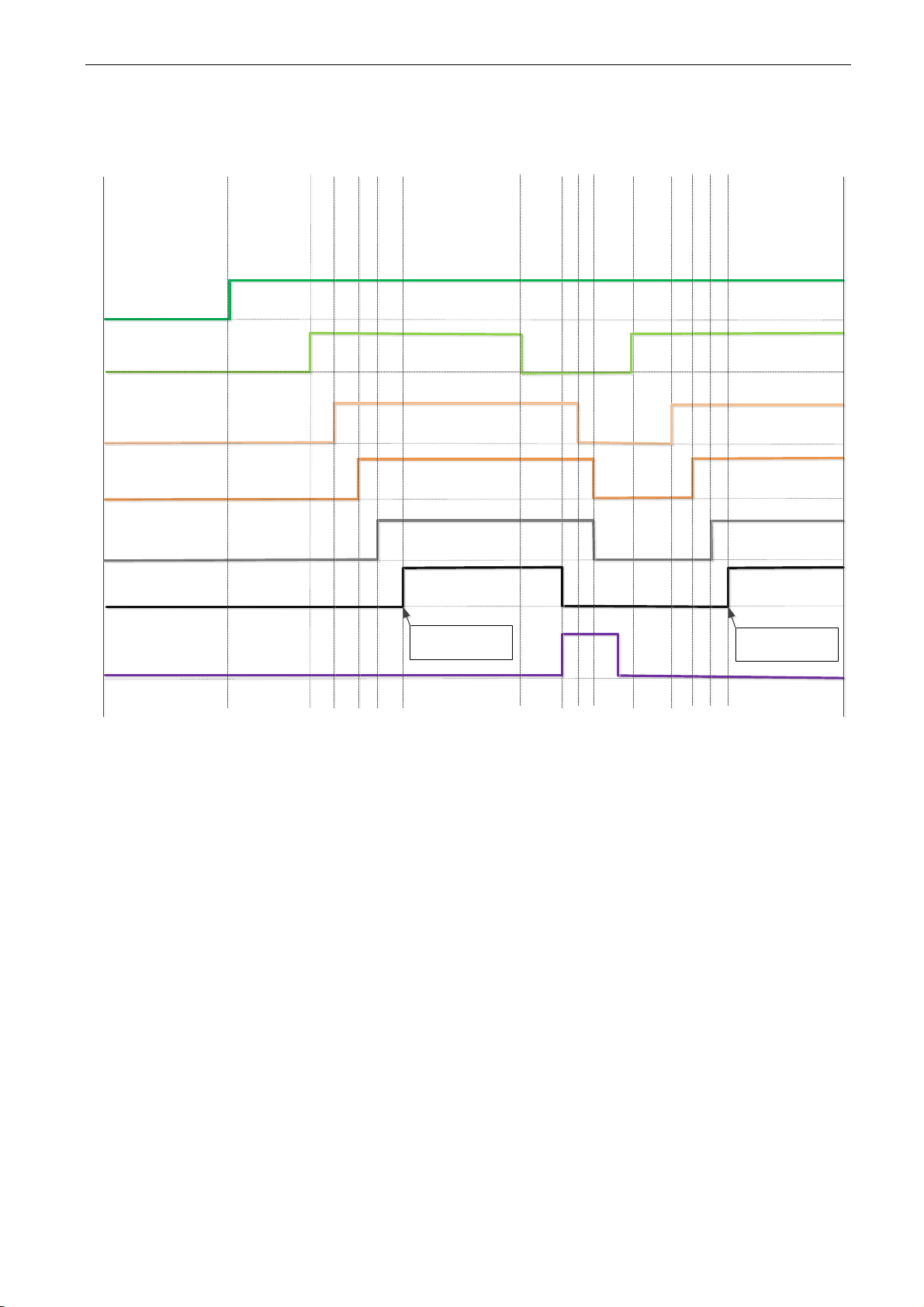

3.7 Start Stop timing diagram

DC Voltage

Charge Control

MCB Feedback

MCB Close Control

MCB Close level

Stable DC

Ready

IO Start

Run

FB CW.B00

Control in

FB Control

FB CW.B03

Contro in

IO Control

P. Start Delay

IO MCB Open

Command

Above example when “Standard” state machine is used. With “Basic” state machine operation

is like in IO Control.

Page 24

24 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

3.8 Start Stop Timing Diagram with Grid Codes

Main Circuit Breaker

Feedback

Main Circuit Breaker

Close Control

Ready State of

Inverter

Start Request

To Inverter

Run

(Modulating)

Line Frequency

and Voltage OK

P. Line OK Delay

P. Start Delay

Grid Code Trip

P. ReConnect

Time

Start

Synchronization

Start

Synchronization

Page 25

arfif106 Grid Converter + Grid Codes VACON® · 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

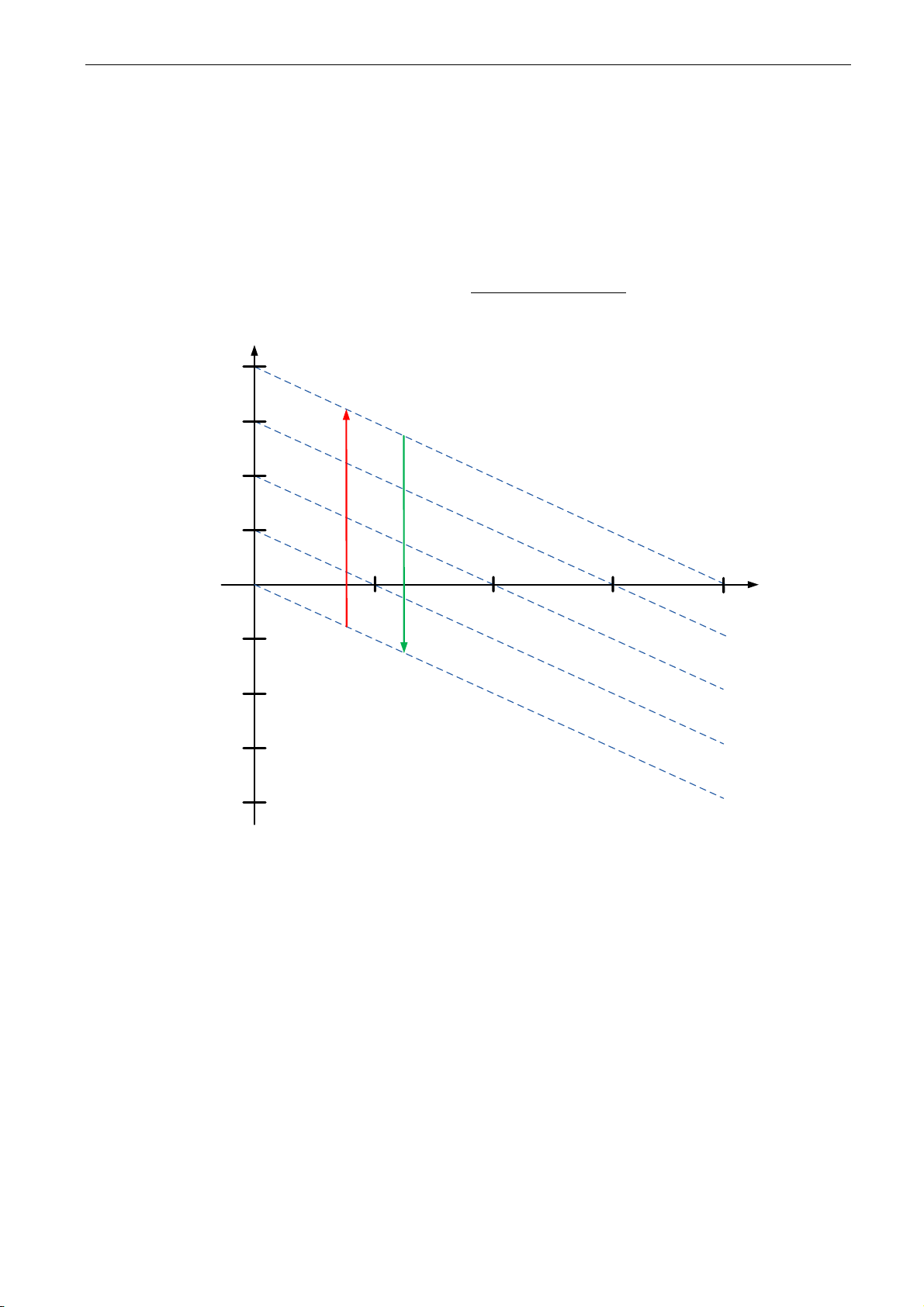

3.9 Operation principle: Droop Speed Control Mode

When the power demand increases, all generators on the grid allow frequency to droop. This will

balance the load between all the generators on the grid. Then the power management system gives

all generators a command to increase frequency so that the grid frequency is maintained at its

nominal value.

When the load is reducing on the grid, the frequency of the generators will increase, and the power

management system gives a command to decrease frequency.

+1%

+2%

+3%

+4%

-1%

-2%

-3%

-4%

50,5 Hz

51,0 Hz

51,5 Hz

52,0 Hz

48,0 Hz

48,5 Hz

49,0 Hz

49,5 Hz

50,0 Hz

Loading

Un-loading

Drooping

Freq. Change

25% 50% 75% 100%

Related

Load

Figure 7.

3.10 Operation principle: Isochronous Control Mode

In the isochronous control mode, the Micro Grid frequency reference is kept the same as the grid

frequency with help of OPT-D7. This will keep power at zero regardless of grid frequency. While

drive operates in drooping mode, the actual power is controlled by base current reference. This

reference needs to be controller by power management system (PMS) that will handle power sharing

between different machines on the grid.

Page 26

26 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

3.11 Voltage compensation

Grid Converter system will have voltage losses. Depending on the system, the losses may be more

than 50 Vac when operating close to Grid Converter nominal currents with low power factor between

points U3 and U5. This voltage loss needs to be compensated so that the grid voltage stays at

nominal. This also sets requirements for the needed DC link voltage.

Q1

T2

U4

U3

U5

UDCU2

=

~

=

~

Filter

Filter

SG

U1

Q2

U4 = Transf. GC Side

U5 = Transf. Grid Side

D7

T1

S1

MCB Control

Utility Grid

50 Hz

60 Hz

Figure 8. Voltage compensation

The normal operation voltage range in a land-based grid is usually between 80% and 115% of the

grid nominal voltage.

The voltage losses compensation is handled separately for Active power (kW) and Reactive power

(kVar), the latter being more significant. The Active power voltage losses are compensated with

Inductor Losses parameter (P2.2.6.6) and Reactive power voltage losses are compensated with

Inductor Size parameter (P2.2.6.5).

Uncompensated system may result in unnecessary reactive power circulation in a grid between the

different power sources and wrong grid voltage.

OPT-D7 can be used to compensate the voltage losses (closed loop voltage compensation) but it is

recommended to do an open loop voltage compensation tuning in case of OPT-D7 failure. When the

OPT-D7 measurements exceed the set limit values, the voltage compensation falls back to open

loop control.

Inductor Size and Losses affect

Grid Nom. Voltage: 400 Vac, Reactive Current: 30%, Active Current 50%, Inductor

Size: 15%, Inductor Losses: 15%, Voltage Correction: 0 Vac.

Reactive Increase: 400 Vac×30%×15%=18 Vac

Active Increase: 400 Vac Increase or Losses: 15% 400 Vac×50%×15%×15%=4.5 Vac

Total increase: 18 Vac+4.5 Vac =22.5 Vac

See also chapter 10.1 Open Loop Voltage Compensation.

Page 27

arfif106 Grid Converter + Grid Codes VACON® · 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

3.12 OPT-D7 voltage measurement option board

OPTD7 is an AC sinusoidal voltage measurement board. Using this board, the drive measures the

line voltage, the frequency and the voltage angle information.

Grid Codes cannot be used or activated without correctly connected OPT-D7 board and Grid Code

functionality is only available when drive is operating in AFE mode.

Measurement accuracies of OPT-D7 board

Frequency Accuracy: ±0,05 Hz

Voltage Accuracy: ±2,5% from full range.

The drive can compare this information with its output voltage angle when it runs. This feature can

be used to make synchronisations to a grid that is measured. For example, for line synchronisation

purposes you can use APFIFF44 LineSynch II Application. That will work as a smooth starter.

In Grid Converter application this can be used:

- To synchronise to existing external grid while the drive is running to enable bumpless transfer

from a generator operation to a shore powered operation in a ship.

- To control the grid voltage (Voltage losses compensation).

- To enable a zero power connection to an existing grid.

- To help in the commissioning of drive active power and reactive power voltage losses

compensation when the actual grid voltage is visible in NCDrive.

The OPT-D7 board is delivered with a measurement transformer (690 :11,5) which is suitable for a

voltage range up to 690 Vac. The measurement transformer cannot be connected directly to drive

output terminal since it can’t measure pulse width modulated (PWM) voltage input.

It is possible to use a customised transformer when the input voltage to be measured is not within

the OPT-D7 transformer voltage range. The transformation ratio parameter can be adjusted

according to the transformer primary to secondary ratio. See details in the OPT-D7 user manual.

Synchronisation to the grid can be made without the OPT-D7 when the drive operates in the AFE or

the Micro Grid mode. This requires that the output terminals of the drive are connected to the

existing grid when the drive is in the STOP state. When a start command has been given in AFE or

Micro Grid mode, the drive will make standard AFE synchronisation. Depending on the operation

mode, the drive will start to keep constant DC voltage (AFE) or start to share power based on grid

frequency (Micro Grid). Using OPT-D7 for synchronisation will make the start of the drive smoother.

If the drive does not detect an existing line voltage or frequency in Micro Grid mode, the output

voltage is raised defined time (VoltageRiseTime). In the Island mode, the detection of the grid is not

made and the voltage is raised from zero in the set time (VoltageRiseTime).

NOTE: The OPT-D7 board (in slot C) is mandatory for the Grid Converter unit.

Page 28

28 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

-

Page 29

arfif106 Grid Converter + Grid Codes VACON® · 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

4. Control I/O

4.1 Slot A and Slot B terminals

Table 1. Minimum recommended I/O configuration.

OPT-A1

Terminal

Signal

Description

1

+10V

ref

Reference voltage output

Voltage for potentiometer, etc.

2

AI1+

Analogue input 1.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Input range selected by jumpers.

Default range: Voltage 0 – 10 V

3

AI1-

I/O Ground

Ground for reference and controls

4

AI2+

Analogue input 2.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Input range selected by jumpers.

Default range: Current 0 – 20 mA

5

AI2-

6

+24V

Control voltage output

Voltage for switches, etc. max 0.1 A

7

GND

I/O ground

Ground for reference and controls

8

DIN1

Programmable G2.2.1

9

DIN2

Programmable G2.2.1

10

DIN3

Programmable G2.2.1

11

CMA

Common for DIN 1– DIN 3

Connect to GND or +24V

12

+24V

Control voltage output

Voltage for switches (see #6)

13

GND

I/O ground

Ground for reference and controls

14

DIN4

MCB Feedback

Programmable G2.2.1

0 = MCB open

1 = MCB closed

15

DIN5

Quick Stop

Programmable G2.2.1

0 = Quick Stop Active

1 = No Quick Stop

16

DIN6

Programmable G2.2.1

17

CMB

Common for DIN4– DIN6

Connect to GND or +24V

18

AO1+

Analogue output 1

Programmable

Range 0– 20 mA/RL, max. 500

19

AO1-

20

DO1

Digital output

READY

Programmable P2.3.1.1

Open collector, I50mA, U48 VDC

OPT-A2

21

RO1

Relay output 1

Programmable P2.3.1.2

Switching capacity

24 VDC / 8 A

22

RO1

23

RO1

250 VAC / 8A

125 VDC / 0.4 A

24

RO2

Relay output 2

MCB control

This RO is not programmable.

Fixed for MCB Control (Close)

25

RO2

26

RO2

4.2 Terminal To Function (TTF)

The programming principle of the input and output signals in the Grid Converter Application is

different compared to the conventional method used in other VACON® NX applications.

In the conventional programming method, Function to Terminal Programming Method (FTT), you

have a fixed input or output that you define a certain function for. The applications mentioned above,

however, use the Terminal to Function Programming method (TTF) in which the programming

pro¬cess is carried out the other way round: Functions appear as parameters which the operator

defines a certain input/output for.

Page 30

30 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

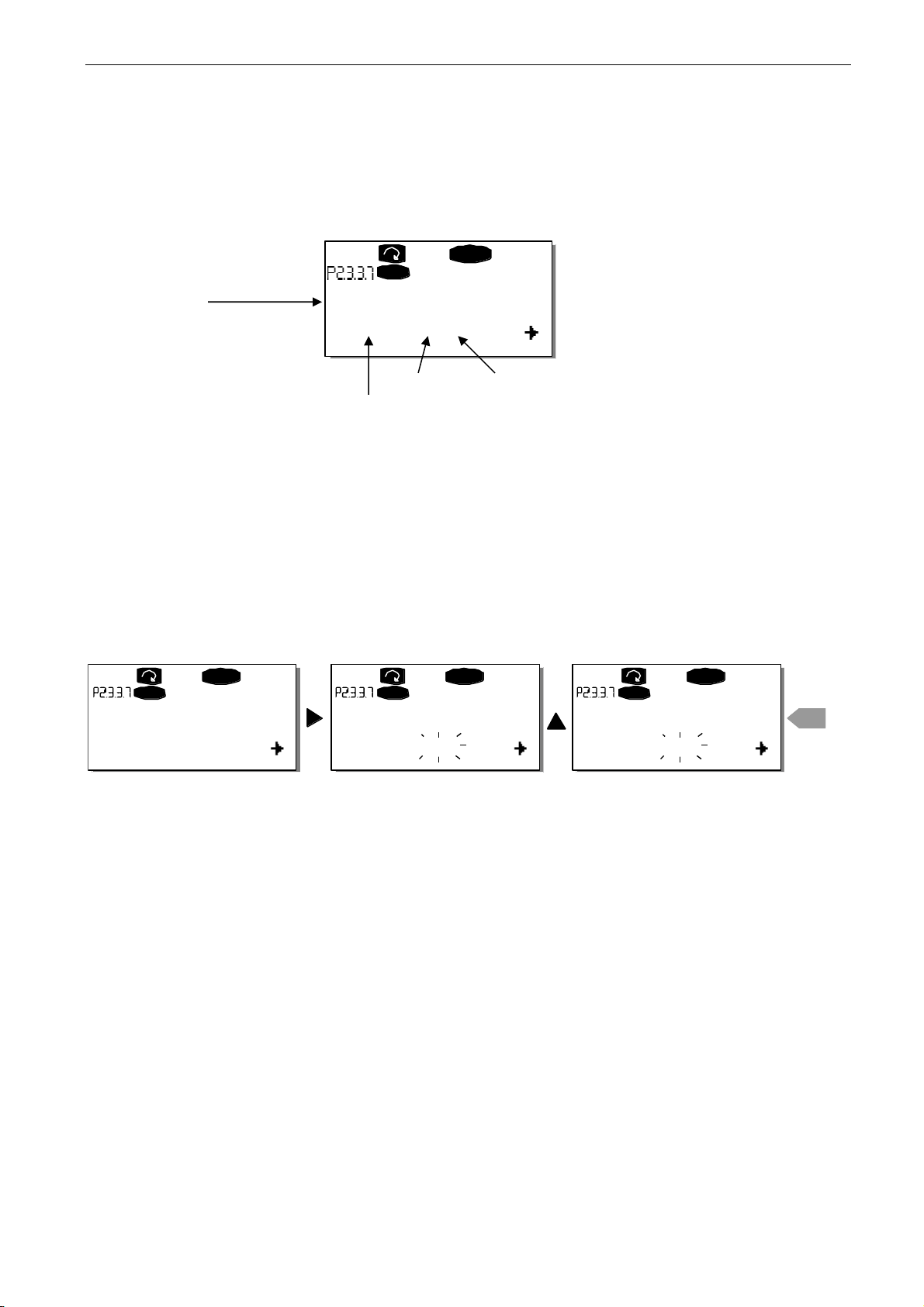

4.1 Defining inputs and outputs

Connecting a certain input or output with a certain function (parameter) is done by giving the

parameter an appropriate value. The value is formed of the Board slot on the VACON® NX control

board (see VACON® NX User Manual) and the respective signal number, see below.

Function name

Slot Terminal number

Terminal type

Example: You want to connect the digital output function Reference fault/warning (parameter

2.3.3.7) to the digital output DO1 on the basic board NXOPTA1 (see VACON® NX User Manual).

First find the parameter 2.3.3.7 on the keypad. Press the Menu button right once to enter the edit

mode. On the value line, you will see the terminal type on the left (DigIN, DigOUT, An.IN, An.OUT)

and on the right, the present input/output the function is connected to (B.3, A.2 etc.), or if not

connected, a value (0.#).

When the value is blinking, hold down the Browser button up or down to find the desired board slot

and signal number. The program will scroll the board slots starting from 0 and proceeding from A to

E and the I/O selection from 1 to 10.

Once you have set the desired value, press the Enter button once to confirm the change.

READY

I/Oterm

DigOUT:B.1

AI Ref Faul/Warn

READY

I/Oterm

DigOUT:0.0

READY

I/Oterm

DigOUT:0.0

READY

I/Oterm

DigOUT:B.1

enter

AI Ref Faul/Warn AI Ref Faul/Warn AI Ref Faul/Warn

Page 31

arfif106 Grid Converter + Grid Codes VACON® · 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

4.1 Defining a terminal in NCDrive

If you use the VACON® NCDrive Programming Tool for parametrizing you will have to establish the

connec¬tion between the function and input/output in the same way as with the control panel. Just

pick the address code from the drop-down menu in the Value column (see the Figure below).

Figure 3 1. Screenshot of NCDrive programming tool; Entering the address code

Be ABSOLUTELY sure not to connect two functions to one and

same output in order to avoid function overruns and to ensure

flawless operation.

!

WARNING

Note: The inputs, unlike the outputs, cannot be changed in RUN state.

Page 32

32 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

5. Monitoring signals

The menu M1 (Monitoring) has all the monitoring values.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter

number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust = Customer’s own setting

ID = ID number of the parameter

_____ = On parameter code: Parameter value can only be changed after the FC has been

stopped.

_____ = Apply the Terminal to Function method (TTF) to these parameters (see chapter

Error! Reference source not found.)

_____ = Monitoring value is possible to control from fieldbus by ID number

The manual presents signals that are not normally visible for monitoring. i.e. is not a parameter or

standard monitoring signal. These signals are presented with [Letter]. e.g.

[FW]MotorRegulatorStatus

[V] Normal monitoring signal

[P] Normal parameter in application.

[FW] Firmware signal, Can be monitored with VACON® NCDrive when signal type is selected

Firmware

[A] Application signal, can be monitored with VACON® NCDrive when signal type is selected

Application.

[R] Reference type parameter on keypad.

[F] Function. Signal is received as a output of function.

[DI] Digital input signal.

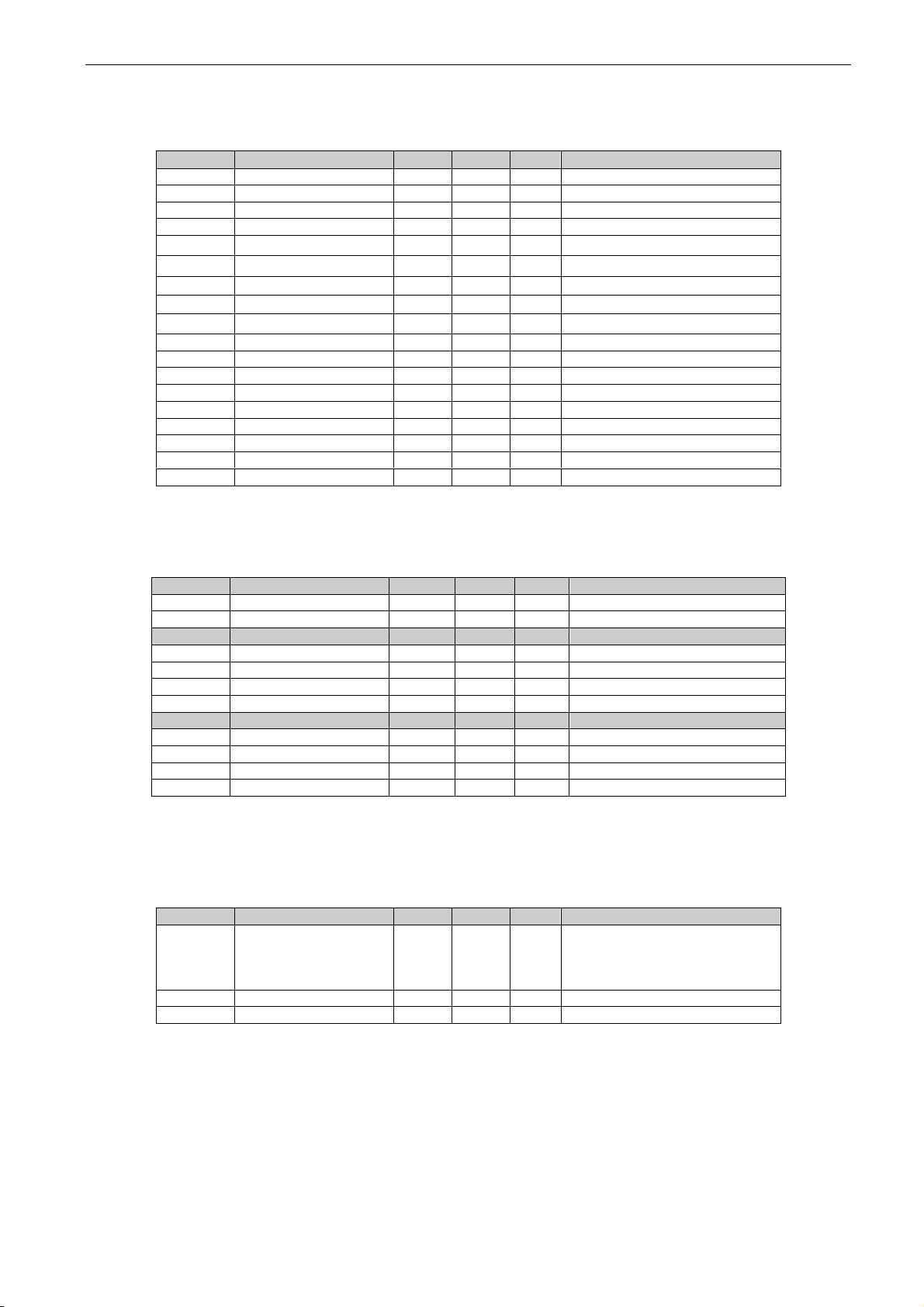

5.1 Monitoring value tables

5.1.1 Monitoring values 1

Code

Parameter

Unit

Form.

ID

Description

V1.1.1

DC-Link Voltage

V # 1108

Measured DC Link voltage in volts,

filtered.

V1.1.2

DC Voltage Ref.

%

#,##

1200

Used DC voltage reference by the

regenerative unit in % of Nominal DC

voltage.

Nominal DC voltage = 1.35 * supply

voltage

V1.1.3

DC Voltage Act.

%

#,##

7

Same scaling as DC Voltage Ref.

V1.1.4

Total Current

A

Varies

1104

Filtered current

V1.1.5

Active Current

%

#,#

1125

> 0 power from AC side to DC side

< 0 power from DC side to AC side

V1.1.6

Reactive Current

%

#,#

1157

V1.1.7

Power kW

kW

Varies

1508

> 0 power from AC side to DC side

< 0 power from DC side to AC side

V1.1.8

Power %

%

#,#

5

> 0 power from AC side to DC side

Page 33

arfif106 Grid Converter + Grid Codes VACON® · 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

< 0 power from DC side to AC side

V1.1.9

Status Word

# 43 V1.1.10

Supply Frequency

Hz

#,##

1

Drive output frequency

V1.1.11

Supply Voltage

V

#,#

1107

Drive output voltage

V1.1.12

Line Frequency D7

Hz

#,##

1654

Measured line frequency

V1.1.13

Line Voltage D7

V # 1650

Measured line voltage

V1.1.14

AC Voltage

Reference

V # 1556

Used AC Voltage Reference

V1.1.15

DC Ref Max Lim

%

#,##

1606

Internal limit for DC Voltage Ref.

Page 34

34 · VACON® arfif106 Grid Converter + Grid Codes

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

5.1.2 Monitoring values 2

Code

Parameter

Unit

Form.

ID

Description

V1.2.1

DC Voltage

V # 44

Measured DC Link voltage in

volts, unfiltered.

V1.2.2

Operation Mode

# 1615

0 = AFE

1 = Island

2 = Micro Grid

V1.2.3

Used Current Ref

%

#,#

1704

Used current reference is

negated to parameter value.

Made to compare values in

NCDrive easier to Active current

V1.2.4

D7 Synch. Error

# 1659

Synchronisation error to external

grid

V1.2.5

Cos Phi Actual

#,###

1706 V1.2.6

Unit Temperature

°C # 1109 V1.2.7

Freq. Reference

Hz

#,#

1752

Used line frequency reference

V1.2.8

Current

A

Varies

1113

Unfiltered current

V1.2.9

Operation Hours

h

#,##

1856

V1.2.10

Reactive Current

Reference

%

#,#

1389

V1.2.11

Grid State

# 1882 V1.2.12

Mindex

%

#,#

1874

Modulation Index

V1.2.13

IU rms

A

Varies

39 V1.2.14

IV rms

A

Varies

40

V1.2.15

IW rms

A

Varies

41

V1.2.16

DC-Link Current

A

Varies

72 V1.2.17

DC-Link ActCurr

%

#,#

1158 V1.2.18

Iq Actual

%

#,#

4

Filtered by P2.17.16.11

V1.2.19

Id Actual

%

#,#

1134

5.1.3 Fieldbus monitoring values

Code

Parameter

Unit

Form.

ID

Description

V1.3.1

FB Control Word

# 1160

Control word from fieldbus

V1.3.2

FB Status Word

# 68

Status word to fieldbus

V1.3.3

Fault Word 1

# 1172

V1.3.4

Fault Word 2

# 1173 V1.3.5

Warning Word 1

# 1174 V1.3.6

FB Micro Grid CW1

# 1700

Control for Micro Grid operations

V1.3.7

FB Micro Grid SW1

# 1701

Status of Micro Grid operations

V1.3.8

Last Active Warning

# 74

V1.3.9

Last Active Fault

# 37 V1.3.10

MC Status

# 64 V1.3.11

FB Analogue Out

%

#,##

48

Page 35

arfif106 Grid Converter + Grid Codes VACON® · 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Classified as Public

5.1.4 I/O monitoring values

Code

Parameter

Unit

Form.

ID

Description

V1.4.1

DIN1, DIN2, DIN3

# 15 V1.4.2

DIN4, DIN5, DIN6

# 16 V1.4.3

DIN Status 1

# 56 V1.4.4

DIN Status 2

# 57

V1.4.5

Analogue Input 1

%

#,##

13 V1.4.6

Analogue Input 2

%

#,##

14

V1.4.7

Analogue input 3

%

#,##

27

AI3, unfiltered.

V1.4.8

Analogue input 4

%

#,##

28

AI4, unfiltered.

V1.4.9

Analogue Out 1

%

#,##

26

V1.4.10

Analogue Out 2

%

#,##

50

AO2

V1.4.11

Analogue Out 3

%

#,##

51

AO3

V1.4.12

PT100 Temp

°C

#,#

42

Maxim temperature

V1.4.13

PT100 Temp. 1

°C

#,#

50

V1.4.14

PT100 Temp. 2

°C

#,#

51 V1.4.15

PT100 Temp. 3

°C

#,#

52 V1.4.16

PT100 Temp. 4

°C

#,#

69 V1.4.17

PT100 Temp. 5

°C

#,#

70

V1.4.18

PT100 Temp. 6

°C

#,#

71

5.1.5 Master / Follower

Code

Parameter

Unit

Form.

ID

Description

V1.5.1

SB SystemStatus

# 1819 V1.5.2

Master CW

# 93 Code

Parameter

Unit ID

Description

V1.5.3.1

Current D1

A

Varies

1820

V1.5.3.2

Current D2

A

Varies

1821

V1.5.3.3

Current D3

A

Varies

1822

V1.5.3.4

Current D4

A

Varies

1823 Code

Parameter

Unit ID

Description

V1.5.4.1

Status Word D1

# 1828

V1.5.4.2

Status Word D2

# 1829

V1.5.4.3

Status Word D3

# 1830

V1.5.4.4

Status Word D4

# 1831

5.1.6 Licence activation status

Code