Page 1

vacon

®

nx

ac drives

arfiff08 power generation

with general grid codes

application manual

Page 2

Page 3

arfiff08 power generation VACON® • 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

VACON® POWER GENERATION APPLICATION MANUAL

INDEX

Document code: DPD02125

Software code: ARFIFF08V040

Date: 26.8.2019

1. Introduction ..................................................................................................................8

1.1 Grid Code Support Information .................................................................................................. 8

1.2 Compatibility issues in parameters between versions ............................................................. 8

2. General .........................................................................................................................9

2.1 Basic features .............................................................................................................................. 9

2.2 Stand Alone .................................................................................................................................. 9

2.3 Multimaster (2 … 8 x inverter size)........................................................................................... 10

2.4 How to use.................................................................................................................................. 11

2.4.1

Keypad push buttons ........................................................................................................ 11

2.4.2

Inverter status indications ................................................................................................ 12

2.4.3

Control place indications .................................................................................................. 13

2.4.4

Status LEDs (green green red) ................................................................................... 13

2.4.5

Text lines............................................................................................................................ 14

3. Application .................................................................................................................. 15

3.1 Quick Application Commissioning Guide ................................................................................. 15

3.1.1

Commissioning Steps ....................................................................................................... 15

3.1.2

Multimaster PLC out of commission ............................................................................... 17

4. Monitoring signals ...................................................................................................... 18

4.1 Basic monitor values ................................................................................................................. 18

4.1.1

Monitoring values 1 ........................................................................................................... 18

4.1.2

Monitoring values 2 ........................................................................................................... 19

4.1.3

Fieldbus monitoring values .............................................................................................. 19

4.1.4

I/O monitoring values........................................................................................................ 19

4.1.5

MPPT .................................................................................................................................. 20

4.1.6

License key activation ....................................................................................................... 20

4.1.7

Grid code ............................................................................................................................ 20

4.1.8

PID Controller ................................................................................................................... 20

4.2 Monitor Values descriptions ..................................................................................................... 21

4.2.1

Monitoring values 1 ........................................................................................................... 21

4.2.2

Monitoring values 2 ........................................................................................................... 23

4.2.3

Fieldbus monitoring values .............................................................................................. 27

4.2.4

I/O monitoring values........................................................................................................ 29

4.2.5

MPPT .................................................................................................................................. 30

4.2.6

License key activation ....................................................................................................... 31

4.2.7

Gird code ............................................................................................................................ 31

4.2.8

PID Controller ................................................................................................................... 32

5. Parameters ................................................................ ................................................. 33

5.1 P2.1 Basic parameters .............................................................................................................. 33

5.1.1

DC Level Setup .................................................................................................................. 34

5.2 Reference Handling ................................................................................................................... 34

Page 4

4 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.2.1

DC Reference .................................................................................................................... 34

5.2.2

Power/frequency reference ............................................................................................. 35

5.2.2.1 PID Power Controller ............................................................................................... 35

5.2.3

AC Voltage reference ........................................................................................................ 35

5.3 IO Signals ................................................................................................................................... 36

5.3.1

Digital Inputs ..................................................................................................................... 36

5.3.1.1 Configuration............................................................................................................. 37

5.3.1.2 Analog Inputs ............................................................................................................ 37

5.3.1.3 Power Limitation ....................................................................................................... 37

5.3.1.4 Analog Input as Digital Input #1 & #2 ..................................................................... 38

5.3.1.5 DC Ground Measurement......................................................................................... 38

5.3.1.6 Customizable Analog Input ...................................................................................... 38

5.3.2

Digital Outputs ................................................................................................................... 39

5.3.2.1 Configuration............................................................................................................. 40

5.3.3

Analog Outputs .................................................................................................................. 41

5.4 Limit Settings ............................................................................................................................. 42

5.4.1

Current Limit ..................................................................................................................... 42

5.4.2

Generator Power Limit ..................................................................................................... 42

5.5 Inverter Control ......................................................................................................................... 43

5.5.1

Standby Control ................................................................................................................. 43

5.5.2

MPP Tracker ...................................................................................................................... 43

5.5.3

Bypass Control .................................................................................................................. 46

5.5.4

Multimaster Follower Control .......................................................................................... 46

5.5.5

Power Adjust ..................................................................................................................... 46

5.6 Drive Control .............................................................................................................................. 46

5.6.1

Control ............................................................................................................................... 46

5.7 Protections ................................................................................................................................. 47

5.7.1

General .............................................................................................................................. 47

5.7.2

DC Earth Fault ................................................................................................................... 47

5.7.3

AC Earth Fault ................................................................................................................... 47

5.7.4

Main Contactor .................................................................................................................. 48

5.7.5

Fieldbus ............................................................................................................................. 48

5.7.6

System bus ........................................................................................................................ 49

5.7.7

Auto reset .......................................................................................................................... 49

5.7.8

Analog Inputs ..................................................................................................................... 50

5.7.9

AC Voltage Protections ..................................................................................................... 50

5.7.10

AC Frequency Protections ............................................................................................ 50

5.8 Fieldbus ...................................................................................................................................... 51

5.9 System Tests .............................................................................................................................. 52

5.9.1

Power Simulation .............................................................................................................. 52

5.9.2

System bus ........................................................................................................................ 52

5.9.3

Simulated Grid................................................................................................................... 52

5.10 Counters ..................................................................................................................................... 53

5.11 Admin Parameters .................................................................................................................... 54

5.11.1

Ext Fan Control ............................................................................................................. 54

5.11.2

Datalogger ..................................................................................................................... 54

5.11.2.1 Trigger ....................................................................................................................... 54

5.11.2.2 Settings ..................................................................................................................... 55

5.12 Grid Codes .................................................................................................................................. 56

5.12.1

FRT ................................................................................................................................. 56

5.12.2

Reconnection ................................................................................................................. 56

5.12.3

Line Voltage ................................................................................................................... 57

5.12.4

Line Frequency .............................................................................................................. 57

Page 5

arfiff08 power generation VACON® • 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.12.5

Voltage Time Trip .......................................................................................................... 58

5.12.6

Line OK Limits ............................................................................................................... 58

5.12.7

Reactive Injection .......................................................................................................... 59

5.12.7.1 Linear UV ................................................................................................................... 59

5.12.7.2 Linear OV ................................................................................................................... 59

5.12.7.3 Power Lock UV .......................................................................................................... 59

5.12.7.4 Power Lock OV .......................................................................................................... 59

5.12.7.5 Q(U) Power ................................................................................................................ 60

5.12.8

Power Limit ................................................................................................................... 60

5.12.8.1 High Frequency ......................................................................................................... 60

5.12.8.2 High Voltage .............................................................................................................. 60

5.12.8.3 Low Frequency Power .............................................................................................. 60

5.12.8.4 Cos Phii Control ........................................................................................................ 61

5.12.8.5 External Input ........................................................................................................... 61

5.12.8.6 Options ...................................................................................................................... 61

5.13 Control........................................................................................................................................ 62

5.14 System menu ............................................................................................................................. 62

5.15 Expander boards (Control keypad: Menu M7) ......................................................................... 62

6. Parameters and descriptions ...................................................................................... 63

6.1 Basic Parameters ...................................................................................................................... 63

6.1.1

Transformer Parameters ................................................................................................. 64

6.1.2

Configuration Parameters ................................................................................................ 65

6.1.3

DC Level Setup .................................................................................................................. 66

6.2 Reference Handling ................................................................................................................... 67

6.2.1

DC Reference .................................................................................................................... 67

6.2.2

Power/ Frequency reference ........................................................................................... 68

6.2.2.1 PID Power Controller ............................................................................................... 69

6.2.3

AC Voltage reference ........................................................................................................ 70

6.3 IO signals.................................................................................................................................... 71

6.3.1

Digital inputs ..................................................................................................................... 71

6.3.1.1 Configuration............................................................................................................. 73

6.3.2

Analog inputs ..................................................................................................................... 74

6.3.2.1 Power limitation ........................................................................................................ 74

6.3.2.2 Analog Input as Digital Input #1 & #2 ..................................................................... 75

6.3.2.3 DC ground measurement ......................................................................................... 76

6.3.2.4 Custom analog input................................................................................................. 77

6.3.3

Digital outputs ................................................................................................................... 78

6.3.3.1 Configuration............................................................................................................. 79

6.3.4

Analog outputs .................................................................................................................. 80

6.4 Limit settings ............................................................................................................................. 81

6.4.1

Current limit ...................................................................................................................... 81

6.4.2

Generator power limit ....................................................................................................... 81

6.5 Inverter Control ......................................................................................................................... 82

6.5.1

Standby settings ................................................................................................................ 82

6.5.2

MPP tracker....................................................................................................................... 83

6.5.3

Bypass control ................................................................................................................... 85

6.5.4

Multimaster follower control ........................................................................................... 85

6.5.5

Power adjust ...................................................................................................................... 85

6.6 Drive Control .............................................................................................................................. 86

6.6.1

Control ............................................................................................................................... 88

6.7 Protections ................................................................................................................................. 89

6.7.1

General .............................................................................................................................. 89

Page 6

6 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.7.2

DC Earth fault .................................................................................................................... 90

6.7.3

AC Earth Fault ................................................................................................................... 90

6.7.4

Main Contactor .................................................................................................................. 90

6.7.5

Control Panel..................................................................................................................... 91

6.7.6

Systembus ......................................................................................................................... 91

6.7.7

Auto reset .......................................................................................................................... 92

6.7.8

Analog Inputs ..................................................................................................................... 93

6.7.9

AC Voltage Protection ....................................................................................................... 93

6.7.10

AC Frequency Protection .............................................................................................. 93

6.8 Fieldbus ...................................................................................................................................... 94

6.9 System Tests .............................................................................................................................. 95

6.9.1

Power Simulation .............................................................................................................. 95

6.9.2

Systembus test .................................................................................................................. 96

6.9.3

Simulated grid ................................................................................................................... 97

6.10 Counters ..................................................................................................................................... 98

6.11 Admin parameters .................................................................................................................... 99

6.11.1

External fan control ...................................................................................................... 99

6.11.2

Datalogger ................................................................................................................... 100

6.11.2.1 Datalogger trigger .................................................................................................. 100

6.11.2.2 Datalogger settings ................................................................................................ 101

6.12 Grid Code parameters ............................................................................................................. 102

6.12.1

FRT ............................................................................................................................... 103

6.12.2

Reconnection ............................................................................................................... 104

6.12.3

Line Voltage ................................................................................................................. 105

6.12.4

Line Frequency ............................................................................................................ 107

6.12.5

Voltage Time Trip ........................................................................................................ 109

6.12.6

Line OK Limits ............................................................................................................. 110

6.12.7

Reactive Injection ........................................................................................................ 111

6.12.7.1 Linear reference under voltage ............................................................................. 112

6.12.7.2 Linear reference over voltage ............................................................................... 113

6.12.7.3 Power Lock In and Out Reference under voltage. ................................................ 114

6.12.7.4 Power Lock In and Out Reference over voltage. .................................................. 115

6.12.7.5 Q(U) Power .............................................................................................................. 116

6.12.8

Power Limit ................................................................................................................. 117

6.12.8.1 High Frequency Power Limit ................................................................................. 117

6.12.8.2 High Voltage Power Limit ...................................................................................... 119

6.12.8.3 Low Freq Power ...................................................................................................... 120

6.12.9

Cos Phii Control .......................................................................................................... 121

6.12.9.1 Lock in and out control .......................................................................................... 121

6.12.9.2 Cos Phii Active Current Control ............................................................................. 122

6.12.10

External Input .............................................................................................................. 123

6.12.11

Grid Code Options ....................................................................................................... 124

7. Control...................................................................................................................... 125

8. Fieldbus interface ..................................................................................................... 126

8.1 Control Word ............................................................................................................................ 127

8.2 Status Words............................................................................................................................ 128

8.3 Warning Status words ............................................................................................................. 129

8.4 Monitoring values for Fieldbus use ........................................................................................ 131

9. Problem solving ........................................................................................................ 132

10. Application Fault Codes ............................................................................................. 133

Page 7

arfiff08 power generation VACON® • 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

11. State Machine: .......................................................................................................... 137

11.1 General state machine: ........................................................................................................... 137

11.1.1

Start Criterions: .......................................................................................................... 138

11.1.2

Activation command: .................................................................................................. 139

11.2 General Substate Machine ...................................................................................................... 140

11.2.1

Field OK ....................................................................................................................... 140

11.3 MPPT State: ............................................................................................................................. 141

12. IO-Connections ......................................................................................................... 142

12.1 Appendix ................................................................................................................................... 143

Page 8

8 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1. INTRODUCTION

In this application is kept backwards compatibility with ARFIFF07. The power generation application

is used to generate power to grid using the maximum power point tracker (MPPT) or manual DC

reference.

1.1 Grid Code Support Information

In this application is used general grid codes.

1.2 Compatibility issues in parameters between versions

NOTE! This application is not kept backwards compatible. See release notes and this chapter before

updating the application.

Update Note 1: When you update the application do not use NCDrive parameter download function.

Instead upload parameters from the unit and compare them to the old parameter file. The

application is constantly developed, and it includes changing parameter default values. If

parameters are directly downloaded to drive, improved default values will be lost.

Page 9

arfiff08 power generation VACON® • 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2. GENERAL

The power generation application is an answer to growing renewable energy market. The inverters

need only DC voltage and the grid to start producing energy.

Picture 1. Basic solar system.

2.1 Basic features

The power generation application works with Multi master and Stand-alone configurations. It can be

used with thin film and polycrystal Solar panels. Multi master configured system is controlled by

external Touch panel.

Additional functions:

• Grid Code functionality.

• Possibility to send Power Limit also from Fieldbus

• Multi-Master functionality with daily master change.

• Maximum Power Point Tracking

• Possibility to set any parameter value through Fieldbus interface.

2.2 Stand Alone

There is only one inverter unit which is producing energy to the grid. This system is working alone and

there is no need to use any external control systems or backup systems.

Page 10

10 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

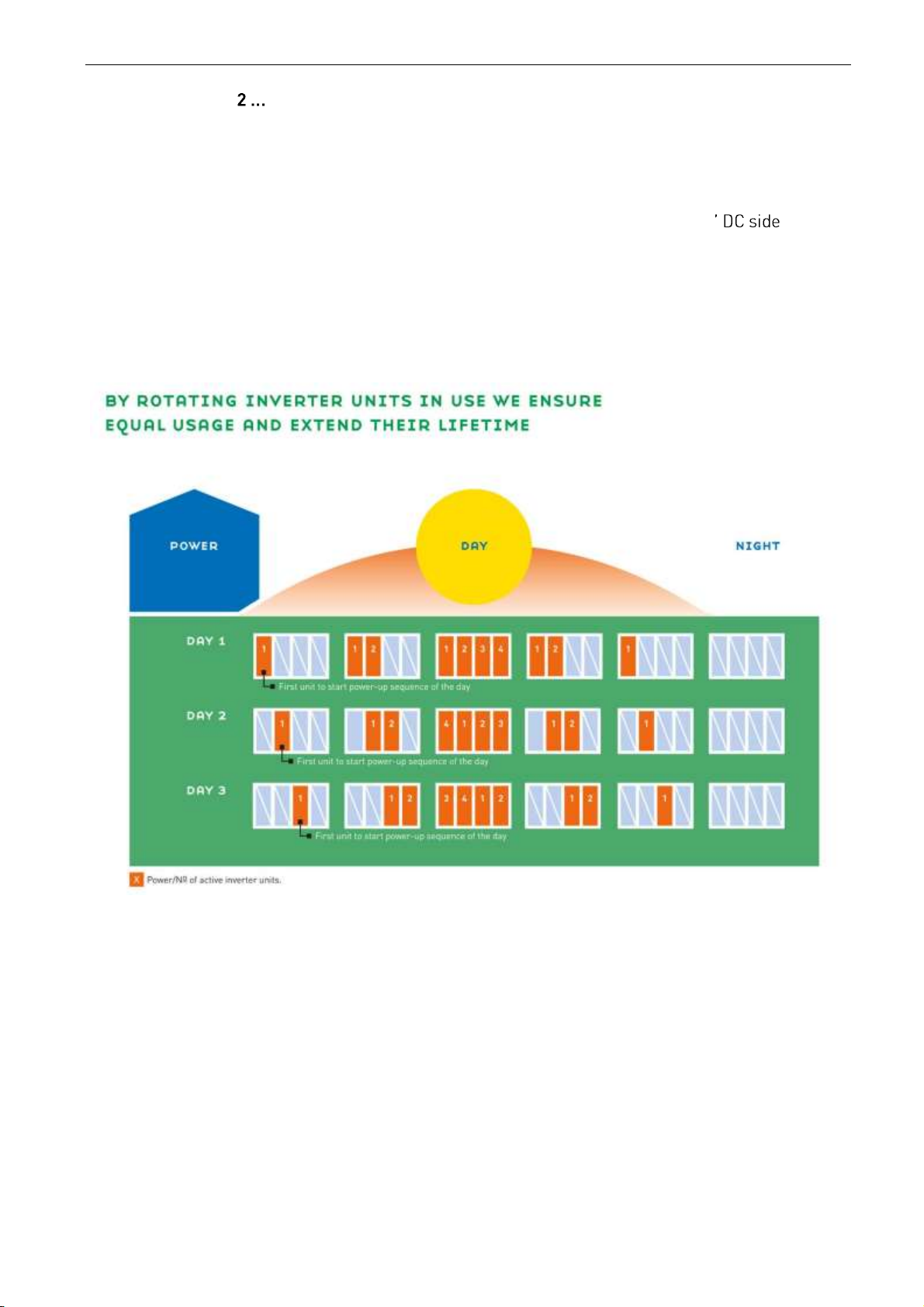

2.3 Multimaster ( 8 x inverter size)

The multi master functionality is used in bigger systems. There are two to eight inverter units which

are producing energy to the grid. This system has always the touch panel, which controls the system.

Inverters are equally loaded, because each time system is started, MPPT master is changed, which

will extend the lifetime of the inverters.

In the multi master system there is one inverter which is controlling other inverters behavior

and that inverter is called master inverter. Master inverter collects information of the DC bus and

makes decisions regarding what DC reference is used.

Other inverters are slave inverters and they follow DC reference coming from the master inverter.

Each of the inverters is responsible of its own behavior on the Grid side, i.e. complying with Grid Code

Standard.

Each unit is sending status information to operator panel and they can be read in touch panel.

Picture 2. Multi master system master change function.

Page 11

arfiff08 power generation VACON® • 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2.4 How to use

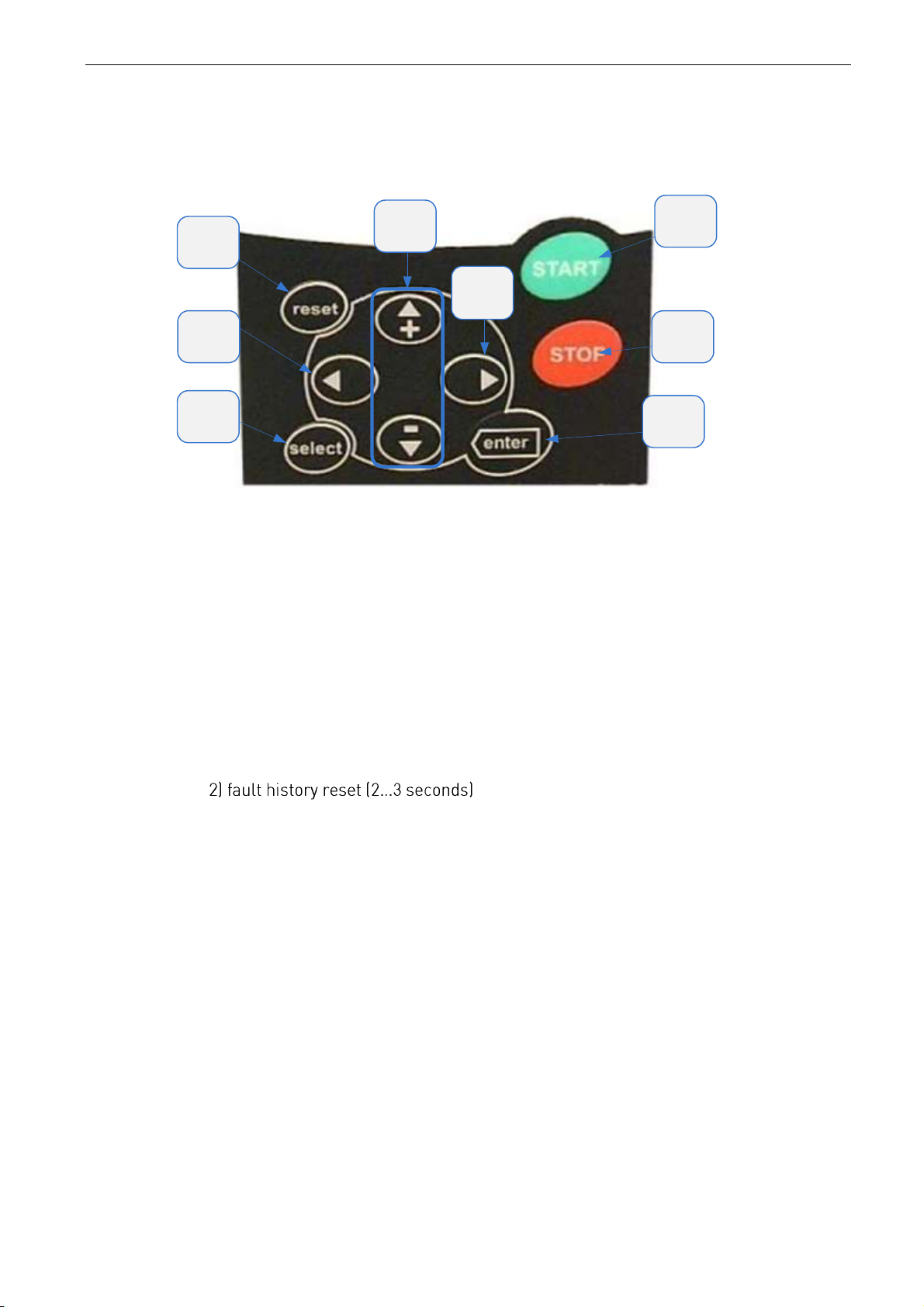

2.4.1

Keypad push buttons

1

1

2

3

4

5

6

7

8

Picture 3. Keypad push buttons

1 = Start button.

Pressing this button unit goes to ready state in multi master system or if standalone configuration is used it goes to ready state and if there is enough DC voltage, it

will try to run.

Pressing start button for 5 seconds when the Control Source is set to Panel forces

the drive to start regardless of DC level.

2 = Stop button.

Pressing this button stops the unit

3 = Enter button serves for:

1) confirmation of selections

4 = Select button is used to switch between two latest displays. May be useful when you

want to see how the changed new value influences some other value.

5 = Reset button is used to reset active faults.

6 = Browser button up and down

Browse the main menu and the pages of different submenus.

Edit values.

7 = Menu button left

Move backward in menu.

Move cursor left (in parameter menu).

Exit edit mode.

8 = Menu button right

Move forward in menu.

Move cursor right (in parameter menu).

Enter edit mode.

Page 12

12 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

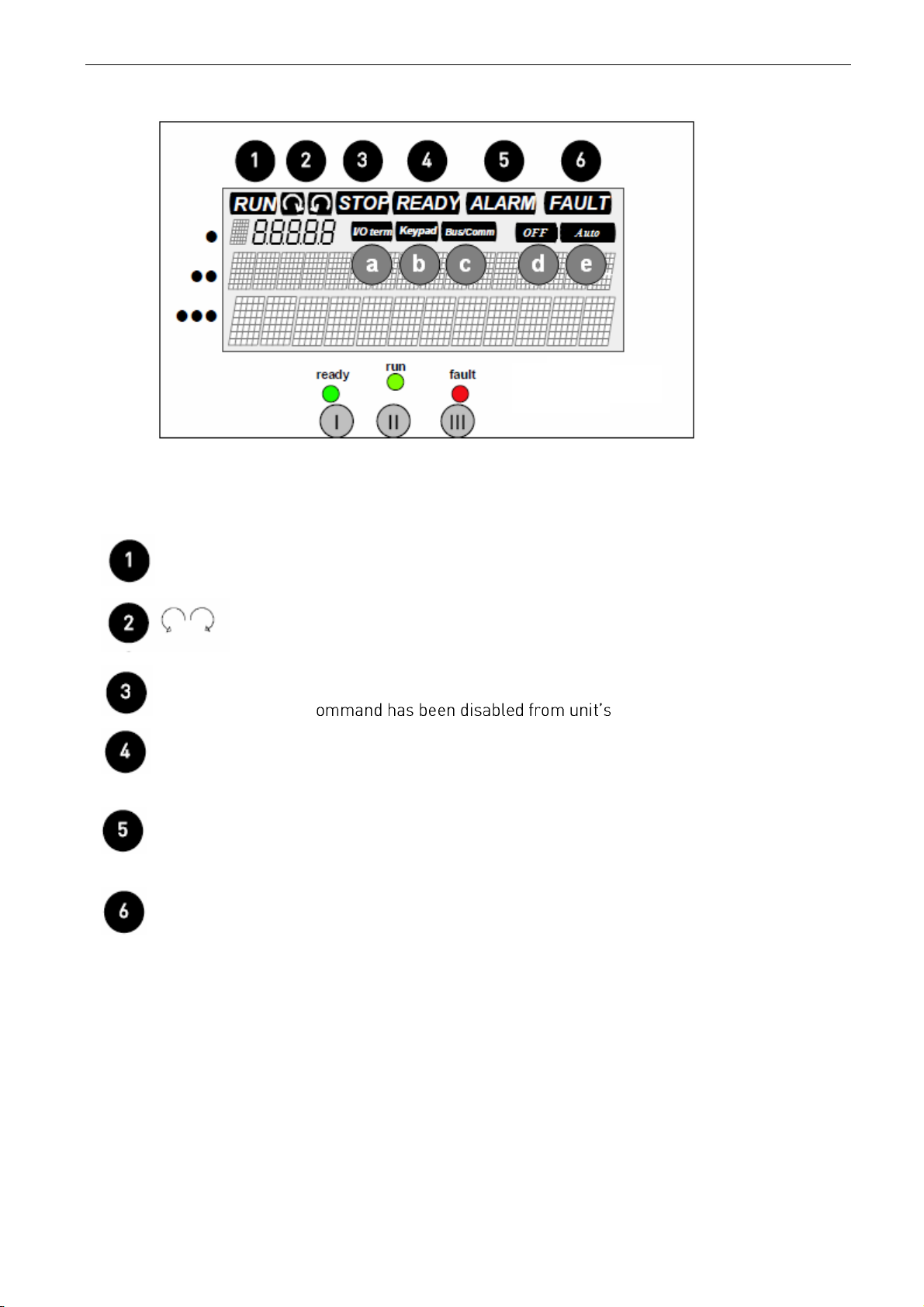

2.4.2

Inverter status indications

Picture 4.Keypad Indicators

The inverter status indications tell the user what the status of the Inverter and the Inverter is and

whether the Inverter control software has detected irregularities in Inverter functions.

RUN = Inverter is running;

= Indicates the direction of current flow.

STOP = Start c control panel.

READY = Lights when AC and DC Voltage is on. In case of a trip or stop button is pushed,

the symbol will not light up.

ALARM = Indicates that the Inverter is running outside a certain limit and a warning is

given.

FAULT = Indicates that unsafe operating conditions were encountered due to which the

Inverter was stopped.

Page 13

arfiff08 power generation VACON® • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

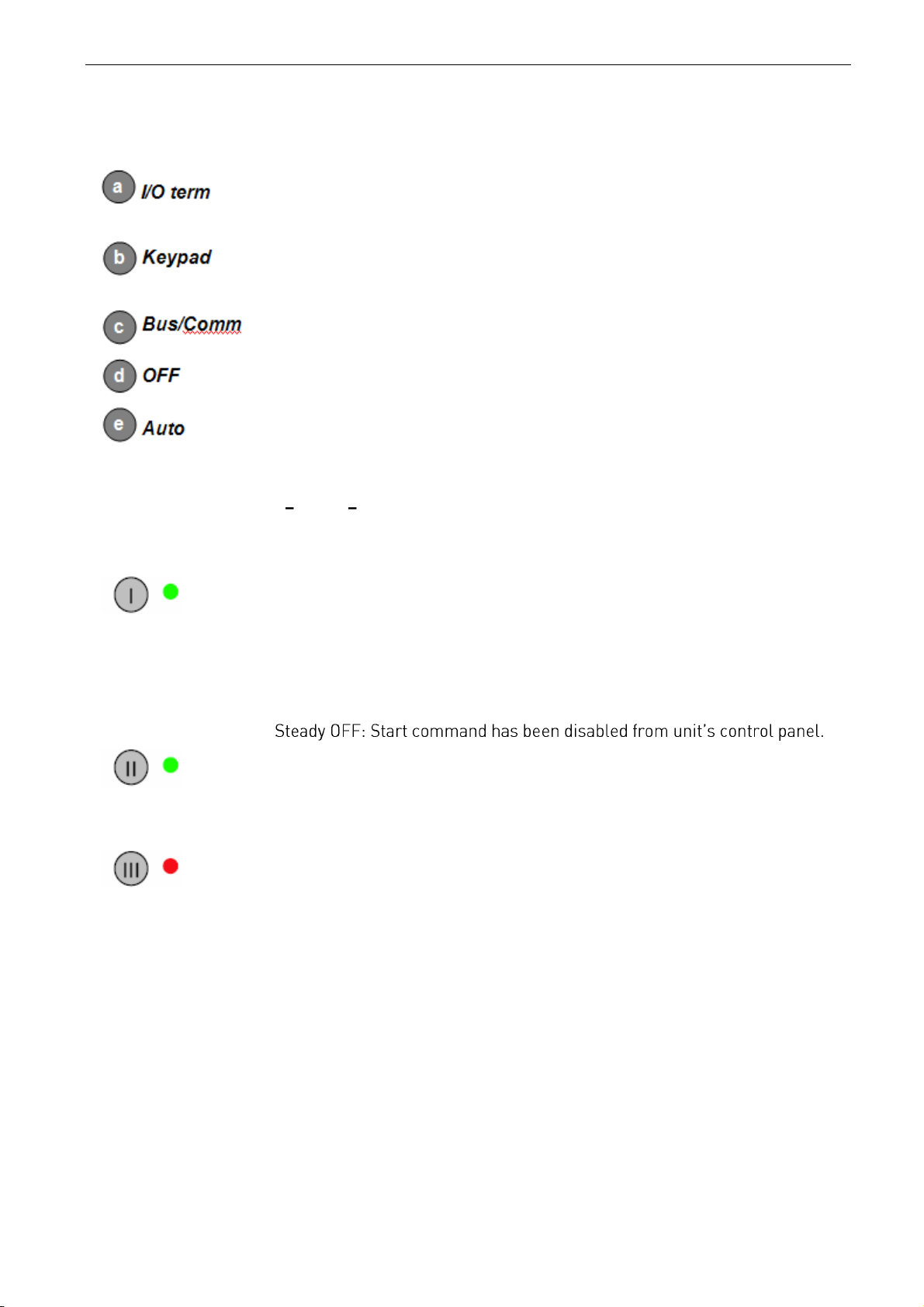

2.4.3

Control place indications

The symbols I/O term, Keypad and Bus/Comm (see Figure 7-1) indicate the choice of control place

made in the Keypad control menu (M3).

= I/O terminals are the selected control place; i.e. START/STOP commands or

reference values etc. are given through the I/O terminals.

= Control keypad is the selected control place; i.e. the Inverter can be started or

stopped, or its reference values etc. altered from the keypad.

= The inverter is controlled through a fieldbus.

= Run enable not active

= Unit is ready to start in the morning.

2.4.4

Status LEDs (green green red)

The status LEDs light up in connection with the READY, RUN and FAULT Inverter status

indicators.

(Ready) = Steady ON (no other LEDs): Start command has been given, all start criterions

have been fulfilled except that the drive has not detected high enough voltage

to start up.

Blinking at 2 Hz: All external start criterions have been fulfilled but no start

command has been given.

(Run) = Steady ON: The Inverter is running.

Blinking: Stop command has been given and the inverter is ramping power

down.

(Fault) = Blinks when unsafe operating conditions were encountered due to which the

Inverter was stopped (Fault Trip). Simultaneously, the Inverter status

indicator FAULT blinks on the display and the fault description can be seen

on the panel.

Page 14

14 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2.4.5

Text lines

menu structure as well as with information related to the operation of the Inverter.

Location indication; displays the symbol and number of menu, parameter etc.

Description line; Displays the description of menu, value or fault.

Value line; Displays the numerical and textual values of references,

parameters etc. and the number of submenus available in each menu.

Page 15

arfiff08 power generation VACON® • 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3. APPLICATION

3.1 Quick Application Commissioning Guide

The Power generation application has been design for easy and fast commissioning. The user only

needs to set the Basic parameters and check if the there are any I/O parameters to be changed.

The Basic parameters are meant to be set in numerical order. Then the option board parameters are

set correctly automatically and system is ready faster.

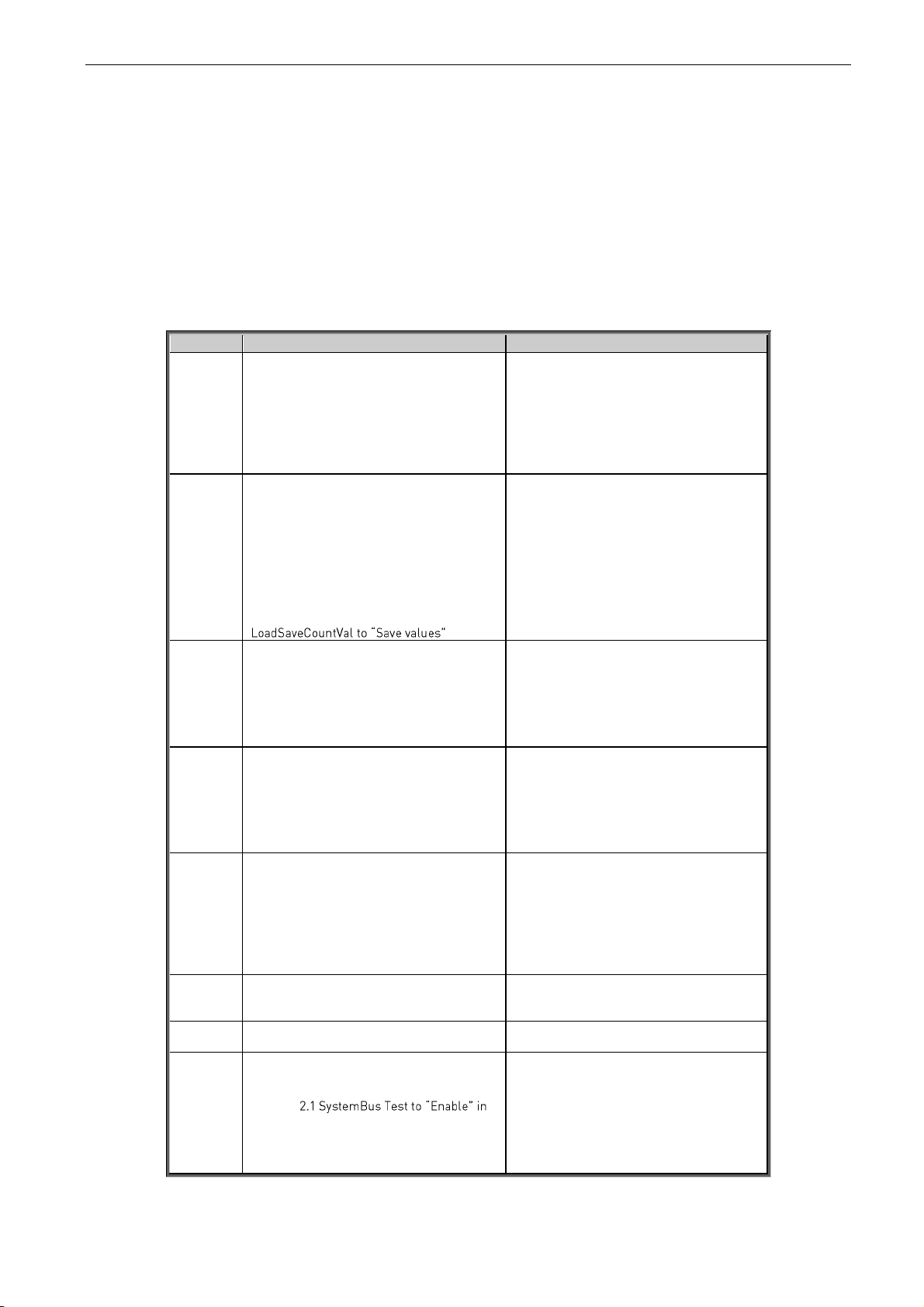

3.1.1

Commissioning Steps

Table 1. Application Commissioning Steps

Step #

Step

Description

1

If you are updating the application to newer

version, write down the following counter

values before updating:

V1.1.10 Total Energy kWh

V1.1.13 RunTime Total

V1.1.16 Grid Connections

V1.1.17 IntFanRunHours

V1.1.18 ExtFanRunHours

These values need to be written down so

that the counters can be reset to correct

values after application update.

2

After application update, write the

corresponding counter values to these

parameters:

P2.10.2 TotalEnergyPreset

P2.10.3 GridConnPreset

P2.10.4 TotalRunTimPrese

P2.10.5 IntFanRuntPresVa

P2.10.6 ExtFanRuntPresVa

Change parameter P2.10.1

This will set the counters to the values

before application update.

3

Define right grid settings

P2.1.1 Grid Nom Voltage

P2.1.2 Grid Nom Freq

P2.1.6 Transf inv. side

P2.1.7 Transf grid side

When grid settings are right drive voltage is

calculated correct.

4

Set parameters P2.1.7 and P2.1.8 in

numerical order.

By setting the parameters in numerical

order the necessary option board

parameters are set also automatically to

their correct/default values.

This speeds up the process especially in

Multimaster system commissioning.

5

If commissioning is done before large scale

power production is possible, set P2.1.9.1

DC Start Level parameter to a level where

the inverter will surely start when the sun is

up.

Otherwise no need to change anything else

in Basic Parameters

This parameter indicates the minimum DC

voltage needed for the drive to try start up. If

this is larger than the current DC level when

the drive is stopped (as it is during morning

or evening commissioning) the drive will not

start.

6

Set the I/O parameters in G2.3 as required.

Some fault or warning may have been

triggered due to wiring in customized

cabinet solutions.

7

Reset any possible faults.

Reset the possible wiring related faults /

warnings.

8

Set P2.9.

any one unit

This will start a SystemBus test procedure

that will blink the Ready, Run and Fault

LEDs in all of the drives in order, starting

from the inverter where the parameter was

set.

If the LEDs do not blink in all of the units,

check the optical cables, jumper settings in

Page 16

16 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

OPT-D2 option boards and Basic parameters

in all of the drives.

9

Set P2.9.1.1 Simulation Mode to

and press start

in the Beijer panel

This activates the simulation mode where

drives use simulated DC voltage (P2.5.1.6)

and simulates power production which the

Beijer touch panel can see.

This test ensures that the system works as a

whole and the communication between the

inverters and Beijer touch panel is working

(in multimaster system) alright without

actually having DC or real output power.

You may need to lower the limit for starting

up the next follower in the Beijer

parameters to enable follower start ups.

10

When every drive in the system has ran,

press stop in the Beijer panel and set

P2.9

This disables the simulation mode and

enables the drive to run normally.

11

Give Start command.

If drive has not started but Ready LED is lit

and power production should be possible,

press Start button for 5 seconds.

If the DC is above the P2.1.9.1 DC Start Level

the drive will start. Pressing the Start button

for 5 seconds forces the drive to start

regardless of DC level.

12

Make sure parameter P2.1.9.6 DC Start

Level Max is set to appropriate value

compared to the specified open circuit

voltage of the panel field.

NOTE: during hot summer days, the actual

open circuit voltage can go as low as 90% of

the specified OC voltage, set the parameter

accordingly!

P2.1.9.6 DC Start Level Max is the absolute

maximum value that the addition of offset

after natural stops will not exceed. This is to

ensure that the start level never rises so

high that the drive will never start up.

13

In Multimaster system when power

production is ~75 % from system maximum,

use P2.2.2 DC Calibration to tweak the

output power of all of the drives to match

each other.

This is done to ensure that the small DC

voltage measurement errors between the

drives are not causing adverse effects on the

power production and the produced power

values are close to the same in the

Multimaster panel.

Page 17

arfiff08 power generation VACON® • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

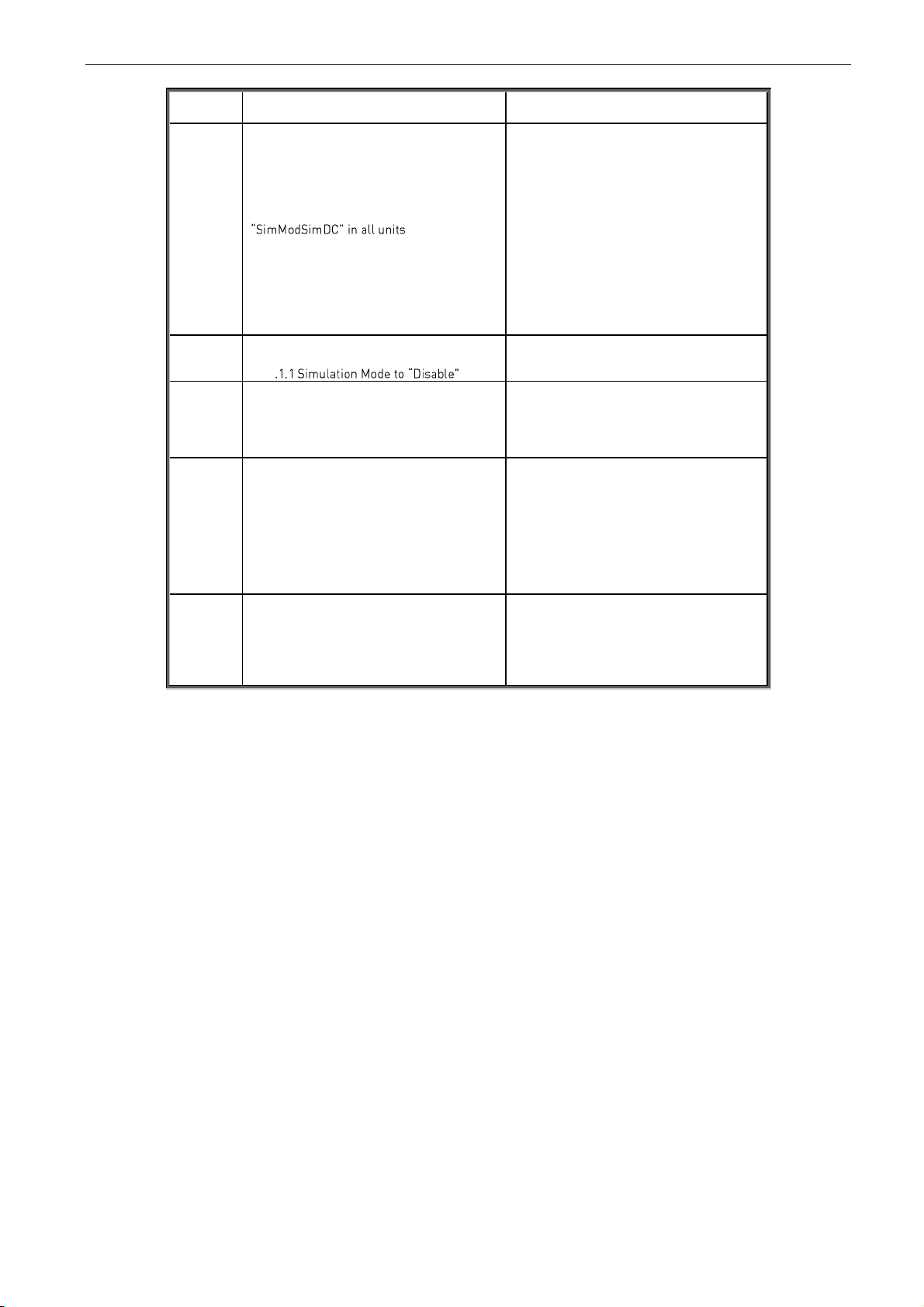

3.1.2

Multimaster PLC out of commission

If it happens that the multimaster control PLC is out of order, the drives are able to work using

master-follower operation mode where all of the drives are always working at the same time:

Step #

Step

Description

1

Set parameter P2.1.8 SB

This setting indicates for the unit #1 that it

needs to send the start command to the

other drives via SystemBus

2

Set P3.1 Control Source in the master to

Panel

This way the user can use the Panel to give

the Start command to the master unit and

the drive no longer listens to commands

from Fieldbus

3

Set P3.1 Control Source in all of the other

drives to SystemBus

This way the follower drives listen for the

Start command from SystemBus

4

Reset possible faults and give Start

command to the master unit.

If drives have not started but Ready LED is lit

in the Master unit and large scale power

production is possible, press Start button for

5 seconds.

The drives start up and start producing

power.

Page 18

18 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4. MONITORING SIGNALS

The monitoring values are the actual values of parameters and signals as well as statuses and

measurements.

On the next pages you will find the lists of monitoring values within the respective monitor values

groups. The monitor values descriptions are given on pages 16 to 25.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter number

Values = Name of monitor value

Unit = Unit of monitor value; Given if available

ID = ID number of the parameter

All monitoring value is possible to monitoring from fieldbus by ID number

4.1 Basic monitor values

4.1.1

Monitoring values 1

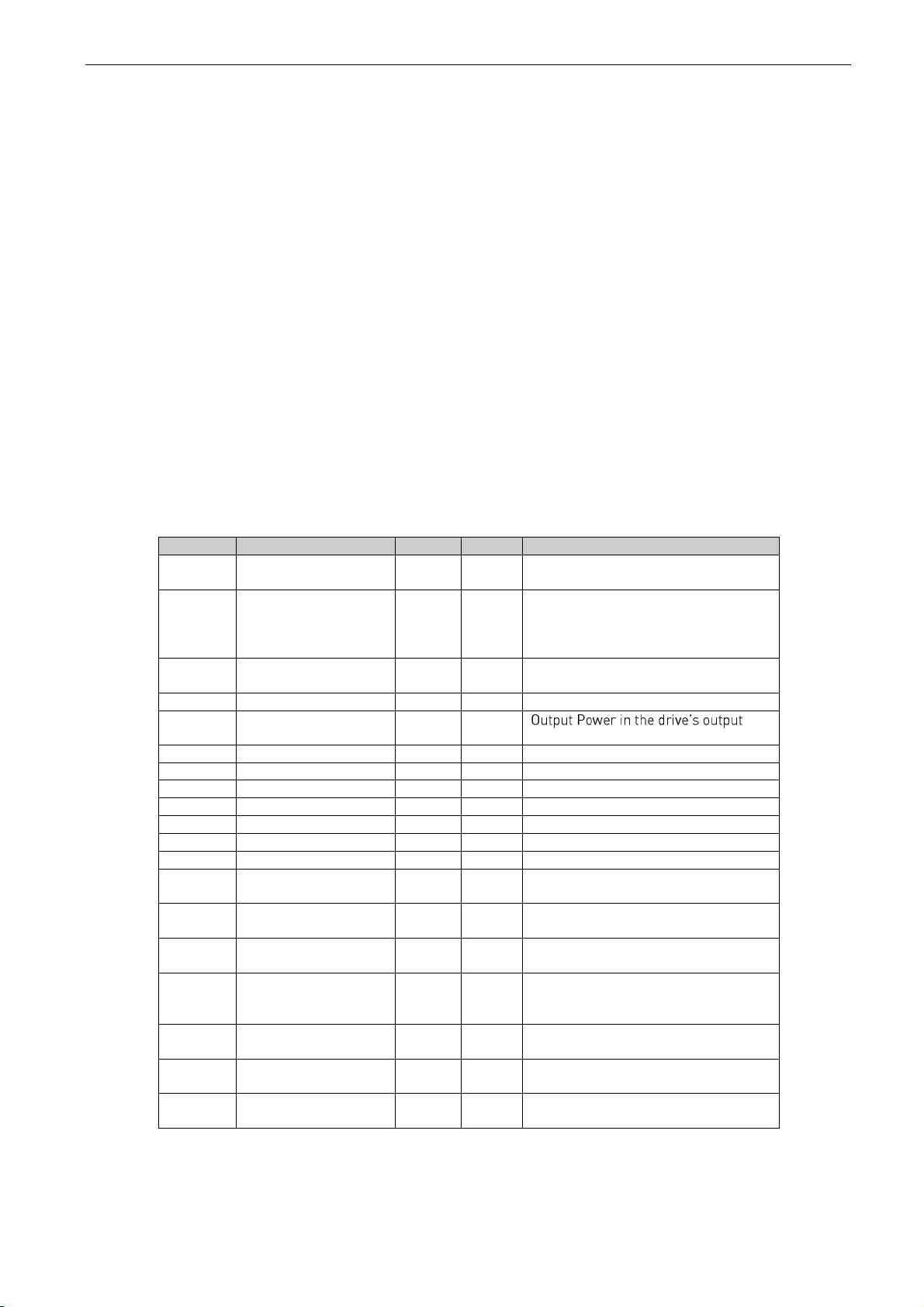

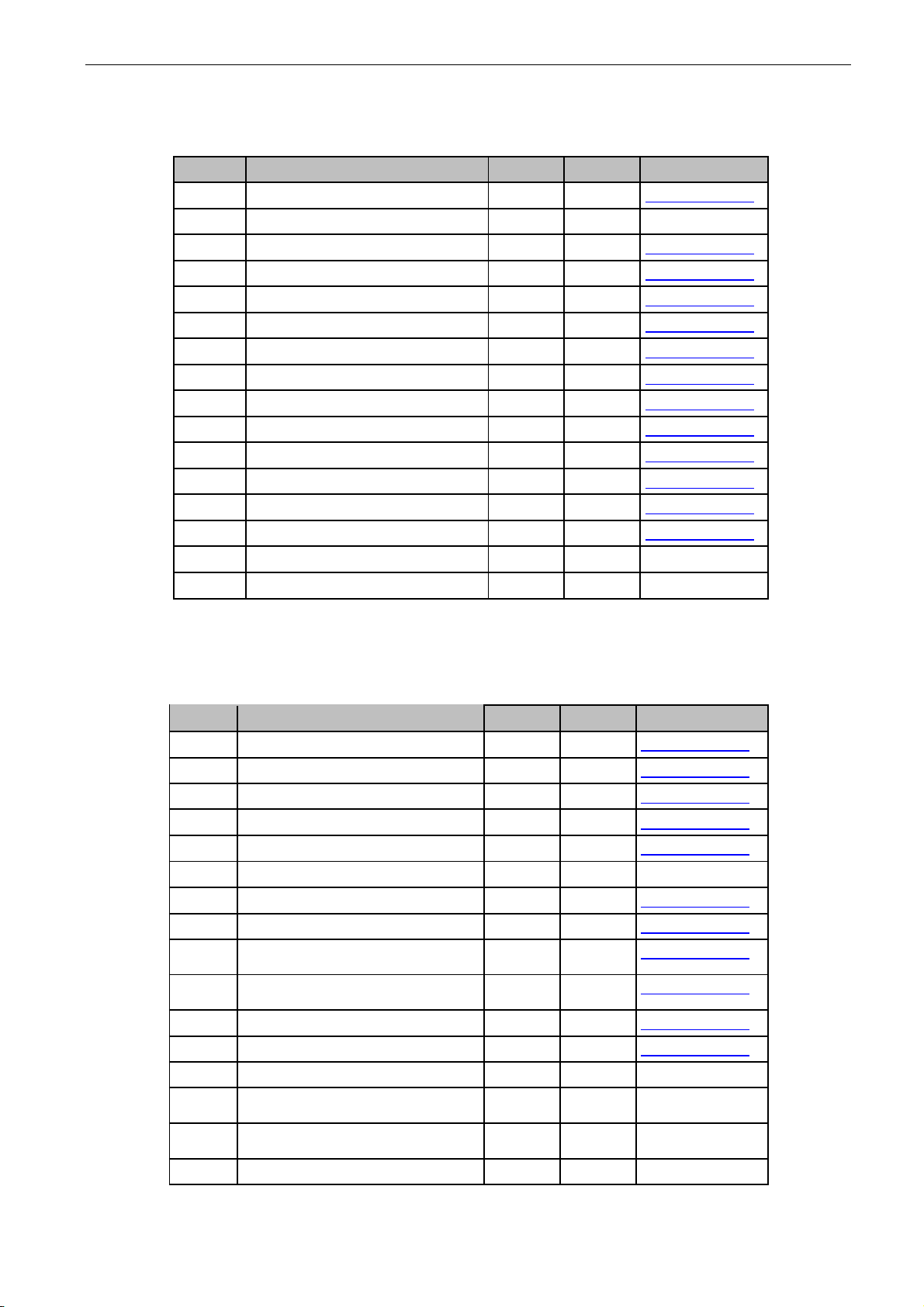

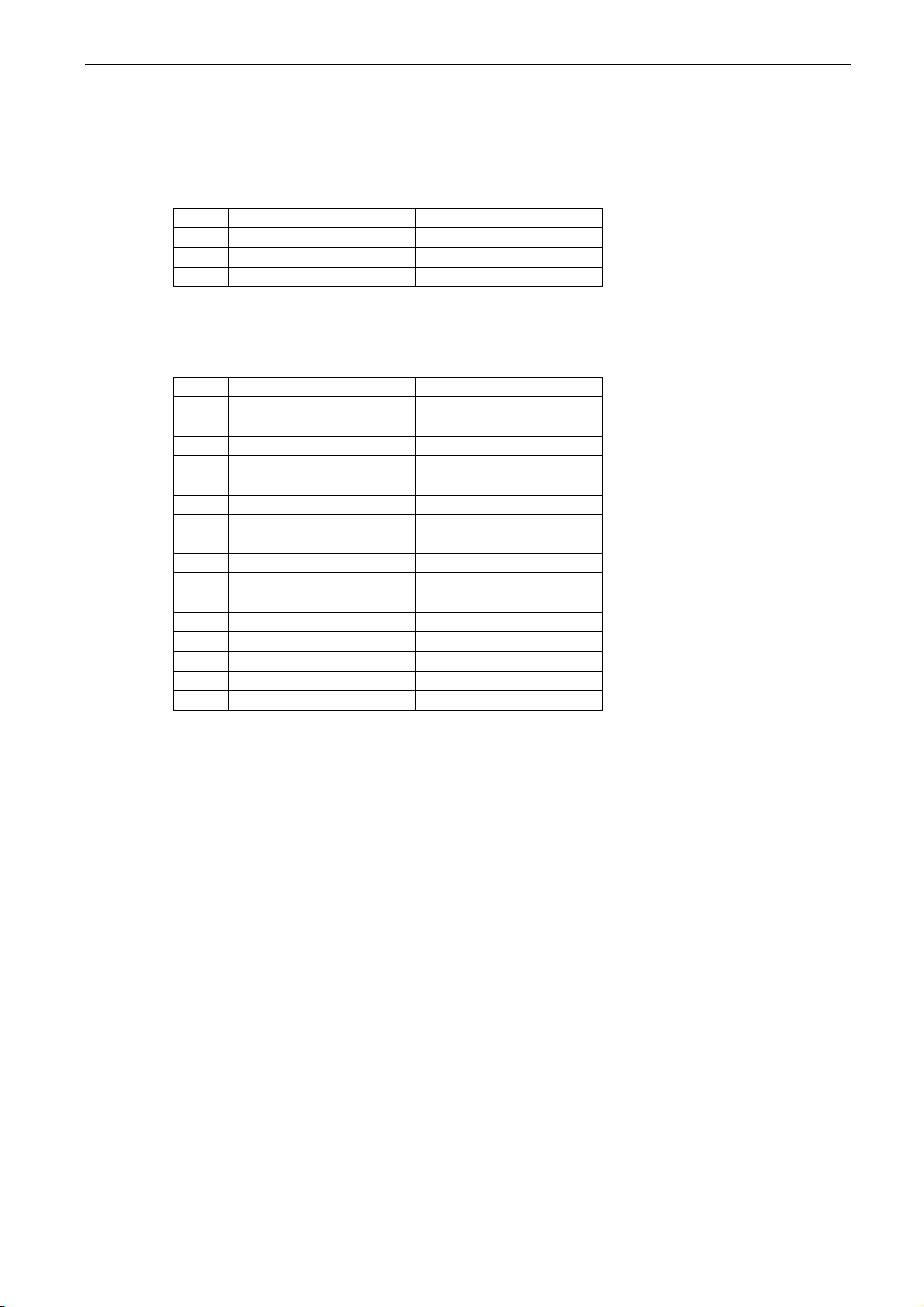

Table 2. Monitoring values 1

Code

Values

Unit

ID

Description

V1.1.1

DC-Link Voltage

V

1108

Measured DC Link voltage in volts,

filtered.

V1.1.2

DC Voltage Ref.

%

1200

Used DC voltage reference by the

regenerative unit in % of Nominal DC

voltage. Nominal DC voltage = 1.35 *

supply voltage

V1.1.3

Output Current

A

1834

Output current of the inverter coming

out of the cabinet.

V1.1.4

Reactive Current

%

1157

V1.1.5

Power kW

kW

1707

terminals.

V1.1.6

Supply Frequency

Hz

1123

Drive output frequency

V1.1.7

Supply Voltage

V

1107

Drive output voltage

V1.1.8

Grid Frequency

Hz

1835

Measured line frequency

V1.1.9

Grid Voltage

V

1709

Measured line voltage

V1.1.10

Total Energy kWh

kWh

1837

Total energy produced.

V1.1.11

Energy Today kWh

kWh

1708

Energy produced today.

V.1.1.12

Energy Yesterday

kWh

1733

Energy produced yesterday.

V1.1.13

Run Time Total

h

1836

Total time the inverter has been

running.

V1.1.14

RunTime Today

h

1731

The time the inverter has been

running today.

V.1.1.15

RunTimeYesterday

h

1732

The time the inverter was running

yesterday.

V1.1.16

Grid Connections

1706

Total number of times the inverter has

closed the main contactor and

connected to the grid.

V1.1.17

Int Fan Run Hours

h

1511

Total time internal fan has been

running

V1.1.18

Ext Fan Run Hours

h

1512

Total time external fan has been

running

V1.1.19

StandbyRemaining

s

1201

Remaining time in standby mode, if

standby mode is activated.

Page 19

arfiff08 power generation VACON® • 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.1.2

Monitoring values 2

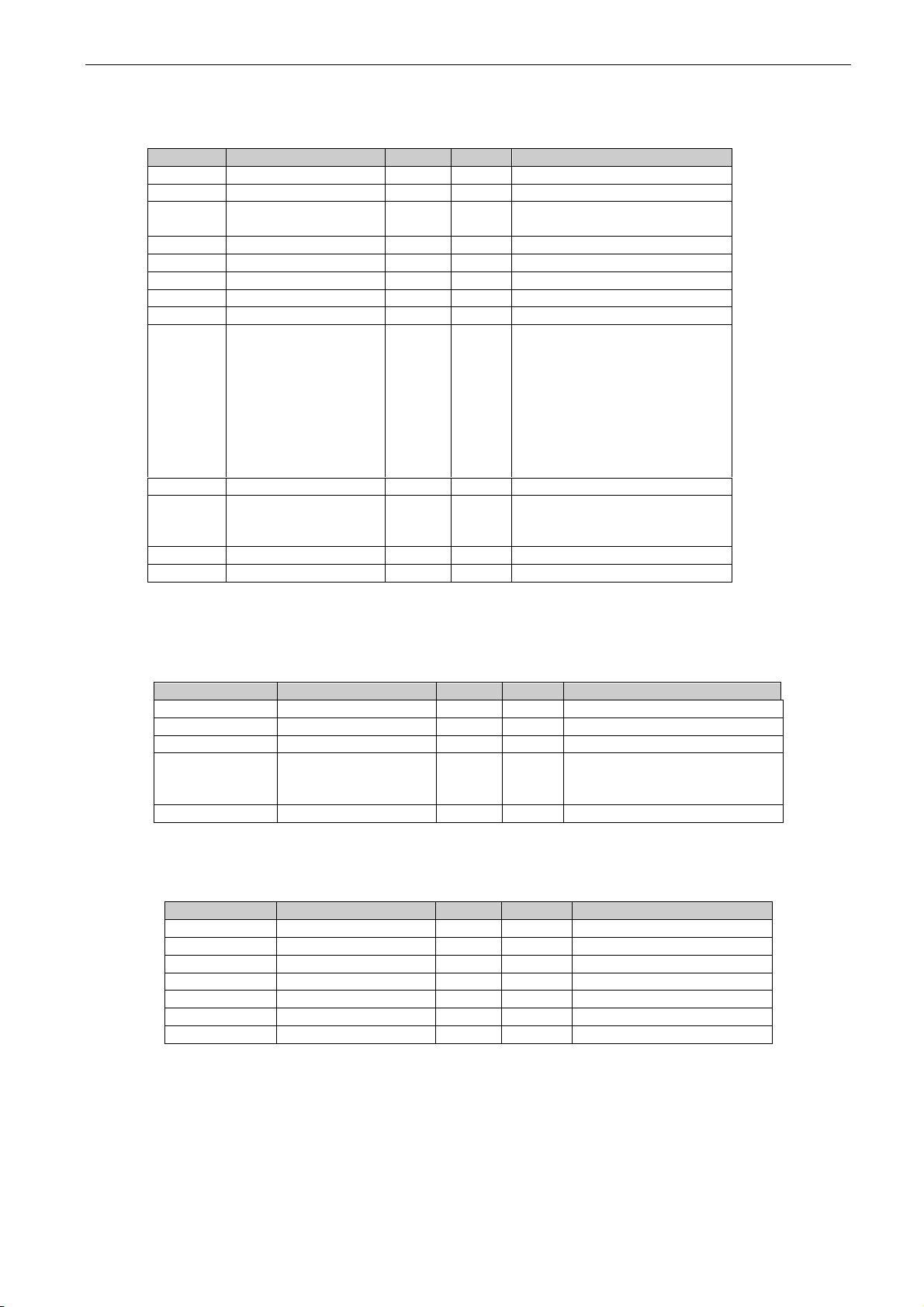

Table 3. Monitoring values 2

Code

Values

Unit

ID

Description

V1.2.1

Cos Phii Actual

1717 V1.2.2

Unit Temperature

°C

1109

V1.2.3

Reactive Current

Reference

%

1389

V1.2.4

Active Current

%

1125

V1.2.5

InverterStatus 1

1819

Diagnostic statusword 1

V1.2.6

InverterStatus 2

1820

Diagnostic statusword 2

V1.2.7

InverterStatus 3

1821

Diagnostic statusword 3

V1.2.8

InverterStatus 4

1822

Diagnostic statusword 4

V1.2.9

EEPROMSaveStatus

1106

Status of the nonvolatile

memory (EEPROM) storing

activated by the application

0 = IDLE

1 = ACTIVE

2 = RESOURCE ERROR

3 = WRITE ERROR

4 = NOT FOUND

5 = NOT SUPPORTED (e.g. NXP2)

V1.2.10

Status Word

43

V1.2.11

Used DC start level

V

1965

Monitoring Value for the

currently used DC Start Level

value.

V1.2.12

Mindex

%

1874

Modulation Index

V1.2.13

Calibrated DC Voltage

V

1839

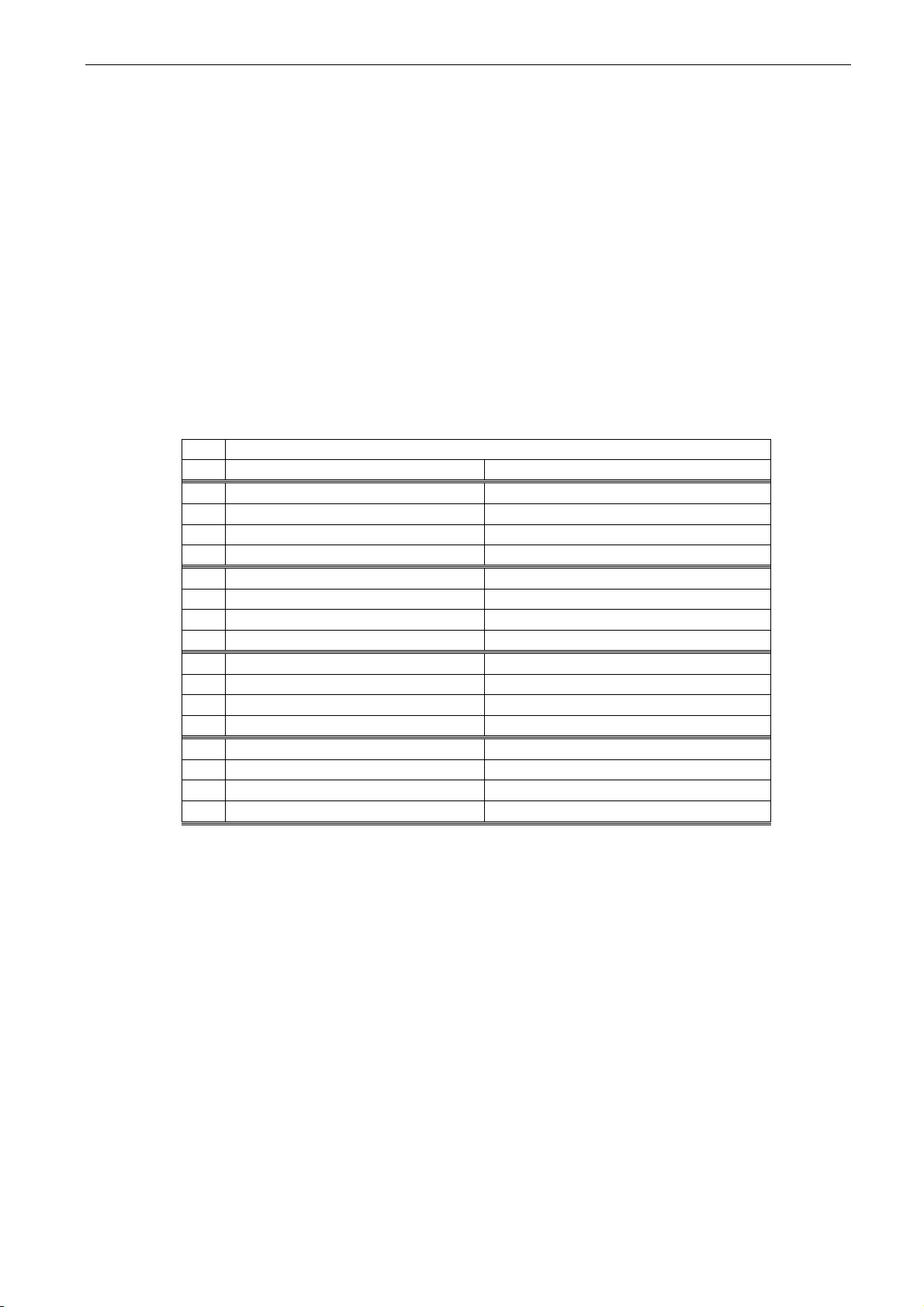

4.1.3

Fieldbus monitoring values

Table 4. Fieldbus

Code

Values

Unit

ID

Description

V1.3.1

FB Control Word

1478

Control word from fieldbus

V1.3.2

FB Status Word

1479

Status word to fieldbus

V1.3.3

FB GenPowerLim

1481

Power limit sent by the fieldbus

V1.3.4

FB Q/PF Ref

Q: %

PF: -

1480

Reactive Current or Power

Factor reference sent by the

fieldbus

V1.3.5

Day from PLC

1719

Day index sent from the PLC

4.1.4

I/O monitoring values

Table 5. I/O Monitor

Code

Values

Unit

ID

Description

V1.4.1

DIN1, DIN2, DIN3

15

V1.4.2

DIN4, DIN5, DIN6

16

V1.4.3

DIN Status 1

56

V1.4.4

DIN Status 2

57

V1.4.5

Analogue Input 1

%

13

V1.4.6

Analogue Input 2

%

14

V1.4.7

Custom AnOut 1

%

1240

Page 20

20 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.1.5

MPPT

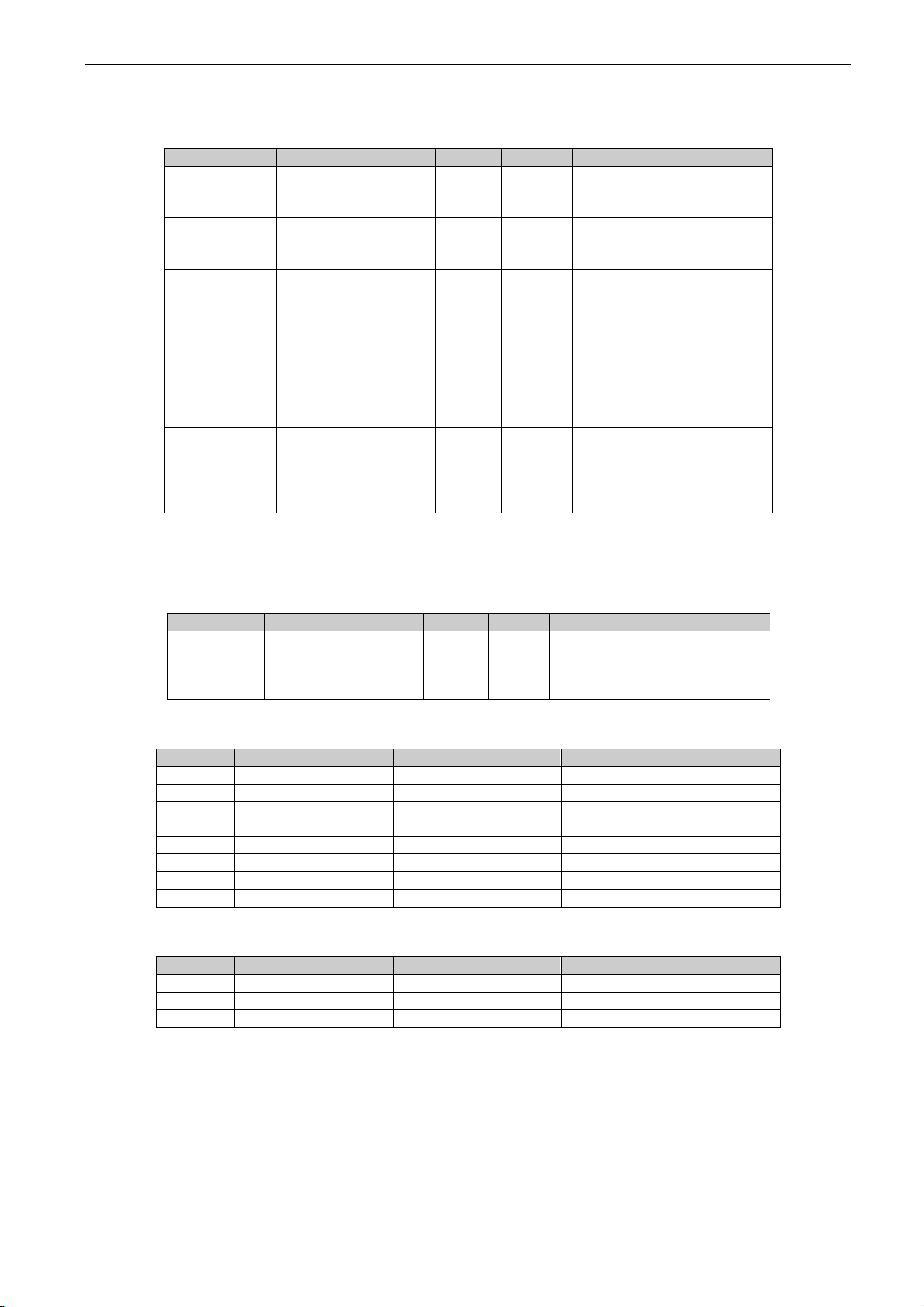

Table 6. MPPT

Code

Values

Unit

ID

Description

V1.5.1

MPPT Reference

1816

The DC reference from the

MPP tracker. Shows without

ramping if ramping is used.

V1.5.2

Actual Step Size

1815

This value shows the actual

momentary step size of the

MPP tracker.

V1.5.3

Actual Step Ratio

1825

This value shows the actual

step ratio. Power change

divided by actual step size.

The value is used for

evaluating the size of the next

step.

V1.5.4

Actual Step State

1817

State of the MPP tracker.

For debugging purpose only.

V1.5.5

Power Window On

0

Power window status.

V1.5.6

Optimal DC Point

1724

Estimated optimal DC Point

is the DC Reference point

which giving the best

simulated power.

4.1.6

License key activation

Table 7. License key activation

Code

Values

Unit

ID

Description

V1.6.1

Serial Number Key

1997

Give this number to the

technical support of the

manufacturer in case of licence

key problems.

4.1.7

Grid code

Code

Parameter

Unit

Form.

ID

Description

V1.7.1

Line State

# 2202

V1.7.2

Line Voltage GC

%

#,##

1912

Line Voltage used by Grid Code

V1.7.3

Line Frequency GC

%

#,##

1913

Line Frequency used by Grid

Code

V1.7.4

Line Voltage L1-L2

%

#,##

2203 V1.7.5

Line Voltage L2-L3

%

#,##

2204 V1.7.6

Line Voltage L3-L1

%

#,##

2205 V1.7.7

Trip State

2206

4.1.8

PID Controller

Code

Parameter

Unit

Form.

ID

Description

V1.8.1

PID Reference

#,#

20 V1.8.2

PID Actual Value

#,#

21 V1.8.3

PID Output

#,##

23

Page 21

arfiff08 power generation VACON® • 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2 Monitor Values descriptions

4.2.1

Monitoring values 1

V1.1 DC -link Voltage V ID 1108

Filtered DC Link voltage in Volts.

V1.2 DC Voltage Reference % ID 1200

Used DC voltage reference. 100 % = 1,35 x Nominal AC Voltage.

V1.3 Output Current A ID 1834

Output current of the inverter coming out of the cabinet.

V1.4 Reactive Current % ID 1157

The reactive current of the regenerative drive in % of System Rated Current.

V1.5 Output Power kW ID 1707

V1.6 Supply Frequency Hz ID 1123

The drive output frequency.

V1.7 Supply Voltage V ID 1107

The drive output voltage.

V1.8 Grid Frequency Hz ID 1835

Grid frequency in ##.## Hz. The sign indicates the phase order. Can be monitored only

when UNIT is in RUN state.

V1.9 Grid Voltage V ID 1709

AC Voltage measured on the grid side of the main contactor by an external measurement

circuit.

V1.10 Total Energy kWh kWh ID 1837

Total produced energy to the grid

V1.11 Energy Today kWh kWh ID 1708

Amount of energy produced today.

Page 22

22 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.12 Energy Yesterday kWh ID 1733

Amount of energy produced yesterday.

V1.13 Run Time Total h ID 1836

Total time the inverter has been running.

V1.14 Run Time Today h ID 1731

The time the inverter has been running today.

V1.15 Run Time Yesterday h ID 1732

The time the inverter was running yesterday.

V1.16 Grid Connections ID 1706

Total number of times the inverter has closed the main contactor and connected to the

grid.

V1.17 Int Fan Run Hours h ID 1511

Total time internal fan has been running

V1.18 Ext Fan Run Hours h ID 1512

Total time external fan has been running

V1.19 Standby Remaining s ID 1201

Remaining time in standby mode, if standby mode is activated.

Page 23

arfiff08 power generation VACON® • 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2.2

Monitoring values 2

V1.2.1 CosPhiiActual ID 1717

The calculated Cos Phi.

V1.2.2 Unit Temperature °C ID 1109

The heatsink temperature of the drive.

V1.2.3 Reactive Current Reference % ID1389

The final reactive current reference.

V1.2.4 Active Current % ID 1125

The active current in % of System Rated Current.

A negative value means that the current is flowing to AC side from DC side.

Page 24

24 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

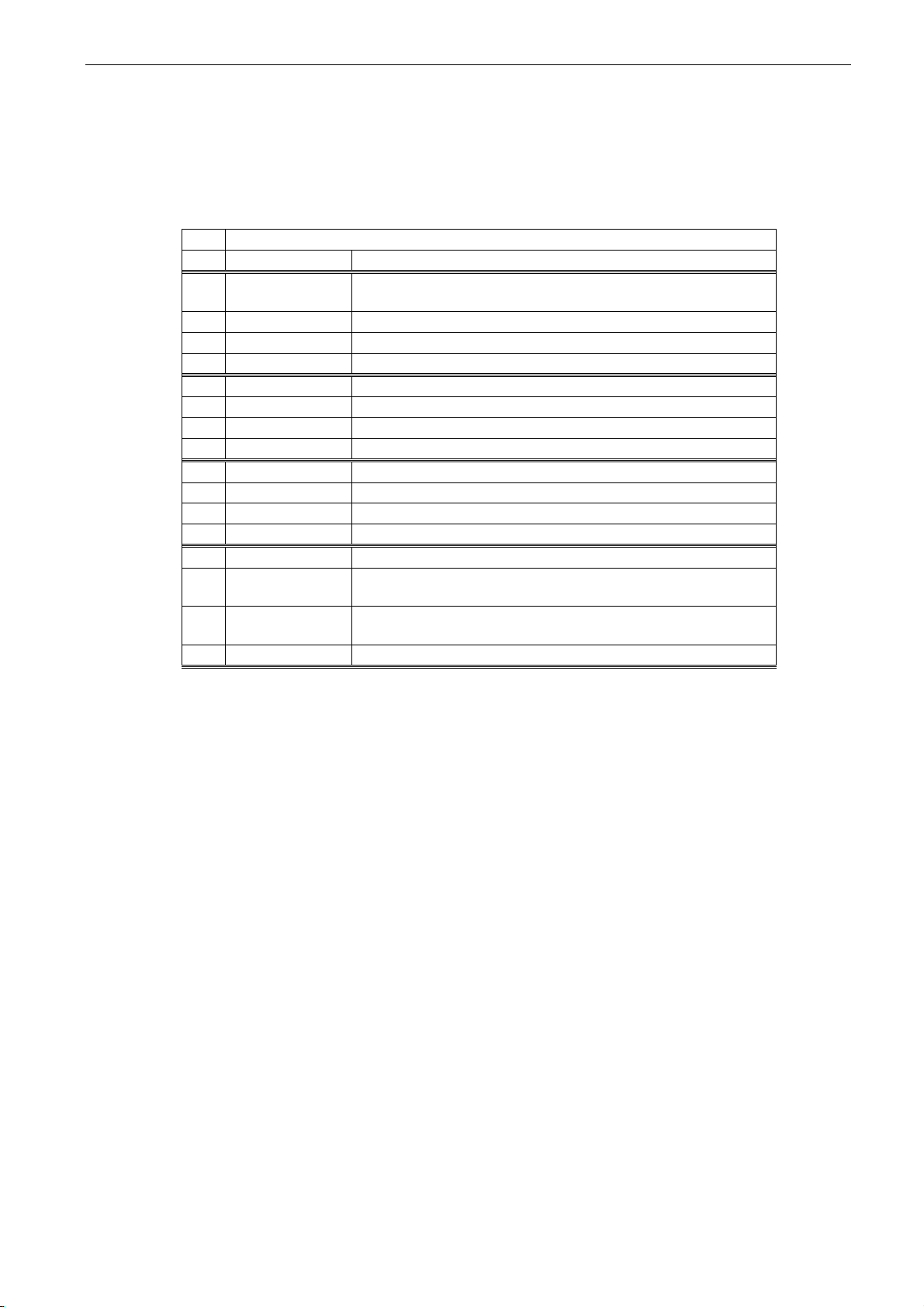

V1.2.5 Inverter statusword 1 ID 1819

Diagnostic statusword 1.

Bit

Name

Value = 0

Value = 1

Description

0

Main Switch Open Fault

No Fault

Fault

See Fault list 64

1

Main Switch Open Warning

No Alarm

Alarm

See Fault list 64

2

AC Voltage Max Fault

No Fault

Fault

See Fault list 72

3

AC Voltage Min Fault

No Fault

Fault

See Fault list 73

4

AC Freg Max Fault

No Fault

Fault

See Fault list 74

5

AC Freg Min Fault

No Fault

Fault

See Fault list 75

6

DC Ground Warning

No Alarm

Alarm

See Fault list 76

7

DC Ground Fault

No Fault

Fault

See Fault list 77

8

Surge Alarm

No Alarm

Alarm

See Fault list 83

9

FB Heardbeat timeout

No Fault

Fault

See Fault list 85

10

Input Switch Alarm

No Alarm

Alarm

See Fault list 86

11

Emergency Switch

No Fault

Fault

See Fault list 87

12

UnBalance

No Alarm

Alarm

See Fault list 18

13

Thermistor Fault

No Fault

Fault

See Fault list 29

14

Safe Disable

No Fault

Fault

See Fault list 30

15

Reserved

No Fault

Fault

V1.2.6 Inverter statusword 2 ID 1820

Diagnostic statusword 2.

Bit

Name

Value = 0

Value = 1

Description

0

Overvoltage

No Fault

Fault

See Fault list 2

1

Earth Fault

No Fault

Fault

See Fault list 3

2

Inverter Fault

No Fault

Fault

See Fault list 4

3

Charge Switch Fault

No Fault

Fault

See Fault list 5

4

Saturation

No Fault

Fault

See Fault list 7

5

Unknown Fault

No Fault

Fault

See Fault list 8

6

Undervoltage

No Fault

Fault

See Fault list 9

7

Input Phase Fault

No Fault

Fault

See Fault list 10

8

Input Phase Warning

No Alarm

Alarm

See Fault list 10

9

Supply Phase Loss

No Fault

Fault

See Fault list 11

10

Supply Phase Warning

No Alarm

Alarm

See Fault list 11

11

Over Temperature

No Fault

Fault

See Fault list 14

12

Over Temperature Warning

No Alarm

Alarm

See Fault list 14

13

Undertemp

No Fault

Fault

See Fault list 13

14

Temperature Power limit warning

No Alarm

Alarm

See Fault list 97

15

OverCurrent

No Fault

Fault

See Fault list 1

Page 25

arfiff08 power generation VACON® • 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.2.7 Inverter statusword 3 ID 1821

Diagnostic statusword 3.

V1.2.8 Inverter statusword 4 ID 1822

Diagnostic statusword 4.

Bit

Name

Value = 0

Value = 1

Description

0

Processor Watchdog

No Fault

Fault

See Fault list 25

1

Reserved

2 IGBT HW Temp

No Fault

Fault

See Fault list 31

3

Cooling Fan

No Fault

Fault

See Fault list 32

4

Application Fault

No Fault

Fault

See Fault list 35

5

Control Unit Fault

No Fault

Fault

See Fault list 36

6

Device Changed

No Fault

Fault

See Fault list 37

7

Device Added

No Fault

Fault

See Fault list 38

8

Device Moved

No Fault

Fault

See Fault list 39

9

Device Unknown

No Fault

Fault

See Fault list 40

10

Device Changed

No Fault

Fault

See Fault list 44

11

Device Added

No Fault

Fault

See Fault list 45

12

EEprom Checksum fault

No Fault

Fault

See Fault list 22

13

Counter Fault

No Fault

Fault

See Fault list 24

14

Reserved

No Fault

Fault 15

Reserved

No Fault

Fault

Bit

Name

Value = 0

Value = 1

Description

0

IGBT Temperature

No Fault

Fault

See Fault list 41

1

EEPROM Fault

No Fault

Fault

See Fault list 48

2

Zero Divice Fault

No Fault

Fault

See Fault list 49

3

External Fault Active

No Fault

Fault

See Fault list 51

4

External Warning Active

No Alarm

Alarm

See Fault list 51

5

Reserved

6 Fieldbus Communication

No Fault

Fault

See Fault list 53

7

Slot Communication

No Fault

Fault

See Fault list 54

8

System bus Master Heartbeat Trip active

No Fault

Fault

See Fault list 59

9

System bus Communication Fault Trip

Active

No Fault

Fault

See Fault list 55

10

LCL OverTemp Fault Active

No Fault

Fault

See Fault list 70

11

LCL OverTemp Warning Active

No Alarm

Alarm

See Fault list 70

12

User Temp Alarm

No Alarm

Alarm

Fault code 99

13

Analog Signal Too Low Fault active

No Fault

Fault

Fault code 50

14

Analog Signal Too Low Warning active

No Alarm

Alarm

Fault code 50

15

Reserved

Page 26

26 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.2.9 EEPROM Saving Status ID 1106

Status of the nonvolatile memory (EEPROM) storing activated by the application

0 = IDLE

1 = ACTIVE

2 = RESOURCE ERROR

3 = WRITE ERROR

4 = NOT FOUND

5 = NOT SUPPORTED (e.g. NXP2)

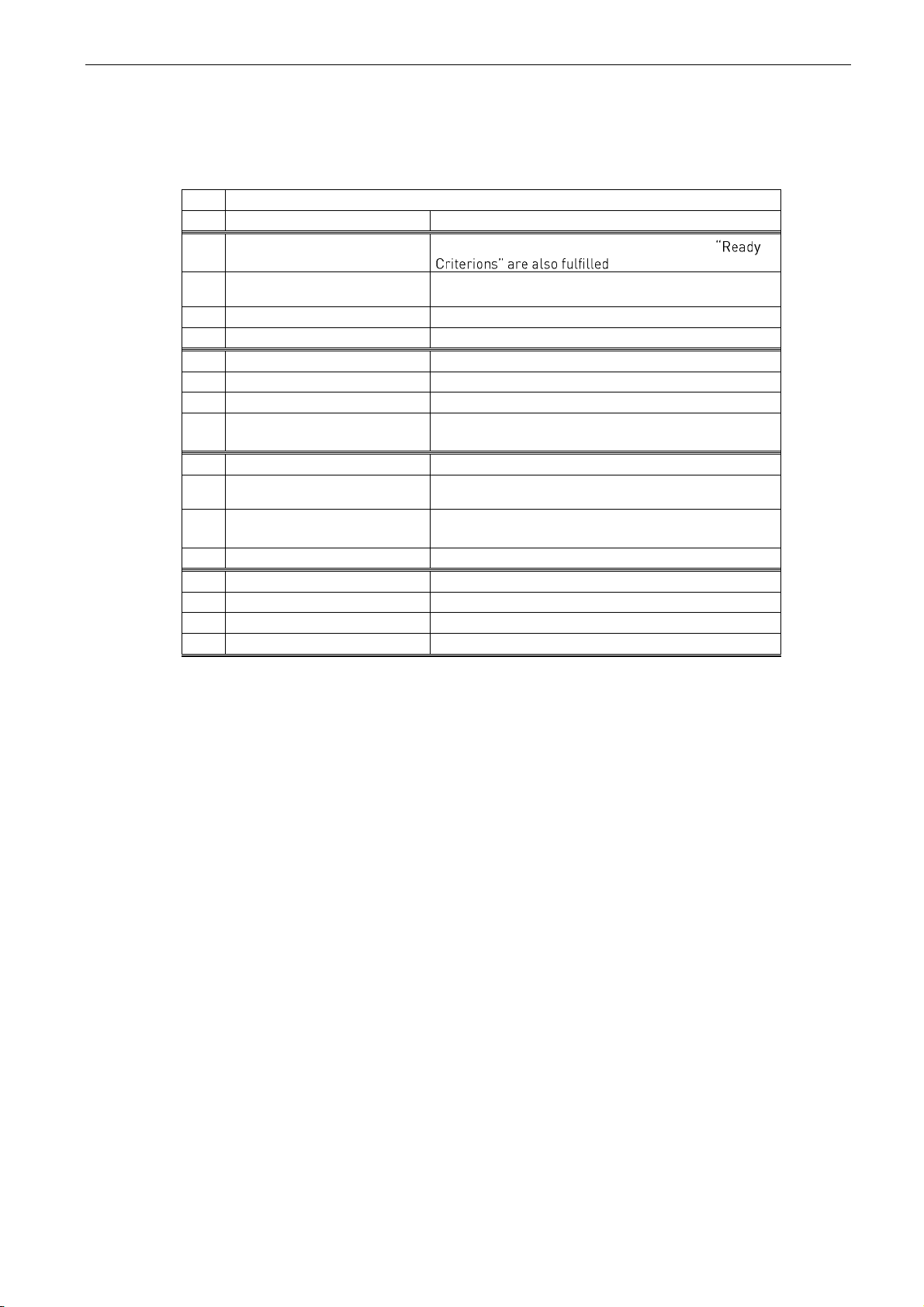

V1.2.10 Status Word ID 43

Application Status Word combines different drive statuses to one data word.

Application Status Word ID43

FALSE

TRUE

b0

b1

Not in Ready state

Ready

b2

Not Running

Running

b3

No Fault

Fault

b4

b5

b6

Run Disabled

Run Enable

b7

No Warning

Warning

b8 Charging Switch closed (internal)

b9 MCB Control (DO Final)

b10 MCB Feedback

b11 DO Charging Active

b12

No Run Request

Run Request

b13

b14 PV Field OK

b15

V2.1.2.11 Used DC start level ID 1965

Monitoring Value for the currently used DC Start Level value.

V2.1.2.12 Mindex ID 1874

This value can be used to recognize low Dc-Link voltage when operating in island mode.

If the value is above 90%, the drive is in limits to make correct voltage to the AC side.

V2.1.2.13 Calibrated DC Voltage ID 1839

Calibrated DC Voltage is used in the parallel drives

Page 27

arfiff08 power generation VACON® • 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2.3

Fieldbus monitoring values

V1.3.1 FB Control Word ID 1478

Control Word received from the Fieldbus Master.

FB Control Word

Signal

Comment

b0

Start

0 = Stop Command

1 = Start Command

b1

b2

Reset

0>1 Reset fault.

b3

b4

b5

b6

b7

b8

Master

Master command

b9

b10

b11

b12

b13

ReactCurrOr

CosPhiiRefSel

0 = Reactive Current Control

1 = CosPhii Control

b14

FB Force start

0 = Normal Start

1 = Force Start regardless of DC voltage level

b15

Page 28

28 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.3.2 FB Status Word ID 1479

Status Word sent to the upper system/PLC via Fieldbus.

FB Status Word

Signal

Comment

b0

StartCriterions

FullFilled

Not only if Inverter control is ready, but if all

b1

Inverter Activated

When active, the inverter can be in either in Standby or

Inverter Running mode.

b2

b3

Fault

b4

Warning

b5

Inverter Activated Standby

b6

b7

Main contactor close

command

b8

Master

Master command

b9

Pulse 1s

Heartbeat bit. The inverter toggles this bit on and off.

1s on, 1s off.

b10

ChargeSwState

0 = Open

1 = Closed

b11

b12

b13

b14

b15

V1.3.3 FB GenPowerLim ID 1481

Power limit sent by the fieldbus.

V1.3.4 FB Q/PF Ref ID 1480

Reactive Current or Power Factor Reference received from Fieldbus. Control Word

states which reverence is used.

V1.3.5 Day From PLC ID 1719

Day index sent from the PLC.

Page 29

arfiff08 power generation VACON® • 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2.4

I/O monitoring values

V1.4.1 DIN1, DIN2, DIN3 ID 15

V1.4.2 DIN4, DIN5, DIN6 ID 16

DIN1/DIN2/DIN3 status

DIN4/DIN5/DIN6 status

b0

DIN3

DIN6

b1

DIN2

DIN5

b2

DIN1

DIN4

V1.4.3 DIN Status 1 ID 56

V1.4.4 DIN Status 2 ID 57

DIN StatusWord 1

DIN StatusWord 2

b0

DIN: A.1

DIN: C.5

b1

DIN: A.2

DIN: C.6

b2

DIN: A.3

DIN: D.1

b3

DIN: A.4

DIN: D.2

b4

DIN: A.5

DIN: D.3

b5

DIN: A.6

DIN: D.4

b6

DIN: B.1

DIN: D.5

b7

DIN: B.2

DIN: D.6

b8

DIN: B.3

DIN: E.1

b9

DIN: B.4

DIN: E.2

b10

DIN: B.5

DIN: E.3

b11

DIN: B.6

DIN: E.4

b12

DIN: C.1

DIN: E.5

b13

DIN: C.2

DIN: E.6

b14

DIN: C.3

b15

DIN: C.4

V1.4.5 Analogue Input 1 % ID 13

V1.4.6 Analogue Input 2 % ID 14

V1.4.7 Custom AnOut 1 % ID 1240

Customized analogue output

Page 30

30 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2.5

MPPT

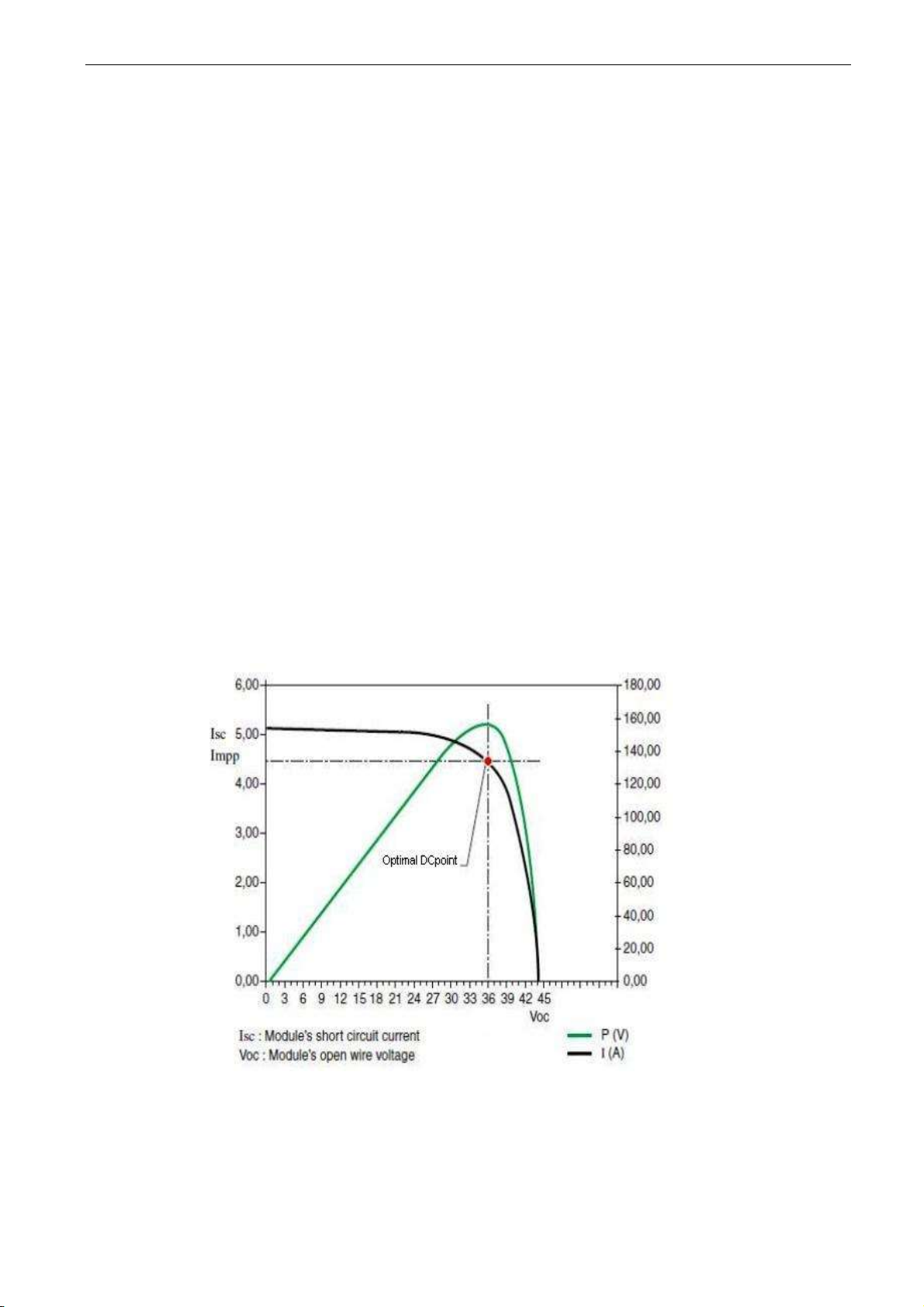

V1.5.1 MPP Reference ID 1816

The DC reference of the MPP tracker.

V1.5.2 Actual Step Size ID 1815

This value shows the actual momentary step size of the MPP tracker.

V1.5.3 Actual Step Ratio ID 1825

This value shows the actual step ratio. Power change divided by actual step size. The

value is used for evaluating the size of the next step.

V1.5.4 MPPT State ID 1817

State of the MPP tracker. For debugging purposes only.

P1.5.5 Power Window On

When the MPP tracker takes a step in any direction, the power change has to be bigger

than the Power Window for making a decision if the Power has increased or decreased.

Otherwise it will take another step in the same direction until the limit is exceeded.

V1.5.6 Simulated Optimal DC point ID 1724

Estimated optimal DC Point is the DC Reference point which giving the best simulated

power.

Picture xx. Optimal DC point.

Page 31

arfiff08 power generation VACON® • 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2.6

License key activation

V1.6.1 Serial Number Key ID 1997

Give this number to the technical support of the manufacturer when there is a problem

in the activation of a function. The drive shows a licence fault.

4.2.7

Gird code

V1.7.1 Line State ID 2202

Give this number to the technical support of the manufacturer when there is a problem

in the activation of a function. The drive shows a licence fault.

Line State

Signal

b0

LineVoltageHighFast_Act

b1

LineVoltageHighSlow_Act

b2

LineVoltageLowSlow_Act

b3

LineVoltageLowFast_Act

b4

LineFreqHighFast_Act

b5

LineFreqHighSlow_Act

b6

LineFreqLowSlow_Act

b7

LineFreqLowFast_Act

b8

LVRTTimerStart

b9

LVRTBiTimerStart

b10

SeparateLimitOrForces

b11

LineFreqRate

b12

10minAverageTrip

b13

FALSE

b14

FALSE

b15

FALSE

V1.7.2 Line Voltage GC % #,## 1912

V1.7.3 Line Frequency GC % #,## 1913

V1.7.4 Line Voltage L1-L2 % #,## 2203

V1.7.5 Line Voltage L2-L3 % #,## 2204

V1.7.6 Line Voltage L3-L1 % #,## 2205

V1.7.7 Trip State 2206

Page 32

32 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4.2.8

PID Controller

Monitoring values for power controller

V1.8.1 PID Reference ID 20

Active Current reference

V1.8.2 PID Actual Value ID 21

Active current

V1.8.3 PID Output ID 23

PID controller output for DC Voltage reference, gives an offset for DC Voltage Reference.

Page 33

arfiff08 power generation VACON® • 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5. PARAMETERS

On the next pages you will find the lists of parameters within the respective parameter groups. The

parameter descriptions are given in the chapter 6. Parameter description includes more than is

available in this application see parameter list what is available.

Column explanations:

Code = Location indication on the keypad; Shows the operator the present parameter number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

ID = ID number of the parameter

All parameters is possible to control from fieldbus by ID number

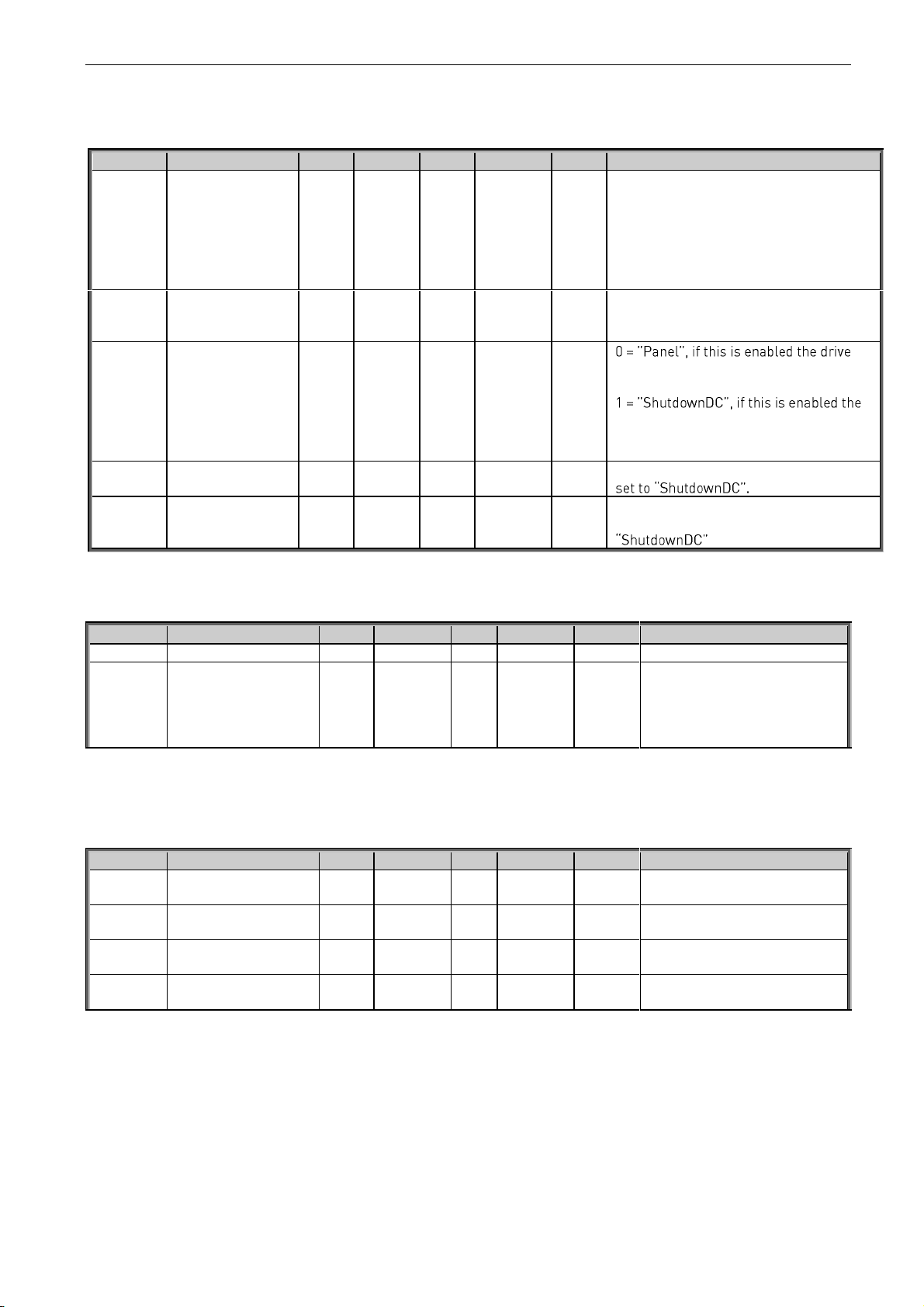

5.1 P2.1 Basic parameters

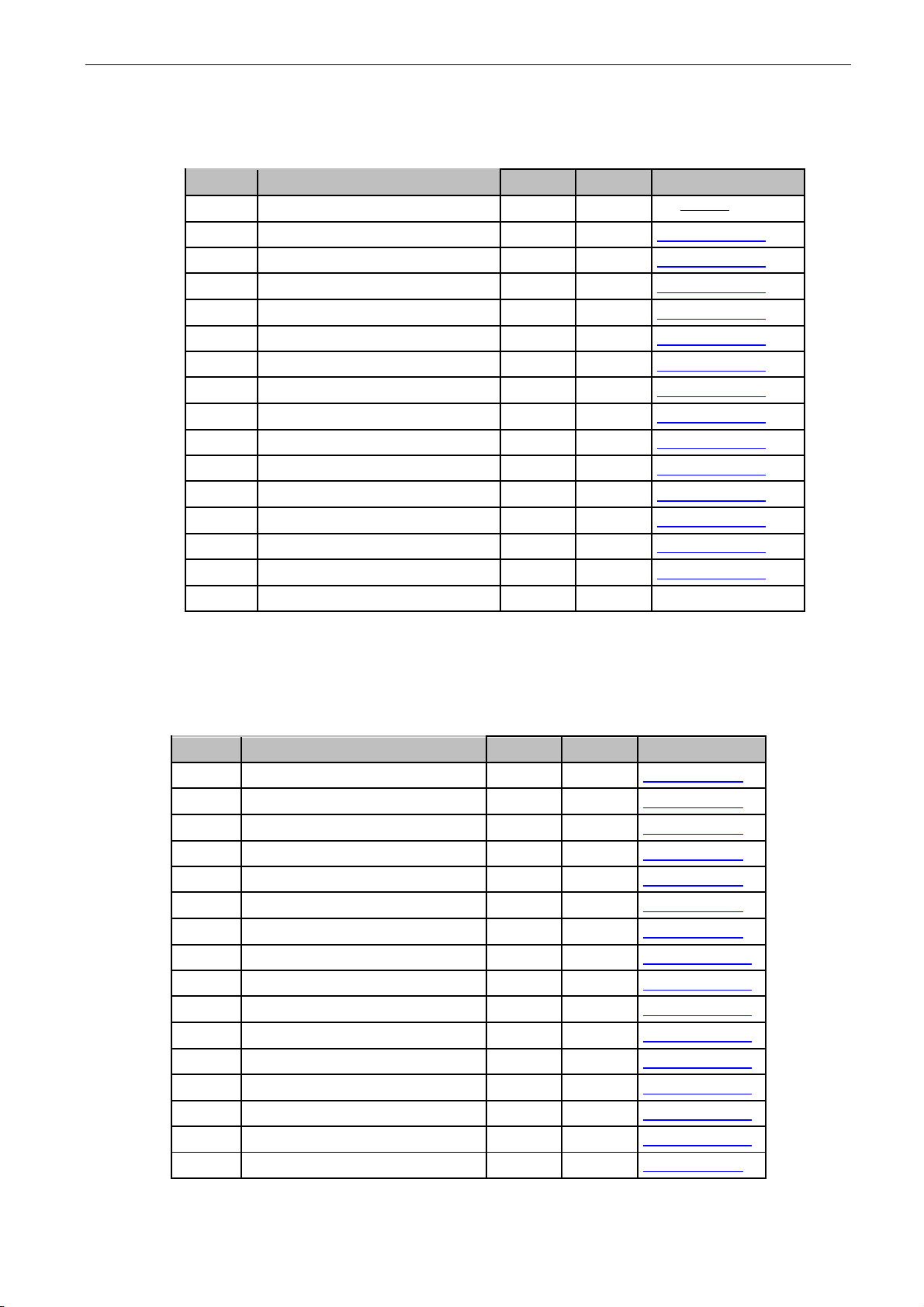

Table 9. Basic parameters

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.1.1

Grid Nom Voltage

200

1000

Vac

500V:400

690V:690

110

Set the nominal voltage of the

grid.

P2.1.2

Grid Nom Frequency

-320,00

320,00

Hz

50,00

1532

Initial start frequency

P2.1.3

Unit nom Current

0.0

Ih A Il

113

Used to scale % values.

P2.1.4

Parallel AFE

0 1 0 1501

0 = Single AFE

1 = Parallel AFE

P2.1.5

Transformer: Inverter

Side

0

3200

Vac

400

1850

P2.1.6

Transformer: Grid Side

0

3200

Vac

400

1851

P2.1.7

Number Of Units

0 8 1 1604

Number of units in array mode

system. Needed e.g. for system

bus communication

P2.1.8

Configuration

-1 9 0 1531

Sets the inverter in a standalone or panel/array mode. In

array mode the inverter has to

be given a unique inverter

number. Communication

parameters for touchpad panel

communication, systembus and

CAN communication are set

based on this value.

Page 34

34 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.1.1

DC Level Setup

Table 10. DC Level Setup

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.1.9.1

DC Start Lvl

0

2000 V 570

1962

If DC voltage is above this limit when the

drive is stopped, DC is considered to be

high enough to start-up.

If the the DC is below this level when the

drive is stopped, the DC is considered to

be too low to produce power and drive

will not try to start-up.

P2.1.9.2

DCStartLvlDelay

1,00

320,00 s 10,00

1964

Delay for when the DC rises above

P2.1.7.2 before DC level is considered

high enough for starting.

P2.1.9.3

DCStartLvlSource

0 1

1

1966

will always use the user-set value in

P2.1.7.1 as the Start Level

drive will use the open circuit DC voltage

from the previous natural stop + offset

from P2.1.7.5 as the new Start Level.

P2.1.9.4

DCStartLvlOffset

0

300 V 15

1967

Offset value to be used when P2.1.7.4 is

P2.1.9.5

DCStartMaxLimit

0

2000 V 590

1968

Absolute maximum value for the Strt/Stp

Level when P2.1.7.4 is set to

5.2 Reference Handling

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.1

Cos phi ref

-1,0

1,0 1,0

2304

Cos phi reference

P2.2.2

Reactive Current

Reference

-300

300 % 0

1459

Regenerative reactive

current reference 100.0 =

Nominal current.

Positive =Inductive

Negative = Capacitive

5.2.1

DC Reference

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.3.1

DC Drooping

0,00

100,00

%

0,00

620

DC Drooping for balancing

current output.

P2.2.3.2

DC Calibration

-5,00

5,00 % 0,00

1777

DC calibration for balancing

the outputs of parallel drives

P2.2.3.3

Manual DC

0 1 0 1808

0 = Disable

1 = Enable

P2.2.3.4

Manual DC Reference

0,00

320.00

%

150,00

1809

Reference for manual DC

control

Page 35

arfiff08 power generation VACON® • 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.2.2

Power/frequency reference

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.4.1

Gen Power Ref.

0

170.0 % 0.0

1533

P2.2.4.2

ReferenceMode

0 1 0 1914

0 = Pure Iq ref

1 = Volt comp Iq

5.2.2.1 PID Power Controller

Code

Parameter

Min

Max

Unit

Default

ID

Description

2.2.4.3.1

PID Power Activation

0.1

W.10

DigIN

0.1

1907

2.2.4.3.2

PID Kp

0,00

1e6 % 100,00

1911 2.2.4.3.3

PID Ti

0

1e5

ms

1000

1906 2.2.4.3.4

PID DC Low

-50,00

50,00 % -5,00

1903 2.2.4.3.5

PID DC High

-50,00

50,00 % 5,00

1904

2.2.4.3.6

Reference Down Rate

-1,00

100

%/s

-1,00

1842

2.2.4.3.7

Reference Up Rate

-1,00

100

%/s

-1,00

1843

5.2.3

AC Voltage reference

Code

Parameter

Min

Max

Unit

Default

ID

Description

P2.2.5.1

Capacitor Size

0,0

100,0 % 5,4

1460

Regen filter capacitor size in

###.# %

P2.2.5.2

Inductor Size

0,0

100,0 % 3,0

1461

Regen total filter inductance in

###.# %

P2.2.5.3

Capacitor Size 2nd

0,0

100,0 % 0,0

3330

P2.2.5.4

Capacitor Size 2nd

Voltage

0,0

1100,0

%

0,0

3331

Page 36

36 • VACON® arfiff08 power generation

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.3 IO Signals

5.3.1

Digital Inputs

Note! Check also G2.3.1.13 Configuration parameters for inverted inputs!

Note! If Digital Input signal source is set to DigIn:F.1 or DigIn:F.2, ANIN as

DIGIN1 ANIN as DIGIN2 respectively as signal source.

Note! To disable certain function, set the signal source to DigIN:0.1 (always FALSE) or DigIN:0.2

(always TRUE).

Table 12. Digital Input parameters

Code

Parameter

Min

Max

Default

ID

Description

P2.3.1.1

External Trip

DigIN:0.1

DigIN:F.10

DigIN:0.1

1214

Select the digital input to

activate External Trip.

P2.3.1.2

Surge Alarm

DigIN:0.1

DigIN:F.10

DigIN:0.1

1806

Select the digital input to

Activate Surge Alarm.

P2.3.1.3

Main Cont Ack

DigIN:0.1

DigIN:F.10

DigIN:0.1

1453

This parameter defines if the

inverter monitors the status of

the main contactor of the unit.

If the monitoring function is

used, the unit monitors the

status and will not start if the

state of the contactor does not

correspond to the required

status, i.e. is open when it

should be closed.

If status of the main contactor

is not monitored in the system

the option DigIN:0.x must be

chosen.

P2.3.1.4

Fault Reset

DigIN:0.1

DigIN:F.10

DigIN:0.1

1208

Select digital input used for

fault reset.

P2.3.1.5

DCSwitchFeedback

DigIN:0.1

DigIN:F.10

DigIN:0.2

1212

This parameter defines which

digital input is used for DC

Switch Feedback signal. If this

is used the inverter will not go

to ready state unless the

DCSwitchFeedback signal is

TRUE.

P2.3.1.6

FilterOverTemp

DigIN:0.1

DigIN:F.10

DigIN:0.1

1179

Digital input for trigging a LCL

filter over temperature fault.

P2.3.1.7

DC Insulation

DigIN:0.1

DigIN:F.10

DigIN:0.1

1180

Digital input for trigging DC

Insulation.

P2.3.1.8

Emergency Switch

DigIN:0.1

DigIN:F.10

DigIN:0.1

1181

Digital input for trigging

Emergency Switch.

P2.3.1.9

Start Ok

DigIN:0.1

DigIN:F.10

DigIN:0.2

1974

Digital input for giving external

Start Ok signal.

P2.3.1.10

Power Limit 1

DigIN:0.1