Page 1

vacon

®

nx

ac drives

apfiff08 advanced

application manual

Page 2

Page 3

apfiff08 advance VACON® • 3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

VACON ADVANCED APPLICATION MANUAL

INDEX

Document code: DPD01973

Software code: APFIFF08V236

Date: 5.2.2020

1. Advanced Application - introduction ....................................................................................................... 7

1.1 General ........................................................................................................................................... 7

1.2 Basic Features.................................................................................................................................. 8

1.3 Fast response .................................................................................................................................. 8

2. Version parameter compatibility issues .................................................................................................. 9

3. Commissioning notes ............................................................................................................................ 10

3.1 Frequency scale ............................................................................................................................. 10

3.2 Parameter download ..................................................................................................................... 10

4. Control I/O ............................................................................................................................................ 11

5. “Terminal To Function” (TTF) programming principle ............................................................................ 12

5.1 Defining an input/output for a certain function on keypad ............................................................. 12

5.2 Defining a terminal for a certain function with NCDrive programming tool ..................................... 13

5.3 Defining unused inputs/outputs ..................................................................................................... 14

6. Advance Application – Monitoring values ............................................................................................. 15

6.1 Monitoring values (Control keypad: menu M1) .............................................................................. 16

6.1.1 Monitoring values 2 (Control keypad: menu M1.23) .................................................................. 17

6.1.2 FieldBus Monitoring values (Control keypad: menu M1.24) ...................................................... 18

6.2 Monitoring values description ........................................................................................................ 19

6.2.1 Monitoring values 2 ................................................................................................................... 21

6.2.2 FieldBus Monitoring values ........................................................................................................ 24

7. Advanced Application – Parameter List ................................................................................................. 30

7.1 Basic parameters (Control keypad: Menu M2 → G2.1) ................................................................... 30

7.2 Reference Handling ....................................................................................................................... 31

7.2.1 Basic Settings ............................................................................................................................ 31

7.2.2 Constant Reference ................................................................................................................... 31

7.2.3 Torque Reference ...................................................................................................................... 31

7.2.4 Prohibit frequency parameters (Control keypad: Menu M2 → G2.5) .......................................... 33

7.2.5 Motor Potentiometer (Control keypad: Menu M2 → G2.5) ........................................................ 33

7.2.6 Adjust Reference ....................................................................................................................... 33

7.3 Ramp Control ................................................................................................................................ 34

7.3.1 Basic Settings ............................................................................................................................ 34

7.3.2 Ramp Control Options ............................................................................................................... 34

7.4 Input Signals .................................................................................................................................. 35

7.4.1 Basic Settings ............................................................................................................................ 35

7.4.2 Digital inputs (Control keypad: Menu M2 → G2.2.4) .................................................................. 36

7.4.3 Analogue input 1 (Control keypad: Menu M2 → G2.2.2) ............................................................ 36

7.4.4 Analogue input 2 (Control keypad: Menu M2 → G2.2.3) ............................................................ 37

7.4.5 Analogue input 3 (Control keypad: Menu M2 → G2.2.4) ............................................................ 37

7.4.6 Analogue input 4 (Control keypad: Menu M2 → G2.2.5) ............................................................ 38

7.4.7 Options ..................................................................................................................................... 38

7.5 Output Signals ............................................................................................................................... 38

Page 4

4 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.5.1 Digital output signals (Control keypad: Menu M2 → G2.3.3) ...................................................... 38

7.5.2 Analogue output 1 (Control keypad: Menu M2 → G2.3.5) .......................................................... 40

7.5.3 Analogue output 2 (Control keypad: Menu M2 → G2.3.6) .......................................................... 40

7.5.4 Analogue output 3 (Control keypad: Menu M2 → G2.3.7) .......................................................... 41

7.5.5 Delayed digital output 1 (Keypad: Menu M2 → G2.3.1).............................................................. 41

7.5.6 Delayed digital output 2 (Keypad: Menu M2 → G2.3.2).............................................................. 41

7.5.7 Supervision Limits ...................................................................................................................... 42

7.6 Limit Settings ................................................................................................................................. 42

7.6.1 Current handling........................................................................................................................ 42

7.6.2 Power Handling ......................................................................................................................... 43

7.6.3 Torque Handling ........................................................................................................................ 44

7.6.4 Frequency Handling ................................................................................................................... 44

7.6.5 DC-Link Handling ....................................................................................................................... 45

7.7 Flux and DC Current handling ......................................................................................................... 46

7.7.1 Flux and DC Current handling OL Settings .................................................................................. 46

7.7.2 Flux and DC Current handling CL Settings ................................................................................... 46

7.8 Motor Control ............................................................................................................................... 47

7.8.1 Motor Control Basic Settings ..................................................................................................... 47

7.8.2 U/f Settings ............................................................................................................................... 47

7.8.3 Closed Loop Control Settings ..................................................................................................... 47

7.8.4 PMSM Control settings .............................................................................................................. 48

7.8.5 Stabilators ................................................................................................................................. 48

7.8.6 Tuning parameters .................................................................................................................... 49

7.8.7 Identification parameters (Control keypad: Menu M2→ G2.6.6) ................................................ 50

7.8.8 Fine tuning parameters.............................................................................................................. 50

7.9 Speed Control ................................................................................................................................ 51

7.9.1 Speed Control Basic settings ...................................................................................................... 51

7.9.2 Speed Control OL Settings.......................................................................................................... 51

7.9.3 Speed Control CL Settings .......................................................................................................... 51

7.10 Drive Control ................................................................................................................................. 52

7.11 Master Follower Control Parameters (Control keypad: Menu M2 → G2.5) ..................................... 53

7.12 Protections (Control keypad: Menu M2 → G2.7) ............................................................................ 53

7.12.1 Common settings .................................................................................................................. 53

7.12.2 Temperature sensor protections............................................................................................ 54

7.12.3 Stall Protection ...................................................................................................................... 54

7.12.4 Speed error monitoring ......................................................................................................... 55

7.12.5 Motor thermal protections .................................................................................................... 55

7.12.6 Living Zero monitoring ........................................................................................................... 55

7.12.7 Underload protection ............................................................................................................ 55

7.12.8 Earth Fault protection ........................................................................................................... 56

7.12.9 Fieldbus protection ............................................................................................................... 56

7.13 Fieldbus parameters (Control Keypad: Menu M2 →G2.9) ............................................................... 57

7.14 ID Control Functions ...................................................................................................................... 58

7.14.1 Value Control (Keypad: Menu M2 → G2.2.9) ........................................................................ 58

7.14.2 DIN ID Control 1 .................................................................................................................... 58

7.14.3 DIN ID Control 2 .................................................................................................................... 58

7.14.4 DIN ID Control 3 .................................................................................................................... 59

7.15 Brake Control (Control keypad: Menu M2 → G2.15)...................................................................... 59

7.15.1 Brake Control Start up torque for CL ...................................................................................... 59

7.16 Autorestart parameters (Control keypad: Menu M2 → G2.8) ......................................................... 60

7.17 Keypad control (Control keypad: Menu M3) ................................................................................... 61

7.18 System menu (Control keypad: Menu M6) ..................................................................................... 61

7.19 Expander boards (Control keypad: Menu M7) ................................................................................ 61

8. Description of parameters ..................................................................................................................... 62

8.1 Basic Parameters ........................................................................................................................... 62

8.2 Reference Handling – “Ref Handling” ............................................................................................. 72

Page 5

apfiff08 advance VACON® • 5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8.2.1 Basic Parameters ....................................................................................................................... 73

8.2.2 Constant Reference ................................................................................................................... 77

8.2.3 Torque Reference ...................................................................................................................... 79

8.2.4 Prohibited frequencies .............................................................................................................. 85

8.2.5 Motor potentiometer ................................................................................................................ 86

8.2.6 Adjust Reference ....................................................................................................................... 87

8.3 Ramp control ................................................................................................................................. 89

8.3.1 Ramp Options ............................................................................................................................ 93

8.4 Input signals .................................................................................................................................. 94

8.4.1 Basic Settings ............................................................................................................................ 94

8.4.2 Digital inputs ............................................................................................................................. 96

8.4.3 Analogue Input 1 & 2 ............................................................................................................... 101

8.4.4 Analogue input 3 & 4 ............................................................................................................... 105

8.4.5 Inversion control ..................................................................................................................... 109

8.5 Output signlas ............................................................................................................................. 110

8.5.1 Digital output signals ............................................................................................................... 110

8.5.2 Analogue outputs 1 & 2 & 3 ..................................................................................................... 115

8.5.3 Delayed Digital Output 1 & 2 ................................................................................................... 119

8.5.4 Supervision limits .................................................................................................................... 122

8.6 Limit settings ............................................................................................................................... 124

8.6.1 Current limit handling .............................................................................................................. 124

8.6.2 Power limit handling ................................................................................................................ 125

8.6.3 Torque limit handling............................................................................................................... 127

8.6.4 Frequency limit handling ......................................................................................................... 129

8.6.5 DC Link handling ...................................................................................................................... 131

8.7 DC current and magnetization handling ....................................................................................... 135

8.7.1 Open loop settings .................................................................................................................. 135

8.7.2 Closed loop settings ................................................................................................................. 139

8.8 Motor Control ............................................................................................................................. 141

8.8.1 U/f Settings ............................................................................................................................. 144

8.8.2 Close Loop Settings .................................................................................................................. 148

8.8.3 Permanent magnet synchronous motor settings ...................................................................... 151

8.8.4 Stabilator settings .................................................................................................................... 156

8.8.5 Tuning settings ....................................................................................................................... 157

8.8.6 Identification settings ............................................................................................................. 157

8.9 Speed Control settings ................................................................................................................. 160

8.10 Drive Control ............................................................................................................................... 165

8.11 Master Follower .......................................................................................................................... 168

8.11.1 Master Follower: Standard system ...................................................................................... 168

8.11.2 Master follower configuration ............................................................................................. 169

8.12 Protections .................................................................................................................................. 173

8.12.1 General settings .................................................................................................................. 173

8.12.2 Temperature sensor protections.......................................................................................... 175

8.12.3 Stall protection .................................................................................................................... 176

8.12.4 Speed Error ......................................................................................................................... 178

8.12.5 Motor Protection ................................................................................................................ 178

8.12.6 4mA Protection ................................................................................................................... 181

8.12.7 Underload protection .......................................................................................................... 182

8.12.8 Earth Fault .......................................................................................................................... 184

8.12.9 Fieldbus communication...................................................................................................... 185

8.13 Fieldbus settings .......................................................................................................................... 187

8.13.1 General settings .................................................................................................................. 187

8.14 ID Functions................................................................................................................................. 192

8.14.1 Value Control ...................................................................................................................... 192

8.14.2 DIN ID Control ..................................................................................................................... 194

8.14.3 DIN ID Control 2 .................................................................................................................. 194

8.14.4 DIN ID Control 3 .................................................................................................................. 196

Page 6

6 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

8.15 Brake Control............................................................................................................................... 197

8.15.1 Brake monitoring function ................................................................................................... 201

8.15.2 Closed Loop settings ............................................................................................................ 202

8.16 Auto Fault Reset .......................................................................................................................... 203

8.17 Keypad control parameters .......................................................................................................... 206

9. Identification function for permanent magnet synchronous motor ..................................................... 207

9.1 Identification with absolute encoder. ........................................................................................... 207

9.2 Identification with incremental encoder without Z-pulse input. .................................................... 207

9.3 Identification with incremental encoder with Z-pulse input. ......................................................... 207

10. Problem solving .............................................................................................................................. 209

11. Fault codes ...................................................................................................................................... 210

Page 7

apfiff08 advance VACON® • 7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1. ADVANCED APPLICATION - INTRODUCTION

Software APFIFF08, Advanced application

1.1 General

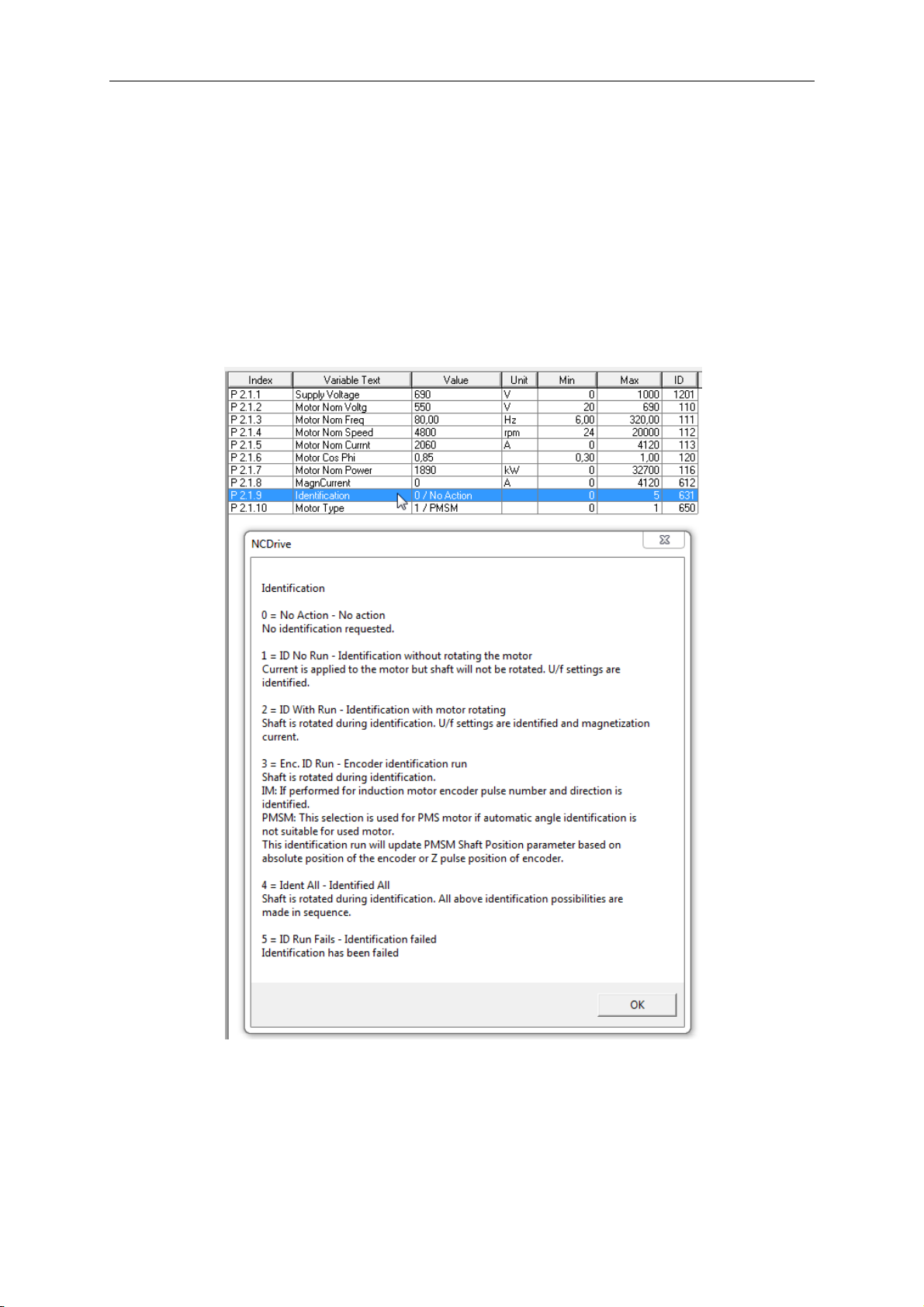

This application is not backwards compatible. Please read the application change note or

chapter 2 Version parameter compatibility issues in this application manual to see what

needs to be noted when updating the application. See also the updated parameter

description in NCDrive when commissioning.

Help is available in NCDrive through selecting “Variable Text” and pressing “F1”.

Below an example from Identification parameter help text from the NCDrive.

Page 8

8 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1.2 Basic Features

Advanced application provides a wide range of parameters for controlling motors. It can be

used for various kinds of different processes, where wide flexibility of I/O signals is needed

and PID-control is not necessary (if you need PID-control functions, use the PID Control

Application or Pump and Fan Control Application).

The frequency reference can be selected e.g. from the analogue inputs, joystick control,

motor potentiometer and from a mathematical function of the analogue inputs. There are

parameters also for Fieldbus communication. Multi-step speeds and jogging speed can also

be selected if digital inputs are programmed for these functions.

1.3 Fast response

This application digital inputs and analogue inputs are handled in 1 ms time level.

- A type option boards.

- By using hardware bypassing filtering function to OPT-A1 option board

o See ID1084 Control Options

Support for Fast Profibus profile

- When fast mode is activated it’s not possible to use B-type boards.

- Only bypass mode can be used when fast Profibus mode is activated.

- Service data is not supported by fast Profibus

Additional functions:

• Power limit functions

• Different power limits for motoring and generating side

• Master Follower function

• Different torque limits for motoring and generating side

• Cooling monitor input from heat exchange unit

• Brake monitoring input and actual current monitor for immediate brake close.

• Separate speed control tuning for different speeds and loads

• Inching function two different references

• Possibility to connect the FB Process data to any parameter and some monitoring

values

• Analogue input 3 and 4 can control any parameter by ID number.

• Possibility to control single parameters with digital inputs.

• Redundant Profibus; possibility to connect two PB masters to control same drive,

freezing of control values and changing control slot in case of FBFault.

Page 9

apfiff08 advance VACON® • 9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2. VERSION PARAMETER COMPATIBILITY ISSUES

• V200 Major compatibility issue:

o ID numbers has been changed to be more compatible with

APFIFF09 (Marine) and APFIFF40 (SIA-II) applications:

o FreqRefInterp. TC: ID1780 -> ID1184

o Torque Scale: ID1601 -> ID1247

o DeadTimeComp. ID1580 -> ID1751

o DeadTimeContCurL ID1581 -> ID1752

o DeadTHWComp.Disa ID1704 -> ID1750

o ContrInSignal ID ID1582 -> ID1580

o Contrl Off Limit ID1583 -> ID1581

o Contrl On Limit ID1584 -> ID1582

o Contrl Off Value ID1585 -> ID1583

o Contrl On Value ID1586 -> ID1584

o ControlOutSignID ID1587 -> ID1585

o Control Mode ID1588 -> ID1586

o Control Filt TC ID1589 -> ID1721

o I/f Control Lim ID1608 -> ID1790

o I/f Current ID1609 -> ID1693

o FBFaultDelay ID1500 -> ID1850

o ID Control DI B1 ID1574 -> ID1277

o B10 Value ID1578 -> ID1193

o B11 Value ID1575 -> ID1182

o Ramp Rate ID1579 -> DI1112

Page 10

10 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3. COMMISSIONING NOTES

3.1 Frequency scale

This application support output frequency up to 599 Hz. if higher output frequencies are

needed ask APFIFF41 Advanced HS application from Vacon technical support and guidance

to how to obtain license key for high speed operations.

3.2 Parameter download

Before downloading parameters to drive it is recommended to select first frequency range

and after that download parameters to drive. Parameter to select frequency range is P2.1.12

Frequency Scale.

Page 11

apfiff08 advance VACON® • 11

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

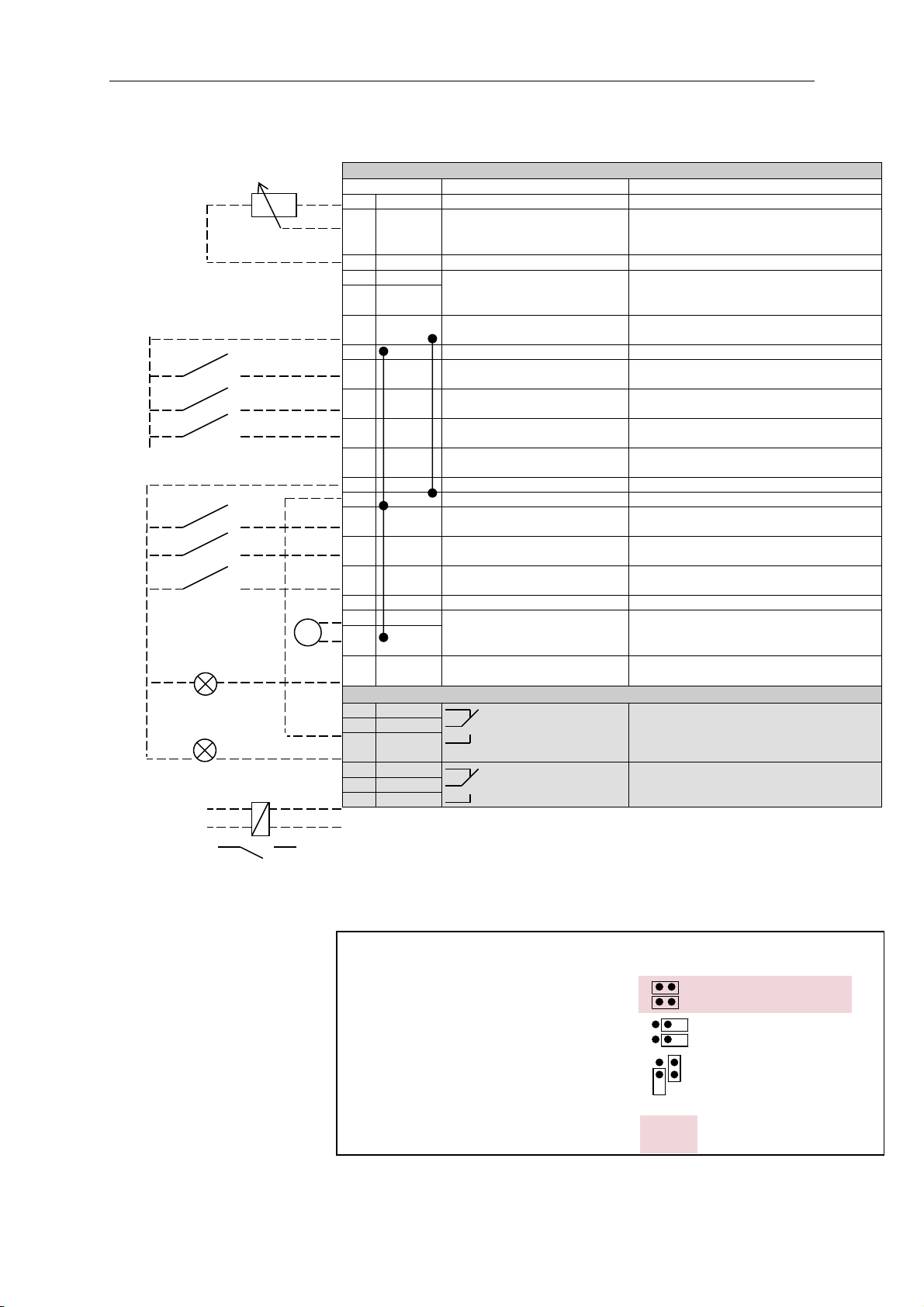

Jumper block X3:

CMA and CMB grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA

internally connected together,

isolated from GND

= Factory default

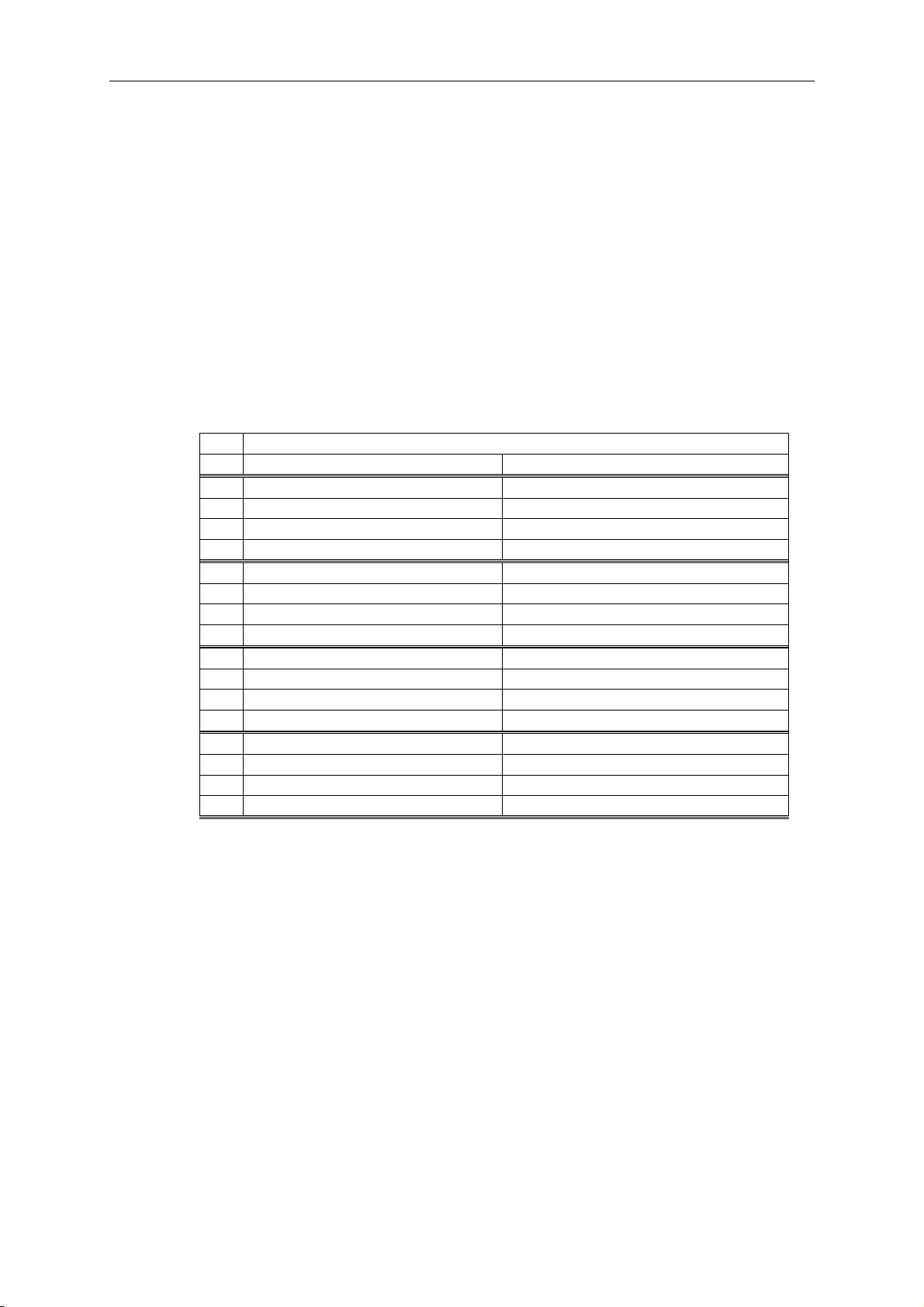

4. CONTROL I/O

NXOPTA1

Terminal

Signal

Description

1

+10V

ref

Reference voltage output

Voltage for potentiometer, etc.

2

AI1+

Analogue input 1.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Analogue input 1 frequency reference.

Input range selected by jumpers.

Default range: Voltage 0 – 10 V

3

AI1-

I/O Ground

Ground for reference and controls

4

AI2+

Analogue input 2.

Range 0-10V, Ri = 200

Range 0-20 mA Ri = 250

Analogue input 2 frequency reference

Input range selected by jumpers.

Default range: Current 0 – 20 mA

5

AI2-

6

+24V

Control voltage output

Voltage for switches, etc. max 0.1 A

7

GND

I/O ground

Ground for reference and controls

8

DIN1

Start forward

Programmable G2.2.7

Contact closed = start forward

Programmable start logic P2.2.1

9

DIN2

Start reverse

Programmable G2.2.7

Contact closed = start reverse

Programmable logic P2.2.1

10

DIN3

Fault reset

Programmable G2.2.7

Contact open = no fault

Contact closed = fault

11

CMA

Common for DIN 1—DIN 3

Connect to GND or +24V

12

+24V

Control voltage output

Voltage for switches (see #6)

13

GND

I/O ground

Ground for reference and controls

14

DIN4

Programmable G2.2.7

No function defined at default

15

DIN5

Programmable G2.2.7

No function defined at default

16

DIN6

Programmable G2.2.7

No function defined at default

17

CMB

Common for DIN4—DIN6

Connect to GND or +24V

18

AOA1+

Analogue output 1

Programmable P2.3.1.2

Output range selected by jumpers.

Range 0—20 mA. RL, max. 500

Range 0—10 V. RL > 1k

19

AOA1-

20

DOA1

Digital output

Programmable

Open collector, I50mA, U48 VDC

NXOPTA2

21

RO1

Relay output 1

Programmable G2.3.3

Switching capacity

24 VCD / 8 A

250 VAC / 8 A

125 VDC / 0.4 A

22

RO1

23

RO1

24

RO2

Relay output 2

Programmable G2.3.3

Programmable

No function defined at default

25

RO2

26

RO2

Table 4-1. Advance application default I/O configuration and

connection example.

Note: See Users Manual, chapter Control Connections, for hardware specification and

configuration.

Note: See jumper selections below.

More information in Vacon NX

User's Manual, Chapter 6.2.2.2.

220

VAC

Reference potentiometer,

1…10 k

mA

Page 12

12 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5. “TERMINAL TO FUNCTION” (TTF) PROGRAMMING PRINCIPLE

The programming principle of the input and output signals in the Multipurpose Control

Application NXP as well as in the Pump and Fan Control Application (and partly in the

other applications) is different compared to the conventional method used in other Vacon NX

applications.

In the conventional programming method, Function to Terminal Programming Method (FTT),

you have a fixed input or output that you define a certain function for. The applications

mentioned above, however, use the Terminal to Function Programming method (TTF) in

which the programming process is carried out the other way round: Functions appear as

parameters which the operator defines a certain input/output for. See Warning on page 13.

5.1 Defining an input/output for a certain function on keypad

Connecting a certain input or output with a certain function (parameter) is done by giving the

parameter an appropriate value. The value is formed of the Board slot on the Vacon NX

control board (see Vacon NX User's Manual, Chapter 6.2) and the respective signal number,

see below.

Function name

Slot Terminal number

Terminal type

Example: You want to connect the digital output function Reference fault/warning

(parameter 2.3.3.7) to the digital output DO1 on the basic board NXOPTA1 (see Vacon NX

User's Manual, Chapter 6.2).

First find the parameter 2.3.3.7 on the keypad. Press the Menu button right once to enter the

edit mode. On the value line, you will see the terminal type on the left (DigIN, DigOUT,

An.IN, An.OUT) and on the right, the present input/output the function is connected to (B.3,

A.2 etc.), or if not connected, a value (0.#).

When the value is blinking, hold down the Browser button up or down to find the desired

board slot and signal number. The program will scroll the board slots starting from 0 and

proceeding from A to E and the I/O selection from 1 to 10.

Once you have set the desired value, press the Enter button once to confirm the change.

READY

I/Oterm

DigOUT:B.1

AI Ref Faul/Warn

READY

I/Oterm

DigOUT:0.0

READY

I/Oterm

DigOUT:0.0

READY

I/Oterm

DigOUT:B.1

enter

AI Ref Faul/Warn AI Ref Faul/Warn AI Ref Faul/Warn

Page 13

apfiff08 advance VACON® • 13

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

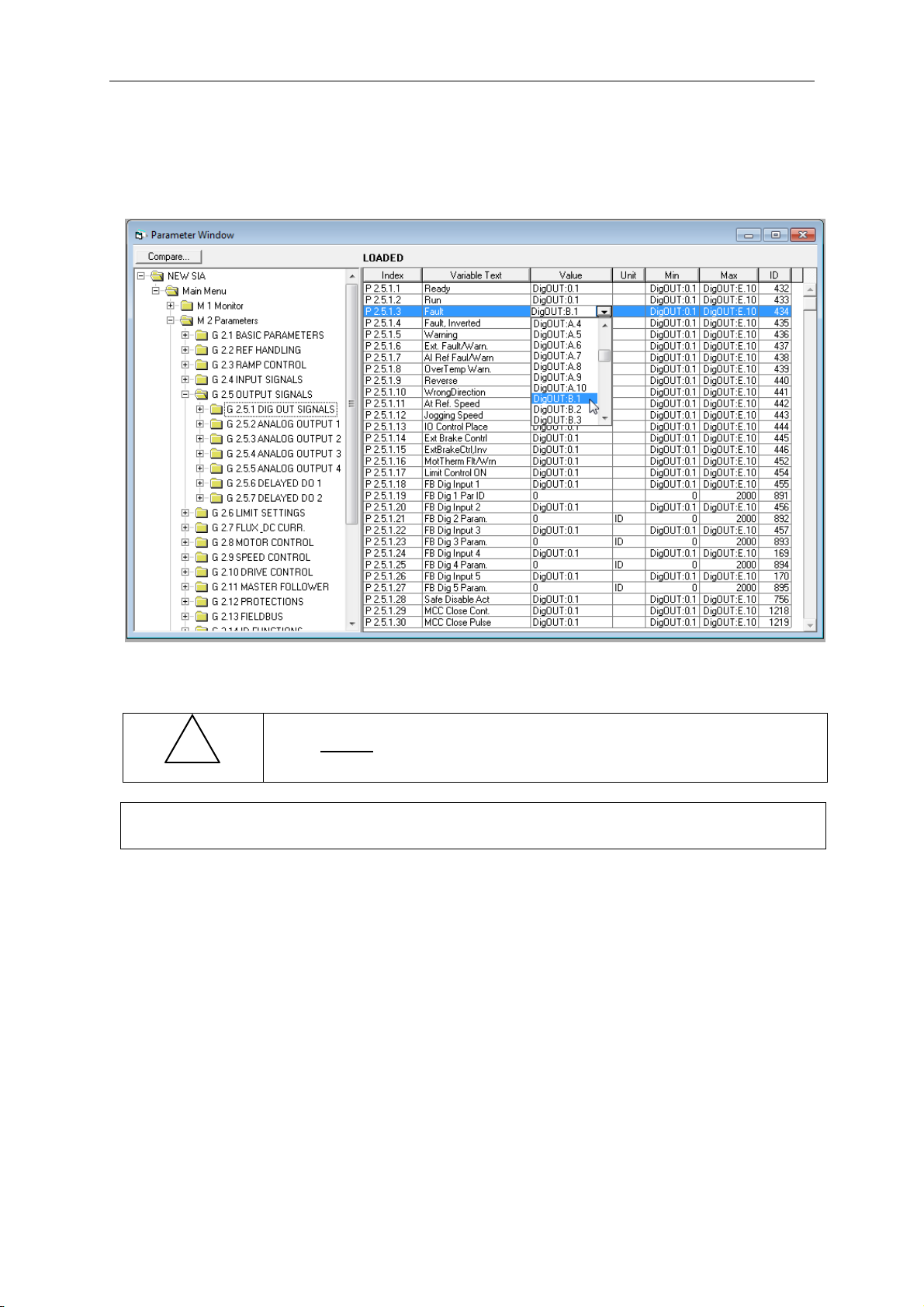

5.2 Defining a terminal for a certain function with NCDrive programming tool

If you use the NCDrive Programming Tool for parametrizing you will have to establish the

connection between the function and input/output in the same way as with the control panel.

Just pick the address code from the drop-down menu in the Value column (see the Figure

below).

Figure 5-1. Screenshot of NCDrive programming tool; Entering the address code

Be ABSOLUTELY sure not to connect two functions to one and

same output in order to avoid function overruns and to ensure

flawless operation.

!

WARNING

Note: The inputs, unlike the outputs, cannot be changed in RUN state.

Page 14

14 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5.3 Defining unused inputs/outputs

All unused inputs and outputs must be given the board slot value 0 and the value 1 also for

the terminal number. The value 0.1 is also the default value for most of the functions.

However, if you want to use the values of a digital input signal for e.g. testing purposes

only, you can set the board slot value to 0 and the terminal number to any number between

2…10 to place the input to a TRUE state. In other words, the value 1 corresponds to 'open

contact' and values 2 to 10 to 'closed contact'.

In case of analogue inputs, giving the value 1 for the terminal number corresponds to 0%

signal level, value 2 corresponds to 20%, value 3 to 30% and so on. Giving value 10 for the

terminal number corresponds to 100% signal level.

Page 15

apfiff08 advance VACON® • 15

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6. ADVANCE APPLICATION – MONITORING VALUES

On the next pages you will find the lists of parameters within the respective parameter

groups. The parameter descriptions are given on pages 62 to 202. Parameter description

includes more than is available in this application see parameter list what is available.

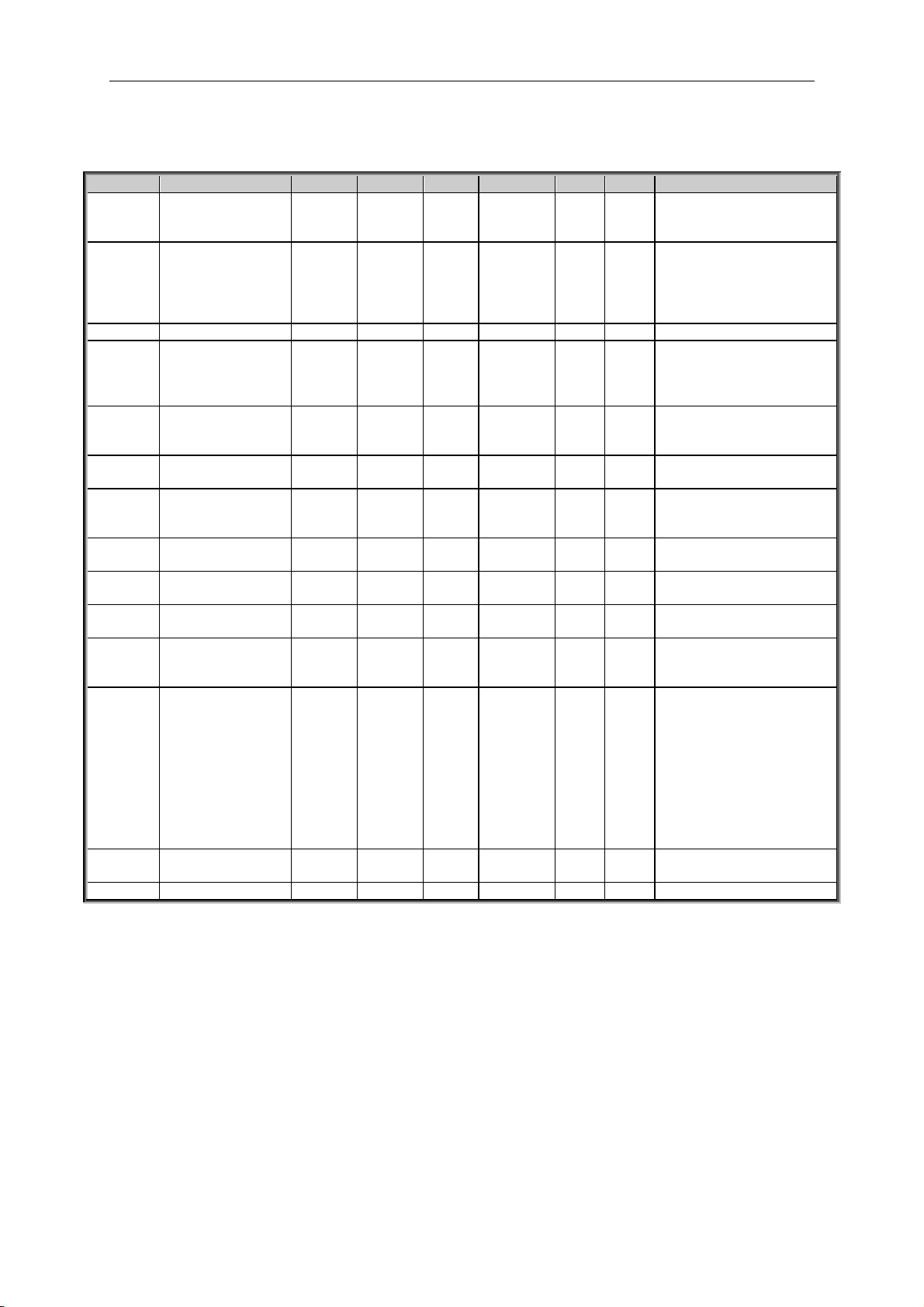

Column explanations:

Code = Location indication on the keypad; Shows the operator the present

parameter number

Parameter = Name of parameter

Min = Minimum value of parameter

Max = Maximum value of parameter

Unit = Unit of parameter value; Given if available

Default = Value preset by factory

Cust = Customer’s own setting

ID = ID number of the parameter

_____ = On parameter code: Parameter value can only be changed after the FC

has been stopped.

_____ = Apply the Terminal to Function method (TTF) to these parameters (see

chapter 5)

_____ = Monitoring value is possible to control from fieldbus by ID number

The manual presents signals that are not normally visible for monitoring. i.e. is not a

parameter or standard monitoring signal. These signals are presented with [Letter]. e.g.

[FW]MotorRegulatorStatus

[V] Normal monitoring signal

[P] Normal parameter in application.

[FW] Firmware signal, Can be monitored with NCDrive when signal type is selected

Firmware

[A] Application signal, can be monitored with NCDrive when signal type is selected

Application.

[R] Reference type parameter on keypad.

[F] Function. Signal is received as a output of function.

[DI] Digital input signal.

Page 16

16 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

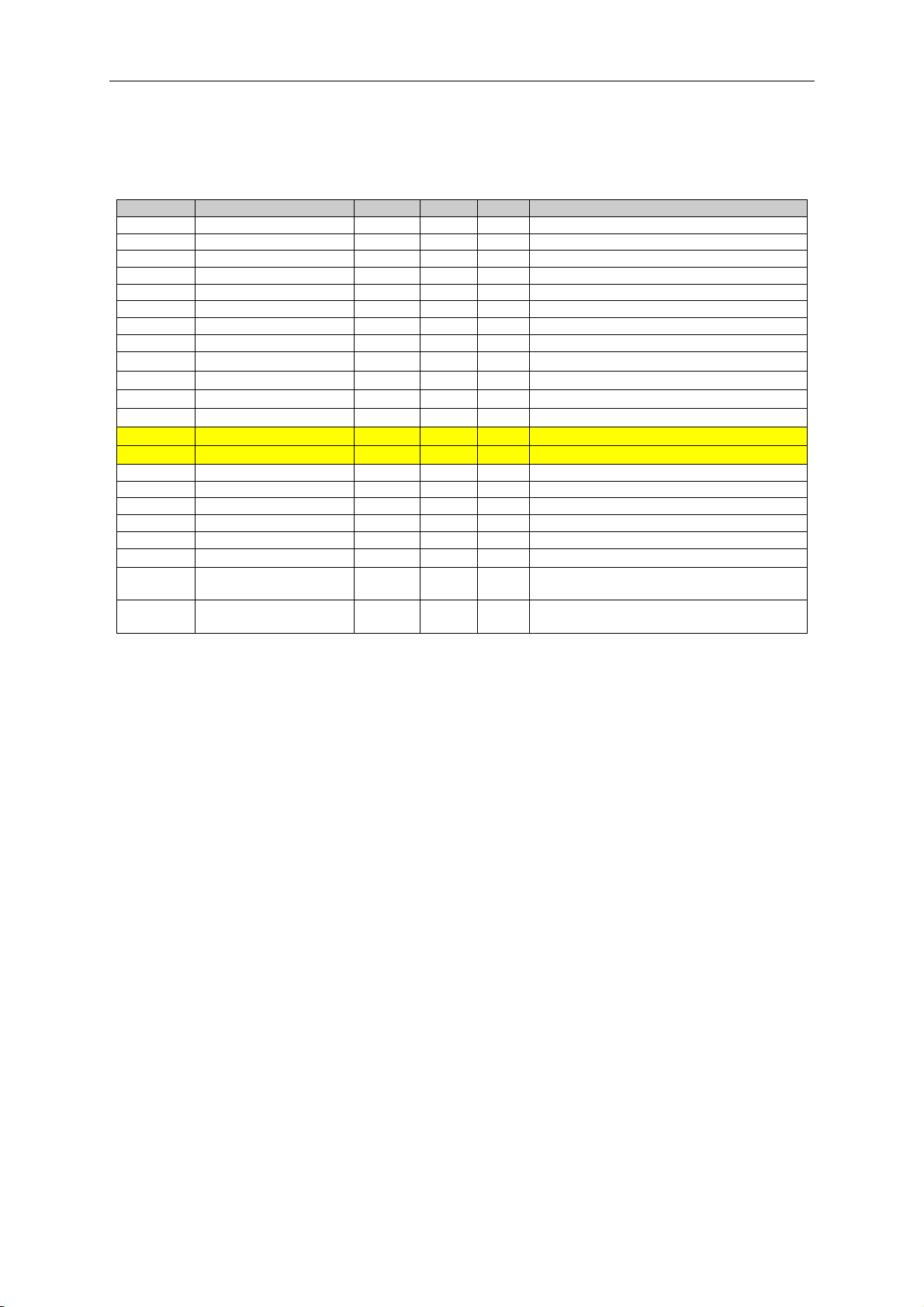

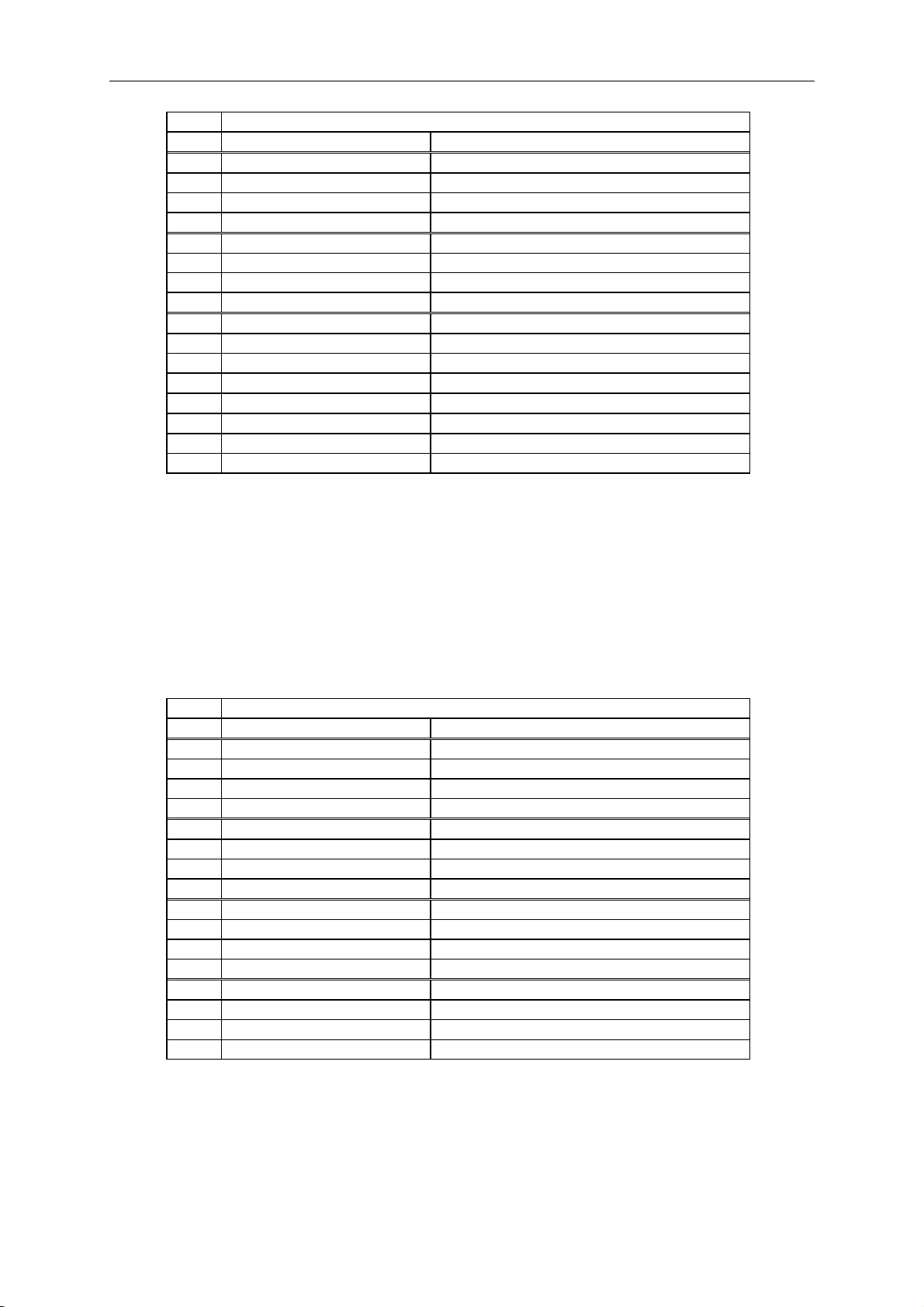

6.1 Monitoring values (Control keypad: menu M1)

The monitoring values are the actual values of parameters and signals as well as statuses

and measurements.

Code

Parameter

Unit

Form.

ID

Description

V1.1

Output frequency

Hz

#,##

1

Output frequency to motor

V1.2

Frequency reference

Hz

#,##

25

Frequency reference to motor control

V1.3

Motor speed

rpm # 2

Motor speed in rpm

V1.4

Motor current

A

Varies

3

1 s linear filtering

V1.5

Motor torque

%

#,#

4

In % of Motor nominal torque

V1.6

Motor Power

%

#,#

5 V1.7

Motor voltage

V

#,#

6

Calculated motor voltage

V1.8

DC link voltage

V # 7

Measured DC voltage, filtered.

V1.9

Unit temperature

C

# 8 Heatsink temperature

V1.10

Motor temperature

%

#

9

Calculated motor temperature

V1.11

Analogue input 1

%

#,##

13

AI1, unfiltered.

V1.12

Analogue input 2

%

#,##

14

AI2, unfiltered.

V1.13

Analogue input 3

%

#,##

27

AI3, unfiltered.

V1.14

Analogue input 4

%

#,##

28

AI4, unfiltered.

V1.15

Analogue Out 1

%

#,##

26

AO1

V1.16

Analogue Out 2

%

#,##

31

AO2

V1.17

Analogue Out 3

%

#,##

32

AO3

V1.18

DIN1, DIN2, DIN3

15

Digital input statuses

V1.19

DIN4, DIN5, DIN6

16

Digital input statuses

V1.20

Torque reference

%

#,#

18

Used Torque Reference

V1.21

Sensor max Temp

Cº

#,#

42

Highest temperature of OPTB8 board. 4 s

filtering.

G1.22

Multimonitoring items

Displays three selectable monitoring

values

Table 6-1. Monitoring values

Page 17

apfiff08 advance VACON® • 17

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

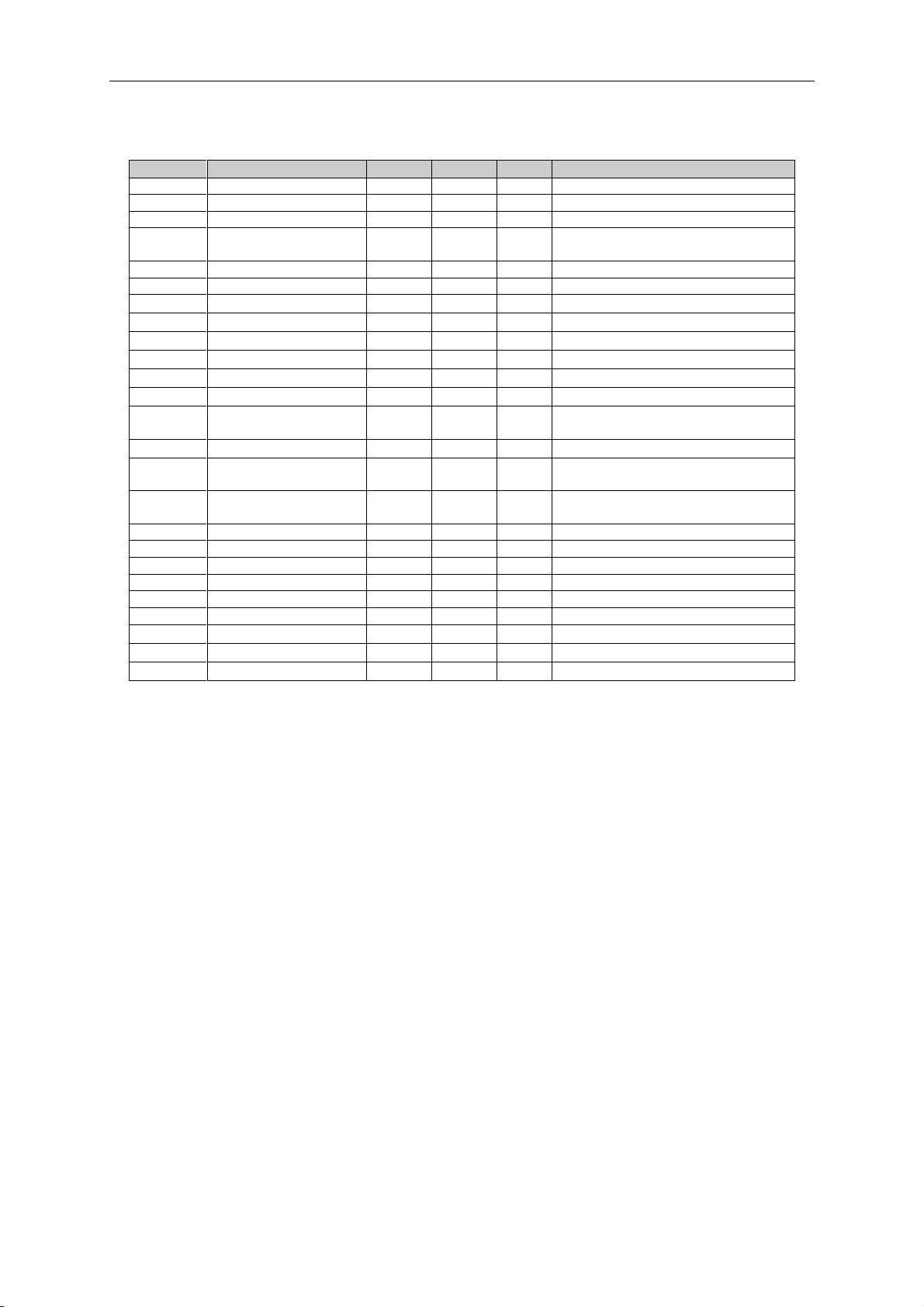

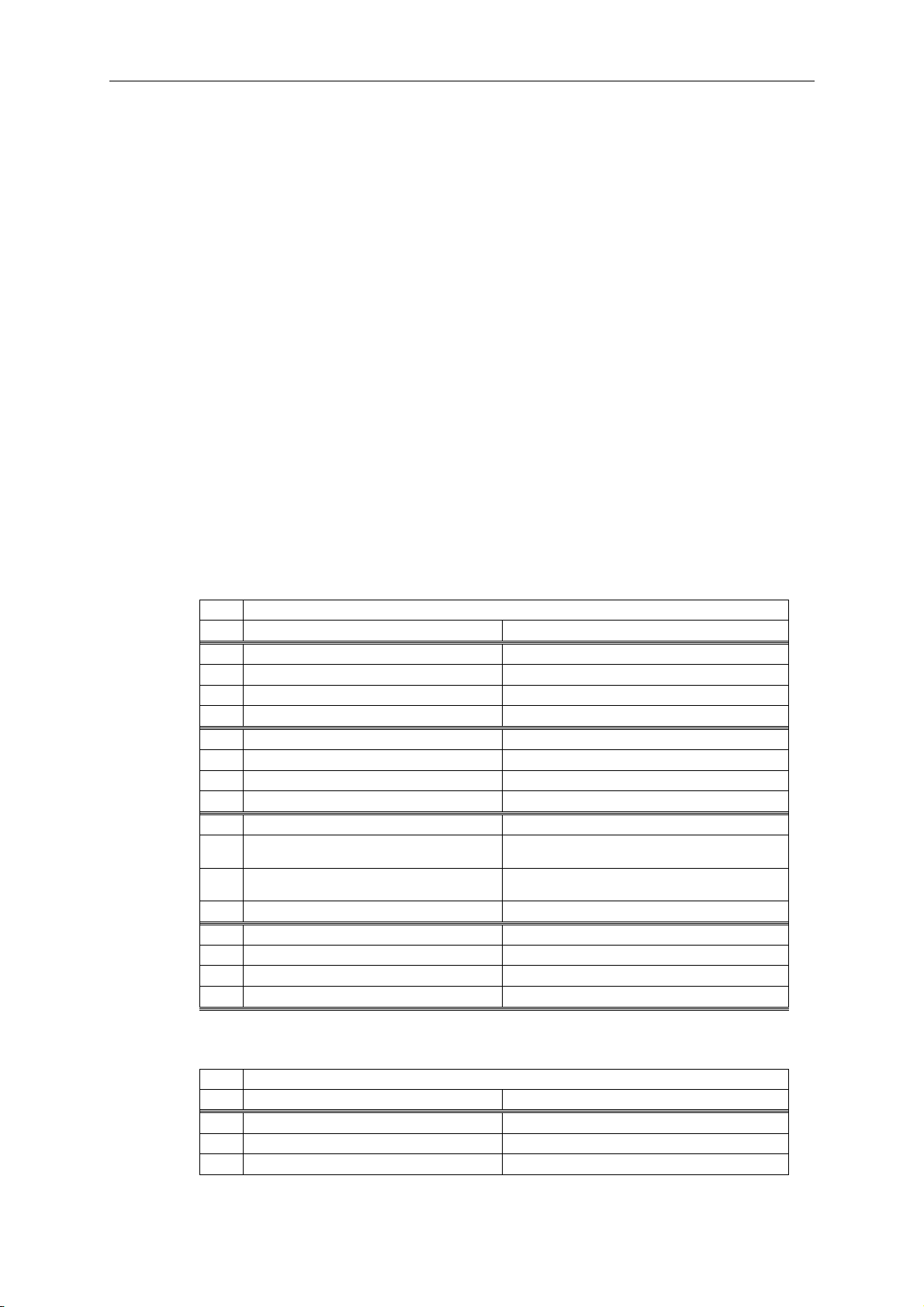

6.1.1 Monitoring values 2 (Control keypad: menu M1.23)

Code

Parameter

Unit

Form.

ID

Description

V1.23.1

Current

A

Varies

1113

Unfiltered motor current

V1.23.2

Torque

%

#,#

1125

Unfiltered motor torque

V1.23.3

DC Voltage

V # 44

Unfiltered DC link voltage

V1.23.4

Application Status

Word

43

V1.23.5

Encoder 1 Frequency

Hz

#,##

1124

Unfiltered

V1.23.6

Output Power

kw

Varies

1508

Unfiltered electrical power

V1.23.7

Sensor 1 Temp

Cº

#,#

50

4 s filtering.

V1.23.8

Sensor 2 Temp

Cº

#,#

51

4 s filtering.

V1.23.9

Sensor 3 Temp

Cº

#,#

52

4 s filtering.

V1.23.10

Sensor 4 Temp

Cº

#,#

69

4 s filtering.

V1.23.11

Sensor 5 Temp

Cº

#,#

70

4 s filtering.

V1.23.12

Sensor 6 Temp

Cº

#,#

71

4 s filtering.

V1.23.13

ABS Encoder

Revolutions

r

#

55

V1.23.14

ABS Encoder Position

#

54

V1.23.15

Actual Torque

Reference

%

#,#

Final torque reference from speed

control and/or torque control

V1.23.16

Final Frequency

Reference

Hz

#,##

1131

Final reference to speed controller.

V1.23.17

Step response

Hz

#,##

1132

V1.23.18

Encoder 2 Frequency

Hz

#,##

53

V1.23.19

ID Run Status

49

V1.23.20

Pole Pair Number

58 V1.23.21

Encoder 1 Frequency

Hz

#,##

1164

V1.23.22

ABS FreqOut

Hz

#,##

1704

V1.23.23

Identfail

98 V1.23.24

Non Ready Cause

#

1608

V1.23.25

Prevent MC Ready

#

1609

Table 6-2. Monitoring values 2

Page 18

18 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

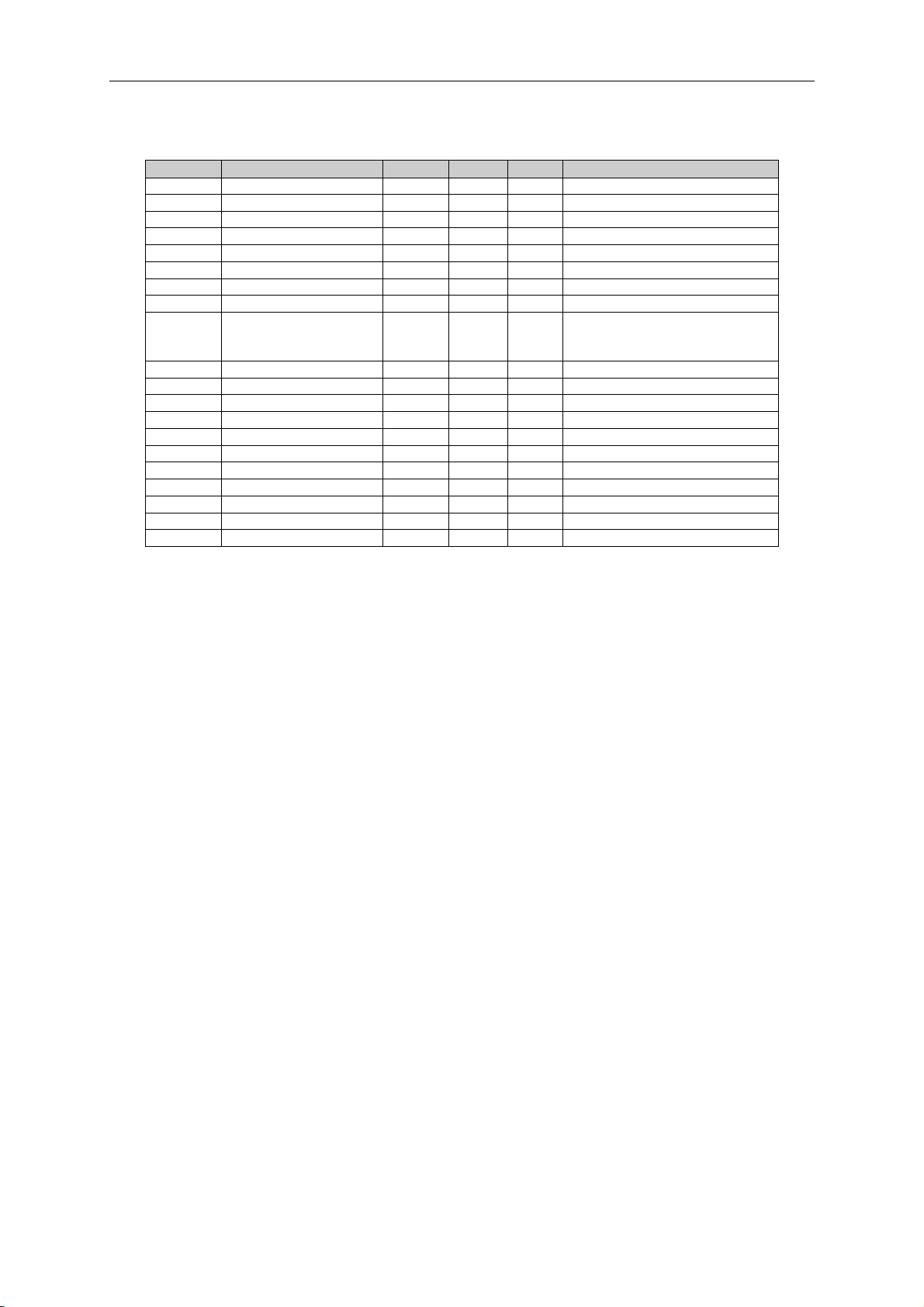

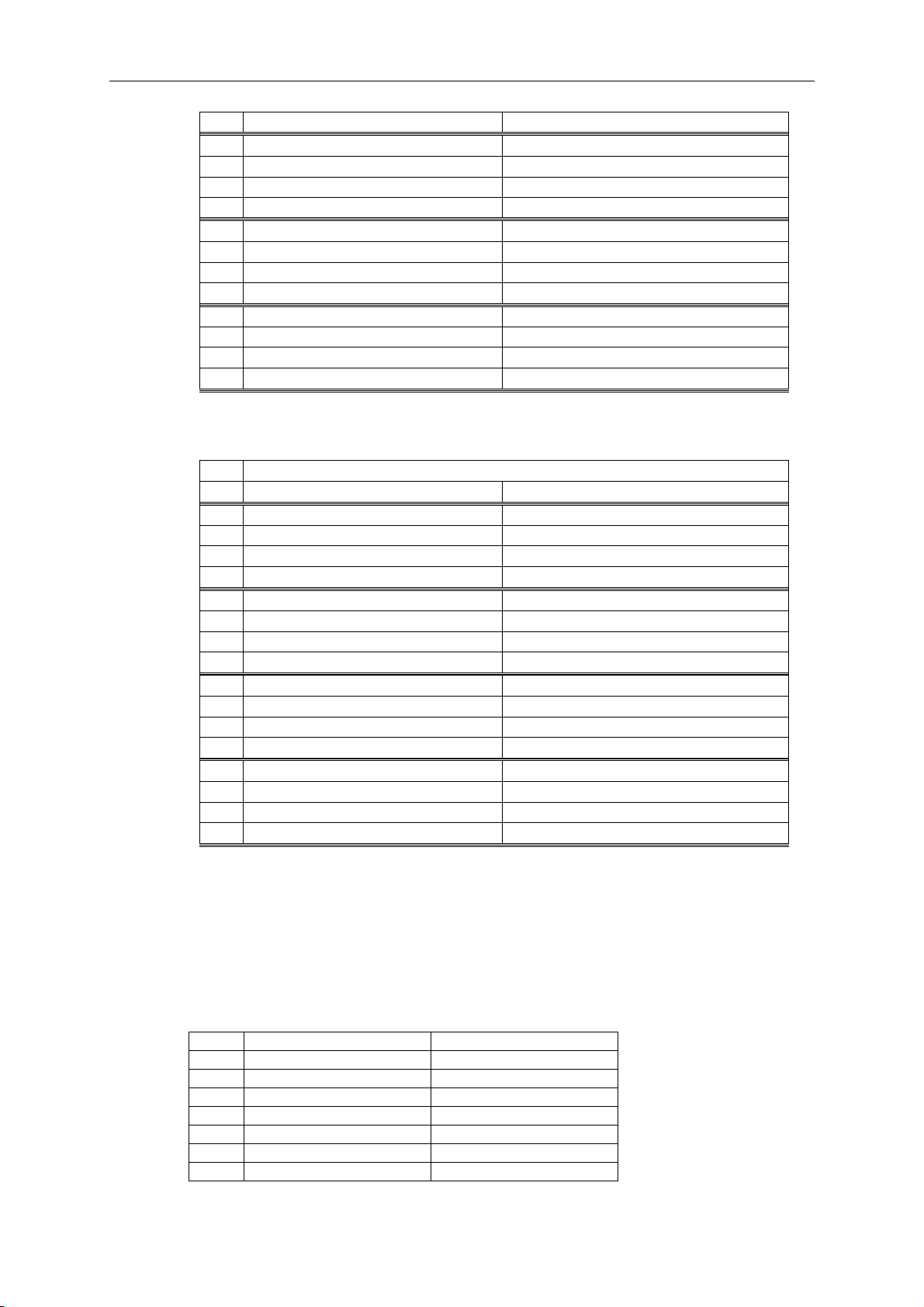

6.1.2 FieldBus Monitoring values (Control keypad: menu M1.24)

Code

Parameter

Unit

Form.

ID

Description

V1.24.1

FB Control Word

1160

V1.24.2

FB Speed Ref

875 V1.24.3

FB Status Word

65 V1.24.4

FB Actual Speed

865 V1.24.5

FB Torque Reference

%

#,#

1140

Default Control of FB PD 1

V1.24.6

FB Limit Scaling

%

#,##

46

Default Control of FB PD 2

V1.24.7

FB Adjust Reference

%

#,##

47

Default Control of FB PD 3

V1.24.8

FB Analog Output

%

#,##

48

Default Control of FB PD 4

V1.24.9

FB Motor Current

A

#,#

45

Motor current (drive

independent) given with one

decimal point

V1.24.10

Fault Word 1

1172

V1.24.11

Fault Word 2

1173

V1.24.12

Warning Word 1

1174

V1.24.13

Last Active Fault

37

V1.24.14

Din Status Word

56 V1.24.15

Din Status Word 2

57 V1.24.16

MC Status

64 V1.24.17

Last Active Warning

74

V1.24.18

Shaft Rounds

1170

V1.24.19

Shaft Angle

1169

V1.24.20

FB Scale Speed

1703

Table 6-3. FieldBus Monitoring values

Page 19

apfiff08 advance VACON® • 19

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.2 Monitoring values description

V1.1 Output frequency [#,## Hz] ID1

Output frequency to motor, updated at 10 ms time level.

V1.2 Frequency reference [#,## Hz] ID 25

Frequency reference to motor control, after speed share function. updates at 1

ms time level.

V1.3 Motor speed [ # rpm] ID 2

Motor speed in rpm

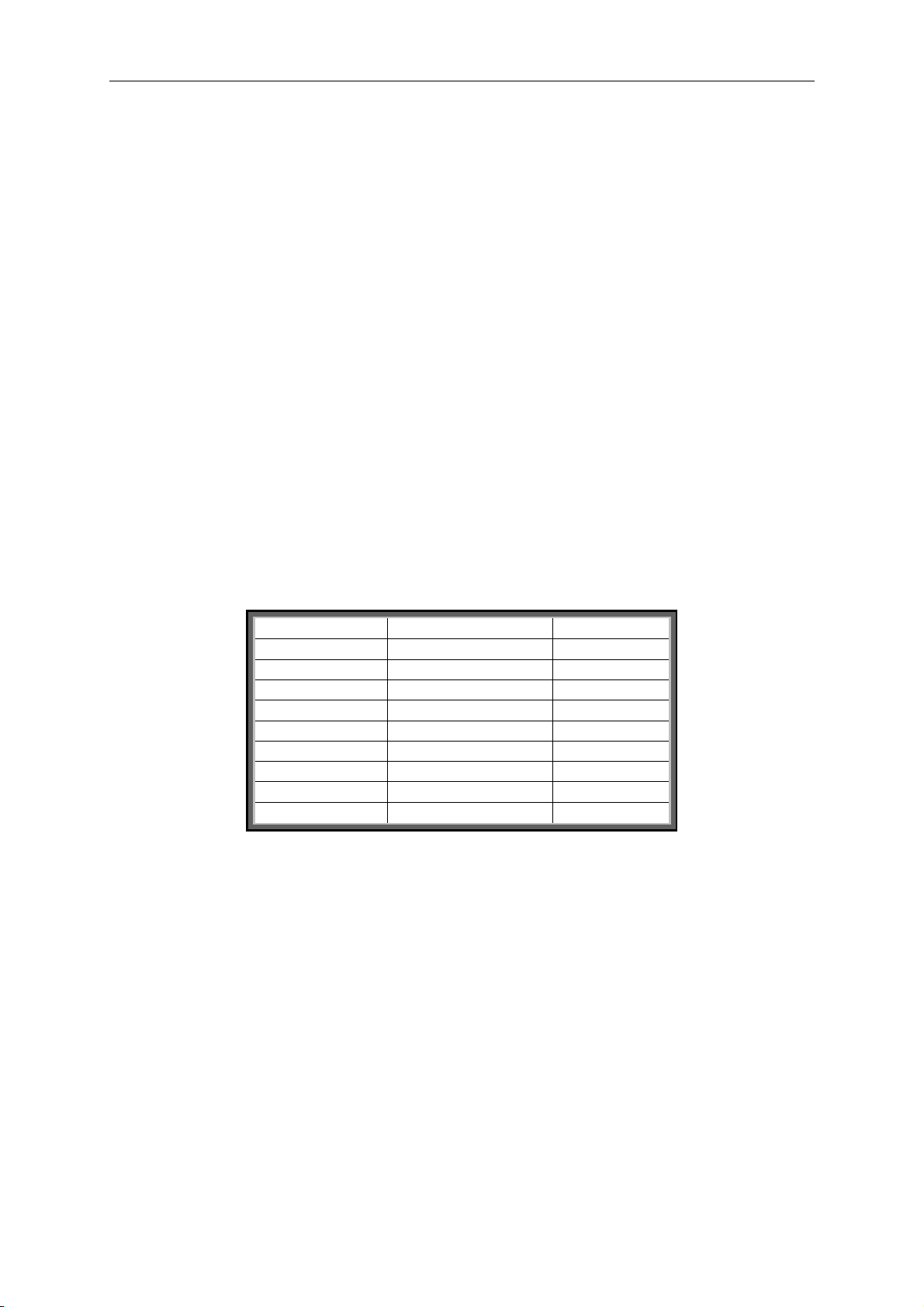

V1.4 Motor current [A] ID 3

Open loop:

1 s linear filtering.

Closed Loop:

32 ms filtering

Current scaling in different size of units

Note: ID45, usually in Process data OUT 3 is scaled to be with one decimal

always.

Voltage

Size

Scale

208 – 240 Vac

NX0001 – NX0011

100 – 0,01A

208 – 240 Vac

NX0012 – NX0420

10 – 0,1A

208 – 240 Vac

NX0530

1 – 1A

380 – 500 Vac

NX0003 – NX0007

100 – 0,01A

380 – 500 Vac

NX0009 – NX0300

10 – 0,1A

380 – 500 Vac

NX0385 – NX2643

1 – 1A

525 – 690 Vac

NX0004 – NX0013

100 – 0,01A

525 – 690 Vac

NX0018 – NX0261

10 – 0,1A

525 – 690 Vac

NX0325 – NX1500

1 – 1A

V1.5 Motor torque % ID 4

In % of Motor nominal torque

Open loop

1 s linear filtering

Closed Loop

32 ms filtering

V1.6 Motor Power % ID 5

Calculated motor power

Page 20

20 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

V1.7 Motor voltage V ID 6

Calculated motor voltage

V1.8 DC link voltage V ID 7

Measured DC voltage, filtered.

V1.9 Unit temperature C ID 8

Heatsink temperature

V1.10 Motor temperature % ID 9

Calculated motor temperature

105 % is tripping limit if response is fault.

V1.11 Analogue input 1 % ID 13

V1.12 Analogue input 2 % ID 14

Unfiltered analogue input level.

0 % = 0 mA / 0 V, -100 % = -10 V, 100 % = 20 mA / 10 V.

Monitoring scaling is determined by the option board parameter.

V1.13 Analogue input 3 % ID 27

V1.14 Analogue input 4 % ID 28

It is possible to adjust this input value from fieldbus when the input terminal

selection is 0.1. This way it is possible to adjust the free analogue input from

fieldbus and have all analogue input functions available for fieldbus process

data.

V1.15 Analogue Out 1 % ID 26

V1.16 Analogue Out 2 % ID 50

V1.17 Analogue Out 3 % ID 51

V1.18 DIN1, DIN2, DIN3 ID 15

V1.19 DIN4, DIN5, DIN6 ID 16

DIN1/DIN2/DIN3 status

DIN4/DIN5/DIN6 status

b0

DIN3

DIN6

b1

DIN2

DIN5

b2

DIN1

DIN4

V1.20 Torque reference % ID 18

Torque reference value before load share.

V1.21 PT-100 Temperature Cº ID 42

Highest temperature of OPTB8 board. 4 s filtering.

Page 21

apfiff08 advance VACON® • 21

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6.2.1 Monitoring values 2

V1.23.1 Current A ID 1113

Unfiltered motor current, recommended signal for NCDrive monitoring.

V1.23.2 Torque % ID 1125

Unfiltered motor torque, recommended signal for NCDrive monitoring.

V1.23.3 DC Voltage V ID 44

Unfiltered DC link voltage, recommended signal for NCDrive monitoring.

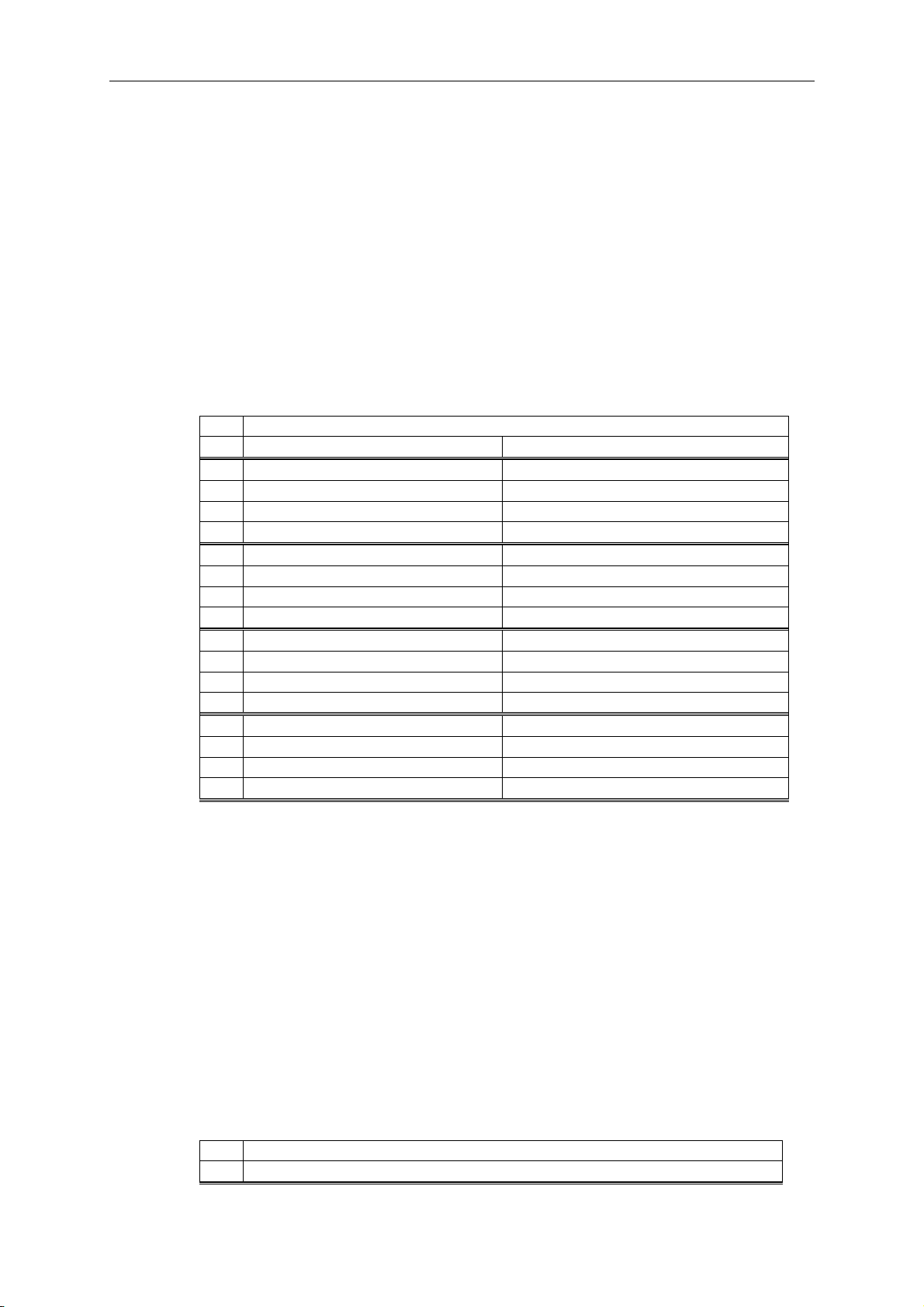

V1.23.4 Application Status Word ID 43

Application Status Word combines different drive statuses to one data word.

Recommended signal for NCDrive monitoring.

Application Status Word ID43

FALSE

TRUE

b0

Flux not ready

Flux ready (>90 %)

b1

Not in Ready state

Ready

b2

Not Running

Running

b3

No Fault

Fault

b4

Direction Forward

Direction Reverse

b5

Emergency Stop Active

Emergency Stop NOT Active

b6

Run Disabled

Run Enable

b7

No Warning

Warning

b8

b9

b10

b11

No DC Brake

DC Brake is active

b12

No Run Request

Run Request

b13

No Limit Controls Active

Limit control Active

b14

External Brake Control OFF

External Brake Control ON

b15

V1.23.5 Encoder 1 Frequency Hz ID 1124

Encoder frequency after filter. P2.8.4.6 Encoder1FiltTime.

V1.23.6 Output Power kw ID 1508

Unfiltered electrical drive output power.

V1.23.7 Sensor 1 temperature Cº ID 50

V1.23.8 Sensor 2 temperature Cº ID 51

V1.23.9 Sensor 3 temperature Cº ID 52

V1.23.10 Sensor 4 temperature Cº ID 69

V1.23.11 Sensor 5 temperature Cº ID 70

V1.23.12 Sensor 6 temperature Cº ID 71

Page 22

22 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Separate measurement from two temperature measurement boards. The signal

has 4 s filtering time.

V1.23.13 ABS Encoder Revolutions ID55

Absolute encoder revolution information.

V1.23.14 ABS Encoder Position ID54

Absolute encoder position within one rotation. See encoder manual for scaling.

V1.23.15 Actual Torque Reference % ID1180

Final torque reference from speed control and torque control. Also includes

torque step and acceleration compensation factors.

V1.23.16 Final Frequency Reference Hz ID 1131

Final reference to speed controller. After ramp generator and after Speed Step

function, used for closed loop speed tuning when used together with Encoder 1

frequency.

V1.23.17 Step response Hz ID 1132

Frequency error. Compares ramp output to actual encoder frequency with 0,001

Hz accuracy. Can be used for speed control tuning in closed loop control.

V1.23.18 Encoder 2 freq Hz ID 53

V1.23.19 ID Run Status ID 49

Status of identification run. Bits are set if items are done successfully.

V1.23.20 PolePairNumber ID 58

Pole pair number of the motor.

V1.23.21 Encoder 1 freq Hz ID 1164

Unfiltered encoder frequency, directly from encoder.

V1.23.22 ABS FreqOut Hz ID 1704

Absolute value from output frequency to motor.

V1.23.23 Identfail ID 98

Failure code for failed identification:

Page 23

apfiff08 advance VACON® • 23

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1 = Current measurement offset

2 = Identification current level

3 = Acceleration time too long

4 = Identification frequency reference not reached

5 = Too low or high magnetization current

6 = Flux curve outside expected levels

7 = PMSM, Encoder zero position

8 = Too low maximum frequency limit

9 = PMSM, encoder zero pulse not found.

10 = Ls Identification timeout

11 = Ls Identification current

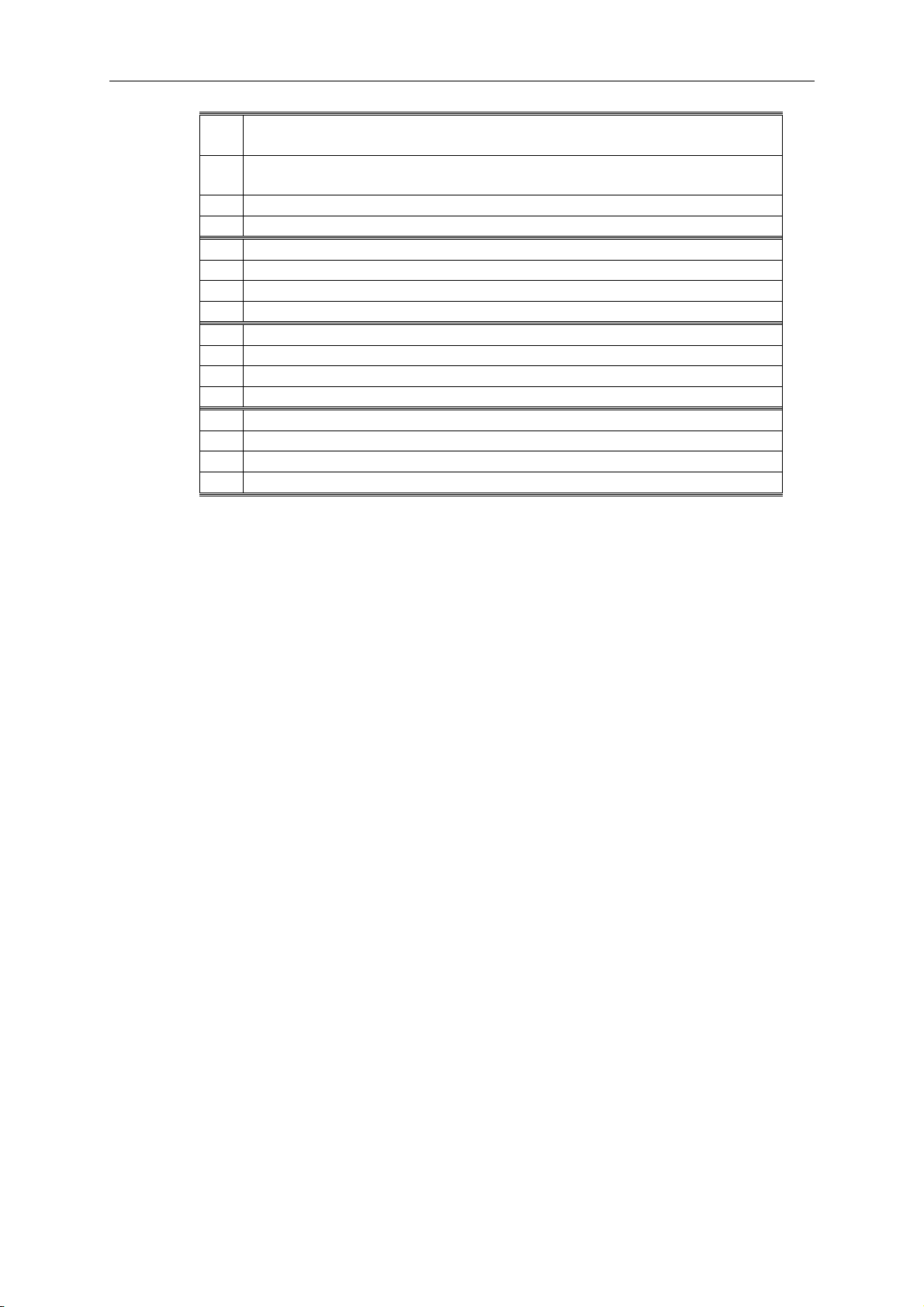

V1.23.24 Non Ready Cause ID 1608

Non Ready Cause ID1608

Signal

b0

Fault is Active

b1

PreventMCReady is set

b2

Charge switch is open

b3

DC Voltage not OK

b4

Power unit state not OK

b5

StartUp Wizard is active

b6

Run Enable is not set

b7

Ready state prevented by STO

b8

b9

b10

b11

b12

b13

b14

b15

V1.23.25 Prevent MC Ready ID 1609

Prevent MC Ready ID1609

Signal

Page 24

24 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

b0

Endat option board (OPTBB, OPTBE) communication is not initialized

after power-up.

b1

Drive sync master has wrong modulator or 1000ms task parameters

are not initialized

b2

Drive sync follower delay is active

b3

Drive sync failure in sw modulator double period mode

b4

Charge switch delay is active

b5

AFE fast run disable through ENC C1 is active

b6

100ms task not executed

b7 b8 b9 b10 b11

b12

b13 b14 b15

6.2.2 FieldBus Monitoring values

V1.24.1 FB Control Word ID1160

Control word used in bypass mode. See P2.13.22 and option board ByPass.

Page 25

apfiff08 advance VACON® • 25

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Bit

Description

Value = 0

Value = 1

0

OFF

ON, Reset after Fault or b1 and b2

1

Emergency stop by coast

ON, On normal operation: Keep TRUE

2

Emergency stop by ramp

ON, On normal operation: Keep TRUE

3

STOP REQUEST

RUN REQUST

4

Force ramp to Zero

Enable Ramp,

5

Freeze Ramp

Enable Ramp,

6

Force Ref to Zero

Enable Ramp,

7

No Action

FAULT RESET (0 -> 1)

8

No Action

Inching 1

9

No Action

Inching 2

10

Disable Profibus control

Enable Profibus control

11

Fieldbus DIN1=OFF

Fieldbus DIN1=ON (Watchdog pulse)

12

Fieldbus DIN2=OFF

Fieldbus DIN2=ON

13

Fieldbus DIN3=OFF

Fieldbus DIN3=ON

14

Fieldbus DIN4=OFF

Fieldbus DIN4=ON

15

No Action

No Action

V1.24.2 FB Speed Reference ID 875

Speed reference value from fieldbus.

V1.24.3 FB Status Word ID65

Profibus type status word. Generated in the application level.

Needs to be selected with P2.13.19 GSW to be used. When needed with

profibus board, operation mode needs to be set to ByPass in option board and

with P2.14.22 ProfiBus Mode select: 2 / ProfiDrive.

Bit

Description

Value = 0

Value = 1

0

Not ready to switch on

Ready to switch on

1

Not ready to operate

Ready to operate

2

Not Running

Running

3

No Fault

Fault

4

Coast stop Active

Coast stop not active

5

Quick stop active

Quick stop not active

6

Switch not inhibited

Switch on inhibit

7

No Warning

Warning

8

Speed error

Speed At Reference

9

No FB Control request

FB Control Active

10

Fout < Fmax

Fout > Fmax

11

not used

not used

12

not used

not used

13

not used

not used

14

not used

not used

15

Fieldbus DIN1=OFF

Fieldbus DIN1=ON (Watchdog pulse)

V1.24.4 FB Actual Speed ID 865

Actual speed 0-100% from fieldbus.

V1.24.5 FB Torque Reference % ID 1140

Page 26

26 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Torque reference value from fieldbus

Default Control of FB PD 1

V1.24.6 FB Limit Scaling % ID 46

Limit scaling input value from fieldbus.

Default Control of FB PD 2.

V1.24.7 FB Adjust Reference % ID 47

Reference adjustment value from fieldbus.

Default Control of FB PD 3.

V1.24.8 FB Analog Output % ID 48

Fieldbus value to control analogue output.

Default Control of FB PD 4.

V1.24.9 FB Motor Current A ID 45

Motor current (drive independent) given with one decimal point.

V1.24.10 Fault Word 1 ID 1172

Different faults are collected to two words that can be read from fieldbus or with

NCDrive PC software.

Fault Word 1 ID1172

Fault

Comment

b0

Over Current or IGBT

F1, F31, F41

b1

Over Voltage

F2

b2

Under Voltage

F9

b3

Motor Stalled

F15

b4

Earth Fault

F3

b5

Motor Under Load

F17

b6

Drive over temperature

F14

b7

Over Temperature

F16, F56, F29

b8

Input Phase

F10

b9

Brake resistor over temperature

F42

(Not implemented)

b10

Device Changed

F37, F38, F39, F40, F44, F45

(Not implemented)

b11

Keypad or PCControl

F52

b12

FielBus

F53

b13

SystemBus

F59

b14

Slot

F54

b15

4 mA

F50

V1.24.11 Fault Word 2 ID 1173

Fault Word 2 ID1173

Fault

Comment

b0

Output phase

F11

b1

Charge Switch

F5 (Not implemented)

b2

Encoder

F43

Page 27

apfiff08 advance VACON® • 27

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

b3

Inverter

F4, F7 (Not implemented)

b4

b5

EEPROM

F22 (Not implemented)

b6

External

F51

b7

Brake Chopper

F12 (Not implemented)

b8

Watch Dog

F25 (Not implemented)

b9

IGBT

F31, F41

b10

Brake

F58

b11

Fan Cooling

F32

b12

Application

F35 (Not implemented)

b13

Control fault

F33, F36, F8 (Not implemented)

b14

Main Switch Open

F64 (Not implemented)

b15

V1.24.12 Warning Word 1 ID 1174

Warning Word 1 ID1174

Fault

Comment

b0

Motor stalled

W15

b1

Motor over temperature

W16

b2

Motor under load

W17

b3

Input phase loss

W10

b4

Output phase loss

W11

b5

Safe disable

W30 (Not implemented)

b6

FieldBus communication fault in slot D

W53 (Not implemented)

b7

FieldBus communication fault in slot E

W67 (Not implemented)

b8

Drive over temperature

W14

b9

Analogue input < 4mA

W50

b10

Not used

b11

Emergency stop

W63 (Not implemented)

b12

Run disabled

W62 (Not implemented)

b13

Not used

b14

Mechanical Brake

W58

b15

Not used

V1.24.13 Fault History ID 37

Fault number of the last active fault.

V1.24.14 Din Status Word ID 56

V1.24.15 Din Status Word 2 ID 57

DIN StatusWord 1

DIN StatusWord 2

b0

DIN: A.1

DIN: C.5

b1

DIN: A.2

DIN: C.6

b2

DIN: A.3

DIN: D.1

b3

DIN: A.4

DIN: D.2

b4

DIN: A.5

DIN: D.3

b5

DIN: A.6

DIN: D.4

b6

DIN: B.1

DIN: D.5

Page 28

28 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

b7

DIN: B.2

DIN: D.6

b8

DIN: B.3

DIN: E.1

b9

DIN: B.4

DIN: E.2

b10

DIN: B.5

DIN: E.3

b11

DIN: B.6

DIN: E.4

b12

DIN: C.1

DIN: E.5

b13

DIN: C.2

DIN: E.6

b14

DIN: C.3

b15

DIN: C.4

V1.24.16 MC Status ID 64

This is the value that is also send to fieldbus on those fieldbus that do not use

own state machine.

Motor Control Status Word

FALSE

TRUE

b0

Not in Ready state

Ready

b1

Not Running

Running

b2

Direction Clockwise

Counterclockwise

b3

No Fault

Fault

b4

No Warning

Warning

b5 At reference speed

b6 At Zero Speed

b7 Flux Ready

b8 TC Speed Limiter Active

b9

Encoder Direction

Counterclockwise

b10 Under Voltage Fast stop

b11

No DC brake

DC Brake is active

b12

b13 Restart delay active

b14

b15

V1.24.17 Warning ID 74

Last active warning.

V1.24.18 Shaft Rounds ID 1170

Rounds information from incremental encoder. The value is reset when 24 Vdc is

removed from the drive.

V1.24.19 Shaft Angle ID 1169

Angle information from incremental encoder. The value is reset when 24 Vdc is

removed from the drive.

V1.24.20 FB Scale Speed ID 1703

Page 29

apfiff08 advance VACON® • 29

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 30

30 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7. ADVANCED APPLICATION – PARAMETER LIST

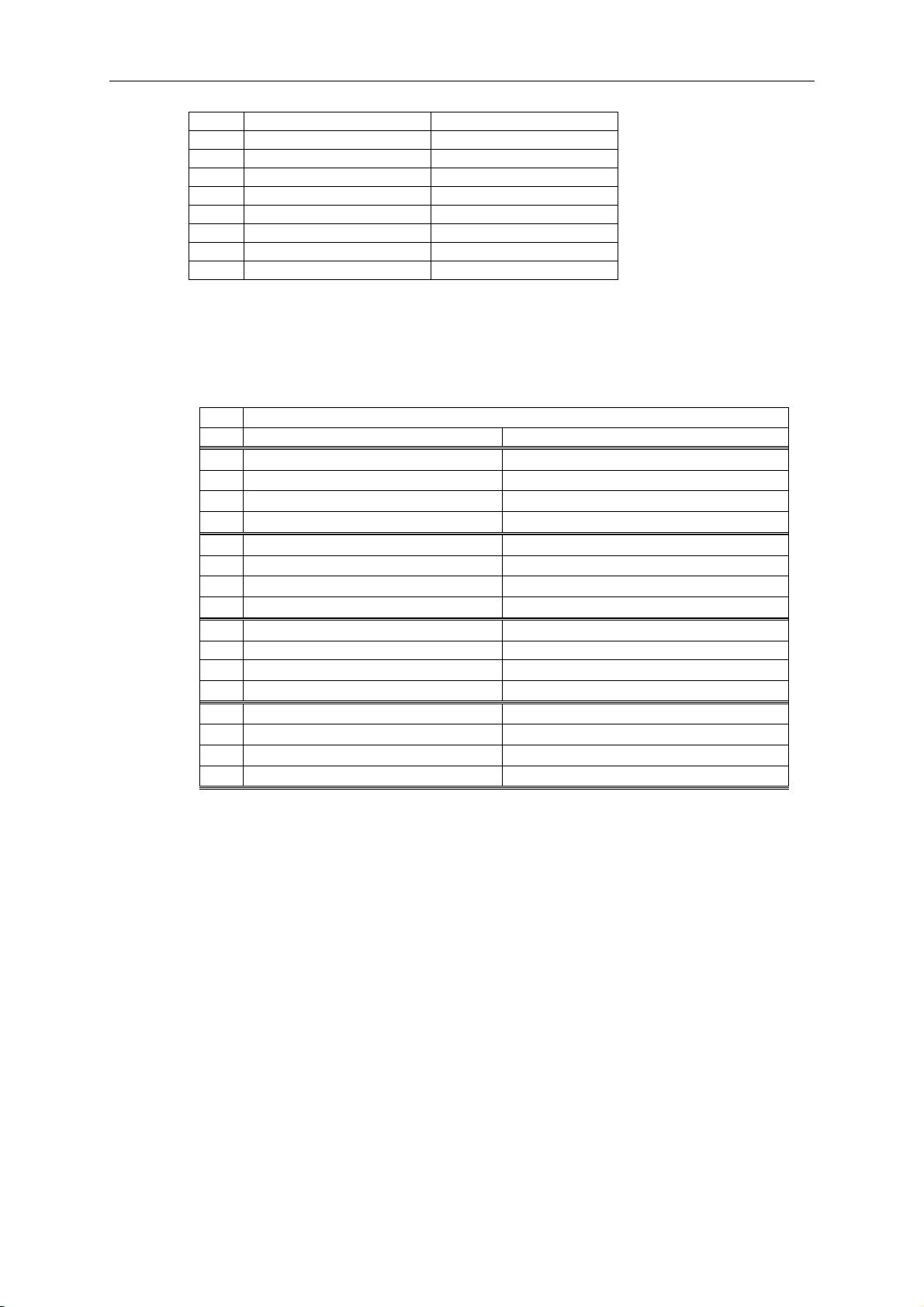

7.1 Basic parameters (Control keypad: Menu M2 → G2.1)

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.1.1

Frequency Scale

0 2 1

523

0 = 0,000 – 32,000 Hz

1 = 0,00 – 320,00 Hz

2 = 0,0 – 599,0 Hz

P2.1.2

RPM Format

0 4 0

1852

0 = Default

1 = #,# rpm

2 = # rpm

3 = #,## krpm

4 = #,# krpm

P2.1.3

Minimum frequency

0,00

P2.1.2

Hz

0,00

101

P2.1.4

Maximum frequency

P2.1.1

320,00

Hz

50,00

102

NOTE: If f

max

> than the

motor synchronous speed,

check suitability for motor

and drive system

P2.1.5

Motor nominal

voltage

180

690

V

NX2: 230V

NX5: 400V

NX6: 690V

110

Check the rating plate of

the motor. Note also used

connection Delta/Star

P2.1.6

Motor nominal

frequency

8,00

320,00

Hz

50,00

111

Check the rating plate of

the motor

P2.1.7

Motor nominal

speed

24

20 000

rpm

1440

112

The default applies for a 4pole motor and a nominal

size frequency converter.

P2.1.8

Motor nominal

current

0,1 x IH

2 x IH A IH

113

Check the rating plate of

the motor.

P2.1.9

Motor cos

0,30

1,00 0,85

120

Check the rating plate of

the motor

P2.1.10

Motor Nominal

Power

0,0

3200,0

kW

0,0

116

Check the rating plate of

the motor

P2.1.11

Magnetizing current

0,00

100,00

A

0,00

612

0,00 A = Drive uses

estimated value from

motor name plate values

P2.1.12

Identification

0 5

0

631

0=No action

1=Identification w/o run

2=Identification with run

3=Encoder ID Run

4=Ident All

5=Absolute encoder,

locked rotor

NOTE: Set motor control

mode to Freq Control

before identification!

P2.1.13

Motor type

0 1

0

650

0=Induction Motor

1=PMS Motor

P2.1.14

Supply Voltage

0

1000 0

1201

Table 7-1. Basic parameters G2.1

Page 31

apfiff08 advance VACON® • 31

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.2 Reference Handling

7.2.1 Basic Settings

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.1

Torque Scale

0 1 0

1207

0 = 1000 = 100,0 %

1 = 10000 = 100,00 %

P2.2.2

I/O Reference

0

16 0

117

0=AI1

1=AI2

2=AI1+AI2

3=AI1-AI2

4=AI2-AI1

5=AI1xAI2

6=AI1 Joystick

7=AI2 Joystick

8=Keypad

9=Fieldbus

10=Motor potentiometer

11=AI1, AI2 minimum

12=AI1, AI2 maximum

13=Max frequency

14=AI1/AI2 selection

15=Encoder 1

16=Encoder 2

P2.2.3

Keypad reference

selector

0 9 8

121

0=AI1

1=AI2

2=AI1+AI2

3=AI1-AI2

4=AI2-AI1

5=AI1xAI2

6=AI1 Joystick

7=AI2 Joystick

8=Keypad

9=Fieldbus

P2.2.4

Fieldbus control

reference

0 9 9

122

See par. 2.2.2

P2.2.5

I/O Reference 2

0

16 1

131

See ID117 & ID422

P2.2.6

Speed Share

-300,00

300,00

%

100,00

1241

P2.2.7

Load Share

0,0

500,0

%

100,0

1248

7.2.2 Constant Reference

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.8.1

Jogging speed

reference

0,00

320,00

Hz

5,00

124

P2.2.8.2

Preset speed 1

0,00

320,00

Hz

10,00

105

Multi-step speed 1

P2.2.8.3

Preset speed 2

0,00

320,00

Hz

15,00

106

Multi-step speed 2

P2.2.8.4

Preset speed 3

0,00

320,00

Hz

20,00

126

Multi-step speed 3

P2.2.8.5

Preset speed 4

0,00

320,00

Hz

25,00

127

Multi-step speed 4

P2.2.8.6

Preset speed 5

0,00

320,00

Hz

30,00

128

Multi-step speed 5

P2.2.8.7

Preset speed 6

0,00

320,00

Hz

40,00

129

Multi-step speed 6

P2.2.8.8

Preset speed 7

0,00

320,00

Hz

50,00

130

Multi-step speed 7

P2.2.8.9

Inching reference 1

-320,00

320,00

Hz

2,00

1239

P2.2.8.10

Inching reference 2

-320,00

320,00

Hz

-2,00

1240

7.2.3 Torque Reference

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

Page 32

32 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

P2.2.9.1

Torque reference

selection

0 8

0

641

0=Not used

1=AI1

2=AI2

3=AI3

4=AI4

5=AI1 joystick (-10 – 10

V)

6=AI2 joystick (-10 – 10

V)

7=Torque reference from

keypad, R3.5

8=FB Torque Reference

9=Master Torque

10=Power Reference

P2.2.9.2

Torque reference

max.

–300,0

300,0 % 100

642

P2.2.9.3

Torque reference

min.

–300,0

300,0 % 0,0

643

P2.2.9.4

Torque reference

filtering time

0

32000

ms

0

1244

P2.2.9.5

Torque Reference

Dead Zone

0,0

300,0 % 0,00

1246

P2.2.9.6

Torque Select

0 5

2

1278

0 = Speed control

1 = Pos/neg freq limits

2 = RampOut (-/+)

3 = NegFreqLimit-

RampOut

4 = RampOutPosFreqLimit

5 = RampOut Window

6 = 0-RampOut

7 = RampOut Window

On/Off

P2.2.9.7

Window negative

0,00

50,00

Hz

2,00

1305

P2.2.9.8

Window positive

0,00

50,00

Hz

2,00

1304

P2.2.9.9

Window negative off

0,00

P2.10.11

Hz

0,00

1307

P2.2.9.10

Window positive off

0,00

P2.10.12

Hz

0,00

1306

7.2.3.1 Torque Reference OL Settings

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.9.11.1

Open loop torque

control minimum

frequency

0,00

50,00

Hz

3,00

636

P2.2.9.11.2

Open loop torque

controller

P gain

0

32000 150

639

P2.2.9.11.3

Open loop torque

controller

I gain

0

32000 10 640

P2.2.9.11.4

Torque speed limit

for Open Loop

0 2

1 644

0=Max. frequency

1=Selected frequency ref.

2=Preset speed 7

7.2.3.2 Torque Reference CL Settings

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.9.12.1

Torque Step

-300,0

300,0 % 0,0

1253

Page 33

apfiff08 advance VACON® • 33

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.2.4 Prohibit frequency parameters (Control keypad: Menu M2 → G2.5)

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.10.

1

Prohibit frequency

range 1 low limit

-1,00

320,00

Hz

0,00

509

0=Not used

P2.2.10.

2

Prohibit frequency

range 1 high limit

0,00

320,00

Hz

0,00

510

0=Not used

P2.2.10.

3

Ramp time factor

0,1

10,0 x 1,0

518

Multiplier of the currently

Selected ramp time

between prohibit

frequency limits.

Table 7-2. Prohibit frequencies (G2.5)

7.2.5 Motor Potentiometer (Control keypad: Menu M2 → G2.5)

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.11.

1

Motor potentiometer

ramp rate

0,10

2000,00

Hz/s

1,00

331

Ramp rate for motor

potentio meter

P2.2.11.

2

Motor potentiometer

frequency reference

memory reset

0 2 1

367

0=No reset

1=Reset in stop state

2=Reset in powered down

Table 7-3. Motor potentiomer (G2.5)

7.2.6 Adjust Reference

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.2.12.1

Adjust input

0 5 0

493

0=Not used

1=AI1

2=AI2

3=AI3

4=AI4

5=Fieldbus

P2.2.12.2

Adjust minimum

0,0

100,0 % 0,0

494

Adjust limit to decrease

ref.

P2.2.12.3

Adjust maximum

0,0

100,0 % 0,0

495

Adjust limit to increase

ref.

P2.2.12.4

Speed step

-200,0

200,0 % 0

1252

Page 34

34 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.3 Ramp Control

7.3.1 Basic Settings

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.3.1

Start function

0 2

0

505

0=Ramp

1=Flying start

2=Conditional flying start

P2.3.2

Stop function

0 1

0

506

0=Coasting

1=Ramp

P2.3.3

Acceleration time 1

0,01

327,00

s

3,00

103

0 Hz to Max frequency

P2.3.4

Deceleration time 1

0,01

327,00

s

3,00

104

Max frequency to 0 Hz

P2.3.5

Ramp 1 shape

0

100 % 2

500

0=Linear

>0=S-curve ramp time

P2.3.6

Acceleration time 2

0,01

327,00

s

10,00

502 P2.3.7

Deceleration time 2

0,01

327,00

s

10,00

503

P2.3.8

Ramp 2 shape

0

100 % 4

501

0=Linear

>0=S-curve ramp time

P2.3.9

Inching Ramp

0,01

320,00

s

1,00

1257

P2.3.10

Reducing of

acc./dec. times

0 5

0

401

Scales active ramp from

100 % to 10 %.

0=Not used

1=AI1

2=AI2

3=AI3

4=AI4

5=Fieldbus

P2.3.11

IO Quick Stop Mode

0 1

0

1276

0=Coasting

1= Ramp

7.3.2 Ramp Control Options

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.3.12.1

Ramp Input

Interpolator TC

0

200

ms

10

1184

Page 35

apfiff08 advance VACON® • 35

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.4 Input Signals

7.4.1 Basic Settings

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.4.1.1

Start/Stop logic

selection

0 7 0

300

Start

signal 1

(Default:

DIN1)

Start

signal 2

(Default:

DIN2)

0

1

2

3

4

5

6

7

Start fwd

Start/Stop

Start/Stop

Start pulse

Start

Start fwd*

Start*/Stop

Start*/Stop

Start rvs

Reverse

Run enable

Stop pulse

Mot.Pot UP

Start rvs*

Reverse

Run Enable

Table 7-4. Input signals: basic settings, G2.2.1

* = Rising edge required to start

Page 36

36 • VACON® apfiff08 advance

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7.4.2 Digital inputs (Control keypad: Menu M2 → G2.2.4)

Code

Parameter

Min

Default

Cust

ID

Note

P2.4.2.1

Start signal 1

0.1

A.1 403

Forward, See ID300

P2.4.2.2

Start signal 2

0.1

A.2 404

Reverse. See ID300

P2.4.2.3

Run enable

0.1

0.2 407

Motor start enabled (cc)

P2.4.2.4

Reverse

0.1

0.1 412

Direction forward (oc)

Direction reverse (cc)

P2.4.2.5

Preset speed 1

0.1

0.1 419

See preset speeds in basing

parameter group G2.1

P2.4.2.6

Preset speed 2

0.1

0.1 420 P2.4.2.7

Preset speed 3

0.1

0.1 421

P2.4.2.8

Motor potentiometer

reference DOWN

0.1

0.1 417

Mot.pot. reference decreases (cc)

P2.4.2.9

Motor potentiometer

reference UP

0.1

0.1 418

Mot.pot. reference increases (cc)

P2.4.2.10

Fault reset

0.1

0.1 414

All faults reset (cc)

P2.4.2.11

External fault (close)

0.1

0.1 405

Ext. fault displayed (cc)

P2.4.2.12

External fault (open)

0.1

0.2 406

Ext. fault displayed (oc)

P2.4.2.13

Acc/Dec time selection

0.1

0.1 408

Acc/Dec time 1 (oc)

Acc/Dec time 2 (cc)

P2.4.2.14

Acc/Dec prohibit

0.1

0.1 415

Acc/Dec prohibited (cc)

P2.4.2.15

DC braking

0.1

0.1 416

DC braking active (cc)

P2.4.2.16

Jogging speed

0.1

0.1 413

Jogging speed selected for

frequency reference (cc)

P2.4.2.17

IO reference 1 / 2 selection

0.1

0.1 422

IO reference selection:14 ID117

P2.4.2.18

Control from I/O terminal

0.1

0.1 409

Force control place to I/O terminal

(cc)

P2.4.2.19

Control from keypad

0.1

0.1 410

Force control place to keypad (cc)

P2.4.2.20

Control from fieldbus

0.1

0.1 411

Force control place to fieldbus (cc)

P2.4.2.21

Parameter set 1/set 2

selection

0.1

0.1 496

Closed cont.=Set 2 is used

Open cont.=Set 1 is used

P2.4.2.22

Motor control mode 1/2

0.1

0.1 164

Closed cont.=Mode 2 is used

Open cont.=Mode 1 is used

See par 2.6.1, 2.6.12

P2.4.2.23

External Brake

Acknowledge

0.1

0.2 1210

Monitoring signal from mechanical

brake

P2.4.2.24

Cooling Monitor

0.1

0.2 750

Used when water cooled unit

P2.4.2.25

Enable Inching

0.1

0.1 532

Enables Inching function

P2.4.2.26

Inching 1

0.1

0.1 531

Inching reference 1 (Default

Forward 2 Hz. See P2.4.16). This

will start the drive.

P2.4.2.27

Inching 2

0.1

0.1 532

Inching reference 2 (Default

Reverse -2 Hz. See P2.4.17).

This will start the drive.

P2.4.2.28

Reset Position

0.1

0.1 1090

P2.4.2.29

MF Mode 2

0.1

0.1 1092

P2.4.2.30

Emergency Stop

0.1

0.2 1213

P2.4.2.31

Input Switch Ack

0.1

0.1 1209

Table 7-5. Digital input signals, G2.2.4

7.4.3 Analogue input 1 (Control keypad: Menu M2 → G2.2.2)

Code

Parameter

Min

Max

Unit

Default

Cust

ID

Note

P2.4.3.1

AI1 signal selection

0.1

E.10 A.1

377

Slot . Board input No.

P2.4.3.2

AI1 filter time

0,000

32,000

s

0,000

324

0=No filtering

P2.4.3.3

AI1 signal range

0 3 0

320

0=0…100%*

cc = closing contact

oc = opening contact

Page 37

apfiff08 advance VACON® • 37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1=20…100%* 4 mA Fault

2= -10V…+10V*

3= Custom range*

P2.4.3.4

AI1 custom minimum

setting

-160,00

160,00

%

0,00

321

Custom Range:

Minimum input

P2.4.3.5

AI1 custom

maximum setting

-160,00

160,00

%

100,00

322

Custom Range:

Maximum input

P2.4.3.6

AI1 reference