Page 1

vacon nx

®

ac drives

active front end (afe)

arfiff02

application manual

Page 2

Page 3

vacon • 1

TABLE OF CONTENTS

Document: DPD000905B

Software code: ARFIFF02V148

Release date : 21/2/17

1. Introduction .....................................................................................................3

2. AFE units..........................................................................................................4

2.1 500 Vac units Air Cooled ....................................................................................................4

2.2 690 Vac units Air Cooled ....................................................................................................5

2.3 500 Vac units Liquid-Cooled ..............................................................................................6

2.4 690 Vac units Liquid-Cooled ..............................................................................................7

3. Operation .........................................................................................................8

3.1 Main contactor control.......................................................................................................8

3.2 Quick Start instructions .....................................................................................................9

4. CONTROL IO ...................................................................................................12

5. AFE Application - Monitoring values ..............................................................14

5.1 Monitoring values.............................................................................................................15

5.1.1 Monitoring 1 .....................................................................................................................15

5.1.2 Monitoring values 2..........................................................................................................16

5.1.3 FieldBus Monitoring values .............................................................................................16

5.1.4 IO Monitoring values ........................................................................................................16

5.1.5 Unit Monitoring Values.....................................................................................................17

5.1.6 Monitoring 1 values..........................................................................................................17

5.1.7 Monitoring 2 values..........................................................................................................19

5.1.8 Fieldbus monitoring values .............................................................................................19

5.1.9 IO Monitoring values ........................................................................................................27

5.1.10 Unit Monitoring values.....................................................................................................28

6. AFE Application - Parameter lists..................................................................29

6.1 Basic parameters.............................................................................................................30

6.2 Reference Handling .........................................................................................................31

6.3 Input signals.....................................................................................................................32

6.3.1 Digital inputs ....................................................................................................................32

6.3.2 Analogue inputs ...............................................................................................................33

6.4 Output signals ..................................................................................................................34

6.4.1 Digital Outputs .................................................................................................................34

6.4.2 Analogue Output 1............................................................................................................35

6.5 Limit Settings ...................................................................................................................36

6.5.1 Current Limit....................................................................................................................36

6.5.2 Power Limit ......................................................................................................................36

6.5.3 Auto Start Stop .................................................................................................................36

6.5.4 DC Voltage........................................................................................................................36

6.6 Drive Control parameters................................................................................................37

6.7 Control parameters .........................................................................................................38

6.8 Fieldbus parameters........................................................................................................39

6.9 Protections .......................................................................................................................40

6.9.1 General.............................................................................................................................40

6.9.2 PT-100 ..............................................................................................................................41

6.9.3 Earth fault ........................................................................................................................41

6.9.4 Fieldbus............................................................................................................................41

6.10 Auto reset parameters.....................................................................................................42

6.11 DIN ID Control ..................................................................................................................42

6.12 Keypad control .................................................................................................................42

6.13 System menu ...................................................................................................................42

6.14 Expander boards ..............................................................................................................42

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 4

vacon • 2

7. Description of parameters .............................................................................43

7.1 Basic parameters.............................................................................................................43

7.2 Reference Handling .........................................................................................................44

7.3 Input signals.....................................................................................................................46

7.3.1 Digital inputs ....................................................................................................................46

7.3.2 Analogue Inputs ...............................................................................................................49

7.4 Output signals ..................................................................................................................50

7.4.1 Digital outputs..................................................................................................................50

7.4.2 Analogue outputs .............................................................................................................50

7.5 Limit settings ...................................................................................................................52

7.5.1 Current Limits..................................................................................................................52

7.5.2 Power Limits ....................................................................................................................52

7.5.3 Auto Start Stop function...................................................................................................52

7.5.4 DC Voltage limit parameters ...........................................................................................53

7.6 Drive control.....................................................................................................................54

7.6.1 Drive control.....................................................................................................................56

7.7 Fieldbus parameters........................................................................................................58

7.8 Protections .......................................................................................................................59

7.8.1 PT100 Temperature .........................................................................................................60

7.8.2 Earth fault ........................................................................................................................61

7.8.3 Fieldbus............................................................................................................................62

7.9 Auto restart ......................................................................................................................63

7.10 DIN ID Control ..................................................................................................................64

7.11 Keypad control .................................................................................................................64

8. Fieldbus Profile for VACON® Regenerative Drive .........................................65

8.1 Signals from Overriding System to VACON® regenerative Drive...................................65

8.2 Signals from VACON® Drive to Overriding system.........................................................65

8.3 Main Control Word ...........................................................................................................66

8.4 FB Reference Control ......................................................................................................67

8.5 Main Control Word (in DeviceNet) ...................................................................................68

8.6 Main Status Word.............................................................................................................70

8.7 Fault Word 1.....................................................................................................................72

8.8 Fault Word 2.....................................................................................................................72

8.9 Warning Word 1................................................................................................................73

8.10 Auxiliary Control Word.....................................................................................................74

8.11 Auxiliary Control Word (in DeviceNet) .............................................................................75

8.12 FB Reference Control (Device net) ..................................................................................76

8.13 Aux Status Word ID 1163.................................................................................................77

8.14 Status Word (Application) ID 43 ......................................................................................78

9. Fault codes.....................................................................................................80

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 5

Introduction vacon • 3

11280.emf

1. INTRODUCTION

The AFE unit is a regenerative power converter for the front-end of a common DC bus product line.

The AFE unit is used with inverter hardware and special software. An external L(CL)-filter and

charging circuit is needed. This unit is selected when low harmonics are required. The connection

of AFE drive has been described in Figure .

The Regenerative Application is easy and flexible to use due to its versatile fieldbus features. The

parameters of the Regenerative Application are explained in Chapter 8.

The basic I/O-configuration of the AFE drive consists of OPT-A1 and OPT-A2 option cards. The basic

I/O configuration has been described in Table 5. An option card OPT-B5 can be used if additional

digital outputs are needed. Configuration has been described in Table 6.

By default the control place (P3.1) of the AFE drive is keypad.

This application requires NXP control board 661 or 761.

Figure 1. AFE connection

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Page 6

vacon • 4 AFE units

2. AFE UNITS

2.1 500 Vac units Air Cooled

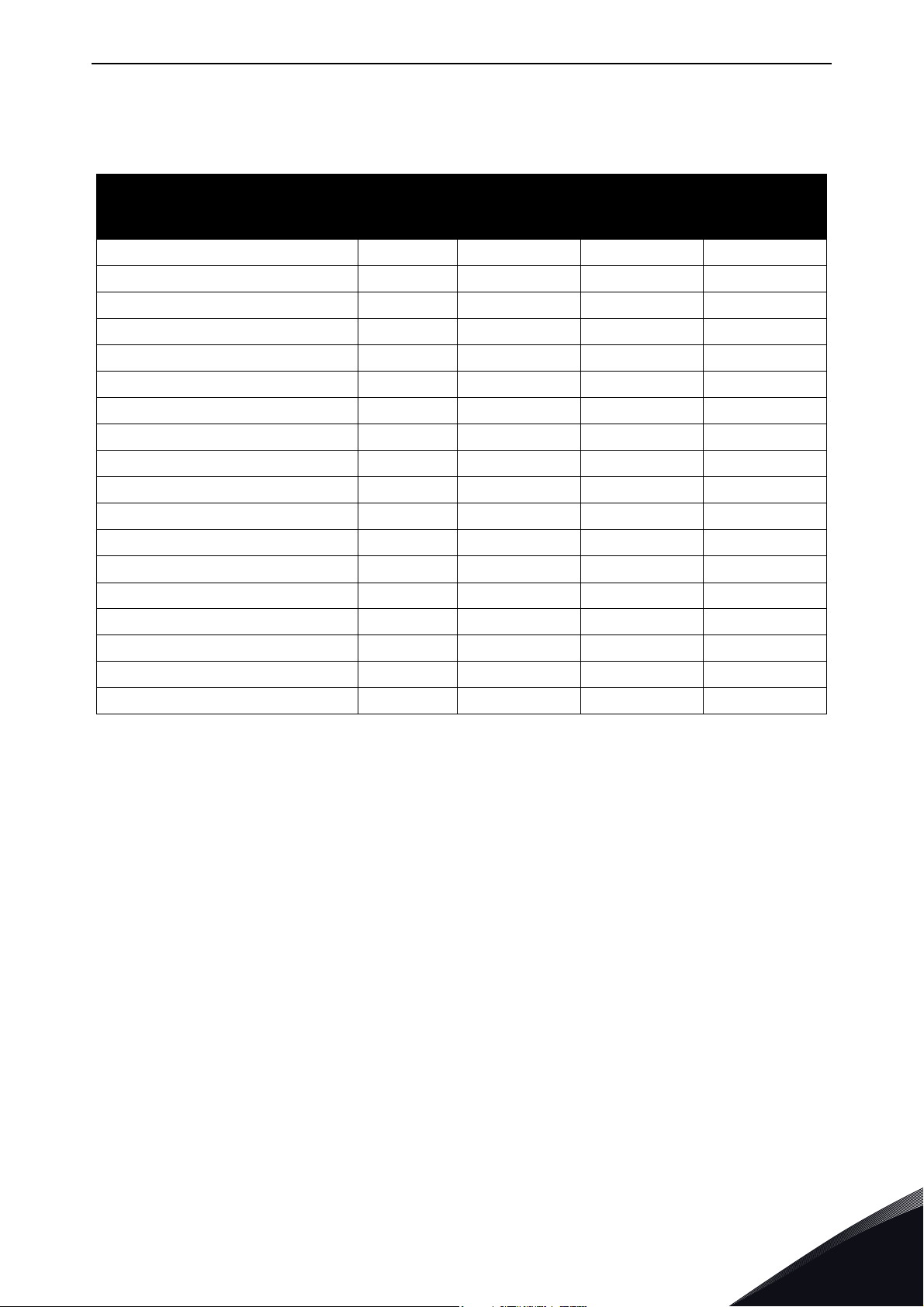

Table 1. 500 Vac units Air Cooled

Unit

Code

NXA_0168 5 A0T02SF 1xFI9 170 140

NXA_0205 5 A0T02SF 1xFI9 205 170

NXA_0261 5 A0T02SF 1xFI9 261 205

NXA_0385 5 A0T02SF 1xF10 385 300

NXA_0460 5 A0T02SF 1xFI10 460 385

NXA_1150 5 A0T02SF 1xFI13 1150 1030

NXA_1300 5 A0T02SF 1xFI13 1300 1150

Enclosure

size

IL-cont [A] IH-cont [A]

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 7

AFE units vacon • 5

2.2 690 Vac units Air Cooled

Table 2. 690 Vac units Air Cooled

Unit

Code

NXA_0125 6 A0T02SF 1xFI9 125 100

NXA_0144 6 A0T02SF 1xFI9 144 125

NXA_0170 6 A0T02SF 1xFI9 170 144

NXA_0261 6 A0T02SF 1xFI10 261 208

NXA_0325 6 A0T02SF 1xFI10 325 261

NXA_0920 6 A0T02SF 1xFI13 920 820

NXA_1030 6 A0T02SF 1xFI13 1030 920

Enclosure

size

IL-cont [A] IH-cont [A]

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

Page 8

vacon • 6 AFE units

2.3 500 Vac units Liquid-Cooled

Table 3. 500 Vac units Liquid-Cooled

Unit

Code Chassis Ith-cont [A] IL-cont [A] IH-cont [A]

NXA01685A0T02WS CH5 168 153 112

NXA02055A0T02WS CH5 205 186 137

NXA02615A0T02WS CH5 261 237 174

NXA03005A0T02WF CH61 300 273 200

NXA03855A0T02WF CH61 385 350 257

NXA04605A0T02WF CH62 460 418 307

NXA05205A0T02WF CH62 520 473 347

NXA05905A0T02WF CH62 590 536 393

NXA06505A0T02WF CH62 650 591 433

NXA07305A0T02WF CH62 730 664 487

NXA08205A0T02WF CH63 820 745 547

NXA09205A0T02WF CH63 920 836 613

NXA10305A0T02WF CH63 1030 936 687

NXA11505A0T02WF CH63 1150 1045 767

NXA13705A0T02WF CH64 1370 1245 913

NXA16405A0T02WF CH64 1640 1491 1093

NXA20605A0T02WF CH64 2060 1873 1373

NXA23005A0T02WF CH64 2300 2091 1533

2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 9

AFE units vacon • 7

2.4 690 Vac units Liquid-Cooled

Table 4. 690 Vac units Liquid-Cooled

Unit

Code Chassis Ith-cont [A] IL-cont [A] IH-cont [A]

NXA01706A0T02WF CH61 170 155 113

NXA02086A0T02WF CH61 208 189 139

NXA02616A0T02WF CH61 261 237 174

NXA03256A0T02WF CH62 325 295 217

NXA03856A0T02WF CH62 385 350 257

NXA04166A0T02WF CH62 416 378 277

NXA04606A0T02WF CH62 460 418 307

NXA05026A0T02WF CH62 502 456 335

NXA05906A0T02WF CH63 590 536 393

NXA06506A0T02WF CH63 650 591 433

NXA07506A0T02WF CH63 750 682 500

NXA08206A0T02WF CH64 820 745 547

NXA09206A0T02WF CH64 920 836 613

NXA10306A0T02WF CH64 1030 936 687

NXA11806A0T02WF CH64 1180 1073 787

NXA13006A0T02WF CH64 1300 1182 867

NXA15006A0T02WF CH64 1500 1364 1000

NXA17006A0T02WF CH64 1700 1545 1133

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

Page 10

vacon • 8 Operation

3. OPERATION

3.1 Main contactor control

The AFE application controls the main contactor of the system with Relay Output RO2. When charging of the DC bus is ready, the main contactor will be closed. The status of the main contactor is

monitored via digital input (Default is DIN4). The digital input used for monitoring is chosen with parameter P2.3.1.4.

NOTE! Main Contactor feedback is required for correct AFE functionality.

Faults can be set to open the main contactor by selecting the response "3=Fault, DC OFF". When a

fault occurs, the drive will open Relay Output RO2 that controls the main contactor after one second

(See wiring details from VACON

ulating before an open command is given. If the DC is still high enough when a fault reset is given,

the drive will close the Relay Output R02.

An external charging circuit is needed to charge the DC bus.

The AFE start up sequence has been illustrated in Figure and fault handling in Figure .

®

NX Active Front End User Manual). Thus the drive will stop mod-

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 11

Operation vacon • 9

Time* 500 ms

Stop

AFE 1

Run

Stop

AFE 2

Run

Stop

AFE 3

Run

Stop

AFE 4

Run

11281.emf

3.2 Quick Start instructions

NOTE! Before taking any commissioning actions, read carefully the safety instructions in VACON®

NXS/P User Manual.

1. Connect the unit according to Figure .

2. Power up the control unit

3. Set Basic parameters G2.1 (see Table 21).

4. Check that the digital input parameters (P2.3.1.1 - P2.3.1.10) have been set according to connections. All the unused input signals must be set to "0 = Not used" state, except for the main

contactor feedback which must be used.

5. Change the control place to I/O (P3.1).

6. Precharge the unit.

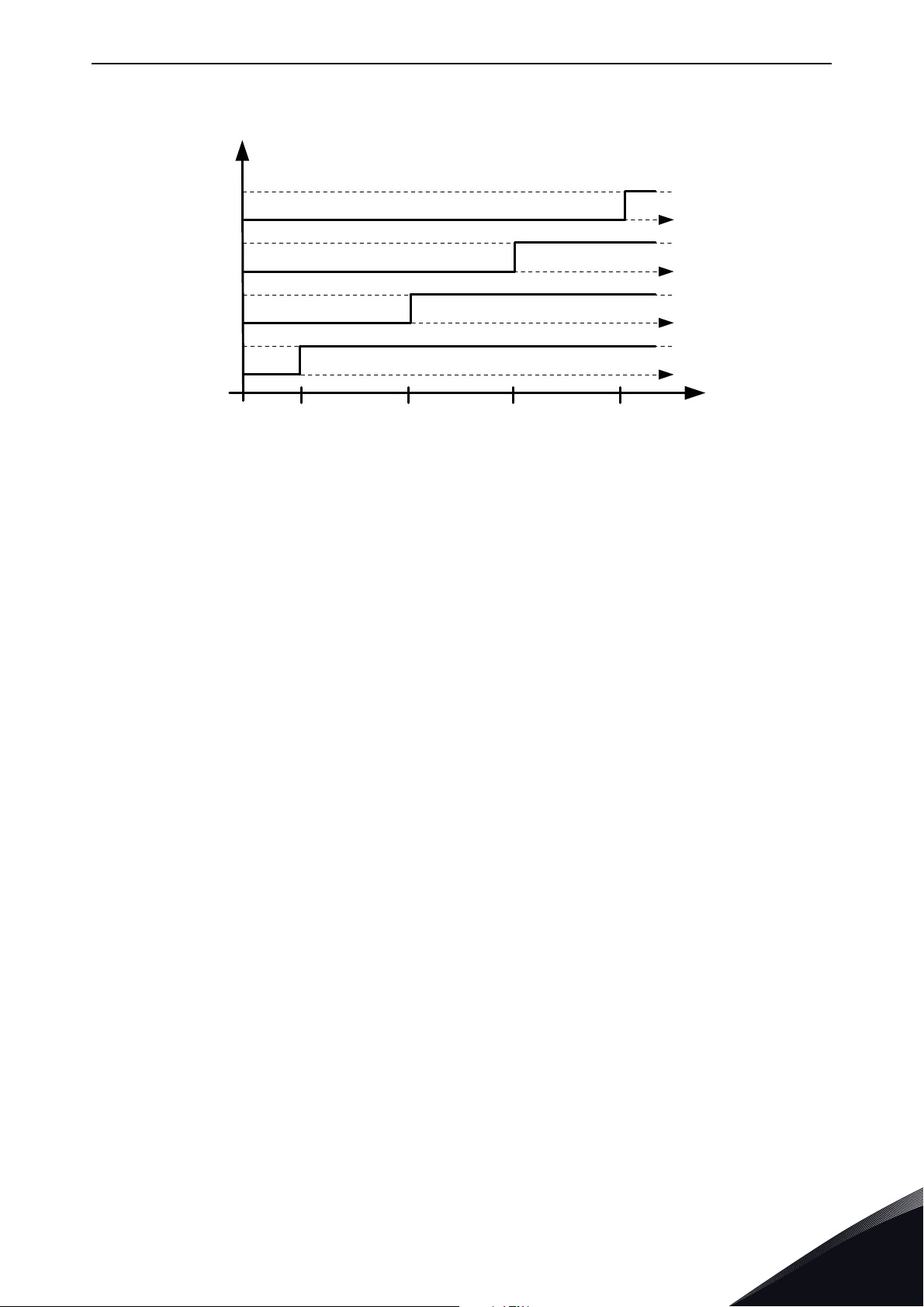

In case of parallel AFE:

1. Set the Parallel AFE parameter (P2.1.4) = YES (in every AFE). (This will set also DC Drooping to

4.00%)

2. Set the Start Up Delay in AFE units so that starting is in sequence with e.g. 500 ms intervals.

Figure 2.

Figure 3.Setting the Start Up Delay in AFE units

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 12

vacon • 10 Operation

Init

SoftwareInit

complete

11282.emf

Ready to

switch on

Charging the DC link

with external charging circuit

DC link voltage

> 0.8*DC nominal?

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Main Conctactor

Close throughRO2

RunEnable (P2. 3.1.1)

And

Main contactor Ack (P2.3.1.4)?

(programmable)

Ready to Run

(Ready led is on)

Run command from I/O,

Keypad or Fieldbus. Depends

on the se lected contro l place (P3.1)

Startup delay

(P2.6.3) elapsed?

Synchronise

with mains

Synchnronizing

OK?

Synchnronizing

tries > 5

AFE Running

(Ready led is on)

Fault F10:

LineSyncFail

Figure 4. AFE start sequence

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 13

Operation vacon • 11

11284.emf

AFE Running

Fault active

Stop the AFE

Is response

Main contactor

open?

Yes

No

Faul t ack nowle dge

Main contactor

open

Main contactor

close

Fault

acknowledge

Figure 5.Fault handling in AFE application

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

3

Page 14

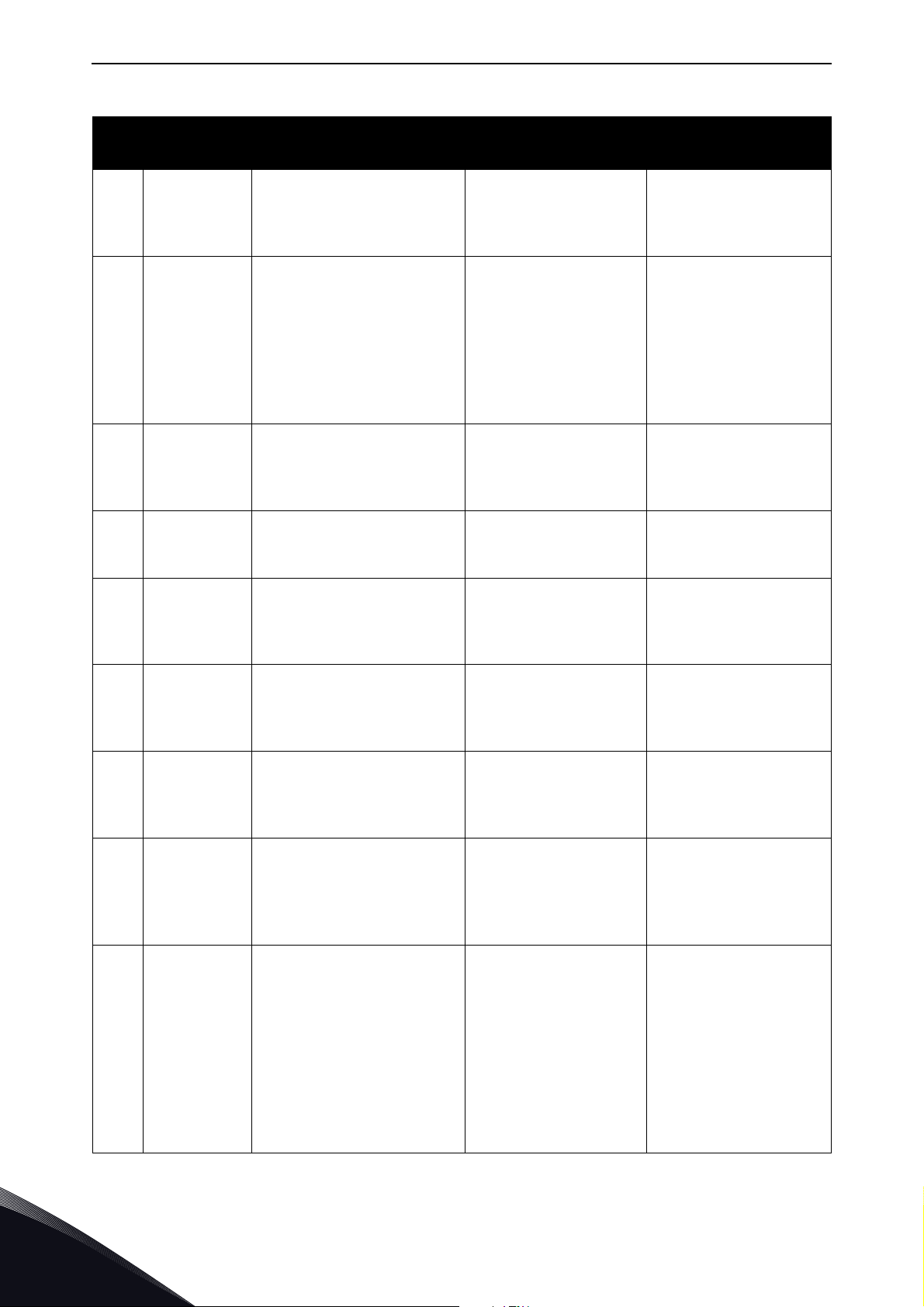

vacon • 12 CONTROL IO

K1

NXOPTA1

NXOPTA2

Termi nal Sig nal Description

1

+10 Vref Reference voltege output

2

AI1+

Analogue input 1.•

Range 0-10V, Ri= 200

Ω

Range 0-20 nA, Ri= 250

Ω

Analogue input 2.•

Range 0-10V, Ri= 200Ω•

Range 0-20 nA, Ri= 250Ω

3

AI1-

I/O ground

4

AI2+

5

AI2-

6

+24V

7

GND I/O ground

8

DIN1

Contact closed = Start Request

9

DIN2

10

DIN3

11

CMA

Common for DIN 1—DIN 3

12

+24V

13

GND I/O ground

14

DIN4

Contact closed = MCC Closed

15

DIN5

16

DIN6

Rising edge will reset•

active faults.

17

CMB

18

AOA1+

Output range selected by jumpers.

Range 0—20 mA. R

L

, max. 500Ω

Range 0—10 V. R

L

> 1kΩ

19

AOA1-

20

21

22

23

DOA1

Digital output

Ready / Warning (Blinking)

mA

9429_uk

Voltege for•

potentiometer, etc.

Analogue input 1Input range

selected by jumpers.

Default range: Voltage 0–10 V

Ground for reference

and controls

Ground for reference

and controls

Analogue input 2

Input range selected by

jumpers.

Default range:•

Current 0 – 20 mA

Voltage for switches, etc.

max 0.1 A

Start Request

Programmable G2.3.1

Programmable G2.3.1

Programmable P2.3.1

No function defined at default

No function defined at default

No function defined at default

Connect to GND or +24V

Voltage for switches (see #6)

Ground for reference and

controls

Main Contactor Acknowledge

Programmable G2.2.1

Fault Reset

Programmable G2.3.1

Connect to GND or +24V

Analogue output 1

Programmable G2.3.1

Programmable

Open collector, I≤50mA,

U≤48 VDC

RO 1

RO 1

RO 1

24

25

26

RO 2

RO 2

RO 2

Relay output 1

Run State

Programmable G2.4.2

Relay output 2

Main Contactor Control

Cannot be reprogrammed

G2.4.1

Switchin capacity

24 VCD / 8 A

250 VAC / 8 A

125 VDC / 0.4 A

Fixed to main contactor

control.

Closes when DC at 80 % of

nominal DC.

Opens when DC below 75 %•

of nominal DC

220

VAC

K1

Control voltage output

Programmable G2.3.1

Common for DIN4—DIN6

4. CONTROL IO

Table 5. Default I/O configuration

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 15

CONTROL IO vacon • 13

OPT-B5

22

23

25

9430_uk

RO 1•

common

RO 2•

common

RO 3•

common

RO 1 NO

26

28

29

RO 2

RO 3

Relay output 1

Fault

Relay output 2

Warning

Relay output 3

Temperature warning

Switching capacity 24VDC/8A•

250VAC/8A•

125VDC/0.4A

Switching capacity 24VDC/8A•

250VAC/8A•

125VDC/0.4A

Switching capacity 24VDC/8A•

250VAC/8A•

125VDC/0.4A

The default I/O configuration if the option card PT-B5 is used:

Table 6. Default I/O configuration

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

Page 16

vacon • 14 AFE Application - Monitoring values

5. AFE APPLICATION - MONITORING VALUES

This chapter presents the lists of parameters within the respective parameter groups.

Column explanations

Code

Parameter = Name of the parameter

Min = Minimum value of the parameter

Max = Maximum value of the parameter

Unit = Unit of the parameter value; given if available

Default = Value preset by factory

Cust = Customer's own setting

ID = ID number of the parameter

The manual presents the signals that are not normally visible for monitoring. These are not parameters or standard monitoring signals. These signals are presented with [Letter], e.g. [FW]MotorRegulatorStatus.

[V] Normal monitoring signal

[P] Normal parameter in application.

[FW]

[A]

Firmware signal, can be monitored with NCDrive when signal type Firmware is

selected

Application signal, can be monitored with NCDrive when signal type Application is

selected

= Location indication on the keypad; shows the operator the present parameter

number

[R] Reference type parameter on keypad.

[F] Function. Signal is received as an output of function.

[DI] Digital input signal.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 17

AFE Application - Monitoring values vacon • 15

5.1 Monitoring values

The monitoring values are actual values of parameters and signals as well as statuses and measurements. Monitoring values cannot be edited.

5.1.1 Monitoring 1

Table 7. Monitoring 1

Code Signal Unit ID Description

V1.1.1 DC Voltage V 1108 Measured DC Link voltage in Volts

Used DC voltage reference by the

regenerative unit in percentage of

Nominal DC Voltage.

Nominal DC voltage = 1.35 * Supply

voltage

V1.1.2

Used DC Voltage

Reference

% 1200

V1.1.3 Total Current A 1104

V1.1.4 Active Current % 1125

V1.1.5 Reactive Current % 1157

V1.1.6 Active Power kW 1511

V1.1.7 Power % % 5

V1.1.8 Status Word 43

V1.1.9 Supply Frequency Hz 1101

V1.1.10 Supply Voltage V 1107

Total current of the regenerative unit

in Amperes.

Reactive current of the regenerative

drive in percentage of Rated Line

Current.

> 0 power from AC side to DC side

< 0 power from DC side to AC side

Reactive current of the regenerative

drive in percentage of Rated Line

Current.

> 0 Inductive current

< 0 Capacitive current

> 0 power from AC side to DC side

< 0 power from DC side to AC side

> 0 power from AC side to DC side

< 0 power from DC side to AC side

Supply frequency in ##.## Hz. The

sign indicates the phase order.

Input AC voltage, RMS line to line

Volts.

V1.1.11 Line Frequency D7 Hz 1654 Measured line frequency by OPT-D7

V1.1.12 Line Voltage D7 V 1650 Measured line voltage by OPT-D7

Signed phase difference compared

V1.1.13 D7 Synch.Error 1659

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

to measurement with optD7 card (-

3072...3071) = -180...180deg

5

Page 18

vacon • 16 AFE Application - Monitoring values

5.1.2 Monitoring values 2

Table 8. Monitoring values 2

Code Signal Unit ID Description

V1.2.1 Unit Temperature °C 1109 Heat sink temperature

V1.2.2 Current A 1113 Unfiltered current

V1.2.3 DC Voltage V 44 Unfiltered DC Voltge

V1.2.4 Operation Hours h 1856 Operation hours in format of #,##

V1.2.5

V1.2.6 Line Votlage THD % 1670

Reactive Current

Reference

% 1389

Used reactive current reference

100.0 = Rated Line Current

Total harmonic distortion of the

line voltage

5.1.3 FieldBus Monitoring values

Table 9. FieldBus Monitoring values

Code Signal Unit ID Description

V1.3.1 Main Control Word 1160 Control word from fieldbus

V1.3.2 Main Status Word 1162 Status word to fieldbus

V1.3.3 Fault Word 1 1172

V1.3.4 Fault Word 2 1173

V1.3.5 Warning Word 1 1174 Alarm Word 1

V1.3.6 Warning 74 Last active warning code

V1.3.7 Fault History 37 Last active fault

V1.3.8 Aux Control Word 1 1161

V1.3.9 Aux Status Word 1163

5.1.4 IO Monitoring values

Table 10. IO Monitoring values

Code Signal Unit ID Description

V1.4.1 DIN1, DIN2, DIN3 15

V1.4.2 DIN4, DIN5, DIN6 16

V1.4.3 DIN Status 1 56

V1.4.4 DIN Status 2 57

V1.4.5 Analogue Input 1 % 13

V1.4.6 Analogue Input 2 % 14

V1.4.7 Analogue Out 1 % 26

V1.4.8 PT100 Temp. 1 °C 50

V1.4.9 PT100 Temp. 2 °C 51

V1.4.10 PT100 Temp. 3 °C 52

Digital Inputs A1, A2 and A3

Status (sum)

Digital Inputs B4, B5 and B6

Status (sum)

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 19

AFE Application - Monitoring values vacon • 17

Table 10. IO Monitoring values

Code Signal Unit ID Description

V1.4.11 DO1, RO1, RO2 17

Digital Output and Relay 1&2

Status (sum)

5.1.5 Unit Monitoring Values

Table 11. Unit Monitoring Values

Code Signal Unit ID Description

V1.5.1 Unit Nominal Voltage V 1117 Unit rated AC Voltage

V1.5.2 Unit Nominal Current A 1118

V1.5.3 U Phase Current A 1149 U Phase RMS current

V1.5.4 V Phase Current A 1150 V Phase RMS current

V1.5.5 W Phase Current A 1151 W Phase RMS current

5.1.6 Monitoring 1 values

V1.1.1 DC-

LINK VOLTAGE [# V] ID 1108

Measured DC voltage, filtered.

V1.1.2 U

SED DC VOLTAGE REFERENCE [#,## %] ID 1200

Used DC voltage reference by the regenerative unit in percentage of Nominal DC Voltage.

Nominal DC Voltage = Supply Voltage * 1.35

DC Voltge = Supply Voltage * 1.35 * Boost

e.g.

621 Vdc = 400 Vac * 1.35 * 1.15

V1.1.3 T

OTAL CURRENT [A] ID 1104

Total current of the regenerative unit in Amperes, filtered.

V1.1.4 A

CTIVE CURRENT [#,# %] ID 1125

Active current in percentage of System Rated Current. A negative value means that the current is

flowing to AC side from DC side i.e. regenerating.

V1.1.5 R

EACTIVE CURRENT [#,# %] ID 1157

Reactive current of the regenerative drive in percentage of System Rated Current.

Positive value means Inductive current.

Negative value means capacitive current.

V1.1.6 P

OWER KW [KW] ID 1511

Drive output power in kW.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 20

vacon • 18 AFE Application - Monitoring values

A negative value means that current is flowing to AC side from DC side i.e. regenerating.

V1.1.7 P

OWER % [#,# %] ID 5

Drive output power in percentage.

A negative value means that current is flowing to AC side from DC side i.e. regenerating.

V1.1.8 S

TATUS WORD (APPLICATION) ID 43

Application Status Word combines different drive statuses to one data word.

Table 12. Application Status Word

FALSE TRUE

b0

b1 Not in Ready state Ready

b2 Not Running Running

b3 No Fault Fault

b4 Positive frequency Negative frequency

b5 No fault or AutoResetFault Fault or Auto Reset Fault

b6 Run Disabled Run Enable

b7 No Warning Warning

b8 Charging Switch closed (internal)

b9 Main Contactor Control (DO Final)

b10 Main Contactor Feedback

b11

b12 No Run Request Run Request

b13 Motoring Side Generator Side

b14 F1, F31 or F41 active

b15

V1.1.9 S

UPPLY FREQUENCY [#,## HZ] ID 1101

Supply frequency in ##.## Hz .The sign indicates the phase order. Updated when the drive is in run

state. Updated also in stop state when OPT-D7 is used or Regen Options B9 is activated.

V1.1.10 S

UPPLY VOLTAGE [#,# V] ID 1107

Input AC voltage, RMS line to line Volts. Updated when the drive is in run state.

Updated also when OPT-D7 is used.

V1.1.11 L

INE FREQUENCY [#,## HZ] ID 1654

Measured Line Voltage Frequency when using OPT-D7 option board in slot C.

5

V1.1.12 L

INE VOLTAGE [# V] ID 1650

Measured line voltage rms value when using OPT-D7 option board in slot C.

V1.1.13 D7 S

YNCH ERROR [# V] ID 1659

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 21

AFE Application - Monitoring values vacon • 19

Voltage angle error between OPT-D7 line voltage and AFE unit voltage. If error is not close to zero

when in run state phase order of OPT-D7 may be wrong.

5.1.7 Monitoring 2 values

V1.2.1 U

NIT TEMPERATURE [# °C] ID 1109

Temperature of the unit in degrees Celsius.

V1.2.2 C

URRENT [A] ID 1113

Unfiltered current of the drive.

V1.2.3 DC V

OLTAGE [# V] ID 44

Unfiltered DC Voltage.

V1.2.4 O

PERATION HOURS [#,## H] ID1856

This shows operation hours of the drive. P2.6.7 is used to enter the old value if software is updated.

V1.2.5 R

EACTIVE CURRENT REFERENCE [#,# %] ID1389

Used reactive current reference 100.0 = Rated Line Current.

Positive value means Inductive current.

Negative value means capacitive current.

V1.2.6 L

INE VOLTAGE THD ID1670

OPT-D7 measured line voltage THD.

5.1.8 Fieldbus monitoring values

V1.3.1 M

AIN CONTROL WORD ID 1160

Control word from fieldbus. The table below is for the bypass operation for such fieldbus board that

natively supports this or can be parameterized to bypass mode.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 22

vacon • 20 AFE Application - Monitoring values

Table 13. Main Control Word

FALSE TRUE

b0 DC charge Contactor close

b1 OFF2 =Stop

b2 Reserved for future use.

b3 Run

b4 Reserved for future use.

b5 Reserved for future use.

b6 Reserved for future use.

b7 Reset 0>1 Reset fault.

b8 Set DC Voltage Ref 1

b9 Set DC Voltage Ref 2

b10 Fieldbus Control

b11 Watchdog

0= No Action

1= Close DC charge contactor

0=stop Active. Regenerative control is

stopped.

1=stop not active

0= Drive stop command

1= Drive start command

DC Voltage Reference 1, see details in

Chapter 8.4 "FB Reference Control".

DC Voltage Reference 2, see details in

Chapter 8.4 "FB Reference Control".

0= No control from fieldbus

1=Control from fieldbus

0>1>0>1…1 sec square wave clock.

This is used to check the data communication between fieldbus master

and the drive. Used to generate FB

Comm. Fault. This monitoring can be

switched off by setting P2.8.4.2 FB

Watchdog Delay=0. The drive’s internal communication monitoring is still

active at this time.

5

b12 Reserved for future use.

b13 Reserved for future use.

b14 Reserved for future use.

b15 Reserved for future use.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 23

AFE Application - Monitoring values vacon • 21

V1.3.1 MAIN CONTROL WORD (IN DEVICENET) ID 1160

Table 14. Main Control Word (in DeviceNet)

FALSE TRUE

b0 Run

b1

b2 Reset 0>1 Reset fault.

b3

b4

b5 Fieldbus Control

b6

b7

b8

b9

b10

b11

b12

b13

b14

b15

0= Drive stop command

1= Drive start command

0= No control from fieldbus

1=Control from fieldbus

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 24

vacon • 22 AFE Application - Monitoring values

V1.3.2 MAIN STATUS WORD ID 1162

Status word to fieldbus. The table below gives details for the bypass operation of such fieldbus

boards that natively support this or can be parameterized to bypass mode.

Table 15. Main Status Word

FALSE TRUE

0=Drive not ready to switch on

b0 Ready On

b1 Ready Run

b2 Running

b3 Fault

b4 Off2 Status

b5 Reserved for future use.

b6 Reserved for future use.

1=Drive ready to switch Main Contactor ON

0=Drive not ready to run

1=Drive ready and Main Contactor is

ON

0=Drive not running

1=Drive in Run state (Modulating)

0=No active fault

1=Fault is active

0= Run Disabled. Drive in stop state

1= Run Enabled. Drive can be started.

b7 Warning

b8 At Reference

b9 Fieldbus Control Active

b10 Above Limit

b11 Reserved for future use.

b12 Reserved for future use.

b13 Reserved for future use.

b14 Reserved for future use.

b15 Watchdog

0= No active warnings

1= Warning active

0= DC Voltage Ref and Act DC Voltage

are not same.

0=Fieldbus control not active

1=Fieldbus control active

0= DC Voltage is below the level specified by P2.5.6.1

1=The DC Voltage is above the specified level by P2.5.6.1

Same as received on bit 11 of the

main control word.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 25

AFE Application - Monitoring values vacon • 23

V1.3.3 FAULT WORD 1 ID 1172

Table 16. Fault Word 1

FALSE TRUE

b0 Over Current F1

b1 Overvoltage F2

b2 Under voltage F9

b3 Not used

b4 Earth Fault F3

b5 Not used

b6 Unit Over Temperature F14

b7 Over Temperature F59, F56, F71

b8 Input Phase loss F11

b9 Not used

b10 Device Fault F37, F38, F39, F40, F44, F45

b11 Not used

b12 Not used

b13 Not used

b14 Not used

b15 Not used

V1.3.4 F

b0 Not used

b1 Charging Switch Fault F5

b2 Not used

b3 Drive Hardware fault F4, F7

b4 Under Temperature F13

b5 EPROM or Checksum fault F22

b6 External fault F51

b7 Not used

b8 Internal Communication F25

b9 IGBT Temperature F31, F41

AULT WORD 2 ID 1173

Table 17. Fault Word 2

FALSE TRUE

b10 Not used

b11 Cooling fan F32, F70

b12 Application fault F35

b13 Drive Internal fault F33, F36, F8, F26

b14 Main Switch open F64

b15 Not used

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 26

vacon • 24 AFE Application - Monitoring values

V1.3.5 WARNING WORD 1 ID 1174

Table 18. Warning Word 1

FALSE TRUE

b0 Not used

W29: Thermistor warning,

b1 Temperature protection

b2

b3 Supply Phase Warning W11

b4 Not used

b5 Not used

b6 Not used

b7 Drive over temperature W14

b8 Not used

b9 Not used

b10 Fan Warning

b11 Not used

b12 Not used

W56: FPT100 warning or

W71: LCL over temperature warning

W32: Fan Cooling

W70: LCL Fan monitor warning

b13 Not used

b14 Not used

b15 Not used

V1.3.6 W

Last active warning number.

V1.3.7 L

Last active fault number.

ARNING ID74

AST ACTIVE FAULT ID37

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 27

AFE Application - Monitoring values vacon • 25

V1.3.8 AUX CONTROL WORD ID 1161

Table 19. Aux Control Word

FALSE TRUE

b0 Reserved for future use.

b1 Reserved for future use.

b2 Reserved for future use.

b3 Reserved for future use.

b4 Reserved for future use.

b5 Reserved for future use.

b6 Reserved for future use.

b7 Reserved for future use.

b8 Reserved for future use.

b9 Reserved for future use.

b10 Reserved for future use.

b11 Reserved for future use.

0= DC Voltage Level control from

Main Control Word (MCW) is not

b12

b13 DO control

b14 Reserved for future use.

b15 Reserved for future use.

Enable DC Level control from

MCW

active and DC Voltage reference is

from fieldbus data (reference value).

1= DC Voltage Level control from

MCW is enabled

This signal can be connected to digital output with parameters in G2.4.1

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 28

vacon • 26 AFE Application - Monitoring values

V1.3.8 AUX CONTROL WORD (IN DEVICE NET) ID 1161

Table 20. Auxiliary Control Word (in DeviceNet)

FALSE TRUE

b0 DC charge Contactor close

b1 OFF2 =Stop

b2 Set DC Voltage Ref 1

b3 Set DC Voltage Ref 2

b4 Watchdog

b5 Reserved for future use.

b6 Reserved for future use.

0= No Action

1= Close DC charge contactor

0=stop Active. Regenerative control is

stopped.

1=stop not active

DC Voltage Reference 1. For details,

see Chapter 8.4 "FB Reference Control".

DC Voltage Reference 2, see detail

from Chapter 8.4 "FB Reference Control".

0>1>0>1…1 sec square wave clock.

This is used to check data communication between fieldbus master and

the drive. Used to generate FB

Comm. Fault. This monitoring can be

switched off by setting P2.8.4.2 FB

Watchdog Delay=0. The drive’s internal communication monitoring is still

active at this time.

b7 Reserved for future use.

b8 Reserved for future use.

b9 Reserved for future use.

b10 Reserved for future use.

b11 Reserved for future use.

b12

b13 DO control

b14 Reserved for future use.

b15 Reserved for future use.

V1.3.9 A

Reserved for future use.

Enable DC Level control from

UX STATUS WORD ID 1163

MCW

0= DC Voltage Level control from

Main Control Word (MCW) is not

active and DC Voltage reference is

from fieldbus data (reference value).

1= DC Voltage Level control from

MCW is enabled

This signal can be connected to digital output with parameters in G2.4.1

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 29

AFE Application - Monitoring values vacon • 27

5.1.9 IO Monitoring values

V1.4.1 DIN1, DIN2, DIN3 ID 15

V1.4.2 DIN4, DIN5, DIN6 ID 16

DIN1/DIN2/DIN3 status DIN4/DIN5/DIN6 status

b0 DIN3 DIN6

b1 DIN2 DIN5

b2 DIN1 DIN4

V1.4.3 DIN S

V1.4.4 DIN S

b0 DIN: A.1 DIN: C.5

b1 DIN: A.2 DIN: C.6

b2 DIN: A.3 DIN: D.1

b3 DIN: A.4 DIN: D.2

b4 DIN: A.5 DIN: D.3

b5 DIN: A.6 DIN: D.4

b6 DIN: B.1 DIN: D.5

b7 DIN: B.2 DIN: D.6

b8 DIN: B.3 DIN: E.1

b9 DIN: B.4 DIN: E.2

b10 DIN: B.5 DIN: E.3

b11 DIN: B.6 DIN: E.4

b12 DIN: C.1 DIN: E.5

b13 DIN: C.2 DIN: E.6

TATUS 1 ID 56

TATUS 2 ID 57

DIN Status Word 1 DIN Status Word 2

b14 DIN: C.3

b15 DIN: C.4

V1.4.5 A

V1.4.6 A

NALOGUE INPUT 1 [#,## %] ID13

NALOGUE INPUT 2 [#,## %] ID14

Unfiltered analogue input level.

0% = 0 mA / 0 V, -100% = -10 V, 100% = 20 mA / 10 V.

Monitoring scaling is determined by the option board parameter.

V1.4.7 A

NALOGUE OUT 1 [#,## %] ID 26

Analogue Output value 0% = 0 mA / 0 V, 100% = 20 mA / 10 V.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

Page 30

vacon • 28 AFE Application - Monitoring values

V1.4.8 PT100 TEMP. 1 [#,# °C] ID 50

V1.4.9 PT100 T

V1.4.10 PT100 T

EMP. 2 [#,# °C] ID 51

EMP. 3 [#,# °C] ID 52

Separate measurement from PT100 board. The signal has 4 s filtering time.

V1.4.11 DO1, RO1, RO2 ID 17

Digital Output and Relay 1&2 Status (sum).

5.1.10 Unit Monitoring values

V1.5.1 U

NIT NOMINAL VOLTAGE [# V] ID 1117

Unit rated AC voltage in volts.

V1.5.2 U

NIT NOMINAL CURRENT [A] ID 1118

Nominal current rating of the converter in Amperes. Unit Ih Current.

V1.5.3 U P

HASE CURRENT [A] ID 1149

U Phase RMS current.

V1.5.4 V P

HASE CURRENT [A] ID 1150

V Phase RMS current.

V1.5.5 W P

HASE CURRENT [A] ID 1151

W Phase RMS current.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 31

AFE Application - Parameter lists vacon • 29

6. AFE APPLICATION - PARAMETER LISTS

This chapter presents the lists of parameters within the respective parameter groups.

Column explanations

Code

Parameter = Name of the parameter

Min = Minimum value of the parameter

Max = Maximum value of the parameter

Unit = Unit of the parameter value; given if available

Default = Value preset by factory

Cust = Customer's own setting

ID = ID number of the parameter

The manual presents the signals that are not normally visible for monitoring. These are not parameters or standard monitoring signals. These signals are presented with [Letter], e.g. [FW]MotorRegulatorStatus.

[V] Normal monitoring signal

[P] Normal parameter in application.

[FW]

[A]

Firmware signal, can be monitored with NCDrive when signal type Firmware is

selected

Application signal, can be monitored with NCDrive when signal type Application is

selected

= Location indication on the keypad; shows the operator the present parameter

number

[R] Reference type parameter on keypad.

[F] Function. Signal is received as an output of function.

[DI] Digital input signal.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 32

vacon • 30 AFE Application - Parameter lists

6.1 Basic parameters

Table 21. Basic parameters

Code Parameter Min Max Unit Default ID Note

500V:

380V

P2.1.1 Rated Line Voltage

690V:

525V

P2.1.2 Rated Line Current 0.0 I

P2.1.3 Rated Line Power 0 32000 kW 0 116 Motor nominal shaft power.

P2.1.4 Parallel AFE 0 1 0 1501

500V:

50V

690V:

690V

L

500V:

400

V

690 V:

690 V

AIH113

1201

Set here the nominal voltage of

the grid.

Capacity of supply, used if

oversized AFE.

0 = single AFE

1 = parallel AFE

Activation will set DC Drooping to

4%.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 33

AFE Application - Parameter lists vacon • 31

6.2 Reference Handling

Table 22. Reference handling

Code Parameter Min Max Unit Default ID Note

500V:

105%

P2.2.1 DC Voltage Ref.

690V:

105%

P 2.2.2 DC Voltage Drooping 0.00 100.00 0.00 620

P 2.2.3

P2.2.4 ReactiveCurr.Ref -100.0 100.0 % 0.0 1459

Reactive Current

Reference Selector

0 2 0 1384

500V:

130%

% 110.00 1462

690V:

115%

DC Voltage reference as

percentage of Nominal DC Voltage

Nominal DC voltage = 1.35 *

Supply voltage

AFE drooping DC-voltage. Set to

4.00% when parallel AFE

operation is selected

Reactive current reference

source:

0 = Panel

1 = Analogue Input 1

2 = Analogue Input 2

Regenerative reactive

current reference 100.0 =

nominal current.

Positive =Inductive

Negative = Capacitive

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 34

vacon • 32 AFE Application - Parameter lists

6.3 Input signals

6.3.1 Digital inputs

Table 23. Digital input parameters

Code Parameter Min Max Unit Default ID Description

0 = Not used

1 = DIN1

2 = DIN2

P2.3.1.1 Run Request 0 6 1 1206

P2.3.1.2

Open Contactor

(Forced Open)

0 12 0 1508

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

0 = Not used

1 = DIN1

2 = DIN2

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

7 = DIN1 (inverted)

8 = DIN2 (inverted)

9 = DIN3 (inverted)

10 = DIN4 (inverted)

11 = DIN5 (inverted)

12 = DIN6 (inverted)

P2.3.1.3

P2.3.1.4

P2.3.1.5

P2.3.1.6 Fault Reset 0 6 6 1208 As par. P2.3.1.1

P2.3.1.7 External fault 0 12 0 1214 As par. P2.3.1.2

P2.3.1.8 Run Enable 0 6 0 1212 As par. P2.3.1.1

P2.3.1.9 Cooling Monitor 0 6 0 750 OK input from the cooling unit

P2.3.1.10

LCL Temperature

monitoring X52

Main contactor

Acknowledge

LCL Fan Monitoring

(X51)

LCL Temperature

monitoring X51

0 12 0 1179 As par. P2.3.1.2

0 = 3s start Delay

1 = DIN1

2 = DIN2

0 6 4 1453

0 12 0 1178 As par. P2.3.1.2

0 12 0 1180 As par. P2.3.1.2

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 35

AFE Application - Parameter lists vacon • 33

6.3.2 Analogue inputs

Table 24. Analogue input parameters

Code Parameter Min Max Unit Default ID Description

Minimum voltage or

Current at AI1.

0 = 0 V / 0 A

1 = 2 V / 4 mA

P2.3.2.1

Analogue Input 1

Minimum

0 1 0 1227

P2.3.2.2

P2.3.2.3

P2.3.2.4

Analogue Input 1 Filter

Time

Analogue Input 2

Minimum

Analogue Input 2 Filter

Time

0.00 10.00 s 1.00 1228

0 1 0 1231

0.00 10.00 s 1.00 1232

Filter time for AI1 in ###.## sec.

0 = No filtering

Minimum voltage or

Current at AI2 in.

0 = 0 V / 0 A

1 = 2 V / 4 mA

Filter time for AI2 ###.## sec.

0 = No filtering

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 36

vacon • 34 AFE Application - Parameter lists

6.4 Output signals

6.4.1 Digital Outputs

Table 25. Digital output parameters

Code Parameter Min Max Unit Default ID Description

Signal selection for DO1.

0 = DO Control from FB

(AuxControlWord, bit 13)

1 = Ready

2 = Running

3 = Fault

P2.4.1.1

Digital output 1

function

0 11 9 1216

4 = No Fault

5 = Warning

6 = At Reference

7 = Regen Active

8 = Charge DC

9 = Ready / Warning (blink).

10 = Temperature Warning.

11 = DC Voltage Above Limit

P2.4.1.2

P2.4.1.3

P2.4.1.4 DO4 0 11 3 1385 Digital Output 4 function

P2.4.1.5 DO5 0 11 5 1386 Digital Output 5 function

P2.4.1.6 DO6 0 11 10 1390 Digital Output 6 function

P2.4.1.7 DO7 0 11 0 1391 Digital Output 7 function

P2.4.1.8 DO8 0 11 0 1395 Digital Output 8 function

P2.4.1.9 DO9 0 11 0 1396 Digital Output 9 function

P2.4.1.10 DO10 0 11 0 1423 Digital Output 10 function

P2.4.1.11 DO11 0 11 0 1427 Digital Output 11 function

P2.4.1.12 DO12 0 11 0 1428 Digital Output 12 function

P2.4.1.13 DO13 0 11 0 1429 Digital Output 13 function

Relay Output 1

function

Relay Output 2

function

0 11 2 1217

00 01218

Signal selection for the digital

indication through RO1.

Main Contactor Control

Slot B, Output 2

This parameter cannot be

changed.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 37

AFE Application - Parameter lists vacon • 35

6.4.2 Analogue Output 1

Table 26. Analog Output 1 parameters

Code Parameter Min Max Unit Default ID Description

P2.4.2.1 AO1 Signal ID 0 2000 0 1233

P2.4.2.2 AO1 Offset 0 1 0 1234

P2.4.2.3 AO1 Filter 0.02 10.00 s 10.00 1235 Filter time for AO1 in ##.## sec.

P2.4.2.4 AO1 Max Value -30000 30000 1500 1236

P2.4.2.5 AO1 Min Value -30000 30000 0 1237

Set the ID no. of a signal to be

connected to AO1.

Minimum voltage or current at

AO1.

0= OV/0mA.

1= 2V/4mA

Maximum value of a signal

connected to AO1. This will

correspond to +10V/20mA.

Minimum value of a signal

connected to AO1. This will

correspond to 0V/0mA or 2V/4mA

depending on the AO1 Offset

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 38

vacon • 36 AFE Application - Parameter lists

6.5 Limit Settings

6.5.1 Current Limit

Table 27. Current Limit

Code Parameter Min Max Unit Default ID Description

P2.5.1.1 Current Limit 0 Varies A I

L

107 Total current limit

6.5.2 Power Limit

Table 28. Power Limit

Code Parameter Min Max Unit Default ID Description

P 2.5.2.1

P 2.5.2.2

Power Limit Motoring

Side

Power Limit Generator

Side

0 300 % 300 1289

0 300 % 300 1290

Motoring power limit in AFE mode

to DC-link.

Generating power limit in AFE

mode to grid.

6.5.3 Auto Start Stop

Table 29. Auto Start Stop

Code Parameter Min Max Unit Default ID Description

P2.5.3.1 Start/Stop Function 0 1 0 1274

P2.5.3.2 Auto Stop Level -100.0 100.0 % -3.0 1099

0 = Normal

1 = Auto

P2.5.3.4 Minimum Run Time 0 32000 ms 100 1281

P2.5.3.5 Stop delay 0 32000 ms 1000 1282

6.5.4 DC Voltage

Table 30. DC Voltage

Code Parameter Min Max Unit Default ID Description

P2.5.4.1

DC Voltage

Supervision Limit

0 1100 V 600 1454

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 39

AFE Application - Parameter lists vacon • 37

6.6 Drive Control parameters

Table 31. Drive control parameters

Code Parameter Min Max Unit Default ID Description

P2.6.1 Switching frequency 3.6 Varies kHz 3.6 601 Switching frequency

This packed bit word is made for

P2.6.2 Regen Options 1 0 65535 544 1463

P2.6.3 Regen Options 2 0 65535 0 1464

P2.6.4 Start Up Delay 0.00 320.00 s 0.00 1500

P2.6.5 Modulator Type 0 4 1 1516

enabling/ disabling different

control options for regeneration

control.

Starting delay when run

command is given. When you

program different delays to the

paralleled units, the units will

start in sequence.

0 = Hardware

1 = Software 1

2 = Software 2

3 = Software 3

4 = Software 4

P2.6.6 Control Options 0 65536 0 1798

P2.6.7 Operation Time 0 2^32 0 1855 Stored AFE Running time

Control word for activating special

features.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 40

vacon • 38 AFE Application - Parameter lists

6.7 Control parameters

Table 32. Control parameters

Code Parameter Min Max Unit Default ID Description

P2.6.8.1 Voltage Controller Kp 0 32000 200 1451

P2.6.8.2 Voltage Controller Ti 0 1000 ms 50 1452

P2.6.8.3 Active current Kp 0 4000 400 1455 Active current controller gain.

P2.6.8.4 Active current Ti 0.0 100.0 ms 1.5 1456

P2.6.8.5 Sync Kp 0 32000 2000 1457 Synchronization gain

P2.6.8.6 Sync Ti 0 1000 50 1458

P2.6.8.7 Modulator Index Limit 0 200 % 100 655

P2.6.8.8

P2.6.8.9 Capacitor Size 0.0 100.0 % 6.3 1460

P2.6.8.10 Inductor Size 0.0 100.0 % 15.5 1461

P2.6.8.11 DynamicSupportKp 0 32000 0 1797

Main Contactor Start

Delay

0.00 10.00 s 0.40 1519

Gain for the DC voltage controller

of the unit

Integral time for the DC Voltage

controller of the regenerative unit

Active current controller integral

time

Synchronisation integral time (15

= 7ms).

Lower value may improve current

waveform, but causes the DC

voltage to increase when the line

voltage is high.

Start delay from Main Contactor

Acknowledge

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 41

AFE Application - Parameter lists vacon • 39

6.8 Fieldbus parameters

Table 33. Fieldbus parameters

Code Parameter Min Max Unit Default ID Description

P2.7.1

P2.7.2

P2.7.3

P2.7.4

P2.7.5

P2.7.6

P2.7.7

P2.7.8

P2.7.9

P2.7.10

Fieldbus data out 1

selection

Fieldbus data out 2

selection

Fieldbus data out 3

selection

Fieldbus data out 4

selection

Fieldbus data out 5

selection

Fieldbus data out 6

selection

Fieldbus data out 7

selection

Fieldbus data out 8

selection

Fieldbus data in 1

selection

Fieldbus data in 2

selection

0 65535 1104 1490

0 65535 1174 1491

0 65535 1172 1492

0 65535 1173 1493

0 65535 56 1494

0 65535 57 1495

0 65535 0 1496

0 65535 1107 1497

0 65535 0 876

0 65535 1161 877

Choose monitoring data with

parameter ID. Default Total

Current.

Choose monitoring data with

parameter ID. Warning Word 1.

Choose monitoring data with

parameter ID. Fault Word 1.

Choose monitoring data with

parameter ID. Fault Word 2.

Choose monitoring data with

parameter ID. Din Status 1.

Choose monitoring data with

parameter ID. Din Status 2.

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID. Supply Voltage.

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID. Aux Control Word.

P2.7.11

P2.7.12

P2.7.13

P2.7.14

P2.7.15

P2.7.16

P2.7.18 Control Slot Selector 0 8 0 1440

Fieldbus data in 3

selection

Fieldbus data in 4

selection

Fieldbus data in 5

selection

Fieldbus data in 6

selection

Fieldbus data in 7

selection

Fieldbus data in 8

selection

0 65535 0 878

0 65535 0 879

0 65535 0 880

0 65535 0 881

0 65535 0 882

0 65535 0 883

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

Choose monitoring data with

parameter ID

0=All

4=Slot D

5=Slot E

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 42

vacon • 40 AFE Application - Parameter lists

6.9 Protections

6.9.1 General

Table 34. Protections parameters

Code Parameter Min Max Unit Default ID Description

0=No response

2.8.1.1

Response to

Thermistor fault

0 3 1 732

1=Warning

2=Fault

3=Fault, DC OFF

Drive Over

2.8.1.2

2.8.1.3

2.8.1.4 Reserved 1990

2.8.1.5

2.8.1.6 Max Charge Time 0.00 10.00 s 5.00 1522

2.8.1.7

2.8.1.8

2.8.1.9

Temperature Fault

Response

Over Voltage Fault

Response

Input Filter Over

Temp er at ure

Response

Main Contactor on

Fault

Main Contactor Fault

Delay

Input Phase

supervision Fault

Response

2 3 3 1517

2 3 2 1507

0 3 3 1505

0 1 0 1510

0.00 10.00 s 3.50 1521

0 3 2 1518

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

2=Fault

3=Fault, DC OFF

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

Charging time limit when the

drive charging options are used.

0 = Keep closed

1 = Open

Delay for (F64) MCC Open Fault.

Defines the max delay time

between the main contactor close

command and the acknowledge

signal.

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

6

2.8.1.10

2.8.1.11 Fan Fault Response 3 2 1 1524

2.8.1.12

2.8.1.13 Cooling Flt. Delay 0 7 s 2 751

P2.8.5 Reset Data Logger 0 1 0 1857

Response to external

fault

Input Filter Fan Fault

Response

0 3 2 701

3 1 1 1509

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

Page 43

AFE Application - Parameter lists vacon • 41

6.9.2 PT-100

Table 35. PT-100

Code Parameter Min Max Unit Default ID Description

0= Not used

1= Analogue Input 1

2= PT100 input 1

P2.8.2.1 PT100 Inputs 0 6 0 1221

P2.8.2.2 PT100 FaultResponse 0 3 2 / Fault 740

P2.8.2.3 PT100 Warn.Limit -30 200 °C 120 741

P2.8.2.4 PT100 Fault Lim. -30 200 °C 130 742

3= PT100 input 1 & 2

4= PT100 input 1 & 2 & 3

5= PT100 input 2 & 3

6= PT100 input 3

0=No response

1=Warning

2=Fault

3=Fault, DC OFF

6.9.3 Earth fault

Table 36. Earth fault

Code Parameter Min Max Unit Default ID Description

P2.8.3.1 EarthFlt Response 2 5 2 / Fault 1332

P2.8.3.2 EarthFaultLevel 0 100 % 50 1333

P2.8.3.3 Earth Fault Delay 0 30000 ms 800 774

0=No response

1=Fault

6.9.4 Fieldbus

Table 37. Fieldbus

Code Parameter Min Max Unit Default ID Description

P2.8.4.1

P2.8.4.2 FB Watchdog delay 0 5.00 s 2.00 1354

FB Communication

fault response

0 2 1 733

0=No response

1=Warning

2=Fault

Watchdog fault delay for FB

master. The function can be

disabled if set to zero.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

Page 44

vacon • 42 AFE Application - Parameter lists

6.10 Auto reset parameters

Table 38. Auto reset parameters

Code Parameter Min Max Unit Default ID Description

P2.9.1 Wait time 0.10 10.00 s 0.50 717

P2.9.2 Trial time 0.00 60.00 s 30.00 718

P2.9.3

P2.9.4

P2.9.5

P2.9.6 Fault Simulation 0 65535 0 1569

Number of tries after

overvoltage trip

Number of tries after

over current trip

Number of tries after

external fault trip

0 10 0 721

0 3 0 722

0 10 0 725

6.11 DIN ID Control

Table 39. DIN ID Control parameters

Code Parameter Min Max Unit Default Cust ID Description

P2.10.1 ID Control DIN 0.1 E.10 0.1 1570 Slot. Board input No.

P2.10.2 Controlled ID 0 10000 0 1571

P2.10.3 False value -32000 32000 0 1572 Value when DI is low

P2.10.4 True value -32000 32000 0 1573 Value when DI is high

Select ID that is controlled by

digital input

6.12 Keypad control

Table 40. Keypad control parameters

Code Parameter Min Max Unit Default ID Description

0=Fieldbus

P3.1 Control place 2 0 2 1403

1=I/O terminal

2=Keypad (Default)

6.13 System menu

For parameters and functions related to the general use of the AC drive, such as application and

language selection, customised parameter sets or information about the hardware and software,

see the VACON

®

NXS/P User Manual.

6.14 Expander boards

The M7 menu shows the expander and option boards attached to the control board and board-related information. For more information, see the VACON

tion Board User Manual.

®

NXS/P User Manual and VACON® I/O Op-

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 45

Description of parameters vacon • 43

7. DESCRIPTION OF PARAMETERS

7.1 Basic parameters

P2.1.1 RATED LINE VOLTAGE [# V] ID1201

This parameter sets the incoming line voltage for the regenerative drive. The maximum value is 690

V. Set this parameter to the nominal line voltage at the installation site.

P2.1.2 R

Rated current capacity of the supply or the transformer. May need to be set if AFE is oversized compared to LCL or feeding transformer capacity. For testing purposes, the feeding transformer should

not be less than 20% of the unit nominal current or following breakers or fuses.

P2.1.3 R

Set here the rated active power of the system.

P2.1.4 P

0 = Single AFE

1 = Parallel AFE

When selecting the parallel AFE DC, Drooping is set to 4.00% and modulation is synchronized to reduce circulating current if drives are in common DC bus.

ATED LINE CURRENT [A] ID113

ATED LINE POWER [KW] ID116

ARALLEL AFE ID1501

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 46

vacon • 44 Description of parameters

FW

LIMIT

MIN

IN

MAX

105,00 %

SEL

G

IN 0

IN 1

690 Vac Unit

130,00 %

115,00 %

OR

IN 1

IN 2

SEL

G

IN 0

IN 1

A IO_Control

LT

IN 1

IN 2

5,00 %

P DCVoltReference

FB DC Reference

FB DC Reference

7.2 Reference Handling

P2.2.1 DC VOLTAGE REFERENCE [#,## %] ID1462

This parameter sets the DC Voltage reference in percentage of Nominal DC voltage (Nominal DC

voltage = 1.35 * Supply voltage). The DC Voltage will be maintained at this level when the regenerative unit is running. For 500V units the maximum limit is 130% and for 690V units the maximum

limit is 115%. The default value is 110%.

NOTE! DC-link voltage should not exceed the following values:

• 800V for 500V unit

• 1100V for 690V unit

P2.2.2 DC D

When AFEs are used in parallel in independent mode, drooping can be used for current balancing.

The DCV voltage reference drooping is set as percentage of active current reference.

E.g. if drooping is 3.00% and the active current is 50% then the DC voltage reference is reduced by

1.5%. With drooping, the paralleled units can be balanced by adjusting the DCVoltReference to

slightly different values.

P2.2.3 R

This parameter defines which source the Reactive current reference is taken from. If Panel is chosen then the reactive current reference is taken from parameter P2.2.4.

0 = Panel

1 = Analog Input 1

2 = Analog Input 2

If reference value is taken from either of the analog inputs, it is recommended to use bipolar analog

input (-10V…10V, selected with a jumper).

7

Figure 6.DC Voltage Reference Chain

ROOP ID620

EACTIVE CURRENT REFERENCE SOURCE SELECTION ID1384

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 47

Description of parameters vacon • 45

voltage

11286_uk

Reactive current ref. [%]

100,0%

-10V

10V

-100,0%

Input

[V]

Figure 7.Analog input scaling (bipolar)

P2.2.4 R

EACTIVE CURRENT REFERENCE ID1459

This parameter sets the reference for the reactive current in percentage of the rated current. This

can be used for power factor correction of AFE system or reactive power compensation.

A positive value makes inductive power to the grid

A negative value makes capacitive power to the grid.

Reactive current reference is taken from this parameter if panel has been chosen to be the source

for Reactive current reference (P2.2.3 = 0).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 48

vacon • 46 Description of parameters

7.3 Input signals

7.3.1 Digital inputs

P2.3.1.1 R

This parameter is used to choose the input used for the Run Request signal. When controlling the

AFE from I/O this signal must be connected.

0 = Not used

1 = DIN1

2 = DIN2

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

P2.3.1.2 O

This parameter is used to choose the input for the Contactor Open signal. The signal is used to force

the Relay Output RO2 (main contactor) open and stop modulating.

When this input is used to stop AFE and open a main contactor, the DC-link must be discharged and

recharged to close the main contactor again and continue modulation (see Figure ).

If the Force Main Contactor Open signal is not used, choose the option "0 = Not used".

0 = Not used

1 = DIN1

2 = DIN2

3 = DIN3

4 = DIN4

5 = DIN5

6 = DIN6

7 = DIN1 (inverted)

8 = DIN2 (inverted)

9 = DIN3 (inverted)

10 = DIN4 (inverted)

11 = DIN5 (inverted)

12 = DIN6 (inverted)

UN REQUEST ID1206

PEN CONTACTOR ID1508

7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 49

Description of parameters vacon • 47

nominal

(RO2) = 1)

started

11287_uk

DC-link voltage

0.8 * DC

Chargingis

Contactor Open Contactor Close

Figure 8.Contactor Open

P2.3.1.3 LCL T

EMPERATURE MONITOR X52 ID1179 "LCL TEMP. X52"

This parameter defines if the drive monitors the status of the LCL over temperature switch signal.

This wire is marked as "X52" when not using integrated DC/DC power supply.

This signal is normally used in cabinet installations. If the LCL Over temperature monitoring signal

is not used in the system, choose the option "0 = Not used".

See parameter P2.3.1.2 for the list of values.

P2.3.1.4 M

AIN CONTACTOR ACKNOWLEDGE ID1453

This parameter defines what input is used to monitor the status of the main contactor of the unit. If

the feedback does not correspond the control signal within set time delay, the drive will indicate

MCC Fault and will not be able to start until proper feedback is given.

See parameter P2.3.1.1 for the list of values.

NOTE! AFE needs feedback signal for correct operation. If feedback is not used there will be 3 second delay after closing command before drive can be started.

P2.3.1.5 LCL F

AN MONITORING (X51) ID1178

This parameter defines if the drive monitors the status of the LCL Fan of the unit. When the monitoring function is used, the unit will give a warning if the LCL fan stops working and the LCL temperature reaches warning level.

Check from hardware if LCL is using X51 for fan monitoring or for LCL Temperature monitoring. If

hardware uses X51 for fan monitoring, use this parameter. If it is used for LCL temperature monitoring, use P2.3.1.10 LCL Temperature Monitoring X51.

This signal is normally used in cabinet installations. If the status of the LCL fan is not monitored in

the system, choose the option "0 = Not used".

See parameter P2.3.1.2 for the list of values.

P2.3.1.6 F

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

AULT RESET ID1208

7

Page 50

vacon • 48 Description of parameters

This parameter defines which digital input is used to reset faults.

See parameter P2.3.1.1 for the list of values.

P2.3.1.7 E

This parameter defines if the drive monitors the status of the External fault input. The response to

the fault can be selected with the parameter P2.7.2.

See parameter P2.3.1.2 for the list of values.

P2.3.1.8 R

This parameter defines which digital input is used for the external Run Enable signal. If Run Enable

is used, the drive does not go to Ready state until the Run Enable goes high.

See parameter P2.3.1.1 for the list of values.

P2.3.1.9 C

OK input from the cooling unit.

P2.3.1.10 LCL T

This parameter defines if the drive monitors the status of the LCL over temperature switch signal

from X51. This wire is marked as "X51" when not using integrated DC/DC power supply.

Check from hardware if LCL is using X51 for fan monitoring or for LCL Temperature monitoring. If

hardware uses X51 for temperature monitoring, use this parameter. If it is used for LCL fan monitoring, use P2.3.1.5 LCL Fan Monitoring (X51).

XTERNAL FAULT ID1214

UN ENABLE ID1212

OOLING MONITOR ID750

EMPERATURE MONITOR X51 ID750 "LCL TEMP. X51"

This signal is normally used in cabinet installations. If LCL Over temperature monitoring signal is

not used in the system, choose the option "0 = Not used".

See parameter P2.3.1.2 for the list of values.

7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 51

Description of parameters vacon • 49

7.3.2 Analogue Inputs

P2.3.2.1 A

Minimum voltage or Current level at AI1.

0=0V / 0mA,

1=2V / 4mA

P2.3.2.2 A

Filter time in seconds for the filtering of signal connected to AI1. The range of time can be selected

from 0.01 sec to 10.00 sec.

P2.3.2.3 A

This parameter defines the minimum voltage or current on the AI2 terminal on OPT-A1 board.

0=0V / 0mA,

1=2V / 4mA

P2.3.2.4 A

NALOG INPUT 1 MINIMUM ID1227

NALOG INPUT 1 FILTER TIME ID1228

NALOG INPUT 2 MINIMUM ID1231

NALOGUE INPUT 2 FILTER TIME ID1232

Filter time in seconds for the filtering of signal connected to AI2. The range of time can be selected

from 0.01 sec to 10.00 sec.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 52

vacon • 50 Description of parameters

7.4 Output signals

7.4.1 Digital outputs

P2.4.1.1 DO1 ID1216

This parameter defines which signal is connected to digital output 1.

0 = Digital output can be set from Fieldbus (Auxiliary Control Word, bit 13).

1 = Ready

2 = Running

3 = Fault

4 = No Fault

5 = Warning

6 = At Reference

7 = Regen Active (Unit is regenerating power)

8 = Charge DC

This output function is used to charge DC. This function can be used only when the Run Enable function is also in use. When run enable is HIGH and there are no active faults, the rising edge on the

start command will start the DC charging and if charging is successful, the drive will go to Run

State.

9 = Ready / Warning (blink).

10 = Over temperature fault (Drive over temperature or Fan not working)

11 = DC voltage above limit set with parameter P2.5.6.1

P2.4.1.2 DO2 ID1217

Select the signal for controlling the RO1 of OPT-A2 option board.

See parameter P2.3.1.1 for the list of values.

P2.4.1.3 DO3, S

This output control Main Contactor. Function cannot be changed.

P2.4.1.4P2.4.1.13 DO4- DO12 ID1385 - ID1429

LOT B: OUTPUT 2 (RO2) ID1218

7

These parameters are only visible when there are option cards with digital outputs installed in the

AFE. If, for example, the option card OPT-B5 has been installed, the parameters for outputs DO3DO5 become visible.

See parameter P2.3.1.1 for the list of values.

7.4.2 Analogue outputs

NOTE! This menu is visible in the panel, if Analogue Input 1 is not used for PT100 measurement

(P2.2.2.2 = 0).

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Page 53

Description of parameters vacon • 51

11288_uk

P2.4.2.1 ANALOGUE OUTPUT 1 SIGNAL ID ID1233

Set the ID number of the signal to be connected to AO1. For example, to connect the DC-link voltage

to Analog output 1, enter 1108 as the parameter value.

NOTE! If Analogue input has been chosen to be used for PT100 measurement (P2.2.2.2 > 0), the Analogue Output 1 is forced to 10mA level.

P2.4.2.2 A

NALOGUE OUTPUT 1 OFFSET ID1234

This parameter defines the minimum voltage or current at Analog Output 1.

0 = 0V/0mA,

1 = 4mA

P2.4.2.3 A

NALOGUE OUTPUT FILTER TIME ID1235

This parameter defines the filtering time of the analogue output signal.

Figure 9. Analogue output filtering

P2.4.2.4 A

NALOGUE OUTPUT MAXIMUM VALUE ID1236

Maximum value of a signal selected for AO1. This will correspond to +10V/20mA

P2.4.2.5 A

NALOGUE OUTPUT MINIMUM VALUE ID1237

Minimum value of a signal selected for AO1. This will correspond to 0V/0mA or 2V/4mA depending

on the offset parameter.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

Page 54

vacon • 52 Description of parameters

7.5 Limit settings

7.5.1 Current Limits

P2.5.1.1 C

URRENT LIMIT [A] ID107

Sets the current limit for the regenerative supply unit. Set this to correspond to the maximum required load or peak overload of the unit, bearing in mind that the load might consist of several motor

drive units.

Maximum value 2 * IH depends on the unit size.

7.5.2 Power Limits

P2.5.2.1 P

OWER LIMIT MOTORING SIDE ID1289

This parameter sets the power limit for the motor side operation of the regenerative unit. 100.0% is

equal to nominal power. Motoring Side operation means that the power flows from AC side to DC

side.

P2.5.2.2 P

OWER LIMIT GENERATOR SIDE ID1290

This parameter sets the power limit for the generator side operation of the regenerative unit.