Page 1

VACON CX /CXL/CXS

FREQUENCY CONVERTERS

Multi-purpose Control

Application II

USER'S MANUAL

Subject to changes without notice

Page 2

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 1

VV

aconacon

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purposeMulti-purpose

Multi-purpose

Multi-purposeMulti-purpose

Control Application IIControl Application II

Control Application II

Control Application IIControl Application II

(par. 0.1 = 0)

CONTENTSCONTENTS

CONTENTS

CONTENTSCONTENTS

1 General ................................................... 2

2 Control I/O............................................... 2

3 Control signal logic ................................. 3

4 Parameter Group 0 ................................. 4

5 Parameters Group 1 ............................... 5

5.1 Parameter table ............................ 5

5.2 Description of Group1 par. ............ 6

6 Special parameters, Groups 2-11......... 10

6.1 Parameter tables .........................

6.2 Description of Group 2 par..........

7 Fault code ............................................. 46

8 Monitoring data ..................................... 46

10

19

Software ID: smf089xx

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 3

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 2

11

1

11

GeneralGeneral

General

GeneralGeneral

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose II application is an extender

version of the normal Multipurpose application.

It has parameters for torque control and,

furthermore, for Fieldbus communication.

Following fieldbuses are supported: Interbus,

Modbus, Profibus, LonWorks, CAN-bus

(SDS, DeviceNet).

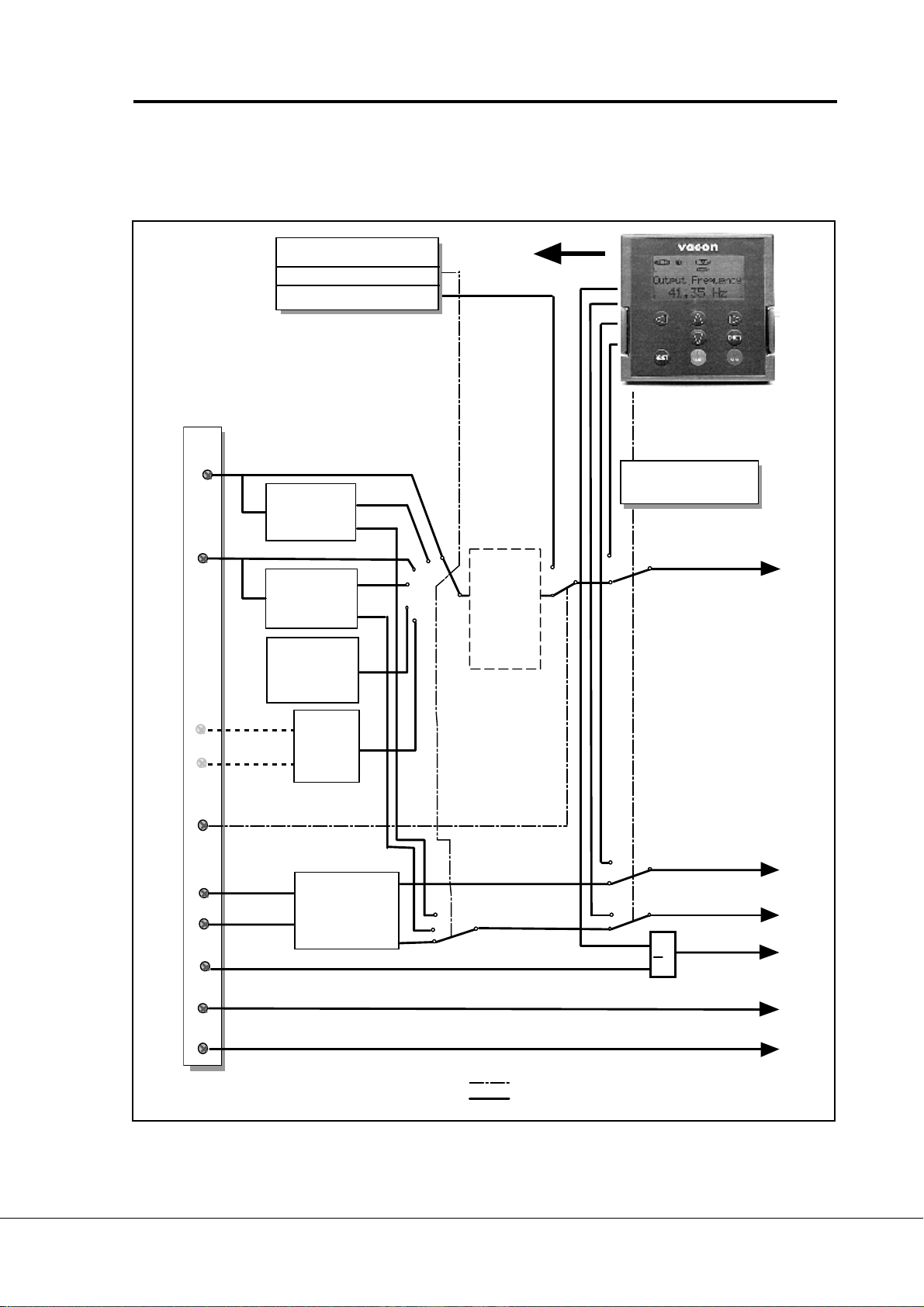

2 Control I/O2 Control I/O

2 Control I/O

2 Control I/O2 Control I/O

VV

aconacon

V

acon

VV

aconacon

Frequency reference, analogue and digital

outputs have extra alternatives in their control

parameters. Source of free analogue input can

now be selected from the I/O Expander. These

inputs have also parameters for signal area

etc. programming.

Reference

potentiometer

READY

RUN

220

VAC

FAULT

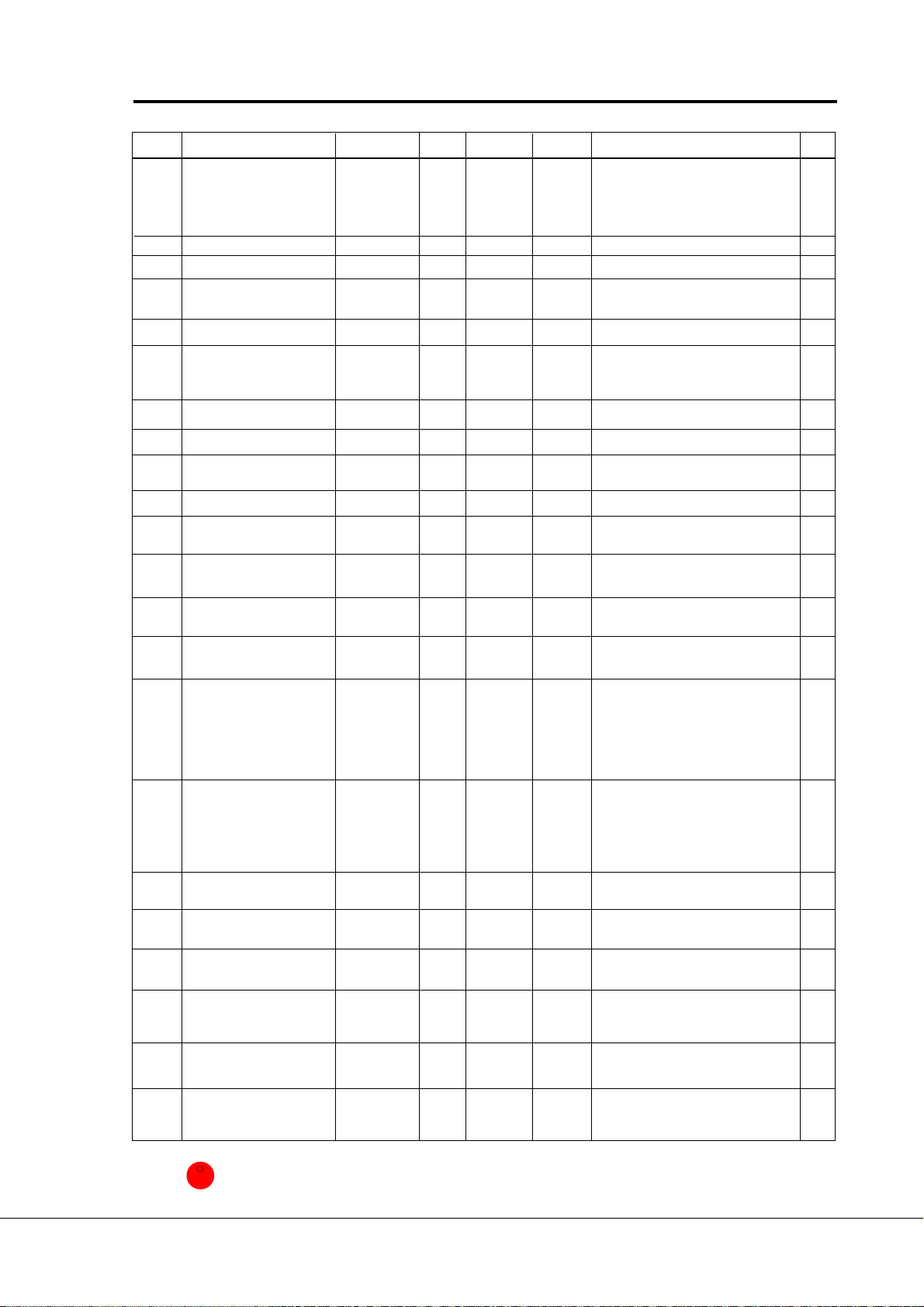

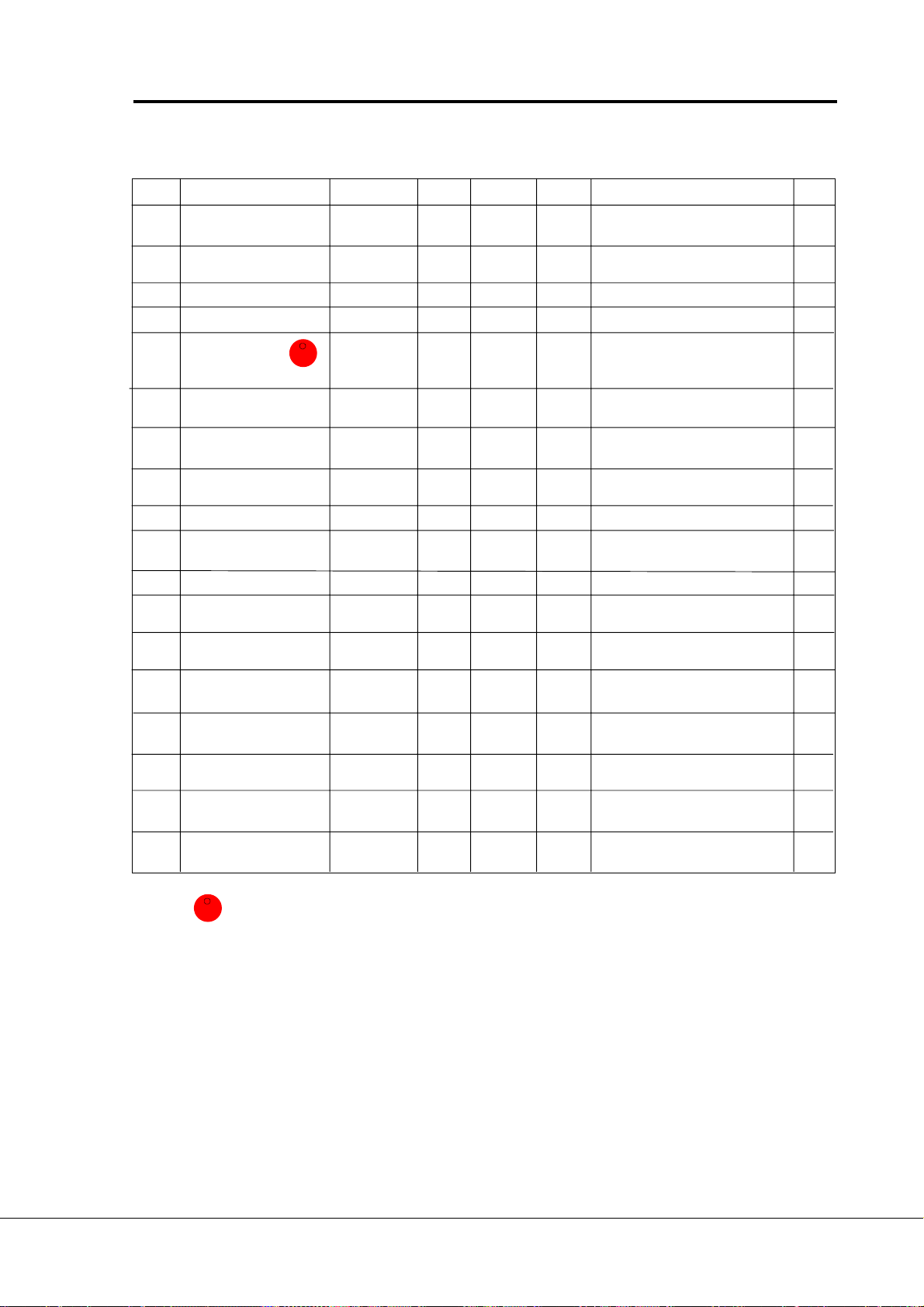

Terminal Signal Description

1 +10V

2Uin+ Analogue input, Frequency reference

3 GND I/O ground Ground for reference and controls

4Iin+ Analogue input, Default setting: not used

- current (programmable) range 0—20 mA

5I

in

6 +24V Control voltage output Voltage for switches, etc. max. 0.1 A

7 GND I/O ground Ground for reference and controls

8 DIA1 Start forward Contact closed = start forward

9 DIA2 Start reverse Contact closed = start reverse

10 DIA3 Fault reset Contact open = no action

11 CMA Common for DIA1—DIA3 Connect to GND or + 24V

12 +24V Control voltage output Voltage for switches, (same as #6)

13 GND I/O ground Ground for reference and controls

14 DIB4 Jogging speed select Contact open = no action

15 DIB5 External fault Contact open = no fault

16 DIB6 Accel./deceler. time select Contact open = par. 1.3, 1.4 in use

17 CMB Common for DIB4—DIB6 Connect to GND or + 24V

18 I

out

19 I

out

20 DO1 Digital output Programmable (par. 3

21 RO1 Relay output 1 Programmable (par. 3

22 RO1 RUN

23 RO1

24 RO2 Relay output 2 Programmable (par. 3

25 RO2 FAULT

26 RO2

Reference output Voltage for a potentiometer, etc.

ref

voltage (programmable) range 0—10 V DC

(programmable)

(Programmable)

(programmable) Contact closed = fault reset

(programmable) Contact closed = jogging speed

(programmable) Contact closed = fault

(programmable) Contact closed = par. 4.3, 4.4 in use

+ Output frequency Programmable (par. 3

- Analogue output Range 0—20 mA/RL max. 500 Ω

READY Open collector, I

..

. 1)

..

..

. 6)

..

<50 mA, U<48 VDC

..

. 7)

..

..

. 8)

..

Figure 2-1 Default I/O configuration and connection example of the

Multi-purpose Control Application.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 4

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 3

VV

aconacon

3 Control signal logic3 Control signal logic

3 Control signal logic

3 Control signal logic3 Control signal logic

Multi-purpose Control Application IIMulti-purpose Control Application II

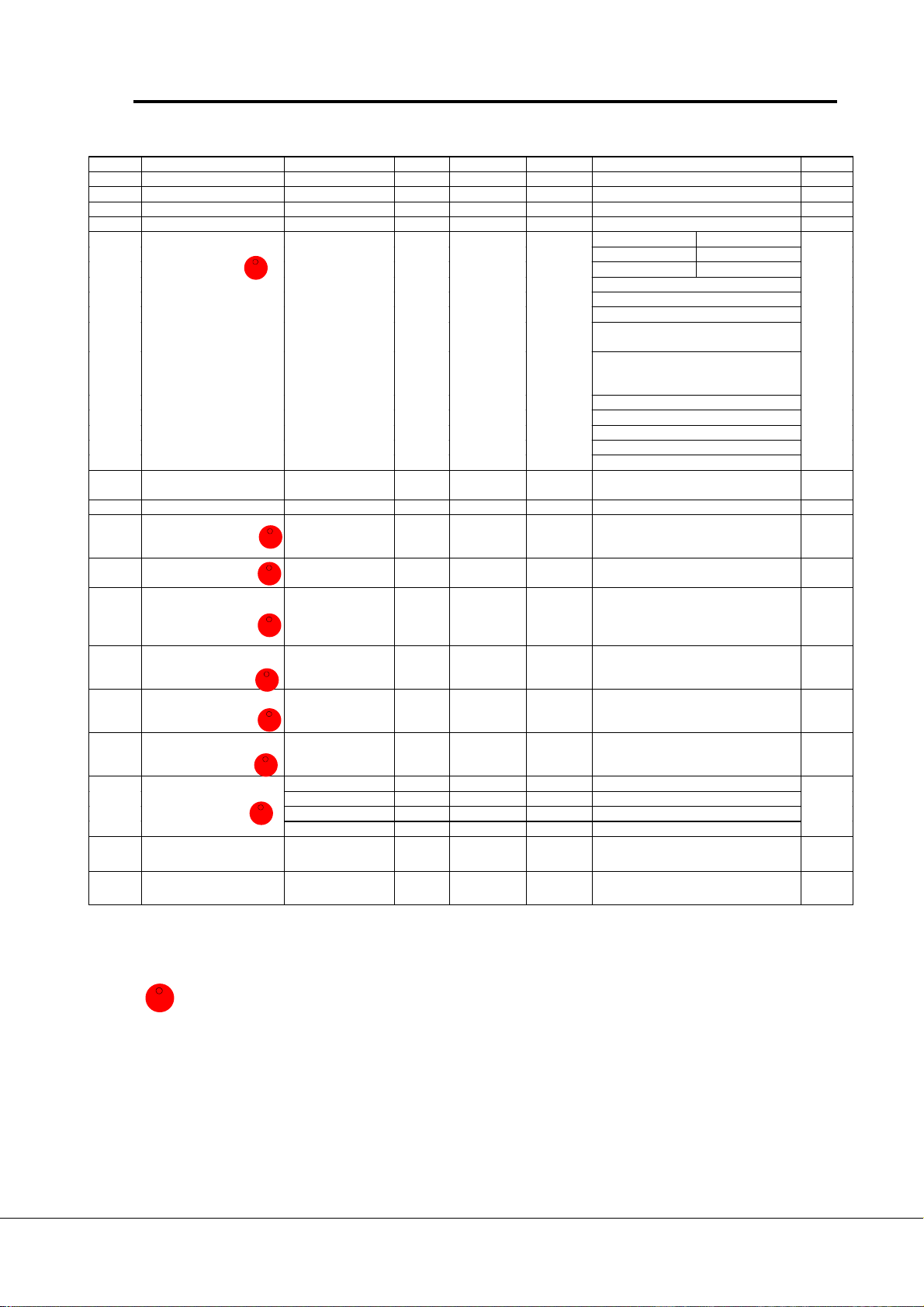

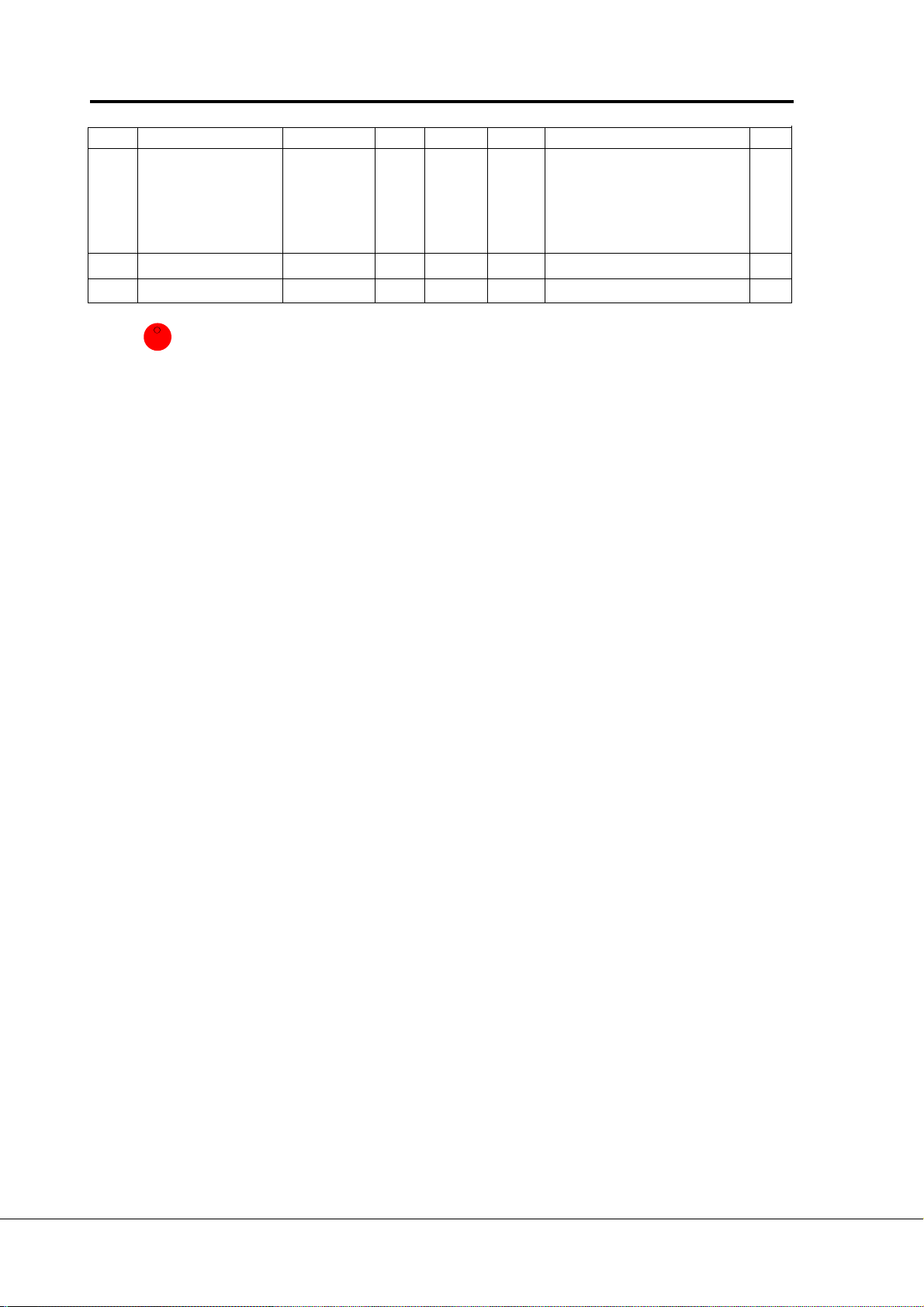

In figure 3-1 the logic of I/O-control signals and push button signals from the panel are presented.

PARAMETERS

1. 5 Reference selection

1. 6 Jogging speed ref.

Uin+

Joystick

control

Iin±

Joystick

control

Uin + I

Uin - I

I

in

Uin x I

DIB5

Up

DIB6

Down

Jogging speed selection

DIB4

(programmable)

DIA1

Start FWD

DIA2

Start REV.

DIA3

Fault reset

(programmable)

DIB5

External fault

(programmable)

DIB6

Accel./deceler. time select

(programmable)

Motorised

potentiometer

reference

Programm.

Start/Stop

and Reverse

signal logic

- U

PROGRAMMABLE

PUSH-BUTTON 2

Internal

P

Multi-step

speeds

(If any of

DI_ inputs

are programmed

for this

in

in

in

in

function)

P

P

>1

control line

=

signal line

=

frequency

reference

Internal

Start/Stop

Internal

reverse

Internal

fault reset

UD012K05

Figure 3-1 Control signal logic of the Multipurpose II Application.

Switch positions correspond to factory settings.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 5

Page 4

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

44

4

44

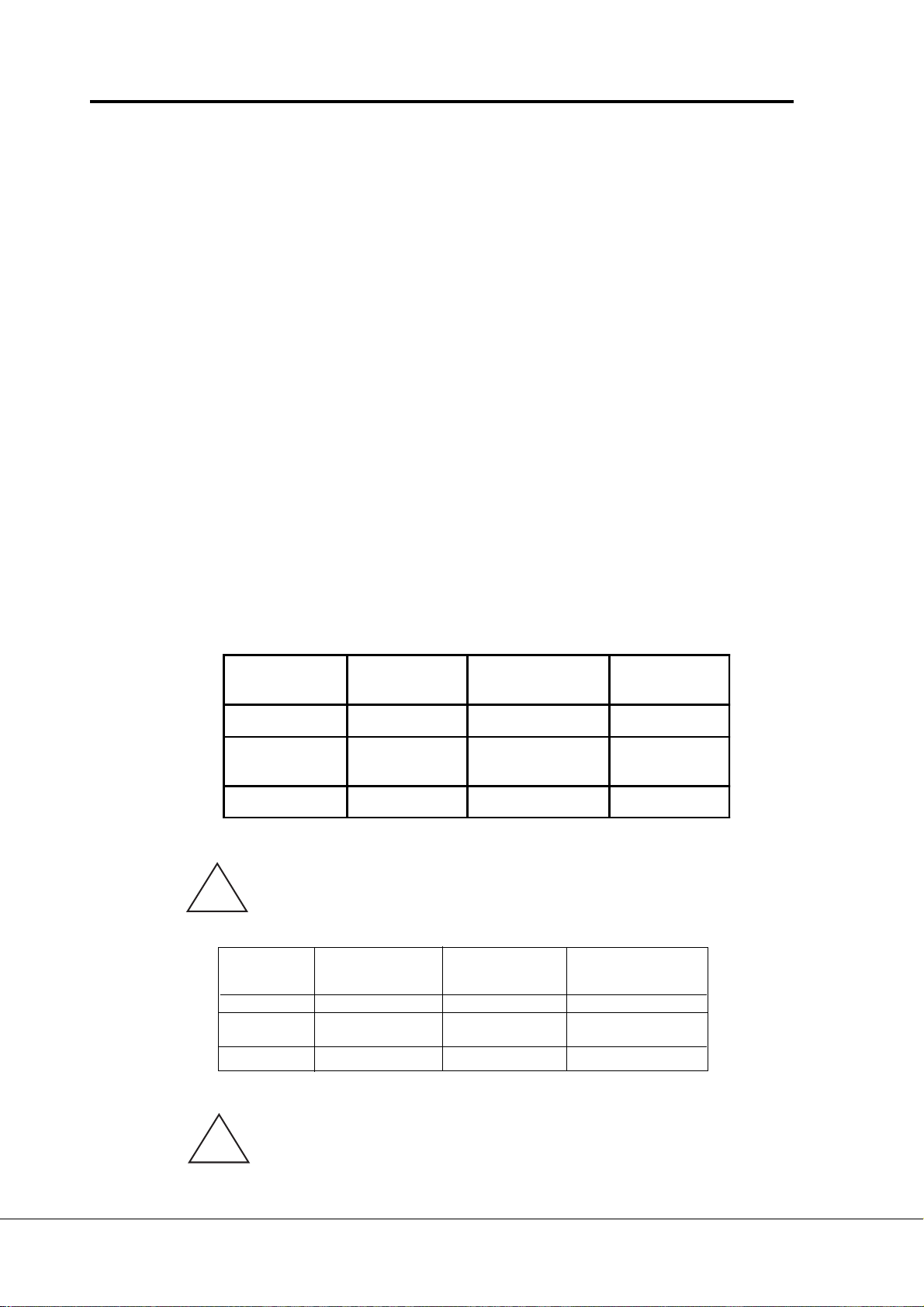

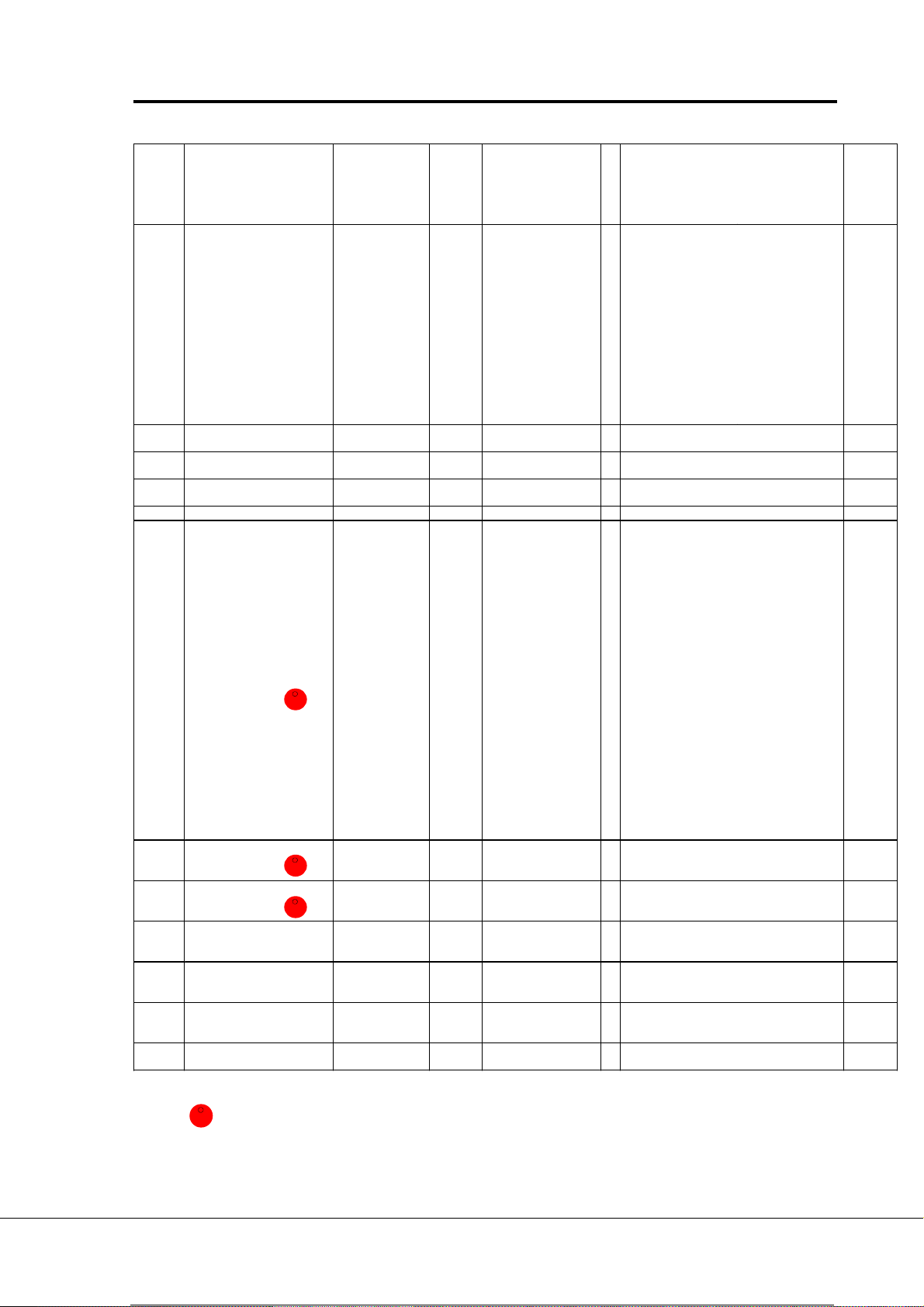

Number Parameter Range Step Default Customer Description

0.1

0.2 Parameter loading 0-5 1 0

Parameter group 0Parameter group 0

Parameter group 0

Parameter group 0Parameter group 0

Application

selection

0-7 1 0

0 = Multipurpose II (loaded special

application)

1 = Basic Application

2 = Standard Application

3 = Local/Remote Control

Application

4 = Multi-step Speed Application

5 = PI-control Application

6 = Multi-purpose Control

Application

7 = Pump and Fan Control

Application

0 = Loading ready / Select loading

1 = Load default setting

2 = Read up parameters to user's

set

3 = Load down user's set

parameters

4 = Read parameters up to the

panel (possible only with graphical

panel)

5 = Load down parameters from

panel (possible only with graphical

panel)

0 = English

0.3 Language selection 0-2 1 0

1 = Germany

2 = Finnish

Table 4-1 Parameter group 0.

0.10.1

0.1

0.10.1

Application selectionApplication selection

Application selection

Application selectionApplication selection

With this parameter the active application can be selected. If the device has been

ordered from the factory equipped with Multipurpose II application this has been loaded

to the unit as application 0. The application has also been set active at the factory.

However, check that the value of the parameter 0.1 is zero when you want to use

Multipurpose II.

If the application should be loaded to the device later it has to be set active always after

loading by setting the value of parameter 0.1 to zero.

0.20.2

0.2

0.20.2

Parameter loadingParameter loading

Parameter loading

Parameter loadingParameter loading

See User's Manual chapter 11.

0.30.3

0.3

0.30.3

LanguageLanguage

Language

LanguageLanguage

With this parameter, the language of the graphical panel can be selected.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 6

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 5

VV

aconacon

55

Basic Parameters, Group 1Basic Parameters, Group 1

5

Basic Parameters, Group 1

55

Basic Parameters, Group 1Basic Parameters, Group 1

5.15.1

Parameter tableParameter table

5.1

Parameter table

5.15.1

Parameter tableParameter table

Multi-purpose Control Application IIMulti-purpose Control Application II

Code Parameter Range Step Default Custom Description Page

1.1 Minimum frequency 0—120/500 Hz 1 Hz 0 Hz 6

1.2 Maximum frequency 0—120/500 Hz 1 Hz 50 Hz *) 6

1.3 Acceleration time 1 0.1—3000 s 0.1 s 3 s Time from f

1.4 Deceleration time 1 0.1—3000 s 0.1 s 3 s Time from f

1.5 Reference selection 0—15 1 0 0 = U

1 = I

STOP

STOP

STOPSTOP

in

2 = Uin + I

6 = U

(1.1) to f

min

(1.2) to f

max

in

in

joystick control

in

(1.2) 6

max

(1.1) 6

min

3 = Uin – I

4 = Iin – U

5 = Uin * I

in

in

in

7 = Iin joystick control

8 = Signal from internal motor pot.

9 = Signal from internal motor pot.

6

reset if Vacon unit is stopped

10 = Signal from internal motor

pot. (stored in menory over

mains break

11= Min (Uin, Iin)

12 = Max (Uin, Iin)

13 = Panel reference r1

14 = Max reference

15 = Uin/Iin selection

Jogging speed

1.6

reference

1.7 Current limit 0.1—2.5 x I

f

– f

min

max

(1.1) (1.2)

0.1 Hz 5 Hz 7

nCX

0.1 A 1.5 x I

cCX

Output current limit [A] of the unit 7

0 = Linear

1.8 U/f ratio selection 0—210

STOP

STOP

STOPSTOP

1 = Squared

7

2 = Programmable U/f ratio

1.9 U/f optimisation 0—110

STOP

230 V

1.10

Nominal voltage of the

motor

STOP

STOP

STOPSTOP

180—690 1 V

400 V

500 V

690 V

Nominal frequency of

1.11

1.12

the motor

Nominal speed of the

motor

STOP

STOP

STOPSTOP

30—500 Hz 1 Hz 50 Hz fn on the rating plate of the motor

300—20000 rpm 1 rpm 1440 rpm

STOP

STOP

STOPSTOP

0 = None

1 = Automatic torque boost

Vacon range CX/CXL2

Vacon range CX/CXL/CXS4

Vacon range CX/CXL/CXS5

Vacon range CX6

n

on the rating plate of the motor

n

8

9

9

9

1.13

Nominal current of the

motor

STOP

STOP

STOPSTOP

2.5 x I

nCX

0.1 A I

nCX

180—250 230 V Vacon range CX/CXL2

1.14 Supply voltage

STOP

STOP

STOPSTOP

380—440 400 V Vacon range CX/CXL/CXS4

380—500 500 V Vacon range CX/CXL/CXS5

525—690 690 V Vacon range CX6

1.15 Parameter conceal 0—110

1.16 Parameter value lock 0—110

Table 5-1. Group 1 basic parameters

..

*) If 1

. 2 >motor synchr. speed, check suitability for motor and drive system.

..

STOP

STOP

Note!Note!

Note!

Note!Note!

STOPSTOP

= Parameter value can be changed only when the frequency converter is stopped. (Continues)

In on the rating plate of the motor 9

0 = All parameter groups visible

1 = Only group 1 visible

0 = Parameter changes enabled

1 = parameter changes disabled

9

9

9

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 7

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 6

5.2 Description of Group 1 parameters 5.2 Description of Group 1 parameters

5.2 Description of Group 1 parameters

5.2 Description of Group 1 parameters 5.2 Description of Group 1 parameters

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

1. 1, 1. 21. 1, 1. 2

1. 1, 1. 2

1. 1, 1. 21. 1, 1. 2

1. 3, 1. 41. 3, 1. 4

1. 3, 1. 4

1. 3, 1. 41. 3, 1. 4

1. 51. 5

1. 5

1. 51. 5

Minimum / maximum frequencyMinimum / maximum frequency

Minimum / maximum frequency

Minimum / maximum frequencyMinimum / maximum frequency

Defines frequency limits of the frequency converter.

The default maximum value for parameters 1

..

. 1 and 1

..

120 Hz when the device is stopped (RUN indicator not lit) parameters 1

..

. 2 is 120 Hz. By setting 1

..

..

. 1 and 1

..

. .

. 2 =

. .

..

. 2

..

are changed to 500 Hz. At the same time the panel reference resolution is changed

from 0.01 Hz to 0.1 Hz.

Changing the max. value from 500 Hz to 120 Hz is done by setting the parameter

..

1

. 2 = 119 Hz when the device is stopped.

..

Acceleration time 1, deceleration time 1:Acceleration time 1, deceleration time 1:

Acceleration time 1, deceleration time 1:

Acceleration time 1, deceleration time 1:Acceleration time 1, deceleration time 1:

These limits correspond to the time required for the output frequency to

accelerate from the set minimum frequency (par. 1

frequency (par. 1

Reference selectionReference selection

Reference selection

Reference selectionReference selection

00

0 Analogue voltage reference from terminals 2—3, e.g. a potentiometer

00

11

1 Analogue current reference trom terminals 4—5, e.g. a transducer.

11

22

2 Reference is formed by adding the values of the analogue inputs

22

33

3 Reference is formed by subtracting the voltage input (U

33

. .

. 2).

. .

..

. 1) to the set maximum

..

) value

in

from the current input (Iin) value.

44

4 Reference is formed by subtracting the current input (Iin ) value from the

44

voltage input (Uin) value.

55

5 Reference is the formed by multiplying the values of the analogue inputs

55

66

6 Joystick control from the voltage input (Uin).

66

Signal range

0—10 V 0 V 5 V +10 V

Custom Par. 2.7 x 10 V

-10 V—+ 10 V -10 V 0 V +10 V

WW

arning!arning!

W

arning! Use only -10V—+10 V signal range. If a custom or 0—10 V signal

WW

arning!arning!

Max reverse

speed

Direction change

In the middle of

custom range

Max forward

speed

Par. 2.8 x 10 V

range is used, the drive starts to run at the max. reverse speed if the

!

77

7 Joystick control from the current input (I

77

Signal range Max reverse Direction change Max forward

WW

arning!arning!

W

arning! Use only 4—20 mA signal range. If custom or 0—20 mA signal range

WW

arning!arning!

reference signal is lost.

).

in

speed speed

0—20 mA 0 mA 10 mA 20 mA

Custom Par. 2

4—20 mA 4 mA 12 mA 20 mA

..

. 13 x 20 mA In the middle of Par. 2

..

custom range

..

. 14 x 20 mA

..

is used, the drive runs at max. reverse speed if the control signal is lost.

!

Set the reference fault (par. 7

is used, then the drive will stop to the reference fault if the reference

. .

. 2) active when the 4—20 mA range

. .

signal is lost.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 8

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 7

VV

aconacon

Note!Note!

Note! When joystick control is used, the direction control is generated from joystick

Note!Note!

Multi-purpose Control Application IIMulti-purpose Control Application II

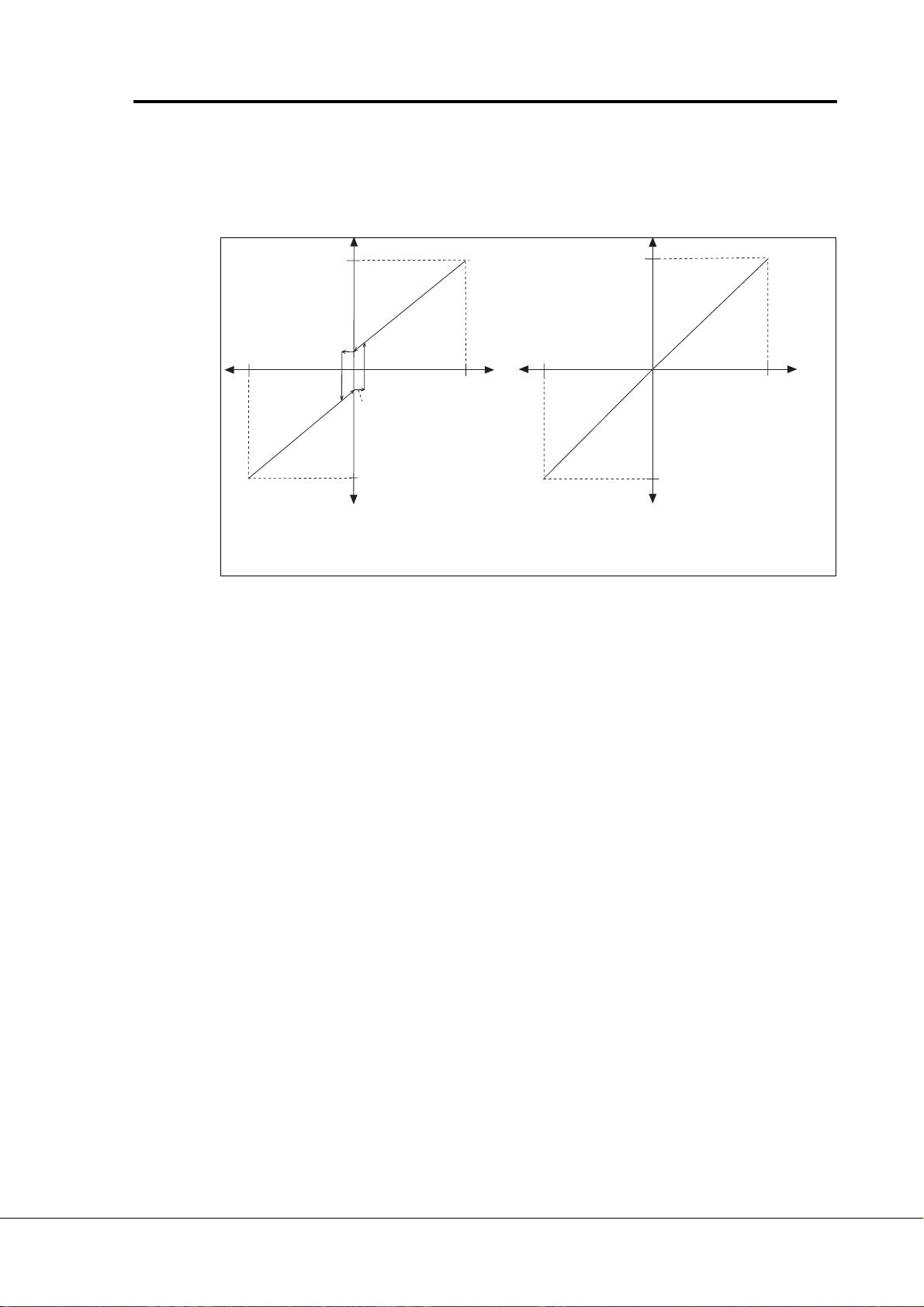

reference signal. See figure 5.4-1.

Analogue input scaling, parameters 2

..

. 16—2

..

. .

. 19 are not used when joystick

. .

control is used.

Fout

Fmax

(par 1.2)

Fmin.

-10V

If minimum frequency (par 1

hysteresis is ± 2% at reversing point. there is no hysteresis at reversing point.

(par 1.1)

Fmin.

(par 1.1)

hystereesi +/-2% (+/-0,2 V)

Fmax

(par 1.2)

..

. 1) >0, If minimum frequency (par 1

..

Uin

+10V

-10V

Fmax

(par 1.2)

Fout

Fmax

(par 1.2)

+10V

..

. 1) = 0,

..

Uin

Uin

Fig. 5-1 Joystick control Uin signal -10 V—+10 V.

88

8 Reference value is changed with digital input signals DIB5 and DIB6.

88

- switch in DIB5 closed = frequency reference increases

- switch in DIB6 closed = frequency reference decreases

Speed of reference change can be set with the parameter 2

99

9 Same as setting 8 but the reference value is set to the minimum frequency

99

(par. 1

1010

10 Same as setting 8 but the reference is stored to the memory over mains break.

1010

When the value of the parameter 1

parameters 2

11

11

1

1 The minor of signals Uin and Iin is the frequency reference

11

11

1212

12 The greater of signals Uin and Iin is the frequency reference

1212

1313

13 Panel reference r1 is the frequency reference

1313

1414

14 Maximum reference selection (recommended only at torque control)

1414

1515

15 Uin/Iin digital selection (see par. 2.3)

1515

..

. 1) each time the frequency converter is stopped.

..

..

. 5 is set to 8, 9 or 10, the values of the

..

..

. 4 and 2

..

. .

. 5 are automatically set to 11.

. .

..

. 20.

..

1. 61. 6

1. 6

1. 61. 6

Jogging speed referenceJogging speed reference

Jogging speed reference

Jogging speed referenceJogging speed reference

Parameter value defines the jogging speed selected with the digital input

1. 71. 7

1. 7

1. 71. 7

Current limitCurrent limit

Current limit

Current limitCurrent limit

This parameter determines the maximum motor current from the freqeuency

converter. To avoid motor overload, set this parameter according to the rated current

of the motor.

1. 81. 8

1. 8

1. 81. 8

U/f ratio selectionU/f ratio selection

U/f ratio selection

U/f ratio selectionU/f ratio selection

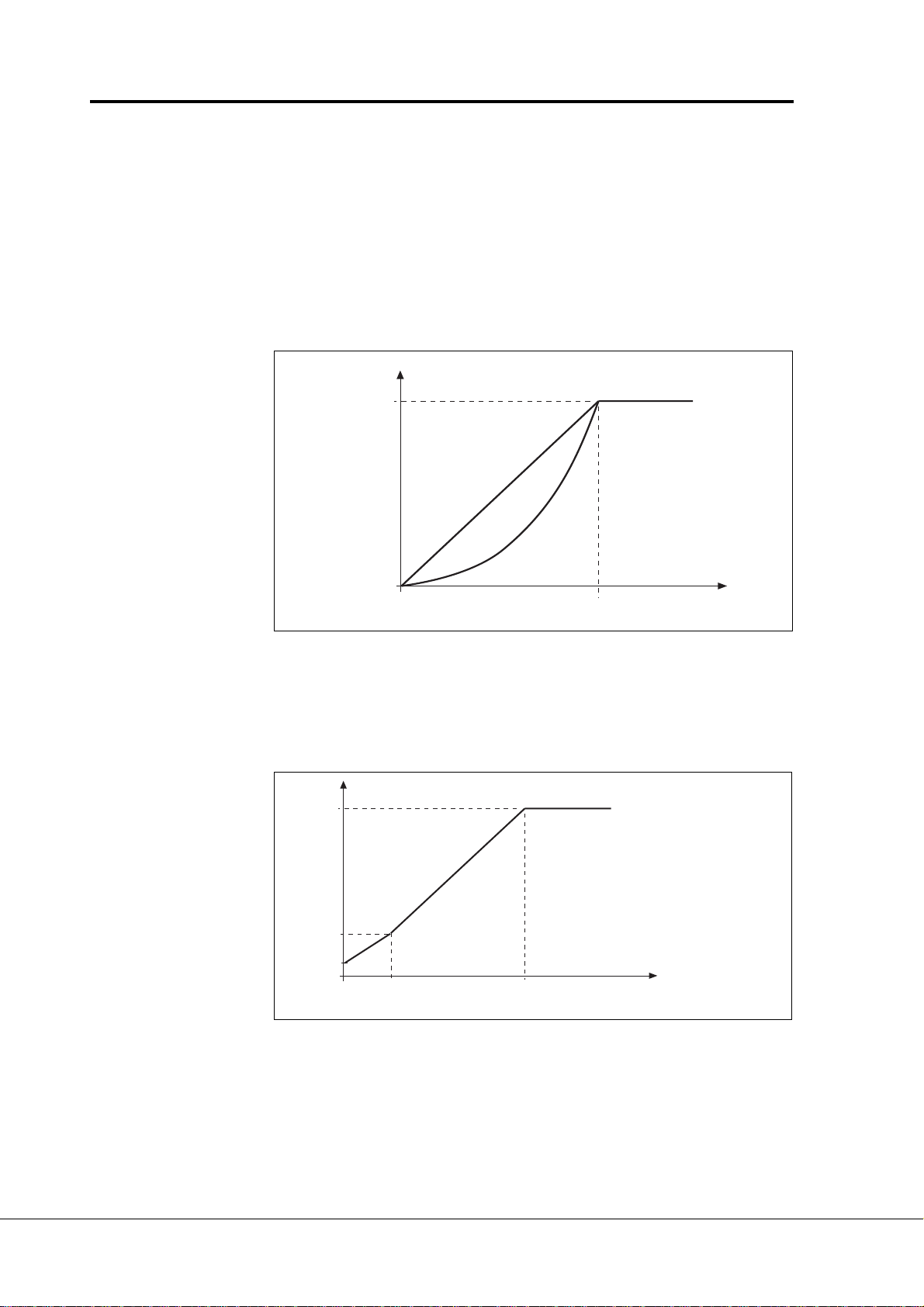

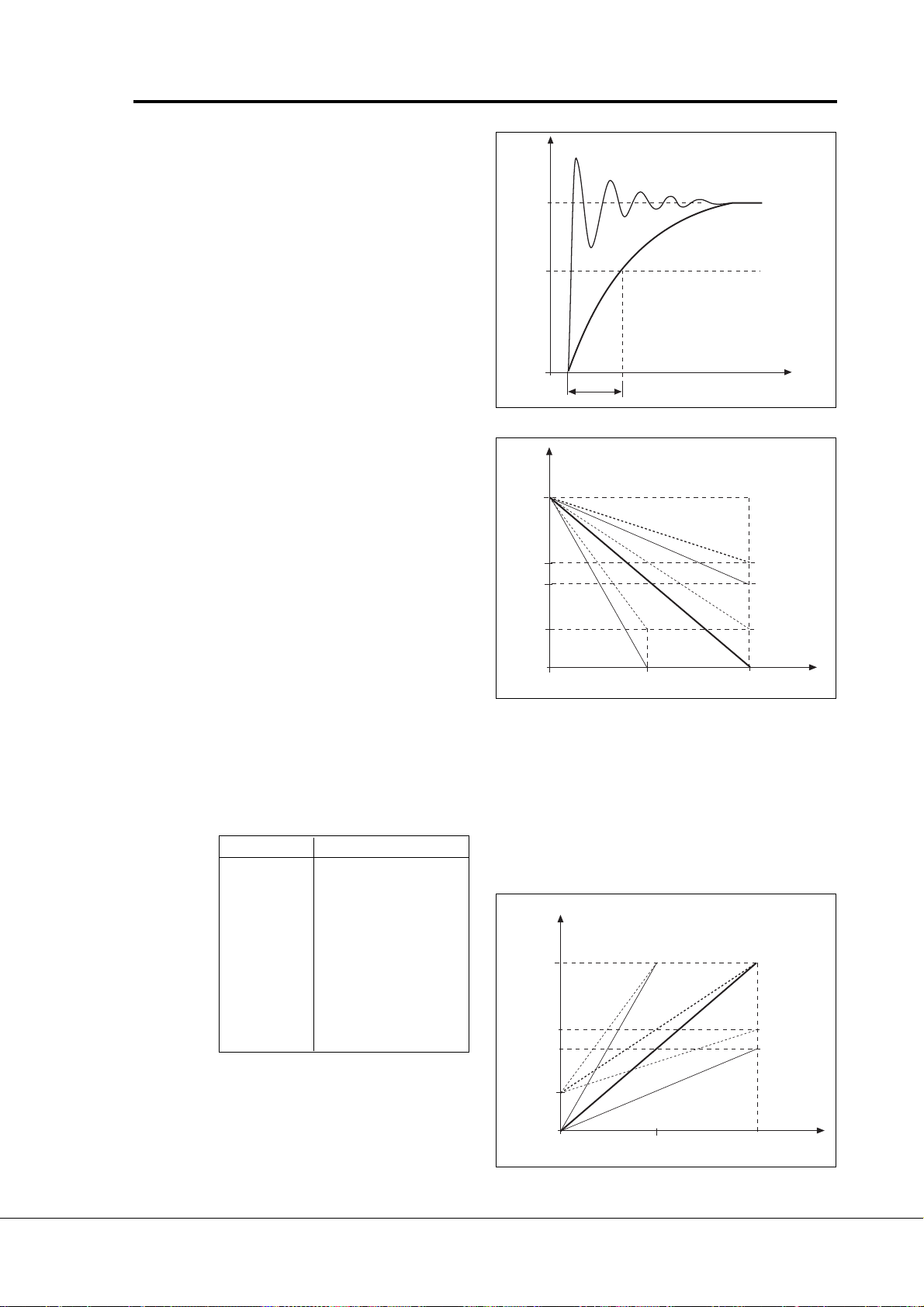

Linear: The voltage of the motor changes linearly with the frequency in the

00

0 constant flux area from 0 Hz to the field weakening point (par. 6

00

where the nominal voltage is also supplied to the motor. See figure

5-2. Linear U/f ratio should be used in constant torque applications.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

..

. 3)

..

Page 9

Page 8

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

This default setting should be used if there is no special needThis default setting should be used if there is no special need

This default setting should be used if there is no special need

This default setting should be used if there is no special needThis default setting should be used if there is no special need

for another setting.for another setting.

for another setting.

for another setting.for another setting.

VV

aconacon

V

acon

VV

aconacon

Squared: The voltage of the motor changes following a squared curve form

11

1 with the frequency in the area from 0 Hz to the field weakening

11

point (par. 6

..

. 3) where the nominal voltage is also supplied to

..

the motor. See figure 5-2.

The motor runs undermagnetised below the field weakening point

and produces less torque and electromechanical noise. Squared

U/f ratio can be used in applications where torque demand of

the load is proportional to the square of the speed, e.g. in centrifugal

fans and pumps.

U[V]

Un

(Par 6. 4)

Default: Nominal

voltage of the motor

Linear

Field weakening

point

Squared

Default: Nominal

frequency of the

motor

(Par. 6. 3)

f[Hz]

UD012K07

Figure 5-2 Linear and squared U/f curves.

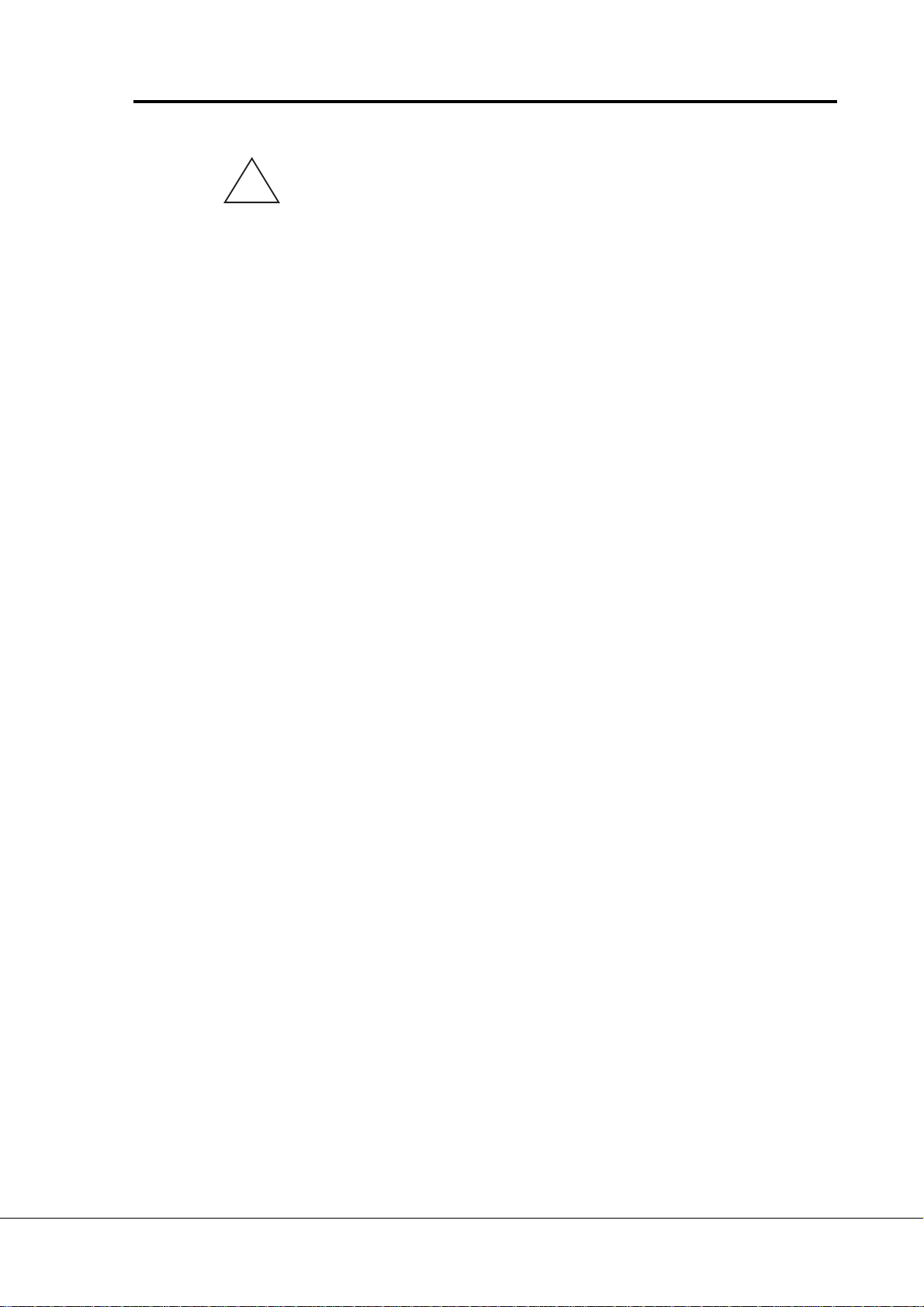

Programm. The U/f curve can be programmed with three different points.

U/f curve The parameters for programming are explained in chapter 5.2.

22

2 Programmable U/f curve can be used if the other settings do not

22

satisfy the needs of the application. See figure 5-3.

U[V]

Un

Par 6. 4

Par. 6. 6

(Def. 10%)

Par. 6. 7

(Def. 1.3%)

Default: Nominal

voltage of the motor

Par. 6. 5

(Def. 5 Hz)

Field weakening

point

Default: Nominal

frequency of the

motor

Par. 6. 3

f[Hz]

UD012K08

Figure 5-3 Programmable U/f curve.

1.9 U/f optimisation1.9 U/f optimisation

1.9 U/f optimisation

1.9 U/f optimisation1.9 U/f optimisation

Automatic The voltage to the motor changes automatically which makes the

torque motor produce sufficient torque to start and run at low frequencies. The

boost voltage increase depends on the motor type and power.

Automatic torque boost can be used in applications where starting

torque due to starting friction is high, e.g. in conveyors.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 10

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 9

VV

aconacon

Multi-purpose Control Application IIMulti-purpose Control Application II

NOTE! In high torque - low speed applications - it is likely the motor will

overheat.

!

If the motor has to run a prolonged time under these

conditions,

special attention must be paid to cooling the motor. Use external

cooling for the motor if the temperature tends to rise too high.

1. 101. 10

1. 10

1. 101. 10

1. 11. 1

1. 1

1. 11. 1

1. 121. 12

1. 12

1. 121. 12

1. 131. 13

1. 13

1. 131. 13

1. 141. 14

1. 14

1. 141. 14

1. 151. 15

1. 15

1. 151. 15

Nominal voltage of the motorNominal voltage of the motor

Nominal voltage of the motor

Nominal voltage of the motorNominal voltage of the motor

Find this value Un on the rating plate of the motor.

This parameter sets the voltage at the field weakening point, parameter 6

100% x U

11

1

11

Nominal frequency of the motorNominal frequency of the motor

Nominal frequency of the motor

Nominal frequency of the motorNominal frequency of the motor

Find this value fn on the rating plate of the motor.

This parameter sets the field weakening point, parameter 6. 3, to the same value.

Nominal speed of the motorNominal speed of the motor

Nominal speed of the motor

Nominal speed of the motorNominal speed of the motor

Find this value nn on the rating plate of the motor.

Nominal current of the motorNominal current of the motor

Nominal current of the motor

Nominal current of the motorNominal current of the motor

Find this value In on the rating plate of the motor.

Supply voltageSupply voltage

Supply voltage

Supply voltageSupply voltage

Set parameter value according to the nominal voltage of the supply.

Values are predefined for CX/CXL2, CX/CXL/CXS4, CX/CXL/CXS5 and CX6

ranges, see table 5-1.

Parameter concealParameter conceal

Parameter conceal

Parameter concealParameter conceal

Defines which parameter groups are available for editing:

0 = all parameter groups are visible

1 = only group 1 is visible

nmotor

.

. .

. 4, to

. .

1. 161. 16

1. 16

1. 161. 16

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Parameter value lockParameter value lock

Parameter value lock

Parameter value lockParameter value lock

Defines access to the changes of the parameter values:

0 = parameter value changes enabled

1 = parameter value changes disabled

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 11

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 10

66

Special Parameters, Groups 2—10Special Parameters, Groups 2—10

6

Special Parameters, Groups 2—10

66

Special Parameters, Groups 2—10Special Parameters, Groups 2—10

6.16.1

Parameter tablesParameter tables

6.1

Parameter tables

6.16.1

Parameter tablesParameter tables

Group 2, Input signal parametersGroup 2, Input signal parameters

Group 2, Input signal parameters

Group 2, Input signal parametersGroup 2, Input signal parameters

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

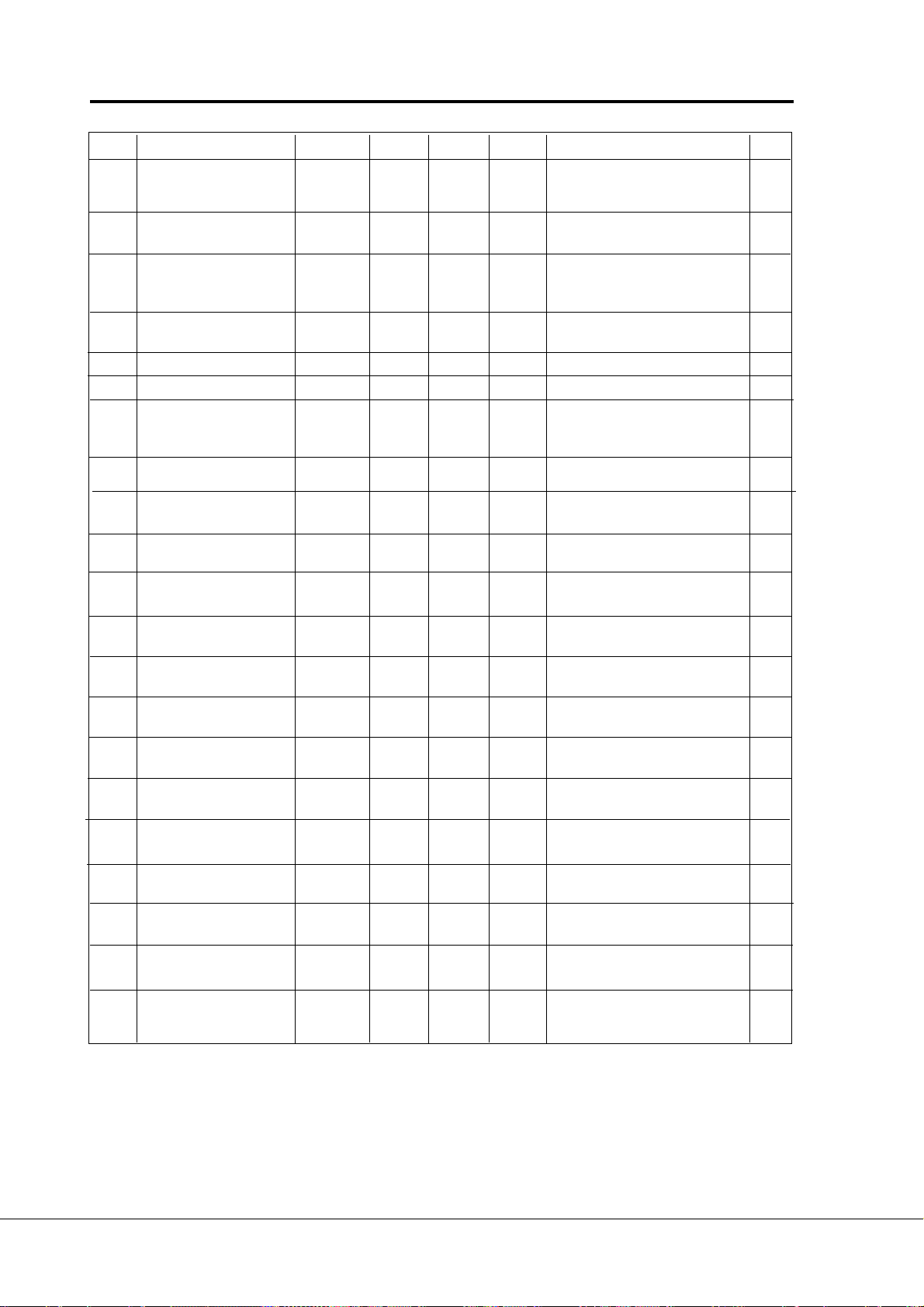

Code Parameter Range Step Default Description Page

DIA1 DIA2

2.1

Start/Stop logic

selection

STOP

STOP

STOPSTOP

0—41 0

0 = Start forw.

1 = Start/Stop

2 = Start/Stop

3 = Start pulse

4 = Start/stop pulse

Start reverse

Reverse

Run enable

Stop pulse

Run enable

0 = Not used

1 = External fault, closing contact

2 = External fault, opening contact

3 = Run enable

STOP

STOP

2.2

DIA3 function

(terminal 10)

STOPSTOP

0—12 1 7

4 = Accel./decel. time selection

5 = Reverse

6 = Jogging speed

7 = Fault reset

8 = Accel./decel. operation prohibit

9 = DC-braking command

10 = Torque control

11 = Torque reference sign

12 = Run enable with coasting

0 = Not used

1 = External fault, closing contact

2 = External fault, opening contact

3 = Run enable

STOP

STOP

STOPSTOP

4 = Accel./decel. time selection

5 = Reverse

6 = Jogging speed

2.3

DIB4 function

(terminal 14)

0—15 1 6

7 = Fault reset

8 = Accel./decel. operation prohibit

9 = DC-braking command

10 = Multi-step speed select 1

11 = Selection between I

and U

in

in

12 = Run enable with coasting

13 = Fieldbus control

14 = Par. 1.5 / U

15 = Par. 1.5 / I

in

in

0 = Not used

1 = External fault, closing contact

2 = External fault, opening contact

3 = Run enable

4 = Accel./decel. time selection

5 = Reverse

6 = Jogging speed

7 = Fault reset

2.4

DIB5 function

(terminal 15)

STOP

STOP

STOPSTOP

0—13 1 1

8 = Accel./decel. operation prohibit

9 = DC-braking command

10 = Multi-step speed select 2

11 = Motorised pot. speed up

12 = Run enable with coasting

13 = Fieldbus control

0 = Not used

1 = External fault, closing contact

2 = External fault, opening contact

3 = Run enable

4 = Accel./decel. time selection

5 = Reverse

6 = Jogging speed

7 = Fault reset

2.5

DIB6 function

(terminal 16)

STOP

STOP

STOPSTOP

0—13 1 4

8 = Accel./decel. operation prohibit

9 = DC-braking command

10 = Multi-step speed select 3

11 = Motorised pot. speed down

12 = Run enable with coasting

13 = Fieldbus control

19

20

22

22

22

STOP

STOP

Note!Note!

Note!

Note!Note!

STOPSTOP

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

= Parameter value can be changed only when the frequency converter is stopped.

Service: +358-40-8371 150 E-mail: vacon@vacon.com

(Continues)

Page 12

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 11

VV

aconacon

Multi-purpose Control Application IIMulti-purpose Control Application II

Code Parameter Range Step Default Custom Description Page

2. 6 U

signal range 0—2 1 0 0 = 0—10 V

in

1 = Custom setting range

2 = -10—+10 V (can be used with

Joystick control only)

. .

2

. 7U

. .

. .

2

. 8U

. .

. .

2

. 9U

. .

custom setting min. 0—100% 0.01% 0.00% 22

in

custom setting max. 0—100% 0.01% 100.00% 22

in

signal inversion

in

0—1

1 0 0 = Not inverted 22

1 = Inverted

..

2

. 10 U

..

..

2

. 11 I

..

signal filter time

in

signal range 0—210 0 = 0—20 mA 23

in

0 —10s

0.01s 0.1s 0 = No filtering 22

1 = 4—20 mA

2 = Custom setting range

..

2

. 12 I

..

..

2

. 13 I

..

..

2

. 14 I

..

custom setting minim. 0—100% 0.01% 0.00% 23

in

custom setting maxim. 0—100% 0.01% 100.00% 23

in

signal inversion

in

0—1

1 0 0 = Not inverted 23

1 = Inverted

. .

2

. 15 I

. .

..

2

. 16 U

..

signal filter time

in

minimum scaling -320,00%— 0% 0,01 0% = no minimum scaling 23

in

0 —10s

0.01s 0.1s 0 = No filtering 23

+320,00 %

..

2

. 17 U

..

maximum scaling -320,00%— 100% 0,01 100% = no maximum scaling 23

in

+320,00 %

..

2

. 18 I

..

minimum scaling -320,00%— 0% 0,01 0% = no minimum scaling 23

in

+320,00 %

..

2

. 19 I

..

maximum scaling -320,00%— 100% 0,01 100% = no maximum scaling 23

in

+320,00 %

. .

2

. 20 Free analogue input, 0—5 1 0 0 = Not use 24

. .

signal selection 1 = U

(analogue voltage input)

in

2 = Iin (analogue current input)

3 = Ain1 (option board)

4 = Ain2 (option board)

5 = Fieldbus signal

..

2

. 21 Free analogue input, 0—4 1 0 0 = No function 24

..

function 1 = Reduces current limit

(par. 1

..

.7)

..

2 = Reduces DC-braking current

3 = Reduces acc. and decel. times

4 = Reduces torque supervis. limit

..

2

. 22 Motorised potentiometer 0.1—2000.0 0.1 10.0 25

..

ramp time Hz/s Hz/s Hz/s

. .

2

. 23 Option board Ain1 signal 0—1 1 0 0 = Not inverted 25

. .

inversion 1 = Inverted

..

2

. 24 Option board Ain1 signal 0—10s 0.01s 0.1s 0 = No filtering 25

..

filter time

..

2

. 25 Option board Ain2 signal 0—210 0 = 0—20 mA 25

..

signal range 1 = 4—20 mA

2 = 0—10 V

..

2

. 26 Option board Ain2 signal 0—1 1 0 0 = Not inverted 25

..

inversion 1 = Inverted

. .

2

. 27 Option board Ain2 signal 0 —10s 0.01s 0.1s 0 = No filtering 25

. .

filter time

STOP

STOP

Note! Note!

Note!

Note! Note!

STOPSTOP

= Parameter value can be changed only when the frequency converter is stopped. (Continues)

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 13

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 12

Code Parameter Range Step Default Custom Description Page

2.28 Adjust Input 0 - 5 1 0 0 = Not used

2.29 Adjust Percentage 0.0% - 200.0% 0.1% 0.0%

2.30 Adjust Offset 0.0% - 100.0% 0.1% 0.0%

STOP

STOP

Note!Note!

Note!

Note!Note!

STOPSTOP

= Parameter value can be changed only when the frequency converter is stopped.

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

1 = Voltage input

2 = Current input

3 = AIN1 I/O-expand

4 = AIN2 I/O-expand

5 = FB signal

VV

aconacon

V

acon

VV

aconacon

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 14

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 13

VV

aconacon

Group 3, Output and supervision parametersGroup 3, Output and supervision parameters

Group 3, Output and supervision parameters

Group 3, Output and supervision parametersGroup 3, Output and supervision parameters

Code Parameter Range Step Default C

Multi-purpose Control Application IIMulti-purpose Control Application II

Description Page

u

s

t

o

m

Analogue output func-

3.1

tion

0—14 1 1

0 = Not used

1 = O/P frequency

2 = Motor speed

3 = O/P current

4 = Motor torque

5 = Motor power

6 = Motor voltage

7 = DC-link volt.

8 = Input signal U

9 = Input signal I

10 = Refer. freq.

Scale 100%

(0—f

(0—max. speed

(0—2.0 x I

(0—2 x T

(0—2 x P

(0—100% x U

(0—1000 V)

in

in

max

)

)

nCX

)

nCX

)

nCX

nM

11 = Refer. torque

nMOT

nMOT

)

)

)

Analogue output filter

3.2

time

Analogue output inver-

3.3

sion

Analogue output mini-

3.4

mum

12 = Motor±torque

13 = Motor±power

14 = O/P freq.

(-2--+2xT

(-2--+2xT

(f

min—fmax

0.01—10 s 0.01 1.00 26

0—11 0

0—11 0

0 = Not inverted

1 = Inverted

0 = 0 mA

1 = 4 mA

3.5 Analogue output scale 10—1000% 1% 100% 26

0 = Not used

1 = Ready

2 = Run

3 = Fault

4 = Fault inverted

5 = Vacon overheat warning

6 = External fault or warning

7 = Reference fault or warning

8 = Warning

9 = Reversed

10 = Jogging speed selected

3.6 Digital output function 0—22 1 1

STOP

STOP

STOPSTO P

11 = At speed

12 = Motor regulator activated

13 = Output frequency limit superv. 1

14 = Output frequency limit superv. 2

15 = Torque limit supervision

16 = Reference limit supervision

17 = External brake control

18 = Control from I/O terminals

19 = Frequency converter temperature

limit supervision

20 = Unrequested rotation direction

21 = External brake control inverted

22 = Termistor fault or warning

3.7 Relay output 1 function 0—22 1 2 As parameter 3.6

STOP

STOP

STOPSTO P

3.8 Relay output 2 function 0—22 1 3 As parameter 3.6

STOP

STOP

STOPSTO P

3.9

3.10

3.11

3.12

Output frequency limit 1

supervision function

Output frequency limit 1

supervision value

Output frequency limit 2

supervision function

Output frequency limit 2

supervision value

0—21 0

0—f

max

(par. 1.2) 0.1 Hz 0 Hz 27

0—21 0

0—f

max

(par. 1.2)

0.1 Hz 0 Hz 27

0 = No

1 = Low limit

2 = High limit

0 = No

1 = Low limit

2 = High limit

)

26

26

26

27

27

27

27

27

STOP

STOP

Note!Note!

Note!

Note!Note!

STOPSTOP

= Parameter value can be changed only when the frequency converter is stopped. (Continues)

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 15

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 14

Code Parameter Range Step Default Custom Description Page

..

3

. 13 Torque limit 0—2 1 0 0 = No 28

..

supervision function 1 = Low limit

..

3

. 14 Torque limit 0—200% 1% 100% 28

..

supervision value xT

..

3

. 15 Reference limit 0—2 1 0 0 = No 28

..

supervision function 1 = Low limit

..

3

. 16 Reference limit 0—f

..

supervision value (par. 1

..

3

. 17 Extern. brake Off-delay 0—100.0 s 0.1 s 0.5 s 28

..

..

3

. 18 Extern. brake On-delay 0—100.0 s 0.1 s 1.5 s 28

..

..

3

. 19 Frequency converter 0—2 1 0 0 = No 28

..

temperature limit 1 = Low limit

supervision function 2 = High limit

..

3

. 20 Frequency converter -10—+75°C1°C +40°C28

..

temperature limit value

..

3

. 21 I/O-expander board (opt.) 0—14 1 3 See parameter 3

..

analogue output content

..

3

. 22 I/O-expander board (opt.) 0.01—10 s 0.01 1.00 See parameter 3

..

analogue output filter time

..

3

. 23 I/O-expander board (opt.) 0—1 1 0 See parameter 3

..

analogue output inversion

..

3

. 24 I/O-expander board (opt.) 0—1 1 0 See parameter 3

..

analogue output minimum

..

3

. 25 I/O-expander board (opt.) 10—1000% 1 100% See parameter 3

..

analogue output scale

3. 26 Analog output offset -100— 1 100% 29

(basic control board) 100,0%

3. 27 I/O-expander board (opt.) -100— 1 100% 29

analogue output offset +100,0%

..

3

. 28 Digital output DO1 0—320,00s 0,01 0,00 0,00 = delay not in use 29

..

on delay

..

3

. 29 Digital output DO1 0—320,00s 0,01 0,00 0,00 = delay not in use 29

..

off delay

..

3

. 30 Relay output RO1 0—320,00s 0,01 0,00 0,00 = delay not in use 29

..

on delay

..

3

. 31 Relay output RO1 0—320,00s 0,01 0,00 0,00 = delay not in use 29

..

off delay

..

3

. 32 Relay output RO1 0—320,00s 0,01 0,00 0,00 = delay not in use 29

..

on delay

3.33 Relay output RO2 0—320,00s 0,01 0,00 0,00 = delay not in use 29

off delay

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

2 = High limit

nCX

2 = High limit

0.1 Hz 0 Hz 28

max

..

. 2)

..

..

. 1 –

..

..

. 2 –

..

..

. 3 –

..

..

. 4 –

..

..

. 5 –

..

VV

aconacon

V

acon

VV

aconacon

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 16

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 15

VV

aconacon

Group 4, Drive control parametersGroup 4, Drive control parameters

Group 4, Drive control parameters

Group 4, Drive control parametersGroup 4, Drive control parameters

Multi-purpose Control Application IIMulti-purpose Control Application II

Code Parameter Range Step Default Custom Description Page

. .

4

. 1 Acc./Dec. ramp 1 shape 0—10 s 0.1 s 0 0 = Linear 30

. .

>0 = S-curve acc./dec. time

. .

4

. 2 Acc./Dec. ramp 2 shape 0—10 s 0.1 s 0 0 = Linear 30

. .

>0 = S-curve acc./dec. time

. .

4

. 3 Acceleration time 2 0.1—3000 s 0.1 s 10 s 31

. .

. .

4

. 4 Deceleration time 2 0.1—3000 s 0.1 s 10 s 31

. .

..

4

. 5 Brake chopper 0—1 1 0 0 = Brake chopper not in use 31

..

STOP

STOP

STOPSTOP

1 = Brake chopper in use

2 = External brake chopper

..

4

. 6 Start function 0—1 1 0 0 = Ramp 31

..

1 = Flying start

. .

4

. 7 Stop function 0—1 1 0 0 = Coasting 31

. .

1 = Ramp

. .

4

. 8 DC-braking current 0.15—1.5 0.1 A 0.5 x I

. .

x I

(A)

nCX

. .

4

. 9 DC-braking time at Stop 0—250.0 s 0.1 s 0 s 0 = DC-brake is off at Stop 32

. .

. .

4

. 10 Execute freq. of DC- 0.1—10 Hz 0.1 Hz 1.5 Hz 33

. .

nCX

brake during ramp Stop

. .

4

. 11 DC-brake time at Start 0.0—25.0 s 0.1 s 0 s 0 = DC-brake is off at Start 33

. .

..

4

. 12 Multi-step speed f

..

reference 1 (1

..

4

. 13 Multi-step speed f

..

reference 2 (1

..

4

. 14 Multi-step speed f

..

reference 3 (1

..

4

. 15 Multi-step speed f

..

reference 4 (1

..

4

. 16 Multi-step speed f

..

reference 5 (1

..

4

. 17 Multi-step speed f

..

reference 6 (1

..

4

. 18 Multi-step speed f

..

reference 7 (1

—f

min

..

. 1) (1

..

—f

min

..

. 1) (1

..

—f

min

..

. 1) (1

..

—f

min

..

. 1) (1

..

—f

min

..

. 1) (1

..

—f

min

..

. 1) (1

..

—f

min

..

. 1) (1

..

0.1 Hz 10 Hz 33

max

..

. 2)

..

0.1 Hz 15 Hz 33

max

..

. 2)

..

0.1 Hz 20 Hz 33

max

..

. 2)

..

0.1 Hz 25 Hz 33

max

..

. 2)

..

0.1 Hz 30 Hz 33

max

..

. 2)

..

0.1 Hz 40 Hz 33

max

..

. 2)

..

0.1 Hz 50 Hz 33

max

..

. 2)

..

31

STOP

STOP

Note!Note!

Note! = Parameter value can be changed only when the frequency converter is stopped.

Note!Note!

STOPSTOP

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 17

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 16

Group 5, Prohibit frequency parameters Group 5, Prohibit frequency parameters

Group 5, Prohibit frequency parameters

Group 5, Prohibit frequency parameters Group 5, Prohibit frequency parameters

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

Code Parameter Range Step Default Custom Description Page

. .

5

. 1 Prohibit frequency 0—f

. .

range 1 low limit (1

..

5

. 2 Prohibit frequency 0—f

..

range 1 high limit (1

. .

5

. 3 Prohibit frequency 0—f

. .

range 2 low limit (1

..

5

. 4 Prohibit frequency 0—f

..

range 2 high limit (1

. .

5

. 5 Prohibit frequency 0—f

. .

range 3 low limit (1

..

5

. 6 Prohibit frequency 0—f

..

range 3 high limit (1

Group 6, Motor control parameters Group 6, Motor control parameters

Group 6, Motor control parameters

Group 6, Motor control parameters Group 6, Motor control parameters

max

..

. 2)

..

max

..

. 2)

..

max

..

. 2)

..

max

..

. 2)

..

max

..

. 2)

..

max

..

. 2)

..

0.1 Hz 0 Hz 33

0.1 Hz 0 Hz 0 = Prohibit range 1 is off 33

0.1 Hz 0 Hz 33

0.1 Hz 0 Hz 0 = Prohibit range 2 is off 33

0.1 Hz 0 Hz 33

0.1 Hz 0 Hz 0 = Prohibit range 3 is off 33

Code Parameter Range Step Default Custom Description Page

. .

6

. 1 Motor control mode 0—2 1 0 0 = Frequency control 33

. .

STOP

STOP

STOPSTOP

. .

6

. 2 Switching frequency 1—16 kHz 0.1 kHz 10/3.6 kHz Dependant on kW 34

. .

. .

6

. 3 Field weakening point 30—500 Hz 1 Hz Param. 34

. .

..

6

. 4 Voltage at field 15 —200% 1% 100% 34

..

weakening point x U

. .

6

. 5 U/F-curve mid 0—500 Hz 0,1 Hz 0 Hz 34

. .

point frequency

. .

6

. 6 U/F-curve mid 0—100% 0.01% 0 % 34

. .

point voltage x U

. .

6

. 7 Output voltage at 0—100% 0.01% 0 % 34

. .

zero frequency x U

. .

6

. 8 Overvoltage controller 0—1 1 1 0 = Controller is not operating 35

. .

..

6

. 9 Undervoltage controller 0—1 1 1 0 = Controller is not operating 35

..

STOP

STOP

STOPSTOP

STOP

STOP

STOPSTOP

STOP

STOP

STOPSTOP

STOP

STOP

STOPSTOP

STOP

STOP

STOPSTOP

STOP

STOP

STOPSTOP

nmot

nmot

nmot

..

1

. 11

..

1 = Speed control (open loop)

2 = Torque control (open loop)

1 = Controller is operating

1 = Controller is operating

STOP

STOP

STOPSTOP

= Parameter value can be changed only when the frequency converter is stopped.

Note!Note!

Note!

Note!Note!

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 18

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 17

VV

aconacon

Group 7, Protections Group 7, Protections

Group 7, Protections

Group 7, Protections Group 7, Protections

Code Parameter Range Step Default Custom Description Page

. .

7

. 1 Response to 0—3 1 0 0 = No action 35

. .

reference fault 1 = Warning

. .

7

. 2 Response to 0—3 1 2 0 = No action 35

. .

external fault 1 = Warning

. .

7

. 3 Phase supervision of 0—2 1 2 0 = No action 35

. .

the motor 1 = Warning

. .

7

. 4 Earth fault protection 0—2 1 2 0 = No action 35

. .

. .

7

. 5 Motor thermal protection 0—2 1 2 0 = No action 36

. .

..

Motor thermal

7

. 6

..

break point current x I

..

7

. 7

Motor thermal

..

zero frequency current x I

..

7

. 8

Motor thermal

..

time constant minutes min. to motor nominal current

..

7

. 9

Motor thermal

..

break point frequency

..

7

. 10 Stall protection 0—2 1 1 0 = No action 38

..

..

7

. 11 Stall current limit 10.0—200% 1.0% 130.0% 39

..

..

7

. 12 Stall time 2.0—120 s 1.0 s 15.0 s 39

..

..

7

. 13 Maximum stall frequency 1—f

..

..

7

. 14 Underload protection 0—2 1 0 0 = No action 40

..

..

7

. 15 Underload prot., field 20.0—150 % 1.0% 50.0% 40

..

weakening area load x T

..

7

. 16 Underload protection, 10.0—150.0% 1.0% 10.0% 40

..

zero frequency load x T

..

7

. 17 Underload time 2.0—600.0 s 1.0 s 20.0s 40

..

. .

7

. 18 Phase supervision of 0—2 1 2 0 = No action 41

. .

the supply voltage 1 = Warning

. .

7

. 19 Termistor input of 0—2 1 2 0 = No action 41

. .

I/O-Expander 1 = Warning

7.20 Response to fieldbus 0—2 1 0 0 = Not used 41

fault 1 = Warning

protection 50.0—150 % 1.0 % 100.0% 36

protection 10.0—150% 1.0 % 45.0% 37

protection 0.5—300.0 0,5 Default value is set according 37

protection 10—500 Hz 1 Hz 35 Hz 38

Multi-purpose Control Application IIMulti-purpose Control Application II

2 = Fault, stop according to

par 4.7

3 = Fault, stop always by coasting

2 = Fault, stop according to par 4.7

3 = Fault, stop always by coasting

2 = Fault

1 = Warning

2 = Fault

1 = Warning

2 = Fault

nMOTOR

nMOTOR

1 = Warning

2 = Fault

x I

nMOTOR

max

nMOTOR

nMOTOR

1 Hz 25 Hz 39

1 = Warning

2 = Fault

2 = Fault

2 = Fault

2 = Fault

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 19

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 18

Group 8, Autorestart parametersGroup 8, Autorestart parameters

Group 8, Autorestart parameters

Group 8, Autorestart parametersGroup 8, Autorestart parameters

Code Parameter Range Step Default Custom Description Page

..

8

. 1 Automatic restart: 0—10 1 0 0 = not in use 41

..

number of tries

. .

8

. 2 Automatic restart: 1—6000 s 1 s 30 s 41

. .

trial time

..

8

. 3 Automatic restart: 0—1 1 0 0 = Ramp 42

..

start function 1 = Flying start

..

8

. 4 Automatic restart of 0—1 1 0 0 = No 42

..

undervoltage 1 = Yes

..

8

. 5 Automatic restart of 0—1 1 0 0 = No 42

..

overvoltage 1 = Yes

..

8

. 6 Automatic restart of 0—1 1 0 0 = No 42

..

overcurrent 1 = Yes

. .

8

. 7 Automatic restart of 0—1 1 0 0 = No 42

. .

reference fault 1 = Yes

..

8

. 8 Automatic restart after 0—1 1 0 0 = No 42

..

over/undertemperature 1 = Yes

fault

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

2 = Fault

VV

aconacon

V

acon

VV

aconacon

Group 9, TGroup 9, T

Group 9, T

Group 9, TGroup 9, T

Code Parameter Range Step Default Custom Description Page

Torque reference

9.1

selection

Torque reference

9.2

scaling bias

Torque reference

9.3

scaling gain

9.4 TC time constant 1—1000 ms 1 ms 15 ms 43

TC minimum control

9.5

limit

orque Controlorque Control

orque Control

orque Controlorque Control

–100%--

–320%--

0—10.00 Hz

0—610

+100%

+320%

1 0 0 = Not in use 43

1 100 100 = No scaling 43

0.01

3.00 Hz 43

Hz

0 = None

1 = U

in

2 = I

in

3 = Panel Trq reference r2

4 = Ain1 (option board)

5 = Ain2 (option board)

6 = Fieldbus control

43

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 20

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 19

VV

aconacon

Group 10, Fieldbus parametersGroup 10, Fieldbus parameters

Group 10, Fieldbus parameters

Group 10, Fieldbus parametersGroup 10, Fieldbus parameters

Code Parameter Range Step Default Custom Description Page

..

10

. 1 Fieldbus control select 0—1 1 0 0 = Control via I/O terminals 44

..

. .

10

. 2 DIC1 function 0—1 0 1 0 = Fieldbus control 44

. .

(term. 301, fieldbus board) 1 = External fault

..

10

. 3 MODBUS Slave address 1—247 1 1 44

..

..

10

. 4 Baud rate 1—7 1 6 1 = 300 baud 44

..

..

10

. 5 MB Parity type 0—2 1 0 0 = None 44

..

..

10

. 6 Modbus time-out 0—3600 s 1 s 0 s 0 = No time-out 44

..

10.7 Profibus slave address 2—126 1 126 44

10.8 Profibus baud rate 1—10 1 10 1 = 9.6 kbaud 45

10.9 Profibus PPO Type 1—4 1 1 1 = PPO 1 45

10.10 Profibus Process Data 1 0—99 1 1 45

10.11. Profibus Process Data 2 0—99 1 2 45

10.12 Profibus Process Data 3 0—99 1 3 45

10.13 Profibus Process Data 4 0—99 1 99 45

10.14 LonWorks Service Button 0—110 45

Multi-purpose Control Application IIMulti-purpose Control Application II

1 = Control via Fieldbus board

2 = 600 baud

3 = 1200 baud

4 = 2400 baud

5 = 4800 baud

6 = 9600 baud

7 = 19200 baud

1 = Even

2 = Odd

2 = 19.2 kbaud

3 = 93.75 kbaud

4 = 187.5 kbaud

5 = 500 kbaud

6 = 1.5 Mbaud

7 = 3 Mbaud

8 = 6 Mbaud

9 = 12 Mbaud

10 = AUTO

2 = PPO 2

3 = PPO 3

4 = PPO 4

Table 6-1. Special parameters, Groups 2-10

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 21

Multi-purpose Control Application IIMulti-purpose Control Application II

Page 20

6.2 Description of Groups 2—10 parameters6.2 Description of Groups 2—10 parameters

6.2 Description of Groups 2—10 parameters

6.2 Description of Groups 2—10 parameters6.2 Description of Groups 2—10 parameters

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

2. 12. 1

2. 1

2. 12. 1

Start/Stop logic selectionStart/Stop logic selection

Start/Stop logic selection

Start/Stop logic selectionStart/Stop logic selection

0:0:

0: DIA1: closed contact = start forward

0:0:

DIA2: closed contact = start reverse,

See figure 6-1.

Output

FWD

frequency

REV

DIA1

DIA2

Figure 6-1 Start forward/Start reverse.

Stop function

(par 4. 7)

= coasting

1 2 3

UD009K09

t

1 The first selected direction has the highest priority

2 When DIA1 contact opens, the direction of rotation starts to change

3 If Start forward (DIA1) and Start reverse (DIA2) signals are active

simultaneously, the Start forward signal (DIA1) has priority.

1:1:

1: DIA1: closed contact = start open contact = stop

1:1:

DIA2: closed contact = reverse open contact = forward

See figure 6-2.

Output

FWD

frequency

REV

DIA1

DIA2

Figure 6-2 Start, Stop,reverse.

Stop function

(par 4. 7

= coasting

t

UD012K10

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 22

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 21

VV

aconacon

2:2:

2: DIA1: closed contact = start open contact = stop

2:2:

Multi-purpose Control Application IIMulti-purpose Control Application II

DIA2: closed contact = start enabled open contact = start disabled

3:3:

3: 3-wire connection (pulse control):

3:3:

DIA1: closed contact = start pulse

DIA2: closed contact = stop pulse

(DIA3 can be programmed for reverse command)

See figure 6-3

Output

FWD

REV

DIA1

Start

DIA2

Stop

frequency

min 50 ms

Stop function

(par 4. 7)

= coasting

If Start and Stop pulses are

simultaneous the Stop pulse

overrides the Start pulse

t

UD009K11

Figure 6.3 Start pulse / Stop pulse

4:4:

4: DIA1: closed contact = start/stop pulse

4:4:

DIA2: closed contact = start enabled

Output

FWD

frequency

REV

DIA1

Start

DIA2

Stop

Run Enable

Figure 6-4. Start / Stop pulse, Run enable.

min. 50 ms

t

UD009K12

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 23

Page 22

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

2.22.2

2.2

2.22.2

DIA3 functionDIA3 function

DIA3 function

DIA3 functionDIA3 function

1:1:

1: External fault, closing contact =

1:1:

Fault is shown and motor is stopped when the input is active.

2:2:

2: External fault, opening contact =

2:2:

Fault is shown and motor is stopped when the input is not active.

3:3:

3: Run enable

3:3:

contact open = Motor start disabled

contact closed = Motor start enabled

4:4:

4: Acc./Dec contact open = Acceleration/deceleration time 1 selected

4:4:

time select. contact closed = Acceleration/deceleration time 2 selected

5:5:

5: Reverse

5:5:

contact open = Forward Can be used for reversing if

contact closed = Reverse parameter 2.1 has value 3

6:6:

6: Jogg. speed

6:6:

contact closed = Jogging speed selected for freq. reference

7:7:

7: Fault reset

7:7:

contact closed = Resets all faults

8:8:

8: Acc./Dec. operation prohibited

8:8:

contact closed = Stops acceleration or deceleration until the contact is opened

9:9:

9: DC-braking command contact closed =

9:9:

In Stop mode, the DC-braking operates until the contact is opened,

see figure 6.5. DC-brake current is set with parameter 4.8.

10:10:

10: Torque control

10:10:

contact closed = Forces the motor control mode to torque control, refer to par. 6.1

11

1:1:

1

1:

Torque reference sign

11

1:1:

This selection changes the sign of the torque reference

12: 12:

12: Run enable with coasting

12: 12:

contact open = Run and start disabled (stop always with coasting)

contact closed = Motor run enabled

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 24

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 23

VV

aconacon

Multi-purpose Control Application IIMulti-purpose Control Application II

Output

frequency

Param. 4. 10

DIA3

RUN

STOP

a) DIA3 as DC-brake command input and stop-mode =

Ramp

t

UD012K32

t

DIA3

RUN

STOP

b) DIA3 as DC-brake command input and stop-mode =

Coasting

UD012K32

Figure 6-5 DIA3 as DC-brake command input: a) Stop-mode = Ramp,

b) Stop-mode = Coasting.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 25

Page 24

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

2. 32. 3

2. 3

2. 32. 3

2. 42. 4

2. 4

2. 42. 4

2. 52. 5

2. 5

2. 52. 5

DIB4 functionDIB4 function

DIB4 function

DIB4 functionDIB4 function

Selections are the same as in 2

10:10:

10: Multi-Step contact closed = Selection 1 active

10:10:

. .

. 2 except :

. .

speed select 1

11

1:1:

1

1: Uin/Iin digital selection for frequency reference

11

1:1:

13:13:

13: Fieldbus control: Selection between I/O and fieldbus control

13:13:

14:14:

14: Parameter 1.5 / Uin

14:14:

15:15:

15: Parameter 1.5 / Iin

15:15:

DIB5 functionDIB5 function

DIB5 function

DIB5 functionDIB5 function

Selections are the same as in 2

10:10:

10: Multi-Step contact closed = Selection 2 active

10:10:

..

. 2 except :

..

speed select 2

11

1:1:

1

1: Motor pot. contact closed = Reference decreases until the contact is

11

1:1:

UP opened

13:13:

13: Fieldbus control: Selection between I/O and fieldbus control

13:13:

DIB6 functionDIB6 function

DIB6 function

DIB6 functionDIB6 function

Selections are the same as in 2

10:10:

10: Multi-Step contact closed = Selection 3 active

10:10:

..

. 2 except :

..

speed select 3

11

1:1:

1

1: Motor pot. contact closed = Reference decreases until the contact is

11

1:1:

DOWN opened

13:13:

13: Fieldbus control: Selection between I/O and fieldbus control

13:13:

Note! Note!

Note! (

Note! Note!

ParPar

. 2.3, 2.4, 2.5. 2.3, 2.4, 2.5

Par

. 2.3, 2.4, 2.5): In the fieldbus control par. 10.1 = 1 and 10.2 = 0.

ParPar

. 2.3, 2.4, 2.5. 2.3, 2.4, 2.5

2. 62. 6

2. 6

2. 62. 6

UU

signal rangesignal range

U

signal range

UU

signal rangesignal range

inin

in

inin

0 = Signal range 0—+10 V

1 = Custom setting range from custom minimum (par. 2

maximum (par. 2

..

. 5)

..

..

. 4) to custom

..

2 = Signal range -10—+10 V , can be used only with Joystick control

2. 72. 7

2. 7

2. 72. 7

2. 82. 8

2. 8

2. 82. 8

UU

custom setting minimum/maximum custom setting minimum/maximum

U

custom setting minimum/maximum

UU

custom setting minimum/maximum custom setting minimum/maximum

inin

in

inin

With these parameters, Uin can be set for any input signal span within 0—10 V.

Minimum setting: Set the Uin signal to its minimum level, select parameter 2

press the Enter button

Maximum setting: Set the Uin signal to its maximun level, select parameter 2

press the Enter button

Note!Note!

Note! These parameters can only be set with this procedure (not with the Browser

Note!Note!

buttons)

2. 92. 9

2. 9

2. 92. 9

UU

signal inversionsignal inversion

U

signal inversion

UU

signal inversionsignal inversion

inin

in

inin

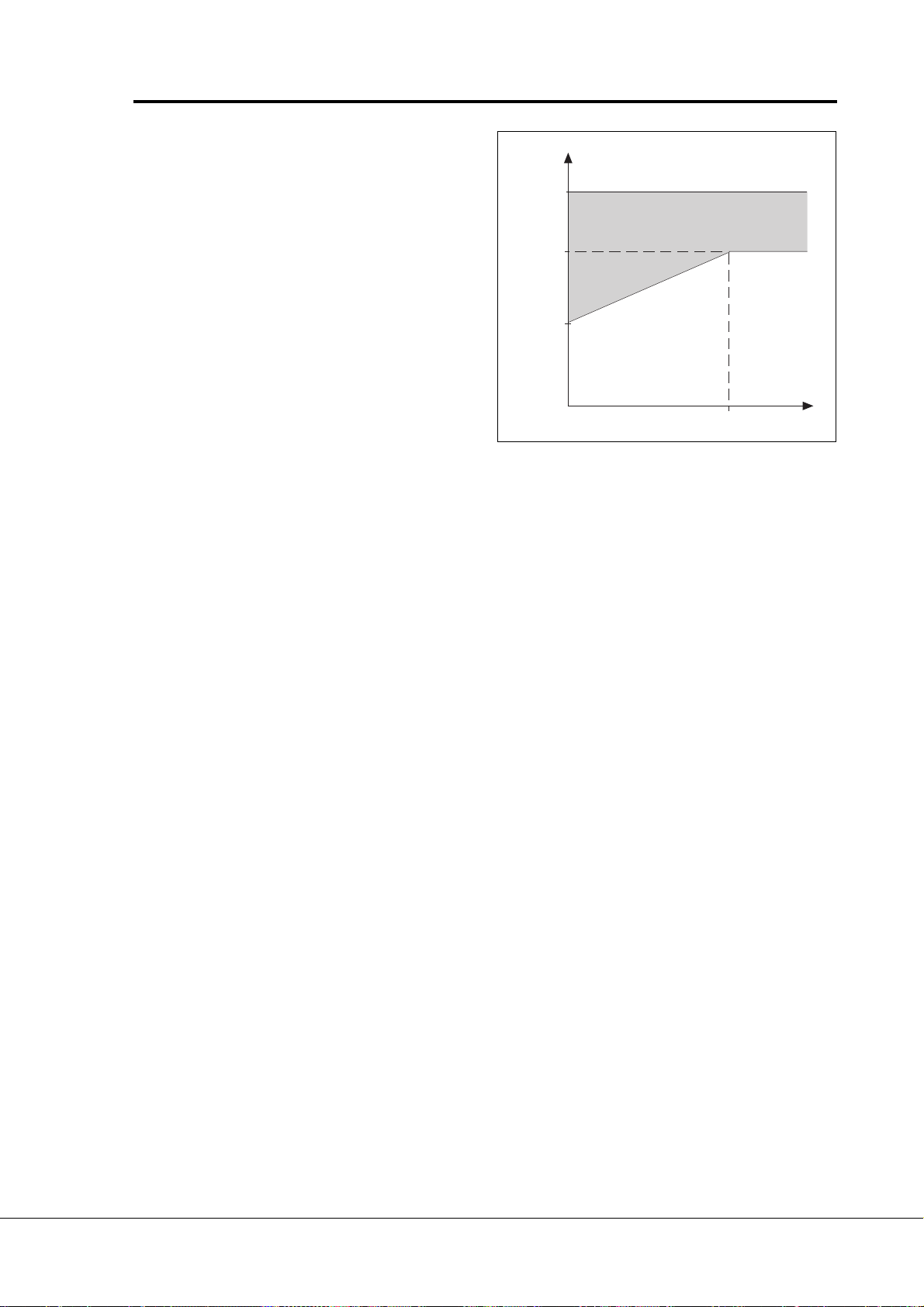

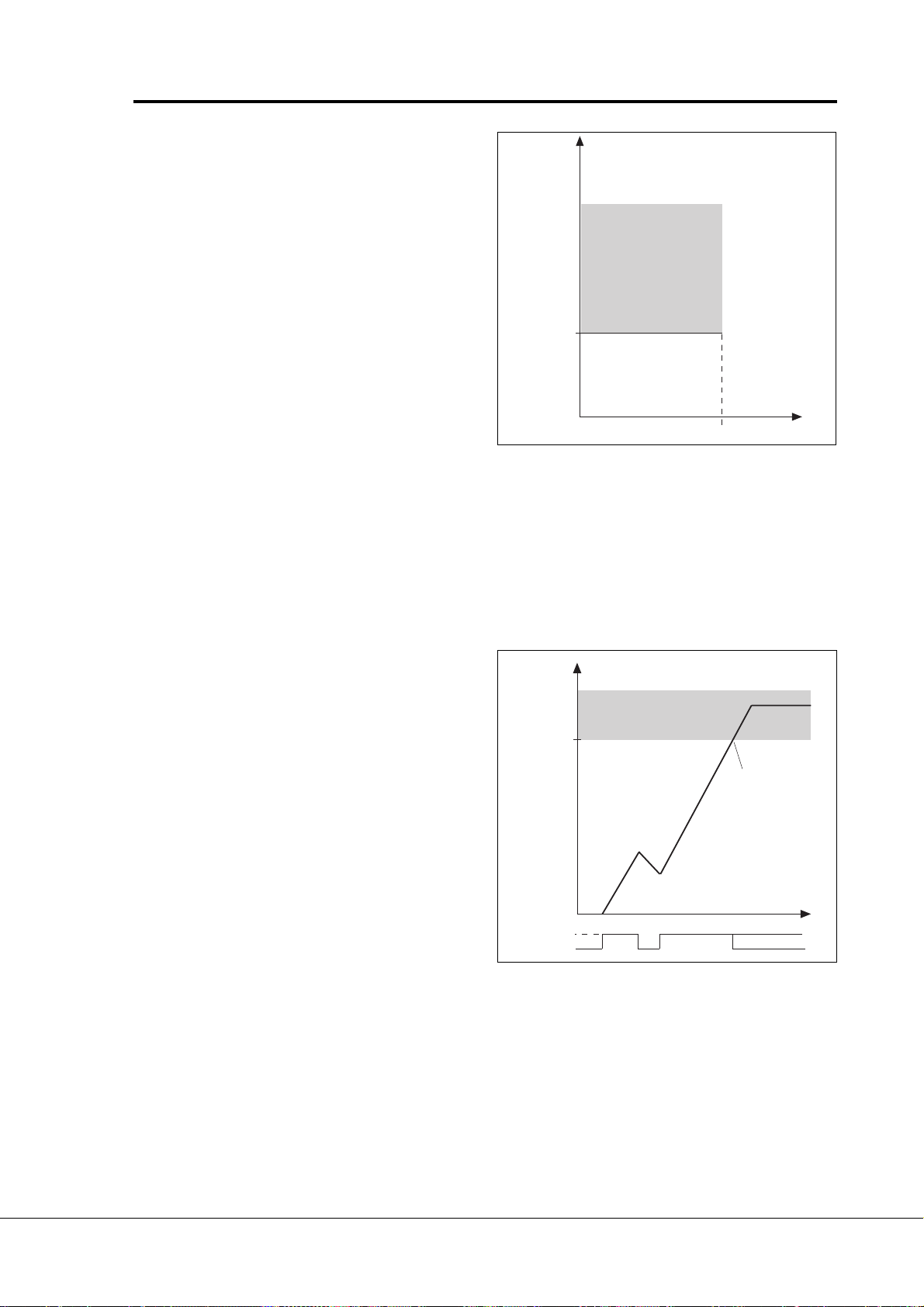

Parameter 2. 9 = 0, no inversion

of analogue U

signal.

in

%

Unfiltered signal

100%

Parameter 2. 9 = 1, inversion

2. 102. 10

2. 10

2. 102. 10

of analogue U

signal filter timesignal filter time

UU

signal filter time

U

signal filter timesignal filter time

UU

inin

in

inin

signal.

in

63%

Filtered signal

Filters out disturbances from the

incoming analogue U

Long filtering time makes regulation response slower.

signal.

in

Par. 2. 10

t [s]

UD009K37

See figure 6-6.

Figure 6-6 U

signal filtering.

in

..

. 4,

..

..

. 5,

..

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 26

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 25

VV

aconacon

2. 12. 1

2. 1

2. 12. 1

11

1

11

Analogue inputAnalogue input

Analogue input

Analogue inputAnalogue input

Multi-purpose Control Application IIMulti-purpose Control Application II

II

signal range signal range

I

signal range

II

signal range signal range

inin

in

inin

0 = 0—20 mA

1 = 4—20 mA

2 = Custom signal span

2. 122. 12

2. 12

2. 122. 12

2. 132. 13

2. 13

2. 132. 13

Analogue inputAnalogue input

Analogue input

Analogue inputAnalogue input

setting minimum/maximumsetting minimum/maximum

setting minimum/maximum

setting minimum/maximumsetting minimum/maximum

II

custom custom

I

custom

II

custom custom

inin

in

inin

With these parameters, the

scaling of the input current

signal (Iin) range can be set

between 0—20 mA.

Minimum setting:

Set the Iin signal to its minimum

level, select parameter 2

..

. 12,

..

press the Enter button.

Maximum setting:

Set the Iin signal to its maximun

level, select parameter 2

..

. 13,

..

press the Enter button.

Note!Note!

Note! These parameters can only

Note!Note!

be set by this procedure (not with

the browser buttons)

%

Unfiltered signal

100%

Filtered signal

63%

Par. 2. 15

Figure 6-7 Analogue input Iin filter time

t [s]

UD012K40

2. 142. 14

2. 14

2. 142. 14

2. 152. 15

2. 15

2. 152. 15

2. 162. 16

2. 16

2. 162. 16

2. 172. 17

2. 17

2. 172. 17

2. 182. 18

2. 18

2. 182. 18

2. 192. 19

2. 19

2. 192. 19

Analogue input IAnalogue input I

Analogue input I

Analogue input IAnalogue input I

Parameter 2. 14 = 0, no inversion of I

Parameter 2. 14 = 1, inversion of I

Analogue input IAnalogue input I

Analogue input I

Analogue input IAnalogue input I

Filters out disturbances from the incoming analog I

inversion inversion

inversion

inversion inversion

inin

in

inin

filter time filter time

filter time

filter time filter time

inin

in

inin

input.

in

input

in

in

Long filtering time makes regulation response slower.

See figure 6-7.

UU

signal minimum scalingsignal minimum scaling

U

signal minimum scaling

UU

signal minimum scalingsignal minimum scaling

in in

in

in in

Sets the minimum scaling point for U

UU

signal maximum scalingsignal maximum scaling

U

signal maximum scaling

UU

signal maximum scalingsignal maximum scaling

in in

in

in in

Sets the maximum scaling point for U

I I

signal minimum scalingsignal minimum scaling

I

signal minimum scaling

I I

signal minimum scalingsignal minimum scaling

in in

in

in in

Sets the minimum scaling point for I

I I

signal maximum scalingsignal maximum scaling

I

signal maximum scaling

I I

signal maximum scalingsignal maximum scaling

in in

in

in in

Sets the maximum scaling point for I

signal. See figure 6-8.

in

signal. See figure 6-8.

in

signal. See figure 6-8.

in

signal. See figure 6-8.

in

signal.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 27

Page 26

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

Multi-purpose Control Application IIMulti-purpose Control Application II

VV

aconacon

V

acon

VV

aconacon

2. 202. 20

2. 20

2. 202. 20

2. 212. 21

2. 21

2. 212. 21

functionfunction

function

functionfunction

100

0

0

0

4

Scaled

input signal [%]

Par. 2. 19 = 30%

Par. 2. 20 = 80%

Analogue

1008030

input [%]

10.0 V

8.03.0

20.0 mA

16.06.0

16.88.8 20.0 mA

(15.3 mA)

-30

100

76.5

17.7

(3.5 mA)

Scaled

input signal [%]

Par. 2. 19 = -30%

Par. 2. 20 = 140%

0

0

0

4

100 140

10.0 V

20.0 mA

20.0 mA

Analogue

input [%]

UD012K34

Figure 6-8 Examples of the scaling of Uin and Iin inputs .

Free analogue input signalFree analogue input signal

Free analogue input signal

Free analogue input signalFree analogue input signal

Selection of input signal of free analogue input (an input not used for reference

signal):

0 = Not in use

1 = Voltage signal U

2 = Current signal I

in

in

3 = Voltage signal Ain1 from terminals 202-203 of I/O Expander

4 = Analogue signal Ain2 from terminal 204-205 of I/O Expander

- current signal Vacon CX 100 Opt

- voltage signal Vacon CX 102 Opt

5 = Fieldbus signal

- the signal comes through the fieldbus and depends on the option

board used

100%

Par. 1. 7

Torque limit

Free analogue input signalFree analogue input signal

Free analogue input signal

Free analogue input signalFree analogue input signal

This parameter sets the function

of the free analogue input:

00

0 = Function is not used

00

11

1 = Reducing motor current limit

11

(par. 1

..

. 7)

..

This signal will adjust the

10 V

20 mA

20 mA

Custom

Analogue

input

UD012K61

maximum motor current

between 0 and parameter

max. limit set with parameter

0 V

0 mA

4 mA

Custom

Signal range

1.7. See figure 6-9.

Figure 6-9 Reducing of max. motor current.

DC-braking

100%

Par. 4. 8

current

2 2

2 = Reducing DC brake current.

2 2

The DC braking current can

be reduced with the free

analogue input signal,

between 0.15xI

nCX

and

current set with parameter

..

4

. 8.

..

0,15 x I

See figure 6-10.

Figure 6-10 Reducing DC brake current.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

nFU

0

Signal range

Free analogue

input

UD012K58

Page 28

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II

VV

aconacon

V

acon Page 27

VV

aconacon

33

3 Reducing acceleration and

33

deceleration times.

The acceleration and

deceleration times can be

Multi-purpose Control Application IIMulti-purpose Control Application II

Factor R

10

reduced with the free analog

input signal, according to the

following formula:

Reduced time =set acc./eceler.

..

..

..

time (par. 1

divided by the factor R from

figure 6-11.

. 3, 1

..

. 4; 4

..

Figure 6-11 Reducing acceleration

and deceleration times.

44

4 Reducing torque supervision

44

. 3, 4

..

..

. 4)

..

2

1

Signal range

limit.

The set torque supervision

100%

Par. 3. 14

Torque limit

limit can be reduced with the

free analogue input signal

between 0 and set

supervision limit (par. 3

..

. 14),

..

see figure 6-12.

Free analogue

input

UD012K59

2. 222. 22

2. 22

2. 222. 22

2.232.23

2.23

2.232.23

2.242.24

2.24

2.242.24

2.252.25

2.25

2.252.25

2.262.26

2.26

2.262.26

Figure 6-12 Reducing torque

supervision limit.

Free analogue

input

UD012K60

Motor potentiometer ramp timeMotor potentiometer ramp time

Motor potentiometer ramp time

Motor potentiometer ramp timeMotor potentiometer ramp time

0

Signal range

Defines how fast the electronic motor potentiometer value changes.

Ain1 signal inversion (I/O-Expander)Ain1 signal inversion (I/O-Expander)

Ain1 signal inversion (I/O-Expander)

Ain1 signal inversion (I/O-Expander)Ain1 signal inversion (I/O-Expander)

Parameter 2.23 = 0, no inversion

Ain1 signal filter timeAin1 signal filter time

Ain1 signal filter time

Ain1 signal filter timeAin1 signal filter time

Filters out disturbances from the incoming analogue Ain1 signal. Long filtering

time makes regulation response slower.

Ain2 input (I/O-Expander) signal rangeAin2 input (I/O-Expander) signal range

Ain2 input (I/O-Expander) signal range

Ain2 input (I/O-Expander) signal rangeAin2 input (I/O-Expander) signal range

0 = 0—20 mA

1 = 4—20 mA

2 = 0—10 V (must be used with 102 OPT)

Ain2 signal inversion (I/O-Expander)Ain2 signal inversion (I/O-Expander)

Ain2 signal inversion (I/O-Expander)

Ain2 signal inversion (I/O-Expander)Ain2 signal inversion (I/O-Expander)

Parameter 2.26 = 0, no inversion

2.272.27

2.27

2.272.27

Ain2 signal filter time (I/O-Expander)Ain2 signal filter time (I/O-Expander)

Ain2 signal filter time (I/O-Expander)

Ain2 signal filter time (I/O-Expander)Ain2 signal filter time (I/O-Expander)

Filters out disturbances from the incoming analogue Ain2 signal. Long filtering

time makes regulation response slower.

V acon Plc Phone: +358-(0)201 2121 Fax: +358-(0)201 212 205

Service: +358-40-8371 150 E-mail: vacon@vacon.com

Page 29

Page 28

Multi-purpose Control Application IIMulti-purpose Control Application II

Multi-purpose Control Application II