Page 1

Fact Sheet

VACON® Advanced Safety Options

Improve flexibility with integrated safety

The VACON® Advanced Safety

Options operate the safety functions

of an AC drive via the PROFIsafe

fieldbus or I/O control. They improve

flexibility by connecting safety devices within a plant.

The Advanced Safety Options are a

preferred choice for highly flexible

machines with modular and variable

quantity of safety zones in any manufacturing production line. Central and

decentral drives located at different

machinery cells can easily be interconnected with the PROFIsafe safety

fieldbus or with I/O inputs. These safety

functions are implemented and tested

according to:

- EN 61800-5-2

- IEC 61508

- EN ISO 13849-1

- IEC 61511-1

- EN 62061

Advanced

safety functionality

for VACON® NXP AC

drives

Advanced Functional Safety

with VACON® NXP

The VACON® Advanced Safety Options

expand the capabilities of the VACON®

Advanced safety functions

The VACON® Advanced Safety Option

adds a total of nine additional safety

functions to the VACON® NXP family.

NXP air and liquid cooled AC drives

by integrating nine advanced safety

functions into the AC drives including

both safe speed functions as well as a

PROFIsafe interface.

n OPT-BL – Advanced safety with

Safe Stop functions

n STO – Safe Torque Off

n SS1 – Safe Stop 1

n SS2 – Safe Stop 2

n SBC – Safe Brake Control

n SQS – Safe Quick Stop

proximity switch and PROFIsafe

n OPT-BM – Advanced safety with

HTL/TTL encoder and PROFIsafe

n OPT-BN – Advanced safety with

SIN/COS encoder and PROFIsafe

Safe Speed functions

n SLS – Safely-limited Speed

n SSM – Safe Speed Monitor

n SSR – Safe Speed Range

n SMS – Safe Maximum Speed

Fieldbus profiles like PROFIsafe and

PROFI drive are elements of the

PROFIBUS and PROFINET fieldbus

protocols. This permits the transmission

of standard and safety-related data on

a single bus cable. The existing network

Purchase the drive fully-configured

from the factory, or add the VACON®

Advanced Safety Options in the field

– whatever is the best fit for your

business.

infrastructure is optimally utilised, since

no separate cabling is required.

VACON® Advanced Safety Option is available to install in slot C, D or E of

VACON® NXP Air and Liquid Cooled drives

Feature Benefit

– Integrates 9 Advanced Safety functions

Standard safety option integrated

in the VACON® NXP Air and Liquid Cooled drives

– configurable through the VACON® Safe tool

Four configurable safe digital inputs

Two configurable safe outputs

PROFIsafe device

(with PROFIBUS or PROFINET option card)

Easy to retrofit – fits in slot C, D and E of

VACON® NXP Air and Liquid Cooled drives

GSD files that are easy to incorporate

in Step 7 and TIA Portal

PROFIBUS, PROFINET and PROFIsafe are registered trademarks of the PROFIBUS User Organisation PNO

(PROFIBUS Nutzerorganisation e.V )

inside the AC drive

– Reduced wiring and components

– Simple selection, configuration, project

planning, and installation

– Easy to configure via VACON® Safe

– Connect door switches or emergency stop

switches directly to the drive

– Select whether the inputs directly activate the

STO, or if the failsafe controller monitors the

safe inputs for use in its failsafe program

– Enables control of external devices that are not

connected with PROFIsafe

– Usable in a wide range of safety applications

– Increased plant availability possible by

formation of safe I/O groups

– High level of flexibility when expanding plants

– Drives already running on PROFINET or

PROFIBUS are easy to upgrade to PROFIsafe

– Closed-loop control, without additional encoder

board, possible when installed in slot C

– Efficient programming and commissioning

drives.danfoss.com

Page 2

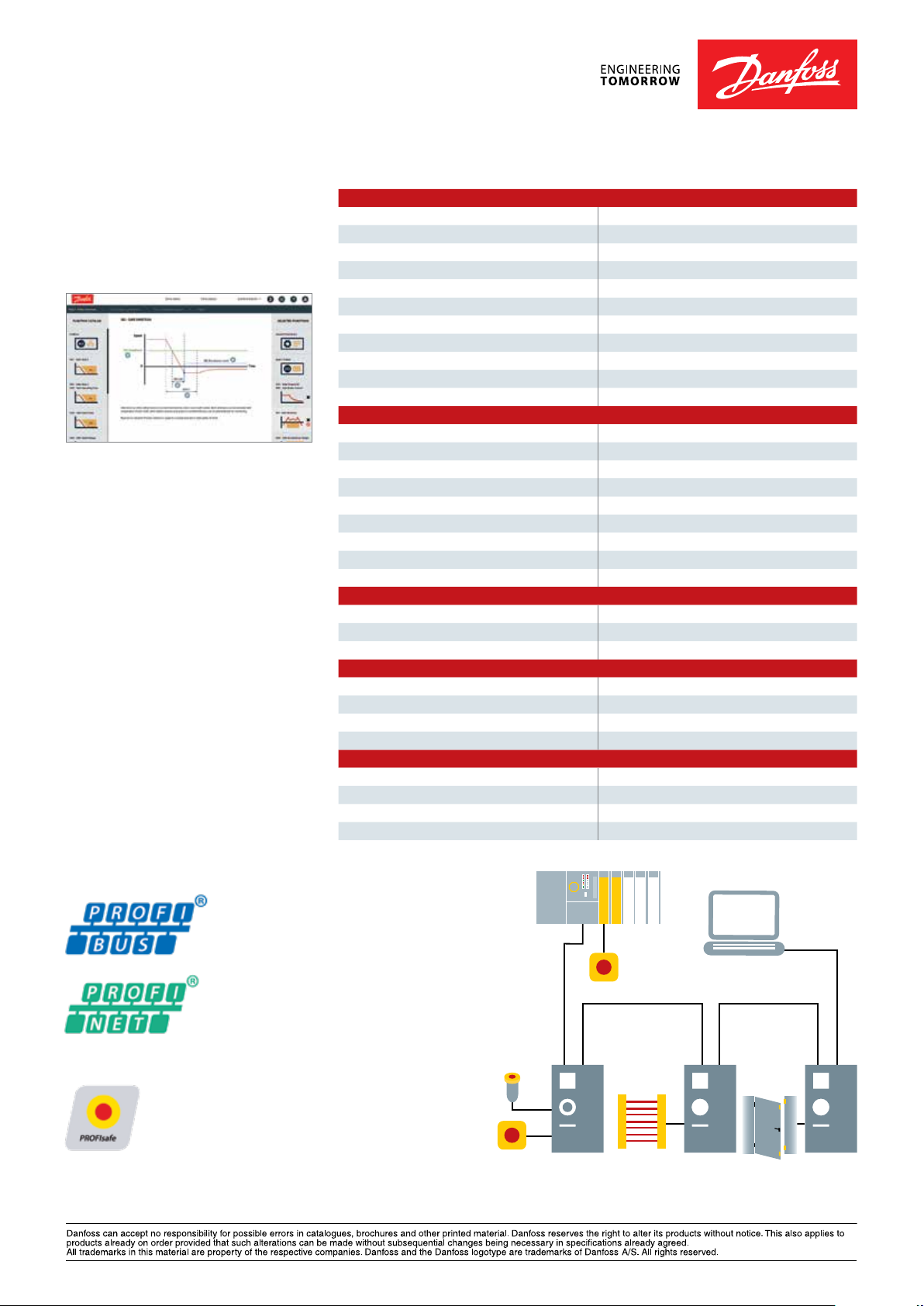

Easy configuration

To customize the safety application,

adapt the settings of safety parameters.

To configure via software, use the

VACON® Safe PC tool.

Convenient PC-based VACON® Safe user interface.

Easy integration

Fail-safe controllers, fail-safe I/O,

and fail-safe drives permit the

implementation of safety requirements

in every machine. The PROFIsafe device

extends the advantages of functional

safety to the next level of flexibility.

It enables extension from an isolated

safety device to interconnecting and

cooperating safety-related devices

within a plant.

Specifications

Digital inputs

Number of digital inputs 8 (4 x 2-channel digital safety input)

Input voltage range 0-24 V DC

Input voltage, logic 0 < 5 V DC

Input voltage, logic 1 > 13 V DC

Input voltage (maximum) 30 V DC

Input current (minimum) 3 mA @ Vin = 24 V

Input resistance > 3 kΩ

Galvanic isolation No

Short circuit-proof Yes

Input pulse recognition time (min.) 4 ms

Discrepancy time (min.) 500 ms

Digital output (Safe output)

Number of outputs 2 (2 x 2-channel digital output)

Output voltage low < 5 V DC

Output voltage high > 17 V DC

Output voltage (maximum) 27 V DC

Maximum output current (@24 V) 100 mA

Maximum output current (@0 V) < 0.1 mA

Galvanic Isolation No

Diagnostic test pulse < 1 ms

Short circuit-proof Yes

24 V supply output

Supply voltage 24 V DC ±15%

Maximum output current 160 mA

Short circuit-proof Yes

Encoder input (TTL/HTL & SIN/COS)

Voltage 5, 12, 15, 24 V DC ± 5%

Number of Pulses per rotation (PPR) Configurable

Zero pulse Configurable

Maximum frequency 350 kHz

Proximity switch input

Supported switch type 4-wire PNP

Voltage 24 V DC ±15%

Number of Pulses per rotation (PPR) Configurable

Maximum frequency 10 kHz

STOP

The VACON® Advanced

Safety Options allow full

flexibility to connect safety

switches, light curtains or

door switches where they

are most optimally located.

Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, drives.danfoss.com, info@danfoss.com

DKDD.PFO.619.A2.02 © Copyright Danfoss Drives | 2019.07

STOP

EtherNet/IP™ and DeviceNet™ are trademarks of ODVA, Inc.

Loading...

Loading...