Page 1

Page 2

1 vacon

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Product Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Overview of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 User’s Manual Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. TECHNICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Interpreting Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Power and Current Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 230-volt drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.2 380-480-volt drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.3 575-volt drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Control Features Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. RECEIVING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Preliminary Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Dissipation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Cover Assembly and Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6 Conduit Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 General Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.1 Wiring Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.2 Considerations for Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.3 Considerations for Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Input Line Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.1 Line Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.2 Use of Isolation Transformers and Line Reactors . . . . . . . . . . . . . . . . . . . . . . 25

4.2.3 Line Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.4 Phase Imbalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.5 Single-phase Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.6 Ground Fault Circuit Interrupters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.7 Motor Lead Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.8 Using Output Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Terminals Found on the Vacon 50X Power Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 Description of the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.2 Typical Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4 Dynamic Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 Terminals Found on the Vacon 50X Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.1 Description of the Control Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.2 Typical Connection Diagrams for Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5.3 Typical Connection Diagrams for Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.4 Typical Connection Diagrams for Analog Outputs . . . . . . . . . . . . . . . . . . . . . . 36

4.6 Reducing Current Surges and Voltage Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5. KEYPAD OPERATION AND PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 LCD Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.1 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.2 Vacon 50X Keypad Status and Warning Messages . . . . . . . . . . . . . . . . . . . . . . 42

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 3

vacon 2

5.3.3 Rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3.4 Other Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.4 Keypad Display Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.5 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

5.5.1 Accessing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.2 Changing the Display Scroll Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.3 Programming Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.5.4 Restoring Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5.5 Viewing Parameters That Have Changed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.5.6 Using Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.6 Measuring Stator Resistance (RS Measurement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.6.1 Activating Automatic RS Measurement via Keypad . . . . . . . . . . . . . . . . . . . . . 46

5.6.2 Activating Automatic RS Measurement via Serial Link (Modbus) . . . . . . . . . . 47

6. USING MACRO MODE AND GETTING A QUICK START. . . . . . . . . . . . . . . . 49

6.1 Entering Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2 Description of Parameters Used in Macro Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 Macro Mode Applications and Included Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7. VACON 50X PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.2 Level 1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3 Description of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4 Using the Vacon 50X Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.4.1 Enabling the Vacon 50X Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.4.2 Controlling the Vacon 50X Program Sequencer . . . . . . . . . . . . . . . . . . . . . . . . 92

7.4.3 Sequencer State Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.4.4 Sequencer Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.4.5 Sample Sequencer Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.1 Vacon 50X Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9. HEXADECIMAL TO BINARY CONVERSION . . . . . . . . . . . . . . . . . . . . . . . . 105

10. FUNDAMENTALS OF PI CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.2 Configuration of PI Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.2.1 Parameter 490 (Appl Macro). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.2.2 Parameter 857 (PI High Corr) and 858 (PI Low Corr) . . . . . . . . . . . . . . . . . . . 107

10.2.3 Parameter 852 (PI Prop Gain). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

10.2.4 Parameter 853 (PI Int Gain). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

10.2.5 Parameter 854 (PI Feed Gain). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

10.2.6 Parameter 850 (PI Configure). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

10.3 Tuning the PI Control Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11. EU DECLARATION OF CONFORMITY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

12. SUMMARY OF VACON 50X PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . 113

12.1 Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

12.2 Parameter Names in 5 Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

12.3 Settings and Messages in 5 Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

Page 4

3 vacon introduction

1. Introduction

1.1 Product Overview

Although the Vacon 50X AC drive is small in size, it is big on performance. It is an economical yet powerful

solution for many industrial applications. It features remote communications capability (using Modbus®

protocol), a keypad for easy configuration, and standard NEMA 4X / IP66 and NEMA 12 / IP55 enclosures

that eliminate the need for mounting in a separate enclosure.

The Vacon 50X product family includes a wide variety of models to suit almost any input voltage requirement. An ‘x’ in the following table indicates what models are currently available. Refer to Chapter 2 on

page 5 for help in interpreting model numbers.

Input Voltage

Power (kW) Power (hp)

0.75 1 x x x

1.5 2 x x x

2.2 3 x x x

4.0 5 x x x

5.5 7.5 x x x

7.5 10 x x x

11 15 x x x

15 20 x x x

18.5 25 x x x

22 30 x x

30 40 x x

37 50 x x

45 60 x x

55 75 x x

75 100 x x

90 125 x x

110 150 x x

150 200 x x

230 Vac

3 Phase

1.2 Overview of This Manual

This manual contains specifications, receiving and installation instructions, configuration, description of

operation, and procedures for Vacon 50X AC drive devices.

For experienced users, a “Quick Start” section begins on page 57.

1.3 User’s Manual Publication History

Date Form Number Nature of Change

16.7.2008 DPD00080A Original version

10.12.2008 DPD00080B

Changed installation diagrams to reflect changes in product;

changed photographs of product; added information to Chapter 2

on current surges and voltage transients; deleted mention of

Model 0002 5; other minor changes and corrections.

460 Vac

3 Phase

575 Vac

3 Phase

1

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 5

introduction vacon 4

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

1

Page 6

5 vacon Technical Characteristics

2. Technical Characteristics

2.1 Interpreting Model Numbers

The model number of the Vacon 50X AC drive appears on the shipping carton label and on the technical

data label affixed to the model. The information provided by the model number is shown below:

VACON

This segment is common for all products.

0050

Product range:

0050=Vacon 50X

3L

Input/Function:

3L=Three-phase input

0023

Drive rating in ampere; e.g. 0023 = 23 A

5

Supply voltage:

2=230 V

5=400 V

6=575 V

2

X

Information for factory

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 7

technical characteristics vacon 6

2.2 Power and Current Ratings

2.2.1 230-volt drives

Mains voltage 230V, IP66, EMC N, 50-60 Hz, 3~

Motor shaft power and current

Converter

S0

S1

S2

S3

High overload Low overload

type

0004 0,37 2,2 0,75 4,2 165x241x155 3,9

0007 0,75 4,2 1,5 6,8 165x241x155 3,9

0010 1,5 6,8 2,2 9,6 165x241x155 3,9

0015 2,2 9,6 4,0 15,2 221x306x166 6,35

0022 4,0 15,2 5,5 22,0 221x306x166 6,35

0028 5,5 22,0 7,5 28,0 221x306x166 6,35

0042 7,5 28,0 11 42,0 273x442x201 13,38

0054 11,0 42,0 15 54,0 273x442x201 13,38

0068 15,0 54,0 18,5 68,0 286x513x314 22,68

50%

overload

50°C

[kW]

50%

overload

current

[A]

10%

overload

40°C

[kW]

20%

overload

current

[A]

Dimensions

W x H x D

[mm]

Weig ht

[kg]

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 8

7 vacon Technical Characteristics

2.2.2 380-480-volt drives

Mains voltage 380-480V, IP66, EMC N, 50-60 Hz, 3~

Motor shaft power and current

Converter

S0

S1

S2

S3

S4

a

S5

a. Enclosure class IP54

High overload Low overload

type

0002 0,55 1,8 0,75 2,4 165x241x155 3,9

0004 0,75 2,4 1,5 3,8 165x241x155 3,9

0005 1,5 3,8 2,2 5,1 165x241x155 3,9

0009 2,2 5,1 4,0 8,9 221x306x166 6,35

0012 4,0 8,9 5,5 12,0 221x306x166 6,35

0016 5,5 12,0 7,5 15,6 221x306x166 6,35

0023 7,5 15,6 11,0 23,0 273x442x201 13,38

0031 11,0 23,0 15,0 31,0 273x442x201 13,38

0037 15,0 31,0 18,5 37,0 273x442x201 13,38

0043 18,5 37,0 22,0 43,0 273x442x201 13,38

0061 22,0 43,0 30,0 61,0 286x513x314 22,68

0071 30,0 61,0 37,0 71,0 286x513x314 22,68

0086 37,0 71,0 45,0 86,0 326x745x351 43,1

0105 45,0 86,0 55,0 105,0 326x745x351 43,1

0140 55,0 105,0 75,0 140,0 326x745x351 43,1

0168 75,0 140,0 90,0 168,0 414x1296x429 138,35

0205 90,0 168,0 110,0 205,0 414x1296x429 138,35

0240 110,0 205,0 132,0 240,0 414x1296x429 138,35

50%

overload

50°C

[kW]

50%

overload

current

[A]

10%

overload

40°C

[kW]

20%

overload

current

[A]

Dimensions

W x H x D

[mm]

Weig ht

[kg]

2

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 9

technical characteristics vacon 8

2.2.3 575-volt drives

Mains voltage 575V, IP66, EMC N, 50-60 Hz, 3~

Motor shaft power and current

Converter

S1

S2

S3

S4

a

S5

a. Enclosure class IP55

High overload Low overload

type

0002 0,5 1 1,1 1,7 221x306x166 6,35

0003 1,1 1,7 1,5 2,7 221x306x166 6,35

0004 1,5 2,7 2,2 3,9 221x306x166 6,35

0006 2,2 3,9 3,0 6,1 221x306x166 6,35

0009 3,0 6,1 5,0 9,0 221x306x166 6,35

0011 5,0 9,0 7,5 11,0 221x306x166 6,35

0017 7,5 11,0 11,0 17,0 273x442x201 13,38

0022 11,0 17,0 15,0 22,0 273x442x201 13,38

0027 15,0 22,0 18,5 27,0 273x442x201 13,38

0032 18,5 27,0 22,0 32,0 273x442x201 13,38

0041 22,0 32,0 30,0 41,0 286x513x314 22,68

0052 30,0 41,0 37,0 52,0 286x513x314 22,68

0062 37,0 52,0 45,0 62,0 326x745x351 43,1

0077 45,0 62,0 55,0 77,0 326x745x351 43,1

0099 55,0 77,0 75,0 99,0 326x745x351 43,1

0125 75,0 99,0 90,0 125,0 414x1296x429 138,35

0144 90,0 125,0 110,0 144,0 414x1296x429 138,35

0192 110,0 144,0 132,0 192,0 414x1296x429 138,35

50%

overload

50°C

[kW]

50%

overload

current

[A]

10%

overload

40°C

[kW]

20%

overload

current

[A]

Dimensions

W x H x D

[mm]

Weig ht

[kg]

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 10

9 vacon Technical Characteristics

2.3 Environmental Specifications

For 0010 2, 0015 2, and 0040 5 models:

Operating temperature

Storage temperature –20 °C to +65 °C (–4 °F to 149 °F)

Humidity 0% to 95% non-condensing

Altitude 1000 m (3300 ft) without derating

Maximum vibration per EN50178 (1g @ 57-150 Hz)

Acoustic noise 80 dba sound power at 1 m (3 ft), maximum

Cooling

2.4 Electrical Specifications

Input voltage

Line frequency 50 / 60 Hz ±2 Hz

Source kVA (maximum) 10 times the unit rated kVA (see note below)

DC bus voltage for:

Overvoltage trip

Dynamic brake activation

Nominal undervoltage (UV) trip

Control system

Output voltage 0–100% of line voltage, three-phase

Overload capacity

Frequency range 0,1–400 Hz

Frequency stability 0.1 Hz (digital), 0.1% (analog) over 24 hours ±10 °C

Frequency setting

NOTE: Unit Rated kVA = rate Voltage × rated Current × 1.732

2.5 Control Features Specifications

Vin1 reference input

Vin2 reference input

Cin reference input

Reference voltage 10 Vdc (10 mAdc maximum)

Digital inputs – 10

Digital supply voltage 24 Vdc (150 mAdc maximum)

Preset frequencies 3 inputs for seven preset frequencies (selectable)

Digital outputs

–10 °C to +35 °C

For all other models:

–10 °C to +40 °C

0,75–4,0 kW models: Natural convection.

5,5–150 kW models: Forced air.

230 Vac, 3 phase, ±15%

380–460 Vac, 3 phase, ±15%

230 Vac models

406 Vdc

388 Vdc

199 Vdc

V/Hz or SVC

Carrier frequency = 1–16 kHz, programmable; 8 kHz max. for 90–150 kW

models

120% of rated normal duty rms current for 60 seconds.

150% of rated heavy duty rms current for 60 seconds.

By keypad or by external signal

(Speed Pot 0–5 Vdc; 0–10 Vdc; 0–20 mA, or 4–20 mA)

OR by pulse train up to 100 kHz

0–5/10 Vdc, 0/4–20 mAdc (250 Ω load)

Pulse train input, 0–1/10/100 kHz pulse input, inverted function, 0–5–10 bipolar input, broken wire detection. Span and offset adjustment.

0–5/10 Vdc, 0–5–10 bipolar input, inverted function, broken wire detection,

span and offset adjustment. Programma ble for frequency reference or current limit input.

0/4–20 mAdc (50 Ω load), inverted function, span and offset adjustment.

Programmable for frequency reference or current limit input.

Off = 0 to 3 Vdc; On = 10 to 32 Vdc (pullup logic), selectable between pullup

and pulldown logic

2 SPDT relay output – 130 Vac, 1 A/250 Vac, 0.5 A.

2 open collector outputs 50 mA per device

460 Vac models

814 Vdc

776 Vdc

397 Vdc

575 Vac models

1017 Vdc

970 Vdc

497 Vdc

2

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 11

technical characteristics vacon 10

Digital pulse train output Open collector output pulse train proportional to output frequency

Vmet analog output 0 to 10 Vdc (5 mAdc maximum)

Imet analog output 0–20 mAdc output into a 500 Ω load (maxim um)

DC holding / injection braking

Current limit Four quadrant adjustable from 5 to 150%

Speed ramps Primary and alternate adjustable from 0.1 to 3200.0 seconds

Voltage boost Fixed boost adjustable from 0 to 50% or auto boost

Voltage characteristic (V/Hz) Linear, pump, fan or 2-piece linear

Timed overload

Protective features

Program Sequence Logic Controller (PSLC)

Serial communications Modbus Standard: RTU

At start, stop, by frequency with adjustable current level and time or continuous DC injection by digital input

Adj ustabl e inve rse ti me tri p (she ar pin , 30 s ec, 60 sec, 5 min), stand ard or i nverterduty motors

Overcurrent, overvoltage fault, ground fault, short circuit, dynamic brake

overload, drive temperature, power wiring fault, drive timed overload, input

voltage quality, overvoltage ridethrough

9-step PLC type functionality that can control speed, direction, and ramps

based on time, analog input, digital input, or pulse input

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 12

11 vacon Technical Characteristics

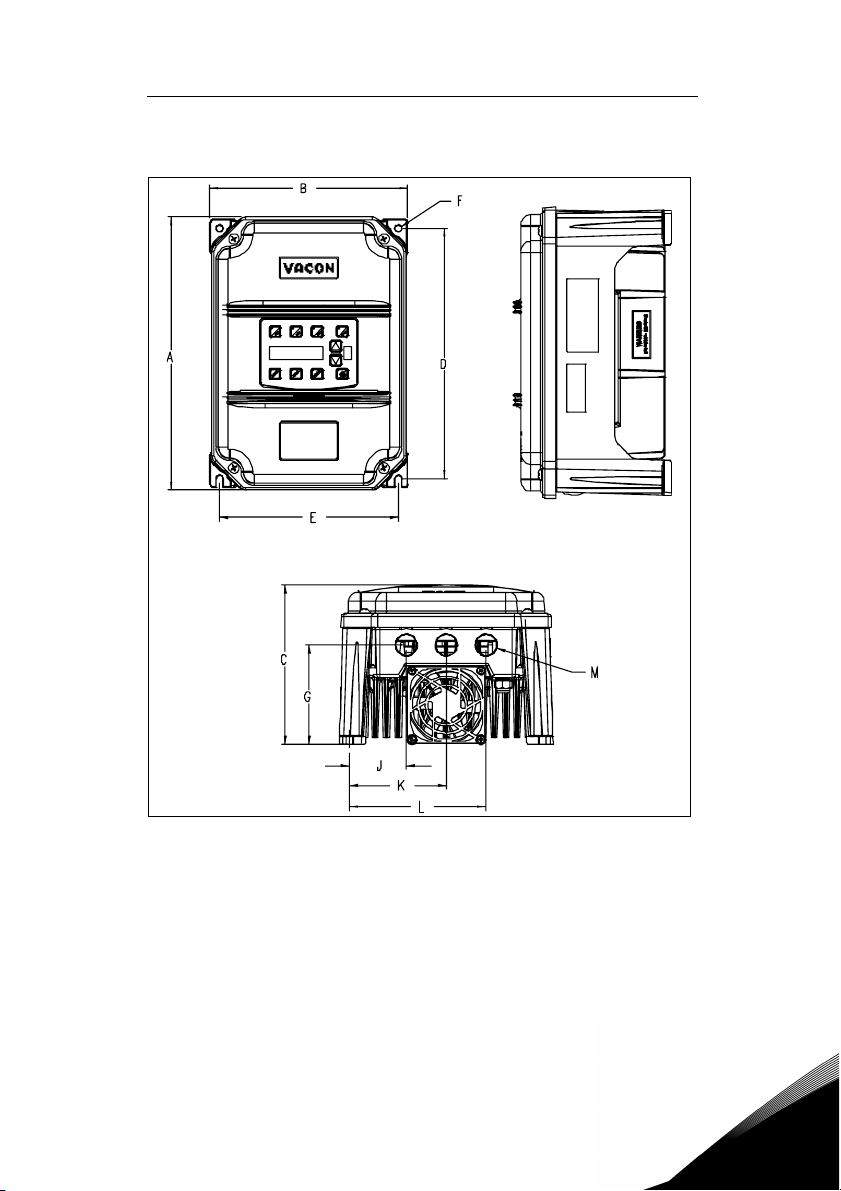

2.6 Dimensions and Weights

Table 1 lists dimensions and weights for the Vacon 50X frame size 0, 1, 2, and 3 models. Dimensions and

weights for the Vacon 50X frame size 4 and 5 models are shown in Table 2 on page 12.

See Figures on pages 13–18 for locations of dimensions. Dimensions A through Q are in millimeters

(mm). Weight is in kilograms (kg).

Frame 0 1 2 3

Voltage (V) 230 460 230 460 575 230 460 575 230 460 575

KW 0.75–2.2 4–5.5 4–7.5 1.1-7.5 7.5–11 11–22 11-22 15–22 30–37 30-37

hp 1–3 5–7.5 5–10 1-10 10–15 15–30 15–30 20–30 40–50 40–50

A 241 306 442 513

B 165 221 274 289

C (with-

out Filter)

C1 (with

Filter)

Dimen-

sions

in mm

Weight (kg) without

Filter (C)

Weight (kg) with Fil-

ter (C1)

Table 1:Dimensions and Weights for Frame Sizes 0–3

156 167 202 314

217 252 303

D 215 280 419 489

E 144 198 248 200

F 7.1 7.1 9.0 7.1

G 95 104 119 199

H 69 – - –

J 49 56 72 63

K 71 98 123 58

L 95 100 172 100

M 22 25.5 32 44

N – – 25.5 25.5

P –– – 142

Q –– – 184

3.9 6.7 12.7 23.7

7.8 15.6

2

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 13

technical characteristics vacon 12

Frame 4 5

Voltage (V) 460 575 460 575

KW 45–75 45-75 90–132 90–132

hp 60–100 60-100 125–200 125–200

Dimensions in mm

Weight (kg) without Filter (C) 43.1 138.4

Table 2:Dimensions and Weights for Frame Sizes 4–5

A 745 1296

B 326 414

C (without Filter) 351 429

D 711 1163

E 200 194

F 11 11

G 219 319

H 210 282

J 13 5

K 68 59

L 100 97

M 62 75

N 22 22

P 132 135

Q 187 189

R 260 –

S 49 47

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 14

13 vacon Technical Characteristics

2

Figure 1: Vacon 50X Frame Size 0 Models

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 15

technical characteristics vacon 14

(4 pla ces)

X

series

Figure 2: Vacon 50X Frame Size 1 Models

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

(3 places)

2

Page 16

15 vacon Technical Characteristics

B

A

X

ser ies

E

C

GH

(4 places)

F

D

N

M

(3 p laces)

2

J

K

L

Figure 3: Vacon 50X Frame Size 2 Models

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 17

technical characteristics vacon 16

Figure 4: Vacon 50X Frame Size 3 Models

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 18

17 vacon Technical Characteristics

2

Figure 5: Vacon 50X Frame Size 4 Models

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 19

technical characteristics vacon 18

Figure 6: Vacon 50X Frame Size 5 Models

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

2

Page 20

19 vacon receiving and installation

3. Receiving and Installation

3.1 Preliminary Inspection

Before storing or installing the Vacon 50X AC drive, thoroughly inspect the device for possible shipping

damage. Upon receipt:

1. Remove the drive from its package and inspect exterior for shipping damage. If damage is apparent, no-

tify the shipping agent and your sales representative.

2. Remove the cover and inspect the drive for any apparent damage or foreign objects. (See Figure 7 on

page 21 for locations of cover screws.) Ensure that all mounting hardware and terminal connection

hardware is properly seated, securely fastened, and undamaged.

3. Read the technical data label affixed to the dr ive and ensure that the correct horsepower and input volt-

age for the application has been purchased.

4. If you will be storing the drive after receipt, place it in its original packaging and store it in a clean, dry

place free from direct sunlight or corrosive fumes, where the ambient temperature is not less than –20

°C (–4 °F) or greater than +65 °C (+149 °F).

EQUIPMENT DAMAGE HAZARD

Do not operate or install any drive that appears damaged.

Failure to follow this instruction can result in injury or equipment damage.

CAUTION

3.2 Installation Precautions

Improper installation of the Vacon 50X AC drive will greatly reduce its life. Be sure to observe the following precautions when selecting a mounting location. Failure to observe these precautions may void the

warranty!

• Do not install the drive in a place subjected to high temperature, high humidity,

excessive vibration, corrosive gases or liquids, or airborne dust or metallic

particles. See Chapter 2 for temperature, humidity, and maximum vibration limits.

• Do not mount the drive near heat-radiating elements or in direct sunlight.

• Mount the drive vertically and do not restrict the air flow to the heat sink fins.

• The drive generates heat. Allow sufficient space around the unit for heat dissipation.

See “Dissipation Requirements” on page 20.

3

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 21

receiving and installation vacon 20

3.3 Dissipation Requirements

Model

0004 2

0007 2

0010 2

0015 2

0022 2

0028 2

0042 2

0054 2

0068 2

0004 5

0005 5

0009 5

0012 5

0016 5

0023 5

0031 5

0037 5

0043 5

0061 5

0071 5

0086 5

0105 5

0140 5

0168 5

0205 5

0240 5

Required Dissipation for Models

Entirely Inside an Enclosure at Rated

Current, 3 kHz Carrier Frequency (Watts)

47 13

48 14

71 17

92 16

132 20

177 23

263 67

362 68

550 97

46 16

71 20

91 21

114 28

155 30

304 77

393 76

459 78

458 77

695 95

834 100

776 130

988 135

1638 155

1656 353

1891 372

2302 382

Table 3:Dissipation Requirement for Vacon 50X Models

Required Dissipation When Fins are

External to the Enclosure (Watts)

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

3

Page 22

21 vacon receiving and installation

3.4 Cover Assembly and Torque Specifications

Figure 7 shows the locations of the Vacon 50X cover screws. The torque range for the Size 0 and 1 covers

is 2–3 Nm (18–26 in/lbs).

Cover screw locations

Figure 7: Vacon 50X Cover Assembly and Screw Locations

Torque specifications for control terminals and power terminals are listed in “General Wiring Information” on page 23.

3.5 Serial Number Label

To determine if your drive is within the warranty time frame, find the bar code label or look in the lower

left of the technical nameplate. The serial number can be broken down as follows:

3.6 Conduit Usage

The Vacon 50X drive in the IP66 enclosure is rated for 70 bar washdown from 15 cm. To keep this rating,

the use of a sealed conduit is required. The use of a Romex-type conduit will not prevent water entry into

the enclosure. If the approved conduit is not used, all warranty claims against water damage will be void.

3.7 Condensation

The washdown process of an Vacon 50X drive may create a temperature and humidity change in and

around the drive. If the unit is mounted in a cool environment and washed down with higher-temperature

water, as the drive cools to room temperature, condensation can form inside the drive, especially around

the display. To prevent this from happening, avoid using sealed connectors around rubbercoated cables

to seal the drive. These do not allow any air transfer and hence create a level of condensation and humidity that exceeds the drive’s rating.

• yywwxxxx = yy ... year of manufacture

• ww ... week of manufacture

• xxxx....sequential number drive during that week.

Cover screw locations

3

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 23

receiving and installation vacon 22

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

3

Page 24

23 vacon connections

4. Connections

This chapter provides information on connecting power and control wiring to the Vacon 50X AC drive.

HAZARDOUS VOLTAGE

• Read and understand this manual in its entirety before installing or operating the Vacon 50X AC drive. Installation,

adjustment, repair, and maintenance of these drives must

be performed by qualified personnel.

• Disconnect all power before servicing the drive. WAIT 5

MINUTES until the DC bus capacitors discharge.

• DO NOT short across DC bus capacitors or touch unshielded components or terminal strip screw connections

Danger

4.1 General Wiring Information

Pay conscientious attention to ensuring that the installation wiring is installed in conformity with local

standards. Where local codes exceed these requirements, they must be followed.

4.1.1 Wiring Practices

When making power and control connections, observe these precautions:

• Never connect input AC power to the motor output terminals T1/U, T2/V, or T3/W.

Damage to the drive will result.

• Power wiring to the motor must have the maximum possible separation from all

other power wiring. Do not run in the same conduit; this separation reduces the

possibility of coupling electrical noise between circuits.

• Cross conduits at right angles whenever power and control wiring cross.

• Good writing practice also requires separation of control circuit wiring from all

power wiring. Since power delivered from the drive contains high frequencies which

may cause interference with other equipment, do not run control wires in the same

conduit or raceway with power or motor wiring.

4.1.2 Considerations for Power Wiring

Power wiring refers to the line and load connections made to terminals L1/R, L2/S, L3/T, and T1/U, T2/V,

T3/W respectively. Select power wiring as follows:

1. Use only VDE, UL or CUL recognized wire.

2. Wire voltage rating must be a minimum of 300 V for 230 Vac systems and 600 V

(Class 1 wire) for 400 Vac systems.

with voltage present.

• Install all covers before applying power or starting and

stopping the drive.

• The user is responsible for conforming to all applicable

code require-ments with respect to grounding all equipment.

• Many parts in this drive, including printed circuit boards,

operate at line voltage. DO NOT TOUCH. Use only electrically-insulated tools.

Before servicing the drive:

• Disconnect all power.

• Place a “DO NOT TURN ON” label on the drive disconnect.

• Lock the disconnect in the open position.

Failure to observe these precautions will cause shock or

burn, resulting in severe personal injury or death.

4

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 25

connections vacon 24

3. Wire gauge must be selected based on 125% of the continuous input current rating

of the drive. Wire gauge must be selected from wire tables for 75 °C insulation rating, and must be of copper construction. The 230 V 5.5 and 11 kW models, and the

460 V 22 kW models require 90 °C wire to meet UL requirements. See Chapter 2 for

the continuous output ratings for the drive.

4. Grounding must be in accordance with VDE, NEC and CEC. If multiple Vacon 50X

drives are installed near each other, each must be connected to ground. A central

earthing point should be used for interference suppression (e.g. equipotential

bonding strip or centrally at an interference suppression filter). The earthing lines

are routed to the respective terminals radially from this point. Conductor loops of

See Table 4 below for a summary of power terminal wiring specifications.

Vacon 50X Size /

Models

Size 0

Size 1

Size 2

Size 3

Size 4

Size 5

Table 4:Vacon 50X Power Terminal Wiring Specifications

NOTE: Wire type not specified by the manufacturer. Some types of wire may not fit within the

constraints of the conduit entry and bend radius inside the drive.

4.1.3 Considerations for Control Wiring

Control wiring refers to the wires connected to the control terminal strip. Select control wiring as follows:

See Table 5 below for a summary of power terminal control wiring specifications.

Vacon 50X Size / Models Specifications

All Sizes / Models

Table 5:Vacon 50X Control Wiring Specifications

the earthing lines are impermissible and can lead to unnecessary interference.

Specifications

1.36 Nm (12 in-lbs) nominal torque or

1.47 Nm (13 in-lbs) maximum torque

2

1.5–4 mm

(11–15 awg wire)

1.8 Nm (16 in-lbs) nominal torque or

2.0 Nm (18 in-lbs) maximum torque

2

(7–15 awg wire)

1.5–10 mm

3.4 Nm (30 in-lbs) nominal torque

2

(5–7 awg wire)

10–16 mm

4.0 Nm (35 in-lbs) nominal torque

2

(3 awg wire)

25 mm

7.3 Nm (64 in-lbs) nominal torque

2

(3 awg wire max)

25 mm

14.9 Nm (131 in-lbs) nominal torque

2

(250MCM wire max)

120 mm

1. Shielded wire is recommended to prevent electrical noise interference from causing improper operation or nuisance tripping.

2. Use only VDE, UL or CUL recognized wire.

3. Wire voltage rating must be at least 300 V for 230 Vac systems. It must be at least

600 V for 460 Vac systems.

0.5 Nm (4.4 in-lbs) maximum torque

2

0.2–4 mm

(12–24 awg wire)

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 26

25 vacon connections

4.2 Input Line Requirements

4.2.1 Line Voltage

See “Power and Current Ratings” on chapter 2.2 for the allowable fluctuation of AC line voltage for your

particular Vacon 50X model. A supply voltage above or below the limits given in the table will cause the

drive to trip with either an overvoltage or undervoltage fault.

Exercise caution when applying the Vacon 50X AC drive on low-line conditions.

For example, an Vacon 50X 2-series unit will operate properly on a 208 Vac line, but the maximum output

voltage will be limited to 208 Vac. If a motor rated for 230 Vac line voltage is controlled by this drive, higher

motor currents and increased heating will result.

Therefore, ensure that the voltage rating of the motor matches the applied line voltage.

4.2.2 Use of Isolation Transformers and Line Reactors

In nearly all cases, the Vacon 50X drive may be connected directly to a power source. However, in the following cases, a properly–sized isolation transformer or line reactor should be utilized to minimize the

risk of drive malfunction or damage:

• When the line capacity exceeds the requirements of the drive (see Section 4.2.3).

• When power factor correction capacitors are used on the drive’s power source.

• When the power source experiences transient power interruptions or voltage

spikes.

• When the power source supplying the drive also supplies large devices (such as DC

drives) that contain controlled rectifiers.

Drive kW 0.75 1.5 2.2 4.0 5.5 7.5 11 15 18.5 30 37 45 55 75 90 110 150

Drive hp 1 2 3 5 7.5 10 15 20 25 40 50 60 75 100 125 150 200

Transformer kVA 2 4 5 9 13 18 23 28 36 57 70 90 112 150 180 220 250

Table 6:Transformer Sizing for the Vacon 50X Drive

4.2.3 Line Capacity

If the source of AC power to the Vacon 50X drive is greater than 10 times the kVA rating shown in Table 6,

an isolation transformer or line reactor is recommended. Consult VACON for assistance in sizing the reactor.

NOTE: Vacon 50X AC drive devices are suitable for use on a circuit capable of delivering not

more than 65,000 rms symmetrical amperes at 10% above the maximum rated voltage.

4.2.4 Phase Imbalance

Phase voltage imbalance of the input AC source can cause unbalanced currents and excessive heat in the

drive’s input rectifier diodes and DC bus capacitors. Phase imbalance can also damage motors running

directly across the line. The phase imbalance should not exceed 2% of the voltage rating.

4

CAUTION

EQUIPMENT DAMAGE HAZARD

Never use power-factor correction capacitors on motor terminals T1/U, T2/

V, or T3/W of the Vacon 50X AC drive. Doing so will damage the

semiconductors.

Failure to follow this instruction can result in injury or equipment damage.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 27

connections vacon 26

4.2.5 Single-phase Operation

Vacon 50X AC drive 230 Vac models are designed for both three-phase and singlephase input power. If

one of these models is operated with single-phase power, use any two line input terminals. The output of

the device will always be three-phase.

The safe derating of the Vacon 50X series of drives is 50% of the nominal current (hp) rating. Consult the

factory with the particular application details for exact derating by model.

4.2.6 Ground Fault Circuit Interrupters

Vacon 50X drives rated for 230 Vac are not designed to operate with ground fault circuit interrupters (GFCI). The GFCI breakers are designed for residential use to protect personnel from stray currents to

ground. Most GFCI breakers will shut off at 5 mA of leakage. It is not uncommon for an AC drive to have

30 to 60 mA of leakage.

4.2.7 Motor Lead Length

The distance from the Vacon 50X drive to the motor should not exceed 300 meters. If the leads for motor

connections exceed 30 meters, the motor windings may be subjected to voltage stresses two to three

times nominal values unless an output filter is utilized. Consult with the motor manufacturer to ensure

compatibility. Line disturbance and noise can be present in motor wiring of any distance. The carrier frequency for the drive should also be reduced using parameter 803 (PWM Frequency).

Nuisance trips can occur due to capacitive current flow to ground.

Some applications can have a restricted lead length because of type of wire, motor type, or wiring placement. Consult VACON and the motor manufacturer for additional information.

4.2.8 Using Output Contactors

Contactors in the output wiring of an AC drive may be needed as part of the approved safety circuit. Problems can arise if these contactors are opened for the safety circuit and the drive is left in run mode of

operation. When the contactor is open, the drive is in a no-load, no-resistance state, but is still trying to

supply current to the motor. However, when the contactor closes, the drive sees the motor resistance and

instantly demands current. This inrush of current when the contactor closes can fault or cause failure to

the drive.

To prevent problems, interlock an auxiliary contact to the drive's Run or Enable circuit to stop the drive

when the contactor opens. In this way, the drive will be disabled and no inrush will occur when the contactor is closed again.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 28

27 vacon connections

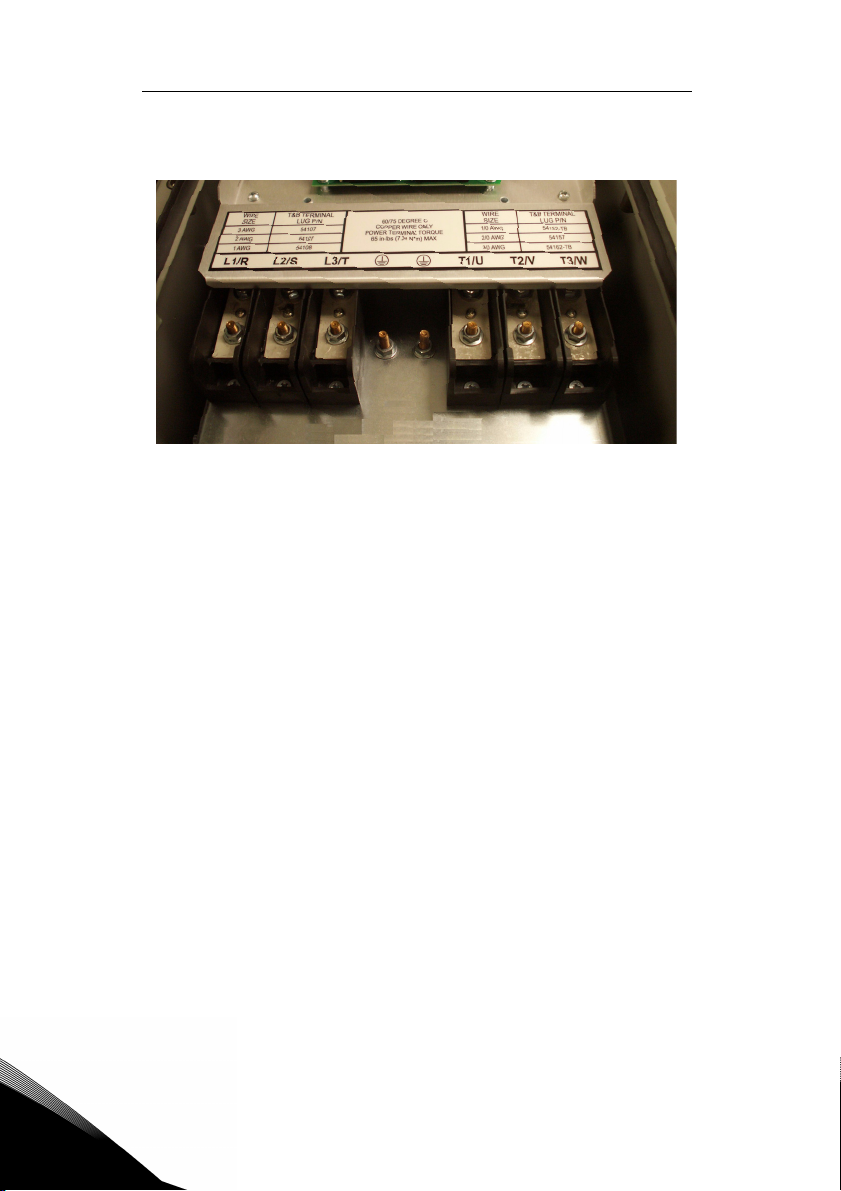

4.3 Terminals Found on the Vacon 50X Power Board

4.3.1 Description of the Terminals

Table 7 describes the Vacon 50X power terminals.

Terminal Description

L1/R (L)

L2/S

L3/T (N)

T1/U

T2/V

T3/W

Table 7:Description of Vacon 50X Power Terminals

Note that earth ground is on the terminal strip (see Figure 8 below). See page 31 for specific information

about dynamic braking.

These terminals are the line connections for input power. (Single-phase 230 Vac, 0,75 to 4,0

kW models connect to any two of these terminals.) See Figure 8 on page 27.

These terminals are for motor connections.

GND L1/R L2/S L3/T T1/U T2/V T3/W GND

AC line power

Single or

Three phase

Figure 8: Power Terminals Size 0

AC

motor

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

4

Page 29

connections vacon 28

Plug-in

connection

Figure 9: Power Terminals Size 1

Figure 10: Power Terminals Size 2 and 3

Plug-in

connection

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 30

29 vacon connections

Figure 11: Power Terminals Size 4 and 5

4

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 31

connections vacon 30

4.3.2 Typical Power Connections

See Section 4.2 starting on page 25 for input line requirements. Note that when testing for a ground fault,

do not short any motor lead (T1/U, T2/V, or T3/W) back to an input phase (L1/R, L2/S, or L3/T).

It is necessary to provide fuses and a disconnect switch for the input AC line in accordance with all applicable electrical codes. The Vacon 50X AC drive is able to withstand a 150% overload for 60 seconds for

heavy duty rating, and 120% overload for normal duty rating.

The fusing and input protection of the drive must always meet UL, NEC (National Electric Code), CEC (Canadian Electric Code) and local requirements. All fuse ratings included in Table 8 below are for reference

only and do not supersede code requirements. For 230/400 V mains supplies we recommend time-lag

type NEOZED-fuses. The recommended supplier is Bussman.

Fuse

Model Number

0004

0007

0010

0015

0022

0028

0042

0054

230 V drives

0068

0002

0004

0005

0009

0012

0016

0023

0031

0037

0043

0061

0071

0086

380-480 V drives

0105

0140

0168

0205

0240

Table 8:Fuse Ratings

Size

208 Vac

JJS/JJN

10 6 — —

15 10 — —

20 15 — —

30 25 — —

40 35 — —

50 40 — —

70 60 — —

90 80 — —

100 90 — —

–– 6 6

–– 106

– – 10 10

– – 16 16

– – 20 20

– – 25 20

– – 40 35

– – 50 40

– – 63 50

– – 80 63

– – 100 80

– – 100 100

– – 125 100

– – 160 125

– – 200 160

– – 250 200

– – 250 250

– – 315 315

Fuse S ize

230 Vac

JJS/JJN

Fuse Size

380 Vac

Fuse Size

460 Vac

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 32

31 vacon connections

4.4 Dynamic Braking

The Vacon 50X AC drive is supplied with an integrated dynamic braking (DB) resistor, and is designed to

have adequate dynamic braking for most applications. In cases where short stopping times or high inertia

loads require additional braking capacity, install an external resistor.

NOTE: External braking cannot be added to Size 0 models. For Size 4 (45–75 kW) and Size 5 (90–

150 kW) models, additional external dynamic braking requires a kit that provides the connections to the braking transistors. The XDBKITS4 and XDBKITS5 kits can be purchased through

VACON .

• Starting from size 1 the internal DB resistor can be replaced by an external DB

resistor.

• The terminal identifications of the DB resistor are “B+” and “DB”.

• On the size 1 the DB resistor is connected by fast-on terminals 6.35 mm (see Figure

9 on page 28).

• Starting from size 2 the DB resistor is connected by 2 separate terminals (see

Figure 3 on page 29). The internal DB resistor is connected by fast-on terminals “J3/

DB” and “J4/B+”, which are placed on the power board (right and left side of the

display).

To install an external resistor, first disconnect the internal DB resistor and properly terminate the wires

leading to it. Connect now the external resistance over the connections planned for it.

Changes to Parameter 410 must be made when using external DB resistors.

Verify with the manufacturer of the selected resistor that the resistor is appropriate for your application.

Contact VACON Application Engineering for further assistance with other possible sizing limitations.

Refer to Table 9 below for information about dynamic braking capacity for each Vacon 50X model.

Model kW

0004 2 0,75

0007 2 1,5

0010 2 2,2

0015 2 4,0

0022 2 5,5

0028 2 7,5

0042 2 11

0054 2 15

0068 2 18,5

0002 5

0004 5

0005 5

0009 5

0012 5

0016 5

0023 5

0031 5

0037 5

0043

Table 9:Vacon 50X Dynamic Braking Capacity

Standard

Resistance

(Ω)

0,75 500 163% 270 2253 302%

1,5 500 82% 270 2253 151%

2,2 500 54% 270 2253 101%

4,0 120 136% 100 6084 163%

5,5 120 91% 75 8112 145%

7,5 120 68% 75 8112 109%

11 120 45% 57 12944 116%

15 120 34% 47 12944 87%

18,5 120 27% 47 12944 69%

22 120 23% 39 15600 70%

Standard

DB %

of Drive

125 164% 125 1,223 164%

125 82% 125 1,223 82%

125 55% 125 1,223 55%

60 68% 43 3,555 95%

60 45% 30 5,096 91%

60 34% 27 5,662 76%

60 23% 20 7,644 68%

30 34% 10 15,288 102%

30 27% 10 15,288 82%

Min. Allowed

Res. (Ω)

Max. Peak

Watts

Max. Ext. DB %

of Drive

4

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 33

connections vacon 32

Model kW

0061

0071

0086

0105

0140

0168

0205

0240

Table 9:Vacon 50X Dynamic Braking Capacity

*Note that the asterisked Vacon 50X model numbers cannot have external braking added.

Standard

Resistance

(Ω)

30 60 34% 20 30420 102%

37 60 27% 20 30420 82%

45 60 23% 15 40560 91%

55 60 18% 10 60840 109%

75 60 14% 10 60840 82%

90 60 11% 10 60840 65%

110 60 9% 10 60840 54%

132 60 7% 10 60840 41%

Standard

DB %

of Drive

Min. Allowed

Res. (Ω)

Max. Peak

Watts

Max. Ext. DB %

of Drive

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 34

33 vacon connections

4.5 Terminals Found on the Vacon 50X Control Board

4.5.1 Description of the Control Terminals

Figure 12 shows the control terminals found on the I/O board of the Vacon 50X AC drive. See page 9 for

specifications. Table 10 on page 33 describes the control terminals.

The drive’s control terminals are referenced to earth ground through a resistor / capacitor network. Use

caution when connecting analog signals not referenced to earth ground, especially if the communications

port (J3) is being used. The J3 port includes a common reference that can be connected to earth ground

through the host PLC or computer.

4

Figure 12: Vacon 50X Control Terminals

Terminal Description

Table 10:Description of Vacon 50X Control Terminals

Analog output 1, which is a dedicated voltage output.

The default signal range is from 0 to 10 Vdc (5 mA maximum). It is proportional to the variable

Vmet

configured by parameter 700 (Vmet Config) (see page 79). It may be calibrated while the drive

is running via parameter 701 (Vmet Span) (see page 79).

Analog output 2, which is a dedicated current output.

The default signal ranges from 0 to 20 mAdc (50 to 500 Ω). It is proportional to the variable

Imet

configured by parameter 702 (Imet Config) (see page 80). It ma y be calibrated while the drive is

running via parameters 704 (Imet Offset) and 703 (Imet Span) (see page 80).

Analog Input 1, which is used to provide speed references.

The default input signal is 0 to 10 Vdc (the type of input signal is selected with parameter 205

(Vin1 Config); see page 64). Parameters 206 (Vin1 Offset) and 207 (Vin1 Span) may be used to

offset the starting value of the range and the size of the range, respectively; see page 64 for

Vin1

more information.

If a 0 to 20 mAdc input signal is configured, the burden is 250 ohm. If a 0 to 10 Vdc input

signal is configured, the input impedance is 475 kohm.

A potentiometer with a range of 1 to 2 kohm is suggested for this inpu t.

This terminal is a +10 Vdc source for customer-supplied potentiometers. The maximum load on

+10

this supply cannot exceed 10 mAdc.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 35

connections vacon 34

Terminal Description

Current Input.

The default input signal is 4–20 mA, although this range may be adjusted by using parameters

Cin+ / Cin–

DI1–DI5

209 (Cin Offset) (which configures an offset for the range) and 210 (Cin Span) (to reduce or

enlarge the range – for example, setting this parameter to 50% results in a range of 4–12 mA).

See page 65 for more information on these parameters.

The burden for this terminal is 50 .

Voltage Input 2, which is used to provide speed references.

The default input signal is 0 to 10 Vdc (the type of input signal is selected with parameter 211

(Vin2 Config); see page 65). Parameters 212 (Vin2 Offset) and 213 (Vin2 Span) may be used to

offset the starting value of the range and the size of the range, respectively; see page 65 for

Vin2

more information.

If a 0 to 20 mAdc input signal is configured, the burden is 250 . If a 0 to 10 Vdc input signal is

configured, the input impedance is 475 k.

A potentiometer with a range of 1 to 2 k is suggested for this input.

Common for the Analog Inputs and Outputs. Note that while there are three Acom (common)

Acom

terminals, they connect to the same electrical point.

+24 A source for positive nominal 24 Vdc voltage, and has a source capacity of 150 mA.

Forward Direction Selection terminal. This may be connected for two-wire maintained or

FWD

three w ire momentar y operatio n.

Reverse Direction Selection Terminal. This may be connected for two-wire maintained or

REV

threewire momentary operation.

Run/Jog Selector. When this terminal is connected to +24 or common (depending upon Active

R/J

Logic setting), momentarily connecting either FWD or REV to +24 results in a latched run mode

(3-wire operation).

Motor Overload input terminal. This requires a N/O or N/C contact for operation, referenced to

MOL

+24 or COM, depending on Active Logic setting.

Enable terminal. A jumper is placed between this terminal and the +24 terminal at the factory.

You may replace this with a contact, if desired. The circuit from EN to +24 must be closed for

the drive to operate.

EN

Note that unlike all other terminals, this terminal cannot be configured for “pull-down logic.”

That is, a high input to this terminal is always regarded as true, and must be present for the

drive to operate.

Dcom Digital Common for use with digital inputs and +24 internal power.

Digital inputs.

The function of a digital input is configured by the parameter with the same name as the digital

input (for example, DI2 is configured by parameter 722 (DI2 Configure); see page 81.

The first auxiliary relay.

The function of the relay is set by parameter 705 (Relay 1 Select) (see page 80); the default

NC1

setting is for the relay to activate when a fault occurs (Drv Fault).

NO1

Terminal NO1 is the normally-open contact, which closes when the relay is activated. Terminal

RC1

NC1 is the normally-closed contact, which opens when the relay is activated. Terminal RC1 is

the common terminal.

The second auxiliary relay.

The function of the relay is set by parameter 706 (Relay 2 Select) (see page 80); the default

NC2

NO2

setting is for the relay to activate when the drive is running (Drv Run).

RC2

Terminal NO2 is the normally-open contact; it will close when the relay is activated. RC2 is

the common terminal.

Digital Outputs 1 and 2.

The function of the outputs is set by parameters 707 (DO1 Select) and 708 (DO2 Select).

DO1

The default setting for DO1 is Drive Ready; for DO2 it is At Speed. See page 80.

DO2

Note that if you are using a high-impedance meter to this terminal, the pull-up resistor value

may need to change. Please consult the factory for more information.

Open collector transistor output that supplies a pulse train proportional to speed. The

frequency of the output is set by p arameter 812 (Freq Ref Output) to either 6x or 48x the running

frequency. The output has a maximum rating of 28 Vdc and requires a pull-up resistor

DOP

(4.7 kOhms) if using the drive’s internal supply.

Note that if you are using a high-impedance meter to this terminal, the pull-up resistor value

may need to change. Please consult the factory for more information.

Table 10:Description of Vacon 50X Control Terminals

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 36

35 vacon connections

4.5.2 Typical Connection Diagrams for Digital Inputs

RUN/STOP

Typical connection for 2-wire control

Typical connection for 3-wire control

Figure 13: Connections for 2-wire and 3-wire Control

PS3 (Bit 3) PS2 (Bit 2) PS1 (Bit 1) Speed Selected

000

0 0 1 Preset frequency F1 (303-F1).

0 1 0 Preset frequency F2 (304-F2).

0 1 1 Preset frequency F3 (305-F3).

1 0 0 Preset frequency F4 (306-F4).

1 0 1 Preset frequency F5 (307-F5).

1 1 0 Preset frequency F6 (308-F6).

1 1 1 Maximum frequency (302, Max Frequency).

Table 11:Selection of Preset Speeds

Figure 14: Connections fo r Preset Speeds

Normal reference speed as defined by parameters 201 (Input

Mode) and 204 (Ref Select)

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

4

Page 37

connections vacon 36

4.5.3 Typical Connection Diagrams for Analog Inputs

Figure 15: Connections for Speed Potentiometer

+-

Process

signal

Figure 16: Connections for Process Signal

4.5.4 Typical Connection Diagrams for Analog Outputs

-

+

-

Figure 17: Connections for Process Meters

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

+

4

Page 38

37 vacon connections

4.6 Reducing Current Surges and Voltage Transients

Inrush currents to coils of magnetic contactors, relays, and solenoids associated with or near the

drive can induce high current spikes in the power and control wiring, causing faulty operation. If this

occurs, a snubber network consisting of a series resistor and capacitor for AC loads, or a freewheeling

or flyback diode for DC loads, can be placed across the relay coil to prevent this condition.

The following component values should be used for 115 VAC or 230 VAC relays or solenoids.

For Main Circuit Contactors and Solenoids

C = 0.2 MFD, 500 VDC R = 500 5 Watts

AC

RC Ty pe

Coil Coil

Figure 18: Connection Diagram for AC and DC Relay Coils and So lenoids

For magnetic contactors, relays, and solenoids energized from a DC source, use a free-wheeling diode of

the high-speed, fast-recovery type. Connect the diode across the coil as shown above in Figure 18. The

diode current and voltage should be selected using the following formulae:

Snubber

Diode Current Rating (A)

For Auxiliary Control Circuit Relays

C = 0.1 MFD, 500 VDC R = 200 2 Watts

+

-

Coil Capacity (VA)

=

DC

Rated Voltage of Coil (V)

=

Rated Voltage of Coil (V) x 2Diode Voltage Rating

Freewheeling

Diode

4

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 39

connections vacon 38

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

Page 40

39 vacon keypad operation and programming

5. Keypad Operation and Programming

5.1 Introduction

The Vacon 50X AC drive is pre-programmed to run a standard, 4-pole AC induction motor. For many applications, the drive is ready for use right out of the box with no additional programming needed. The digital keypad controls all operations of the unit. The ten input keys allow “press and run” operation of the

motor (Operation mode) and straightforward programming of the parameters (Program mode).

Figure 19: The Vacon 50X Keypad

To simplify programming, the parameters are grouped into three levels:

The parameter table on page 113 shows the standard settings, the table on page 117 the parameter

names in 5 languages and on page 121 the setti ngs and messages in 5 languages. “Vacon 50X Parameter”

describes the individual parameters starting from page 59.

If you want to get started quickly, see the “Quick Start” section on page 57.

1. Enter Level 1 by pressing the Program (PROG) key at any time. Level 1 allows you

to access the most commonly used parameters.

2. Enter Level 2 by holding down the SHIFT key while pressing the PROG key. Level 2

allows access to all Vacon 50X parameters, including those in Level 1, for applications which require more advanced features.

3. Enter Macro mode by holding the Program (PROG) key down for more than 3 seconds. The display then shows “Hold PROG for Macro Mode.” See Chapter 6, “Using

Macro Mode and Getting a Quick Start”, starting on page 49, for more information.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

5

Page 41

keypad operation and programming vacon 40

5.2 Keypad Operation

Parameter 201, Input Mode (see page 62), determines whether the Vacon 50X AC drive accepts its Run/

Stop and speed commands from the digital keypad or from the input terminals. Table 12 describes the

function of the keys in Operation mode.

Initiates forward run when pressed momentarily. If the drive is running in reverse

when FWD is pressed, it will decelerate to zero speed, change direction, and accelerate

to the set speed.

The green FWD designation in the key illuminates whenever a FWD command has been

given.

When both the FWD and REV lights are on, the DC braking function is active.

Initiates reverse run when pressed momentarily. If the drive is running in forward

when REV is pressed, it will decelerate to zero speed, change direction, and accelerate

to the set speed. The green REV in the key illuminates whenever a REV command has

been issued. When both the FWD and REV lights are on, the DC braking function is active.

Causes a Ramp-to-Stop when pressed. Programmable to Coast- to-Stop by parameter

401, Ramp Select (page 67). The red STOP indicator in the key illuminates whenever a

STOP command has been given. If the drive has stopped because of a fault, this indicator flashes to call attention to the display.

Press the Jog key to enter Jog mode. The green JOG indicator in the key illuminates

when the drive is in the JOG mode of operation. To jog the motor in either direction,

press either the FWD or REV (if REV is enabled in parameter 202). The motor will operate at the speed programmed in parameter 303. To exit Jog mode, press the JOG key

again.

When the drive is stopped, pressing this key increases the desired running speed.

When the drive is running, pressing this key increases the actual running speed in 0.1

Hz increments. Holding the SHIFT key while pressing the INC (UP arrow) key moves the

decimal place to the left with each press (0.1 Hz, 1.0 Hz, 10.0 Hz increments).

When the drive is stopped, pressing this key decreases the desired running speed.

When the drive is running, pressing the DEC (down arrow) key decreases the actual

running speed in 0.1 Hz increments. Holding the SHIFT key while pressing the DEC key

moves the decimal place to the right with each press (10.0 Hz, 1.0 Hz, 0.1 Hz increments).

NOTE: The operating speed for the drive is stored on Power Down.

Pressing this key while a parameter is displayed allows that parameter to have its value changed by use of the INC and DEC (up and down arrow) keys. The P indicator flashes to show that the parameter can be programmed. See also the descriptions for the

INC and DEC keys above to see how they work with the SHIFT key.

The ENTER key has no function when the drive is running or stopped. ENTER can be

used to store the speed command so that it is saved through a power-down. To enable

this function, see the description for parameter 802 (Start Options) on page 83.

Table 12:Function of Keys in Operation Mode (Vacon 50X Running or Stopped)

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 42

41 vacon keypad operation and programming

Whether the drive is running or stopped, pressing this key places the drive in Program

mode. See Table 13 on page 41 for more information on how this key functions.

Pressing this key toggles drive control between the LOCal and REMote control modes,

as selected by parameter 201 (Input mode). It can be configured to shift:

• the Run/Stop command (either FWD or REV)

• the speed reference signal

• both of the above

It can also be set to “disabled,” which is the factory setting. It will operate either in Stop

mode or while the drive is running. If power is removed and reapplied, the memory will

retain the last selected function.

Table 12:Function of Keys in Operation Mode (Vacon 50X Running or Stopped)

You can access Program mode by stopping the Vacon 50X drive and pressing the Program (PROG) key for

Level 1 access; or holding down SHIFT while pressing PROG for Level 2 access. Pressing and holding the

Enter key and then pressing the Program key will show only those parameters that have been changed

from the factory defaults. Table 13 describes the function of the keys in Program mode.

Press this key to have the drive enter Program mode and have Level 1 parameters

available. (To access Level 2 parameters, hold down SHIFT while pressing this key;

to access Macro mode, hold down the PROG key for more than 3 seconds.) Once

Program mode is active, pressing this key at any time returns the drive to the Operation mode. If an Access Code has been programmed, it must be entered to proceed with programming. See Parameter 811 (Access Code) (page 85).

NOTE: To see what parameters have changed from the factory default, press ENTER + PROG. If the display flashes “Factory Defaults,” no parameters have

changed.

5

In the Program mode, pressing this key scrolls forward through the parameters. If

the P indicator is flashing, it increases the value of the parameter. To change the

scroll rate, hold the SHIFT key at the same time to increase the scroll rate; release

the SHIFT key to return to the normal scroll rate. Press the ENTER key to store the

new value.

In the Program mode, pressing this key scrolls backward through the parameters.

If the P indicator is flashing, it decreases the value of the parameter. To change the

scroll rate, hold the SHIFT key at the same time to increase the scroll rate; release

the SHIFT key to return to the normal scroll rate. Press the ENTER key to store the

new value.

NOTE: If the P indicator on the keypad display is flashing, momentarily pressing

and releasing both the INC and DEC keys at the same time restores the parameter

to the factory default value. Press ENTER to store the new value.

Pressing this key while a parameter is displayed allows that parameter to have its

value changed by use of INC and DEC (up and down arrow) keys. The P indicator

flashes to show that the parameter can be programmed. See also the descriptions

for INC and DEC (up and down arrow) keys above to see how they work with the

SHIFT key.

Table 13:Function of Keys in Program Mode

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 43

keypad operation and programming vacon 42

This key must be pressed after the value of a parameter has been changed to store

the new value. The display will show “stored” for one second indicating that the

new value has been entered into memory.

NOTE: The Vacon 50X unit allows you to view only those parameters that have

changed. If you press keypad keys ENTER and PROGram simultaneously, only

those parameters that have been changed from the factory defaults will be shown.

Table 13:Function of Keys in Program Mode

In Fault mode, pressing the INC (up arrow) and DEC (down arrow) keys allows the

operator to view the drive’s status immediately before the fault occurred. Use the

INC or DEC keys to scroll through the status parameters.

Press the STOP (Reset) key to return to normal operation.

See “Troubleshooting” on page 101 for information about viewing Advanced Fault

Codes and understanding error codes.

The red STOP key functions as a reset button when in Fault mode. If the drive has

stopped because of a fault, this light flashes to call attention to the display.

Table 14:Function of Keys in Fault Mode

5.3 LCD Displays

The Vacon 50X drive’s digital keypad display provides information such as source of drive control, status,

mode, and access rights.

5.3.1 Control

The first 3 characters of the display show the source of control for the drive:

Display Values Meaning

LOC Local control via the keypad

REM Remote control from the terminal strip

SIO Remote control via the RS485 Serial SIO Link

SQx Control via the Program Sequencer

MEA The Stator Resistance Measurement is armed

5.3.2 Vacon 50X Keypad Status and Warning Messages

Table 4 shows Vacon 50X keypad status messages that may appear during operation:

Message Meaning

Stopped

FWD Accel

REV Accel

The drive is not spinning the motor or injecting DC voltage. The drive is ready to run when

given the proper signal.

The drive is spinning the motor in the forward direction and the speed of the motor is increasing.

The drive is spinning the motor in the reverse direction and the speed of the motor is increasing.

Table 15:Keypad Status States

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 44

43 vacon keypad operation and programming

FWD Decel

REV Decel

Jog FWD The drive is jogging in the forward direction.

Jog REV The drive is jogging in the reverse direction.

FWD At Spd

REV At Spd

Zero Speed

DC Inject The drive is injecting DC voltage into the motor.

Faulted The drive is faulted.

Reset-Flt The drive is faulted, but has the possibility of being automatically reset.

LS Lockout

Catch Fly The Catch on the Fly functionality is actively searching for the motor frequency.

Forw ard

Reverse

Not Enabled

Volt Range

Low Voltage The drive has reached an undervoltage state.

Kpd Stop

Table 16 shows Vacon 50X keypad warning messages that may appear during operation:

Message Meaning

DB Active The DB Resistor is being actively pulsed.

Curr Limit The drive is operating in current limit.

HS Fan Err Either the heatsink fan should be on and is off, or vice-versa.

Addr XXX

High Temp

Low Temp

Vac Im bln ce

Power Supp A power supply short occurred.

The drive is spinning the motor in the forward direction and the speed of the motor is decreasing.

The drive is spinning the motor in the reverse direction and the speed of the motor is decreasing.

The drive is spinning the motor in the forward direction and the speed of the motor is at the

reference frequency.

The drive is spinning the motor in the reverse direction and the speed of the motor is at the

reference frequency.

The drive has an active run signal but the motor is not spinning because the reference

speed to the drive must be 0.0 Hz.

Line-Start Lockout functionality has become active. This means there was an active run

signal during power-up or when a fault was reset. This run signal must be removed before

the Line-Start Lockout functionality will be removed.

The drive is running forward without accelerating, decelerating or residing at the reference

frequency. This means that something is keeping the drive from the reference frequency

(for example, Current Limit).

The drive is running in reverse without accelerating, decelerating or residing at the reference frequency. This means that something is keeping the drive from the reference frequency (for example, Current Limit).

The drive is not allowed to run either because the digital input enable is not active or because ARCTIC mode has shut down the run operation.

The drive has not met the input voltage requirements that it needs to be able to run. In other

words,the Bus Voltage of the drive is either too low or too high.

A stop command was given from the keypad when the keypad was not the active control

source. To remove this condition, the run signal to the drive must be removed.

Table 15:Keypad Status States

This is the node address of the drive when it receives a valid message through the IR

port

address to another node. The XXX will be replaced with the node address.

The temperature of either the heatsink or the control board is nearing a high temperature limit that will fault the drive.

The temperature of either the heatsink or the control board is nearing a low temperature limit that will fault the drive.

Either the drive has lost an input phase or the input voltage is unbalanced more than

2%.

Table 16:Keypad Warnings

5

Tel. +358 (0)201 2121 • Fax +358 (0)201 212205

Page 45

keypad operation and programming vacon 44

Seq Dwell The sequencer is active, but the transition to the next step is halted.

Int Fan Err Either the internal fan is on and should be off, or vice-versa.

DB OverTemp

ARCTIC Mode The ARCTIC DB Resistor mode is actively pulsing the DB Resistor.

CPU Warning A system error occurred in the software of the Vacon 50X.

Mtr Measure An RS Measurement is armed or active.

IR Active Valid IR communications are occurring.

Seq Running The program sequencer functionality is active.

Table 16:Keypad Warnings

The temperature of the DB Resistor is nearing a high temperature and will fault the

drive.

5.3.3 Rights

After Program mode is entered, the operator’s access rights are displayed:

Display Values

ACCESS

RIGHTS

P

V

The first character of the second line indicates if the particular parameter can be changed

(P) or only examined (V). If an attempt is made to change data while in the View (V) mode,

the message **NO ACCESS** will appear for one second.

This indicates that while in Programming mode, parameter data can be

changed.

If the drive is in Run mode (FWD or REV) when the PROG key was pressed,

param eters can be viewed, but not changed.

5.3.4 Other Data

The top line gives 16-character description of the parameter being accessed. The parameter number will

flash when data is being changed. Up to 10 characters are used to display the information stored in the

parameter. Some parameters have a unit designator such as:

s Seconds

hHours

C Degrees centigrade

Hz Hertz

% Percent

A Amperes

When the drive stops because of a fault trip, a unique error message will be displayed, along with the

flashing STOP indicator. “Pages,” or screens of information are available concerning the actual fault and

drive status.

“Troubleshooting” on page 101 gives information about fault codes and troubleshooting.

5.4 Keypad Display Window

The keypad display provides information on drive operation and programming. Special symbols provide

further information about drive operation (see the following section). Figure 20 shows an example of the

Vacon 50X keypad display.

Figure 20: Vacon 50X Keypad Display

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

5

Page 46

45 vacon keypad operation and programming

5.5 Programming

5.5.1 Accessing Parameters

When PROG (or SHIFT+PROG) is pressed after application of power or a fault reset, parameter 201, Input

Mode, is always the first parameter displayed. Figure 21 shows a typical programming display.

Figure 21: Typical Programming Display

If a different parameter is accessed and Program mode is exited, that parameter is the first one displayed

the next time Program mode is entered. The drive remembers a different “last parameter accessed” for

Levels 1 and 2.

5.5.2 Changing the Display Scroll Rate

Pressing the INC or DEC keys (up or down arrows) arrows causes the display to scroll at a slow rate. To

increase the scroll rate, hold the SHIFT key at the same time that you press the INC key. Release the

SHIFT key to return to the slow scroll rate. This procedure works in all programming and operation

modes.

5.5.3 Programming Procedure

To program the value of a parameter, follow these steps:

To program a text parameter, follow these steps:

1. Press the Program (PROG) key to enter Level 1 Program mode. To enter Level 2,

press SHIFT+PROG. The P indicator will appear on the display. You must enter one

level of programming or the other; you cannot switch between levels without exiting

Program mode.

Note that some parameters cannot be changed in Run mode. For example, if you

wish to program parameter 201, Input Mode, you must stop the drive before

beginning programming. Refer to the Parameter Summary Table at the front of

this manual to see which parameters cannot be changed in Run mode (they

appear as shaded entries in the table).