Danfoss vacon 100 industrial, vacon 100 flow, vacon 100 hvac, vacon 100 x Installation guide

vacon

®

100 industrial

vacon

vacon

®

100 flow

®

100 hvac

vacon® 100 x

ac drives

integrated bacnet

installation manual

vacon • 1

Table of Contents

Document: DPD00091D

Version release date: 8.12.16

1. Safety................................................................................................................2

1.1 Danger.................................................................................................................................2

1.2 Warnings .............................................................................................................................3

1.3 Earthing and earth fault protection ....................................................................................4

2. BACnet - general info .......................................................................................5

3. BACnet technical data.......................................................................................6

3.1 BACnet MS/TP protocol ......................................................................................................6

3.2 BACnet IP protocol..............................................................................................................6

3.3 ACD (Address Conflict Detection).......................................................................................6

4. Programming....................................................................................................7

4.1 BACnet MS/TP parameters and monitoring values ...........................................................8

4.2 BACnet IP parameters and monitoring values...................................................................9

4.2.1 Ethernet common settings .................................................................................................9

4.2.2 BACnet IP settings ..............................................................................................................9

4.3 BACnet MS/TP parameter descriptions ...........................................................................11

4.3.1 BACnet MS/TP Parameters ..............................................................................................11

4.3.2 BACnet MS/TP monitoring values ....................................................................................12

4.4 BACnet IP parameter descriptions...................................................................................13

4.4.1 Ethernet common settings ...............................................................................................13

4.4.2 BACnet IP settings ............................................................................................................14

4.4.3 BACnet IP monitoring values............................................................................................15

5. Installation......................................................................................................16

5.1 VACON® 100 family AC drive............................................................................................16

5.1.1 Prepare for use through Ethernet....................................................................................17

5.1.2 Prepare for use through RS485........................................................................................20

5.2 Installation in VACON® 100 X...........................................................................................24

5.2.1 Prepare for use through Ethernet....................................................................................24

5.2.2 Prepare for use through RS485........................................................................................25

6. Communications .............................................................................................27

6.1 Device Object.....................................................................................................................27

6.2 Object types and properties supported ............................................................................27

6.2.1 Binary Value Object...........................................................................................................28

6.2.2 Analogue Value Object ......................................................................................................29

6.3 Control word bits...............................................................................................................31

6.4 Status word bits ................................................................................................................31

6.5 COV functionality ...............................................................................................................31

6.6 Processdata mapping in drive application .......................................................................32

7. Fault tracing ...................................................................................................33

7.1 Typical fault conditions .....................................................................................................33

7.2 Other fault conditions .......................................................................................................34

8. Quick setup .....................................................................................................36

9. Annex - Protocol implementation conformance statement ............................37

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

vacon • 2 Safety

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a measuring equipment to absolutely ensure that no

absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always ensure

Before connecting the AC drive to mains make sure that the front and cable covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

Safety vacon • 3

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to stan-

dard EN61800-5-1, a reinforced protective ground connection must be ensured.

See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by VACON

®

can be used.

At power-up, power break or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Start/Stop logic has been selected

Furthermore, the I/O functionalities (including start inputs) may change if parameters, applications or software are changed. Disconnect, therefore, the motor if

an unexpected start can cause danger.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

Wear protective gloves when you do mounting, cabling or maintenance operations. There can be sharp edges in the AC drive that can cause cuts.

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

vacon • 4 Safety

13006.emf 13006.emf

1.3 Earthing and earth fault protection

CAUTION!

The AC drive must always be earthed with an earthing conductor connected to the earthing terminal

marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

a) The protective conductor must have a cross-sectional area of at least 10 mm2 Cu or 16

mm2 Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm2 Cu or 16

mm2 Al, a second protective conductor of at least the same cross-sectional area must be

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm2 Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective conduc-

tor.

The cross-sectional area of every protective earthing conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure may result in damaged product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from

http://drives.danfoss.com/knowledge-center/technical-documentation/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site http://drives.danfoss.com/knowledge-center/technical-documentation/

.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

1

BACnet - general info vacon • 5

BACnet IP - Ethernet

Ethernet to

MS/TP

Router

Switch

BACnet IP

BACnet MS/TP

7061.emf

2. BACNET - GENERAL INFO

BACnet stands for ‘Building Automation and Control Networks’. It is the common name for the

communication standard ISO 16484-5 which defines the methods and the protocol for cooperating

building automation devices to communicate. Devices can be designed to operate using BACnet

communication protocol as well as utilising BACnet protocol to communicate between systems.

BACnet is an internationally accepted protocol for building automation (e.g. lightning control, air

conditioning and heating automation) and control over a communications network.

BACnet provides a method by which computer-based control equipment, from different

manufacturers can work together, or 'interoperate'. For this to be achieved, components must be

able to exchange and understand BACnet data messages.

®

Your VACON

100 family AC drive is equipped with BACnet support as standard.

Figure 1. Principal example diagram of BACnet

®

If you need to contact VACON

problem together with the Drive Info File taken with VACON

download the Service Information file with the VACON

service in problems related to BACnet, send a description of the

®

®

Live to your local support. You can

Live tool. In BACnet/IP networks, also send

a log file captured with the Wireshark tool that contains the error situation.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

2

vacon • 6 BACnet technical data

3. BACNET TECHNICAL DATA

3.1 BACnet MS/TP protocol

Table 2.

Interface RS-485

Data transfer method RS-485 MS/TP, half-duplex

Transfer cable

Connections and

communications

Connector

Electrical isolation Functional

BACnet MS/TP

Baud rate

3.2 BACnet IP protocol

Interface 100BaseTX, IEEE 802.3 compatible

Data transfer method Ethernet half/full -duplex

Data transfer speed 10/100 MBit/s, autosensing

Connections and

communications

Protocol BACnet over UDP/IP

Connector Shielded RJ45 connector.

Cable type CAT5e STP

STP (Shielded Twisted Pair), type

Belden 9841 or similar

2.5 mm

As described in ANSI/ASHRAE Standards 135-2010 Ver.1 Rev.12

9600, 19200, 38400 and 76800

baud(supports autobaud detection)

Table 3.

2

BACnet IP

IP address mode Selectable: Static or DHCP

As described in ANSI/ASHRAE Standards 135-2010 Ver.1 Rev.12

3.3 ACD (Address Conflict Detection)

The VACON® 100 family AC drives implement the ACD algorithm (IETF RFC 5227).

The ACD algorithm tries to actively detect if the IP address configured to this device is been used by

another device in the same network. To accomplish this, ACD sends four ARP request packets when

the device's Ethernet interface goes up or when its IP address changes. ACD prevents the use of the

Ethernet interface until the ARP probing finishes. This delays the startup of fieldbus protocols about

one second. During the delay or after it, the ACD passively checks incoming ARP messages for use

of the device's IP address.

If another device with the same IP address is detected, the ACD will try to defend its IP address with

a single ARP message. If the other device with the same IP address also supports ACD, it should

stop using the address. If not, the ACD will close the Ethernet connection and indicate the situation

with an Alarm. This is done according the "DefendWithPolicyB". Acknowledging of the Alarm is not

possible if the problem is active. ACD opens Ethernet connection if the other device with the same

IP address disappears from the network. Alarm can be acknowledged after this. Other policies are

not supported. If the fieldbus protocol has been active, a fieldbus fault may be activated (depends

on the fieldbus and drive application configuration).

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Programming vacon • 7

4. PROGRAMMING

You will find basic information on how to use the control keypad in the Application Manual of your

VACON

Below you will find some examples of navigation paths to the fieldbus parameters.

®

100 family AC drive.

Table 4.

1. First ensure that the right fieldbus protocol is selected.

Activating BACnet MSTP (P5.8.1.1)

Main Menu > I/O and Hardware > RS-485 > Common settings > Protocol > BACnet MSTP <

Activating BACnet IP (P5.9.3.1.4)

Main Menu > I/O and Hardware > Ethernet > Bacnet IP > Protocol in

use > Yes <

2. Select

3. Activate Remote control.

4. Select controlling fieldbus

5. Set up Protocol Parameters.

‘Fieldbus control’ as the Remote Control Place.

Control Place (P3.2.1)

Main Menu > Parameters > Start/Stop Setup > Rem Control Place >

FieldbusCTRL <

Local/Remote (P3.2.2)

Main Menu > Parameters > Start/Stop Setup > Local/Remote >

Remote <

Controlling Fieldbus (P5.13.1)

Main Menu > I/O and Hardware > Fieldbus General > Controlling

Fieldbus > Automatic/BACnet IP/RS-485 <

BACnet MS/TP parameters see Chapter 4.1

BACnet IP parameters see Chapter 4.2

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 8 Programming

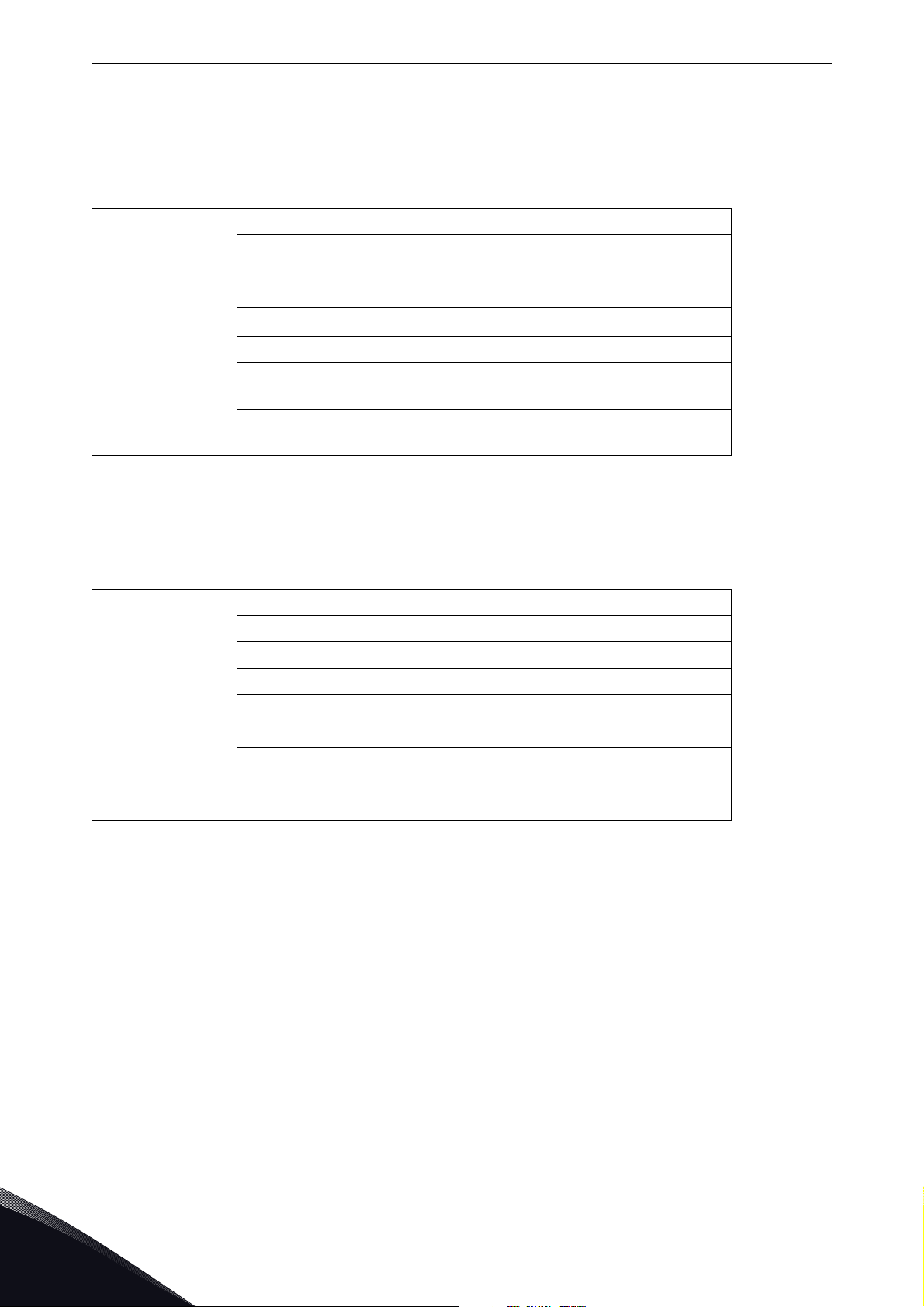

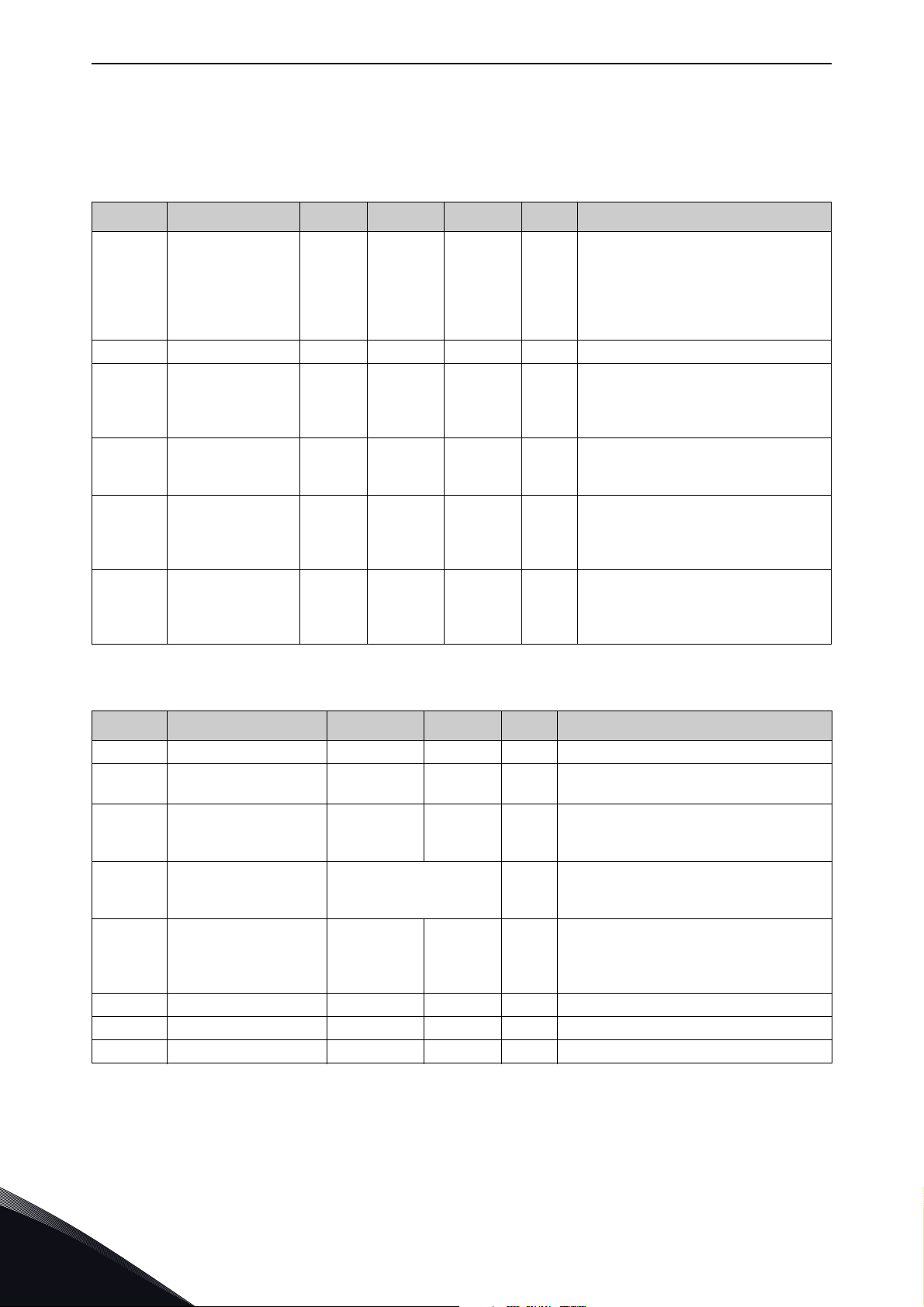

4.1 BACnet MS/TP parameters and monitoring values

Table 5. Parameters related with BACnet used through MS/TP

Code Parameter Min Max Default ID Description

Communication speed

1 = 9600

P5.8.3.1.1 Baud rate 9600 76800 9600 2392

P5.8.3.1.2 MAC Address 1 127 1 2331 BACnet device MAC address

P5.8.3.1.3 Instance number 0 4194304 automatic 2332

P5.8.3.1.4 MaxMaster 1 127 127 2561

P5.8.3.1.5

P5.8.3.1.6 MaxAPDUcycle 0 65535 0 2554

Communication

time-out

0 65535 10 2333

2 = 19200

3 = 38400

4 = 76800

5 = Autobaud

Device Object's instance number.

0 = Automatically

generated from the last 22 bit from

Ethernet MAC address.

Max Master parameter of device object.

This can be used to reduce poll for

master cycles.

Defines the number of seconds after

which a communication timeout is indicated after a communication break.

Value 0 disables this feature.

Defines the number of seconds after

which the next application level message is shown after a communication

break. Value 0 disables this feature.

Table 6. Monitoring values

Code Parameter Min Max ID Description

V5.8.3.2.1 Fieldbus protocol status INITIALIZING INACTIVE 2393 See Table 11

V5.8.3.2.2 Communication status 0.0 99.999 2394

V5.8.3.2.3 Actual instance 0 4194304 2395

See fault codes

V5.8.3.2.4 Last fault

V5.8.3.2.5 UartDBG 0.0.0

V5.8.3.2.6 ActiveCOVcount 0 20 2558 Number of active COV subscriptions

V5.8.3.2.7 Control Word 0 FFFFFFFF 2397 Control word monitor value

V5.8.3.2.8 Status Word 0 FFFFFFFF 2398 Status word monitor value

(table Table 10) 2396 Information about the latest fault detected.

32767.

32767.

32767

2559

Counter for failed and good messages

failed msg's <-> good msg's

Actual instance in use. If the instance

parameter is 0, the generated instance

number shows here.

Uart error counters in the following order:

framing errors.

overrun errors.

parity errors.

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Programming vacon • 9

4.2 BACnet IP parameters and monitoring values

4.2.1 Ethernet common settings

Table 7. Eth e r net Common S ettings

Code Parameter Min Max Default ID Description

P5.9.1.1 IP address mode 0 1 1 2482

P5.9.1.2

P5.9.1.2.1 IP address 1.0.0.0 223.255.255.255 192.168.0.10 2529

P5.9.1.2.2 Subnet mask 0.0.0.0 255.255.255.255 255.255.0.0 2530

P5.9.1.2.3 Default gateway 0.0.0.0 255.255.255.255 192.168.0.1 2531

P5.9.1.3 IP address - - 0 2483 IP address in use

P5.9.1.4 Subnet mask - - 0 2484 Subnet mask in use

P5.9.1.5 Default gateway - - 0 2485 Default gateway in use

P5.9.1.6 MAC address - - - 2486 MAC address

Duplicate IP Detec-

tion

0 1 1 2569

0 = Fixed IP

1 = DHCP with AutoIP

This is setting for enabling ACD

(See Chapter 3.3). When disabled

drive does not check for or react to

address conflict situation.

0 = Disabled

1 = Enabled

The parameter is in use if P5.9.1.1

= 0/Fixed IP

The parameter is in use if P5.9.1.1

= 0/Fixed IP

The parameter is in use if P5.9.1.1

= 0/Fixed IP

4.2.2 BACnet IP settings

Table 8. Parameters related with BACnet used through Ethernet

Code Parameter Min Max Default ID Description

Device Object’s instance

P5.9.3.1.1 Instance number 0 4194304 automatic 2406

P5.9.3.1.2 BACnet Port Number 47808 47823 47808 2538

P5.9.3.1.2 Communication time-out 0 65535 10 2407

P5.9.3.1.3 Protocol in use 0 1 0 2408 Activates BACnet IP protocol

P5.9.3.1.4 ForeignDevice Sub menu for Foreign Device setting

P5.9.3.1.5.1 ForeignDevice No Yes No 2555

P5.9.3.1.5.2 BBMD IP 192.168.0.1 2409

P5.9.3.1.5.3 BBMD Port 47808 47823 47808 2410 BBMD port number

P5.9.3.1.5.4 RegistrationInterval 1 65535 10 2411

0 = Automatically generated from

the last 22 bit from the Ethernet

MAC address.

UDP port for BACnet IP communication.

Defines the number of seconds

after which a communication

timeout is indicated after a communication break. Value 0 disables this feature.

Activates foreign device registration

IP address of BBMD device to

send registration

Registration interval to keep a

live connection to BBMD.

NOTE! Registration message

TTL is twice as long as this time.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 10 Programming

Table 9. Monitoring values

Code Parameter Min Max ID Description

V5.9.3.2.1

V5.9.3.2.2

V5.9.3.2.3 Actual instance 0 4194304 2414

V5.9.3.2.4 Last fault

V5.9.3.2.5 ActiveCOVcount 0 20 2557 Number of active COV subscriptions

V5.9.3.2.6 Control Word 0 FFFFFFFF 2397 Control word monitor value

V5.9.3.2.7 Status Word 0 FFFFFFFF 2398 Status word monitor value

Fieldbus protocol

status

Communication

status

INITIALIZING INACTIVE 2412 See Table 11

0.0 99.999 2413

See fault codes

(Table 10)

2556 The fault code of the latest fault detected.

Counter for failed and good messages

failed msg's <-> good msg's

Actual instance is use. In case instance parameter is zero you can see here generated

instance number

Table 10. Fault Code values

Fault

Number

0 No fault No fault detected since the last power-up.

1 Connection timeout Timeout occurred in communication.

2 MAC address Duplicate MAC address detected.

3 Autobaud Error Error during baudrate detection.

4 Ethernet link lost Ethernet cable disconnected during communication.

Fault Text Description

Table 11. Fieldbus Protocol Status

Value Tex t Description

1 INITIALIZING Protocol is starting

2 STOPPED Protocol is stopped

3OPERATIONALCommunicating

4 FAULTED Timeout/APDU time expired

5 INACTIVE No communication

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Programming vacon • 11

4.3 BACnet MS/TP parameter descriptions

4.3.1 BACnet MS/TP Parameters

P5.8.3.1.1 BAUD RATE

Select the communication speed for the network. The default value is 9600 baud. If Autobauding is

selected, the node will detect the baudrate. There must be at least one device in the bus to select

the baud rate and to start token transmitting. When the baudrate is detected, it is saved into this

parameter.

NOTE! Autobauding is disabled after baudrate is detected.

P5.8.3.1.2 MAC ADDRESS

The parameters of every device must be set before connecting to the bus. Especially the

parameters

The first parameter, BACnet MAC (Medium Access Control) address, must be unique on the

network to which it is connected. The same MAC address may be used on a device on another

network within the internetwork.

Addresses 128-254 are reserved for slaves. Addresses 1-127 are valid for both masters and slaves.

The portion of the address space that is actually used for masters in a particular installation is

determined by the value of the Max_Master property of the Device object.

MAC address and Baud rate must be the same as in the master’s configuration.

It is recommended that MAC address 0 be reserved for use by the MS/TP router. 255 is reserved for

broadcasts.

P5.8.3.1.3 INSTANCE NUMBER

The Device Object's Instance number must be unique across the entire BACnet internetwork

because it is used to uniquely identify the BACnet devices. It may be used to conveniently identify

the BACnet device from other devices during installation.

If 0 (default) is selected, the Device Instance number is generated from the last 22 bit of the

Ethernet MAC address. This unique number is then shown in the Monitor menu (actual instance).

P5.8.3.1.4 MAXMASTER

This parameter defines the last possible master on the network segment. Each master node is

responsible for searching new devices from network using the ‘poll for master’ messages. The

nodes are searched up to MAC address defined by MaxMaster parameter.

This parameter affects the cycle time of the token. We recommend to use the highest MAC address

value in the network for this parameter.

P5.8.3.1.5 COMMUNICATION TIMEOUT

The BACnet MS/TP indicates timeout error if the node is not receiving a token within time defined

by this parameter. It can be used to detect communication loss to other nodes. Time unit is

seconds.

NOTE! Application parameter P3.9.1.6 (ID 733) can be use to define action for communication

timeout.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 12 Programming

P5.8.3.1.6 MAXAPDUCYCLE

This parameter defines the maximum time in seconds between APDU messages addressed to this

node. The APDU messages are Application layer messages, for example, 'ReadParameter' and

'Write Parameter' messages. This can be used to detect communication loss to the controlling

node.

NOTE! The application parameter P3.9.1.6 (ID 733) can be used to define the action for

communication timeout.

4.3.2 BACnet MS/TP monitoring values

V5.8.3.2.1 FIELDBUS PROTOCOL STATUS

Fieldbus Protocol Status tells the status of the protocol.

V5.8.3.2.2 COMMUNICATION STATUS

The Communication status shows how many error and how many good messages the AC drive has

received. The Communication status includes a common error counter that counts CRC and parity

errors and a counter for good messages.

Only messages to the current slave in use are counted in the good messages, not MS/TP token

packages.

Table 12 .

Good messages

0…999

Number of messages received without errors

Bad Frames

0…99

V5.8.3.2.3 ACTUAL INSTANCE NUMBER

Number of messages received with

errors

Shows the actual instance number.

V5.8.3.2.4 LAST FAULT

This monitor value consist of text string that gives extra information about the fault condition. Can

be used to track the reason for communication timeout. See Table 10.

V5.8.3.2.5 UARTDBG

This is advanced debug information from RS-485 uart module. It shows parity, framing and overrun

errors occurred while receiving the MSTP messages.

4

V5.8.3.2.6 ACTIVECOVCOUNT

This shows the number of active COV subscriptions on the device.

V5.8.3.2.7 CONTROL WORD

Shows control word that is written by BACnet MS/TP into drive application. This is shown in panel

as hexadecimal format.

V5.8.3.2.8 STATUS WORD

Shows control word that is written by BACnet MS/TP into drive application. This is shown in panel

as hexadecimal format.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Programming vacon • 13

4.4 BACnet IP parameter descriptions

4.4.1 Ethernet common settings

P5.9.1.1 IP ADDRESS MODE

Selectable alternatives are DHCP (Dynamic Host Configuration Protocol) and Fixed.

DHCP protocol gives IP addresses to new devices connecting to local network. This address is valid

for a certain period of time.

A fixed IP address is specified manually and it does not change.

If the fixed IP mode is selected, the addresses defined in the 'Fixed IP' menu come into use. The

default Fixed IP is shown below.

IP: 192.168.0.10

Subnet mask: 255.255.0.0

Default gateway: 0.0.0.0

P5.9.1.3 IP ADDRESS

An IP address is a series of numbers (like above) specific to the device connected to the Internet.

P5.9.1.4 SUBNET MASK

The network mask marks all the bits of an IP address for the identification of the network and the

subnetwork.

P5.9.1.5 DEFAULT GATEWAY

Gateway address is the IP address of a network point that acts as an entrance to another network.

This needs to be defined if the device communicates with nodes on different networks, for example,

if the 'Foreign Device' functionality is active.

P5.9.1.6 MAC ADDRESS

The Ethernet MAC address of the control board.

MAC address (Media Access Control) is a unique address given to each network host.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 14 Programming

4.4.2 BACnet IP settings

P5.9.3.1.1 INSTANCE NUMBER

Similar to BACnet MS/TP device object instance number (see Chapter 4.3.1).

P5.9.3.1.2 BACNET PORT NUMBER

The UDP port for the BACnet IP communication.

P5.9.3.1.3 COMMUNICATION TIME-OUT

Defines the number of seconds after a timeout is indicated after a communication break or

disconnected ethernet link. Value 0 disables communication and link supervision.

NOTE! The Application parameter P3.9.1.6 (ID 733) can be used to define the action for

communication timeout.

P5.9.3.1.4 PROTOCOL IN USE

BACnet/IP protocol can be enabled and disabled with this parameter. When the parameter value is

set to "1" the BACnet/IP protocol is enabled and disabled when set to "0".

P5.9.3.1.5 FOREIGNDEVICE

The foreign device settings are located under this submenu. The foreign device feature is used

when the device is located in a different network than the BBMD. A normal router does not send

broadcast messages between different networks. The 'Foreign device' feature solves this problem

by establishing a connection to the BBMD with unicast messages. All broadcast messages are

forwarded to a BBMD device that takes care of receiving and transmitting broadcast messages in

both directions for all foreign devices.

P5.9.3.1.5.1 FOREIGNDEVICE

If this parameter is set to value 'Yes', the foreign device registration becomes active.

P5.9.3.1.5.2 BBMD IP

The IP address of the BACnet IP Broadcast Management Device.

P5.9.3.1.5.3 BBMD PORT

The BBMD Port number.

P5.9.3.1.5.4 REGISTRATIONINTERVAL

The registration interval to keep a live connection to the BBMD. Unit is seconds.

NOTE! The Registration TTL is twice as long as this time.

4

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Programming vacon • 15

4.4.3 BACnet IP monitoring values

V5.9.3.2.1 FIELDBUS PROTOCOL STATUS

Fieldbus Protocol Status tells the status of the protocol.

V5.9.3.2.2 COMMUNICATION STATUS

The Communication status shows how many error and how many good messages the AC drive has

received. The Communication status includes a common error counter that counts CRC and parity

errors and a counter for good messages.

Table 13 .

Good messages

0…999

Number of messages received without errors

Bad Frames

0…99

V5.9.3.2.3 ACTUAL INSTANCE NUMBER

Number of messages received with

errors

The Device Object's actual instance number. This monitoring value is needed when value 0 is

written to parameter P5.8.3.1.1.

V5.9.3.2.4 LAST FAULT

This monitor value contains a text string that gives extra information about the fault condition. Can

be used to track reason for communication timeout. See Table 10.

V5.9.3.2.5 ACTIVECOVCOUNT

This shows the number of active COV subscriptions on the device.

V5.9.3.2.6 CONTROL WORD

Shows control word that is written by BACnet IP into drive application. This is shown in panel as

hexadecimal format.

V5.9.3.2.7 STATUS WORD

Shows status word that is written by drive application to BACnet IP. This is shown in panel as

hexadecimal format.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

4

vacon • 16 Installation

M4x55

9174.emf

9000.emf

5. INSTALLATION

5.1 VACON® 100 family AC drive

Open the cover of the AC drive.

1

2

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

Open the inner cover of the drive.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Installation vacon • 17

Ethernet

cable

9316.emf

5.1.1 Prepare for use through Ethernet

Connect the Ethernet cable (see specification in Chapter 3.2) to its terminal as

shown in figure below.

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 18 Installation

9068.emf

Protection class IP21: Cut free the opening on the AC drive cover for the Ethernet cable.

Protection class IP54: Cut the rubber grommets open to slide the cables

through. Should the grommets fold in while inserting the cable, just draw the

cable back a bit to straighten the grommets up. Do not cut the grommet openings wider than what is necessary for the cables you are using.

NOTE! To meet the requirements of the enclosure class IP54, the connection

between the grommet and the cable must be tight. Therefore, lead the first bit of

the cable out of the grommet straight before letting it bend. If this is not possible, the tightness of the connection must be ensured with insulation tape or a

cable tie.

4

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Installation vacon • 19

IP54

9265.emf

IP21

Ethernet

cable

Remount the AC drive cover.

NOTE! When planning the cable runs, remember to keep the distance between

the Ethernet cable and the motor cable at a minimum of 30 cm.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 20 Installation

9189.emf

10

5

1

5

m

m

9188.emf

5.1.2 Prepare for use through RS485

Strip about 15 mm of the RS485 cable (see specification in Chapter 3.1) and cut

off the grey cable shield. Remember to do this for both bus cables (except for the

last device).

Leave no more than 10 mm of the cable outside the terminal block and strip the

cables at about 5 mm to fit in the terminals. See picture below.

Also strip the cable now at such a distance from the terminal that you can fix it to

1

the frame with the grounding clamp. Strip the cable at a maximum length of 15

mm. Do not strip the aluminum cable shield!

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Installation vacon • 21

Cable clamp

3020.emf

Then connect the cable to its appropriate terminals on VACON® 100 family AC

2

drive standard terminal block, terminals A and B (A = negative, B = positive). See

figure below.

3

Using the cable clamp included in the delivery of the drive, ground the shield of

the RS485 cable to the frame of the AC drive.

NOTE! This can be done in all drives if there is no difference in PE potentialbetween the drives. However, if there is PE potential difference then the shieldshould be connected to PE only at one point in the system. The shields of

thecables shall be joint but not connected to several PE points with different

poten-tial.

NOTE! This is only a principle drawing and the actual drive may look different.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 22 Installation

RS-485 bus termination

OFF

ON

9110.emf

9201.emf

9202.emf

Fieldbus

cables

If VACON® 100 family AC drive is the last device on the bus, the bus termination

must be set. Locate the DIP switches to the right of the control keypad of the

drive and turn the switch for the RS485 bus termination resistor to position ON.

Biasing is built in the termination resistor. See also step 6 on page 23.

4

5

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

RS485 cable (protection class IP21).

NOTE! This is only a principle drawing and the

actual drive may look different.

Remount the AC drive cover and run the RS485

cables as shown in picture.

NOTE! When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm.

5

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Installation vacon • 23

Fieldbus cable

= Bus termination

Termination

activated

Termination

activated with

jumper

Ter min ati on

deactivated

Vacon 100 Vacon 100 Vacon 100 Vacon 100 Vacon 100

3007.emf

The bus termination must be set for the first and the last device of the fieldbus

line. See picture below. See also step 3 on page 22.

7

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 24 Installation

Ethernet

connection

1234567891011

12 13 14 15 16 17 18 19 30

BA

RS485

terminals

5.2 Installation in VACON® 100 X

The AC drive can be connected to fieldbus either through RS485 or Ethernet. The connection for

RS485 is on the standard I/O terminals (A and B) and the connection for Ethernet is left to the control

terminals.

Figure 2.

5.2.1 Prepare for use through Ethernet

1

2

For more detailed information, see the user’s manual of the fieldbus you are using.

Connect the Ethernet cable (see specification in Chapter 3.2) to its terminal and

run the cable through the conduit plate.

Remount the powerhead.

NOTE: When planning the cable runs, remember to keep the distance between

the Ethernet cable and the motor cable at a minimum of 30 cm.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Installation vacon • 25

9189.emf

10

5

1

5

m

m

9188.emf

5.2.2 Prepare for use through RS485

Strip about 15 mm of the RS485 cable (see specification in Chapter 3.1) and cut

off the grey cable shield. Remember to do this for both bus cables (except for the

last device).

Leave no more than 10 mm of the cable outside the terminal block and strip the

cables at about 5 mm to fit in the terminals. See picture below.

Also strip the cable now at such a distance from the terminal that you can fix it to

the frame with the grounding clamp. Strip the cable at a maximum length of 15

1

mm. Do not strip the aluminum cable shield!

Then connect the cable to its appropriate terminals on VACON® 100 X AC drive

standard terminal block, terminals A and B (A = negative, B = positive). See

Figure 2.

Using the cable clamp included in the delivery of the drive, ground the shield of

the RS485 cable to the frame of the AC drive.

2

3

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

5

vacon • 26 Installation

Fieldbus

= Bus termination

Termination

activated

Termination

activated with

DIP switch

Termination

deactivated

Vacon 100X Vacon 100X Vacon 100X Vacon 100X Vacon 100X

11782_uk

120 Ohm

If VACON® 100 X AC drive is the last device on the bus, the bus termination must

be set. Locate the DIP switches to the top of the control unit (see figure below).

4

5

Turn the right most switch to position “1”. Biasing is built

in the termination resistor. See also step 6.

NOTE: When planning the cable runs, remember to keep

the distance between the fieldbus cable and the motor

cable at a minimum of 30 cm.

The bus termination must be set for the first and the last device of the fieldbus

line. See picture below and step 4. We recommend that the first device on the bus

and, thus, terminated, was the Master device.

5

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Communications vacon • 27

6. COMMUNICATIONS

6.1 Device Object

Device object provides information about device and its configuration. Note that the Device Object

"Object_Name" property corresponds to the AC drive’s “Drive name” (P6.7).

Device object ‘Object_Name’ property value should be unique in the BACnet network. You can

®

change the ‘Drive Name’ using VACON

PC tool. The new “Drive Name” becomes active when the

drive/protocol is restarted.

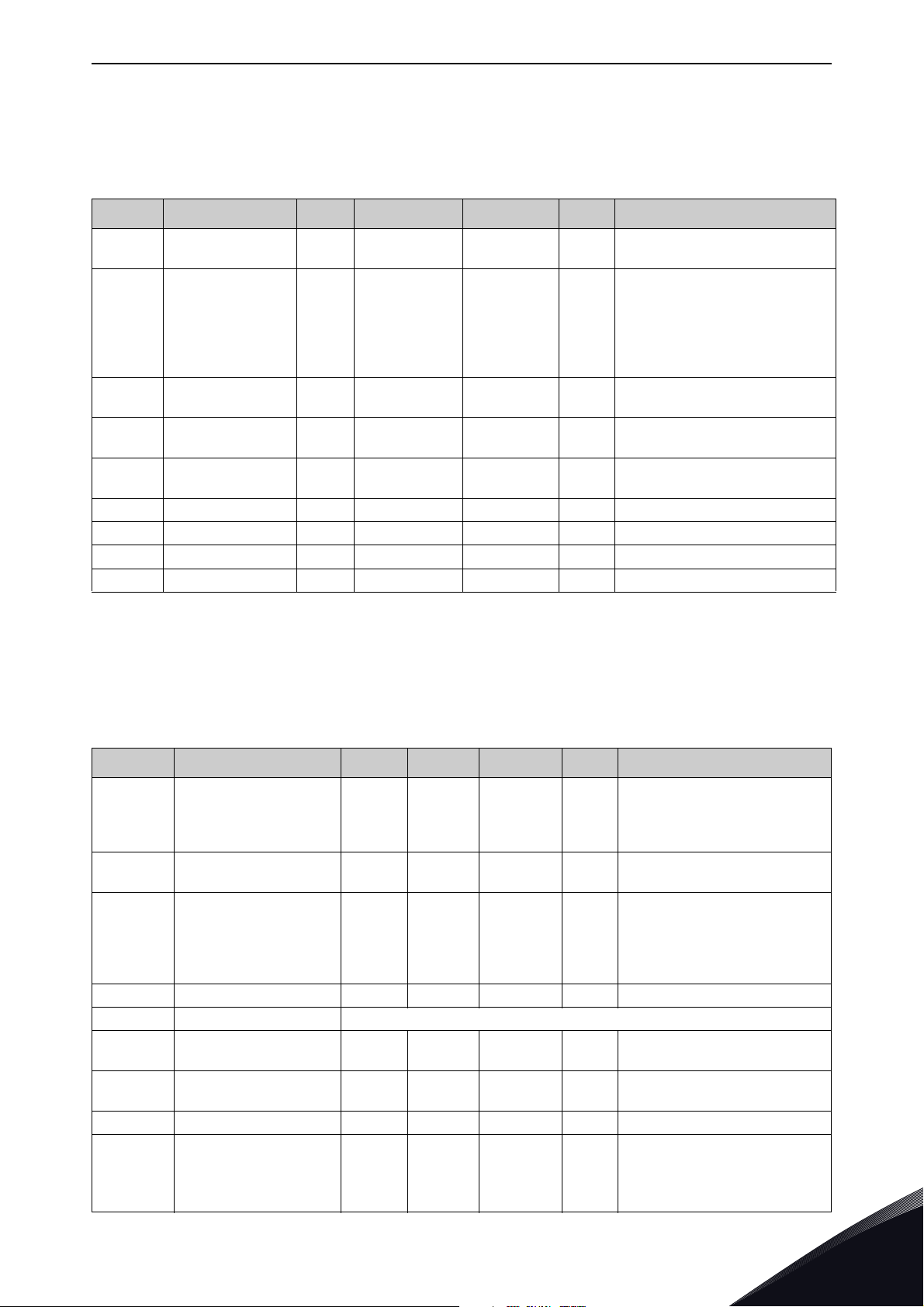

6.2 Object types and properties supported

Table 14. Object types and properties supported

Object Type

Property

Device Binary Value Analogue Value

Object_Identifier X X X

Object_Name X X X

Object_Type X X X

System_Status X

Vendor_Name X

Vendor_Identifier X

Model_Name X

Firmware_Revision X

Application_Software_Version X

Description

Protocol_Version X

Protocol_Revision X

Protocol_Services_Supported X

Protocol_Object_Types_Supported X

Object_List X

Max_APDU_Length_Accepted X

Segmentation_Supported X

Max_Segments_Accepted X

Local_Time X

Local_Date X

UTC_Offset X

Daylight_Savings_Status X

APDU_Segment_Timeout X

APDU_Timeout X

Number_Of_APDU_Retries X

Max_Master X

Max_Info_Frames X

Device_Address_Binding X

Database_Revision X

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 28 Communications

Table 14. Object types and properties supported

Active_COV_Subscriptions X

Event_State X X

Out_Of_Service X X

Present_Value X X

Priority_Array X * X *

Relinquish_Default X * X *

Status_Flags X X

COV_Increment X

Units X

*. Only with commandable values

6.2.1 Binary Value Object

Table 15.

Instance ID Object Name Description

BV0

BV1

BV2

BV3

BV4

BV5

BV6

BV7

BV8

BV9

BV10

Ready State

Run/Stop State

Fwd/Rev State

Fault State Indicates if a fault is active OK / Fault R

Alarm State Indicates if an alarm is active OK / Alarm R

At Setpoint Ref. Frequency reached False / True R

At Zero Speed Motor Running at zero speed False / True R

fb_ProcessdataOut_01 Bit_0 ProcessDataOut1 bit 0 0 / 1 R

fb_ProcessdataOut_01 Bit_1 ProcessDataOut1 bit 1 0 / 1 R

fb_ProcessdataOut_01 Bit_2 ProcessDataOut1 bit 2 0 / 1 R

fb_ProcessdataOut_01 Bit_3 ProcessDataOut1 bit 3 0 / 1 R

Indicates whether the drive is ready

or not

Indicates whether the drive is running

or stopped

Indicates the rotation direction of the

motor

Present

Inactive /

Active

Value

Access

Type

Not Ready / Ready R

Stop / Run R

Fwd / Rev R

6

BV11

BV12

BV13

BV14

BV15

BV16

BV17

fb_ProcessdataOut_01 Bit_4 ProcessDataOut1 bit 4 0 / 1 R

fb_ProcessdataOut_01 Bit_5 ProcessDataOut1 bit 5 0 / 1 R

fb_ProcessdataOut_01 Bit_6 ProcessDataOut1 bit 6 0 / 1 R

fb_ProcessdataOut_01 Bit_7 ProcessDataOut1 bit 7 0 / 1 R

Run/Stop CMD

Fwd/Rev CMD Command to run forward/reverse Fwd/Rev C

Reset Fault

Command to start drive (FB control is

active)

Command to reset Active Fault from

drive

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Stop / Run C

0 / Reset C

Communications vacon • 29

Table 15.

BV18

BV19

BV20

BV21

BV22

BV23

BV24

BV25

BV26

BV27

BV28

BV29

BV30

Stop By Coast Stop Drive by coast 0 / 1 C

Stop By Ramp Stop Drive by ramp 0 / 1 C

Quick Stop Quick Stop 0 / 1 C

Zero Ramp Stop by zero ramp 0 / 1 C

Hold Ramp Hold ramp 0 / 1 C

BusCtrl Activate Bus control 0 / 1 C

BusRef Activate Bus reference 0 / 1 C

fb_control_word Bit_10 fb_control_word bit 10 0 / 1 C

fb_control_word Bit_11 fb_control_word bit 11 0 / 1 C

fb_control_word Bit_12 fb_control_word bit 12 0 / 1 C

fb_control_word Bit_13 fb_control_word bit 13 0 / 1 C

fb_control_word Bit_14 fb_control_word bit 14 0 / 1 C

fb_control_word Bit_15 fb_control_word bit 15 0 / 1 C

NOTE! Present Value Access Types: R = Read-only, W = Writeable, C = Commandable.

Commandable values support priority arrays & relinquish defaults.

6.2.2 Analogue Value Object

Table 16.

Instance ID Object Name Description Units

AV0

AV1

AV2

AV3

AV4

AV5

AV6

AV7

AV8

AV9

Frequency Setpoint Frequency Setpoint Hz R

Output Frequency Output Frequency Hz R

Motor Speed Motor Speed rpm R

Load (power) Motor Shaft Power % R

Kilowatt Hours total Kilowatt Hour Counter (Total) kWh R

Motor Current Motor Current A R

DC link Voltage DC link Voltage V R

Motor Voltage Motor Voltage V R

Unit Temperature Heatsink Temperature °C R

Motor Torque In % of motor nominal Torque % R

Present Value

Access Type

AV10

AV11

AV12

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Operating Days Operating Days (resettable) Day R

Operating Hours Operating Hours (resettable) Hour R

Kilowatt Hours Kilowatt Hours (resettable) kWh R

6

vacon • 30 Communications

Table 16.

AV13

AV14

AV15

AV16

AV17

AV18

AV19

AV20

AV21

AV22

AV23

AV24

AV25

Torque Reference Torque Reference %

Calculated motor tempera-

Temperature Rise

fb_ProcessdataOut_01

fb_ProcessdataOut_02

fb_ProcessdataOut_03

fb_ProcessdataOut_04

fb_ProcessdataOut_05

fb_ProcessdataOut_06

fb_ProcessdataOut_07

fb_ProcessdataOut_08

Active Fault Code Active Fault Code - R

Speed Reference

Current Limit Current Limit A W

ture 100.0% = nominal temperature of motor

Application specific

Application specific

Application specific

Application specific

Application specific

Application specific

Application specific

Application specific

Speed Reference, percentage of nominal speed

2)

2)

2)

2)

2)

2)

2)

2)

%R

%C

R

R

R

R

R

R

R

R

R

AV26

AV27

AV28

AV29

AV30

AV31

AV32

AV33

AV34

AV35

AV36

AV37

AV38

AV39

Min Frequency Minimum Frequency Hz W

Maximum Frequency Maximum Frequency Hz W

Accel Time Acceleration Time s W

Decel Time Deceleration Time s W

fb_ProcessdataIn_01

fb_ProcessdataIn_02

fb_ProcessdataIn_03

fb_ProcessdataIn_04

AnyParam ID

AnyParam Value Value of ID defined by AV34 32 bits Value W

1)

Fb_Control_Word Lo16

1)

Fb_Control_Word Hi16

Fb_Status_Word Lo16

Fb_Status_Word Hi16

Application specific

Application specific

Application specific

Application specific

ID number that is used in

AV35

Fixed Control Word First 16

bits 0-15

Fixed Control Word Last 16

bits 16-31

Fixed Status Word First 16

bits 0-15

Fixed Status Word Last 16

bits 16-31

2)

2)

2)

2)

0 to 65535

resolution 1

range 65535 - 0 C

range 65535 - 0 C

range 65535 - 0 R

range 65535 - 0 R

C

C

C

C

W

6

1) ANSI/IEEE-754 floating point. Binary coding can be done only if the value has no decimals.

2) Map only analog data to these objects. If binary coded data is mapped into these objects, the data may be

invalid because of ANSI/IEEE-754 floating point to 32bit integer conversion.

NOTE! Present Value Access Types: R = Read-only, W = Writeable, C = Commandable.

Commandable values support priority arrays & relinquish defaults.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Communications vacon • 31

High and Low limits for the objects are defined in the application. See corresponding application for

exact limits.

6.3 Control word bits

Table 17. Control Word bits

Bit Name Value = 1 Value = 0 Description

B0 Start/Stop Start request Stop request Start/Stop command to application

B1 Fwd/Rev

B2 Fault reset Reset faults No action Command to reset fault

B3-B15 Not used

Reverse

direction

Forward

direction

Controls the direction of motor axis rotation

6.4 Status word bits

Table 18. Status Word bits

Bit Name Value = 1 Value = 0 Description

B0 Ready Ready Not ready Indicates whether the drive is ready or not

B1 Run Running Stop

B2 Direction Counterclockwise Clockwise

B3 Fault Faulted Not faulted Indicates if a fault is active

B4 Alarm Alarm No alarm Indicates if an alarm is active

B5 AtReference True False Reference frequency reached

B6 ZeroSpeed True False Motor running at zero speed

B7-B15 Not used

Indicates whether the drive is running or

stopped

Indicates the rotation direction of the

motor

6.5 COV functionality

It is possible to subscribe to up to 20 objects for COV monitoring. When the change occurs, the

subscribed object COV indication is sent with new object value.

When you subscribe to objects for COV monitoring, the object are added into background monitoring

list that has 150ms update cycle per item. So, the update rate for COV indication is depending on the

amoount of subscribed objects. The maximum amount of COV items to subscribe to is 20. This

means that the update rate is 150ms – 3000ms for the whole list.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

6

vacon • 32 Communications

6.6 Processdata mapping in drive application

The drive application allows you to choose freely which data is mapped into processdata out objects.

See the drive appllication 'Fieldbus DataMap' parameters (P3.6).

Some of the drive processdata values are available in BACnet analog value object and some are

available via binary value objects.

fb_ProcessdataOut_01 BV7 - BV14 and AV15

fb_ProcessdataOut_02 - 08 AV16 - AV22

If binary coded data needs to be produced over BACnet, we recommend to use

‘fb_ProcessdataOut_01’ which is available via BV objects. Note that ‘fb_ProcessdataOut_01’ is also

available via AV15 object but we recommend to use it only when an analog value is mapped into

‘fb_ProcessdataOut_01’. Follow the same principle with ‘fb_ProcessdataOut_01’ –

‘fb_ProcessdataOut_08’ which are available in AV objects 16-22.

6

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Fault tracing vacon • 33

7. F AULT TRACING

When an unusual operating condition is detected by the AC drive control diagnostics, the drive

initiates a notification visible, for example, on the keypad. The keypad will show the ordinal number

of the fault, the fault code and a short fault description.

The fault can be reset with the Reset button on the control keypad or via the I/O terminal. The faults

are stored in the Fault history menu, which can be browsed. The different fault codes you will find in

the table below. This fault table presents only the faults related to the fieldbus in use.

NOTE! If you need support in problems related to BACnet, send a description of the problem

®

together with the Drive Info File taken with VACON

Live to your local support. In case of BACnet IP

protocol please send also a "Wireshark" log from the situation if applicable.

7.1 Typical fault conditions

Table 19. Typical fault conditions

Fault condition Possible cause Remedy

Termination

resistor

Cabling

Grounding Inadequate grounding. Ensure grounding in all points on the net

Connections

Parameter

Missing or excessive termination resistor.

• Supply or motor cables are located

too close to the fieldbus cable

• Wrong type of fieldbus cable

• Too long cabling

Faulty connections:

• Excessive stripping of cables

• Conductors in wrong terminals

• Too loose connections of conductors

• Faulty address

• Overlapping slave addresses

•Wrong baud rate

• Wrong control place selected

Install termination resistors at both ends of

the fieldbus line.

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

vacon • 34 Fault tracing

Drivedoes notstart from the

bus

C

heckcommuni-

cati

o

nsta

t

us

(

par.

5.7.

3

.

2.

1/5.8.3.2.2

)

C

o

unter does not

run

C

o

unter for b

a

d

fra

m

es (s

e

e

T

a

b

l

e

3) in

cr

eases

C

o

u

nter

O

K

.

No

co

m

m

unic

atio

n

P

o

or

c

o

m

m

u

n

ic

a

tio

n

Is the

d

e

vice i

n

READY s

ta

te?

Che

c

ktheledon

key

p

ad

Che

c

kexterna

l

inter

l

ockings (

I

/

O

)

Is fieldbus selec

t

e

d

as c

o

ntro

l

place?

Che

c

k

p

aramete

r

Doe

sMaster

g

ive

RUN c

o

m

m

an

d

?

Us

ek

eypad to

mon

ito

r

S

e

tvariable AV36

to ‘1’

C

he

c

k

fieldb

u

s

param

e

te

r

s

C

h

eck

o

th

e

rfi

e

ld-

bus par

a

mete

r

s

C

he

c

k

selected

protocol

Che

c

kMaster’s

pa

ra

met

e

rs

Che

c

kconfigura

-

tio

n

s(

S

la

v

e

a

d

d

-

re

s

s

,

b

a

ud

ra

t

e

e

t

c.

)

Che

c

kterminat

i

o

n

r

e

s

i

sto

r

s

Check that both

en

d

softhefield

b

us

lin

e

h

a

ve

t

erm

i

na

-

tio

n

r

e

s

i

s

to

rs

(c

h

apter 4.2)

Ch

e

c

k

cab

l

ing

Ch

e

c

k

cab

l

efor

cuts

C

h

e

ck c

orr

e

ct p l

a

ce-

ment o

fc

ondu cto

rs

i

n

te

rm

i

n

a

ls

Oth

e

r

b

us devices

Check o

th

er

nec

e

s

sa

ry dev ice

s

(

e

.g

.

r

ou

te

r)

C

h

eck t

e

rmin

a

ti

o

n

re

s

i

s

tors

C

he

c

k

th

a

t

b

o

th

en

d

so

f

t

h

efi

e

l

db

u

s

line

ha

v

e

t

e

r

m

i-

n

a

tio

n

resist

o

rs

(cha

pt

e

r

4.2)

Che

c

kcabling

Ch

e

c

kdis

tan

c

e

s

be

t

w

e

en

c

a

bl

e

s

,

s

e

e

c

h

a

pter

4

.2

.

Ch

e

c

k

cab

l

e

t

y

p

e

s

,

s

e

e

c

h

a

pter

3

.

Che

c

k

g

roundi ng

Ch

e

c

k

g

ro

u

nd

in

g

,

se

ec

h

a

p

te

r

4.

R

e

-

me

m

b

e

rto

m

a

ke

gro

u

nd

i

ng for eac

h

devi

c

e!

C

h

eckconnect

i

on

s

C

h

e

c

kst

ripp

ing

o

f

c

a

b

le

sand

c

o

n

d

u

c

t

or

s

,s

e

e

chapter 4.

C

h

e

c

k

t

er

mi

n

a

l

sf

o

r

l

oo

s

ec

onn

e

ct

i

o

n

s

7076A_uk

M3.2.1

FB Control

Word (M2.12)

7.2 Other fault conditions

The following fault tracing diagram will help you to locate and fix some of the most usual problems.

If the problem persists contact your local distributor.

7

Figure 3. Fault tracing diagram for BACnet MS/TP

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Fault tracing vacon • 35

Drivedoes not

start from the bus

Check communi-

cation status(par.

Counter does not

run

Counter for bad

frames (see Table

3) increases

Counter OK.

No communication

Poor

communication

Is the device in

READY state?

Check the led on

keypad

Check external

interlockings (I/O)

Is fieldbus selected

as control place?

Check parameter

M1.15 or P3.2.1

Does Master give

RUN command?

Use keypad t o

monitor

FB Control

Set variable AV36

to ‘1’

Check fieldbus

parameters

Check other field-

bus parameters

Check Master’s

parameters

Check IP address,

gateway etc.

Check cabling

Check cable for

cuts

Check correct plac e-

ment of conductors

in termi na ls

Other bus devices

Check other

necessary devices

(e.g. switches)

Check cabling

Check distances

between cables,

seechapter 4.2.

Check cable types,

seechapter 3.

Check connections

Check stripping of

cables and

conductors, see

chapter 4.

Check e.gWLAN or

other routers

7075A_uk

P5.9.3.2.2)

Word (M2.12)

Check BACnet IP ‘protocol

in use’ parameter (P5.9.3.1.4)

Figure 4. Fault tracing diagram for BACnet IP

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

7

vacon • 36 Quick setup

8. QUICK SETUP

Following these instructions, you can easily and fast set up your BACnet bus for use.

1

2

Parametrize BACnet functionality as described in Chapter 4. “Programming”.

Make these settings in the master software.

A. Set

B. Set

C. AC drive status is RUN.

D. Set Reference value to ‘50’ (50.00%) (AV24 Speed Reference).

E.

F. Set

G. AC drive status is STOP.

Control Word to ‘0’ (AV36 Fb_Control_Word_Lo16).

Control Word to

Frequency setpoint is 25.00 Hz (if MinFreq is 0.00 Hz and MaxFreq is 50.00 Hz)

Control Word to ‘0’ (AV36 Fb_Control_Word_Lo16).

‘1’

(AV36 Fb_Control_Word_Lo16).

8

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Annex - Protocol implementation conformance statement vacon • 37

9. A NNEX - PROTOCOL IMPLEMENTATION CONFORMANCE

STATEMENT

PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT (NORMATIVE)

(This annex is part of this Standard and is required for its use.)

BACnet Protocol Implementation Conformance Statement

Date: December 17, 2014

Vendor Name: VACON

Product Name: VACON 100

Product Model Number: VACON 100, VACON 100 X, VACON FLOW

Applications Software Version: 1.0

Firmware Revision: 1.0

BACnet Protocol Revision: 12

Product Description: VACON 100 Variable Frequency Drive (VFD) product range contains the

following models based on the same software: VACON 100, VACON 100 FLOW, VACON 100 X

BACnet Standardized Device Profile (Annex L):

List all BACnet Interoperability Building Blocks Supported (Annex K): DS-RP-B, DS-RPM-B, DS-

WP-B, DS-WPM-B, DS-COV-B, DM-TS-B, DM-UTC-B, DM-RD-B, DM-DDB-B, DM-DOB-B, DMDCC-B.

BACnet

Application Specific Controller (B-

ASC

)

Segmentation Capability:

Segmented requests supportedWindow Size 8

Segmented responses supportedWindow Size 8

Standard Object Types Supported:

®

VACON

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

100 product family supports:

• Device Object

•Analog Value Object

• Binary Value Object

9

vacon • 38 Annex - Protocol implementation conformance statement

The Analog Values that are commandable contain the priority array and relinquish default

properties. All Analog Values that are not

property is set to true.

commandable become writable when the out of service

The Binary Values that are

properties. All Binary Values that are not

property is set to true.

Device Object

Table 20:

object-identifier x

object-name x

object-type x

system-status x

vendor-name x

vendor-identifier x

model-name x

firmware-revision x

application-software-version x

description x

protocol-version x

protocol-revision x

commandable contain the priority array and relinquish default

Object property Readable Writable

commandable become writable when out of service

protocol-services-supported x

protocol-object-types-supported x

object-list x

max-apdu-length-accepted x

segmentation-supported x

max-segments-accepted x

local-time x

local-date x

apdu-segment-timeout x

apdu-timeout x

number-of-apdu-retries x

max-master x

max-info-frames x

device-address-binding x

database-revision x

active-cov-subscriptions x

9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Annex - Protocol implementation conformance statement vacon • 39

Analog Value Object

Table 21:

Analog Value Object - Commandable

Object property Readable Writable Commandable

object-identifier x

object-name x

object-type x

present-value x x

status-flags x

event-state x

out-of-service x x

units x

priority-array x

relinquish-default x x

cov-increment x x

Table 22:

Analog Value Object - writable when out-of-service is set true

Object property Readable Writable

object-identifier x

object-name x

object-type x

* x Normally ‘read only’ but

present-value x

status-flags x

event-state x

out-of-service x x

units x

cov-increment x x

becomes writable when out-of-

service set to true

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

9

vacon • 40 Annex - Protocol implementation conformance statement

Binary Value Object

Table 23:

Binary Value Object - Commandable

Object property Readable Writable Commandable

object-identifier x

object-name x

object-type x

present-value x x

status-flags x

event-state x

out-of-service x x

priority-array x

relinquish-default x x

Table 24:

Binary Value Object - writable when out-of-service is set true

Object property Readable Writable

object-identifier x

object-name x

object-type x

* x Normally ‘read only’ but

present-value x

status-flags x

event-state x

out-of-service x x

priority-array x

relinquish-default x x

becomes writable when out-

of-service set to true

9

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

Annex - Protocol implementation conformance statement vacon • 41

Data Link Layer Options:

MS/TP master (Clause 9), baud rate(s): 9600,19200,34800, 76800 (supports autobaud detection)

BACnet IP, (Annex J), Foreign Device

Device Address Binding:

Is static device binding supported? (This is currently necessary for two-way communication with

MS/TP slaves and certain other devices.)

Networking Options:

Yes No

Router, Clause 6 - List all

routing configurations

, e.g.,

ARCNET-Ethernet

, Ethernet-MS/TP, etc.

Annex H, BACnet Tunneling Router over IP

BACnet/IP Broadcast Management Device (BBMD)

Character Sets Supported:

Indicating support for multiple character sets does not imply that they can all be supported

simultaneously.

ISO 10646 (UTF-8) IBM

TM

/MicrosoftTM DBCS ISO 8859-1

ISO 10646 (UCS-2) ISO 10646 (UCS-4) JIS X 0208

Local contacts: http://drives.danfoss.com/danfoss-drives/local-contacts/

9

www.danfoss.com

Vacon Ltd

Member of the Danfoss Group

Runsorintie 7

65380 Vaasa

Finland

Document ID:

DPD00091D

Rev. D

Sales code: DOC-INSBACNET+DLUK

Loading...

Loading...