Application Guide

VACON® 100 INDUSTRIAL

drives.danfoss.com

VACON® 100 INDUSTRIAL

Application Guide

Contents

1

Introduction 11

1.1

Purpose of this Application Guide 11

Manual and Software Version 11

1.2

Additional Resources 11

1.3

1.4

Parameter Table Reading Guide 11

1.5

Functions of the AC Drive 12

1.6

Start-up Quick Guide 13

1.6.1

Start-Up Wizard 13

User Interfaces 15

2

Description of the Control Panel 15

2.1

Control Panel and the Keypad 15

2.1.1

Displays of the Control Panel 15

2.1.2

Contents

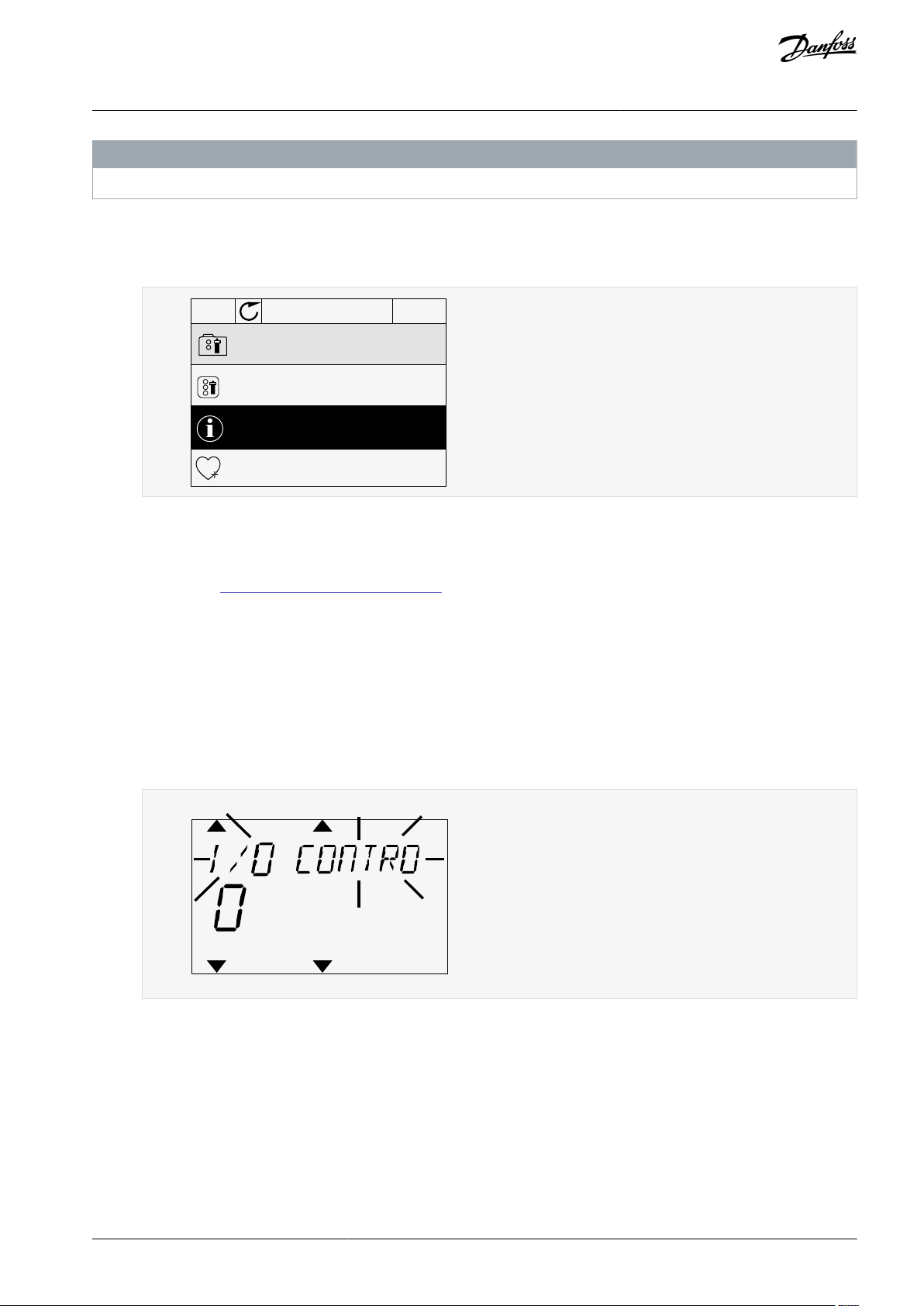

Menu Structure 16

2.2

2.3

Graphical Display 19

2.3.1

Editing the Text Values 19

2.3.2

Editing the Numerical Values 19

2.3.3

Selecting More than 1 Value 20

2.3.4

Resetting a Fault 20

2.3.5

[FUNCT] Button 20

2.3.5.1

2.3.5.2

2.3.5.3

2.3.5.4

2.3.5.5

2.3.6

Copying the Parameters of an AC Drive 23

2.3.7

Comparing the Parameters 23

2.3.8

Reading Help Texts 24

2.3.9

Using the Favourites Menu 25

Different Control Places 20

Changing the Control Place 21

Going into the Control Page 21

Changing the Rotation Direction 22

Using the Quick Edit Function 22

2.4

Text Display 25

2.4.1

Editing the Text Values 25

2.4.2

Editing the Numerical Values 25

2.4.3

Resetting a Fault 20

2.4.4

[FUNCT] Button 26

2.4.4.1

2.4.4.2

2.4.4.3

Different Control Places 20

Changing the Control Place 26

Going into the Control Page 27

AB275637269262en-000101/DPD00927 | 3Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

2.4.4.4

2.4.4.5

2.5

VACON® Live PC Tool 28

3

Applications 29

3.1

Using the Applications 29

3.2

Standard Application 29

3.3

Local/Remote Application 33

3.4

Multi-step Speed Application 37

3.5

PID Control Application 42

3.6

Multi-purpose Application 46

3.7

Motor Potentiometer Application 51

4

Wizards 56

4.1

Application Wizards 56

Changing the Rotation Direction 27

Using the Quick Edit Function 22

Contents

4.1.1

Standard Application Wizard 56

4.1.2

Local/Remote Application Wizard 56

4.1.3

Multi-step Speed Application Wizard 57

4.1.4

PID Control Application Wizard 57

4.1.5

Multi-purpose Application Wizard 58

4.1.6

Motor Potentiometer Application Wizard 59

4.2

Function Wizards 59

4.2.1

Wizards in Menu 1.1 59

4.2.2

Multi-pump Wizard 60

4.2.3

Fire Mode Wizard 61

5

Monitor Menu 62

5.1

Uses of the Monitor Menu 62

5.2

Multimonitor Monitoring 62

5.2.1

Changing the Items to Monitor 62

5.3

Trend Curve Monitoring 62

5.3.1

Uses of the Trend Curve 62

5.3.2

Changing the Values in Trend Curve Monitoring 62

5.3.3

Stopping the Progression of the Curve 63

5.3.4

Trend Curve Parameters 64

5.4

Basic Monitoring 64

5.4.1

Uses of the Basic Monitoring 64

5.4.2

Basic Monitoring Parameters 64

5.5

I/O Monitoring 65

AB275637269262en-000101/DPD009274 | Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

5.6

Temperature Inputs 65

5.7

Extras and Advanced 66

5.8

Timer Functions Monitoring 67

5.9

PID Controller Monitoring 68

5.10

External PID Controller Monitoring 68

5.11

Multi-pump Monitoring 68

5.12

Monitoring of Maintenance Counters 69

5.13

Fieldbus Process Data Monitoring 69

5.14

Drive Customizer Monitoring 70

5.15

Condition-based Monitoring 71

6

Parameters Menu 73

6.1

Group 3.1: Motor Settings 73

6.2

Group 3.2: Start/Stop Setup 76

6.3

Group 3.3: References 77

Contents

6.4

Group 3.4: Ramps and Brakes Setup 82

6.5

Group 3.5: I/O Configuration 83

6.6

Group 3.6: Fieldbus Data 90

6.7

Group 3.7: Prohibit Frequencies 92

6.8

Group 3.8 Supervisions 92

6.9

Group 3.9: Protections 93

6.10

Group 3.10: Automatic Reset 97

6.11

Group 3.11: Application Settings 98

6.12

Group 3.12: Timer Functions 98

6.13

Group 3.13: PID Controller 100

6.14

Group 3.14: External PID Controller 107

6.15

Group 3.15: Multi-pump 110

6.16

Group 3.16: Maintenance Counters 111

6.17

Group 3.17: Fire Mode 111

6.18

Group 3.18: Motor Preheat Parameters 112

6.19

Group 3.19: Drive Customizer 113

6.20

Group 3.20: Mechanical Brake 113

6.21

Group 3.21: Pump Control 114

6.22

Group 3.22: Advanced Harmonic Filter 115

6.23

Group 3.23: Condition-based Monitoring 115

7

Diagnostics Menu 120

7.1

Faults 120

7.1.1

Uses of the Active Faults Submenu 120

AB275637269262en-000101/DPD00927 | 5Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

7.1.2

Reset Faults 120

7.1.2.1

7.1.2.2

7.1.2.3

7.1.3

Uses of the Fault History 121

7.1.3.1

7.1.3.2

7.2

Software Info 122

7.3

Drive Info 122

7.4

Unit Status 123

8

I/O and Hardware Menu 124

8.1

Basic I/O 124

8.2

Option Board Slots 124

8.3

Real-time Clock 125

Resetting Faults with the [BACK/RESET] Button 120

Resetting Faults with a Parameter on the Graphical Display 120

Resetting Faults with a Parameter on the Text Display 120

Examining the Fault History on the Graphical Display 121

Examining the Fault History on the Text Display 121

Contents

8.4

Simple Network Time Protocol (SNTP) 125

8.5

Power Unit Settings 126

8.6

Keypad 126

8.7

Fieldbus 127

8.8

Fieldbus General 129

8.9

STO 130

8.10

Fieldbus Redundancy 130

9

User Settings, Favourites, and User Level Menus 131

9.1

User Settings 131

9.1.1

User Settings Parameters 131

9.1.2

Parameter Back-up Parameters 131

9.1.3

Parameter Compare Parameters 132

9.1.4

License Parameters 132

9.2

Favourites 132

9.2.1

Using the Favourites Menu 132

9.2.2

Adding an Item to the Favourites 132

9.2.3

Removing an Item from the Favourites 132

9.3

User Levels 133

9.3.1

Using the User Levels Menu 133

9.3.2

The User Level Parameters 133

9.3.3

Changing the Access Code of the User Levels 133

AB275637269262en-000101/DPD009276 | Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

10

Monitoring value descriptions 135

Multimonitor 135

10.1

10.2

Basic 136

I/O 137

10.3

10.4

Temperature Inputs 138

10.5

Extras and Advanced 139

10.6

Timer Functions 140

10.7

PID Controller 141

10.8

External PID Controller 141

10.9

Multi-pump 142

10.10

Maintenance Counters 142

10.11

Fieldbus Data 142

10.11.7

Fieldbus Data In 144

10.11.8

Fieldbus Data Out 145

Contents

Drive Customizer 147

10.12

10.13

Condition-based Monitoring 147

10.13.1

Baseline Data 147

10.13.2

Stator Winding Monitor 148

10.13.3

Vibration 149

10.13.4

Load 149

11

Parameter descriptions 151

11.2

Trend Curve 151

11.3

Fieldbus Redundancy 152

11.4

Motor Settings 152

11.4.1

Motor Nameplate Parameters 152

11.4.2

Motor Control Parameters 153

11.4.3

Motor Limits 158

11.4.4

Open Loop Parameters 159

11.4.5

I/f Start Function 162

11.4.6

Torque Stabilator Function 162

11.4.7

Advanced Sensorless Control 163

11.5

Start/Stop Setup 165

11.5.1

Start and Stop Commands in Different Control Places 165

11.6

References 173

11.6.1

Frequency Reference 173

11.6.2

Torque Reference 174

11.6.3

Torque Control in Open Loop Control 177

AB275637269262en-000101/DPD00927 | 7Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

11.6.4

Torque Control in Advanced Sensorless Control 178

11.6.5

Preset Frequencies 178

11.6.6

Motor Potentiometer Parameters 181

11.6.7

Joystick Parameters 182

11.6.8

Jogging Parameters 183

11.7

Ramps and Brakes Setup 185

11.7.1

Ramp 1 185

11.7.2

Ramp 2 186

11.7.3

Start Magnetizing 187

11.7.4

DC Brake 188

11.7.5

Flux Braking 188

11.8

I/O Configuration 188

11.8.1

Programming of Digital and Analog Inputs 188

11.8.1.1

Contents

General Information on the Programming 188

11.8.1.2

11.8.1.3

11.8.1.4

11.8.1.5

11.8.1.6

11.8.1.7

11.8.2

Descriptions of Signal Sources 194

11.8.3

Default Functions of Programmable Inputs 195

11.8.4

Digital Inputs 195

11.8.5

Analog Inputs 200

11.8.6

Digital Outputs 204

11.8.7

Analog Outputs 208

11.9

Fieldbus Data 210

11.10

Prohibit Frequencies 212

11.11

Supervisions 214

11.12

Protections 215

Programming of Digital Inputs 189

Programming of Digital Inputs in the Graphical Display 191

Programming of Digital Inputs in the Text Display 191

Programming of Analog Inputs 192

Programming of Analog Inputs in the Graphical Display 193

Programming of Analog Inputs in the Text Display 194

11.12.1

General 215

11.12.2

Motor Thermal Protections 217

11.12.3

Motor Stall Protection 220

11.12.4

Underload Protection 221

11.12.5

Quick Stop 223

11.12.6

Temperature Input Fault 224

11.12.7

AI Low Protection 225

11.12.8

User Defined Fault 1 226

AB275637269262en-000101/DPD009278 | Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

11.12.9

User Defined Fault 2 226

11.13

Automatic Reset 227

11.14

Application Settings 229

11.15

Timer Functions 230

11.15.1

Introduction to Timer Functions 230

11.15.2

Time Channels, Intervals, and Timers 230

11.15.3

Editing an Interval 232

11.16

PID Controller 234

11.16.1

Basic Settings 234

11.16.2

Setpoints 235

11.16.3

Feedback 237

11.16.4

Feedforward 237

11.16.5

Sleep Function 239

11.16.6

Feedback Supervision 241

Contents

11.16.7

Pressure Loss Compensation 243

11.16.8

Soft Fill 245

11.16.9

Input Pressure Supervision 247

11.16.10

Frost Protection 249

11.17

External PID Controller 250

11.17.1

Basic Settings 250

11.17.2

Setpoints 252

11.17.3

Feedback 253

11.17.4

Feedback Supervision 253

11.18

Multi-pump Function 255

11.18.1

The Multi-pump Function 255

11.18.12

Overpressure Supervision 261

11.19

Maintenance Counters 261

11.19.1

The Maintenance Counters 261

11.20

Fire Mode 262

11.20.1

The Fire Mode Function 262

11.21

Motor Preheat Function 265

11.22

Drive Customizer 266

11.23

Mechanical Brake 266

11.23.1

The Mechanical Brake Function 266

11.24

Pump Control 268

11.24.1

Auto-Cleaning 268

11.24.2

Jockey Pump 270

11.24.3

Priming Pump 271

AB275637269262en-000101/DPD00927 | 9Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

11.25

Advanced Harmonic Filter 272

11.26

Condition-based Monitoring 273

11.26.1

Introduction to Condition-based Monitoring 273

11.26.1.1

11.26.6

Manual Run 275

11.26.7

Stator Winding Monitoring 275

11.26.8

Threshold Value 275

11.26.9

Warning and Alarm/Fault Stages 277

11.27

Default Values of Parameters in the Different Applications 282

11.28

Settings for Different Motor Types 285

11.28.1

Automatic Tuning of the U/f Curve 285

11.28.2

Manual Tuning of the U/f Curve 286

12

Fault tracing 288

12.1

Fault Types 288

Stages of Condition-based Monitoring 273

Contents

12.2

Alarms and Warnings 288

12.3

Fault Codes 288

12.4

Total and Trip Counters 314

12.4.1

Operating Time Counter 314

12.4.2

Operating Time Trip Counter 315

12.4.3

Run Time Counter 315

12.4.4

Power on Time Counter 316

12.4.5

Energy Counter 316

12.4.6

Energy Trip Counter 317

AB275637269262en-000101/DPD0092710 | Danfoss A/S © 2021.05

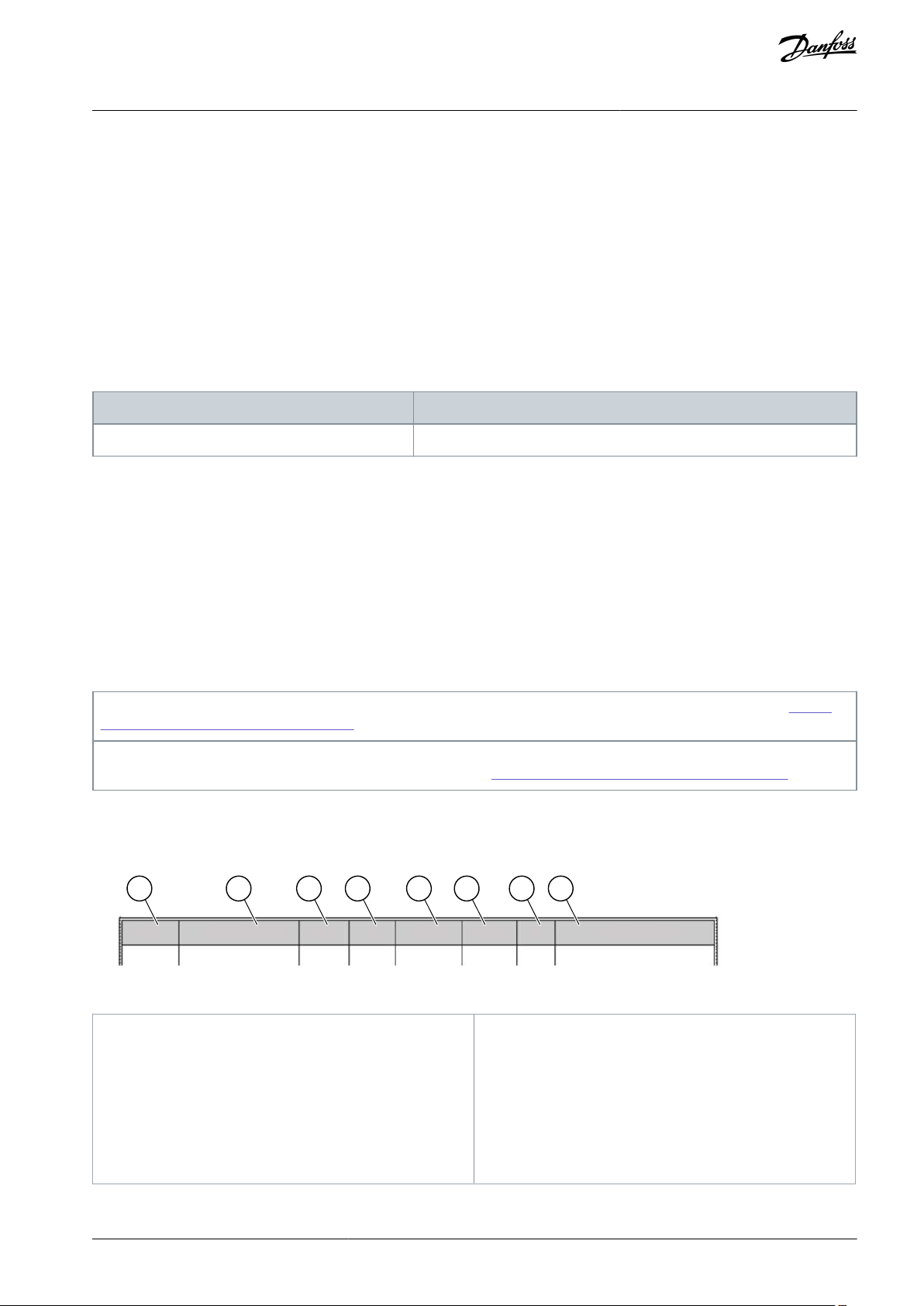

Edition

Software version

DPD00927K

FW0072V033

NOTE! Download the English and French product guides with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des guides produit contenant l'ensemble des informations

de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

Index

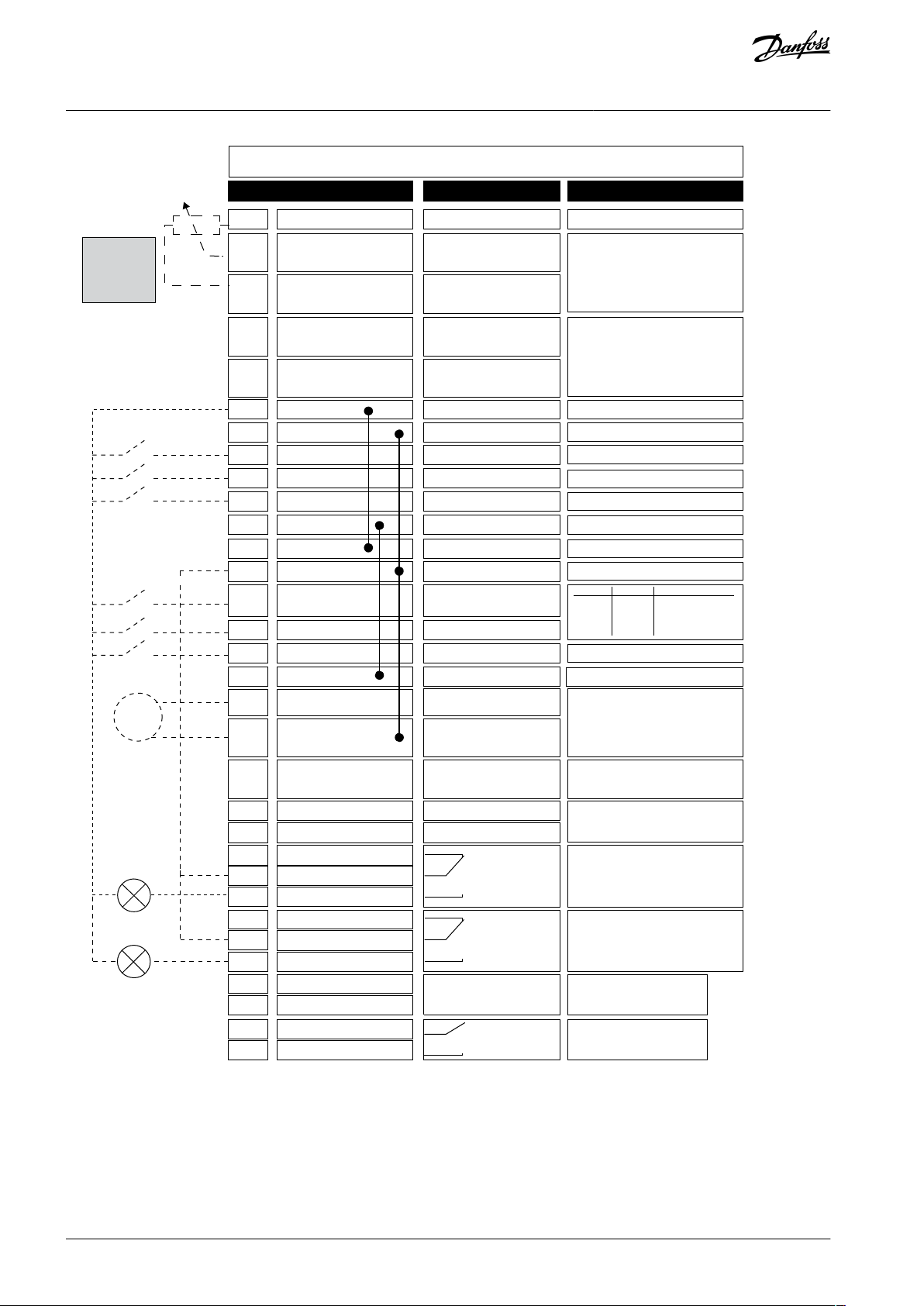

Min Max Unit Default

ID Description

Parameter

e30bg858.10

A

B

C

D E F G H

A

The location of the parameter in the menu, that is,

the parameter number.

B

The name of the parameter.

C

The minimum value of the parameter.

D

The maximum value of the parameter.

E

The unit of the value of the parameter. The unit

shows if it is available.

F

The value that was set in the factory.

G

The ID number of the parameter.

H

A short description of the values of the parameter

and/or its function.

VACON® 100 INDUSTRIAL

Application Guide

Introduction

1 Introduction

1.1 Purpose of this Application Guide

This Application Guide provides information for configuring the system, controlling the AC drive, accessing parameters, programming, and troubleshooting of the AC drive. It is intended for use by qualified personnel. Read and follow the instructions to use the

drive safely and professionally. Pay particular attention to the safety instructions and general warnings that are provided in this

manual and other documentation delivered with the drive.

1.2 Manual and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Manual and Software Version

1.3 Additional Resources

Other resources are available to understand advanced AC drive functions and operation.

•

VACON® 100 Wall-mounted Drives Operating Guide

•

VACON® 100 Enclosed Drives Installation Manual

VACON® 100 IP00 Drive Modules Installation Manual

•

VACON® 100 X Installation Manual

•

Instructions for operation with option boards and other optional equipment.

•

Supplementary publications and manuals are available from Danfoss.

For US and Canadian markets:

1.4 Parameter Table Reading Guide

This manual includes a large quantity of parameter tables. These instructions tell you how to read the tables.

Illustration 1: Parameter Table Reading Guide

AB275637269262en-000101 / DPD00927 | 11Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

1.5 Functions of the AC Drive

•

Easy setup functions

-

Applications with preset parameters and I/O configuration for your process: Standard, Local/Remote, Multi-step speed, PID

control, Multi-purpose, or Motor potentiometer

-

Start-up wizards for fast and easy parameterization

•

Navigation functions

-

The [FUNCT] button for an easy change between the local and the remote control place (I/O or fieldbus)

-

A control page to operate and monitor of the most important values quickly

•

Advanced monitoring functions

-

Multimonitor

-

Trend curve

•

Fieldbus and I/O control

•

Motor control

-

Open loop control with frequency, speed, and torque reference

-

Advanced sensorless control mode

-

Support for induction, permanent magnet, and synchronous reluctance motors

-

Identification run for setup of motor parameters

-

Many advanced functions for motor control setting, such as load drooping

-

Flux and DC brake

•

Start and stop logic configuration

•

Reference selection and handling

-

8 preset frequencies

-

Motor potentiometer functions

-

A joystick control

-

A jogging function

-

2 programmable ramp times

-

3 ranges of prohibited frequencies

-

A forced stop

•

PID control

-

An external PID controller is available. Use it, for example, to control a valve with the I/O of the AC drive.

-

A sleep mode function that automatically enables and disables the operation of the drive to save energy

-

A 2-zone PID controller with 2 different feedback signals: minimum and maximum control

-

2 setpoint sources for the PID control. Selection to be made with a digital input.

-

A function for PID setpoint boost

-

A feedforward function to make the response to the process changes better

•

Pump control

-

Multi-pump control

-

Priming pump control, jockey pump control, pump impeller auto-cleaning, pump input pressure supervision, and frost protection function

•

Mechanical brake control

•

Timer functions and a real-time clock and (an optional battery is necessary)

•

Fire mode

•

Diagnostic and maintenance functions

-

Variety of configurable protection functions including user-defined faults

-

Supervision functions for frequency and motor variables and analog inputs

Introduction

AB275637269262en-000101 / DPD0092712 | Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

-

Motor overload protections

-

An automatic reset

-

Different preheat modes to prevent condensation problems

-

Maintenance counters

•

Drive Customizer for custom logic programming

•

Control, parametrization, and diagnostics via PC-tools

Introduction

1.6 Start-up Quick Guide

There are 6 applications available for the product. When an application is selected, a group of parameters get their preset values.

The selection of the application makes the commissioning of the drive easy and reduces the manual work with the parameters. It is

also possible to edit these parameters later.

W A R N I N G

ACCIDENTAL START BECAUSE OF CHANGE OF SETTINGS

Running the Startup wizard, changing the application or the software can cause the I/O functions to change.

Disconnect the motor from the drive if an accidental start can be dangerous.

-

The available applications:

•

Standard application (3.2 Standard Application)

•

Local/remote application (3.3 Local/Remote Application)

•

Multi-step speed application (3.4 Multi-step Speed Application)

•

PID control application (3.5 PID Control Application)

•

Multi-purpose application (3.6 Multi-purpose Application)

•

Motor potentiometer application (3.7 Motor Potentiometer Application)

Wizards make it more convenient to use the AC drive. There is a start-up wizard (see 1.6.1 Start-Up Wizard), 6 applications wizards

(see 4.1 Application Wizards), and 2 function wizards (see 4.2.2 Multi-pump Wizard and 4.2.3 Fire Mode Wizard).

1.6.1 Start-Up Wizard

The Start-up wizard asks for necessary data for the drive to control the procedure.

Procedure

1.

Select language (P6.1).

If a battery is installed, the steps 2–5 are shown.

2.

Set daylight saving time (P5.5.5). (Russia, US, EU, or OFF)

3.

Set time (P5.5.2).

4.

Set year (P5.5.4).

5.

Set date (P5.5.3).

6.

Run Startup wizard?

If the selection is No, the Start-up wizard ends.

7.

Select an application (P1.2 Application, ID212).

8.

Set a value for P3.1.2.2 Motor Type (so that it agrees with the nameplate).

9.

Set a value for P3.1.1.1 Motor Nominal Voltage (so that it agrees with the nameplate).

10.

Set a value for P3.1.1.2 Motor Nominal Frequency (so that it agrees with the nameplate).

11.

Set a value for P3.1.1.3 Motor Nominal Speed (so that it agrees with the nameplate).

12.

Set a value for P3.1.1.4 Motor Nominal Current.

13.

Set a value for P3.1.1.5 Motor Cos Phi.

If parameter P3.1.2.2 Motor Type is set to Induction Motor, this step is shown. If the selection is PM Motor, the value of

parameter P3.1.1.5 Motor Cos Phi is set to 1.00 and the wizard goes directly to step 14.

14.

Set a value for P3.3.1.1 Minimum Frequency Reference.

15.

Set a value for P3.3.1.2 Maximum Frequency Reference.

AB275637269262en-000101 / DPD00927 | 13Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

16.

Set a value for P3.4.1.2 Acceleration Time 1.

17.

Set a value for P3.4.1.3 Deceleration Time 1.

18.

Run the Application wizard?

a.

To continue to the application wizard, set the selection to Yes and push the [OK] button. See the description of the

different application wizards in chapter 4.1 Application Wizards.

After these selections, the Start-up wizard is completed. To start the Start-up wizard again, there are 2 alternatives.

Go to the parameter P6.5.1 Restore Factory Defaults or to the parameter B1.1.1 Start-up Wizard. Then set the value

to Activate.

Introduction

AB275637269262en-000101 / DPD0092714 | Danfoss A/S © 2021.05

e30bu012

A

B C

I

H D

G

F E

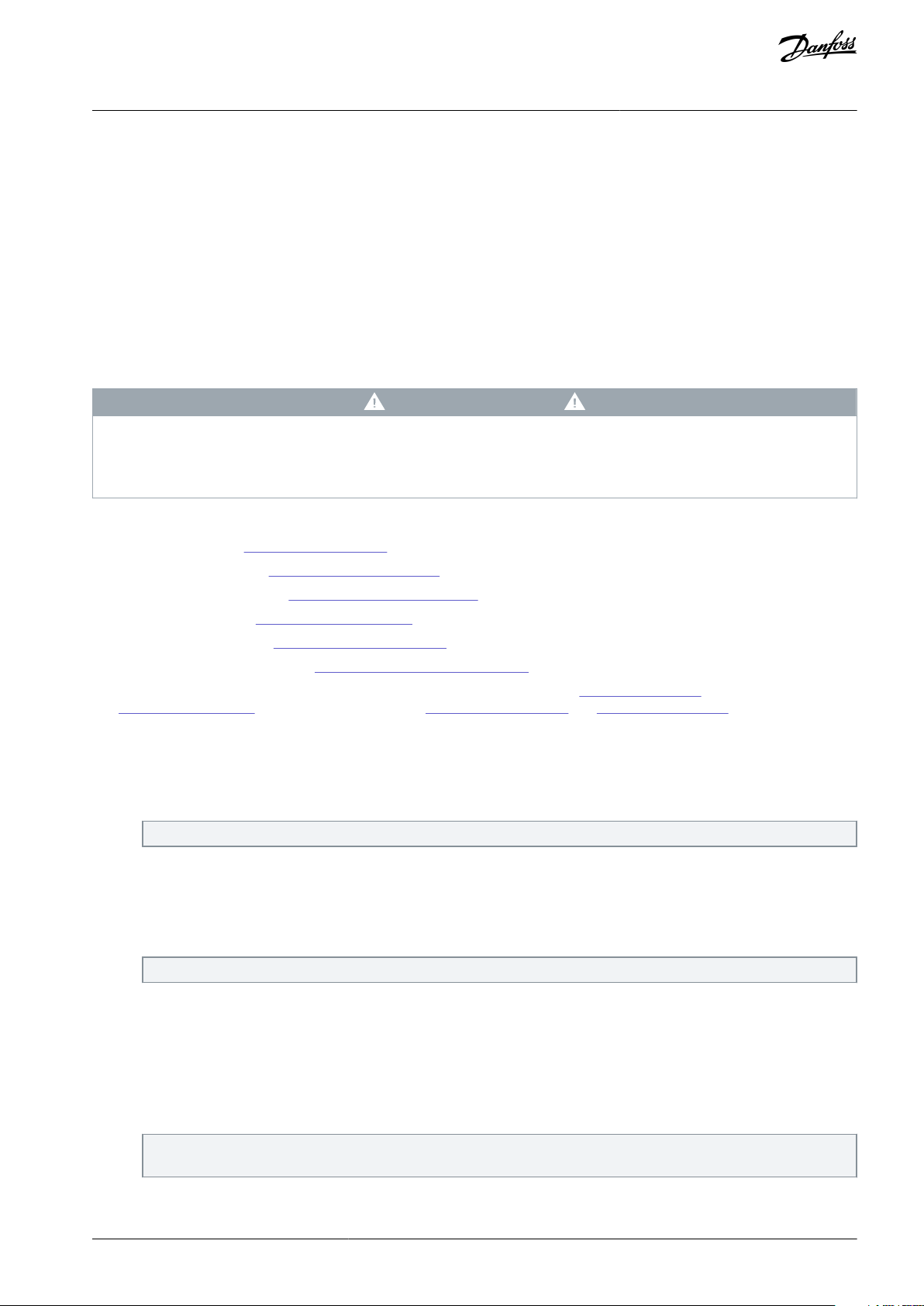

A

The [BACK/RESET] button. Use it to move back in the

menu, exit the Edit mode, reset a fault.

B

The arrow button UP. Use it to scroll up the menu

and to increase a value.

C

The [FUNCT] button. Use it to change the rotation

direction of the motor, access the control page, and

change the control place.

D

The arrow button RIGHT.

E

The START button.

F

The arrow button DOWN. Use it to scroll the menu

down and to decrease a value.

G

The STOP button.

H

The arrow button LEFT. Use it to move the cursor

left.

I

The [OK] button. Use it to go into an active level or

item, or to accept a selection.

VACON® 100 INDUSTRIAL

Application Guide

User Interfaces

2 User Interfaces

2.1 Description of the Control Panel

2.1.1 Control Panel and the Keypad

The control panel is the interface between the AC drive and the user. With the control panel, it is possible to control the speed of a

motor and monitor the status of the AC drive. It is also possible to set the parameters of the AC drive.

Illustration 2: Buttons of the VACON® 100 Keypad

2.1.2 Displays of the Control Panel

There are 2 display types: the graphical display and the text display. The control panel always has the same keypad and buttons.

The display shows this data.

•

The status of the motor and the drive.

•

Faults in the motor and in the drive.

•

Your location in the menu structure.

If the text in the text display is too long for the display, the text scrolls to show the full text string. Some functions are only available

in the graphical display.

AB275637269262en-000101 / DPD00927 | 15Danfoss A/S © 2021.05

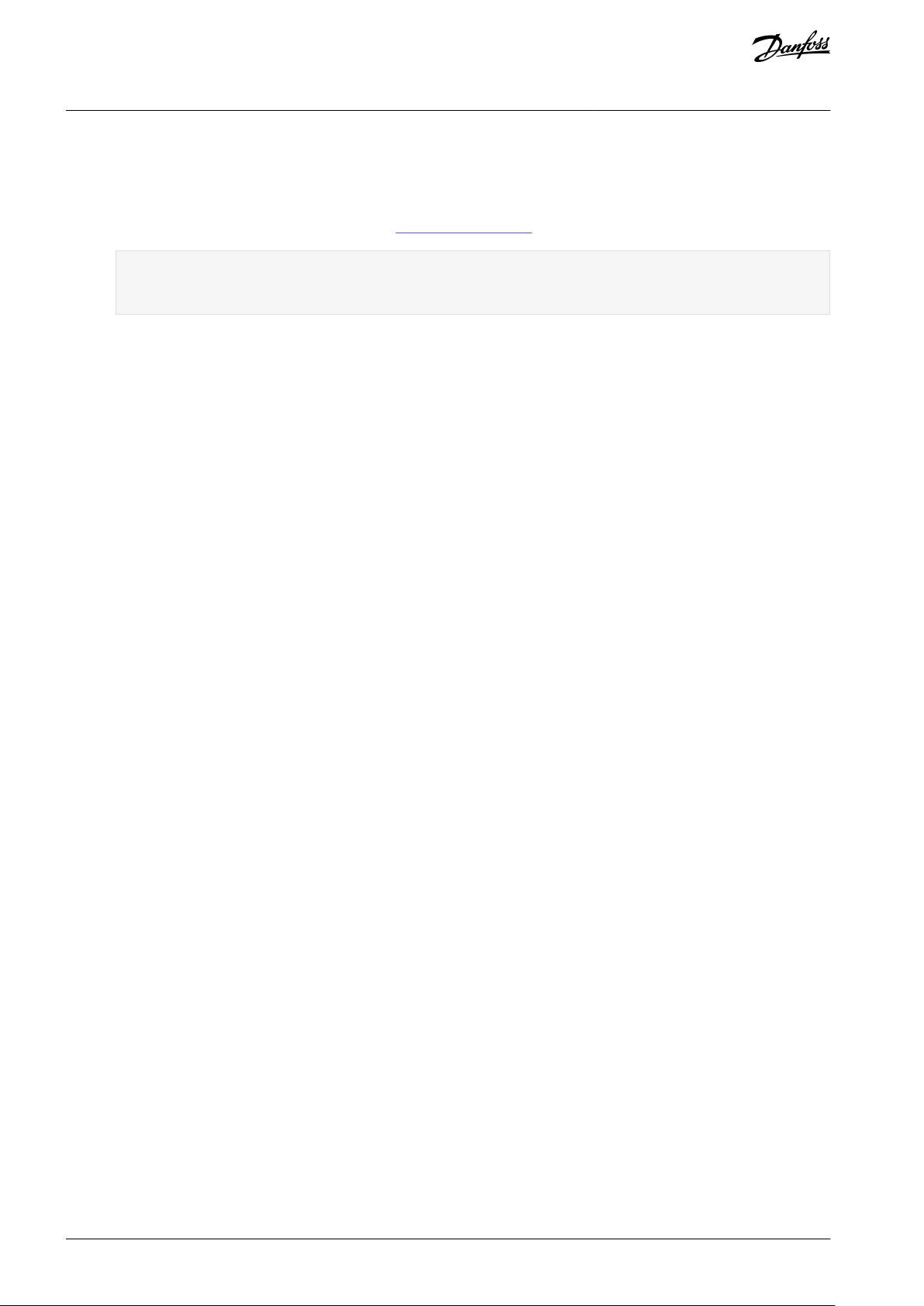

STOP

READY

I/O

Main Menu

A

B C D E

F

H

G

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

( 12 )

M1ID:

e30bu013.10

A

The first status field: STOP/RUN

B

The rotation direction of the motor

C

The second status field: READY/NOT READY/FAULT

D

The alarm field: ALARM/-

E

The control place field: PC/I/O/KEYPAD/ FIELDBUS

F

The location field: the ID number of the parameter

and the current location in the menu

G

An activated group or item

H

The number of items in the group in question

A B

F

C

D

E

e30bu014.10

A

The indicators of status

B

The indicators of alarm and fault

C

The name of the group or item of the current locationDThe current location in the menu

E

The indicators of the control place

F

The indicators of the rotation direction

VACON® 100 INDUSTRIAL

Application Guide

Illustration 3: Graphical Display of the Control Panel

User Interfaces

Illustration 4: Text Display of the Control Panel

2.2 Menu Structure

The data of the AC drive is in menus and submenus. To move between the menus, use the arrow buttons Up and Down in the

keypad. To go into a group or an item, push the [OK] button. To go back to the previous level, push the [BACK/RESET] button.

On the display, current location in the menu shows, for example M3.2.1. The display also shows the name of the group or item in the

current location.

AB275637269262en-000101 / DPD0092716 | Danfoss A/S © 2021.05

Menu

Function

M1 Quick setup

Wizards (Content depends on P1.2 Application.)

M2 Monitor

Multimonitor

Trend curve

Basic

I/O

Temperature inputs

Extras/Advanced

Timer functions

PID controller

External PID controller

Multi-pump

Maintenance counters

Fieldbus data

Drive customizer

Condition-based monitoring

M3 Parameters

Motor settings

Start/Stop setup

References

Ramps and brakes

I/O Configuration

Fieldbus data

Prohibit frequencies

Supervisions

Protections

Automatic reset

Application settings

Timer functions

PID controller

External PID controller

Multi-pump

Maintenance counters

Fire mode

VACON® 100 INDUSTRIAL

Application Guide

Table 2: Menu Structure

User Interfaces

AB275637269262en-000101 / DPD00927 | 17Danfoss A/S © 2021.05

Menu

Function

Motor preheat

Drive customizer

Mechanical brake

Pump control

Advanced harmonic filter

Condition-based monitoring

M4 Diagnostics

Active faults

Reset faults

Fault history

Total counters

Trip counters

Software info

Drive info

Unit status

M5 I/O and Hardware

Basic I/O

Slot C

Slot D

Slot E

Real-time clock

Power unit settings

Keypad

RS485

Ethernet

Fieldbus general

M6 User settings

Language selections

Parameter back-up

Drive name

Parameter compare

Licenses

M7 Favourites

See 9.2.1 Using the Favourites Menu.

M8 User levels

See 9.3.1 Using the User Levels Menu.

VACON® 100 INDUSTRIAL

Application Guide

User Interfaces

AB275637269262en-000101 / DPD0092718 | Danfoss A/S © 2021.05

STOP

READY

I/O

Rem Control Place

M3.2.1

ID:

Edit

Help

Add to favourites

e30bu017.10

STOP

READY

I/O

Rem Control Place

M3.2.1ID:

FieldbusCTRL

I/O Control

e30bu018.10

STOP

READY

I/O

MinFreqReference

P3.3.1.1

ID:101

0.00 Hz

Min: 0.00Hz

Max: 50.00Hz

e30bu020.10

VACON® 100 INDUSTRIAL

Application Guide

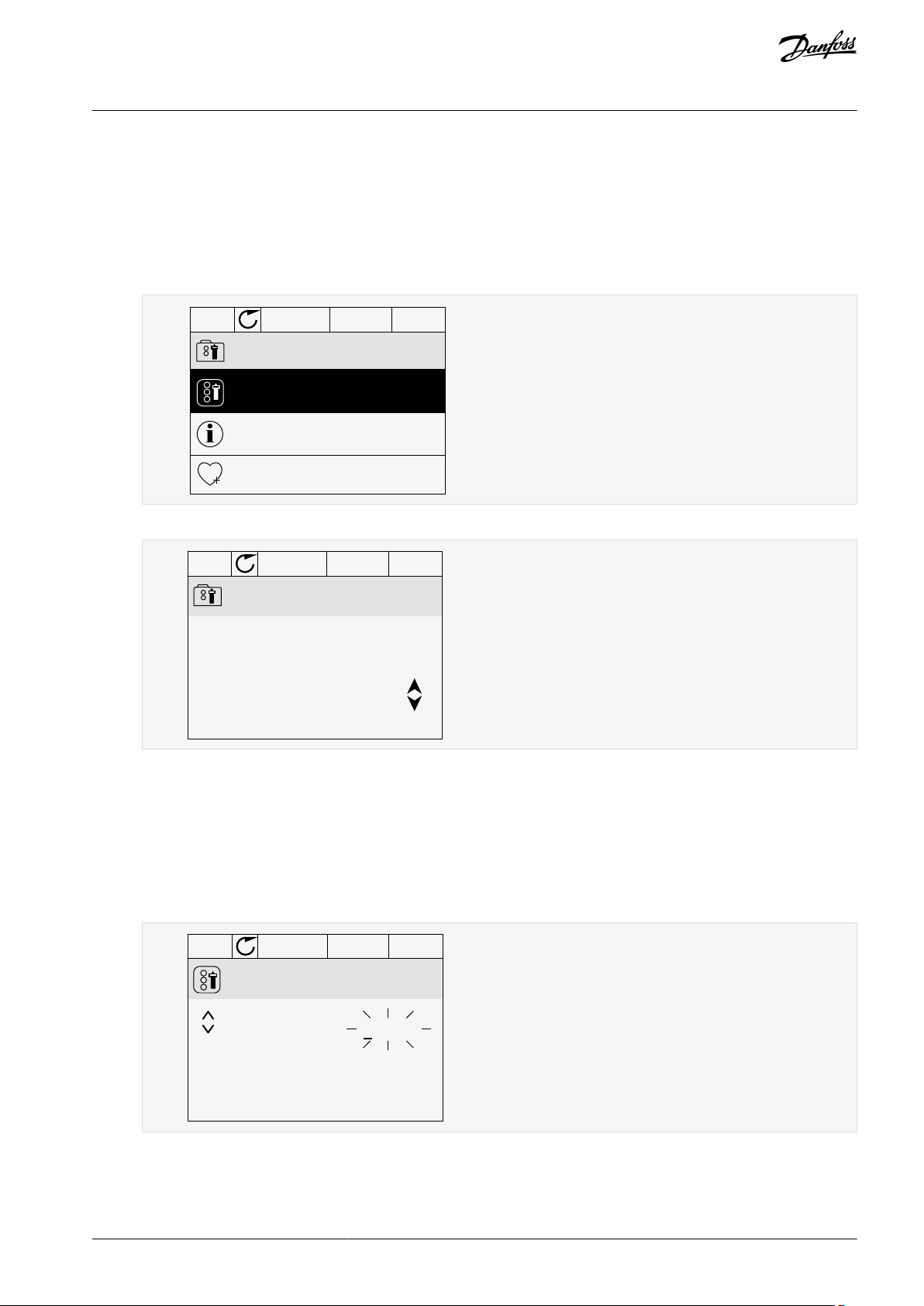

2.3 Graphical Display

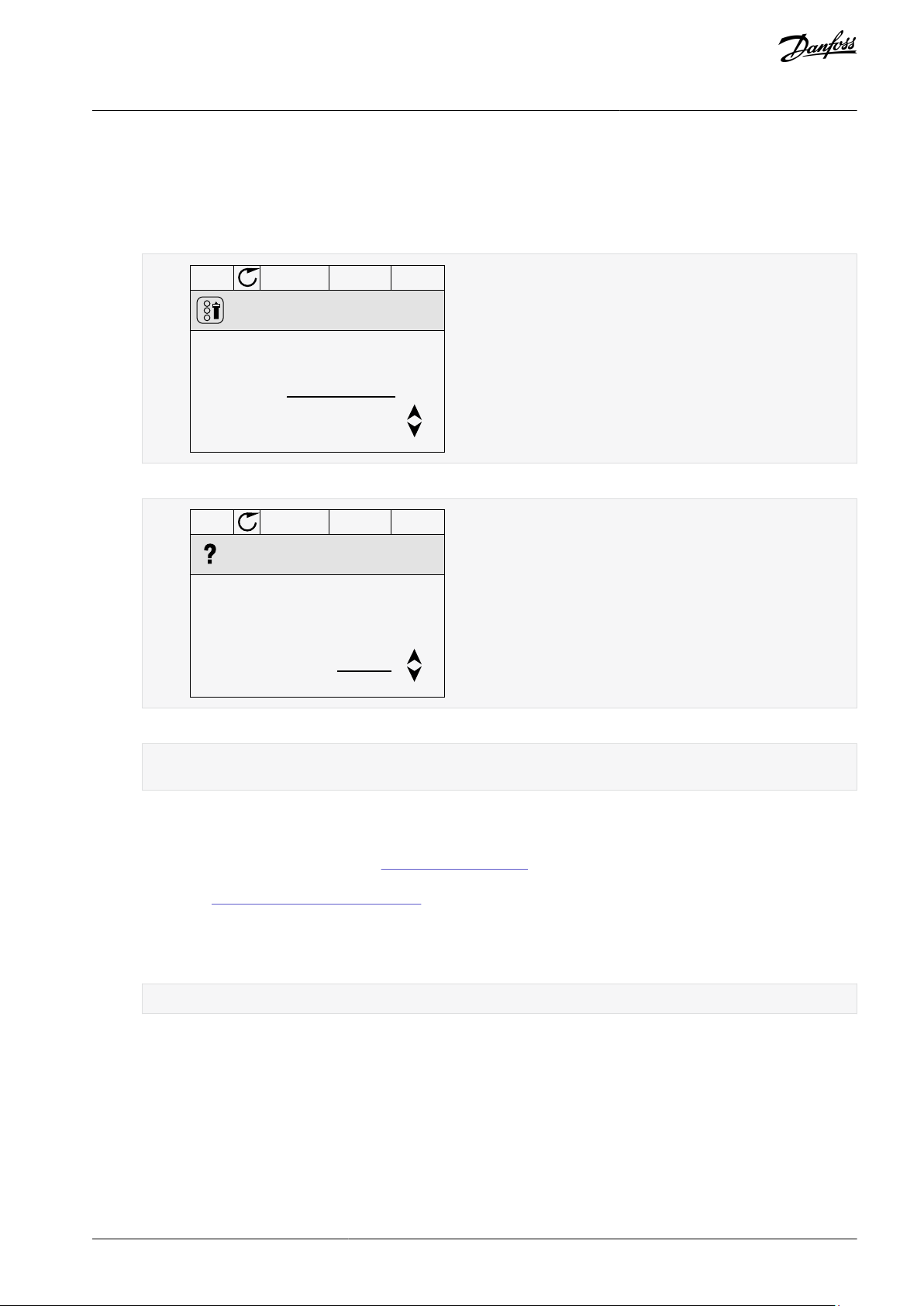

2.3.1 Editing the Text Values

This topic gives instructions on how to edit the text values on the graphical display.

Procedure

1.

Find the parameter with the arrow buttons.

2.

To go to the Edit mode, push the [OK] button 2 times or push the arrow button Right.

3.

To set a new value, push the arrow buttons Up and Down.

User Interfaces

4.

To accept the change, push the [OK] button. To ignore the change, use the [BACK/RESET] button.

2.3.2 Editing the Numerical Values

This topic gives instructions on how to edit the numerical values on the graphical display.

Procedure

1.

Find the parameter with the arrow buttons.

2.

To go to the Edit mode, push the [OK] button 2 times or push the arrow button Right.

Move from digit to digit with the arrow buttons Left and Right. Change the digits with the arrow buttons Up and Down.

3.

4.

To accept the change, push the [OK] button. To ignore the change, use the [BACK/RESET] button.

AB275637269262en-000101 / DPD00927 | 19Danfoss A/S © 2021.05

STOP

READY

I/O

P3.12.1.3ID:1466

Interval 1

00:00:00

00:00:00

ON Time

OFF Time

Days

0

A

e30bu023.10

A

The symbol of the checkbox selection

STOP

READY

I/O

M 3.12.1.3.1

ID:

Days

Monday

Tuesday

Wednesday

Thursday

Friday

Sunday

e30bu025.10

VACON® 100 INDUSTRIAL

Application Guide

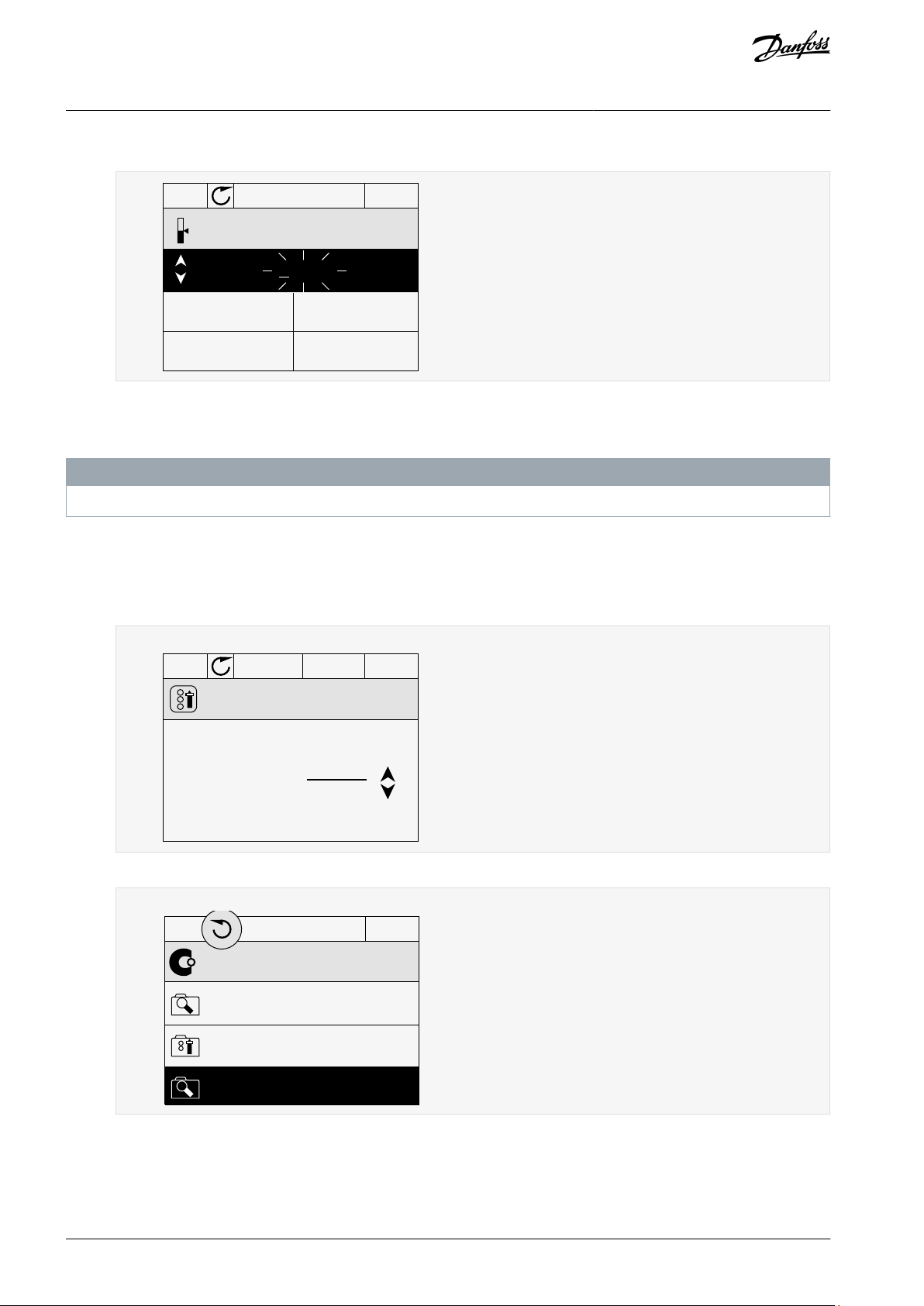

2.3.3 Selecting More than 1 Value

With some parameters, more than 1 value can be selected. Select a checkbox at each necessary value.

Procedure

1.

Find the parameter. There is a symbol on the display when a checkbox selection is possible.

2.

To move in the list of values, use the arrow buttons Up and Down.

3.

To add a value into your selection, select the box that is next to it with the arrow button Right.

User Interfaces

2.3.4 Resetting a Fault

To reset a fault, use the [BACK/RESET] button or the parameter Reset Faults. See 7.1.2 Reset Faults.

2.3.5 [FUNCT] Button

The [FUNCT] button can be used for 4 functions.

•

To have access to the Control page.

•

To change easily between the Local and Remote control places.

•

To change the rotation direction.

•

To edit quickly a parameter value.

2.3.5.1 Different Control Places

The selection of the control place determines from where the AC drive takes the start and stop commands. All the control places

have a parameter for the selection of the frequency reference source. The Local control place is always Keypad. The Remote control

place is I/O or Fieldbus. The status bar of the display shows the current control place.

It is possible to use I/O A, I/O B, and Fieldbus as Remote control places. I/O A and Fieldbus have the lowest priority. Select them with

P3.2.1 (Remote Control Place). I/O B can bypass the Remote control places I/O A and Fieldbus with a digital input. Select the digital

input with parameter P3.5.1.7 (I/O B Control Force).

Keypad is always used as a control place when the control place is Local. Local control has higher priority than Remote control. For

example, if parameter P3.5.1.7 bypasses the control place with a digital input, and Local is selected in Remote control, Keypad becomes the control place. Use the [FUNCT] button or P3.2.2 Local/Remote to change between the Local and Remote control.

AB275637269262en-000101 / DPD0092720 | Danfoss A/S © 2021.05

STOP

READY Keypad

ID:1805

Choose action

Control page

Change direction

Local/Remote

e30bu027.10

STOP

READY Keypad

ID:211

Local/Remote

Remote

Local

e30bu028.10

VACON® 100 INDUSTRIAL

Application Guide

2.3.5.2 Changing the Control Place

This topic gives instructions on how to change the control place on the control panel.

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

To select Local/Remote, use the arrow buttons Up and Down. Push the [OK] button.

3.

To select Local or Remote, use the arrow buttons Up and Down again. To accept the selection, push the [OK] button.

User Interfaces

4.

If Remote control place is changed to Local, that is, Keypad, give a keypad reference.

After the selection, the display goes back into the same location where it was when the [FUNCT] button was push-

ed.

2.3.5.3 Going into the Control Page

It is easy to monitor the most important values in the Control page.

See more information about Keypad Reference in

display shows the frequency reference, which cannot be edited. The other values on the page are Multimonitor values. These values

can be selected (see 5.2.1 Changing the Items to Monitor).

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

To select the Control page, push the arrow buttons Up and Down. Go in with the [OK] button.

The Control page opens.

With the Local control place and the keypad reference selected, P3.3.1.8 Keypad Reference can be set with the [OK] button.

3.

6.3 Group 3.3: References. If other control places or reference values are used, the

AB275637269262en-000101 / DPD00927 | 21Danfoss A/S © 2021.05

STOP

READY Keypad

ID: 168

Keypad Reference

0.00Hz

Output Frequency

Motor Current

Motor Torque

Motor Power

0.00Hz

0.00A

0.00%

0.00%

e30bg671.10

RUN

READY Keypad

ID:1805

Choose action

Forward

Reverse

e30bg672.10

STOP

READY I/O

ID:

M1

Main Menu

Monitor

( 7 )

Parameters

( 15 )

Diagnostics

( 6 )

e30bg673.10

VACON® 100 INDUSTRIAL

Application Guide

4.

To change the digits in the value, push the arrow buttons Up and Down. Accept the change with the [OK] button.

2.3.5.4 Changing the Rotation Direction

The rotation direction of the motor can be changed quickly with the [FUNCT] button.

N O T I C E

The command Change direction is available in the menu only if the current control place is Local.

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

To select Change direction, push the arrow buttons Up and Down. Push the [OK] button.

3.

Select a new rotation direction.

User Interfaces

The current rotation direction blinks.

4.

Push the [OK] button.

The rotation direction changes immediately. The arrow indication in the status field of the display changes.

2.3.5.5 Using the Quick Edit Function

With the Quick Edit function, a parameter can be accessed quickly by typing the ID number of the parameter.

Procedure

Anywhere in the menu structure, push the [FUNCT] button.

1.

AB275637269262en-000101 / DPD0092722 | Danfoss A/S © 2021.05

STOP

READY Keypad

ID: M6.5

User settings

Language selection

English

Parameter backup

( 7 )

Drive name

Drive

e30bg674.10

STOP

READY Keypad

ID: M6.5.1

Parameter backup

Restore factory defaults

Save to keypad

Restore from keypad

e30bg675.10

VACON® 100 INDUSTRIAL

Application Guide

2.

Push the arrow buttons Up and Down to select Quick Edit and accept with the [OK] button.

3.

Write the ID number of a parameter or monitoring value. Push [OK].

The display shows the parameter value in the edit mode and the monitoring value in the monitoring mode.

User Interfaces

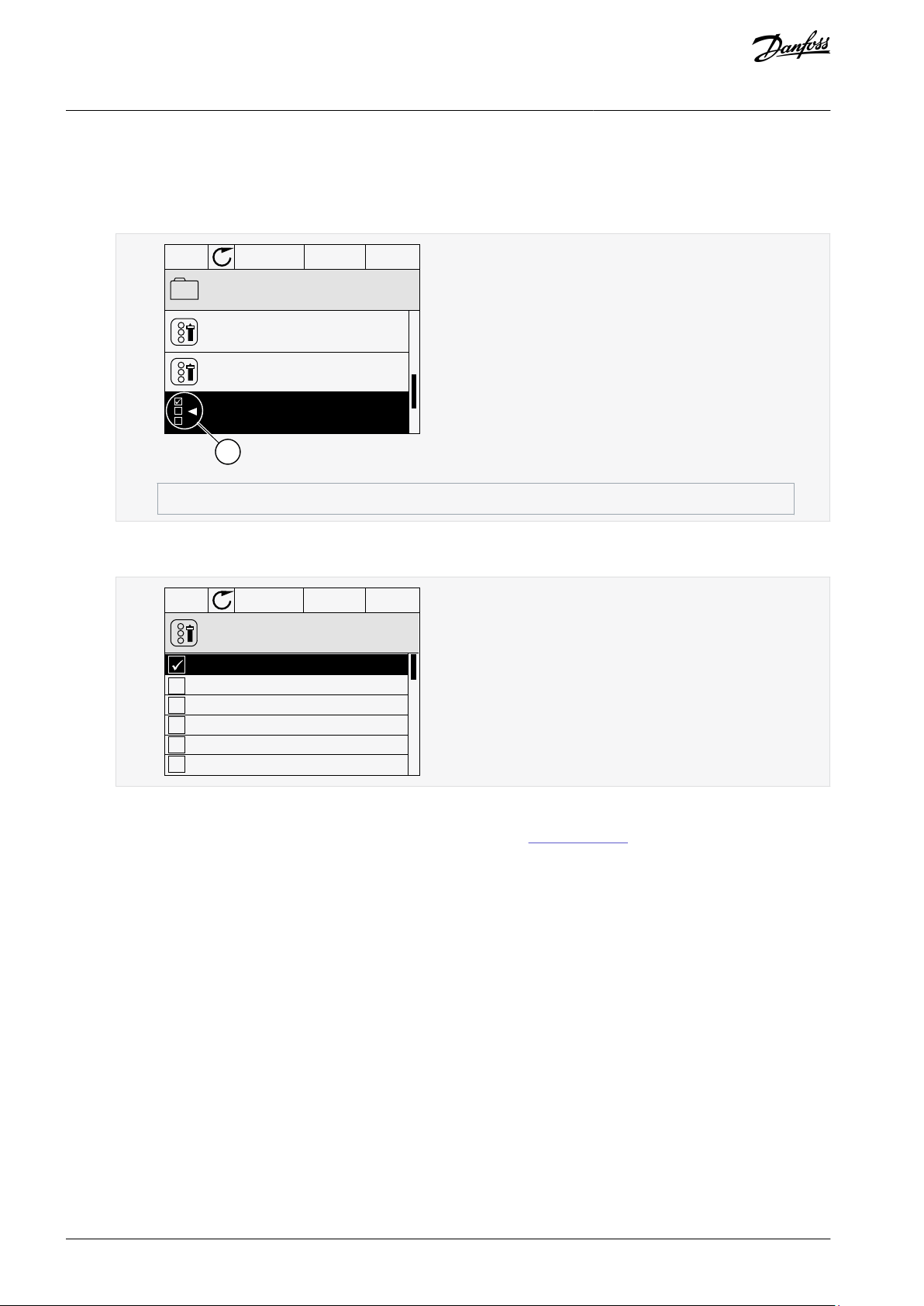

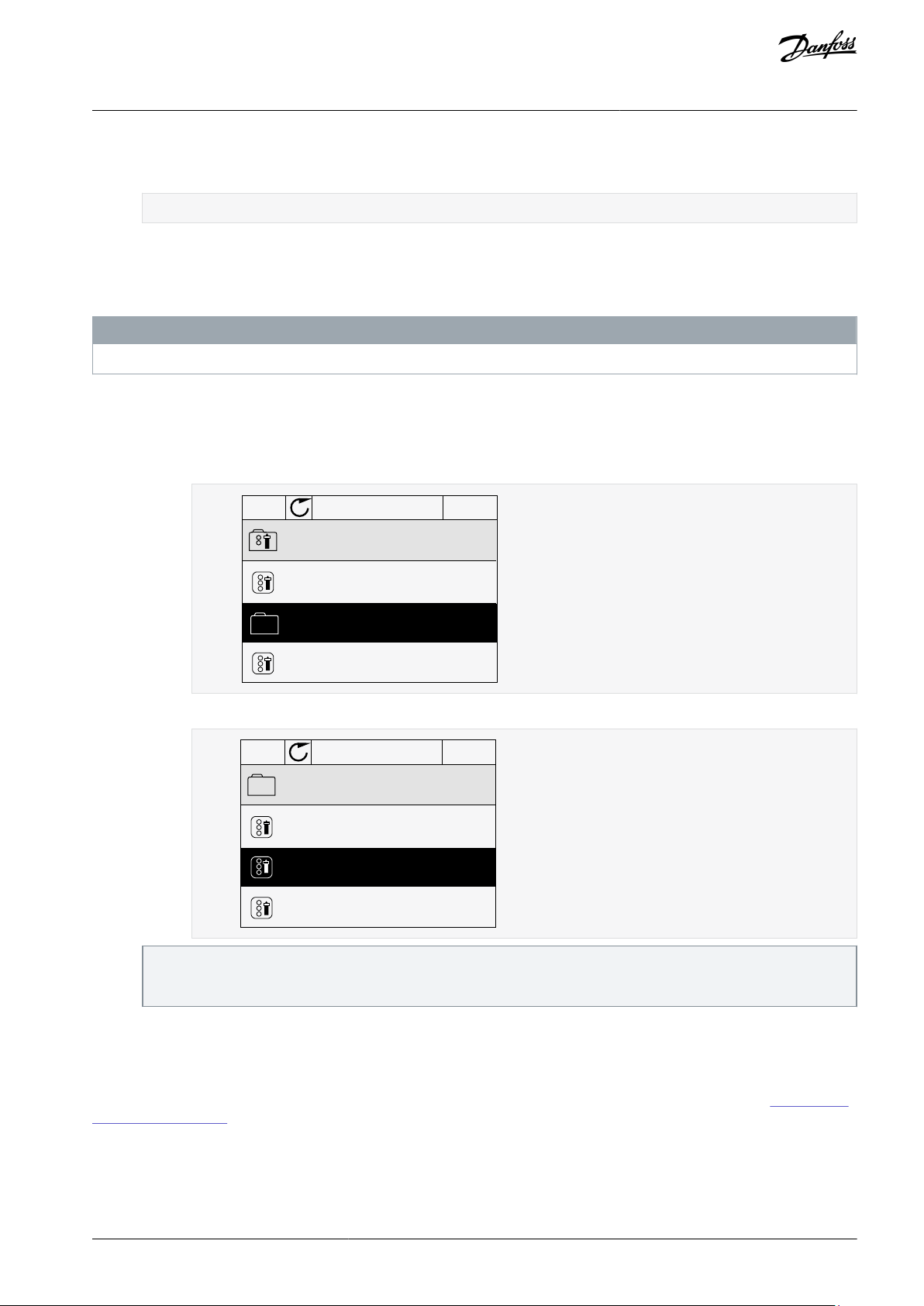

2.3.6 Copying the Parameters of an AC Drive

Use this function to copy parameters from a drive to another. Before downloading parameters from the control panel to the drive,

stop the drive.

N O T I C E

This function is available only in the graphical display.

Procedure

1.

Save the parameters to the control panel.

a.

Go into the User settings menu.

b.

Go into the Parameter backup submenu.

2.

3.

2.3.7 Comparing the Parameters

Use this function to compare the current parameter set with one of these 4 sets. See more about these parameters in

ter Back-up Parameters.

•

Set 1 (P6.5.4 Save to Set 1)

•

Set 2 (P6.5.6 Save to Set 2)

•

Defaults (P6.5.1 Restore Factory Defaults)

•

Keypad set (P6.5.2 Save to Keypad)

c.

Use the arrow buttons Up and Down to select a function. Accept the selection with the [OK] button.

The command Restore factory defaults brings back the parameter settings that were made at the factory. Use the command Save to keypad to copy all the parameters to the control panel. The command Restore from keypad copies all the

parameters from the control panel to the drive.

Detach the control panel and connect it to another drive.

Download the parameters to the new drive with the command Restore from keypad.

9.1.2 Parame-

AB275637269262en-000101 / DPD00927 | 23Danfoss A/S © 2021.05

STOP

READY I/O

ID: M6.6

User Settings

Language Selection

Parameter Backup

Parameter Compare

English

(4)

(7)

e30bg676.10

STOP

READY I/O

ID:

B6.6.1

Parameter Compare

Active set-Set 1

Active set-Set 2

Active set-Defaults

e30bg677.10

STOP

READY I/O

ID:113

Active set-Set 1

Motor Nom Currnt

Motor Cos Phi

0.56A

1.90A

0.68

1.74

A B C D

e30bg678.10

A

The current value

B

The value of the other set

C

The current value

D

The value of the other set

VACON® 100 INDUSTRIAL

Application Guide

User Interfaces

N O T I C E

If the parameter set with which the current set is compared was not saved, the display shows the text Comparing failed.

Procedure

1.

Go into the User settings menu.

2.

Go into the Parameter Compare function.

3.

Select the pair of sets. Push [OK] to accept the selection.

4.

Select Active and push [OK].

5.

Examine the comparing between the current values and the values of the other set.

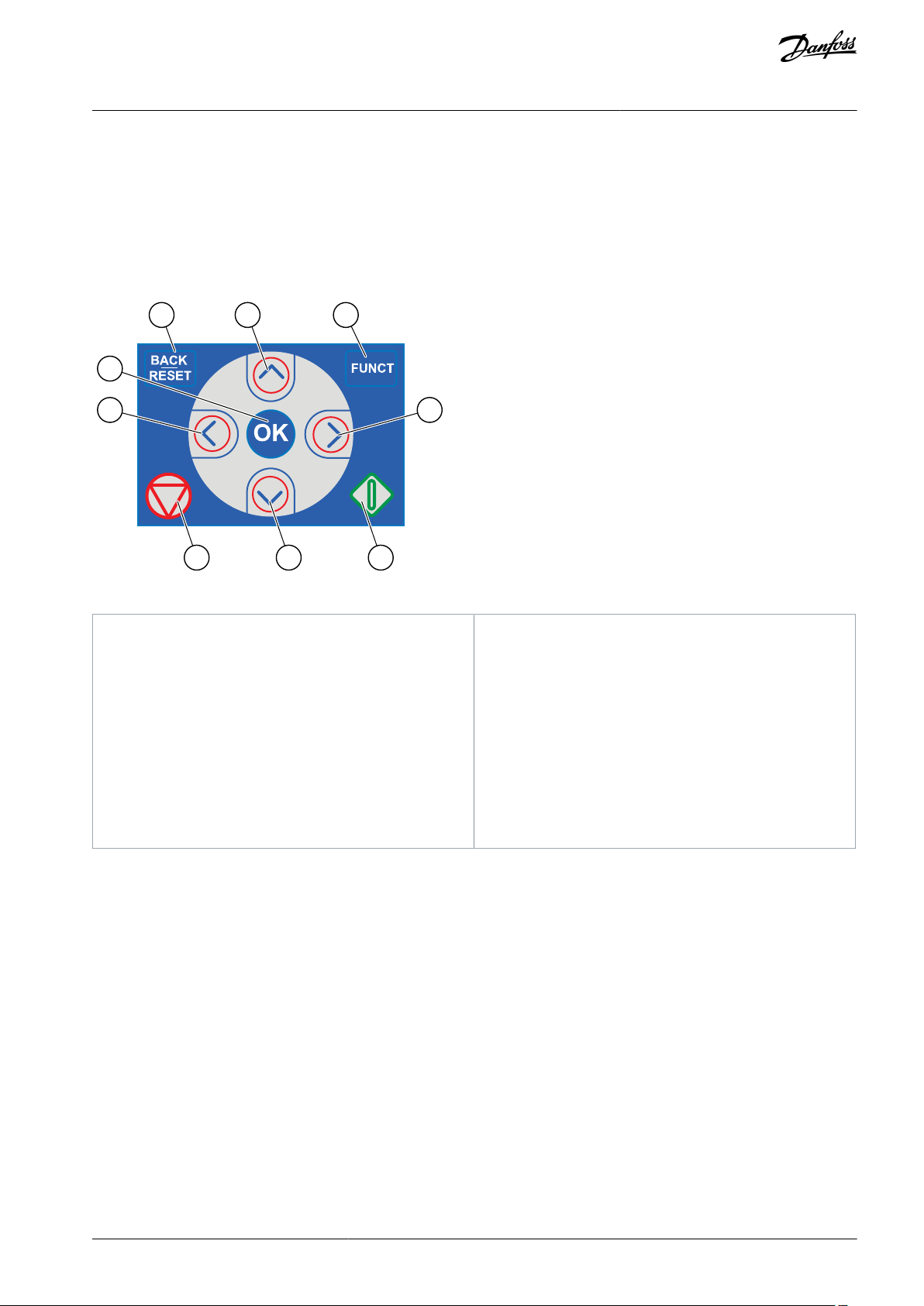

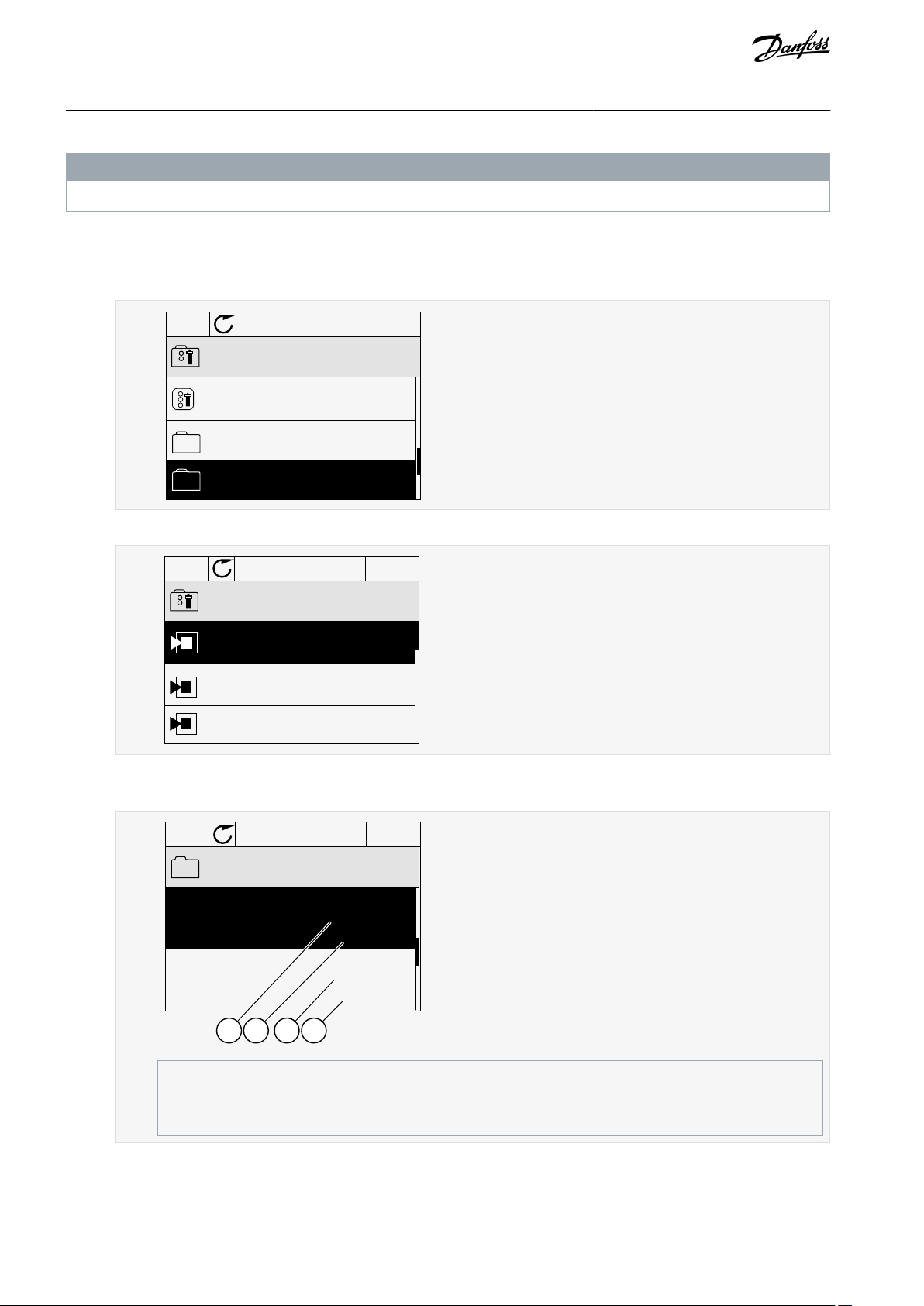

2.3.8 Reading Help Texts

The graphical display can show help texts on many topics. All the parameters have a help text. The help texts are also available for

the faults, alarms, and the start-up wizard.

AB275637269262en-000101 / DPD0092724 | Danfoss A/S © 2021.05

STOP

READY I/O

ID:403 M3.5.1.1

Ctrl signal 1 A

Edit

Help

Add to favourites

e30bg679.10

READY

FAULT

ALARM

STOP

RUN

KEYPAD

I/O

REV

FWD

BUS

e30bg680.10

VACON® 100 INDUSTRIAL

Application Guide

The help texts are always in English.

Procedure

1.

Find the item to read.

2.

Use the arrow buttons Up and Down to select Help.

3.

To open the help text, push the [OK] button.

User Interfaces

N O T I C E

2.3.9 Using the Favourites Menu

If the same items are used frequently, add them into Favourites. Collect a set of parameters or monitoring signals from all the control panel menus. See 9.2.2 Adding an Item to the Favourites.

2.4 Text Display

2.4.1 Editing the Text Values

This topic gives instructions on how to edit text values on the text display.

Procedure

1.

Find the parameter with the arrow buttons.

2.

To go to the Edit mode, push the [OK] button.

3.

To set a new value, push the arrow buttons Up and Down.

4.

Accept the change with the [OK] button. To ignore the change, use the [BACK/RESET] button.

2.4.2 Editing the Numerical Values

This topic gives instructions on how to edit the numerical values on the text display.

Procedure

1.

Find the parameter with the arrow buttons.

2.

3.

4.

Go to the Edit mode.

Move from digit to digit with the arrow buttons Left and Right. Change the digits with the arrow buttons Up and Down.

Accept the change with the [OK] button. To ignore the change, use the [BACK/RESET] button.

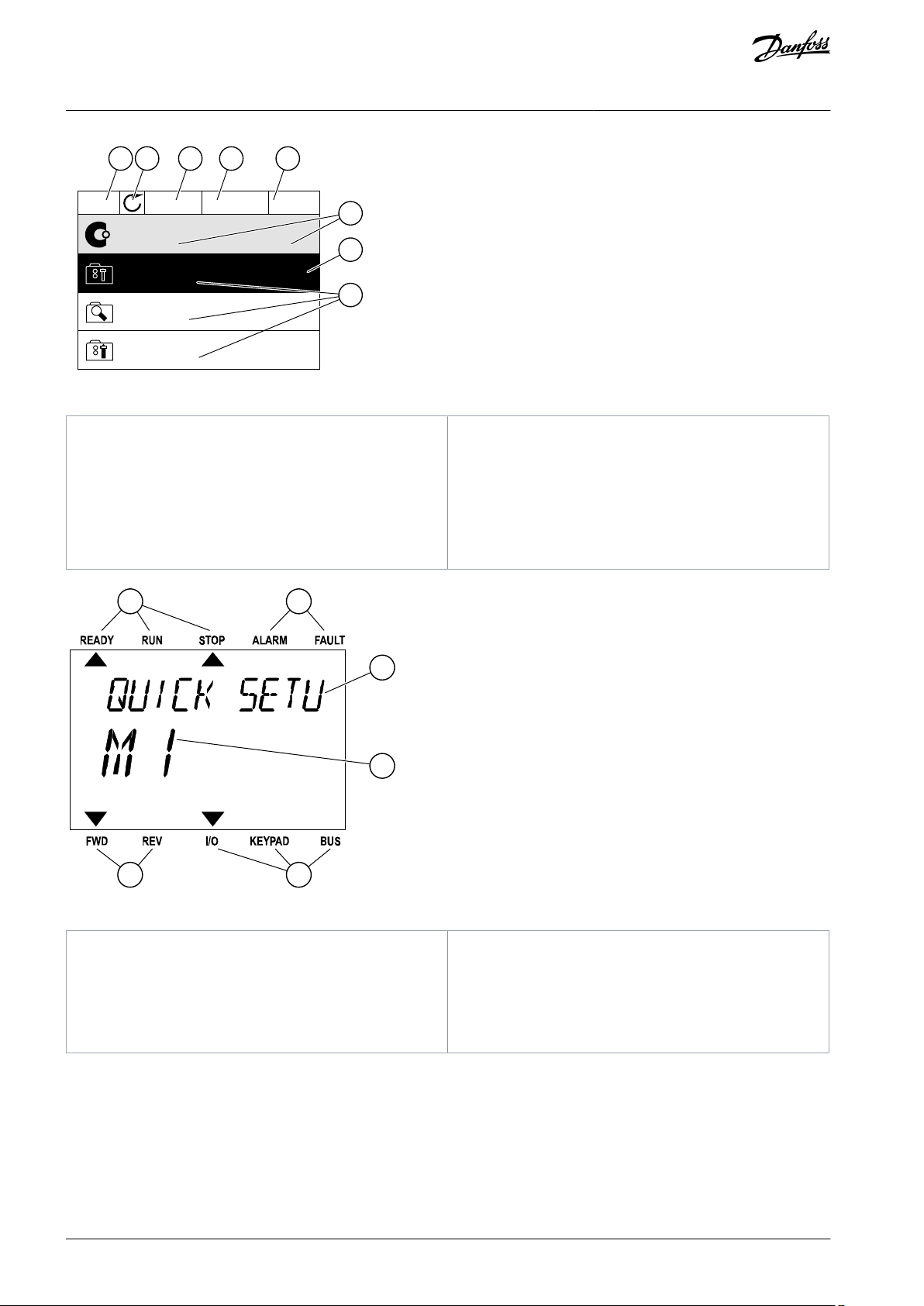

AB275637269262en-000101 / DPD00927 | 25Danfoss A/S © 2021.05

READY

FAULT

ALARM

STOP

RUN

KEYPAD

I/O

REV

FWD

BUS

e30bg681.10

READY

FAULT

ALARM

STOP

RUN

KEYPAD

I/O

REV

FWD

BUS

e30bg682.10

VACON® 100 INDUSTRIAL

Application Guide

User Interfaces

2.4.3 Resetting a Fault

To reset a fault, use the [BACK/RESET] button or the parameter Reset Faults. See 7.1.2 Reset Faults.

2.4.4 [FUNCT] Button

The [FUNCT] button can be used for 4 functions.

•

To have access to the Control page.

•

To change easily between the Local and Remote control places.

•

To change the rotation direction.

•

To edit quickly a parameter value.

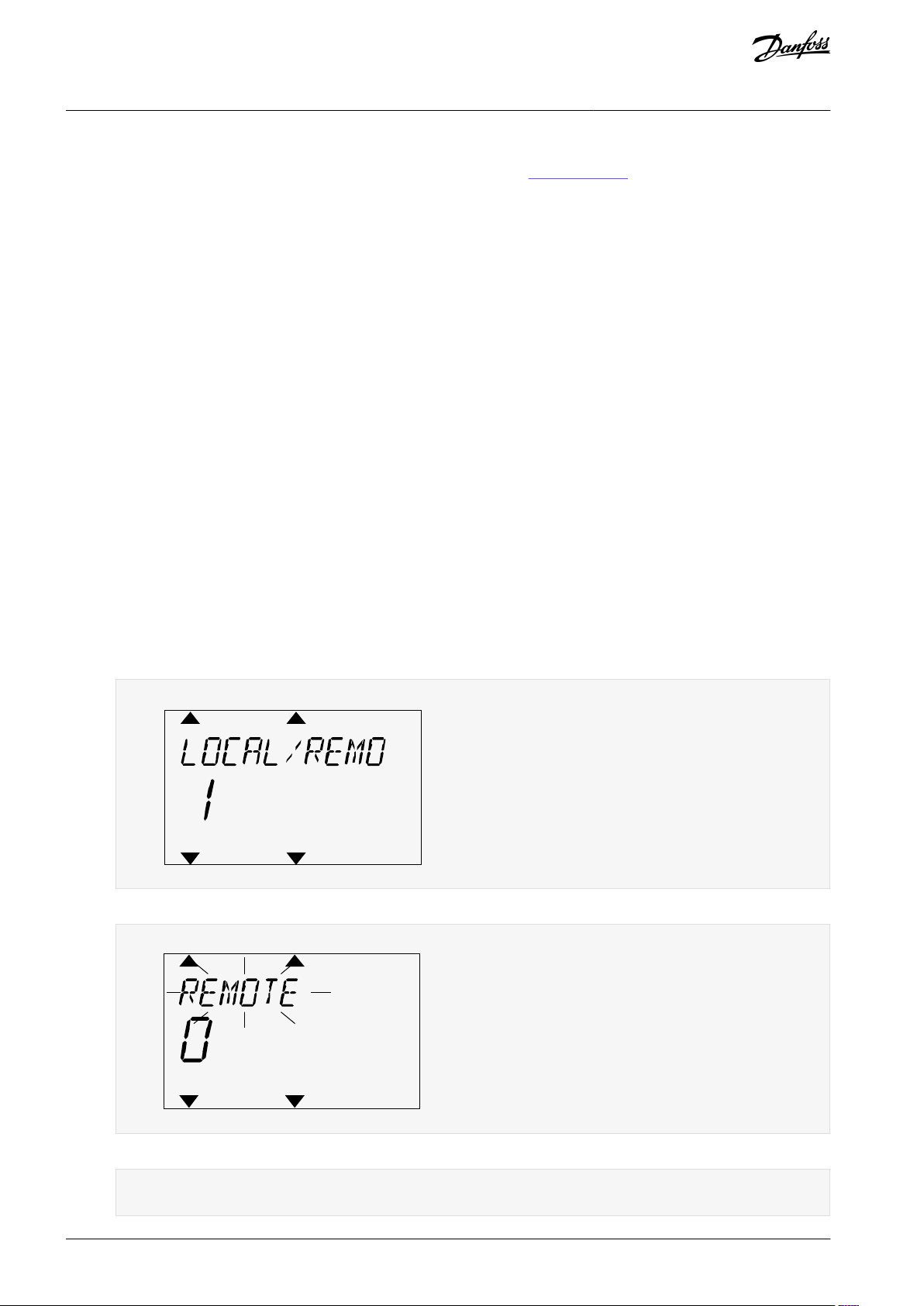

2.4.4.1 Different Control Places

The selection of the control place determines from where the AC drive takes the start and stop commands. All the control places

have a parameter for the selection of the frequency reference source. The Local control place is always Keypad. The Remote control

place is I/O or Fieldbus. The status bar of the display shows the current control place.

It is possible to use I/O A, I/O B, and Fieldbus as Remote control places. I/O A and Fieldbus have the lowest priority. Select them with

P3.2.1 (Remote Control Place). I/O B can bypass the Remote control places I/O A and Fieldbus with a digital input. Select the digital

input with parameter P3.5.1.7 (I/O B Control Force).

Keypad is always used as a control place when the control place is Local. Local control has higher priority than Remote control. For

example, if parameter P3.5.1.7 bypasses the control place with a digital input, and Local is selected in Remote control, Keypad becomes the control place. Use the [FUNCT] button or P3.2.2 Local/Remote to change between the Local and Remote control.

2.4.4.2 Changing the Control Place

This topic gives instructions on how to change the control place on the control panel.

Procedure

Anywhere in the menu structure, push the [FUNCT] button.

1.

2.

To select Local/Remote, use the arrow buttons Up and Down. Push the [OK] button.

3.

To select Local or Remote, use the arrow buttons Up and Down again. To accept the selection, push the [OK] button.

4.

If Remote control place is changed to Local, that is, the keypad, give a keypad reference.

After the selection, the display goes back into the same location where it was when the [FUNCT] button was pushed.

AB275637269262en-000101 / DPD0092726 | Danfoss A/S © 2021.05

READY

FAULT

ALARM

STOP

RUN

KEYPAD

I/O

REV

FWD

BUS

e30bg683.10

READY

FAULT

ALARM

STOP

RUN

KEYPAD

I/O

REV

FWD

BUS

e30bg684.10

VACON® 100 INDUSTRIAL

Application Guide

User Interfaces

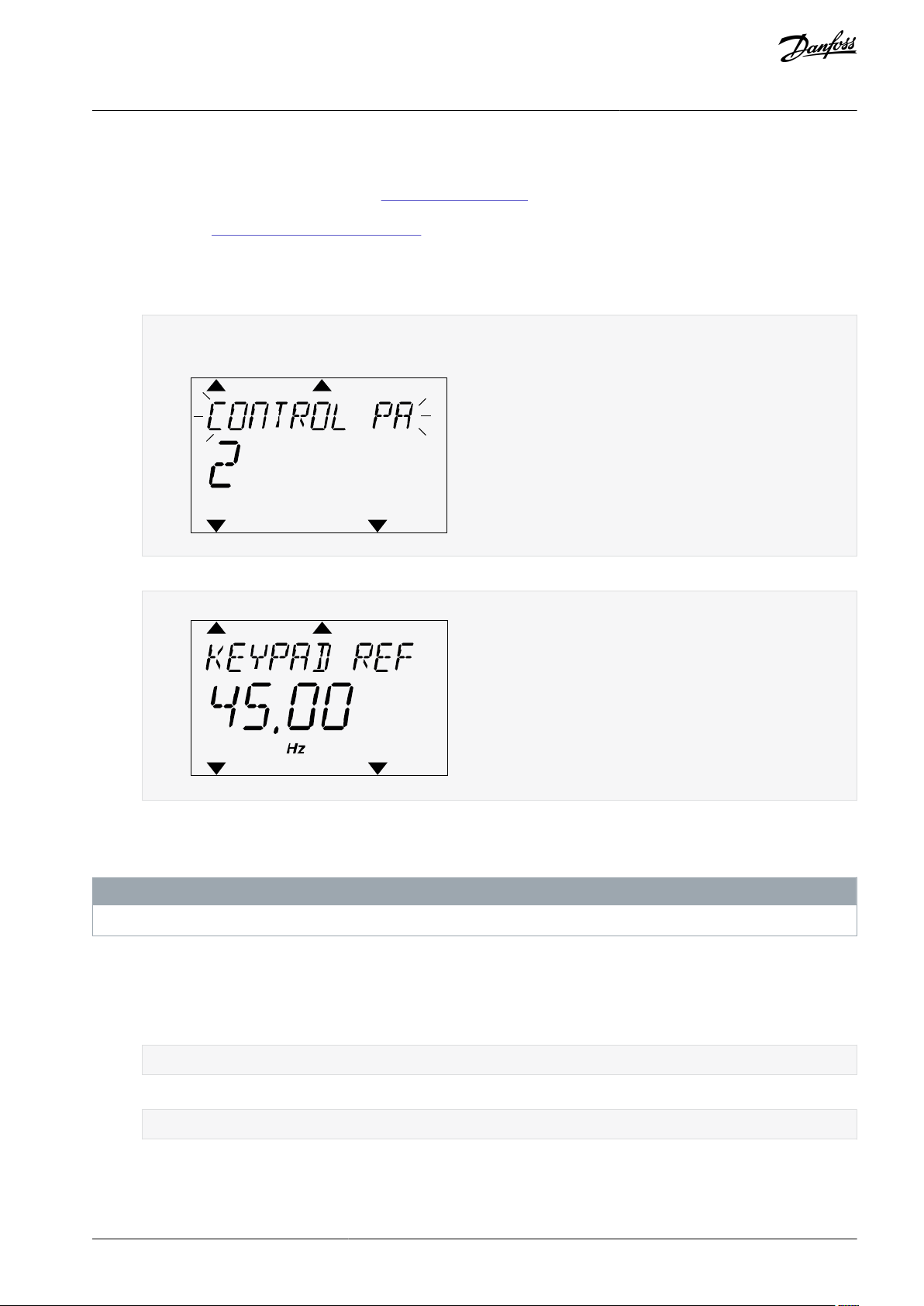

2.4.4.3 Going into the Control Page

It is easy to monitor the most important values in the Control page.

See more information about Keypad Reference in 6.3 Group 3.3: References. If other control places or reference values are used, the

display shows the frequency reference that cannot be edited. The other values on the page are Multimonitor values. These values

can be selected (see

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

To select the Control page, push the arrow buttons Up and Down. Go in with the [OK] button.

5.2.1 Changing the Items to Monitor).

The Control page opens.

3.

If the Local control place and the keypad reference are used, P3.3.1.8 Keypad Reference can be set with the [OK] button.

2.4.4.4 Changing the Rotation Direction

The rotation direction of the motor can be changed quickly with the [FUNCT] button.

N O T I C E

The command Change direction is available in the menu only if the current control place is Local.

Procedure

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

To select Change direction, push the arrow buttons Up and Down. Push the [OK] button.

3.

Select a new rotation direction.

The current rotation direction blinks.

4.

Push the [OK] button.

The rotation direction changes immediately. The arrow indication in the status field of the display changes.

2.4.4.5 Using the Quick Edit Function

With the Quick Edit function, a parameter can be accessed quickly by typing the ID number of the parameter.

Procedure

AB275637269262en-000101 / DPD00927 | 27Danfoss A/S © 2021.05

e30bg685.10

VACON® 100 INDUSTRIAL

Application Guide

1.

Anywhere in the menu structure, push the [FUNCT] button.

2.

Push the arrow buttons Up and Down to select Quick Edit and accept with the [OK] button.

3.

Write the ID number of a parameter or monitoring value. Push [OK].

The display shows the parameter value in the edit mode and the monitoring value in the monitoring mode.

User Interfaces

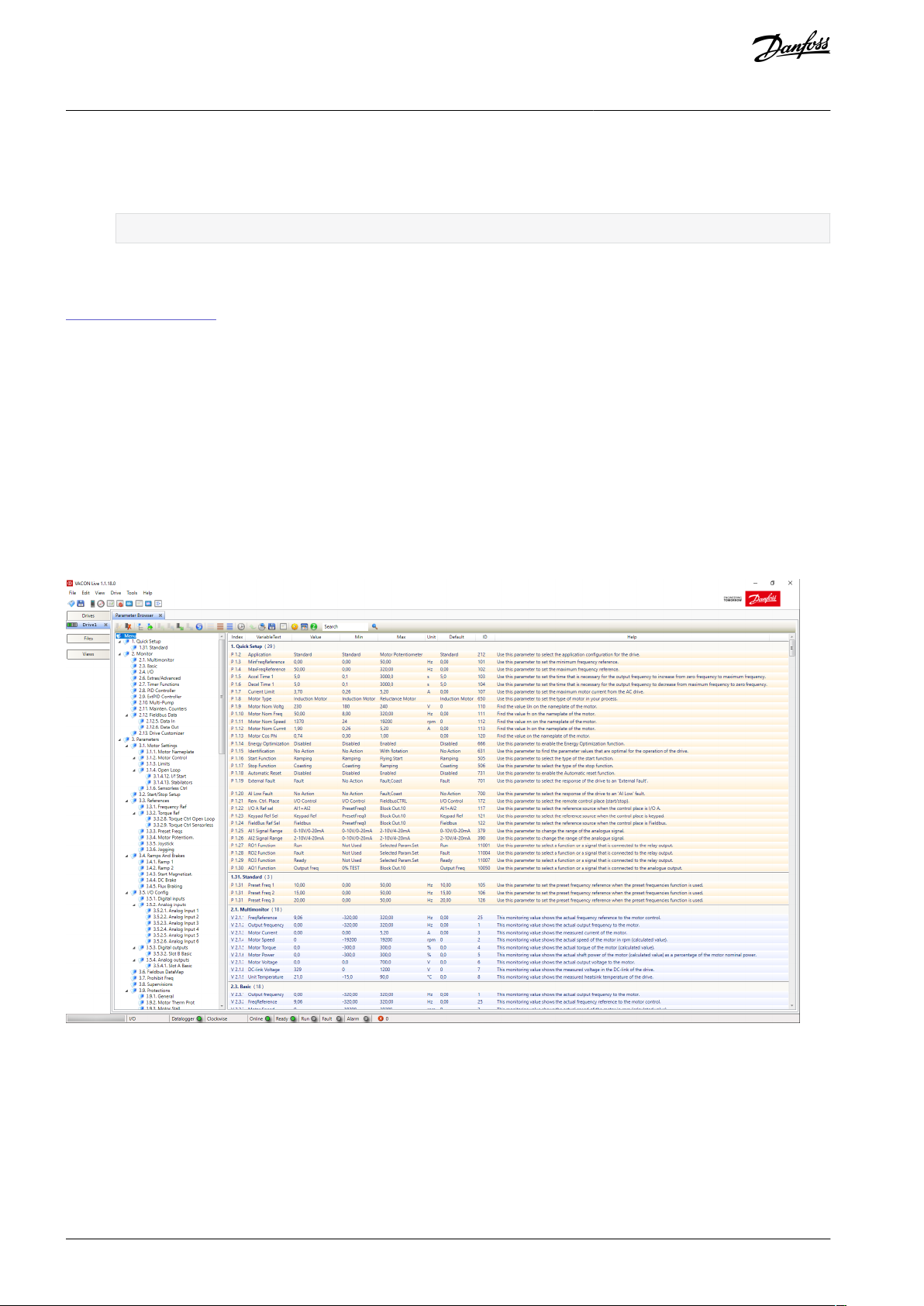

2.5 VACON® Live PC Tool

VACON® Live is a PC tool for commissioning and maintenance of the VACON® AC drives. VACON® Live can be downloaded from

https://www.danfoss.com.

The VACON® Live PC tool includes these functions.

•

Parameterization, monitoring, drive info, data logger, and so on.

•

The software download tool VACON® Loader

Serial communication and Ethernet support

•

Windows XP, Vista, 7, 8, and 10 support

•

17 languages: English, German, Spanish, Finnish, French, Italian, Russian, Swedish, Chinese, Czech, Danish, Dutch, Polish, Portu-

•

guese, Romanian, Slovak and Turkish

Make the connection between the AC drive and the PC tool with the VACON® serial communication cable. The serial communication drivers are installed automatically during the installation of VACON® Live. After the cable is installed, VACON® Live finds the

connected drive automatically.

See more on how to use VACON® Live in the help menu of the program.

Illustration 5: The VACON® Live PC Tool

AB275637269262en-000101 / DPD0092728 | Danfoss A/S © 2021.05

VACON® 100 INDUSTRIAL

Application Guide

Applications

3 Applications

3.1 Using the Applications

Use the parameter P1.2 (Application) to select an application for the drive. Immediately when the parameter P1.2 changes, parameter groups get their preset values.

3.2 Standard Application

Use the Standard application in speed-controlled processes where no special functions are necessary, for example pumps, fans, or

conveyors.

It is possible to control the drive from the control panel (keypad), Fieldbus, or I/O terminal.

When the drive is controlled with the I/O terminal, the frequency reference signal is connected to AI1 (0…10 V) or AI2 (4…20 mA).

The connection depends the type of the signal. There are also 3 preset frequency references available. The preset frequency references can be activated with DI4 and DI5. The start/stop signals of the drive are connected to DI1 (start forward) and DI2 (start reverse).

It is possible to configure all the drive outputs freely in all the applications. There is 1 analog output (Output Frequency) and 3 relay

outputs (Run, Fault, Ready) available on the basic I/O board.

AB275637269262en-000101 / DPD00927 | 29Danfoss A/S © 2021.05

DI4

DI5

**)

*)

Modbus RTU,

N2, BACnet

1

6

2

3

4

5

18

19

30

12

7

13

8

9

10

14

15

16

21

22

23

11

17

A

B

24

25

26

32

33

28

29

e30bg590.10

mA

FAULT

RUN

RUN

AO1-

+24Vin

24Vout

GND

GND

DI1

DI2

DI3

DI4

DI5

DI6

R

O1/1 NC

R

O1/2 CM

R

O1/3 NO

CM

CM

RS485

RS485

R

O2/1 NC

R

O2/2 CM

R

O2/3 NO

R

O3/2 CM

R

O3/3 NO

Standard I/O board

Terminal Signal Description

+10 Vref

AI1+

AI1-

AI2+

AI2-

24Vout

Reference output

Analog input 1 +

Analog input 1 -

Analog input 2 +

Analog input 2 -

24 V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Common for DI1-DI6

Common for DI1-DI6

24 V auxiliary voltage

I/O ground

Analog output 1 +

Analog output 1 -

24V auxiliary

input voltage

Output

frequency

0...20 mA)

READY

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

FAULT

Fault reset

AO1+

Frequency reference

(default 0...10 V)

Frequency reference

(Default 4...20 mA)

Start forward

Start reverse

External fault

Freq. ref.

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Analog input 1

Preset Freq. 1

Preset Freq. 2

Preset Freq. 3

Reference-

potentiome-

ter

1...10 kΩ

TI1+

TI1-

Thermistor input

VACON® 100 INDUSTRIAL

Application Guide

Applications

Illustration 6: The Default Control Connections of the Standard Application

*) Available only in VACON® 100 X. **) For the DIP switch configurations in VACON® 100 X, see the VACON® 100 X Installation manual.

AB275637269262en-000101 / DPD0092730 | Danfoss A/S © 2021.05

A

B

C

e30bg589.10

A

Digital input DIP switch

B

Floating

C

Connected to GND (Default)

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.2

Application

050

212

0 = Standard

1 = Local/Remote

2 = Multi-step Speed

3 = PID Control

4 = Multi-purpose

5 = Motor Potentiometer

1.3

Minimum Frequency

Reference

0.00

P1.4Hz0.0

101

1.4

Maximum Frequency

Reference

P1.3

320.0

Hz

50.0/60.0

102

1.5

Acceleration Time 1

0.1

300.0

s

5.0

103

1.6

Deceleration Time 1

0.1

300.0

s

5.0

104

1.7

Motor Current Limit

IH*0.1

ISA

Varies

107

1.8

Motor Type

020

650

0 = Induction Motor

1 = Permanent Magnet Motor

2 = Reluctance Motor

1.9

Motor Nominal Voltage

Varies

Varies

V

Varies

110

Find this value Un on the nameplate of the motor.

NOTE! Find out if the motor connection is Delta

or Star.

1.10

Motor Nominal Frequency

8.0

320.0

Hz

50/60

111

Find this value fn on the nameplate of the motor.

VACON® 100 INDUSTRIAL

Application Guide

Illustration 7: The DIP Switch

Applications

See information on the Startup, Multi-pump, and Fire mode wizards in 4.2.1 Wizards in Menu 1.1.

Table 3: M1 Quick Setup

AB275637269262en-000101 / DPD00927 | 31Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.11

Motor Nominal Speed

24

19200

RPM

Varies

112

Find this value nn on the nameplate of the motor.

1.12

Motor Nominal Current

IH * 0.1

IH * 2

A

Varies

113

Find this value In on the nameplate of the motor.

1.13

Motor Cos Phi (Power

Factor)

0.30

1.00

Varies

120

Find this value on the nameplate of the motor.

1.14

Energy Optimization

010

666

0 = Disabled

1 = Enabled

1.15

Identification

020

631

0 = No action

1 = At standstill

2 = With rotation

1.16

Start Function

010

505

0 = Ramping

1 = Flying Start

1.17

Stop Function

010

506

0 = Coasting

1 = Ramping

1.18

Automatic Reset

010

731

0 = Disabled

1 = Enabled

1.19

Response to External

Fault

032

701

0 = No action

1 = Alarm

2 = Fault (Stop according to stop mode)

3 = Fault (Stop by coasting)

1.20

Response to AI Low

Fault

050

700

0 = No action

1 = Alarm

2 = Alarm+preset fault frequency (P3.9.1.13)

3 = Alarm + previous frequency

4 = Fault (Stop according to stop mode)

5 = Fault (Stop by coasting)

1.21

Remote Control Place

010

172

0 = I/O control

1 = Fieldbus control

1.22

I/O Control Reference

A Selection

1206

117

1 = Preset Frequency 0

2 = Keypad reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID reference

8 = Motor potentiometer

9 = Joystick reference

10 = Jogging reference

11 = Block Out.1

12 = Block Out.2

13 = Block Out.3

VACON® 100 INDUSTRIAL

Application Guide

Applications

AB275637269262en-000101 / DPD0092732 | Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

14 = Block Out.4

15 = Block Out.5

16 = Block Out.6

17 = Block Out.7

18 = Block Out.8

19 = Block Out.9

20 = Block Out.10

1.23

Keypad Control Reference Selection

1202

121

See P1.22.

1.24

Fieldbus Control Reference Selection

1203

122

See P1.22.

1.25

AI1 Signal Range

010

379

0= 0..10 V/0...20 mA

1= 2...10 V/4...20 mA

1.26

AI2 Signal Range

011

390

0= 0..10 V/0...20 mA

1= 2...10 V/4...20 mA

1.27

RO1 Function

0612

11001

See P3.5.3.2.1.

1.28

RO2 Function

0563

11004

See P3.5.3.2.1.

1.29

RO3 Function

0561

11007

See P3.5.3.2.1.

1.30

AO1 Function

0312

10050

See P3.5.4.1.1.

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.31.1

Preset Frequency 1

P1.3

P1.4Hz10.0

105

1.31.2

Preset Frequency 2

P1.3

P1.4Hz15.0

106

1.31.3

Preset Frequency 3

P1.3

P1.4Hz20.0

126

VACON® 100 INDUSTRIAL

Application Guide

Applications

Table 4: M1.31 Standard

3.3 Local/Remote Application

Use the Local/Remote application when, for example, it is necessary to switch between 2 different control places.

To change between the Local and the Remote control place, use DI6. When Remote control is active, the start/stop commands can

be given from Fieldbus or from I/O terminal (DI1 and DI2). When Local control is active, give the start/stop commands from the

control panel.

For each control place, the frequency reference can be selected from the control panel (keypad), Fieldbus, or I/O terminal (AI1 or

AI2).

It is possible to configure all the drive outputs freely in all the applications. There is 1 analog output (Output Frequency) and 3 relay

outputs (Run, Fault, Ready) available on the basic I/O board.

AB275637269262en-000101 / DPD00927 | 33Danfoss A/S © 2021.05

1

6

2

3

4

5

18

19

30

12

7

13

8

9

10

14

15

16

21

22

23

11

17

A

B

24

25

26

32

33

Modbus RTU,

N2, BACnet

28

29

*)

**)

e30bg591.10

mA

FAULT

RUN

RUN

AO1-/GND

+24Vin

24Vout

GND

GND

DI1

DI2

DI3

DI4

DI5

DI6

R

O1/1 NC

R

O1/2 CM

R

O1/3 NO

CM

CM

RS485

RS485

R

O2/1 NC

R

O2/2 CM

R

O2/3 NO

R

O3/2 CM

R

O3/3 NO

Standard I/O board

Terminal

Signal Description

+10 Vref

AI1+

AI1-

AI2+

AI2-

24 Vout

Reference output

Analog input 1 +

Analog input 1 -

Analog input 2 +

Analog input 2 -

24 V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Common for DI1-DI6

Common for DI1-DI6

24 V auxiliary voltage

I/O ground

Analog output 1 +

Analog output 1 -

24 V auxiliary

input voltage

Output

frequency

0...20 mA)

READY

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

FAULT

AO1+

Reference

potentiome-

ter

1...10 kΩ

Remote reference

(4...20 mA)

Remote

control

(+24 V)

Remote

control ground

REMOTE:

Frequency reference

(default: 4...20 mA)

LOCAL:

Frequency reference

(default: 0...10 V)

REMOTE: Start forward

REMOTE: Start reverse

External fault

LOCAL: Start forward

LOCAL: Start reverse

LOCAL/REMOTE selection

TI1+

TI1-

Thermistor input

VACON® 100 INDUSTRIAL

Application Guide

Applications

Illustration 8: The Default Control Connections of the Local/Remote Application

*) Available only in VACON® 100 X. **) For the DIP switch configurations in VACON® 100 X, see the VACON® 100 X Installation manual.

AB275637269262en-000101 / DPD0092734 | Danfoss A/S © 2021.05

A

B

C

e30bg589.10

A

Digital input DIP switch

B

Floating

C

Connected to GND (Default)

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.2

Application

051

212

0 = Standard

1 = Local/Remote

2 = Multi-step Speed

3 = PID Control

4 = Multi-purpose

5 = Motor Potentiometer

1.3

Minimum Frequency

Reference

0.00

P1.4Hz0.0

101

1.4

Maximum Frequency

Reference

P1.3

320.0

Hz

50.0/60.0

102

1.5

Acceleration Time 1

0.1

300.0

s

5.0

103

1.6

Deceleration Time 1

0.1

300.0

s

5.0

104

1.7

Motor Current Limit

IH*0.1

ISA

Varies

107

1.8

Motor Type

020

650

0 = Induction Motor

1 = Permanent Magnet Motor

2 = Reluctance Motor

1.9

Motor Nominal Voltage

Varies

Varies

V

Varies

110

Find this value Un on the nameplate of the motor.

NOTE! Find out if the motor connection is Delta

or Star.

1.10

Motor Nominal Frequency

8.0

320.0

Hz

50/60

111

Find this value fn on the nameplate of the motor.

VACON® 100 INDUSTRIAL

Application Guide

Illustration 9: The DIP Switch

Applications

See information on the Startup, Multi-pump, and Fire mode wizards in 4.2.1 Wizards in Menu 1.1.

Table 5: M1 Quick Setup

AB275637269262en-000101 / DPD00927 | 35Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.11

Motor Nominal Speed

24

19200

RPM

Varies

112

Find this value nn on the nameplate of the motor.

1.12

Motor Nominal Current

IH * 0.1

IH * 2

A

Varies

113

Find this value In on the nameplate of the motor.

1.13

Motor Cos Phi (Power

Factor)

0.30

1.00

Varies

120

Find this value on the nameplate of the motor.

1.14

Energy Optimization

010

666

0 = Disabled

1 = Enabled

1.15

Identification

020

631

0 = No action

1 = At standstill

2 = With rotation

1.16

Start Function

010

505

0 = Ramping

1 = Flying Start

1.17

Stop Function

010

506

0 = Coasting

1 = Ramping

1.18

Automatic Reset

010

731

0 = Disabled

1 = Enabled

1.19

Response to External

Fault

032

701

0 = No action

1 = Alarm

2 = Fault (Stop according to stop mode)

3 = Fault (Stop by coasting)

1.20

Response to AI Low

Fault

050

700

0 = No action

1 = Alarm

2 = Alarm+preset fault frequency (P3.9.1.13)

3 = Alarm + previous frequency

4 = Fault (Stop according to stop mode)

5 = Fault (Stop by coasting)

1.21

Remote Control Place

010

172

0 = I/O control

1 = Fieldbus control

1.22

I/O Control Reference

A Selection

1205

117

1 = Preset Frequency 0

2 = Keypad reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID reference

8 = Motor potentiometer

9 = Joystick reference

10 = Jogging reference

11 = Block Out.1

12 = Block Out.2

13 = Block Out.3

VACON® 100 INDUSTRIAL

Application Guide

Applications

AB275637269262en-000101 / DPD0092736 | Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

14 = Block Out.4

15 = Block Out.5

16 = Block Out.6

17 = Block Out.7

18 = Block Out.8

19 = Block Out.9

20 = Block Out.10

1.23

Keypad Control Reference Selection

1202

121

See P1.22.

1.24

Fieldbus Control Reference Selection

1203

122

See P1.22.

1.25

AI1 Signal Range

010

379

0= 0..10 V/0...20 mA

1= 2...10 V/4...20 mA

1.26

AI2 Signal Range

011

390

0= 0...10 V/0...20 mA

1= 2...10 V/4...20 mA

1.27

RO1 Function

0612

11001

See P3.5.3.2.1.

1.28

RO2 Function

0563

11004

See P3.5.3.2.1.

1.29

RO3 Function

0561

11007

See P3.5.3.2.1.

1.30

AO1 Function

0312

10050

See P3.5.4.1.1.

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.32.1

I/O Control Reference B Selection

1204

131

See P1.22.

1.32.2

I/O B Control Force

digIN SlotA.6

425

CLOSED = Force control place to I/O B

1.32.3

I/O B Reference Force

digIN SlotA.6

343

CLOSED = Used frequency reference is

specified by I/O Reference B parameter

(P1.32.1)

1.32.4

Control Signal 1 B

digIN SlotA.4

423

1.32.5

Control Signal 2 B

digIN SlotA.5

424

1.32.6

Keypad Control Force

digIN SlotA.1

410

1.32.7

Fieldbus Control Force

digIN Slot0.1

411

1.32.8

External Fault (Close)

digIN SlotA.3

405

OPEN = OK

CLOSED = External fault

1.32.9

Fault Reset (Close)

digIN Slot0.1

414

Resets all active faults when CLOSED

VACON® 100 INDUSTRIAL

Application Guide

Applications

Table 6: M1.32 Local/Remote

3.4 Multi-step Speed Application

Use the Multi-step speed application with processes where more than 1 fixed frequency reference is necessary (for example test

benches).

It is possible to use 1 + 7 frequency references: 1 basic reference (AI1 or AI2) and 7 preset references.

AB275637269262en-000101 / DPD00927 | 37Danfoss A/S © 2021.05

DI4 DI5

1

DI6

0

0

0

0

0

1

0

0

1

1

1

1

1

1

1

0

0

0

0

0

1

1

1

1

6

2

3

4

5

18

19

30

12

7

13

8

9

10

14

15

16

21

22

23

11

17

A

B

24

25

26

32

33

Modbus RTU,

N2, BACnet

28

29

*)

**)

e30bg592.10

mA

FAULT

RUN

RUN

AO1-

+24Vin

24 Vout

GND

GND

DI1

DI2

DI3

DI4

DI5

DI6

R

O1/1 NC

R

O1/2 CM

R

O1/3 NO

CM

CM

RS485

RS485

R O2/1 NC

R O2/2 CM

R O2/3 NO

R O3/2 CM

R O3/3 NO

Standard I/O board

Terminal Signal Description

+10 Vref

AI1+

AI1-

AI2+

AI2-

24 Vout

Reference output

Analog input 1 +

Analog input 1 -

Analog input 2 +

Analog input 2 -

24 V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Digital input 4

Digital input 5

Digital input 6

Common for DI1-DI6

Common for DI1-DI6

24V auxiliary voltage

I/O ground

Analog output 1 +

Analog output 1 -

24 V auxiliary

input voltage

Output

frequency

0...20 mA)

READY

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

FAULT

AO1+

Frequency reference

(default 0...10 V)

Frequency reference

(Default 4...20 mA)

Start forward

Start reverse

External fault

Analog input

Preset Freq. 1

Preset Freq. 2

Preset Freq. 3

Preset Freq. 4

Preset Freq. 5

Preset Freq. 6

Preset Freq. 7

Freq. ref.

TI1+

TI1-

Thermistor input

Reference

potentiome-

ter

1...10 kΩ

VACON® 100 INDUSTRIAL

Application Guide

Applications

Make a selection of the preset frequency references with digital signals DI4, DI5, and DI6. If none of these inputs are active, the

frequency reference is removed from the analog input (AI1 or AI2). Give the start/stop commands from the I/O terminal (DI1 and

DI2).

It is possible to configure all the drive outputs freely in all the applications. There is 1 analog output (Output Frequency) and 3 relay

outputs (Run, Fault, Ready) available on the basic I/O board.

Illustration 10: The Default Control Connections of the Multi-step Speed Application

AB275637269262en-000101 / DPD0092738 | Danfoss A/S © 2021.05

A

B

C

e30bg589.10

A

Digital input DIP switch

B

Floating

C

Connected to GND (Default)

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.2

Application

052

212

0 = Standard

1 = Local/Remote

2 = Multi-step Speed

3 = PID Control

4 = Multi-purpose

5 = Motor Potentiometer

1.3

Minimum Frequency

Reference

0.00

P1.4Hz0.0

101

1.4

Maximum Frequency

Reference

P1.3

320.0

Hz

50.0/60.0

102

1.5

Acceleration Time 1

0.1

300.0

s

5.0

103

1.6

Deceleration Time 1

0.1

300.0

s

5.0

104

1.7

Motor Current Limit

IH*0.1

ISA

Varies

107

1.8

Motor Type

020

650

0 = Induction Motor

1 = Permanent Magnet Motor

2 = Reluctance Motor

1.9

Motor Nominal Voltage

Varies

Varies

V

Varies

110

Find this value Un on the nameplate of the motor.

NOTE! Find out if the motor connection is Delta

or Star.

VACON® 100 INDUSTRIAL

Application Guide

*) Available only in VACON® 100 X. **) For the DIP switch configurations in VACON® 100 X, see the VACON® 100 X Installation manual.

Illustration 11: The DIP Switch

Applications

See information on the Startup, Multi-pump, and Fire mode wizards in 4.2.1 Wizards in Menu 1.1.

Table 7: M1 Quick Setup

AB275637269262en-000101 / DPD00927 | 39Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.10

Motor Nominal Frequency

8.0

320.0

Hz

50/60

111

Find this value fn on the nameplate of the motor.

1.11

Motor Nominal Speed

24

19200

RPM

Varies

112

Find this value nn on the nameplate of the motor.

1.12

Motor Nominal Current

IH * 0.1

IH * 2

A

Varies

113

Find this value In on the nameplate of the motor.

1.13

Motor Cos Phi (Power

Factor)

0.30

1.00

Varies

120

Find this value on the nameplate of the motor.

1.14

Energy Optimization

010

666

0 = Disabled

1 = Enabled

1.15

Identification

020

631

0 = No action

1 = At standstill

2 = With rotation

1.16

Start Function

010

505

0 = Ramping

1 = Flying Start

1.17

Stop Function

010

506

0 = Coasting

1 = Ramping

1.18

Automatic Reset

010

731

0 = Disabled

1 = Enabled

1.19

Response to External

Fault

032

701

0 = No action

1 = Alarm

2 = Fault (Stop according to stop mode)

3 = Fault (Stop by coasting)

1.20

Response to AI Low

Fault

050

700

0 = No action

1 = Alarm

2 = Alarm+preset fault frequency (P3.9.1.13)

3 = Alarm + previous frequency

4 = Fault (Stop according to stop mode)

5 = Fault (Stop by coasting)

1.21

Remote Control Place

010

172

0 = I/O control

1 = Fieldbus control

1.22

I/O Control Reference

A Selection

1206

117

1 = Preset Frequency 0

2 = Keypad reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID reference

8 = Motor potentiometer

9 = Joystick reference

10 = Jogging reference

VACON® 100 INDUSTRIAL

Application Guide

Applications

AB275637269262en-000101 / DPD0092740 | Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

11 = Block Out.1

12 = Block Out.2

13 = Block Out.3

14 = Block Out.4

15 = Block Out.5

16 = Block Out.6

17 = Block Out.7

18 = Block Out.8

19 = Block Out.9

20 = Block Out.10

1.23

Keypad Control Reference Selection

1202

121

See P1.22.

1.24

Fieldbus Control Reference Selection

1203

122

See P1.22.

1.25

AI1 Signal Range

010

379

0= 0...10 V/0...20 mA

1= 2...10 V/4...20 mA

1.26

AI2 Signal Range

011

390

0= 0...10 V/0...20 mA

1= 2...10 V/4...20 mA

1.27

RO1 Function

0612

11001

See P3.5.3.2.1.

1.28

RO2 Function

0563

11004

See P3.5.3.2.1.

1.29

RO3 Function

0561

11007

See P3.5.3.2.1.

1.30

AO1 Function

0312

10050

See P3.5.4.1.1.

Index

Parameter

Min

Max

Unit

Default

ID

Description

1.33.1

Preset Frequency 1

P1.3

P1.4Hz10.0

105

1.33.2

Preset Frequency 2

P1.3

P1.4Hz15.0

106

1.33.3

Preset Frequency 3

P1.3

P1.4Hz20.0

126

1.33.4

Preset Frequency 4

P1.3

P1.4Hz25.0

127

1.33.5

Preset Frequency 5

P1.3

P1.4Hz30.0

128

1.33.6

Preset Frequency 6

P1.3

P1.4Hz40.0

129

1.33.7

Preset Frequency 7

P1.3

P1.4Hz50.0

130

1.33.8

Preset Frequency Mode

010

182

0 = Binary Coded

1 = Number of inputs. Preset frequency is selec-

ted according to how many of preset speed digital inputs are active.

1.33.9

External Fault (Close)

DigIN SlotA.3

405

CLOSED = OK

VACON® 100 INDUSTRIAL

Application Guide

Applications

Table 8: M1.33 Multi-step Speed

AB275637269262en-000101 / DPD00927 | 41Danfoss A/S © 2021.05

Index

Parameter

Min

Max

Unit

Default

ID

Description

OPEN = External fault

1.33.10

Fault Reset (Close)

DigIN Slot0.1

414

Resets all active faults when CLOSED

VACON® 100 INDUSTRIAL

Application Guide

Applications

3.5 PID Control Application

Use the PID control application with processes where the process variable (for example pressure) is controlled through control of

the speed of the motor.

In this application, the internal PID controller of the drive is configured for 1 setpoint and 1 feedback signal.

It is possible to use 2 control places. Make the selection of the control place A or B with DI6. When control place A is active, the start/

stop commands are given by DI1, and the PID controller gives the frequency reference. When control place B is active, start/stop

commands are given by DI4, and AI1 gives the frequency reference.

It is possible to configure all the drive outputs freely in all the applications. There are 1 analog output (Output Frequency) and 3

relay outputs (Run, Fault, Ready) available on the basic I/O board.

AB275637269262en-000101 / DPD0092742 | Danfoss A/S © 2021.05

1

6

2

3

4

5

18

19

30

12

7

13

8

9

10

14

15

16

21

22

23

11

17

A

B

24

25

26

32

33

Modbus RTU,

N2, BACnet

28

29

+

-

*)

**)

e30bg593.10

mA

FAUL

T

RUN

RUN

AO1-/GND

+24Vin

24 Vout

GND

GND

DI1

DI2

DI3

DI4

DI5

DI6

R

O1/1 NC

R

O1/2 CM

R

O1/3 NO

CM

CM