Operating Guide

VACON® 100 Wall-mounted Drives

VACON® 100 INDUSTRIAL, VACON® 100 FLOW,

VACON® 100 HVAC

Operating Guide | VACON® 100 Wall-mounted Drives

Contents

Contents

1 Introduction 7

1.1 Additional Resources 7

1.2 Disposal 7

1.3 Type Approvals and Certifications 7

2 Safety 9

2.1 Safety Symbols 9

2.2 Danger and Warnings 9

2.3 Cautions and Notices 11

3 Product Overview 13

3.1 Manual Version 13

3.2 Package Label 13

3.3 Description of the Type Code 14

3.4 Enclosure Sizes 15

4 Receiving the Delivery 19

4.1 Checking the Delivery 19

4.2 Accessories 19

4.2.1 Accessories Bag, MR4 19

4.2.2 Accessories Bag, MR5 19

4.2.3 Accessories Bag, MR6 20

4.2.4 Accessories Bag, MR7 20

4.2.5 Accessories Bag, MR8 21

4.2.6 Accessories Bag, MR9 21

4.3 Storing the Product 22

4.4 Lifting the Enclosure Sizes MR8 and MR9 22

4.5 Using the Product Modified Label 23

5 Mounting 25

5.1 Wall-mounting Requirements 25

5.2 Flange-mounting Requirements 25

5.3 Cooling Requirements 27

5.3.1 General Cooling Requirements 27

5.3.2 Cooling 27

5.3.3 Necessary Quantity of Cooling Air 30

6 Electrical Installation 31

6.1 Cable Connections 31

6.1.1 General Cable Requirements 31

AQ298036140958en-000101 / | 3Danfoss A/S © 2019.05

Operating Guide | VACON® 100 Wall-mounted Drives

6.1.2 UL Standards on Cabling 32

6.1.3 Cable Selection and Dimensioning 32

6.1.4 Cable Selection and Dimensioning, North America 32

6.1.5 Fuse Selection 33

6.1.6 Fuse Selection, North America 33

6.1.7 Brake Resistor Cables 33

6.2 EMC-compliant Installation 34

6.2.1 Installation in a Corner-grounded Network 35

6.3 Grounding 35

6.4 Get Access and Locate the Terminals 36

6.4.1 Get Access and Locate the Terminals for MR4-MR7 36

6.4.2 Get Access and Locate the Terminals for MR8 38

6.4.3 Get Access and Locate the Terminals for MR9 40

6.5 Installation of Cables 43

6.5.1 Additional Instructions for Cable Installation 43

6.5.2 Installing the Cables, MR4-MR7 44

6.5.3 Installing the Cables, MR8-MR9 48

6.6 Installation in an IT System 53

6.6.1 Installing the AC drive in an IT System, MR4-MR6 53

6.6.2 Installing the AC drive in an IT System, MR7 55

6.6.3 Installing the AC drive in an IT System, MR8 58

6.6.4 Installing the AC drive in an IT System, MR9 60

6.7 Installation in a Marine Environment 63

Contents

7 Control Unit 64

7.1 Control Unit Components 64

7.2 Control Unit Cabling 65

7.2.1 Selection of the Control Cables 65

7.2.2 Control Unit Terminals 65

7.3 DIP Switches on the Control Unit 67

7.3.1 Selection of Terminal Functions with DIP Switches 67

7.3.2 Isolation of the Digital Inputs from Ground 69

7.4 Fieldbus Connection 69

7.4.1 Fieldbus Terminals 69

7.4.2 Internal Fieldbuses in VACON® 100 Products 70

7.4.3 General Cabling Instructions for Fieldbus 71

7.4.3.1 Cable Routing 71

7.4.3.2 Strain Relief 73

7.4.4 Ethernet Commissioning and Cabling 73

7.4.4.1 General Cabling Instructions for Ethernet 73

7.4.4.2 Grounding the Cable Shield 73

7.4.4.3 Using Fieldbus through an Ethernet Cable 75

AQ298036140958en-000101 /4 | Danfoss A/S © 2019.05

Operating Guide | VACON® 100 Wall-mounted Drives

7.4.5 RS485 Commissioning and Cabling 78

7.4.5.1 General Cabling Instructions for RS485 78

7.4.5.2 Grounding the Cable Shield 79

7.4.5.3 The RS485 Bus Biasing 80

7.4.5.4 Using Fieldbus through an RS485 Cable 80

7.5 Available Option Boards 84

7.6 Option Board Installation 85

7.7 Battery for the Real-Time Clock (RTC) 87

7.8 Galvanic Isolation Barriers 87

7.9 Description of the Control Panel 88

7.9.1 Control Panel and the Keypad 88

7.9.2 Displays of the Control Panel 89

Contents

8 Commissioning 91

8.1 Safety Checks before Starting the Commissioning 91

8.2 Commissioning the AC Drive 92

8.3 Measuring the Cable and Motor Insulation 92

8.3.1 Insulation Checks of the Motor Cable 93

8.3.2 Insulation Checks of the Mains Cable 93

8.3.3 Insulation Checks of the Motor 93

8.4 Checking the AC Drive after Commissioning 94

9 Maintenance 95

9.1 Maintenance Schedule 95

10 Specifications 96

10.1 Weight of the Drive 96

10.2 Dimensions 96

10.2.1 Dimensions for Wall-mounting 96

10.2.1.1 Dimensions for Wall-mounting for MR4 96

10.2.1.2 Dimensions for Wall-mounting for MR5 97

10.2.1.3 Dimensions for Wall-mounting for MR6 98

10.2.1.4 Dimensions for Wall-mounting for MR7 99

10.2.1.5 Dimensions for Wall-mounting for MR8 100

10.2.1.6 Dimensions for Wall-mounting for MR9 101

10.2.2 Dimensions for Flange-mounting 102

10.2.2.1 Dimensions for Flange-mounting for MR4 102

10.2.2.2 Dimensions for Flange-mounting for MR5 103

10.2.2.3 Dimensions for Flange-mounting for MR6 104

10.2.2.4 Dimensions for Flange-mounting for MR7 105

10.3 Cable and Fuse Sizes 105

10.3.1 List of Cable and Fuse Size Information 105

10.3.2 Cable and Fuse Sizes, Mains Voltage 208–240 V and 380–500 V 106

AQ298036140958en-000101 / | 5Danfoss A/S © 2019.05

Operating Guide | VACON® 100 Wall-mounted Drives

10.3.3 Cable and Fuse Sizes, Mains Voltage 525–690 V 107

10.3.4 Cable and Fuse Sizes, Mains Voltage 208–240 V and 380–500 V, North America 109

10.3.5 Cable and Fuse Sizes, Mains Voltage 525–690 V, North America 111

10.4 Cable Stripping Lengths 112

10.5 Tightening Torques of the Terminals 113

10.6 Power Ratings 114

10.6.1 Power Ratings of VACON® 100 INDUSTRIAL, 208–240 V 114

10.6.2 Power Ratings of VACON® 100 INDUSTRIAL, 380–500 V 116

10.6.3 Power Ratings of VACON® 100 INDUSTRIAL, 525–600 V 117

10.6.4 Power Ratings of VACON® 100 INDUSTRIAL, 525–690 V 118

10.6.5 Power Ratings of VACON® 100 FLOW, 208–240 V 119

10.6.6 Power Ratings of VACON® 100 FLOW, 380–500 V 120

10.6.7 Power Ratings of VACON® 100 FLOW, 525–600 V 121

10.6.8 Power Ratings of VACON® 100 FLOW, 525–690 V 122

10.6.9 Power Ratings of VACON® 100 HVAC, 208–240 V 123

10.6.10 Power Ratings of VACON® 100 HVAC, 380–500 V 124

10.7 Overload Capability 124

10.8 Brake Resistor Ratings 126

10.8.1 Brake Resistor Ratings 126

10.8.2 Brake Resistance in Light duty and Heavy Duty 126

10.8.3 Brake Resistor Types, Mains Voltage 208–240 V and 380–500 V 127

10.8.4 Brake Resistor Types, Mains Voltage 525–690 V 127

10.8.5 Brake Resistance and Brake Power, Mains Voltage 208–240 V 128

10.8.6 Brake Resistance and Brake Power, Mains Voltage 380–500 V 129

10.8.7 Brake Resistance and Brake Power, Mains Voltage 525–600 V 129

10.8.8 Brake Resistance and Brake Power, Mains Voltage 525–690 V 129

10.9 Control Connections 130

10.10 Technical Data, VACON® 100 INDUSTRIAL 133

10.11 Technical Data, VACON® 100 FLOW 138

10.12 Technical Data, VACON® 100 HVAC 142

Contents

AQ298036140958en-000101 /6 | Danfoss A/S © 2019.05

Operating Guide | VACON® 100 Wall-mounted Drives

Introduction

1 Introduction

1.1 Additional Resources

Other resources are available to understand advanced AC drive functions and operation.

• VACON® 100 INDUSTRIAL Application Guide

• VACON® 100 FLOW Application Guide

• VACON® 100 HVAC Application Guide

• VACON® 100 Enclosed Drives Installation Manual

• VACON® 100 IP00 Drive Modules Installation Manual

• VACON® 100 X Installation Manual

• Instructions for operation with option boards and other optional equipment.

Supplementary publications and manuals are available from Danfoss.

For US and Canada market:

NOTE! Download the English and French product manuals with applicable safety, warning and caution information from https://

www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit contenant l'ensemble des informations

de sécurité, avertissements et mises en garde applicables sur le site https://www.danfoss.com/en/service-and-support/.

1.2 Disposal

Context:

Do not dispose of equipment containing electrical components together with domestic waste. Collect it separately in accordance with

local and currently valid legislation.

1.3 Type Approvals and Certifications

The following list is a selection of possible type approvals and certifications for Danfoss drives:

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 7

089

Operating Guide | VACON® 100 Wall-mounted Drives

Introduction

NOTI CE

The specific approvals and certification for the drive are on the nameplate of the drive. For more information, contact the local

Danfoss office or partner.

8 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

DA NG ER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WA RN IN G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CA UT IO N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Safety

NO TI CE

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

2.2 Danger and Warnings

DA NG ER

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. A contact with this voltage can lead to death or

serious injury.

Do not touch the components of the power unit when the drive is connected to mains. Before connecting the drive to

-

mains, make sure that the covers of the drive are closed.

DA NG ER

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, the brake resistor terminals, or the DC terminals are live when the drive is connected to mains, also

when the motor does not operate. A contact with this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, the brake resistor terminals, or the DC terminals when the drive is connected to

-

mains. Before connecting the drive to mains, make sure that the covers of the drive are closed.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 9

Operating Guide | VACON® 100 Wall-mounted Drives

DA NG ER

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live 5 minutes after the drive is disconnected from the mains

and the motor has stopped. Also the load side of the drive can generate voltage. A contact with this voltage can lead to death

or serious injury.

Before doing electrical work on the drive:

-

• Disconnect the drive from the mains and make sure that the motor has stopped.

• Lock out and tag out the power source to the drive.

• Make sure that no external source generates unintended voltage during work.

• Wait 5 minutes before opening the cabinet door or the cover of the AC drive.

• Use a measuring device to make sure that there is no voltage.

WA RN IN G

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this

voltage can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

Safety

WA RN IN G

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the

pulse control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions

(including the start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic

fault reset. See the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start

can result in personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to

-

operate under any condition.

WA RN IN G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

WA RN IN G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B

or a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and

therefore can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

10 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

2.3 Cautions and Notices

CA UT IO N

DAMAGE TO THE AC DRIVE FROM INCORRECT MEASUREMENTS

Doing measurements on the AC drive when it is connected to mains can damage the drive.

Do not do measurements when the AC drive is connected to mains.

-

CA UT IO N

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

CA UT IO N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identified with the PE symbol.

Safety

CA UT IO N

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

CA UT IO N

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

NO TI CE

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Remember to use ESD protection always when working with electronic components of the AC drive. Do not touch the

-

components on the circuit boards without proper ESD protection.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 11

Operating Guide | VACON® 100 Wall-mounted Drives

NO TI CE

DAMAGE TO THE AC DRIVE FROM MOVEMENT

Movement after installation can damage the drive.

Do not move the AC drive during operation. Use a fixed installation to prevent damage to the drive.

-

NO TI CE

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

NO TI CE

RADIO INTERFERENCE

In a residential environment, this product can cause radio interference.

Take supplementary mitigation measures.

-

Safety

NO TI CE

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

NO TI CE

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not

operate correctly.

NO TI CE

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

12 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

3 Product Overview

3.1 Manual Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

Table 1: Manual and Software Version

Edition Remarks

DPD01711H Information about the new enclosure size MR9B and internal fieldbuses was added.

Information about option boards was updated.

EC declaration was removed.

Information about VACON® 100 IP00 drive modules was removed.

Hyperlink to company web page was updated.

Product Overview

Structure of the manual was changed.

Minor changes throughout the manual.

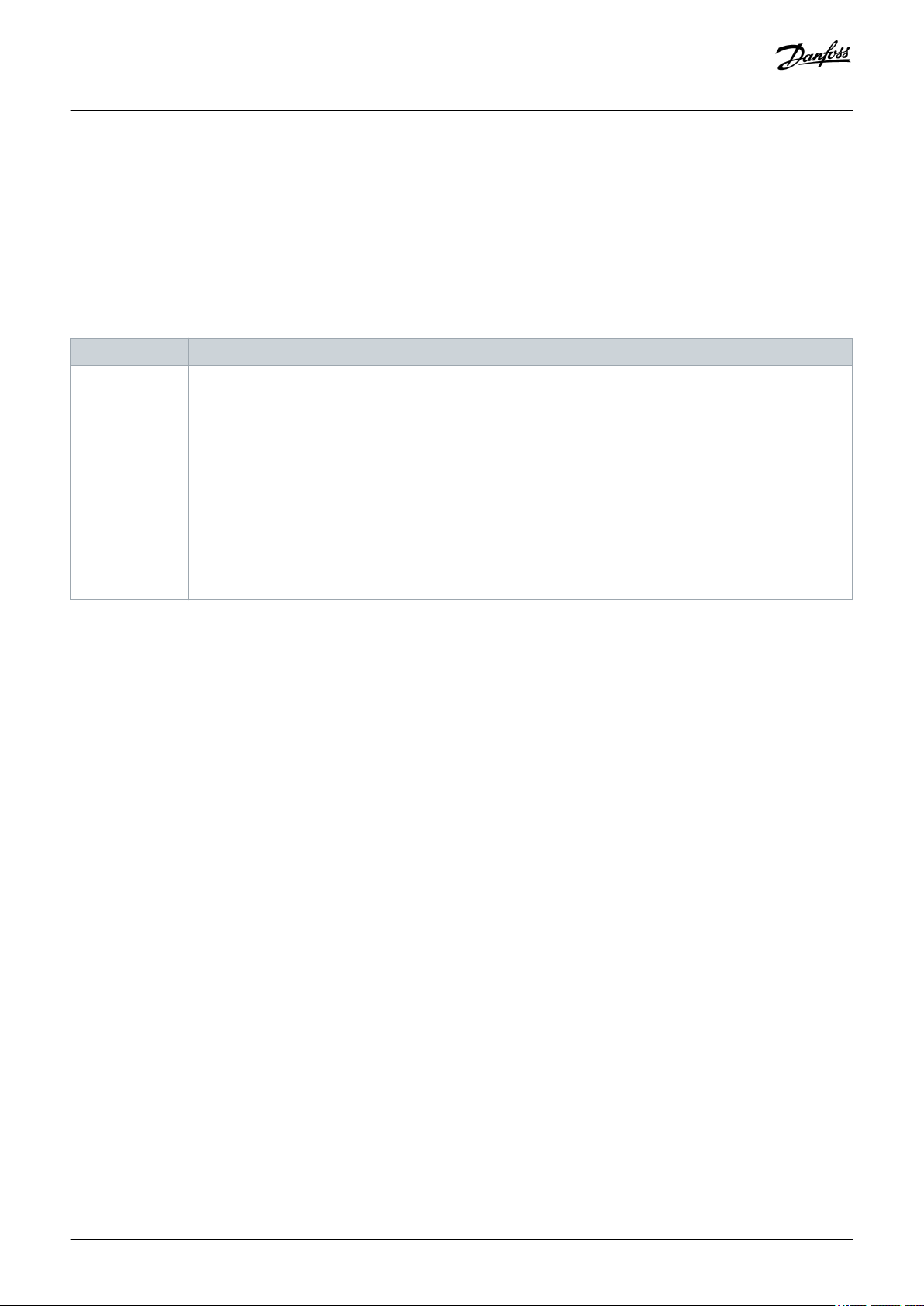

3.2 Package Label

The package label gives detailed information about the delivery.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 13

1003350719

V00002373919

70-AB3L00045W04B220BM2H-00055783

135U1814

Danfoss A/S, 6430 Nordborg, Denmark

1.5kW:400V / 2HP:480V

IP21/Type1

3~AC,0-Uin, 0-320Hz,

Uin:3~AC,380-500V, 50/60Hz,4.6A

Made in Finland

POWER:

4.8A

OUTPUT:

INPUT:

Danfoss S.A.

DLES

VACON0100-3L-0004-5-FLOW+FL03+DPAP+

190304

0021396473

FW0159V021

Marks:

Cust. Ord. No:

Application:

Firmware:

B.ID:

V00002373919

S/N:

70-AB3L00045W04B220BM2H-00055783

Code:

Type:

AC DRIVE

A

C

B

D

F

E

G

H

I

e30bh338.10

Operating Guide | VACON® 100 Wall-mounted Drives

Product Overview

A The batch ID

C The type code

E The mains voltage

G The protection rating

B

The VACON® order number

D The serial number

F The nominal output current

H The application code

I The order number of the customer

Illustration 1: Package Label of VACON® 100 Wall-mounted Drives

3.3 Description of the Type Code

The type code of VACON® is made of standard codes and optional codes. Each part of the type code agrees to the data in the order.

14 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

Example:

The code can have this format, for example:

• VACON0100-3L-0061-5+IP54

• VACON0100-3L-0061-5-FLOW

Table 2: Description of the Type Code

Code Description

Product Overview

VACON0100

3L Input/Function: 3L = A 3-phase input

0061 The drive rating in amperes. For example, 0061 = 61 A

5 The mains voltage:

FLOW The product:

+IP54 The optional codes. There are many options, for example +IP54 (an AC drive with the protection rating IP54).

The product family: VACON0100 = the VACON® 100 product family

2 = 208–240 V

5 = 380–500 V

6 = 525–600 V

7 = 525–690 V

(empty) = The VACON® 100 INDUSTRIAL AC drive

FLOW = The VACON® 100 FLOW AC drive

HVAC = The VACON® 100 HVAC AC drive

3.4 Enclosure Sizes

The codes for nominal current and nominal mains voltage are part of the type code (see 3.3 Description of the Type Code) on the

package label (see 3.2 Package Label). Use these values to find out the enclosure size of the AC drive from the table.

In the example "VACON0100-3L-0061-5+IP54", the code for nominal current is 0003 and the code for nominal mains voltage is 5.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 15

Operating Guide | VACON® 100 Wall-mounted Drives

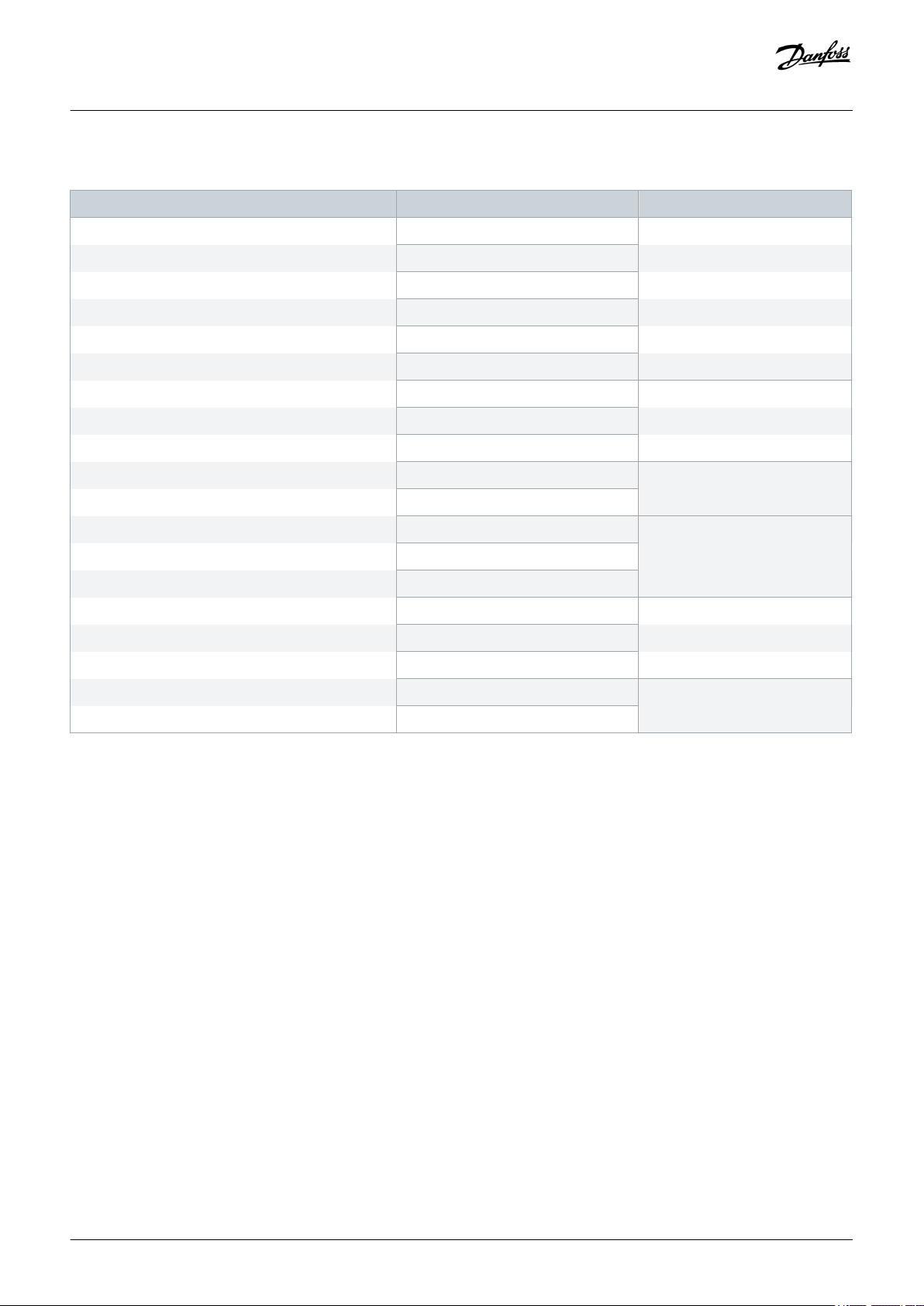

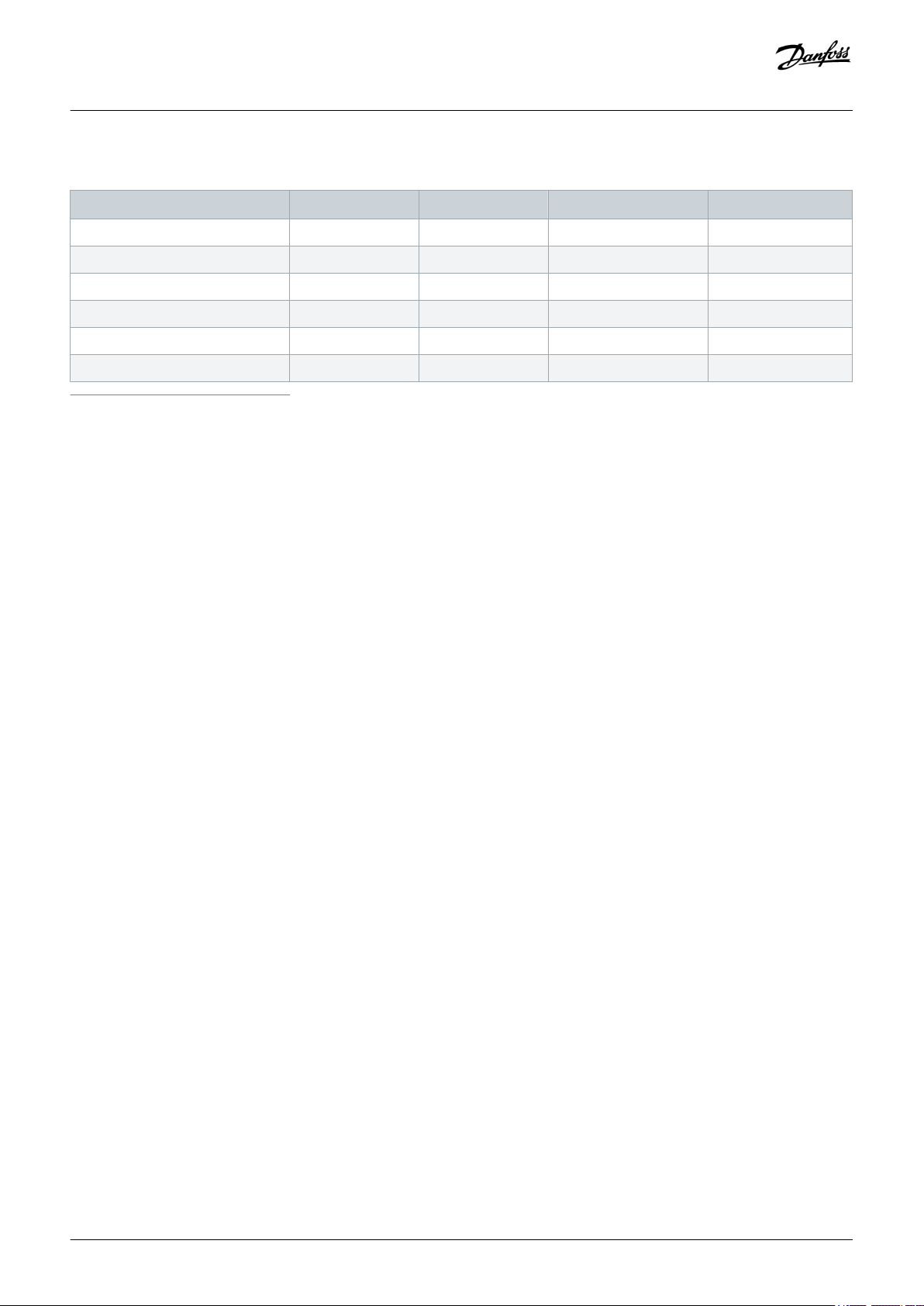

Table 3: Enclosure Sizes

Nominal mains voltage Nominal current Enclosure size

2 (208–240 V) 0003 MR4

0004

0007

0008

0011

0012

0018 MR5

0024

0031

0048 MR6

0062

0075 MR7

Product Overview

0088

0105

0140 MR8

0170

0205

0261 MR9A

0310

16 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

Nominal mains voltage Nominal current Enclosure size

5 (380–500 V) 0003 MR4

0004

0005

0008

0009

0012

0016 MR5

0023

0031

0038 MR6

0046

0061

0072 MR7

Product Overview

0087

0105

0140 MR8

0170

0205

0261 MR9A

0310

0386 MR9B

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 17

Operating Guide | VACON® 100 Wall-mounted Drives

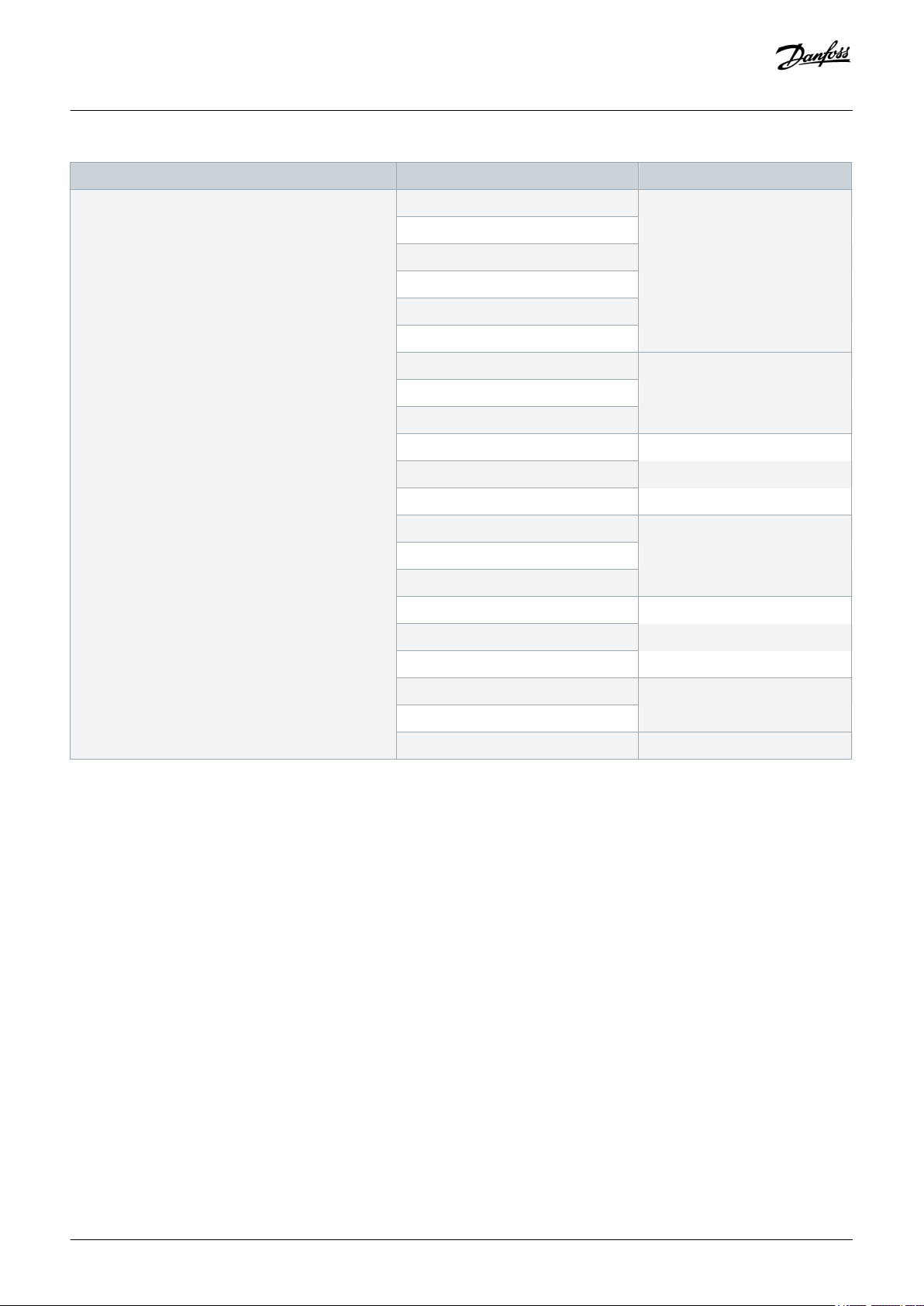

Nominal mains voltage Nominal current Enclosure size

6 (525–600 V) 0004 MR5

0006

0009

0011

0018 MR6

0022

0027

0034

0041 MR7

0052

0062

0080 MR8

0100

Product Overview

0125

0144 MR9A

0208

0262 MR9B

7 (525–690 V) 0007 MR6

0010

0013

0018

0022

0027

0034

0041 MR7

0052

0062

0080 MR8

0100

0125

18 | Danfoss A/S © 2019.05

0144 MR9A

0170

0208

0262 MR9B

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

Receiving the Delivery

4 Receiving the Delivery

4.1 Checking the Delivery

Context:

Procedure

1. After you remove the packaging, examine the drive for transport damages.

A If the drive was damaged during the shipping, speak to the cargo insurance company or the carrier.

2. To make sure that the delivery is correct, compare your order data to the data on the package label.

A If the delivery does not agree with your order, speak to the vendor immediately.

3. To make sure that the contents of the delivery is correct and complete, compare the type designation of the product to the type

code.

4.2 Accessories

4.2.1 Accessories Bag, MR4

Table 4: The Content of the Accessories Bag

Item Quantity Description

M4x16 screw 11 Screws for the grounding clamps for cable shield (6), the grounding

clamps for control cable (3), and the grounding clamps for grounding

conductor (2)

M4x8 screw 1 Screw for the optional grounding

M5x12 screw 1 Screw for the external grounding of the drive

Grounding clamp for control cable 3 Control cable grounding

Grounding clamp for cable shield, size M25 3 Clamping the power cables

Grounding clamp for grounding conductor 2 Power cable grounding

"Product modified" label 1 Data about changes

IP21: Cable grommet 3 Sealing for the cables

IP54: Cable grommet 6 Sealing for the cables

4.2.2 Accessories Bag, MR5

Table 5: The Content of the Accessories Bag

Item Quantity Description

M4x16 screw 13 Screws for the grounding clamps for cable shield (6), the grounding

clamps for control cable (3), and the grounding clamps for grounding

conductor (4)

M4x8 screw 1 Screw for the optional grounding

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 19

Operating Guide | VACON® 100 Wall-mounted Drives

Item Quantity Description

M5x12 screw 1 Screw for the external grounding of the drive

Grounding clamp for control cable 3 Control cable grounding

Grounding clamp for cable shield, size M25 1 Clamping the brake cable

Grounding clamp for cable shield, size M32 2 Clamping the power cables

Grounding clamp for grounding conductor 2 Power cable grounding

"Product modified" label 1 Data about changes

IP21: Cable grommet, hole diameter 25.3 mm 1 Sealing for the cables

IP54: Cable grommet, hole diameter 25.3 mm 4 Sealing for the cables

Cable grommet, hole diameter 33.0 mm 2 Sealing for the cables

4.2.3 Accessories Bag, MR6

Table 6: The Content of the Accessories Bag

Receiving the Delivery

Item Quantity Description

M4x20 screw 10 Screws for the grounding clamps for cable shield (6), and the ground-

ing clamps for grounding conductor (4)

M4x16 screw 3 Screws for the control cable clamps

M4x8 screw 1 Screw for the optional grounding

M5x12 screw 1 Screw for the external grounding of the drive

Grounding clamp for control cable 3 Control cable grounding

Grounding clamp for cable shield, size M32 1 Clamping the brake resistor cable

Grounding clamp for cable shield, size M40 2 Clamping the power cables

Grounding clamp for grounding conductor 2 Power cable grounding

"Product modified" label 1 Data about changes

Cable grommet, hole diameter 33.0 mm 1 Sealing for the cables

Cable grommet, hole diameter 40.3 mm 2 Sealing for the cables

IP54: Cable grommet, hole diameter 25.3 mm 3 Sealing for the cables

4.2.4 Accessories Bag, MR7

Table 7: The Content of the Accessories Bag

Item Quantity Description

M6x30 slotted nut 6 Nuts for the grounding clamps for cable shield

M4x16 screw 3 Screws for the grounding clamps for control cable

M6x12 screw 1 Screw for the external grounding of the drive

Grounding clamp for control cable 3 Control cable grounding

20 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

Item Quantity Description

Grounding clamp for cable shield, size M25 3 Clamping the power cables

Grounding clamp for grounding conductor 2 Power cable grounding

"Product modified" label 1 Data about changes

IP21: Cable grommet 3 Sealing for the cables

IP54: Cable grommet 3 Sealing for the cables

Receiving the Delivery

4.2.5 Accessories Bag, MR8

Table 8: The Content of the Accessories Bag

Item Quantity Description

M4x16 screw 3 Screws for the grounding clamps for control cable

Grounding clamp for control cable 3 Control cable grounding

Grounding clamp for cable shield KP40 3 Clamping the power cables

Cable insulator 11 To prevent contact between cables

Cable grommet, hole diameter 25.3 mm 4 Sealing for the cables

Bushing rubber 4 Sealing for the control cables

M8 hexagon nut 15 For cable installation

Conical spring washer 11 For cable installation

Split spring washer 4 For grounding clamp installation

M4x10 pan head screw 2 For touch cover installation (IP00)

Grounding clamp for grounding conductor 2 Clamping the grounding conductor of the power cables

Product modified label 1 Data about changes

4.2.6 Accessories Bag, MR9

Table 9: The Content of the Accessories Bag

Item Quantity Description

M4x16 screw 3 Screws for the grounding clamps for control cable

Grounding clamp for control cable 3 Control cable grounding

Cable insulator 10 To prevent contact between cables

Cable grommet, hole diameter 25.3 mm 4 Sealing for the cables

Bushing rubber 4 Sealing for the control cables

M4x8 screw 2 For installation

M8 hexagon nut 6 For installation

Split spring washer 4 For grounding clamp installation

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 21

Operating Guide | VACON® 100 Wall-mounted Drives

Item Quantity Description

M10 hexagon nut 9 For cable installation

Conical spring washer 9 For cable installation

Grounding clamp for grounding conductor 2 Grounding cover

Product modified label 1 Data about changes

4.3 Storing the Product

Context:

If you need to store the product before installing it, follow these instructions.

Procedure

1. Make sure that the ambient conditions agree to these:

Temperature: -40...+70 °C (-40...+158°F)

Humidity: 0...95%, no condensation

2. If you keep the package in storage for more than 2 months, keep it in controlled conditions.

A Make sure that the temperature variation is small.

B Make sure that the humidity is less than 50%.

Receiving the Delivery

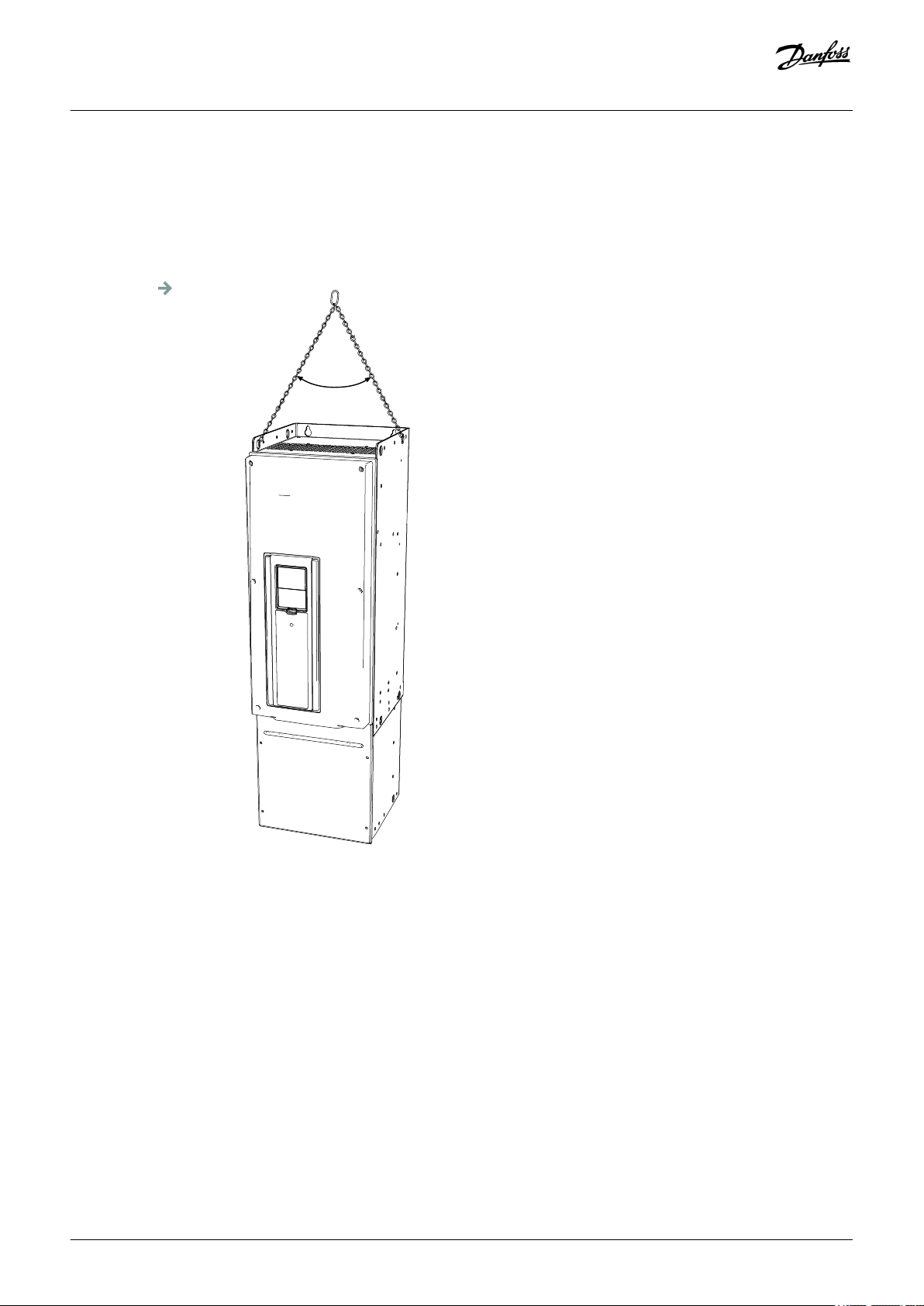

4.4 Lifting the Enclosure Sizes MR8 and MR9

Context:

The weights of AC drives of different enclosure sizes are different. It can be necessary for you to use a lifting device to move the drive

from its package. See the weights of the different enclosure sizes in table 23.

WA RN IN G

LIFTING HEAVY LOAD

Not following the safe lifting instructions can result in death or serious injury.

Do not walk under suspended loads. Use lifting devices that are appropriate for the weight of the unit. Use the

-

recommended lifting method.

22 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

≤45°

e30bh138.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Remove the drive from the pallet where it was bolted to.

2. Use a lifting device that is sufficiently strong for the weight of the drive.

3. Put the lifting hooks symmetrically in a minimum of 2 holes.

A The maximum lifting angle is 45 °.

Receiving the Delivery

Illustration 2: Maximum Lifting Angle

4.5 Using the Product Modified Label

Context:

In the accessories bag, there is also a "product modified" label. The function of the label is to tell the service personnel about the

changes that are made in the AC drive.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 23

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

Illustration 3: The Product Modified Label

Procedure

1. Attach the label on the side of the AC drive to know where to find it.

2. If changes are made in the AC drive, write the change on the label.

Receiving the Delivery

24 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A

B

D

A

C

E

e30bh167.10

Operating Guide | VACON® 100 Wall-mounted Drives

Mounting

5 Mounting

5.1 Wall-mounting Requirements

Install the AC drive in a vertical position on the wall.

If you install the drive in a horizontal position, there is no protection against drops of water that fall vertically. Use the same mounting

points as with vertical installation and pay special attention to cooling requirements (see 5.3.2 Cooling).

Install the AC drive with the screws and other components included in the delivery.

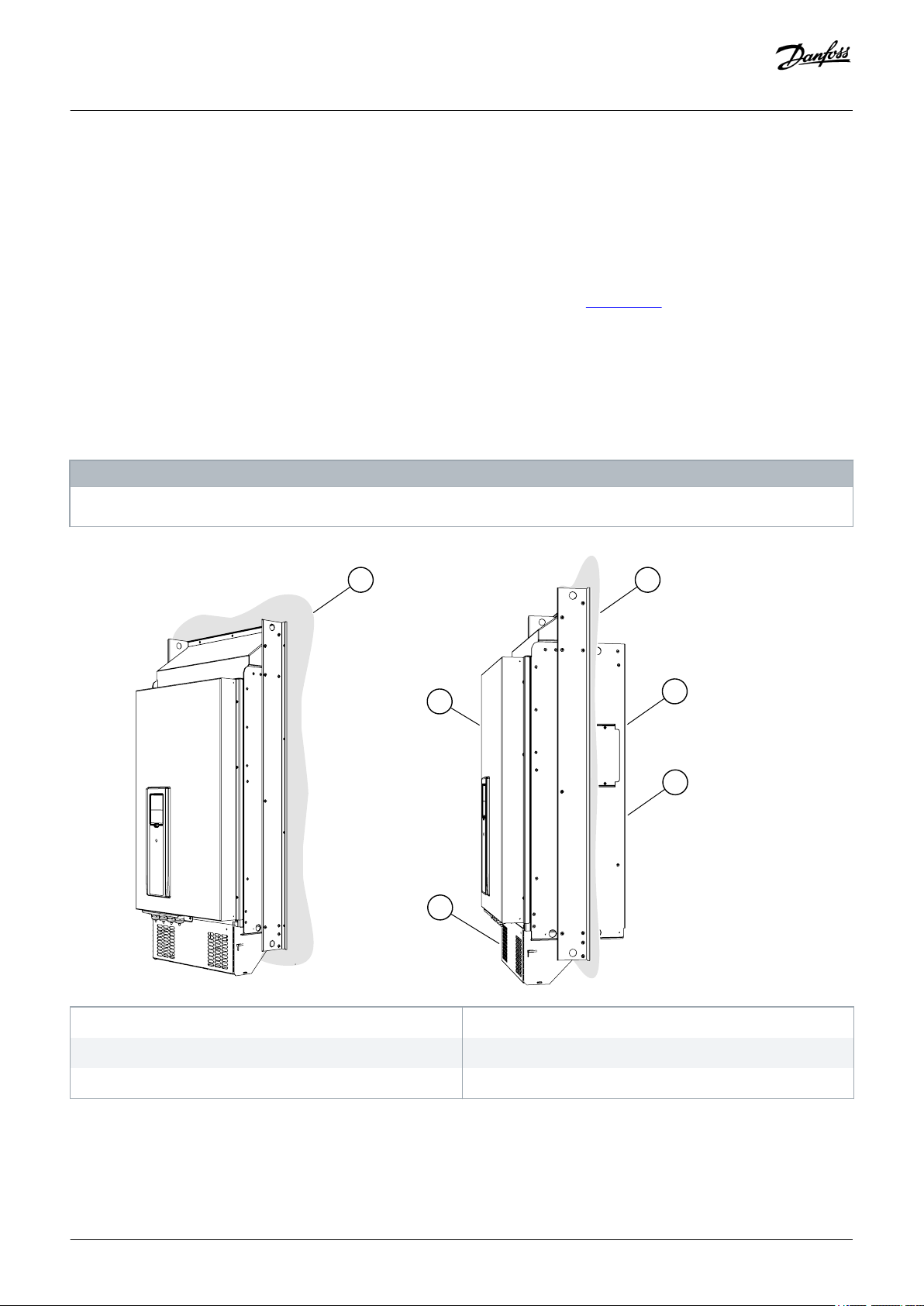

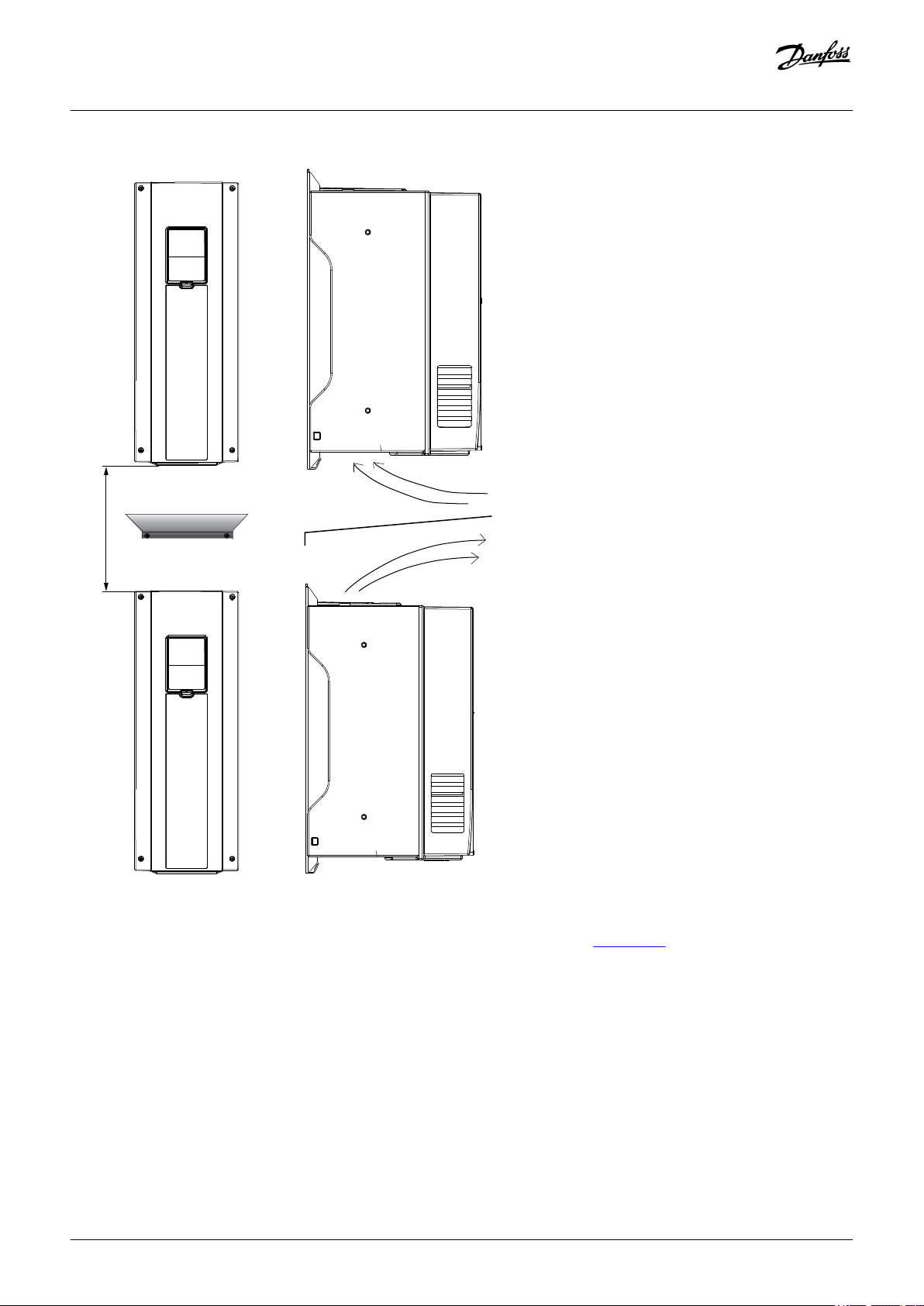

5.2 Flange-mounting Requirements

You can also install the AC drive into the cabinet wall with a flange mounting option.

NO TI CE

The protection classes are different in different sections of the drive.

A The cabinet wall or other surface

C The rear

E IP54/UL Type 12

Illustration 4: Example of Flange Mounting

Danfoss A/S © 2019.05

B The front

D IP21/UL Type 1

AQ298036140958en-000101 / DPD01711| 25

G

F

A E

B

D

C

H

e30bh168.10

Operating Guide | VACON® 100 Wall-mounted Drives

Mounting

A The height of the opening

C The height of the drive

E The distance between the bottom of the drive and the

bottom of the opening

G The outline of the drive

Illustration 5: Dimensions of the Opening and Drive Outline with Flange

Table 10: The Dimensions of the Drive, MR4 to MR7, in mm (in inch)

Enclosure size C D

MR4 357 (14.1) 152 (6.0)

MR5 454 (17.9) 169 (6.7)

MR6 580 (22.8) 220 (8.7)

MR7 680 (26.8) 286 (11.3)

Table 11: The Dimensions of the Opening for the Flange Mounting, MR4 to MR7, in mm (in inch)

Enclosure size A B E

MR4 315 (12.4) 137 (5.4) 24 (0.9)

B The width of the opening

D The width of the drive

F The outline of the opening

H The top of the drive

MR5 408 (16.1) 152 (6.0) 23 (0.9)

MR6 541 (21.3) 203 (8.0) 23 (0.9)

MR7 655 (25.8) 240 (9.4) 13 (0.5)

26 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A

D

A

B

B

C

e30bg010.10

Operating Guide | VACON® 100 Wall-mounted Drives

Mounting

5.3 Cooling Requirements

5.3.1 General Cooling Requirements

The AC drive produces heat in operation. The fan moves air and decreases the temperature of the drive. Make sure that there is

sufficiently free space around the drive. Some free space is also necessary for maintenance.

Make sure that the temperature of the cooling air does not go above the maximum ambient operating temperature or below the

minimum ambient operating temperature of the drive.

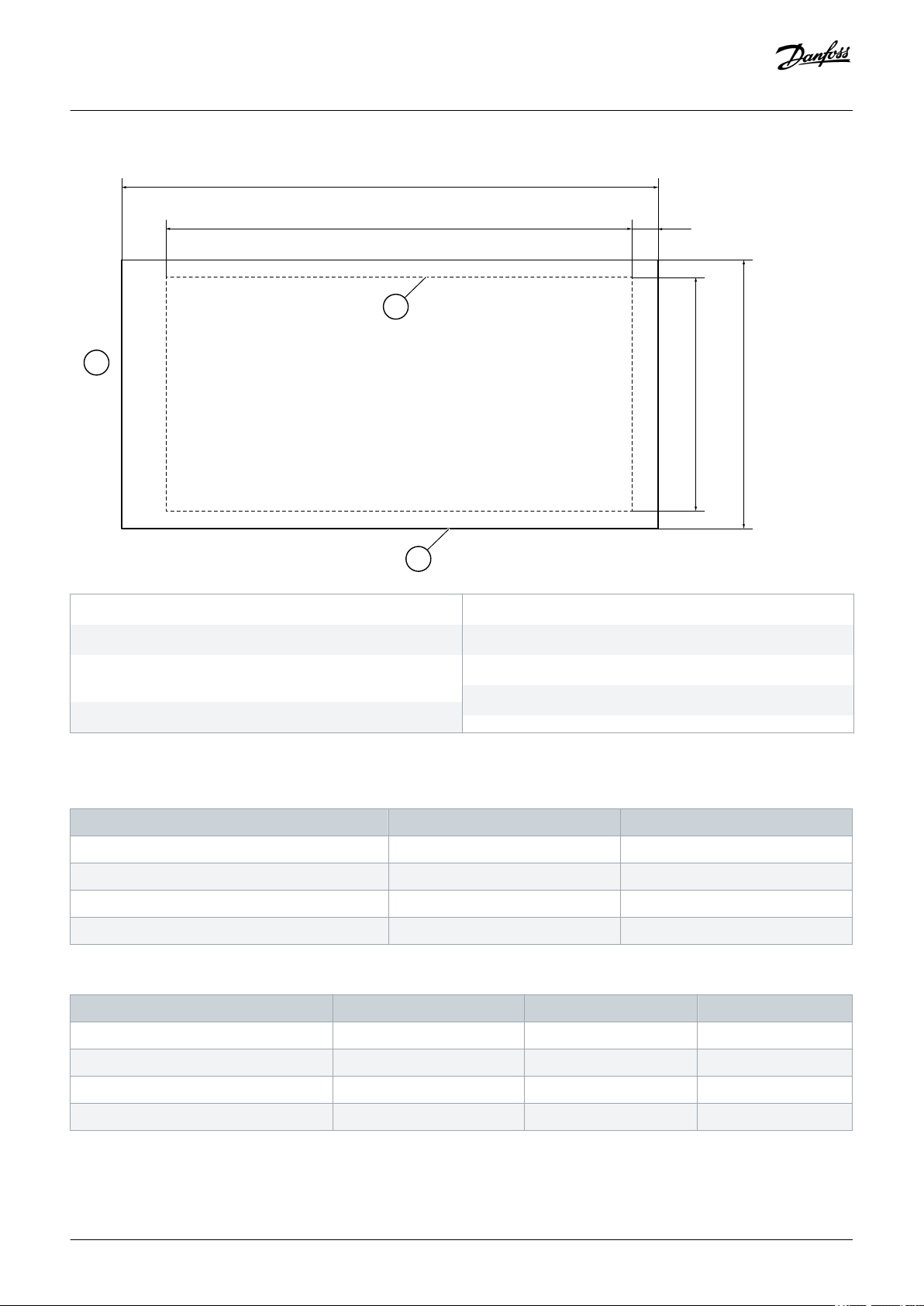

5.3.2 Cooling

A The clearance around the drive (see also B and C)

C The free space above the drive

Illustration 6: Installation Space

Danfoss A/S © 2019.05

B The distance from a drive to a second drive, or the distance to

the cabinet wall

D The free space below the drive

AQ298036140958en-000101 / DPD01711| 27

Operating Guide | VACON® 100 Wall-mounted Drives

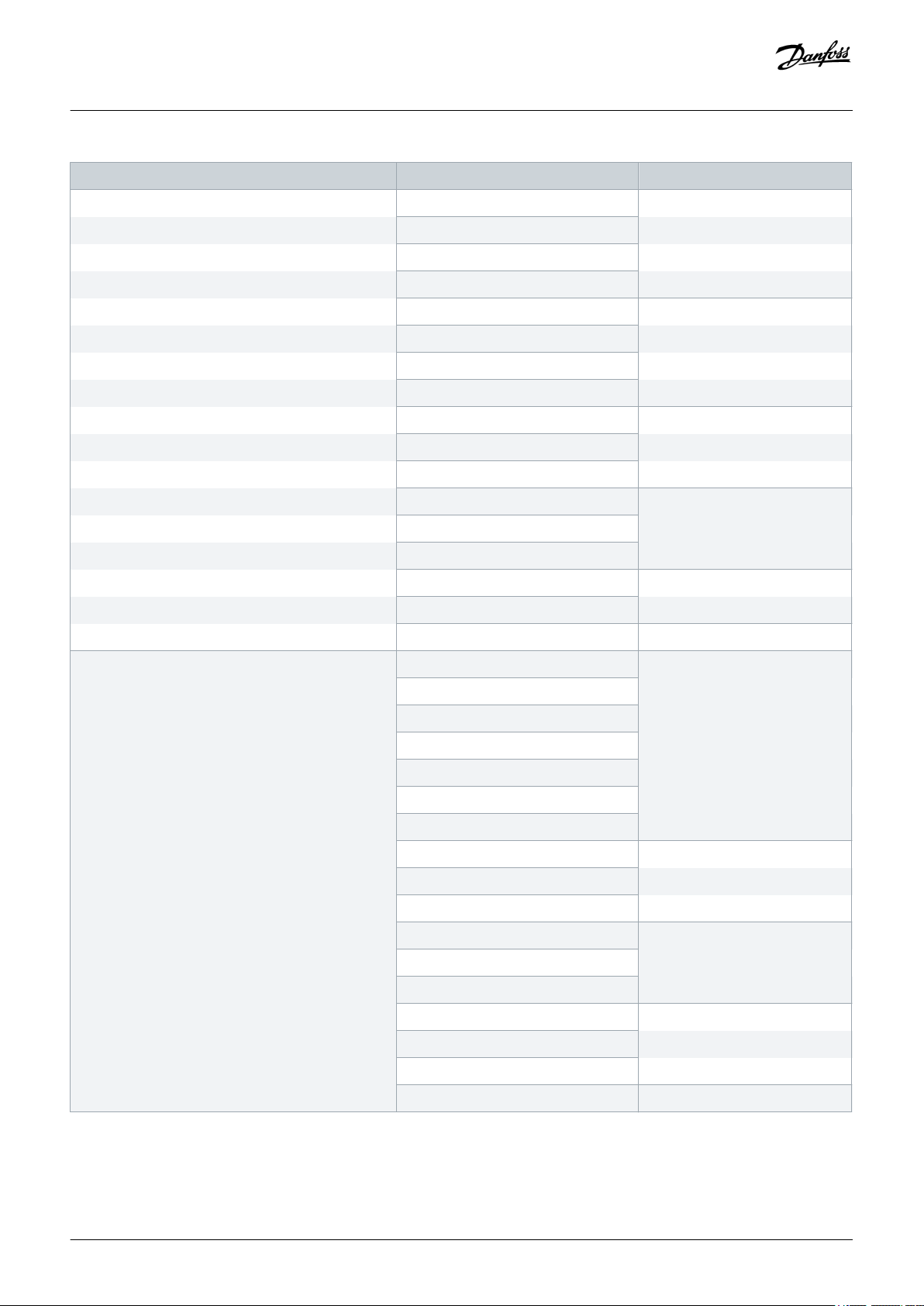

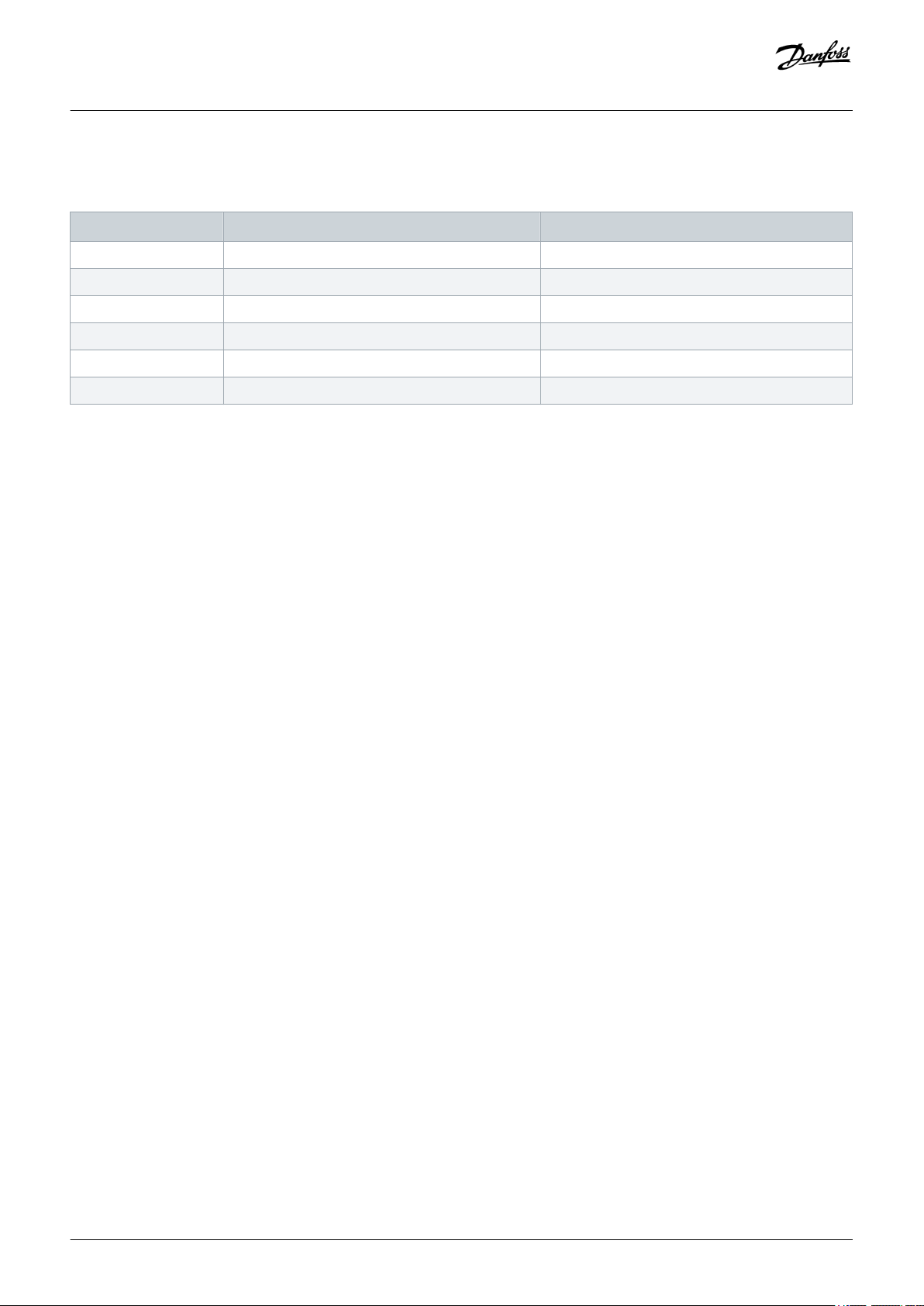

Table 12: Minimum Clearances around the AC Drive in mm (in inch)

Mounting

Enclosure size

(1)

A

(1)

B

C D

MR4 20 (0.8) 20 (0.8) 100 (3.9) 50 (2.0)

MR5 20 (0.8) 20 (0.8) 120 (4.7) 60 (2.4)

MR6 20 (0.8) 20 (0.8) 160 (6.3) 80 (3.1)

MR7 20 (0.8) 20 (0.8) 250 (9.8) 100 (3.9)

MR8 20 (0.8) 20 (0.8) 300 (11.8) 150 (5.9)

MR9 20 (0.8) 20 (0.8) 350 (13.8) 200 (7.9)

1

For a drive with IP54/UL Type 12, the minimum clearances A and B are 0 mm/0 in.

28 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bh172.10

C+D

Operating Guide | VACON® 100 Wall-mounted Drives

Mounting

Illustration 7: Installation Space when Drives Are Installed on Top of Each Other

• If many AC drives are installed above each other, the necessary free space is C + D (see illustration 6).

• Make also sure that the outlet air from the lower drive goes to a different direction than the air intake of the top drive. To do this,

attach a metal plate to the cabinet wall between the drives.

• When the drives are installed in a cabinet, make sure to prevent recirculation of air.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 29

Operating Guide | VACON® 100 Wall-mounted Drives

5.3.3 Necessary Quantity of Cooling Air

Table 13: The Necessary Quantity of Cooling Air

Mounting

Enclosure size

MR4 45 26

MR5 75 44

MR6 190 112

MR7 185 109

MR8 335 197

MR9 620 365

The quantity of cooling air, m3/h

The quantity of cooling air, CFM

30 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A

B

C

e30bh206.10

U/T1

V/T2

W/T3

L1

L2

L3

DC-

DC+/R+

R-

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

6 Electrical Installation

6.1 Cable Connections

The mains cables are connected to terminals L1, L2, and L3. The motor cables are connected to terminals U, V, and W.

A The control panel

C The power unit

Illustration 8: Principal Connection Diagram

For EMC-compliant installation, see 6.2 EMC-compliant Installation.

6.1.1 General Cable Requirements

Use cables with a minimum heat resistance of +70 °C (158 °F). In the selection of the cables and the fuses, refer to the nominal output

current of the drive. Find the nominal output current on the nameplate.

For information on how to make the cable installation to comply with the UL standards, see 6.1.2 UL Standards on Cabling.

These instructions are valid only for processes that have 1 motor and 1 cable connection from the AC drive to the motor. In other

conditions, speak to the manufacturer to get more information.

B The control unit

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 31

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

6.1.2 UL Standards on Cabling

To comply with the UL (Underwriters Laboratories) regulations, use a UL-approved copper wire with a minimum heat resistance of

60 °C or 75 °C (140 °F or 167 °F).

To comply with the standards, use cables with +90 °C (194 °F) heat resistance for the 500 V drive.

Use Class 1 wire only.

When the drive has Class T and J fuses, it can be used on a circuit that gives a maximum of 100 000 rms symmetrical amperes, and a

maximum of 600 V.

The integral solid-state short-circuit protection does not give a branch circuit protection. Obey the National Electric Code and any

additional local codes to get the branch circuit protection. Only fuses give the branch circuit protection.

For the tightening torques of the terminals, see 10.5 Tightening Torques of the Terminals.

6.1.3 Cable Selection and Dimensioning

Find the typical sizes and types of cables used with the AC drive in the tables in 10.3.1 List of Cable and Fuse Size Information. In the

selection of cables, refer to local regulations, cable installation conditions, and cable specification.

The dimensions of the cables must comply with the requirements of the standard IEC60364-5-52.

• The cables must be PVC-isolated.

• The maximum ambient temperature is +30 °C.

• The maximum temperature of the cable surface is +70 °C.

• Use only cables with a concentric copper shield.

• The maximum number of parallel cables is 9.

When using parallel cables, make sure to obey the requirements of the cross-sectional area and the maximum number of cables.

For important information on the requirements of the grounding conductor, see

For the correction factors for each temperature, see the standard IEC60364-5-52.

6.3 Grounding.

6.1.4 Cable Selection and Dimensioning, North America

Find the typical sizes and types of cables used with the AC drive in the tables in 10.3.1 List of Cable and Fuse Size Information. In the

selection of cables, refer to local regulations, cable installation conditions, and cable specification.

The dimensions of the cables must comply with the requirements of the Underwriters Laboratories UL 61800-5-1.

• The cables must be PVC-isolated.

• The maximum ambient temperature is +86 °F.

• The maximum temperature of the cable surface is +158 °F.

• Use only cables with a concentric copper shield.

• The maximum number of parallel cables is 9.

When using parallel cables, make sure to obey the requirements of the cross-sectional area and the maximum number of cables.

For important information on the requirements of the grounding conductor, see the Underwriters Laboratories standard UL 61800-5-1.

32 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

For the correction factors for each temperature, see the instructions of the Underwriters Laboratories UL 61800-5-1.

Electrical Installation

6.1.5 Fuse Selection

We recommend the fuse type gG/gL (IEC 60269-1). To make a selection of the fuse voltage rating, refer to the mains. Refer also to local

regulations, cable installation conditions, and cable specification. Do not use larger fuses than what is recommended.

Find the recommended fuses in tables in 10.3.1 List of Cable and Fuse Size Information.

Make sure that the operation time of the fuse is less than 0.4 s. The operation time agrees with the fuse type and the impedance of the

supply circuit. For more information on faster fuses, speak to the manufacturer. The manufacturer can also recommend some aR (UL

recognized, IEC 60269-4) and gS (IEC 60269-4) fuse ranges.

6.1.6 Fuse Selection, North America

We recommend the fuse class T (UL & CSA). To make a selection of the fuse voltage rating, refer to the mains. Refer also to local

regulations, cable installation conditions, and cable specification. Do not use larger fuses than what is recommended.

Find the recommended fuses in tables in 10.3.1 List of Cable and Fuse Size Information.

Make sure that the operation time of the fuse is less than 0.4 s. The operation time agrees with the fuse type and the impedance of the

supply circuit. For more information on faster fuses, speak to the manufacturer. The manufacturer can also recommend some highspeed Class J (UL & CSA) and aR (UL recognised) fuse ranges.

The solid-state short circuit protection does not supply protection for the branch circuit of the AC drive. To supply the branch circuit

protection, refer to the National Electric Code and the local regulations. Do not use other devices than fuses to supply branch circuit

protection.

6.1.7 Brake Resistor Cables

VACON® 100 wall-mounted drives have terminals for an optional external brake resistor. These terminals are identified with R+ and R(in MR4) or DC+/R+ and R- (in MR5, MR6, MR7, MR8, and MR9). Find the dimensions that we recommend for the brake resistor cables in

the tables linked in 10.3.1 List of Cable and Fuse Size Information. See also the brake resistor ratings in 10.8.1 Brake Resistor Ratings.

CA UT IO N

SHOCK HAZARD FROM MULTI-CONDUCTOR CABLES

With a multi-conductor cable, the conductors that are not connected can cause an accidental contact with a conducting

component.

If a multi-conductor cable is used, cut off all conductors that are not connected.

-

The enclosure sizes MR7, MR8, and MR9 have the brake chopper only if their type code has the code +DBIN. The frames MR4, MR5, and

MR6 have the brake chopper as standard.

NO TI CE

The VACON® 100 FLOW and HVAC software do not have the dynamic braking or the brake resistor functions.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 33

A

C

B

e30bg079.10

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

6.2 EMC-compliant Installation

For cable selections in different EMC levels, see table 14.

To comply with the EMC levels, use a grommet when installing the motor cable at the two ends. For the EMC level C2, it is necessary to

have a 360º grounding of the shield with grommets in the motor end.

Table 14: Recommendations for Cables

Cable

type

Motor cable

Mains cable

Control

cable

1

st

1

environment

2

2nd environment

Category C2

(1)

A symmetrical power cable with a compact low-impe-

Category C3

A symmetrical power cable with a concentric protection wire.

(2)

Category C4

(2)

dance shield.

A cable for the specified mains voltage.

A cable for the specified mains voltage.

We recommend an MCMK cable. See illustration 9.

We recommend an MCCMK, or an EMCMK cable. See

illustration 9.

We recommend that the cable transfer impedance

(1–30 MHz) is a maximum of 100 mΩ/m.

A power cable for a fixed installation.

A cable for the specified mains voltage.

A shielded cable is not necessary.

We recommend an MCMK cable.

A shielded cable with a compact low-impedance shield, for example a JAMAK, or an SAB/ÖZCuY-O cable.

For the definitions of EMC protection levels, see IEC/EN 61800-3 + A1.

A The PE conductor and the shield

C The shield

Illustration 9: Cables with PE Conductors

B The PE conductors

34 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

In all the enclosure sizes, to comply with the EMC standards, use the default values of the switching frequencies.

If installing a safety switch, make sure that the EMC protection continues from the start of the cables until their ends.

Electrical Installation

The drive must obey the standard IEC 61000-3-12. To obey it, the short circuit power SSC must be a minimum of 120 R

interface point between mains and the public mains. Make sure to connect the drive and the motor to mains with a short circuit power

SSC that is a minimum of 120 R

. If necessary, contact the mains operator.

SCE

SCE

at the

6.2.1 Installation in a Corner-grounded Network

Corner grounding can be used in these conditions:

• Enclosure sizes MR4-MR6 with mains voltage 208–240 V up to 2000 m

• Enclosure sizes MR7-MR9 with a rating of 75–310 A and with mains voltage 208–240 V

Enclosure sizes MR7-MR9 with a rating of 72–385 A and with mains voltage 380–500 V

Do not use corner grounding in these conditions:

• Enclosure sizes MR4-MR6 with a rating of 3.4–61 A and with mains voltage 380–500 V

• Drives with mains voltage 525–600 V or 525–690 V

When using corner grounding, the drive must have EMC protection level C4. To change the EMC protection level from C2 or C3 to C4,

see instructions in 6.6 Installation in an IT System.

6.3 Grounding

Ground the AC drive in accordance with applicable standards and directives.

CA UT IO N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Make sure that the AC drive is always grounded with a grounding conductor that is connected to the grounding terminal

-

that is identified with the PE symbol.

WA RN IN G

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

The standard EN 61800-5-1 tells that 1 or more of these conditions for the protective circuit must be true.

The connection must be fixed.

• The protective earthing conductor must have a cross-sectional area of minimum 10 mm2 Cu or 16 mm2 Al. OR

• There must be an automatic disconnection of the mains, if the protective earthing conductor breaks. OR

• There must be a terminal for a second protective earthing conductor in the same cross-sectional area as the first protective

earthing conductor.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 35

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

Cross-sectional area of the phase conductors (S) [mm2]

S ≤ 16 S

16 < S ≤ 35 16

35 < S S/2

The values of the table are valid only if the protective earthing conductor is made of the same metal as the phase conductors. If this is

not so, the cross-sectional area of the protective earthing conductor must be determined in a manner that produces a conductance

equivalent to that which results from the application of this table.

The cross-sectional area of each protective earthing conductor that is not a part of the mains cable or the cable enclosure, must be a

minimum of:

• 2.5 mm2 if there is mechanical protection, and

• 4 mm2 if there is not mechanical protection. With cord-connected equipment, make sure that the protective earthing conductor in

the cord is the last conductor to be interrupted, if the strain-relief mechanism breaks.

Obey the local regulations on the minimum size of the protective earthing conductor.

The minimum cross-sectional area of the protective earthing

conductor in question [mm2]

NO TI CE

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not

operate correctly.

NO TI CE

VOLTAGE WITHSTAND TESTS

Doing voltage withstand tests can damage the drive.

Do not do voltage withstand tests on the AC drive. The manufacturer has already done the tests.

-

WA RN IN G

SHOCK HAZARD FROM PE CONDUCTOR

The drive can cause a DC current in the PE conductor. Failure to use a residual current-operated protective (RCD) device Type B

or a residual current-operated monitoring (RCM) device can lead to the RCD not providing the intended protection and

therefore can result in death or serious injury.

Use a type B RCD or RCM device on the mains side of the drive.

-

6.4 Get Access and Locate the Terminals

6.4.1 Get Access and Locate the Terminals for MR4-MR7

Context:

Follow these instructions to open the AC drive for installing the cables, for example.

36 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

M4x55

e30bh222.10

M4x8

e30bh223.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Open the cover of the AC drive.

2. Remove the screws of the cable cover. Remove the cable cover. Do not open the cover of the power unit.

Electrical Installation

3. Locate the terminals.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 37

A B C

e30bh286.10

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

A Mains terminals

C Motor terminals

Illustration 10: Locating the Terminals, MR4-MR7

B Brake resistor terminals

6.4.2 Get Access and Locate the Terminals for MR8

Context:

Follow these instructions to open the AC drive for installing the cables, for example.

38 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bh251.10

M4x8

e30bh252.10

M4x8

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Open the cover of the AC drive.

2. Remove the cable cover.

Electrical Installation

3. Remove the cable entry plate.

4. Remove the EMC shield plate.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 39

M5

M4x8

A

e30bh253.10

L1

U V W

L2 L3 DC-

DC+

R+

R-

e30bh254.10

Operating Guide | VACON® 100 Wall-mounted Drives

A The wing nut

Electrical Installation

Illustration 11: Removing the EMC Shield Plate, MR8

5. Find the motor terminals. The location of the terminals is different than usually, especially in MR8.

6.4.3 Get Access and Locate the Terminals for MR9

Context:

Follow these instructions to open the AC drive for installing the cables, for example.

40 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

M4x10

e30bh244.10

M4x8

e30bh245.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Open the cover of the AC drive.

Electrical Installation

2. Remove the cable cover.

3. Remove the cable entry plate.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 41

e30bh246.10

M5x10

e30bh247.10

M4x8

Operating Guide | VACON® 100 Wall-mounted Drives

4. Loosen the screws and remove the sealing plate.

Electrical Installation

5. Remove the EMC shield plate.

42 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bh248.10

L1

U V W

L2

L3 DC-

DC+

R+

R-

e30bh249.10

Operating Guide | VACON® 100 Wall-mounted Drives

6. Find the motor terminals. The location of the terminals is different than usually, especially in MR8.

Electrical Installation

6.5 Installation of Cables

6.5.1 Additional Instructions for Cable Installation

• Before starting, make sure that none of the components of the AC drive is live. Read carefully the warnings in Safety section.

• Make sure that the motor cables are sufficiently far from other cables.

• The motor cables must go across other cables at an angle of 90°.

• If it is possible, do not put the motor cables in long parallel lines with other cables.

• If the motor cables are in parallel with other cables, obey the minimum distances (see table 15).

• The distances are also valid between the motor cables and the signal cables of other systems.

• The maximum lengths of shielded motor cables are 100 m/328 ft (for MR4), 150 m/492 ft (for MR5 and MR6), and 200 m/656 ft (for

MR7, MR8, and MR9).

• If the cable insulation checks are necessary, see

Table 15: Minimum Distances between Cables

The distance between cables [m]

0.3 ≤ 50 1.0 ≤ 164.0

1.0 ≤ 300 3.3 ≤ 656.1

The length of the shielded cable

[m]

8.3 Measuring the Cable and Motor Insulation.

The distance between cables [ft]

The length of the shielded cable

[ft]

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 43

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

6.5.2 Installing the Cables, MR4-MR7

Context:

Follow these instructions to install the cables and cable accessories. For information on how to comply with the UL regulations in cable

installation, see 6.1.2 UL Standards on Cabling.

Prerequisites:

Make sure that the delivery contains all necessary components. For the installation, the contents of the accessories bag is needed, see

4.2 Accessories.

Open the covers according to instructions in 6.4.1 Get Access and Locate the Terminals for MR4-MR7.

44 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A B C

e30bh224.10

e30bg086.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Strip the motor cable, the mains cable, and the brake resistor cable. See 10.4 Cable Stripping Lengths.

The VACON® 100 FLOW and HVAC software do not have the dynamic braking or the brake resistor functions.

2. Put the grommets in the openings of the cable entry plate. These parts are included in the package.

3. Put the cables in the openings of the cable entry plate.

4. Cut the grommets open to move the cables through them.

A Do not cut the grommet openings wider than what is necessary for the used cables.

B If the grommets fold in when putting the cable, pull the cable back to make the grommets straight.

Electrical Installation

A The mains cable

B The brake cable

C The motor cable

Illustration 12: Installing Cables through Grommets

5. With the protection rating IP54, the connection between the grommet and the cable must be tight. Pull the first bit of the cable out

of the grommet so that is stays straight. If this is not possible, make the connection tight with some insulation tape or a cable tie.

6. Remove the grounding clamps for cable shield and the grounding clamps for grounding conductor. The tightening torque is 2.2

Nm or 19.5 lb-in.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 45

M4x16

(2.2 Nm)

e30bh225.10

e30bh226.10

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

7. Put the cable entry plate with the cables into the groove on the frame of the drive.

8. Connect the cables. See the correct tightening torques in 10.5 Tightening Torques of the Terminals.

A Expose the shield of all the 3 cables to make a 360-degree connection with the grounding clamps for cable shield.

B Connect the phase conductors of the mains cable and of the motor cable, and the conductors of the brake resistor cable into

the correct terminals.

C Attach the grounding conductor of each cable to a grounding terminal with a grounding clamp for grounding conductor.

D Make sure that the external grounding conductor is connected to the grounding bar. See

6.3 Grounding.

46 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

C

D

F

C

B

A

e30bh227.10

E

e30bh228.10

= M5; 2 Nm

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

A The grounding clamp for cable shield

C The grounding terminal

E The brake resistor cable

Illustration 13: Connecting the Stripped Cables

B The terminals

D The mains cable

F The motor cable

9. Make sure that the grounding conductor is connected to the motor and also to the terminals that are identified with the PE symbol.

A To comply with the requirements of the standard EN 61800-5-1, obey the instructions in 6.3 Grounding.

B If a double grounding is necessary, use the grounding terminal under the drive. Use an M5 screw and tighten it to 2.0 Nm or

17.7 lb-in.

10. Attach again the cable cover.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 47

e30bh229.10

e30bh230.10

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

11. Close the cover of the drive.

6.5.3 Installing the Cables, MR8-MR9

Context:

Follow these instructions to install the cables and cable accessories. For information on how to comply with the UL regulations in cable

installation, see 6.1.2 UL Standards on Cabling.

Prerequisites:

Make sure that the delivery contains all necessary components. For the installation, the contents of the accessories bag is needed, see

4.2 Accessories.

Open the covers according to instructions in 6.4.2 Get Access and Locate the Terminals for MR8 and 6.4.3 Get Access and Locate the

Terminals for MR9.

48 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bh277.10

e30bh278.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Strip the motor cable, the mains cable, and the brake resistor cable. See 10.4 Cable Stripping Lengths.

The VACON® 100 FLOW and HVAC software do not have the dynamic braking or the brake resistor functions.

2. Cut the grommets open to move the cables through them.

A Do not cut the grommet openings wider than what is necessary for the used cables.

B If the grommets fold in when putting the cable, pull the cable back to make the grommets straight.

Electrical Installation

3. Attach the grommet and the cable so that the frame of the drive goes into the groove of the grommet.

A With the protection rating IP54 (UL Type 12), the connection between the grommet and the cable must be tight. Pull the first

bit of the cable out of the grommet so that it stays straight.

B If this is not possible, make the connection tight with some insulation tape or a cable tie.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 49

e30bh279.10

e30bh280.10

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

4. If thick cables are used, put the cable insulators in between the terminals to prevent contact between the cables.

5. Connect the cables. See the correct tightening torques in 10.5 Tightening Torques of the Terminals.

A Connect the phase conductors of the mains cable and of the motor cable into the correct terminals. If a brake resistor cable is

used, connect its conductors into the correct terminals.

B Attach the grounding conductor of each cable to a grounding terminal with a grounding clamp for grounding conductor.

C Make sure that the external grounding conductor is connected to the grounding bar. See

6.3 Grounding.

50 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A

e30bh255.10

A

e30bh250.10

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

A The grounding connection

Illustration 14: Connecting the Cables, MR8

A The grounding connection

Illustration 15: Connecting the Cables, MR9

6. If many cables are used on one connector, put the cable lugs on top of each other.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 51

A

C

B

e30bh281.10

e30bh282.10

Operating Guide | VACON® 100 Wall-mounted Drives

7. Expose the shield of all 3 cables to make a 360° connection with the grounding clamp for cable shield.

Electrical Installation

8. Make sure that the grounding conductor is connected to the motor and also to the terminals that are identified with the PE symbol.

A To comply with the requirements of the standard EN 61800-5-1, obey the instructions in 6.3 Grounding.

B Connect the protective conductor to one of the screw connectors with a cable shoe and an M8 screw.

52 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bh285.10

Operating Guide | VACON® 100 Wall-mounted Drives

9. For MR8, attach the EMC shield plate, the cable entry plate, and the cable cover.

10. For MR9, attach the EMC shield plate, the sealing plate, the cable entry plate, and the cable cover.

11. Close the cover of the drive.

Electrical Installation

6.6 Installation in an IT System

If your mains is impedance-grounded (IT), the AC drive must have the EMC protection level C4. If the drive has the EMC protection level

C2 or C3, it is necessary to change it to C4. To do this, remove the EMC jumpers.

WA RN IN G

SHOCK HAZARD FROM THE COMPONENTS

The components of the drive are live when the drive is connected to mains.

Do not make changes in the AC drive when it is connected to mains.

-

NO TI CE

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

NO TI CE

For a 600 and 690V product that is configured for a C4 installation on IT network, the maximum switching frequency is limited

to the default 2 kHz.

6.6.1 Installing the AC drive in an IT System, MR4-MR6

Context:

Use these instructions to change the EMC protection of the AC drive to level C4.

Prerequisites:

Open the cover of the AC drive (for MR4-MR6) and remove the cable cover (for MR4-MR5) as instructed in

the Terminals for MR4-MR7.

6.4.1 Get Access and Locate

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 53

e30bh297.10

MR4 MR5

e30bh299.10

MR6, 200–500 V

MR6, 600/690 V

e30bh301.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Find the EMC jumpers that connect the RFI filters to ground.

Electrical Installation

2. To disconnect the RFI filters from ground, remove the EMC jumpers. Pull the EMC jumper out with the tool.

54 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

3. For MR4 and MR5, attach the cable cover.

4. Close the cover of the AC drive.

5. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

6.6.2 Installing the AC drive in an IT System, MR7

Context:

Use these instructions to change the EMC protection of the AC drive to level C4.

Prerequisites:

Open the cover of the AC drive and remove the cable cover (for 600/690 V) as instructed in

for MR4-MR7.

6.4.1 Get Access and Locate the Terminals

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 55

e30bh302.10

e30bh303.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure for 200–500 V

1. Find the EMC box. To get access to the EMC jumper, remove the cover of the EMC box.

2. Remove the EMC jumper. Attach the cover of the EMC box again.

Electrical Installation

3. Find the DC grounding busbar between the terminals R- and U. To remove the busbar from the frame, remove the M4 screw.

56 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

L1

L2 L3

DC-

R-

DC+

R+

U

V

W

T1

T2 T3

e30bh304.10

e30bg773.10

Product modified

Date:

Date:

Date:

e30bh306.10

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

4. Close the cover of the AC drive.

5. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

Procedure for 600/690 V

1. Remove the EMC jumper.

2. Attach the cable cover.

3. Close the cover of the AC drive.

4. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 57

Operating Guide | VACON® 100 Wall-mounted Drives

6.6.3 Installing the AC drive in an IT System, MR8

Context:

Use these instructions to change the EMC protection of the AC drive to level C4.

Prerequisites:

Open the cover of the AC drive and remove the cable cover as instructed in

6.4.2 Get Access and Locate the Terminals for MR8.

Electrical Installation

58 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A

e30bh307.10

A

B

e30bh308.10

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure

1. Find the EMC box. To get access to the EMC jumper, remove the cover of the EMC box.

A The EMC jumper

Illustration 16: Removing the EMC Box Cover, MR8

2. Remove the EMC jumper. Attach the cover of the EMC box again.

3. Find the grounding arm and push it down.

Electrical Installation

A The grounding arm is up B The grounding arm is down (level C4)

Illustration 17: Finding the Grounding Arm, MR8

4. Attach the cable cover.

5. Close the cover of the AC drive.

6. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 59

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

6.6.4 Installing the AC drive in an IT System, MR9

Context:

Use these instructions to change the EMC protection of the AC drive to level C4.

Prerequisites:

Open the cover of the AC drive as instructed in

6.4.3 Get Access and Locate the Terminals for MR9.

Electrical Installation

60 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

e30bh375.10

e30bh376.10

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

Procedure for EMC Jumper 1, MR9A

1. Remove the cover of the fan.

2. In IP54, also remove the fan.

3. Loosen the screws of the cover plate and remove it.

4. Find the place of the jumper behind the fan. Remove the EMC jumper.

Electrical Installation

5. Attach the cover plate.

6. In IP54, attach the fan.

7. Attach the cover of the fan.

8. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 61

e30bh377.10

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

Procedure for EMC Jumper 1, MR9B

1. Remove the EMC jumper.

2. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

62 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

A

e30bh378.10

e30bg773.10

Product modified

Date:

Date:

Date:

Operating Guide | VACON® 100 Wall-mounted Drives

Electrical Installation

Procedure for EMC Jumpers 2 + 3, MR9A and MR9B

1. Remove the cover of the extension box, the touch shield, and the I/O plate with the I/O grommet plate.

2. Find the 2 EMC jumpers on the EMC board. They are not next to each other. Remove the EMC jumpers.

A The EMC jumpers

Illustration 18: EMC Jumpers 2 and 3, MR9A and MR9B

3. Attach the I/O plate with the I/O grommet plate, the touch shield, and the cover of the extension box.

4. Close the cover of the AC drive.

5. After the change, write "The EMC level was changed" and the date on the "product modified" label. If the label is not yet attached,

attach it on the drive near the nameplate.

6.7 Installation in a Marine Environment

When you install the AC drive in a marine environment, see the Marine Installation Guide.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 63

STO JMP

L

I

M

K

H

G

F

J

E

D

A

B

C

e30bh331.10

Operating Guide | VACON® 100 Wall-mounted Drives

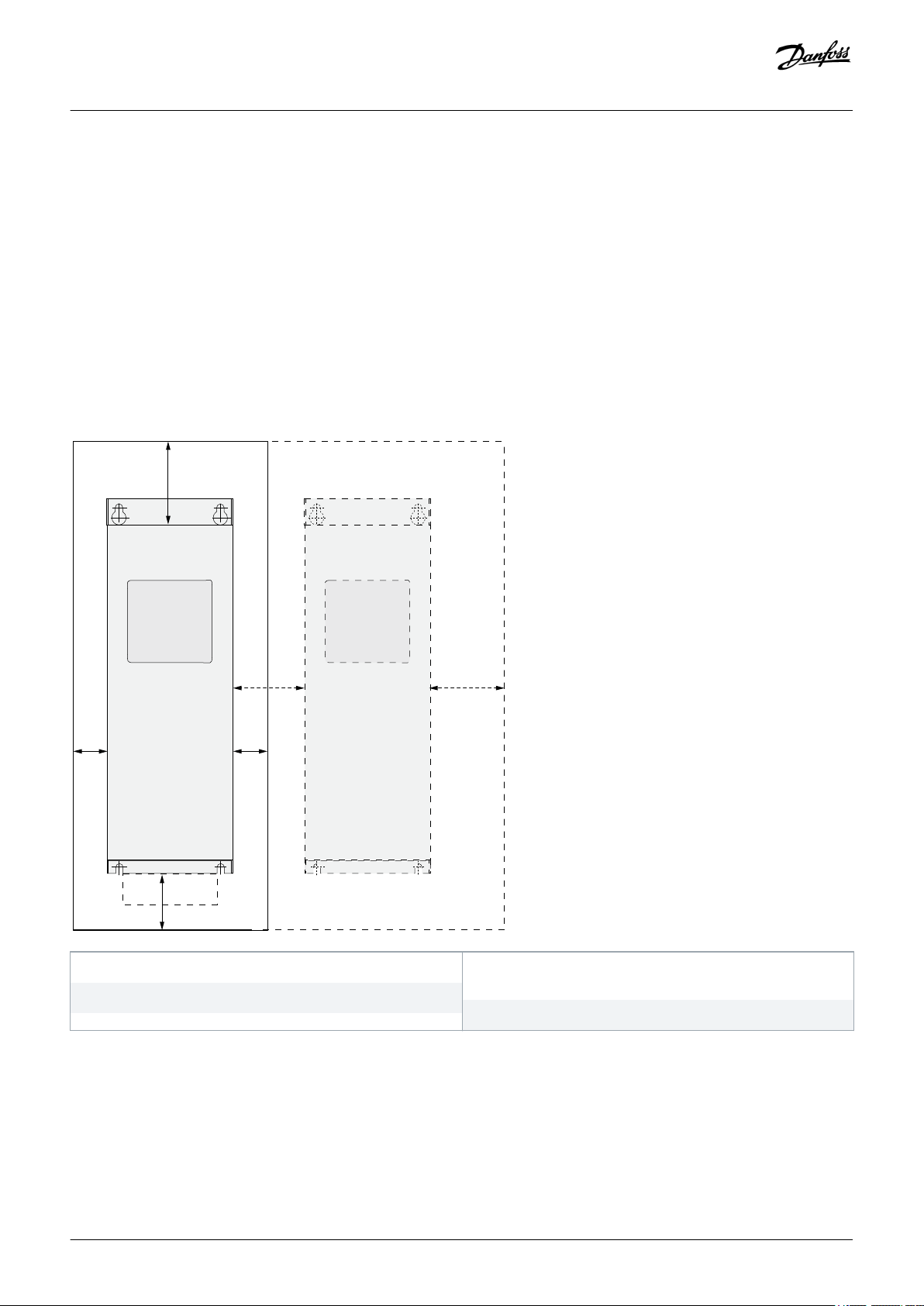

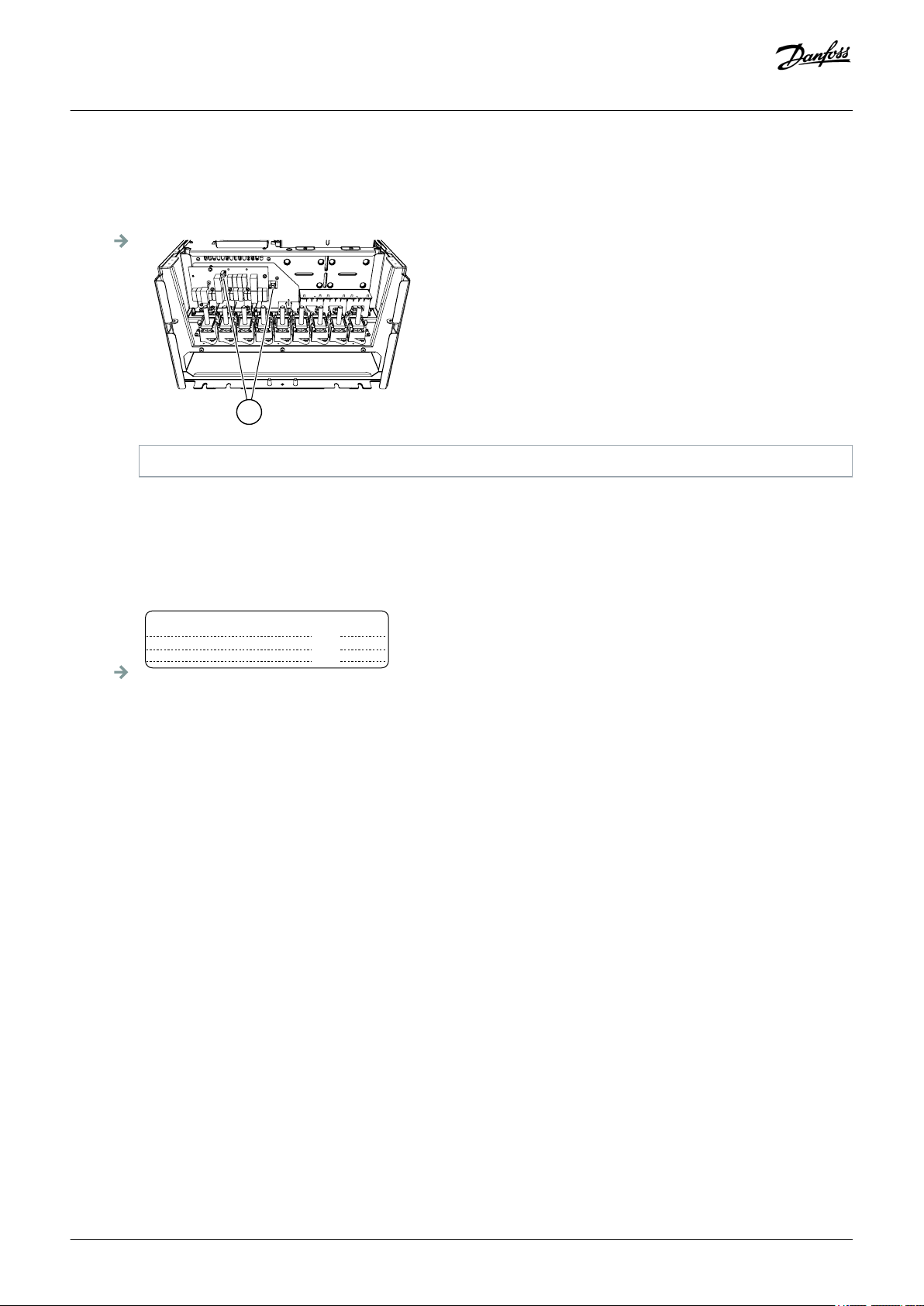

7 Control Unit

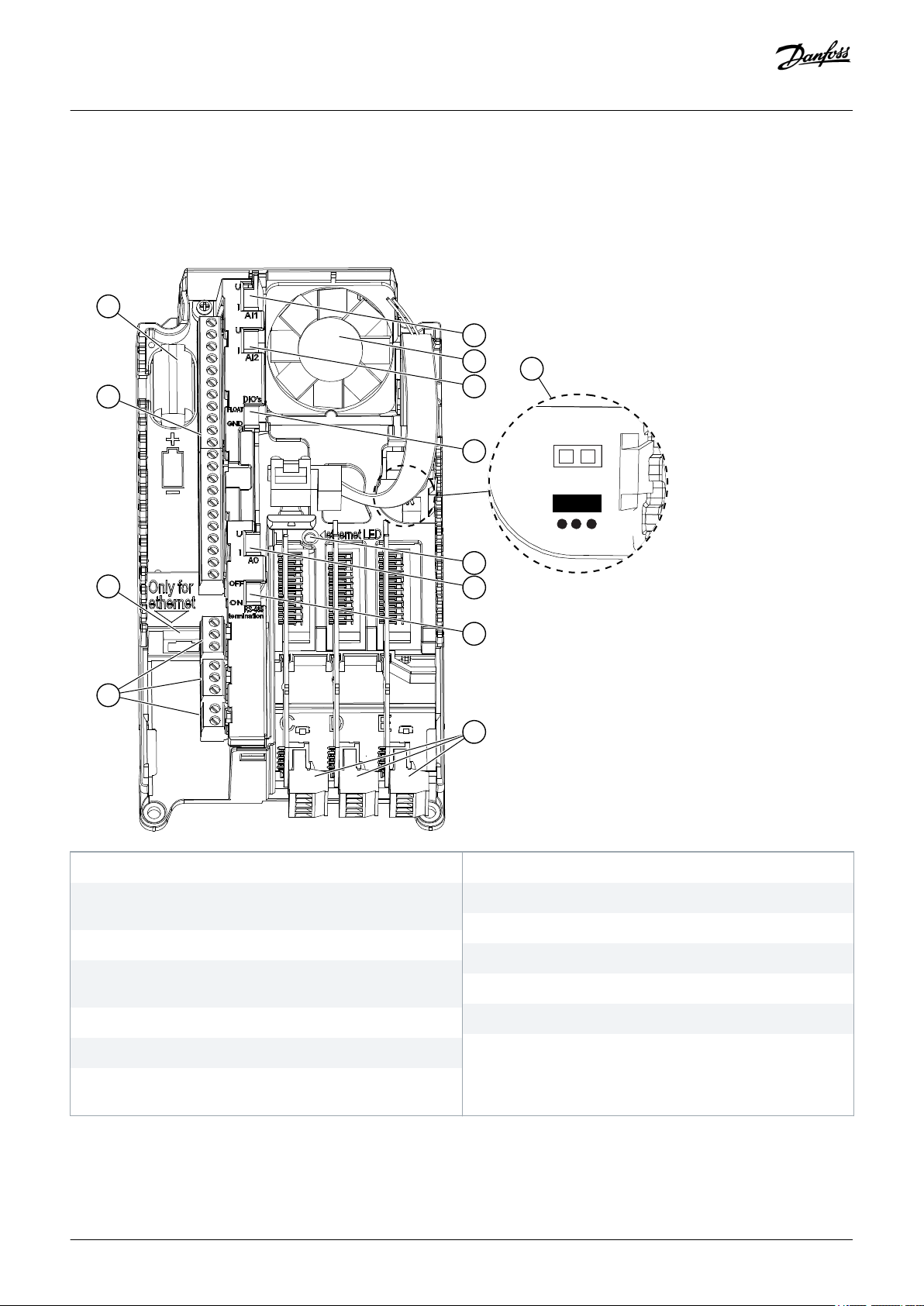

7.1 Control Unit Components

Control Unit

A The control terminals for the standard I/O connections

C The relay board terminals for 3 relay outputs or 2 relay

outputs and a thermistor

E A DIP switch for the RS485 bus termination

G A DIP switch for the isolation of the digital inputs from

ground

I A DIP switch for the signal selection of Analog Input 1

K A fan (only in IP54 of MR4 and of MR5)

M The location and the default position of the Safe Torque Off

(STO) jumper

Illustration 19: Components of the Control Unit

B The Ethernet connection

D The option boards

F A DIP switch for the signal selection of Analog Output

H A DIP switch for the signal selection of Analog Input 2

J The status indicator of the Ethernet connection

L The battery for the RTC

64 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

Operating Guide | VACON® 100 Wall-mounted Drives

On delivery of the AC drive, the control unit contains the default control interface (graphical keypad). If special options were selected in

the order, the option boards are included loose in the delivery. On the next pages, there is information on the terminals and general

wiring examples.

It is possible to use the drive with an external power source with these properties: +24 V DC ±10%, minimum 1000 mA. Connect the

external power source to terminal 30. This voltage is sufficient to keep the control unit on and for setting the parameters. The

measurements of the main circuit (for example, the DC-link voltage, and the unit temperature) are not available when the drive is not

connected to mains.

The status indicator on the control unit shows the status of the drive. The status indicator is located in the control panel, below the

keypad, and it can show five different statuses.

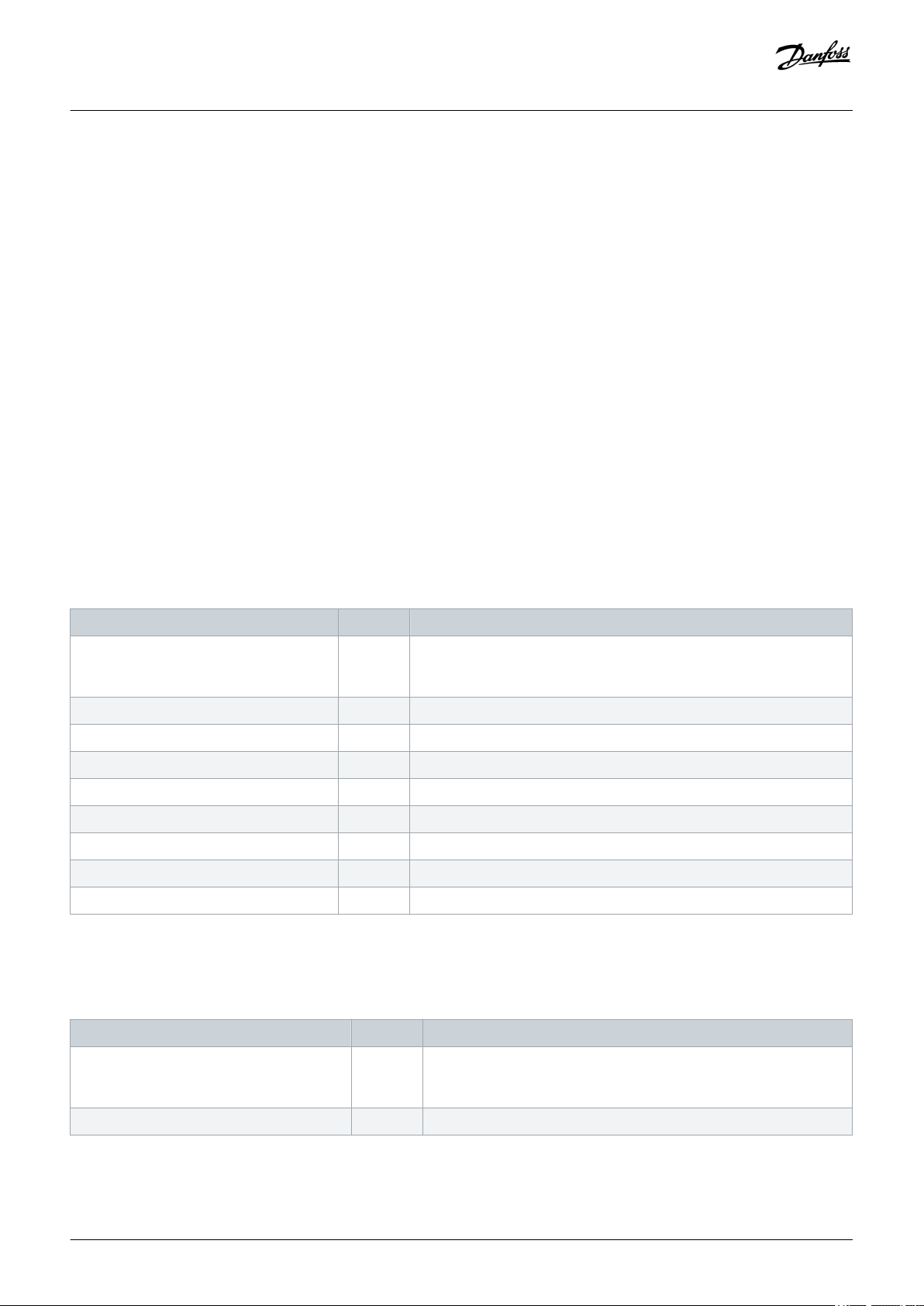

Table 16: Control Unit LED Status Definitions

Color/status of the LED Status of the drive

Blinking slowly Ready

Green Run

Red Fault

Orange Alarm

Control Unit

Blinking fast Downloading software

7.2 Control Unit Cabling

7.2.1 Selection of the Control Cables

NO TI CE

CABLE SELECTION

Obey regional low-voltage standards in the cable selection.

The control cables must be a minimum of 0.5 mm2 (AWG20) multi-core shielded cables. The terminal wires must be a maximum of 2.5

mm2 (AWG13) for the relay board terminals and other terminals.

Table 17: The Tightening Torques of the Control Cables

Terminal Terminal screw size Tightening torque

(Nm)

All the terminals of the I/O board and the relay board M3 0.5 4.5

Tightening torque (lb-in)

7.2.2 Control Unit Terminals

Here is the basic description of the terminals of the default I/O and relay board. The standard I/O board has 22 fixed control terminals

and 8 relay board terminals.

Some terminals are assigned for signals that have optional functions that can be used with the DIP switches. For more information, see

7.3 DIP Switches on the Control Unit.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 65

e30bh417.10

RUN

FAULT

READY

*)

*)

Reference output

+10 Vref

Terminal

Standard I/O board

Signal

1

24V auxiliary voltage

24Vout6

Analog input,

voltage or current

Reference

potentiometer

1...10kΩ

Actual value

2-wire transmitter

I = (0)4...20mA

AI1+2

Analog input

common, (current)

AI1-3

Analog input,

voltage or current

AI2+4

Analog input

common, (current)

AI2-5

Analog signal

(+output)

AO1+

RUN

18

Analog output

common / I/O ground

AO1-/GND19

24V auxiliary

input voltage

+24Vin

30

24V auxiliary voltage

24Vout

12

I/O ground

GND7

I/O ground

GND13

Digital input 1

DI18

Digital input 2

DI29

Digital input 3

DI310

Digital input 4

DI414

Digital input 5

DI515

Digital input 6

DI616

Relay output 1

RO1 NC21

22

RO1 CM

RO1 NO23

Common for DI1-DI6

CM11

Common for DI1-DI6

CM

17

Serial bus, negative

RS485A

Serial bus, positive

RS485

B

Relay output 2

Relay output 3

RO2 NC24

25

RO2 CM

RO2 NO26

32

RO3 CM

RO3 NO33

Description

Frequency reference

Frequency reference

Start forward

Start reverse

External fault

DI4

DI5

Freq. ref.

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Analog input 1

Preset Freq. 1

Preset Freq. 2

Preset Freq. 3

Fault reset

Output frequency

Modbus RTU

BACnet, N2

mA

Operating Guide | VACON® 100 Wall-mounted Drives

Control Unit

Illustration 20: The Signals of the Control Terminals on the Default I/O Board and the Default Control Connections

66 | Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711

RO1 NC

RO1 CM

RO1 NO

RO2 NC

RO2 CM

RO2 NO

RO3 CM

RO3 NO

21

22

23

24

25

26

32

33

e30bh329.10

RUN

RUN

FAULT

READY

Relay output 1

Relay output 2

Relay output 3

From Standard I/O board

Terminal Signal

Default

Relay board 1

From term. #6

or 12

From term.

#13

RO1 NC

RO1 CM

RO1 NO

RO2 NC

RO2 CM

RO2 NO

TI1+

TI1-

21

22

23

24

25

26

28

29

e30bh330.10

RUN

RUN

FAULT

NO ACTION

Relay output 1

Relay output 2

From Standard I/O board

Terminal Signal

Default

Relay board 2

From term.

#12

From term.

#13

Thermistor input

Operating Guide | VACON® 100 Wall-mounted Drives

*) You can isolate digital inputs from ground with a DIP switch. See 7.3.2 Isolation of the Digital Inputs from Ground.

There are 2 different relay boards available. If you include the optional code +SBF4 in your order, the relay output 3 is replaced with a

thermistor input.

The thermistor input function is not automatically active. To use the thermistor input function, activate the parameter Thermistor Fault

in the software. See the Application Guide.

Control Unit

Illustration 21: Standard Relay Board (+SBF3)

Illustration 22: Optional Relay Board (+SBF4)

7.3 DIP Switches on the Control Unit

7.3.1 Selection of Terminal Functions with DIP Switches

Two selections for specified terminals can be done with the DIP switches. The switches have two positions: up and down. See the

location of the DIP switches and the possible selections in illustration 23.

Danfoss A/S © 2019.05

AQ298036140958en-000101 / DPD01711| 67

A B

A

B

C

D

E

AI1

U

I

AO1

U

I

RS485

OFF

ON