Page 1

Operating Guide

VACON® 1000

drives.danfoss.com

Page 2

Page 3

VACON® 1000

Operating Guide

Contents

1

Introduction 8

1.1

Purpose of this Operating Guide 8

Additional Resources 8

1.2

Manual Version 8

1.3

1.4

Disposal 8

2

Safety 9

2.1

Safety Symbols 9

2.2

Qualified Personnel 9

2.3

Danger and Warnings 9

2.4

Cautions and Notices 10

Product Overview 13

3

Product Characteristics 13

3.1

Contents

3.2

Applications 13

3.3

System Hardware 14

3.3.1

Control Cabinet 15

3.3.1.1

3.3.2

Power Cell Cabinet 18

3.3.3

Transformer Cabinet 20

3.3.4

Junction Cabinet 21

3.3.5

Start-up Cabinet 21

3.3.6

Output Filter Cabinet 23

3.3.7

Bypass Cabinet 24

3.3.7.1

3.3.7.2

3.3.7.3

3.4

System Operation 29

3.4.1

Main Circuit 29

3.4.2

Power Cells 30

Controls and Indicators 17

Manual Bypass Cabinet 24

Automatic Bypass Cabinet 25

Synchronous Transfer Cabinet 28

3.4.3

Control System 31

3.5

Type Code Description 33

3.6

Available Options 34

3.6.1

Cabinet Bypass 36

3.6.2

Input Devices 36

3.6.3

Output Devices 37

3.6.4

Mechanical Options 37

AQ363633621020en-000201/172F3117 | 3Danfoss A/S © 2021.06

Page 4

VACON® 1000

Operating Guide

3.7

VACON® 1000 PC Tool 37

4

Receiving the Delivery 38

4.1

Checking the Delivery 38

4.2

Storage 38

4.3

Lifting and Moving the Drive 38

4.3.1

Lifting the Standalone Cabinets 38

4.3.2

Lifting the Line-up Cabinets 40

4.3.3

Using a Forklift 40

5

Mechanical Installation 42

5.1

Operating Environment 42

5.2

Cabinet Installation 42

5.2.1

Attaching the Cabinets 42

5.2.2

Mounting the Cabinets 44

Contents

5.3

Installing the Power Cells 44

5.4

Dimensions of the Enclosed Drive 45

5.5

Cooling and Free Space Around the Enclosed Drive 45

5.5.1

Air Ducting Guidelines 46

6

Electrical Installation 47

6.1

The Main Circuit 47

6.2

Main Circuit Breaker and Fuses 47

6.3

Galvanic Isolation Between the MV and LV Sections 47

6.4

Terminals 47

6.4.1

Terminal Locations in the Standalone Cabinet 47

6.4.2

Terminal Locations in the Line-up Cabinet 48

6.5

Cable Entry and Termination 49

6.5.1

Power Cable Entry of Standalone Cabinet 49

6.5.2

Power Cable Entry of Line-up Cabinet 50

6.5.3

Power Cable Termination 51

6.5.4

Control Cable Entry 51

6.6

Grounding 53

6.7

Power Cable Selection 53

6.8

Additional Instructions for Cable Installation 54

6.9

Control Wiring 54

6.9.1

Control Cable Selection 54

6.9.2

Control Power Wiring 54

6.9.3

Control Circuit Wiring 55

AQ363633621020en-000201/172F31174 | Danfoss A/S © 2021.06

Page 5

VACON® 1000

Operating Guide

6.9.4

Application Wiring Example 59

6.9.5

PLC Configuration 60

6.9.5.1

6.9.5.2

7

Human-Machine Interface 63

7.1

The VACON® 1000 HMI 63

7.2

HMI Homepage 63

7.2.1

System Status 63

7.2.2

Dashboard 64

7.2.3

Single-line Diagram 64

7.3

Control Panel 64

7.4

Status 65

7.4.1

Power Cell 65

7.4.2

Cooling Fan 65

PLC Basic Configuration 60

Options and Customized Designs 61

Contents

7.5

Graphs & Reports 65

7.6

Setup & Service 66

7.6.1

Operation Mode 67

7.6.2

Motor Parameter 67

7.6.3

Functions 68

7.6.4

Protections 68

7.6.5

PID Setup 68

7.6.6

System Configuration 69

7.7

Events 69

7.7.1

Warning & Fault 69

7.7.2

Event Log 70

7.8

Administration 71

7.9

Tool Settings 72

7.9.1

Language 72

7.9.2

Software Version 72

7.9.3

HMI Set 72

8

Commissioning 74

8.1

Safety Checks before Starting the Commissioning 74

8.2

Personnel Requirements 74

8.3

Commissioning Checks 74

8.4

Commissioning Report 76

8.5

Operating the Drive 76

8.5.1

Powering the Drive 76

AQ363633621020en-000201/172F3117 | 5Danfoss A/S © 2021.06

Page 6

VACON® 1000

Operating Guide

8.5.2

Starting the Drive 76

8.5.3

Stopping the Drive 77

8.5.4

Powering Off the Drive 77

8.6

Interlocking System 78

8.6.1

Electromagnetic Interlocking System 78

8.6.2

Mechanical Interlocking System 78

9

Maintenance 79

9.1

Safety 79

9.2

Standard Maintenance Process 80

9.3

Maintenance Schedule 80

9.3.1

Daily Maintenance 80

9.3.2

Yearly Maintenance 81

9.4

Replacing the Air Filters 82

9.4.1

Air Filters of Standalone Cabinets 82

Contents

9.4.2

Air Filters of Transformer and Power Cell Cabinets 83

9.4.3

Air Filters of Control Cabinet 84

9.5

Replacing the HMI Battery 84

9.6

Replacing the Cooling Fans 85

9.6.1

Diagram of the Cooling Fan Replacement 86

9.7

UPS Battery 86

9.7.1

Replacing the UPS Battery 86

9.7.2

UPS Battery Maintenance 86

9.8

Power Cells 87

9.8.1

Power Cell Maintenance 87

9.8.2

Replacing the Power Cells 88

9.8.2.1

9.8.3

Reforming the Power Cell Capacitors 90

9.8.3.1

9.8.3.2

9.9

Dielectric Withstand Test 91

Diagram of the Power Cell Replacement 89

Reforming with an AC Supply 90

Reforming with a DC Supply 91

9.9.1

Testing Input and Output Together 92

9.9.2

Testing Input and Output Separately 92

10

Fault Tracing 94

10.1

Fault Types 94

10.2

Fault Response Configuration 94

10.3

Faults and Alarms 94

AQ363633621020en-000201/172F31176 | Danfoss A/S © 2021.06

Page 7

VACON® 1000

Operating Guide

11

Specifications 108

Technical Data 108

11.1

11.2

Power Ratings and Dimensions 111

IEC Ratings 111

11.2.1

11.2.2

UL Ratings 119

11.3

Internal Cables and Terminals 133

11.4

Replacement Fuses 135

11.5

Standards 136

11.6

Abbreviations 140

Contents

AQ363633621020en-000201/172F3117 | 7Danfoss A/S © 2021.06

Page 8

Version

Release date

Remarks

B

29.06.2021

Updates to dimensions and weights

VACON® 1000

Operating Guide

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This Operating Guide provides information for safe installation and commissioning of the AC drive. It is intended for use by qualified

personnel.

Read and follow the instructions to use the drive safely and professionally.

Pay particular attention to the safety instructions and general warnings. Always keep this Operating Guide with the drive.

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

Other resources are available to understand advanced AC drive functions, programming, and options.

•

The VACON® 1000 Application Guide provides greater detail on how to work with the application and how to set the parameters of the AC drive.

•

User guides for product options.

Supplementary publications and manuals are available from Danfoss. See

1.3 Manual Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

www.danfoss.com for listings.

Table 1: VACON® 1000 Operating Guide Version

1.4 Disposal

Do not dispose of equipment containing electrical components together with domestic waste. Collect it separately in accordance

with local and currently valid legislation.

AQ363633621020en-000201 / 172F31178 | Danfoss A/S © 2021.06

Page 9

VACON® 1000

Operating Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

D A N G E R

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

W A R N I N G

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

C A U T I O N

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

N O T I C E

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

Safety

2.2 Qualified Personnel

To allow trouble-free and safe operation of the unit, only qualified personnel with proven skills are allowed to transport, store, assemble, install, program, commission, maintain, and decommission this equipment.

Persons with proven skills:

•

Are qualified electrical engineers, or persons who have received training from qualified electrical engineers and are suitably

experienced to operate devices, systems, plant, and machinery in accordance with pertinent laws and regulations.

•

Are familiar with the basic regulations concerning health and safety/accident prevention.

•

Have read and understood the safety guidelines given in all manuals, especially the instructions given in the operating guide of

the unit.

•

Have good knowledge of the generic and specialist standards applicable to the specific application.

•

Are familiar with the structure and operation of medium-voltage drives and the related risks. Special training for medium-voltage installations may be necessary.

2.3 Danger and Warnings

D A N G E R

SHOCK HAZARD FROM POWER UNIT COMPONENTS

The power unit components are live when the drive is connected to mains. Contact with this voltage can result in death or seri-

ous injury.

Do not touch the components of the power unit when the drive is connected to mains.

-

Do not do any work on live equipment.

Before doing any work on internal drive components, follow proper lock out and tag out procedure.

Before connecting the drive to mains, make sure that all covers are installed on the drive and the enclosure doors are closed.

D A N G E R

SHOCK HAZARD FROM TERMINALS

The motor terminals U, V, W, and the DC-link terminals must be treated as live when the drive is connected to mains. Contact with

this voltage can lead to death or serious injury.

Do not touch the motor terminals U, V, W, or the DC terminals when the drive is connected to mains.

-

Do not do any work on live equipment.

Before doing any work on the drive, follow proper lock out and tag out procedure.

Before connecting the drive to mains, make sure that all covers are installed on the drive and the enclosure doors are closed.

AQ363633621020en-000201 / 172F3117 | 9Danfoss A/S © 2021.06

Page 10

VACON® 1000

Operating Guide

D A N G E R

SHOCK HAZARD FROM DC LINK OR EXTERNAL SOURCE

The terminal connections and the components of the drive can be live several minutes after the drive is disconnected from the

mains and the motor has stopped. The load side of the drive can also generate voltage. A contact with this voltage can lead to

death or serious injury.

Do not do touch the main circuit of the drive or the motor before the system is powered off and grounded.

-

Disconnect the drive from the mains and make sure that the motor has stopped.

Disconnect the motor.

Lock out and tag out the power source to the drive.

Make sure that no external source generates unintended voltage during work.

Ground the drive for work.

Wait at least 15 minutes for the DC-link capacitors to discharge fully before opening the cabinet door or the cover of the AC

drive.

Use a measuring device to make sure that there is no voltage.

W A R N I N G

SHOCK HAZARD FROM CONTROL TERMINALS

The control terminals can have a dangerous voltage also when the drive is disconnected from mains. A contact with this voltage

can lead to injury.

Make sure that there is no voltage in the control terminals before touching the control terminals.

-

Safety

W A R N I N G

ACCIDENTAL MOTOR START

When there is a power-up, a power break, or a fault reset, the motor starts immediately if the start signal is active, unless the pulse

control for Start/Stop logic is selected. If the parameters, the applications or the software change, the I/O functions (including the

start inputs) can change. If you activate the auto reset function, the motor starts automatically after an automatic fault reset. See

the Application Guide. Failure to ensure that the motor, system, and any attached equipment are ready for start can result in

personal injury or equipment damage.

Disconnect the motor from the drive if an accidental start can be dangerous. Make sure that the equipment is safe to operate

-

under any condition.

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT HAZARD >3.5 MA

Leakage currents exceed 3.5 mA. Failure to connect the drive properly to protective earth (PE) can result in death or serious in-

jury.

Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regula-

-

tions for high touch current equipment. The reinforced protective earthing of the drive can be done with:

a PE conductor with a cross-section of at least 10 mm2 (8 AWG) Cu or 16 mm2 (6 AWG) Al.

-

an extra PE conductor of the same cross-sectional area as the original PE conductor as specified by IEC 60364-5-54 with a

-

minimum cross-sectional area of 2.5 mm2 (14 AWG) (mechanical protected) or 4 mm2 (12 AWG) (not mechanical protected).

a PE conductor completely enclosed with an enclosure or otherwise protected throughout its length against mechanical

-

damage.

a PE conductor part of a multi-conductor power cable with a minimum PE conductor cross-section of 2.5 mm2 (14 AWG)

-

(permanently connected or pluggable by an industrial connector. The multi-conductor power cable shall be installed with an

appropriate strain relief).

NOTE: In IEC/EN 60364-5-54 cl. 543.7 and some application standards (for example IEC/EN 60204-1), the limit for requiring

-

reinforced protective earthing conductor is 10 mA leakage current.

2.4 Cautions and Notices

AQ363633621020en-000201 / 172F311710 | Danfoss A/S © 2021.06

Page 11

VACON® 1000

Operating Guide

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INCORRECT SPARE PARTS

Using spare parts that are not from the manufacturer can damage the drive.

Do not use spare parts that are not from the manufacturer.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM CHANGES TO DRIVE COMPONENTS

Doing electrical or mechanical changes to the drive components can cause malfunctions and can damage the AC Drive.

Do not make electrical or mechanical changes to the drive components.

-

C A U T I O N

DAMAGE TO THE AC DRIVE FROM INSUFFICIENT GROUNDING

Not using a grounding conductor can damage the drive.

Always ground the AC drive with a grounding conductor that is connected to the grounding terminal that is identified with

-

the PE symbol.

Safety

C A U T I O N

DAMAGE TO THE AC DRIVE DUE TO DISCONNECTED CONTROL POWER

Disconnecting the control auxiliary power when the AC drive is connected to mains or when the power indicator is on can cause

abnormalities in the function of the power cells and damage the cells.

Do not disconnect the control auxiliary power supply when the AC drive is connected to mains or if the power indicator is

-

on.

C A U T I O N

CUT HAZARD FROM SHARP EDGES

There can be sharp edges in the AC drive that can cause cuts.

Wear protective gloves when mounting, cabling, or doing maintenance operations.

-

C A U T I O N

BURN HAZARD FROM HOT SURFACES

Touching surfaces, which are marked with the 'hot surface' sticker, can result in injury.

Do not touch surfaces which are marked with the 'hot surface' sticker.

-

N O T I C E

DAMAGE TO THE AC DRIVE FROM STATIC VOLTAGE

Some of the electronic components inside the AC drive are sensitive to ESD. Static voltage can damage the components.

Use ESD protection when working with electronic components of the AC drive. Do not touch the components on the circuit

-

boards without proper ESD protection.

N O T I C E

DAMAGE TO THE AC DRIVE FROM INCORRECT EMC LEVEL

The EMC level requirements for the AC drive depend on the installation environment. An incorrect EMC level can damage the

drive.

Before connecting the AC drive to the mains, make sure that the EMC level of the AC drive is correct for the mains.

-

AQ363633621020en-000201 / 172F3117 | 11Danfoss A/S © 2021.06

Page 12

VACON® 1000

Operating Guide

N O T I C E

MAINS DISCONNECTION DEVICE

If the AC drive is used as a part of a machine, the machine manufacturer must supply a mains disconnection device (refer to EN

60204-1).

N O T I C E

MALFUNCTION OF FAULT CURRENT PROTECTIVE SWITCHES

Because there are high capacitive currents in the AC drive, it is possible that the fault current protective switches do not operate

correctly.

N O T I C E

VOLTAGE WITHSTAND TESTS

If done improperly, doing voltage withstand tests can damage the drive.

Megohmmeter testing is the only recommended test type for field installations.

-

Only a qualified field service engineer is allowed to perform this test.

Refer to the proper high potential/megohmmeter testing instructions in the service guide.

Safety

N O T I C E

WARRANTY

If the power modules are opened, the warranty is not valid.

Do not open the power modules.

-

N O T I C E

PERSONAL PROTECTIVE EQUIPMENT AND APPROVED TOOLS

When doing electrical work on the AC drive, always use personal protective equipment (PPE) and tools which are approved for

work with medium-voltage devices.

AQ363633621020en-000201 / 172F311712 | Danfoss A/S © 2021.06

Page 13

VACON® 1000

Operating Guide

Product Overview

3 Product Overview

3.1 Product Characteristics

The VACON® 1000 medium-voltage drive is an alternating current speed regulating device from Danfoss. The drive features include

excellent performance, easy and convenient operation, and a wide range of applications using IGBT power devices and complete

digital control.

High efficiency and low distortion

•

The used multi-pulse input rectification transformer technology efficiently lowers the content of the input side distortion current to less than 5%. It meets the IEEE 519-1992 standard and the strict requirements of electric grids for distortion, and enhances the power factor to more than 0.96 lagging.

•

With the used cell-cascaded multilevel technology, there is normally no need for an output filter, and the output voltage waveform is similar to a sine-wave.

•

System efficiency >98.5% (at rated frequency, excluding transformer).

Tolerant to power disturbances and wide applicable scope

•

When the input voltage is as low as 70%, the system can still continue derated operation.

•

With automatic output voltage adjusting function, when the input voltage fluctuates between 90–110%, the output voltage

can still be kept steady. Thus, safe and steady operation of the motor is possible.

High reliability

•

SOA (Service-oriented architecture) design ensures that the system operates in a wide safe range:

-

Sufficient design margin makes sure that each device operates in the middle area of the safe operating area.

-

Optimized thermal design ensures temperature margin for the devices.

-

The DC-link capacitors are designed for long lifetime service.

•

Redundant auxiliary control power.

•

The system provides a self-diagnosis function to show the position and type of failure and warn the user about the fault occurrence.

•

Automatic detection and warning function for cooling fan failure or excessive dust in the inlet air filter notifying the user to

conduct maintenance.

•

Production quality management, control flow process, and perfect test equipment and methods ensure the effective implementation of each test item for devices, components, and units during the manufacturing process at Danfoss.

Site flexibility

•

The compact structure and high power density of VACON® 1000 can reduce the space requirements on site.

•

The electric connections between the cabinets use highly reliable connectors which are easy to install and maintain.

•

Easy-to-operate human-machine interface.

•

Sufficient communication interfaces, which can be professionally configured in accordance with the application requirements.

•

All PCBs are coated to avoid problems with pollution and corrosive environments.

3.2 Applications

VACON® 1000 is used for the speed control of square torque loads such as fans, pumps, and compressors, as well as for mills, crushers, and conveyor belts that require constant torque operation over the entire speed range. Accurate speed and torque controls

result in better energy saving, improved process quality, and prolonged equipment lifetime. Various industries that require reliable

and stable operation can benefit from the high performance of VACON® 1000.

•

Power generation: Coal mills, blower fans, and water pumps.

•

Metallurgy: Conveyor belts, positive displacement pumps, fans, and water pumps.

•

Mining: Crushers, conveyor belts, PD pumps, fans, and water pumps.

•

Petrochemical: Compressors, PD pumps, centrifugal pumps, fans, and water pumps.

•

Cement and materials: Crushers, mixers, extruders, rotary kilns, drying furnaces, fans, and water pumps.

•

Sugar and ethanol: Mills, pumps, and fans.

•

Municipal works: Water supply pumps, sewage pumps, heat network pumps.

AQ363633621020en-000201 / 172F3117 | 13Danfoss A/S © 2021.06

Page 14

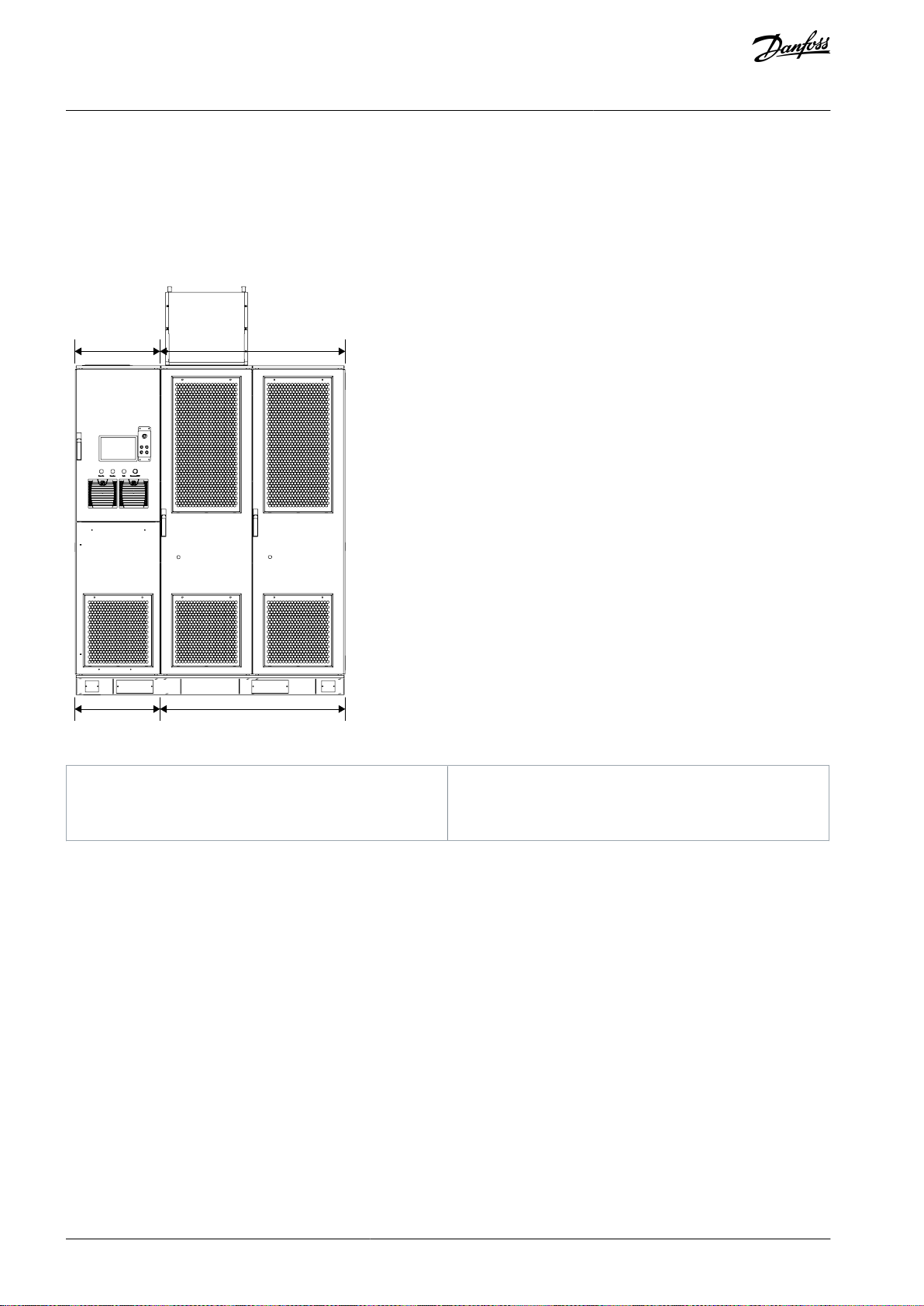

C

D

e30bi640.10

A

B

A

Control cabinet

B

Power cell cabinet

C

Junction cabinet

D

Transformer cabinet

VACON® 1000

Operating Guide

Product Overview

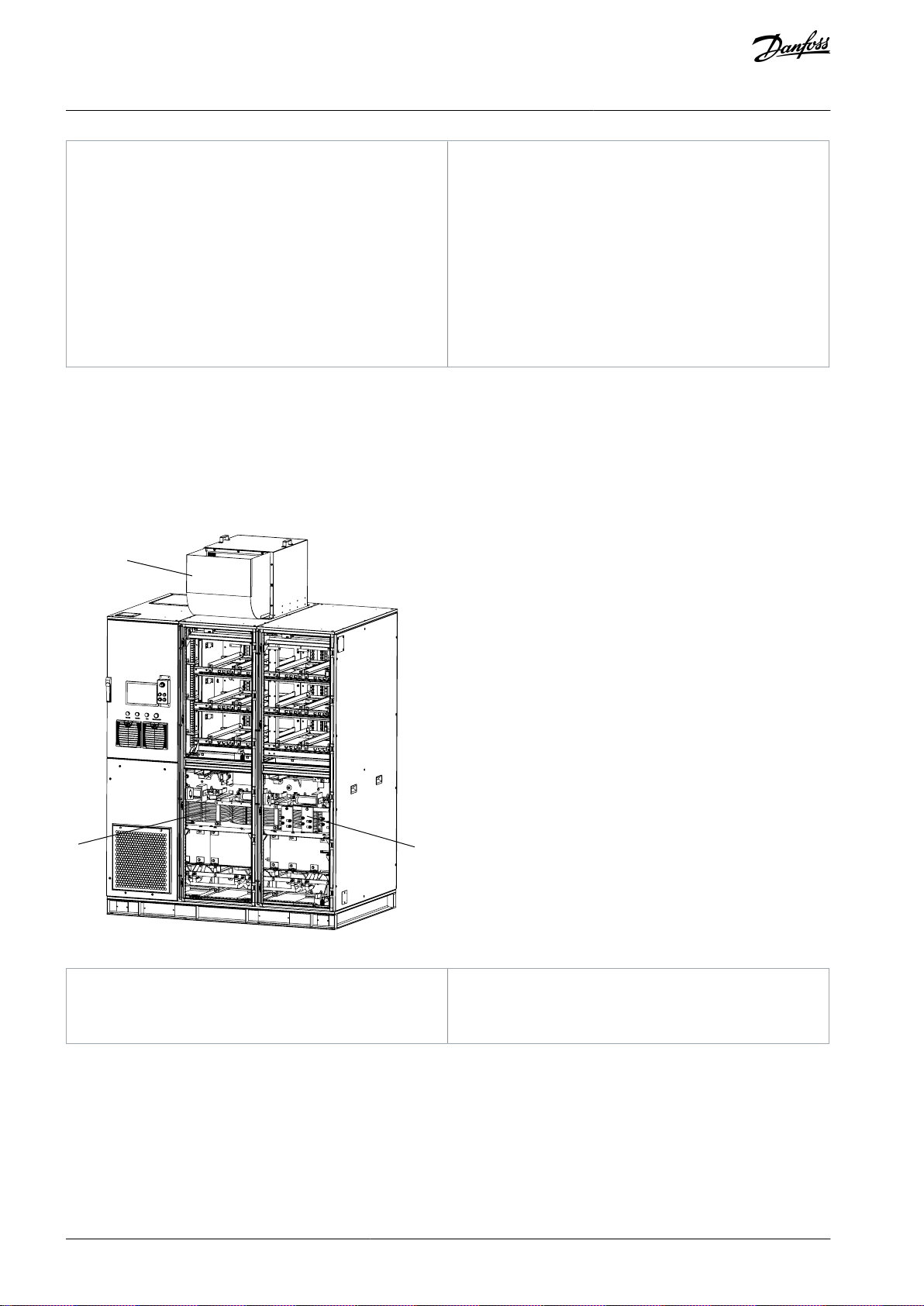

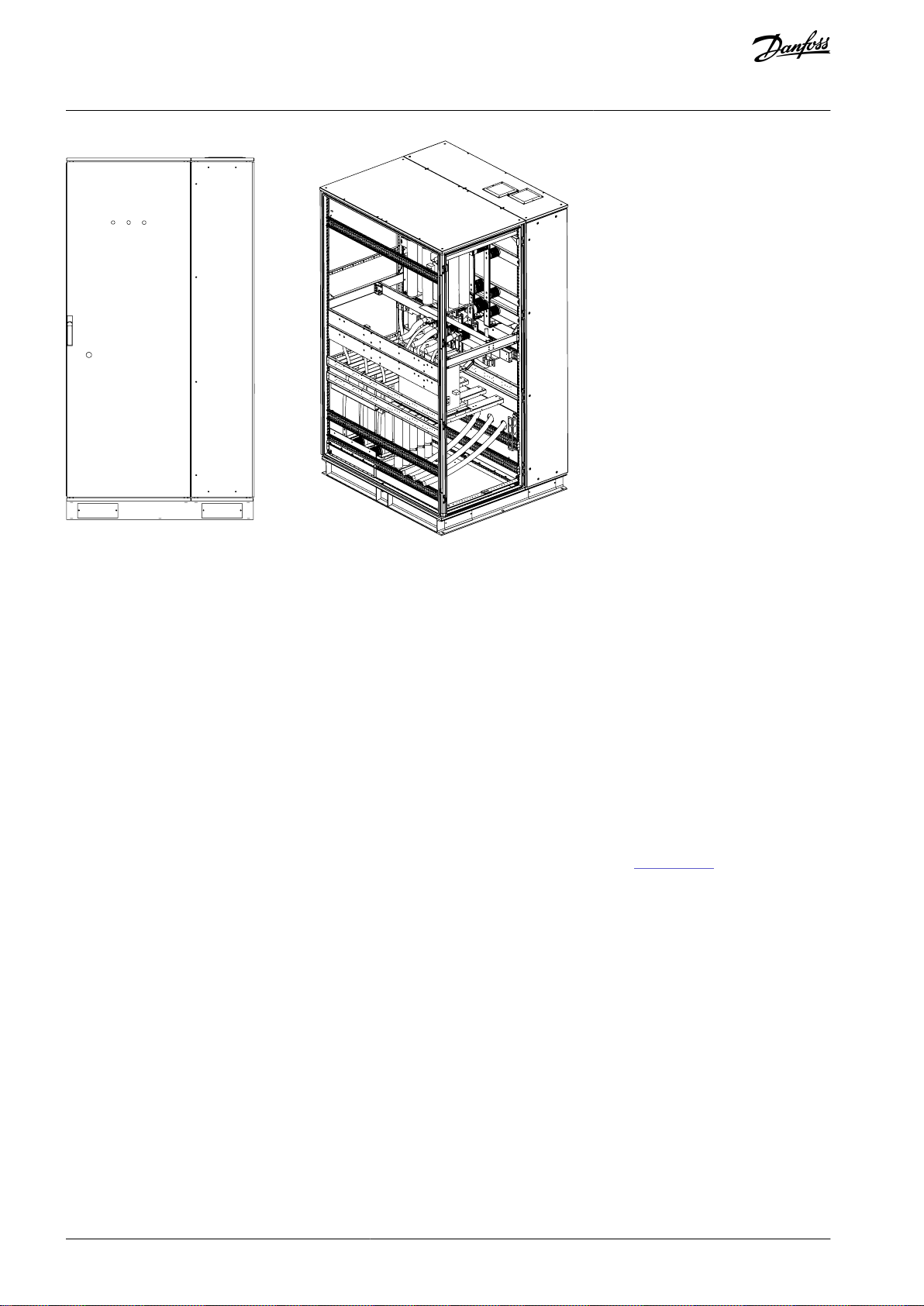

3.3 System Hardware

The VACON® 1000 medium-voltage drive consists of a controller cabinet, power cell cabinet, transformer cabinet, and junction cabinet. Other cabinets can be configured in accordance with customer requirements in the actual application.

There are two types of drive enclosure:

•

Standalone type with current ratings up to 215 A

•

Line-up type with current ratings 215–680 A (IEC ratings up to 11 kV, UL ratings up to 6.9 kV)

Illustration 1: Standalone System Structure

AQ363633621020en-000201 / 172F311714 | Danfoss A/S © 2021.06

Page 15

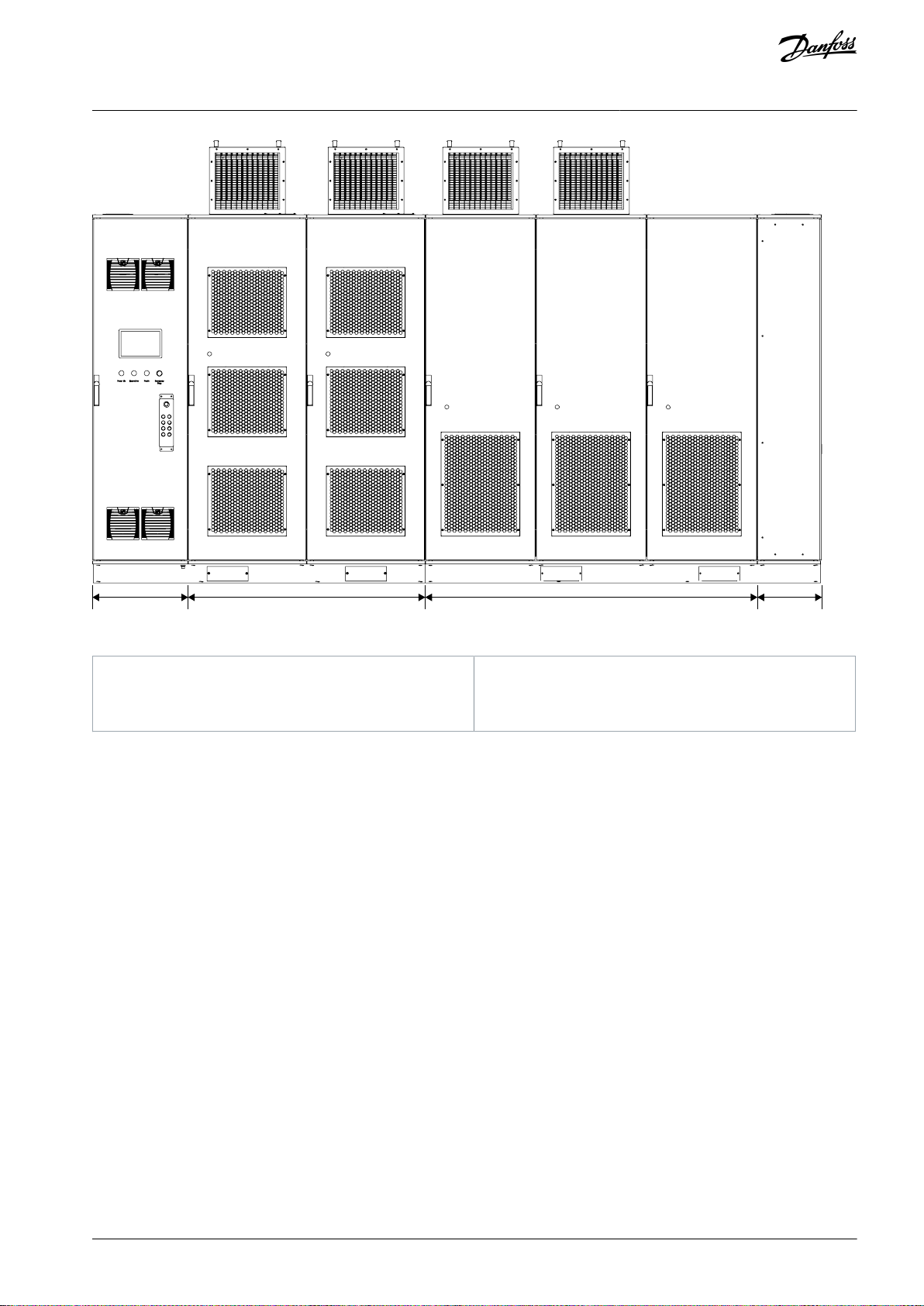

A B C D

e30bi639.10

A

Control cabinet

B

Power cell cabinet

C

Transformer cabinet

D

Junction cabinet

VACON® 1000

Operating Guide

Product Overview

Illustration 2: Line-up System Structure

3.3.1 Control Cabinet

The control cabinet includes:

•

Main control system

•

PLC

•

HMI

•

Battery

•

Other accessories

AQ363633621020en-000201 / 172F3117 | 15Danfoss A/S © 2021.06

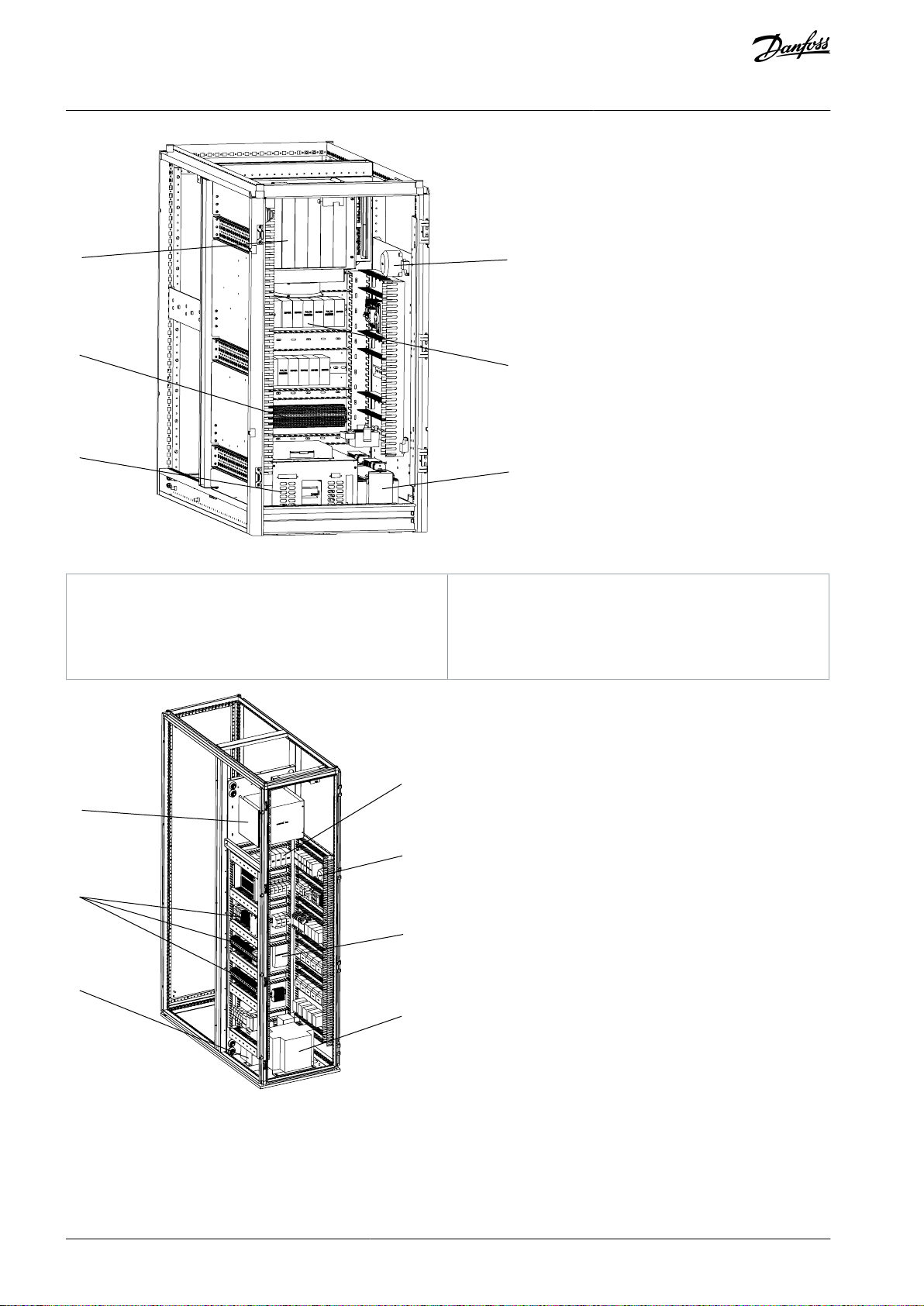

Page 16

e30bi642.10

A

B

C

D

E

F

A

Control rack

B

Terminal block

C

UPSDAirflow pressure switch

E

PLCFIsolation transformer

e30bi641.10

A

B

C

D

E

F

G

VACON® 1000

Operating Guide

Product Overview

Illustration 3: Control Cabinet in VACON® 1000 Standalone Systems

Illustration 4: Control Cabinet in VACON® 1000 Line-up Systems

AQ363633621020en-000201 / 172F311716 | Danfoss A/S © 2021.06

Page 17

A

Control rack

B

Terminal block

C

Battery

D

PLCEAirflow pressure switch

F

DC power supply

G

Isolation transformer

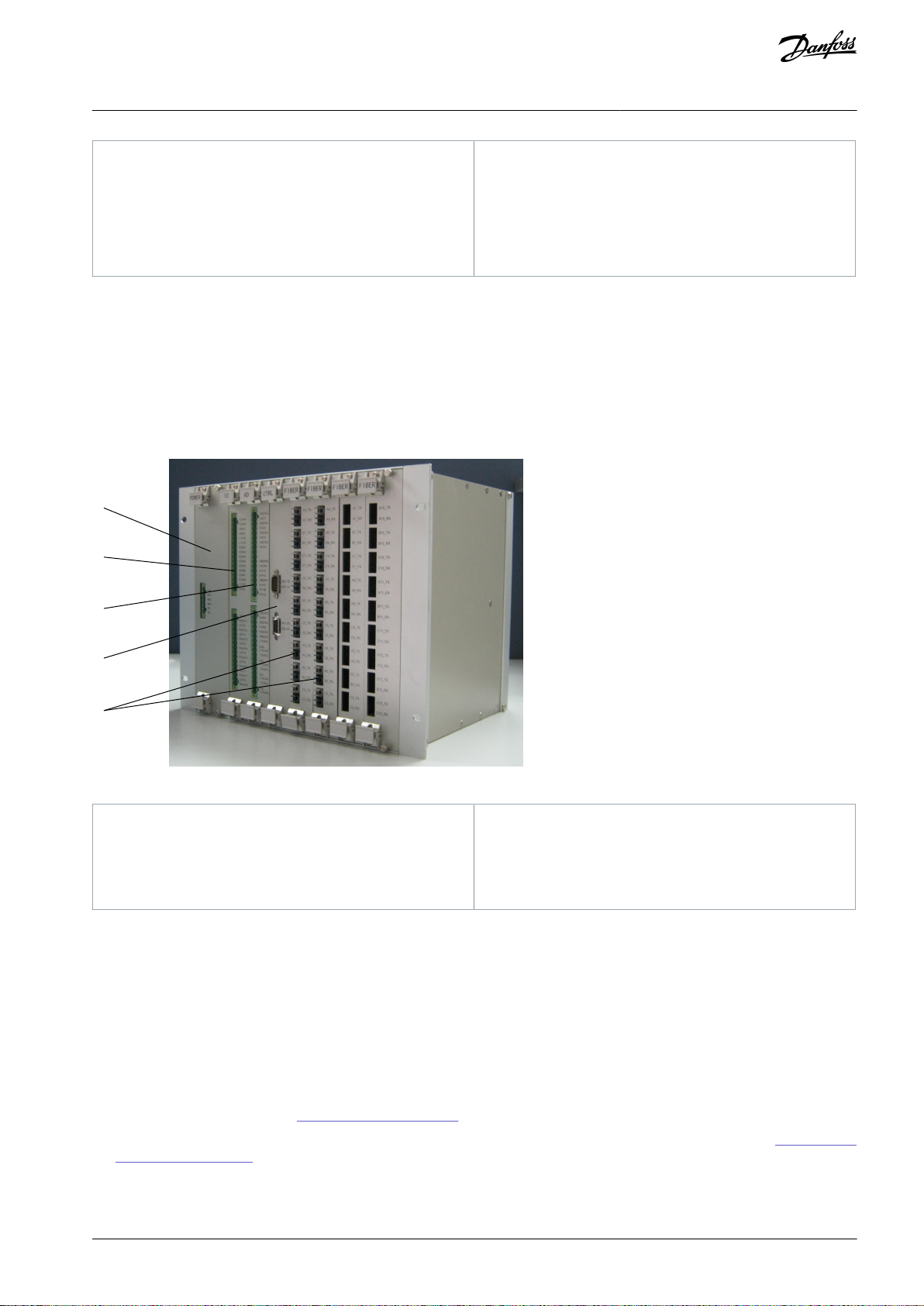

e30bi643.10

A

B

C

D

E

A

Power supply board

B

I/O board

C

A/D board

D

Main control board

E

Fiber optical boards

VACON® 1000

Operating Guide

The main control system is mounted in the control rack and consists of:

•

Main control board

•

I/O board

•

A/D board

•

Two fiber optical boards (extendable)

•

Power supply board

•

Bus motherboard, which connects the boards to each other.

Product Overview

Illustration 5: Main Control System

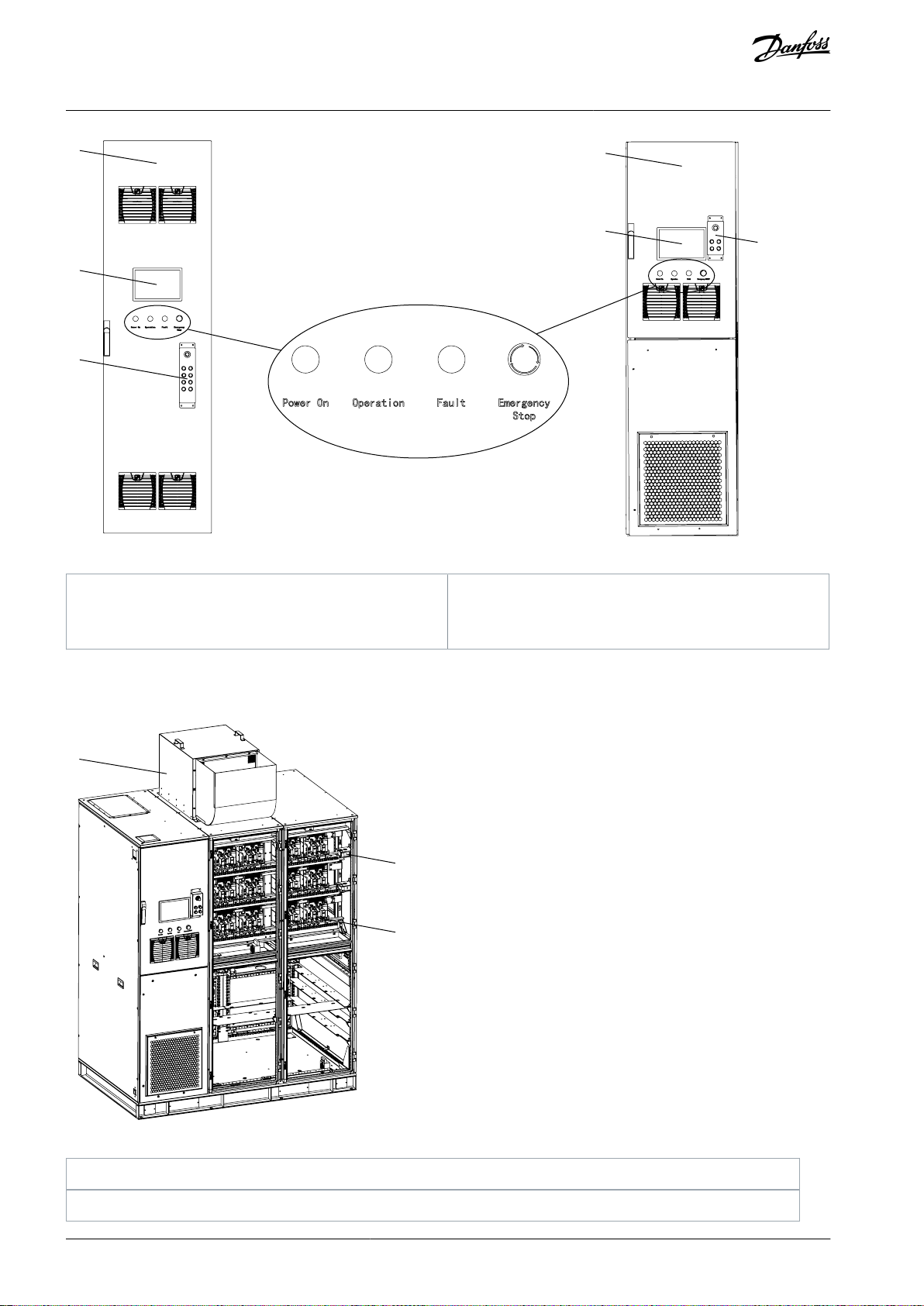

3.3.1.1 Controls and Indicators

The following are mounted on the control cabinet door:

•

High voltage power-on indicator: A green indicator, which indicates high voltage applied to the drive.

•

Operation indicator: A green indicator, which indicates that the drive is in operation.

•

Fault indicator: A red indicator, which indicates that the system is in “failure” state.

•

Emergency Stop button (E-stop): This button is used to break the high-voltage power of the drive when the system has an

emergency (such as unexpected incidents threatening the safety of the personnel or equipment). The button has a self-locking

function. Turn the button clockwise to reset and to turn power on again.

•

Human-machine interface: See 7 Human-Machine Interface.

•

Mechanical interlocking system: Standard in UL type drives and available as option +MMKI for IEC type drives. See 8.6.2 Mechan-

ical Interlocking System.

AQ363633621020en-000201 / 172F3117 | 17Danfoss A/S © 2021.06

Page 18

e30bi644.10

A

B

D

C

C

D

A

Line-up cabinet

B

Standalone cabinet

C

HMIDMechanical interlocking system

e30bi646.10

A

B

C

A

Cooling fan

B

Output current Hall sensor

VACON® 1000

Operating Guide

Product Overview

Illustration 6: Controls and Indicators on the Door of the Control Cabinet

3.3.2 Power Cell Cabinet

The power cell cabinet contains the power cells and their accessories.

Illustration 7: Power Cell Cabinet in VACON® 1000 Standalone Systems

AQ363633621020en-000201 / 172F311718 | Danfoss A/S © 2021.06

Page 19

C

Power cell

e30bi645.10

A

B

A

Cooling fan

B

Power cell

e30bi647.10

A

B

C

D

E

VACON® 1000

Operating Guide

Product Overview

Illustration 8: Power Cell Cabinet in VACON® 1000 Line-up Systems

The power cells in the cabinet have the same electrical and mechanical parameters and can be replaced by each other.

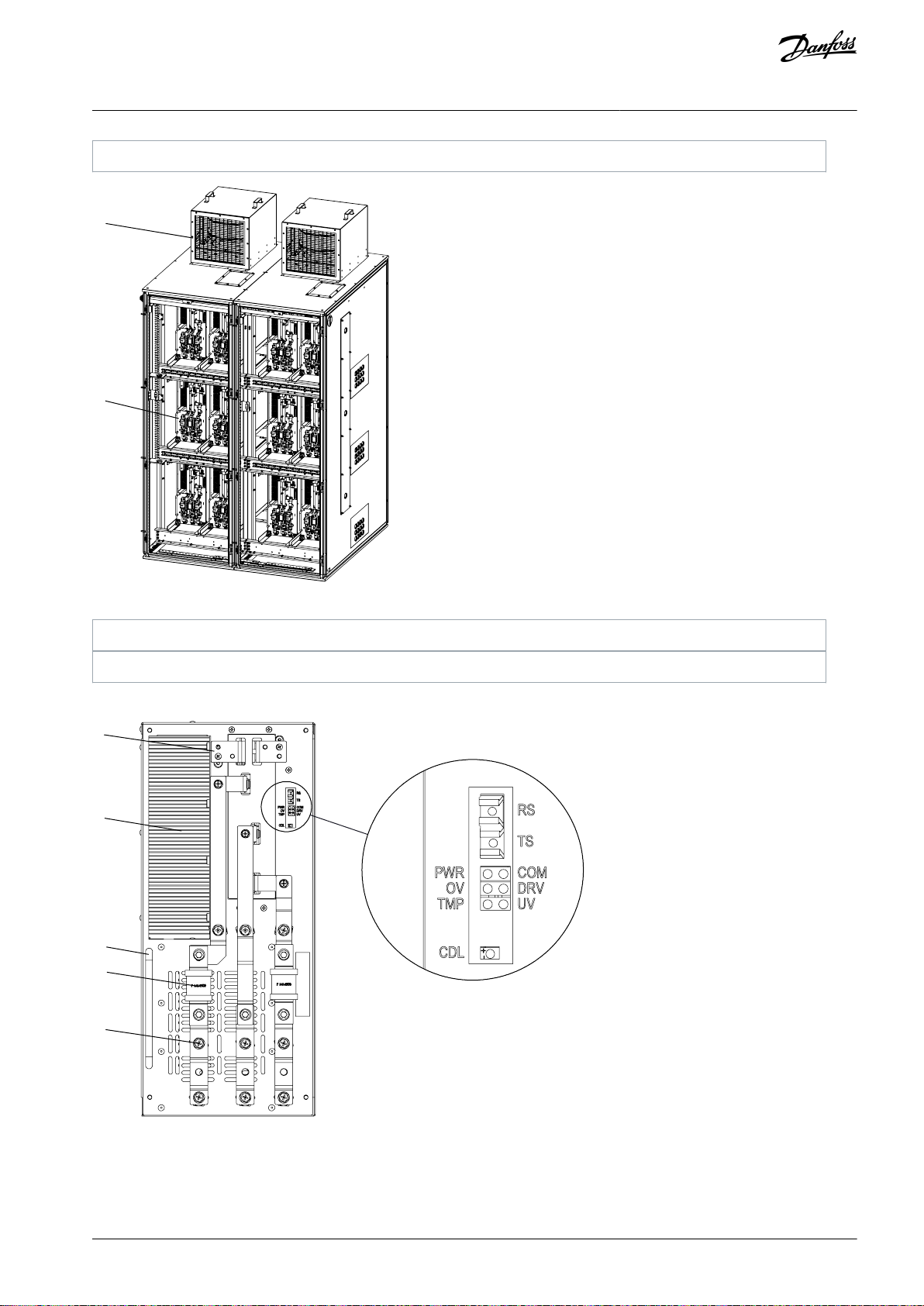

Illustration 9: Power Cell

AQ363633621020en-000201 / 172F3117 | 19Danfoss A/S © 2021.06

Page 20

A

Output terminal

B

Heat sink

C

Handle

D

FuseEInput terminal

RS

Optical fiber (receive)

TS

Optical fiber (transmit)

COM

Communication fail indicator

DRV

Drive fault indicator

UV

Undervoltage indicator

TMP

Overtemperature indicator

PWR

Power indicator

OV

Overvoltage indicator

CDL

50 V DC-link voltage indicator

e30bi649.10

A

B

C

A

Cooling fan

B

Phase-shift transformer

C

Input current Hall sensor

VACON® 1000

Operating Guide

Product Overview

3.3.3 Transformer Cabinet

The transformer cabinet includes the phase-shift transformer and its accessories.

The transformer is integrated with the cabinet base through screws for the convenience of transportation and installation. The sys-

tem default setting is that, when the transformer temperature exceeds 95°C, the system reports an excessive high temperature

alarm but does not shut down. When the temperature exceeds 110°C, the system reports an extra-high temperature fault and shuts

down.

In standalone systems, the same fan is used to cool the transformer and power cell cabinets.

Illustration 10: Transformer Cabinet in VACON® 1000 Standalone Systems

AQ363633621020en-000201 / 172F311720 | Danfoss A/S © 2021.06

Page 21

e30bi648.10

A

B

C

D

A

Cooling fan

B

Phase-shift transformer

C

Input current Hall sensor

D

Output current Hall sensor

HV~

MCB

M

Junction

cabinet

Startup

cabinet

Drive

KM51

Output filter

cabinet

e30bi650.10

VACON® 1000

Operating Guide

Product Overview

Illustration 11: Transformer Cabinet in VACON® 1000 Line-up Systems

3.3.4 Junction Cabinet

The junction cabinet is used for field cable connections. See 6.5 Cable Entry and Termination.

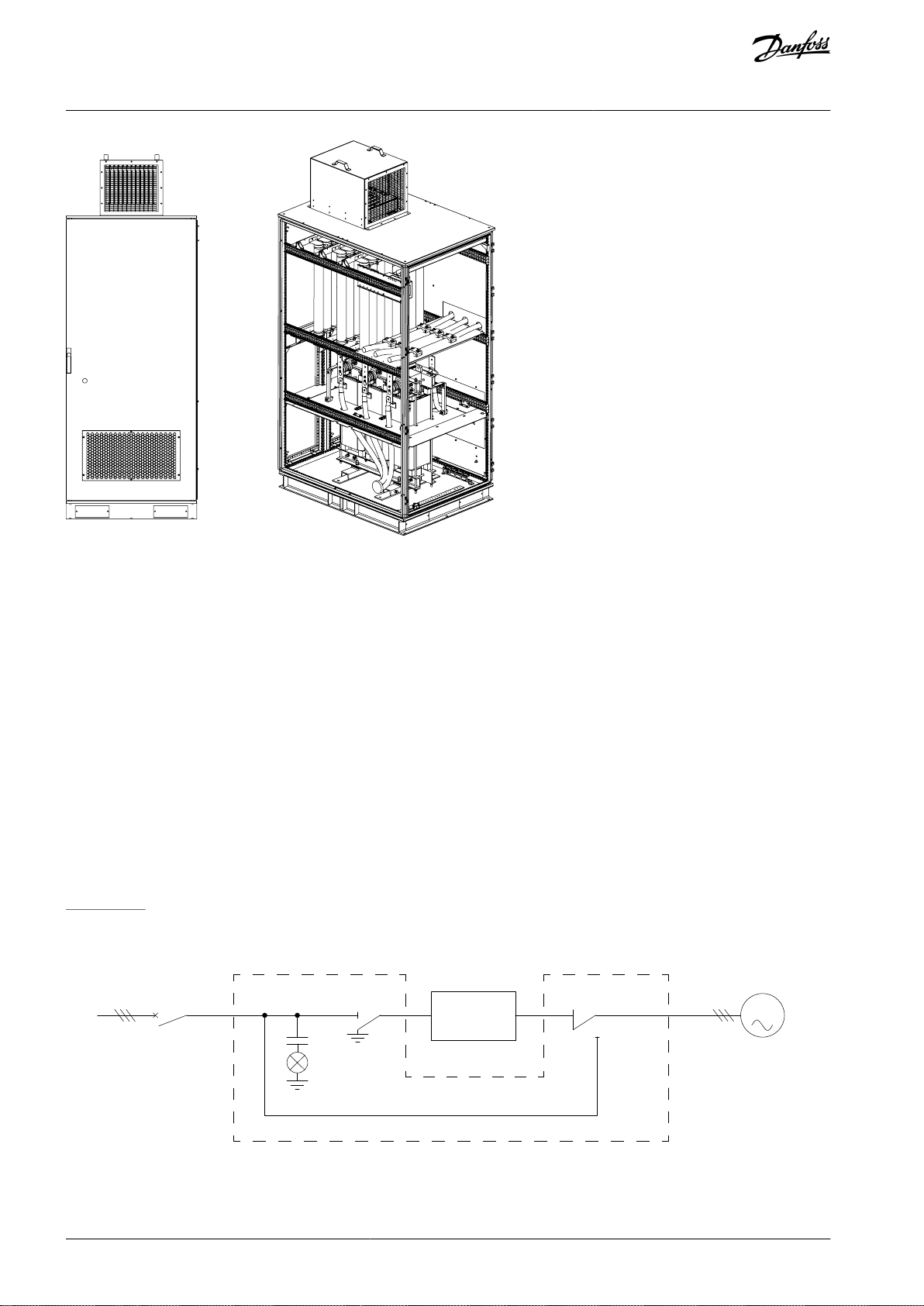

3.3.5 Start-up Cabinet

The start-up cabinet (+PSTC) is an option for the VACON® 1000 line-up systems. The main function of the start-up cabinet is to depress inrush currents that can lead to a dip in the supply voltage:

•

A phase-shifting transformer with a large capacity can produce a magnetizing surge as high as 6–8 times the rated current of

the transformer itself.

•

The power cells of the drive contain several capacitors, which require a large precharge current when high voltage is applied.

Illustration 12: Start-up Cabinet Primary Side Diagram

Install the start-up cabinet between the high-voltage power input and phase-shifting transformer. When the MCB of the drive is

closed, the start-up cabinet limits the magnetizing surge and charge current of the capacitance quickly and efficiently. After the

drive is powered up, the current-limiting resistance passes through the KM51 bypass, and the drive can function normally.

The main electrical components of the start-up cabinet are a high-voltage switch (vacuum contactor or vacuum breaker) and a current-limiting resistor.

AQ363633621020en-000201 / 172F3117 | 21Danfoss A/S © 2021.06

Page 22

e30bi651.10

VACON® 1000

Operating Guide

Product Overview

Illustration 13: Start-up Cabinet

The function of current-limiting resistance is to limit the primary current when a high voltage is connected. Each resistor can bear a

30 kJ energy during the power-up. The capacity of the drive defines how much resistance is needed in the start-up cabinet: the

larger the capacity, the more current-limiting resistors are needed.

The function of the high-voltage switch is to bypass the current-limiting resistor after the powering-up procedure, making the drive

function under normal load. If the rated current is small, a vacuum contactor can be used. If the rated current is large, a vacuum

breaker can be used.

Operation process

•

Power up the drive.

•

The control program confirms if the system is ready and if the cabinet switch is separated or not.

•

Power up the start-up cabinet and the control program counts the time it takes to complete the process. The process requires

about 5 s.

•

The closing of the start-up cabinet switch bypasses the charged resistor and the drive has status 'running allowed'.

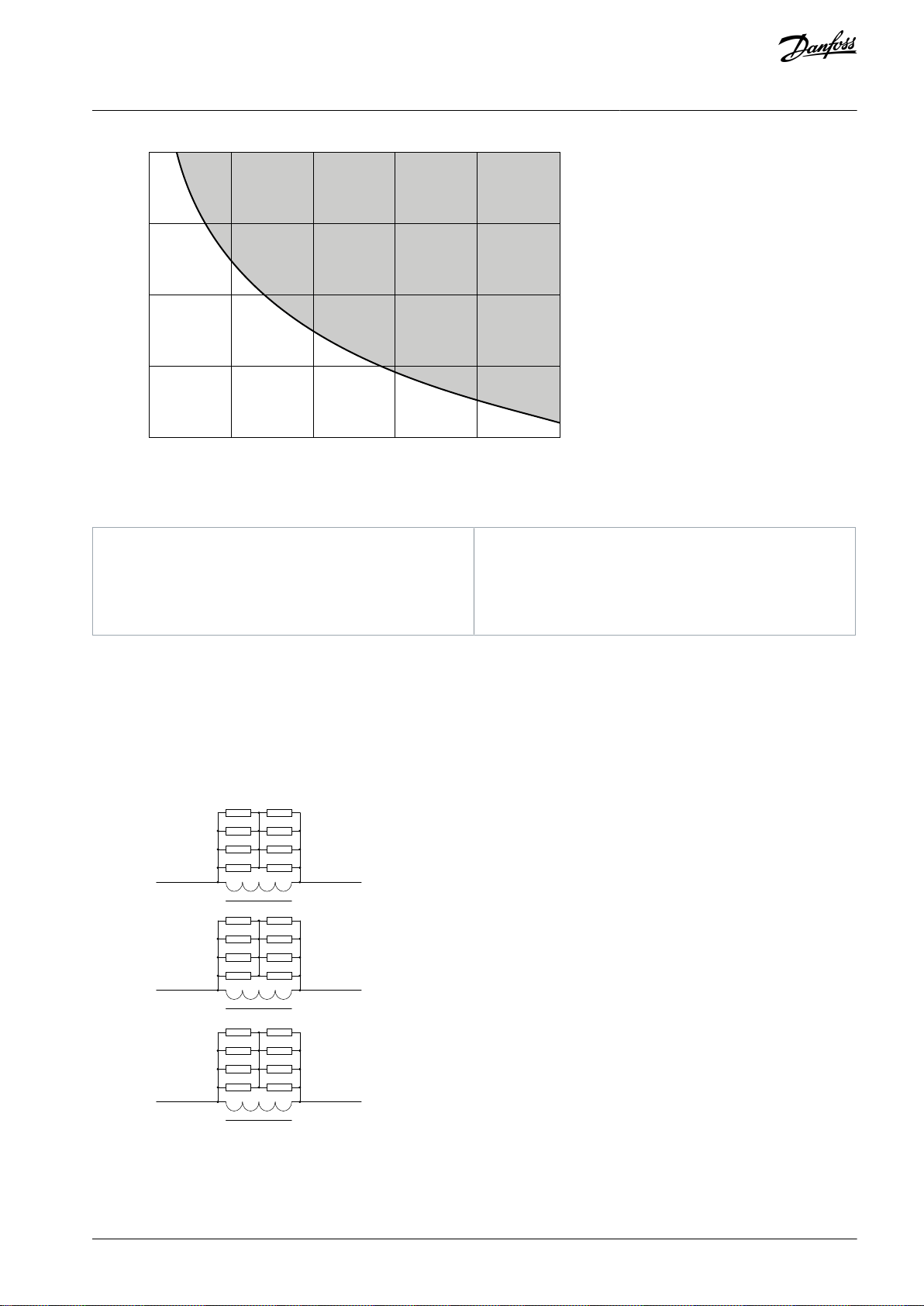

When to select the Start-up cabinet option?

The MCB protection at the installation site must not trip because of the inrush current when the drive is powered up or in normal

overload conditions. The overcurrent protection of the MCB must be set in the grey area shown in Illustration 14.

If the MCB meets these requirements, the start-up cabinet is not required. It is important to verify this condition, especially in retrofit

applications where a circuit breaker is already installed at the motor control center panel.

Even if it is not required, a start-up cabinet can still be installed to:

•

Reduce inrush current.

•

Reduce stresses in the electrical installation during the drive power-up operation.

AQ363633621020en-000201 / 172F311722 | Danfoss A/S © 2021.06

Page 23

20T

O

t(I)

I/I

LN

0.2I

ratio

0.4I

ratio

0.6I

ratio

0.8I

ratio

I

ratio

15T

O

10T

O

5T

O

0

0

e30bj032.10

I

Inrush current

ILNRated input current of the drive

I

ratio

I/I

LN

t(I)

Time of the inrush current decay

TOThe basic period: 20 ms for 50 Hz or 16.7 ms for

60 Hz

L71-a

L71-b

L71-c

To

inverter

To

motor

R72A

R74A

R78A

R76A

R71A

R73A

R77A

R75A

R72B

R74B

R78B

R76B

R71B

R73B

R77B

R75B

R72C

R74C

R78C

R76C

R71C

R73C

R77C

R75C

e30bi652.10

VACON® 1000

Operating Guide

Illustration 14: Overcurrent Protection Setting Area

Product Overview

3.3.6 Output Filter Cabinet

The output filter cabinet is an optional cabinet which is connected at the output of the drive, between the inverter and motor. The

filter is used to:

•

Reduce the dU/dt of the voltage waveform.

•

Prevent resonance/overvoltage caused by motor cables.

•

Reduce the charging current of the cable.

Illustration 15: Output Filter Cabinet Circuit Diagram

Install the output filter cabinet between the drive and motor. The filter consists of a reactor and paralleling damping resistors. The

reactor decreases the rising edge of the PWM. The resistor damps the resonance caused by the reactor and stray inductance.

AQ363633621020en-000201 / 172F3117 | 23Danfoss A/S © 2021.06

Page 24

e30bi653.10

HV~

MCB

M

Manual bypass cabinet

QS41

DN41

QS42

QS43

Drive

e30bi747.10

VACON® 1000

Operating Guide

Product Overview

Illustration 16: Output Filter Cabinet

When to select the Output Filter cabinet option?

The need for an output filter is application and case specific. Several things must be considered to find out if a dU/dt Filter is required:

•

The type of the motor.

•

The type of the motor cable.

•

The length of the motor cable.

To evaluate if a dU/dt Filter is required, contact Danfoss.

3.3.7 Bypass Cabinet

Different bypass cabinets are available as options:

•

Manual bypass cabinet

•

Automatic bypass cabinet

•

Synchronous transfer cabinet

3.3.7.1 Manual Bypass Cabinet

Illustration 17 shows a typical bypass cabinet configuration, where:

•

QS41 is a single-pole isolation switch with a manual grounding knife gate.

•

QS42 and QS43 are double-pole double-throw manual knife gate isolation switches.

Illustration 17: Manual Bypass Cabinet Circuit Diagram

The bypass cabinet includes an isolation switch, which:

AQ363633621020en-000201 / 172F311724 | Danfoss A/S © 2021.06

Page 25

A

B

e30bi750.10

A

Manual knife gate switch

B

Dual-isolation switch panel

HV~

MCB

M

Automatic bypass/Synchronous transfer cabinet

Manual bypass cabinet

QS41KM41 KM42

KM43

DN41

QS42

Drive

e30bi748.10

VACON® 1000

Operating Guide

•

Realizes the electrical isolation between the phase-shift transformer and the power distribution system.

•

Provides the power frequency and variable frequency switching function and related electrical protection measures.

Product Overview

Illustration 18: Manual Bypass Cabinet

3.3.7.2 Automatic Bypass Cabinet

Illustration 19 shows an automatic bypass cabinet configuration, where:

•

KM41–KM43, high-voltage vacuum contactors.

•

QS41–QS42, manual separation knife switches.

Illustration 19: Automatic Bypass Cabinet Circuit Diagram

When the drive is running:

•

QS41 and QS42 are closed.

•

KM41 and KM42 are closed.

•

KM43 is open.

When the drive is bypassed:

•

KM41 and KM42 are open.

•

KM43 is closed.

When maintenance is performed on the drive:

AQ363633621020en-000201 / 172F3117 | 25Danfoss A/S © 2021.06

Page 26

VACON® 1000

Operating Guide

•

QS41 and QS42 are open.

•

KM41 and KM42 are open.

•

KM43 is closed.

The sequence in which the drive is switched from running to bypassed:

•

1. KM41 is opened.

•

2. KM42 is opened.

•

3. KM43 is closed.

Secondary Control Logic

The three switches KM41–KM43 use assistant contact interlock to ensure that the time course is followed.

•

KM41 does not open and KM42 does not act when the normally closed contactor of KM41 is connected into the opening circuit

of KM42.

•

The normally closed contactor of KM42 is connected to the MCB-closed circuit of KM43.

•

The normally closed contactor of KM43 is connected to the MCB-closed circuit of KM42.

•

KM43 is not able to close the MCB when KM42 is not opening.

•

KM42 is not able to close MCB when KM43 is not opening.

The status of the five switches KM41–KM43 and QS41–QS42 is monitored through the PLC.

•

If any switch is not at the right working position, the system does not allow the MCB to close, and powering up high voltage to

the system is forbidden.

•

If the drive goes into fault, the system breaks the switch automatically to cut off the HV input for safety, if KM41 is not able to

open during the process of VF switching to working frequency automatically.

The two switches KM42 and KM43 control the function of reserving postponed action in the circuit, which can adjust the action

interval of the switch during the process of VF switching to working frequency. It can be more convenient to calibrate the machine

on site according to the status of the electric motor and load, to switch speed reasonably to avoid an overcurrent malfunction because of the electric motor remanence.

Product Overview

AQ363633621020en-000201 / 172F311726 | Danfoss A/S © 2021.06

Page 27

e30bi751.10

AC/DC 220 V

501

ZK1

FU21

504

415

415

415

415

415

415

415

415

415

415

415

417

1

2

1

2

5

6

7

8

3

4

542

543

548

527

530

537

538

539

533

544

415

540

541

524

536

535

534

546

413

532

528

KA12

SF2

SA3

SB2

SF1

SF2

SB1

SF1

KT2

KA1-I

KA1

KA1

KA1

K4

SB3

SA2

SA1

KA2

KT3

KT3

KT3

KT2

KT1

KT1

KM43

KM43

KM43

KM42

KM41

KA2

KA2

KA2

KA2

KA1

KA1-II

KA2-I

KA2-II

KT1

KM42

KM43

KM41

KM41

KM42

KM43 closing coil

KM41 opening

coil

KM42 opening coil

KM43 opening coil

KM42 open switch

KM43 opening switch

KM43 close switch

KM41 close switch

KM41 close switch

KM42 close switch

SF1

503

505

AC 220 V

Micro breaker

Fuse

PF auto transfer switch

VF to PF manual transfer switch SF2

PF to VF manual transfer switch SF2

KA2 self-lock circuit

Operation mode switch SF1

KM41 open push button SB1

KM43 open push button SB3

KM42 close push button SA2

KM41 close push button SA1

KM42 open command

KM43 open command

KM42 open push button SB2

KM43 close command

KM41 close command

KM42 close command

Time relay

Time relay circuit

KM43 close push button

KM42 close coil

KM41 close coil

e30bi752.10

VACON® 1000

Operating Guide

Product Overview

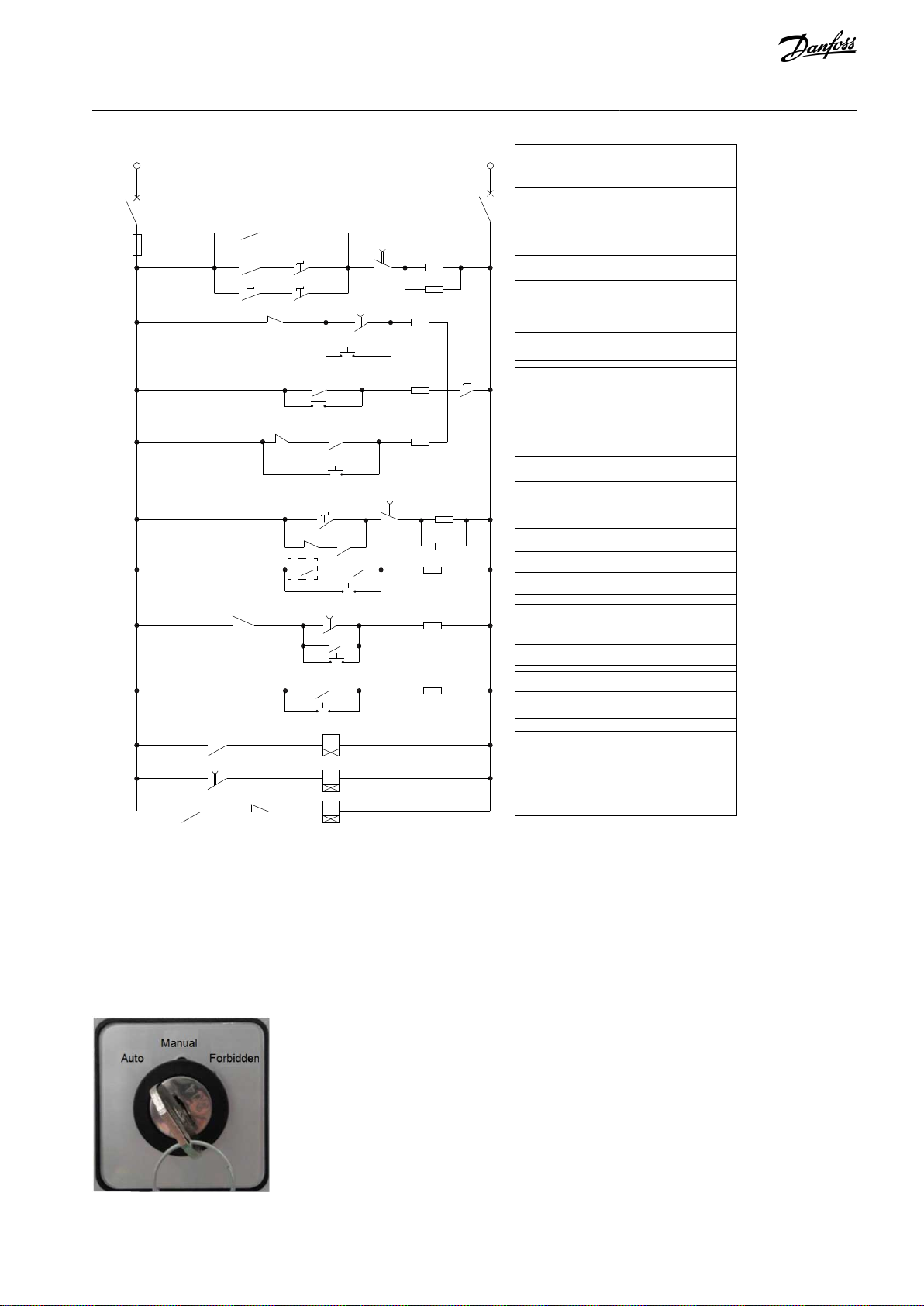

Illustration 20: Secondary Control Logic Diagram of VF Switching to PF

Operation Mode Switches

Switch SF1 is used to select the working mode to prevent incorrect operation.

•

Auto: Allows switching to PF bypass automatically when the drive is in a serious fault.

•

Manual: Allows manual switching to working-frequency bypass according to the real production requirements when the drive is

normally running.

•

Forbidden: If the production conditions do not allow the switching to working-frequency bypass, this mode can be selected to

prevent incorrect operation.

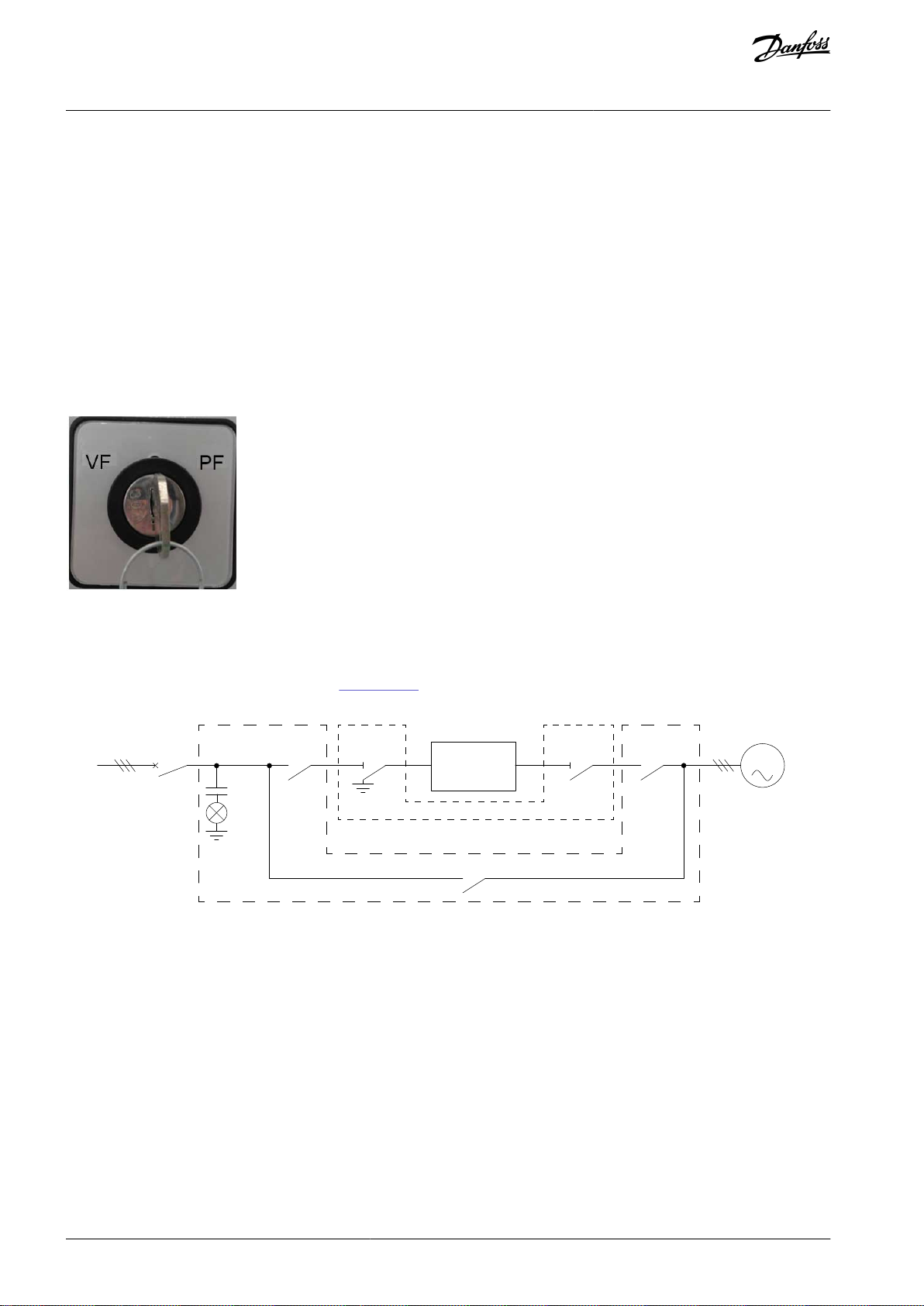

Illustration 21: Working Mode Selection Switch SF1

AQ363633621020en-000201 / 172F3117 | 27Danfoss A/S © 2021.06

Page 28

e30bi753.10

HV~

MCB

M

Automatic bypass/Synchronous transfer cabinet

Manual bypass cabinet

QS41KM41 KM42

KM43

DN41

QS42

Drive

e30bi748.10

VACON® 1000

Operating Guide

Product Overview

Switch SF2 is used to select between variable-frequency (VF) and power-frequency (PF) switching.

•

When the automatic bypass cabinet is in manual operation mode, and switch SF2 is in PF position, the drive switches the system

to PF bypass status automatically.

•

When switch SF2 is in VF position, the drive can switch from power-frequency bypass status to variable-frequency mode automatically (QS41 and QS42 must be closed). This function needs the coordination of engine racing starting-up. Therefore, engine

racing must be enabled and must comply with all the related electric motor parameters.

•

VF logic sequence:

-

KM41 is closed.

-

If self-detection shows normal after 10 s, bypass switch KM43 is opened.

-

KM42 is closed.

-

Automatic engine racing of the drive starts up.

-

PF is switched to VF.

Illustration 22: Switching Mode Selection Switch SF2

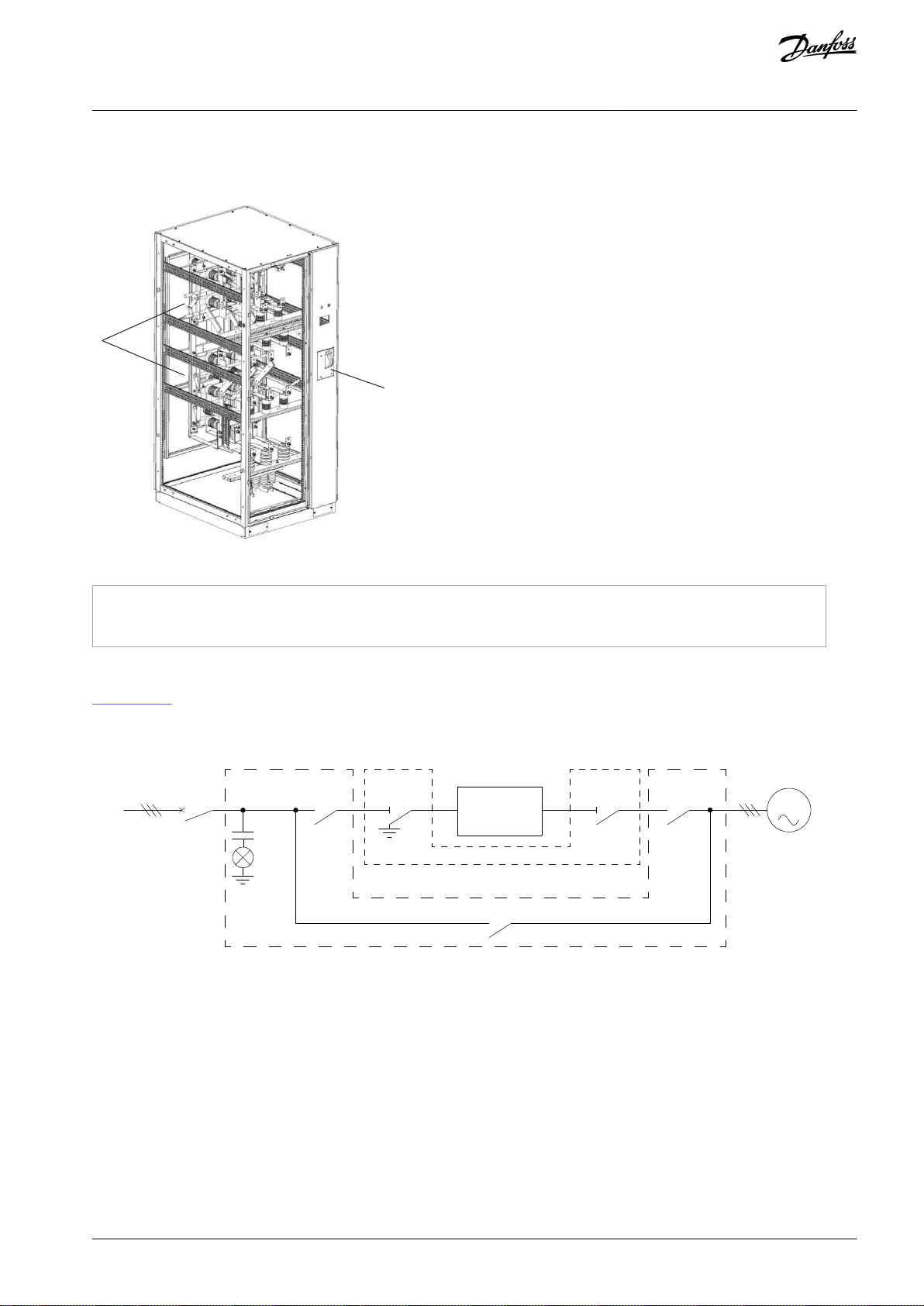

3.3.7.3 Synchronous Transfer Cabinet

The synchronous transfer function can realize undisturbed transfer between the grid and the drive, and reduce the impact on the

motor and grid. The primary circuit is shown in Illustration 23. The switching devices and cabinets are the same as in the automatic

bypass cabinet. QS41 and QS42 are for drive maintenance use and are closed during operation.

Illustration 23: Synchronous Transfer Cabinet Circuit Diagram

Process sequence of load transfer from the drive to the grid

•

Initial state: KM41 and KM42 are closed, and KM43 is open.

•

Phase lock: The drive runs to grid frequency and starts to lock phase to grid voltage.

•

Synchronous transfer: After phase lock, KM43 is closed and the load transfer to grid is started.

•

Synchronous transfer finished: After the load transfer, KM42 and KM41 are opened.

Process sequence of load transfer from the grid to the drive

•

Initial state: KM41 and KM42 are open, and KM43 is closed.

•

Phase lock: KM41 is closed. The drive runs to grid frequency and starts to lock phase to grid voltage.

•

Synchronous transfer: After phase lock, KM42 is closed and the load transfer to the drive is started.

•

Synchronous transfer finished: After the load transfer, KM43 is opened.

AQ363633621020en-000201 / 172F311728 | Danfoss A/S © 2021.06

Page 29

Motor

Phase-shift

Transformer

-12°

-24°

0°

12°

24°

Power Cells

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

Source

e30bi654.10

Drive series

Number of power cells per phase

System cell number

Output phase voltage (V)

Output line voltage (V)

2.4 kV

391385

2400

3 kV39

1732

3000

3.3 kV

391905

3300

4.16 kV

4122400

4160

6 kV515

3464

6000

VACON® 1000

Operating Guide

Product Overview

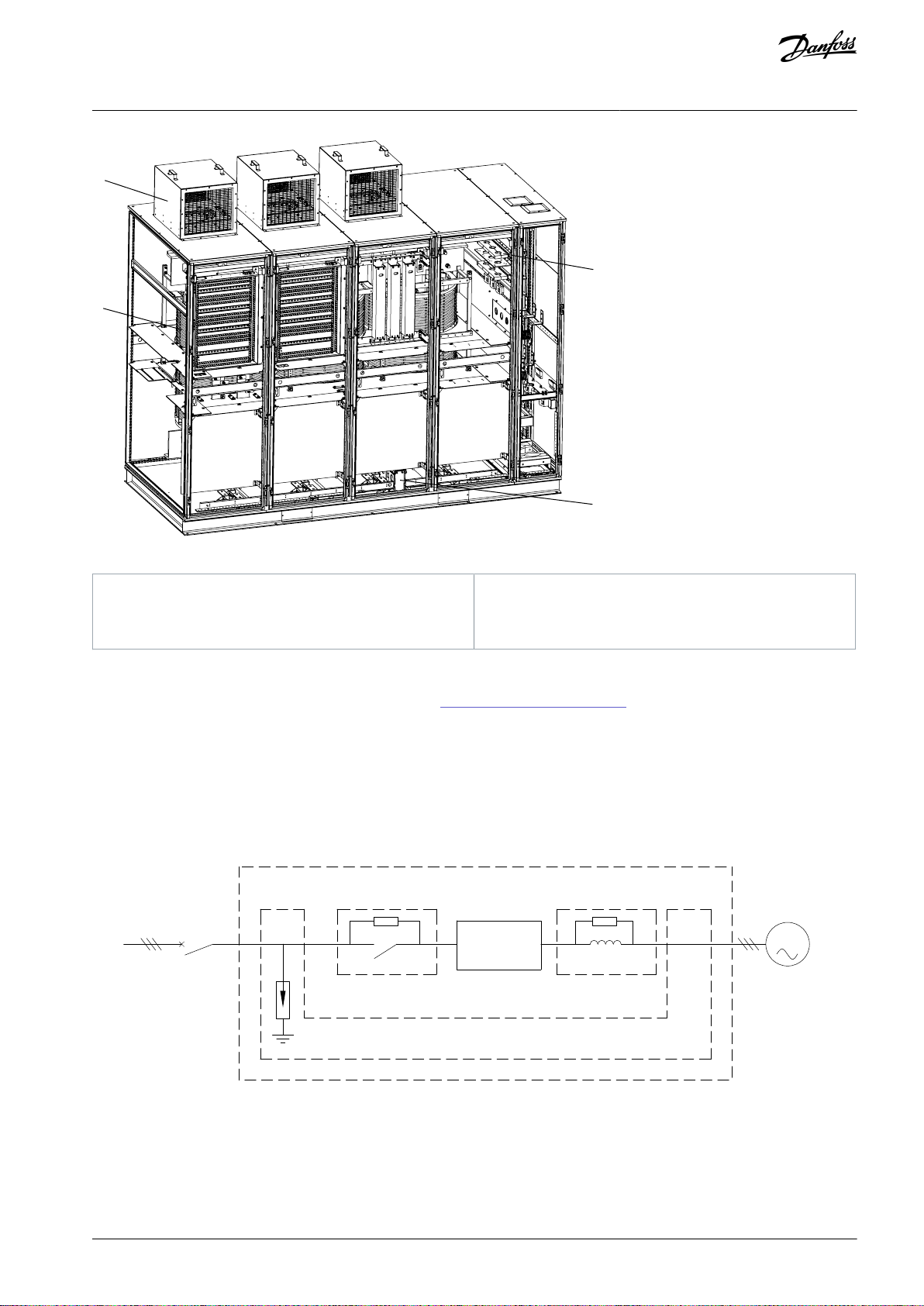

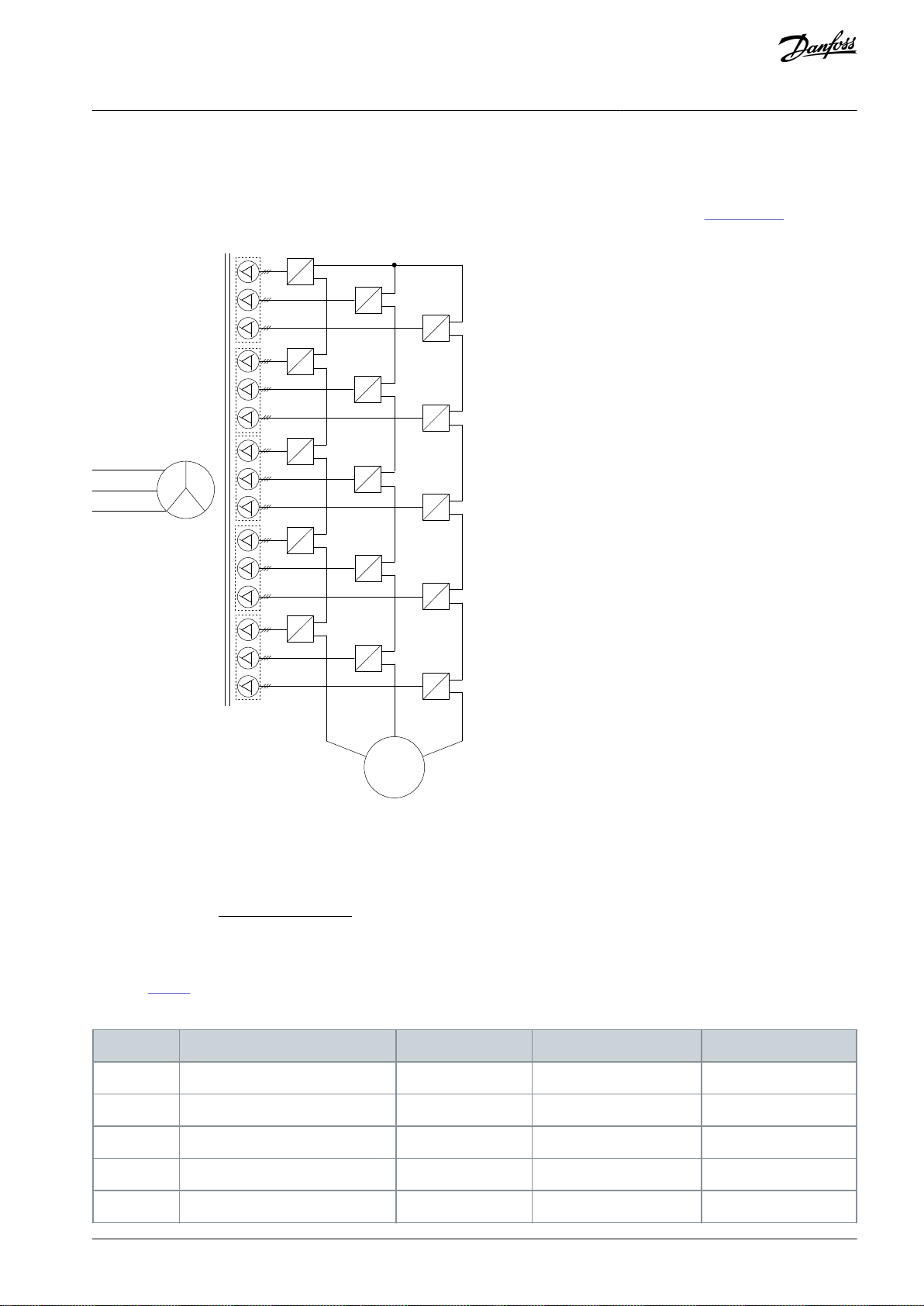

3.4 System Operation

3.4.1 Main Circuit

The typical main circuit topological structure diagram of VACON® 1000 medium-voltage drive is shown in Illustration 24.

Illustration 24: Main Circuit Diagram of VACON® 1000

The phase-shift rectifier transformer is a 3-phase air-cooled dry-type transformer directly connected with the incoming high voltage.

The secondary windings use an extended delta connection, which can lower the content of the input side current distortion. The

phase-shift angle between the secondary windings can be calculated according to the following formula:

Phase − shiftangle =

The secondary windings of the transformer provide input power for each power cell respectively. The number of secondary windings and the phase-shift angle between the windings are determined according to the voltage level and structure of the drive, as

Numberofpowercells

shown in Table 2.

Table 2: Power Cell Configuration for VACON® 1000

60°

AQ363633621020en-000201 / 172F3117 | 29Danfoss A/S © 2021.06

Page 30

Drive series

Number of power cells per phase

System cell number

Output phase voltage (V)

Output line voltage (V)

6.6 kV

6183810

6600

6.9 kV

6183984

6900

10 kV

8245774

10000

11 kV

9276351

11000

PWM1

PWM2

PWM3

PWM4

PWM5

PWM6

Time (ms)

Output phase voltage

0 4 8 12 16

20

e30bi655.10

VACON® 1000

Operating Guide

Product Overview

3.4.2 Power Cells

The power cell is the basic module of the medium-voltage drive, which produces a variable voltage and frequency output. It is composed of fast acting fuses, a rectification bridge, DC-link capacitance, IGBT inverting bridge, and so on.

The input terminals of the power cells are connected with the 3-phase winding of the secondary side of the phase-shift transformer.

The 3-phase diode provides full-wave rectification to charge the DC-link capacitance, and the voltage on the capacitance is provided to the H-bridge 1-phase bridge inverter circuit formed by 4 IGBTs.

The power cell receives signals through optical fibers, and controls the closing and opening of the S1–S4 IGBTs by using PWM modulation mode to output a 1-phase impulse modulated waveform. Each cell has only 3 possible output states:

•

When S1 and S4 are closed, the state of the output voltage VUV is VDC.

•

When S2 and S3 are closed, the output voltage VUV is -VDC.

•

When S1 and S3 or S2 and S4 are closed, the output voltage VUV is 0.

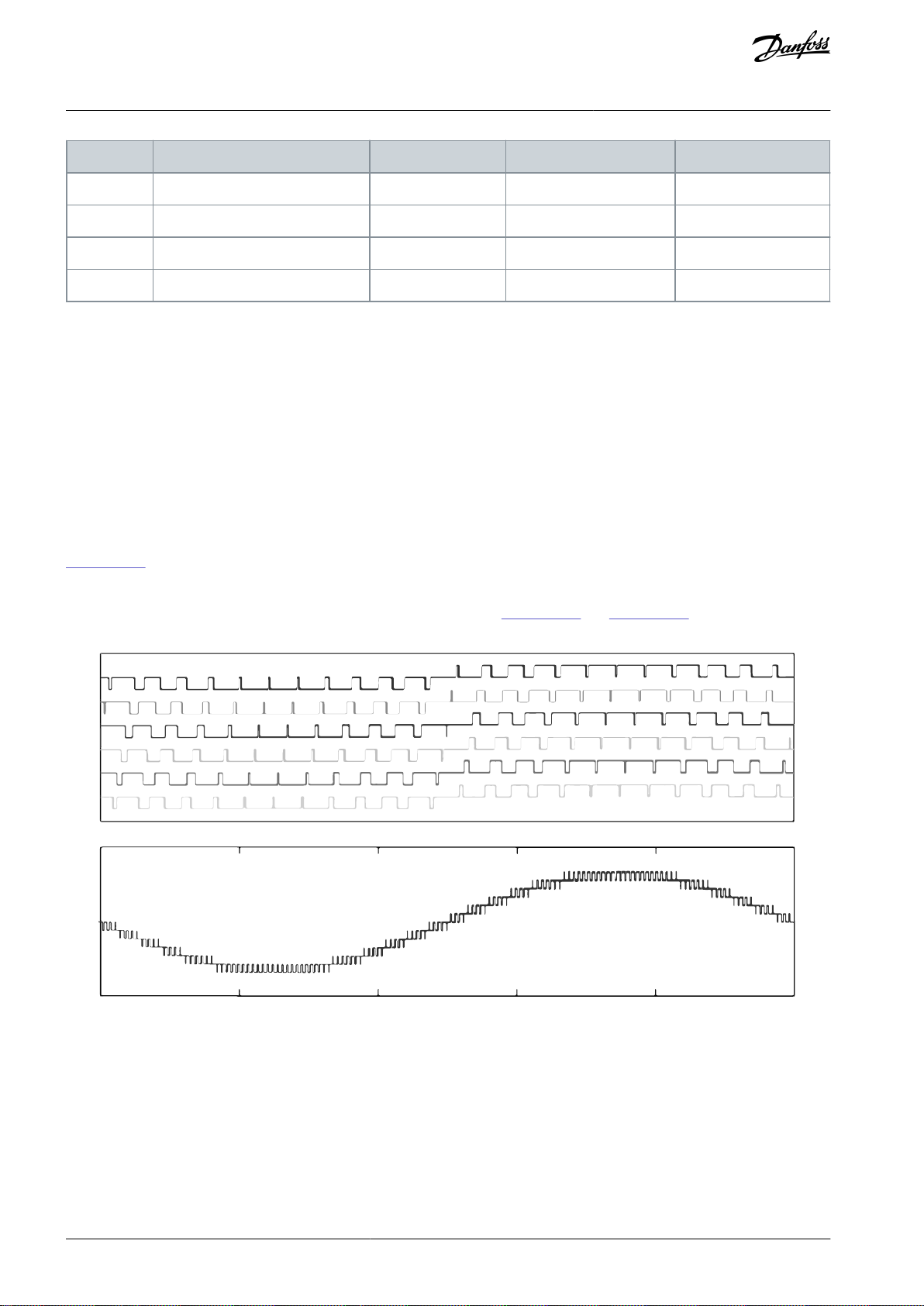

Illustration 25 shows the waveform diagram of the output voltage of each power cell and the superimposed output phase voltage

waveform when 6 cells are connected in series. As shown in the figure, 13 voltage levels are obtained through connecting the 6

power cells in series. The increasing number of the voltage levels reduces the distortion content of the output voltage and simultaneously lowers the risk of damaging the motor insulation caused by dU/dt. Illustration 26 and Illustration 27 are the waveform diagrams of the output voltage and current of the drive when loaded by a motor.

Illustration 25: Output and Phase-Voltage Diagrams

AQ363633621020en-000201 / 172F311730 | Danfoss A/S © 2021.06

Page 31

e30bi656.10

e30bi657.10

VACON® 1000

Operating Guide

Illustration 26: Output Line-to-line Voltage Waveform

Illustration 27: Output Current Waveform

Product Overview

Each power cell has an independent cell control board and driver board. The cell control board receives the PWM signal transmitted

by the main control system through optical fiber to control the IGBT. Simultaneously, the status information of each power cell is

fed back to the main control system by the cell control board through optical fiber. The driver board is used to drive the IGBT and

feedback the failure signal of the IGBTs to the cell control board, such as short-circuit protection.

3.4.3 Control System

An example structure diagram of the control system is shown in Illustration 28. The number of power cells depends on the nominal

voltage of the drive.

AQ363633621020en-000201 / 172F3117 | 31Danfoss A/S © 2021.06

Page 32

Motor

Phase-shifted

transformer

Input current sensor

Output current sensor

Input

Power

-12°

-24°

0°

12°

24°

Optical

fiber

communication

Main

control

system

User

end

Power cells

PLC

HMI

I/O

signals

RS485

RS485

4-20mA/0-10V

Analog signals

Digital signals

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

≈

RS485

Auxiliary winding

Input

voltage

sensor

Output

voltage

sensor

e30bi658.10

VACON® 1000

Operating Guide

Product Overview

Illustration 28: Structure Diagram of the Control System

The main functions of the main control system include:

•

Digital input and output

•

Analog input and output

•

PWM control signal generation of each power cell

•

Encoding and decoding of the control signal

•

System self-diagnosis

•

Delivery of various implementation instructions

•

Collection and handling of various failures

•

Communication with external systems

To enhance the flexibility at the site application, a PLC is used for the logical processing of the internal switching signals, site operation signals, and status signals of the medium-voltage drive. The VACON® 1000 medium-voltage drive uses a high-quality PLC to:

•

Accomplish the input and output drive signal control

•

Protection and interlocking

•

External failure detection

•

Communication with the main control system

•

Control of the human-machine interface

The HMI (Human-machine interface) is based on a high-definition liquid-crystal touch-type screen. It is easy to operate and is used

to set functional parameters, display and record the system status, operation status, and faults through the connection to the PLC.

See 7 Human-Machine Interface.

AQ363633621020en-000201 / 172F311732 | Danfoss A/S © 2021.06

Page 33

PWM

Inverter

Coordinate

transformation

Flux & Speed

Estimation

Coordinate

transformation

Motor

Voltage & Current

measurements

Calculation

Calculation

Calculation

Calculation

Calculation

Encoder

ω

*

ω

T

e

*

T

e

*

i

q

*

i

d

*

i

d

*

u

d

*

u

d

*

i

d

i

d

Ψ

Ψ

r

Ψ

r

*

iAiBi

C

u

A

u

A

*

u

B

*

u

C

*

uBu

C

i

q

i

q

u

d

u

q

i

q

*

u

q

*

u

q

*

e30bi659.10

Code

Voltage (V)

Frequency (Hz)

024

240060030

300060033

330050041

416060060

600050066

660050069

690060100

10000

50

110

11000

50

VACON® 1000

Operating Guide

Product Overview

VACON® 1000 delivers high performance control accuracy using Vector Control. The ability to control motor flux and speed independently yields fast dynamic response to load fluctuations and high torque at low speeds, including during motor startup. The

control diagram is shown in Illustration 29.

Both encoder and sensorless Vector Control approaches are available for selection. The speed sensors can be installed depending

on actual application conditions. For cases without the speed sensors, the system can still provide fast dynamic responses and high

output torque when the motor is running at low speed.

Illustration 29: Vector Control Diagram

3.5 Type Code Description

The type code for VACON® 1000 has four basic parts and option codes.

•

VACON1000-ED-019-024+____+____

1. Product series

VACON® 1000. This part of the code is always the same.

2. Product type

The VACON® 1000 product.

•

ED: Enclosed Drive

3. Nominal output current

For example, -040 = 40 A. See the available output currents in 11.2 Power Ratings and Dimensions.

4. Nominal system voltage

Table 3: Available System Voltages

AQ363633621020en-000201 / 172F3117 | 33Danfoss A/S © 2021.06

Page 34

Option

Description

Degree of protection

+IP42

Protection rating IP42

Input frequency

+LS50

50 Hz input frequency

+LS60

60 Hz input frequency

I/O options

+IAF1

Synchronous transfer I/O (8DI/8DO)

+IBF2

Advanced control module

+ICF3

Excitator control I/O

+IDF4

PID control module

+IEF5

Motor temperature module (8 channels)

I/O PLC options

+IAP1

PLC DI module (16 DI)

+IBP2

PLC DIO module (8DI/8DO)

+ICP3

PLC AIO module (2AI/4AO)

+IDP4

Motor temperature module (8 channels); Not compatible with all bypass options

Fieldbus options

+S_E2

Modbus RTU

+S_E5

PROFIBUS DP-V0

+S_E6

CANopen

+S_E7

DeviceNet

™

+S_EC

EtherCAT

+S_EI

Modbus TCP

+S_EL

POWERLINK

+S_EN

ControNet

™

+S_EP

PROFINET I/O

+S_EQ

EtherNet/IP

™

User interface

VACON® 1000

Operating Guide

5. Options

Optional components or specifications.

See the available codes in 3.6 Available Options.

3.6 Available Options

Table 4: Available Options for VACON® 1000

Product Overview

AQ363633621020en-000201 / 172F311734 | Danfoss A/S © 2021.06

Page 35

Option

Description

+MHMI

HMI 10"

System firmware

+F101

Induction motor

+F102

Synchronous motor (external exciter)

Cell bypass

+PPCB

Power cell bypass

Cell redundancy

(1)

+PPCR

Power cell redundancy

Cabinet bypass

(1)

+PMBP

Manual motor bypass

+PABP

Automatic motor bypass

+PSBP

Synchronous transfer (1 motor only)

+PSB2

Engineered synchronous transfer

Input devices

(1)

+PSTC

Start-up cabinet available for drives >215 A

Output devices

(1)

+POCK

Reactor for synchronous transfer

+PODU

dU/dt filter for cable <2000 m

Cabinet options

+QDFR

Cooling fan redundancy

+QDEX

External cooling fan supply

+QSPD

Surge protection device (standard for UL, optional for IEC variants)

+QT01

Control power without heater XFMR

+QT02

Control power with heater XFMR

Mechanical options

+MHET

Heater + Thermostat

+MHEH

Heater + Humidity sensor

+MMKI

Mechanical key interlock (standard for UL, optional for IEC variants)

Input voltage options

(1)

+I023

Input voltage: 2300 V

+I024

Input voltage: 2400 V

+I030

Input voltage: 3000 V

VACON® 1000

Operating Guide

Product Overview

AQ363633621020en-000201 / 172F3117 | 35Danfoss A/S © 2021.06

Page 36

Option

Description

+I033

Input voltage: 3300 V

+I040

Input voltage: 4000 V

+I041

Input voltage: 4160 V

+I042

Input voltage: 4200 V

+I048

Input voltage: 4800 V

+I050

Input voltage: 5000 V

+I060

Input voltage: 6000 V

+I063

Input voltage: 6300 V

+I066

Input voltage: 6600 V

+I069

Input voltage: 6900 V

+I072

Input voltage: 7200 V

+I084

Input voltage: 8400 V

+I100

Input voltage: 10000 V

+I110

Input voltage: 11000 V

+I114

Input voltage: 11400 V

+I120

Input voltage: 12000 V

+I124

Input voltage: 12400 V

+I132

Input voltage: 13200 V

+I138

Input voltage: 13800 V

Environment

+THAL

High altitude, >2000 m above sea level

+T50C

50°C ambient temperature operation

Seismic zone

+SZ04

Zone 4

Factory Acceptance Test

+QFAT

FAT

+QFNO

No-load FAT

VACON® 1000

Operating Guide

Product Overview

1

If this option is selected, it can impact the overall dimensions and weight of the product.

3.6.1 Cabinet Bypass

See 3.3.7 Bypass Cabinet.

3.6.2 Input Devices

See 3.3.5 Start-up Cabinet.

AQ363633621020en-000201 / 172F311736 | Danfoss A/S © 2021.06

Page 37

Option

+MHET

+MHEH

Devices

Heater and thermostat

Heater and hygrostat

Application

area

Low operation temperature area (-5 °C...0 °C)

High relative humidity and condensation area

Purpose

To warm up the drive before turning it on if the temperature is lower than 0 °C (but higher than -5 °C). The

low temperatures exceed the rated operation temperature of the micro chips and capacitors inside control

cabinet and power cells.

To prevent devices and cabinets from condensation and

corrosion in a high relative humidity operation environment, otherwise break down or flashover can occur during operation.

Location

Control cabinet and power cell cabinet

Power cell cabinet, transformer cabinet, junction cabinet, or any other cabinets with high voltage parts

Key parameters

Thermostat setting range: -10...50°C (14–122 °F),0 °C as

default preset value.

Heater power: 220 V, 400/150 W, depending on the

cabinet size.

Hygrostat setting range: 35–95% RH, 80% as default preset value.

Heater power: 220 V, 400/150 W, depending on the cabinet size.

VACON® 1000

Operating Guide

3.6.3 Output Devices

See 3.3.6 Output Filter Cabinet.

3.6.4 Mechanical Options

Heater Options +MHET/+MHEH

Table 5: Heater Options +MHET and +MHEH

Product Overview

Mechanical Interlocking System, +MMKI

See 8.6.2 Mechanical Interlocking System.

3.7 VACON® 1000 PC Tool

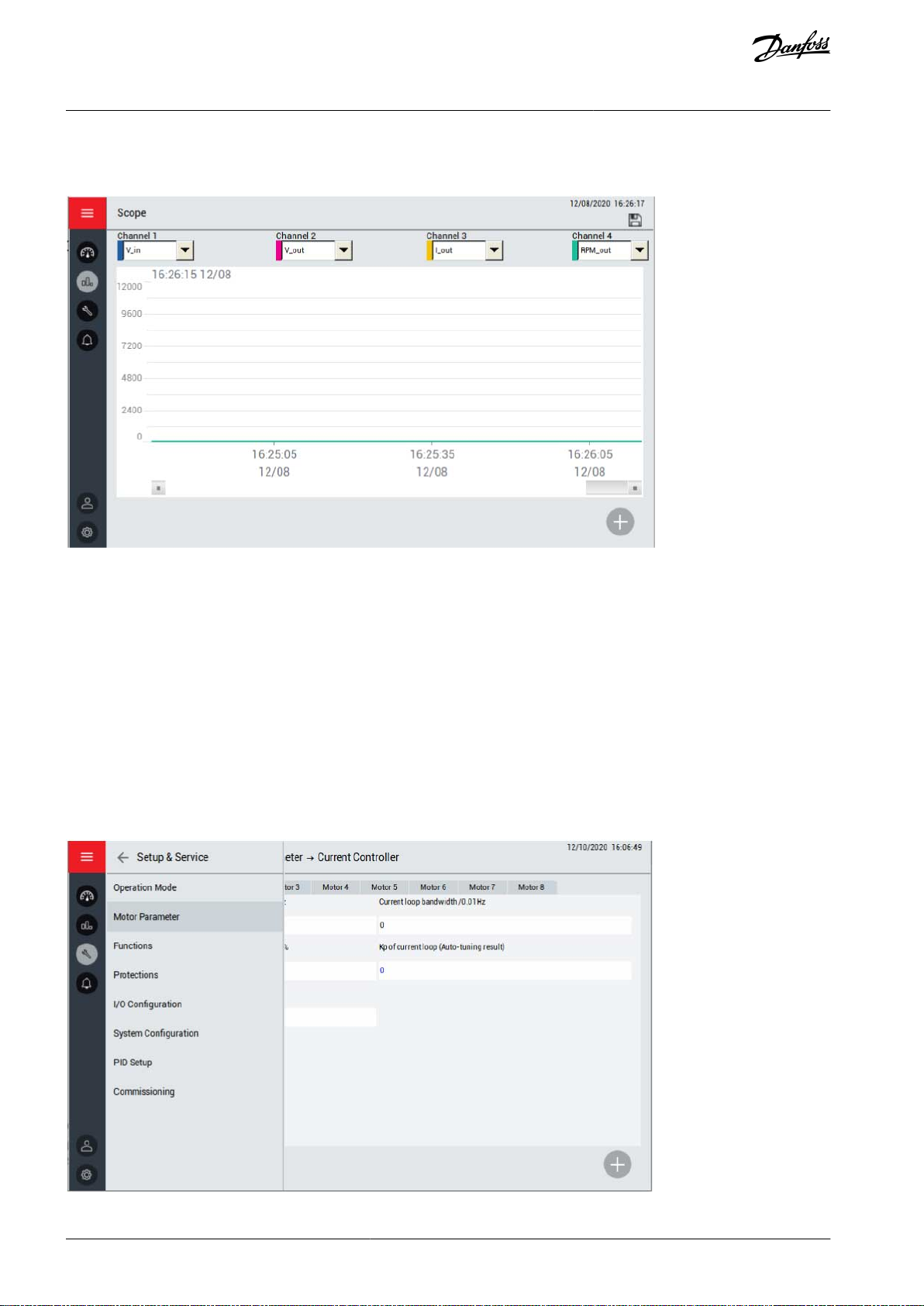

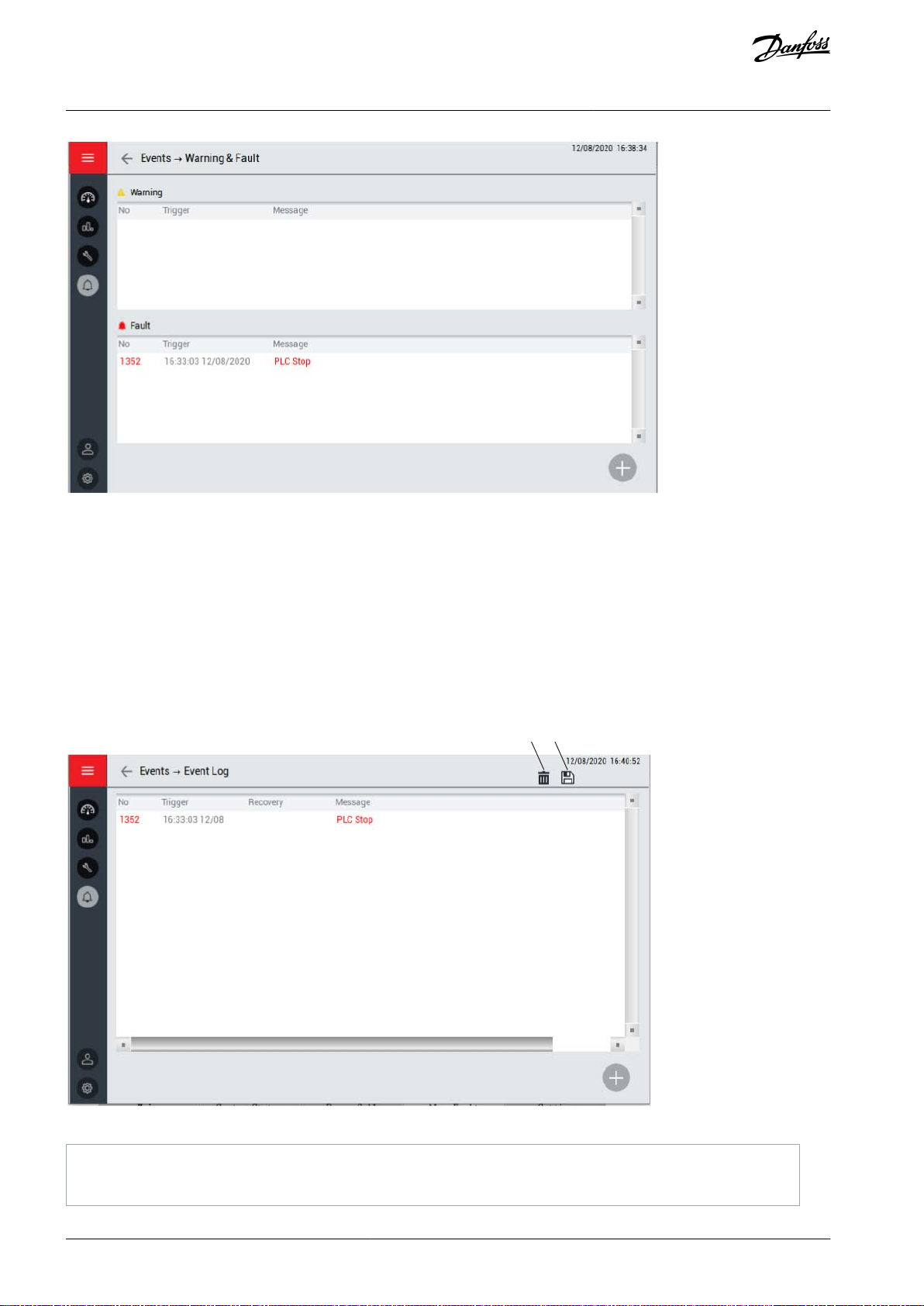

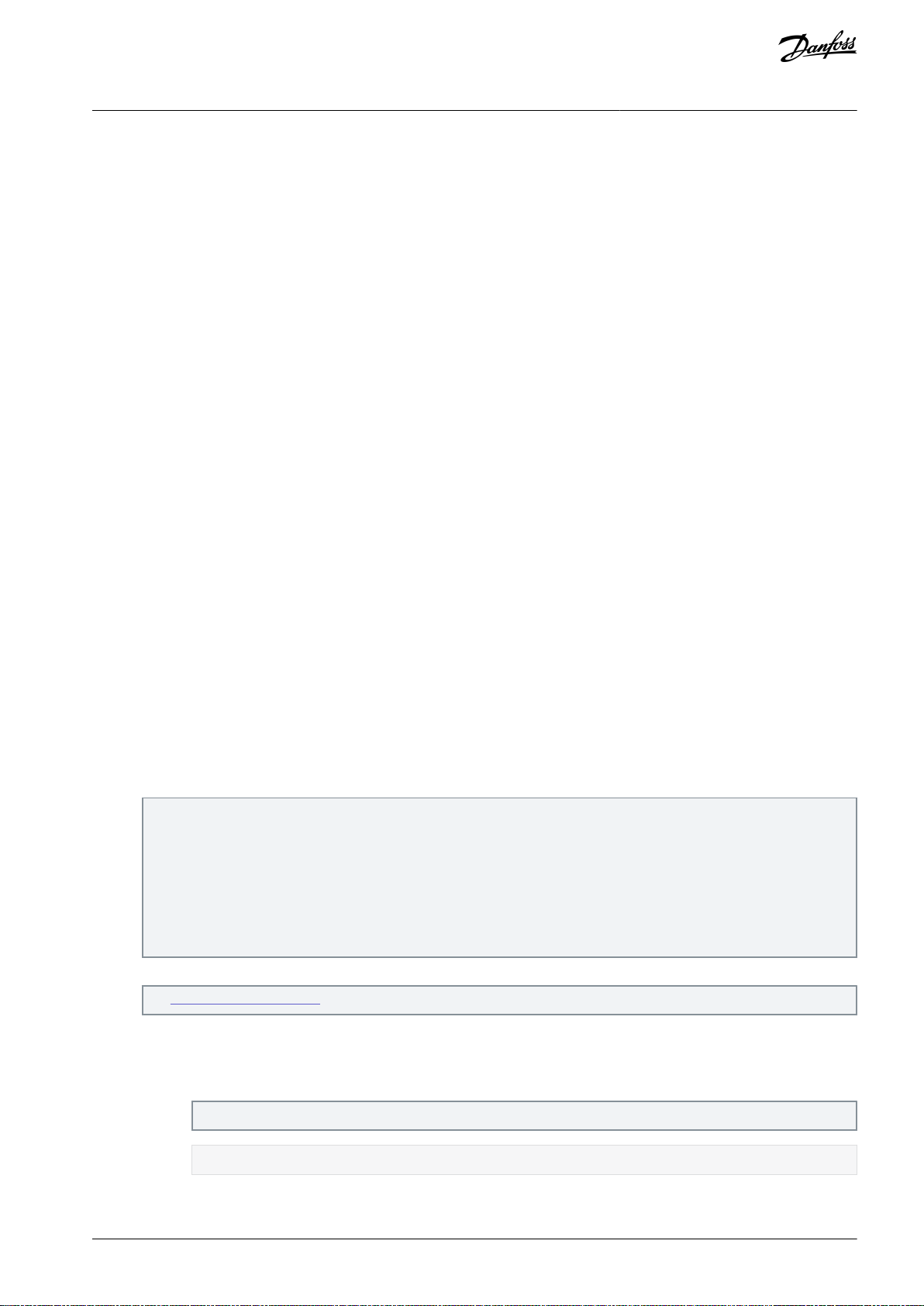

The VACON® 1000 PC Tool is an Ethernet-based computer-assisted software. Only one network cable is needed, and the monitoring

and fault diagnosis of the drive can be completed with this software.

The VACON® 1000 PC Tool integrates some auxiliary functions that are often used during normal operation and commissioning.

•

The status display panel shows the running status of the drive in real time.

•

The waveform display function allows the direct observation of the internal variables when the drive is running.

•

The parameter management function allows the direct modification or saving of the current system parameters on the computer.

•

The fault analysis function can process the fault information in the DSP cache, list the fault content of the system, and the time

of occurrence, and show the waveform of the system input and output near the fault point.

In addition to these functions, the VACON® 1000 PC Tool also provides commissioning auxiliary functions and DSP program update

functions.

Minimum requirements for the VACON® 1000:

•

Operating system: Windows 10

•

Processor: Intel® Core™ i5-6300U CPU @2.40 GHz 2.50 GHz

•

RAM: 8.00 GB

AQ363633621020en-000201 / 172F3117 | 37Danfoss A/S © 2021.06

Page 38

VACON® 1000

Operating Guide

Receiving the Delivery

4 Receiving the Delivery

4.1 Checking the Delivery

1.

Before unpacking, check the number of packing boxes according to the shipping list and then check whether the appearance of the packing boxes is in good condition.

2.

After removing the packaging, check the product and enclosed documents according to the shipping list to see whether

anything is missing or does not match the order. Compare the type code for the order to the type code on the package

label. See 3.5 Type Code Description.

-

If the delivery does not agree with the order, speak to the vendor immediately.

3.

Examine the product for any transport damage.

-

If the drive was damaged during the shipping, speak to the cargo insurance company or the carrier.

4.2 Storage

The storage temperature range of the VACON® 1000 drive is between -40°C to 70°C, and the relative humidity must not exceed 95%.

The storage environment must be out of direct sunlight, corrosion, inflammable gas, conductive dust, salt smog, oil smoke, and so

on.

Keep the equipment sealed in its packaging until installation. In its packaging, the drive can be stored in a dry and ventilated place

for more than one year. If the drive is required to be stored for a longer period, contact Danfoss.

If the drive is unpacked, apply desiccant on the drive when stored again. The wrapped product with VCI bag can be put on the

wooden pallet and stored for more than one year in a dry and ventilated place.

4.3 Lifting and Moving the Drive

W A R N I N G

LIFTING HEAVY EQUIPMENT

Follow local safety regulations for lifting heavy weights. Failure to follow recommendations and local safety regulations can result

in death or serious injury.

Ensure that the lifting equipment is in proper working condition.

-

Move the cabinets in vertical position. To lift the cabinets, use a lifting device that can lift the weight of the cabinets. Refer to the

shipping marks on the package for more information, such as weight, center of gravity, and lifting positions.

Move the drive to the installation location before removing the packaging material.

VACON® 1000 standalone cabinets are delivered in one piece, but line-up designs are delivered in separate sections:

•

Control cabinet

•

Power cell cabinet

•

Transformer cabinet

•

Options cabinet

To divide the weight of the cabinets equally, and to prevent damage to the equipment, always use 4 lifting holes. Align the lifting

locations with the center of gravity, which is marked on the package.

Move the cabinets slowly and carefully. Switchgear parts can easily fall because their center of gravity is high up at the back of the

cabinets.

4.3.1 Lifting the Standalone Cabinets

After the packaging of the cabinets is removed, a crane or forklift is required to lift them off the wooden pallets and to the installation location.

1.

Use a crane to lift the cabinet from the bottom.

The distance (D) between crane hook and cabinet top must be more than 1.5 m (4.92 ft).

The minimum angle between two lifting ropes must be 45°.

AQ363633621020en-000201 / 172F311738 | Danfoss A/S © 2021.06

Page 39

e30bi662.10

D

≥45°

e30bi663.10

e30bi664.10

VACON® 1000

Operating Guide

Illustration 30: Lifting the Standalone Cabinets

2.

Use the shackles in the holes of the lifting bar.

Use only 33 mm (1.3 in) diameter holes and 30 mm (0.75–1.125 in) width for the shackles.

Receiving the Delivery

Illustration 31: Shackle Attached to Lifting Bar

3.

Make sure that the crane lifting ropes do not compress the cabinet and damage it. Use spreader bars or a block of wood

between the ropes on the top of the cabinet.

Illustration 32: Lifting Ropes Spread with a Block of Wood

4.

Lift the cabinet slowly and without jerking. Lower in the same manner to a standstill position.

AQ363633621020en-000201 / 172F3117 | 39Danfoss A/S © 2021.06

Page 40

D

e30bi660.10

D

e30bi661.10

VACON® 1000

Operating Guide

Receiving the Delivery

4.3.2 Lifting the Line-up Cabinets

After the packaging of the cabinets is removed, a crane or forklift is required to lift them off the wooden pallets and to the installation location.

1.

To lift the power cell cabinet and control cabinet, use the four holes of angle steels on the top of the cabinet.

The distance (D) between crane hook and cabinet top must be more than 1.5 m (4.92 ft).

Remove the angle steels after the lifting.

Illustration 33: Lifting Points of the Power Cell Cabinet

2.

To lift the options cabinet, use the eyebolts at the four corners on the top of the cabinet.

3.

Since the transformer cabinet is heavy, do not lift it from the lifting rings on the top of the cabinet. Instead, use the lifting

rings of the transformer.

The distance (D) between crane hook and cabinet top must be more than 1.5 m (4.92 ft).

Illustration 34: Lifting Points of the Transformer

4.

Lift the cabinet slowly and without jerking. Lower in the same manner to a standstill position.

4.3.3 Using a Forklift

The forklift must be able lift and bear the weight of the cabinet.

AQ363633621020en-000201 / 172F311740 | Danfoss A/S © 2021.06

Page 41

e30bi665.10

A

B

A

Block of wood

B

Center of gravity

VACON® 1000

Operating Guide

Receiving the Delivery

1.2.To prevent the truck arm from scratching the cabinet, add a block of wood or something similar between the forklift and

the cabinet.

Illustration 35: Using a Forklift to move a Cabinet

Lift the cabinet slowly and reduce vibration as much as possible.

Consider the center of gravity of the cabinet before lifting.

AQ363633621020en-000201 / 172F3117 | 41Danfoss A/S © 2021.06

Page 42

VACON® 1000

Operating Guide

Mechanical Installation

5 Mechanical Installation

5.1 Operating Environment

N O T I C E

CONDENSATION

Moisture can condense on the electronic components and cause short circuits. Avoid installation in areas subject to frost. Install

an optional space heater when the drive is colder than the ambient air.

N O T I C E

EXTREME AMBIENT CONDITIONS

Hot or cold temperatures compromise unit performance and longevity.

To ensure the long-term and reliable operation of the drive, the installation environment must meet the following requirements:

•

The temperature in the normal operating environment must be between -5°C...+40°C. If the ambient temperature exceeds

these values, the equipment must be used in derated operation or equipped with corresponding air conditioning equipment.

•

The installation altitude must be less than 1000 m above sea level. If the altitude is higher than 1000 m, use the equipment in

derated operation.

•

The relative humidity must be within 5% to 95% without condensation.

•

Pollution degree: II

-

Chemical gas: IEC 721-3-3, class 3C1

-

Solid particle: IEC 721-3-3, class 3S2

5.2 Cabinet Installation

Installation guidelines:

•

To keep motor cable length as short as possible, locate the drive close to the motor.

•

Ensure unit stability by mounting the enclosure on a solid surface.

•

Ensure that the strength of the mounting location supports the unit weight.

•

For safety and easier cabling, it is recommended to install the cabinet on a cable trench.

•

Do not install the cabinet on top of inflammable objects.

•

Ensure that there is enough space around the unit for proper cooling.

•

Ensure that there is enough room to open the cabinet doors and for working on the equipment.

•

Remove the moving and lifting parts from the cabinet before installation.

5.2.1 Attaching the Cabinets

Once the cabinets are in position and aligned, attach the cabinets to each other.

For line-up cabinets, secure the power cell cabinet with control part and the transformer cabinets with junction part to each other.

Install the optional cabinets on the right side of the transformer cabinet in sequence.

For standalone cabinets, install the optional cabinets on the left side of the cabinet.

AQ363633621020en-000201 / 172F311742 | Danfoss A/S © 2021.06

Page 43

e30bi667.10

e30bi666.10

VACON® 1000

Operating Guide

Illustration 36: Attachment Points in Standalone Cabinets

Mechanical Installation

Illustration 37: Attachment Points in Line-up Cabinets

Notice the following points:

•

When handling and installing the cabinet, consider safety protection measures, such as shockproof and moisture proof, to avoid

deformation of the frame and damage to the paint coating.

•

Align the cabinets well before attachment.

•

When attaching the cabinets, the bases of the two cabinets can be leaned against each other completely by using a lifting truck

or chain-reversing hoist before they are fixed.

•

Use M6×40 hexagonal spacers and M6×10 screws to connect the adjacent cabinets.

•

The cabinets must be grounded reliably.

•

The fastening parts used in installation must be standard parts with Zn-Ni alloy plating.

•

If the cabinet is placed against the wall or the depth of the cabinets is different, the hexagonal spacers cannot be used for attaching the back side of the cabinet. In this case, use angle steel parts to connect the cabinets.

AQ363633621020en-000201 / 172F3117 | 43Danfoss A/S © 2021.06

Page 44

e30bi668.10

e30bi669.10

VACON® 1000

Operating Guide

Illustration 38: Angle Steel

Mechanical Installation

5.2.2 Mounting the Cabinets

Connect and fix the round hole on each channel steel base with the trench channel steel. Use M12×35 screws. The cabinet can also

be welded to the channel steel base.

Illustration 39: Mounting the Cabinets to the Foundation

5.3 Installing the Power Cells

At least two persons are required for cooperation during the installation.

A power cell lifting cart is available from Danfoss as an option.

1.

Once the power cell is removed from the package, make sure that it is not damaged.

2.

Use the power cell lifting cart or other lifting device to move and lift the power cell.

The lifting device must:

•

Be able to lift the weight of the power cells.

•

Be able to lift the power cells to the required height.

•

Have a locking mechanism.

3.

Push the power cell completely into the fixing support slot in the cabinet.

AQ363633621020en-000201 / 172F311744 | Danfoss A/S © 2021.06

Page 45

e30bi670.10

A

e30bi671.10

VACON® 1000

Operating Guide

4. After the power cell is in place, use M6 screws to fix the corners to the fixing support.

Mechanical Installation

Illustration 40: Power Cell Installation

5.4 Dimensions of the Enclosed Drive

See the dimensions of the drive cabinet in 11.2 Power Ratings and Dimensions.

Always refer to the delivery-specific information for the accurate dimensions.

5.5 Cooling and Free Space Around the Enclosed Drive

The AC drive produces heat in operation. VACON® 1000 uses forced air cooling to control the temperature of the transformer, power

cells, and other components. Fans on the top of the cabinet provide the airflow. The cool air is drawn into the cabinet through the

inlet and directed out from the outlet as shown in the picture.

Illustration 41: Flow of Cooling Air

Make sure that the temperature of the cooling air does not become higher than the maximum ambient operating temperature or

lower than the minimum ambient operating temperature of the drive. See 5.1 Operating Environment.

AQ363633621020en-000201 / 172F3117 | 45Danfoss A/S © 2021.06

Page 46

VACON® 1000

Operating Guide

Make sure that the hot air goes out of the cabinet and does not come back into the cabinet. There must be free space above the

cabinet without obstacles that can stop the airflow. Some free space in front of the cabinet is also necessary to be able to open the

cabinet doors and for maintenance.

•

The back side of the cabinet can be placed against a wall.

•

The distance between the cabinet front and walls ≥1500 mm.

•

The distance between the cabinet fan cover top and ceiling:

-

≥400 mm for non-ducted drives.

-

≥1000 mm for ducted drives.

The power loss of the AC drive can change significantly, when the load, the output frequency or the switching frequency changes. It

is useful to know the power loss, when planning the cooling equipment in an electrical room.

To calculate the power loss, use the ecoSmart tool. See http://ecosmart.danfoss.com/#/app/intro.

Mechanical Installation

5.5.1 Air Ducting Guidelines

Air ducts can be used to direct the warm outlet air from the VACON® 1000 out from the electrical room.

Guidelines for using an air duct:

•

The outlet area of the air duct must be larger than the sum of the cabinet fan outlet areas.

•

The air inlet area of the cabinet location must be larger than 1.2–1.5 times the sum of the fan outlet areas. The air inlet must

have a primary air filter.

•

The outlet of the air duct must be waterproof to prevent water entering the air duct.

•

The recommended maximum length of the air duct is 3 m. For longer air ducts, support brackets and an induced draft fan are

required.

AQ363633621020en-000201 / 172F311746 | Danfoss A/S © 2021.06

Page 47

HV~

MCB

M

Junction

cabinet

Startup

cabinet

Drive

KM51

Output filter

cabinet

e30bi650.10

VACON® 1000

Operating Guide

6 Electrical Installation

6.1 The Main Circuit

The typical main circuit of VACON® 1000 is shown in Illustration 42.

•

The circuit breaker (MCB), the motor, and the mains and motor cables are not included in the delivery.

•

The start-up cabinet and output filter cabinet are optional.

Illustration 42: Main Circuit of VACON® 1000

Electrical Installation

6.2 Main Circuit Breaker and Fuses

For the short-circuit protection of the drive, install fuses or a circuit breaker on the grid side of the equipment in accordance with all

applicable installation codes.

When selecting the size of the fuses or mains circuit breaker, refer to the available

•

Short circuit power

•

Continuous current

•

Supply voltage

6.3 Galvanic Isolation Between the MV and LV Sections