Page 1

vacon

ac drives

®

opte2/e8

rs485 multiprotocol option board

installation manual

Page 2

Page 3

vacon • 3

TABLE OF CONTENTS

Document: DPD01780C

Release date : 7/1/19

1. Safety...............................................................................................................5

1.1 Danger................................................................................................................................5

1.2 Warnings ............................................................................................................................6

1.3 Grounding and earth fault protection ................................................................................7

2. General ............................................................................................................8

3. Option board technical data .............................................................................9

3.1 General...............................................................................................................................9

3.2 New features ......................................................................................................................9

4. Layout and connections..................................................................................10

4.1 OPTE2 (screw plug) option board layout .........................................................................10

4.2 OPTE8 (Sub-D9) option board layout ...............................................................................11

4.3 LED indications ................................................................................................................12

4.4 Jumpers ...........................................................................................................................12

4.5 Bus terminal and bias resistors ......................................................................................13

5. Cabling instructions .......................................................................................15

5.1 Selecting cable.................................................................................................................15

5.2 Setting the termination resistance..................................................................................15

5.3 Shield grounding options .................................................................................................15

5.3.1 Shield grounding when equipotential bonding is good ...................................................15

5.3.2 Shield grounding when equipotential bonding is poor....................................................16

6. Installation.....................................................................................................17

6.1 Installation in VACON® 20 ...............................................................................................18

6.1.1 Enclosures MI1, MI2, MI3.................................................................................................18

6.1.2 Enclosures MI4, MI5.........................................................................................................21

6.2 Installation in VACON

6.3 Installation in VACON

6.4 Installation in VACON

6.5 Installation in VACON

®

6.6 VACON

PC tools.............................................................................................................37

6.6.1 PC tool support ................................................................................................................37

6.6.2 OPTE2/E8 option board firmware update with VACON® Loader....................................37

6.6.3 PC tools for VACON

6.6.4 PC tools for VACON

7. Commissioning ..............................................................................................45

7.1 Option board menu...........................................................................................................45

7.1.1 Option board monitor menu.............................................................................................45

7.1.2 Option board parameter menu ........................................................................................46

7.1.3 System Parameter menu.................................................................................................47

8. Modbus RTU ...................................................................................................48

8.1 Overview ...........................................................................................................................48

8.2 Modbus RTU communications.........................................................................................48

8.2.1 Data addresses in Modbus message...............................................................................48

8.2.2 Modbus memory map ......................................................................................................48

8.2.3 Modbus exception responses ..........................................................................................49

8.3 Modbus data mapping......................................................................................................49

8.3.1 Holding and input registers .............................................................................................49

8.4 Quick setup.......................................................................................................................59

8.5 Example messages ..........................................................................................................60

®

20 X and 20 CP ...........................................................................25

®

100 family ..................................................................................28

®

100 X (enclosures MM4-MM6)...................................................31

®

NX...............................................................................................35

®

NXP/NXS: NCDrive .......................................................................40

®

100 family and VACON® 20: VACON® Live...................................42

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 4

vacon • 4

8.5.1 Example 1: Write process data........................................................................................60

8.5.2 Example 2: Read process data ........................................................................................61

8.5.3 Example 3: Exception response.......................................................................................62

9. Metasys N2.....................................................................................................63

9.1 Overview ...........................................................................................................................63

9.2 Metasys N2 communication.............................................................................................63

9.2.1 Analogue Input (AI)...........................................................................................................63

9.2.2 Binary Input (BI) ...............................................................................................................63

9.2.3 Analogue Output (AO).......................................................................................................64

9.2.4 Binary Output (BO) ...........................................................................................................64

9.2.5 Internal Integer (ADI) .......................................................................................................64

9.3 Metasys N2 point map......................................................................................................65

9.3.1 Analogue Input (AI)...........................................................................................................65

9.3.2 Binary Input (BI) ...............................................................................................................65

9.3.3 Analogue Output (AO).......................................................................................................67

9.3.4 Binary Output (BO) ...........................................................................................................67

9.3.5 Internal Integer (ADI) .......................................................................................................68

9.4 Quick setup.......................................................................................................................69

10. Appendix A - Fieldbus parametrization..........................................................70

10.1 Fieldbus control and basic reference selection ..............................................................70

10.2 Controlling fieldbus parameter .......................................................................................71

10.3 Torque control parametrization ......................................................................................72

10.4 Response to fieldbus fault ...............................................................................................72

11. Appendix B - VACON® IO data description...................................................... 74

11.1 VACON® profile................................................................................................................74

11.1.1 VACON

11.2 Control Word bit support in VACON

11.3 VACON

11.4 Status Word bit support in VACON

11.5 Monitoring of control and status words in VACON

11.6 VACON

11.7 Process data.....................................................................................................................80

11.8 Fieldbus process data mapping and scaling ...................................................................80

11.8.1 Monitoring of process data in VACON

®

Control Word - FBFixedControlWord ...............................................................74

®

Status Word - FBFixedStatusWord ..................................................................77

®

speed reference and actual speed - FBSpeedReference and FBActualSpeed79

®

AC drives..............................................................76

®

AC drives ...............................................................78

®

AC drives ..........................................................82

®

AC drives.......................................78

12. Appendix C - Fieldbus option board communication ......................................84

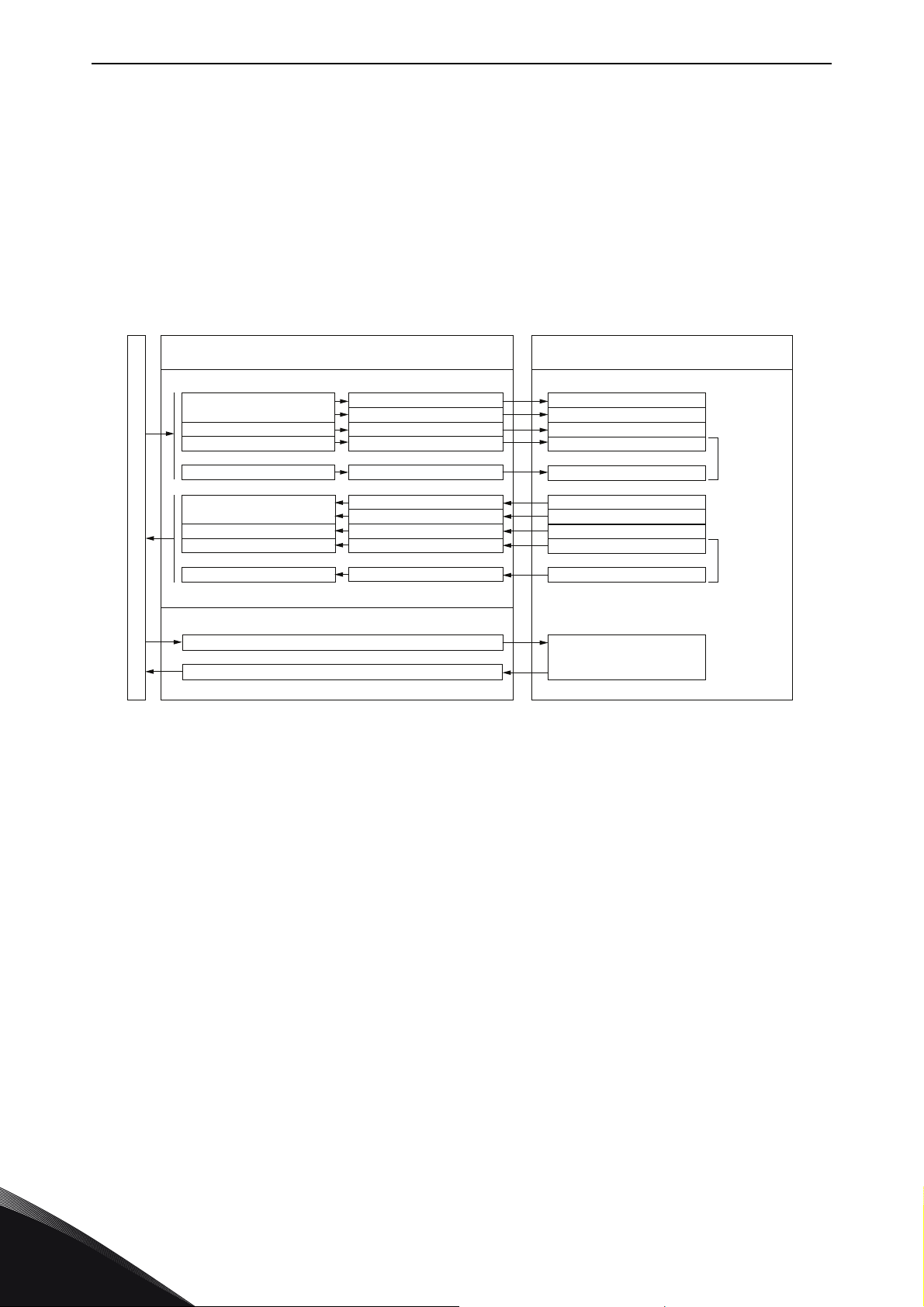

12.1 Normal fieldbus communication .....................................................................................85

12.2 Normal Extended Mode ...................................................................................................86

12.3 Fast fieldbus communication ..........................................................................................87

12.4 Fast safety fieldbus communication................................................................................88

12.5 Fast PROFIBUS fieldbus communication ........................................................................89

13. Appendix D - Parameters for application developers ....................................91

14. Appendix E - Fault tracing..............................................................................93

14.1 Diagnostic information.....................................................................................................94

14.2 Typical fault conditions ....................................................................................................94

14.2.1 PLC master cannot get response from OPTE2/E8 RS485...............................................94

14.2.2 Data corruption in communication..................................................................................95

14.2.3 AC drive does not start to run..........................................................................................95

14.2.4 Drive runs with wrong speed ...........................................................................................96

14.2.5 AC drive reports Fieldbus timeout fault (F53).................................................................96

14.2.6 Fieldbus timeout fault (F53) cannot be reset ..................................................................96

14.3 Fieldbus timeout fault (F53).............................................................................................96

14.3.1 OPTE2/E8 RS485 fault conditions....................................................................................96

14.3.2 Fieldbus timeout fault (F53) diagnostic info....................................................................97

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 5

Safety vacon • 5

9000.emf

13006.emf

9001.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

9000.emf

1. SAFETY

This manual contains clearly marked cautions and warnings that are intended for your personal

safety and to avoid any unintentional damage to the product or connected appliances.

Read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

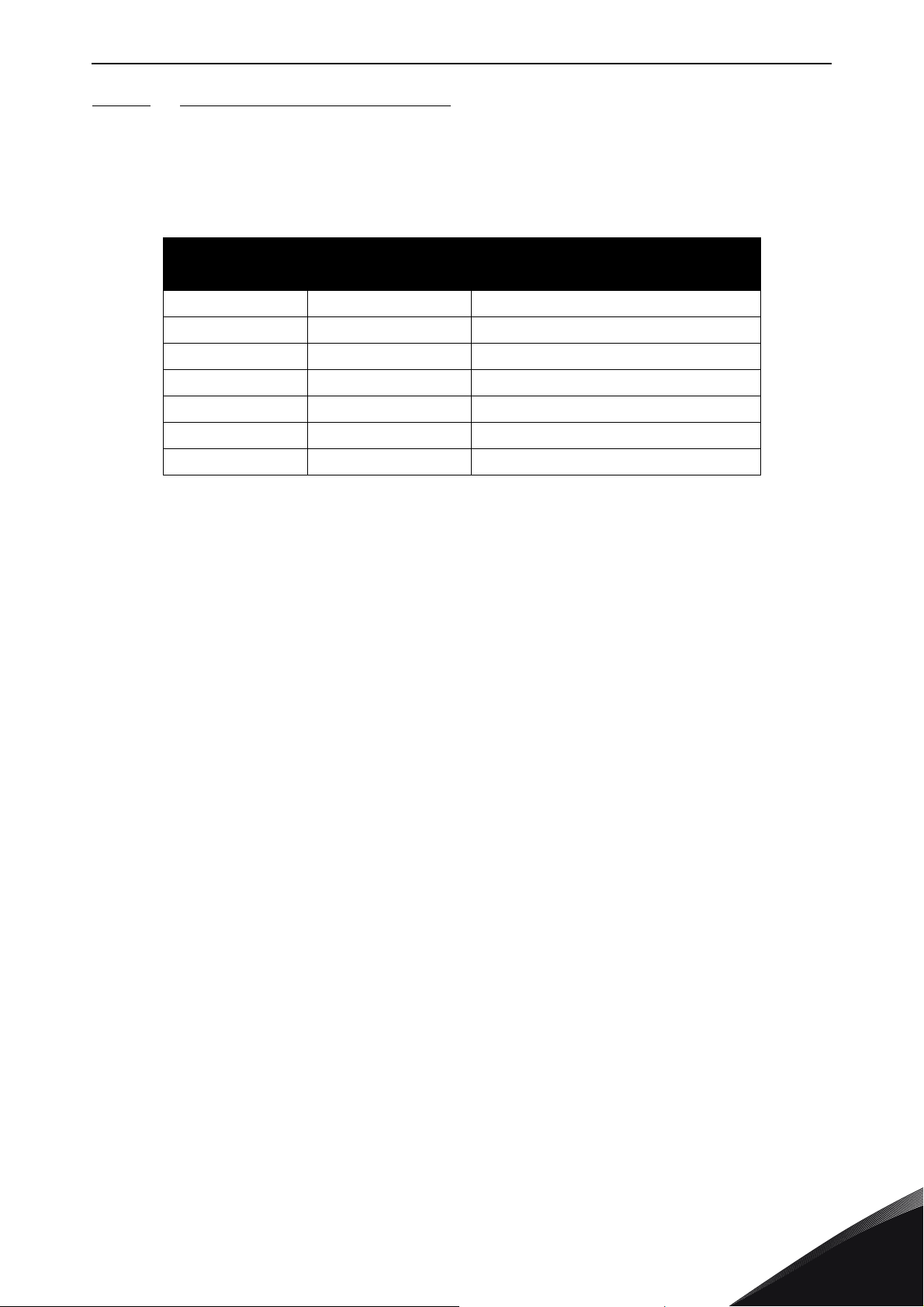

Table 1. Warning signs

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

1.1 Danger

The components of the power unit are live when the drive is connected to mains

potential. Coming into contact with this voltage is extremely dangerous and may

cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when the

AC drive is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached, see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of the drive. Do not open

the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the AC drive is disconnected from mains.

voltage is present.

Always

Before connecting the AC drive to mains make sure that the front and cable

covers of the drive are closed.

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached, see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Page 6

vacon • 6 Safety

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

13006.emf

1.2 Warnings

The AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of the AC drives exceeds 3.5mA AC. According to

standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See Chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by VACON

®

can be used.

At power-up, power break or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Start/Stop logic has been selected

Furthermore, the I/O functionalities (including start inputs) may change if

parameters, applications or software are changed. Disconnect, therefore, the

motor if an unexpected start can cause danger.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of your

supply network.

.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Page 7

Safety vacon • 7

13006.emf 13006.emf

1.3 Grounding and earth fault protection

CAUTION!

The AC drive must always be earthed with an grounding conductor connected to the grounding

terminal marked with .

The earth leakage current of the drive exceeds 3.5mA AC. According to EN61800-5-1, one or more

of the following conditions for the associated protective circuit must be satisfied:

a) The protective conductor must have a cross-sectional area of at least 10 mm

Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm

2

Al, a second protective conductor of at least the same cross-sectional area must be

mm

provided up to a point where the protective conductor has a cross-sectional area not less

than 10 mm

2

Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

2

Cu or 1 6 mm2

2

Cu or 16

The cross-sectional area of every protective grounding conductor which does not form part of the

supply cable or cable enclosure must, in any case, be not less than:

-2.5mm

-4mm

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

The earth fault protection inside the AC drive protects only the drive itself against earth faults in the

motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches may

not function properly.

Do not perform any voltage withstand tests on any part of the AC drive. There is

a certain procedure according to which the tests must be performed. Ignoring

this procedure can cause damage to the product.

NOTE! You can download the English and French product manuals with applicable safety,

warning and caution information from https://www.danfoss.com/en/service-and-support/.

REMARQUE Vous pouvez télécharger les versions anglaise et française des manuels produit

contenant l’ensemble des informations de sécurité, avertissements et mises en garde

applicables sur le site https://www.danfoss.com/en/service-and-support/.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

1

Page 8

vacon • 8 General

2. GENERAL

OPTE2/E8 RS-485 multiple protocols field option board supports both Modbus RTU and Metasys N2

protocols. With these fieldbuses, the AC drives can then be controlled and monitored from the

master.

®

OPTE2/E8 RS485 can be installed to the following VACON

•VACON® 20

®

•VACON

•VACON

•VACON

•VACON

•VACON

•VACON

•VACON

20 X / CP

®

100 INDUSTRIAL

®

FLOW

®

HVAC

®

100 X

®

NXP

®

NXS

AC drives:

2

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 9

Option board technical data vacon • 9

3. OPTION BOARD TECHNICAL DATA

3.1 General

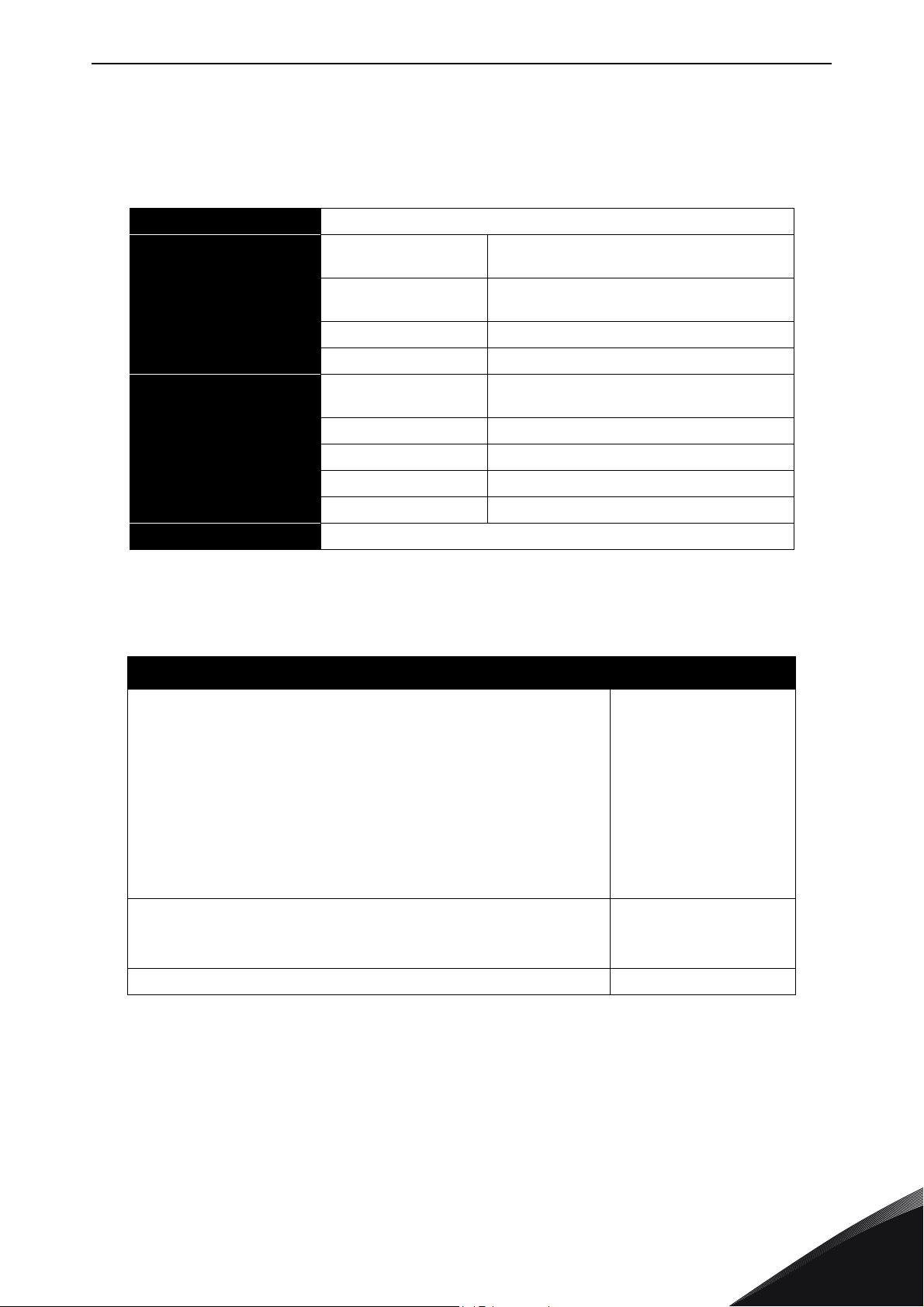

Table 2. Technical da ta

Protocols Modbus RTU / Metasys N2

Interface

Data transfer

Communications

method

Transfer cable Shielded Twisted Pair

Electrical isolation 500 VDC

Ambient operating

temperature

Storing temperature -40°C–70°C

Environment

Humidity <95%, no condensation allowed

Altitude Max. 1,000 m

Vibration 0.5 G at 9–200 Hz

Safety Fulfills EN50178 standard

OPTE2: 5-pin pluggable connector

OPTE8: 9-pin D-SUB connector (female)

RS-485, half-duplex

-10°C–50°C

3.2 New features

• Support for VACON® NXP and VACON® NXS AC drives. See control firmware requirements in Chapter 6 "Installation".

• Support for 16 Modbus RTU process data items in VACON

®

NXP, VACON

drives. See details in Chapter 8.3 "Modbus data mapping" and

Chapter 12 "Appendix C - Fieldbus option board communication".

• Support for OPTC2/OPTC8 backward compatibility mode in

VACON

"OPTC2/OPTC8 RS485 compatibility mode".

• Support for VACON® 100 INDUSTRIAL, VACON® 100 FLOW,

VACON

drives.

•Initial version.

®

®

100 INDUSTRIAL and VACON® 100 FLOW AC

NX and VACON® 100 family AC drives. See Chapter

100 X, VACON® 100 HVAC and VACON® 20X/CP AC

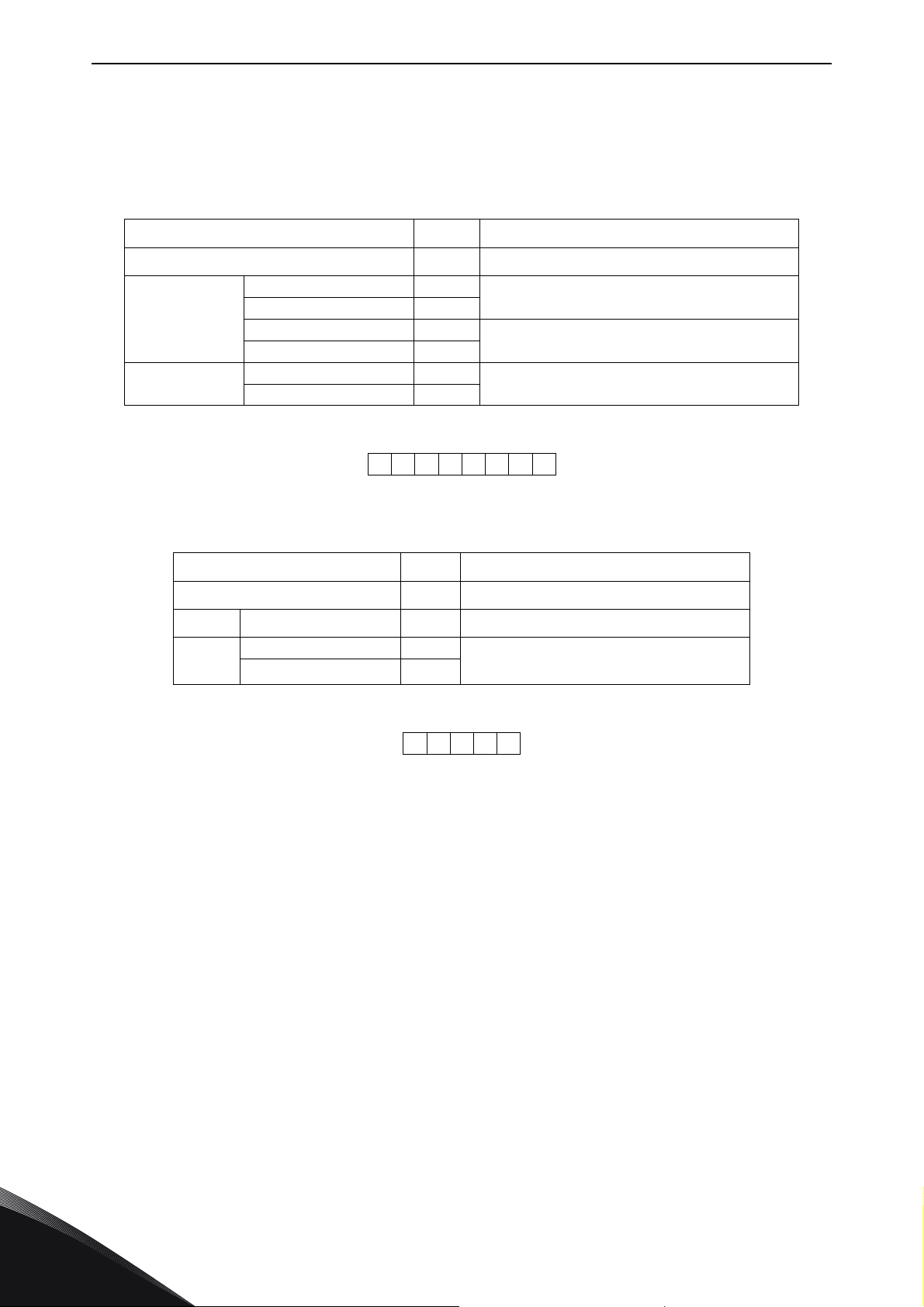

Table 3. OPTE2/E8 RS485 firmware versions

New features Firmware version

®

V003

V002

V001

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

3

Page 10

vacon • 10 Layout and connections

4. LAYOUT AND CONNECTIONS

The difference between OPTE2 option board and OPTE8 option board is bus connector. OPTE2 option

board has a 5-pin pluggable bus connector, and OPTE8 option board has a 9-pin female D-SUB

connector. Except that, they have the same LED indications, jumpers and interface board connector.

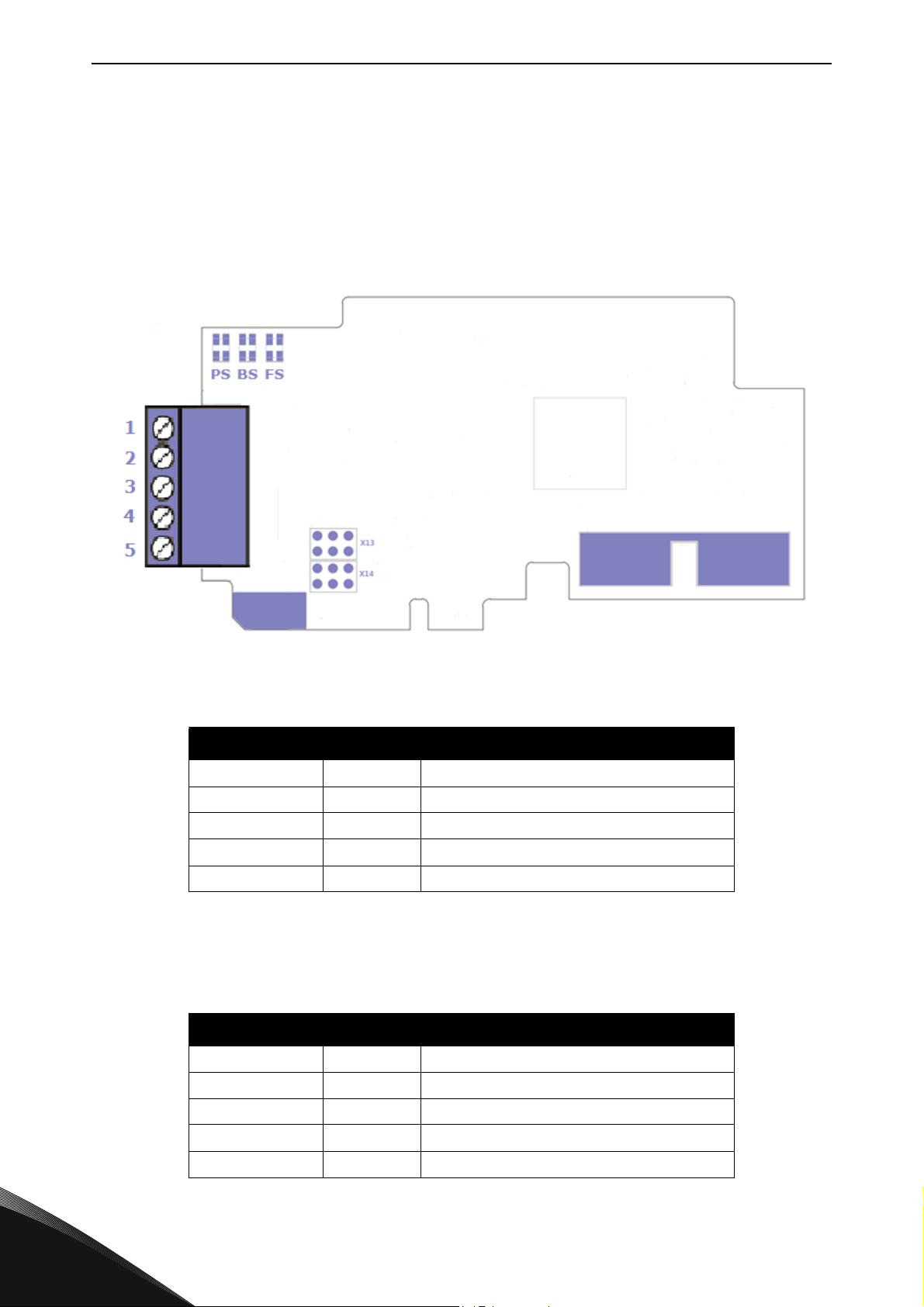

4.1 OPTE2 (screw plug) option board layout

Figure 1. OPTE2 (screw plug) option board layout

Table 4. OPTE2 (screw plug) connector pinout

Signal Pin Description

Shield 1 Cable Shield

VP 2 Supply voltage - plus (5V)

RxD / TxD-P 3 Receive/Transmit data - plus(B)

RxD / TxD-N 4 Receive/Transmit data - minus(A)

DGND 5 Data ground (reference potential for VP)

NOTE! When replacing the OPTC2 option board with the OPTE2 option board, note that Receive/

Transmit data - plus (B) and Receive/Transmit data - minus (A) pins have switched places. In OPTC2,

the pin 1 is not connected to the cable shield.

Table 5. OPTC2 (screw plug) connector pinout

Signal Pin Description

NC 1 No connection

VP 2 Supply voltage - plus (5V)

RxD / TxD-N 3 Receive/Transmit data - minus (A)

RxD / TxD-P 4 Receive/Transmit data - plus (B)

4

DGND 5 Data ground (reference potential for VP)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 11

Layout and connections vacon • 11

12345

9876

5

9

8 7 6

4 3 2 1

11727_00

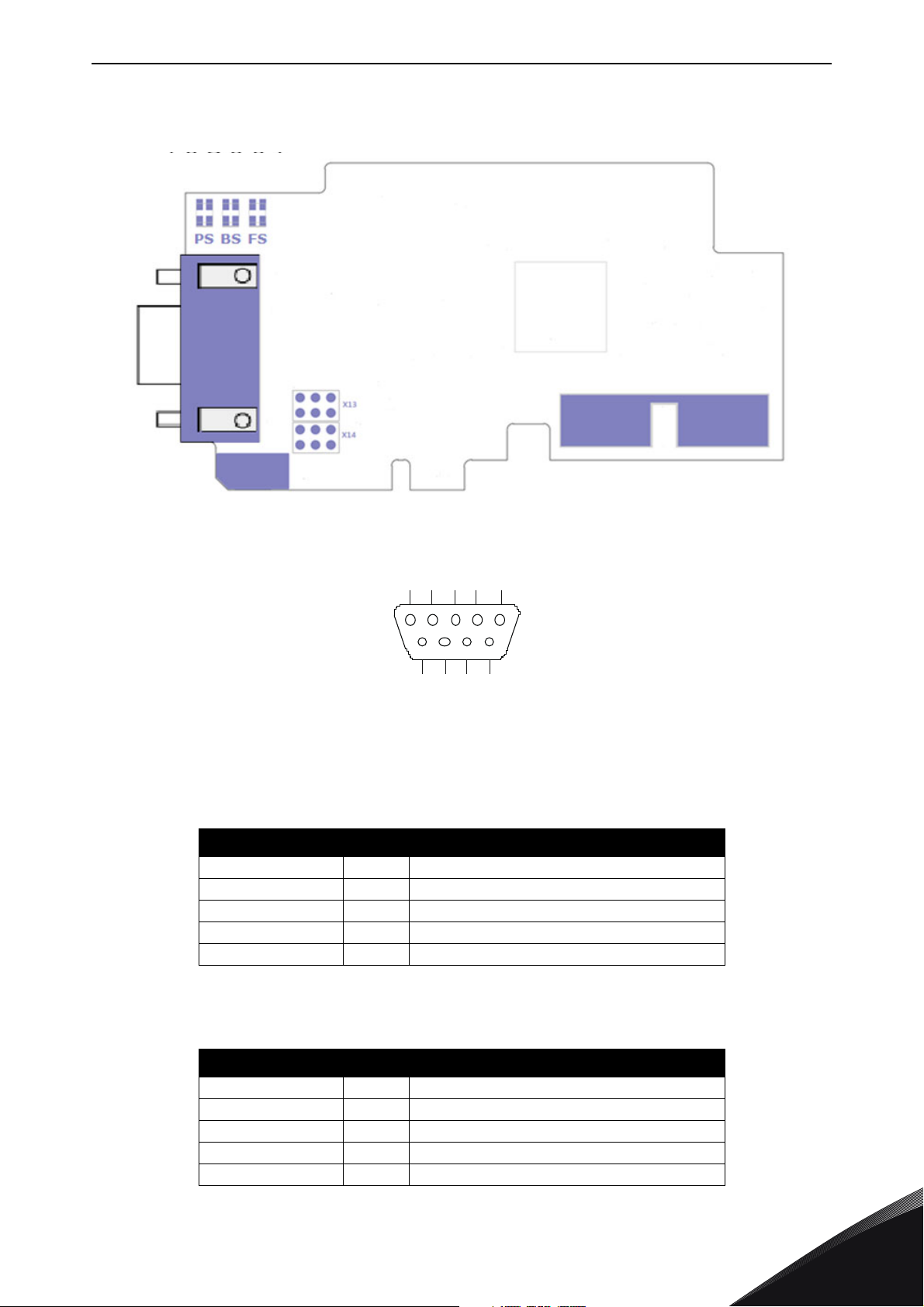

4.2 OPTE8 (Sub-D9) option board layout

Figure 2. OPTE8 (Sub-D9) option board layout

Figure 3. 9-pin female sub-D connector pinout

Table 6. OPTE8 (9-pin female sub-D) connector pinout

Signal Pin Description

Shield 1 Cable Shield

VP 6 Supply voltage - plus (5V)

RxD / TxD-P 3 Receive/Transmit data - plus (B)

RxD / TxD-N 8 Receive/Transmit data - minus (A)

DGND 5 Data ground (reference potential for VP)

NOTE! When replacing the OPTC8 option board with the OPTE8 option board, note that Receive/

Transmit data - plus (B) and Receive/Transmit data - minus (A) pins have switched places.

Table 7. OPTC8 (9-pin female sub-D) connector pinout

Signal Pin Description

Shield 1 Cable Shield

VP 6 Supply voltage - plus (5V)

RxD / TxD-N 3 Receive/Transmit data - minus (A)

RxD / TxD-P 8 Receive/Transmit data - plus (B)

DGND 5 Data ground (reference potential for VP)

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

4

Page 12

vacon • 12 Layout and connections

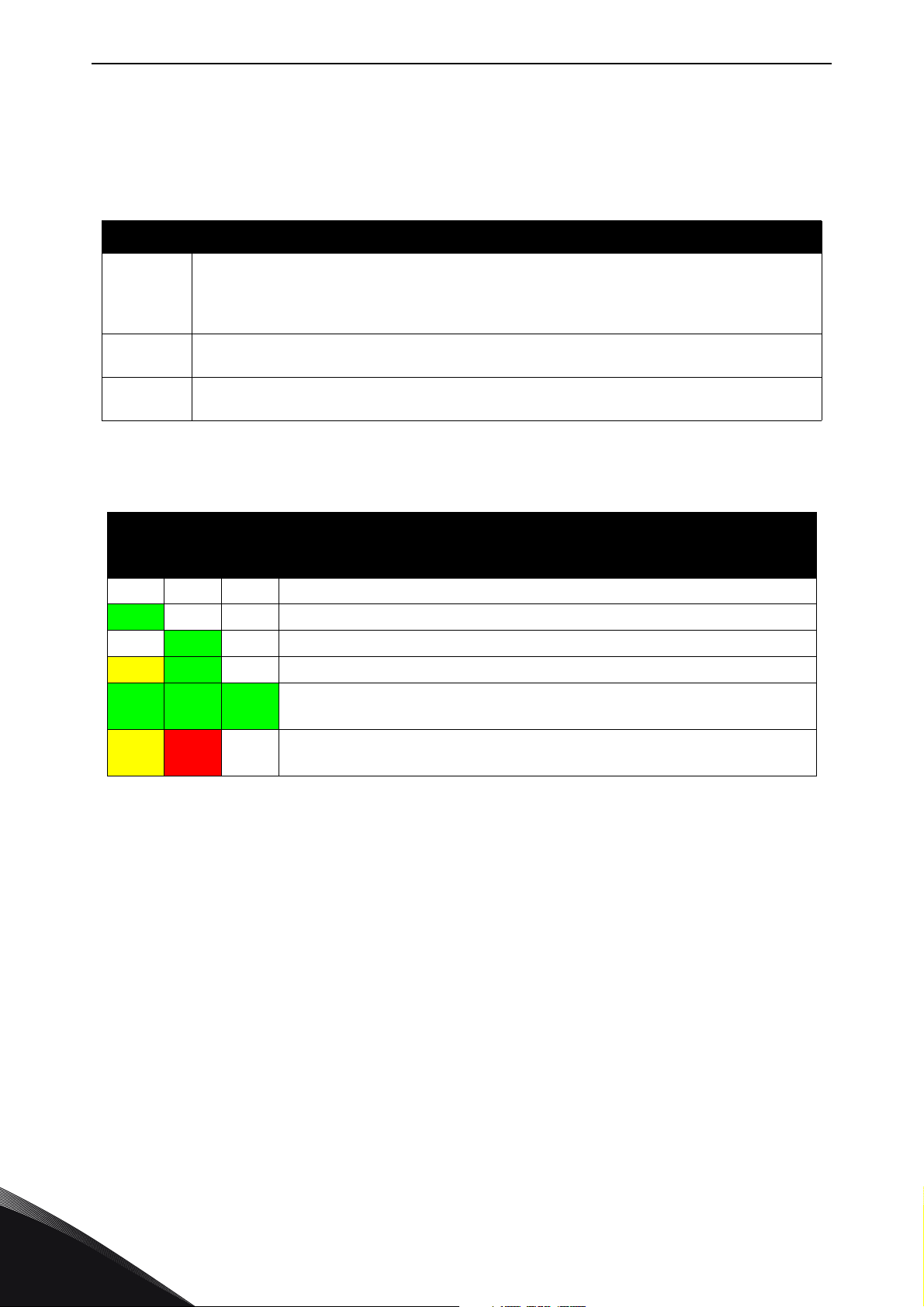

4.3 LED indications

There are three LEDs on OPTE2/E8 option board to indicate board and communication status. This

table describes their indications.

Table 8. LED indications

LEDs Indication

• Green ON when protocol is communicating

PS

BS

FS

Figure below lists possible LED indication combinations.

• Yellow blinking (1s ON / 1s OFF) when protocol is ready for external communication

• OFF when protocol is not ready for communications

• Green blinking (fast) when firmware is corrupted or missing

• Green ON when board is operational.

• Red blinking (1s ON / 1s OFF) when protocol is in fault state

• Green ON when protocol is communicating.

• OFF when protocol is not communicating.

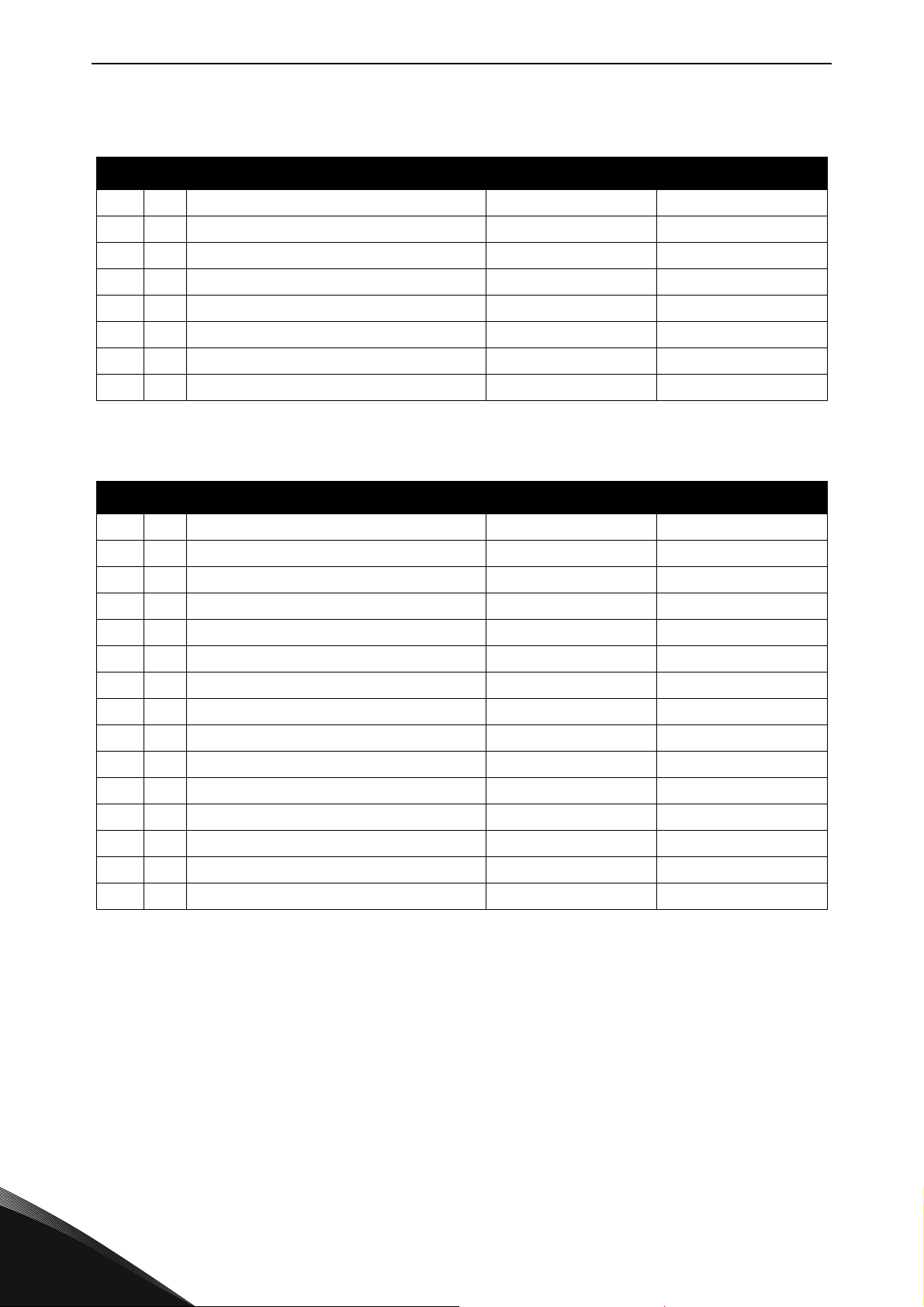

Table 9. LED combinations

LED combinations

Description

PS BS FS

Dim Dim Dim No power. All LEDs are OFF

Green Dim Dim Option board firmware is corrupted or missing. PS is blinking fast

Dim

Yello w Green Dim Protocol is ready for communications. PS is blinking (1s ON / 1s OFF)

Green Green Green

Yello w Red Dim

Green Dim Option board is operational

Protocol is communicating. The option board is receiving requests

from the PLC master and sending responses to the requests.

Protocol communication fault. BS is blinking to indicate a fault. PS is

blinking to indicate that protocol is ready for communications.

4.4 Jumpers

Setting of termination resistance and cable shield grounding options is described in Chapter 5.

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 13

Layout and connections vacon • 13

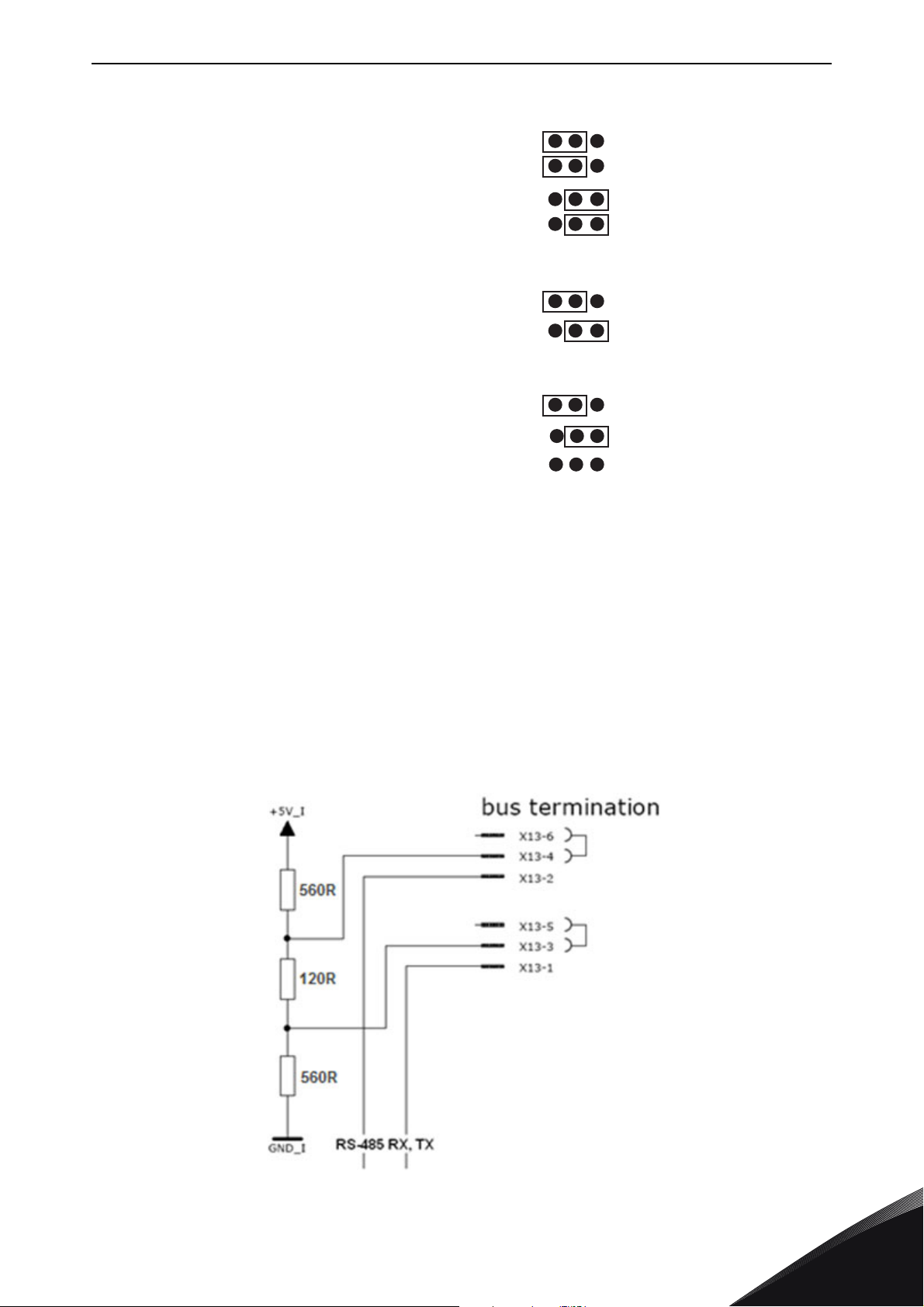

Bus termination ON

GND connected to cable shield

Jumper X13, termination resistor

Cable shield is connected to PE through RC

Cable shield is connected directly to PE

Cable shield is not connected

Bus termination OFF

GND not connected to cable shield

Jumper X14, upper row

Jumper X14, lower row

3022B_uk

Factory default

setting

Factory default

setting

Factory default

setting

Figure 4. Position definition of jumpers

4.5 Bus terminal and bias resistors

If VACON® AC drive is the last device of RS-485 line, the bus termination must be set. Use jumper

X13 (ON position) or external termination resistors.

Bus biasing is required to ensure faultless communication between devices at RS-485 bus. Bus

biasing makes sure that the bus state is at proper potential when no device is transmitting. Without

biasing, faulty messages can be detected when the bus is in idle state. RS-485 bus state should be

neither +0.200...+7 V or -0.200...-7 V. Illegal bus state is <200 mV...-200 mV.

The resistance of internal termination and biasing are 120 Ω and 560 Ω.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

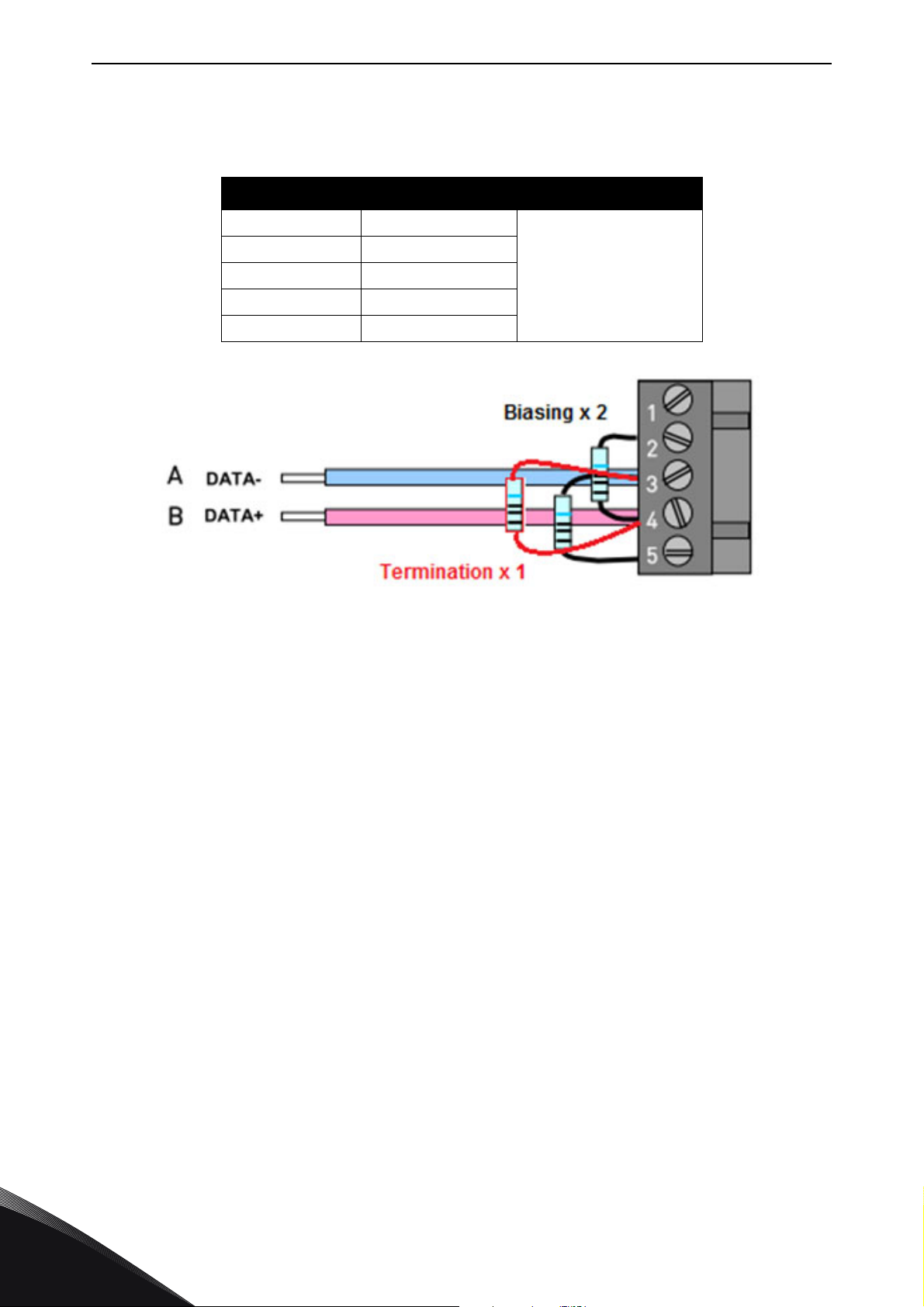

Figure 5. Bus termination

4

Page 14

vacon • 14 Layout and connections

If necessary, external termination and biasing can be added depending on number of nodes and

total length of cable.

Table 10. Bias resistance and termination resistance

Number of nodes Bias resistance Termination resistance

2-5 1.8 kΩ

5-10 2.7 kΩ

11-20 12 kΩ

21-30 18 kΩ

31-40 27 kΩ

120 Ω

Figure 6.

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 15

Cabling instructions vacon • 15

5. CABLING INSTRUCTIONS

5.1 Selecting cable

In EIA-485 systems, use only shielded cables with twisted-pair signal wires. With EIA-485 protocols,

use for example:

• Lapp Kabel UNITRONICR BUS LD FD P A, part number 2170813 or 2170814

5.2 Setting the termination resistance

Install termination resistors at or near both ends of the EIA-485 segment. The typically termination

resistor for EIA-485 is 120 Ω.

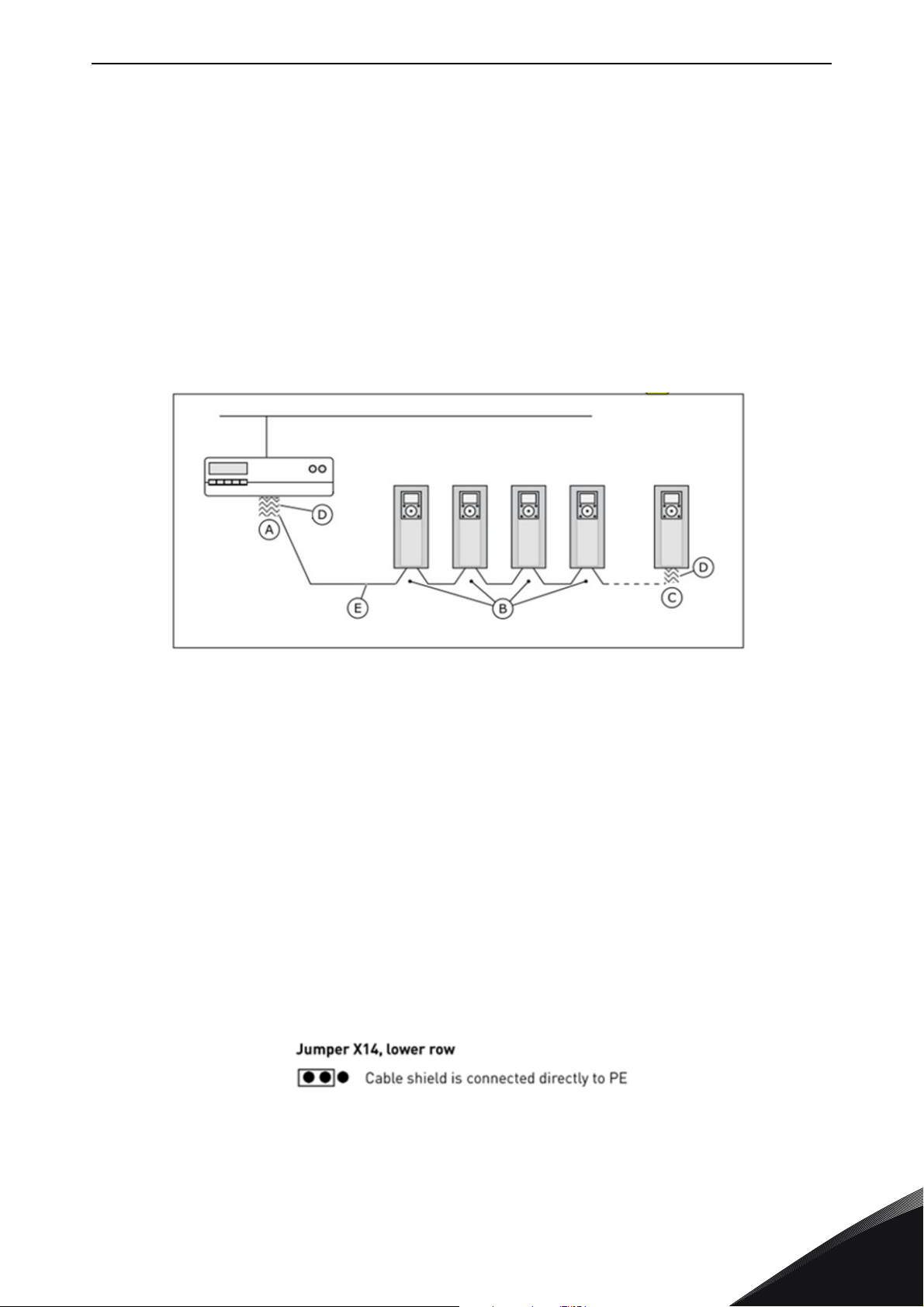

A. The termination is activated D. The bus termination

B. The termination is deactivated E. The fieldbus cable

C. The termination is activated with a jumper

Figure 7. Setting the termination resistance

5.3 Shield grounding options

The equipotential bonding system in an installation refers to metalwork that is used to bring earth

potential everywhere in the installation to a common level, the system earth. The purpose is that the

earth potential for all devices and equipment would be same, avoiding undesirable current flow

through paths not normally designed to carry current, and to allow efficient shielding of cables.

5.3.1 Shield grounding when equipotential bonding is good

When the equipotential bonding is good, the fieldbus cable shield can be grounded at each AC drive.

The grounding can be done by connecting the shield to the drive frame directly, or it can be done

through the fieldbus connector and the grounding tab in the option board.

Figure 8. Jumper X14 setting (all points in system)

If the fieldbus cable is subjected to tensile load, it is recommended to do this grounding via the

fieldbus board connector and grounding tab. The strain relief of the cable is then done without

exposing the cable shield, which reduces the risk of mechanical wear on the cable.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

5

Page 16

vacon • 16 Cabling instructions

Figure 9. Grounding by clambing the cable to the AC drive frame

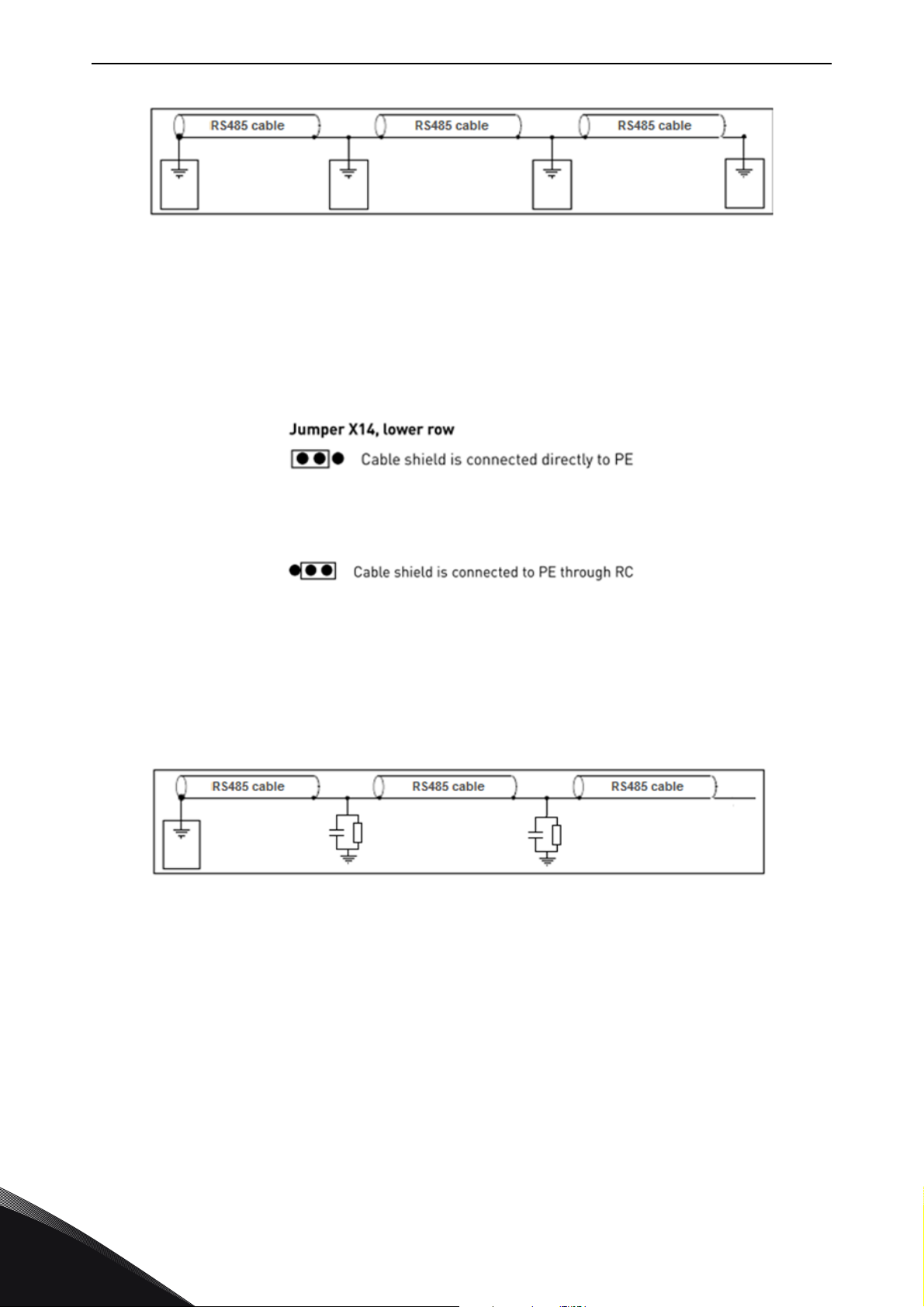

5.3.2 Shield grounding when equipotential bonding is poor

In a situation where the equipotential bonding is poor, the fieldbus cable should be grounded directly

only at one point in the system. This can be a VACON

the system. The fieldbus cable should not be directly grounded elsewhere in the system, because

difference in electrical potential can cause equalization currents to appear in the shield, causing

unnecessary disturbances.

Figure 10. Jumper X14 setting (cable grounding to drive)

Figure 11. Jumper X14 setting (cable shield to RC filter)

In VACON

filter, which helps filter out disturbances in the shield without directly connecting it to the earth. In

this case, the shield is connected to the option board connector and through an RC filter to the

grounding tab in the option board. The strain relief is done without exposing the cable shield.

®

AC drives, the fieldbus cable can in these cases be connected to ground through an RC

®

AC drive but can also be some other point in

5

Figure 12. Grounding with RC filter

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 17

Installation vacon • 17

6. INSTALLATION

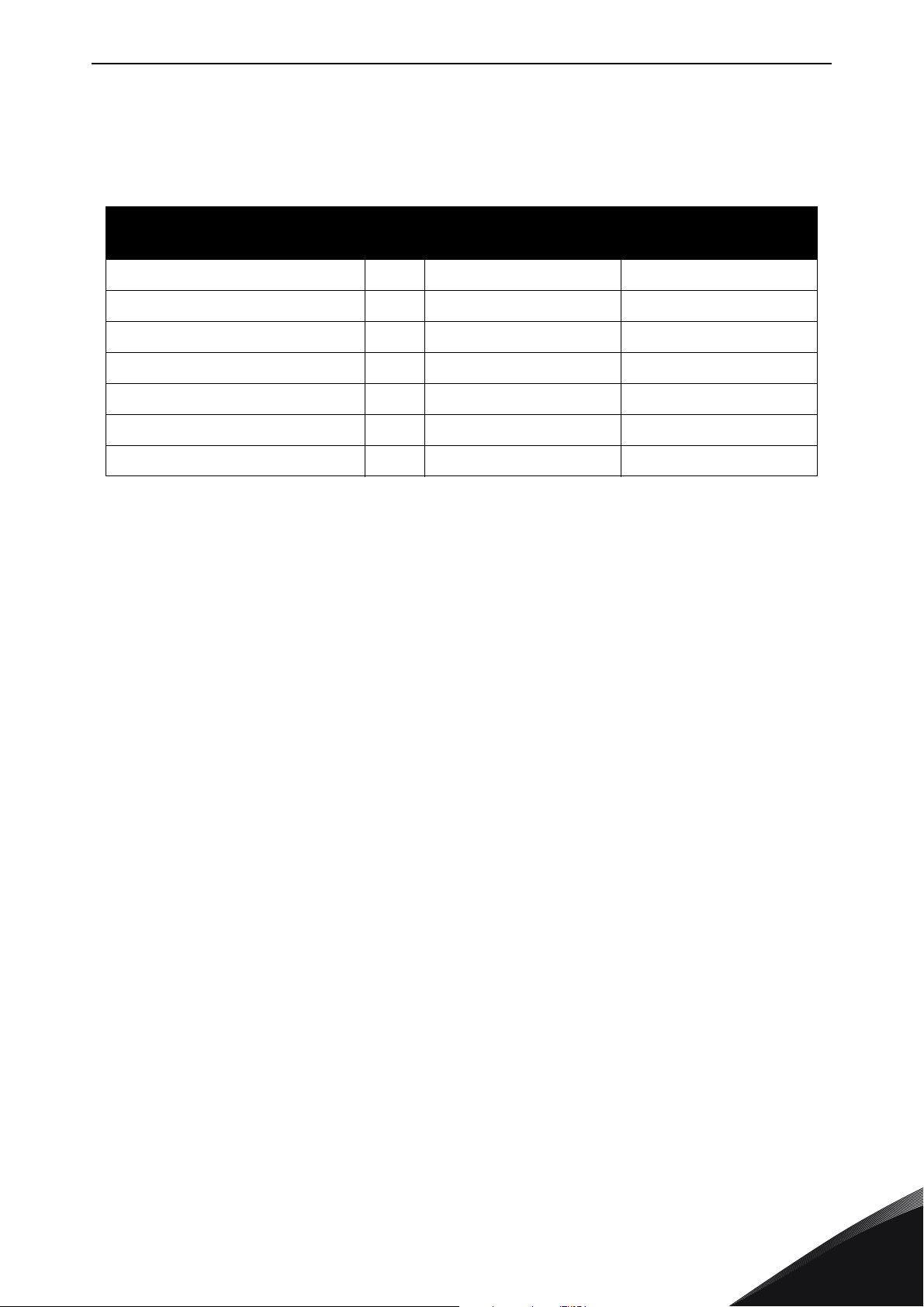

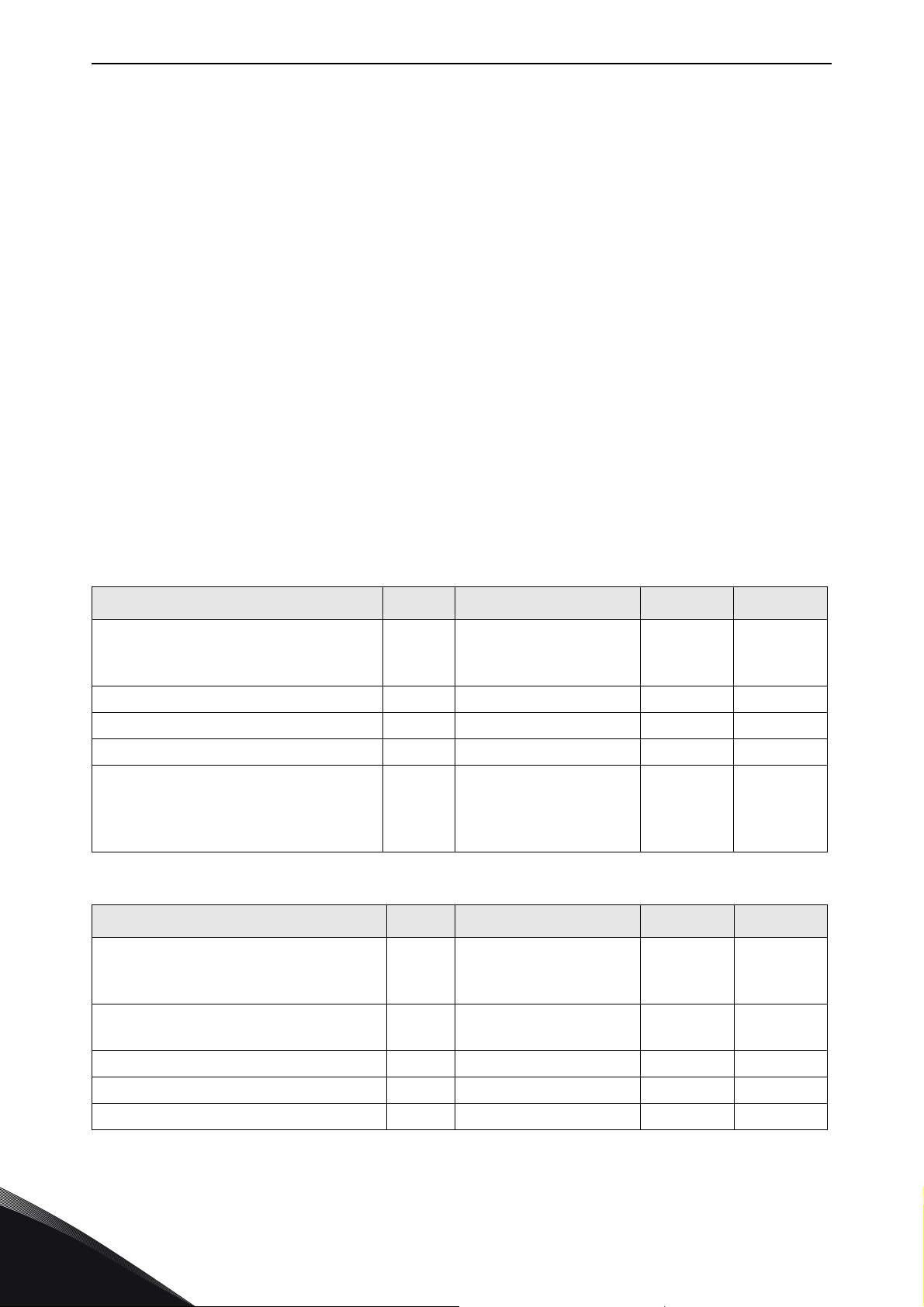

Following table shows which drives support OPTE2/E8 option board.

Table 11. OPTE2/E8 option board support

VACON

VACON

VACON

VACON

VACON

VACON

VACON

Drive Slot

®

20

®

20 X/CP

®

100 INDUSTRIAL /100 X

®

100 FLOW

®

100 HVAC

®

NXP

®

NXS

Since drive software

version

E FW0107V013 FW0204V002

E FW00117V012 FW0204V002

D, E FW0072V026 FW0204V002

D, E FW0159V017 FW0204V002

D, E FW0065V035 FW0204V002

D, E NXP00002V197 FW0204V003

D, E NXS00002V184 FW0204V003

Since OPTE2/E8

software version

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 18

vacon • 18 Installation

13006.emf

6.1 Installation in VACON® 20

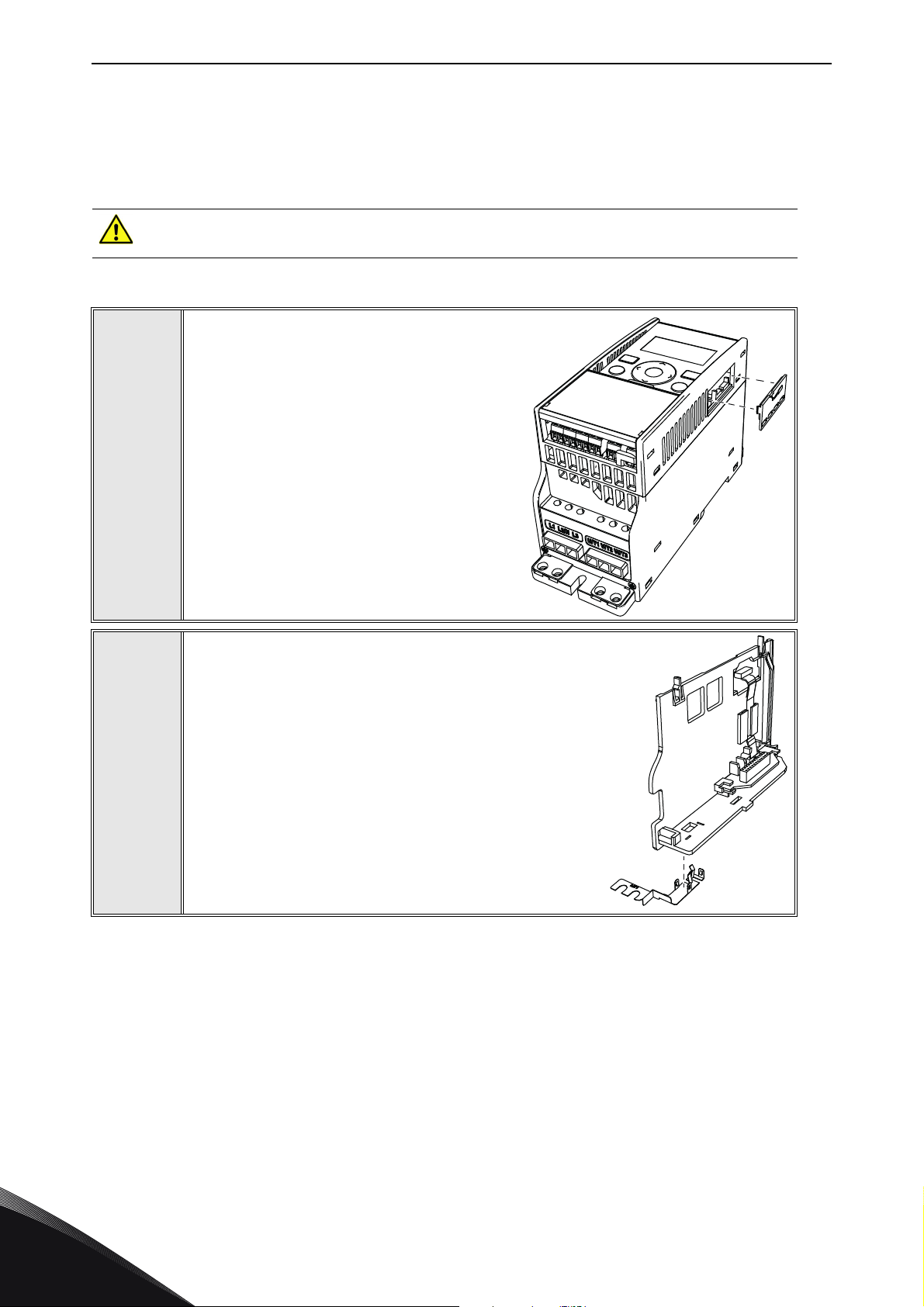

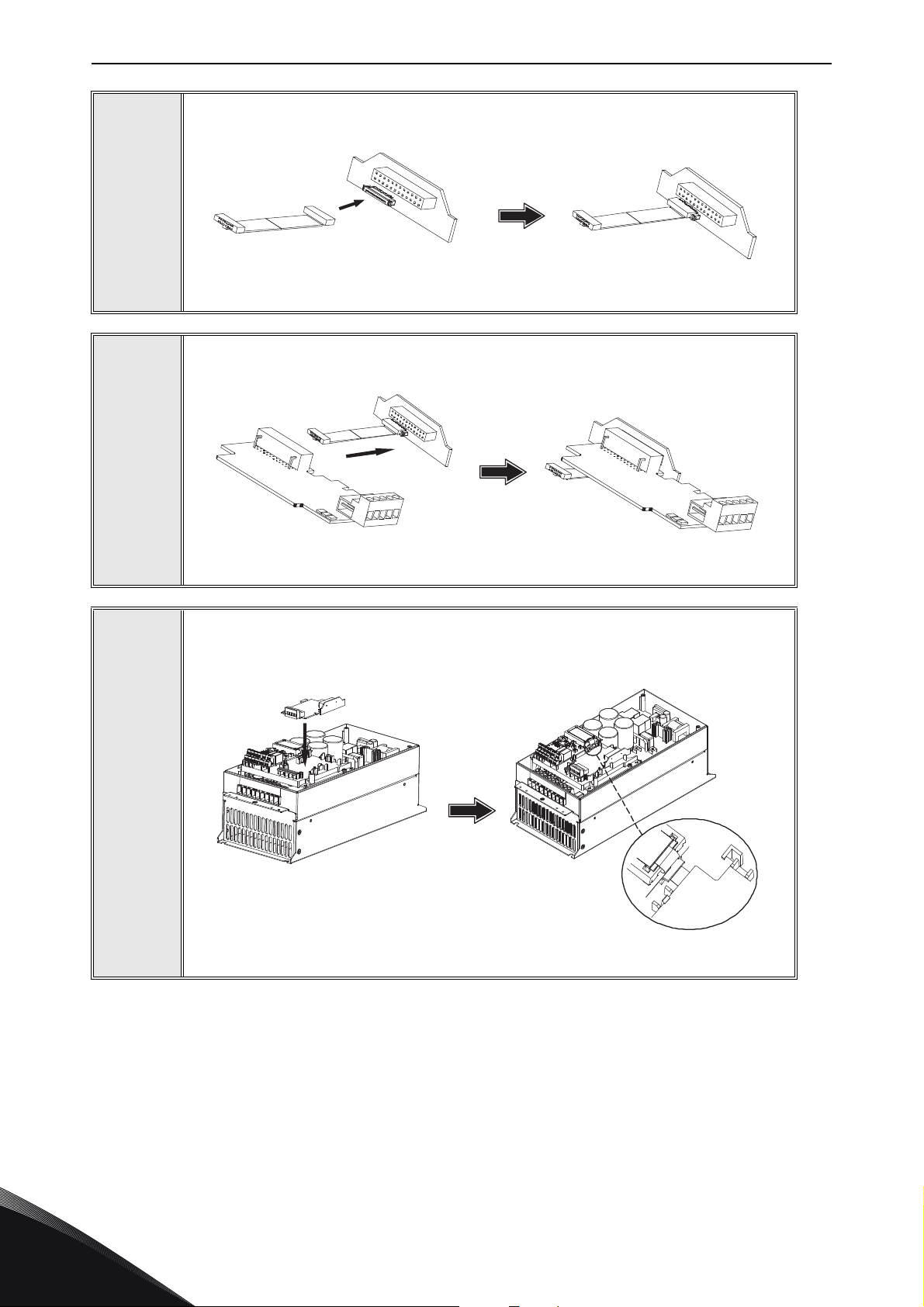

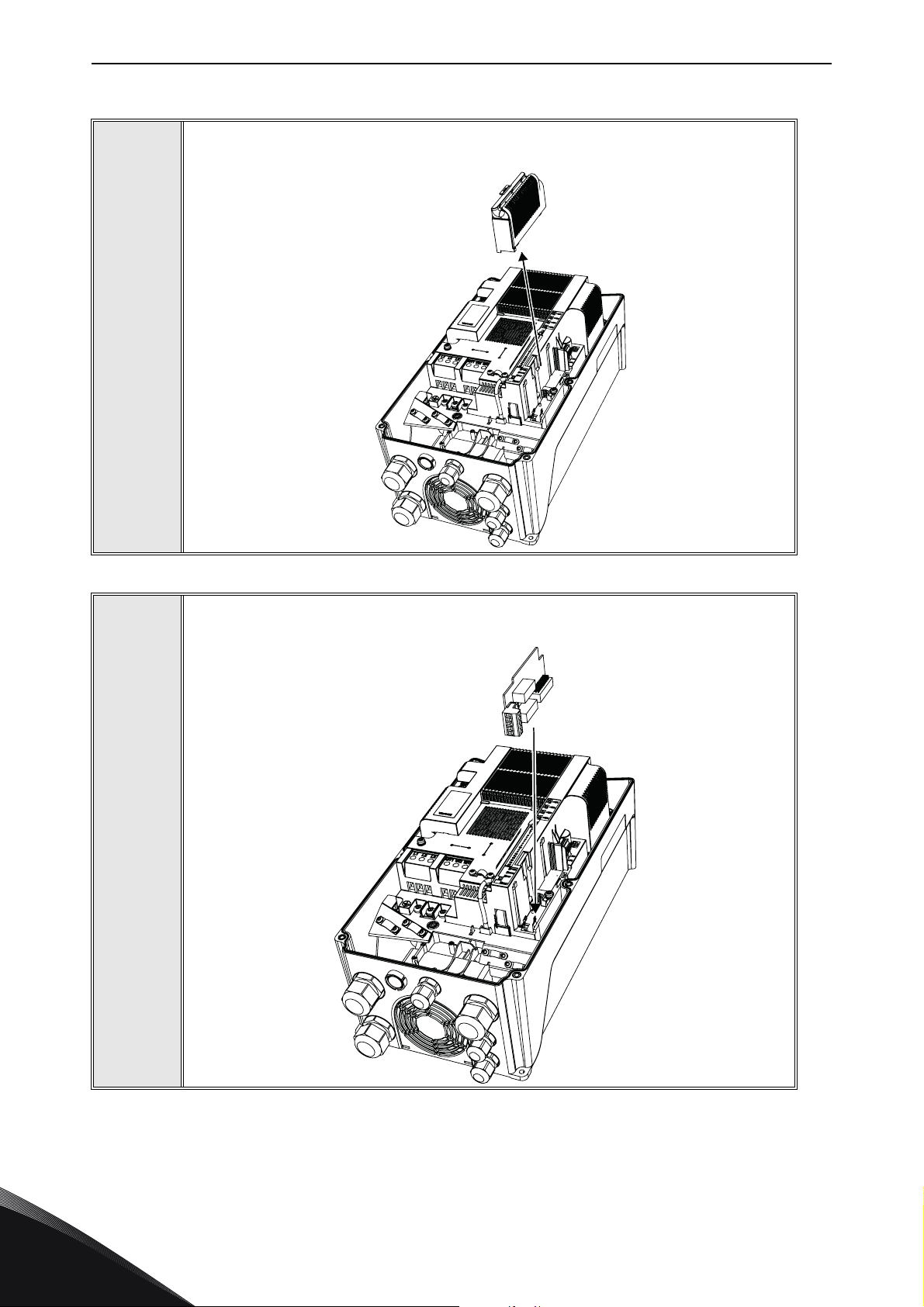

6.1.1 Enclosures MI1, MI2, MI3

Make sure power is disconnected before installing the option board mounting kit.

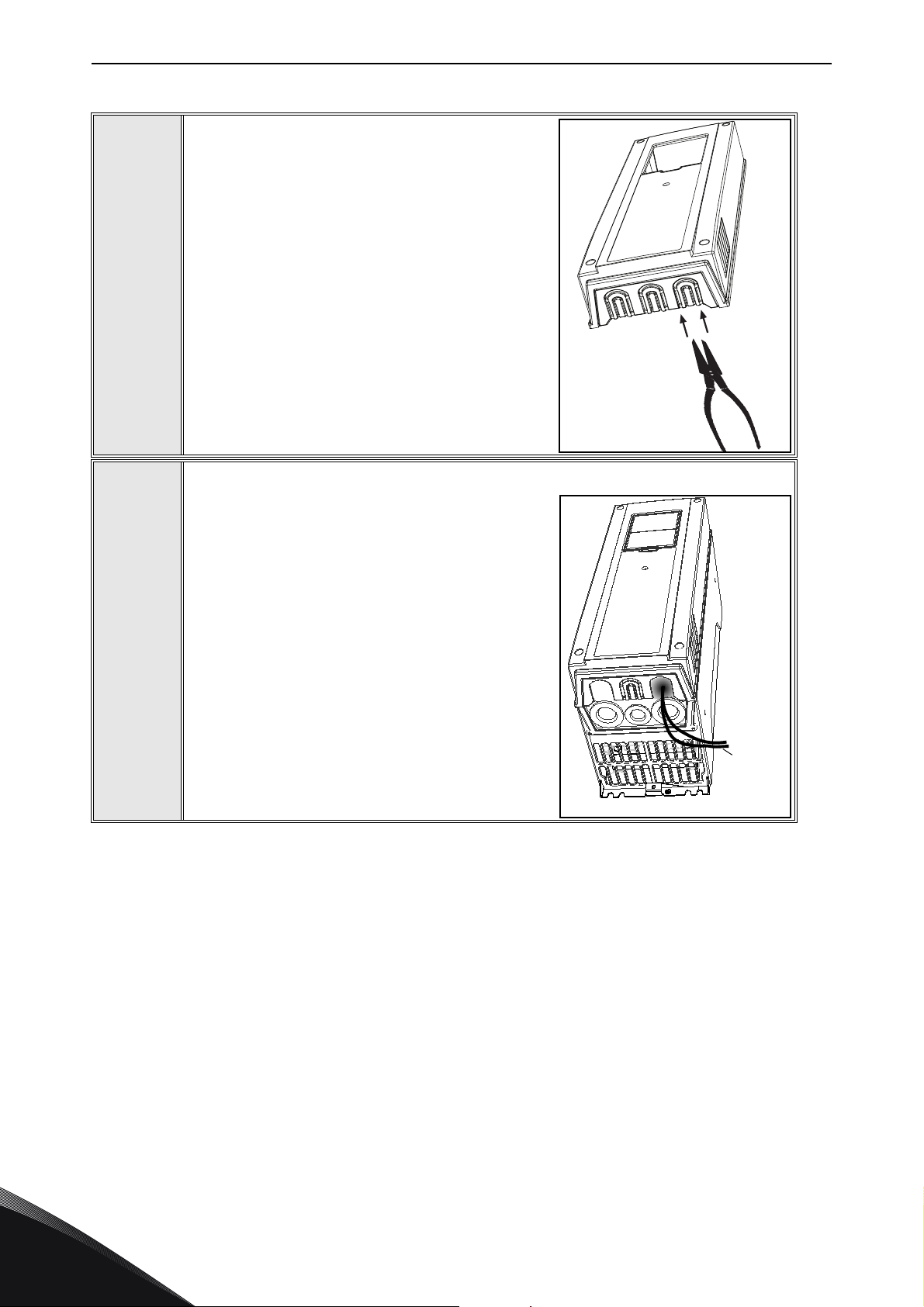

Remove the cable connector lid from AC

drive.

1

2

11555A_00

Select a correct grounding plate and attach it to the

option board mounting frame. The grounding plate is

marked with the supported enclosure size.

11649_00

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 19

Installation vacon • 19

11556A_

11558A_00

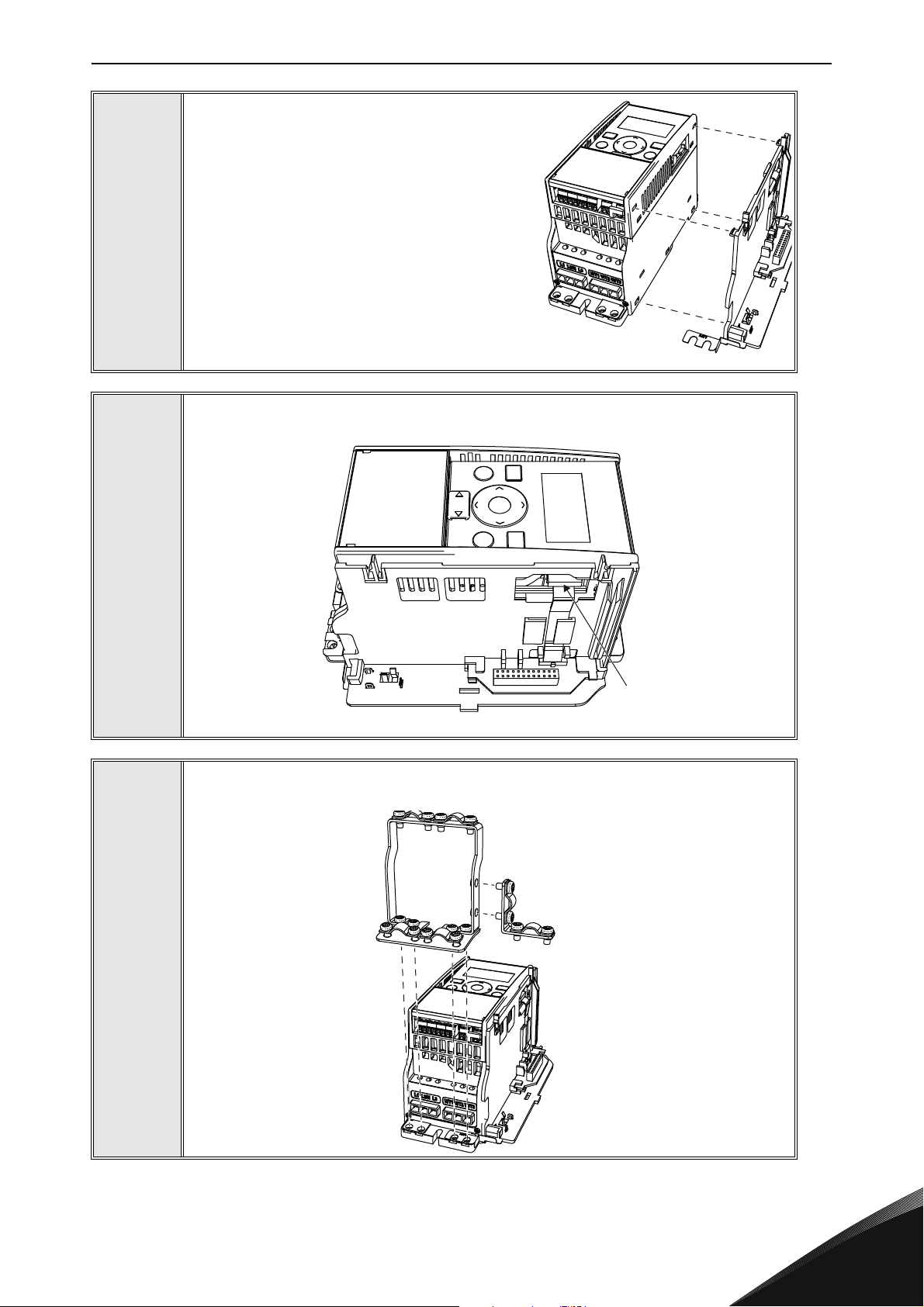

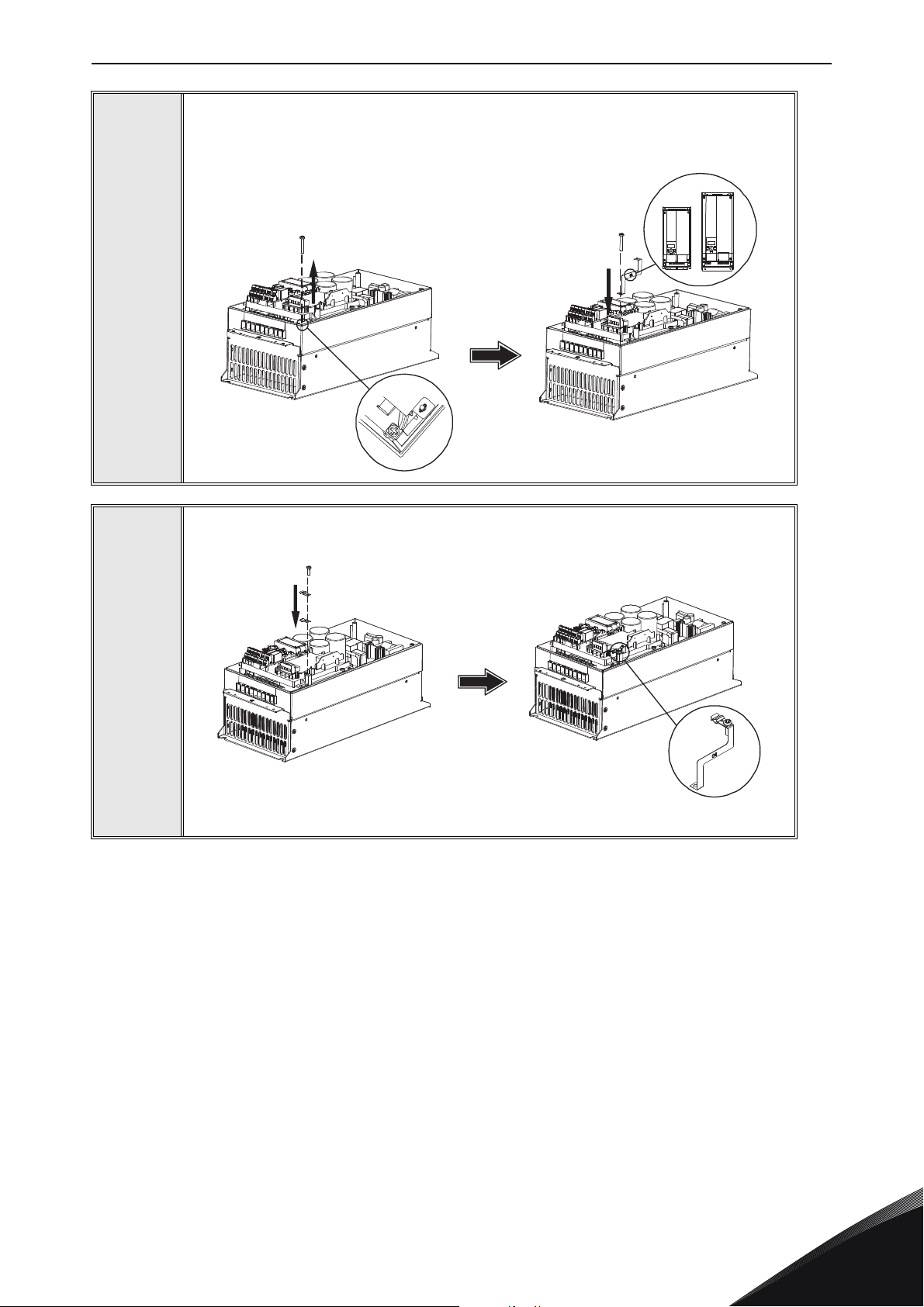

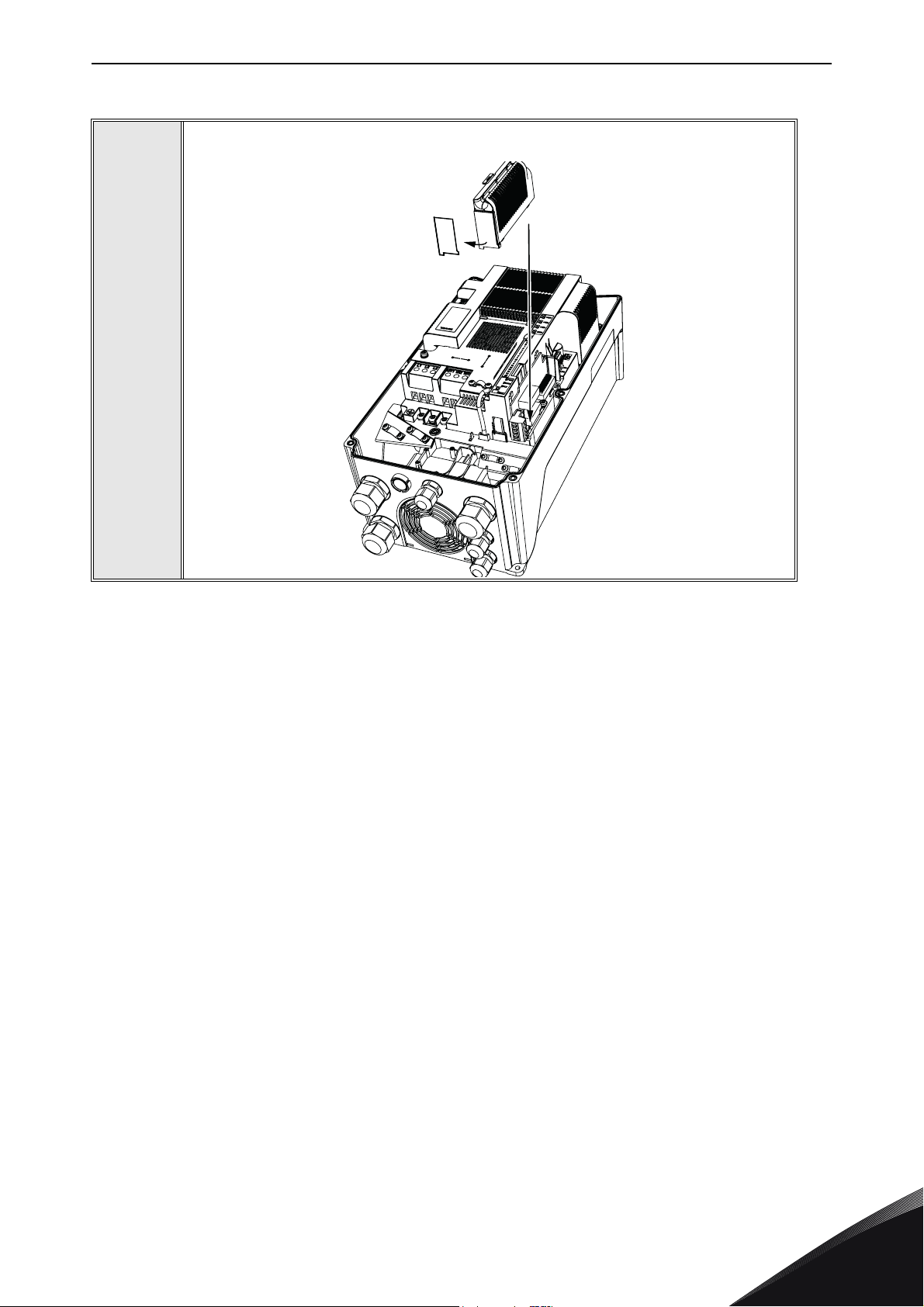

Attach an option board mounting frame to the

AC drive.

3

Connect the flat cable from the option board mounting frame to the AC drive.

4

5

11557A_00

If a cable strain relief is required, attach the parts as shown in the figure.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 20

vacon • 20 Installation

11559A_00

11650_00

11560A_00

Install the option board to the option board

holder. Make sure that the option board is

securely fastened.

6

Cut free a sufficiently wide opening for the

option board connector.

7

8

Attach the option board cover to the AC drive. Attach the strain relief cable clamp

with screws if needed.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 21

Installation vacon • 21

13006.emf

11562_00

11563_00

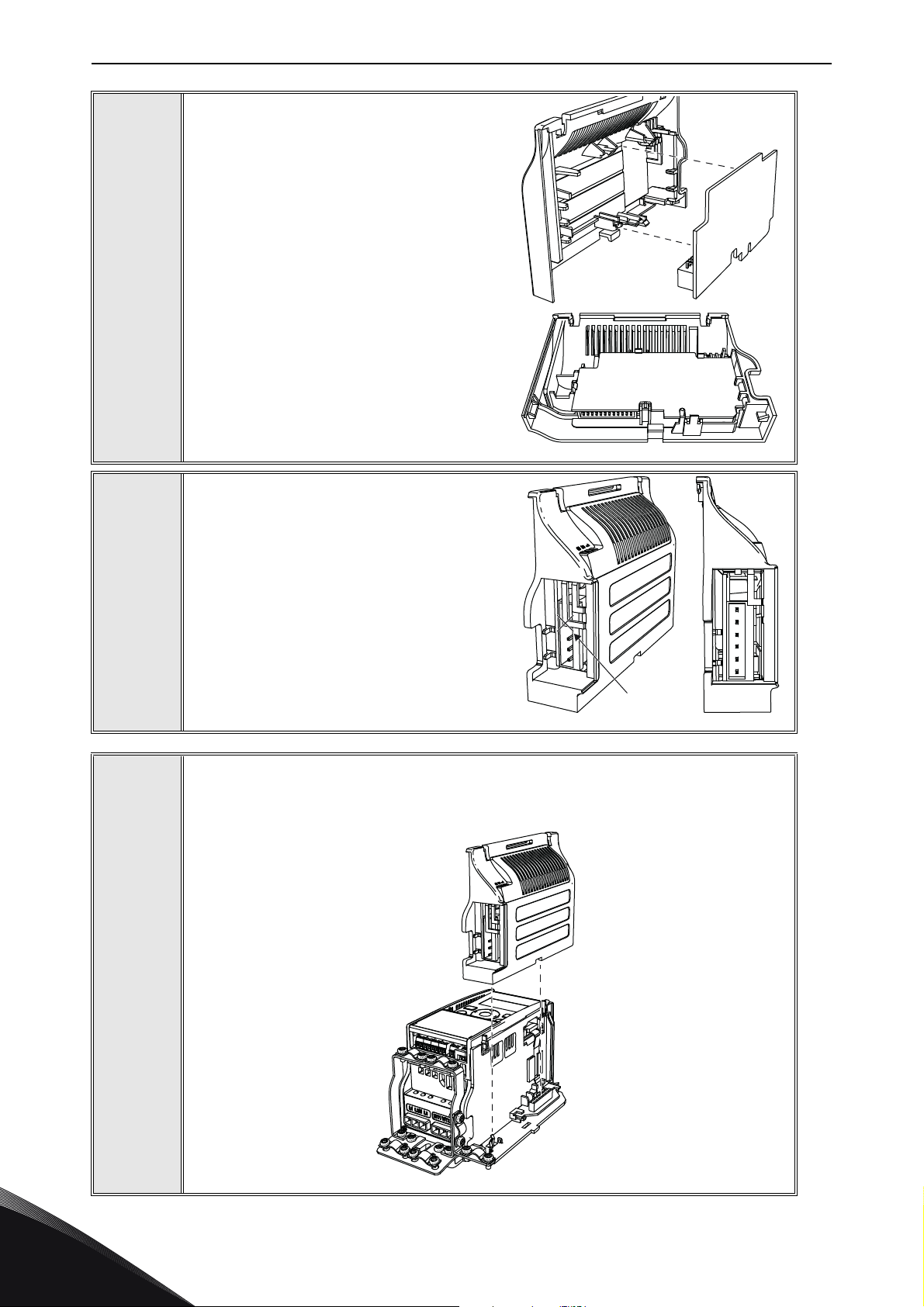

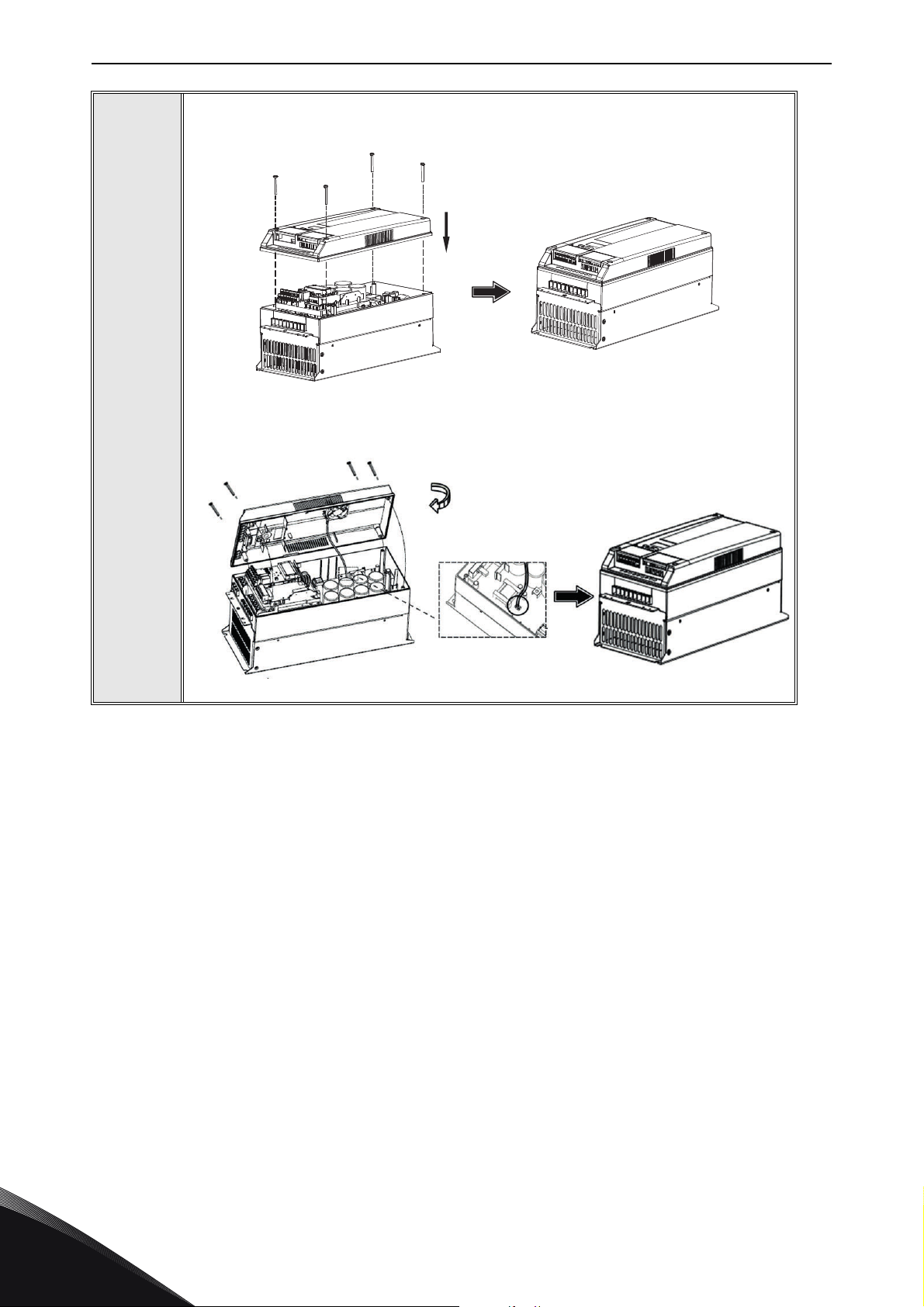

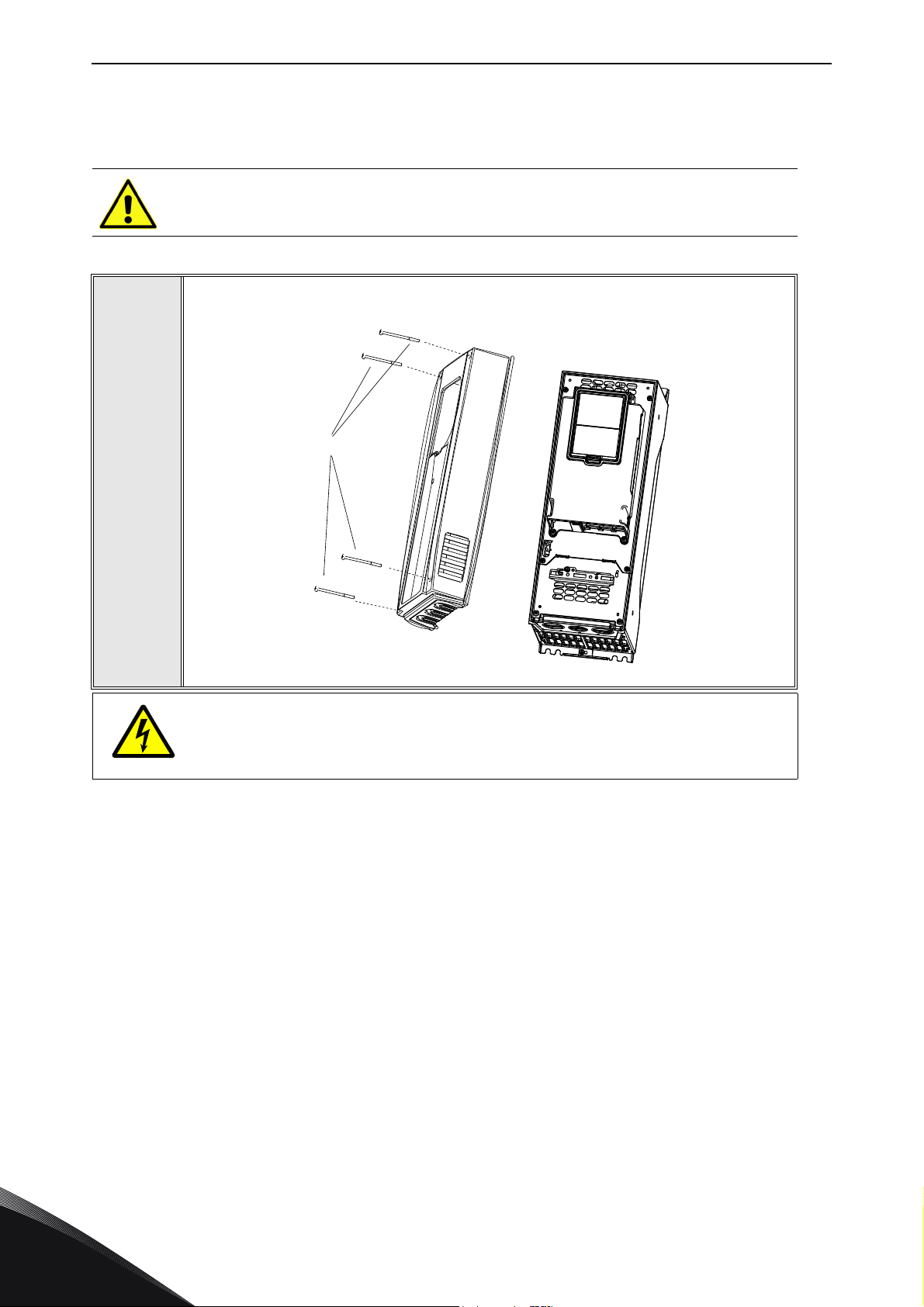

6.1.2 Enclosures MI4, MI5

Make sure power is disconnected before opening the cover of the AC drive.

1a: For MI4: Open the cover.

1

11561_00

1b: For MI5: Open the cover and release the fan connector.

OPTE2: Attach the option board support.

OPTE8: Option board support is not used.

2

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 22

vacon • 22 Installation

11564_00

11565_00

Connect the flex cable to option board connector PCB.

3

Connect the option board to connector PCB.

4

5

Attach the option board with connector PCB to the AC drive and connect the flex

cable.

11566_00

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 23

Installation vacon • 23

MI 04

MI 05

11567_00

11568_00

Attach a suitable grounding plate to VACON® 20. The grounding plate is marked

with supported enclosure size.

6

7

Assemble a clamp on top of the grounding plate on both sides of the option board.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 24

vacon • 24 Installation

11569_00

11570_00

8a: For MI4: Close the cover.

8

8b: For MI5: Remount the fan connector and close the cover.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 25

Installation vacon • 25

13006.emf

13006.emf

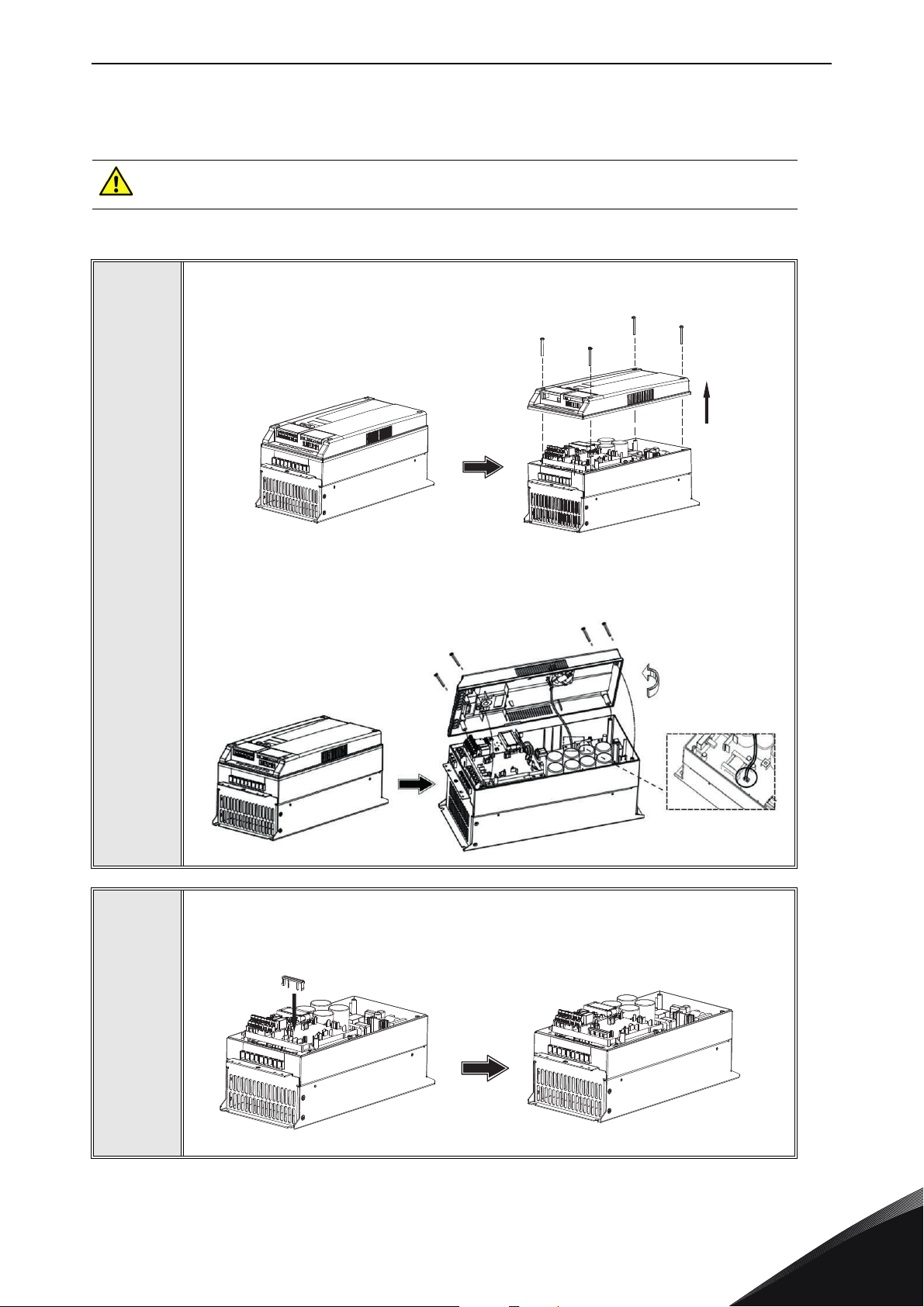

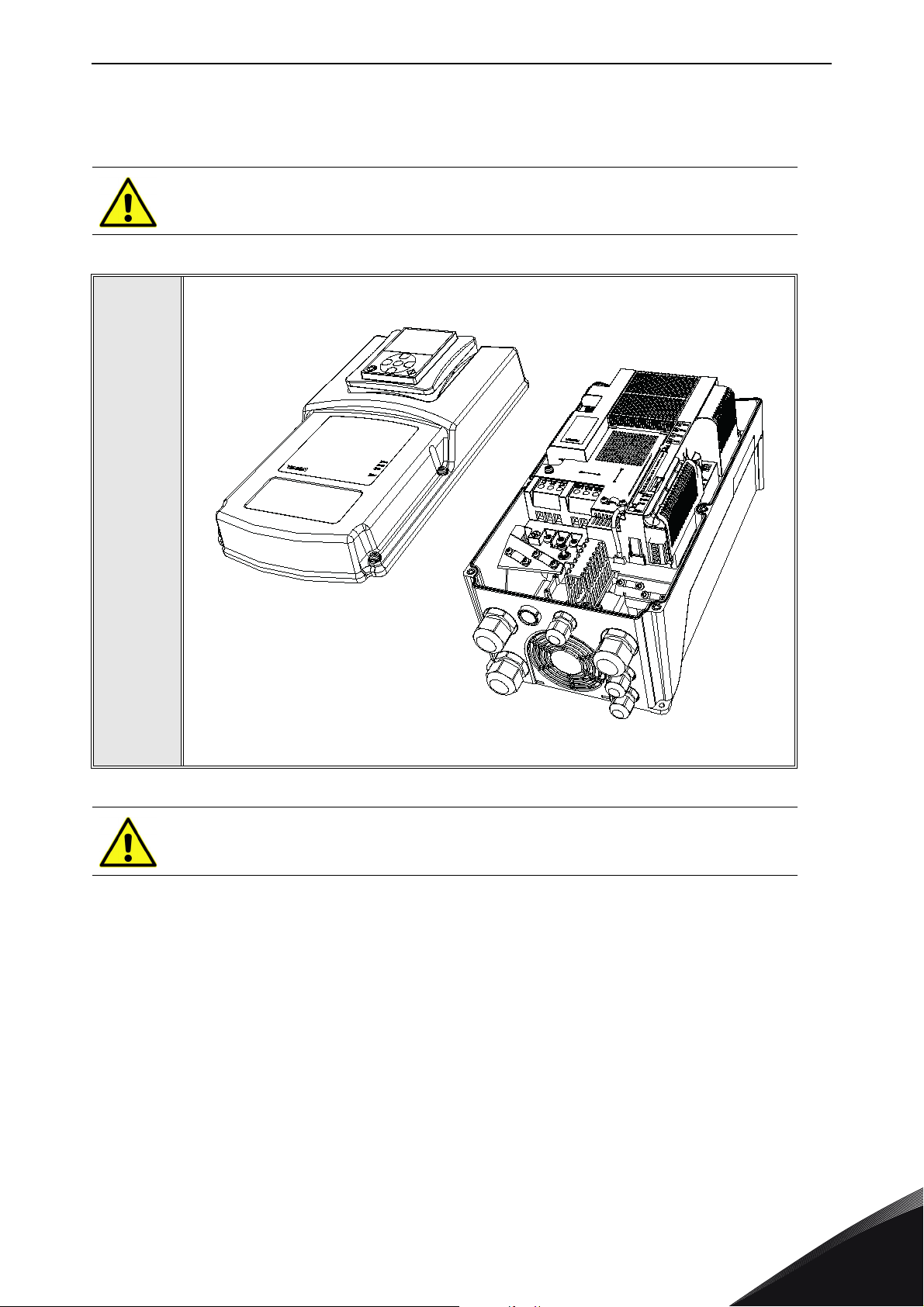

6.2 Installation in VACON® 20 X and 20 CP

Do not add or replace option boards or fieldbus boards on an AC

drive with the power switched on. This may damage the boards.

Open the cover of the drive.

1

11643_00

MU3 example

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when the drive is disconnected from mains.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 26

vacon • 26 Installation

7089_00

Remove the option slot cover.

2

3

Install the option board into the slot as shown in the figure.

6

7090_00

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 27

Installation vacon • 27

7091_007091_00

Mount the option slot cover. Remove the plastic opening for the option board

terminals.

4

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 28

vacon • 28 Installation

13006.emf

M4x55

9174.emf

DANGER

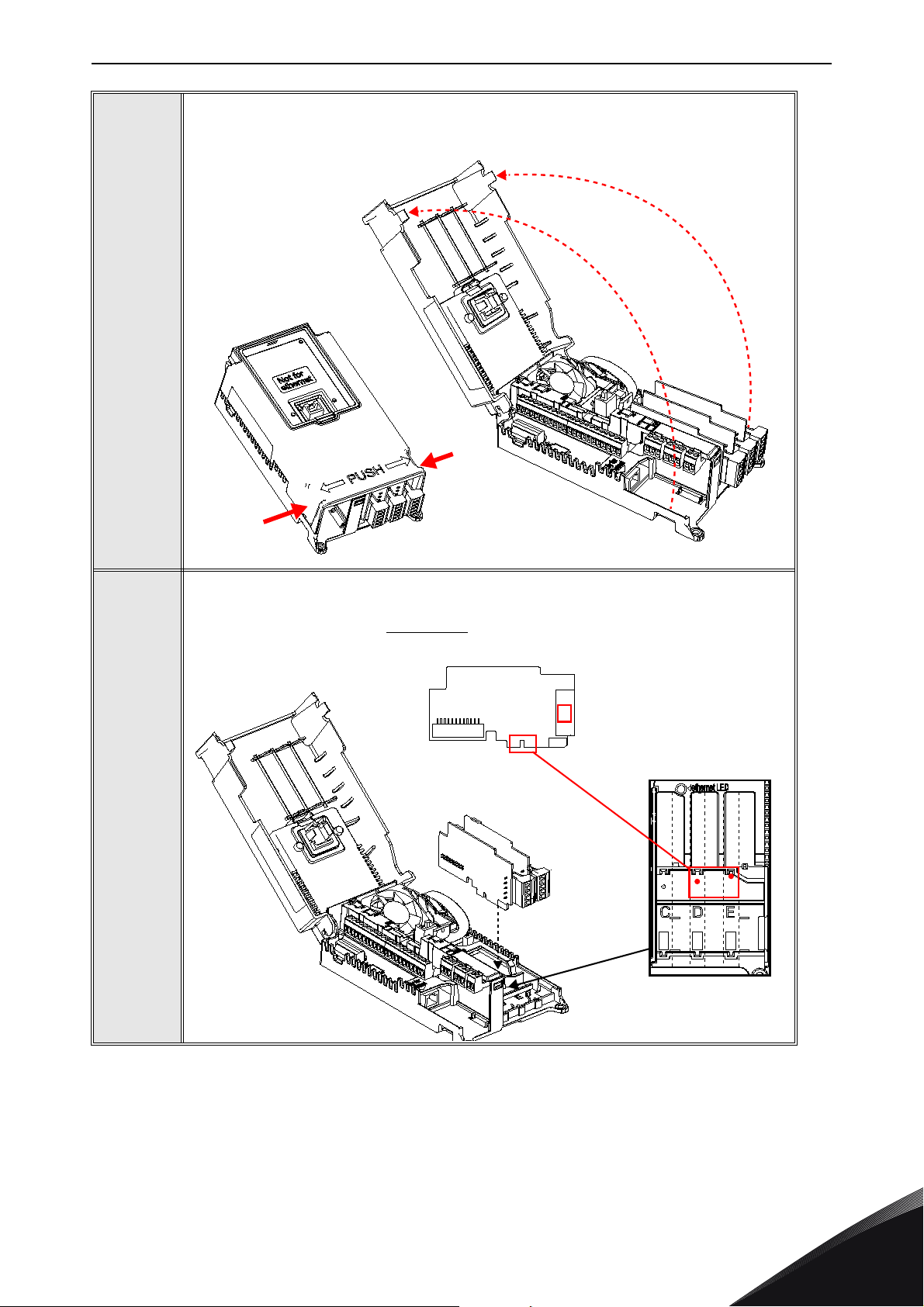

6.3 Installation in VACON® 100 family

Do not add or replace option boards or fieldbus boards on an AC

drive with the power switched on. This may damage the boards.

Open the cover of the AC drive.

1

The relay outputs and other I/O-terminals may have a dangerous control voltage

®

present even when VACON

100 family AC drive is disconnected from mains.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 29

Installation vacon • 29

3023.emf

DE

3024.emf

Open the inner cover to reveal the option board slots (C,D,E). See the figure

below.

2

3

Install the fieldbus board into slot D or E. See the figure below.

®

NOTE! Incompatible boards cannot be installed on VACON

Compatible boards have a slot coding

that enable the placing of the board.

100 family AC drive.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 30

vacon • 30 Installation

f

9202.emf

Fieldbus

cables

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

fieldbus cable (protection class IP21).

NOTE! Cut the opening on the same side you

have installed the board in

4

5

9201.em

Remount the AC drive cover and run the cable as shown in the figure.

NOTE! When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm. It is

recommended to route the option board cables

away from the power cables as shown in the

figure.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 31

Installation vacon • 31

6.4 Installation in VACON® 100 X (enclosures MM4-MM6)

Open the cover of the AC drive.

1

11638_00

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 32

vacon • 32 Installation

11639_00

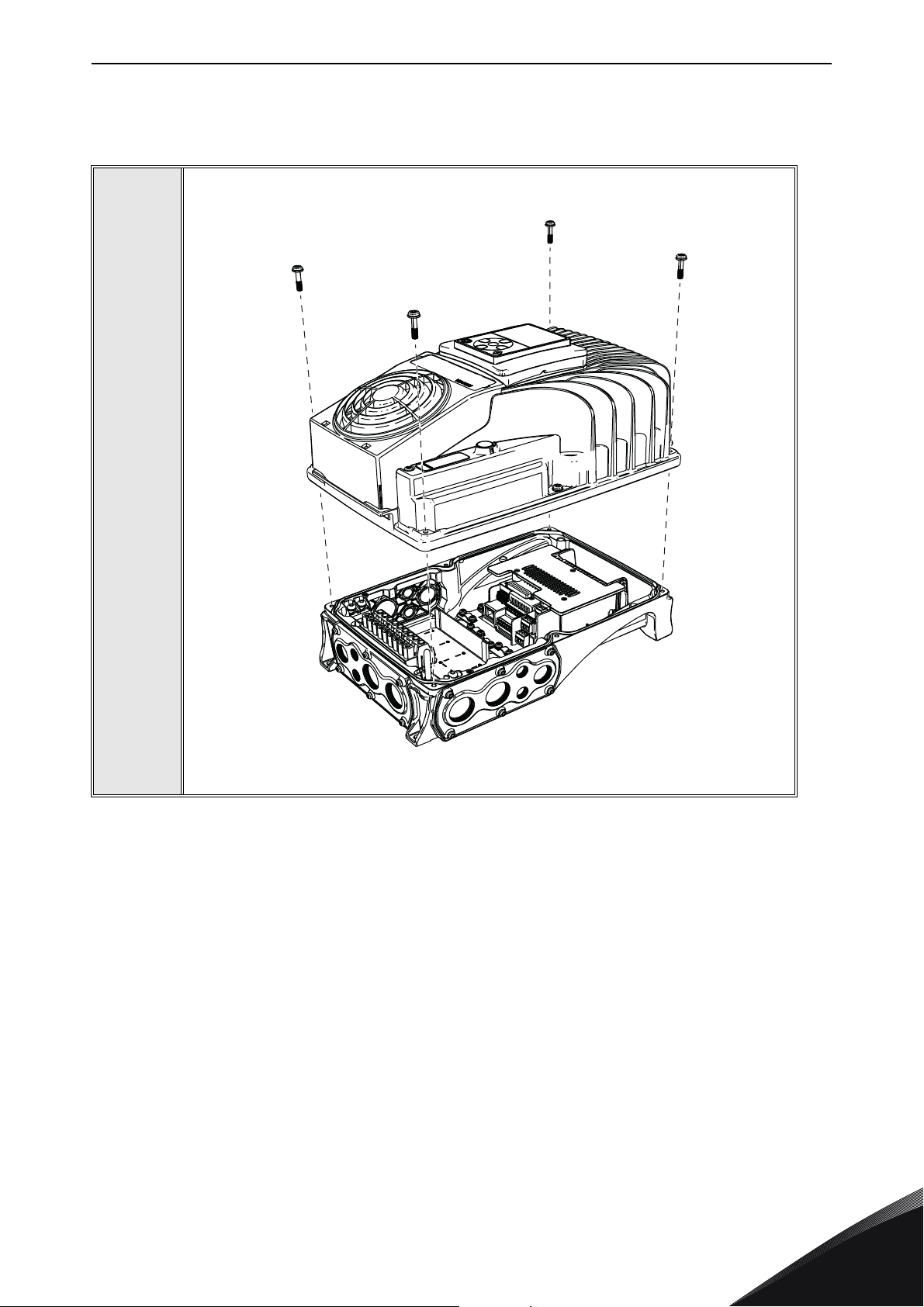

To get access to the option board slots, remove the screws and open the cover of

the control unit.

2

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 33

Installation vacon • 33

DE

11640_00

11641_00

Install the option board into the correct slot, D or E.

3

4

Close the option board cover.

5

Remove the cable entry plate. If you

installed the option board in the slot

D, use the cable entry plate on the

right side. If you installed the option

board in the slot E, use the cable

entry plate on the left side.

NOTE! The cable entry plate at the

bottom of the drive is used only for

mains and motor cables.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 34

vacon • 34 Installation

6

7

Open the necessary holes in the cable entry plate. Do not open the other holes.

See the VACON

Attach a cable gland on the hole in the

cable entry plate. Pull the fieldbus cable

through the hole.

NOTE! The fieldbus cable must go through

the correct cable entry plate to avoid going

near the motor cable.

®

100 X Installation Manual for the dimensions of the holes.

11642_00

8

9

Put the cable entry plate back.

Close the cover of the AC drive.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 35

Installation vacon • 35

13006.emf

6.5 Installation in VACON® NX

Make sure that the AC drive is switched off before an option or fieldbus board is

changed or added!

VACON® NX AC drive.

1

2

3

Remove the cable cover.

Open the cover of the control unit.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 36

vacon • 36 Installation

Install the OPTE2/E8 RS485 option board in slot D or E on the control board of the

AC drive. Make sure that the grounding plate fits tightly in the clamp.

4

Make a sufficiently wide opening for your cable by cutting the grid as wide as

necessary.

5

6

Close the cover of the control unit and the cable cover.

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 37

Installation vacon • 37

6.6 VACON® PC tools

With VACON® PC tools it is possible to do following operations for OPTE2/E8 RS485:

• Update firmware into OPTE2/E8 RS485 option board

• Set parameters for OPTE2/E8 RS485

• Read monitor values of OPTE2/E8 RS485

6.6.1 PC tool support

This table describes what PC tools are supported in each AC drive type. The connection type "serial"

means a direct serial connection to the AC drive. The connection type "Ethernet" means that

Ethernet connection is supported by using for example via VACON

interface or via OPTE9 Dual Port Ethernet option board.

Table 12. The supported PC tools with different AC drives

VACON® 100 family VACON® NXS/NXP VACON® 20 family

Too l

Serial Ethernet Serial Ethernet Serial Ethernet

®

100 family built-in Ethernet

VACON® Loader

VACON

®

Live

xxx

xx x

NCIPConfig Not used with OPTE2/E8 RS485

NCDrive x x

NCLoad Not used with OPTE2/E8 RS485

6.6.2 OPTE2/E8 option board firmware update with

You can update OPTE2/E8 RS485 firmware with VACON

•PC with VACON

®

•VACON

AC drive in which OPTE2/E8 RS485 option board is installed

®

Loader installed

®

Loader PC tool. You need to have:

VACON

®

Loader

• Serial cable:

®

-VACON

NXP/NXS is connected to PC with RS232 serial cable which is connected from PC to

NXP/NXS control unit's 9-pin DSUB connector (female). If PC does not contain RS232 serial

port, then USB - RS232 converter device is needed between PC and NXP/NXS control.

®

-VACON

The VACON

100 family and VACON® 20 are connected to PC with VACON® Serial Cable.

®

Loader can be downloaded from https://www.danfoss.com/en/service-and-support/

Downloads Software Select "Drives" as Business unit. It is bundled with the VACON

software package. After starting the installation program, follow the on-screen instructions.

®

Live

The OPTE2/E8 RS485 firmware can be downloaded from https://www.danfoss.com/en/service-and-

support/ Downloads Software Select "Drives" as Business unit Fieldbus firmware.

To update the option board firmware, follow the steps below.

NOTE! With VACON

the following baud rates are supported: 9600, 19200, 38400 or 57600. With VACON

®

VACON

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

NX family AC drives VACON® Loader selects a correct baud rate automatically.

®

20, the baud rate 9600 must be used. With VACON® 20 X and VACON® 20 CP,

®

100 family and

6

Page 38

vacon • 38 Installation

Step 1: Connect your PC to the controller by using the serial cable.

Then select the firmware file which you want to load to the option board and double click it. This will

start the VACON

In this case, select the firmware file using the "Browse" button.

®

Loader software. You can also start the program from the Windows Start menu.

Figure 13. VACON

Step 2: Press 'next' and wait for the loader to find the network drives. Then select a drive from the

list and press 'Connect to Selected'.

Figure 14. VACON

®

Loader: File selection

®

Loader: Connecting to drive

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 39

Installation vacon • 39

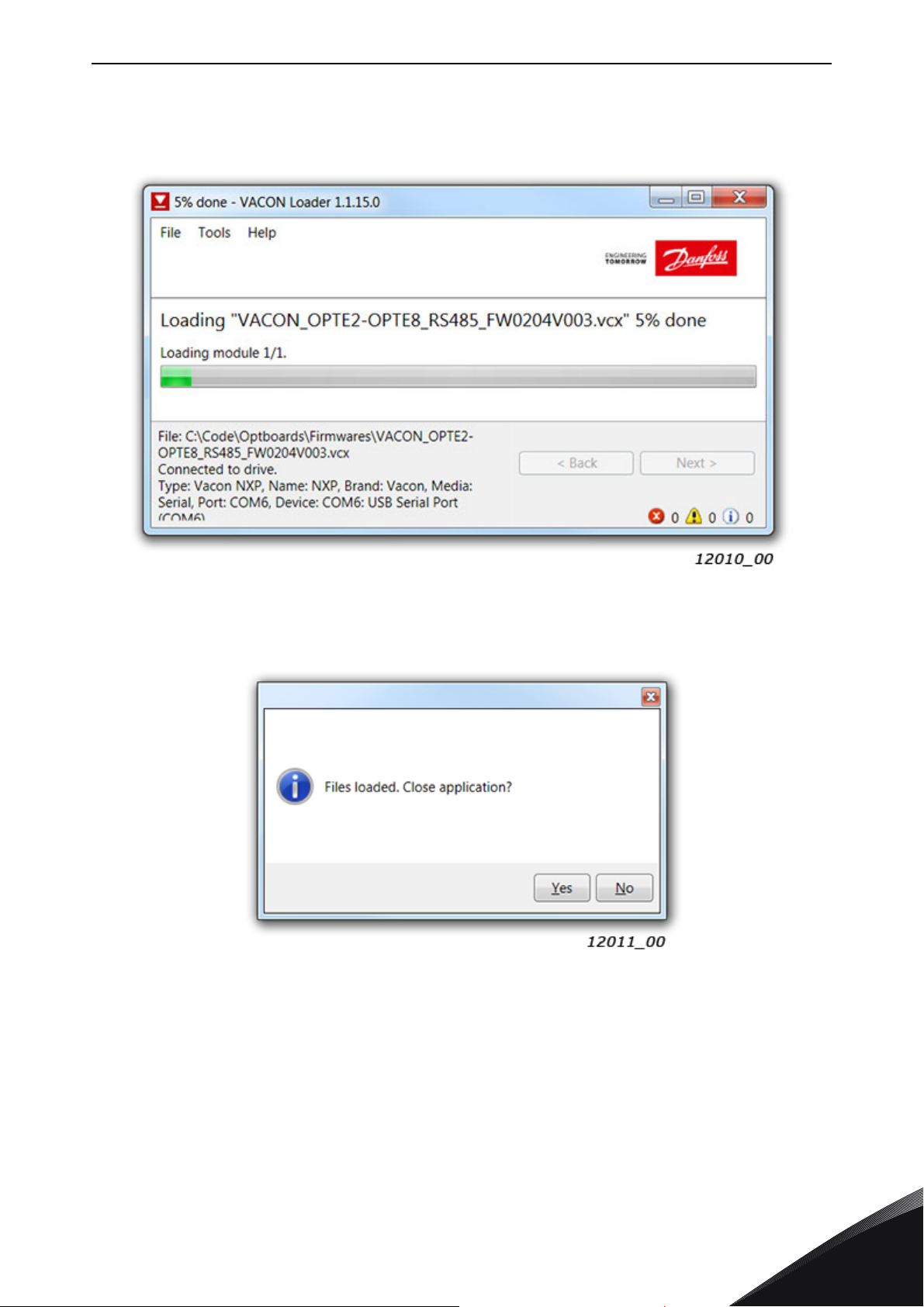

Step 3: Select the modules to be updated, press 'next' and wait until the operation is finished. See

Figures below.

Figure 15. VACON

Figure 16. VACON

®

Loader: Firmware loading

®

Loader: Loading is finished

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 40

vacon • 40 Installation

6.6.3 PC tools for VACON® NXP/NXS: NCDrive

You can configure the VACON

NCDrive PC tool. You need to have:

• PC with NCDrive installed

®

•VACON

• In case of Serial connection:

- If PC contains RS232 serial port, then connect the serial cable from PC to NXP/NXS control

unit's 9-pin DSUB connector (female).

- If PC does not contain RS232 serial port, then USB - RS232 converter device is needed

between PC and NXP/NXS control.

• In case of Ethernet connection:

- Ethernet cable which is connected to option board's Ethernet interface.

-VACON

OPTE9 Dual Port Ethernet option board.

The NCDrive can be downloaded from https://www.danfoss.com/en/service-and-support/

Downloads Software Select "Drives" as Business unit. After starting the installation program,

follow the on-screen instructions.

Once the program is installed successfully, you can launch it by selecting it in the Windows Start

menu. Select Help Contents if you want more information about the software features.

6.6.3.1

NXP/NXS drive

®

NXP/NXS requires option board supporting Ethernet communication. For example,

NCDrive Serial communication settings

®

NXP/NXS AC drive and OPTE2/E8 RS485 parameters with the

Connect your PC to the controller by using the USB/RS485 cable.

Select Tools Options… Communication tab. Then define settings for your USB - RS232 adapter

and press OK.

6

Figure 17. NCDrive: Serial communication settings

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 41

Installation vacon • 41

6.6.3.2 NCDrive Ethernet communication settings

For NCDrive Ethernet connection you need to have:

• Working Ethernet connection between PC and AC drive

• NCDrive is parametrized to use Ethernet connection

See instructions from Ethernet option board manual. Option board manuals can be downloaded

from https://www.danfoss.com/en/service-and-support/ Documentation Select "Drives" as

Business unit Select "VACON

®

Option Boards" as Product Series.

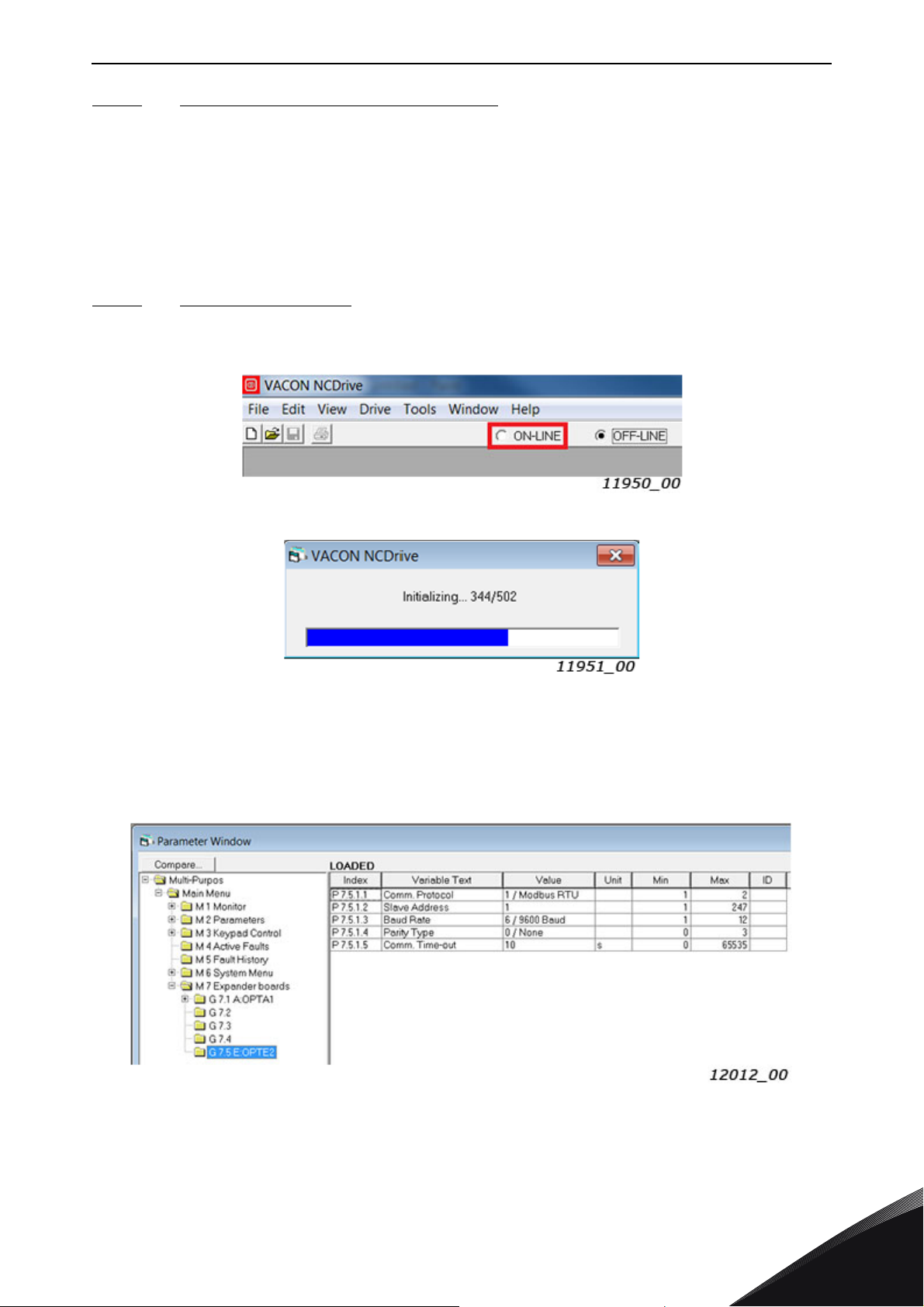

6.6.3.3

Press the "ON-LINE" button. The NCDrive will connect to the drive and start loading parameter

information. See Figures below.

Connecting to NCDrive

Figure 18. NCDrive: Going online

Figure 19. NCDrive: Loading information from the drive

To change the option board settings, navigate to the "M 7 Expander boards" menu and select the slot

to which OPTE2/E8 RS485 is connected. It is possible to change parameters defined in chapter 7.1.2

Option board parameter menu.

Figure 20. NC Drive: Parameter menu

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 42

vacon • 42 Installation

6.6.4 PC tools for VACON® 100 family and VACON® 20: VACON® Live

You can configure the VACON

RS485 parameters with VACON

VACON

®

Live. You need to have:

®

100 family AC drives, VACON® 20 family AC drives and OPTE2/E8

®

Live PC tool. Also monitor values of these devices can be read with

•PC with VACON® Live installed

®

•VACON

100 family or VACON® 20 family AC drive

• In case of Serial connection:

-VACON

®

Serial Cable (USB - Serial cable) which is connected from PC to AC drive control

unit.

®

-In case of VACON

not needed in case of VACON

20 also MCA (Micro Communications Adapter) is required. This adapter is

®

20 X / CP.

• In case of Ethernet connection:

- Ethernet cable which is connected to AC drive's Ethernet interface.

®

-In case of VACON

100 family it is possible to use built-in Ethernet connection or Ethernet

option board (for example OPTE9 Dual Port Ethernet).

NOTE! VACON

®

20, VACON® 20 X and VACON® 20 Cold Plate do not support VACON® Live

connection over Ethernet.

®

VACON

Live can be downloaded from https://www.danfoss.com/en/service-and-support/

Downloads Software Select "Drives" as Business unit. After starting the installation program,

follow the on-screen instructions.

Once the program is installed successfully, you can launch it by selecting it in the Windows Start

menu. Select Help Contents if you want more information about the software features.

6.6.4.1

VACON® Live Serial communication settings

Step 1: Connect your PC to VACON® AC drive with VACON® Serial Cable.

®

Step 2: Start VACON

Live. When the program starts, it asks "Select startup mode". Select "Online"

startup mode. After this the program scans compatible drives.

®

Figure 21. VACON

Live: To online mode

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 43

Installation vacon • 43

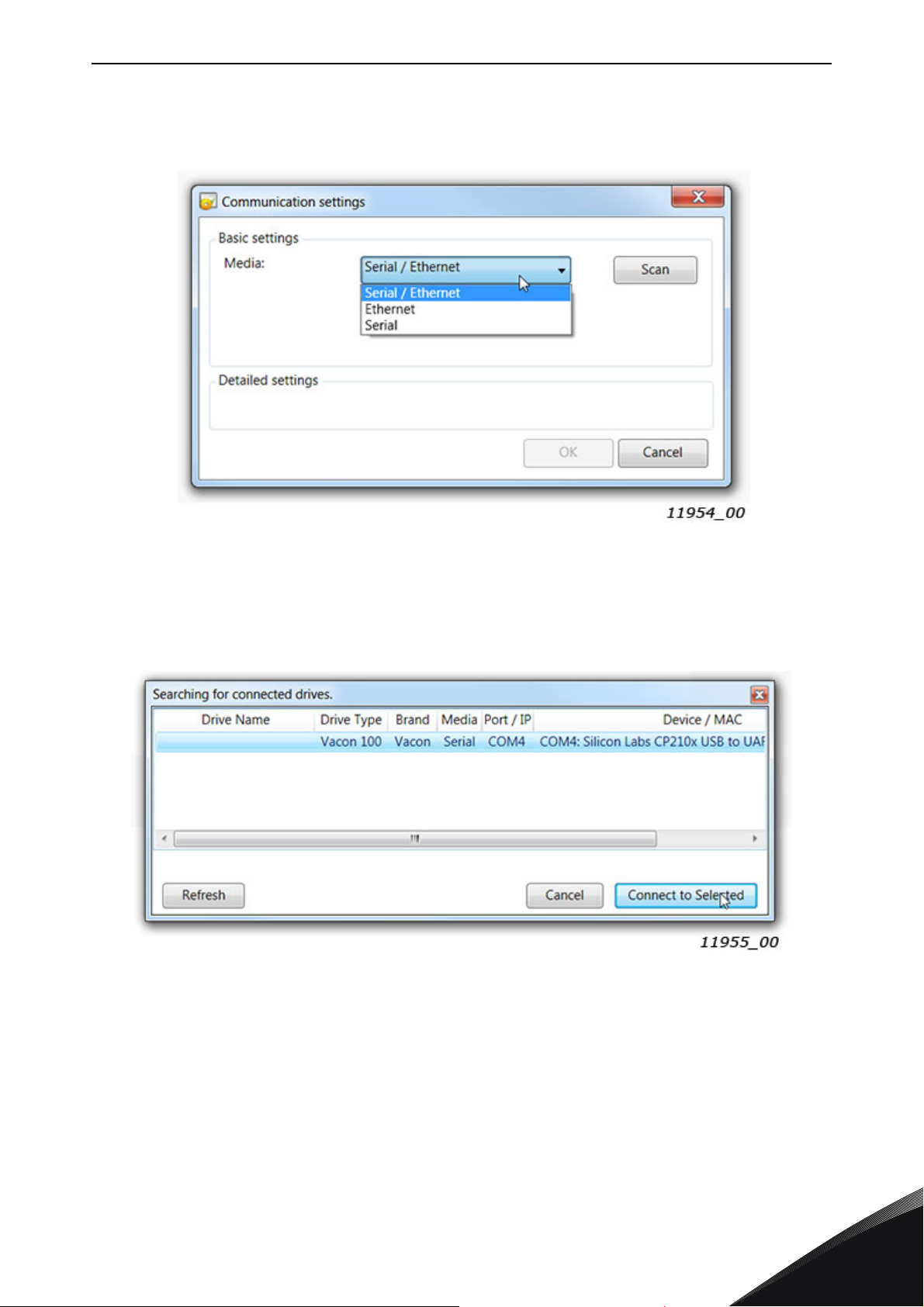

Step 2b: If VACON® Live cannot find your AC drive, then ensure that "Serial / Ethernet" or "Serial"

is selected. After that press "Scan".

Figure 22. VACON

Step 3: After successful scanning, VACON

the drive and press "Connected to Selected". After this VACON

value tree from the drive.

Figure 23. VACON

®

Live: Communication settings

®

Live shows the drive in connected drives window. Select

®

Live: Communication settings

®

Live reads parameter and monitor

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

6

Page 44

vacon • 44 Installation

6.6.4.2 VACON® Live Ethernet communication settings

For VACON® Live Ethernet connection you need to have:

• Working Ethernet connection between PC and AC drive

•VACON

®

Live is parametrized to use Ethernet connection

See instructions from Modbus, PROFINET IO, EtherNet/IP, BACnet/IP or OPTEA-OPTE9 Ethernet

option board manuals for VACON

®

100 family. Manuals can be downloaded from https://

www.danfoss.com/en/service-and-support/ Documentation Select "Drives" as Business unit

Select "VACON

6.6.4.3

®

Option Boards" as Product Series.

OPTE2/E8 RS485 parameters in VACON® Live

OPTE2/E8 RS485 parameters and monitor values can be found from "5. I/O and Hardware" menu.

®

With VACON

Live it is possible to modify OPTE2/E8 RS485 parameters and view monitor values.

Figure 24. VACON

®

Live: OPTE2/E8 RS485 parameters

6

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 45

Commissioning vacon • 45

7. COMMISSIONING

OPTE2/E8 is commissioned with VACON® 20 keypad, VACON® 100 family panel or with VACON® NX

family panel by setting appropriate parameters in the option board menu. Also PC tools can be used

for OPTE2/E8 parametrization (see Chapter 6.6 "VACON

Keypad/Panel commissioning and location of parameters are different between these two types of

drives.

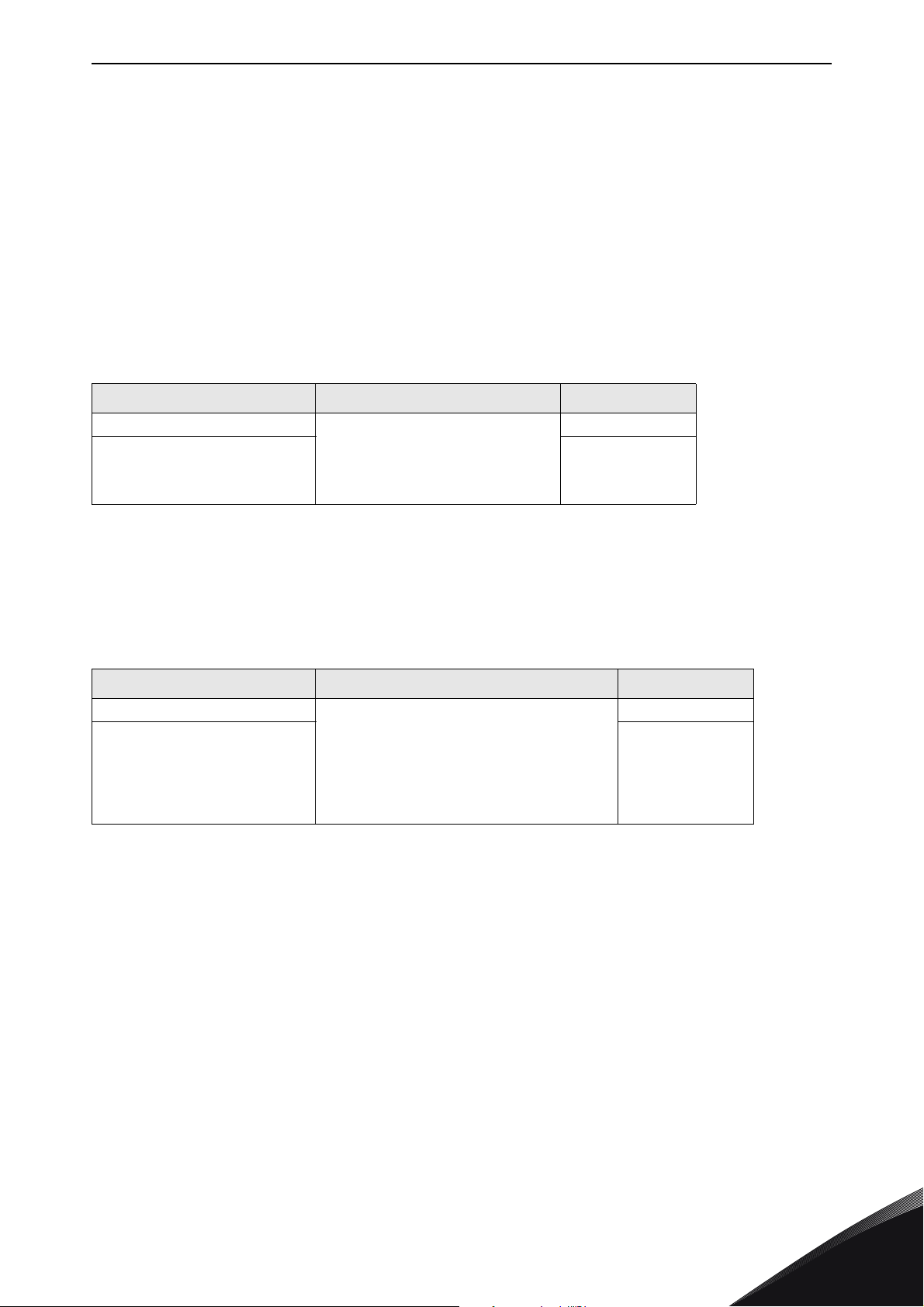

Table 13. Parameter location for commissioning

Drive Parameters location

®

PC tools").

VACON® 20

VACON

VACON

NOTE! The AC drive application must be parametrized to enable motor controlling from the fieldbus.

For application parametrization instructions, see Chapter 10 "Appendix A - Fieldbus

parametrization".

®

100 family

®

NX family

'System Menu' P 2.x

'I/O and Hardware (M7)' Slot D' or 'Slot E'

Expander boards menu (M7) Slot D' or

'Slot E'

7.1 Option board menu

The keypad/panel makes it possible for users to see which option board is connected to drive, and

to reach and edit the parameters associated with option board.

7.1.1 Option board monitor menu

Table 14. Option board monitor menu

Monitor Range Description

Fieldbus protocol

status

1 = Initializing,

3 = Operational,

4 = Faulted

Communication Status

Protocol/fieldbus

control word

Protocol/fieldbus status

word

Communication status

The number of messages with errors counter is increased when OPTE2/E8 receives a corrupted

frame from the bus. The content of the corrupted message cannot be parsed.

The number of messages without communication errors counter is increased when OPTE2/E8

receives a valid Modbus RTU or N2 frame from the bus. Also the frame that is addressed to some

other slave device increases the counter.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

X.Y

0.0 … 64.999

- Control word received from RS-485

-Status word in drive format

X = Number of messages with errors

Y = Number of messages without communication errors

7

Page 46

vacon • 46 Commissioning

7.1.2 Option board parameter menu

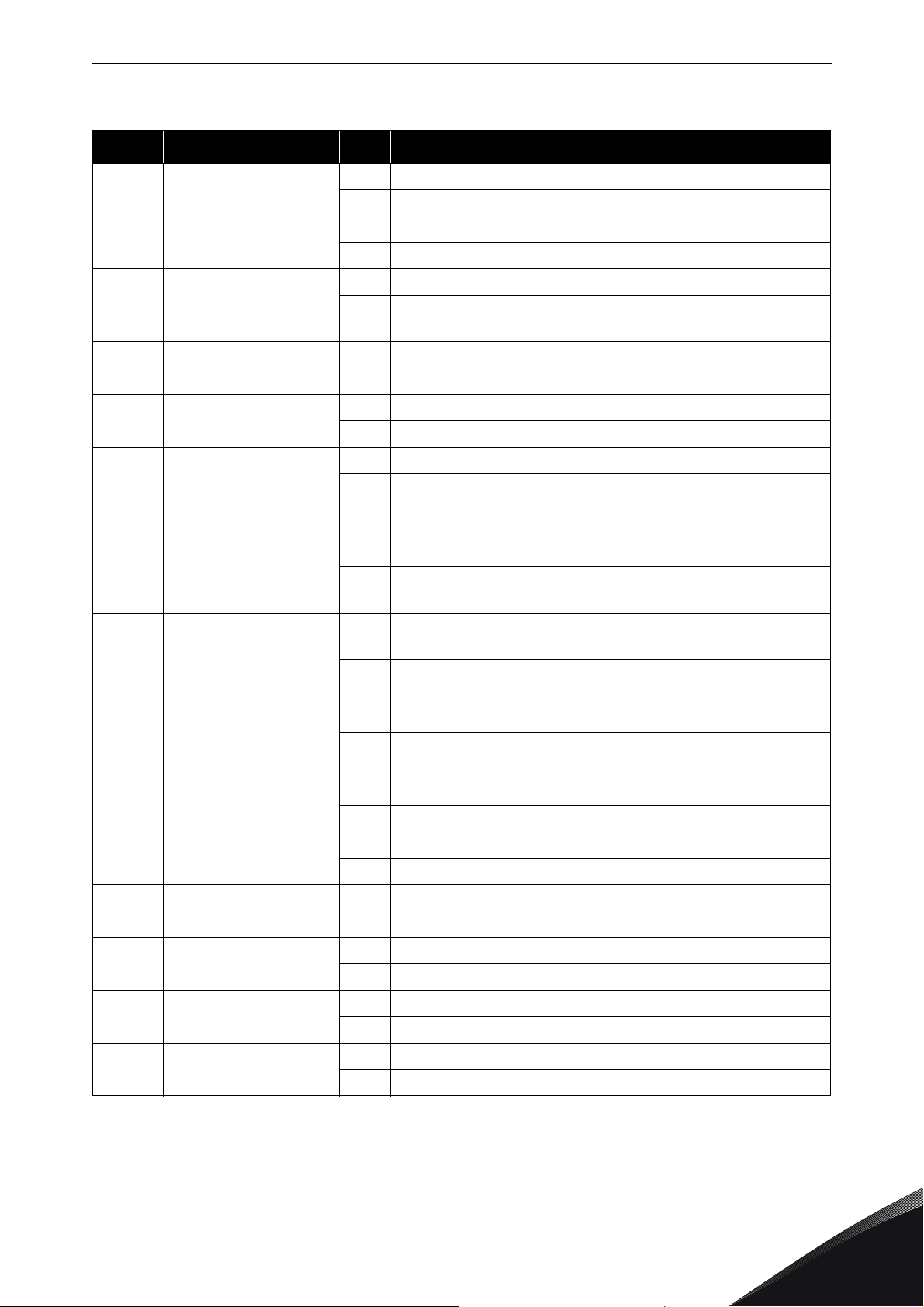

Table 15. Option board parameter menu

Parameter Range Description

Communication protocol

Slave address 1 … 247 Slave address

Baud rate

Parity

Communication timeout

Mode

1 = Modbus RTU

2 = N2

1 = 300 bps

2 = 600

3 = 1200

4 = 2400

5 = 4800

6 = 9600

7 = 19200

8 = 38400

9 = 57600

10 = 76800

11 = 115200

12 = 230400

0 = None

1 = Even

2 = Odd

3 = None Stopbits1

0 = Disable

1 … 65535 s

1 = Normal

2 = NX mode

Current active fieldbus protocol. Default

communication protocol is Modbus RTU

Baud rate. Default baud rate is 9600 bps. When

N2 protocol is used baud rate must be set to

9600.

Modbus RTU:

Parity None 2 stop bit

Parity Even 1 stop bit

Parity Odd 1 stop bit

Parity None Stopbits1 1 stop bit

N2 always uses 1 stop bit.

Protocol communication timeout

NX mode enables OPTC2/OPTC8 RS485

emulation. See Chapter "OPTC2/OPTC8 RS485

compatibility mode".

Communication timeout

The OPTE2/E8 RS485 option board reports communication timeout fault to the AC drive if the option

board cannot receive Modbus RTU or Metasys N2 request during a communication timeout time. For

more information on the fault, see Chapter 14.3 "Fieldbus timeout fault (F53)".

Only Modbus RTU or Metasys N2 requests that are pointed to the option board are taken into account

in the communication timeout calculation. Requests that are pointed to other devices do not affect

the timeout calculation.

Timeout monitoring starts after one valid request is received from the master.

The OPTE2/E8 RS485 does not create communication timeout fault to the drive when the timeout

value is set to zero. This is useful for example when Modbus RTU or N2 is used only for monitoring

the AC drive.

OPTC2/OPTC8 RS485 compatibility mode

OPTE2/OPTE8 firmware V003 and newer support the NX mode which enables emulation of the old

OPTC2/OPTC8 RS485 option board.

•In case of VACON

automatically.

- See also the related system parameter “Show to Application as” in Chapter 7.1.3 "System

Parameter menu".

®

NXP or VACON® NXS AC drive the emulation mode is enabled

7

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 47

Commissioning vacon • 47

•In case of VACON® 100 family AC drives the emulation mode can be enabled by selecting

"NX mode" with "Mode" parameter. See parameter in Chapter 7.1.2 "Option board

parameter menu".

The OPTC2/OPTC8 compatibility mode causes the following functionality changes in OPTE2/OPTE8

RS485 option board:

• N2 Binary input (BI) mapping is different. See Chapter 9.3.2 "Binary Input (BI)".

• N2 Binary output (BO) mapping is different. See Chapter 9.3.4 "Binary Output (BO)".

• Modbus RTU reading/writing of multiple VACON

writing of at least one ID succeeds. Normally OPTE2/8 returns "Illegal Data Address" (2)

Modbus error when access to one ID fails.

• Modbus RTU Holding/input register 98 reads the first active fault code.

7.1.3 System Parameter menu

Table 16. System Parameter menu

Parameter Range Description

®

application ID’s succeeds when reading/

0 = Default

Show to Application As*

*Available in VACON® NXP

Show to Application As

Some VACON

the application. In such cases, the application may refuse to go to the run state if a wrong type of

fieldbus option is installed to the drive.

With the Show to Application As parameter it is possible to modify the option board type information

that is fed to the application. For example, if an OPTC2 option board is replaced with an OPTE2 option

board, with the Show to Application As parameter it is possible to lie to the application that an OPTC2

board is installed to the drive.

With the default setting the application normally sees the OPTE2/OPTE8 option board as OPTE2 or

OPTE8 option board.

The Show to Application As parameter is available in VACON

NXP00002V198 and newer.

®

NXP applications assume that a certain fieldbus option board is used together with

17202 = OPTC2

17208 = OPTC8

Application sees the OPTE2/OPTE8 option

board as OPTC2 or OPTC8 option board if

“OPTC2” and “OPTC8” is selected.

®

NXP control firmware version

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

7

Page 48

vacon • 48 Modbus RTU

8. MODBUS RTU

8.1 Overview

The MODBUS protocol is an industrial communications and distributed control system to integrate

PLCs, computers, terminals, and other monitoring, sensing, and control devices. MODBUS is a

Master-Slave communications protocol. The Master controls all serial activity by selectively polling

one or more slave devices. The protocol provides for one master device and up to 247 slave devices

on a common line. Each device is assigned an address to distinguish it from all other connected

devices.

The MODBUS protocol uses the master-slave technique, in which only one device (the master) can

initiate a transaction. The other devices (the slaves) respond by supplying the request data to the

master, or by taking the action requested in the query. The master can address individual slaves or

initiate a broadcast message to all slaves. Slaves return a message ('response') to queries that are

addressed to them individually. Responses are not returned to broadcast queries from the master.

8.2 Modbus RTU communications

Features of the Modbus-VACON® interface:

• Acts as a Modbus slave

®

• Direct control of VACON

• Full access to all VACON

• Monitor the status of the VACON

code)

8.2.1 Data addresses in Modbus message

All data addresses in Modbus messages are referenced to zero. The first occurrence of a data item

is addressed as item number zero. For example:

• Holding register 40001 is addressed as register 0000 in the data address field of the

message. The function code field already specifies a 'holding register' operation. Therefore

the '4XXXX' reference is implicit.

• Holding register 40108 is addressed as register 006B hex (107 decimal).

8.2.2 Modbus memory map

The VACON

Modbus. The parameter addresses are determined in the application. Every parameter and actual

value has been given an ID number in the application. The ID numbering of the parameters as well

as the parameter ranges and steps can be found in the application manual in question. The

parameter value is given without decimals. If several parameters/actual values are read with one

message, the addresses of the parameters/actual values must be consecutive.

®

variables and fault codes as well as the parameters can be read and written from

AC drive (e.g. Run, Stop, Direction, Speed reference, Fault reset)

®

parameters

®

AC drive (e.g. Output frequency, Output current, Fault

8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 49

Modbus RTU vacon • 49

Table 17. Modbus memory map

Function

code

3 (0x03) Read holding registers 16bit 40000-4FFFF

4 (0x04) Read input registers 16bit 30000-3FFFF

6 (0x06) Write single register 16bit 40000-4FFFF

16 (0x10) Write multiple registers 16bit 40000-4FFFF

23 (0x17) Read/Write multiple registers 16bit 40000-4FFFF

8.2.3 Modbus exception responses

Code Function Description

01 ILLEGAL FUNCTION

02 ILLEGAL DATA ADDRESS

03 ILLEGAL DATA VALUE

04 SLAVE DEVICE FAILURE

06 SLAVE DEVICE BUSY

Current terminology

Table 18. Modbus exception responses

The function code received in the query is not an allowable action

for the slave

The data address received in the query is not an allowable

address for the slave

A value contained in the query data field is not an allowable value

for the slave

An unrecoverable error occurred while slave was attempting to

perform the requested action.

The slave is engaged in processing a long-duration program

command.

Access

type

Address range (hex

08 MEMORY PARITY ERROR

The slave attempted to read record file, but detected a parity

error in memory.

8.3 Modbus data mapping

8.3.1 Holding and input registers

Values can be read with function code 3 and code 4 (all registers are 3X and 4X reference). Modbus

registers are mapped to the drive IDs as follows:

Table 19. Modbus register mapping to drive IDs

Address range Purpose Access type

0001 - 2000

98

2001 - 2050 FBProcessDataIN 16bit

2051 - 2099 FBProcessDataIN 32bit

2101 - 2150 FBProcessDataOUT 16bit

2151 - 2199 FBProcessDataOUT 32bit

2200 - 10000

10501 - 10530 IDMap 16bit

VACON

If “NX mode” is enabled: Read

active fault code

VACON

®

Application IDs

®

Application IDs

16bit

16bit

16bit

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

8

Page 50

vacon • 50 Modbus RTU

Table 19. Modbus register mapping to drive IDs

Address range Purpose Access type

10601 - 10630 IDMap Read/Write 16bit

10701 - 10760 IDMap Read/Write 32bit

20001 - 40000

25101 - 25102 Drive system time 32bit

40001 - 40005 Operation day counter 16bit

40011 - 40012 Operation day counter 32bit

40201 - 40203 Energy counter 16bit

40211 - 40212 Energy counter 32bit

40301 - 40303 Resettable energy counter 16bit

40311 - 40312 Resettable energy counter 32bit

40401 - 40430 Fault history 16bit

40501 Communication timeout 16bit

VACON

®

Application IDs

32bit

8.3.1.1 VACON® application IDs

Application IDs are parameters that depend on the drive's application. These parameters can be

read and written by pointing the corresponding memory range directly or by using the so-called ID

map (more information below). It is easiest to use a straight address if you want to read a single

parameter value or parameters with consecutive ID numbers. It is possible to read 12 consecutive

ID addresses.

Table 20. VACON

Address range Purpose ID

0001-2000 Application parameters (16bit) 1-2000

2200-10000 Application parameters (16bit) 2200-10000

20001 - 40000 Application parameters (32bit) 1-10000

Read register/registers can fail with Modbus error "ILLEGAL DATA ADDRESS" in the following

cases:

• Reading of a single application ID fails if the ID does not exist.

®

•In case of VACON

reading of one ID fails.

- In "NX mode" OPTE2/E8 tries to read all registers. The read request succeeds if reading of

one application ID succeeds. The failed application IDs are set to zero in the Modbus

response data. If OPTE2/8 is used in VACON® NX AC drives, this mode is enabled

automatically.

• In case of 32-bit address space the read operation fails if only half of the 32-bit value is read.

The read request must read complete 32-bit values.

100 and VACON® 20 AC drives reading of multiple application IDs fails if

®

application IDs

8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 51

Modbus RTU vacon • 51

Write register/registers can fail with Modbus error "ILLEGAL DATA ADDRESS" in the following

cases:

• Writing of a single application ID fails if the ID does not exist.

®

•In case of VACON

NXP/NXS AC drives writing of 32-bit value fails if the application ID is not

32-bit.

®

•In case of VACON

100 family AC drives writing of register fails if the value written by

Modbus is not inside the application ID value limits.

®

•In case of VACON

100 family AC drives writing of register fails if the application ID is a

monitor value.

®

•In case of VACON

100 and VACON® 20 AC drives writing of multiple application IDs fails if

writing of one ID fails.

- In "NX mode" OPTE2/8 tries to write all registers. The write request succeeds if writing of

®

one application ID succeeds. If OPTE2/8 is used in VACON

NX drives, this mode is enabled

automatically.

• In case of 32-bit address space the write operation fails if only half of the 32-bit value is

written. The write request must write complete 32-bit values.

8.3.1.2

Drive System time

VACON® NX and VACON® 100 product families support reading and setting of drive system time via

fieldbus. It is also possible to synchronize time by using SNTP protocol. For details of the

functionality, see Ethernet fieldbus manuals.

With OPTE2/E8 Modbus RTU it is possible to read and write drive system time via ID 2551. The time

is presented as unsigned 32-bit unix time. For example, unix time 1536315873 (0x5B9251E1) stands

for 07-Sep-2018 10:24:33.

Example: Read or write drive system time by using 32-bit application parameter access. Modbus

address 25102 (low data) becomes from calculation "32-bit area start address" + (application ID * 2)

= 20000 + (2551 * 2).

Modbus index 25101 value: 23442 (0x5B92)

Modbus index 25102 value: 20961 (0x51E1)

NOTE! VACON

time zone and setting the daylight saving mode. If the VACON

®

100 family's default time zone is UTC. Local time can be configured by changing the

®

100 family AC drive is equipped with

a real-time clock battery, setting the time is not necessary after power cycle.

NOTE! VACON

must be local time. VACON

®

NX family AC drives do not have time settings. Therefore the value written to this ID

®

NX system time is zero after the drive boots up. The system time is

started after writing into ID 2551.

8.3.1.3

FB Process data IN

The process data in fields are used for fast controlling of the AC drive (e.g. Run, Stop, Reference and

Fault Reset).

The 32-bit process data can be used with all VACON

®

AC drives, but only VACON® 100 family

applications are able to process 32-bit data. In other AC drives the upper 16 bits are ignored.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

8

Page 52

vacon • 52 Modbus RTU

Table 21. Process Data Master -> Slave (max 22 bytes)

Address

Name Range/Type

16-bit

*

32-bit

2001

2051 = High data

2052 = Low data

FB Control Word

2002 - FB General Control Word

2003

2004

2005

2006

2007

2008

2009

2053 = High data

2054 = Low data

2055 = High data

2056 = Low data

2057 = High data

2058 = Low data

2059 = High data

2060 = Low data

2061 = High data

2062 = Low data

2063 = High data

2064 = Low data

2065 = High data

2066 = Low data

FB Speed Reference

FB Process Data In 1 See Chapter 11.7 "Process data".

FB Process Data In 2 See Chapter 11.7 "Process data".

FB Process Data In 3 See Chapter 11.7 "Process data".

FB Process Data In 4 See Chapter 11.7 "Process data".

FB Process Data In 5 See Chapter 11.7 "Process data".

FB Process Data In 6 See Chapter 11.7 "Process data".

See Chapter 11.2 "Control Word bit

®

support in VACON

AC drives".

See Chapter 11.2 "Control Word bit

®

support in VACON

AC drives".

-10000...10000d

®

See Chapter 11.6 "VACON

speed

reference and actual speed FBSpeedReference and

FBActualSpeed".

2010

2011

**

2012

**

2013

**

2014

**

2015

**

2016

**

2017

**

2018

**

2019

*In VACON® 100 family, the Control Word and the Status Word are formed of 32 bits. Only the initial 16

bits can be read in the 16-bit area.

**See requirements for 9–16 process data items in

board communication"

2067 = High data

2068 = Low data

2069 = High data

2070 = Low data

2071 = High data

2072 = Low data

2073 = High data

2074 = Low data

2075 = High data

2076 = Low data

2077 = High data

2078 = Low data

2079 = High data

2080 = Low data

2081 = High data

2082 = Low data

2083 = High data

2084 = Low data

2085 = High data

2086 = Low data

FB Process Data In 7 See Chapter 11.7 "Process data".

FB Process Data In 8 See Chapter 11.7 "Process data".

FB Process Data In 9 See Chapter 11.7 "Process data".

FB Process Data In 10 See Chapter 11.7 "Process data".

FB Process Data In 11 See Chapter 11.7 "Process data".

FB Process Data In 12 See Chapter 11.7 "Process data".

FB Process Data In 13 See Chapter 11.7 "Process data".

FB Process Data In 14 See Chapter 11.7 "Process data".

FB Process Data In 15 See Chapter 11.7 "Process data".

FB Process Data In 16 See Chapter 11.7 "Process data".

Chapter 12 "Appendix C - Fieldbus option

.

8

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 53

Modbus RTU vacon • 53

Control word bits

See Control word bits definition in Chapter 11.8 "Fieldbus process data mapping and scaling".

8.3.1.4

FB Process data OUT

The process data out fields are used for fast monitoring of the AC drive (e.g. drive status and actual

speed).

The 32-bit process data can be used with all VACON

®

AC drives, but only VACON® 100 family

applications are able to transmit 32-bit data. In other drives the upper 16 bits are set to zero.

Table 22. FB Process data OUT

Address

*

16-bit

2101

32-bit

2151 = High data

2152 = Low data

FB Status Word

2102 - FB General Status Word

Name Range/Type

See Chapter 11.3 "VACON

Status Word FBFixedStatusWord".

See Chapter 11.3 "VACON

Status Word -

®

®

FBFixedStatusWord".

-10000...10000d

®

2103

2153 = High data

2154 = Low data

FB Actual Speed

See Chapter 11.6 "VACON

speed reference and actual

speed - FBSpeedReference

and FBActualSpeed".

2104

2105

2106

2107

2108

2109

2110

2111

2112

2113

2114

2115

2116

2)

**

**

**

**

2155 = High data

2156 = Low data

2157 = High data

2158 = Low data

2159 = High data

2160 = Low data

2161 = High data

2162 = Low data

2163 = High data

2164 = Low data

2165 = High data

2166 = Low data

2167 = High data

2168 = Low data

2169 = High data

2170 = Low data

2171 = High data

2172 = Low data

2173 = High data

2174 = Low data

2175 = High data

2176 = Low data

2177 = High data

2178 = Low data

2179 = High data

2180 = Low data

FB Process Data Out 1

FB Process Data Out 2

FB Process Data Out 3

FB Process Data Out 4

FB Process Data Out 5

FB Process Data Out 6

FB Process Data Out 7

FB Process Data Out 8

FB Process Data Out 9

FB Process Data Out 10

FB Process Data Out 11

FB Process Data Out 12

FB Process Data Out 13

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

8

Page 54

vacon • 54 Modbus RTU

Table 22. FB Process data OUT

Address

Name Range/Type

16-bit

*

32-bit

**

2117

**

2118

**

2119

*In VACON® 100 family, the Status Word is formed of 32 bits. Only the lower 16bits can be read in the

16-bit area.

**See requirements for 9–16 process data items in Chapter 12 "Appendix C - Fieldbus option board

communication".

2181 = High data

2182 = Low data

2183 = High data

2184 = Low data

2185 = High data

2186 = Low data

FB Process Data Out 14

FB Process Data Out 15

FB Process Data Out 16

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

See Chapter 11.7 "Process

data".

Status word bits

See Status word bits definition in Chapter 11.3 "VACON® Status Word - FBFixedStatusWord".

The use of process data depends on the application. In a typical situation, the device is started and

stopped with the Control Word (CW) written by the Master and the Rotating speed is set with

Reference (REF). With PD1…PD8 the device can be given other reference values (e.g. Torque

reference).

With the Status Word (SW) read by the Master, the status of the device can be seen. Actual Value

(ACT) and PD1…PD8 show the other actual values.

8.3.1.5

ID map

Using the ID map, you can read consecutive memory blocks that contain parameters whose ID's are

not in a consecutive order. The address range 10501 - 10530 is called 'IDMap', and it includes an

address map in which you can write your parameter IDs in any order. The address range 10601 to

10630 is called 'IDMap Read/Write,' and it includes values for parameters written in the IDMap. As

soon as one ID number has been written in the map cell 10501, the corresponding parameter value

can be read and written in the address 10601, and so on. The address range 10701 - 10730 contains

the ID Map for 32bit values.

8

Figure 25.

Local contacts: https://www.danfoss.com/en/contact-us/contacts-list/

Page 55

Modbus RTU vacon • 55

Once the IDMap address range has been initialized with parameter IDs, the parameter values can

be read and written in the IDMap Read/Write address range address (IDMap address + 100).

Table 23.

Address Data

410601 Data included in parameter ID700

410602 Data included in parameter ID702

410603 Data included in parameter ID707

410604 Data included in parameter ID704

If the IDMap table has not been initialized, all fields show index as '0'. If it has been initialized, the

parameter IDs included in it are stored in the flash memory of the option board.

Table 24. Example of 32bit IDMap

Address Data

410701 Data High, parameter ID700

410702 Data Low, parameter ID700

410703 Data High, parameter ID702

410704 Data Low, parameter ID702

8.3.1.6

Control unit operating time counter (total value). This counter cannot be reset.

Operation day counter as seconds