Page 1

Data sheet

760 nm 1 mm10 nm 380 nm

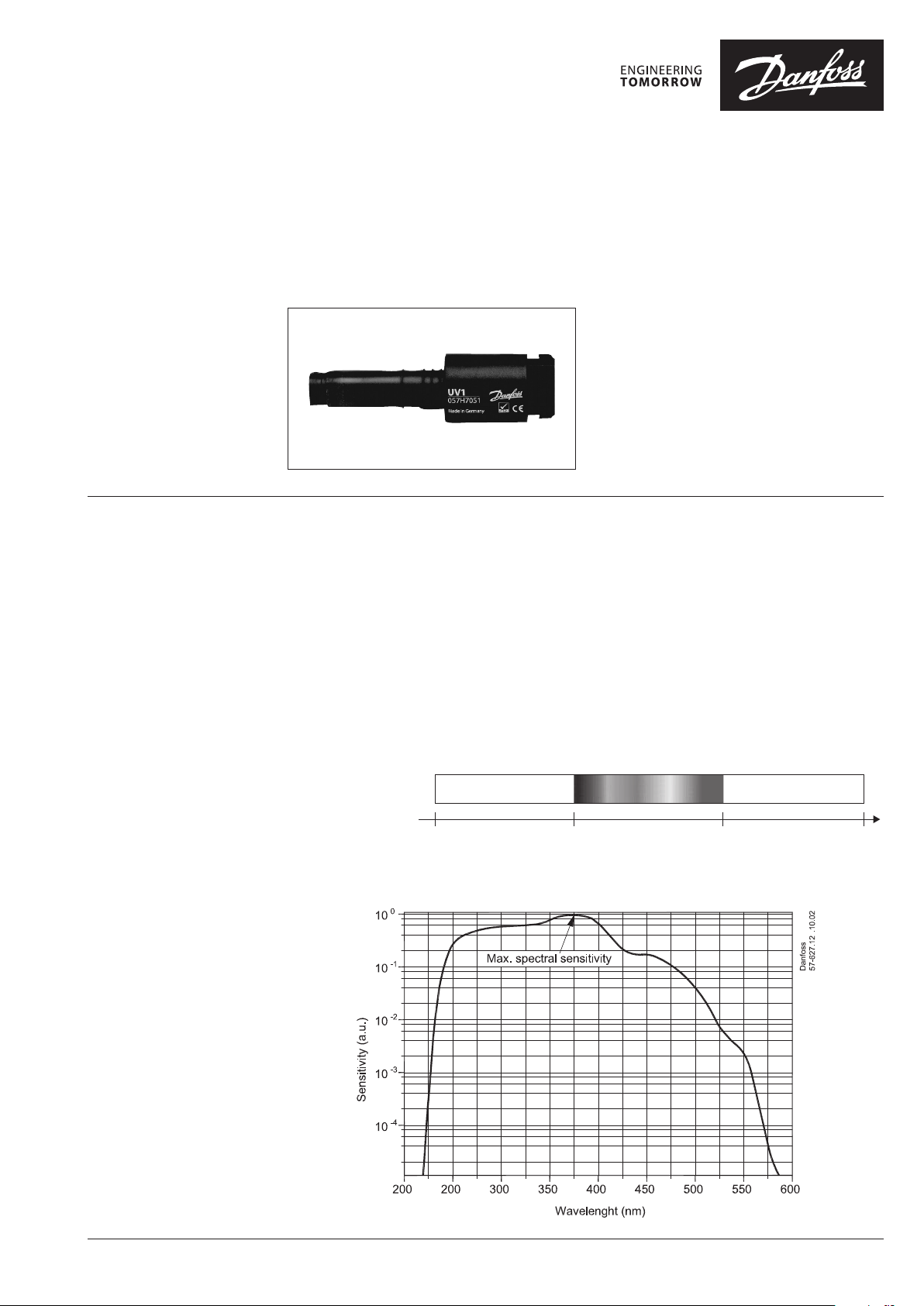

Ultraviolet Flame Sensor UV

Application

Function

Light rays are sent at different wavelengths. The

light that the human eye can see lies in the range

of 380 to 760 nm and is called visible light.

In the blue flame oil burner the flame’s visible

light is very dim and therefore cannot be

detected by the LD/LDS sensor series, which is

built on the photoresistance principle.

In the case of UV sensors, the flame’s ultraviolet

light is used instead, which is detected by a UV

diode. In the sensors, the sensor signal is

converted by an amplifier circuit into a signal that

the control can use.

Ultraviolet light Visible light Infrared light

Danfoss UV sensors are used to detect the flame

in blue flame oil burners. They are intended for

use together with Danfoss controls in the OBC 80

and BHO 70 series.

The UV sensors meet the requirements of the

EN230:2005 standard and also meets the

requirements of the RoHS and WEEE Directives.

To ensure unambiguous detection of the

ultraviolet light, it is first transmitted through a

lens that focusses the light rays onto the surface

of the UV diode, and then through a filter that

reduces the sensitivity to a desired wavelength

range.

Danfoss UV sensors have max. sensitivity at 375

nm, which is apparent from the logarithmic

diagram, where sensitivity at 375 nm is given to

100%.

Wavelength

© Danfoss | 2019.07 VD.AU.A3.02 | 1

Page 2

Data sheet Ultraviolet Flame Sensor UV

12

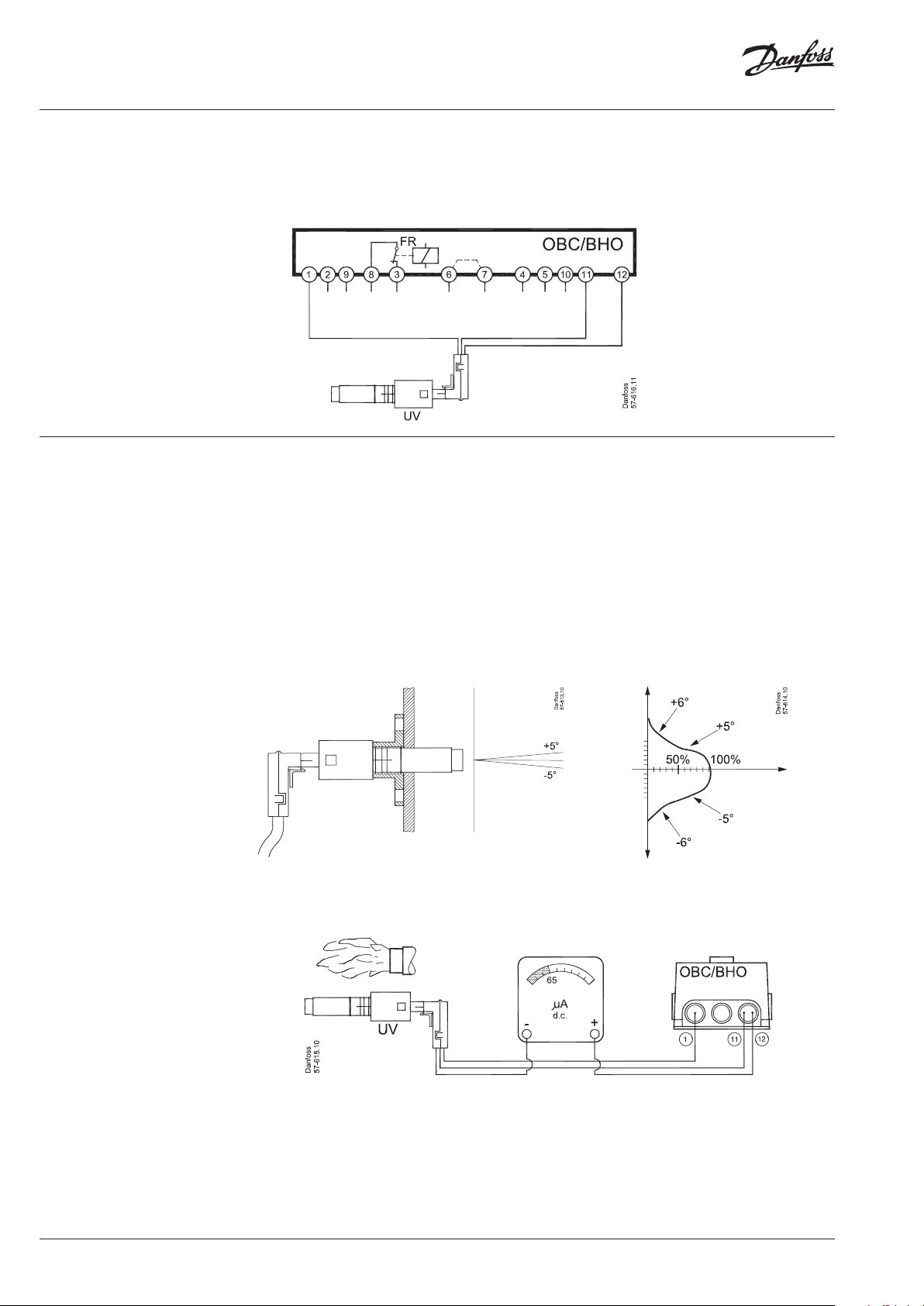

Electrical connection

Mounting

The UV sensors are connected to Danfoss

controls in the OBC 80 and BHO 70 series as

shown in the diagram.

The UV sensors are designed to be very directional to limit the influence of other light sources,

primarily the ignition spark that emits UV light.

The sensors must be installed so that they are not

affected by light from the ignition spark and, at

the same time, so that the best possible input

from the flame is achieved.

It is very important that the mounting flange or

piping used has the UV sensor fixed in the correct

position.

Note that the blue wire must be connected to

terminal 11 and not to the common 0 on terminal

2 or the appertaining auxiliary terminals in the

base section.

3

The UV sensors’ sensitivity is shown as a function

of the angle deviation in Fig. 1 and 2.

If a sufficient signal is not achieved, we recommend selecting a UV sensor of higher sensitivity.

To determine the quality of the signal, use the

measurement setup below.

If there is no flame/darkness, the value should be

≤ 5 µA and when there is a flame/light it should

be ≥65 µA.

1. Brown

2. Blue

3. Black

Fig. 1 Fig. 2

Fig. 3

2 | VD.AU.A3.02 © Danfoss | 2019.07

Page 3

Data sheet Ultraviolet Flame Sensor UV

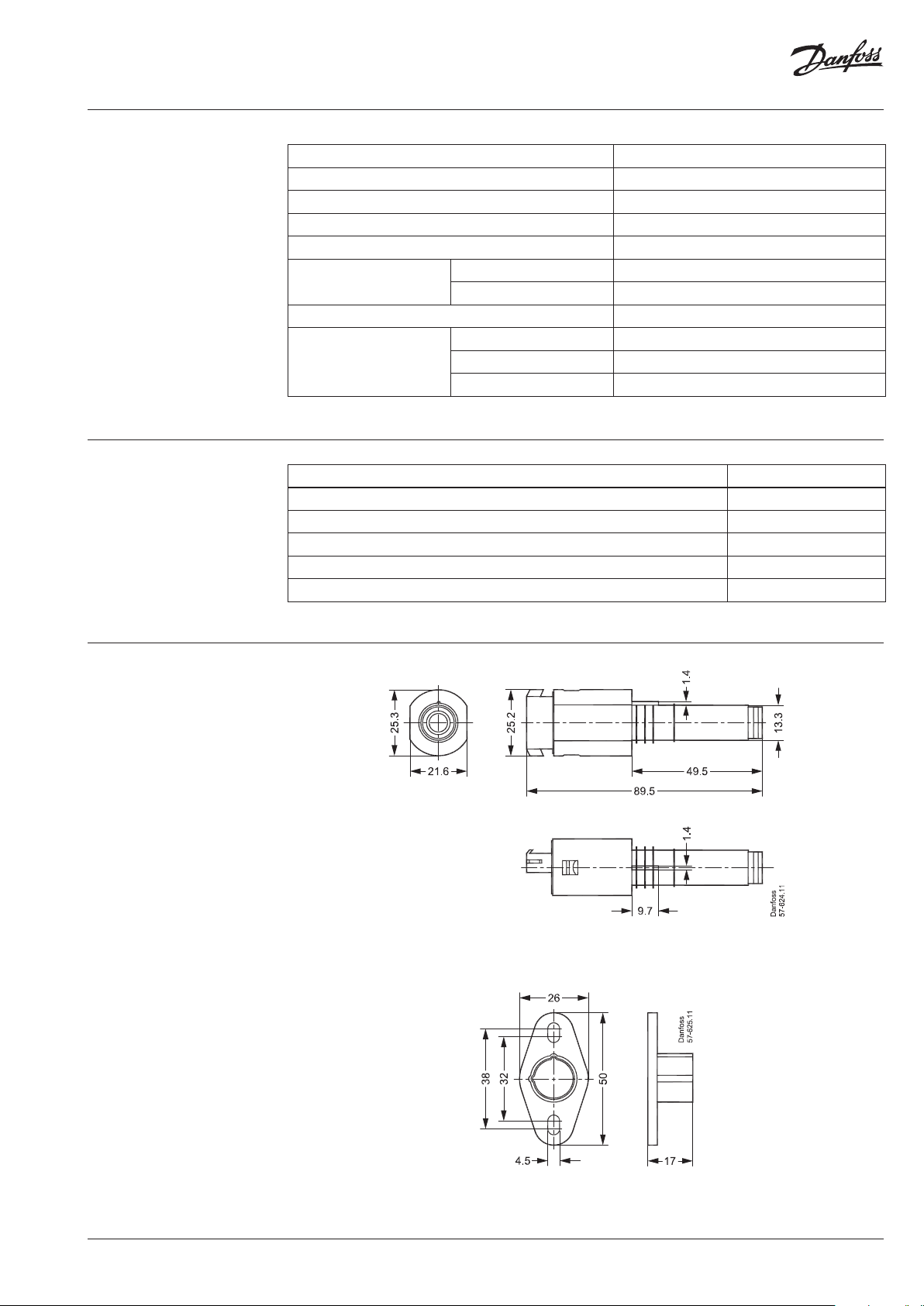

Technical Data

Ordering

Mains connection 230 V, 50/60 Hz, 0.3 VA

Enclosure IP 40

Signal output max. 100 µA

Recommended min. signal output 65 µA

Signal for no light max. 5 µA

Ambient temperature

Weight 23 g

Wiring OBC 80/

BHO 70 series

Product Code no.

UV1 – Normal sensitivity 057H7051

Flange 057H7061

300 mm cable 057H1040

400 mm cable 057H1041

500 mm cable 057H1042

Operation -20 - +70 °C, short time operation up to 75 °C

Transp ort -30 - +70 °C

Brown wire, 230 V mains terminal 1

Blue wire, neutral terminal 11

Black wire, signal terminal 12

Dimensions

UV sensor

Flange

VD.AU.A3.02 | 3© Danfoss | 2019.07

Page 4

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet Ultraviolet Flame Sensor UV

Additional documentation on burner components is available on http://heating.danfoss.com/

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all D anfoss logotypes are trademarks of Danfoss A/S. All rights reserve d.

© Danfoss | DHS-SDBT | 2019.074 | VD.AU.A3.02

Loading...

Loading...