Page 1

Data sheet

Balancing valves

USV-S

Application / Description

USV-S

USV-S valves are to be used in radiator heating

systems to limit the flow in risers or horizontal

loops.

USV-S valves are designed for manual hydronic

balancing of heating and cooling systems.

USV-S (black knob) is used to limit the flow

in heating or cooling installation or can work

separately as manual balancing valves for flow

limitation.

USV-S is compact valves in which the operating

elements and connections are placed within

an arc of 90°, so that in spite of small valve

dimensions, access for installation and operation

is optimal. Insulation caps for temperature up to

80 oC or 120 oC are available as accessory.

USV-S is supplied in a set-pack with internal

thread.

DEN-SMT/SI

USV-S in radiator application - vertical riser

USV-S can also be used in floor heating systems.

To limit the flow, every manifold with constant

flow should be used together with USV-S valves.

USV-S in oor heating systems

VD.C 1.N1.02 © Danfoss 06/2015

USV-S in radiator application - horizontal loop

1

Page 2

Data sheet Balancing valves USV-S

Application / Description

(continued)

Ordering

The USV-S valves are to be used in systems with

fan coils to limit the ow in order to provide

ecient heat distribution.

USV-S valve

k

Int. thread

Typ e DN

VS

[m3/h]

15 1,6 Rp ½

20 2,5 Rp ¾

25 4 Rp 1

32 6,3 Rp 1¼

40 10 Rp 1½

50 16 Rp 2

USV-S in cooling systems

ISO 7/1

Code No.

003Z2231

003Z2232

003Z2233

003Z2234

003Z2235

003Z2236

Accessories and spare parts

Typ e Comments/connection Code No.

Insulation cap

up to 80 °C DN 15 003L8165

DN 20 003L8166

DN 25 003L8167

DN 32 0 03L8168

DN 40 003L8169

DN 50 003L8164

up to 120 ° C DN 15 003L8170

DN 20 003 L8171

DN 25 00 3L8172

DN 32 003L 8173

DN 40 00 3L 8139

DN 50 00 3L 8138

2

VD.C1.N1.02 © Danfoss 06/2015

DEN-SMT/SI

Page 3

Data sheet Balancing valves USV-S

S

E

B

C

P

.A

L

L

E

N

K

E

Y

.

00

1

.0

1

Technical data

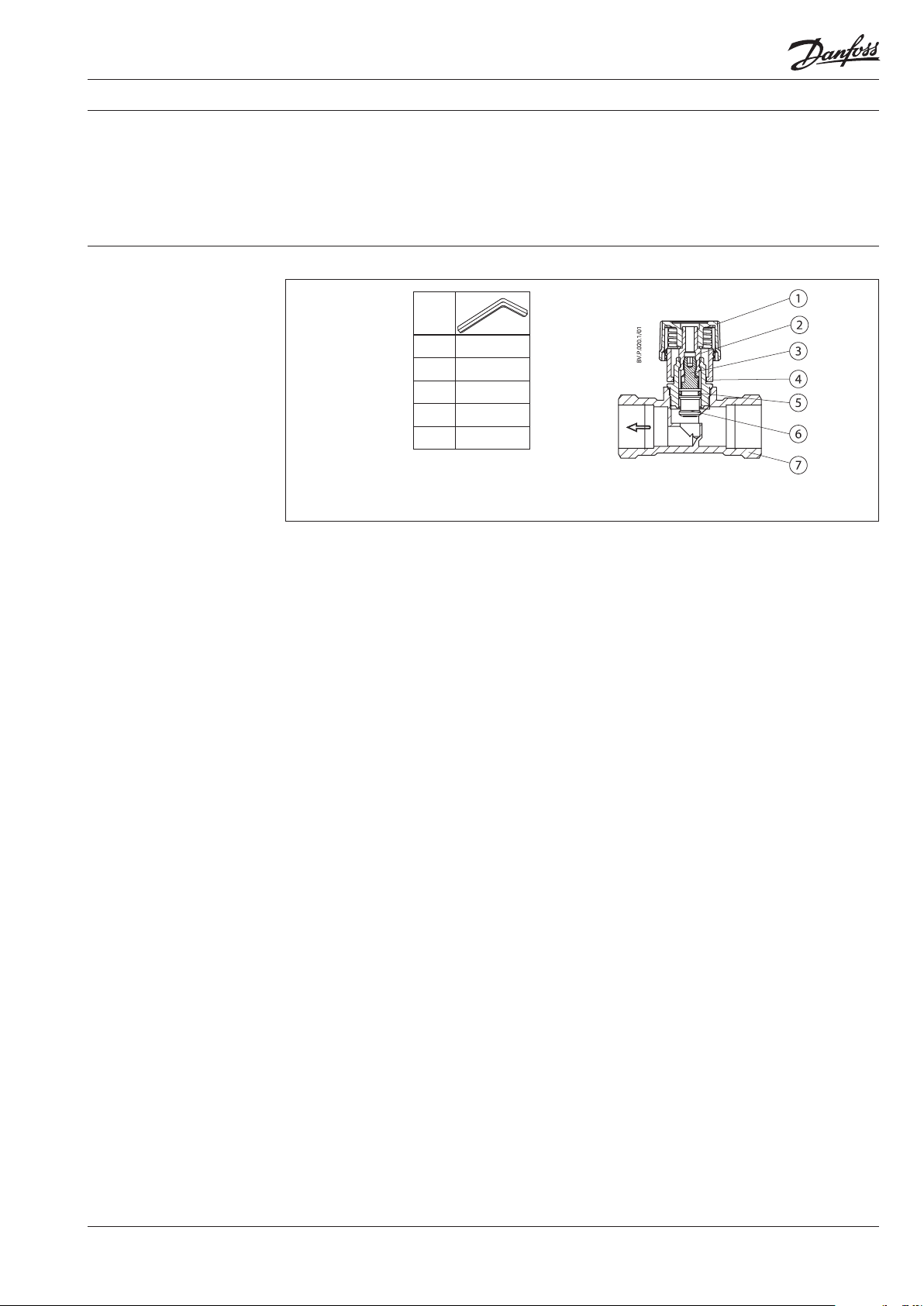

Design

1. Shut- of f knob

2. Shut-off spindle

3. Setting spindle

4. Scale disc

5. O-rings

6. Valve cone

7. Valve body

Max. working pressure ........................................ 16 bar

Test pressure ...........................................................25 bar

Max. dierential pressure across

the valve (USV-S) ............................. 1,5 bar (150 kPa)

Flow temperature ...................... -20 to 120 °C

DN

S

S

O

F

N

A

D

15 2,5

20 3

25 4

32 5

40 5

Fig. 8 USV-S

USV-S incorporates a double cone (3.6) able to

give maximum stroke limitation, thus achieving

ow limitation. It also incorporates shut o

function.

Use the following procedure to limit the ow:

• turn the valve knob ① fully counter clockwise

to open the valve. The mark on the knob will

now be opposite »0« on the scale ④.

• turn the valve knob ① clockwise to the

required setting (e.g. for setting 2.2 the knob

must be rotated two full turns and then

forward to »2« on the scale.

• hold the knob ① to keep the setting (e.g. 2.2)

and using a hexagon socket key turn the

spindle ③ fully counter clockwise (until a stop

can be felt).

Material of parts in contact with water:

Valve body, spindle, etc. ....................................... Brass

Cone ................................................................... DZR Brass

Diaphragm and O-rings ...................................... EPDM

Spring ........................................................ Stainless steel

Port A Port B

• turn the valve knob ① fully counter clockwise

so that the mark on the knob is opposite »0«

on the scale ④. The valve is now open as

many turns from the closed position (2.2) as

indicated by the convertion from required

flow.

• to annul the setting, turn the hexagon socket

key fully clockwise (until a stop can be felt).

Remember, at the same time the knob must be

held on its »0« setting.

DEN-SMT/SI

VD.C1.N1.02 © Danfoss 06/2015

3

Page 4

Data sheet Balancing valves USV-S

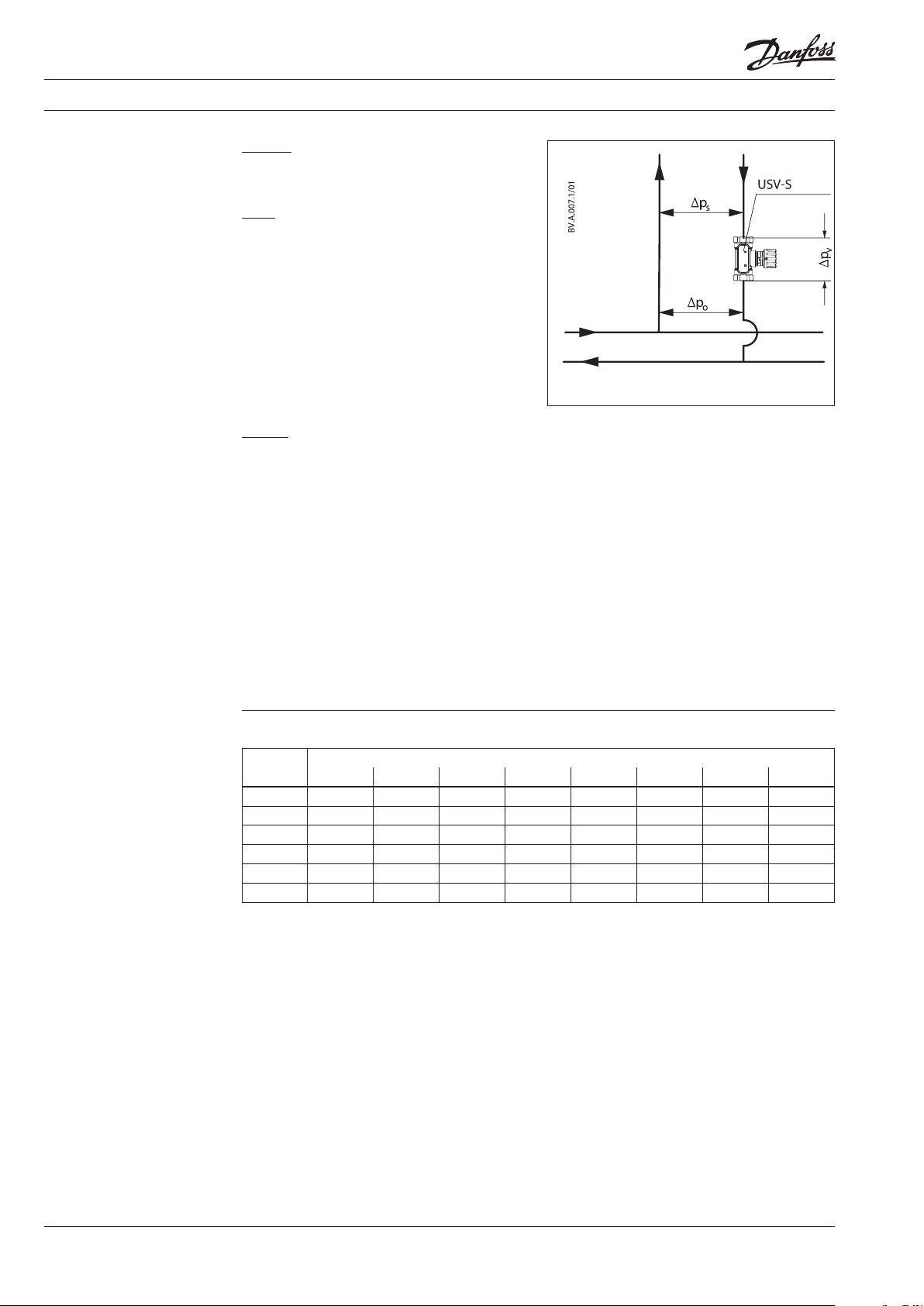

Sizing

Required:

A. Correct valve size USV-S

B. Correct USV-S presetting

Given:

1. Required max. flow in the riser

Q = 0,80 [m3/h]

2. Pressure drop across riser

Δps = 15 [kPa]

3. Available pump pressure

Δpo = 35 [kPa]

4. Connection pipe: DN 25

Solution:

A) USV-S DN20 is selected (same size as

connection pipe).

A straight line conecting this point and

Q = 0,80 [m3/h] intersects the differential

pressure bar at Δpv (USV-S) = 10 [kPa].

Δpo = Δps + Δpv (USV-S)

B) Correct valve size and presetting of USV-S:

The differential pressure across USV-S can be

calculated as follows:

Δpv (USV-S) = Δpo – Δp

s

Δpv = 35 [kPa] – 15 [kPa]

The example selects USV-S DN 20. Presetting

is read from the sizing diagram (page 5) by

taking a straight line from from max. flow

Q = 0,80 [m3/h] to the differential pressure Δpv

(USV-S)= 20 [kPa] and to the intersection with

kV-axis at kV = 1,8 [m3/h].

Draw a horizontal line from this point to the

adjustment curve of the chosen valve

(DN 20). Starting from closed valve, the

presetting of 1,6 turns is required.

kV-values [m3/h] for various presettings:

Size

0,2 0,5 1,0 1,5 2,0 2,5 3,0 3,2

Number of turns

DN 15 0,2 0,4 0,8 1,1 1, 3 1,5 1,6 1,6

DN 20 0,3 0,7 1,3 1,7 2,0 2,3 2,5 2,5

DN 25 0,4 1,1 1,9 2,7 3,3 3,6 3,9 4,0

DN 32 0,7 1,7 3,1 4,3 5,2 5,7 6 ,1 6,3

DN 40 0,9 2,1 4,2 5,9 7,4 8,7 9,7 10,0

DN 50 1,7 4,1 7,6 10,5 12, 7 14,0 15, 2 16,0

4

VD.C1.N1.02 © Danfoss 06/2015

DEN-SMT/SI

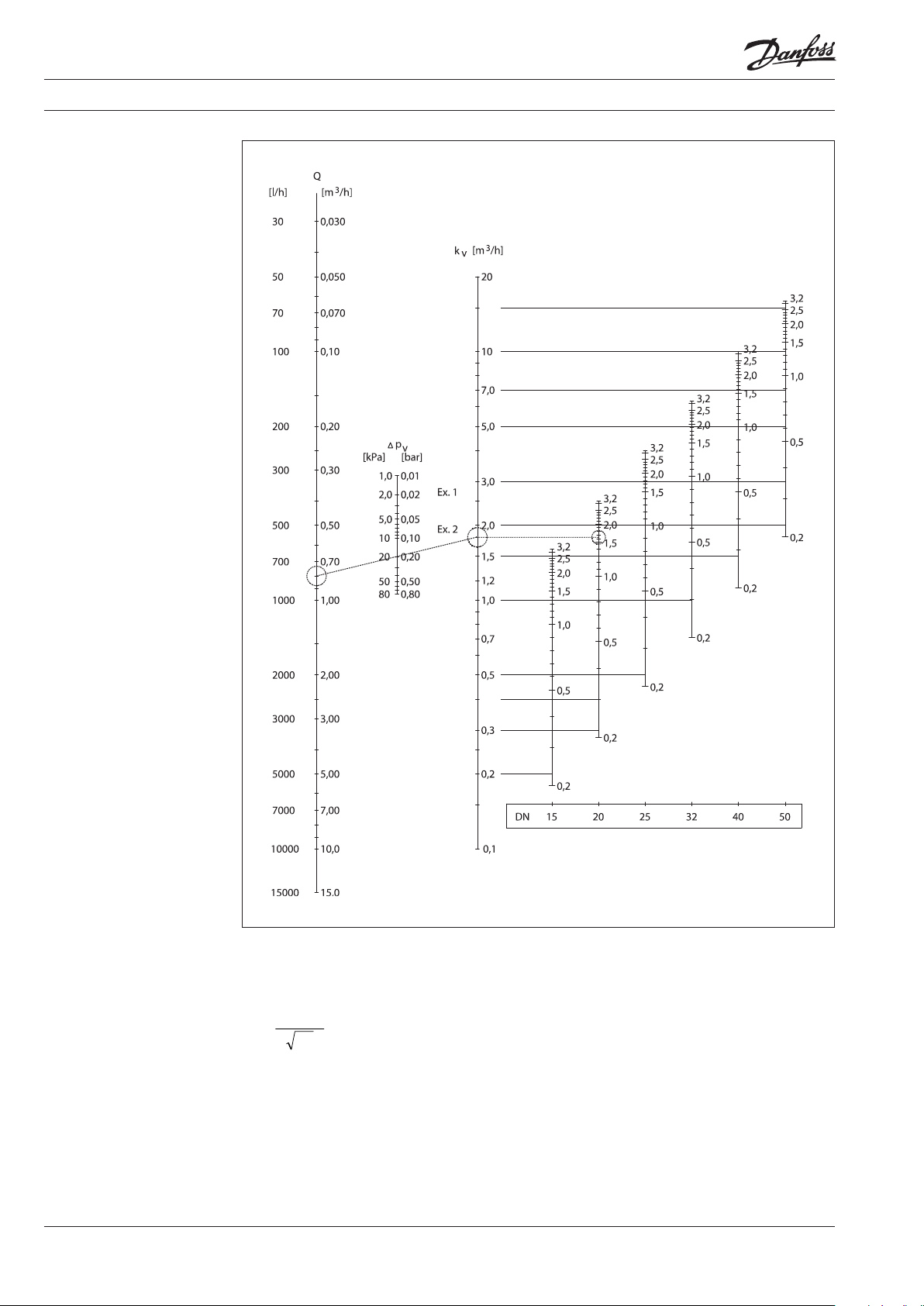

Page 5

Q x1 0

Data sheet Balancing valves USV-S

Sizing (continued)

A straight line connecting the bars of flow,

differential pressure and kV value shows the

relationship between these three variables.

k

=

v

p

Δ

A horizontal line from the intersection with the

kV bar shows the presetting value for each valve

size.

Q [m3/h]

Δp [kPa]

5

VD.C1.N1.02 © Danfoss 06/2015

DEN-SMT/SI

Page 6

Data sheet Balancing valves USV-S

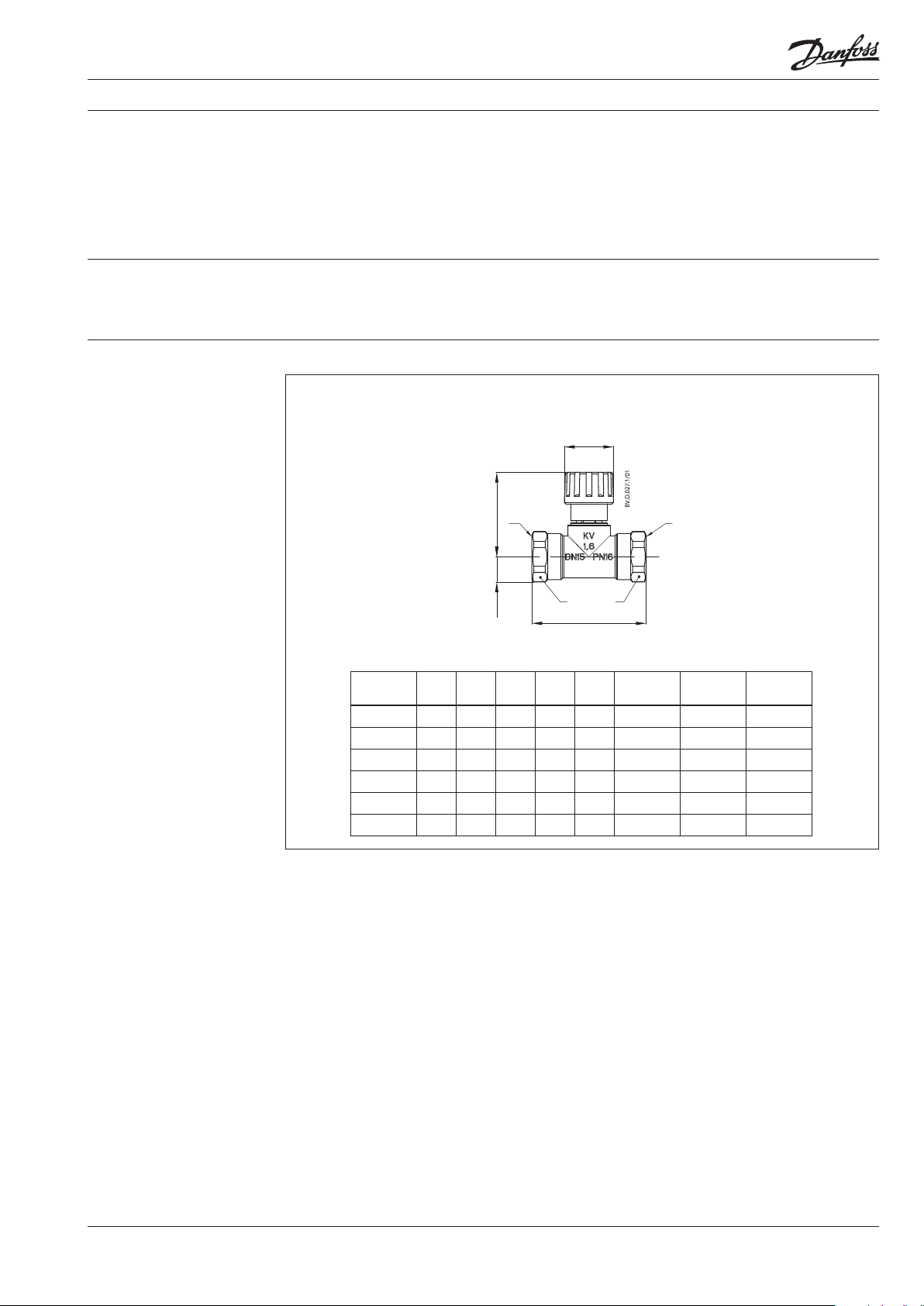

Installation

Pressure testing

Dimensions

USV-S should be instaled in the ow or return

pipe. The direction of the ow must follow the

direction of the arrow on the valve body.

Small installation dimensions enable easy

installation and shut-o of the system.

Max. test pressure ............................................... 25 bar

1

a a

H

2

H

USV-S can be installed in any positions if

installation instructions are being observed. It is

recommended that a lter i.e. Danfoss Typ FV is

installed in the supply pipe.

D

1

S S

L

1

USV-S

L

H

H

1

DN

[mm]

[mm]

1

[mm]

15 65 48 15 28 27 Rp ½ G ¾ A 0, 31

20 75 60 18 35 32 Rp ¾ G 1 A 0,4

25 85 75 23 45 41 Rp 1 G 1¼ A 0,67

32 95 95 29 55 50 Rp 1¼ G 1½ A 1,1

40 100 100 31 55 55 Rp 1½ G 1¾ A 1,22

50 130 10 6 38 55 67 Rp 2 G 2¼ A 2

D

2

1

[mm]S[mm]aIS O 7/1bISO 228/1

Weight

[kg]

DEN-SMT/SI

VD.C1.N1.02 © Danfoss 06/2015

6

Page 7

Data sheet Balancing valves USV-S

7

VD.C1.N1.02 © Danfoss 06/2015

DEN-SMT/SI

Page 8

Data sheet Balancing valves USV-S

8

VD.C1.N1.02

Produce d by Danfoss A/S © 06/2 015

Loading...

Loading...