Data sheet

Upgradable balancing valves

USV

Application / Description

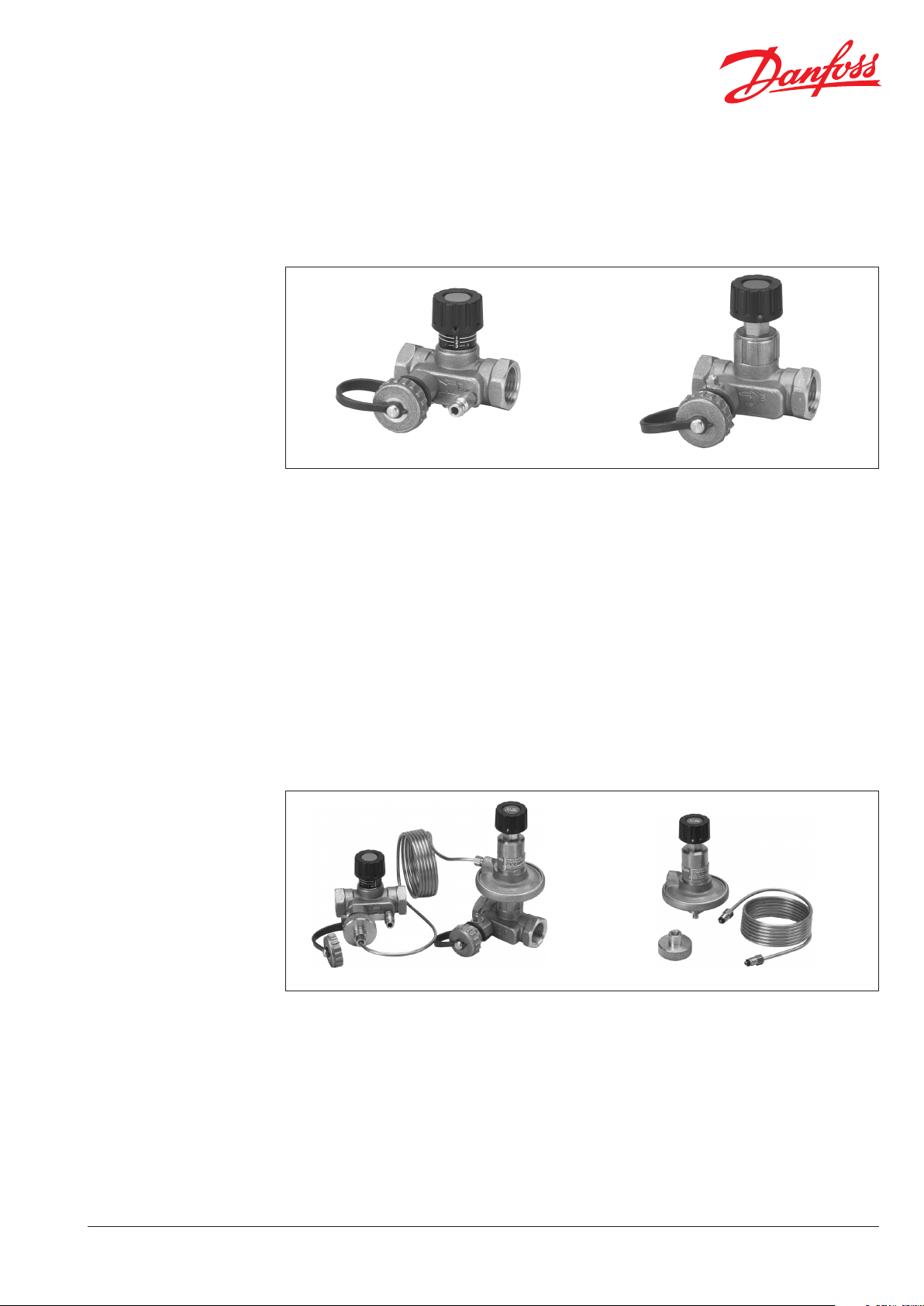

USV-I

USV valves are designed for manual hydronic

balancing of heating and cooling systems.

USV-I (red knob) is used together with USV-M to

limit the flow in heating or cooling installation

or can work separately as manual balancing

valves for flow limitation. If certain pipe sectors

do not require a control of differental pressure,

USV-I and USV-M can be used as shut-off- and

measuring valve.

USV-M (blue knob) valve can be upgraded into

an automatic USV-PV balancing valve. USV-M is

designed for installation in the return pipe.

Upgrading from manual to automatic balancing

is done by mounting PV-controller to an USV-M

valve.

USV-M

System does not need to be depressurized

during the upgrade and the kV-values does not

change. USV-PV maintains constant differential

pressure across a riser.

Due to its special design USV-PV has a firm

connection between diaphragm housing and

valve cone. Diaphragm controller thus acts only

against the force of reference spring. Excelent

control of differential pressure is achieved by the

following design characteristics:

• pressure released cone.

• adapted membrane for every valve

dimension which provides constant quality of

performances for all sizes.

DEN-SMT/SI

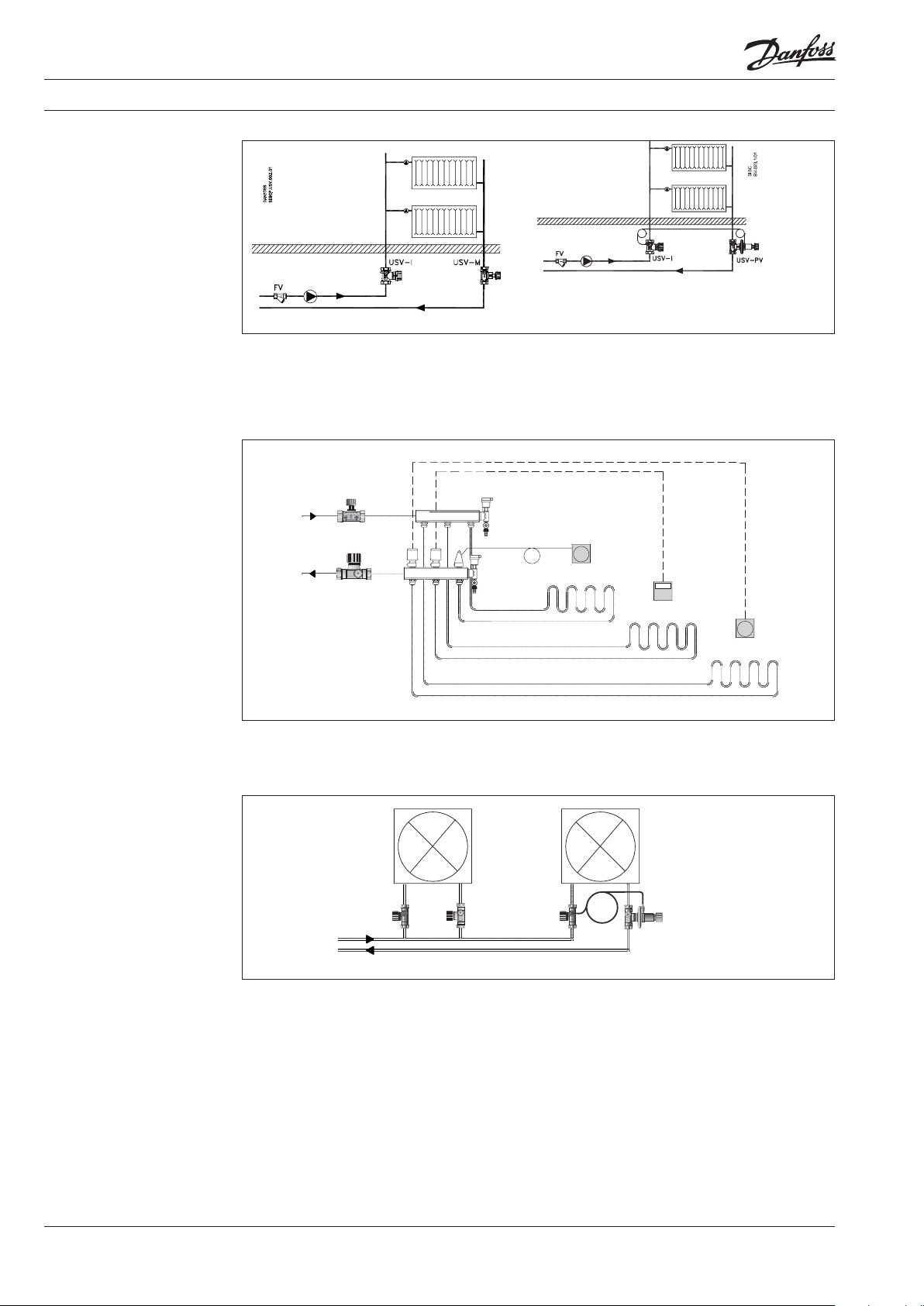

USV-PV / I Upgrading of PV-controller from USV-M to USV-PV

USV-PV (blue knob) is designed to maintain

a constant set dierential pressure across a

riser. Eventual operating noise caused by high

dierential pressure induced by changes in the

system can be avoided by upgrading the manual

valve to the dierential pressure controller.

USV-PV can be set to control the dierential

pressure between 0,05 bar to 0,25 bar (5 kPa

to 25 kPa). The PV controller is factory pre-set

to 0,1 bar (10 kPa). PV-controller upgrading

set includes an impulse tube and a threaded

connector for the drain connection of USV-I.

VD.C 1.F3.02 © Danfoss 10/2015

USV-M (PV) and USV-I are compact valves in

which the operating elements and connections

are placed within an arc of 90o, so that in spite

of small valve dimensions, access for installation

and operation is optimal. Insulation caps for

temperature up to 80 oC or 120 oC are available as

accessory.

USV-M and USV-I are supplied in a set-pack with

internal or external thread. If an external thread

is chosen, a threaded or welded plug can be

supplied as an accessory.

1

USV-PV

Data sheet Upgradable balancing valves USV

Application / Description

(continued)

Before upgrading After upgrading

Upgradable USV valves are to be used for

manual as well as automatic balancing of

heating systems. If system has to be fitted with

differential pressure controller, USV can be

upgraded with PV controller.

USV-I

USV-M

TWA

CFD

CFE

CFE

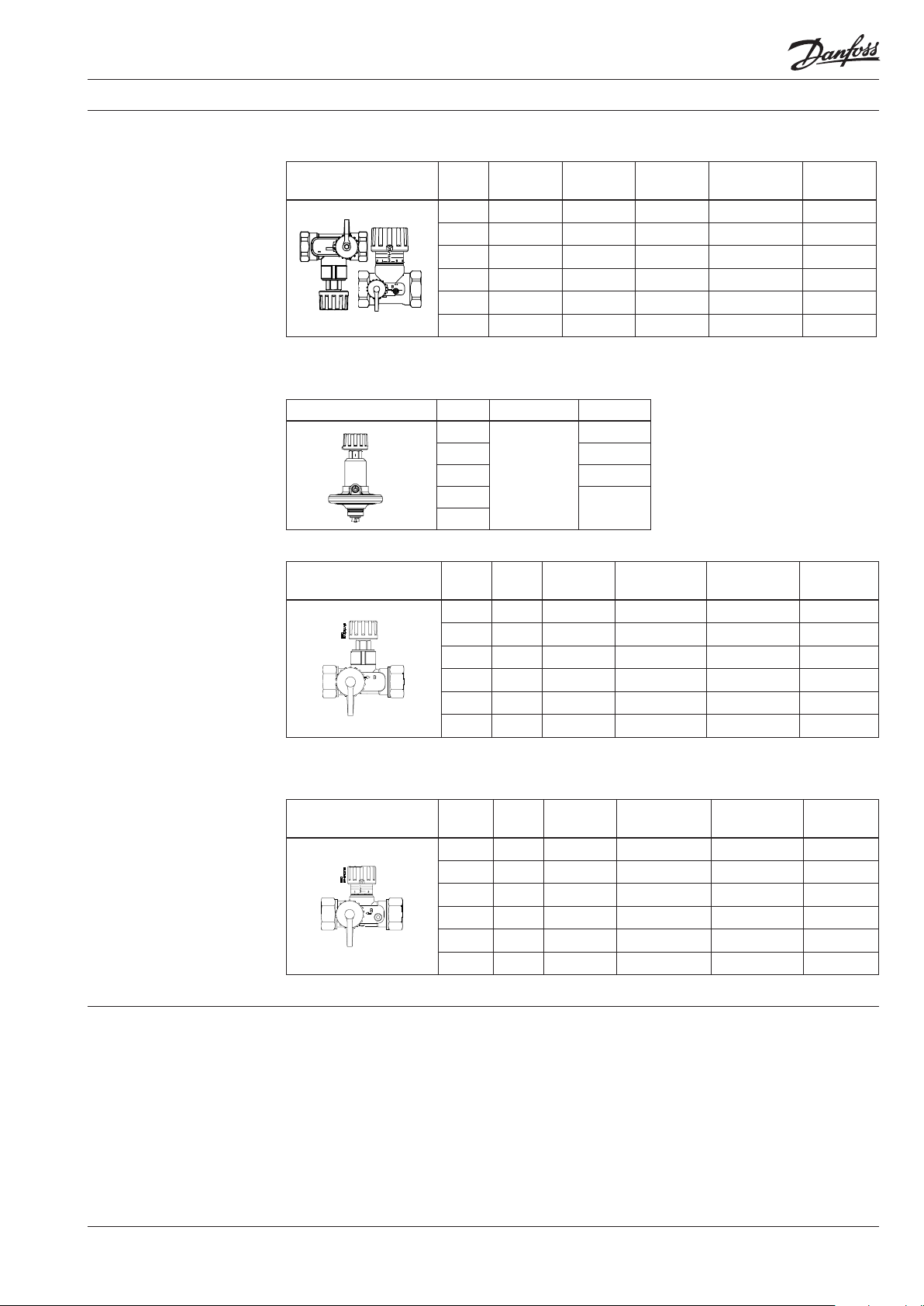

USV in oor heating systems

Upgradable control valves are to be used for

manual balancing of a floor system manifold.

USV-I

USV-M

RA5062

TP5000

RET

USV-I

USV iin cooling systems

Upgradable USV control valves are to be used

for manual or automatic hydronic balancing of

cooling devices i.e. as fan coils or chilled ceilings.

2

VD.C1.F3 .02 © Danfoss 10/2015

DEN-SMT/SI

Data sheet Upgradable balancing valves USV

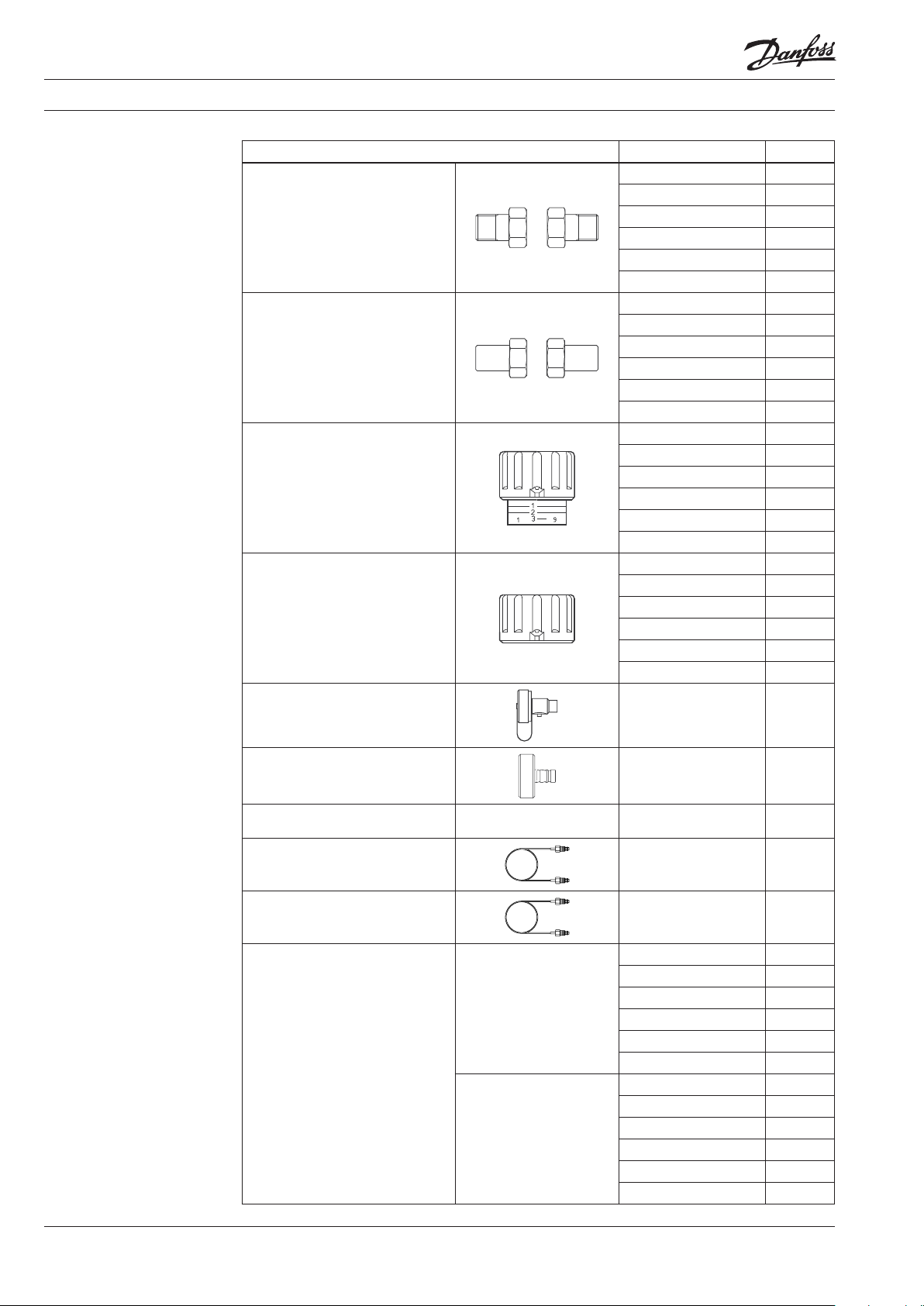

Ordering

USV set-pack (containing one USV-M and one USV-I)

Typ e DN

k

[m3/h]

VS

Int. thread

ISO 7/1

15 1,6 Rp ½

20 2,5 Rp ¾

25 4,0 Rp 1

32 6,3 Rp 1¼

40 10 Rp 1½

50* 16 Rp 2

* DN 50 is not upgrada ble

PV controller for upgrading USV-M valve

Typ e DN Comments Code No.

15 Include:

impulse

20 003Z2157

tube1,5 m

and threaded

25 003 Z2158

connector

32

40

003Z2156

003Z2159

USV-M valve

k

Int. thread

Typ e DN

VS

[m3/h]

ISO 7/1

15 1,6 Rp ½

20 2,5 Rp ¾

25 4,0 Rp 1

32 6,3 Rp 1¼

40 10 Rp 1½

50* 16 Rp 2

* DN 50 is not upgrada ble

Code No.

003Z 2141

003Z 2142

003Z 2143

003Z 2144

003Z 2145

003Z2155

Ext. thread

ISO 228/1

G ¾ A

G 1 A

G 1¼ A

G 1½ A

G 1¾ A

G 2¼ A

It is not neccessary to depressurize

the system in order to upgrade into

dierential pressure controller.

Kv value does not change.

Code No.

003Z2121

003Z 2122

003Z 2123

003Z 2124

003Z 2125

003Z2153

Ext. thread

ISO 228/1

G ¾ A

G 1 A

G 1¼ A

G 1½ A

G 1 ¾ A

G 2¼ A

Code No.

003Z 2146

003Z 2147

003Z 2148

003Z 2149

003Z2150

003Z2160

Code No.

003Z 2126

003Z 2127

003Z 2128

003Z 2129

003Z 2130

003Z2154

Technical data

USV-I valve

k

Int. thread

Typ e DN

VS

[m3/h]

15 1,6 Rp ½

20 2,5 Rp ¾

25 4 Rp 1

32 6,3 Rp 1¼

40 10 Rp 1½

50 16 Rp 2

Max. working pressure ........................................ 16 bar

Test pressure ...........................................................25 bar

Max. dierential pressure across

the valve (USV-M/PV) ....................... 0,8 bar (80 kPa)

Max. dierential pressure across

the valve (USV-I) ............................... 1,5 bar (150 kPa)

Flow temperature ...................... -20 to 120 °C

Ext. thread

ISO 228/1

G ¾ A

G 1 A

G 1¼ A

G 1½ A

G 1 ¾ A

G 2¼ A

ISO 7/1

Code No.

003Z 2131

003Z 2132

003Z 2133

003Z 2134

003Z 2135

003Z2151

Material of parts in contact with water:

Valve body, spindle, etc. ....................................... Brass

Cone (USV-M/PV) ..........................................DZR Brass

Diaphragm and O-rings ...................................... EPDM

Spring ...................................................................Stainless

steel ........................................................................................

Code No.

003Z 2136

003Z 2137

003Z 2138

003Z2139

003Z 2140

003Z2152

DEN-SMT/SI

VD.C1.F3 .02 © Danfoss 10/2015

3

Data sheet Upgradable balancing valves USV

Accessories and spare

parts

Typ e Comments/connection Code No.

Tailpiece threaded

(for external thread only)

Tailpiece welding

(for external thread only)

Shut-o knob for USV-I

(black)

Shut-o knob for USV-M

(black)

DN 15, G ¾ A

DN 20, G 1 A

DN 25, G 1¼ A

DN 32, G 1½ A

DN 40, G 1¾ A 065F6060

DN 50, G 2¼ A 003L8162

DN 15, G ¾ A

DN 20, G 1 A

DN 25, G 1¼ A

DN 32, G 1½ A

DN 40, G 1 ¾ A 065F6080

DN 50, G 2¼ A 003L8163

DN 15 003L 8155

DN 20 003L 8156

DN 25 003L 8157

DN 32 0 03L8158

DN 40 003L8158

DN 50 003L8158

DN 15 003L 8146

DN 20 00 3L8147

DN 25 003L 8148

DN 32 0 03L8149

DN 40 003L 8149

DN 50 003L 8149

003N5070

003N5071

003N5072

003N5073

003N5090

003N5091

003N5092

003N5093

Drain connection 003L 8141

Masuring connector For drain connection 003L8143

Connection plug for impulse tube

(spare part)

Impulse tube 1,5 m 003L8152

Impulse tube 5 m 003L 8153

Insulation cap

up to 80 °C DN 15 003L8165

up to 120 ° C DN 15 00 3L8170

For drain connection 003Z0109

DN 20 003L8166

DN 25 003 L8167

DN 32 003L816 8

DN 40 003L8169

DN 50 003L8164

DN 20 003L8171

DN 25 00 3L817 2

DN 32 0 03L 8173

DN 40 003L 8139

DN 50 003L 8138

4

VD.C1.F3 .02 © Danfoss 10/2015

DEN-SMT/SI

Data sheet Upgradable balancing valves USV

S

E

B

C

P

.A

L

L

E

N

K

E

Y

.

00

1

.0

1

Design

1. Shut-off knob

2. Shut-off spindle

3. Setting spindle

4. Scale disc

5. O-rings

6. Valve cone

7. Valve body

DN

S

S

O

F

N

A

D

15 2,5

20 3

25 4

32 5

40 5

Fig. 8 USV-I

USV-I incorporates a double cone (3,6) able to

give maximum stroke limitation, thus achieving

ow limitation. It also incorporates shut o

function. ASV-I is equipped with the plugs for

the ow measurement and a connection for the

USV-P/PV impulse tube.

Use the following procedure to limit the ow:

turn the valve knob (1) fully counter clockwise to

open the valve. The mark on the knob will now

be opposite »0« on the scale (4). Turn the valve

knob (1) clockwise to the required setting (e.g.

for setting 2,2 the knob must be rotated two full

turns and then forward to »2« on the scale. Hold

USV-M

Port A Port B

the knob (1) to keep the setting (e.g. 2,2) and

using a hexagon socket key turn the spindle (3)

fully counter clockwise (until a stop can be felt).

Turn the valve knob (1) fully counter clockwise

so that the mark on the knob is opposite »0«

on the scale (4). The valve is now open as many

turns from the closed position (2,2) as indicated

by the convertion from required ow. To annul

the setting, turn the hexagon socket key fully

clockwise (until a stop can be felt).

Remember, at the same time the knob must be

held on its »0« setting.

DEN-SMT/SI

DN 15 - 40 DN 50

USV-M can be upgraded to USV-PV automatic

USV-M dimension DN 50 is not upgradable.

balancing valve. The system does not need to be

depressurized during the upgrade.

VD.C1.F3 .02 © Danfoss 10/2015

5

Data sheet Upgradable balancing valves USV

S

E

B

C

P

.A

L

L

E

N

K

E

Y

.

00

1

.0

1

Design (continued)

1. Shut-off knob

2. Differential pressure setting

spindle

3. O-ring

4. Reference spring

5. Impulse tube connection

6. Diaphragm element

7. Control diaphragm

8. Pressure-relieved valve cone

9. Valve body

USV-PV valve

DN

15

20

25

32

40

2,5

Tur ns

(n)

S

S

O

F

N

A

D

0 0,25

bar

1 0,24

3

4

5

5

2 0,23

3 0,22

4 0, 21

5 0,2

6 0,19

7 0 ,18

8 0,17

9 0 ,16

10 0,15

11 0 ,14

12 0,13

13 0,12

14 0 ,11

15 * 0,1

16 0,09

17 0,08

18 0,07

19 0,06

20 0,05

* Factory se tting

USV-PV is designed to maintain a constant set

dierential pressure. Via an internal connection

- trough the cone (8) and together with the

reference spring (4), pressure in the return pipe

acts on the underside of the control diaphragm

(7) while via an impulse tube (5), pressure in the

ow pipe acts on the top of the diaphragm. In

this way the balancing valve maintains adjusted

dierential pressure in the riser.

USV-PV is factory-set on 0,1 bar (10 kPa). The

dierential pressure can be varied between

0,05bar and 0,25 bar (5 kPa and

25 kPa).

6

VD.C1.F3 .02 © Danfoss 10/2015

DEN-SMT/SI

Data sheet Upgradable balancing valves USV

Sizing Required:

A. Correct valve size USV-M / I

B. Correct USV-I presetting

Given:

1. Required max. flow in the riser

Q = 0,80 [m3/h]

2. Pressure drop across riser

Δps = 15 [kPa]

3. Available pump pressure

Δpo = 45 [kPa]

Solution:

A) Correct valve size :

Pipe size and low pressure drop (fully opened

valve) can be criterions for valve selection.

The example selects USV-M 20 valve. Pressure

drop is read from sizing diagram (page 8) by

taking a horizontal line from DN 20 valve with

presetting 3,2 (fully opened valve) to intersect

kV-axis at 2,5 [m3/h].

Δpo = Δpv(USV-I) + Δps + Δpv (USV-M)

B) Correct valve size and presetting of USV-I:

The differential pressure across USV-I can be

calculated as follows:

Δpv (USV-I) = Δpo – Δps – Δpv(USV-M)

Δpv = 45 [kPa] – 15 [kPa] – 10 [kPa] = 20 [kPa]

The example selects USV-I 20. Presetting is

read from the sizing diagram (page 7) by

taking a straight line from from max. flow

Q = 0,80 [m3/h] to the differential pressure Δpv

(USV-I)= 20 [kPa] and to the intersection with

kV-axis at kV = 1,8 [m3/h].

A straight line conecting this point and

Q = 0,80 [m3/h] intersects the differential

pressure bar at Dpv (USV-M) = 10 [kPa].

Draw a horizontal line from this point to the

adjustment curve of the chosen valve

(DN 20). Starting from closed valve, the

presetting of 1,6 turns is required.

USV-PV

Required:

Diff. pressure setting of USV-PV

Given:

1. Required max. flow in the riser

Q = 0,80 [m3/h]

2. Pressure drop across riser

3. Δps = 15 [kPa]

4. Available pump pressure

Δpo = 45 [kPa]

Solution:

Δpa = Δpv (USV-I) - Δpo - Δpv (USV-PV)

USV-M is upgraded to USV-PV by mounting the

PV controler to the USV-M valve and connecting

it to the USV-I by the means of impulse tube.

USV-PV maintains constant differential pressure

Δpa (pressure drop across riser - see fig.). USV-PV

is to be set at Δpa = 15 [kPa].

kV-values [m3/h] for various presettings:

Size

0,20 0,60 1,00 1,40 1,80 2,20 2,70 3,20

Number of turns

DN 15 0,2 0,5 0,8 1,1 1,2 1,4 1,6 1,6

DN 20 0,3 0,8 1,3 1,6 1,9 2,1 2,4 2,5

DN 25 0,4 1,3 1,9 2,6 3 ,1 3,4 3,7 4,0

DN 32 0,7 2,0 3,1 4,1 4,9 5,4 5,9 6,3

DN 40 1,1 3,1 4,9 6,4 7,6 8,5 9,1 10,0

DN 50 1,7 4,9 7,6 10,0 11,9 13, 3 14,4 16,0

DEN-SMT/SI

VD.C1.F3 .02 © Danfoss 10/2015

7

Data sheet Upgradable balancing valves USV

Q x1 0

Sizing (continued)

A straight line connecting the bars of flow,

differential pressure and kV value shows the

relationship between these three variables.

k

=

v

p

Δ

A horizontal line from the intersection with the

kV bar shows the presetting value for each valve

size.

Q [m3/h]

Δp [kPa]

8

VD.C1.F3 .02 © Danfoss 10/2015

DEN-SMT/SI

Data sheet Upgradable balancing valves USV

Measurement of flow and

differential pressure

Installation

Pressure testing

USV-I is tted with a test plug and a drain

connection and the pressure drop across valve

can be measured with Danfoss measuring device

PFM 3000 or other standard devices.

Using the pressure drop characteristics of USV-I

and dierential pressure of the fully opened

valve, actual ow can be obtained.

USV-I must be instaled in the ow pipe.

USV-M must be installed in the returned pipe.The

direction of the ow must follow the direction of

the arrow on the valve body.

USV-M and USV-I can be installed in any

positions if installation instructions are being

observed. t is recommended that a lter i.e.

Danfoss Typ FV is installed in the supply pipe.

After upgrading USV-M to USV-PV the impulse

tube between USV-I and USV-PV must be ushed

through before installation.

Max. test pressure ............................................... 25 bar

When pressure testing the system you must

secure that both sides of the membrane have the

same static pressure to prevent damage of the

pressure controller. That means the impulse tube

must be connected and any needle valves must

be open.

Note:

When measuring the pre-set ow all radiator

valves must be set for the nominal ow.

Dierential pressure [Δpr ] measuring in the

riserdes.

Drain connection of the USV-I and USV-M is to be

tted wit a measuring connector (Danfoss Code

No. 003L8143) .

A 90° angle between service features (shut-o

on the one side, measuring and draining on the

other), allow upside down installation and easy

measuring, shut-o and draining of the system.

If USV-PV is installed in combination with USV-I,

both valves can be open or closed (both valves

must be in the same position!).

DEN-SMT/SI

VD.C1.F3 .02 © Danfoss 10/2015

9

Data sheet Upgradable balancing valves USV

Dimensions

Ext. thread Int. thread

With tailpiece welding With tailpiece threaded

L

L

L

1

Typ e

[mm]

[mm]

2

[mm]

US V-I 15 65 131 139 48 15 28 27 Rp ½ G ¾ A 0, 31

USV-I 20 75 147 159 60 18 35 32 Rp ¾ G 1 A 0,4

USV-I 25 85 169 169 75 23 45 41 Rp 1 G 1¼ A 0,67

USV-I 32 95 191 179 95 29 55 50 Rp 1¼ G 1½ A 1,1

USV-I 40 10 0 202 18 4 100 31 55 55 Rp 1½ G 1¾ A 1,22

USV-I 50 130 246 214 106 38 55 67 Rp 2 G 2¼ A 2

H

3

[mm]

H

1

[mm]

D

2

1

[mm]S[mm]aIS O 7/1bISO 228/1

Weight

[kg]

Ext. thread Int. thread

With tailpiece welding With tailpiece threaded

L

L

L

H

H

Typ e

[mm]

1

2

3

[mm]

[mm]

[mm]

1

D

2

[mm]

1

[mm]S[mm]aIS O 7/1bISO 228/1

US V-M 15 65 131 139 61 15 28 27 Rp ½ G ¾ A 0,28

USV-M 20 75 147 159 76 18 35 32 Rp ¾ G 1 A 0,4

USV-M 25 85 169 169 96 23 45 41 Rp 1 G 1¼ A 0,73

USV-M 32 95 191 179 121 29 55 50 Rp 1¼ G 1½ A 1,28

USV-M 40 100 202 184 126 31 55 55 Rp 1½ G 1¾ A 1,35

USV-M 50 130 246 214 106 38 55 67 Rp 2 G 2¼ A 2

Weight

[kg]

10

VD.C1.F3 .02 © Danfoss 10/2015

DEN-SMT/SI

Data sheet Upgradable balancing valves USV

Dimensions (continued)

L

L

L

1

Typ e

[mm]

[mm]

2

US V-PV 15 65 131 139 115 15 28 61 27 Rp ½ G ¾ A 0,55

USV-PV 20 75 147 159 14 4 18 35 76 32 Rp ¾ G 1 A 0,9

USV-PV 25 85 169 169 184 23 45 98 41 Rp 1 G 1¼ A 1,8

USV-PV 32 95 191 179 230 29 55 122 50 R p 1¼ G 1½ A 3,35

USV-PV 40 100 202 184 235 31 55 122 55 Rp 1½ G 1¾ A 3,45

3

[mm]

H

[mm]

1

H

[mm]

D

2

D

1

[mm]

2

mmS[mm]aIS O 7/1bISO 228/1

Weight

[kg]

DEN-SMT/SI

VD.C1.F3 .02 © Danfoss 10/2015

h

[mm]

DN 15 150

DN 20 200

DN 25 250

DN 32/4 0 320

min

11

Data sheet Upgradable balancing valves USV

12

VD.C1.F3 .02

Produce d by Danfoss A/S © 10/2015

Loading...

Loading...