Page 1

Data sheet

UnoFloor Mixing

General description

and application

Ordering

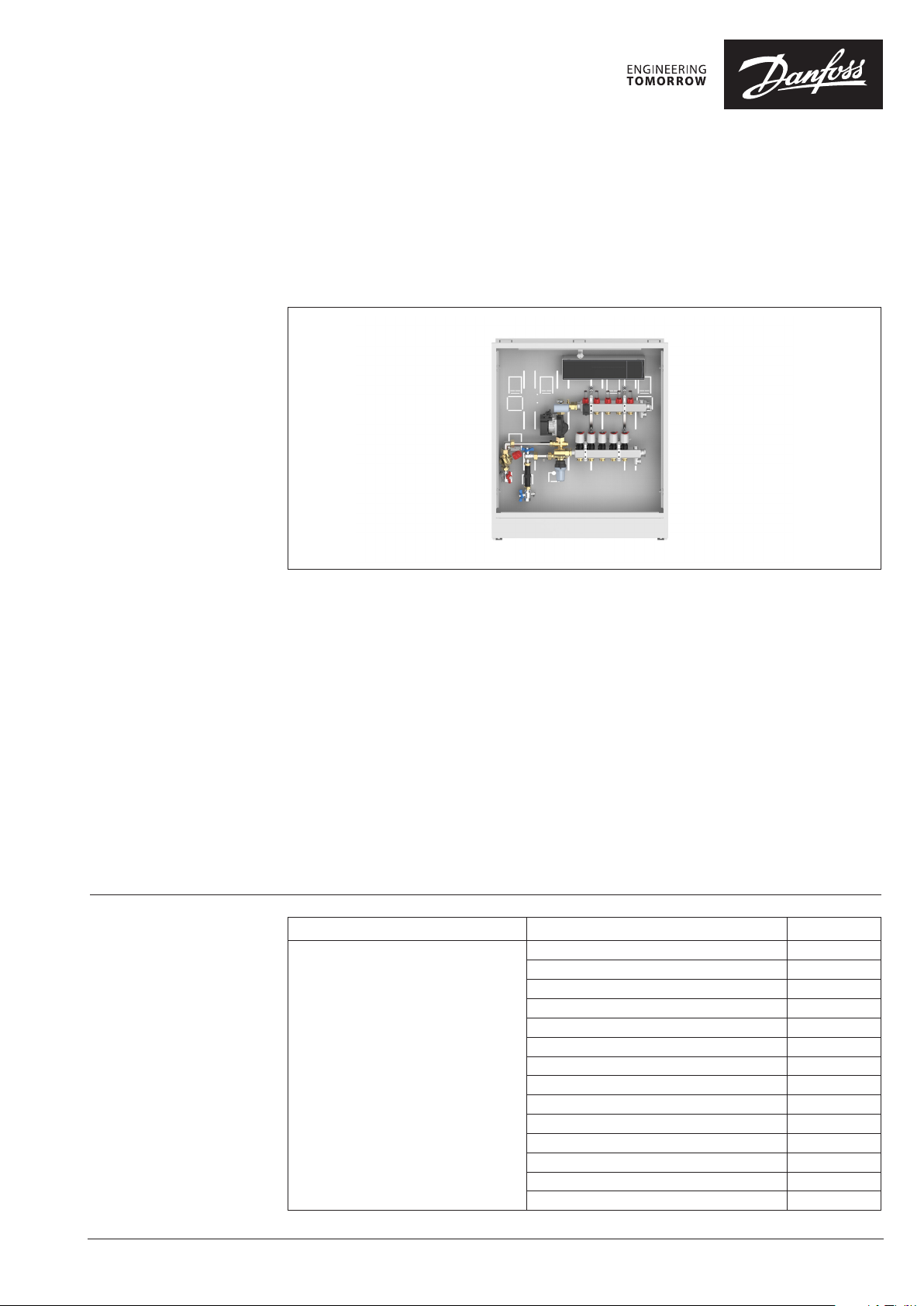

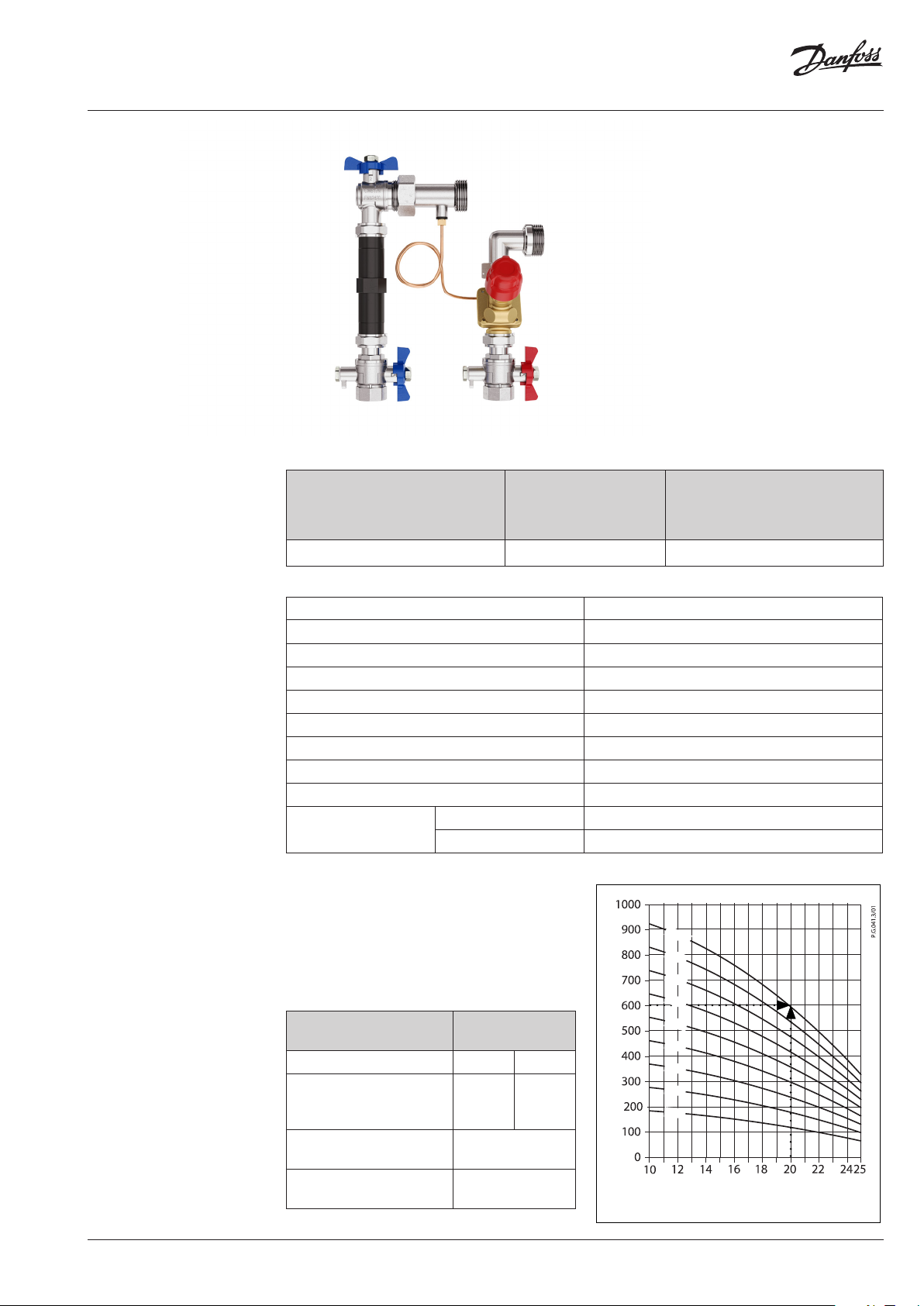

The Danfoss UnoFloor Mixing is a preassembled

pressure independent underfloor heating

balancing and control distribution unit. UnoFloor

comes wired and premounted. UnoFloor Mixing

includes Danfoss Icon™ 230V Wiring Center or

Danfoss Icon™ 24V Master Controller.

The SSM stainless-steel manifold is used for

controlling water flow. Each tube of the floor

heating system is connected to the manifold,

thus making it possible to control water flow

or heat supply to each room in the building

individually.

The AB-PM set ensures optimal hydronic balance.

Flow limitation independent of differential

pressure is now guaranteed.

The Danfoss compact mixing shunt is used for

regulation of flow and supply temperature in

hydronic floor heating systems.

Description Typ e Code no.

Pressure independent underfloor

heating balancing and control

distribution unit includes:

• Danfoss Icon 230V Wiring Center

or Danfoss Icon™ 24V

Master Controller.

• Actuators

• Stainless steel manifold

• AB-PM set

• FHM-C1 Mixing shunt

• Cabinet

• Nominal pressure PN 6

• Max. Temperature 90 °C

• G ¾” internal thread

Use heating water according VDI 2035

or ONORM H 5195.

Unofloor Mixing 4 Loops Left Icon 230V 088X4604

Unofloor Mixing 5 Loops Left Icon 230V 088X4605

Unofloor Mixing 6 Loops Left Icon 230V 088X4606

Unofloor Mixing 7 Loops Left Icon 230V 088X4607

Unofloor Mixing 8 Loops Left Icon 230V 088X4608

Unofloor Mixing 10 Loops Left Icon 230V 088X4610

Unofloor Mixing 12 Loops Left Icon 230V 088X4612

Unofloor Mixing 4 Loops Right Icon 230V 088X4624

Unofloor Mixing 5 Loops Right Icon 230V 088X4625

Unofloor Mixing 6 Loops Right Icon 230V 088X4626

Unofloor Mixing 7 Loops Right Icon 230V 088X4627

Unofloor Mixing 8 Loops Right Icon 230V 088X4628

Unofloor Mixing 10 Loops Right Icon 230V 088X4630

Unofloor Mixing 12 Loops Right Icon 230V 088X4632

Features:

• Compact design - fits in even

the smallest places

• In-wall cabinet ensures flush installation

• Pre-mounted - minimal risk

of installation faults

• Easy ordering - only one number necessary

• Short installation time

• Correct heat distribution, even

under partial load

• Reliable hydronic balancing

for lower heating costs

• Energy-saving

• Pressure-independent AB-PM valve integrated

• Integrated mixing shunt with safety

thermostat and self-acting thermostatic sensor

© Danfoss | 2022.03

AI405949559758en-010201 | 1

Page 2

Data sheet UnoFloor Mixing

Accessories

SSM

Floor Heating Manifold

Description Code no.

Danfoss Icon™ Dial,

In-wall

Danfoss Icon™

Display, In-wall

Danfoss Icon™

Programmable,

In-wall

Floor sensor 088U1110

088U1000

088U1010

088U1020

Description Code no.

Danfoss Icon™ Dial,

On-wall

Danfoss Icon™

Display, On-wall

Danfoss Icon™

Programmable,

On-wall

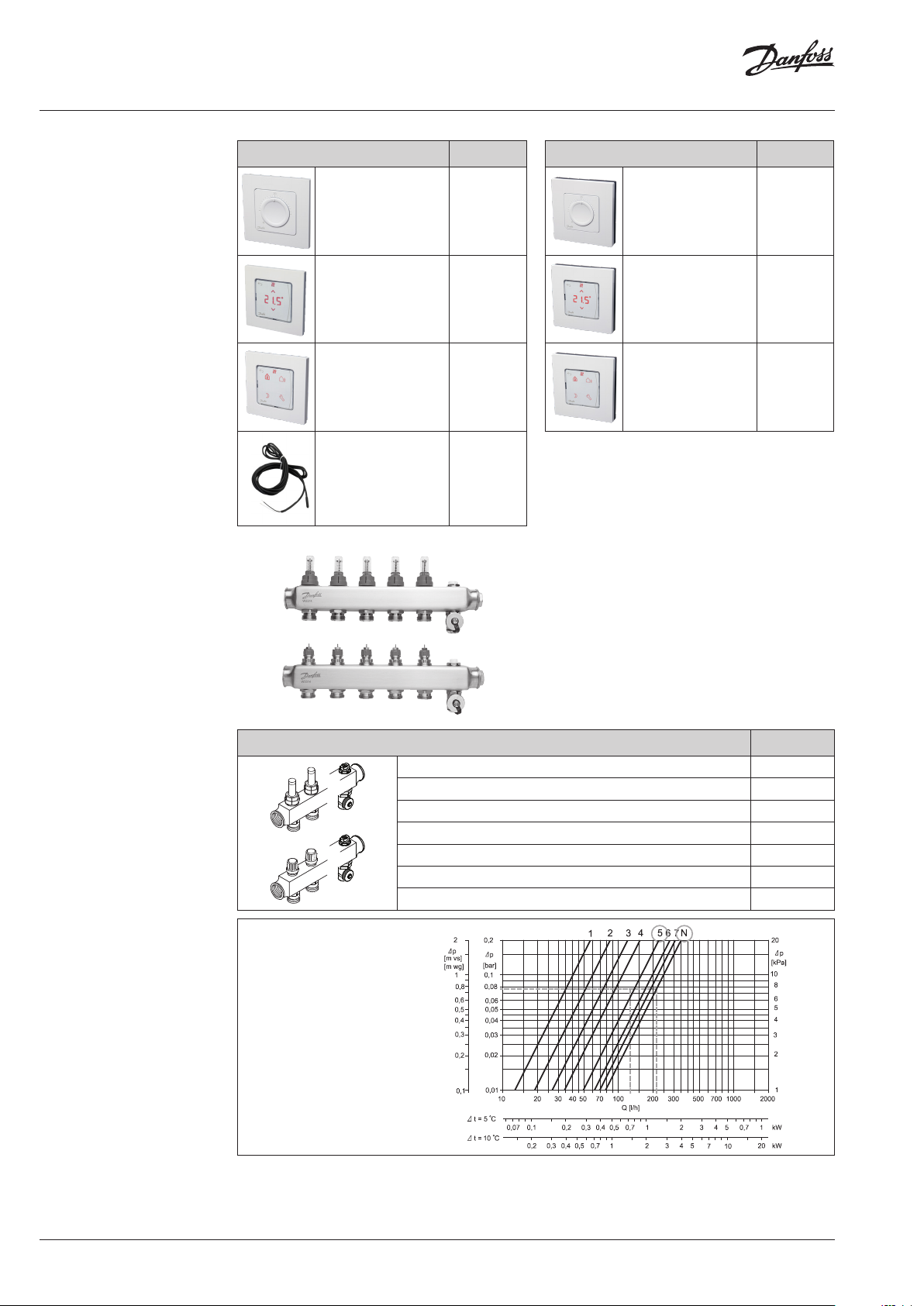

The SSM manifold is used for controlling water

flow in under floor heating systems. Each tube of

the floor heating system is connected to the

manifold, thus making it possible to control water

flow or heat supply to each room in the building

individually.

088U1005

088U1015

088U1025

Part of assembly

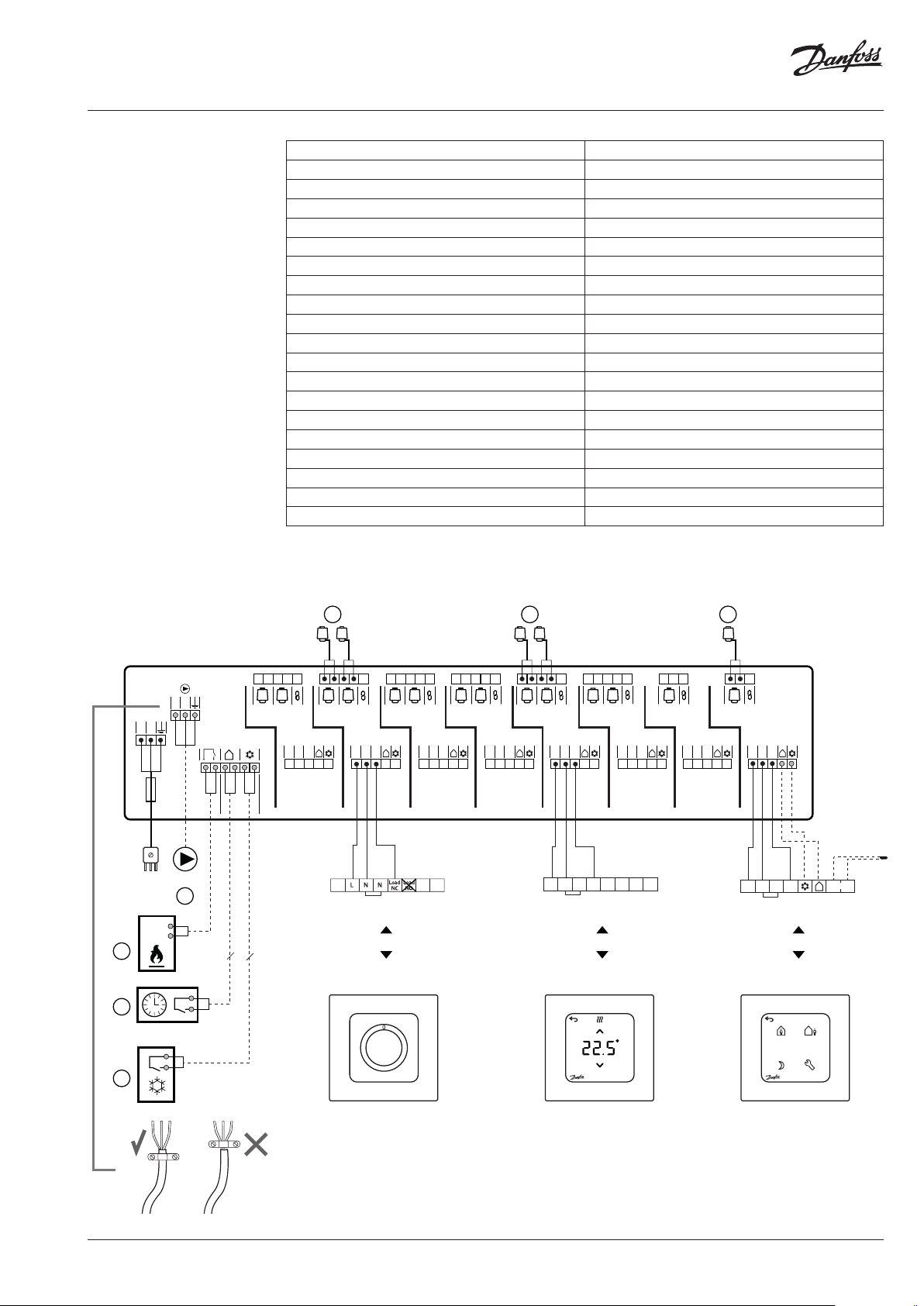

Pre-setting diagram

Presetting the manifold

valves

Description Type

Manifold set 4+4, with flowmeter SSM-4F

Manifold set 5+5, with flowmeter SSM-5F

Manifold set 6+6, with flowmeter SSM-6F

Manifold set 7+7, with flowmeter SSM-7F

Manifold set 8+8, with flowmeter SSM-8F

Manifold set 10+10, with flowmeter SSM-10F

Manifold set 12+12, with flowmeter SSM-12F

Manifold,

with flowmeter

The diagram shows the capacities for each

heating circuit at different presettings of the

manifold valves.

Based on the above calculations and capacity diagram each manifold valve is preset by rotating

the red ring until the correct value on the ring is

in-line with the sight mark on the valve.

2 | © Danfoss | 2022.03

AI405949559758en-010201

Page 3

Data sheet UnoFloor Mixing

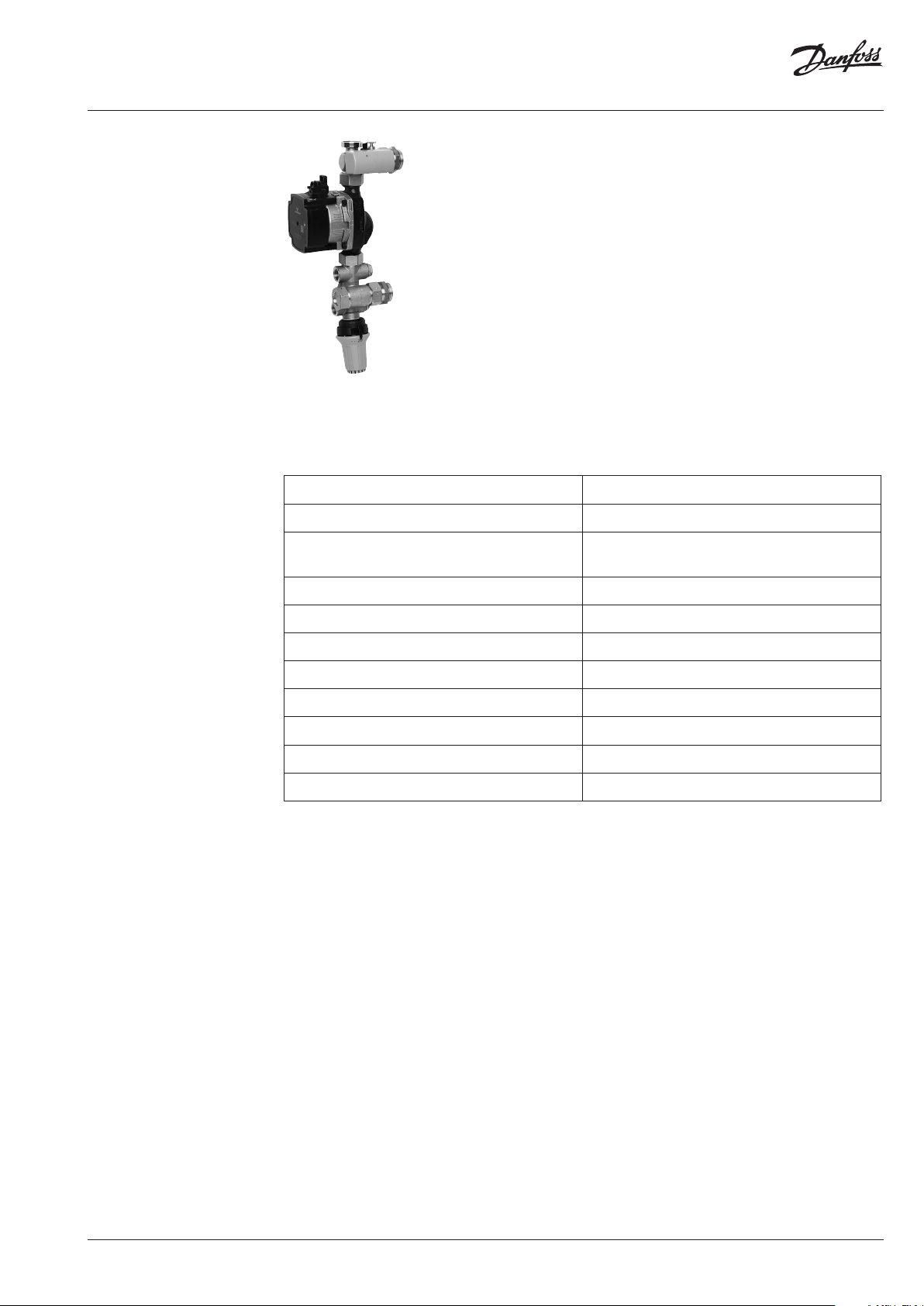

FHM-C1 Mixing shunt

Mixing shunt

FHM-C1

Technical specifications

Supply voltage 230 V AC

Primary connection ½” (DN15)

Max. differential pressure with Danfoss Floor

Heating manifolds

Max. working pressure PN10

Max. flow temperature 90 °C

FTC flow temperature control 18 °C to 50 °C

FH-DT supply flow thermometer 0 °C to 60 °C

Integrated check valve POM / Stainless steel

Body, unions and other metal parts Brass / Stainless steel

O-rings and seals EPDM

Weight approx. 3,5 kg to 4 kg (depending on model)

0,6 bar

AI405949559758en-010201

© Danfoss | 2022.03 | 3

Page 4

Data sheet UnoFloor Mixing

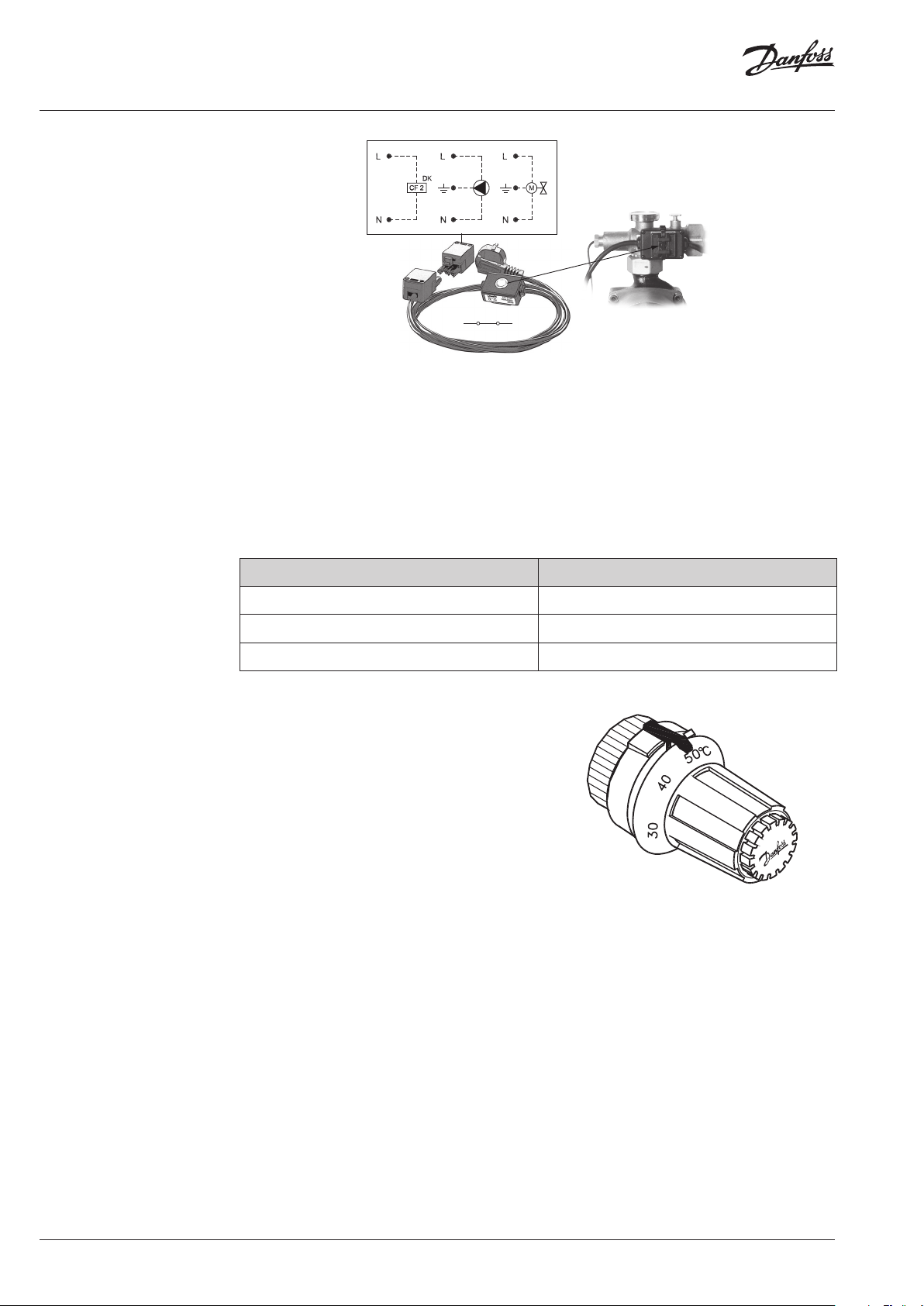

FH-ST55

Safety thermostat

230V / 16A

55°C

T

S

Electrical connection

FTC

Temperature controller

The FH-ST safety thermostat is fixed on the tube

and protects floor and system against too high

temperatures, especially important for wooden

floors. The FH-ST thermostat switches off the pow-

automatically and the floor heating system is protected.

The FH-ST55 can also be connected to a pump or

a zone valve.

er supply of the floor heating base unit, when the

temperature reaches 55 °C.

By switching off the power supply of the floor

Note! The electrical installation must be carried out

by an authorized installer only (230 V DC).

heating base unit, the actuators (NC) will close

Code no. 088U0301

Shut-off temperature 55 °C

Switch difference 4 K

Classification IP 40 (mounted)

FTC is a self-acting thermostatic sensor used for

flow temperature control of floor heating.

The water temperature is measured by a surface

sensor. The snap-lock connector of the sensor element secures a firm connection to the valve.

Features:

• Closes on rising sensor temperature.

• Temperature range: 15 °C to 50 °C

4 | © Danfoss | 2022.03

AI405949559758en-010201

Page 5

Data sheet UnoFloor Mixing

AB-PM DN20 HP set

vertical

Part of assembly

The AB-PM connection set is an compact and time

saving configuration — designed for creating optimal hydronic balance in horizontal loops — radiator and underfloor heating applications. Flow limitation independent of differential pressure is now

guaranteed. It can be combined with most types

of manifolds, heat meters and manifold cabinets.

One packing unit contains the following products:

• AB-PM valve;

• Impulse tube, 1,5 m, R 1/16;

•

Adapter R 1/16 for AB-PM impulse tube connection;

•

3-piece ball valve with connection for impulse

tube heat meter;

• Adapter for heat meter;

•

Connector/bracket for underfloor heating distributor G 1 A.

External thread

connection to underfloor

heating distributor

(ISO 228/1)

Typ e

External thread

AB-PM

(ISO 228/1)

AB-PM DN20 HP set vertical G 1 A G 1 A

Technical data

Nominal diameter DN 20 HP

Qmax (at ∆pr = 20 kPa) 600 l/h (at 100 % setting)

Upper limit of pressure controller at zero flow 35 kPa

Differential pressure (p for the valve + circuit) 28–400 kPa

Nominal maximal pressure 16 bar (PN 16)

Control valves characteristic Linear

Shut-off leakage rate Acc. to ISO 5208 class A — no visible leakage

Medium temperature −10 °C to +120 °C

CV stroke 2,25 mm

Connection Ext. thread ISO 228/1 G 1 A

Actuator M 30 × 1,5

Sizing AB-PM is to be sized based on manifold’s needed

flow (Q) [l/h], and needed differential pressure

drop for the loop (∆pr). Manifold pre-setting data

are presented on page 4. Max AB-PM flow data are

presented in table 1.

For any other Q and ∆pr needed, AB-PM size and

setting can be indetified based on Fig. 1.

Typ e

DN 20 HP at

100% setting

Q max. 600 l/h 915 l/ h

Maximum pressure drop

available for system at

20 kPa 10 kPa

max flow

Upper limit of pressure

controller at zero flow

Start required differential

pressure (for the valve)

35 kPa

8 kPa

DN 20 HP

100 %

90 %

80 %

70 %

60 %

50 %

40 %

30 %

20 %

flow [l/h]

∆pr [kPa]

Fig. 1

AI405949559758en-010201

© Danfoss | 2022.03 | 5

Page 6

Data sheet UnoFloor Mixing

TWA

Thermal Wax Actuator

Part of assembly

Technical specifications

The TWA is a small actuator for electrical on/off

controls to activate several types of valves and

floor heating manifolds.

Actuator Connection type Supply Voltage

TWA-A RA 230 V AC or 24 V AC/DC

Supply voltage 230 V (3 A pre-fuse) or 24 V (Class II (SELV))

Max. inrush current 230 V: 250 mA or 24 V: 250 mA

Frequency 50- 60 Hz

Running power consumption 2 W

Spindle travel time ~3 min.

Ambient temperature 0 °C to 60 ° C

Enclosure IP 41

Cable length 950 m m

kvs (m³/H) 0,10 to 1,10

Max. ∆p (Bar) 0,6

Danfoss Icon 230V

Wiring Center

Danfoss Icon™ 230V Wiring Center is a connection

box for use in hydronic floor heating using 230V

thermostats and actuators.

The Icon™ 230V Wiring Center can connect up

to 14 thermal actuators from up to 8 room thermostats. It is provided with 230V Live circulation

pump output and a voltage-free relays for controlling a boiler. The relays are activated when one or

more thermostats require heat.

The Wiring Center also supports away and cooling

mode which can be controlled by a 230 V signal as

well as LED’s to indicate when outputs are active.

Mounting is made easy due to a simple layout of

the terminals and clear marking on the screw terminals. Mounting can be done by using screws.

6 | © Danfoss | 2022.03

AI405949559758en-010201

Page 7

Data sheet UnoFloor Mixing

Technical data

Wiring

Max. number of thermostats 8

Max number of actuators 14

Supported actuator types Normally closed (NC)

Internal fuse 3 A

Conforms with diectives LVD, EMC, RoHs, WEEE

Supply voltage 220-240 V AC

Supply frequency 50/60 Hz

Output voltage, actuators 230 V AC

Ambient temp. range, operation 0 °C to 50 °C

Storage temp. range −20 °C to +60 °C

Output relay, pump 230 V Max. 100 W

Output relay, boiler Voltage-free Max. 2 A

Output cooling 230 V when active

Output Setback 230 V when active

Input Cooling External switch input (230 V rating)

Input setback External switch input (230 V rating)

Rated impulse voltage 4 kV

Temperature for ball pressure test 75 °C

Control pollution degree Pollution degree 2

Disposal instructions As electronic waste

Icon™ 230V Wiring Center

MAX. 100 W

L N

L N

3A

Mains

Option

220 -240 VAC

Option

2

Option

3

50/60 Hz

HE AT!

1

2× ≤ 1,5 mm

5 5 5

1 1 2 2 3 3 4 4 5 5 6 6 7 8

THE RMO STAT 1 THE RMOS TAT 2 THE RMOS TAT 3 THER MOS TAT 4 THER MOST AT 5 THER MOSTAT 6 THER MOSTAT 7 THERM OSTAT 8

SWITCH

EXTERNAL

L N

2× ≤ 1,5 mm

L N

LOAD

≤ 1,5 mm ≤ 1,5 mm ≤ 1,5 mm

L N

LOAD

L N

LOAD

L N

LOAD

L NN

L N

LOAD

Load

L

L N

LOAD

L N

LOAD

L N N NTC

Example: Icon™ ProgrammableExample: Icon™ DisplayExample: Icon™ Dial

LOAD

Options

Option

Load

L

Sensor

Option

4

AI405949559758en-010201

© Danfoss | 2022.03 | 7

Page 8

Data sheet UnoFloor Mixing

Danfoss Icon™

Master Controller 24V

Technical data

Master Controller 24V and

Expansion Module (optional)

Danfoss Icon™ is a modular heating system for

individual room control. It can be configured as

a wired or wireless system or as a combination, if

required.

For all applications please see Installation guide for Expansion Module.

Supply voltage 220-240 V AC

Supply frequency 50/60 Hz

Output voltage, actuators 24 V DC

Max. power consumption per actuator output 2 W

Number of actuator outputs

(1 actuator per output terminal)

Output voltage, thermostats 24 V DC

Max. number of thermostats 10

Dimensions W: 370 mm, H: 100 mm, D: 53 mm

Encapsulation (IP Class) IP 20

The center of the system is the Danfoss Icon™

Master Controller 24 V, which configures and ties

the system together.

Installation and set-up of the Danfoss Icon™

Master Controller 24 V is made easy by using the

pre-defined application and intuitive touch user

interface.

10

8 | © Danfoss | 2022.03

AI405949559758en-010201

Page 9

Data sheet UnoFloor Mixing

Dimensions

C

B

110

B

A

number of

circuits

A B C

4, 5, 6 753 mm 790 mm 939 mm

7, 8 864 mm 940 mm 939 mm

10, 12 1057 mm 114 0 mm 939 mm

159

AI405949559758en-010201

© Danfoss | 2022.03 | 9

Page 10

Data sheet UnoFloor Mixing

Tender text

Pre-assembled underfloor heating balancing and

control distribution unit must come wired and

pre-mounted, suitable for left- and right-hand

side connection to the manifold, fitted in in-wall

cabinet. Cabinet must be painted in white (RAL

9016), 939 mm in height, up to 1140 in width and

110 in depth.

The manifold is used for heat regulation in floor

heating systems. Each circuit in the floor heating

system is connected to the manifold, which

makes it possible to regulate the heat supply to

each room in the building independently.

The manifold shall consist of a flow and return

manifold where the flow manifold must be able

to close each circuit independently. The return

manifold must be equipped with presetting

valves, ensuring optimal balancing of the system.

Balancing of the floor heating system shall be

done on a swivel scale ranging from 1-7 and

N so that the value can be read and checked

after commissioning. Valves shall be controlled

electronically by thermal actuators installed

without adapters.

The manifold must be provided in modules of up

to 12 outlets with air vent and drain / fill function

valve. Ball valves must be available as an option

for positive shut-off between manifold and

system.

The manifold must be made of stainless steel

and have the following specifications:

• Maximum flow temperature : 90 °C

• Maximum differential pressure: 0,6 bar

• Maximum operating pressure with

flow meter: 6 bar

• Max Kv setting of the valve (N): 0,97 m

The mixing shunt shall be compact, has a flexible

design, which allows mounting directly to the

manifold on both left and right side. Primary

pipe connection must be from the side or below.

Mixing shunt must have a possibility to

regulate the supply temperature by self-acting

proportional regulator. The regulator ensures

that the desired supply temperature to the

floor heating system always remains constant

and can be set from 15°C to 50°C. Mixing shunt

must be equipped with a built-in check valve,

which ensures correct flow direction. An air-vent

on top and a thermometer shall complete the

mixing shunt. Mixing shunt must be equipped

with a low-energy, variable speed pump 130mm

mounting length.

The mixing shunt must be made of brass and

stainless-steel components and have the

following specifications:

• Supply voltage: 230V

• Primary connection: G ½ “

• Manifold connection: G 1”

• Maximum flow temperature: 90°C

• Flow temperature control: 15°C to 50°C

• Maximum different pressure: 0.6 bar

• Maximum working pressure: 10 bar

• Pump type: low-energy, variable speed,

130mm mounting length

• Weight: 3.5 - 4 kg

Icon 230V wiring center:

It must be possible to connect the room

thermostats to the NC actuators via a connection

box.

The connection box must have not less

8 channels and 14 actuator outputs, have two

potential free relays: one for the pump and one

for the boiler. Distribution voltage: 230 V AC.

Voltage: 230 V AC, max. power per output: 3 W.

The actuator must be premounted on a valve.

The actuator receives a signal from the room

thermostat. Based on the signal, it opens and

closes the valve which makes it possible to

regulate the energy supply to each room in the

building independently. For easy and secure

installation, the actuator must be delivered

as one part (no adapter) and mounted on the

manifold by use of an Allen screw.

Icon 24V master controller:

It must be possible to connect the room

thermostats to the NC/NO actuators via

a connection box.

The connection box must have not less

10 channels and 10 actuator outputs, have

potential-free relay, one micro disconnection

output and permanent 230 V (max 50W) output.

Supply voltage: 230 V AC. Output voltage for

actuators: 24 V DC, max. power per output: 2 W.

It must be possible to set up to 10 actuators for

1 room thermostat. It must be possible to control

system by smartphone app and have pre-set

work profiles with applications. Connection box

must have possibility to be upgraded to wireless

solution by Wireless module. For accurate

hydronic control, automatic heat load control

feature must be available.

The actuator must be premounted on a valve.

The actuator receives a signal from the room

thermostat. Based on the signal, it opens and

closes the valve which makes it possible to

regulate the energy supply to each room in the

building independently. For easy and secure

installation, the actuator must be delivered

as one part (no adapter) and mounted on the

manifold by use of an Allen screw.

10 | © Danfoss | 2022.03

AI405949559758en-010201

Page 11

Data sheet UnoFloor Mixing

Spare parts

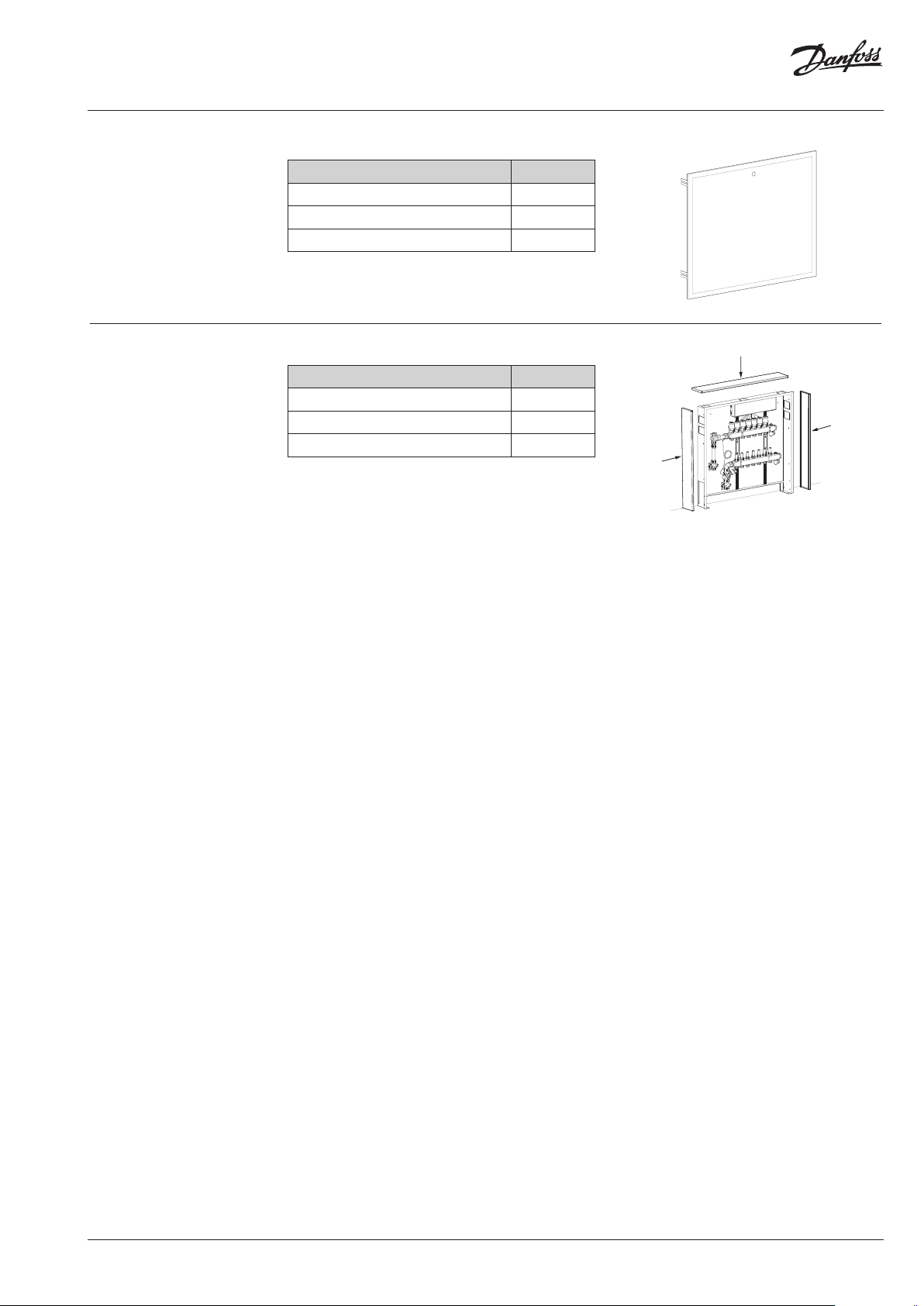

Accessories

Frame and door for service are available on demand.

Description Code no.

Frame and door for cabinet 790 088X3020

Frame and door for cabinet 940 088X3022

Frame and door for cabinet 1140 088X3024

Panels for wall mounting are available on demand.

Description Code no.

On wall panels for cabinet 790 088X3026

On wall panels for cabinet 940 088X3028

On wall panels for cabinet 1140 088X3030

AI405949559758en-010201

© Danfoss | 2022.03 | 11

Page 12

Data sheet UnoFloor Mixing

12 | © Danfoss | DCS-SGDPT/PL | 2022.03

AI405949559758en-010201

Loading...

Loading...