Data Sheet

UnoFloor Control

Description

The Danfoss UnoFloor Control is a preassembled pressure independent underfloor

heating electronic balancing and control

distribution unit. UnoFloor comes wired and

pre-mounted. The UnoFloor’s Danfoss Icon™

Master controller 24V is modular heating

center for individual room control. It can be

configured as a wired or wireless system or as

a combination, if required. Can connect up to

10 thermal actuators and room thermostats.

The SSM stainless-steel manifold is used for

controlling water flow. Each tube of the floor

heating system is connected to the manifold,

thus making it possible to control water flow

or heat supply to each room in the building

individually.

The The AB-PM set ensures optimal hydronic

balance. Flow limitation independent of

differential pressure is now guaranteed.

Features:

• Compact design - fits in even the smallest

places.

• In-wall cabinet ensures flush installation.

• Pre-mounted - minimal risk of installation

faults.

• Easy ordering - only one number necessary.

• Short installation time.

• Correct heat distribution, even under partial

load.

• Reliable hydronic balancing for lower heating costs.

• Auto balancing provided by Danfoss Icon™

Master controller

• Intuitive touch user interface.

Ordering

Key UnoFloor Control 4L, Comfort - version, 4- number of circuits, L - left assembly, if R - right assembly

© Danfoss | 2020.03

Description Type

Pressure independent Underfloor heating

Electronic Balancing and control distribution unit

• Danfoss Icon Master controller 24V

• Actuators

Stainless steel manifold

•

• AB-PM set

• Cabinet

• Nominal pressure PN 6

• Max. Temperature 90 ° C

Use heating water according VDI 2035.

Code no.

UnoFloor Control 4L 088X3604

UnoFloor Control 5L 088X3605

UnoFloor Control 6L 088X3606

UnoFloor Control 7L 088X3607

UnoFloor Control 8L 088X3608

UnoFloor Control 10L 088X3610

UnoFloor Control 12L 088X361

UnoFloor Control 4R

UnoFloor Control 5R

UnoFloor Control 6R

UnoFloor Control 7R

UnoFloor Control 8R

UnoFloor Control 10R

UnoFloor Control 12R

AI333535898456en-000102 | 1

088X3624

088X3625

088X3626

088X3627

088X3628

088X3630

088X3632

2

Data Sheet UnoFloor Control

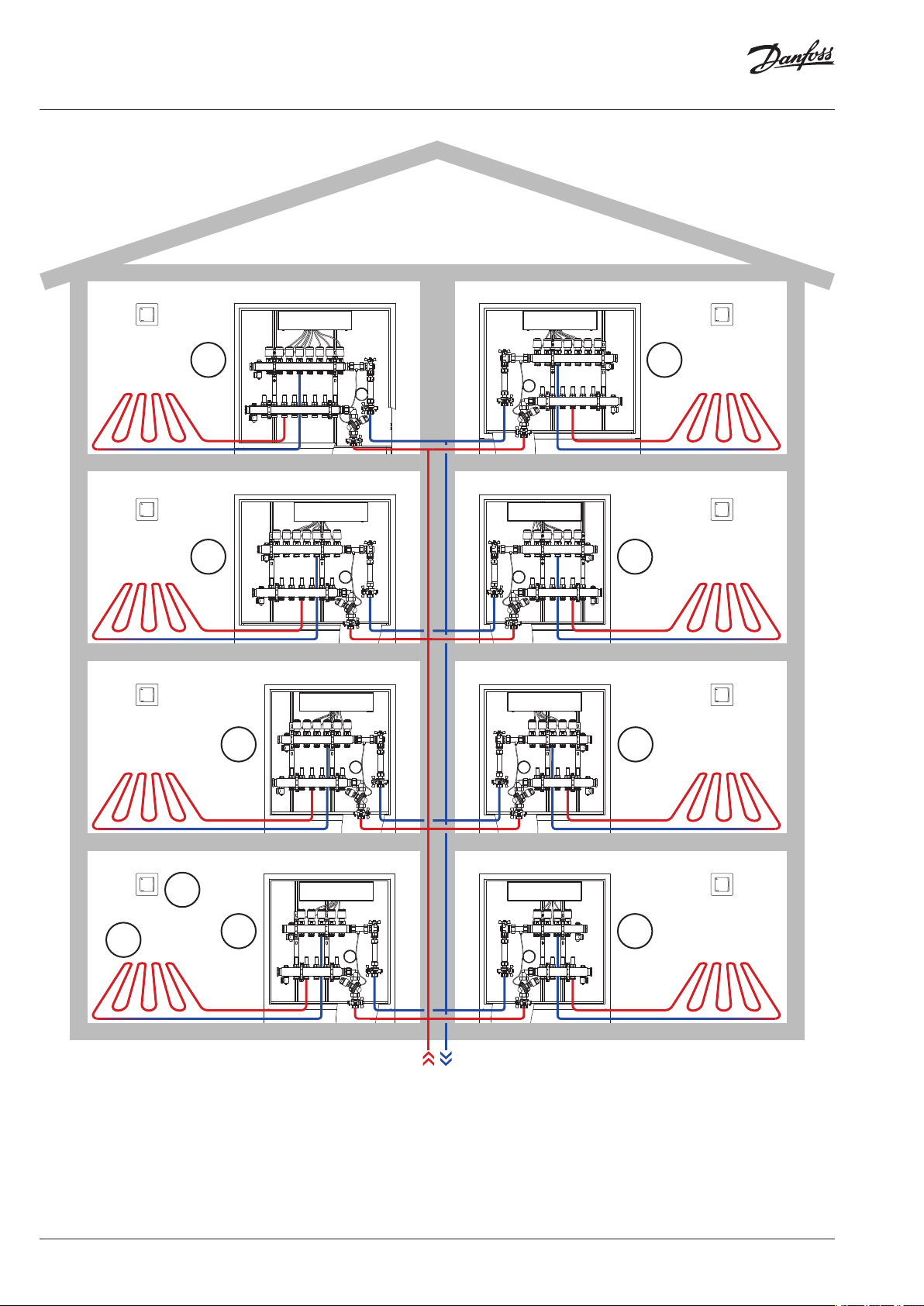

System

109

87

5

6

1

2

3

4

2 | © Danfoss | 2020.03

1. Room Thermostats

2. Underfloor heating circuit

3. UnoFloor Control 5R

4. UnoFloor Control 4L

5. UnoFloor Control 6R

6. UnoFloor Control 5L

7. UnoFloor Control 7R

8. UnoFloor Control 6L

9. UnoFloor Control 8R

10. UnoFloor Control 7L

AI333535898456en-000102

Data Sheet UnoFloor Control

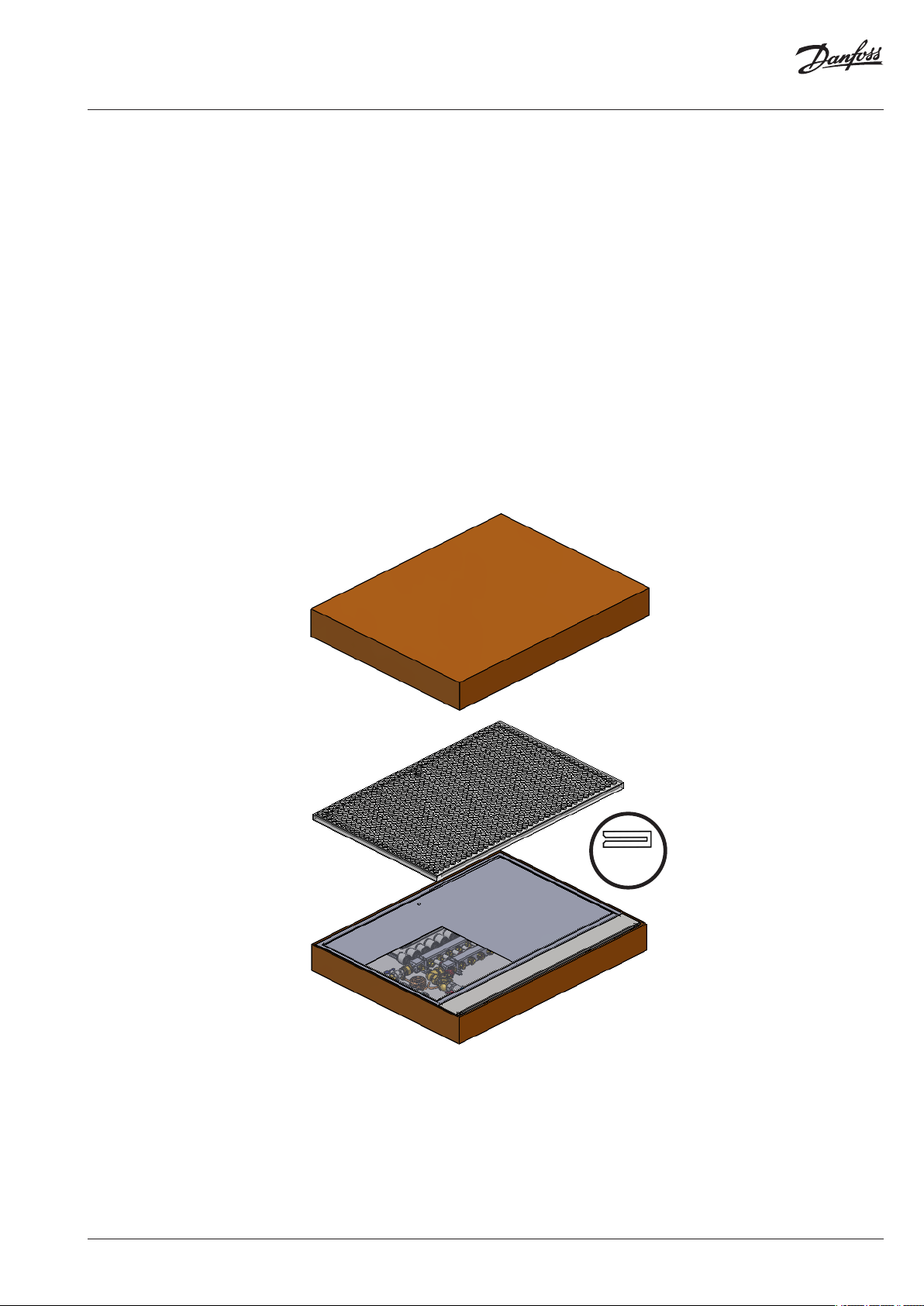

UnoFloor Control is a

Time saving provider

Take the prefab for each apartment and put away frame and door which are packed

together for protection. The cardboard box can be used to protect frames and doors

construction phase

Time saving solution provider:

• Manifold mounted in the cabinet

• premounted AB-PM set

• I

con Master Controller fixed

• All TWA actuators are wired with the Icon Master Controller

.

during

© Danfoss | 2020.03

x4

AI333535898456en-000102 | 3

Data Sheet UnoFloor Control

Accessories

Description

Danfoss Icon™ Display, In-wall

Danfoss Icon™ Display, On-wall

Danfoss Icon™ Display, On-wall

Danfoss Icon™ Infrared, On-wall

Floor sensor

Code no.

088U1050

088U1055

088U1081

088U1082

088U1110

24V

Wireless

App module

ZigBee Radio module 088U1130

Radio module

(not for inside cabinet installation)

Repeater

Expansion module

Dew-point sensor

088U1101

088U1103

088U1102

088U1100

088U0251

4 | © Danfoss | 2020.03

Surface temperature sensor, ESM-11

087B 1165

AI333535898456en-000102

Data Sheet UnoFloor Control

SSM

Floor Heating Manifold

Part of assembly

Pre-setting diagram

The SSM manifold is used for controlling water

flow in under floor heating systems. Each tube

of the floor heating system is connected to the

manifold, thus making it possible to control

water flow or heat supply to each room in the

building individually.

Description Type

Manifold set 4+4, with flowmeter SSM-4F

Manifold set 5+5, with flowmeter SSM-5F

Manifold set 6+6, with flowmeter SSM-6F

Manifold set 7+7, with flowmeter SSM-7F

Manifold set 8+8, with flowmeter SSM-8F

Manifold set 10+10, with flowmeter SSM-10F

Manifold set 12+12, with flowmeter SSM-12F

Manifold with

flowmeter

Presetting the manifold valves

© Danfoss | 2020.03

The diagram shows the capacities for each heating

circuit at different presettings of the manifold

valves.

Based on the above calculations and capacity

diagram each manifold valve is preset by rotating

the red ring until the correct value on the ring is

in-line with the sight mark on the valve.

AI333535898456en-000102 | 5

Data Sheet UnoFloor Control

AB-PM DN20 HP set

vertical

Part of assembly

Technical data

The AB-PM connection set is an compact and time

saving configuration – designed for creating optimal hydronic balance in horizontal loops - radiator

and underfloor heating applications. Flow limitation independent of differential pressure is now

guaranteed. It can be combined with most types

of manifolds, heat mete

rs and manifold cabinets.

One packing unit contains the following products:

• AB-PM valve

• Impulse tube, 1,5 m, R 1/16

• Adapter R 1/16 for AB-PM impulse tube connection

• 3-piece ball valve with connection for impulse

tube heat meter

• Adapter for heat meter

•

Connector/bracket for underfloor heating distributor G 1 A

External thread

connection to underfloor

heating distributor

(ISO 2 28/1)

Typ e

External thread

AB-PM

(ISO 2 28/1)

AB-PM DN20 HP set vertical G 1 A G 1 A

Nominal diameter DN 20 HP

Qmax (at Δp

r = 20 kPa) 600 l/h (at 100 % setting)

Upper limit of pressure controller at zero flow 35 kPa

Differential pressure (Δp for the valve + circuit) 28 – 400 kPa

Nominal maximal pressure 16 bar (PN 16)

Control valves characteristic Linear

Shut-off leakage rate Acc. to ISO 5208 class A - no visible leakage

Medium temperature -10 °C to +120 °C

CV stroke 2,25 mm

Connection Ext. thread ISO 228/1 G 1 A

Actuator M 30 × 1,5

Sizing

6 | © Danfoss | 2020.03

AB-PM is to be sized based on manifold’s needed

flow (Q) [l/h], and needed differential pressure

drop for the loop (Δpr). Manifold pre-setting data

are presented on page 4. Max AB-PM flow data are

presented in table 1.

For any other Q and Δpr needed, AB-PM size and

setting can be indetified based on Fig. 1.

Typ e

DN 20 HP at

100% setting

Q max. 600 l/h 915 l/ h

Maximum pressure drop

available for system at

20 kPa 10 kPa

max flow

Upper limit of pressure

controller at zero flow

Start required differential

pressure (for the valve)

35 kPa

8 kPa

DN 20 HP

100 %

90 %

80 %

70 %

60 %

50 %

40 %

30 %

20 %

flow [l/h]

˜ pr [kPa]

Fig. 1

AI333535898456en-000102

Data Sheet UnoFloor Control

Danfoss Icon™

Master Controller 24V

Technical data

Master Controller 24V and

Expansion Module (optional)

Danfoss Icon™ is a modular heating system for

individual room control. It can be configured as

a wired or wireless system or as a combination, if

required.

The center of the system is the Danfoss Icon™

Master Controller 24 V, which configures and ties

the system together.

Installation and set-up of the Danfoss Icon™

Master Controller 24 V is made easy by using the

pre-defined application and intuitive touch user

interface.

For all applications please see Installation guide for Expansion Module.

Supply voltage 220-240 V AC

Supply frequency 50/60 Hz

Output voltage, actuators 24 V DC

Max. power consumption per actuator output 2 W

Number of actuator outputs

(1 actuator per output terminal)

Output voltage, thermostats 24 V DC

Max. number of thermostats 10

Dimensions W: 370 mm, H: 100 mm, D: 53 mm

Encapsulation (IP Class) IP 20

10

TWA

Thermal Wax Actuator

Ordering

Technical specifications

The TWA is a small actuator

for electrical on/off controls to

activate several types of valves

and floor heating manifolds.

Actuator Connection type Supply Voltage Function

TWA-A RA 24 V AC/DC NC

Supply voltage 24 V (Class II (SELV))

Max. inrush current 350 mA

Frequency 50-60 Hz

Running power consumption 2 W

Spindle travel time ~3 min.

Ambient temperature 0 °C to 60 °C

Enclosure IP 41

Cable length 950 mm

kvs (m³/H) 0,10 to 1,10

Max. Δp (Bar) 0,6

© Danfoss | 2020.03

AI333535898456en-000102 | 7

Data Sheet UnoFloor Control

Dimensions

0-70

0-70

Number

of circuits

4, 5, 6 610 mm 647 mm

7, 8 760 mm 797 mm

10, 12

A B

960 mm

997 mm 750 mm

110

C

750 mm

750

mm

C

145

130

104

0-80

84

B

A

8 | © Danfoss | 2020.03

AI333535898456en-000102

Data Sheet UnoFloor Control

Tender text

Pre-assembled pressure independent underfloor

heating electronic balancing and control distribution unit must come wired and pre-mounted,

suit-able

connection to the manifold, fitted in in-wall

cabinet.

Cabinet must be painted in white (RAL 9016), 750

mm in height, up to 960 mm in width and 110

mm in depth.

It must be possible to connect the room thermostats to the NC/NO actuators via a connection

box. The connection box must have not less 10

chan-nels and 10 actuator outputs, have potential

free relay, one micro disconnection output and

perma-nent 230 V (max 50W) output. Supply

voltage: 230 V AC. Output voltage for actuators:

24 V DC, max. power per output: 2 W. It must be

possible to set up to 10 actuators for 1 room

thermostat. It must be possible to control system

by smartphone app and have presetted work

profiles with applica-tions. Connection box must

have possibility to be upgraded to wireless

solution by Wireless mod-ule. For accuracy

hydronic control, automatic heat load control

feature must be available.

The manifold is used for heat regulation in floor

heating systems. Each circuit in the floor heating

system is connected to the manifold, which

makes it possible to regulate the heat supply

to each room in the building independently.

The manifold shall consist of a flow and return

manifold where the flow manifold must be able

to close each circuit independently. The return

mani-fold must be equipped with presetting

valves, ensuring optimal balancing of the

system. Flow control of the floor heating system

shall be done on a visible presetting scale, so that

the value can be read and checked after

commissioning. Valves shall be controlled

electronically by thermal ac-

for left- and right-hand side

tuators installed without adapters.

The manifold must be provided in modules with

air vent and drain / fill function valve.

The manifold must be made of stainless steel and

have the following specifications:

• Maximum flow temperature : 90 °C

• Maximum differential pressure: 0,6 bar

• Maximum operating pressure: 6 bar

• Max Kv setting of the valve (N): 0,97 m

The actuator must be pre-mounted on a valve.

The actuator receives a signal from the room thermostat. Based on the signal, it opens and closes

the valve which makes it possible to regulate

the energy supply to each room in the building

independently. For easy and secure installation,

the actuator must be delivered as one part (no

adapter) and mounted on the manifold by use of

an Allen screw.

The pressure independent balancing and control

set must consist of a linear control valve, impulse

tube with adapters to it, 3-piece ball valve with

connection to impulse tube and heat meter, connector to manifold . The valve could be used as an

automatic flow limiter. The valve should have a

mechanism to adjust the flow from 100 % to 0 %

of the maximum flow. Maximum recommended

flow setting should not be more than 600 l/h at

maximum system pressure drop 10 kPa, and no

more than 915 l/h at maximum system pressure

drop 5 kPa. Shut off service function should be

possible with setting mechanism. The authority

of the pressure independent control valve should

be 1 at all settings (control valve characteristic is

not changed). Upper limit of pressure controller at

zero flow must be 35 kPa. (Supplier of the valve

should provide lab test results1). Nominal pressure

rating 16 bar.

Accessories

Spare parts

© Danfoss | 2020.03

Panels for on wall mounting are available on demand.

Description

On wall panels for cabinet

On wall

panels for cabinet 760

On wall panels for cabinet 960

Frame and door for service are available on demand.

Description

Frame and door for cabinet 610

Frame

and door for cabinet 760

Frame and door for cabinet 960

610

Code no.

088X3014

088X3016

088X3018

Code no.

088X3008

088X301

088X3012

0

AI333535898456en-000102 | 9

Danfos

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

produc

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in speciÿcations already agreed.

Al

l trademarks in this material are p roperty of the respective companies. Danfoss and all Danfoss logot ypes are trademarks of Danfoss A/S. All rights reserve d.

Danfoss A/S

Heating Segment • heating

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

10 | © Danfoss | 2020.03

AI333535898456en-000102

Loading...

Loading...