Page 1

Fact Sheet

UNISTAT 1016 WR Small

Compact district heating substation from 16 to 30 kW*

Application

The UNISTAT 1016 WR is designed for

use in district heating networks. Depending on type, it can be used both in

micro- and macro-networks, in low temperature (LT) and high temperature (HT)

ranges. The substation is an innovative

product which sets industry standards.

Function

The communicative controller ECL 310 is

used. This controller ensures optimum

regulation of the energy distribution.

The supply temperature for the domestic system is weather compensated.

Energy consumption and temperatures

can be remote monitored.

Construction

The built-in components are connected by means of precisionmanufactured

welded steel pipes. The PN25 version

is featured with welded carbon steel

pipes on primary side and stainless

steel pipes on secondary side. High

quality gaskets are used as sealing

material. The entire water-bearing part

of the substation is thermally insulated

(EPP). This design enables an easy and

quick removal for service purposes.

The benets of this design are:

- Minimal radiation heat losses

- High durability

- Mounting option for pressure

and temperature measuring

instruments is incorporated.

Assembly

The compact substation is easy to wallmount.

FEATURES AND BENEFITS

• Thermal insulation

• Easy installation (by one person)

• Easy electrical connection

- edgewise cable routing

- plenty of space for wiring work

• High serviceability

• Compact and modern design

• Durability due to the use

of precious metals

• PN25 application

• Steel sheet cover

• Danfoss ECL controller

• Easy operation of the controller display

* Power levels and types are dependent

on ow rate and spread

heating.danfoss.com

Page 2

114

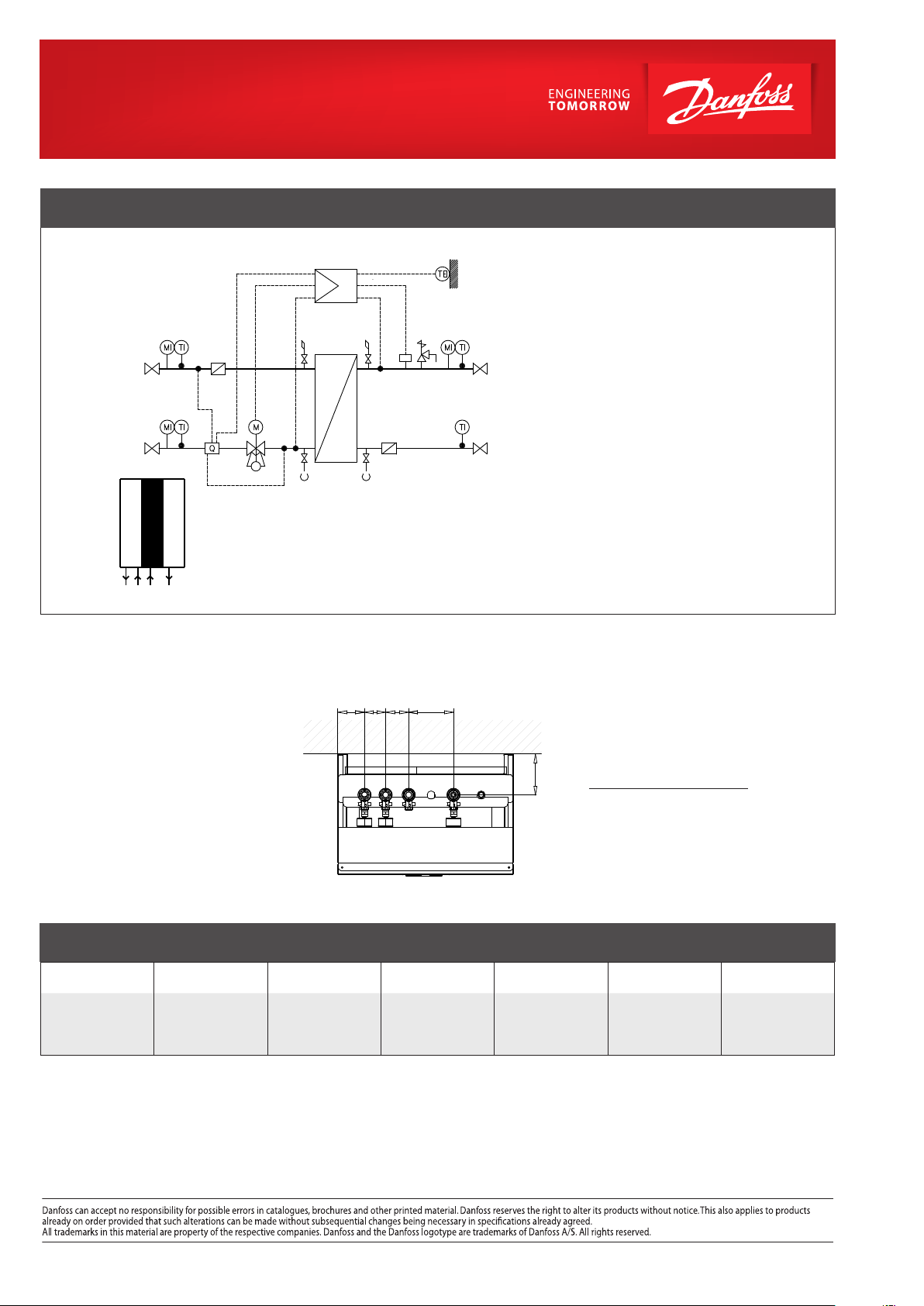

CIRCUIT DIAGRAM – EXAMPLE

3 2

supply

11

4

Primary

3 2

11

Primary

10*

return

B A C D

Technical parameters:

Nominal pressure: PN25

Δ T: 35 oC / 20 oC

Capacity: 16/30 kW

Weight: 40 - 45 kg

Cover: Steel sheet

Dimensions (mm):

With cover (incl. connections):

H 870 × W 490 × D 337

Connections:

A Primary supply

B Primary return

C Secondary return

D Secondary supply

9

1

1 External sensor

2 Thermometer

3 Manometer

4 Sensor

3 2

5 5

7

13

12

11

Secondary

8*

4

supply

5 Air vent

6 Drainage

7 Strainer

8 Safety thermostat

9 Controller

10* Heat meter

2

44

7

11

Secondary

return

14*

1)

6 6

Connection sizes:

Primary: G ¾”

Secondary: Rp ¾”

Heat meter: G ¾” × 110 mm

Regulation possibilities for ECL 310:

• With different application keys

Options*:

11 Ball valve

12 Safety valve

13 Heat exchanger

14* Dierential pressure and ow

controller

• Heat meter

74.5 59

64.5

125

• Safety thermostat

• Actuator with emergency o function

The substation is delivered preassembled, electrically wired internally and tested for function and

leak tightness.

1)

primary side / secondary side

B A C D

Seen from above

STANDARD OPERATING TEMPERATURES*:

Primary

°C

Secondary

°C

* Capacity may vary depending on temperature

Danfoss A/S · 6430 Nordborg · Denmark

Tel.: +45 74 88 22 22 · Fax: +45 74 49 09 49 · danfoss@danfoss.com · www.danfoss.com

© Danfoss | DHS-SRMT/ PL | 2016 . 02

95 - 65 90 - 60

60 - 85

55 - 80

50 - 70

50 - 75

55 - 75

55 - 80

90 - 50 95 - 60 95 - 55

45 - 65

47 - 70

45 - 75

55 - 75

57 - 80

55 - 80

50 - 70

50 - 75

52 - 75

80 - 50

45 - 65

VL.IQ.F2.02

Loading...

Loading...