Installation Guide

UNISTAT 1016 A/W and WR

Unistat 1016 A/W Unistat 1016 WR

Contents

1.0 Table of contents ............................................................................................................................................................................................................................................................1

2.0 Safety note .........................................................................................................................................................................................................................................................................2

3.0 Storage and Handling ..............................................................................................................................................................................................................................................5

4.0 Disposal ........................................................................................................................................................................................................................................................................ 5

5.0 Diagrams ..........................................................................................................................................................................................................................................................................6

6.0 Mounting ...........................................................................................................................................................................................................................................................................8

7.0 Installation and Start-up ........................................................................................................................................................................................................................................ 9

7.1 Heat transfer medium treatment ...........................................................................................................................................................................................................9

8.0 Commissioning .......................................................................................................................................................................................................................................................... 10

9.0 Electrical installation .............................................................................................................................................................................................................................................. 11

9.1 Electrical diagrams ........................................................................................................................................................................................................................................ 12

10.0 Maintenance ............................................................................................................................................................................................................................................................... 15

11.0 Troubleshooting ....................................................................................................................................................................................................................................................... 16

12.0 EC - Declaration of conformity ....................................................................................................................................................................................................................... 19

Danfoss District Energy VM.IQ.A1.02 DEN-SMT/PL

1

Danfoss District Energy UNISTAT 1016 –

2.0 Safety note

This section provides you with an overview of all relevant

safety aspects for optimum protection for you and your

personnel and the safe and fault-free operation of the

unit. The individual sections also contain specic, symbol-

-identied safety notes for averting immediate dangers.

General

The unit is built in accordance with the sound engineering

practise and follow all relevant EU regulations applicable at

the time of its development and production. The unit can,

however, entail dangers if it is used by unskilled or not properly

trained personnel or is used improperly or not as intended.

Every person assigned to work on or with the unit must therefore have read and understood the operating instructions before the work begins. The operator is recommended to have all

relevant personnel conrm the understanding of the operating instructions in writing.

Changes of any kind and additions to or conversions on the

unit are strictly forbidden, and all warranty and product responsibly will on longer by covered by Danfoss District Energy.

Please always agree conversion and extension work

with the manufacturer. All safety, warning and operating

notices on the unit must always be kept in an easy to

read condition. Damaged signs or stickers must be renewed immediately. Given setting values or ranges must

be observed.

Safety note

Operator/owner’s responsibility

• Always keep operating instructions close to the unit and

accessible for the installation, operating, maintenance

and cleaning personnel at all times.

• Only operate the unit within the product specied

pressure and temperature limits.

• Always keep safety devices freely accessible and check

regularly.

The information on safety at work applies to the European

Union ordinances and is applicable at the time the unit is produced. The operator is obliged to determine the compliance

of the safety at work rules and regulations and must observe

and updated if new regulations is adopted by the EU during

the entire time of the unit’s life time.

Outside the EU the applicable safety at work legislation and

regional provisions and regulations must be complied. In addition to the safety at work, notes in these operating instructions,

and the generally applicable safety, accident-prevention and

environmental protection regulations must be observed and

complied with for the specic area of application.

The operator and the authorised personnel are responsible for the fault-free operation of the unit, and for the

clear denition of responsibilities with the unit’s installation, operation, maintenance and cleaning. The information

provided in the operating instructions must be followed

in full and unrestricted!

The operator must also ensure that:

- All residual risk that arises as a result from the point of

installation must be determined and minimized.

2

DEN-SMT/PL VM.IQ.A1.02 Danfoss District Energy

Danfoss District Energy UNISTAT 1016 –

Proper use

The unit’s functional and operational safety is only guaranteed

when used properly in accordance with the information in

this instruction.

Proper use also includes correct compliance with installation,

operating, maintenance and cleaning instructions.

Any other use of the unit is forbidden and applies as improper!

Safety at work

Adhering to the notes on safety at work dangers to people

and/or the system must be prevented. Ignoring or non-

-compliance with these notes can cause dangers to people and property from mechanical eects or the failure

of the system and the entire workplace. Non-compliance

with safety regulations will result in the loss of all rights no

claims to damages.

Personal protection equipment

The following must personal protection equipment must be

worn when working on or with the unit:

Claims of any kind against the manufacturer and/or their

agents for damages caused by improper use of the unit

shall be excluded. The operator and/or owner alone are

the sole responsible party for all damages caused by

improper use.

Safety note

• Protective gloves for protecting the hands against

abrasion, grazes, or deeper injuries and against contact

with hot surfaces.

• Protective glasses for protecting the eyes against

ejecting parts and hot liquid splashes.

• Safety shoes for protecting against falling parts and

slipping on slippery surfaces.

Danfoss District Energy VM.IQ.A1.02 DEN-SMT/PL

33

Danfoss District Energy UNISTAT 1016 –

2.1 Residual risk

The unit has undergone a risk analysis as required by the

Machinery directive and is preformed according to En14121.

The unit design complies with the current state of technology. Nonetheless there are residual risks! The unit generates

a strong liquid jet when opening the draining or venting components, for example.

Possible harm caused by liquid squirting

under high pressure.

Wear personal protection equipment

with all work on the unit.

The unit works with high voltages 230/240

Vac 50Hz and a maximum current on 6 A.

Possible Harm caused by electrical current!

The electrical forces can cause fatal injuries.

Damage on insulation or individual components

can endanger life.

– Switch main switch o (1F1) or disconnect supply,

before maintenance, cleaning or repair work and

secure or monitor against accidental or unintended

reengagement of the power supply.

– Do not remove any safety components or put

them out of service.

Residual risks

The unit weighs app. 40 – 45 kg.

Possible harm! Danger of crushing.

Heavy weights can cause crushing dangers when

transporting, including with lifting gear.

The unit can have sharp edges and corners.

Possible harm! Sharp-edged mounting plate and

brackets and pointed corners can cause cuts.

Wear protective gloves when working on the unit!

Possible harm! Danger of burns.

Hot surfaces can cause serious burn injuries. Wear

protective gloves when working on the unit!

4

DEN-SMT/PL VM.IQ.A1.02 Danfoss District Energy

Danfoss District Energy UNISTAT 1016 –

1st issue, 2008-02

Page 1 of 1

This standard shall be observed when new technical literature or changes are designed

for DH products. The standard is valid throughout DH.

The standard shall describe the rules for implementing disposal instructions in technical

DH literature (Data sheet, Instruction, etc.).

In spite of, that none of the electronic and electro-mechanical DH-products are within

the scope of WEEE, it has been decided to put a relevant standard text and a bin-symbol

in the technical literature for these products (see clause 5).

The text and the bin-symbol do not relate to the WEEE, but emphasizes that Danfoss is

an environmental friendly company. Please notice that bin symbol with registration

number, below the bin, should not be used.

There are no legal requirements to have disposal instructions included in technical DH

literature like data sheets or instructions for non electronic and non electro-mechanical

products. Nevertheless we foresee that there will be requirements in the future.

In order to prepare ourselves we therefore have decided to add a general disposal in-

struction also in this product group (see clause 5).

Following general text in connection with the waste bin shall be implemented in all

technical literature for DH products:

3.0 Storage and handling

If the substation is stored before installation, make sure

that the place is dry and heated. (Humidity max. 60 % and

storage temperature 5 – 70 °C).

Do not stack the unit higher than factory shipped.

Units that are shipped in cardboard packaging are to

be lifted by the carrying handles of the packaging.

Transport/removals over great distances should be carried

out on pallets.

During and after unpacking, the substation can be lifted by

using straps, tted around the pipes or it can be lifted by hand

in the pipes. Lifting in the pipes can cause leaks. ALWAYS retighten.

4.0 Disposal

HANDLING

When working on the substation suitable

safety shoes must be worn.

Storage and handling / disposal

Disposal instruction:

This product should be dismantled and its components

sorted, if possible, in various groups before recycling or disposal.

Always follow the local disposal regulations.

Danfoss District Energy VM.IQ.A1.02 DEN-SMT/PL

55

Danfoss District Energy UNISTAT 1016 –

14

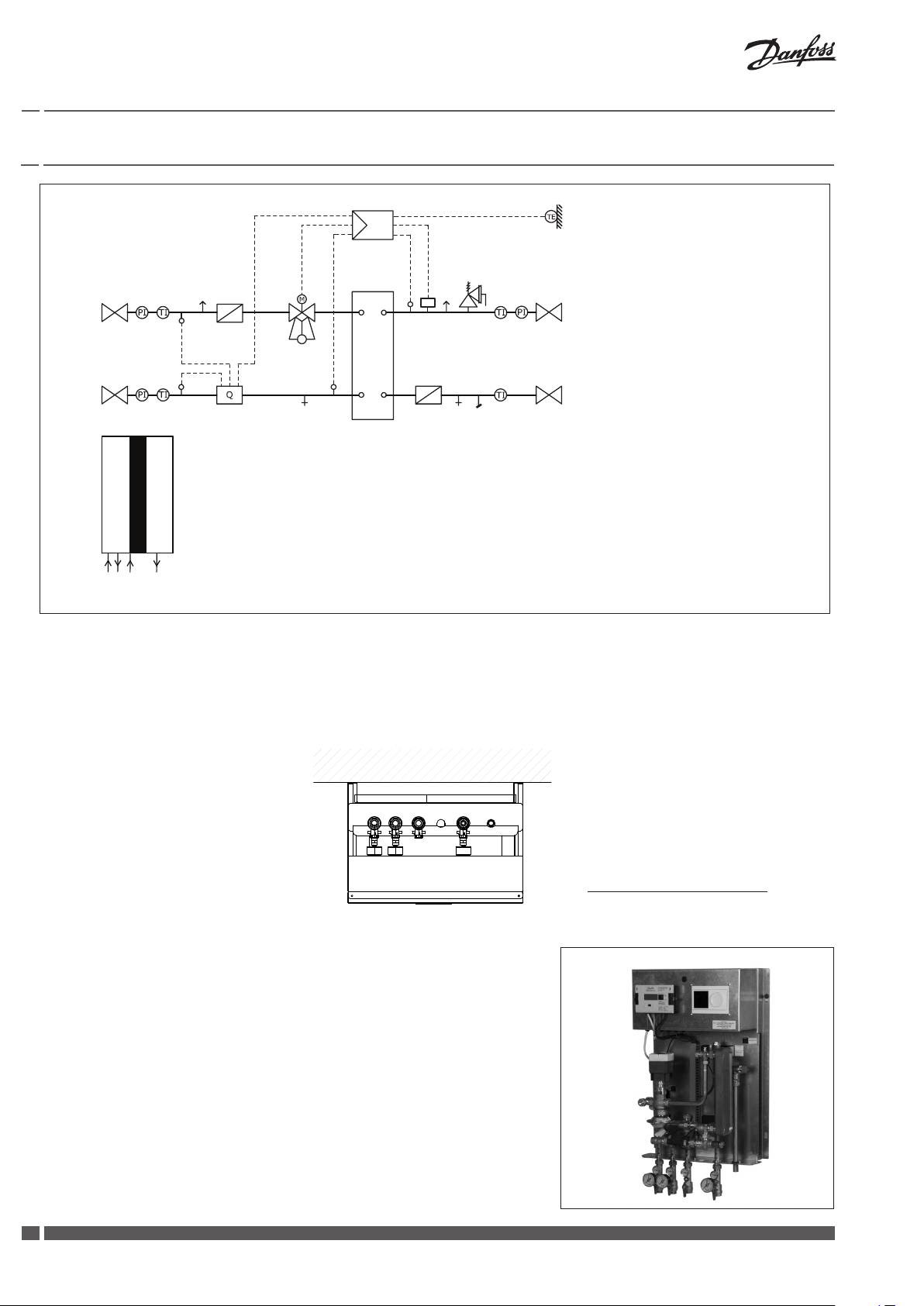

5.0 Diagram Unistat 1016 A/W

Diagrams

Primary

supply

Primary

return

12 324

D

B

A

43212 57

C

Technical parameters:

Nominal pressure:

- 1016A: PN16

- 1016W: PN25

T: 35 oC / 20 oC

Capacity: 16/30 kW

Weight: 40 - 45 kg

1

10

*

15

11

64

4

Connection sizes:

Primary: G ¾”

1358*

23 12

Secondary

supply

Secondary

return

122967

Regulation possibilities for ECL 310:

• With different application keys

1 External sensor

2 Thermometer

3 Manometer

4 Sensor

5 Air vent

6 Drainage

7 Strainer

8* Safety thermostat

9 Connection for expansion

vessel

10 Controller

11* Heat meter

12 Ball valve

13 Safety valve

14 Plate heat exchanger

15* Dierential pressure and ow

controller

Secondary: Rp ¾”

1)

Heat meter: G ¾” × 110 mm

Options*:

• Heat meter

• Safety thermostat

• Actuator with emergency o function

Cover: Steel sheet

Dimensions (mm):

The substation is delivered preassembled,

electrically wired internally and tested for

function and leak tightness.

With cover (incl. connections):

C

D

B

H 870 × W 490 × D 337

Connections:

A

Primary supply

B

Primary return

C

Secondary supply

D

Secondary return

6

DEN-SMT/PL VM.IQ.A1.02 Danfoss District Energy

A

Seen from above

primary side ⁄ secondary side

Loading...

Loading...