Quick Guide ThermoDual®- S

D

C

B

A

51 2 3 4 6 7 8

F

E

HEL

DTA

LPU

SFV

FI

29

Z1

2

21

3

22

22

25

3 / 23

1

G

R

Q

P

5

3

D

37

Z4

M

4

N

3:25

Assembly / Installing the system

Legend:

1) Domestic water (cold)

2) Domestic water (hot)

3) Circulation (connection optional)

4) Heating, supply

5) Heating, return

37) Connection for instantaneous water heater (HEL)

DTA Domestic buer tank

HEL instantaneous water heater (heat exchanger)

LPU Storage tank charging pump

D Balancing and ow control valve

SFV Safety valve

FI Thermometer (charge)

21 Thermometer (tank)

G Shut-o ball valve

M Upper connection piece

with shut-o ball valve (gunmetal)

N Lower connection piece (gunmetal)

P Heat exchanger bracket

Q Connection part (brass)

R Connection pipe (stainless steel)

Z1 Safety temperature monitor mu

(see tank data sheet)

22 Sensor mu

22 Fühlermue

Z4 Connection for sensor charge

23 Drain connection mu

25 Cleaning and inspection opening

29 Ventilation sleeve / lifting eye connection

Note:

Unused connections/mus must

be closed (plugs/caps not included)

DHS-SMT L / PL

VQ.JV.A2.02 © Danfoss 12/2018

1

Quick Guide ThermoDual®- S

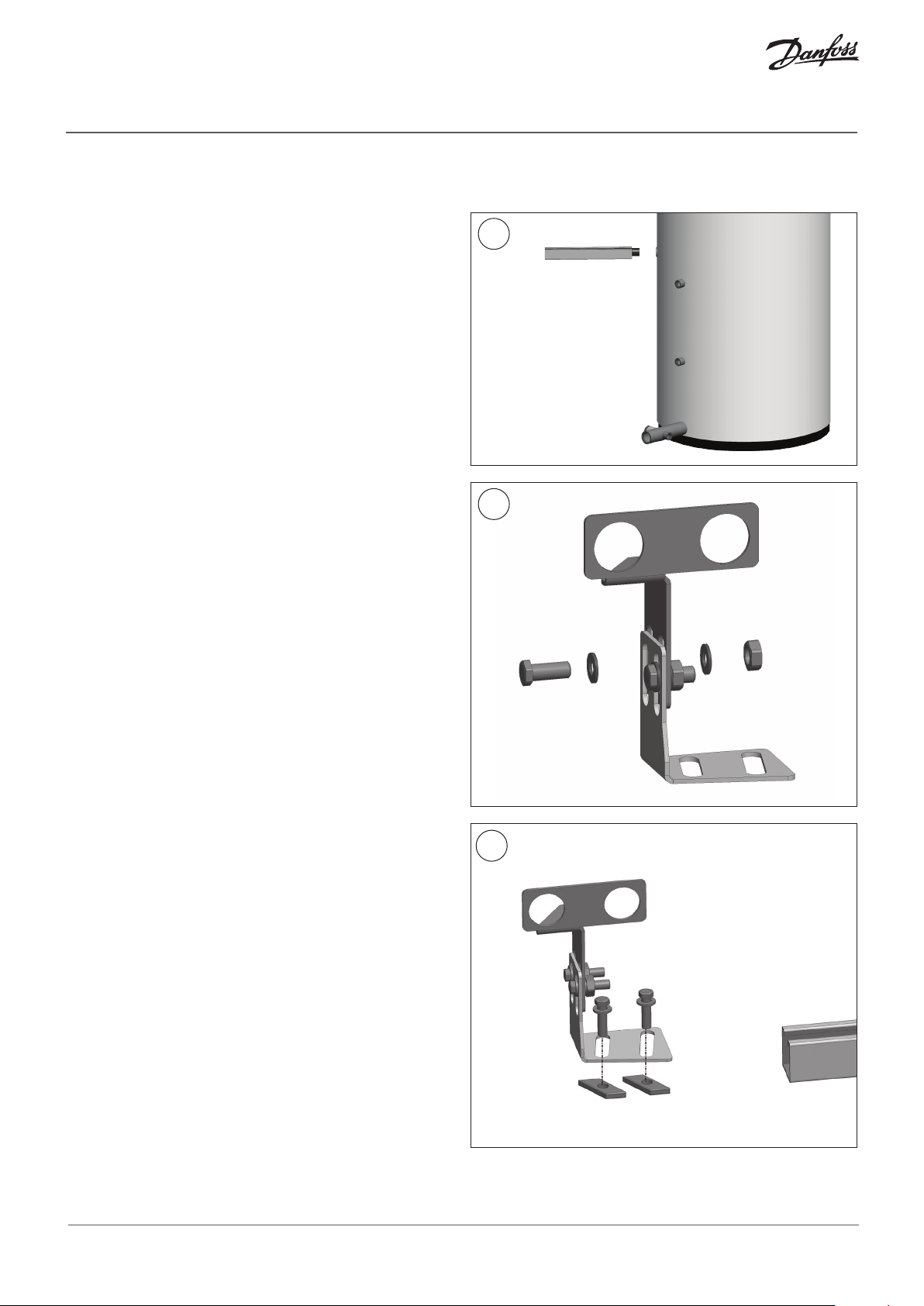

Heat exchanger bracket installation:

Screw the bracket into the mu provided for this purpose;

To fasten, you can use hemp or Teon tape.

Heat exchanger bracket:

Connect both parts with the enclosed screws,

nuts and washers.

Fastening (tightening the connections) takes place after

aligning the heat exchanger later.

1

P

2

Fasten both parts together with the enclosed screws.

Screw connection parts.

Fastening (tightening the connections) takes place after

aligning the heat exchanger later.

2

VQ.JV.A2.02 © Danfoss 12/2018

3

DHS-SMT L / PL

Quick Guide ThermoDual®- S

D

C

B

A

51 2 3 4 6 7 8

DTA

LPU

SFV

FI

29

Z1

2

Fs

3

Z2

Z3

25

25

1

G

R

Q

P

5

3

D

37

Z4

M

4

D

C

B

A

51 2 3 4 6 7 8

E

HEL

DTA

LPU

SFV

FI

29

Z1

2

Fs

3

Z2

Z3

25

25

1

G

R

Q

P

5

3

D

Z4

M

4

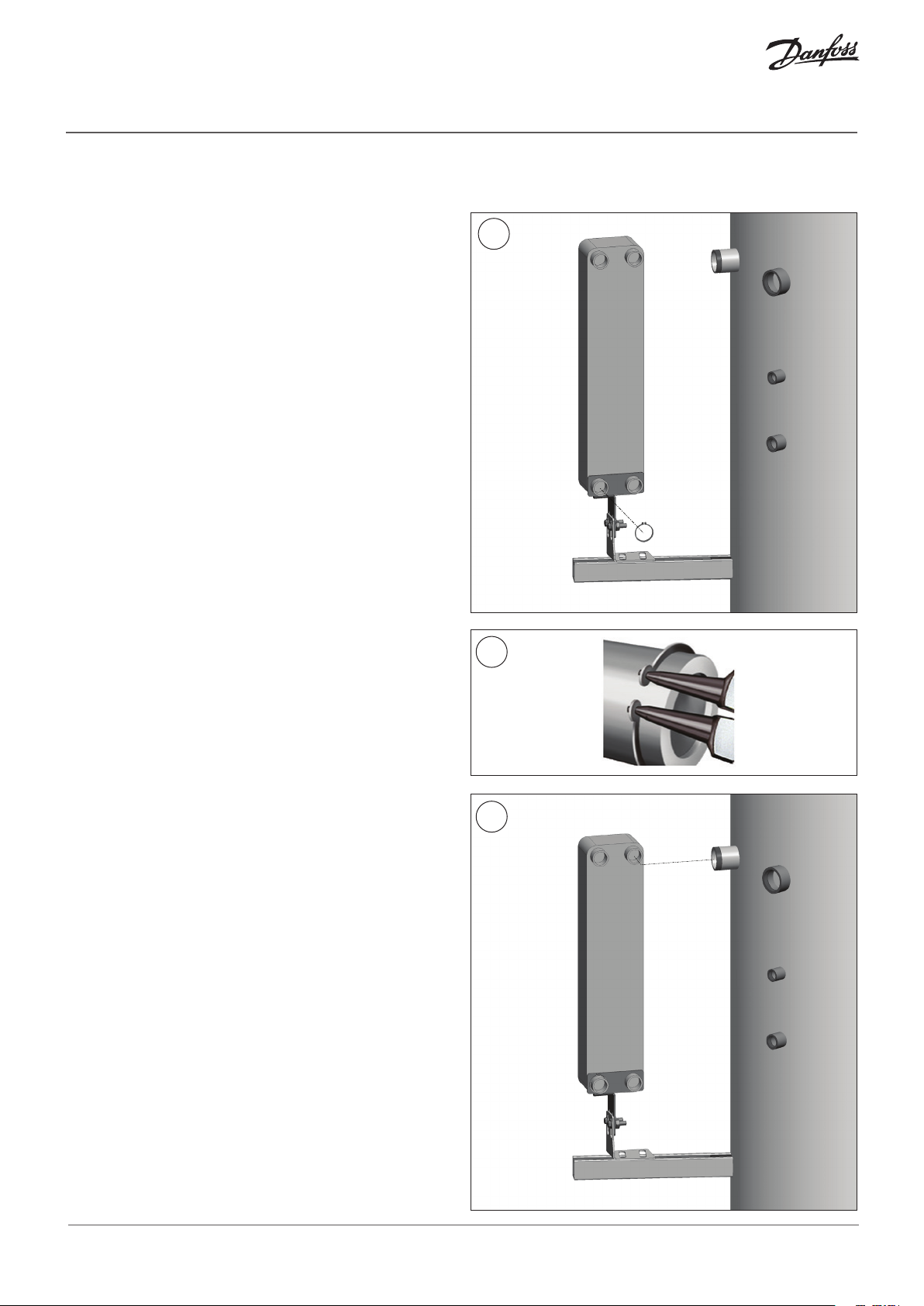

Fasten the heat exchanger using the enclosed

SEEGER ring as shown in Figure 5.

For this, use the left connection (heating, return).

4

HEL

5

Align the heat exchanger connection to t the upper

connection piece (see Fig. 7).

DHS-SMT L / PL

VQ.JV.A2.02 © Danfoss 12/2018

6

37

3

Quick Guide ThermoDual®- S

D

C

B

A

51 2 3 4 6 7 8

E

HEL

DTA

LPU

SFV

FI

29

Z1

2

Fs

3

Z2

Z3

25

25

1

G

R

Q

P

5

3

D

Z4

4

D

C

B

A

51 2 3 4 6 7 8

E

DTA

LPU

SFV

FI

29

Z1

2

Fs

3

Z2

Z3

25

1

G

R

Q

5

3

D

Z4

M

4

Connect the upper connection piece (M)

to the heat exchanger (HEL) and tank (DTA).

Insert the EPDM gaskets provided for this beforehand and

ensure horizontal alignment.

Once the connection has been successfully established, you

can rmly tighten the screws of the mounting bracket.

For the time being, manually tighten the screw connections

on the heat exchanger and tank.

7

M

37

8

37

M

DHS-SMT L / PL

VQ.JV.A2.02 © Danfoss 12/2018

HEL

4

Quick Guide ThermoDual®- S

D

C

B

A

51 2 3 4 6 7 8

E

HEL

DTA

LPU

SFV

29

Z1

2

Fs

3

Z2

Z3

25

25

1

G

R

Q

P

5

3

D

37

Z4

4

D

C

B

A

51 2 3 4 6 7 8

E

HEL

DTA

LPU

SFV

FI

29

Z1

2

3

Z2

Z3

25

25

1

G

R

Q

P

5

3

D

37

Z4

M

4

Carefully insert the capillary of the industrial thermometer

(turn it back and forth) as far as it will go into the immersion

pocket of the upper connection

piece (M) provided for this purpose.

Then fasten the thermometer from below with the existing

screw in the thermometer housing.

Now mount the tank thermometer: Seal the 200 mm

stainless steel pocket with a suitable sealing tape in the

socket provided (see tank data sheet)

and then insert the thermometer.

9

M

FI

10

This can be fastened using

the side screw in the pocket head.

21

DHS-SMT L / PL

VQ.JV.A2.02 © Danfoss 12/2018

5

Quick Guide ThermoDual®- S

D

C

B

A

51 2 3 4 6 7 8

F

E

HEL

DTA

SFV

FI

Z1

2

Fs

3

Z2

Z3

25

1

R

Q

P

5

3

D

37

Z4

M

4

D

C

B

A

51 2 3 4 6 7 8

F

E

DTA

LPU

FI

29

Z1

2

Fs

3

Z2

Z3

25

25

1

G

R

P

5

37

Z4

M

4

Screw the lower ball valve to the cold water connection.

Insert the enclosed EPDM gasket in advance.

Then tighten manually.

Connect the lower connection piece (N), the balancing

valve (D) and the connection part (Q) together one after the

other and to the charging heat exchanger (HEL).

Check the correct ow direction of the balancing valve

(upwards - see arrow on the valve body).

Use enclosed EPDM gaskets and manually tighten all

screwed connections.

The safety valve is screwed onto the

designated port R ¾” as shown.

This connection is self-sealing

and requires no additional sealing material.

11

12

G

HEL

D

SFV

N

DHS-SMT L / PL

VQ.JV.A2.02 © Danfoss 12/2018

Q

6

Quick Guide ThermoDual®- S

D

C

B

A

51 2 3 4 6 7 8

E

HEL

DTA

SFV

FI

29

Z1

2

Fs

3

Z2

Z3

25

25

1

G

R

P

5

3

D

37

Z4

M

4

D

C

B

A

51 2 3 4 6 7 8

F

E

HEL

DTA

SFV

FI

29

Z1

2

Fs

3

Z2

Z3

25

25

1

Q

P

5

3

D

37

Z4

M

4

Now connection part (Q) and

charge pump (LPU) using the EPDM gaskets.

Notice! You should also ensure the correct

ow direction of the pump here (arrow pointing up).

Lastly, you can now screw the connecting pipe (R) between

the charge pump (LPU) and the lower ball valve (G) with the

appropriate EPDM gaskets inserted.

13

Q

LPU

14

Now, if all components are positioned vertically/

horizontally and relatively stress-free, tighten all screw

connections using suitable tools.

Notice! Do not use pipe wrench pliers; for one thing,

the nuts will be damaged and there is also the danger of

excessive tightening, which can destroy the gasket.

EPDM gaskets do not require a high torque to ensure

tightness (~ 10 .. max. 35 Nm).

See also chapter 5.1 in the

installation and operating instructions

It is best to manually tighten all screw connections and

correct when lling the system only until the respective

connection no longer leaks.

R

G

LPU

DHS-SMT L / PL

VQ.JV.A2.02 © Danfoss 12/2018

7

Quick Guide ThermoDual®- S

D

C

B

A

7 8

F

E

HEL

SFV

29

Z2

Z3

25

25

1

G

Q

P

5

3

Z4

M

4

Before installing the heat exchanger’s thermal insulation

(HEL), remove with a knife about 5 mm in the lower

area as shown in Figure 15 to ensure

the insulation above the bracket will close.

15

8

VQ.JV.A2.02

Produce d by Danfoss A/S © 12/2018

Loading...

Loading...