Quick Guide ThermoDual®-FLS

Transport / unpacking the system:

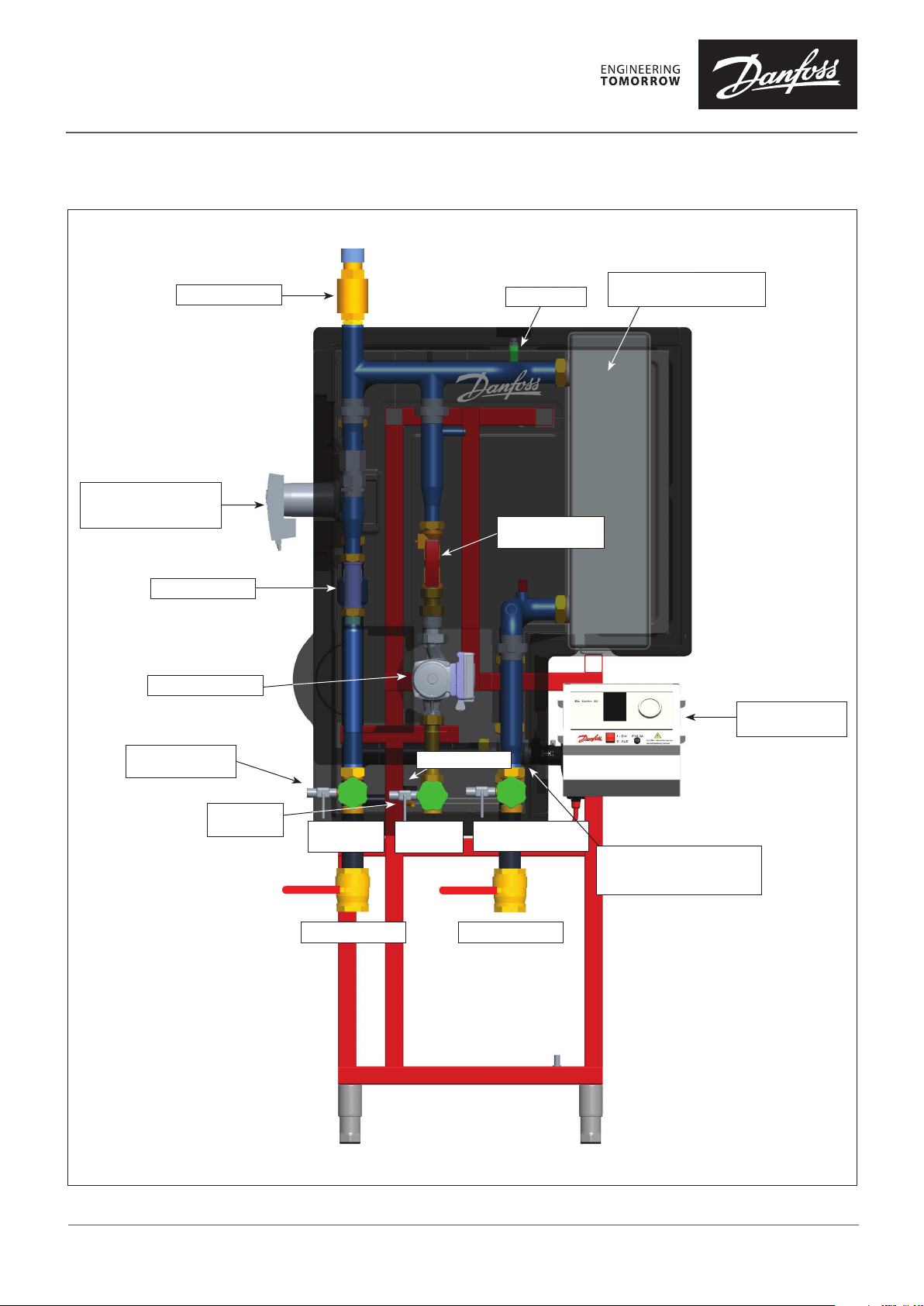

Heating pump

(only for 3-way-vale-

or pump control)

Flow sensor

Circulation pump

Safety valve

Air-vent

Balancing valve

(Taco-Setter)

Heat exchanger

(brazed)

Electronic

Controller

Drain

(Domestic water)

Drain

(Heating)

Domestic

water (cold)

Safety valve

Circulation

(Inlet)

Domestic hot water

(hot/network)

Heating supplyHeating return

Control valve

(only for 2-way-valve.

or 3-way-valve control)

DHS-SMT L / PL

VQ.MP.B1.02 © Danfoss 11/2018

1

Quick Guide ThermoDual®-FLS

Transport / unpacking the system:

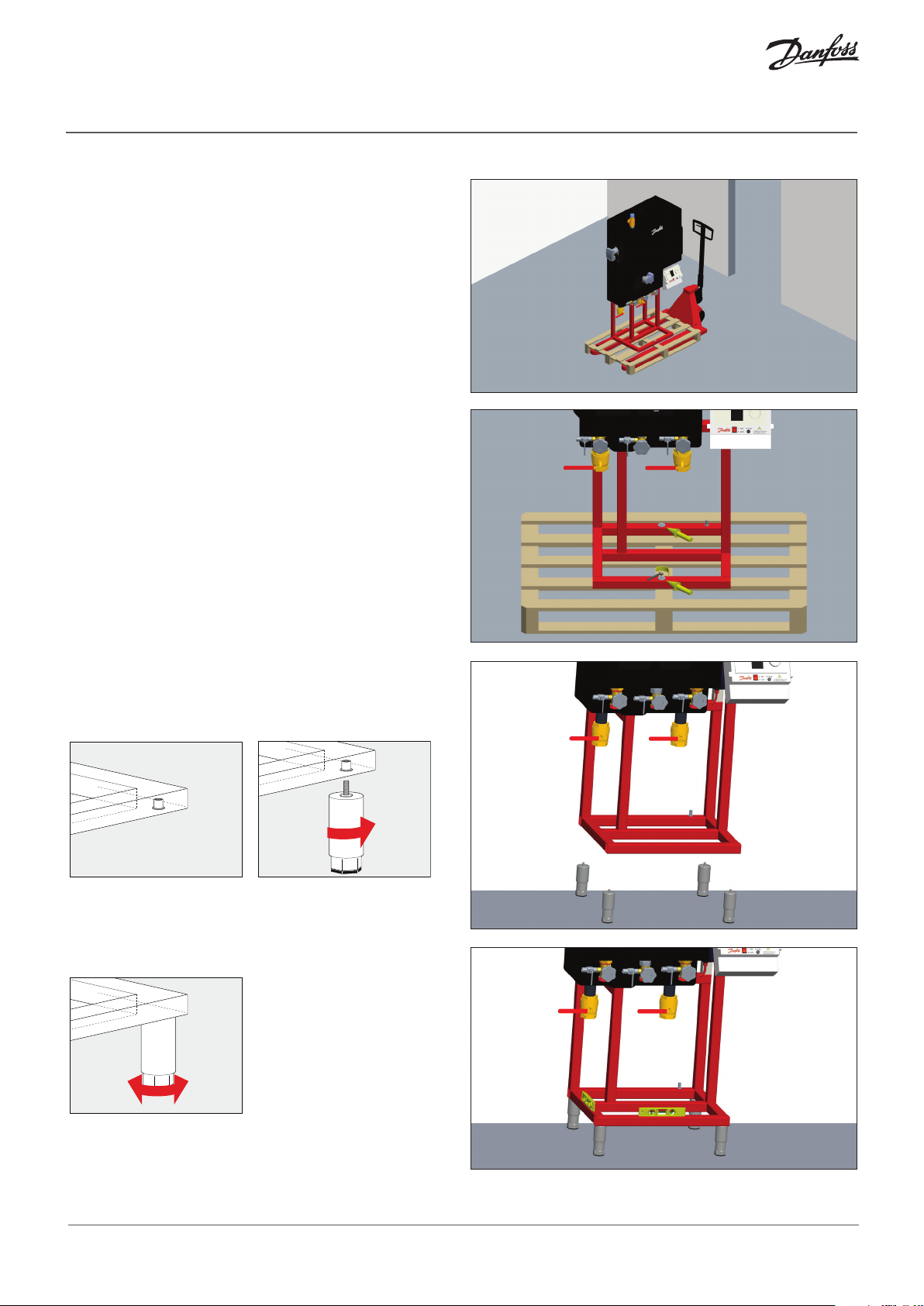

The system is delivered on a standard EUR-pallet. This

makes it easy to transport the product via a forklift

truck or pallet truck.

Remove the packaging (wooden crate/foil)

and dispose of it.

Then detach the system from the pallet;

this is fixed using 2 wooden screws.

Setting up the system:

Screw the height-adjustable, enclosed feet into the threads

beneath the frame:

Align the system horizontally by adjusting the height of the

feet, e.g. using a spirit level.

You can compensate for any unevenness of the installation

area by up to 50 mm:

For more uneven surfaces, it is first necessary to create

a level surface on site, e.g. a boiler platform or similar.

2

VQ.MP.B1.02 © Danfoss 11/2018

DHS-SMT L / PL

Quick Guide ThermoDual®-FLS

Connecting to the pipe network:

Once the system is correctly aligned at the installation site,

it can be connected to the pipe network.

Disassembly of the thermal insulation (cover):

The thermal insulation consists of 3 hard foam parts.

The back part with the left and top cover is firmly

connected to the stand frame:

In addition, pumps and valves are provided

with flexible covers.

First remove the flexible pump covers by carefully pulling

them out of the recesses of the insulating cover.

These are flexible and can be easily dismantled

by pressing them together.

DHS-SMT L / PL

VQ.MP.B1.02 © Danfoss 11/2018

3

Quick Guide ThermoDual®-FLS

The front cover can be pulled out to the front. This is

connected with the rear via multiple connectors (tongue

and groove). Pull the cover as far forward horizontally as

possible to avoid damaging the connections.

The lower end part can then be easily pulled down

obliquely since it is held only by a groove between the

front and back parts. The left wall can also be pulled

forward horizontally.

It is now possible to carry out inspection and maintenance

work on the system, such as replacing defective

components, checking for leaks or re-tightening screw

connections.

You can also check and/or regulate the flow of circulation

on the balancing valve (Taco setter) as shown

in the picture on the right:

The system can be drained after shutting off the 5 main

shut-off valves without removing the cover.

Further details can be found in the complete installation,

commissioning and operating instructions.

Reassembly of the thermal insulation:

The front insulation is installed in reverse order. Pay

particular attention to the correct positioning of the

connectors. Only when all tongue and groove connections

are correctly positioned should the front and back be

pressed together firmly.

4

VQ.MP.B1.02

Produce d by Danfoss A/S © 11/2018

Loading...

Loading...