Data sheet

ThermoDual®- FLS (welded type)

General Description / Use

Maximum operating

parameters

Primary

Maximum permissible supply temperature, primary

Maximum permissible operating pressure, primary

Rated pressure, primary

Maximum permissible pressure differential, primary

Secondary

Maximum permissible temperature, secondary

Maximum permissible operating pressure, secondary

Minimum required pressure (static), water supply

Rated pressure, secondary

Mains power supply / maximum power consumption

Domestic hot water provision by instantaneous

heater is an efficient and hygienic optimal solution.

Hot water is not stored and will be produced only

on request.

Habitats for bacteria,such as legionella are virtually

non-existent. If the conditions for connection of

these systems are given (sufficiently high capacity

on heating side to cover peak load) or buffer tanks

is present, these systems can be used unrestricted.

Significant advantages of the system are:

• no storage of drinking water

• efficient cooling of the primary media

• optimum use of energy

• independent choice of different energy sources

• at any time sufficiently high domestic hot water

temperature, that fulfils all hygienic requirements

• low space requirement

• lime scale is largely avoided

90°C / 150°C (without/with safety function)

10 / 20 bar(g)

PN10 / PN25

only 2-way valve variant: 25 bar (up to 210kW) /16 bar

90°C

10 bar(g)

1.0 bar(g)

PN10

230V AC / 4.0 A

Pumps and 3-way valve variant /

2-way valve variant

Materials

Code numbers

© Danfoss | 2019.08

Pipes, fittings, flanges, valves (domestic side)

ditto (heating side) P235GH-TC1, CuSn5Pb5Zn5-C (RG -5), ST37.0, EN-JL 1040 (GG25)

Heat exchanger 1.4404 with Cu solder

Insulation Hardcover PU hard foam λ=0.029 W/mK (100%ENEV)

Capacity

[ kW]

140 00 4X1814 00 4X1808 004X1653 0 04X1659

210 004X1815 004X1809 004X1654 004X1660

280 00 4X1816 00 4X1810 004X1655 004X1661

350 0 04X1817 00 4X1811 004X1656 00 4X1662

420 004X1818 004X1812 004X1657 00 4X1663

455 004X1819 0 04X1813 00 4X1658 004X1664

Pump +

3-way mixing valve

Pump control

(PWM control signal)

1.4571, bronze or brass as per DIN EN 1982,

also considering DIN 50930-06 and UBA guidelines

Code no.

2-way valve

(without safety function)

2-way valve

(with safety function)

VD.HE.J7.02 | 1

Data sheet ThermoDual®- FLS

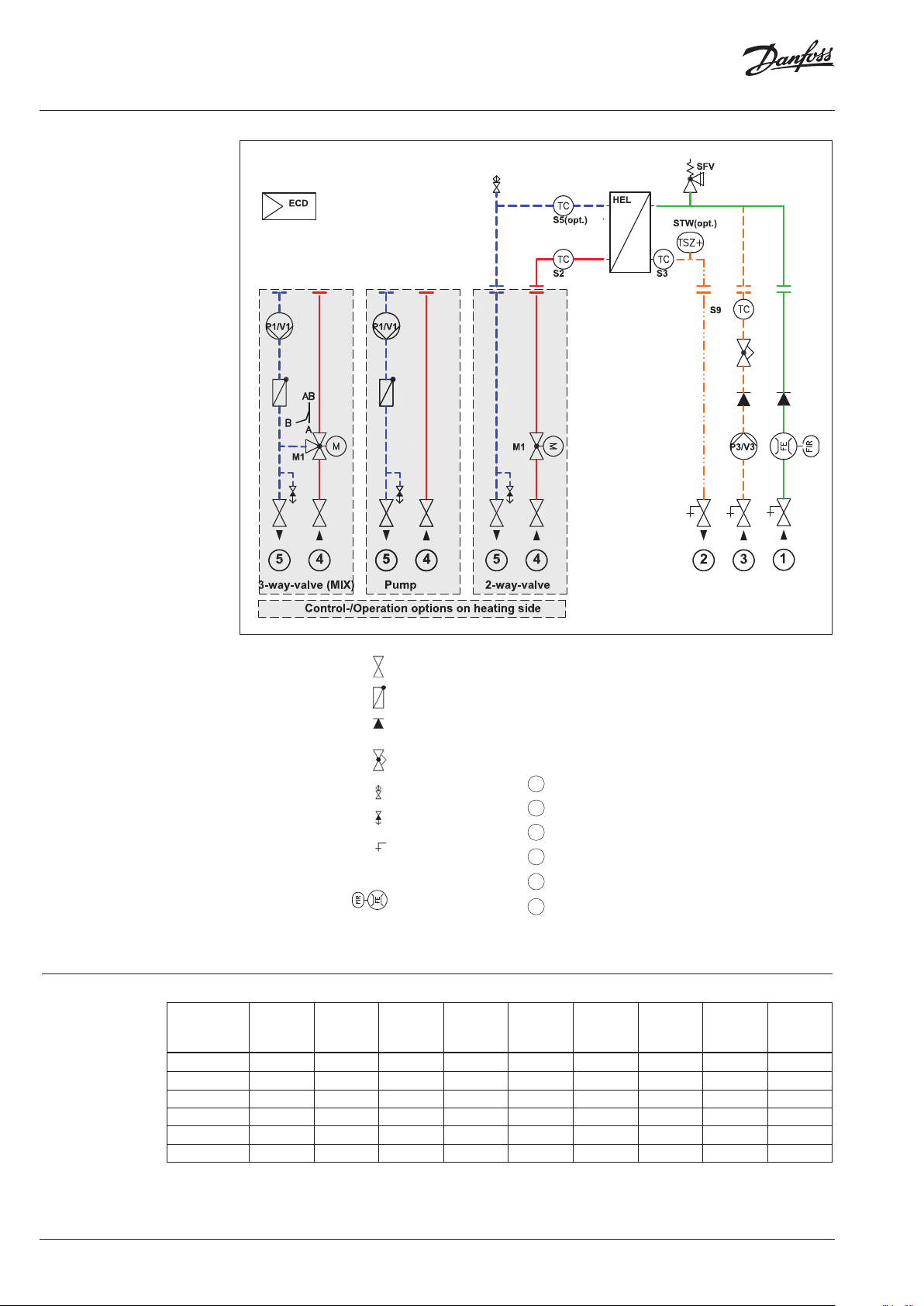

Circuit diagram

Technical data

HEL Heat exchanger

P1 Heating pump

P3 Circulation pump

SFV Safety valve

M1 Motorized control valve (2/3-way)

ECD Electronic domestic hot water controller (ECL310 / P318.10)

STW Safety thermostat (optional)

BTA Hot water buffer tank (installed by customer)

1 Domestic water (cold)

2 Domestic hot water (hot network)

3 Circulation (inlet)

4 Heating supply

5 Heating return

TC Sensors (general: direct , immersion, surface)

“S2”: with designation as for controller

3-way

dpr

[kPa]

FR

DW

(10 ->60 °C)

[m3/h]

DW

dp

[kPa]

*

FR

C

(55 ->60°C )

[m3/h]

Typ e

ThermoDual®

Capacity

[kW]

p

FR

(70 ->25° C)

[m3/h]

Shut-off valve

Non-return valve

Check valve

Balancing valve

Air vent

Drain

Drain, sampling valve

(optional)

F1: Flow sensor

Pump

dpr

[kPa]

2-way

dp

[kPa]

FLS 14 0 140 2,4 52 21 38 2,4 12 1,0 / 2,4 80 / 43

FLS 210 210 3,8 95 30 81 3,6 26 1,5 / 2,4 70 / 43

FLS 280 280 5,1 86 29 76 4,8 28 2,0 / 2,4 57 / 45

FLS 350 350 6,3 74 30 59 6,0 33 2,5 / 3,4 51 / 30

FLS 420 420 7,8 53 30 54 7,2 41 3,0 / 3,4 38 / 30

FLS 455 455 8,0 59 22 54 7, 8 39 3, 3 / 3,4 34 / 31

FR: Flow rate p: primary dpr: Remaining pump head dp: Pressure loss DW: Domestic water C: Circulation

* flow rate: standard setup / maximal possible

** remaining pump head for: standard setup / maximal possible

C

dpr**

[kPa]

2 | © Danfoss | 2019.08

VD.HE.J7.02

Data sheet ThermoDual®- FLS

Function

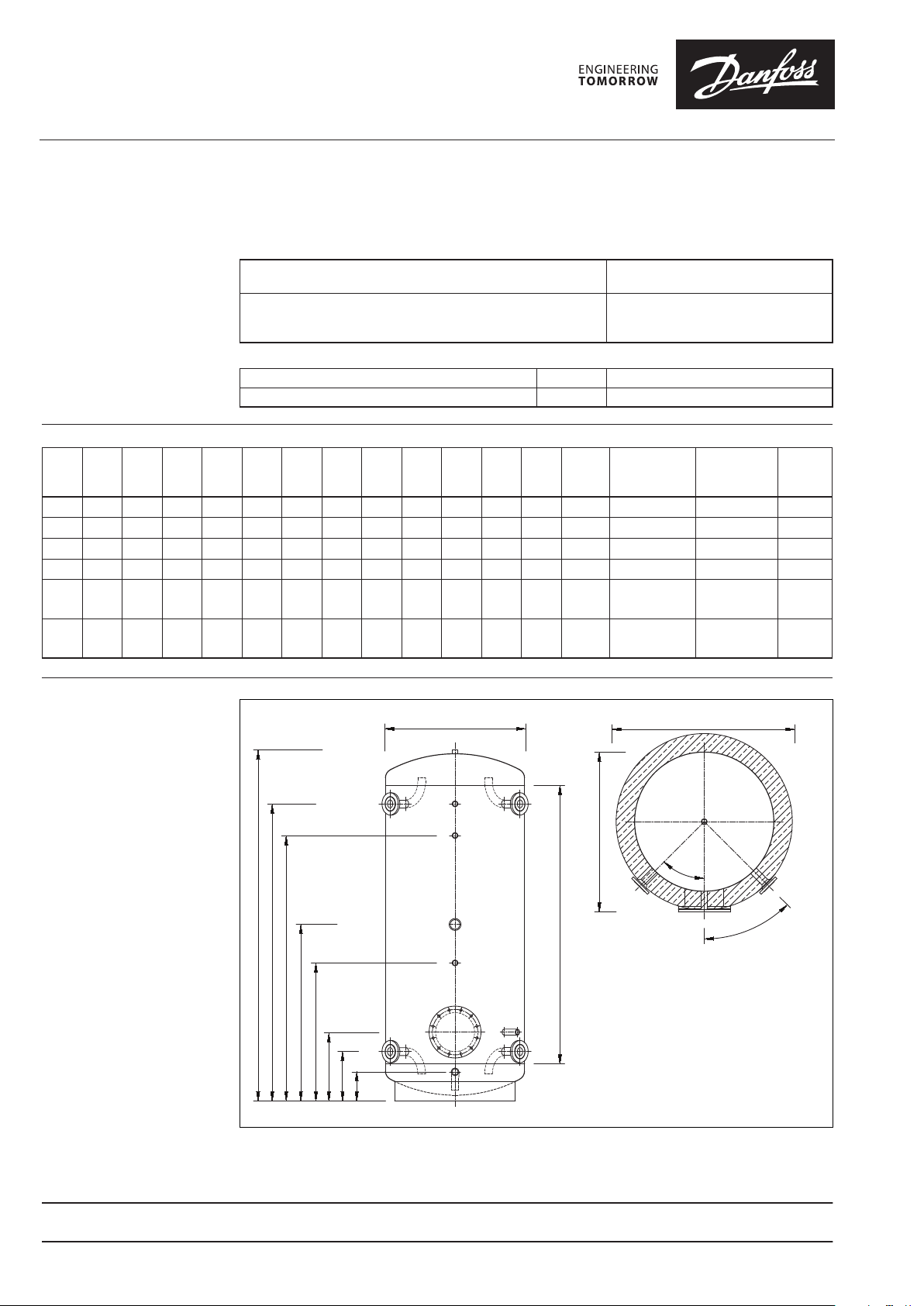

Dimensions

Flow systems provide heated domestic water when requested. By a heat exchanger (HEL), the cold

water flowing into connection (1) will be heated up to set point and provided to the consumer at the

connection (2). The electronic controller (ECD) is measuring the relevant temperatures and controls the

target values that are held constant in all operating conditions. This is i.e. achieved by influencing the

speed of the heating pump (P1), so that the outlet temperature always matches the specified value. In

case of using a control valve, the flow is directly controlled by an electrical actuator. Short-term peaks

in consumption are registered at the flow sensor to intervene quickly and avoid large temperature

fluctuations. The cooled- circulation water from the network (connection 3) is constantly heated in

heat exchanger (HEL), even in times of draw-off , reheated and the temperature control (sensor) in the

amount of the controlled circulation pump (P3) influenced so that only the necessary amount flows to

maintain constant power set point.

The capacity for the peak load is to ensure either by buffering heating water in a tank (BTA) or there

must be a sufficiently large connection value available. The Recharging of a buffer (e.g. from a boiler)

can a requisition (sensor / switch contact) on controller (ECD) using an on-site charging pump (LPU). The

operation of the system by a controlled heating pump (P1) is only possible without differential pressure

between the connections (4) and (5).

Connections: Weight [kg]

Typ e

ThermoDual®

FLS 14 0 1 ¼”A 1 ¼”A 1 ¼” 42,4 93 90 99

FLS 210 1 ¼”A 1 ¼”A 1 ¼” 42,4 96 93 10 0

FLS 280 1 ½”A 1 ¼”A 1 ½” 48,3 102 98 107

FLS 350 1 ½”A 1 ¼”A 1 ½” 48,3 107 102 111

FLS 420 1 ¾”A 1 ¼”A 2” 60,3 116 10 6 120

FLS 455 1 ¾”A 1 ¼”A 2” 60,3 122 112 126

DW C/H Circ.

1/2 G ISO 3 G ISO

HTG (DN)

SL, RL

4/5 PN10 Rp4/5 PN25

HTG (DN)

SL, RL

WELD

Pump +

3-way v.

Pump

control

(PWM)

2-w ay v.

935

132

338

488

1830

1

3

2

Correlation of connections

5

156 174 174

4

415

640

1 Domestic cold water

2 Domestic hot water

3 Circulation (inlet)

VD.HE.J7.02

110 –16 0

4 Heating supply line

5 Heating return line

© Danfoss | 2019.08 | 3

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet ThermoDual®- FLS

Accessories

Heating buffer storage tank, standing model,

Typ e: PSS

Charging-/Discharging Connections

as flange connection

Materials

Maximum operating

parameters

Typ e IH mmH1 mmH2 mmH3 mmH4 mmH5 mmH6 mmH7 mmHMa mmd mmDx mmD

300 1450 1270 1070 780 620 320 215 115 1130 550 660 710 1550 DN 25 / PN 16 640U4984 85

500 1860 1665 1430 990 650 350 245 145 155 0 600 710 800 2010 DN 40 / PN 16 640U4985 115

750 1870 1635 1400 1000 670 370 265 165 150 0 750 860 950 1945 DN 40 / PN 16 640U4986 175

1000 1910 1655 1370 1020 690 390 285 185 150 0 850 960 1050 2090 DN 50 / PN 16 640U4987 240

150 0 2030 1740 1505 1070 725 445 320 220 1550 1000 111 0 1200 2160 DN 50 / PN 16

2000 2 310 1995 175 0 12 20 770 510 375 265 1770 11 00 1210 130 0 2450 DN 65 / PN 16

tank (shell)

Insulation (from 1500 Liter as bypack/not mounted)

Maximum permissible operating temperature TZ 110 ° C

Maximum permissible operating pressure PZ 6 bar

mm

Steel EN 1.0025 S235JRG2

Raw inside, outside undercoat - black

Insulation, polyester fiber fleece + EPS

white, CFC-free,silver with

polypropylene top layer

Tilted

height mmconnections codes

640U4988

+ 640U4994

640U4989 +

640U4995

Weight

kg

325

375

d

24

4

H

H1

H2

H3

H4

H5

H6

5

H7

22

22

6

22

25

26

4

Dx

H max

4 Charging-/Discharging conn. supply (hot)

22

5

5 Charging-/Discharging conn. return (cold)

6 Solar conn. / Reserve El. Heater Rp 2“

22 Thermostat / Thermometer Rp 1/2“

24 Air Vent Rp 3/4“

25 Inspection, diameter opening

219 mm (DN200 / PN6)

26 Drain Rp 3/4“

D

45°

45°

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all Danfoss logot ypes are trademarks of Danfoss A/S. All rights reserved.

4 | © Danfoss | DHS-SDBT/PL | 2019.08

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

VD.HE.J7.02

Loading...

Loading...