Page 1

Fact sheet

Termix VVX-I with complete insulation

District heating substation for direct heating and instantaneous domestic hot water with flow-compensated temperature controller.

Application

The Termix VVX-I is a complete solution for

hot water and space heating with optimal

safety, efficient energy transfer, service-friendly

construction and a compact design. The substation

is used if a heat exchanger is required or on a

conversion to district heating where the existing

equipment is unsuitable for direct connection.

District heating (DH)

The substation is prefabricated with a differential

pres sure controller, fitting piece and sensor pockets

for insertion of an energy meter as well as strainers.

Heating (HE)

The heating side consists of a plate heat exchanger,

safety valve, manometer, drain valve, air valve,

expansion vessel and circulation pump. The

temperature of the heating can be controlled

thermostatically or by an electronic controller with

an outdoor temperature sensor. Depending on the

application, different heat exchangers dimensioned

for central or floor heating will be used.

Domestic hot water (DHW)

The domestic hot water is prepared in the heat

exchanger and the temperature is regulated with a

flow-compensated temperature controller with integrated differential pressure controller. The DH water is cooled very efficiently by the heat exchanger,

thereby creating an excellent operating economy.

The Termix TPV valve ensures a stable hot water

temperature by varying loads, supply temperatures and by high and varying differential pressure

without the need for readjusting the valve. This protects the heat exchanger against overheating and

lime scale formation. Furthermore the Termix TPV

valve has an integrated idle temperature controller, which keeps the house supply line warm. This

shortens the waiting periods during summer when

the heating system is in reduced operation, which

is ideal where high comfort is requested.

Options

The Termix VVX-I can be supplied with a built-in

safety valve mounted in the cold water supply. It

can also be supplied with a thermostatic circulation

valve.

Construction

All pipes are made of stainless steel. The

connections are made by nuts and gaskets.

Insulation:

The Termix VVX-I comes complete with a

fully insulated cover thus minimizing the

heat loss both during tapping of domestic

hot water but also when only space

heating is requiered.

FEATURES AND BENEFITS

• Substation for single and multi-family houses

• Indirect heating, DHW temperature regulation with a thermostatic control valve

• Thermostatic or electronic regulation of heating (HE)

temperature

• Capacity : 45 kW heating, 33-55 kW DHW

• DHW in sufficient quantity

• Operates independently of differential pressure and flow

temperature

• Minimum space required for installation

• Pipes and plate heat exchanger made of stainless steel

• Minimized risk of lime scale and bac teria formation•

• Optimum temperature regulation up to DH supply

temperature 100

•

Low heat loss

°C

www.danfoss.com

Page 2

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

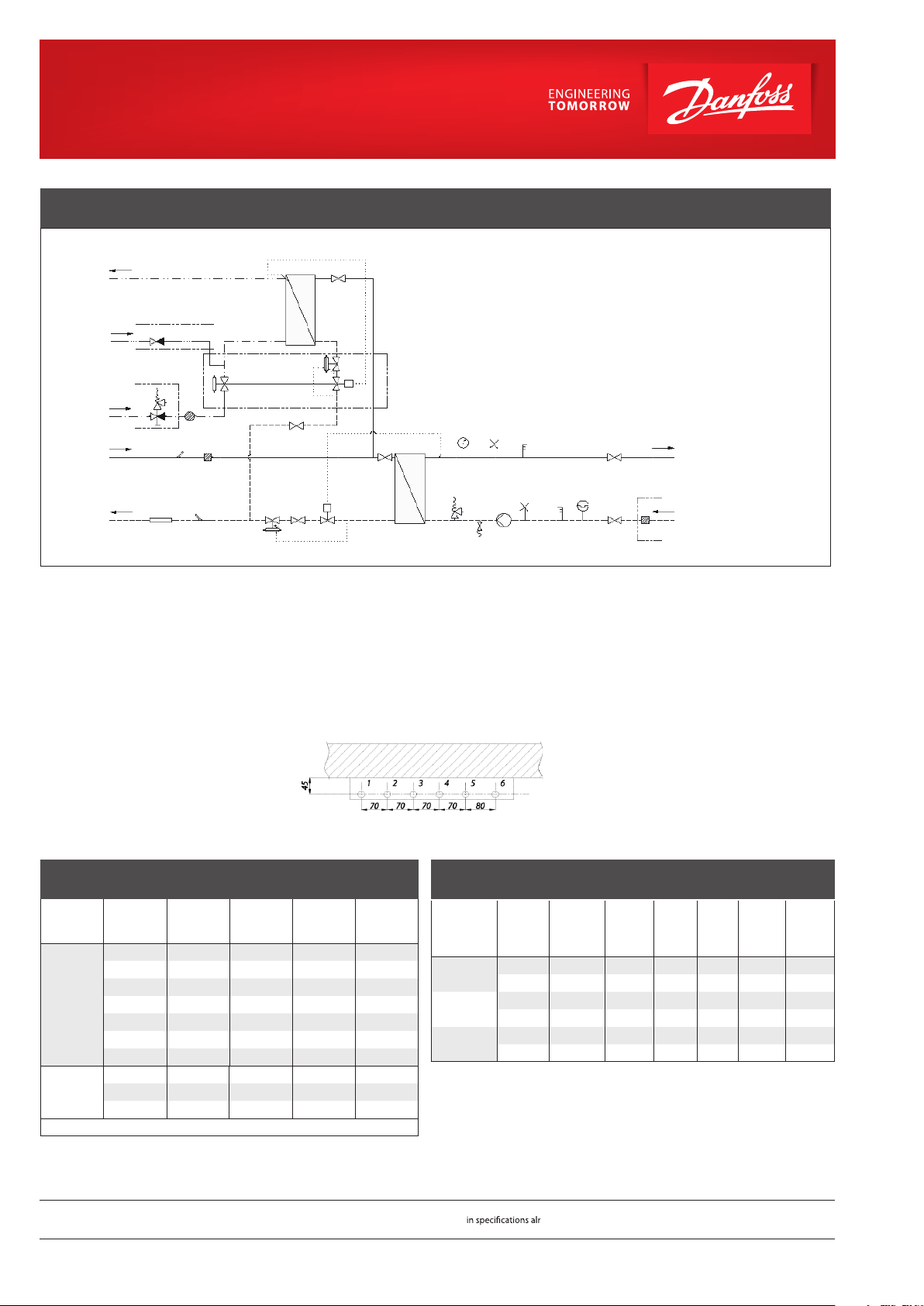

CIRCUIT DIAGRAM - EXAMPLES

DHW

21

21

42

63

14 9

14

41 31

Circ.

DCW

DH

supply

DH

return

2c

Technical parameters:

Nominal pressure: PN 10*

DH supply temperature: Tmax = 120°C

DCW static pressure: pmin = 1 bar

Brazing material (HEX): Copper

* PN 16 versions are available on enquiry

Weight incl. cover: 29 kg

(incl. packing)

Insulation: Anthracity grey EPP

1

B

1

7

1

74

1

Connections:

1 District heating (DH) supply

2 District heating (DH) return

3 Heating (HE) supply

4 Heating (HE) return

5 Domestic hot water (DHW)

6 Domestic cold water (DCW)

A Plate heat exchanger HE

B Plate heat exchanger DHW

1 Ball valve

2c Non-return valve

4 Safety valve

7 Thermostatic valve

9 Strainer

10 Circulation pump

14 Sensor pocket, heat meter

18 Thermometer

20 Filling/drain valve

21 To be ordered separately

4 bar

A

48 18

26

4

10

20

18

48

1

38

1

26 Manometer

31 Differential pressure

controller

38 Expansion vessel

41 Fitting piece, energy meter

42 Safety valve/non-return

valve

48 Air escape, manual

63 Sieve

74 IHPT valve

HE

supply

24

9

HE

return

Connections sizes:

All connections: G ¾” (int. thread)

Options:

• Booster pump (increases DH flow)

• Separate mixing circuit

• Safety valve (10 bar)

• Pressure compensation valve (GTU)

• Electronic controller

• Room thermostat

• Connection for circulation

• On/off zone valve

Dimensions (mm):

With insulation (mounted on wall variant):

H 800× W 530 × D 375

DHW: Capacity examples

Substation-

Typ e

VVX-I 1

VVX-I-2

*Heat meter not included

DHW

Capacity

Supply/Re-

kW

32.3 60/19.8 10/45 23 23

40.3 60/20.7 10/45 33 33

36.5 70/19.1 10/50 20 20

32.3 55/21.9 10/45 26 26

32.3 60/19.6 10/45 20 20

39.5 70/19 10/50 20 20

turn flow

Primary °C

55 70/21.5 10/50 39 39

38 55/22.2 10/45 34 34

47 60/19.6 10/45 34 34

59 70 10/50 34 34

DHW °C

DH W Tap

load l/h

Pressure

loss Primary

kPa*

Heating: Capacity examples

Substation-

Typ e

VVX-I x-1

VVX-I x-2

VVX-I x-3

Heating

Capacity

Supply/

Return

flow pri-

kW

mary °C

12 70/40 60/35 353 30 418 31

24 90/45 70/40 470 45 699 19

19 70/40 60/35 553 30 662 52

35 90/45 70/40 674 45 1019 30

31 70/40 60/35 906 30 1080 41

50 90/45 70/40 956 45 1455 25

Heating

Circuit

°C

Gemina Termix A/S · Member of the Danfoss Group · Navervej 15-17 · DK-7451 Sunds · Denmark

Tel.: +45 9714 1444 · Fax: +45 9714 1159 · mail@termix.dk · www.heating.danfoss.com

Flow

rate

primary

l/h

dp min

kPa

Flow

rate sec-

ondary

l/h

Residual

pump

head

kPa

© Danfoss | DHS-SRMT/ PL | 2016. 12

VL.HE.M2.02

Loading...

Loading...