Page 1

OperatingGuide

TermixDistributionunit

1.0TableofContents

1.0TableofContents.............................................1

2.0Functionaldescription......................................2

3.0Safetynotes.....................................................3

3.1SafetyNotes–general............................................3

4.0Mounting........................................................4

4.1Mounting...........................................................4

4.2Start-up..............................................................6

4.3Electricalconnections.............................................7

5.0Wiring.............................................................8

5.1Wiringdescription.................................................8

5.2Wiringdiagram.....................................................9

6.0Design.............................................................10

6.1Design...............................................................10

6.2Schematicdiagram................................................11

7.0Controls..........................................................12

7.1CirculatorpumpUPM3...........................................12

7.2GrundfosUPM3AUTOLinstructions...........................13

7.3Maintenance........................................................14

9.0Danfossinstallationsguide...............................19

9.1Danfossinstallationsguide......................................19

10.0Declaration......................................................23

10.1Declarationofconformity........................................23

8.0Troubleshooting..............................................15

8.1Troubleshootingingeneral......................................15

8.2TroubleshootingHE...............................................16

8.3Disposal.............................................................18

©Danfoss|2019.05VI.GP .O4.02/LUK40900|1

Page 2

OperatingGuideTermixDistributionunit

2.0Functionaldescription

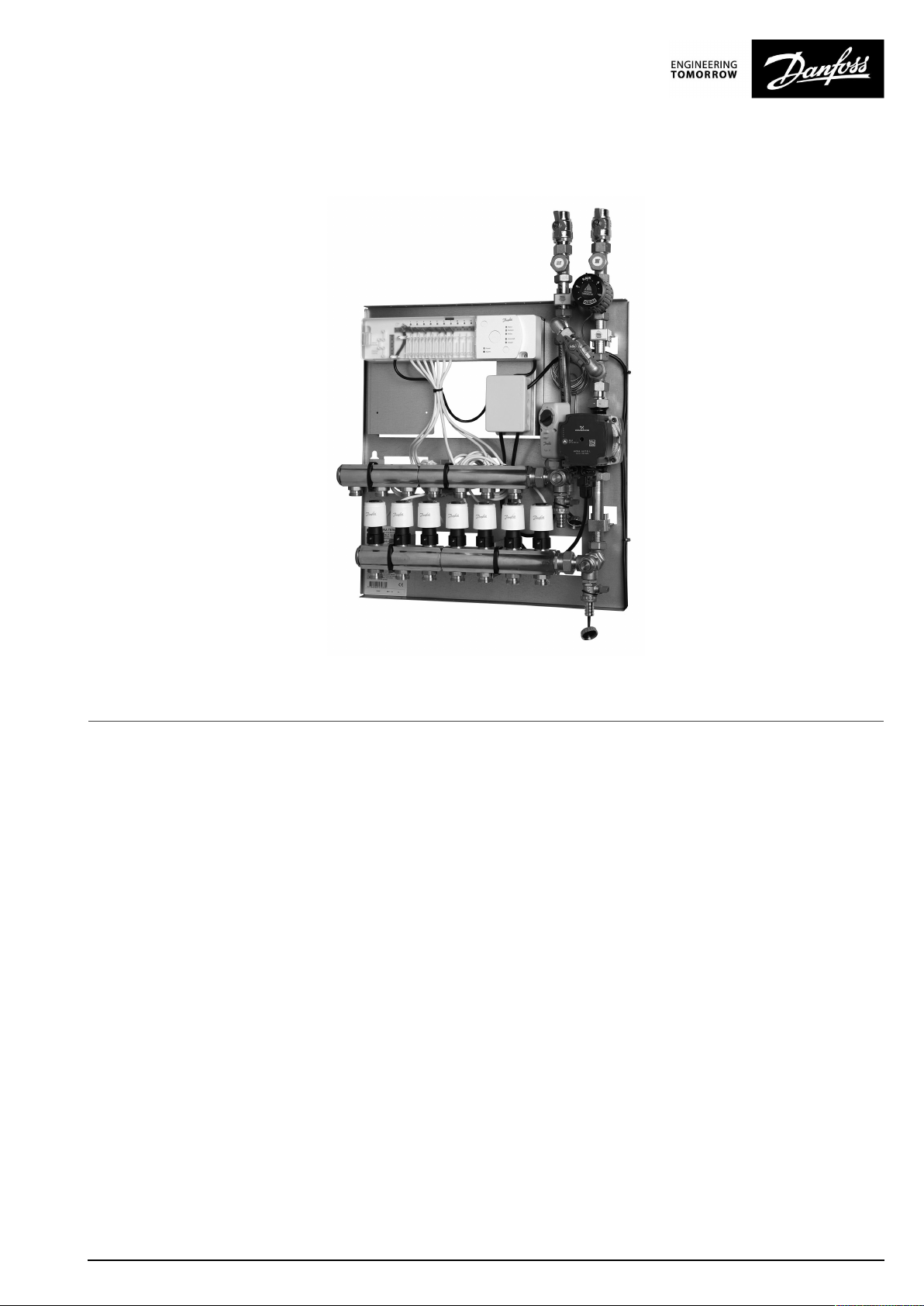

TermixDistributionunit

Manifoldsystemforfloorheating

TheT ermixdistributionunitcanbedirectlyconnectedtothe

TermixVMTD,VMTDmixer,VXandVVXunits.Theunitissupplied

withmeterfittingpiecefordomesticwater,safetysetorCombiluk

asrequired.

TheTermixdistributionunitforconnectionofwaterandheating

pipesinconnectionwithhiddenpipeinstallationsallowsforalarge

numberofconnectionsforcoldwater,hotwater,radiatorsandfloor

heatingwithindimensionsof530x565x380mm(hxwxd).The

compactsolutionensuresthateventhoughallconnectionsarein

usetheunitstillfitsintoa60cmcupboard.TheTermixdistribution

unitcanbemountedwithaspearinthegroundintheearlystages

ofbuilding.Whenthebuildingisfinishedandprotectedagainst

thefttheTermixdistrictheatingunitcanbemounted.

Thereliabilityisveryhigh.Thewirelesscontrolscomplywiththe

newestEUstandards(868MHz)forelectronicequipment.Atthis

frequencytheriskofsignaldisturbancesfromotherelectronic

householdappliancesisverylow.

ThecontrolsfortheT ermixdistributionunitincludeaprogram

forexerciseofvalvesandpumpandapumpstoptoprotectthe

circulationpump.

2|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 3

OperatingGuideTermixDistributionunit

3.0Safetynotes

3.1SafetyNotes–general

Thefollowinginstructionsrefertothestandarddesignof

substation.Specialversionsofsubstationsareavailableon

request.

Thisoperatingmanualshouldbereadcarefullybeforeinstallation

andstart-upofthesubstation.Themanufactureracceptsno

liabilityfordamageorfaultsthatresultfromnon-compliancewith

theoperatingmanual.Pleasereadandfollowalltheinstructions

carefullytopreventaccidents,injuryanddamagetoproperty.

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleasecomplywiththeinstructionsissuedbythesystem

manufacturerorsystemoperator.

Corrosionprotection

Allpipesandcomponentsaremadeofstainlesssteelandbrass.

Themaximumchloridecompoundsoftheflowmediumshouldnot

behigherthan150mg/l.

Theriskofequipmentcorrosionincreasesconsiderablyifthe

recommendedlevelofpermissiblechloridecompoundsis

exceeded.

Energysource

Thesubstationisdesignedfordistrictheatingastheprimary

sourceofenergy.However,alsootherenergysourcescanbeused

wheretheoperatingconditionsallowitandalwaysarecomparable

todistrictheating.

Application

Thesubstationisdesignedtobeconnectedtothehouse

installationinafrost-freeroom,wherethetemperaturedoesnot

exceed50°Candthehumiditydoesnotexceed60%.Donotcover

orwallupthesubstationorinanyotherwayblocktheentrance

tothestation.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleaseobserveinstructionscarefully

Toavoidinjurytopersonsanddamagetothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Warningofhighpressureandtemperature

Beawareoftheinstallation’spermissiblesystempressureand

temperature.

Themaximumtemperatureoftheflowmediuminthesubstationis

110°C.

Themaximumoperatingpressureofthesubstationis10bar.PN16

versionsareavailableonenquiry.

Theriskofpersonsbeinginjuredandequipmentdamagedincreases

considerablyiftherecommendedpermissibleoperatingparameters

areexceeded.

Thesubstationinstallationmustbeequippedwithsafetyvalves,

however,alwaysinaccordancewithlocalregulations.

Choiceofmaterial

Choiceofmaterialsalwaysincompliancewithlocallegislation.

Safetyvalve(s)

Werecommendmountingofsafetyvalve(s),however,alwaysin

compliancewithlocalregulations.

Connection

Thesubstationmustbeequippedwithfeaturesthatensurethat

thesubstationcanbeseparatedfromallenergysources(also

powersupply).

Emergency

Incaseofdangeroraccidents-fire,leaksorotherdangerous

circumstances-interruptallenergysourcestothestationif

possible,andseekexperthelp.

Incaseofdiscolouredorbad-smellingdomestichotwater,closeall

shut-offvalvesonthesubstation,informtheoperatingpersonnel

andcallforexperthelpimmediately.

REACH

AllDanfossA/SproductsfulfilltherequirementsinREACH.

OneoftheobligationsinREACHistoinformcustomersabout

presenceofCandidatelistsubstancesifany,weherebyinform

youaboutonesubstanceonthecandidatelist:Theproduct

containsbrasspartswhichcontainslead(CASno:7439-92-1)ina

concentrationabove0.1%w/w.

Storage

Anystorageofthesubstationwhichmaybenecessarypriorto

installationshouldbeinconditionswhicharedryandheated.

Warningofhotsurface

Thesubstationhasgothotsurfaces,whichcancauseskinburns.

Pleasebeextremelycautiousincloseproximitytothesubstation.

Powerfailurecanresultinthemotorvalvesbeingstuckinopen

position.Thesurfacesofthesubstationcangethot,whichcancause

skinburns.Theballvalvesondistrictheatingsupplyandreturnshould

beclosed.

Warningoftransportdamage

Beforesubstationinstallation,pleasemakesurethatthesubstation

hasnotbeendamagedduringtransport.

IMPORTANT-Tighteningofconnections

Duetovibrationsduringtransportallflangeconnections,screwjoints

andelectricalclampandscrewconnectionsmustbecheckedand

tightenedbeforewaterisaddedtothesystem.Afterwaterhasbeen

addedtothesystemandthesystemhasbeenputintooperation,

re-tightenALLconnections.

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|3

Page 4

OperatingGuideTermixDistributionunit

4.0Mounting

4.1Mounting

Installationmustbeincompliancewithlocalstandardsand

regulations.

Districtheating(DH)-Inthefollowingsections,DHreferstothe

heatsourcewhichsuppliesthesubstations.Avarietyofenergy

sources,suchasoil,gasorsolarpower,couldbeusedasthe

primarysupplytoDanfosssubstations.Forthesakeofsimplicity,

DHcanbetakentomeantheprimarysupply.

Connections:

Floorheatingflowline(FHFL)

Floorheatingreturnline(FHRL)

Connectionsizes:

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

FHFL+FHRL:

Dimensions(mm):

H710xW505xD175

Weight(approx.):20kg

G¾”(int.thread)

4|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 5

OperatingGuideTermixDistributionunit

4.1.1Installation

Mounting:

Adequatespace

Pleaseallowadequatespacearoundthesubstationformounting

andmaintenancepurposes.

Orientation

Thestationmustbemountedsothatcomponents,keyholes

andlabelsareplacedcorrectly.Ifyouwishtomountthestation

differentlypleasecontactyoursupplier.

Drillings

Wheresubstationsaretobewall-mounted,drillingsareprovided

inthebackmountingplate.Floormountedunitshavesupport.

Labelling

Eachconnectiononthesubstationislabelled.

Beforeinstallation:

Cleanandrinse

Priortoinstallation,allsubstationpipesandconnectionsshouldbe

cleanedandrinsed.

Keyholeformounting.

Tightening

Duetovibrationduringtransport,allsubstationconnectionsmust

becheckedandtightenedbeforeinstallation.

Unusedconnections

Unusedconnectionsandshut-offvalvesmustbesealedwitha

plug.Shouldtheplugsrequireremoval,thismustonlybedoneby

anauthorizedservicetechnician.

Installation:

Strainer

Ifastrainerissuppliedwiththestationitmustbefittedaccording

toschematicdiagram.Pleasenotethatthestrainermaybe

suppliedloose.

Connections

Internalinstallationanddistrictheatingpipesconnectionsmustbe

madeusingthreaded,flangedorweldedconnections.

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|5

Page 6

OperatingGuideTermixDistributionunit

4.2Start-up

Start-up,Heatingwithmixingloop

Start-up:

1:Pumpspeed

Setthepumptohighestspeedbeforestart-up.

2:Startpump

Startthepumpandheatthroughthesystem.

3:Openshut-offvalves

Theshut-offvalvesshouldthenbeopenedandtheunitobserved

asitentersservice.Visualcheckingshouldconfirmtemperatures,

pressures,acceptablethermalexpansionandabsenceofleakage.

Ifthesystemoperatesinaccordancewithdesign,itcanbeput

toregularuse.

4:Ventsystem

Switchoffthepumpandventtheinstallationaftertheradiators

havebeenwarmedup.

5:Adjustpumpspeed

Setthepumptothelowestspeedconsistentwithcomfortand

electricityconsumption.

Normallythechange-overswitchissetinthemidposition(default).

Howeverforsystemswithunderfloorheatingorsinglepipeloop

systems,itmaybenecessarytoturnthechange-overswitch

upwards.

Higherpumpspeedsareonlyusediftheheatingrequirement

increases.

Re-thightenconnections

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

Pump

Thepumpmustbeswitchedoffduringsystemfill.

Underfloorheating:

Pumpstopfunction

Ifthesubstationisusedinconnectionwithunderfloorheating,the

circulationpumpmustbeconnectedtothepumpstopfunctionin

theunderfloorheatingcontroller.Thepumpmustbestoppedif

allunderfloorheatingcircuitsareclosed.

Warranty

Ifthisisnotpossible,thenflowmustbecontinuedthroughthe

by-pass.Failingthis,thepumpwillbeatriskofseizureandany

remainingwarrantywillbewithdrawn.

Summeroperation:

Switchoffpump

Insummerthecirculationpumpmustbeswitchedoffandthe

shut-offvalvetoHEsupplyclosed.

Runningpumpbi-weekly

Itisrecommendedtostartupthecirculationpump(for2minutes)

onceamonthduringsummer;theshut-offvalveoftheHEsupply

mustbeshut.

Electroniccontroller

Mostelectroniccontrollerswillstartupthepumpautomatically

(pleasenotemanufacturer´sinstructions).

6|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 7

OperatingGuideTermixDistributionunit

4.3Electricalconnections

Beforemakingelectricalconnections,pleasenotethe

following:

Safetynotes

Pleasereadtherelevantpartsofthesafetynotes.

230V

Thesubstationmustbeconnectedto230VACandearth.

Potentialbonding

Potentialbondingshouldbecarriedoutaccording

to60364-4-41:2007andIEC60364-5-54:2011.

Bondingpointonthemountingplatebelowrightcornermarked

withearthsymbol.

Disconnection

Thesubstationmustbeelectricallyconnectedsothatitcanbe

disconnectedforrepairs.

Outdoortemperaturesensor

Outdoorsensorsshouldbemountedsoastoavoidexposureto

directsunlight.Theyshouldnotbeplacedclosetodoors,windows

orventilationoutlets.

Theoutdoorsensormustbeconnectedtothestationonthe

terminalblockundertheelectroniccontrol.

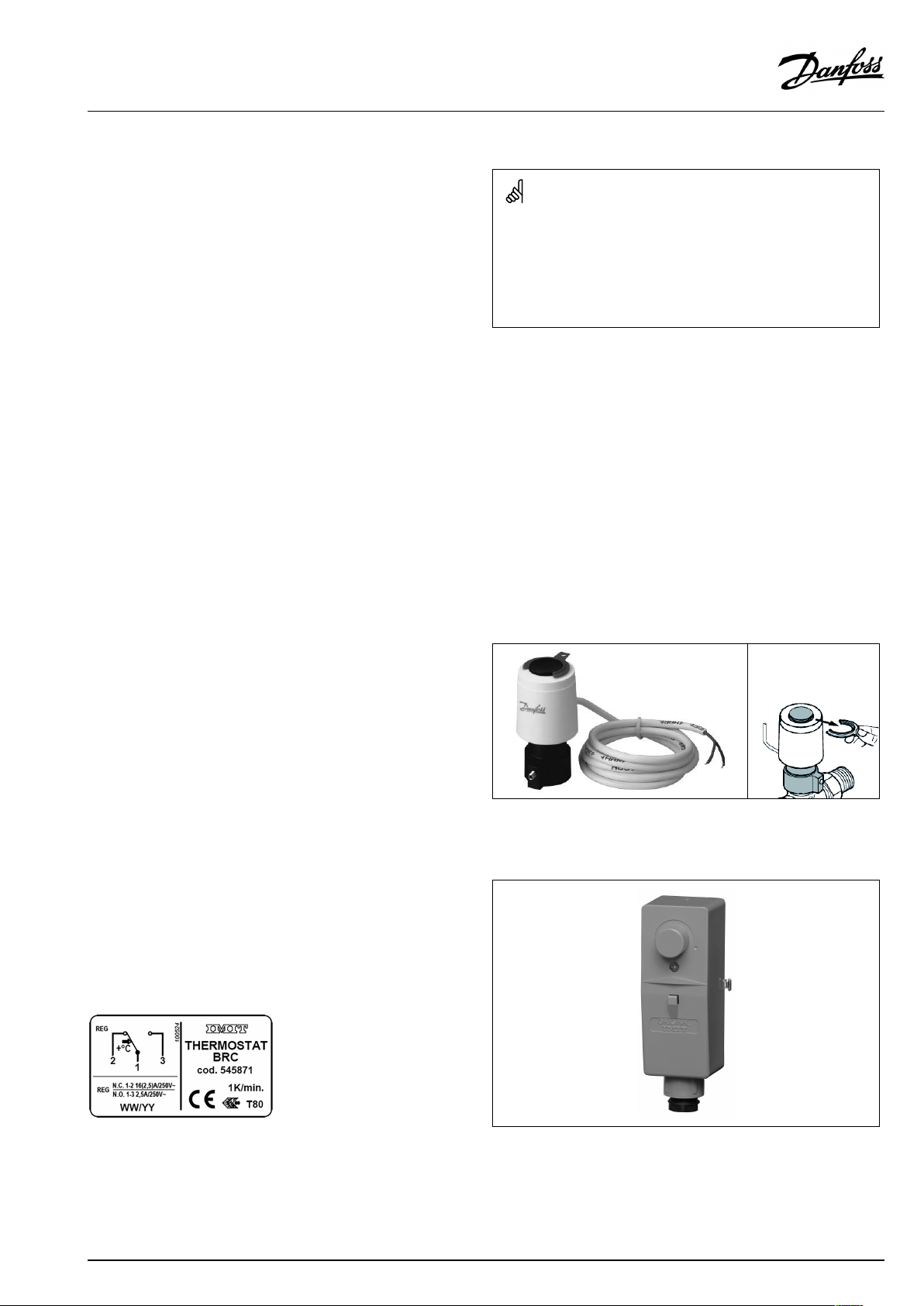

4.3.1Thermoactuators

Activatingthethermoactuators

Thethermoactuatorsaresuppliedwitha“firstopen”function,such

thattheyareslightlyopenforfrostprotectionuntiltheelectrical

controllerisinstalled.Duringcommissioning,the“firstopen”

functionisdisabledbyremovingtheredmountingsplitonthe

thermoactuator.

Pleasecheckthatthethermoactuatorscanfullyclosefollowing

disablementofthe“-firstopen”function.

Seetheinstallationguideincludedwiththethermoactuator.

Authorizedelectrician

Electricalconnectionsmustbemadebyanauthorizedelectricianonly.

Localstandards

Electricalconnectionsmustbemadeinaccordancewithcurrent

regulationsandlocalstandards.

4.3.2IMITThermostat

IMITThermostat

TheIMITThermostatisusedtolimittheunderfloorheatingflow

temperature.TheIMITThermostatispresetto60°C,shutting

offthepumpandtheprimaryon/offvalvewhentheflowtothe

underfloorheatingexceeds60°C.

TheIMITThermostatis(ifnotalreadyfactory-fitted)tobefittedon

thesecondaryflowpipeasclosetotheheatinginterfaceunitas

possibleusingthesteelbandprovided.

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|7

Page 8

OperatingGuideTermixDistributionunit

5.0Wiring

5.1Wiringdescription

Connectingthesystem’ scirculationpump

Thesystem’scirculationpumpshouldbeconnectedtothe

contactrelayintheelectricalfloorheatingcontroller,sothe

pumpcanautomaticallystartandstop,dependingonwhether

thethermoactuatorsareopenorclosed.Ifthepumppushes

againstclosedvalvesitcanoverheatandburnout.Theelectric

floorheatingcontrollerisnotapprovedtosupplypowertothe

circulationpump.

Thepumpmustthereforebesuppliedfromanexternalconnection

box,suchthatonlythe230Vphase(active)isfedthroughtherelay

contactontheelectricalfloorheatingcontroller.

Theneutralandearthconnectionsmustnotenterthefloorheating

controller.

8|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 9

OperatingGuideTermixDistributionunit

5.2Wiringdiagram

230VACconnector

plugwithEarth

Junctionbox

DanfossCF-MC

MasterController

230VACpower

supply230Vplug

iscutoff!

Safetythermostat

PumpRelayin

DanfossCF-MC

MasterController

Circulatorpump

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|9

Page 10

OperatingGuideTermixDistributionunit

6.0Design

6.1Design

Yoursubstationmightlookdifferentthanthesubstationshown.

Designdescription

J

Electroniccontrollerfloorheating

M

Electricalwiringbox

7

Thermostaticcontroller,HE

10

Circulationpump

20

Filling/drainvalve

10|©Danfoss|2019.05

35

Ballvalve/non-returnvalve

48

Airvent,manual

55

Thermoactuator

60

Thermostat

FHFL

Manifoldsystemforfloorheatingflowline

FHRL

Manifoldsystemforfloorheatingreturnline

VI.GP .O4.02/LUK40900

Page 11

OperatingGuideTermixDistributionunit

6.2Schematicdiagram

Yoursubstationmightlookdifferentthantheschematicdiagramshown.

Schematicdescription

(A)

Termixunit

(B)

Floorheatingflowline

(C)

Floorheatingreturnline

(M)

Electricalwiringbox

6.2.1Technicalparameters

Technicalparameters

Nominalpressure:PN10(PN16versionsareavailableonenquiry)

Max.DHsupplytemperature:

Min.DCWstaticpressure:

Brazingmaterial(HEX):

Soundlevel:≤55dB

110°C

0.5bar

Copper

J

Electroniccontrollerfloorheating

1

Ballvalve

7

Thermostaticvalve

10

Circulatorpump

20

Filling/drainvalve

35

Ballvalve/non-returnvalve

39

Connectionclosed

48

Airvent,manual

55

Thermoactuator

60

Thermostat

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|11

Page 12

OperatingGuideTermixDistributionunit

7.0Controls

7.1CirculatorpumpUPM3

UPM3Pumpscanbecontrolledinconstantpressure,proportional

pressureorconstantspeedmodedefinedbythemeansofasmart

userinterface.

Thevariablespeedmodulatingmodesallowthepumptomatchits

performancetothesystemrequirements,helpingtoreducenoise

whenthermostaticvalvesareclosingdown.

EnergylabellingclassA

12|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 13

OperatingGuideTermixDistributionunit

7.2GrundfosUPM3AUTOLinstructions

Controlmode

Youcanswitchfromtheperformanceviewtothesettingsviewbypressingthepushbutton.Thesettingsviewshowswhichmode

controlsthecirculator.After2seconds,thedisplayswitchesbacktoperformanceview.

Ifyoupressthebuttonfor2to10seconds,theuserinterfaceswitchesto"settingselection"iftheuserinterfaceisunlocked.Youcan

changethesettingsastheyappear.Theselectionofthecontrolmodedependsonthesystemtypeandtheallocationofpressurelosses.

Ifyoupressthekeylockformorethan10seconds,youcantogglebetweenenabling/disablingthekeylockfunction.

Function

Proportionalpressure1

Proportionalpressure2

Proportionalpressure3

Constantpressure1

Constantpressure2

Constantpressure3

ConstantCurve1

ConstantCurve2

ConstantCurve3

ConstantCurveMax.

Operationstatus

Function

Standby**OnlyPWMcontrolled

0%≤P1≤25%

25%≤P1≤50%

50%≤P1≤75%

75%≤P1≤100%

Recommendedfor

2-pipesystems

1-pipesystems

Underfloorheating

Green

��

���

����

��

���

����

���

����

�����

����

Green

�

��

���

����

�����

YellowYellowYellowYellow

YellowYellowYellowYellow

Alarmstatus

Function

Blocked

Supplyvoltagelow

Electricalerror

RedYellowYellowYellowYellow

��

��

��

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|13

Page 14

OperatingGuideTermixDistributionunit

7.3Maintenance

Thesubstationrequireslittlemonitoring,apartfromroutine

checks.Itisrecommendedtoreadtheenergymeteratregular

intervals,andtowritedownthemeterreadings.

RegularinspectionsofthesubstationaccordingtothisInstruction

arerecommended,whichshouldinclude:

Strainers

Cleaningofstrainers.

Meters

Checkingofalloperatingparameterssuchasmeterreadings.

Temperatures

Checkingofalltemperatures,suchasDHsupplytemperatureand

DHWtemperature.

Connections

Checkingallconnectionsforleakages.

Safetyvalves

Theoperationofthesafetyvalvesshouldbecheckedbyturning

thevalveheadintheindicateddirection.

Venting

Checkingthatthesystemisthoroughlyvented.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Inspectionsshouldbecarriedoutminimumeverytwoyears.

SparepartscanbeorderedfromDanfoss.Pleaseensurethatany

enquiryincludesthesubstationserialnumber.

14|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 15

OperatingGuideTermixDistributionunit

8.0Troubleshooting

8.1Troubleshootingingeneral

Intheeventofoperatingdisturbances,thefollowingbasicfeatures

shouldbecheckedbeforecarryingoutactualtroubleshooting:

•thesubstationisconnectedtoelectricity,

•thestrainerontheDHsupplypipeisclean,

•thesupplytemperatureoftheDHisatthenormallevel

(summer,atleast60°C-winter,atleast70°C),

•thedifferentialpressureisequaltoorhigherthanthenormal

(local)differentialpressureintheDHnetwork–ifindoubt,ask

theDHplantsupervisor,

•pressureonthesystem-checktheHEpressuregauge.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|15

Page 16

OperatingGuideTermixDistributionunit

8.2TroubleshootingHE

ProblemPossiblecauseSolution

Toolittleornoheat.StrainercloggedinDHorHEcircuit

Unevenheatdistribution.Airpocketsinthesystem.Venttheinstallationthoroughly.

DHsupplytemperaturetoohigh.

DHsupplytemperaturetoolow.

(radiatorcircuit).

ThefilterintheenergymeteronDHcircuit

clogged.

Defectiveorwronglyadjusteddifferential

pressurecontroller.

Sensordefective–orpossiblydirtinthe

valvehousing.

Automaticcontrols,ifany,wronglysetor

defective-possiblypowerfailure.

Pumpoutofoperation.Checkifthepumpisreceivingpowerand

Thepumpissetattoolowspeedof

rotation.

Pressuredrop–thepressuredropon

theradiatorcircuitshowslowerthan

recommendedoperatingpressure.

Airpocketsinthesystem.Venttheinstallationthoroughly.

Limitingofthereturntemperatureadjusted

toolow.

Defectiveradiatorvalves.

Unevenheatdistributioninbuilding

becauseofincorrectlysetbalancingvalves,

orbecausetherearenobalancingvalves.

Diameterofpipetosubstationtoosmallor

branchpipetoolong.

Wrongsettingofthermostatorof

automaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongsettingofautomaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongplacement/fittingofoutdoor

temperaturesensor.

Strainerclogged.Cleangate/strainer.

Cleangate/strainer(s).

Cleanthefilter(afterconsultingtheDH

plantoperator).

Checktheoperationofthedifferential

pressurecontroller–cleanthevalveseatif

required.

Checktheoperationofthethermostat–

cleanthevalveseatifrequired.

Checkifthesettingofthecontroller

iscorrect–seeseparateinstructions.

Checkthepowersupply.Temporary

settingofmotorto“manual”control–see

instructionsonautomaticcontrols.

thatitturns.Checkifthereisairtrappedin

thepumphousing–seepumpmanual.

Setthepumpathigherspeedofrotation.

Fillwateronthesystemandcheckthe

functioningofthepressureexpansion

vesselifrequired.

Adjustaccordingtoinstructions.

Check–replace.

Adjust/installbalancingvalves.

Checkpipedimensions.

Adjustautomaticcontrols,–see

instructionsforautomaticcontrols.

Callautomaticcontrolsmanufactureror

replacetheregulator.

Replacethermostat–orsensoronly.

Adjustautomaticcontrols–seeinstructions

forautomaticcontrols.

Callinautomaticcontrolsmanufactureror

replacecontroller.

Replacethermostat–orsensoronly.

Adjustlocationofoutdoortemperature

sensor.

16|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 17

OperatingGuideTermixDistributionunit

ToohighDHreturntemperature.

Noiseinsystem.

Heatloadtoohigh.

Toosmallheatingsurface/toosmall

radiatorscomparedtothetotalheating

requirementofthebuilding.

Poorutilizationofexistingheatingsurface.

Defectivesensoronself-actingthermostat.

Thesystemissinglepipeloop.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Airinsystem.

Defectiveorincorrectlysetradiatorvalve(s).

Singlepipeloopsystemsrequirespecial

one-piperadiatorvalves.

Dirtinthemotorizedvalveorinthe

differentialpressurecontroller.

Defectivemotorizedvalve,sensoror

automaticcontroller.

Electroniccontrollernotadjustedcorrectly.Adjustaccordingtoinstructions.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Defectivemotorizedvalve,sensoror

electroniccontroller.

Increasetotalheatingsurface.

Makesuretheheatisdistributedevenly

acrossthefullheatingsurface–openall

radiatorsandkeeptheradiatorsinthe

systemfromheatingupatthebottom.It

isextremelyimportanttokeepthesupply

temperaturetotheradiatorsaslowas

possible,whilemaintainingareasonable

levelofcomfort.

Thesystemshouldfeatureelectronic

controlsaswellasreturnsensors.

Ventthesystem.

Check–set/replace.

Check–cleanout.

Check–replace.

Check–replace.

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|17

Page 18

OperatingGuideTermixDistributionunit

8.3Disposal

Disposal

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

18|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 19

OperatingGuideTermixDistributionunit

9.0Danfossinstallationsguide

9.1Danfossinstallationsguide

Installation-CF2

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|19

Page 20

OperatingGuideTermixDistributionunit

Installation-CF2

Installation-CF2

20|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 21

OperatingGuideTermixDistributionunit

21|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 22

OperatingGuideTermixDistributionunit

22|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Page 23

OperatingGuideTermixDistributionunit

10.0Declaration

10.1Declarationofconformity

Category0withelectricalequipment

VI.GP .O4.02/LUK40900

©Danfoss|2019.05|23

Page 24

OperatingGuideTermixDistributionunit

24|©Danfoss|2019.05

VI.GP .O4.02/LUK40900

Loading...

Loading...