Page 1

OperatingGuide

TermixCompact28VMTD-FI

1.0TableofContents

1.0TableofContents.............................................1

........................................................................2

2.0Functionaldescription......................................3

3.0Safetynotes.....................................................4

3.1SafetyNotes–general............................................4

4.0Mounting........................................................5

4.1MountingtheCompactstation..................................5

4.2Start-up..............................................................14

4.3Electricalconnections.............................................15

5.0Design.............................................................16

5.1Design...............................................................16

5.2Schematicdiagram................................................17

6.0Controls..........................................................18

6.1Heatingcircuit......................................................18

6.2DHWtemperaturecontrol........................................21

6.3Other.................................................................23

6.4Maintenance........................................................24

7.0Troubleshooting..............................................25

7.1Troubleshootingingeneral......................................25

7.2TroubleshootingDHW............................................26

7.3TroubleshootingHE...............................................27

7.4Disposal.............................................................29

8.0Declaration......................................................31

8.1Declarationofconformity........................................31

©Danfoss|2019.01VI.LZ.I2.02/LUK42263|1

Page 2

OperatingGuideTermixCompact28VMTD-FI

2|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 3

OperatingGuideTermixCompact28VMTD-FI

2.0Functionaldescription

Districtheatingsubstationfordirectheatingand

instantaneousdomestichotwater.

Spaceheatinganddomestichotwater(DHW)

TheT ermixCompact28VMTD-FIisacompleteunitforspace

heatinganddomestichotwaterfordirectdistrictheatinginlarge

buildingssuchassportscentres,schools,blocksofflatsetc.

Efficientheatexchanger

Thesubstationisfittedwithanefficientplateheatexchanger,

whichensuresthemostfavourableheatextractionandachieves

optimumcomfortandoperatingeconomy.

Electronicregulation

TheTermixCompact28VMTD-FIisbuiltwithaplateheat

exchangerfordomestichotwateranddirectsystemregulationfor

spaceheating.Theelectroniccontrolispre-setfromthefactory.

Electricalcomponentsareconnected,andtheunitisequipped

withaplugfor230Va.c.Asstandard,eachcircuitisalsosupplied

withitsownflowcontroller.

Thisallowsthegreatestdegreeofindividualcontrol,thus

preventingoscillationatdifferentloads.

Itisrecommendedthatdynamicbalancingvalvesbeinstalledin

thebuilding’srisersintheheatsupplyandontheheatingsystem’s

returnlineimmediatelybeforetheunit.

Easyinstallation

Theunitconsistsoftwomodules,oneforspaceheatingandone

fordomestichotwaterproduction,whichiseasilyassembled

intoonesinglemodule.Thismodulardesignmakesworkduring

installationsignificantlyeasier,astheweightissplitbetweentwo

modulesduringhandling.

Flexiblesolution

Pipeconnectioncanbemadefromeitherthetoporbottom,which

makesthissolutionhighlyflexible.Atthesametime,bothspace

andtimearesavedwheninstalling.

Minimalheatloss

Completeinsulationoftheunitensuresminimalheatloss.

Reliableandeasytoinstall

TermixCompact28VMTD-FIisaoperationallyreliable.Aquality

productmanufacturedinDenmark,whichiseasytoinstalland

quicklycommissioned.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|3

Page 4

OperatingGuideTermixCompact28VMTD-FI

3.0Safetynotes

3.1SafetyNotes–general

Thefollowinginstructionsrefertothestandarddesignof

substation.Specialversionsofsubstationsareavailableon

request.

Thisoperatingmanualshouldbereadcarefullybeforeinstallation

andstart-upofthesubstation.Themanufactureracceptsno

liabilityfordamageorfaultsthatresultfromnon-compliancewith

theoperatingmanual.Pleasereadandfollowalltheinstructions

carefullytopreventaccidents,injuryanddamagetoproperty.

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleasecomplywiththeinstructionsissuedbythesystem

manufacturerorsystemoperator.

Corrosionprotection

Allpipesandcomponentsaremadeofstainlesssteelandbrass.

Themaximumchloridecompoundsoftheflowmediumshouldnot

behigherthan150mg/l.

Theriskofequipmentcorrosionincreasesconsiderablyifthe

recommendedlevelofpermissiblechloridecompoundsis

exceeded.

Energysource

Thesubstationisdesignedfordistrictheatingastheprimary

sourceofenergy.However,alsootherenergysourcescanbeused

wheretheoperatingconditionsallowitandalwaysarecomparable

todistrictheating.

Application

Thesubstationisdesignedtobeconnectedtothehouse

installationinafrost-freeroom,wherethetemperaturedoesnot

exceed50°Candthehumiditydoesnotexceed60%.Donotcover

orwallupthesubstationorinanyotherwayblocktheentrance

tothestation.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleaseobserveinstructionscarefully

Toavoidinjurytopersonsanddamagetothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Warningofhighpressureandtemperature

Beawareoftheinstallation’spermissiblesystempressureand

temperature.

Themaximumtemperatureoftheflowmediuminthesubstationis

110°C.

Themaximumoperatingpressureofthesubstationis16bar.

Theriskofpersonsbeinginjuredandequipmentdamagedincreases

considerablyiftherecommendedpermissibleoperatingparameters

areexceeded.

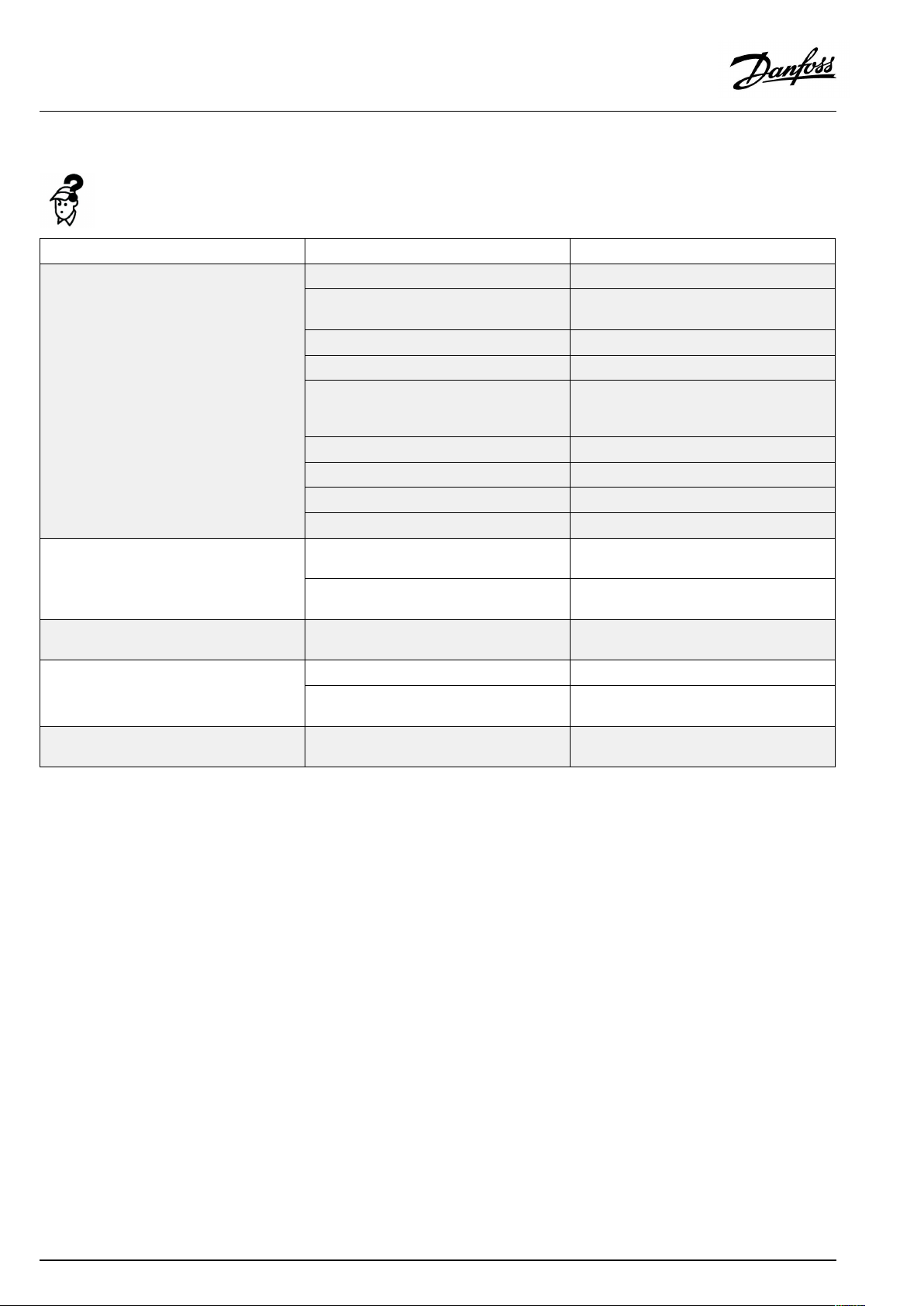

Thesubstationinstallationmustbeequippedwithsafetyvalves,

however,alwaysinaccordancewithlocalregulations.

Choiceofmaterial

Choiceofmaterialsalwaysincompliancewithlocallegislation.

Safetyvalve(s)

Werecommendmountingofsafetyvalve(s),however,alwaysin

compliancewithlocalregulations.

Connection

Thesubstationmustbeequippedwithfeaturesthatensurethat

thesubstationcanbeseparatedfromallenergysources(also

powersupply).

Emergency

Incaseofdangeroraccidents-fire,leaksorotherdangerous

circumstances-interruptallenergysourcestothestationif

possible,andseekexperthelp.

Incaseofdiscolouredorbad-smellingdomestichotwater,closeall

shut-offvalvesonthesubstation,informtheoperatingpersonnel

andcallforexperthelpimmediately.

REACH

AllDanfossA/SproductsfulfilltherequirementsinREACH.

OneoftheobligationsinREACHistoinformcustomersabout

presenceofCandidatelistsubstancesifany,weherebyinform

youaboutonesubstanceonthecandidatelist:Theproduct

containsbrasspartswhichcontainslead(CASno:7439-92-1)ina

concentrationabove0.1%w/w.

Storage

Anystorageofthesubstationwhichmaybenecessarypriorto

installationshouldbeinconditionswhicharedryandheated.

Warningofhotsurface

Thesubstationhasgothotsurfaces,whichcancauseskinburns.

Pleasebeextremelycautiousincloseproximitytothesubstation.

Powerfailurecanresultinthemotorvalvesbeingstuckinopen

position.Thesurfacesofthesubstationcangethot,whichcancause

skinburns.Theballvalvesondistrictheatingsupplyandreturnshould

beclosed.

Warningoftransportdamage

Beforesubstationinstallation,pleasemakesurethatthesubstation

hasnotbeendamagedduringtransport.

IMPORTANT-Tighteningofconnections

Duetovibrationsduringtransportallflangeconnections,screwjoints

andelectricalclampandscrewconnectionsmustbecheckedand

tightenedbeforewaterisaddedtothesystem.Afterwaterhasbeen

addedtothesystemandthesystemhasbeenputintooperation,

re-tightenALLconnections.

4|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 5

OperatingGuideTermixCompact28VMTD-FI

4.0Mounting

4.1MountingtheCompactstation

Installationmustbeincompliancewithlocalstandardsand

regulations.

Districtheating(DH)-Inthefollowingsections,DHreferstothe

heatsourcewhichsuppliesthesubstations.Avarietyofenergy

sources,suchasoil,gasorsolarpower,couldbeusedasthe

primarysupplytoDanfosssubstations.Forthesakeofsimplicity,

DHcanbetakentomeantheprimarysupply.

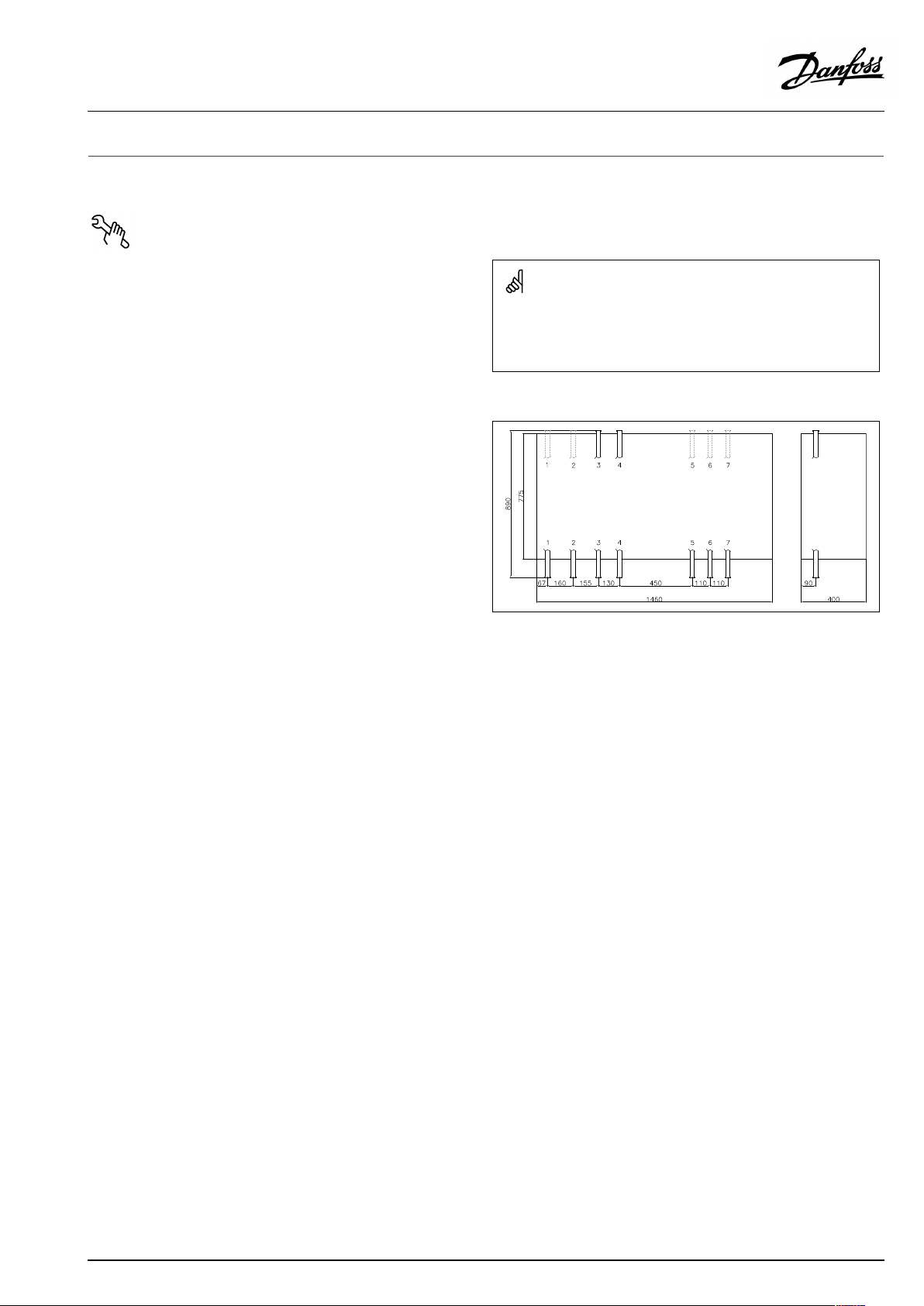

Connections:

1.Districtheating(DH)supply

2.Districtheating(DH)return

3.Heating(HE)supply

4.Heating(HE)return

5.Domestichotwater(DHW)

6.Domesticcoldwater(DCW)

7.Hotwatercirculation(HWC)

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Connectionsizes:

DH+HE:

DCW+DHW:

HWC:

Dimensions(mm):

Withinsulation:

Weight(approx.):95kg

G1”(int.thread)

G1”(int.thread)

G¾”(int.thread)

H890xW1460xD400

Thepipeplacementcandeviatefromtheshowndrawing.Pleasenote

themarkingsonthestation.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|5

Page 6

OperatingGuideTermixCompact28VMTD-FI

Removethefront.

Removetheotherblocksandthewhitepolystyrene.

Attachthemountingrailtothewall.

Liftthestation’sheatingsection.

6|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 7

OperatingGuideTermixCompact28VMTD-FI

Mountthestationasfartotheleftontherailaspossible.

Liftthestation’sinstantaneousdomestichotwaterpart.

Mounttheinstantaneousdomestichotwaterpartonthe

right-handsideofthefittings.

Pushthetwopartstogether.Thetwomountingplatesmustclick

togetherintheoverlap.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|7

Page 8

OperatingGuideTermixCompact28VMTD-FI

Attachthestationtothewallintheholesonthemountingplate.

Assemblethepowerconnectoronthehotwaterpartofthestation.

Forproperfunctionality,connectorsmustbepairedbycolour.

Installtheballvalves.

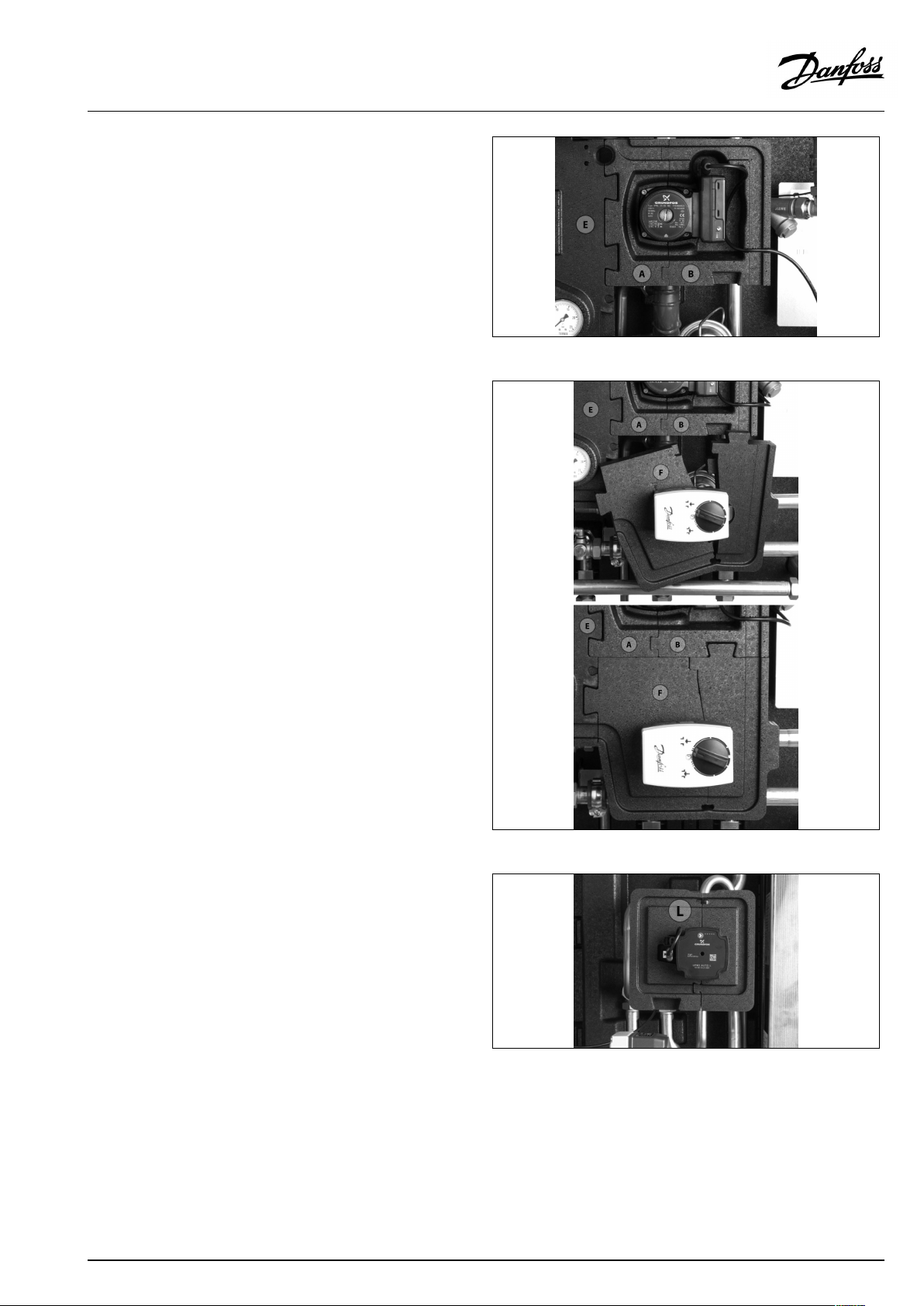

MountblockA(CifitistheMagnapump)ontheleft-handsideof

thepump.AttachblockEtoblockA/C,andattachittothepipe

abovethepumpbyclickingitinplace.

8|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 9

OperatingGuideTermixCompact28VMTD-FI

MountblockB(DifitistheMagnapump)ontheright-handsideof

thepump.

MountblockF(GforVM2valve).Theblockishingedandcanbe

drawnaroundthevalve.AttachtheblocktoblockB/DandE.

MountblockL.Theblockishingedandcanbepulledaroundthe

UPM3pump.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|9

Page 10

OperatingGuideTermixCompact28VMTD-FI

MountblockM.Theblockishingedandcanbedrawnaroundthe

valve.AttachtheblocktoblockL.

Mountthesmallfrontcover.

Mountthelargefrontcover.

10|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 11

OperatingGuideTermixCompact28VMTD-FI

4.1.1InstallingtheCompactstation

Mounting:

Adequatespace

Pleaseallowadequatespacearoundthesubstationformounting

andmaintenancepurposes.

Orientation

Thestationmustbemountedsothatcomponents,keyholes

andlabelsareplacedcorrectly.Ifyouwishtomountthestation

differentlypleasecontactyoursupplier.

Drillings

Wheresubstationsaretobewall-mounted,drillingsareprovided

inthebackmountingplate.Floormountedunitshavesupport.

Labelling

Eachconnectiononthesubstationislabelled.

Beforeinstallation:

Cleanandrinse

Priortoinstallation,allsubstationpipesandconnectionsshouldbe

cleanedandrinsed.

Tightening

Duetovibrationduringtransport,allsubstationconnectionsmust

becheckedandtightenedbeforeinstallation.

Unusedconnections

Unusedconnectionsandshut-offvalvesmustbesealedwitha

plug.Shouldtheplugsrequireremoval,thismustonlybedoneby

anauthorizedservicetechnician.

Installation:

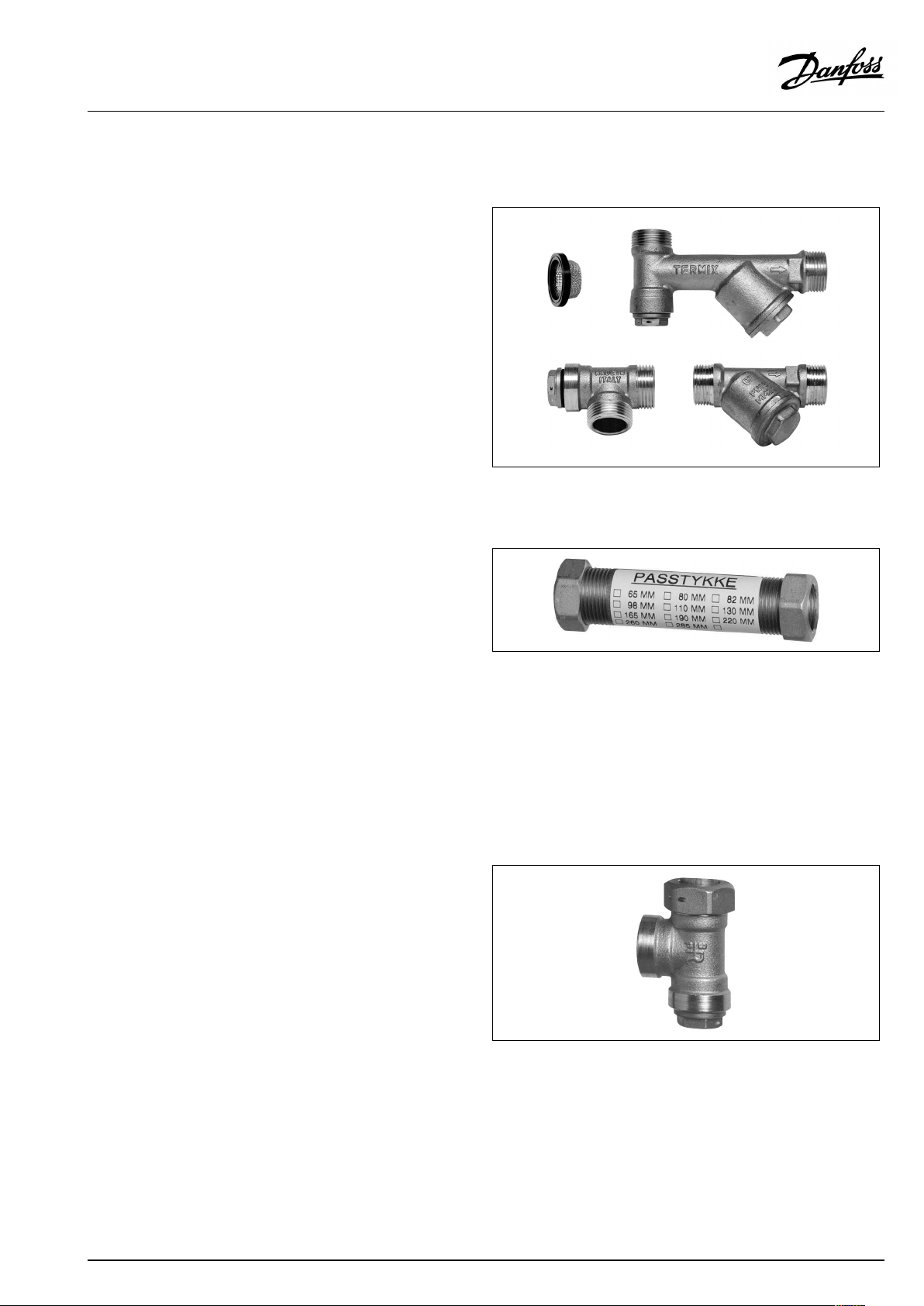

Strainer

Ifastrainerissuppliedwiththestationitmustbefittedaccording

toschematicdiagram.Pleasenotethatthestrainermaybe

suppliedloose.

Connections

Internalinstallationanddistrictheatingpipesconnectionsmustbe

madeusingthreaded,flangedorweldedconnections.

Keyholeformounting.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|11

Page 12

OperatingGuideTermixCompact28VMTD-FI

4.1.2Pipeconnectionsup

Removethetopblock.

Removethepipeplugsatthetopofthestation.

RemoveU-clamps.

Removepipes.

Anglesandteesareturnedsothatpipescanbeinstalledfrom

above.

12|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 13

OperatingGuideTermixCompact28VMTD-FI

Installthepipes.Districtheatingsupplypipestobeinterchanged.

FitU-clamps.

Fitthepipeplugsatthebottomofthestation.

Fitthetopblock.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|13

Page 14

OperatingGuideTermixCompact28VMTD-FI

4.2Start-up

Start-up,Heatingwithmixingloop

Start-up:

1:Pumpspeed

Setthepumptohighestspeedbeforestart-up.

2:Startpump

Startthepumpandheatthroughthesystem.

3:Openshut-offvalves

Theshut-offvalvesshouldthenbeopenedandtheunitobserved

asitentersservice.Visualcheckingshouldconfirmtemperatures,

pressures,acceptablethermalexpansionandabsenceofleakage.

Ifthesystemoperatesinaccordancewithdesign,itcanbeput

toregularuse.

4:Ventsystem

Switchoffthepumpandventtheinstallationaftertheradiators

havebeenwarmedup.

5:Adjustpumpspeed

Setthepumptothelowestspeedconsistentwithcomfortand

electricityconsumption.

Normallythechange-overswitchissetinthemidposition(default).

Howeverforsystemswithunderfloorheatingorsinglepipeloop

systems,itmaybenecessarytoturnthechange-overswitch

upwards.

Higherpumpspeedsareonlyusediftheheatingrequirement

increases.

Re-thightenconnections

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

Pump

Thepumpmustbeswitchedoffduringsystemfill.

Underfloorheating:

Pumpstopfunction

Ifthesubstationisusedinconnectionwithunderfloorheating,the

circulationpumpmustbeconnectedtothepumpstopfunctionin

theunderfloorheatingcontroller.Thepumpmustbestoppedif

allunderfloorheatingcircuitsareclosed.

Warranty

Ifthisisnotpossible,thenflowmustbecontinuedthroughthe

by-pass.Failingthis,thepumpwillbeatriskofseizureandany

remainingwarrantywillbewithdrawn.

Summeroperation:

Switchoffpump

Insummerthecirculationpumpmustbeswitchedoffandthe

shut-offvalvetoHEsupplyclosed.

Runningpumpbi-weekly

Itisrecommendedtostartupthecirculationpump(for2minutes)

onceamonthduringsummer;theshut-offvalveoftheHEsupply

mustbeshut.

Electroniccontroller

Mostelectroniccontrollerswillstartupthepumpautomatically

(pleasenotemanufacturer´sinstructions).

14|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 15

OperatingGuideTermixCompact28VMTD-FI

4.3Electricalconnections

Beforemakingelectricalconnections,pleasenotethe

following:

Safetynotes

Pleasereadtherelevantpartsofthesafetynotes.

230V

Thesubstationmustbeconnectedto230VACandearth.

Potentialbonding

Potentialbondingshouldbecarriedoutaccording

to60364-4-41:2007andIEC60364-5-54:2011.

Bondingpointonthemountingplatebelowrightcornermarked

withearthsymbol.

Disconnection

Thesubstationmustbeelectricallyconnectedsothatitcanbe

disconnectedforrepairs.

Outdoortemperaturesensor

Outdoorsensorsshouldbemountedsoastoavoidexposureto

directsunlight.Theyshouldnotbeplacedclosetodoors,windows

orventilationoutlets.

Theoutdoorsensormustbeconnectedtothestationonthe

terminalblockundertheelectroniccontrol.

Authorizedelectrician

Electricalconnectionsmustbemadebyanauthorizedelectricianonly.

Localstandards

Electricalconnectionsmustbemadeinaccordancewithcurrent

regulationsandlocalstandards.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|15

Page 16

OperatingGuideTermixCompact28VMTD-FI

5.0Design

5.1Design

Yoursubstationmightlookdifferentthanthesubstationshown.

Designdescription

B

Heatexchanger,DHW

F

Electroniccontroller

9

Strainer

10

Circulatorpump

16|©Danfoss|2019.01

11

Domestichotwaterpump

14

Sensorpocket,energymeter

20

Filling/drainvalve

25

Pressuregaugewithballvalve

27AActuator,HE

27BActuator,DHW

48

Airvent,manual

VI.LZ.I2.02/LUK42263

Page 17

OperatingGuideTermixCompact28VMTD-FI

5.2Schematicdiagram

DH

Supply

DH

Return

Yoursubstationmightlookdifferentthantheschematicdiagramshown.

Schematicdescription

B

Heatexchanger,DHW

F

Electroniccontroller

X

Plugconnections

1

Ballvalve

2

Singlecheckvalve

9

Strainer

10

Circulatorpump

11

Domestichotwaterpump

14

Sensorpocket,energymeter

16

Outdoorsensor

18

Thermometer

19

Surfacesensor

24

Deliveredloosewithunit

25

Pressuregaugewithballvalve

27

Actuator

30

Flowcontrollerwithintegratedcontrolvalve

40

Immersionsensor

48

Airvent,manual

HE

Supply

HE

Return

DHW

DCW

HWC

DHSupply:DistrictHeatingSupply

DHReturn:DistrictHeatingReturn

HESupply:HeatingSupply

HEReturn:HeatingReturn

DHW:

HWC:

DCW:

5.2.1Technicalparameters

Nominalpressure:

Max.DHsupplytemperature:

Min.DCWstaticpressure:

Brazingmaterial(HEX):

Heatexchangerstestpressure:30bar

Soundlevel:≤55dB

Domestichotwater

Hotwatercirculation

Domesticcoldwater

PN16

110°C

0.5bar

Copper

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|17

Page 18

OperatingGuideTermixCompact28VMTD-FI

6.0Controls

6.1Heatingcircuit

6.1.1Differentialpressurecontroller

Thedifferentialpressurecontrollersmoothsoutthefluctuationsin

pressurearrivingfromthedistrictheatingnetwork.Theoperating

pressureinthesubstationisthusheldsteady.

6.1.2HEtemperaturecontrol

TheHEflowtemperatureintheheatingcircuitiscontrolledbythe

HEtemperaturecontroller.

6.1.3Flowcontrollerwithintegratedcontrolvalve

Thecontrollerisaself-actingflowcontrollerwithintegratedcontrol

valve.Thecontrollercloseswhensetmax.flowisexceededand

canbeusedincombinationwithDanfosselectricalactuatorswith

orwithoutsafetyfunction.Springreturnmotorcanbeusedas

safetyfunctionbypowerfailure.

18|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 19

OperatingGuideTermixCompact28VMTD-FI

6.1.4Electric2–waymotorizedvalve

Actuatorswithorwithoutsafetyfunctionareavailablefor3-point

controls.Spring-returnactuatorscanbeusedtoprovidesafety

shut-offintheeventofpowerfailure.

6.1.5Electroniccontrol

Substationswithelectroniccontrolmustbesetinaccordancewith

manufacturer´sinstructions.

Wheretheroomtemperatureiscontrolledbyradiatorthermostats,

itisrecommendedthatthermostatsbesetforminimum

temperatureineachroom.

6.1.6Outsidetemperaturesensor

Outdoorsensorsshouldbemountedsoastoavoidexposureto

directsunlight.Theyshouldnotbeplacedclosetodoors,windows

orventilationoutlets.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|19

Page 20

OperatingGuideTermixCompact28VMTD-FI

6.1.7Circulatorpump

TheUPML,UPMXLcirculatorpumpsaredesignedforcirculating

liquidsinheatingsystemswithvariableflows,internallycontrolled

withthreeproportionalpressurecurvesandthreeconstant

pressure/powercurvestobeselectedviauserinterface.

EuP2015Ready.

TheMAGNA3circulatorpumpsaredesignedforcirculatingliquids

inheatingsystemswithvariableflowswhereyouwanttooptimise

thesettingofthepumpdutypoint,thusreducingenergycosts.

EuP2015Ready.

6.1.8GrundfosUPML/UPMXLinstructions

PP=Proportionalpressure(fastflash)

CP=Constantpressure(slowflash)

20|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 21

OperatingGuideTermixCompact28VMTD-FI

6.2DHWtemperaturecontrol

DHWtemperaturecontrol

TherearevarioustypesofDHWtemperaturecontrolusedin

Danfosssubstations.

DHWtemperatureshouldbeadjustedto45-50°C,asthisprovides

optimalutilisationofDHwater.AtDHWtemperaturesabove55°C,

thepossibilityoflimescaledepositsincreasessignificantly.

6.2.1Flowcontrollerwithintegratedcontrolvalve

Thecontrollerisaself-actingflowcontrollerwithintegratedcontrol

valve.Thecontrollercloseswhensetmax.flowisexceededand

canbeusedincombinationwithDanfosselectricalactuatorswith

orwithoutsafetyfunction.Springreturnmotorcanbeusedas

safetyfunctionbypowerfailure.

6.2.2Electric2–waymotorizedvalve

Actuatorswithorwithoutsafetyfunctionareavailablefor3-point

controls.Spring-returnactuatorscanbeusedtoprovidesafety

shut-offintheeventofpowerfailure.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|21

Page 22

OperatingGuideTermixCompact28VMTD-FI

6.2.3Domestichotwaterpump

Important!

Itisnecessarytomountadomestichotwatercirculationpumpon

thewaterheatertoavoidregulationproblems.

Thecirculationpumpcannotbeswitchedoff,sincethiswillresult

inregulationproblems.(noflowatthesensor).

22|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 23

OperatingGuideTermixCompact28VMTD-FI

6.3Other

6.3.1Strainer

Strainersshouldbecleanedregularlybyauthorizedpersonnel.The

frequencyofcleaningwoulddependonoperatingconditionsand

themanufacturer’sinstructions.

6.3.2Fittingpiece

Thesubstationisequippedwithafittingpieceforenergymeter.

Assemblyofenergymeters:

1:Closeballvalves

ClosetheballvalvesonDHSupplyandDHReturn,ifthereiswater

onthesystem.

2:Loosennuts

Loosenthenutsonthefittingpiece.

3:Removefittingpiece

Removethefittingpieceandreplaceitwiththeenergymeter.Do

notforgetthegaskets.

4:Tightenconnections

Aftermountingoftheenergymeterremembertocheckand

tightenallthreadedconnections.

Sensorpocket,energymeter

Thesensorsoftheenergymeterismountedinthesensorpockets.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|23

Page 24

OperatingGuideTermixCompact28VMTD-FI

6.4Maintenance

Thesubstationrequireslittlemonitoring,apartfromroutine

checks.Itisrecommendedtoreadtheenergymeteratregular

intervals,andtowritedownthemeterreadings.

RegularinspectionsofthesubstationaccordingtothisInstruction

arerecommended,whichshouldinclude:

Strainers

Cleaningofstrainers.

Meters

Checkingofalloperatingparameterssuchasmeterreadings.

Temperatures

Checkingofalltemperatures,suchasDHsupplytemperatureand

DHWtemperature.

Connections

Checkingallconnectionsforleakages.

Safetyvalves

Theoperationofthesafetyvalvesshouldbecheckedbyturning

thevalveheadintheindicateddirection.

Venting

Checkingthatthesystemisthoroughlyvented.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Inspectionsshouldbecarriedoutminimumeverytwoyears.

SparepartscanbeorderedfromDanfoss.Pleaseensurethatany

enquiryincludesthesubstationserialnumber.

24|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 25

OperatingGuideTermixCompact28VMTD-FI

7.0Troubleshooting

7.1Troubleshootingingeneral

Intheeventofoperatingdisturbances,thefollowingbasicfeatures

shouldbecheckedbeforecarryingoutactualtroubleshooting:

•thesubstationisconnectedtoelectricity,

•thestrainerontheDHsupplypipeisclean,

•thesupplytemperatureoftheDHisatthenormallevel

(summer,atleast60°C-winter,atleast70°C),

•thedifferentialpressureisequaltoorhigherthanthenormal

(local)differentialpressureintheDHnetwork–ifindoubt,ask

theDHplantsupervisor,

•pressureonthesystem-checktheHEpressuregauge.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|25

Page 26

OperatingGuideTermixCompact28VMTD-FI

7.2TroubleshootingDHW

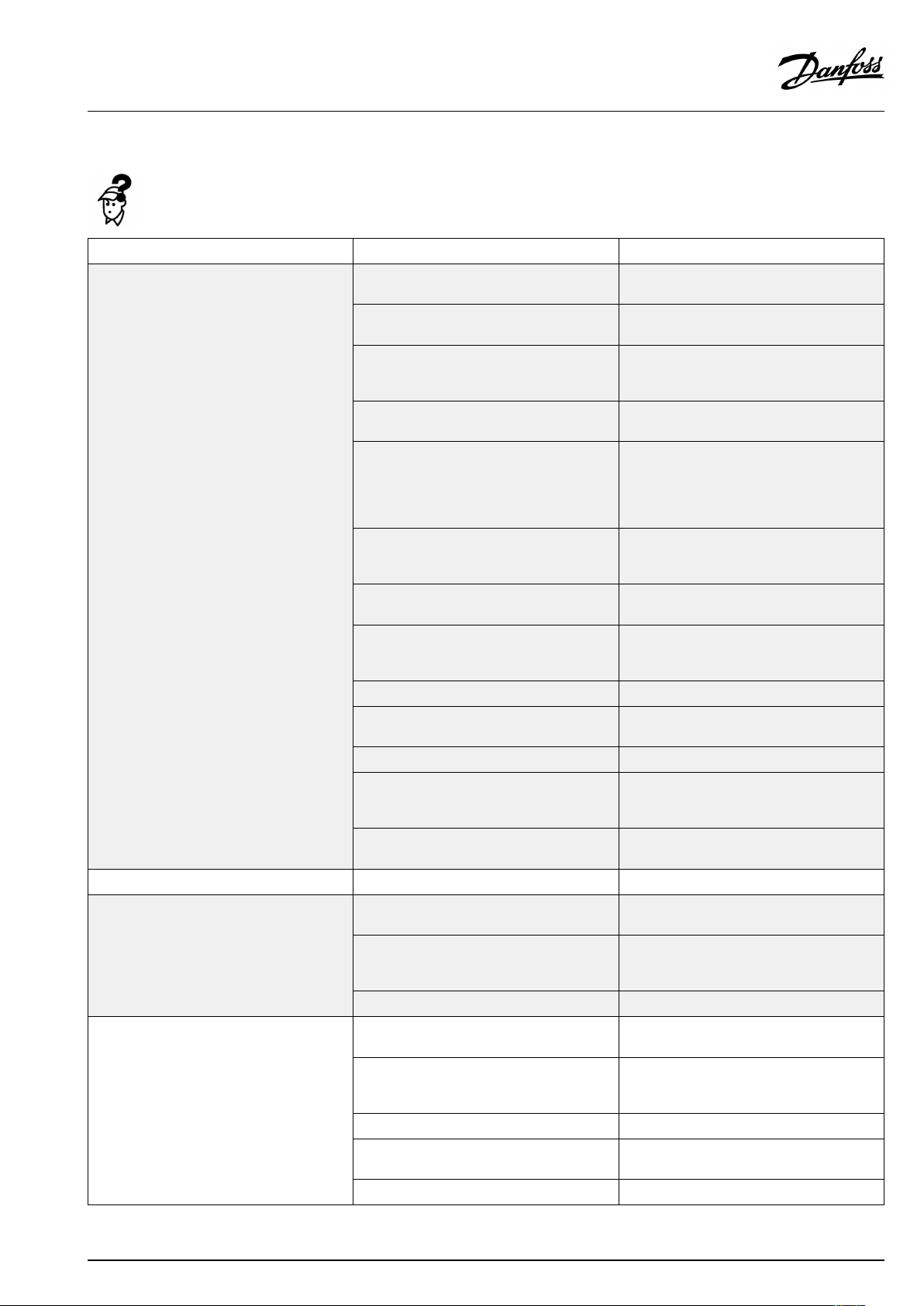

ProblemPossiblecauseSolution

ToolittleornoDHW.

Taptemperaturetoohigh;DHWtapload

toohigh.

Temperaturedropduringtapping.

Thermostaticcontrolvalvedoesnotclose

Strainerinsupplyorreturnlineclogged.Cleanstrainer(s).

DHWcirculationpumpoutoforderorwith

toolowsetting.

Defectiveorcloggednon-returnvalve.

Noelectricity.Check.

Wrongsettingofautomaticcontrols,ifany.Toadjustanelectroniccontrollerfor

Scalingoftheplateheatexchanger.

Defectivemotorizedvalve.Check(usemanualfunction)–replace.

Defectivetemperaturesensors.

Defectivecontroller.

DCWisbeingmixedwiththeDHW,e.g.ina

defectivethermostaticmixingvalve.

Defectiveorcloggednon-returnvalveon

circulationvalve.

Thermostaticvalveadjustedtoatoohigh

level.

Scalingoftheplateheatexchanger.

LargerDHWflowthanthesubstationhas

beendesignedfor.

TemperaturedifferencebetweenDH

supplyandDHWsetpointtoolow.

Checkcirculationpump.

Replace–clean.

DHW,pls.noteenclosedinstructionsfor

electroniccontroller.

Replace–rinseout.

Check–replace.

Check–replace.

Check–replace. Hotwaterinsometapsbutnotinall.

Replace–clean.

Check–set.

Replace–rinseout.

ReduceDHWflow.

Lowerthesetpointtemperatureorincrease

theDHsupplytemperature.

26|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 27

OperatingGuideTermixCompact28VMTD-FI

7.3TroubleshootingHE

ProblemPossiblecauseSolution

Toolittleornoheat.StrainercloggedinDHorHEcircuit

Unevenheatdistribution.Airpocketsinthesystem.Venttheinstallationthoroughly.

DHsupplytemperaturetoohigh.

DHsupplytemperaturetoolow.

(radiatorcircuit).

ThefilterintheenergymeteronDHcircuit

clogged.

Defectiveorwronglyadjusteddifferential

pressurecontroller.

Sensordefective–orpossiblydirtinthe

valvehousing.

Automaticcontrols,ifany,wronglysetor

defective-possiblypowerfailure.

Pumpoutofoperation.Checkifthepumpisreceivingpowerand

Thepumpissetattoolowspeedof

rotation.

Pressuredrop–thepressuredropon

theradiatorcircuitshowslowerthan

recommendedoperatingpressure.

Airpocketsinthesystem.Venttheinstallationthoroughly.

Limitingofthereturntemperatureadjusted

toolow.

Defectiveradiatorvalves.

Unevenheatdistributioninbuilding

becauseofincorrectlysetbalancingvalves,

orbecausetherearenobalancingvalves.

Diameterofpipetosubstationtoosmallor

branchpipetoolong.

Wrongsettingofthermostatorof

automaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongsettingofautomaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongplacement/fittingofoutdoor

temperaturesensor.

Strainerclogged.Cleangate/strainer.

Cleangate/strainer(s).

Cleanthefilter(afterconsultingtheDH

plantoperator).

Checktheoperationofthedifferential

pressurecontroller–cleanthevalveseatif

required.

Checktheoperationofthethermostat–

cleanthevalveseatifrequired.

Checkifthesettingofthecontroller

iscorrect–seeseparateinstructions.

Checkthepowersupply.Temporary

settingofmotorto“manual”control–see

instructionsonautomaticcontrols.

thatitturns.Checkifthereisairtrappedin

thepumphousing–seepumpmanual.

Setthepumpathigherspeedofrotation.

Fillwateronthesystemandcheckthe

functioningofthepressureexpansion

vesselifrequired.

Adjustaccordingtoinstructions.

Check–replace.

Adjust/installbalancingvalves.

Checkpipedimensions.

Adjustautomaticcontrols,–see

instructionsforautomaticcontrols.

Callautomaticcontrolsmanufactureror

replacetheregulator.

Replacethermostat–orsensoronly.

Adjustautomaticcontrols–seeinstructions

forautomaticcontrols.

Callinautomaticcontrolsmanufactureror

replacecontroller.

Replacethermostat–orsensoronly.

Adjustlocationofoutdoortemperature

sensor.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|27

Page 28

OperatingGuideTermixCompact28VMTD-FI

ToohighDHreturntemperature.

Noiseinsystem.

Heatloadtoohigh.

Toosmallheatingsurface/toosmall

radiatorscomparedtothetotalheating

requirementofthebuilding.

Poorutilizationofexistingheatingsurface.

Defectivesensoronself-actingthermostat.

Thesystemissinglepipeloop.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Airinsystem.

Defectiveorincorrectlysetradiatorvalve(s).

Singlepipeloopsystemsrequirespecial

one-piperadiatorvalves.

Dirtinthemotorizedvalveorinthe

differentialpressurecontroller.

Defectivemotorizedvalve,sensoror

automaticcontroller.

Electroniccontrollernotadjustedcorrectly.Adjustaccordingtoinstructions.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Defectivemotorizedvalve,sensoror

electroniccontroller.

Increasetotalheatingsurface.

Makesuretheheatisdistributedevenly

acrossthefullheatingsurface–openall

radiatorsandkeeptheradiatorsinthe

systemfromheatingupatthebottom.It

isextremelyimportanttokeepthesupply

temperaturetotheradiatorsaslowas

possible,whilemaintainingareasonable

levelofcomfort.

Thesystemshouldfeatureelectronic

controlsaswellasreturnsensors.

Ventthesystem.

Check–set/replace.

Check–cleanout.

Check–replace.

Check–replace.

28|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 29

OperatingGuideTermixCompact28VMTD-FI

7.4Disposal

Disposal

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|29

Page 30

OperatingGuideTermixCompact28VMTD-FI

30|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Page 31

OperatingGuideTermixCompact28VMTD-FI

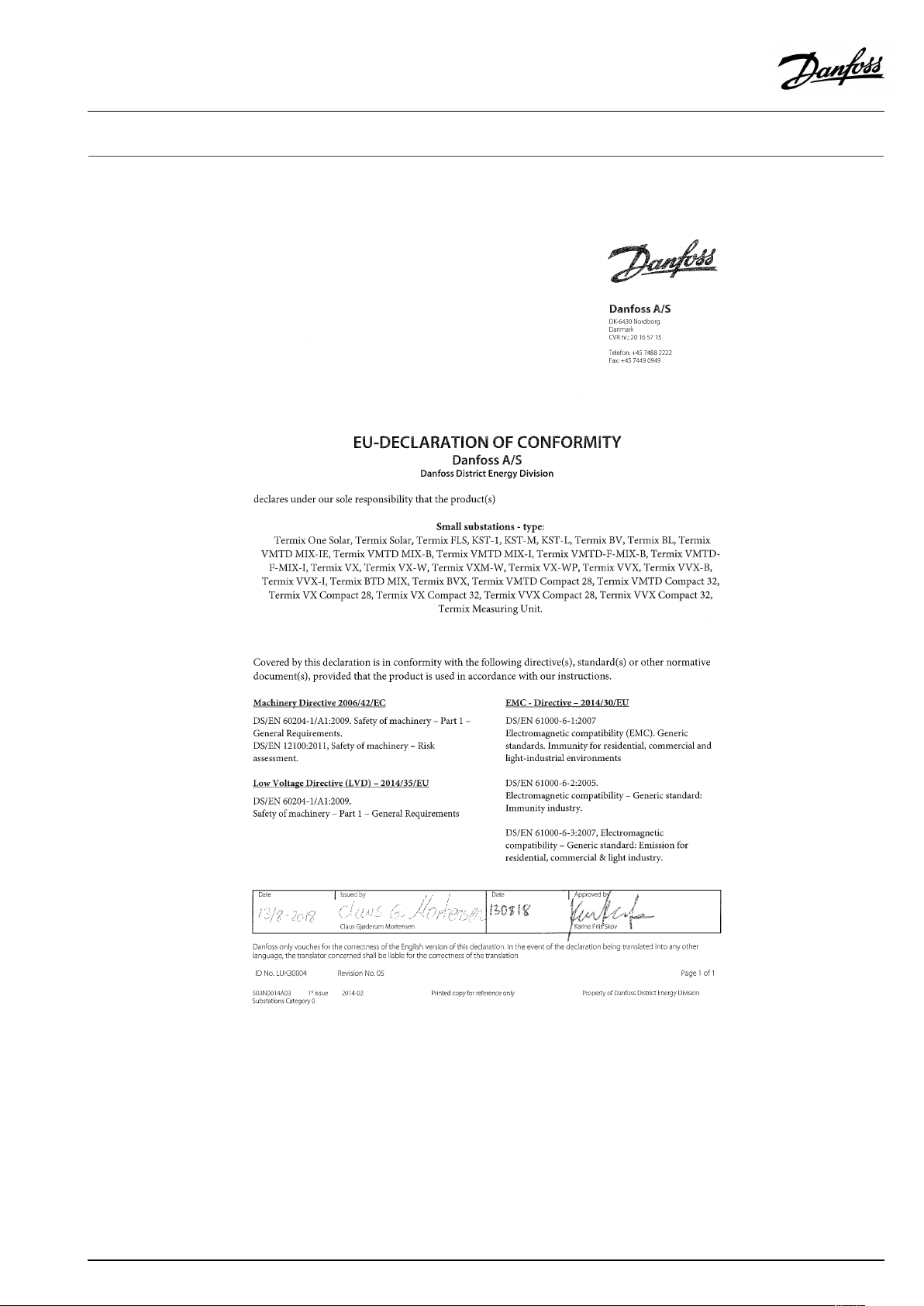

8.0Declaration

8.1Declarationofconformity

Category0withelectricalequipment

VI.LZ.I2.02/LUK42263

©Danfoss|2019.01|31

Page 32

OperatingGuideTermixCompact28VMTD-FI

32|©Danfoss|2019.01

VI.LZ.I2.02/LUK42263

Loading...

Loading...