Page 1

Danfoss Ally eTRV1.18, Zigbee Cluster Specification

This ZigBee cluster specification is based of the ZigBee cluster library specification.

If nothing explicit is mentioned below the commands, clusters and attributes are implemented as per ZigBee Specification

Revision History:

10-09-2020 - KJE-AMO - all changes for Ally 1.08 reviewed and confirmed

11-12-2020 - AMO - Corrected Room Sensor automatic offset functionality description

09-04-2021 - Reviewed at Ally 1.12 release. Corrected typo+formulation for attributes with not configurable reporting to

08-11-2021 - AMO - Ally 1.16 added

08-11-2021 - AMO - Ally 1.18 added, no difference in Zigbee interface, bug fix.

Common ZigBee Cluster Specification

Danfoss eTRV

"fixed".

01-12-2021

AM375549618098en-000102 | 1

Page 2

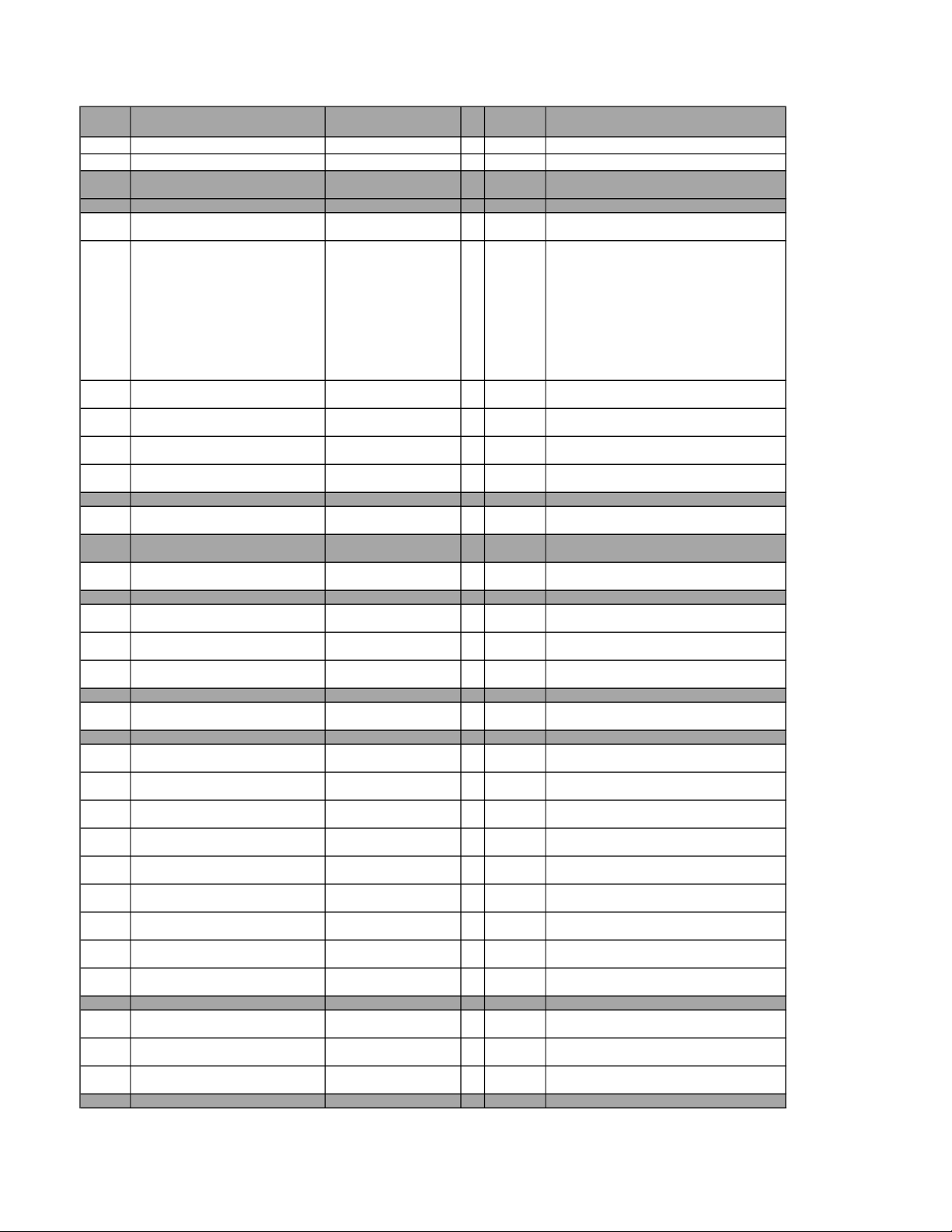

1. Commands

Command Id

Command Name

M/

O

Direction

Description

General

General command frames

0x0000

Basic Cluster (0x0000)

0x0001

Power Configuration Cluster

(0x0001)

0x0003

Identify Cluster (0x0003)

0x000A

Time Server Cluster(0x000A)

0x0019

OTA Update Cluster (0x0019)

0x0020

Poll control Cluster (0x0020)

0x0201

Thermostat Cluster (0x0201)

Profile (0x0104) Home Automation

DeviceID (0x0301)Thermostat

Danfoss Ally eTRV1.18, Zigbee Cluster Specification

General 0x00 Read Attributes M

General 0x02 Write Attribute M

General 0x06 Configure Reporting O

General 0x08

General 0x0A Report Attributes O

General 0x0C Discover Attributes O

0x0000

0x0001

0x0003 0x00 Identify M

0x0003 0x01 Identify Query M

0x0003 0x00

-> no commands are received or

generated

-> no commands are received or

generated

Read Reporting

Configuration O

Identify Time Query

Response M

client>server

client>server

client>server

client>server

server>client

client>server

client>server

client>server

server>client

A write to a standard attribute, where another

attribute defines it range. Writing outside this

range will result in INVALID_VALUE

A write to a standard attribute, with restricted

values. Writing to the restricted values will

result in INVALID_VALUE.

If the device cannot support the supplied value,

the status field of the corresponding write

attribute status record SHALL be set to

INVALID_VALUE

0x000A

0x0019 0x00 Image Notify M

0x0019 0x01

0x0019 0x02

0x0019 0x03 Image Block Request M

0x0019 0x05 Image Block Response M

0x0019 0x06 Upgrade End Request M

0x0019 0x07 Upgrade End Response M

0x0019 0x08 Query specific file request

0x0019 0x09

0x0020 0x00 Check in M

0x0020 0x00 Check in Response M

0x0020 0x01 Fast Poll Stop M

-> no commands are received or

generated

Query Next Image

Request M

Query Next Image

Response M

Query specific file

response

server>client

client>server

server>client

client>server

server>client

client>server

server>client

client>server

server>client

server>client

client>server

client>server

check added in QueryNextImageResponse

device will not initiate OTA if battery low

01-12-2021

AM375549618098en-000102 | 2

Page 3

Danfoss Ally eTRV1.18, Zigbee Cluster Specification

according to Zigbee Specifications (please refer

same as setting the attribute "Occupied Heating

0x0204

Thermostat User Interface Cluster

(0x0204)

0x0B05

Diagnostics Cluster (0x0B05)

0x0201 0x00 Setpoint Raise/Lower M

0x0201 0x01 SetWeeklySchedule O

0x0201 0x02 GetWeeklySchedule O

0x0201 0x03 ClearWeeklySchedule O

0x0201 0x40 Setpoint Command O

0x0201 0x41 Danfoss Modify command O

0x0201 0x42 PreHeatCommand O

client>server

client>server

client>server

client>server Deletes all schedule events

client>server

client>server test purpose

client>server

Vacation day is not used, the schedule is set

to https://zigbeealliance.org/wpcontent/uploads/2019/12/07-5123-06-zigbeecluster-library-specification.pdf section 6)

NOTE: The events within one day must be

ordered chronologically

Can be used to verify that the schedule is

stored in the eTRV (the eTRV does not modify

the schedule itself)

Note! The schedule information is lost after

power cycle or OTA

Setpoint command sends: setpointType

(enum8) + HeatingSetpoint (16bit)

if setpointType = 1 the actuator will make a

large movement to minimize reaction time to UI.

If setpointType = 0 the behavior will be the

Setpoint" to the same value.

if setpointType = 2 displayed setpoint is not

effected but regulated setpoint will change. can

be used for Forecast functionality

Request eTRV to enter pre-heat if in schedule

mode and if other eTRV in same room has

triggeed pre-heat. command needs two

parameter enum8 = 0 = force preheat. Other

values for future needs. Second parameter

uint32 is timestamp received from other eTRV

in the same room that went into preheat.

0x0204

0x0B05

-> no commands are received or

generated

-> no commands are received or

generated

01-12-2021

AM375549618098en-000102 | 3

Page 4

2. Attributes

Profile

(0x0104) Home Automation

DeviceID

(0x0301)Thermostat

Interval

Interval

Change

0x0000

Cluster:

(0x0000) Basic

0x0000

0x0000

ZCL Version

uint8RM

0x00

0xFFNoNo16553400x03

0x0000

0x0001

Application Version

uint8RO

0x00

0xFF

FixedNo1

6553400x00

Reporting will trigger at re-join

0x0000

0x0002

Stack Version

uint8RO

0x00

0xFFNoNo16553400

8 - 6.5.5.0

0x0000

0x0003

HW Version

uint8RO

0x00

0xFFNoNo16553400x5

High nibble of attribute contains Side PCB hardware minor

low nibble revision.

0x0000

0x0004

Manufacturer Name

stringRONoNo165534

"Danfoss"

0x0000

0x0005

Model Identifier

stringRONoNo165534

"eTRV0100"

The number after eTRV is the same as image type ID

0x0001

0x0006

Date Code

stringRONoYes165534

YYYYMMDD

written at production time

0x0000

0x0007

Power Source

enum8RMNoNo165534

0x03

03 = "Battery"

0x0000

0x0010

LocationDescription

string (0-R/ONoYes165534

Empty string (0)

Maximum length: 16 characters.

0x0000

0x4000

SW Build ID

string (16)

RONoNo1

65534

=> PSoC: 00.23 ; => Stack Version: 5 ; => EFR: 00.29

0x0000

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0001

Cluster:

(0x0001) Power Configuration

0x0001

0x0020

BatteryVoltage

uint8RO032NoNo165534

0x00

in decivolt according to Zigbee Specifications

0x0001

0x0021

BatteryPercentageRemaining

uint8RO0255

YesNo3600

4320020xFF

in units of 0.5% - range is to 0-200

0x0001

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0003

Cluster:

(0x0003) Identify

0x0003

0x0000

Identify Time

uint16R/M

0x0000

0xFFFFNoNo

0x0000

Counts down the remaining time in Identify Me state

0x0003

0x4000

Identification button

BooleanRO01

YesNo200x00

"0x01" and after 3 sec "0x00" (triggered at "rising edge")

0x0003

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x000A

Cluster:

(0x000A) Time

0x000A

0x0000

Time

UTCRWM

0x00000000

0xFFFFFFFE

NoNo1

65534

2017, 11:00 AM )

MCU converts it to UTC

0x000A

0x0001

TimeStatus

map8RWM

0x00

0x0FNoNo165534

0x00

"synchronized" bit to "1"

0x000A

0x0002

TimeZone

int32RWO

0xFFFEAE80

0x00015180

No

Yes16553400

Time zone offset in seconds without DST

0x000A

0x0003

DstStart

uint32RWO

0x00000000

0xFFFFFFFE

No

Yes16553400

Must be before DstEnd and in the same year

0x000A

0x0004

DstEnd

uint32RWO

0x00000000

0xFFFFFFFE

No

Yes16553400

Must be after DstStart and in the same year

0x000A

0x0005

DstShift

int32RWO

0xFFFEAE80

0x00015180

No

Yes16553403600

from 3600 (1 hour) the DST shift will always be 1 hour or 0

0x000A

0x0007

LocalTime

uint32RO

0x00000000

0xFFFFFFFE

NoNo1

6553400

Time+Timezone+DST

0x000A

0x0008

LastSetTime

UTCRO

0x00000000

0xFFFFFFFE

NoNo1

65534

0x2000E3B0

0x000A

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0019

Cluster:

(0x0019) OtA Bootloading

0x0019

0x0000

UpgradeServerID

addressRMNoYes165534

0xFFFFF…

0x0019

0x0001

FileOffset

uint32RONoYes16553400xFFFFFFFF

0x0019

0x0002

CurrentFileVersion

uint32RONoYes16553400xFFFFFFFF

example: 0x0000010D

0x0019

0x0003

CurrentZigBeeStackVersion

uint16RONoYes16553400xFFFF

0x0002 = ZigBee Pro

0x0019

0x0004

DownloadedFileVersion

uint32RONoYes16553400xFFFFFFFF

Is written at start OTA upgrade and deleted right after OTA

upgrade successful

0x0019

0x0005

DownloadedZigBeeStackVersion

uint16RONoYes16553400xFFFF

Is written at start OTA upgrade and deleted right after OTA

upgrade successful

0x0019

0x0006

ImageUpgradeStatus

enum8RMNoYes165534

0x00

0x0019

0x0007

Manufacturer ID

uint16RONoYes16553400x1246

ID)

0x0019

0x0008

Image Type ID

uint16RONoYes16553400x0100

0x0019

0x0009

MinimumBlockPeriod

uint16RONoYes16553400x0019

0x000A

Image Stamp

uint16RONoYes16553400x0019

0x000B

Upgrade Activation Policy

enum8RONoNo16553400x00

0x0019

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0020

Cluster:

(0x0020) Poll Control

0x0020

0x0000

Check-in Interval

uint32R/W

M

0x0004

0x006E0000

No

Yes16553400x000004B0 (1200)

Unit: seconds

0x0020

0x0001

Long Poll Interval

uint32RM

0x0005

0x006E0000

No

Yes16553400x0000001C (28)

Unit: quarterseconds

0x0020

0x0002

Short Poll Interval

uint16RM

0x0001

0xFFFFNoYes16553400x0002

Danfoss Ally eTRV1.18, Zigbee Cluster Specification

Cluster: Attribute ID Name Data Type R/W M /O Range M in Range Max Reporting Save Def. Min

Def. Max

Report.

Default Description

Since this is only 8 bits i t will contain only "minor minor"

from EFR version REF: 0x4000 SWBuildID

Ember ZNet released versions:

0 - unknown/invalid/previous

1 - 5.10.1.0

2 - 6.0.0.0

3 - 6.1.0.0

4 - 6.2.3.0

5 - 6.3.0.0

6 - 6.3.1.0

7 - 6.4.1.0

Low nibble of attribute contains Top PCB hardware minor

low nibble revision.

SW build ID will contain top pcba (radio module) sw

version, side pcba (application module) sw version and

stack version in a string. "numbers" will always stay in the

same location.

Unified version string format 16 byt es for, formatt ed

VV.SS.EEEE< vv.ss> (version, sub-version, extension),

with leading zeros, containing application (m ain/host

controller) version andadditional (network) co-processor

version.

VV.SS will be major and mi nor for the application module,

"E1""E2""E3""E4" is meant for extension. To combine

everything, the HS-816 - 0x0002 Stack Version , will be

placed here (in E3 and E4) The rest of the extension shall

remain "00" (for now) vv.ss will be major minor for the

radio module. The minor info will be mapped in HS-815 0x0001 Application version

Examples: "00.23.0005 00.29" (Host, stack and network

co-processor)

IEEE

0x2000E3B0 (Jan 5th

Activating the button on the eTRV will result in reporti ng

This cluster provides a basic interface to a real-tim e clock.

The clock time MAY be read and also written, in order to

synchronize the clock (as close as practical) to a ti me

standard. This time standard is the number of seconds

since 0 hrs 0 mins 0 sec on 1st January 2000 UTC

(Universal Coordinated Time.

The default value is synchronized at boot where the side

MCU sends it in DATETIME format and the top ZigBee

In Time Status attribute only a write to bit "1"

(Synchronized) will result in a change.

A write to any of the other specified bit, bit "0", "2" and "3".

Will not r esult in a change of the attribute.

A write to a bit above "3" will result in an invalid value.

It is the responsibility of t he ZigBee coordinator, after

writing to the "Time" attribute, t o update "Time Status"

Time is kept by side MCU, so even if this is set dif ferently

Device Firmware where:

AB.CD (build.release) - e.g. 01.13 (EFR sw version) =

0x010D

"Danfoss" = 0x1246 (ZigBee Alliance Manufacture Code

01-12-2021

see attribute

see attribute

AM375549618098en-000102 | 4

Page 5

Danfoss Ally eTRV1.18, Zigbee Cluster Specification

0x0020

0x0003

Fast Poll Timeout

uint16R/WM0x0001

0x0006NoYes16553400x0028 (40)

0x0020

0x0004

Check-in Interval Min

uint32RONoYes16553400x000000F0 (240)

0x0020

0x0005

Long Poll Interval Min

uint32RONoYes16553400x0000001C (28)

0x0020

0x0006

Fast Poll Timeout Max

uint16RONoYes16553400x0050 (80)

0x0020

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0201

Cluster:

(0x0201) Thermostat

0x0201

0x0000

Local Temperature

Int16RM

0x954D

0x7FFF

YesNo300

3600100x8000

Unit: Centigrades

0x0201

0x0003

absMinHeatSetpointLimit

Int16RO

0x954D

0x7FFFNoNo16553400x01F4 (500)

centigrades

0x0201

0x0004

absMaxHeatSetpointLimit

Int16RO

0x954D

0x7FFFNoNo16553400x0DAC (3500)

centigrades

0x0201

0x0008

PIHeatingDemand

uint8RO

0x00

0x64

YesNo300

43200

1

0: when the thermostat is in “off”

0x0201

0x0012

OccupiedHeating Setpoint

Int16R/WMYes

Yes14320010x834 (2100)

MaxHeatSetpointLimit

Range: 0x0003 absMinHeatSetpointLimit to 0x0016

0x0201

0x0016

MaxHeatSetpointLimit

Int16R/WOFixed

Yes16553400x0DAC (3500)

absMaxHeatSetpointLimit

0x0201

0x001B

Control Sequence of Operation

enum8R/M

0x02

0x02NoNo165534

0x02

Heating Only (0x02).

0x0201

0x001C

System Mode

enum8R/WM0x04

0x04NoYes165534

0x04

Everything else rejected with INVALID_VALUE

0x0201

0x0020

Start of Week

enum8RONoNo16553400x01

Monday

0x0201

0x0021

Number of Weekly transitions.

uint8RONoNo165534042

"= NumberOfDailyTransitions * 7 days"

0x0201

0x0022

Number of Daily transitions.

uint8RONoNo16553406

Thermostat programming

0x00: Manual setpoint by User.

0x0201

0x4000

eTRV Open Window Detection

enum8RO

0x00

0x04

YesNo60

43200

0x00

closed locally

0x0201

0x4003

External Open Window Detected

booleanR/WO0x00

0x01

FixedNo1

65534

0x00

0x01: Windows are opened

0x0201

0x4010

Exercise day of week

enum8R/WO0x00

0x07NoYes165534

0x04

0x0201

0x4011

Exercise trigger time

uint16R/WO0

1439NoYes16553400x0294 (660)

Minutes since midnight

0x00: Mounted

0x0201

0x4013

Mounting mode control

booleanR/WO01FixedNo1

65534

0x00

mounted on a valve)

0x0201

0x4014

eTRV Orientation

booleanR/WO01FixedNo1

65534

0x00

configuration at Init.

0x0201

0x4015

External Measured Room Sensor

Int16R/WO0x8000

0x7FFFNoNo16553400xE0C0 (-8000)

8000 disables the function

FALSE = Auto Offset Mode for Exposed Radiators

0x0201

0x4020

Control algorithm scale factor

uint8R/WO1

255

Fixed

Yes16553401

0x00 No heat available

0x00 No heat request

0x00 Load balancing is disable and thermostat act as

0x0201

0x4040

Load Radiator Room Mean

Int16WO

0x8000

0x7FFF

FixedNo1

6553400xE0C0 (-8000)

Mean radiator load for room calculat ed by gateway

0x0201

0x404A

Load estimate on this radiator

Int16RO

0x954D

0x7FFF

YesNo60

3600500xE0C0 (-8000)

in steps of 0.1°C.

1=Initiate Adaptation run

bit0=Adaptation run in progress

1=Automatic adaptation run enabled (the one during the

0x00 no preheat. 0x01 pre-heat running. Specific for pre-

0x0201

0x4050

Preheat Time

uint32RO

0x00000000

0xFFFFFFFF

YesNo6001

0x00000000

Time stamp related to Preheat during schedule

0x0201

0x4051

Window Open Feature ON/OFF

booleanR/WO01Fixed

Yes165534

0x01

feature ON.

0x0201

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0204

Cluster:

(0x0204) Thermostat UI

Configuration

0x0204

0x0000

TemperatureDisplayMode

enum8R/WM0x00

0x00NoNo165534

0x00

0x01 = °F Not supported!

see attribute

0x0201 0x0015 MinHeatSetpointLimit Int16R/W O Fixed Yes 1 65534 0 0x01F4 (500)

Manufacturer specific: absolute minimum temperature in

Manufacturer specific: absolute maximum temperature

Level of heating demanded by the PI loop in percent

"official" room setpoint dir ectly displayed on LCD

Range: 0x0015 MinHeatSetpointLimit to 0x0016

MaxHeatSetpointLimit

Range: 0x0015 MinHeatSetpointLimit to 0x0004

0x04: Heating control active

0x0201 0x0025

0x201 0x0030 Setpoint Change Source enum8 R O 0x00 0x02 Yes No 1 0 0

0x0201 0x4012 Mounting mode active boolean R O 0 1 Yes No 1 0 0x00

0x0201 0x4016 Radiator Covered booleanR/W O 0 1 Fixed Yes 1 65534 0

0x0201 0x4030 Heat Available booleanR/W O 0 1 Fixed No 1 65534 0x00

0x0201 0x4031 Heat Supply Request boolean R O 0 1 Yes No 60 43200 0x00

0x0201 0x4032 Load Balancing Enable booleanR/W O 0 1 Fixed No 1 65534 0x01

operation mode. map8R/W O 0 0xFF Fixed No 1 65534 0 0b00000000 Bit 0 = Sim ple setpoint (0) or schedule (1)

0x01: Schedule setpoint change

0x02: Setpoint change by external Attribute Write or

Setpoint Command

0x00: Quarantine

0x01: Windows are closed

0x02: Hold ,Windows are maybe about to open

0x03: Open window detected

0x04: In window open state from external, but detected

0x00: Windows are closed

Range 0-7

0 = Sunday, 1 = Monday, … 6 = Saturday, 7 = undefined

Range 0 to 1439

0x01: Not mounted (after factory reset)

Default is 0, but overwritten to actual st atus at Init.

0x00 Go to mounting mode (the eTRV can now be

mounted on a valve)

0x01 Go to Mounted posittion (the eTRV now act as if it's

0x00: Horizontal (Default)

0x01: Vertical

Default is 0, but overwritten to value from production

Depending on 0x4016:

0x4016 FALSE: Recommended to be received from

Gateway at least every 3 hours but not more often than

every 30 minutes @ every 0,1K change

After 3 hours the function is disabled and goes back to

standard mode

0x4016 TRUE: At least every 30 minutes but not more

often than every 5minutes @ every 0,1K change for

covered radiators (after 35 minutes the function is

disabled and goes back to standard mode) The value -

TRUE = Room Sensor Mode (allows Covered Radiators)

Range 1-10 (lower 4 bit allocated to scale factor)

Scale factor of setpoint filter ti meconstant

("aggressiveness" of control algorithm) 1=5min( Quick) ...

5=30min(Moderate) ... 10=80min(Slow).

Bit4=Quick open feature disable. 1=disable. 0=enable

0x01 Heat avaliable

Default is 0, but overwritten to actual Control value at Init.

(by default the heat is considered on if the gatway does

not send any info about that)

0x01 Heat request

Default is 0, but overwritten to actual st atus at Init.

stand alone thermostat

0x01 Load balancing is enabled and thermostat expected

to receive loads from all thermost ats in room

0x0201 0x404B Regulation SetPoint Offset Int8R/W O 0xE7 0x19 No No 1 65534 0 0x00

0x0201 0x404C Adaptation run control enum8R/W O 0x00 0x02 Fixed No 1 65534 0x00

0x0201 0x404D Adaptation run status bitmap8 R O 0x00 0xFF Yes No 60 43200 0x00

0x0201 0x404E Adaptation run settings bitmap8R/W O 0x00 0x01 No No 1 65534 0x00

0x0201 0x404F Preheat Status boolean R O 0 1 Yes No 60 0 0x01

01-12-2021

The range of this offset is –2.5 °C to +2.5 °C (0xE7 …

0x19).

2=cancel Adaptation run

bit1=Valve Characteristic found

bit2=Valve Characteristic lost

night)

heat in Zigbee Weekly Schedule mode

0x00: window open feature OFF. 0x01: window open

0x00 = °C

AM375549618098en-000102 | 5

Page 6

Danfoss Ally eTRV1.18, Zigbee Cluster Specification

0x0204

0x0001

KeypadLockout

enum8R/WM0x00

0x05

Fixed

Yes16553400x00

0x01 to 0x05 = lockout (child lock)

0x0204

0x4000

Viewing Direction

enum8R/WO0x00

0x01

Fixed

Yes16553400x00

configuration at Init

0x0204

0xFFFD

Cluster revision

uint16NoNo16553400x0001

0x0B05

Cluster:

(0x0B05) Diagnostic

0x0B05

0x0000

Number of resets

uint16RO

0x0000

0xFFFFNoNo16553400x00

0x0B05

0x011B

message sent

uint16RO

0x0000

0xFFFFNoNo16553400x00

retries needed to send an APS message

0x0B05

0x011C

LastMessageLQI

uint8RO

0x00

0xFFNoNo16553400x00

where 0 indicates the worst possible link and 255 indicates

the best possible link.

0x0B05

0x011D

LastMessageRSSI

int8RO

0x00

0xFFNoNo16553400x00

the last message received.

0x0B05

0x4000

SW error code

bitmap16R/WO0x0000

0xFFFF

YesNo60

43200

0x00

minutes and auto-clear on rejoin

0x0B05

0x4001

Wake time avg

uint32RO

0x0000

0xFFFFNoNo16553400x00

Debug

0x0B05

0x4002

Wake time max duration

uint32RO

0x0000

0xFFFFNoNo16553400x00

Debug

0x0B05

0x4003

Wake time min duration

uint32RO

0x0000

0xFFFFNoNo16553400x00

Debug

0x0B05

0x4004

Sleep Postponed count avg

uint32RO

0x0000

0xFFFFNoNo16553400x00

Debug

0x0B05

0x4005

Sleep Postponed count max

uint32RO

0x0000

0xFFFFNoNo16553400x00

Debug

0x0B05

0x4006

Sleep Postponed count min

uint32RO

0x0000

0xFFFFNoNo16553400x00

Debug

0x0B05

0x4010

Motor step counter

uint32RO

0x0000

0xFFFFFFFF

YesNo3600

43200

1000

Resolution = 250 steps in Zigbee interface

0x0B05

0x4020

Data Logger

string(50)R/WOYesNo1

0

Length="50"

0x0B05

0x4021

Control Diagnostics

string(30)RO

YesNo6000

Length="30"

0x0B05

0x4022

Control Diagnostics Frequency

uint16R/WO0x0000

0xFFFF

FixedNo1

65534

0x0000

parameters.

0x0B05

0x4022

Control Diagnostics Frequency

uint16R/WO0x0000

0xFFFF

FixedNo1

65534

0x0005

parameters.

0x0B05

0xFFFD

Cluster revision

uint16NoNo16553400x0001

Range: 0 to 5

0x00 = no lockout

Range: 0 to 1

0x00 = viewing direction 1

0x01 = viewing direction 2

Default is 0, but overwritten to value from production

Average mac retry per aps

octet

octet

A counter that is equal to the average number of MAC

The Link Quality Indicator is a value between 0 and 255

This is the receive signal strength indication (in dBm ) for

Writing "0" will act as a error reset command, but Error

codes auto clear when error recovered, no need to clear

from external.

E12 error only show error if lost coordinator more than 2

Number of motor step run since production

Debug

Debug

Frequency of analog data and ON/OFF. 0=disable. 1-XX

enable logging and minute resolution filter of anal og

Frequency of analog data and ON/OFF. 0=disable. 1-XX

enable logging and minute resolution filter of anal og

01-12-2021

AM375549618098en-000102 | 6

Loading...

Loading...