Page 1

Operatingguide

TermixATBTD

1.0TableofContents

1.0TableofContents.............................................1

2.0Functionaldescription......................................2

3.0Safetynotes.....................................................3

3.1SafetyNotes–general............................................3

4.0Mounting........................................................4

4.1Mounting...........................................................4

4.2Start-up..............................................................5

5.0MountinginstructionsT ermixATBTDwall

cabinet............................................................6

5.1Mounting...........................................................6

6.0Design.............................................................8

6.1DesignTermixATBTD5pipes...................................8

6.2SchematicdiagramT ermixATBTD5Pipes....................9

6.3DesignTermixATBTD4pipes...................................10

6.4SchematicdiagramT ermixATBTD4Pipes....................11

7.0Controls..........................................................12

7.1DHWtemperaturecontrol........................................12

7.2Other.................................................................13

7.3Maintenance........................................................14

8.0Troubleshooting..............................................15

8.1Troubleshootingingeneral......................................15

8.2TroubleshootingDHW............................................15

8.3Disposal.............................................................16

9.0Declaration......................................................19

9.1Declarationofconformity........................................19

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

1

Page 2

OperatingguideTermixATBTD

2.0Functionaldescription

Districtheatingsubstationwithtankfordomestichotwater

preparationandwiththermostaticcontrol.Designedfor

wall-mounting.

Application

TheTermixA TBTDsubstationisacompletesolutionforhot

water.TheT ermixATBTDisapplicableforsingle-familyhouses

orapartments.

Domestichotwater(DHW)

Thedomestichotwatercircuitconsistsofahotwatertankwithcoil

andself-actingthermostaticcontrolvalve.Thehotwatertankand

coilareenamelledandthetankcontainsamagnesiumanode.The

substationisdeliveredwithabuiltinsafetyvalve.

2

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 3

OperatingguideTermixATBTD

3.0Safetynotes

3.1SafetyNotes–general

Thefollowinginstructionsrefertothestandarddesignof

substation.Specialversionsofsubstationsareavailableon

request.

Thisoperatingmanualshouldbereadcarefullybeforeinstallation

andstart-upofthesubstation.Themanufactureracceptsno

liabilityfordamageorfaultsthatresultfromnon-compliancewith

theoperatingmanual.Pleasereadandfollowalltheinstructions

carefullytopreventaccidents,injuryanddamagetoproperty.

Assembly,start-upandmaintenanceworkmustbeperformedby

qualiedandauthorizedpersonnelonly.

Pleasecomplywiththeinstructionsissuedbythesystem

manufacturerorsystemoperator.

Corrosionprotection

Allpipesandcomponentsaremadeofstainlesssteelandbrass.

Themaximumchloridecompoundsoftheowmediumshouldnot

behigherthan150mg/l.

Theriskofequipmentcorrosionincreasesconsiderablyifthe

recommendedlevelofpermissiblechloridecompoundsis

exceeded.

Energysource

Thesubstationisdesignedfordistrictheatingastheprimary

sourceofenergy.However,alsootherenergysourcescanbeused

wheretheoperatingconditionsallowitandalwaysarecomparable

todistrictheating.

Application

Thesubstationisdesignedtobeconnectedtothehouse

installationinafrost-freeroom,wherethetemperaturedoesnot

exceed50°Candthehumiditydoesnotexceed60%.Donotcover

orwallupthesubstationorinanyotherwayblocktheentrance

tothestation.

Choiceofmaterial

Choiceofmaterialsalwaysincompliancewithlocallegislation.

Safetyvalve(s)

Werecommendmountingofsafetyvalve(s),however,alwaysin

compliancewithlocalregulations.

Connection

Thesubstationmustbeequippedwithfeaturesthatensurethat

thesubstationcanbeseparatedfromallenergysources(also

powersupply).

Emergency

Incaseofdangeroraccidents-re,leaksorotherdangerous

circumstances-interruptallenergysourcestothestationif

possible,andseekexperthelp.

Incaseofdiscolouredorbad-smellingdomestichotwater,closeall

shut-offvalvesonthesubstation,informtheoperatingpersonnel

andcallforexperthelpimmediately.

Storage

Anystorageofthesubstationwhichmaybenecessarypriorto

installationshouldbeinconditionswhicharedryandheated.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualiedandauthorizedpersonnelonly.

Pleaseobserveinstructionscarefully

Toavoidinjurytopersonsanddamagetothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Warningofhighpressureandtemperature

Beawareoftheinstallation’ spermissiblesystempressureand

temperature.

Themaximumtemperatureoftheowmediuminthesubstationis

120°C.

Themaximumoperatingpressureofthesubstationis10bar .PN16

versionsareavailableonenquiry.

Theriskofpersonsbeinginjuredandequipmentdamagedincreases

considerablyiftherecommendedpermissibleoperatingparameters

areexceeded.

Thesubstationinstallationmustbeequippedwithsafetyvalves,

however,alwaysinaccordancewithlocalregulations.

Warningofhotsurface

Thesubstationhasgothotsurfaces,whichcancauseskinburns.

Pleasebeextremelycautiousincloseproximitytothesubstation.

Powerfailurecanresultinthemotorvalvesbeingstuckinopen

position.Thesurfacesofthesubstationcangethot,whichcancause

skinburns.Theballvalvesondistrictheatingsupplyandreturnshould

beclosed.

Warningoftransportdamage

Beforesubstationinstallation,pleasemakesurethatthesubstation

hasnotbeendamagedduringtransport.

IMPORTANT-Tighteningofconnections

Duetovibrationsduringtransportallangeconnections,screwjoints

andelectricalclampandscrewconnectionsmustbecheckedand

tightenedbeforewaterisaddedtothesystem.Afterwaterhasbeen

addedtothesystemandthesystemhasbeenputintooperation,

re-tightenALLconnections.

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

3

Page 4

OperatingguideTermixATBTD

4.0Mounting

4.1Mounting

Installationmustbeincompliancewithlocalstandardsand

regulations.

Districtheating(DH)-Inthefollowingsections,DHreferstothe

heatsourcewhichsuppliesthesubstations.Avarietyofenergy

sources,suchasoil,gasorsolarpower,couldbeusedasthe

primarysupplytoDanfosssubstations.Forthesakeofsimplicity,

DHcanbetakentomeantheprimarysupply.

Connectionsizes:

Allconnections:

G¾”(int.thread)

Dimensions(mm):

Withcover:

100L:H1180xW540xD520

150L:H1510xW540xD520

Weight(approx.):85–100kg

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualiedandauthorizedpersonnelonly.

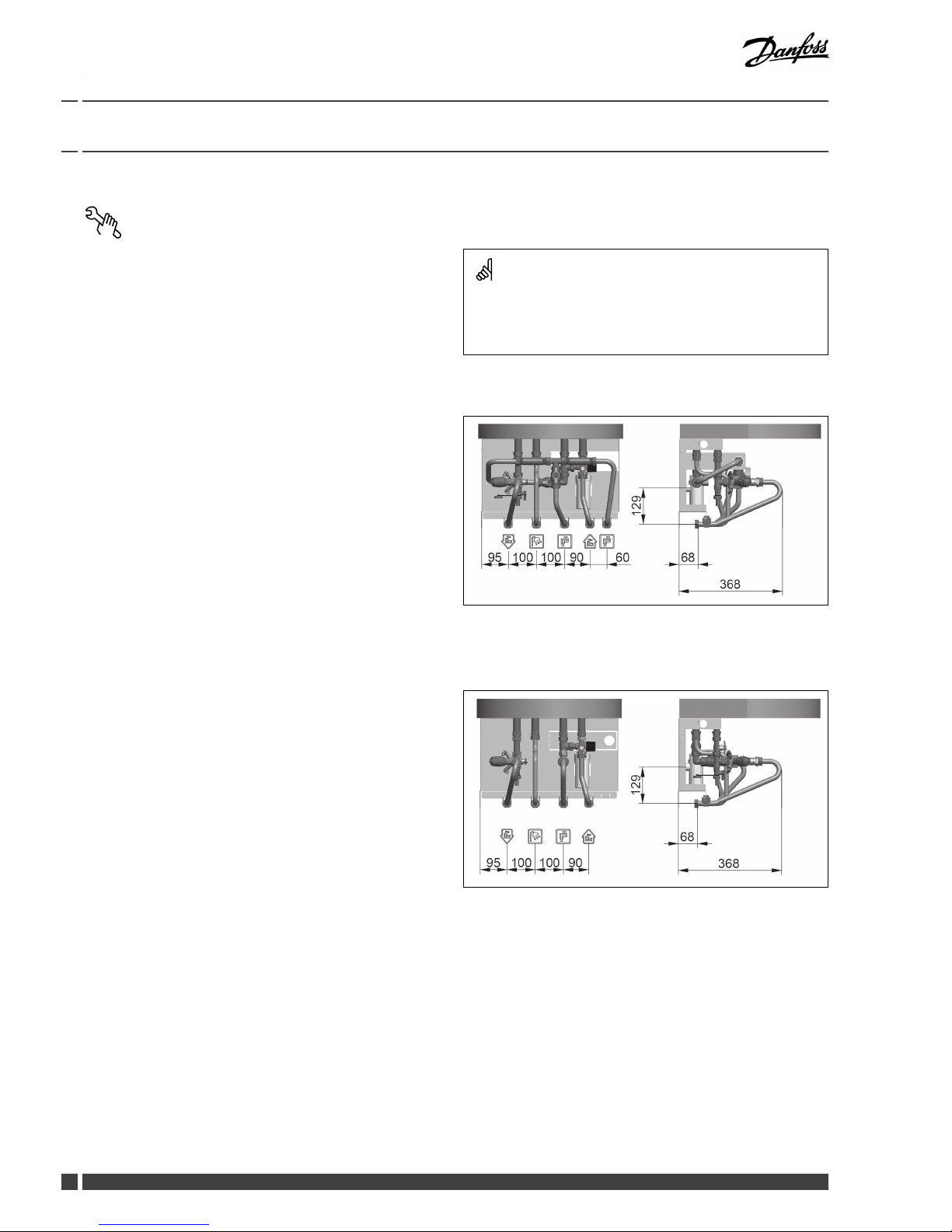

TermixA TBTD5pipes

Thepipeplacementcandeviatefromtheshowndrawing.Pleasenote

themarkingsonthestation.

TermixA TBTD4pipes

Thepipeplacementcandeviatefromtheshowndrawing.Pleasenote

themarkingsonthestation.

4

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 5

OperatingguideTermixATBTD

4.1.1Installation

Mounting:

Adequatespace

Pleaseallowadequatespacearoundthesubstationformounting

andmaintenancepurposes.

Orientation

Thestationmustbemountedsothatcomponents,keyholes

andlabelsareplacedcorrectly.Ifyouwishtomountthestation

differentlypleasecontactyoursupplier.

Drillings

Wheresubstationsaretobewall-mounted,drillingsareprovided

inthebackmountingplate.Floormountedunitshavesupport.

Labelling

Eachconnectiononthesubstationislabelled.

Beforeinstallation:

Cleanandrinse

Priortoinstallation,allsubstationpipesandconnectionsshouldbe

cleanedandrinsed.

Tightening

Duetovibrationduringtransport,allsubstationconnectionsmust

becheckedandtightenedbeforeinstallation.

Unusedconnections

Unusedconnectionsandshut-offvalvesmustbesealedwitha

plug.Shouldtheplugsrequireremoval,thismustonlybedoneby

anauthorizedservicetechnician.

Installation:

Strainer

Ifastrainerissuppliedwiththestationitmustbettedaccording

toschematicdiagram.Pleasenotethatthestrainermaybe

suppliedloose.

Connections

Internalinstallationanddistrictheatingpipesconnectionsmustbe

madeusingthreaded,angedorweldedconnections.

4.2Start-up

Start-up,Directheating

Theshut-offvalvesshouldbeopenedandtheunitobservedas

itentersservice.Visualcheckingshouldconrmtemperatures,

pressures,acceptablethermalexpansionandabsenceofleakage.

Iftheheatexchangeroperatesinaccordancewithdesign,itcanbe

puttoregularuse.

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

Re-thightenconnections

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

5

Page 6

OperatingguideTermixA TBTD

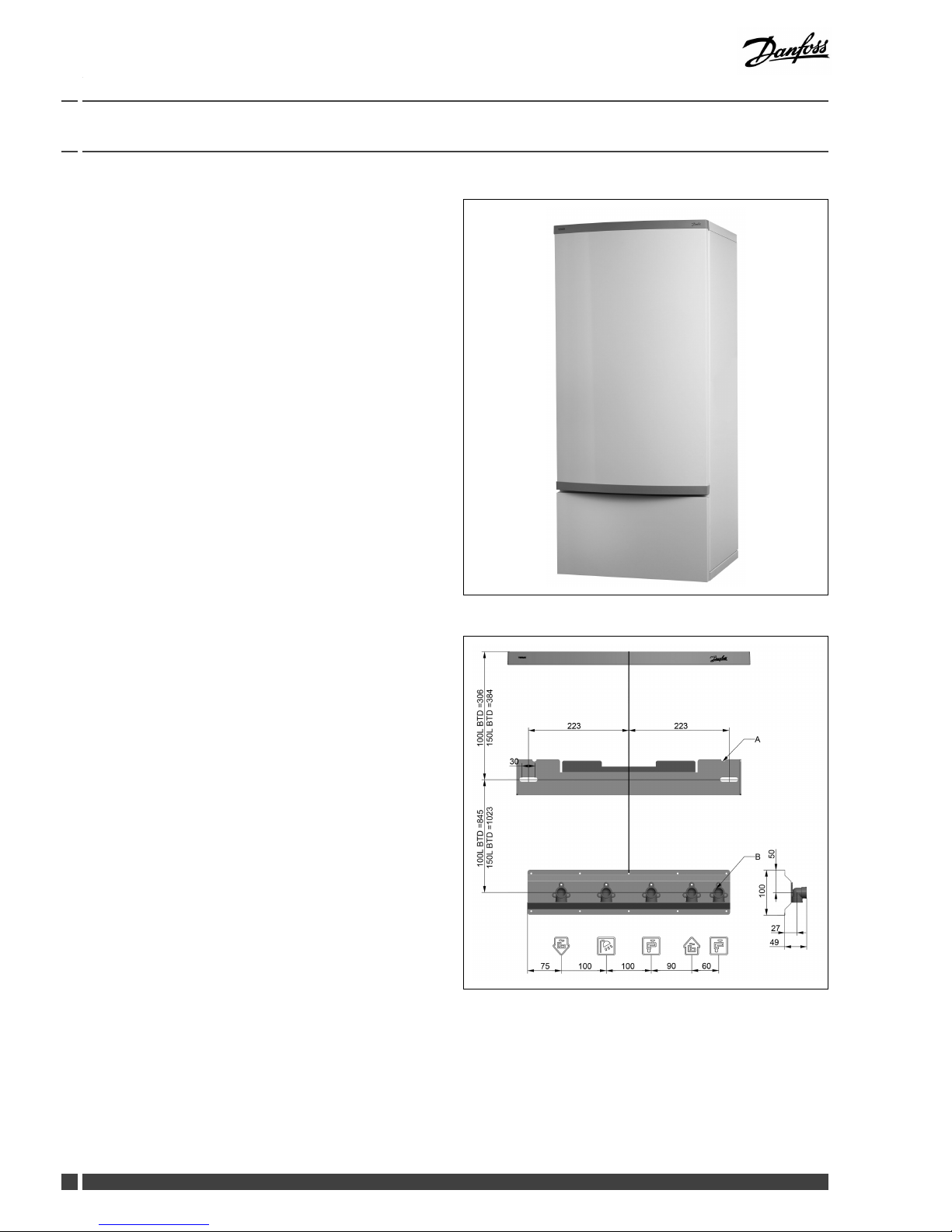

5.0MountinginstructionsT ermixATBTDwallcabinet

5.1Mounting

Wallbracket

MounttheWallbracketaccordingtotheDrawing.

UseAtocenterthetankonthebracket.

B-AllpipethreadsareISO½” .

Mountthecontainerunitinthewallbracket.

6

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 7

OperatingguideTermixA TBTD

Sideplates

Fastentherightandleftsideplatesbyplacingthekeyholesover

thescrewsonthesidesofthewallbracket.

1Bottompanel

Slidetheslotsinthebottompanelontothe2bushesintheside

plates,andfastenthepanelwiththe2screwsinthefront.

2Topplate

Mountthetopplate.

3Frontcover

Mountthefrontcoverbyloweringthekeyholesontothescrews

inthesideplates.

4Clockpanel

Mounttheclockpanelbyloweringthekeyholesontothescrews

inthesideplates.

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

7

Page 8

OperatingguideTermixA TBTD

6.0Design

6.1DesignTermixA TBTD5pipes

Yoursubstationmightlookdifferentthanthesubstationshown.

Designdescription

E

Hotwatertankwithcoil

4

Safetyvalve

S

Siphon

20

Filling/drainvalve

1A

Ballvalve,DVGW

41A

Fittingpiece,coldwatermains

2

Singlecheckvalve

59

Differentialpressure/temperatureregulatorwithowlimiting

8

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 9

OperatingguideTermixA TBTD

6.2SchematicdiagramTermixA TBTD5Pipes

DHW

DCW

CWM

DH

Supply

DH

Return

Yoursubstationmightlookdifferentthantheschematicdiagramshown.

Schematicdescription

E

Hotwatertankwithcoil

4

Safetyvalve

1

Ballvalve

20

Filling/drainvalve

1A

Ballvalve,DVGW

41A

Fittingpiece,coldwatermains

2

Singlecheckvalve

59

Differentialpressure/temperatureregulatorwithowlimiting

DHW:DomesticHotWater

DCW:

DomesticColdWater

CWM:

Coldwatermains

DHSupply:DistrictHeatingSupply

DHReturn:DistrictHeatingReturn

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

9

Page 10

OperatingguideTermixA TBTD

6.3DesignTermixA TBTD4pipes

Yoursubstationmightlookdifferentthanthesubstationshown.

Designdescription

E

Hotwatertankwithcoil

4

Safetyvalve

S

Siphon

20

Filling/drainvalve

1A

Ballvalve,DVGW

59

Differentialpressure/temperatureregulatorwithowlimiting

2

Singlecheckvalve

10

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 11

OperatingguideTermixA TBTD

6.4SchematicdiagramTermixA TBTD4Pipes

DHW

DCW

DH

Supply

DH

Return

Yoursubstationmightlookdifferentthantheschematicdiagramshown.

Schematicdescription

E

Hotwatertankwithcoil

4

Safetyvalve

1

Ballvalve

20

Filling/drainvalve

1A

Ballvalve,DVGW

59

Differentialpressure/temperatureregulatorwithowlimiting

2

Singlecheckvalve

DHW:DomesticHotWater

DCW:

DomesticColdWater

DHSupply:DistrictHeatingSupply

DHReturn:DistrictHeatingReturn

6.4.1Technicalparameters

Technicalparameters

Nominalpressure:

PN10

Max.DHsupplytemperature:

T–max=95°C

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

11

Page 12

OperatingguideTermixA TBTD

7.0Controls

7.1DHWtemperaturecontrol

DHWtemperaturecontrol

TherearevarioustypesofDHWtemperaturecontrolusedin

Danfosssubstations.

DHWtemperatureshouldbeadjustedto45-50°C,asthisprovides

optimalutilisationofDHwater.AtDHWtemperaturesabove55°C,

thepossibilityoflimescaledepositsincreasessignicantly.

7.1.1AB-QMcontroller(45–60°)

QTisaself-actingthermostaticactuatordesignedtobeused

asreturntemperaturecontrolthermostatinone-pipeheating

systems.

QTisdedicatedtobeusedwithAB-QMautomaticbalancing&

controlvalve.

AB-QMDN10-20(45-60°C)

QTSensorsetting(turns)

Temperaturesetting

01

2

34

5

6

20%

48,050,553,0

55,5

58,060,563,0

30%

47,049,552,0

54,5

57,059,562,0

40%

46,048,551,053,556,058,561,0

50%

45,0

47,5

50,052,555,0

57,5

60,0

60%

44,046,549,0

51,5

54,056,559,0

70%

43,0

45,5

48,050,553,0

55,5

58,0

80%

42,0

44,5

47,049,552,0

54,5

57,0

90%

41,043,546,048,551,053,556,0

AB-QM(ow

setting)

100%

40,042,545,0

47,5

50,052,555,0

Thevaluesareintendedasaguide.

12

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 13

OperatingguideTermixA TBTD

7.2Other

7.2.1Coldwatermeterttingpiece

Thesubstationisequippedwithattingpieceforcoldwatermeter.

Assemblyofcoldwatermeter:

1:Closeballvalves

Closetheballvalvesoncoldwater,ifthereiswateronthesystem.

2:Loosennuts

Loosenthenutsonthettingpiece.

3:Removettingpiece

Removethettingpieceandreplaceitwiththecoldwatermeter .

Donotforgetthegaskets.

4:Tightenconnections

Aftermountingofthecoldwatermeterremembertocheckand

tightenallthreadedconnections.

7.2.2Siphon

PlacedtheSiphondirectlyundertheSafetyvalve.

Ensurethatthedrainpipehasaminimuminternaldiameterof

32mm.

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

13

Page 14

OperatingguideTermixA TBTD

7.3Maintenance

Thesubstationrequireslittlemonitoring,apartfromroutine

checks.Itisrecommendedtoreadtheenergymeteratregular

intervals,andtowritedownthemeterreadings.

RegularinspectionsofthesubstationaccordingtothisInstruction

arerecommended,whichshouldinclude:

Strainers

Cleaningofstrainers.

Meters

Checkingofalloperatingparameterssuchasmeterreadings.

Temperatures

Checkingofalltemperatures,suchasDHsupplytemperatureand

DHWtemperature.

Connections

Checkingallconnectionsforleakages.

Safetyvalves

Theoperationofthesafetyvalvesshouldbecheckedbyturning

thevalveheadintheindicateddirection.

Venting

Checkingthatthesystemisthoroughlyvented.

Inspectionsshouldbecarriedoutminimumeverytwoyears.

SparepartscanbeorderedfromDanfoss.Pleaseensurethatany

enquiryincludesthesubstationserialnumber.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualiedandauthorizedpersonnelonly.

14

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 15

OperatingguideTermixA TBTD

8.0Troubleshooting

8.1Troubleshootingingeneral

Intheeventofoperatingdisturbances,thefollowingbasicfeatures

shouldbecheckedbeforecarryingoutactualtroubleshooting:

•thesubstationisconnectedtoelectricity,

•thestrainerontheDHsupplypipeisclean,

•thesupplytemperatureoftheDHisatthenormallevel

(summer,atleast60°C-winter,atleast70°C),

•thedifferentialpressureisequaltoorhigherthanthenormal

(local)differentialpressureintheDHnetwork–ifindoubt,ask

theDHplantsupervisor,

•pressureonthesystem-checktheHEpressuregauge.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualiedandauthorizedpersonnelonly.

8.2TroubleshootingDHW

ProblemPossiblecauseSolution

Strainerinsupplyorreturnlineclogged.Cleanstrainer(s).

DHWcirculationpumpoutoforderorwith

toolowsetting.

Checkcirculationpump.

Defectiveorcloggednon-returnvalve.

Replace–clean.

Noelectricity.Check.

Wrongsettingofautomaticcontrols,ifany.Toadjustanelectroniccontrollerfor

DHW,pls.noteenclosedinstructionsfor

electroniccontroller.

Scalingoftheplateheatexchanger.

Replace–rinseout.

Defectivemotorizedvalve.Check(usemanualfunction)–replace.

Defectivetemperaturesensors.

Check–replace.

ToolittleornoDHW.

Defectivecontroller.

Check–replace.

DCWisbeingmixedwiththeDHW,e.g.in

adefectivethermostaticmixingvalve.

Check–replace. Hotwaterinsometapsbutnotinall.

Defectiveorcloggednon-returnvalveon

circulationvalve.

Replace–clean.

Taptemperaturetoohigh;DHWtapload

toohigh.

Thermostaticvalveadjustedtoatoohigh

level.

Check–set.

Scalingoftheplateheatexchanger.

Replace–rinseout. Temperaturedropduringtapping.

LargerDHWowthanthesubstationhas

beendesignedfor.

ReduceDHWow.

Thermostaticcontrolvalvedoesnotclose

TemperaturedifferencebetweenDH

supplyandDHWsetpointtoolow.

Lowerthesetpointtemperatureor

increasetheDHsupplytemperature.

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

15

Page 16

OperatingguideTermixA TBTD

8.3Disposal

Disposal

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

16

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 17

OperatingguideTermixA TBTD

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

17

Page 18

OperatingguideTermixA TBTD

18

DEN-GT

VI.JV.Y3.02/LUK40692

DanfossDistrictEnergy

Page 19

OperatingguideTermixA TBTD

9.0Declaration

9.1Declarationofconformity

Category0withoutelectricalequipment

DanfossDistrictEnergy

VI.JV.Y3.02/LUK40692

DEN-GT

19

Page 20

OperatingguideTermixA TBTD

ProducedbyDanfossA/S©10/2017

Loading...

Loading...